Design and Application of an Artificial Neural Network Controller Imitating a Multiple Model Predictive Controller for Stroke Control of Hydrostatic Transmission

Abstract

1. Introduction

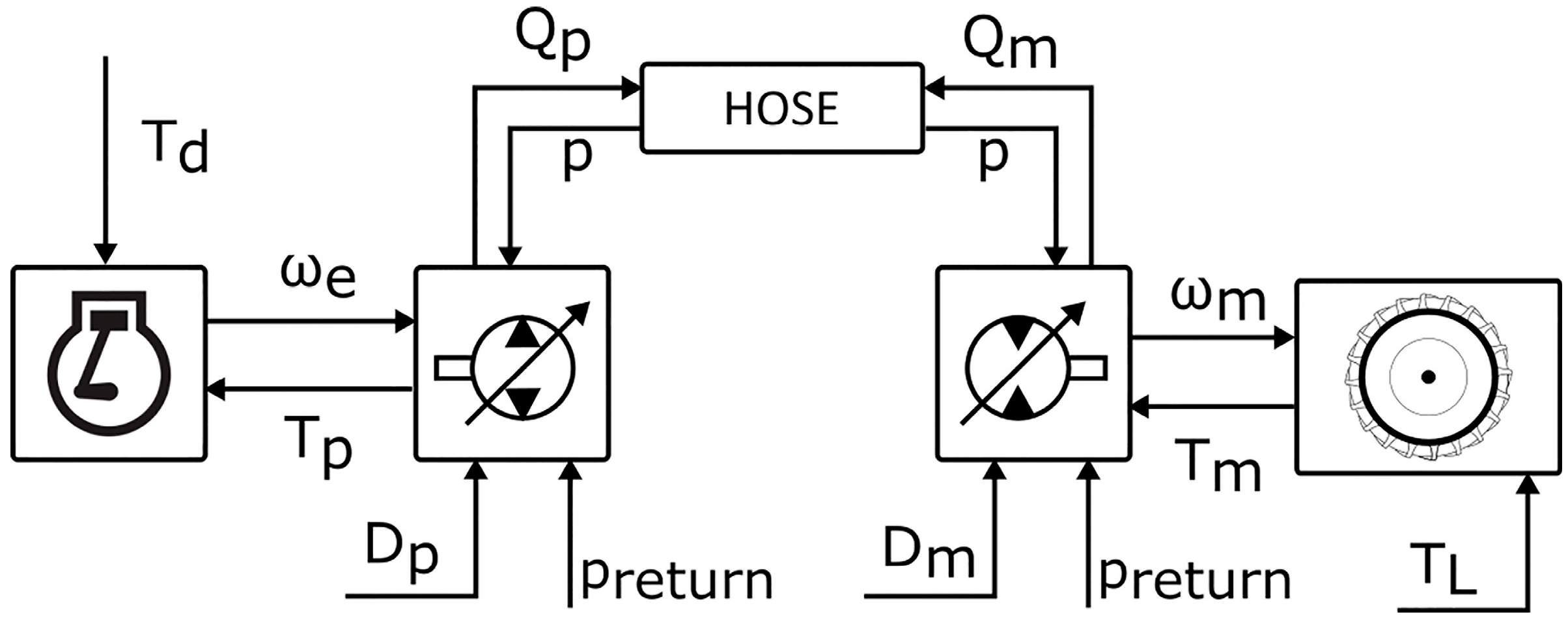

2. Mathematical Model of the Hydrostatic Transmission

3. Multiple Model Predictive Control

- State Estimation: A state observer, utilizing Kalman filtering techniques, estimates the system states at each sampling instant by incorporating measurement updates and disturbance models. This ensures the MPC receives accurate state estimations, leading to more effective control actions.

- Prediction Model Update: The estimated states are then used to update the prediction model, guaranteeing precise future trajectory estimation.

- MPC Optimization: With the updated states, the MPC optimization problem is solved at each sampling instant to determine the optimal control inputs.

- Control Application: The first element of the computed optimal input sequence is applied to the system, and this process repeats at the subsequent time step.

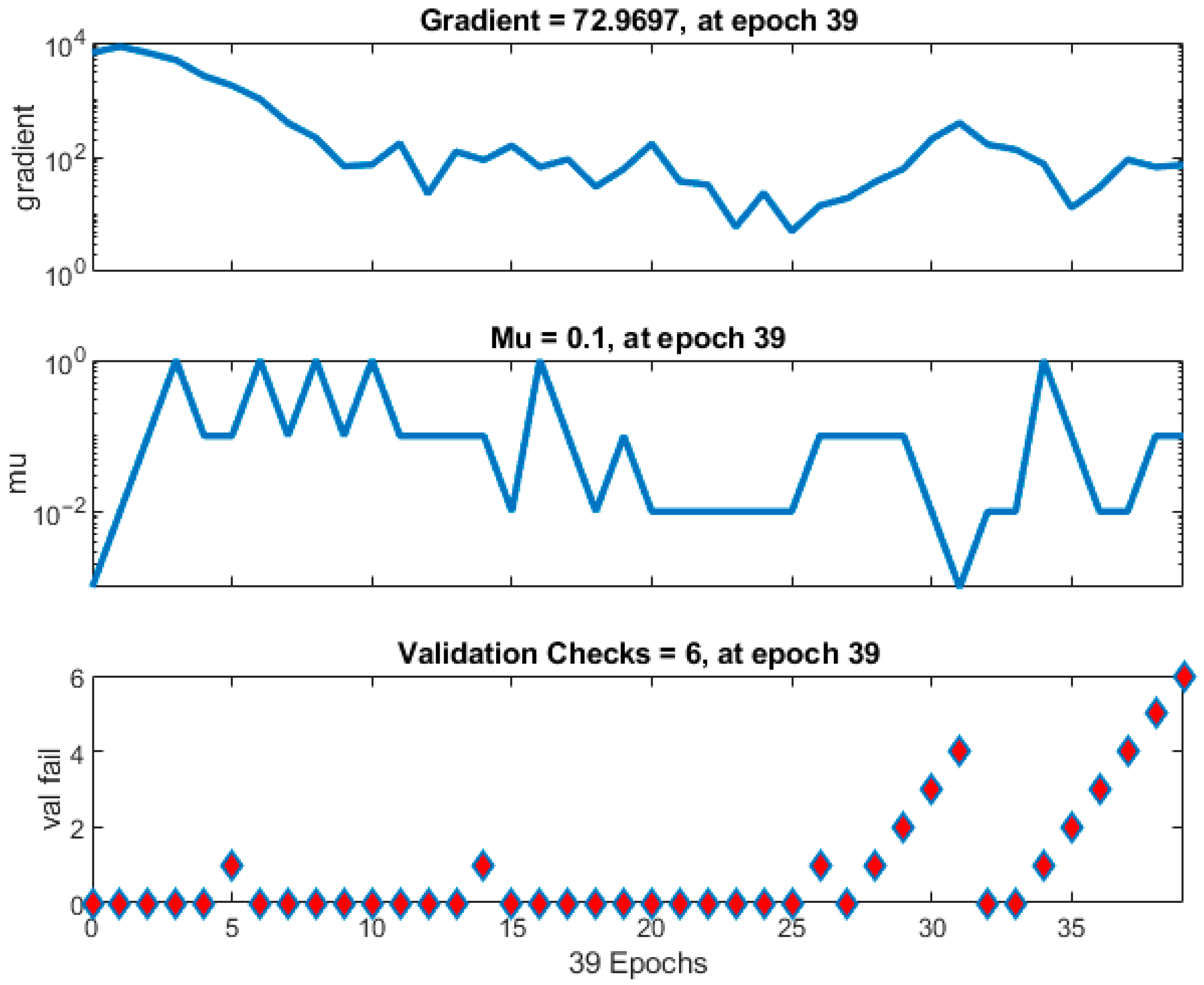

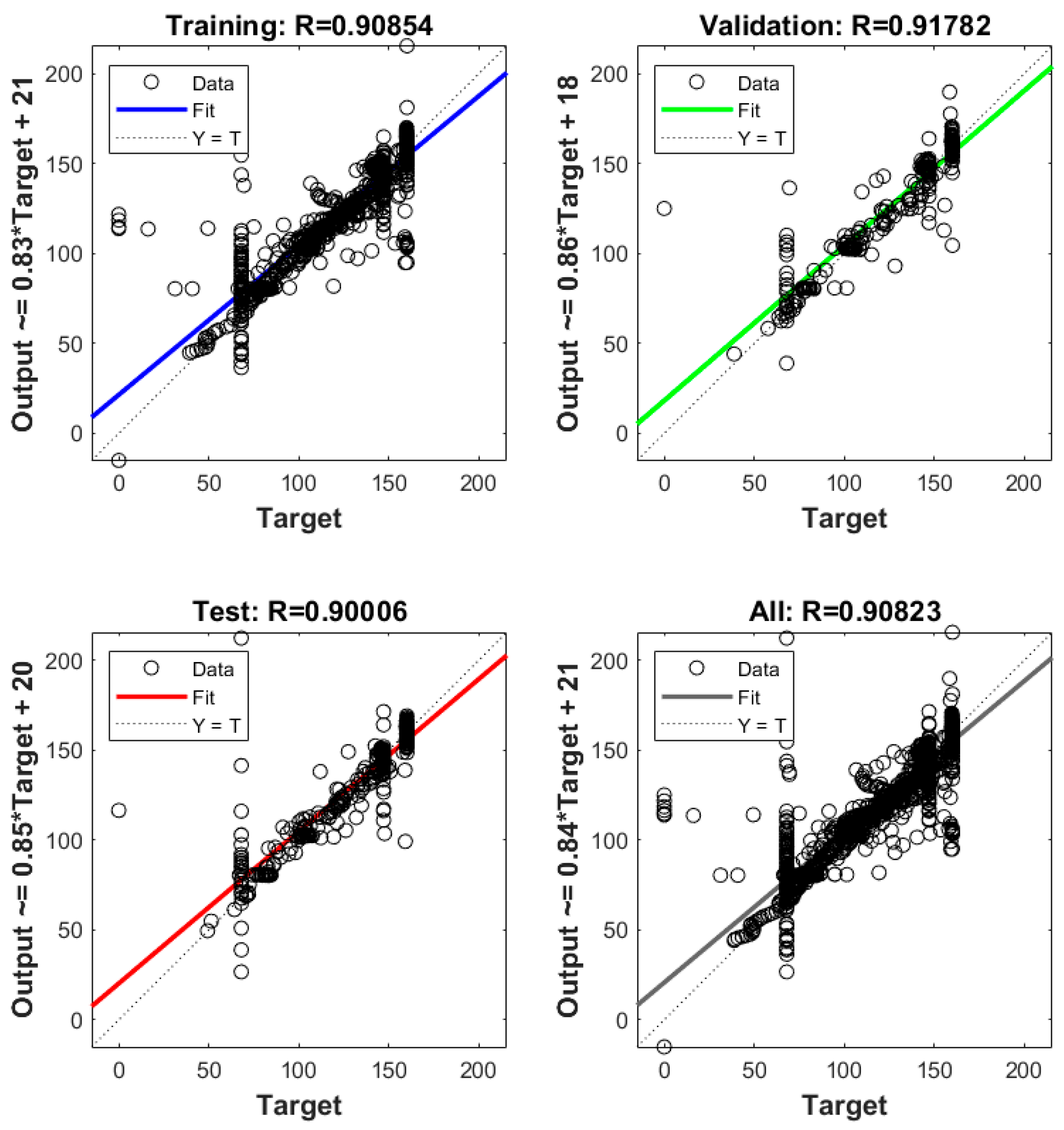

4. Artificial Neural Network Controller

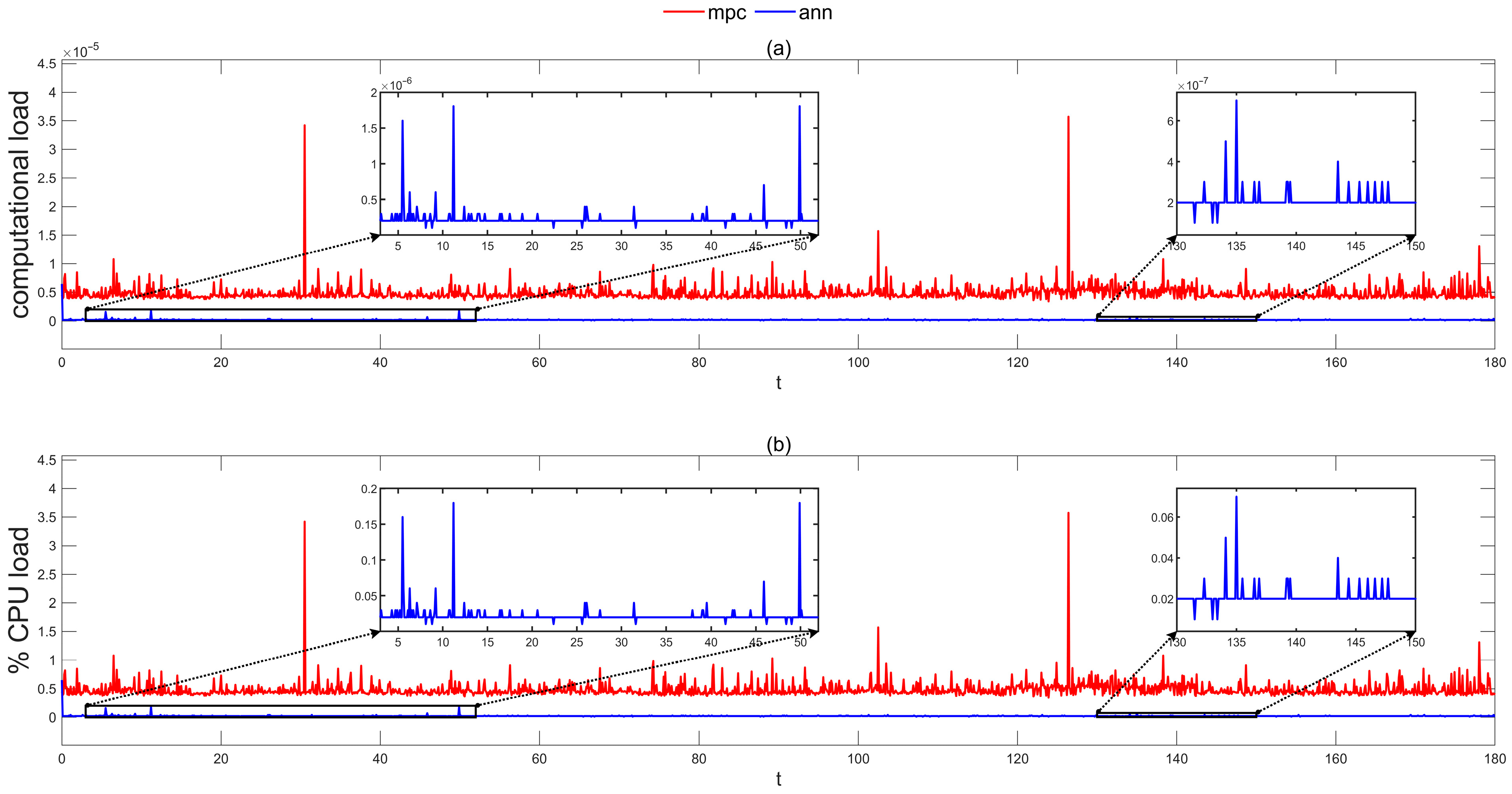

5. Processor-in-the-Loop Simulation Results and Discussion

6. Conclusions

Funding

Conflicts of Interest

References

- Merritt, H.E. Hydraulic Control System; John Wiley & Sons: New York, NY, USA, 1991. [Google Scholar]

- Zarotti, L.G. Hydrostatic Transmissions: Single Directive Control Architectures. Int. J. Model. Simul. 1992, 12, 97–101. [Google Scholar] [CrossRef]

- Weisenbach, C.O. Hydrostatic transmission applications. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 1968; pp. 1–8. [Google Scholar]

- Wu, K.; Zhang, Q.; Hansen, A. Modelling and identification of a hydrostatic transmission hardware-in-the-loop simulator. Int. J. Veh. Des. 2004, 34, 52–64. [Google Scholar] [CrossRef]

- Cundiff, J.S. Fluid Power Circuits and Controls: Fundamentals and Applications; CRC Press LLC: New York, NY, USA, 2001. [Google Scholar]

- Dasgupta, K. Analysis of a hydrostatic transmission system using low speed high torque motor. Mech. Mach. Theory 2000, 35, 1481–1499. [Google Scholar] [CrossRef]

- Nikranjbar, A.; Sharbabaki, A.N. Simulation and Control of Wind Turbine using Hydrostatic Drive Train. Majlesi J. Energy Manag. 2013, 2, 12–17. [Google Scholar]

- Carlsson, E. Modeling Hydrostatic Transmission in Forest Vehicle; Linkopings Universitet: Linköping, Sweden, 2006. [Google Scholar]

- Maciejowski, J.M. Predictive Control with Constraints; Prentice Hall: London, UK, 2002. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, L.; Li, Y.; Li, D. Model predictive control and its application in agriculture: A review. Comput. Electron. Agric. 2018, 151, 104–117. [Google Scholar] [CrossRef]

- Coen, T.; Saeys, W.; Missotten, B.; De Baerdemaeker, J. Cruise control on a combine harvester using model-based predictive control. Biosyst. Eng. 2008, 99, 47–55. [Google Scholar] [CrossRef]

- Sun, H.; Meinlschmidt, T.; Aschemann, H. Comparison of two nonlinear model predictive control strategies with observer-based disturbance compensation for a hydrostatic transmission. In Proceedings of the 2014 19th International Conference on Methods and Models in Automation and Robotics, MMAR 2014, Miedzyzdroje, Poland, 2–5 September 2014; pp. 526–531. [Google Scholar]

- Dutta, A.; lonescu, C.; De Keyser, R. A pragmatic approach to distributed nonlinear model predictive control: Application to a hydrostatic drivetrain. Optim. Control. Appl. Methods 2015, 36, 369–380. [Google Scholar] [CrossRef]

- Backas, J.; Ghabcheloo, R. Nonlinear model predictive energy management of hydrostatic drive transmissions. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2019, 233, 335–347. [Google Scholar] [CrossRef]

- Vu, T.-V.; Chen, C.-K.; Hung, C.-W. A model predictive control approach for fuel economy improvement of a series hydraulic hybrid vehicle. Energy 2014, 7, 7017–7040. [Google Scholar] [CrossRef]

- Vu, T.-V.; Chen, C.-K. A Model-Based Controller Development for a Series Hydraulic Hybrid Vehicle. In AETA 2016 Recent Advances in Electrical Engineering and Related Sciences; Lecture Notes in Electrical Engineering; Springer; Cham, Switzerland; pp. 891–901.

- Deppen, T.O.; Alleyne, A.G.; Stelson, K.A.; Meyer, J.J. Optimal energy use in a light weight hydraulic hybrid passenger vehicle. J. Dyn. Syst. Meas. Control Trans. ASME 2012, 134, 041009. [Google Scholar] [CrossRef]

- Nawrocka, A.; Kwaśniewski, J. Predictive neural network controller for hydrostatic transmission control. Mech./AGH Univ. Sci. Technol. 2008, 27, 62–65. [Google Scholar]

- Narendra, K.S.; Parthasarathy, K. Identification and control of dynamical systems using neural networks. IEEE Trans. Neural Netw. 1990, 1, 4–27. [Google Scholar] [CrossRef]

- Kaluz, M.; Kohut, R.; Dzurkova, D. MPC-Mimicking Neural Network Based on Homomorphic Encryption. In Proceedings of the 2023 24th International Conference on Process Control (PC), Strbske Pleso, Slovakia, 6–9 June 2023; pp. 126–131. [Google Scholar]

- Novak, M.; Dragicevic, T. Supervised imitation learning of finite-set model predictive control systems for power electronics. IEEE Trans. Ind. Electron. 2021, 68, 1717–1723. [Google Scholar] [CrossRef]

- Subramanian, S.B.; Sisay, Z.; Azath, M.; Girma, Y. Design and implementation of an ANN-based MPPT controller for solar-powered BLDC motor systems: A case study in Yalo Lala village, Ethiopia. Eng. Res. Express 2025, 7, 025301. [Google Scholar] [CrossRef]

- Abdullah, A.G.; Ibrahim, M.A.; Salih, A.S. Performance Enhancing Speed Control of a DC Motor Based on an Artificial Neural Network. J. Eur. Des Systèmes Autom. 2024, 57, 1489–1495. [Google Scholar] [CrossRef]

- Mahmoud, I.; Khedher, A. Artificial Neural Network-based Control of a Switched Reluctance Motor for a High-precision Positioning System. Eng. World 2024, 6, 136–143. [Google Scholar] [CrossRef]

- Abdolrasol, M.G.M.; Hannan, M.A.; Hussain, S.M.S.; Ustun, T.S.; Sarker, M.R.; Ker, P.J. Energy Management Scheduling for Microgrids in the Virtual Power Plant System Using Artificial Neural Networks. Energies 2021, 14, 6507. [Google Scholar] [CrossRef]

- Schöning, J.; Riechmann, A.; Pfisterer, H.J. AI for Closed-Loop Control Systems: New Opportunities for Modeling, Designing, and Tuning Control Systems. In Proceedings of the ICMLC 2022: 2022 14th International Conference on Machine Learning and Computing, Guangzhou, China, 18–21 February 2022; pp. 1–11. [Google Scholar]

- Rafiuddin, N.; Khan, Y.U. Nonlinear controller design for mechatronic aeropendulum. Int. J. Dyn. Control. 2023, 11, 1662–1670. [Google Scholar] [CrossRef]

- Antão, R.; Antunes, J.; Mota, A.; Martins, R.E. Model Predictive Control of Non-Linear Systems Using Tensor Flow-Based Models. Appl. Sci. 2020, 10, 3958. [Google Scholar] [CrossRef]

- Bana, P.R.; D’arco, S.; Amin, M. ANN-Based Robust Current Controller for Single-Stage Grid-Connected PV with Embedded Improved MPPT Scheme. IEEE Access 2024, 12, 100251–100262. [Google Scholar] [CrossRef]

- Shneen, S.W.; Gaber, R.K.; Salih, R.S.; Jiaad, S.M. Artificial Neural Network (ANN) Based Proportional Integral Derivative (PID) for Arm Rehabilitation Device. Kufa J. Eng. 2025, 16, 80–103. [Google Scholar] [CrossRef]

- Mishra, S.K.; Singh, P.K. Modeling of a Closed Loop Hydrostatic Transmission System and Its Control Designed for Automotive Applications. In Advances in Engine Tribology. Energy, Environment, and Sustainability; Kumar, V., Agarwal, A.K., Jena, A., Upadhyay, R.K., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 219–238. [Google Scholar]

- Ji, Y.; Huang, Y.; Yang, M.; Leng, H.; Ren, L.; Kiu, H.; Chen, Y. Physics-informed deep learning for virtual rail train trajectory following control. Reliab. Eng. Syst. Saf. 2025, 261, 111092. [Google Scholar] [CrossRef]

- Ramos-Martinez, M.; Torres-Cantero, C.A.; Ortiz-Torres, G.; Sorcia-Vázquez, F.D.J.; Avila-George, H.; Lozoya-Ponce, R.E.; Vargas-Méndez, R.A.; Renteria-Vargas, E.M.; Rumbo-Morales, J.Y. Control for Bioethanol Production in a Pressure Swing Adsorption Process Using an Artificial Neural Network. Mathematics 2023, 11, 3967. [Google Scholar] [CrossRef]

- Ülker, H. Design and application of multiple model predictive control in stroke control of hydrostatic transmission. Adv. Mech. Eng. 2025, 17, 16878132251331720. [Google Scholar] [CrossRef]

- Zavadinka, P.; Kriššák, P. Simulation of vehicle working conditions with hydrostatic pump and motor control algorithm. J. Autom. Mob. Robot. Intell. Syst. 2012, 6, 40–46. [Google Scholar]

- Stosiak, M.; Karpenko, M.; Prentkovskis, O.; Deptuła, A.; Skackauskas, P. Research of vibrations effect on hydraulic valves in military vehicles. Def. Technol. 2023, 30, 111–125. [Google Scholar] [CrossRef]

- Stosiak, M.; Karpenko, M.; Deptuła, A.; Urbanowicz, K.; Skačkauskas, P.; Deptuła, A.M.; Danilevičius, A.; Šukevičius, Š.; Łapka, M. Research of Vibration Effects on a Hydraulic Valve in the Pressure Pulsation Spectrum Analysis. J. Mar. Sci. Eng. 2023, 11, 301. [Google Scholar] [CrossRef]

- Stosiak, M.; Yatskiv, I.; Prentkovskis, O.; Karpenko, M. Reduction of Pressure Pulsations over a Wide Frequency Range in Hydrostatic Systems. Machines 2025, 13, 25. [Google Scholar] [CrossRef]

- Bemporad, A.; Lawrence Ricker, N.; Morari, M. Model Predictive Control ToolboxTM Reference How to Contact MathWorks—R2020a; MathWorks: Natick, MA, USA, 2020; p. 994. [Google Scholar]

- Beale, M.H.; Hagan, M.T.; Demuth, H.B. Deep Learning Toolbox TM User’s Guide; R2024b; The MathWorks, Inc.: Natick, MA, USA, 2024. [Google Scholar]

- Hagan, M.T.; Demuth, H.B.; Beale, M.H.; De Jesús, O. Neural Network Design; Martin Hagan: Stillwater, OK, USA, 2014. [Google Scholar]

- Levenberg, K. A Method for the Solution of Certain Non-Linear Problems in Least Squares. Q. Appl. Math. 1944, 2, 164–168. [Google Scholar] [CrossRef]

- BeagleBoard. What İs BeagleBone Black? Available online: https://www.beagleboard.org/boards/beaglebone-black (accessed on 31 July 2025).

- Ülker, H.; Baykara, C.; Özsoy, C. PIL simulations of an FWUAV under windy conditions. Aircr. Eng. Aerosp. Technol. 2018, 90, 461–470. [Google Scholar] [CrossRef]

| System Parameters of HST | Unit | Value |

|---|---|---|

| Nms2 | 5.02 | |

| Nms2 | 0.1723 | |

| Nm | 0 | |

| Nm | 0 | |

| m3 | 5.98 × 10−4 | |

| Pa | 3.7 × 106 | |

| - | 0.97 | |

| - | 0.92 | |

| Nms | 5 | |

| Nms | 10 |

| (rpm) | 0 | 1100 | 1350 | 1600 | 2500 | |

|---|---|---|---|---|---|---|

| 0 | 0.56 | 0.56 | 0.58 | 0.59 | 0.59 | |

| 85 | 0.84 | 0.84 | 0.86 | 0.87 | 0.87 | |

| 147 | 0.9 | 0.9 | 0.92 | 0.93 | 0.93 | |

| (rpm) | 0 | 600 | 1200 | 2000 | 4000 | |

|---|---|---|---|---|---|---|

| 68 | 0.77 | 0.77 | 0.88 | 0.97 | 0.97 | |

| 105 | 0.81 | 0.81 | 0.91 | 0.97 | 0.97 | |

| 160 | 0.85 | 0.85 | 0.94 | 0.97 | 0.97 | |

| Parameter | Value |

|---|---|

| Input Nodes | 2 |

| Hidden Layer | 1 |

| Hidden Layer Neurons | 5 |

| Hidden Layer Activation Function | Tangent sigmoid |

| Output Nodes | 2 |

| Output Layer Activation Function | Linear |

| Training Data Percentage | 70 |

| Validation Data Percentage | 15 |

| Test Data Percentage | 15 |

| Training Network Algorithm | Levenberg–Marquardt |

| Damping Factor | 0.001 |

| Number of Epochs | 1000 |

| Validation Checks | 6 |

| Performance | Mean Squared Error |

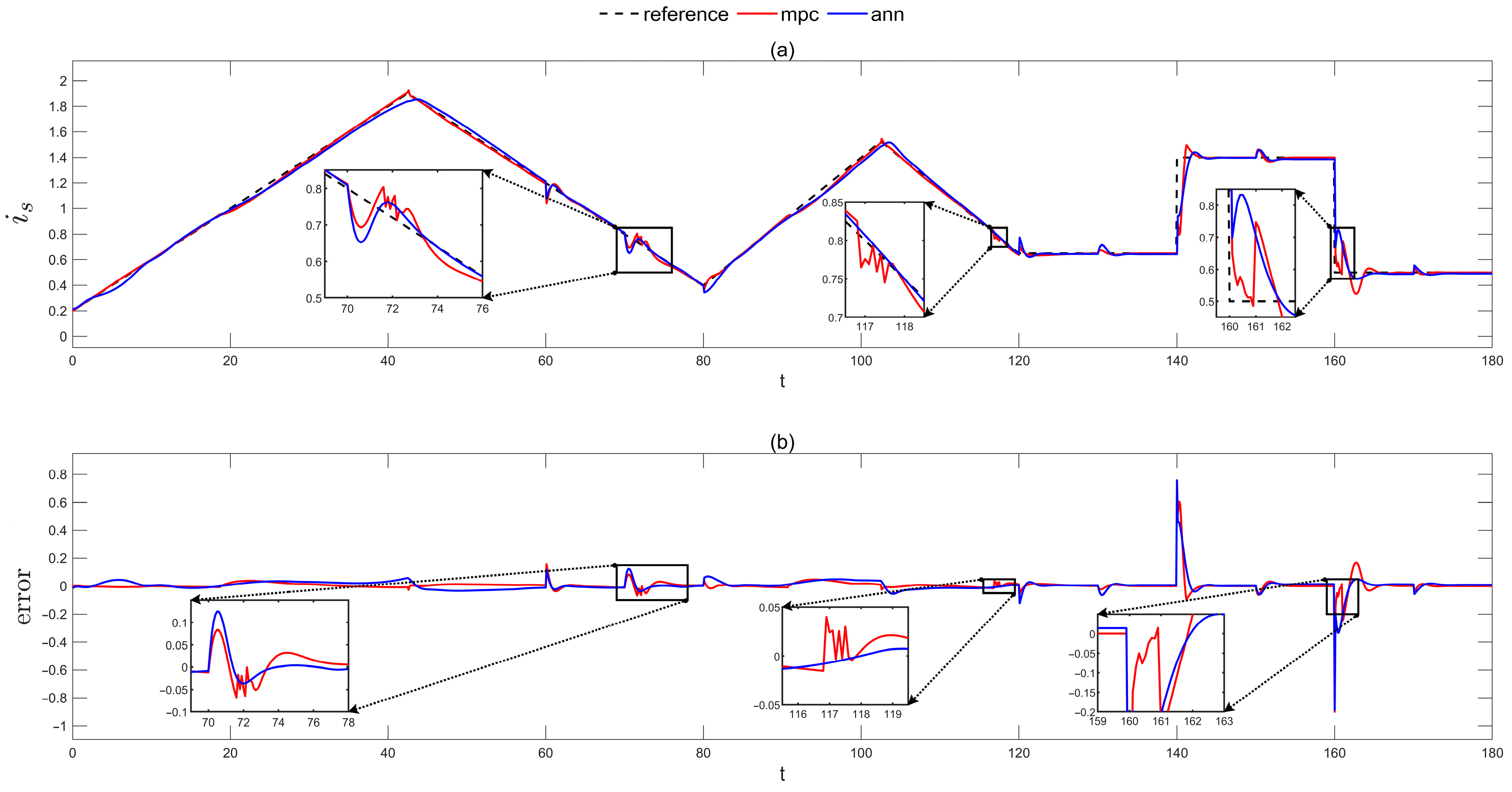

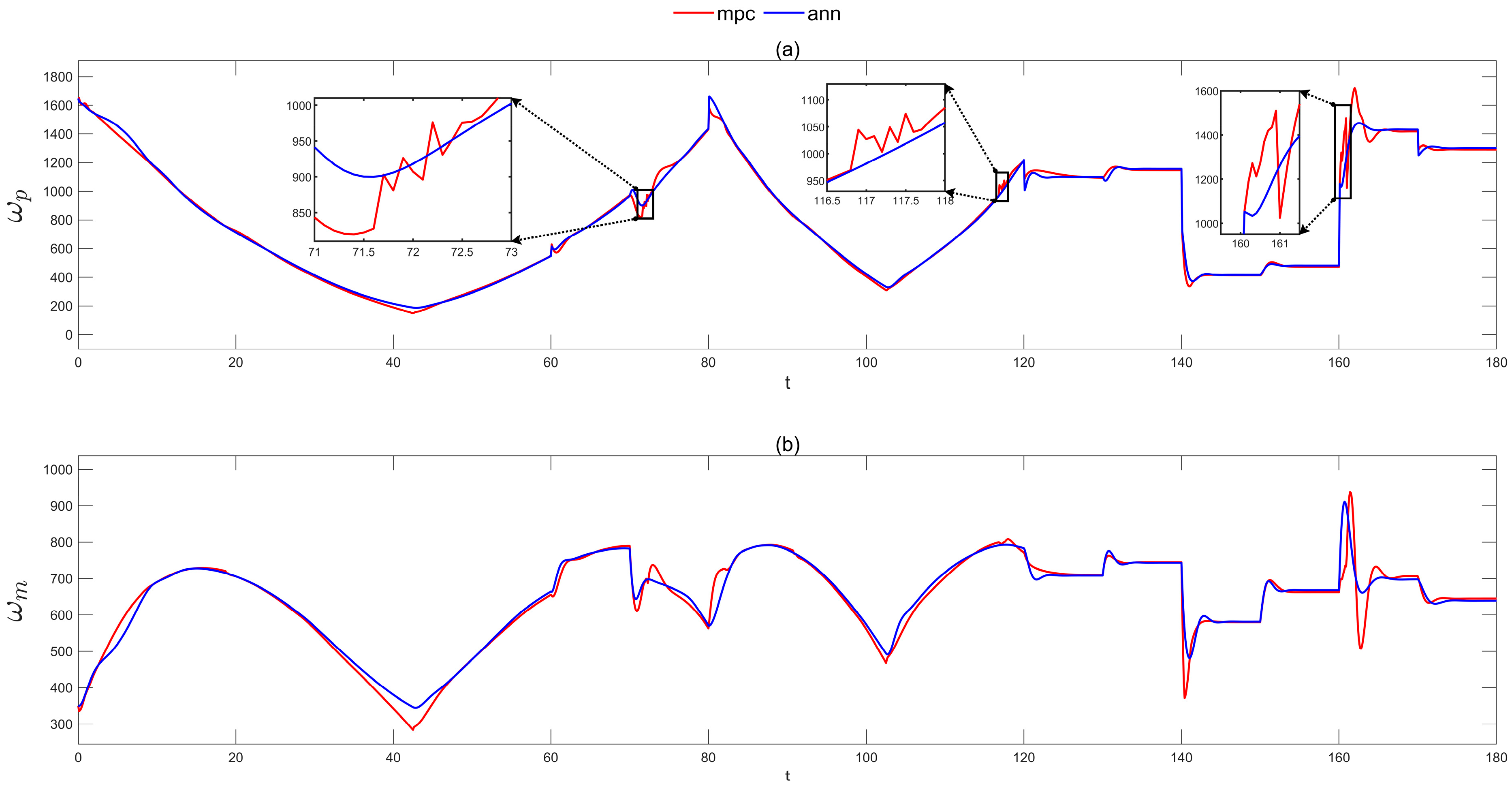

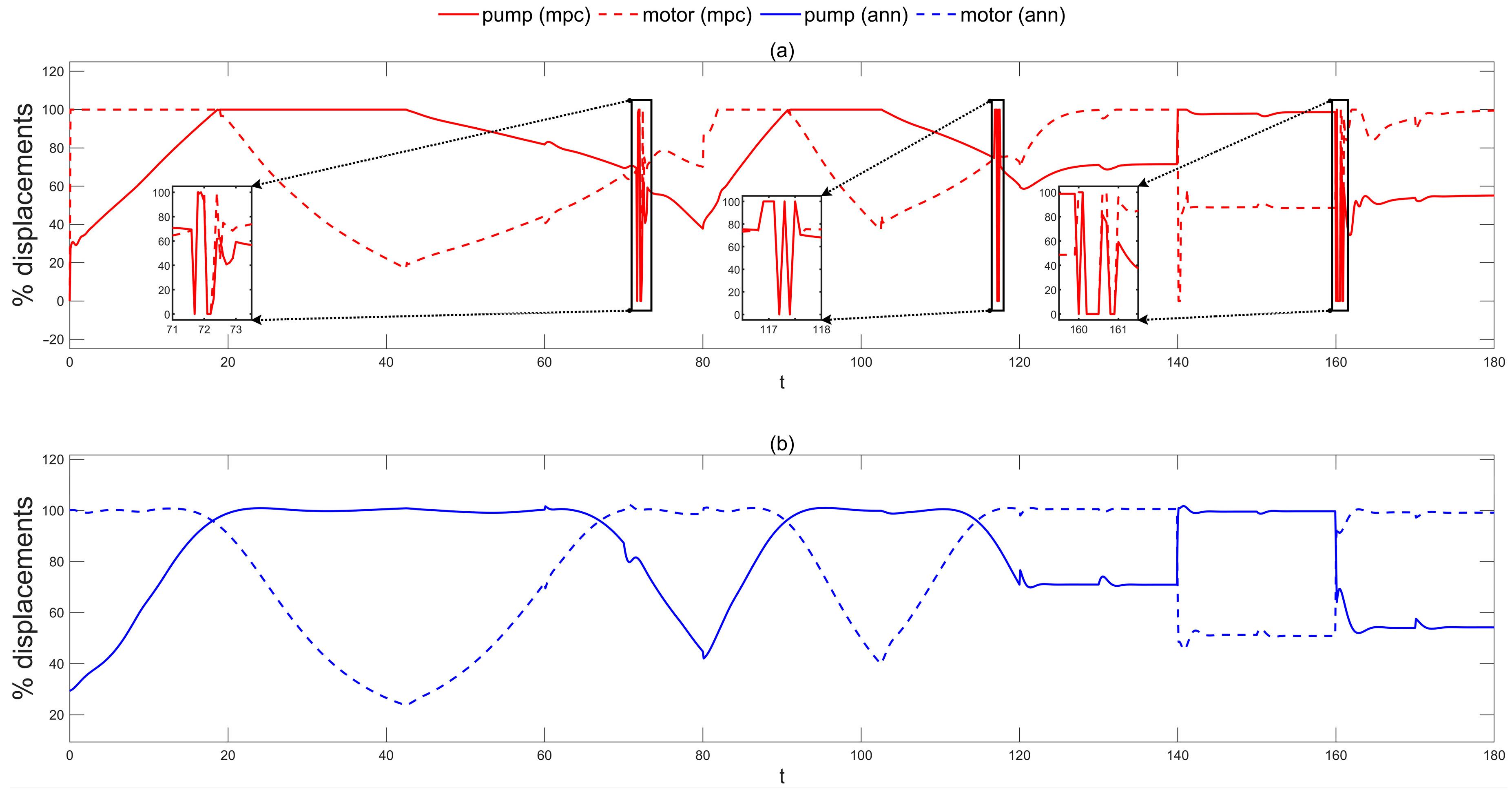

| Control Strategy | Disturbance Profile | MO (%) | (s) | MSE |

|---|---|---|---|---|

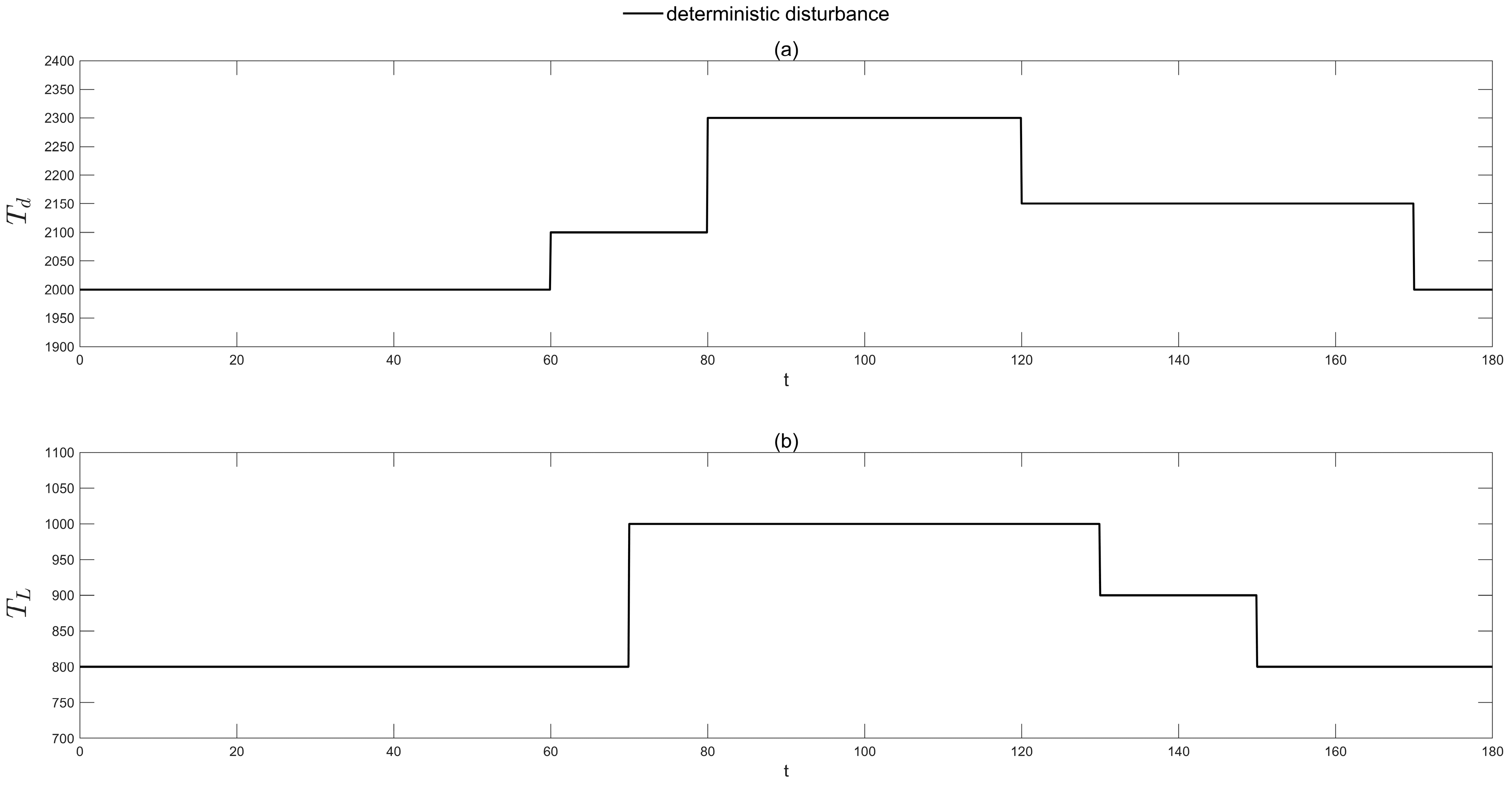

| Multiple MPC | Deterministic (Figure 7) | 25 | 1 | 0.0024 |

| ANN | Deterministic (Figure 7) | 10 | 1 | 0.0016 |

| Control Strategy | Disturbance Profile | MO (%) | (s) | MSE |

|---|---|---|---|---|

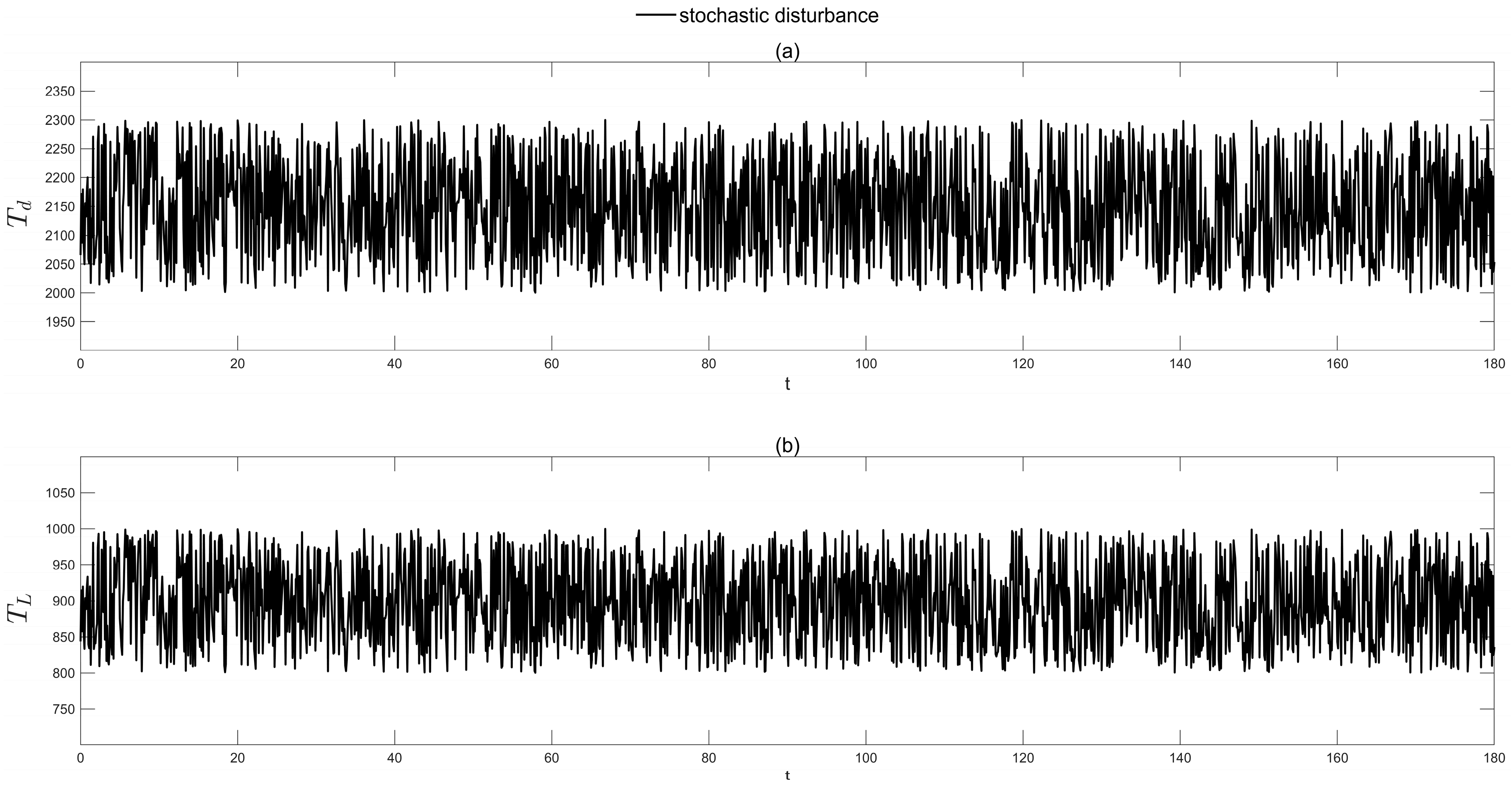

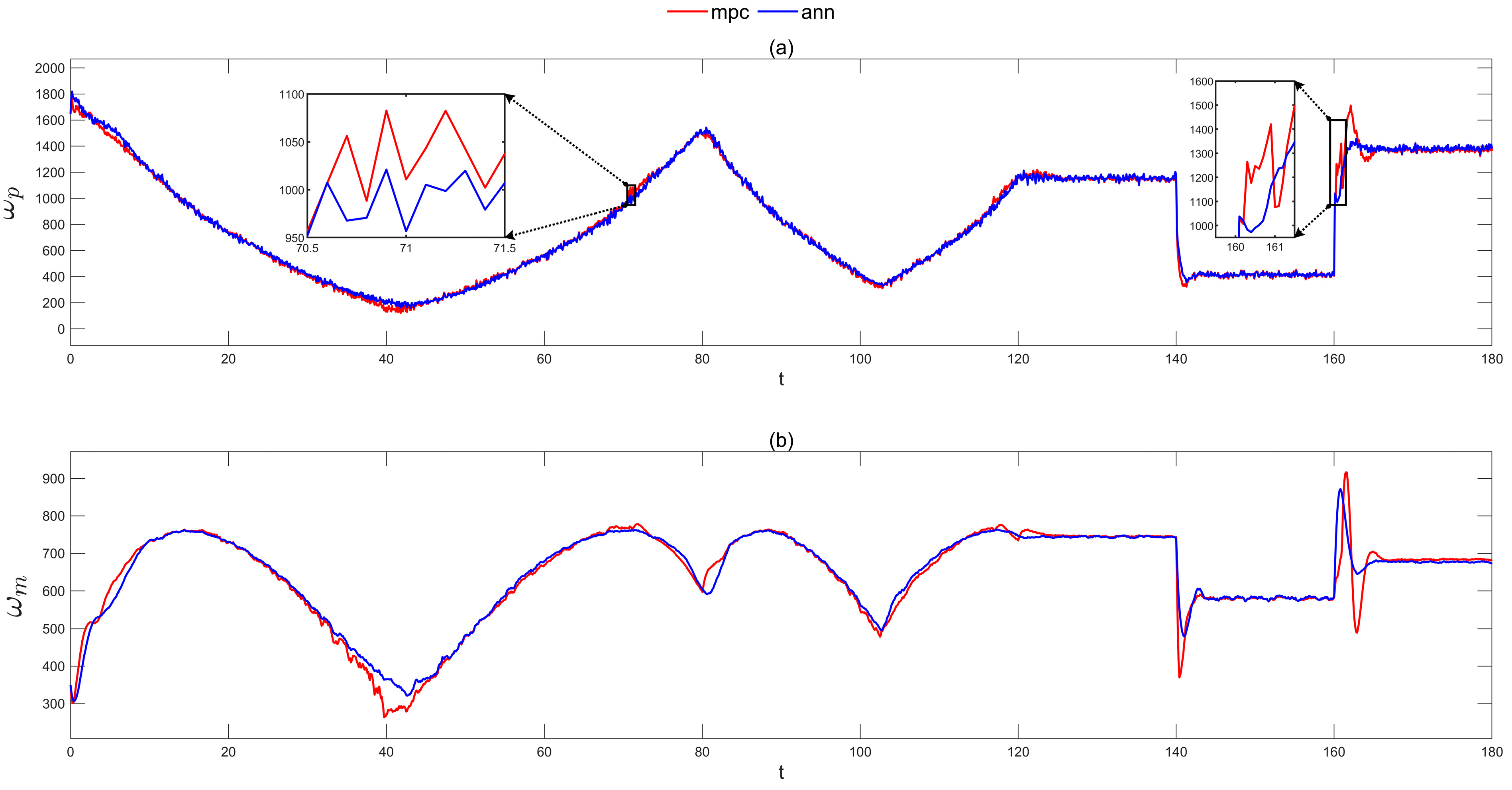

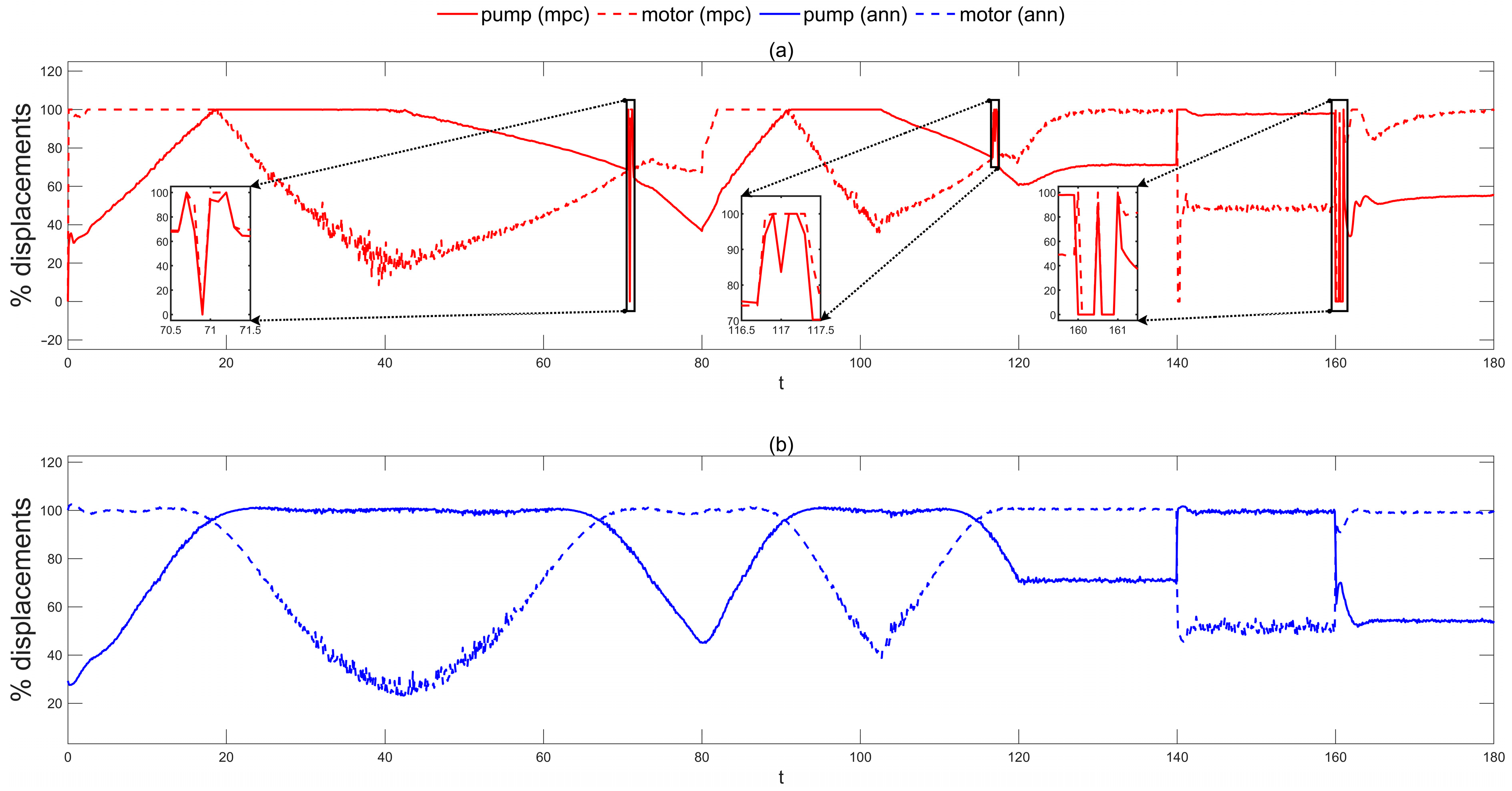

| Multiple MPC | Stochastic (Figure 13) | 24 | 1 | 0.0048 |

| ANN | Stochastic (Figure 13) | 10 | 2.8 | 0.0039 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ülker, H. Design and Application of an Artificial Neural Network Controller Imitating a Multiple Model Predictive Controller for Stroke Control of Hydrostatic Transmission. Machines 2025, 13, 778. https://doi.org/10.3390/machines13090778

Ülker H. Design and Application of an Artificial Neural Network Controller Imitating a Multiple Model Predictive Controller for Stroke Control of Hydrostatic Transmission. Machines. 2025; 13(9):778. https://doi.org/10.3390/machines13090778

Chicago/Turabian StyleÜlker, Hakan. 2025. "Design and Application of an Artificial Neural Network Controller Imitating a Multiple Model Predictive Controller for Stroke Control of Hydrostatic Transmission" Machines 13, no. 9: 778. https://doi.org/10.3390/machines13090778

APA StyleÜlker, H. (2025). Design and Application of an Artificial Neural Network Controller Imitating a Multiple Model Predictive Controller for Stroke Control of Hydrostatic Transmission. Machines, 13(9), 778. https://doi.org/10.3390/machines13090778