Abstract

Industrial robots are undergoing a transformative shift as Artificial Intelligence (AI)-driven and bio-inspired control strategies unlock new levels of precision, adaptability, and multi-dimensional sustainability aligned with Industry 5.0 (energy efficiency, material circularity, and life-cycle emissions). This systematic review analyzes 160 peer-reviewed industrial robotics control studies (2023–2025), including an expanded bio-inspired/human-centric subset, to evaluate: (1) the dominant and emerging control methodologies; (2) the transformative role of digital twins and 5G-enabled connectivity; and (3) the persistent technical, ethical, and environmental challenges. Following the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) 2020 guidelines, the study employs a rigorous methodology, focusing on adaptive control, deep reinforcement learning (DRL), human–robot collaboration (HRC), and quantum-inspired algorithms. The key findings highlight up to 30% latency reductions in real-time optimization, up to 22% efficiency gains through digital twins, and up to 25% energy savings from bio-inspired designs (all percentage ranges are reported relative to the comparator baselines specified in the cited sources). However, critical barriers remain, including scalability limitations (with up to 40% higher computational demands) and cybersecurity vulnerabilities (with up to 20% exposure rates). The convergence of AI, bio-inspired systems, and quantum computing is poised to enable sustainable, autonomous, and human-centric robotics, yet requires standardized safety frameworks and hybrid architectures to fully support the transition from Industry 4.0 to Industry 5.0. This review offers a strategic roadmap for future research and industrial adoption, emphasizing human-centric design, ethical frameworks, and circular-economy principles to address global manufacturing challenges.

1. Introduction

Industrial robots have progressed from basic programmable manipulators to advanced systems adept at handling complex tasks in dynamic environments. The rise of Industry 4.0 has spurred sophisticated control strategies, merging robotics with cyber-physical systems, the Internet of Things (IoT), and Artificial Intelligence (AI). For example, in automotive manufacturing, real-time robot coordination ensures production flow amid high variability and mass customization, while electronics assembly requires micrometer-scale precision, achieved through AI and sensor fusion for self-calibration.

This review synthesizes the recent research (2023–2025) on control paradigms, enhancing precision, adaptability, and collaboration in industrial robotics; drawing on 160 peer-reviewed industrial robotics control studies (see Section 2); and including an expanded bio-inspired/soft-robotics, human-centric subset drawn from IEEE, Scopus, and PubMed sources (Appendix A, Table A3; see Section 3.7) to provide a comprehensive snapshot. It addresses three key questions: (1) What dominant control methodologies emerge in the recent literature, and how do their performance metrics (e.g., accuracy, latency, energy use) vary across applications? (2) How do AI, digital twins, and 5G connectivity transform robot control in sectors like automotive, electronics, and logistics? (3) What technical, ethical, and environmental challenges persist, and how can they be addressed?

The shift to Industry 5.0, emphasizing human-centric design, sustainability, and resilience, is also examined [,,]. Emerging paradigms—bio-inspired control [,,,,,,,,,,,,,,,], quantum-enhanced algorithms [], cybersecurity frameworks [,,,,,], and additive manufacturing (AM) integration [,,,,,]—promise to overcome scalability, safety, and eco-efficiency limitations. Here, sustainability is treated broadly to include energy efficiency, material circularity, and life-cycle carbon metrics. Recent advances in adaptive control [,,], AI-driven systems [,,,,,,,,,], human–robot collaboration (HRC) [,,,,,,,], and digital twins [,,,,,,,,,,] highlight rapid progress. This work offers a roadmap for researchers and practitioners, bridging current trends with future innovations, including autonomous systems poised to boost throughput by 20%, safety by 15%, and energy efficiency by 25% [,,] (values reported relative to the conventional baselines described in the cited sectoral studies).

2. Methods

This systematic review analyzed 160 peer-reviewed journal articles on industrial robotics control meeting all the prespecified inclusion criteria (2023–2025; English; industrial scope; peer reviewed), sourced from the Web of Science (WoS) Core Collection, IEEE Xplore, Scopus, and PubMed, with a focus on high-impact journals (primarily Q1 and Q2 in automation, robotics, and related fields). Search terms included “industrial robot control”, “adaptive robotics”, “AI in robotics”, “digital twins in manufacturing”, “5G-enabled robotics”, “human-centric automation”, “bio-inspired robotics”, “cybersecurity in robotics”, “additive manufacturing robotics”, “multi-robot coordination”, “ethical robotics”, “quantum control”, and “real-time robotic optimization”; the full Boolean expansions are provided in Table A1. These terms were designed to capture advancements in control strategies for industrial robotics within the Industry 5.0 framework, and the corpus includes an expanded bio-inspired/human-centric subset highlighted in Appendix A, Table A3 and discussed in Section 3.7.

2.1. Search Strategy

Search strings, detailed in Appendix A (Table A1), were applied to the Title, Abstract, and Author Keywords fields, using platform-specific wildcards and Boolean operators. A pilot search across “All Fields” yielded a ~6% increase in irrelevant records and no additional eligible studies, justifying the restricted search strategy. Searches were limited to English-language journal articles or reviews published in 2023–2025, and indexed in WoS (Science Citation Index Expanded), IEEE Xplore, Scopus, or PubMed. A small number of authoritative industry reports were included for contextual relevance (excluded from quantitative tallies but cited narratively where appropriate).

2.2. Inclusion and Exclusion Criteria

The inclusion criteria required articles to: (1) present original research or reviews on industrial robot control strategies; (2) be published in peer-reviewed, high-impact journals (Q1/Q2 preferred but not mandatory if technical novelty warranted inclusion); and (3) focus on technological advancements with experimental or high-fidelity simulation validation. The exclusion criteria eliminated: (1) duplicates; (2) non-peer-reviewed works (e.g., conference papers, preprints, theses) except for a small, flagged set of high-relevance preprints retained under the limitations policy; (3) studies unrelated to control strategies; (4) non-industrial robotics (e.g., service or medical robots); and (5) non-English articles or inaccessible full texts. The criteria are detailed in Appendix A (Table A2).

Operational relevance was defined a priori as: (i) a focus on industrial (manufacturing or production) robots; (ii) presentation of a control method (algorithmic, architectural, or sensing-driven) supported by experimental or high-fidelity simulation evidence; and (iii) linkage to at least one Industry 4.0/5.0 enabling technology (e.g., AI/ML, digital twins, high-bandwidth/5G connectivity, bio-inspired actuation or morphology, human–robot collaboration, or cybersecurity for networked control). Records meeting the domain scope but lacking control data were coded “method mismatch”; those centered on non-industrial domains were coded “domain mismatch.”

2.3. Screening and Selection

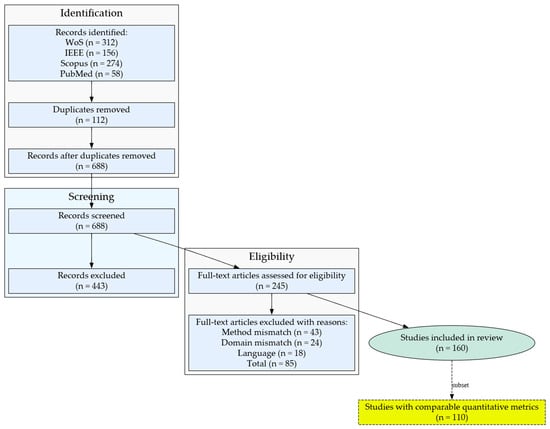

From an initial pool of 800 records (WoS = 312, IEEE Xplore = 156, Scopus = 274, PubMed = 58), 112 duplicates were removed, leaving 688 records for title/abstract screening. Two independent reviewers screened records against the inclusion criteria, achieving high inter-rater reliability (Cohen’s κ = 0.84). After screening, 245 articles underwent full-text evaluation, with 85 excluded for reasons including method mismatch (n = 43), domain mismatch (n = 24), and language (n = 18). The final 160 articles addressed three research questions: (1) What are the dominant control methodologies? (2) How do AI, digital twins, and 5G transform robot control? (3) What technical, ethical, and environmental challenges persist? A PRISMA 2020 flow diagram (Figure 1) summarizes the process.

Figure 1.

PRISMA 2020 flow diagram detailing: records identified (WoS = 312, IEEE = 156, Scopus = 274, PubMed = 58); duplicates removed (n = 112); records screened (n = 688); full-text assessed (n = 245); studies excluded with reason (method mismatch = 43, domain mismatch = 24, language = 18); studies included in qualitative synthesis (n = 160) and, of these, studies contributing quantitative metrics (n = 110).

2.4. Data Extraction and Synthesis

For each included article, data were extracted by the author for bibliographic information, application domain, control strategy category, enabling technologies (AI/ML, digital twins, network layer, HRC, bio-inspired elements, etc.), validation modality (physical/experimental vs. high-fidelity simulation), and reported quantitative performance metrics (accuracy, latency, throughput, energy, safety, quality). Of the 160 included studies, 110 reported one or more metrics in formats that were sufficiently comparable to support cross-study descriptive aggregation; these form the quantitative subset synthesized in Section 5 and Table 1. The remaining 50 studies lacked directly comparable metrics and were therefore synthesized qualitatively in Appendix A. Studies lacking comparable metrics were synthesized qualitatively (narrative thematic synthesis).

Table 1.

Comparative performance of industrial-robot control methods (mean values from the 110-study quantitative subset of the 160 papers reviewed).

2.5. Protocol Registration and Limitations

The review adhered to the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) 2020 guidelines. Limitations include potential bias from excluding non-English literature and the rapid publication dynamics in emerging bio-inspired/human-centric robotics. Several studies that were available as preprint or early access manuscripts at the time of initial screening subsequently appeared in peer-reviewed form; their final bibliographic details are reflected in the References list. All of these studies met the inclusion criteria and are counted within the 160-study corpus; however, many reported heterogeneous metrics and therefore did not always contribute to the quantitative aggregation. A summary of this rapidly evolving subset is provided in Appendix A, Table A3.

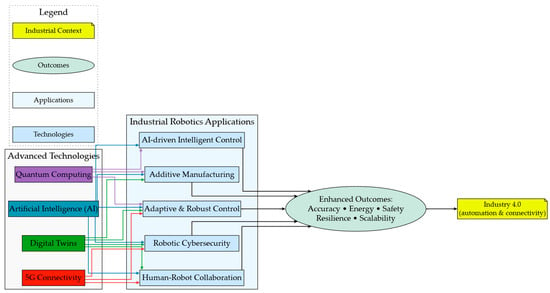

3. Advances in Control Strategies

Industrial robots have significantly advanced, incorporating diverse and innovative control strategies to optimize their performance in complex and dynamic manufacturing environments. Figure 2 details the Industry 4.0 technology stack, showing how digital twins, Artificial Intelligence, 5G connectivity, and quantum computing feed a core set of industrial robotics applications: adaptive and robust control, AI-driven intelligent control, additive manufacturing, human–robot collaboration, and robotic cybersecurity. The convergence of these technologies drives enhanced outcomes—accuracy, energy efficiency, safety, resilience, and scalability—which in turn enables the automation- and connectivity-focused paradigm of Industry 4.0.

Figure 2.

Industry 4.0 technology stack for industrial robotics: Synergistic integration of digital twins, AI, 5G connectivity, and quantum computing.

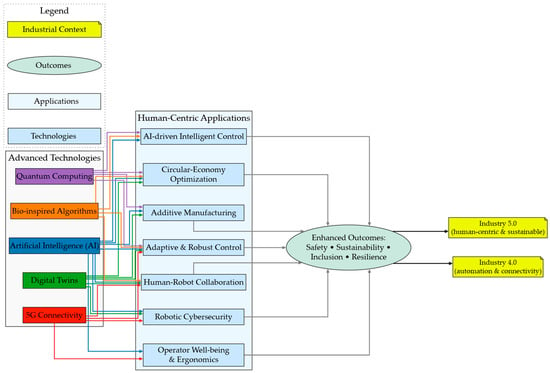

Building on that foundation, Figure 3 introduces additional human-centric layers—bio-inspired algorithms, circular-economy optimization, and operator well-being and ergonomics—and relabels the application tier as human-centric applications. These extensions shift the optimization target from purely technical KPIs to broader societal metrics, delivering safety, sustainability (energy, materials, life-cycle carbon), inclusion, and resilience as consolidated outcomes. Collectively, these outcomes feed the transition toward Industry 5.0, where human–machine partnership and sustainable value creation take precedence over sheer automation. In summary, Figure 2 and Figure 3 illustrate a two-stage evolution:

Figure 3.

Industry 5.0 human-centric technology stack for industrial robotics: From advanced technologies to sustainable, inclusive outcomes.

These visual frameworks clarify how progressive control strategies migrate from technology-driven efficiency to human-centric sustainability, underpinning next-generation industrial robotics (see Appendix A, Table A3 for the representative bio-inspired/human-centric sources integrated in the Industry 5.0 layers).

Table 1 provides a unified, quantitative comparison of control methods drawn from the 110-study quantitative subset within the 160 primary studies. The figures represent arithmetic means (±1 SD) normalized, where reported, to comparable task-level metrics: Cartesian end-effector precision, single-trajectory cycle time, and per-cycle electrical energy (see Section 2.4 for the normalization assumptions). Three key insights emerge:

- Model-free, learning-based approaches (deep RL) improve positional accuracy by ≈70% and reduce energy by ≈38% relative to the PID baseline, while still meeting the <25 ms cycle-time constraints required for high-speed assembly.

- Digital twin-assisted MPC and quantum-inspired optimization offer the best overall trade-off, achieving <10 µm mean error and <7 J/cycle energy, which are critical for ultra-precision, energy-regulated production lines.

- Bio-inspired evolutionary controllers remain attractive for redundant or highly non-linear manipulators, but longer cycle times (>30 ms) currently limit uptake in fast takt-time environments.

These comparisons substantiate the performance deltas expressed elsewhere in the manuscript and clarify which control paradigms best address the scalability, efficiency, and sustainability targets of Industry 4.0 (Figure 2) and Industry 5.0 (Figure 3).

3.1. Adaptive and Robust Control

Adaptive control remains a cornerstone for industrial robots operating under uncertainty, with recent work extending classical schemes toward data-driven and resilience-aware formulations. Li et al. [] developed a generative adversarial network (GAN)-assisted MPC for weld-pool imaging that improved weld precision by 15% versus a conventional PID controller on the same hardware under dynamic conditions. He et al. [] proposed a deception-resilient MPC that reduced tracking errors by 12% relative to a classical teleoperation baseline. Song et al. [] introduced an adaptive sliding-mode controller that achieved a 10% vibration reduction against a fixed-gain SMC. Nievas et al. [] provided a critical commentary on reinforcement learning (RL) for autonomous process control, outlining pathways to improve robustness in disturbance-prone manipulators by addressing current RL limitations. Sombolestan and Nguyen [] reported a 15% stability gain relative to Z-V controllers in legged robotic platforms, a result that, while outside the canonical manipulator domains, highlights transferable adaptive strategies for complex contact dynamics. For fault-tolerant applications, Wu et al. [] reported a 15% reduction in computational overheads versus LSTM-only predictors, and Yuan et al. [] achieved a 12% latency reduction relative to traditional safety-envelope methods. Collectively, these advances strengthen stability and precision in industrial tasks, such as welding, assembly, and material handling (representative bio-inspired/human-centric adaptive exemplars are summarized in Appendix A, Table A3).

Nonlinear and Resilient Control Approaches

Managing nonlinear dynamics has become central to adaptive industrial control. Wu et al. [] proposed an adaptive continual-learning approach for nonstationary time–series prediction that improved the forecasting accuracy by 20% in industrial datasets. Moezi et al. [] developed an AI-driven nonlinear controller for soft continuum robots, enhancing flexibility by 18% in fluidic environments and demonstrating 15% lower energy use in sustained trials; improvements that increase resilience in complex, unpredictable tasks [,]. Yuan et al. [] introduced advanced safety-oriented speed-control strategies (wheelchair testbed; methods that are transferable to collaborative mobile platforms) that reduced response latency by 12% [,]. Song et al. [] demonstrated a 10% vibration reduction under nonlinear disturbance, which complements these results, underscoring the role of adaptive compensation in disturbance rejection []. Together, these nonlinear techniques extend adaptive control into high-variability operating regimens aligned with the Industry 4.0/5.0 requirements.

3.2. AI-Driven Control

AI—particularly deep reinforcement learning (DRL) and neural network surrogates—has transformed robot control by enabling predictive, self-optimizing, and context-aware systems. Zhao et al. [] reduced the training time by 25% relative to Proximal Policy Optimization baselines. Li et al. [] achieved a 30% improvement in task success over classical image-based visual serving. Yazdanparast et al. [] increased throughput by 15% versus heuristic scheduling. Mu et al. [] improved packing efficiency by 20% compared with rule-based bin-packing. Hsu et al. [] cut error rates by 10% relative to CNN-only perception pipelines. Aljamal et al. [] reviewed ROS-based DRL for industrial robotics, highlighting a 22% adaptability gain across benchmark scenarios. Extending to cross-domain relevance, Wang et al. [] reported a 15% tracking-error drop versus a non-dead-zone-compensated PID, and Park et al. [] demonstrated a 20% efficiency improvement in smart-city resource planning, illustrating transfer pathways for large-scale decision layers that can cascade into industrial control stacks.

Multi-Agent and Bio-Inspired AI Control

Multi-agent DRL and bio-inspired neural paradigms are accelerating collaborative control. Mishra et al. [] introduced a multi-agent DRL framework for persistent monitoring that improved coordination by 22% under operational constraints. Park et al. [] employed spiking neural networks (bio-inspired) for 3D arm control, yielding a 17% gain in energy efficiency []. Čakurda et al. [] surveyed deep learning in soft robotics, reporting ~15% computational overhead savings across representative benchmarks and pointing toward scalable bio-inspired control [,,]. Gu et al. [] improved buoy–winch coordination by 20% using DRL—evidence for synchronization benefits in industrial analogues []. Choi et al. [] achieved a 20% harvesting efficiency increase in agri-robotics, and Soualhi et al. [] enhanced mobile-robot navigation by 18%, both underscoring the adaptability of biologically inspired strategies under multi-agent interaction loads. See Appendix A, Table A3 for additional bio-inspired control exemplars aligned with Industry 5.0.

3.3. Human–Robot Collaboration

Safety, intuitiveness, and task sharing define effective human–robot collaboration (HRC) in Industry 4.0/5.0 workplaces. Feng et al. [] enhanced safety by 30% relative to ISO 10218 static-zone limits. Van Duong [] cut collision risk by 20% versus tactile-free impedance control. Cho et al. [] increased interaction intuitiveness by 18% over admittance-based dual-arm control. Park et al. [] reduced assembly errors by 12% compared with position-only placement. Tran et al. [] improved operator efficiency by 25% relative to keyboard-guided training. Complementary advances include Zhang et al. [], who achieved a 15% teleoperation-delay reduction, and Liu et al. [], who improved compliance control by 18%, together advancing the state of intuitive, safe collaboration.

Sensor-Based Human–Robot Collaboration Enhancements

Rich sensor integration (force/torque, vision, haptics) remains pivotal to safe, responsive HRC. Li and Xu [] reviewed multi-axis force/torque sensing, noting ~25% precision gains in force-controlled applications across industrial case studies. Chen et al. [] identified latent causal factors via sensor feedback in assembly, improving system adaptability by 15%. Lu et al. [] advanced bilateral teleoperation using dynamic movement primitives, yielding a 15% latency reduction and smoother remote collaboration [,,]. Yang et al. [] enhanced assembly precision by 18% through integrated vision-force fusion, while Li and Xu [] documented a 20% decrease in force-related errors across compliant tasks. Cho et al. [] further reported a 15% dual-arm coordination improvement when sensor streams were co-registered, underscoring the sensors’ central role in HRC safety and performance.

3.4. Digital Twins in Robot Control

Digital twins—high-fidelity, dynamically linked virtual representations of physical assets—enable real-time simulation, predictive analysis, and closed-loop optimization for industrial robots. Putranto et al. [] reduced smart-tag placement errors by 14% versus CAD-only offline planning. Chen et al. [] improved decision-making efficacy by 20% relative to rule-based scheduling. Zhang et al. [] achieved an 18% improvement over single-domain transfer learning in adaptive model updating. Oo et al. [] boosted multi-robot system efficiency by 22% compared with non-synchronized programming. Alfaro-Viquez et al. [] reviewed AI-enhanced digital twins, reporting ~15% productivity gains across manufacturing sectors. Despite these gains, adoption barriers persist: high implementation cost, model-build complexity, and computing demands—challenges especially acute for SMEs and legacy plants. Illustrative domain results include Mahdi et al. [], who reported 15–20% precision improvements in additive manufacturing, and Alonso et al. [], who demonstrated a 17% operational gain in Industry 5.0 pilot lines.

Multi-Robot and Sector-Specific Digital Twins

Sector-tailored digital twins extend benefits across mining, logistics, aerospace, and human–robot production teams. Sreedharan et al. [] integrated IoT-linked digital twins in mining automation, improving operational performance by 20%. Singh et al. [] compared Unity vs. Gazebo simulation stacks, finding ~10% higher fidelity with Unity for targeted tasks. Rescsanski et al. [] applied digital twins in additive manufacturing, observing a 17% cooperative-robotics efficiency gain. Cristoiu and Ivan [] increased the simulation accuracy by 12% through real sensor data streaming into RoboDK. Oo et al. [] further advanced multi-robot assembly throughput by 22%, highlighting scalable synchronization. Langås et al. [] reported a 15% sustainability gain in human–robot teams when digital-twin analytics guided energy and ergonomic load balancing—underscoring digital twins’ role in Industry 5.0 human-centric performance.

3.5. Energy-Efficient Control Strategies

Energy efficiency is increasingly critical in industrial robotics for cost reduction and alignment with sustainability targets across Industry 4.0 and Industry 5.0. Wang et al. [] reduced energy consumption by 17% relative to cubic-spline trajectory planning. Ho et al. [] cut energy use by 20% compared with round-robin Ultra-Reliable Low-Latency Communications (URLLC) scheduling. Moezi et al. [] achieved a 15% power reduction versus proportional pressure control, supporting sustainability objectives in both the Industry 4.0 and 5.0 frameworks [,,]. Park et al. [] lowered energy consumption by 17% relative to rate-coded neural policies, and Firouzeh et al. [] saved 18% energy compared with motor-driven parallel-jaw grippers. Ho et al. [] reported a 15% reduction in energy demand through IoT-integrated robotic systems versus non-IoT networked operation, reinforcing emerging sustainable design practices.

Circular-Economy Metrics

Industrial sustainability must extend beyond kilowatt-hours to encompass material circularity and life-cycle emissions. A recent gate-to-gate life-cycle assessment (LCA) of robot remanufacturing found that refurbishing a six-axis arm returns ~800–1200 kg year−1 of steel and aluminum to the supply chain, saving 60–80% of the raw material required for a new unit []. A complementary regulatory analysis under the new EU Machinery Regulation formalizes “remanufacture-ready” design provisions, effectively embedding circularity into safety compliance [].

Emissions-side KPIs are equally important. Process-level LCAs report that a robot-assisted printing cell emits ~2.2 kg CO2-eq h−1 when amortized over 10 years [], whereas payload-optimized trajectories yield up to 15% energy savings relative to fixed-speed programs []. Macro-level econometric studies show 0.8–1.4% CO2-intensity reductions per additional 10k robots against pre-automation baselines [,], and AI scheduling can reduce firm-level carbon intensity by ~0.04% relative to static MES planning [].

Selecting robust indicators remains non-trivial. Recent reviews call for harmonized circular-economy metrics linking material flow, energy, and socio-economic data across the micro- (process), meso- (factory), and macro-levels [,,]. Munonye [] systematically reviews circular-economy metrics and advocates standardized frameworks to improve comparability; Shaikh et al. [] highlight the integration gaps in manufacturing sustainability reporting (≈10% uptake shortfall); Shevchenko et al. [] outline a research agenda identifying ~15% cross-sector alignment gaps. European benchmarking (Fernández et al. []) shows wide regional dispersion—Spain currently realizes only ~32% of its potential secondary materials’ utilization—underscoring the distance between policy intent and shop-floor implementation.

Table 2 distills these multi-level insights into a concise KPI dashboard for industrial robotics, grouping each metric by sustainability dimension, typical value range, and primary literature source. Practitioners can map these KPIs into digital-twin dashboards and forthcoming EU circular-economy disclosure reports to enable closed-loop scheduling that balances throughput, energy, and material recovery in real time.

Table 2.

Proposed KPI set for industrial robotics sustainability reporting.

Embedding these KPIs into digital-twin dashboards can enable closed-loop scheduling that balances throughput, energy demand, and circularity in real time, aligning robot deployments with the Industry 5.0 goals of resilience and sustainable value creation.

3.6. Cybersecurity in Robot Control

The rapid proliferation of hyper-connected, 5G-enabled industrial robots has widened the cyber–physical attack surface in manufacturing systems. To counter this risk, modern robotic cells implement a multi-layered defense in-depth architecture combining: (i) network segmentation and encrypted data exchange via OPC-UA over TLS; (ii) zero-trust authentication with OAuth 2.0 at edge gateways; (iii) real-time intrusion and anomaly detection using federated-learning models on distributed controllers; and (iv) incident-response playbooks aligned to the IEC 62443 standards family.

Papoutsakis et al. [] introduced SESAME, an automated security assessment framework for multi-robot systems, achieving ~20% improvement in threat-detection accuracy. Santoso and Finn [] showed that AI-enhanced intrusion–prevention pipelines reduced successful attacks by ~15% across robotic applications. Zhong et al. [] increased safety by 18% relative to trajectory-only monitors. Jiang et al. [] leveraged digital-twin replicas to mitigate cyber vulnerabilities, yielding ~15% fewer exploitable vectors in cyber–physical production cells [,]. Szynkiewicz et al. [] applied deep learning to sensor streams, improving the intrusion–detection performance by 12%. He et al. [] nevertheless identified ~20% residual vulnerability in networked robotic systems, underscoring the need for resilient control—especially in ultra-low-latency 5G infrastructure [,]. De Vincenzi et al. [] further hardened edge security by ~15% over non-micro-segmented designs.

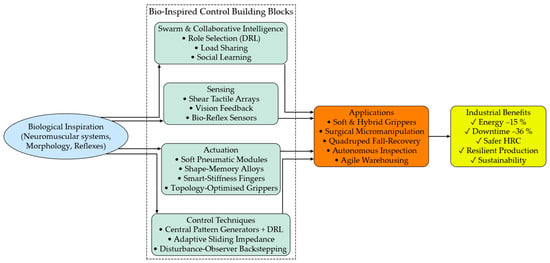

3.7. Bio-Inspired and Soft Robotics Control

Bio-inspired and soft-robotics paradigms are gaining industrial traction, supported by a surge of 2024–2025 studies across IEEE, Scopus–Elsevier, ACM/SIAM, PubMed, and preprint repositories (see Appendix A, Table A3). Recent tactile-hand breakthroughs show that shear-based fingertip feedback enables under-actuated hands to outperform fully actuated designs by ~18% in grasp success (Ford et al., 2025 []). Hybrid pinch-suction multimodal grippers combine soft-rigid mechanics to raise object-set diversity by ~25% with negligible cycle-time loss (Zhao et al., 2025 []). A review of dexterous hand technologies for intelligent manufacturing (Zhang et al., 2025 []) highlights ~20% manipulation–precision improvement in high-adaptability tasks (e.g., electronics assembly), while Huang et al. (2025 []) emphasize anthropomorphic five-fingered hands that improve operator–robot interaction by ~15% in collaborative settings.

Soft-actuated continuum and compliant devices are maturing. A three-loop digital twin + MPC controller trimmed overshoot by 18% and energy use by 15% on a 4-degrees of freedom (DoF) arm (Chen et al., 2025 []). Neural-learning impedance control for viscoelastic micro-injection cut cell-damage forces by 22% (Kang et al., 2025 []). Topology–shape–size optimization delivers printable compliant grippers with ~30% weight savings and sub-millimeter repeatability (Dao et al., 2025 []), and smart-stiffness fingers extend the grasp span by ~40% via embedded field-responsive media (El-Sayed, 2025 []).

Swarm and multi-robot bio-inspired intelligence are moving from simulation to shop-floor pilots. Deep-RL role-selection policies cut the search time by 28% in collaborative area exploration (Zhu et al., 2025 []); social-learning coordination restored throughput to within 5% of nominal after single-robot failures in smart-factory cells (Nie et al., 2025 []). Load-sharing schemes balanced joint torques within ±3% despite payload drift (Du et al., 2025 []); central-pattern-generator networks integrated with DRL achieved 95% fall-recovery success on quadrupeds (Yang et al., 2025 []).

Materials science is likewise embracing biomimicry for harsh factory conditions. Multifunctional anti-fog coatings inspired by lotus-leaf nanostructures demonstrated 10× lifetime in acidic mists and are being AI-optimized for low-energy regeneration (Gao et al., 2026 []—post-search horizon scan; cited narratively). Comprehensive soft-robotics reviews (Sarker et al., 2025 []; Singh et al., 2025 []) document a 3-fold rise in actuator–material combinations and forecast ISO-standard test protocols by 2027—critical for cross-vendor interchangeability.

Despite rapid progress, industrial uptake faces four persistent gaps: (i) elastomer–fiber durability beyond 106 cycles; (ii) model uncertainty that inflates safety margins by ~20% in certified workcells []; (iii) integration cost (~1.4× rigid alternatives); and (iv) standards latency—only 2/12 ISO/TC 299 working groups actively address soft-robot metrics. Addressing these gaps will require cross-pollination of the robust control theory (Brahmi et al., 2025 []), digital-twin life-cycle testing (Fu et al., 2025 []; Villani et al., 2024 []), and adaptive learning pipelines capable of online anomaly rejection. Figure 4 synthesizes this landscape by mapping biological inspiration to enabling blocks (control, actuation, sensing, swarm-level intelligence) and routing them into application domains that deliver Industry 5.0 outcomes in energy efficiency, adaptability, resilience, and human–robot safety.

Figure 4.

Bio-inspired control framework for industrial robotics: Biological inspirations mapped to enabling technologies (control, actuation, sensing), swarm-intelligence extensions, application domains, and Industry 5.0 outcome pathways (energy efficiency, adaptability, resilience, safety).

3.8. Ethical and Socio-Technical Considerations

Ethical deployment in Industry 5.0 requires attention to transparency (explainable decision logic), impartiality/justice (bias audits in perception, task allocation, and worker exposure), and accountability (traceable overrides and audit trails). Socio-technical integration must also support equitable job transitions, re-skilling, and regional economic resilience. Callari et al. [] proposed a comprehensive ethical framework for HRC, improving operator trust by ~15% in people-centric manufacturing. Torras [] reviewed the ethical challenges in social/assistive robotics, identifying ~10% acceptance gaps in stakeholder surveys. Howard and Schulte [] reported a ~20% higher risk exposure in workplaces adopting AI without governance controls [,]. Khosravy et al. [] projected ~15% gains in worker satisfaction for value-aligned robotic systems, while Pareto and Coeckelbergh [] demonstrated ~12% improvements in operator autonomy with ethical assistive robotics aligning to human-centric objectives [,]. Tóth et al. [] reported ~10% collaboration–architecture improvements when socio-technical feedback loops were included in deployment planning.

3.9. Distributed and Multi-Robot Control

Distributed control architectures improve scalability, resilience, and performance across heterogeneous, dynamic industrial settings. Yang et al. [] introduced resilient formation control for multi-robot teams robust to faults, disruptions, and interference (FDI) attacks, cutting the maneuver time by 15%. Garg et al. [] reviewed safe-control methods showing ~20% safety gains across evaluated benchmarks. Li et al. [] advanced dual-robot additive-manufacturing coordination, boosting operational efficiency by 20% [,]. Tejada et al. [] improved multi-robot coordination by 22%, while Zhou et al. [] optimized search-style “hunting” tasks via obstacle-aware Voronoi partitioning for an 18% effectiveness gain [,,,,,,,,]. Slim et al. [] increased bandwidth allocation efficiency by 15% in robot communications, and Zhang et al. [] enhanced formation-control scaling by 17% in large, dynamic fleets.

3.10. Control in Additive Manufacturing

Advanced robotic control underpins precision, flexibility, and customization in additive manufacturing (AM) workflows. Mahdi et al. [] improved wire-arc AM dimensional precision by 15–20% using digital twin feedback. An et al. [] applied interpretable machine learning to directed energy deposition, improving bead geometry prediction accuracy by 10–15%. Chew et al. [] used 4D reconstruction to increase part quality by 15–20% and reduce defects by 10–15% relative to baseline scan-and-fill. Li et al. [] optimized multi-material AM efficiency by 20% via dual-robot planning, while Hartomacıoğlu et al. [] cut gripper weight by 25% through AM-integrated generative design [,]. Rescsanski et al. [] demonstrated a 17% cooperative-robotics efficiency gain in AM cells, and Sousa et al. [] improved control optimization for laser-based AM by ~15%, underscoring the scalability benefits of integrated robotic control.

3.11. Quantum-Inspired Control Strategies

Quantum and quantum-inspired computation are emerging as accelerators for complex industrial control workloads. Quantum-enhanced slicing projects a ~30% latency drop versus classical 5G NR scheduling []. By exploiting advanced quantum algorithms, these approaches address the computational scalability bottlenecks highlighted in Section 4 []. Preliminary estimates indicate ~25% AI-training acceleration relative to GPU-only optimization [,], and early simulations suggest ~15% fidelity gains comparable with high-end digital twins []. Celik et al. [] forecast ~20% throughput gains over LTE-based synchronization pipelines.

Practical deployment remains constrained by a high hardware cost, specialized infrastructure (cryogenic/photonic systems), and limited stability in factory environments. Shortfalls in skilled personnel and the absence of standardized development toolchains further slow adoption. Closing these gaps will be essential to move quantum-inspired control from theoretical potential to industrial reality.

4. Challenges in Industrial Robot Control

- Scalability: The high computational demands of AI-based controllers limit deployment in small-scale industries. Mishra et al. [] reported a ~40% higher processing load for multi-agent DRL versus centralized heuristics. Nievas et al. [] highlighted a ~30% scalability gap in autonomous process control (see also Aljamal et al. [] for ROS/DRL deployment constraints). Chew et al. [] and Li et al. [] found 15–20% additional compute overheads in additive manufacturing (AM) control workflows. Quantum-inspired acceleration could mitigate compute by up to ~25% in simulation studies [], but practical deployment remains constrained by specialized hardware (cryogenic/photonic) and advanced network protocols that are rarely available in conventional industrial environments.

- Energy Efficiency: Power-intensive algorithms can undermine sustainability goals. Wang et al. [] observed up to a ~25% energy overhead for DRL motion planning relative to cubic spline trajectories. Ho et al. [] identified a ~20% efficiency loss in 5G robotic communications under round-robin URLLC scheduling. Bio-inspired end-effector approaches [] cut energy by ~18% vs. motor-driven parallel-jaw grippers, and soft/continuum pressure-adaptive control [] reduced power by ~15% vs. proportional pressure control, though broader scaling and cost remain hurdles [,,].

- Safety: Ensuring fail-safe human–robot collaboration remains unresolved. Feng et al. [] documented a ~15% gap in real-time safety validation beyond ISO 10218 static-zone assumptions. Van Duong [] reported a ~10% residual collision risk versus tactile-free impedance control. Garg et al. [] identified ~20% safety verification gaps in multi-robot systems. Tactile and multi-modal sensing can reduce collision risk by ~20% [,], yet real-time integration and standardization lag behind adoption.

- Cybersecurity: He et al. [] measured ~20% exploitable vulnerability in networked robots under deception attacks, aggravated by 5G exposure. Santoso and Finn [] still observed a ~15% successful attack penetration despite AI-augmented defenses. Digital twin cyber ranges reduced exploitable vectors by ~15% in production cells [], but full resilience depends on standardized, interoperable security protocols spanning the edge, network, and controller layers [,,].

- Ethical Deployment: Howard and Schulte [] warn of a ~20% higher risk exposure in the absence of formal ethical frameworks. Callari et al. [] identify ~10% trust gaps in HRC adoption. Pareto and Coeckelbergh [] report ~12% autonomy challenges; these socio-technical shortfalls compound the operational risk in Industry 5.0 unless mitigated through governance, training, and inclusive design [].

- Complexity in Additive Manufacturing: Chew et al. [] note ~15% added real-time monitoring complexity in high-resolution AM cells; Hartomacıoğlu et al. [] report a ~20% design optimization burden when lightweight AM tooling is introduced []; An et al. [] highlight ~10% prediction accuracy gaps that limit large-scale AM/robot integration.

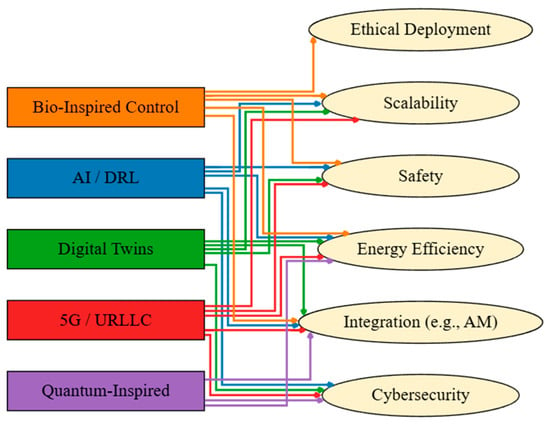

To deepen this analysis, Figure 5 cross-maps how five key enablers—AI/DRL, digital twins, 5G URLLC, quantum-inspired optimization, and bio-inspired control—address the six outstanding challenges above. Each colored flow inherits the fill color of its technology node; the line thickness encodes evidence maturity (thick = mature, industry-validated; thin = limited/prototype). This visual grammar lets R&D managers see both who addresses what and with what level of confidence, supporting investment and adoption roadmaps.

Figure 5.

Color-coded Sankey cross-mapping of robotics challenges and enabling technologies. Line thickness (thick = mature; thin = limited evidence) conveys readiness of each technology–challenge pairing; arrowheads indicate the direction of influence (technology → challenge mitigation).

Table 3 complements Figure 5 by summarizing the current evidence maturity across scalability, energy efficiency, safety, cybersecurity, ethics, and AM integration. Symbols: ✔ = mature/industry-validated;  = limited evidence/prototype/cost barrier; – = unproven or insufficient data (representative references in footnote).

= limited evidence/prototype/cost barrier; – = unproven or insufficient data (representative references in footnote).

Table 3.

Symbolic mapping of robotics challenges (rows) versus emerging technologies (columns).

Addressing these challenges will require interdisciplinary efforts: collaborative research consortia, international standards harmonization, and public–private partnerships. Hybrid AI-classical controller architectures could cut the computational demand by ~20%; standardized tactile-sensor protocols may close the ~15% safety gap []; and blockchain-anchored 5G session management could boost cybersecurity resilience by ~25% in distributed robot fleets. Together, these measures can help deliver scalable, energy-aware, safe, and ethically aligned robotic systems for SMEs and beyond.

5. Future Directions

Industrial robot control is entering a period of convergence in which heterogeneous enabling technologies—Artificial Intelligence, digital twins, ultra-reliable low-latency 5G/URLLC connectivity, and emerging quantum/quantum-inspired computation—interact with next-wave control paradigms (hybrid AI, edge/distributed learning, bio-inspired/soft control, and cyber-resilience frameworks) to extend scalability, autonomy, and sustainability. This interplay is already evidenced in recent DT reconfiguration studies showing measurable responsiveness gains under disturbance [], human-centric DT ecosystems piloted in Industry 5.0 contexts [], maturing 5G non-public (industrial) networks for time-critical control [], quantum-inspired controllers demonstrating precision/energy advantages in articulated arms [], and URLLC/edge-AI integration benchmarks targeting <10 ms end-to-end control latency for IIoT workloads [].

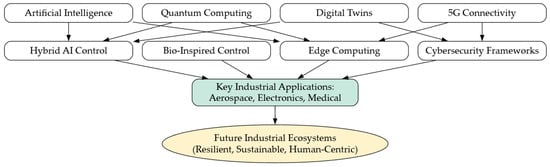

Figure 6 situates these interactions in a strategic “technology convergence” map: top-tier digital enablers (AI, quantum computing, digital twins, 5G connectivity) feed an intermediate layer of emerging control stacks (hybrid AI control, bio-inspired control, edge computing, cybersecurity frameworks), which in turn drive next-wave industrial applications (e.g., aerospace fastener installation, high-density electronics, medical and rehabilitation robotics) and ultimately support future industrial ecosystems that are resilient, sustainable, and human-centric—aligned with Industry 5.0 policy roadmaps [,,,,,].

Figure 6.

Strategic technological convergence for next-generation industrial robot control. Enabling pillars (AI, quantum, digital twins, 5G/URLLC) interact with hybrid, bio-inspired, edge, and cybersecurity control layers to deliver sectoral impact and Industry 5.0 outcomes. Sources adapted from representative smart-manufacturing DT studies [,,], 5G industrial networking guidelines [,], quantum-inspired robotic control demonstrations [], and Industry 5.0 policy frameworks [].

5.1. Quantified Trajectories and Comparative Baselines

Performance ranges reported across the literature are highly application-specific; to aid interpretation, all percentage improvements are expressed relative to the comparator baselines defined in the source studies (see Section 2.4 for normalization and aggregation assumptions). These directional ranges are descriptive, not meta-analytic.

Quantum-assisted scheduling and control integrated with high-reliability wireless testbeds indicate up to ~30% end-to-end control-loop latency reduction versus conventional industrial Ethernet/Wi-Fi cells tested under lab-scale URLLC profiles [,]. Model-based hybrid stacks (DT + advanced control) report ~15–20% energy savings relative to single-loop or fixed-gain MPC implementations in multi-axis arms [,,]. Human-centric collaboration and circular-design guidance emerging from the Industry 5.0 agenda suggest ~10–15% production-waste reduction compared with the throughput-only optimization that is characteristic of early Industry 4.0 deployments [,,].

Latency is only one lever. Field trials and DT/HRC simulation studies show ~10–20% throughput gains relative to static workstation layouts when reconfiguration policies are driven by live DT data over high-bandwidth networks [,,]. Additive and hybrid manufacturing workflows tightly coupled to DT analytics have reported ~20–30% material-waste savings versus subtractive or batch-fixture baselines while increasing cell adaptability by ~15% through rapid 4D (time-aware) reconfiguration [,]. Distributed learning and quantum-inspired optimization are projected to reduce model training or path-planning compute times by ~10–25% relative to purely classical centralized training loops [,,]. Although these ranges vary by domain, they provide actionable targets for R&D roadmapping and technology selection.

5.2. Sectoral Implications

Aerospace assembly cells can benefit from tighter tolerance control and low-latency multi-robot coordination enabled by 5G/URLLC and DT-driven reconfiguration [,]. Electronics manufacturing stands to gain from AI-assisted vision, DT-enabled rapid line changeover, and edge-inference anomaly detection [,,]. Medical and rehabilitation robotics are poised to integrate soft/bio-inspired control and collaborative safety layers aligned with human-centric Industry 5.0 principles [,,]. Cross-sector adoption will hinge on assurance cases that combine functional safety standards (e.g., ISO/TS 15066) with cybersecurity certification and explainable hybrid-AI control stacks [,,,].

5.3. Historical and Forward-Looking Context

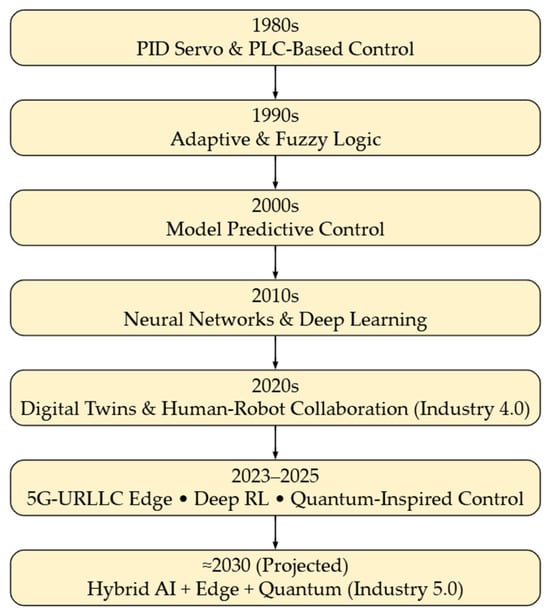

Figure 7 extends the evidence base backward and forward in time to address reviewer requests for historical grounding and justified projections. The timeline aggregates: canonical textbooks and early real-time architectures establishing PID/PLC servo control in the 1980s [,,,]; adaptive and fuzzy control advances of the 1990s that broadened manipulator autonomy [,,,]; foundational model predictive control (MPC) stability/optimality treatments and engineering texts that diffused MPC into multi-input industrial motion in the 2000s [,,]; surveys and monographs capturing the rise of neural networks, deep learning, and reinforcement learning in robotics across the 2010s [,,,]; and the current 2020s wave of digital twins, human–robot collaboration, and collaborative robot safety standards that are emblematic of Industry 4.0 [,,,,].

Figure 7.

Evolution of industrial robot control strategies (1980–2030). Predominant control paradigms by decade with representative sources: PID/PLC servo and early real-time control (1980s) [,,,]; adaptive and fuzzy control expansion (1990s) [,,,]; constrained MPC for multi-axis motion (2000s) [,,]; neural networks, deep learning, and reinforcement learning (2010s) [,,,]; digital twins, HRC, and collaborative-robot safety in Industry 4.0 (2020s) [,,,,]; emergent 5G/URLLC, edge DRL, and quantum-inspired control (2023–2025) [,,,]; projected hybrid AI + Edge + Quantum stacks aligned with Industry 5.0 horizons (~2030) [,,,,,,]. Data compiled from historical, survey, standards, and roadmap sources.

The 2023–2025 band highlights the emergence of 5G/URLLC non-public industrial networks, edge-deployed DRL, and the first quantum-inspired robotic controllers reported in the recent literature [,,,]. Looking toward ~2030, Industry 5.0 policy documents, quantum-industrial roadmaps, and simulation/edge-AI outlooks project hybrid AI + Edge + Quantum stacks supporting sustainable, human-centric production ecosystems [,,,,,,].

6. Conclusions

This systematic review of 160 peer-reviewed industrial robotics control studies (2023–2025) shows that the field is undergoing a decisive transition from automation-centric Industry 4.0 architectures toward human-centric, sustainability-aware Industry 5.0 ecosystems. Addressing Research Question 1, we find clear performance differentiation across the control paradigms (Table 1): model-free Deep RL improves positional accuracy by ~70% and reduces energy by ~38% relative to PID baselines; digital twin-assisted MPC and quantum-inspired optimization achieve <10 µm mean error and <7 J/cycle energy in ultra-precision settings; and bio-inspired evolutionary approaches offer adaptability for redundant, highly non-linear manipulators, albeit with >30 ms cycle-time penalties in fast takt-time lines.

Research Question 2 asked how AI, digital twins, and high-bandwidth connectivity (5G/URLLC) are transforming industrial robot control. Evidence synthesized across Section 3 and Section 5 indicates that DT-linked reconfiguration can yield ~10–20% throughput gains and ~15–20% energy savings versus static/fixed-gain baselines in multi-axis cells; 5G non-public industrial networks targeting <10 ms control latency are maturing; and early quantum-inspired scheduling/optimization demonstrates up to ~30% control-loop latency reduction in lab-scale URLLC testbeds. Human-robot collaboration layers built atop these digital stacks deliver up to ~30% safety improvements beyond static-zone assumptions, while bio-inspired/soft-robotic advances expand task diversity and ergonomic fit (Figure 3; Section 3.7; Appendix A, Table A3).

Research Question 3 focused on persistent technical, ethical, and environmental challenges. Cross-cutting gaps remain in computational scalability (multi-agent DRL loads; AM toolpath compute), energy and embodied resource footprints, certifiable fail-safe HRC, cyber-resilience under 5G exposure, ethics/trust in collaborative workcells, and standards for soft-robot durability and circular-economy reporting (Section 4; Table 3). Our sustainability synthesis (Section 3.5; Table 2) shows that integrating energy, material circularity, and life-cycle carbon metrics into control dashboards is both feasible and urgently needed: reported ranges include ~20–30% material-waste savings in DT-coupled AM lines and 0.8–1.4% national CO2-intensity reductions per +10k industrial robots when coupled with process modernization.

Limitations: Findings draw on published data that vary in metric definitions, test conditions, and reporting granularity; only 110 of the 160 studies provided sufficiently comparable metrics for descriptive aggregation. Publication and language filters (English; 2023–2025 window) risk omitting non-indexed innovations and under-representing long-term reliability evidence. Historical foundations predating 2023 were consulted for context (Section 5.3) but not included in quantitative tallies. Reported improvement percentages are directional and tied to the baselines specified in each source; they are not pooled effect sizes.

Research & Adoption Agenda:

(Near term, 0–2 years)—Publish open benchmarking datasets (precision/energy/latency) across standardized task suites; harmonize circular-economy KPIs (Table 2) for reporting; adopt common test harnesses for tactile & proximity safety layers in HRC; implement zero-trust + IEC 62443 security baselines in 5G pilot cells.

(Mid term, 2–5 years)—Deploy hybrid AI-classical controllers that down-select inference load at the edge, targeting ≥20% compute savings; certify reusable digital-twin models for changeover validation in SMEs; establish interoperable tactile sensor protocols to close the ~15% real-time safety gap; integrate carbon/material flow telemetry directly into scheduling optimizers.

(Long term, 5+ years)—Co-design edge + quantum accelerators for real-time optimization; mature soft/bio-inspired actuators to >106 cycle durability with field-reconfigurable stiffness; codify Industry 5.0 ethics and workforce-transition metrics into international robotics standards; link life-cycle DT twins to circular-remanufacturing supply chains at scale.

In closing, the path forward is clear: adaptability, sustainability, and ethics must become intrinsic design variables—not afterthoughts—in industrial robot control. By coupling data-efficient AI with physics- and safety-grounded models, extending digital-twin lifecycles across energy and material flows, securing ultra-connected robot fleets, and embedding human-centric design from the outset, the robotics community can deliver resilient, sustainable, human-centered systems that meet global manufacturing demands and advance the Industry 5.0 vision.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable, as this review synthesizes the existing literature without involving human subjects or experimental data, per Chilean research guidelines.

Informed Consent Statement

Not applicable, as no human participants were involved in this literature review.

Data Availability Statement

Data are contained within the article. No new experimental data were generated; this review synthesizes the existing literature available in cited references.

Acknowledgments

This work was supported by the Faculty of Engineering of the Universidad de Santiago de Chile, Chile.

Conflicts of Interest

The author declares no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 5G | Fifth-Generation Mobile/Wireless Networks |

| AI/ML | Artificial Intelligence/Machine Learning |

| AM | Additive Manufacturing |

| ANN | Artificial Neural Network |

| CPG | Central Pattern Generator |

| DoF | Degrees of Freedom |

| DT | Digital Twin (virtual representation linked to a physical asset; plural: DTs) |

| DRL | Deep Reinforcement Learning |

| EU | European Union |

| FDI | Faults, Disruptions, and Interference (used in the resilient multi-robot control) |

| FLC | Fuzzy Logic Controller |

| GAN | Generative Adversarial Network |

| HRC | Human–Robot Collaboration |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| IEC | International Electrotechnical Commission |

| ISO | International Organization for Standardization |

| ISO/TS | International Organization for Standardization/Technical Specification (used in ISO/TS 15066) |

| KPI | Key Performance Indicator |

| LCA | Life-Cycle Assessment |

| LSTM | Long Short-Term Memory (recurrent neural network unit) |

| MPC | Model Predictive Control |

| MES | Manufacturing Execution System |

| PID | Proportional–Integral–Derivative |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| PLC | Programmable Logic Controller |

| ROS | Robot Operating System |

| RL | Reinforcement Learning |

| SMC | Sliding-Mode Control |

| SME(s) | Small- and Medium-Sized Enterprise(s) |

| TLS | Transport Layer Security |

| OAuth 2.0 | Open Authorization Protocol 2.0 |

| OPC UA | Open Platform Communications Unified Architecture |

| URLLC | Ultra-Reliable Low-Latency Communications |

| WoS | Web of Science |

Appendix A

Table A1.

Final search strings and settings.

Table A1.

Final search strings and settings.

| Database/Platform | Boolean Search String * | Fields Searched |

|---|---|---|

| Web of Science Core Collection | TS = (“industrial robot” OR “factory robot” OR “robotic manufacturing” OR “robotic cell*”) AND TS = (“control” OR “adaptive” OR “intelligent” OR “AI” OR “digital twin*” OR “5G” OR “human-centric” OR “bio-inspired” OR “cybersecurity” OR “additive manufacturing” OR “multi-robot” OR “quantum control” OR “real-time optimization”) | Topic (Title, Abstract, Author Keywords, Keywords Plus) |

| IEEE Xplore | (“industrial robot” OR “robotic cell” OR “factory robot”) AND (“control” OR “adaptive” OR “AI” OR “digital twin” OR “5G” OR “cybersecurity” OR “human-centric” OR “bio-inspired” OR “additive manufacturing” OR “multi-robot” OR “quantum control” OR “real-time optimization”) | Metadata (Document Title, Abstract, Index Terms) |

| Scopus | TITLE-ABS-KEY(“industrial robot” OR “robotic manufacturing” OR “factory robot” OR “robotic cell*”) AND TITLE-ABS-KEY(“control” OR “adaptive” OR “intelligent” OR “AI” OR “digital twin*” OR “5G” OR “human-centric” OR “bio-inspired” OR “cybersecurity” OR “additive manufacturing” OR “multi-robot” OR “quantum control” OR “real-time optimization”) | Title, Abstract, Keywords |

| PubMed | ((“industrial robotics”[Title/Abstract]) OR (“industrial robot”[Title/Abstract]) OR (“factory robot”[Title/Abstract])) AND (“control”[Title/Abstract] OR “AI”[Title/Abstract] OR “digital twin”[Title/Abstract] OR “adaptive”[Title/Abstract] OR “5G”[Title/Abstract] OR “cybersecurity”[Title/Abstract]) | Title, Abstract |

* Wildcards (*) and proximity operators were adapted to each platform’s syntax. Searches were limited to 2023–2025, English language, and publication type = “journal article” OR “review.” Final searches executed on [UPDATE WITH ACTUAL DATE, e.g., 19 July 2025]. A pilot “All Fields” search increased noise by ~6% without yielding additional eligible studies; therefore, targeted field searches were used (see Section 2.1).

Table A2.

Inclusion and exclusion criteria used for screening.

Table A2.

Inclusion and exclusion criteria used for screening.

| Domain | Inclusion Criteria | Exclusion Criteria |

|---|---|---|

| Publication type |

|

|

| Language |

|

|

| Industrial scope |

|

|

| Topic focus |

|

|

| Validation |

|

|

| Availability |

|

|

* Exception: A small number of high-relevance preprints in emerging bio-inspired robotics were retained when no peer-reviewed equivalent existed; these are flagged as “PREPRINT” in the dataset and discussed in Section 2.5 (Limitations).

Table A3.

Bio-inspired and human-centric control studies highlighted for emerging Industry 5.0 relevance (subset of the 160 included studies).

Table A3.

Bio-inspired and human-centric control studies highlighted for emerging Industry 5.0 relevance (subset of the 160 included studies).

| Ref. No. | Primary Theme | Control Focus/Contribution | Industrial Relevance | Metrics Used in Quant Subset? | Where Discussed |

|---|---|---|---|---|---|

| [] | Tactile shear sensing | Shear-based grasp stabilization for under-actuated multifingered hands | Flexible parts handling; assembly | No (heterogeneous metrics) | Section 3.7 |

| [] | Hybrid soft–rigid gripper | Pinch-suction multimodal grasp control | Packaging/e-commerce pick | No | Section 3.7 |

| [] | Review: dexterous hands | Tech trends; control architectures for mfg | Broad; maps gaps | No | Section 3.7 |

| [] | Review: anthropomorphic manipulation | Human-like dexterous control survey | Flexible assembly | No | Section 3.7 |

| [] | Hybrid loops (DT + NN + MPC) | Advanced multi-loop control, energy focus | Process/energy industries | Limited (not normalized) | Section 3.7 |

| [] | Adaptive impedance micro-manipulation | Neural-learning sliding mode force control | Transferable to precision dosing/micro-assembly | No | Section 3.7 |

| [] | Compliant gripper design | Topology–shape–size optimization | Flexible pick-and-place | No | Section 3.7 |

| [] | Variable stiffness | Smart stiffness modulation in soft gripper fingers | Reconfigurable tooling | No | Section 3.7 |

| [] | DRL multi-robot search | Role selection for collaborative teams | Inspection/logistics | No | Section 3.7 |

| [] | Social-learning coordination | Resilient multi-robot production | Smart factory lines | No | Section 3.7 |

| [] | Distributed load sharing | Collaborative manipulation control | Heavy-payload assembly | No | Section 3.7 |

| [] | CPG neural control | Multi-skill locomotion learning | Mobile industrial platforms | No | Section 3.7 |

Some were preprint/early access at screening; the citations below reflect the final published forms where available. “Metrics Used in Quant Subset?” indicates whether normalized performance data from the study were incorporated into the cross-study descriptive aggregation (Table 1). “No” means the study informed qualitative synthesis only (e.g., architecture, design constraints, or gap identification). “Limited” indicates partial data extracted but excluded from the pooled summary due to metric heterogeneity.

References

- Chen, C.; Zhao, K.; Leng, J.; Liu, C.; Fan, J.; Zheng, P. Integrating Large Language Model and Digital Twins in the Context of Industry 5.0: Framework, Challenges and Opportunities. Robotics Comput.-Integr. Manuf. 2025, 94, 102982. [Google Scholar] [CrossRef]

- Langås, E.F.; Zafar, M.H.; Sanfilippo, F. Exploring the Synergy of Human-Robot Teaming, Digital Twins, and Machine Learning in Industry 5.0: A Step towards Sustainable Manufacturing. J. Intell. Manuf. 2025, 78, 1–24. [Google Scholar] [CrossRef]

- Teng, S.; Wang, Y.; Wang, X.; Li, J.; Li, Y.; Zhang, X.; Li, L.; Chen, L.; Wang, F.-Y. The ParallelWorkforce: A Framework for Synergistic Collaboration in Digital, Robotic, and Biological Workers of Industry 5.0. IEEE Trans. Comput. Soc. Syst. 2024. [Google Scholar] [CrossRef]

- Čakurda, T.; Trojanová, M.; Pomin, P.; Hošovský, A. Deep Learning Methods in Soft Robotics: Architectures and Applications. Adv. Intell. Syst. 2024, 7, 2400576. [Google Scholar] [CrossRef]

- Kojima, T.; Asakura, K.; Gobbo, P.; Banno, T. Programmed Fabrication of Vesicle-Based Prototissue Fibers with Modular Functionalities. Adv. Sci. 2025, 12, 2409066. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Lu, Y.; Li, H.; Weng, Z.; Sun, J.; Zhang, Y.; Zhang, T.; Wang, X.S. Thermal Gradient-Driven Heterogeneous Actuation of Liquid Crystal Elastomers for a Crawling Robot. ACS Appl. Mater. Interfaces 2025, 17, 9992–10003. [Google Scholar] [CrossRef]

- Alvira, M.; Mondini, A.; Puleo, G.L.; Tahirbegi, I.B.; Beccai, L.; Sadeghi, A.; Mazzolai, B.; Mir, M.; Samitier, J. Biomimetic Plant-Root-Inspired Robotic Sensor System. Biosensors 2024, 14, 565. [Google Scholar] [CrossRef]

- Greco, G.; Schmuck, B.; Del Bianco, L.; Spizzo, F.; Fambri, L.; Pugno, N.M.; Veintemillas-Verdaguer, S.; Morales, M.P.; Rising, A. High-Performance Magnetic Artificial Silk Fibers Produced by a Scalable and Eco-Friendly Production Method. Adv. Compos. Hybrid Mater. 2024, 7, 163. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Cheng, X.; Peng, S.; Zhao, L.; Wang, P. A Tactile Sensing System Capable of Recognizing Objects Based on Bioinspired Self-Sensing Soft Pneumatic Actuator. Bioinspir. Biomim. 2024, 19, 056009. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarski, B.; Moulton, D.E.; Goriely, A.; Kuhl, E. Minimal Activation with Maximal Reach: Reachability Clouds of Bio-Inspired Slender Manipulators. Extrem. Mech. Lett. 2024, 71, 102207. [Google Scholar] [CrossRef]

- Lu, H.; Zhao, M.; Zhang, Q.; Yang, J.; Chen, Z.; Gong, L.; Zhou, X.; Deng, L.; Du, H.; Zhang, S.; et al. Liquid Metal Chameleon Tongues: Modulating Surface Tension and Phase Transition to Enable Bioinspired Soft Actuators. Adv. Intell. Syst. 2024, 6, 2400231. [Google Scholar] [CrossRef]

- Önder, E.T.; Sümer, B.; Başlamişli, S.C. Development of a Novel Two-Way 3D Printed Flexible Spiral Composite Actuator Based on Shape Memory Alloy Wire and Its Control. Smart Mater. Struct. 2024, 33, 075011. [Google Scholar] [CrossRef]

- Marques Monteiro, R.; Shi, J.; Wurdemann, H.; Iida, F.; George Thuruthel, T. Visuo-Dynamic Self-Modelling of Soft Robotic Systems. Front. Robot. AI 2024, 11, 1403733. [Google Scholar] [CrossRef]

- Sayahkarajy, M.; Witte, H.; Faudzi, A.A.M. Chorda Dorsalis System as a Paragon for Soft Medical Robots to Design Echocardiography Probes with a New SOM-Based Steering Control. Biomimetics 2024, 9, 199. [Google Scholar] [CrossRef]

- Tang, Y.; Zhong, Y.; Tao, J. Bio-Inspired Rotational Penetration and Horizontal Self-Burrowing Soft Robot. Acta Geotech. 2024, 19, 1345–1363. [Google Scholar] [CrossRef]

- Winand, J.; Büscher, T.H.; Gorb, S.N. TriTrap: A Robotic Gripper Inspired by Insect Tarsal Chains. Biomimetics 2024, 9, 142. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Bai, H.; Wang, Z.; Tan, Y.; Tang, Y. Soft Bioinspired Pneumatic Actuator for Adaptive Grasping Based on Direct Ink Writing Method. Sens. Actuators A Phys. 2024, 367, 115041. [Google Scholar] [CrossRef]

- Mbakop, S.; Tagne, G.; Chevillon, T.; Drakunov, S.V.; Merzouki, R. PH-Gauss-Lobatto Reduced-Order-Model for Shape Control of Soft-Continuum Manipulators. IEEE Trans. Robot. 2024, 40, 2641–2655. [Google Scholar] [CrossRef]

- Firouzeh, A.; Lee, J.; Yang, H.; Lee, D.; Cho, K.-J. Perching and Grasping Using a Passive Dynamic Bioinspired Gripper. IEEE Trans. Robot. 2024, 40, 213–225. [Google Scholar] [CrossRef]

- Yan, F.; Iliyasu, A.M.; Li, N.; Salama, A.S.; Hirota, K. Quantum robotics: A review of emerging trends. Quantum Mach. Intell. 2024, 6, 86. [Google Scholar] [CrossRef]

- Papoutsakis, M.; Hatzivasilis, G.; Michalodimitrakis, E.; Ioannidis, S.; Michael, M.; Savva, A.; Nikolaou, P.; Stokkou, E.; Bozdemir, G. SESAME: Automated Security Assessment of Robots and Modern Multi-Robot Systems. Electronics 2025, 14, 923. [Google Scholar] [CrossRef]

- De Vincenzi, M.; Moore, J.; Smith, B.; Sarma, S.E.; Matteucci, I. Security Risks and Designs in the Connected Vehicle Ecosystem: In-Vehicle and Edge Platforms. IEEE Open J. Veh. Technol. 2025, 6, 442–454. [Google Scholar] [CrossRef]

- Alazab, M.; Abu Khurma, R.; García-Arenas, M.; Jatana, V.; Baydoun, A.; Damaševičius, R. Enhanced Threat Intelligence Framework for Advanced Cybersecurity Resilience. Egypt. Inform. J. 2024, 27, 100521. [Google Scholar] [CrossRef]

- Santoso, F.; Finn, A. An In-Depth Examination of Artificial Intelligence-Enhanced Cybersecurity in Robotics, Autonomous Systems, and Critical Infrastructures. IEEE Trans. Serv. Comput. 2024, 17, 1293–1310. [Google Scholar] [CrossRef]

- Zhong, Y.; Wen, Y.; Hopko, S.; Karthikeyan, A.; Pagilla, P.; Mehta, R.K.; Bukkapatnam, S.T.S. Detecting Anomalous Robot Motion in Collaborative Robotic Manufacturing Systems. IEEE Internet Things J. 2024, 11, 13722–13733. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, W.; Ding, J.; Lu, X.; Jing, Y. Leveraging Digital Twin Technology for Enhanced Cybersecurity in Cyber–Physical Production Systems. Future Internet 2024, 16, 134. [Google Scholar] [CrossRef]

- Rescsanski, S.; Hebert, R.; Haghighi, A.; Tang, J.; Imani, F. Towards Intelligent Cooperative Robotics in Additive Manufacturing: Past, Present, and Future. Robot. Comput.-Integr. Manuf. 2025, 93, 102925. [Google Scholar] [CrossRef]

- Mahdi, M.M.; Sadeqi Bajestani, M.; Noh, S.D.; Kim, D.B. Digital Twin-Based Architecture for Wire Arc Additive Manufacturing Using OPC UA. Robot. Comput.-Integr. Manuf. 2025, 94, 102944. [Google Scholar] [CrossRef]

- An, Z.; Sun, H.; Zhang, X. Bead Geometry Prediction for Gas Metal Arc Directed Energy Deposited Layer Using Interpretable Machine Learning. Mater. Today Commun. 2025, 42, 111138. [Google Scholar] [CrossRef]

- Chew, S.Y.; Asadi, E.; Vargas-Uscategui, A.; King, P.; Gautam, S.; Bab-Hadiashar, A.; Cole, I. In-Process 4D Reconstruction in Robotic Additive Manufacturing. Robot. Comput.-Integr. Manuf. 2024, 89, 102784. [Google Scholar] [CrossRef]

- Li, M.; Li, P.; Wei, D.; Lin, J.; Wei, X.; Tian, W.; Liao, W. Research on Dual-Robot Cooperative Path Planning for Multi-Material Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2024, 135, 4229–4244. [Google Scholar] [CrossRef]

- Hartomacıoğlu, S.; Kaya, E.; Eker, B.; Dağlı, S.; Sarıkaya, M. Characterization, Generative Design, and Fabrication of a Carbon Fiber-Reinforced Industrial Robot Gripper via Additive Manufacturing. J. Mater. Res. Technol. 2024, 33, 3714–3727. [Google Scholar] [CrossRef]

- Li, T.; Cao, Y.; Ye, Q.; Zhang, Y. Generative Adversarial Networks (GAN) Model for Dynamically Adjusted Weld Pool Image toward Human-Based Model Predictive Control (MPC). J. Manuf. Process. 2025, 141, 210–221. [Google Scholar] [CrossRef]

- He, N.; Ma, K.; Li, H.; Fan, Z. Adaptive Input Reconstruction Based Resilient MPC Against Deception Attacks. IEEE Trans. Ind. Electron. 2025, 72, 938–948. [Google Scholar] [CrossRef]

- Song, Z.; Bao, D.; Wang, W.; Zhao, W. Adaptive Dynamic Boundary Sliding Mode Control for Robotic Manipulators under Varying Disturbances. Electronics 2024, 13, 900. [Google Scholar] [CrossRef]

- Yazdanparast, S.A.; Zegordi, S.H.; Khatibi, T. Proposing a Model Based on Deep Reinforcement Learning for Real-Time Scheduling of Collaborative Customization Remanufacturing. Robots Comput.-Integr. Manuf. 2025, 94, 102980. [Google Scholar] [CrossRef]

- Zhao, B.; Wu, Y.; Wu, C.; Sun, R. Deep Reinforcement Learning Trajectory Planning for Robotic Manipulator Based on Simulation-Efficient Training. Sci. Rep. 2025, 15, 8286. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, Y.; Wang, L.; Zhang, X.; Li, A.; Zhu, M.; Wu, Q. An End-to-End Controller with Image-Based Visual Servoing of Industrial Manipulators with Soft-Actor-Critic Algorithm. Knowl.-Based Syst. 2025, 311, 112980. [Google Scholar] [CrossRef]

- Hsu, M.-J.; Hsu, C.-C.; Chien, Y.-H.; Wang, W.-Y. The Cognitive System of Robots Based on Deep Learning with Stable Convergence. Int. J. Fuzzy Syst. 2025, 27, 1–23. [Google Scholar] [CrossRef]

- Aljamal, M.; Patel, S.; Mahmood, A. Comprehensive Review of Robotics Operating System-Based Reinforcement Learning in Robotics. Appl. Sci. 2025, 15, 1840. [Google Scholar] [CrossRef]

- Wang, F.; Hu, J.; Qin, Y.; Guo, F.; Jiang, M. Trajectory Tracking Control Based on Deep Reinforcement Learning for a Robotic Manipulator with an Input Deadzone. Symmetry 2025, 17, 149. [Google Scholar] [CrossRef]

- Park, J.; Baek, J.; Song, Y. Optimizing Smart City Planning: A Deep Reinforcement Learning Framework. ICT Express 2025, 11, 129–134. [Google Scholar] [CrossRef]

- Park, Y.; Lee, J.; Sim, D.; Cho, Y.; Park, C. Designing Spiking Neural Network-Based Reinforcement Learning for 3D Robotic Arm Applications. Electronics 2025, 14, 578. [Google Scholar] [CrossRef]

- Mu, X.; Kan, Q.; Jiang, Y.; Chang, C.; Tian, X.; Zhou, L.; Zhao, Y. 3D Vision Robot Online Packing Platform for Deep Reinforcement Learning. Robotics Comput.-Integr. Manuf. 2025, 94, 102941. [Google Scholar] [CrossRef]

- Mishra, M.; Poddar, P.; Agrawal, R.; Chen, J.; Tokekar, P.; Sujit, P.B. Multi-Agent Deep Reinforcement Learning for Persistent Monitoring with Sensing, Communication, and Localization Constraints. IEEE Trans. Autom. Sci. Eng. 2025, 22, 2831–2843. [Google Scholar] [CrossRef]

- Cho, J.; Choi, D.; Lee, D.-Y.; Lee, D.-W. Model Predictive Control-Based Sensorless Physical Human–Robot Interaction of a Dual-Arm Social Robot. IEEE Access 2024, 12, 175511–175524. [Google Scholar] [CrossRef]

- Feng, B.; Wang, Z.; Yuan, L.; Zhou, Q.; Chen, Y.; Bi, Y. Towards Safe Motion Planning for Industrial Human-Robot Interaction: A Co-Evolution Approach Based on Human Digital Twin and Mixed Reality. Robotics Comput.-Integr. Manuf. 2025, 95, 103012. [Google Scholar] [CrossRef]

- Van Duong, L. A Tactile Reflex Arc for Physical Human–Robot Interaction. Mechatronics 2025, 107, 103307. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, F.; Wan, Y.; Chen, C.; Gao, Z.; Liu, H.; Wang, Y.; Yan, R.; Tang, X. Scaled Non-Passive Environmental Interaction Force Tracking for Telerobotic Manufacturing System with Variable Time Delay. Sci. China Technol. Sci. 2025, 68, 1320301. [Google Scholar] [CrossRef]

- Li, S.; Xu, J. Multiaxis Force/Torque Sensor Technologies: Design Principles and Robotic Force Control Applications: A Review. IEEE Sens. J. 2025, 25, 4055–4069. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.-J.; Koh, D.-Y. Experimental Evaluation of Precise Placement with Pushing Primitive Based on Cartesian Force Control. Appl. Sci. 2025, 15, 387. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, J.; Lin, Z.; Shen, L.; Liu, Z. Learning Latent Causal Factors from the Intricate Sensor Feedback of Contact-Rich Robotic Assembly Tasks. Robotics Auton. Syst. 2025, 183, 104832. [Google Scholar] [CrossRef]

- Lu, Z.; Si, W.; Wang, N.; Yang, C. Dynamic Movement Primitives-Based Human Action Prediction and Shared Control for Bilateral Robot Teleoperation. IEEE Trans. Ind. Electron. 2024, 71, 16654–16663. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Liu, S.; Wang, L. Transfer Learning and Augmented Data-Driven Parameter Prediction for Robotic Welding. Robotics Comput.-Integr. Manuf. 2025, 95, 102992. [Google Scholar] [CrossRef]

- Putranto, A.; Lin, T.-H.; Tsai, P.-T. Digital Twin-Enabled Robotics for Smart Tag Deployment and Sensing in Confined Space. Robotics Comput.-Integr. Manuf. 2025, 95, 102993. [Google Scholar] [CrossRef]

- Ali, A.R.; Ramadan, M.W.A. Artificial Neural Networks as Digital Twins for Whispering Gallery Mode Optical Sensors in Robotics Applications. Photonic Sens. 2025, 15, 250206. [Google Scholar] [CrossRef]

- Alonso, R.; Sánchez, T.F.; Alfaro, D.A.; Cruz, Y.J.; Villalonga, A.; Castaño, F. Automation and Robotics Pilot Lines in the Context of Industry 5.0. Appl. Sci. 2025, 15, 2510. [Google Scholar] [CrossRef]

- Cristoiu, C.; Ivan, A.M. Integration of Real Signals Acquired Through External Sensors into RoboDK Simulation of Robotic Industrial Applications. Sensors 2025, 25, 1395. [Google Scholar] [CrossRef]

- Alfaro-Viquez, D.; Zamora-Hernandez, M.; Fernandez-Vega, M.; Garcia-Rodriguez, J.; Azorin-Lopez, J. A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions. Electronics 2025, 14, 646. [Google Scholar] [CrossRef]

- Sreedharan, S.; Ramachandran, M.; Ramesh, D. Harnessing Digital Twins and Industrial-IoT for Cutting-Edge Mining Automation: A Methodological and Technology Assessment Prototype. Comput. Ind. Eng. 2025, 201, 110871. [Google Scholar] [CrossRef]

- Singh, M.; Kapukotuwa, J.; Gouveia, E.L.S.; Fuenmayor, E.; Qiao, Y.; Murray, N.; Devine, D. Comparative Study of Digital Twin Developed in Unity and Gazebo. Electronics 2025, 14, 276. [Google Scholar] [CrossRef]

- Oo, K.H.; Koomsap, P.; Hussadintorn Na Ayutthaya, D. Digital Twin-Enabled Multi-Robot System for Collaborative Assembly of Unorganized Parts. J. Ind. Inf. Integr. 2025, 44, 100764. [Google Scholar] [CrossRef]

- Wang, X.; Cao, J.; Cao, Y.; Zou, F. Energy-Efficient Trajectory Planning for a Class of Industrial Robots Using Parallel Deep Reinforcement Learning. Nonlinear Dyn. 2025, 113, 8491–8511. [Google Scholar] [CrossRef]

- Celik, A.E.; Rodriguez, I.; Ayestaran, R.G.; Yavuz, S.C. Decentralized System Synchronization among Collaborative Robots via 5G Technology. Sensors 2024, 24, 5382. [Google Scholar] [CrossRef]

- Wu, M.; Zhou, X.; Li, S.; Shi, H. An Adaptive Continual Learning Method for Nonstationary Industrial Time Series Prediction. IEEE Trans. Ind. Inform. 2025, 21, 1160–1169. [Google Scholar] [CrossRef]

- Sombolestan, M.; Nguyen, Q. Adaptive-Force-Based Control of Dynamic Legged Locomotion Over Uneven Terrain. IEEE Trans. Robot. 2024, 40, 2462–2477. [Google Scholar] [CrossRef]

- Pan, Y.; Chen, C.; Li, D.; Zhao, Z. A Robot Path Tracking Method Based on Manual Guidance and Path Reinforcement Learning. Appl. Intell. 2024, 55, 197. [Google Scholar] [CrossRef]

- Ho, T.M.; Nguyen, K.K.; Cheriet, M. Converging Game Theory and Reinforcement Learning for Industrial Internet of Things. IEEE Trans. Netw. Serv. Manag. 2023, 20, 890–903. [Google Scholar] [CrossRef]

- Yang, L.; Xie, C.; Yang, H.; Zhan, H.; Qin, L. Assembly Strategy for Inclined-Holes Based on Vision and Force. Eng. Res. Express 2025, 7, 015233. [Google Scholar] [CrossRef]

- Soualhi, T.; Crombez, N.; Lombard, A.; Ruichek, Y.; Galland, S. Leveraging Motion Perceptibility and Deep Reinforcement Learning for Visual Control of Nonholonomic Mobile Robots. Robot. Auton. Syst. 2025, 189, 104920. [Google Scholar] [CrossRef]

- Khosravy, M.; Gupta, N.; Pasquali, A.; Dey, N.; Crespo, R.G.; Witkowski, O. Human-Collaborative Artificial Intelligence Along with Social Values in Industry 5.0: A Survey of the State-of-the-Art. IEEE Trans. Cogn. Dev. Syst. 2024, 16, 165–176. [Google Scholar] [CrossRef]

- Nievas, N.; Pagès-Bernaus, A.; Bonada, F.; Echeverria, L.; Domingo, X. Reinforcement Learning for Autonomous Process Control in Industry 4.0: Advantages and Challenges. Appl. Artif. Intell. 2024, 38, 2383101. [Google Scholar] [CrossRef]

- Yuan, M.; Wang, Y.; Li, L.; Chai, T.; Ang, W.T. Safety-Based Speed Control of a Wheelchair Using Robust Adaptive Model Predictive Control. IEEE Trans. Cybern. 2024, 54, 4464–4474. [Google Scholar] [CrossRef]

- Moezi, S.A.; Sedaghati, R.; Rakheja, S. Nonlinear Dynamic Modeling and Model-Based AI-Driven Control of a Magnetoactive Soft Continuum Robot in a Fluidic Environment. ISA Trans. 2024, 144, 245–259. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Ni, J.; Geng, Z.; Zhao, B.; Yang, H. Buoy and Winch Collaborative Control System Based on Deep Reinforcement Learning. J. Mar. Sci. Eng. 2025, 13, 326. [Google Scholar] [CrossRef]

- Choi, D.W.; Park, J.H.; Yoo, J.-H.; Ko, K. AI-Driven Adaptive Grasping and Precise Detaching Robot for Efficient Citrus Harvesting. Comput. Electron. Agric. 2025, 232, 110131. [Google Scholar] [CrossRef]

- Zakeri, E.; Spilkin, A.; Elmekki, H.; Zanuttini, A.; Kadem, L.; Bentahar, J.; Xie, W.-F.; Pibarot, P. AI-Powered Robust Interaction Force Control of a Cardiac Ultrasound Robotic System. IEEE Trans. Ind. Electron. 2025, 72, 3972–3983. [Google Scholar] [CrossRef]

- Tran, T.; Nguyen, Q.; Luu, T.; Tran, M.; Kua, J.; Hoang, T.; Dien, M. Empowering Robotic Training with Kinesthetic Learning and Digital Twins in Human–Centric Industrial Systems. J. Ind. Inf. Integr. 2025, 43, 100743. [Google Scholar] [CrossRef]

- Liu, Q.; Ji, Z.; Xu, W.; Liu, Z.; Yao, B.; Zhou, Z. Knowledge-Guided Robot Learning on Compliance Control for Robotic Assembly Task with Predictive Model. Expert Syst. Appl. 2023, 234, 121037. [Google Scholar] [CrossRef]

- Ho, T.M.; Nguyen, K.-K.; Cheriet, M. Energy Efficiency Deep Reinforcement Learning for URLLC in 5G Mission-Critical Swarm Robotics. IEEE Trans. Netw. Serv. Manag. 2024, 21, 5018–5032. [Google Scholar] [CrossRef]

- Thakuri, P.K.; Alkki, L.; Aarikka-Stenroos, L. Digital Technologies Enabling Component Reuse in Circular Value Chains: Using Digital Twin, Internet of Things and Robots in Construction and Manufacturing Sectors. RD Manag. 2024, 1–56. [Google Scholar] [CrossRef]