1. Introduction

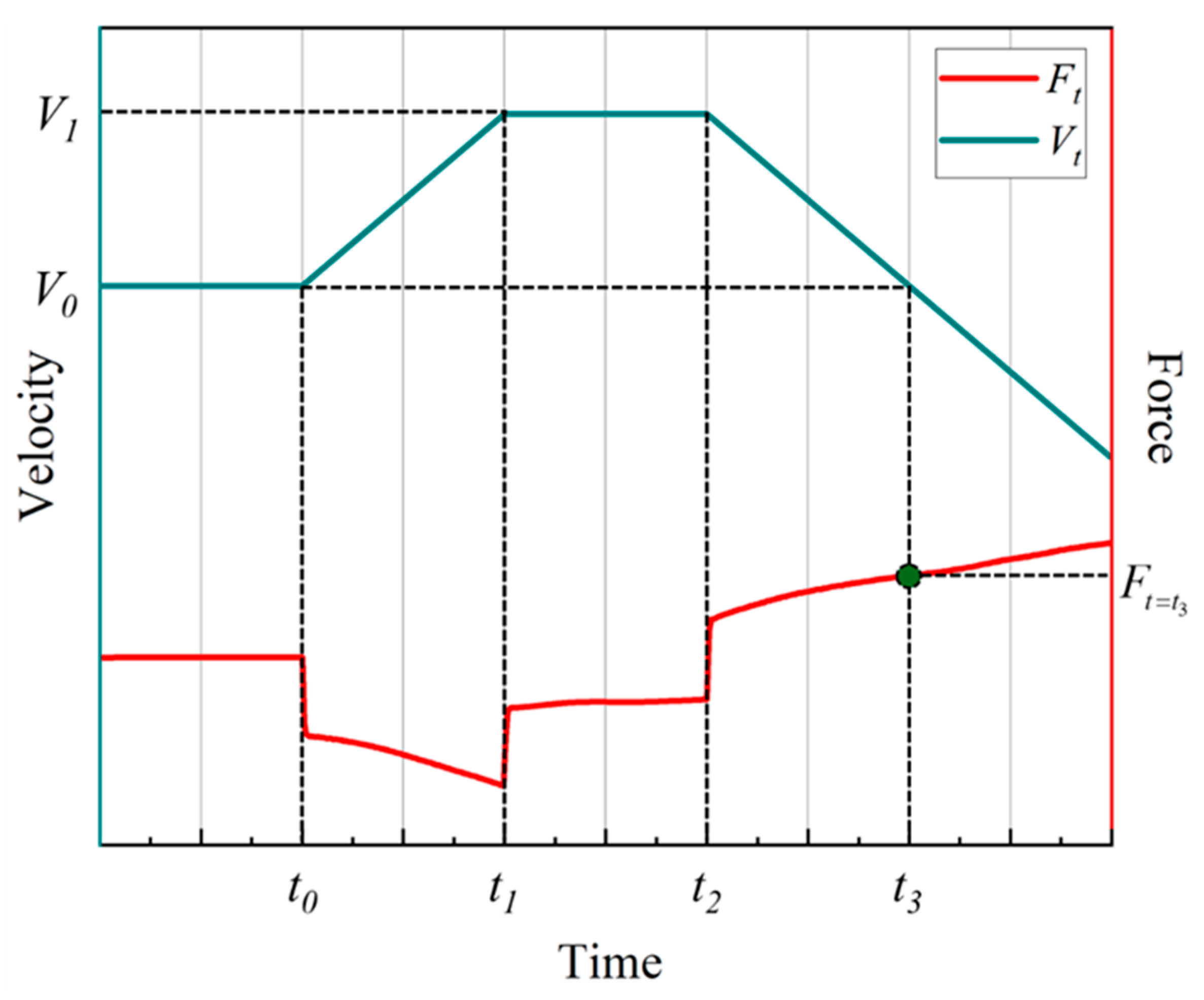

Hydrodynamic coefficients are fundamental dimensionless parameters that characterize the interaction between a body and the surrounding fluid. These coefficients are essential for accurate hydrodynamic modeling. This study focuses on a deep-sea mining vehicle (DSMV) designed for collecting polymetallic nodules from seabed depths of approximately 5000 m (

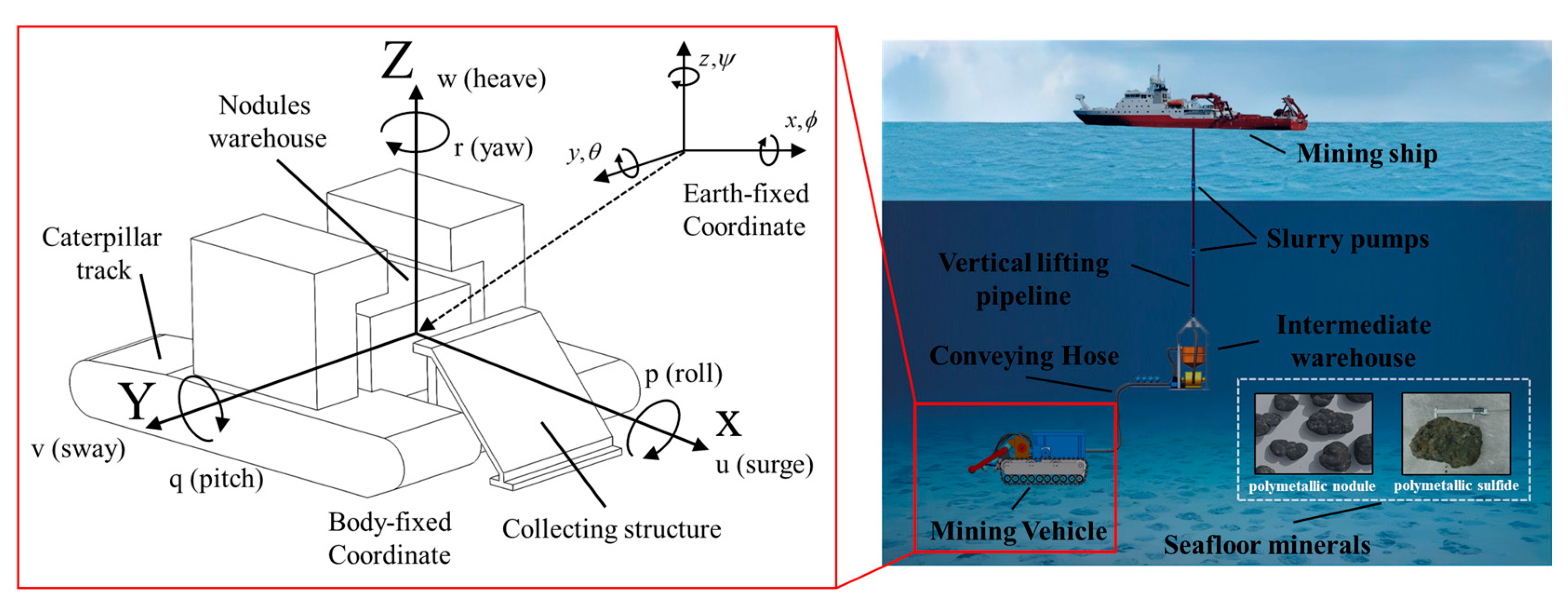

Figure 1). Its complex geometry, required for seabed operations, leads to significant hydrodynamic interactions during prolonged deployment and retrieval phases. During these phases, the vehicle is significantly influenced by hydrodynamic forces. Therefore, the primary objective of this study is to determine the hydrodynamic load coefficients of the DSMV under submerged conditions, providing a theoretical basis for achieving stable motion control during deployment and retrieval operations. For the Deep-Sea Mining Vehicle (DSMV), these coefficients constitute the foundation for formulating the equations of motion and performing hydrodynamic predictions required for control system development [

1,

2,

3].

Among them, the drag coefficient and added mass coefficient are key components that quantify the hydrodynamic resistance and inertial force experienced by the vehicle during steady and accelerating motions, respectively, thereby capturing its dynamic response under complex underwater flow conditions. Accurately obtaining these hydrodynamic coefficients helps to optimize the structural design of the deep-sea mining vehicle and improves its control stability and operational safety during deployment and retrieval.

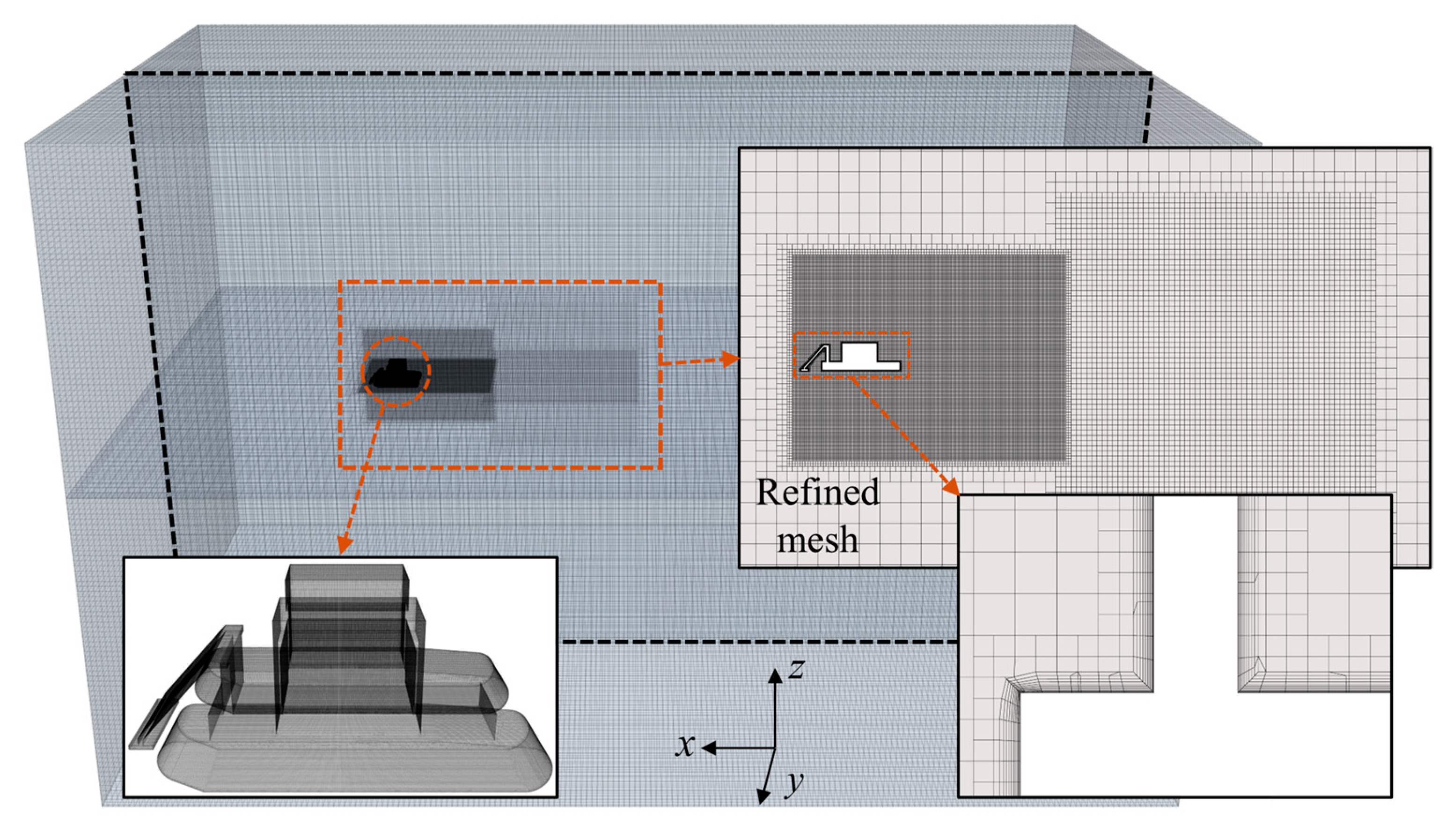

In the hydrodynamic analysis of a DSMV, two reference coordinate systems are utilized: the global coordinate system, which is fixed relative to the Earth, and the local coordinate system, which is fixed relative to the DSMV. The origin of the body-fixed coordinate system (X, Y, Z) is located at the vehicle’s center of buoyancy. This coordinate system translates with the vehicle’s center of mass and maintains a fixed orientation relative to the vehicle’s structure. The linear and angular velocities of the vehicle are expressed in this reference frame. In the Earth-fixed coordinate system (x, y, z), the position and orientation of the vehicle are defined relative to a fixed origin in space, and the origin of this global coordinate system is a stationary reference point. As depicted in

Figure 1, the DSMV exhibits six-degrees-of-freedom (6DOF) motion, which is characterized by using both a body-fixed coordinate system and an Earth-fixed global coordinate system. Within this framework, the hydrodynamic loads acting on the DSMV can be utilized to determine its motion characteristics [

4].

Figure 1.

Body-fixed coordinate system and Earth-fixed global coordinate system of DSMV [

3,

5].

Figure 1.

Body-fixed coordinate system and Earth-fixed global coordinate system of DSMV [

3,

5].

The hydrodynamics of a DSMV is typically analyzed using a 6DOF dynamic model. This model characterizes the hydrodynamic forces and moments acting on the DSMV in all directions. These loads are time-dependent and influenced by the vehicle’s velocity, acceleration, and geometry [

6]. Consequently, the hydrodynamic loads are generally expressed as the products of hydrodynamic coefficients with linear and angular velocities and accelerations. Equations (1)–(6) present the linearized 6DOF motion equations of the DSMV under hydrodynamic loads. These equations incorporate hydrodynamic derivatives and serve as the foundation for the DSMV dynamic model [

7,

8].

The hydrodynamic coefficients in Equations (1)–(6) are typically categorized into two groups: damping coefficients and added-mass coefficients. Damping loads are primarily related to the velocity of the vehicle and depend on its geometry and fluid properties. The corresponding coefficients are referred to as damping coefficients. Added mass loads represent the inertial response of the surrounding fluid to the vehicle’s acceleration, and the associated coefficients are called added mass coefficients.

According to the dynamic model described in Equations (1)–(6), the coefficients , , , , , , , , , , , , , and are classified as damping coefficients. These coefficients represent the hydrodynamic forces and moments associated with the vehicle’s translational and rotational velocities, and they mainly reflect viscous and pressure-induced resistance due to steady motion in water. In contrast, when the vehicle undergoes acceleration or changes in its motion direction, additional hydrodynamic loads arise due to the inertial reaction of the surrounding fluid. These loads are related to translational and angular accelerations as well as Coriolis effects. The coefficients corresponding to these inertial effects are referred to as added mass coefficients, which include , , , , , , , , and . Accurate determination of hydrodynamic coefficients is a critical step for conducting hydrodynamic analysis and ensuring reliable prediction of the vehicle’s hydrodynamic behavior.

In previous studies, numerous researchers have investigated methods for calculating the hydrodynamic coefficients of underwater bodies, primarily employing Analytical and Semi-Empirical (ASE) approaches and Computational Fluid Dynamics (CFD) techniques [

9]. De Barros et al. [

10] employed analytical and semi-empirical (ASE) methods to estimate hydrodynamic derivatives and compared the results with CFD-based lift force evaluations on a fully submerged hull. The approach was applied to the AUV, with predicted derivatives successfully used to estimate its turning diameter during sea trials. Kepler et al. [

11] proposed an approximation method for estimating hydrodynamic coefficients of underwater vehicles using only geometric data. Allotta et al. [

12] conducted a case study on identifying key hydrodynamic parameters of the AUV using a simplified identification approach based on limited sea trial data. Barati et al. [

13] developed highly accurate drag coefficient correlations for smooth spheres across a wide Reynolds number range (up to 10

6) using multi-gene Genetic Programming (GP). Lin and Liao [

14] used FMBEM to efficiently compute added mass coefficients for complex 3D bodies, demonstrating its effectiveness and speed over traditional BEM through SUBOFF submarine simulations. Ferreira et al. [

15] presented the dynamic characterization of an AUV, detailing the main hydrodynamic parameters and the methods used for their identification. Jones et al. [

16] used the Datcom method to calculate hydrodynamic coefficients for four torpedo-shaped vehicles, showing good agreement with experiments. Numerous researchers have also employed analytical and semi-empirical methods to estimate the hydrodynamic derivatives of underwater vehicles [

17,

18,

19,

20].

Numerous researchers have successfully employed the CFD method to determine hydrodynamic coefficients of underwater bodies with high accuracy, establishing CFD as a widely adopted methodology in this field [

21,

22,

23]. Javanmard et al. [

24,

25] used unsteady RANS-based CFD to estimate added mass coefficients under linear acceleration, showing good accuracy and acceleration independence, providing a reliable, efficient alternative to oscillatory simulations and experiments. Nakamura et al. [

26] conducted forced oscillation tests and validated hydrodynamic coefficients through simulation comparisons. Phillips et al. [

27] used the CFD method to estimate AUV stability coefficients, showing good agreement with yawing and rotating arm test data. Raza et al. [

28] presented a novel CFD method for determining the added mass of complex underwater objects. Mishra et al. [

29] developed a CFD-RANS method computing directional added mass coefficients for axisymmetric bodies, validated using spheres and cylinders. Pan et al. [

30] determined appended submarine hydrodynamic coefficients via RANS simulations of Planar Motion Mechanism (PMM) and validated experimentally. Leong et al. [

31] employed RANS CFD to predict SUBOFF hydrodynamic coefficients during maneuvers, validating against experiments. Mesh quality, boundary conditions, and turbulence models critically impacted results. Du et al. [

32] analyzed submarine flow effects on AUV hydrodynamic coefficients during recovery using RANS-based CFD. Results demonstrated significant dependence on AUV attack and sideslip angles, while the Reynolds number influence was negligible. Despite extensive computational fluid dynamics studies of hydrodynamic coefficients for underwater bodies, research specific to the Deep-Sea Mining Vehicle remains absent. Considering the accuracy and cost-effectiveness, this study employs the CFD method to predict hydrodynamic coefficients of the DSMV. Given the geometric complexity of the deep-sea mining vehicle (DSMV), a simplified CFD model was adopted, retaining the key hydrodynamic features such as the collecting structure, nodule warehouse, and caterpillar track. These dominant structures primarily determine the flow separation and wake behavior, while finer geometric details have a negligible influence on overall drag [

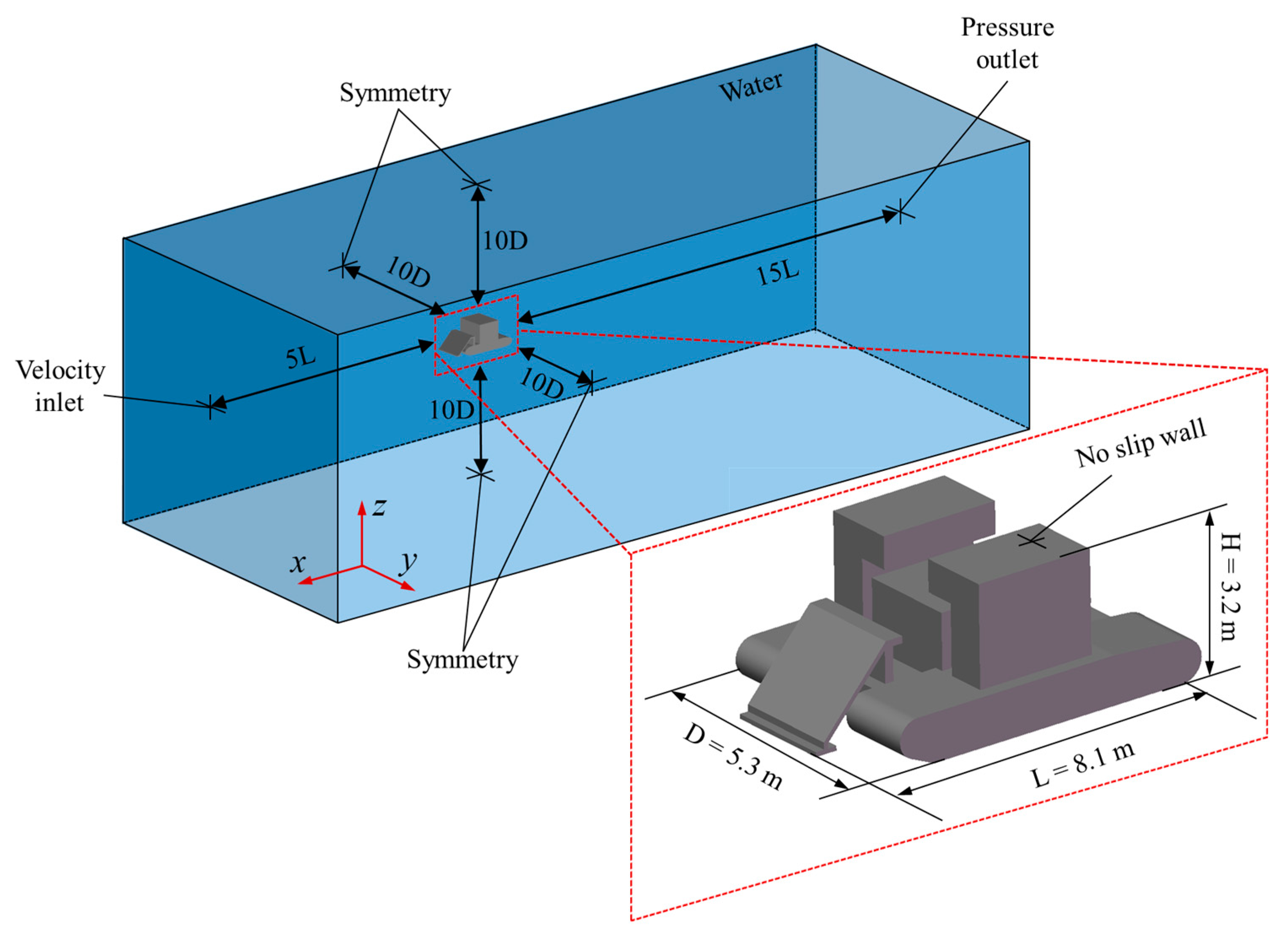

3]. The results of this study will provide critical data for the optimization of hull design and maneuvering control.

4. Results and Discussion

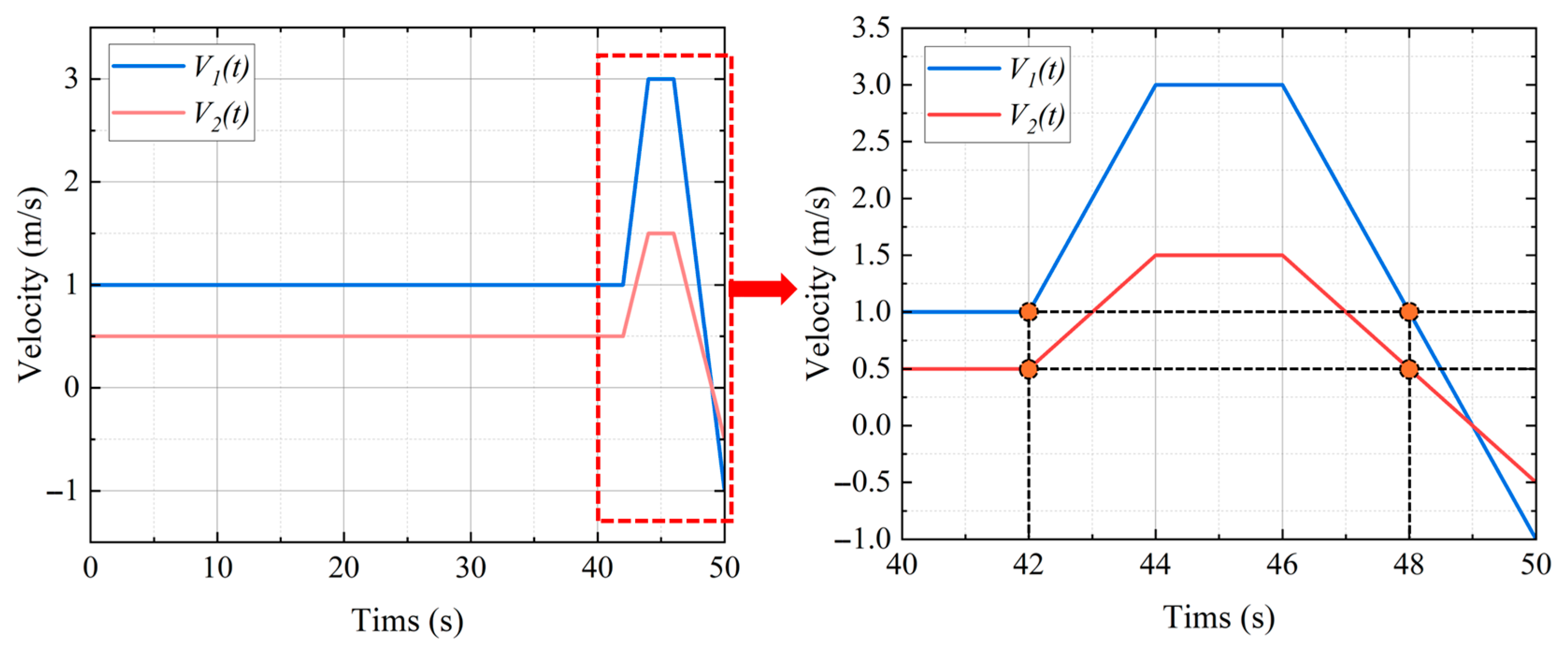

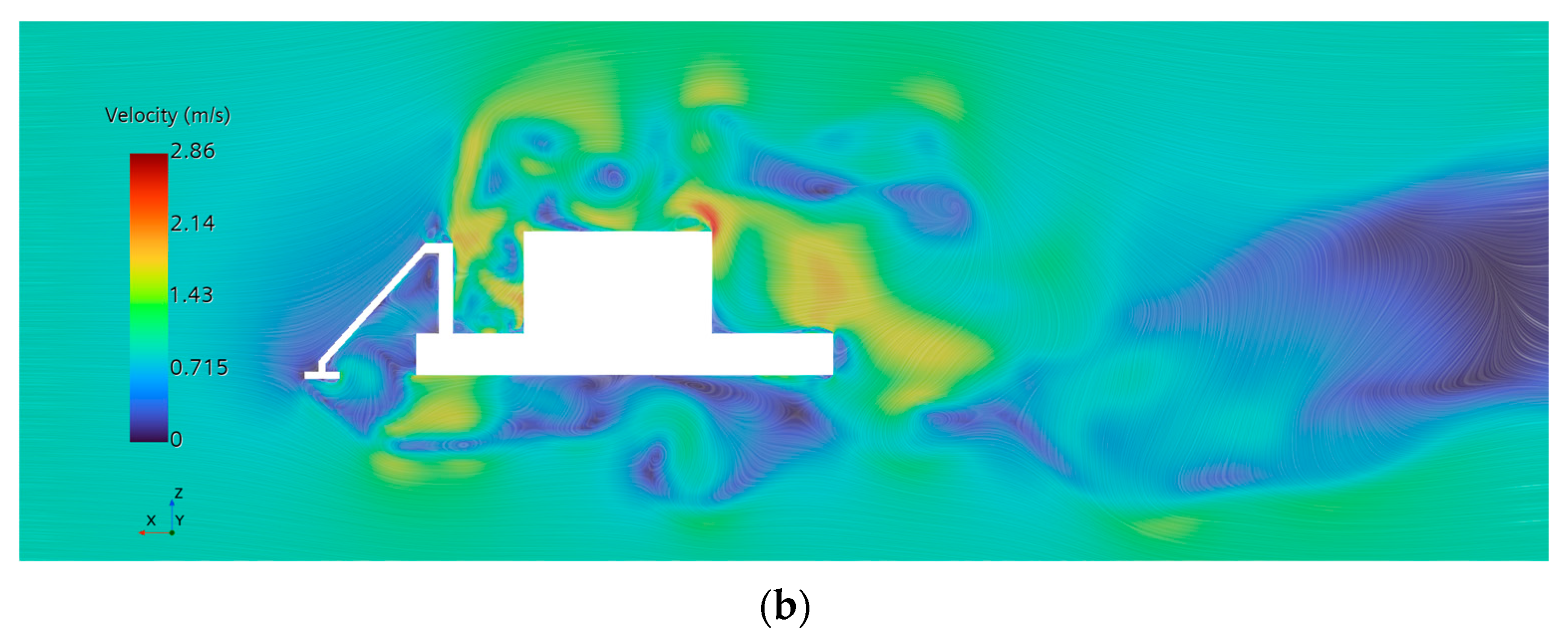

4.1. Analysis of the Transverse Drag Force

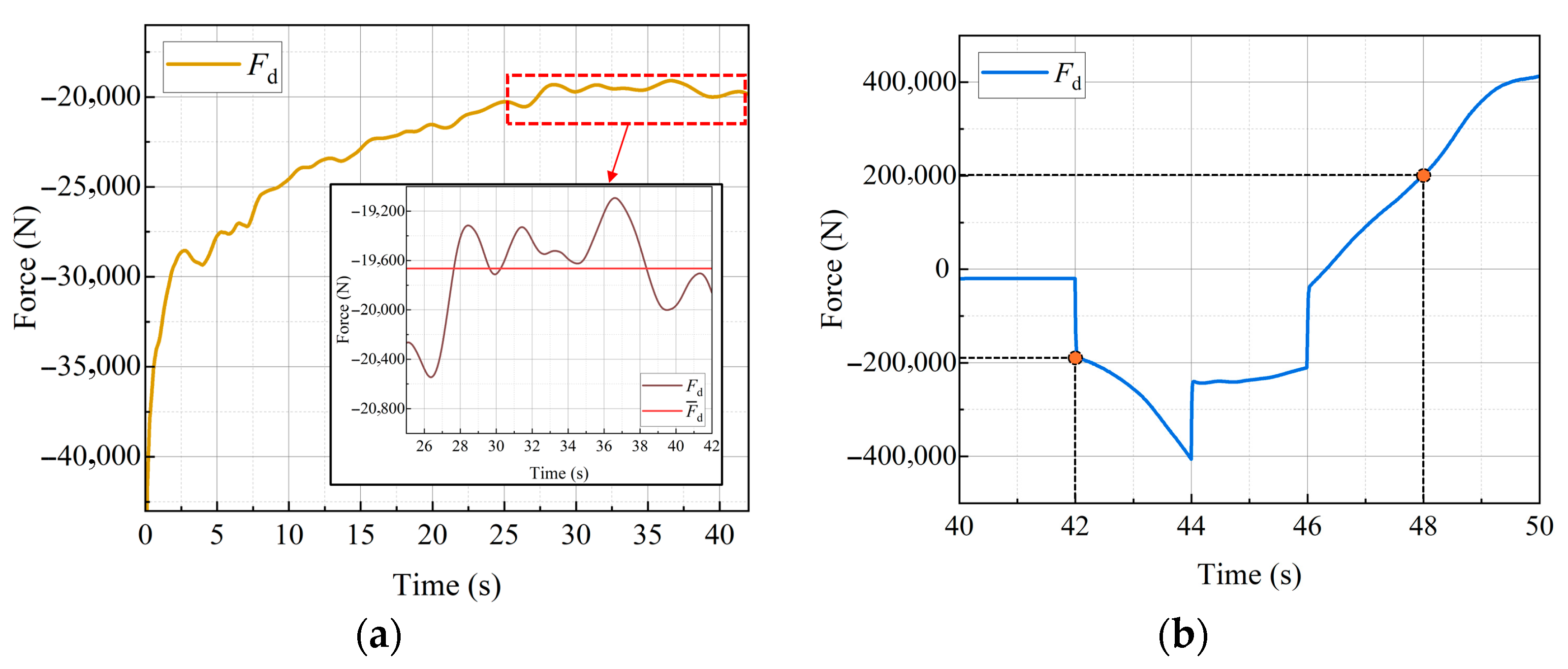

The DSMV exhibits significant differences in wake structure between uniform motion at 1 m/s and deceleration to 1 m/s. During steady motion, the flow remains relatively stable, characterized by the formation of regular vortex structures in the wake region, with the velocity field gradually reaching a stable state, as shown in

Figure 9a. In contrast, during deceleration, changes in vehicle speed induce transient and unsteady interactions between the fluid and the vehicle body, leading to irregular vortex shedding and greater fluctuations within the velocity field, as illustrated in

Figure 9b. These variations are primarily attributed to the inertial response of the fluid and the transient effects caused by changes in the vehicle’s speed on the surrounding flow field.

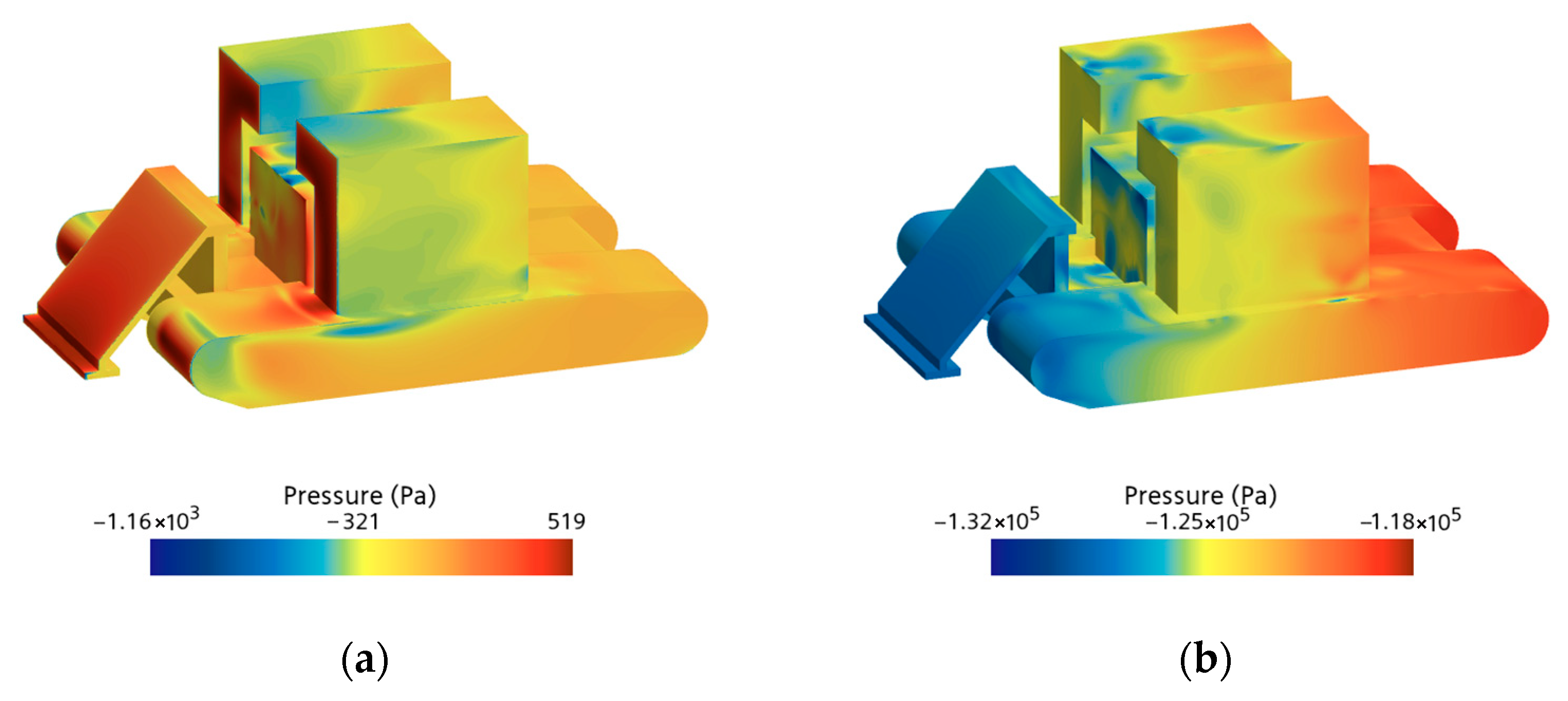

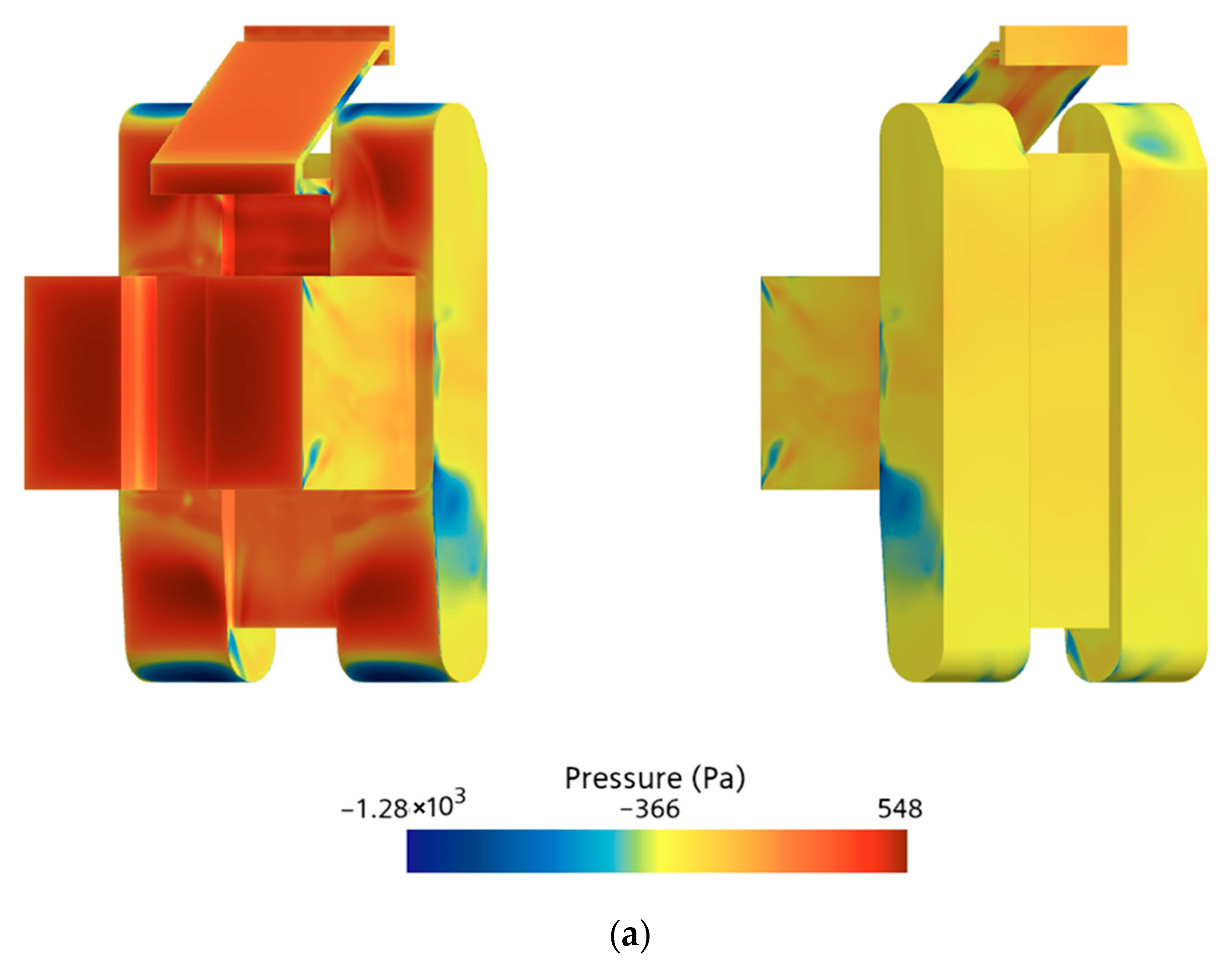

As shown in

Figure 10a, the pressure distribution on the vehicle surface at the steady-state flow field (

t = 42 s) exhibits a distinct pattern. A high-pressure zone forms on the upstream-facing surface due to direct impingement by the incoming flow. In contrast, regions of high-speed flow along the inclined plane, roof, sidewalls, and bottom surface generally exhibit pronounced negative pressure.

Figure 10b shows the surface pressure distribution during the vehicle’s deceleration phase. This stage is characterized by extensive negative pressure regions covering the sloped surface, top, sides, and bottom of the vehicle. Deceleration induces significant fluid inertia and added mass effects, making it difficult for the surrounding fluid to respond instantaneously to the rapid change in velocity. As a result, substantial momentum deficits and isolated fluid regions develop, resulting in a significant decrease in static pressure. Furthermore, the presence of high-speed jets along the slope and sidewalls, the stretching of shear layers, and the continuous shedding of recirculation bubbles and vortices at the rear serve to further intensify both the magnitude and extent of negative pressure zones. The vehicle’s complex geometry also contributes to pronounced spatial nonuniformity and heterogeneity in localized low-pressure regions.

During the deceleration process, a strong correlation exists between the vehicle’s added mass and its wake dynamics. The added mass coefficient quantifies the surrounding fluid’s inertial response to the vehicle’s acceleration or deceleration. During this phase, the fluid’s response lags behind the vehicle’s motion. When the added mass coefficient is high, the fluid’s inertial effects become more pronounced, resulting in irregular vortex shedding, greater flow instability, and increased complexity in the wake region. Higher added mass indicates that the fluid requires more time to adapt its flow state, thereby amplifying unsteady wake behavior.

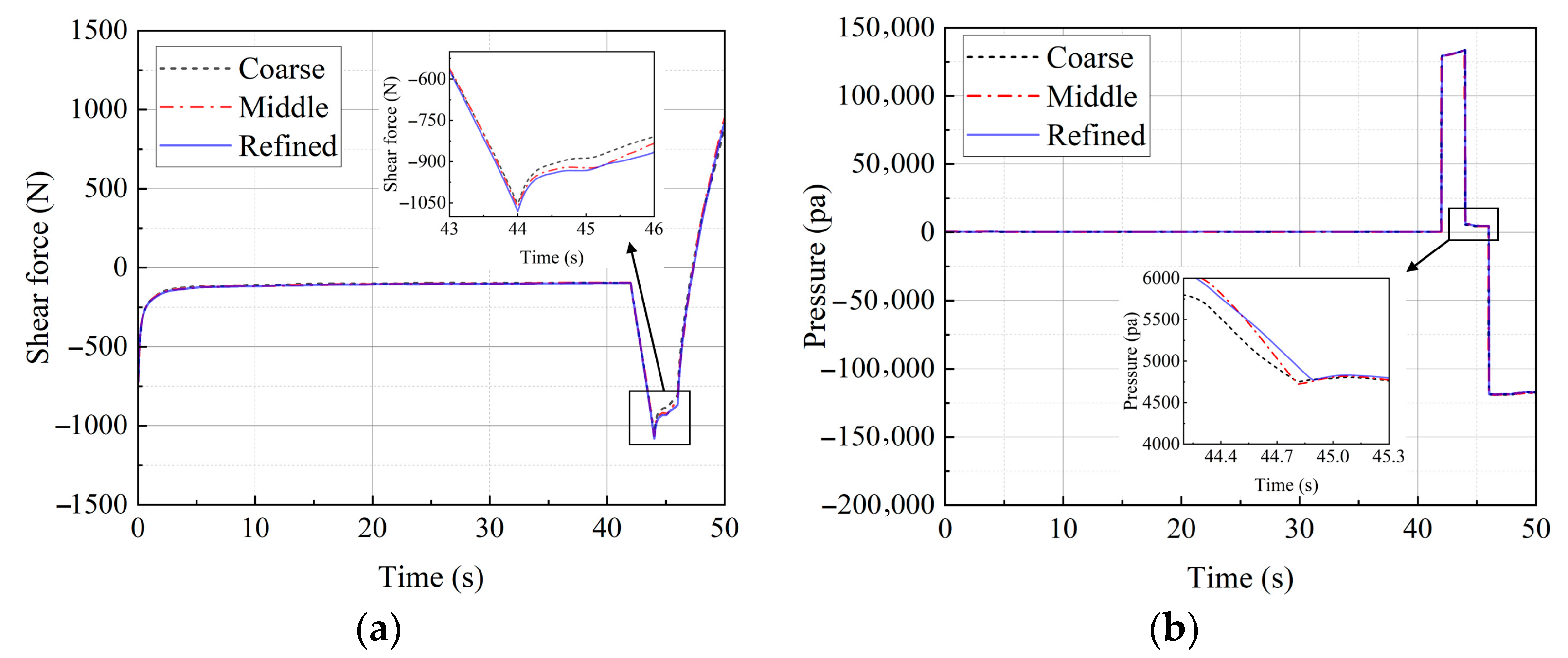

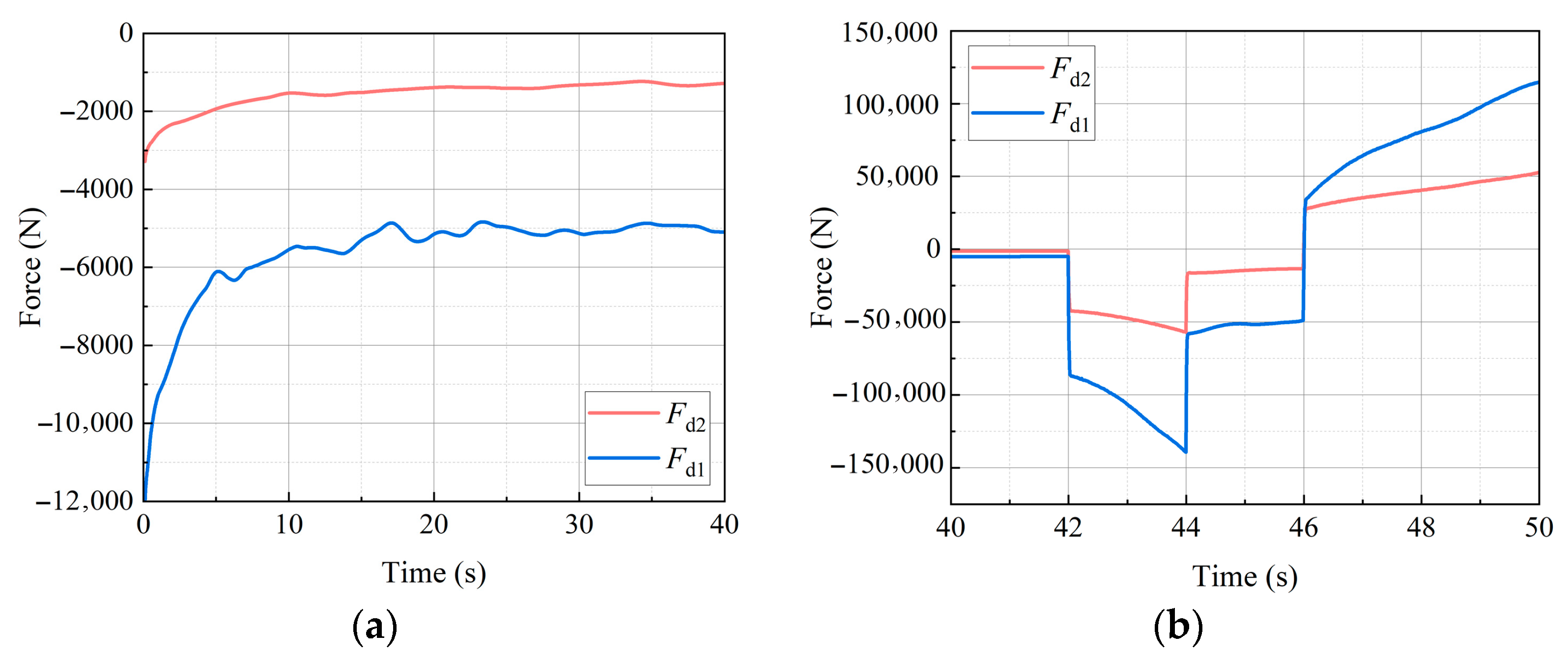

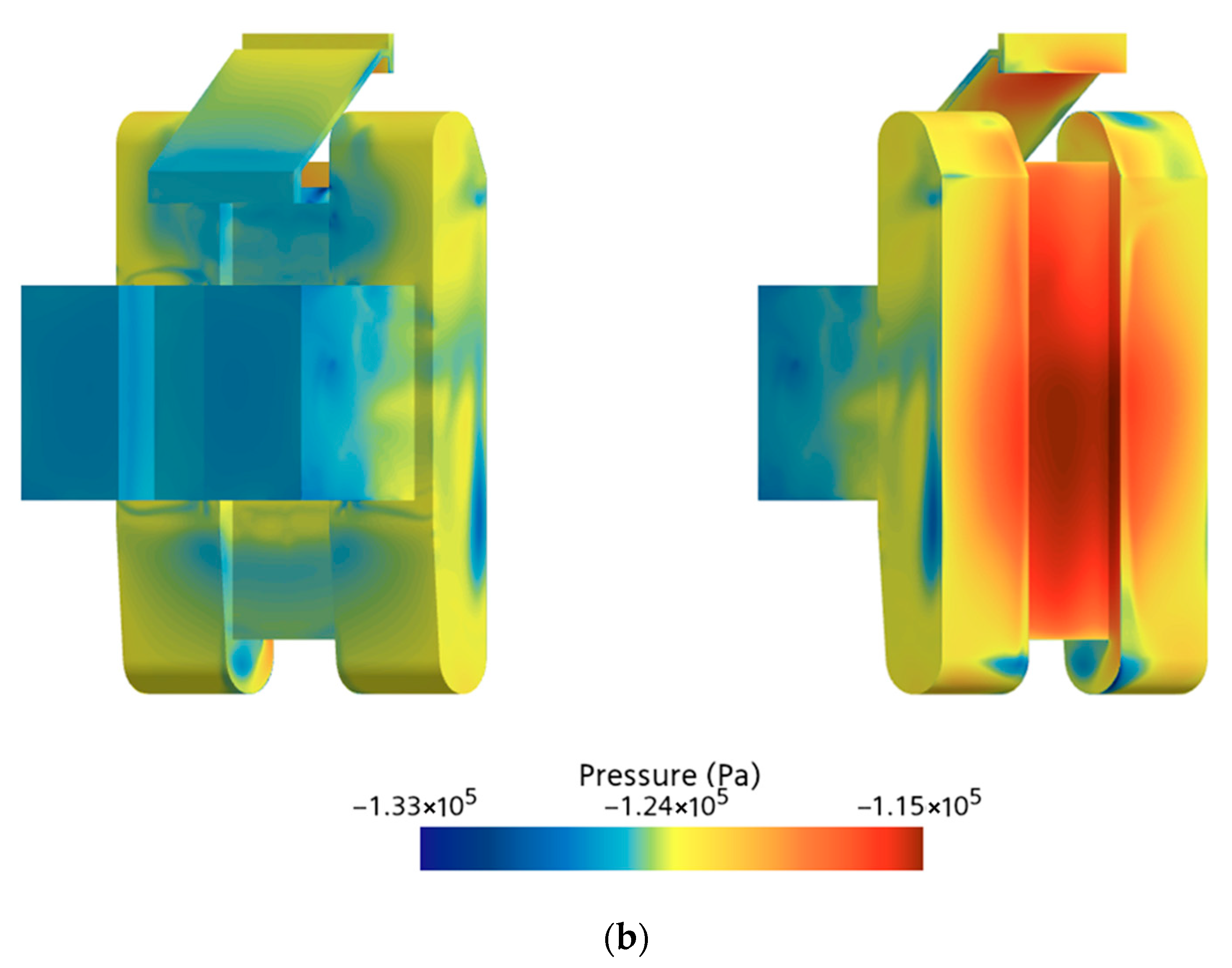

Figure 11 illustrates the variation in the hydrodynamic drag force

acting on the vehicle under flow velocity

.

Figure 11a presents the drag force experienced by the vehicle during the steady velocity phase (at

t = 0–42 s), while

Figure 11b shows the drag force under the variable velocity phase (at

t = 42–50 s).

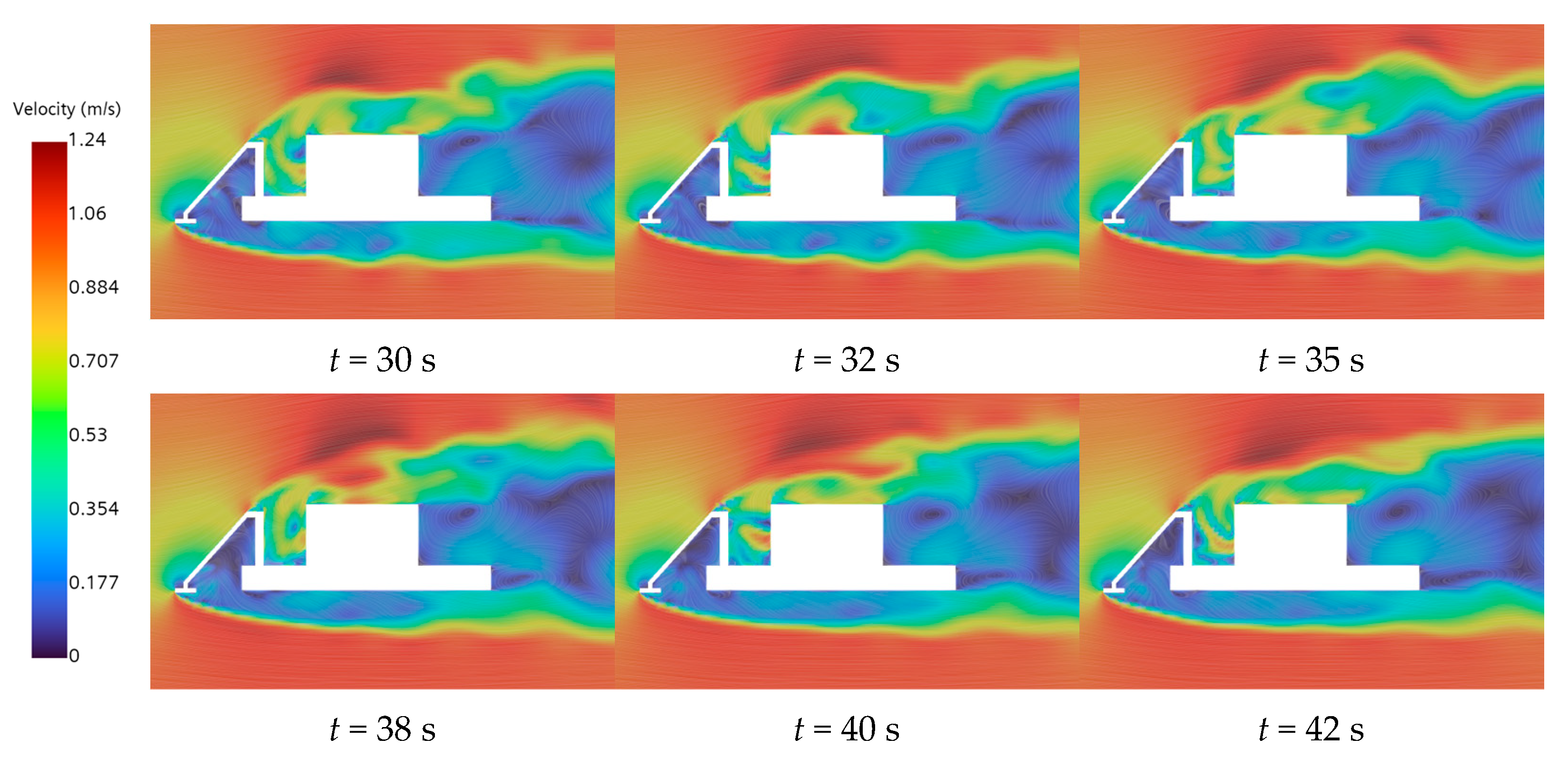

As shown in

Figure 11b, after the DSMV operates under steady flow conditions for a certain duration, the hydrodynamic drag stabilizes and begins to oscillate within a relatively narrow range. These oscillations are closely linked to unsteady flow phenomena such as boundary layer separation and vortex shedding, as illustrated in

Figure 12, which captures the wake evolution and vortex dynamics around the transverse vehicle body. Flow field snapshots from

t = 30–42 s demonstrate periodic vortex shedding from both the upper and lower trailing edges of the vehicle. The presence of swirling streamlines, along with temporally evolving velocity contours in the near-wake region, indicates the development of a vortex street pattern, which exhibits increasing asymmetry as time progresses. A distinct boundary layer separation is observed at the upper trailing edge, where regions of high velocity gradients detach from the vehicle surface into the wake. At later time instants (at

t = 40–42 s), partial flow reattachment is observed in the downstream region, as indicated by a narrowed wake and the emergence of more organized and symmetric flow structures. Furthermore, the shear layers originating from the vehicle’s sharp lateral edges become unstable and roll up into vortices that propagate downstream, contributing to the unsteady pressure drag experienced by the vehicle.

During the steady phase, as the flow field gradually stabilizes, the drag force acting on the vehicle also tends to become stable. However, due to the periodic shedding of wake vortices, the drag force exhibits oscillations within a certain range. Therefore, a time-averaged value of the drag force is calculated during the steady-state period of the flow field, and the drag force acting on the vehicle at a steady flow velocity of 1 m/s is −5030.64 N.

During the variable-speed stage with an imposed acceleration of

, the added mass of the vehicle in water is determined using Equation (17), which separates the viscous force and the inertial force acting on the vehicle.

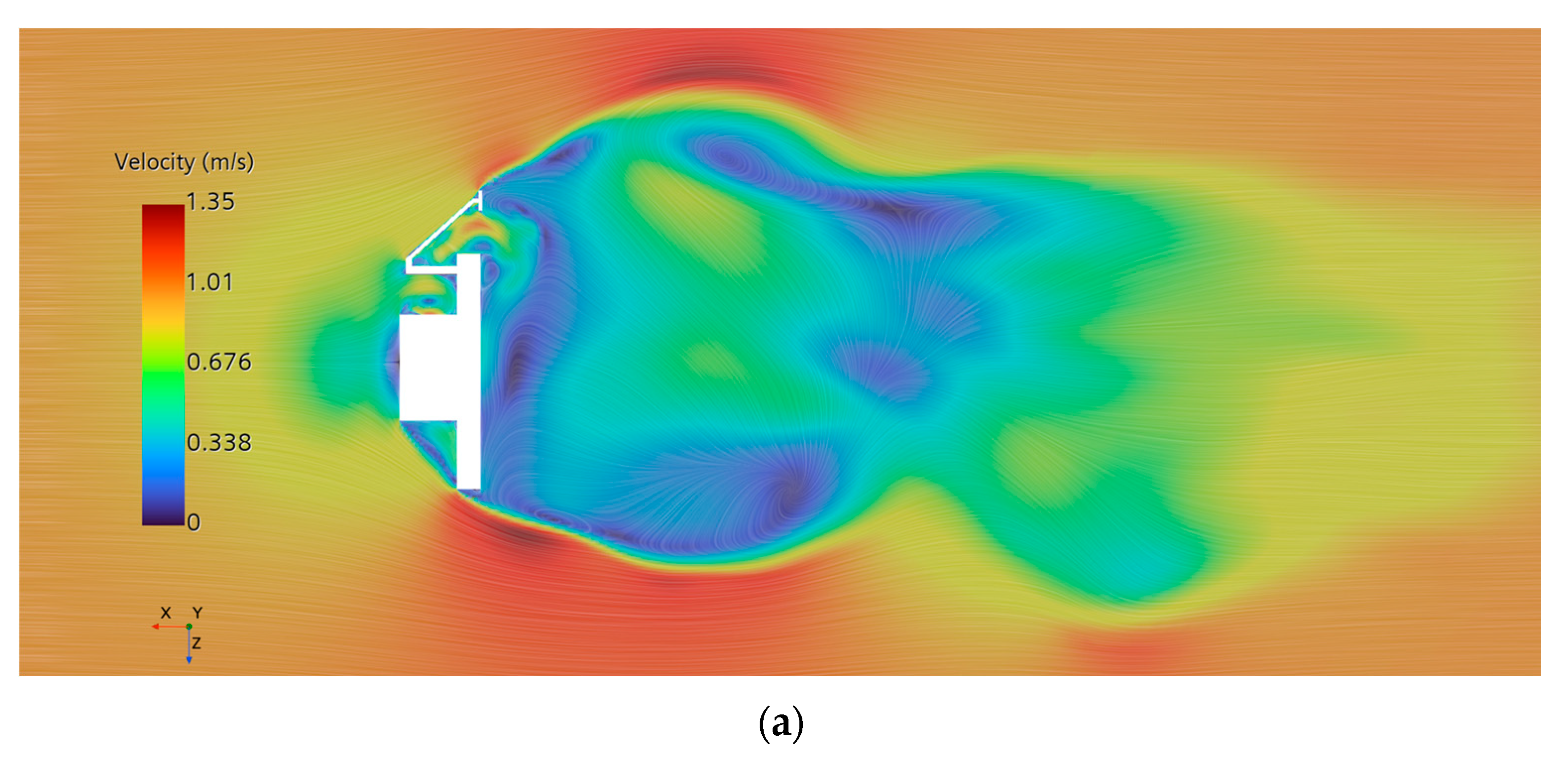

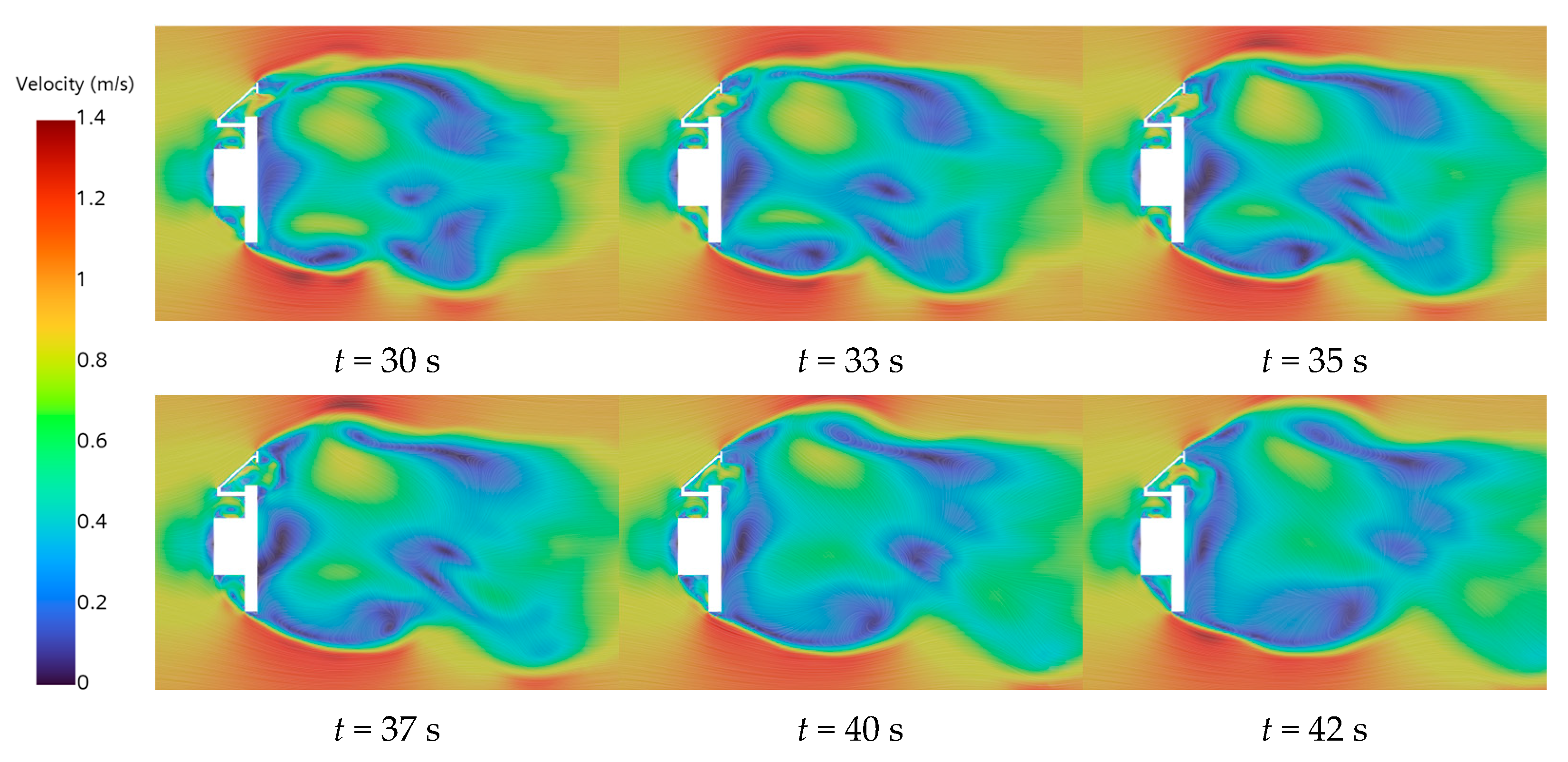

4.2. Analysis of the Vertical Drag Force

The same fluid velocities

were used to perform numerical simulations of the drag force and the added mass in the vertical direction of the vehicle body. The resulting flow field distribution is shown in

Figure 13. During vertical motion, the vehicle exhibits a relatively stable wake structure in the uniform-speed stage, with an overall orderly wake profile and slow kinetic energy dissipation. However, upon entering the deceleration phase, the wake structure shows significant differences compared to the transverse motion, as shown in

Figure 13b. This distinction primarily arises from the geometric transformation of the inflow-facing surface—from a “ramp–platform” configuration to a “narrow vertical wall–ramp” combination, which induces abrupt changes in the separation point location and the formation mechanism of the shear layer, leading to distinct separation patterns and reattachment processes. The change in vehicle attitude not only alters the characteristic length in the inflow direction but also modifies the curvature of the side walls, making inertial pressure pulses more likely to concentrate along the sides during deceleration, thereby strengthening the coupling between the shear layer and the wake.

As a result, the evolution of the added mass layer’s volume and thickness becomes more intense during vertical motion. This rapid variation intensifies the unsteadiness of the wake and enhances the momentum exchange. Under these combined effects, the wake during vertical deceleration becomes more concentrated, vortex shedding occurs more frequently, and the amplitude of unsteady fluctuations significantly surpasses that observed during lateral motion, ultimately resulting in a considerable increase in added mass.

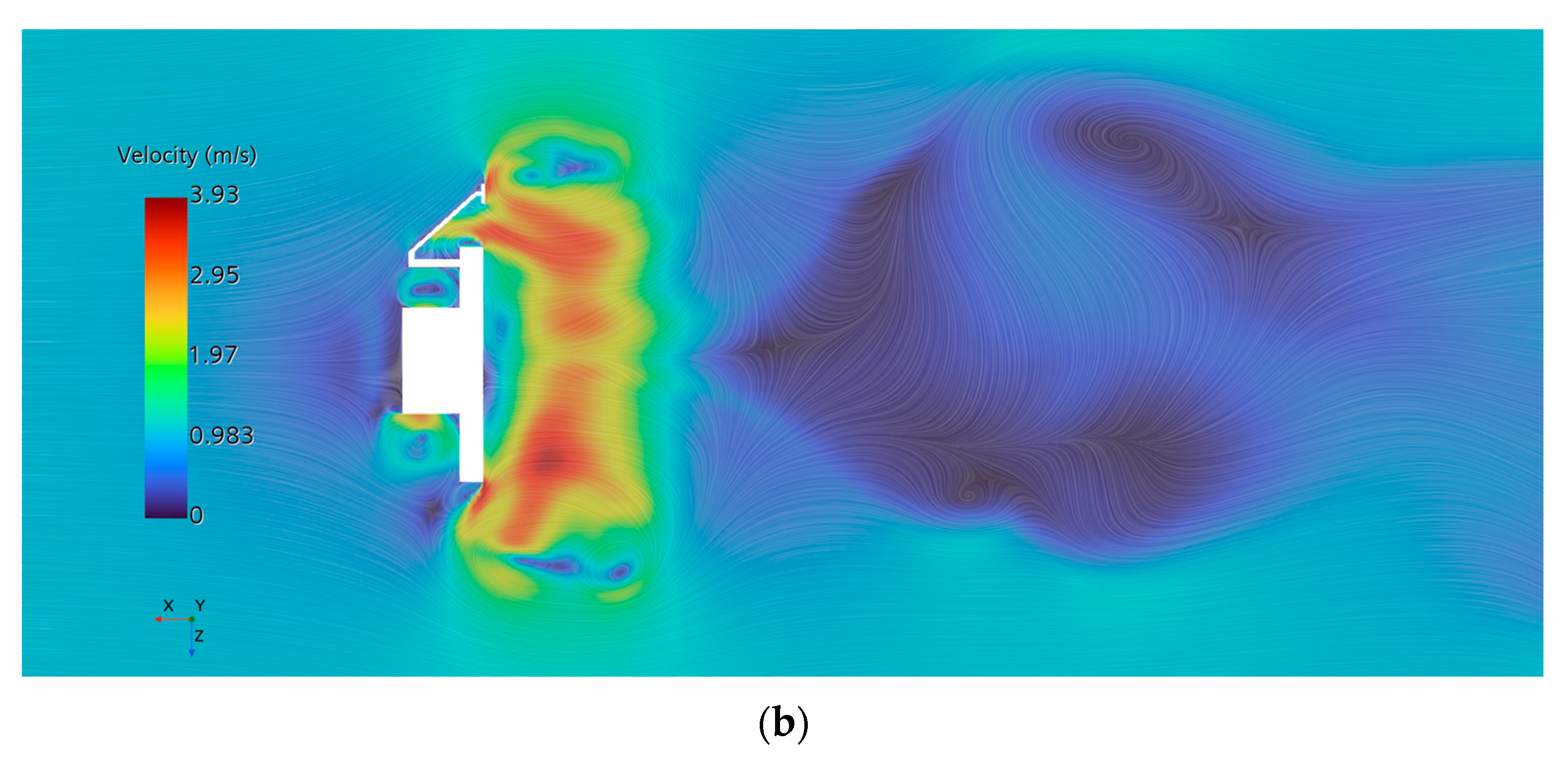

As shown in

Figure 14a, the surface pressure distribution of the vehicle under vertical orientation in a uniform flow field reveals distinct hydrodynamic characteristics. A high static pressure region is formed on the upstream-facing surface due to direct impingement of the incoming flow, while accelerated flow along the sloped surface and sidewalls results in a significant reduction in static pressure. Vortex structures at the vehicle’s rear and in the recirculation, zone further reduce local surface pressure, creating extensive low-pressure regions. During the deceleration phase (

Figure 14b), the vehicle surface experiences widespread negative pressure, mainly due to fluid inertia, added mass effects, and unsteady flow structures. The most significant low-pressure regions appear on the upstream face, sidewalls, and sharp geometrical transitions. This occurs because the surrounding fluid cannot instantly adjust to the vehicle’s speed reduction, causing a pressure imbalance. The added mass effect further lowers pressure by requiring the vehicle to decelerate the adjacent fluid. Accelerated flow along sloped and edged surfaces intensifies shear and reduces pressure via Bernoulli’s principle, and the vortex shedding at the rear also generates sustained low-pressure zones. These effects collectively amplify local stress concentrations and may impact system layout and vehicle stability.

Figure 15 shows the variation trend of the hydrodynamic force acting on the vehicle in the vertical direction. Similarly, the time-averaging method is employed to calculate the hydrodynamic force of the vehicle in a steady uniform flow field, while the added mass is estimated using Equation (9). As illustrated in

Figure 15a, the vertical hydrodynamic force increases significantly, and it takes a longer time to reach a steady state.

Figure 16 illustrates the wake evolution and vortex shedding of the vertical vehicle body. Compared with the results shown in

Figure 12, it can be observed that due to the limited surface length in the streamwise direction, the boundary layer on the vertical body has not developed sufficiently to reach a state where flow separation is likely to occur. As a result, no significant boundary layer separation is observed. However, during the time interval from

t = 30–42 s, although the flow along the body surface remains largely attached, the wake behind the rear edge exhibits asymmetric vortex structures and localized recirculation zones. These features indicate that the wake has entered an early stage of flow instability. The unsteady nature of the shear layers, along with the periodic shedding of weak trailing-edge vortices, induces slight variations in the pressure distribution within the wake region. Consequently, the hydrodynamic drag acting on the vehicle body fluctuates within a limited amplitude range, even in the absence of full boundary layer separation.

After stabilization, the time-averaged drag force

is −19,664.45 N. Furthermore, by utilizing the variable-speed motion to separate viscous and inertial forces, the added mass of the vehicle in the vertical direction

is extracted and found to be 167,581.13 kg.

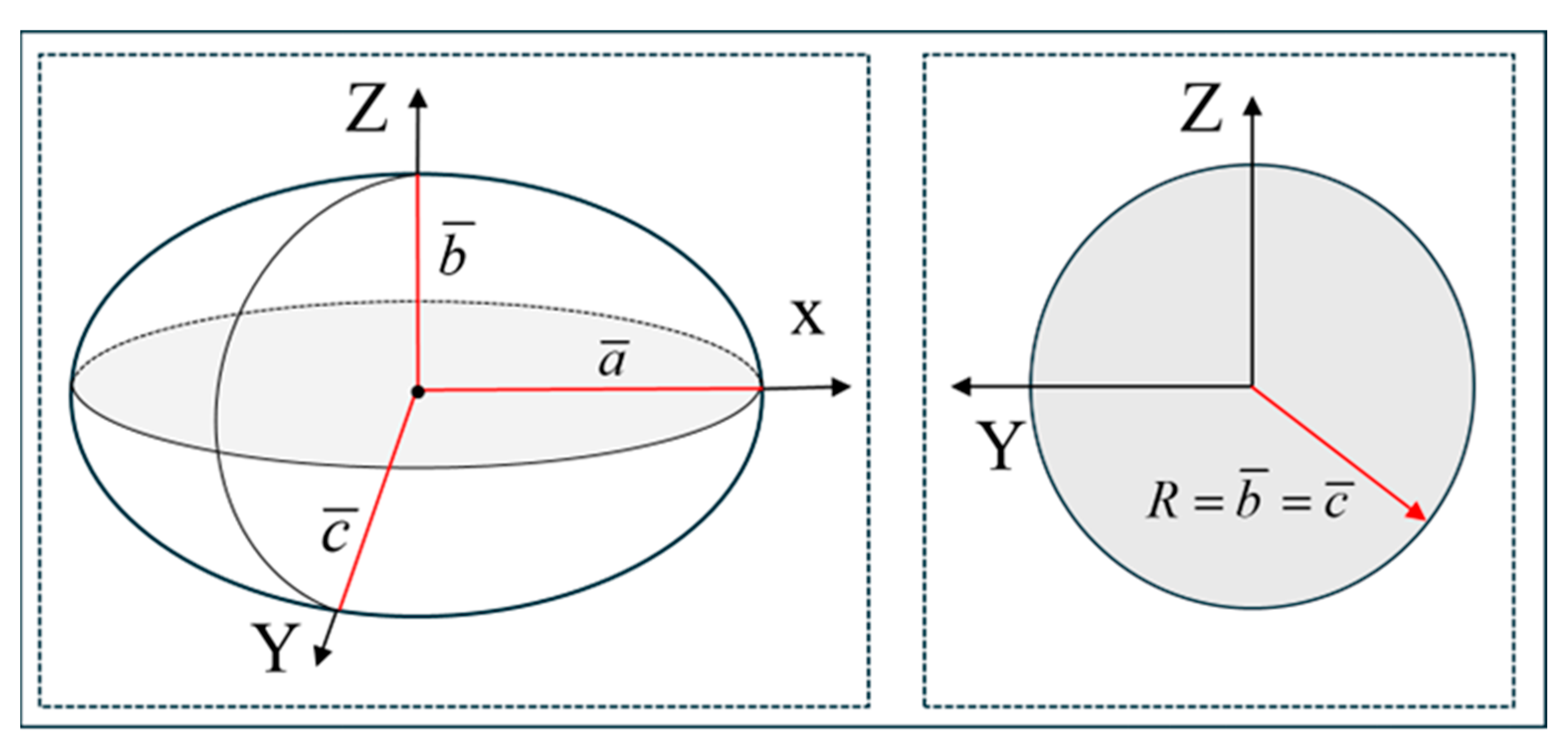

4.3. Drag Coefficient and Added Mass Coefficient

The analysis of the wake structure and variation in hydrodynamic forces acting on the deep-sea mining vehicle (DSMV) in both transverse and vertical orientations demonstrates notable differences in hydrodynamic responses depending on the direction of motion. Specifically, the vertical drag force is approximately 3.909 times higher than that observed in the transverse direction, accompanied by a significant increase in added mass. To facilitate a more precise comparison and quantification of drag and added mass characteristics across different orientations, this study computes the respective drag and added mass coefficients using geometric characteristic lengths specific to each orientation.

Drag force and added mass represent two distinct concepts in fluid dynamics, corresponding to the steady viscous effects and the unsteady inertial response of the fluid to a moving body, respectively. As a result, the characteristic length scales employed in their evaluation differ accordingly. Drag force is primarily determined by flow separation and the development of wake structures in the region adjacent to the body’s frontal area, with its characteristic length generally defined as the dimension perpendicular to the direction of the incoming flow. In contrast, added mass arises from the fluid’s inertial response to the body’s acceleration, which is directly related to the volume of fluid displaced during motion. As a result, the characteristic scale for added mass is typically quantified using the displaced volume of the body or an equivalent volumetric length.

The drag coefficient of the vehicle body is defined as shown in Equation (19):

where

is the incoming flow velocity;

is the projected area of the headward flow.

As shown in

Figure 17, the DSMV projection onto the transverse

x-axis

and the vertical

z-axis

is 13.061 m

2 and 39.166 m

2, respectively. At a flow velocity of 1 m/s, the corresponding Reynolds numbers are 4.07 × 10

6 and 7.04 × 10

6, respectively. The drag coefficient

of the vehicle body is 0.7722 in the transverse direction and the drag coefficient

of the vehicle body is 1.0066 in the vertical direction. The added mass coefficient of the DSMV is calculated by Equation (20), the transverse added mass coefficient

and a vertical added mass coefficient

.

where

denotes the mass of the displaced volume of the water occupied by the DSMV, in this study

= 54,132.06 kg.

There are significant differences in the hydrodynamic responses of the deep-sea mining vehicle (DSMV) between the transverse and vertical directions, particularly in terms of drag coefficients and added mass coefficients. As shown in

Figure 17, the projected area of the vehicle in the transverse (

x-axis) direction is 13.061 m

2, whereas in the vertical (

z-axis) direction, it reaches 39.166 m

2—approximately three times greater. The corresponding drag coefficients are 0.7722 and 1.0066, respectively. These values indicate that, despite the larger vertical projected area, the associated flow separation and wake structures are more complex, leading to a significantly higher drag force and an elevated drag coefficient. Furthermore, the added mass coefficient in the transverse direction is 0.584, while in the vertical direction, it increases to 3.096. This suggests that the fluid’s inertial response during vertical acceleration is considerably stronger. The observed difference primarily stems from variations in the vehicle’s geometric configuration under different orientations: the vertical inflow surface includes large vertical wall structures that induce a broader range of fluid disturbance and inertial coupling, thereby causing a rapid increase in both the volume and thickness of the added mass layer. In contrast, the transverse inflow surface exhibits a more streamlined shape, resulting in weaker inertial effects.