Improved RRT-Based Obstacle-Avoidance Path Planning for Dual-Arm Robots in Complex Environments

Abstract

1. Introduction

- Two-stage sampling-direction strategy. Stage I performs greedy growth toward the goal. Upon collision, Stage II engages a hybrid expansion strategy that combines goal bias with random perturbations to steer the tree. This preserves both exploration and exploitation, enabling efficient discovery of feasible paths.

- Dynamic safety step-size strategy. The expansion step is adaptively scaled according to the obstacle’s minimum enclosing diameter and the approach angle, maintaining collision-checking validity and accelerating search in cluttered environments.

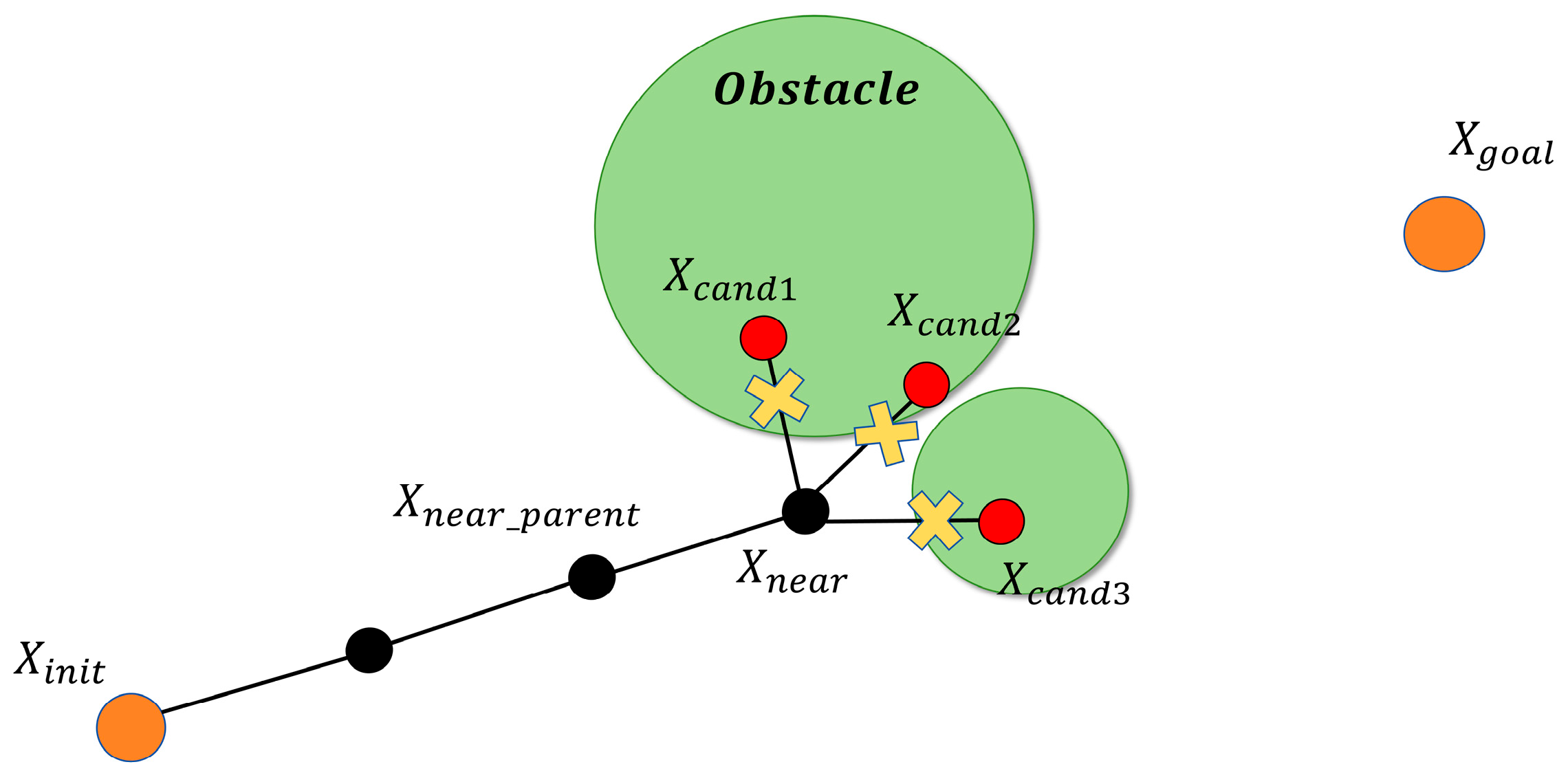

- Expansion-node optimization with backtracking recovery. Multiple candidate nodes are generated and evaluated to select the optimal expansion point. A failure backtracking mechanism resets the search to a parent node after consecutive dead ends, improving node quality and preventing stagnation in local traps.

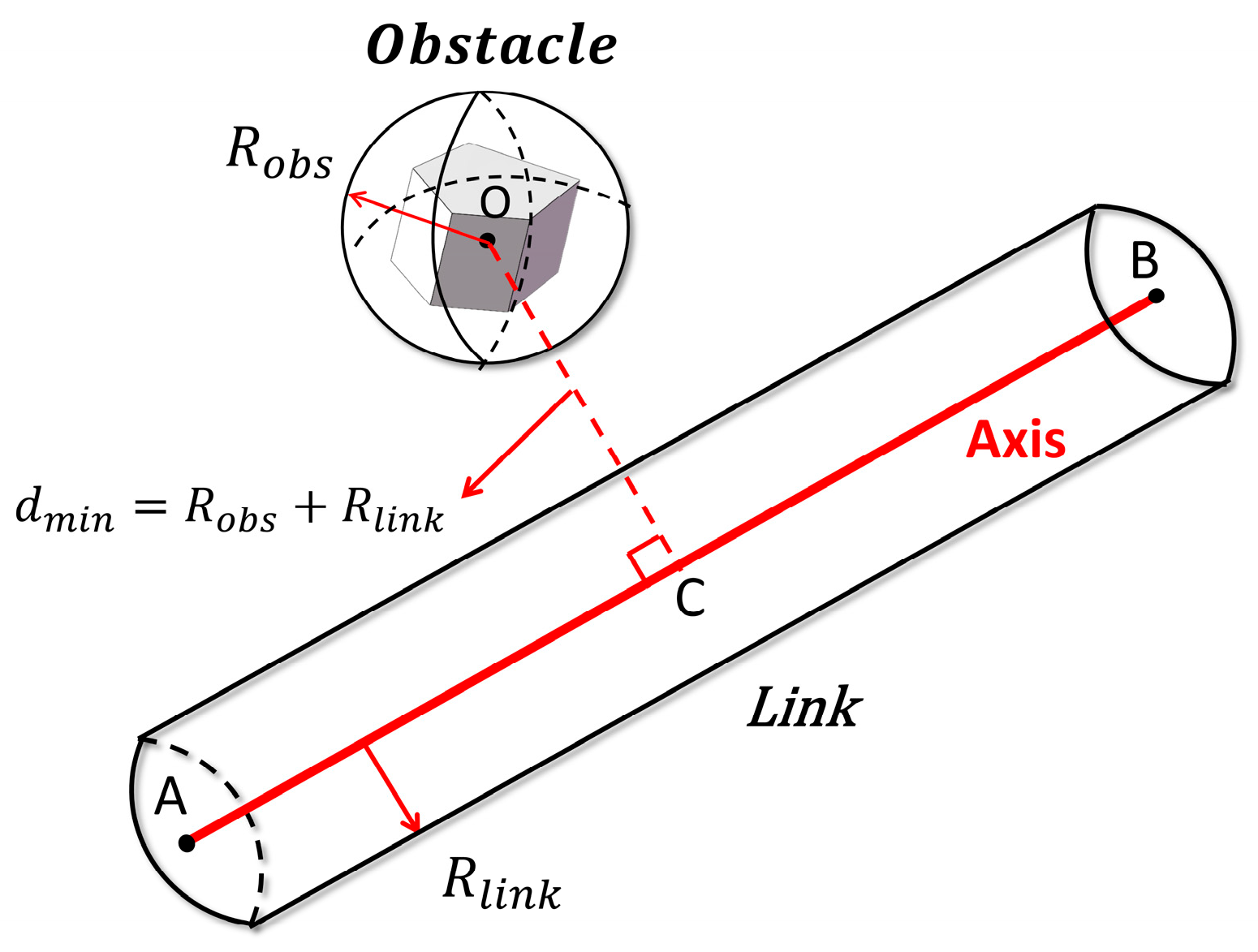

- Cylindrical–spherical collision-detection framework. A unified geometric model streamlines both self-collision and environmental collision computations for dual-arm systems.

- Path optimization and master–slave planning. Segment-wise collision checking prunes redundant nodes, while a master–slave scheme decouples the two arms, enhancing cooperative feasibility and curbing the computational load in high-dimensional spaces.

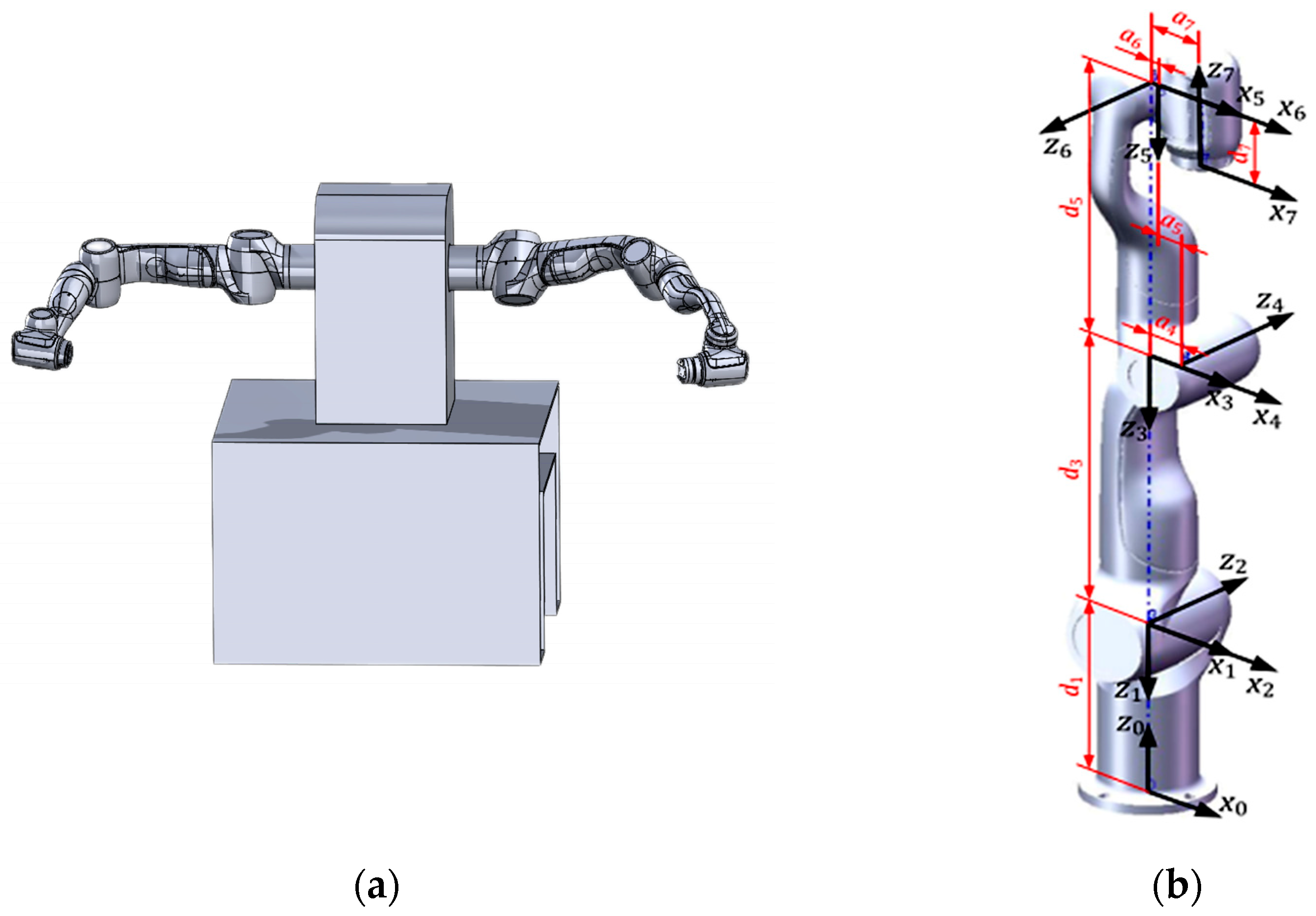

2. Kinematic Modelling

3. Algorithm Improvement

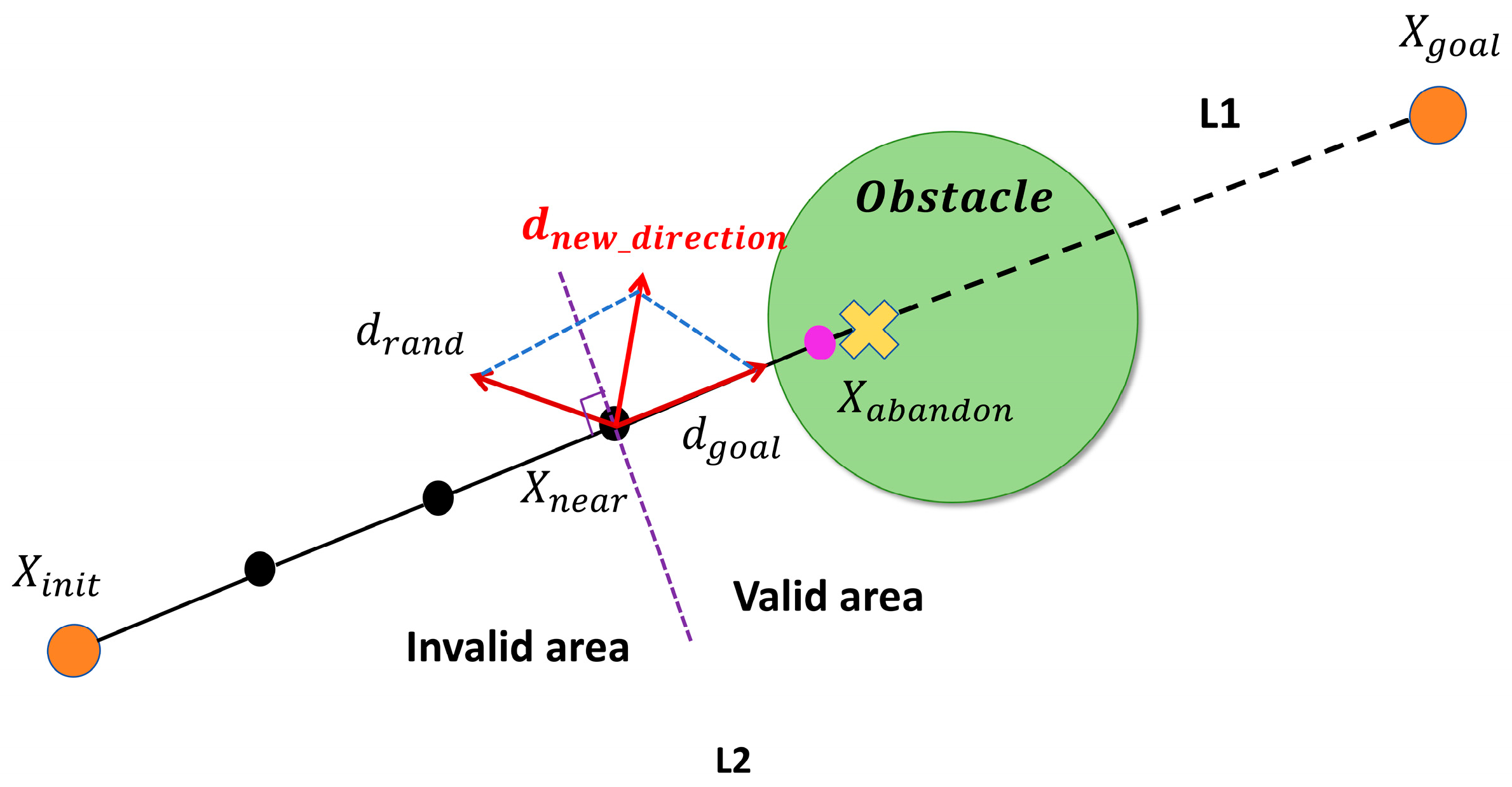

3.1. Two-Stage Sampling-Direction Strategy

- Stage I (desired growth). The exploration tree grows greedily toward the goal configuration.

- Stage II (direction optimization). When the tree encounters an obstacle, the planner switches to Stage II and computes a new sampling direction by combining goal bias with random perturbations. If this expansion succeeds, the algorithm returns to Stage I for the next greedy growth cycle. The two-stage loop proceeds iteratively until the goal is reached.

3.2. Dynamic Safety Step-Size Strategy

3.2.1. Global Upper Bound for Joint-Space Step Size

3.2.2. Segmented Dynamic Step-Size Adjustment

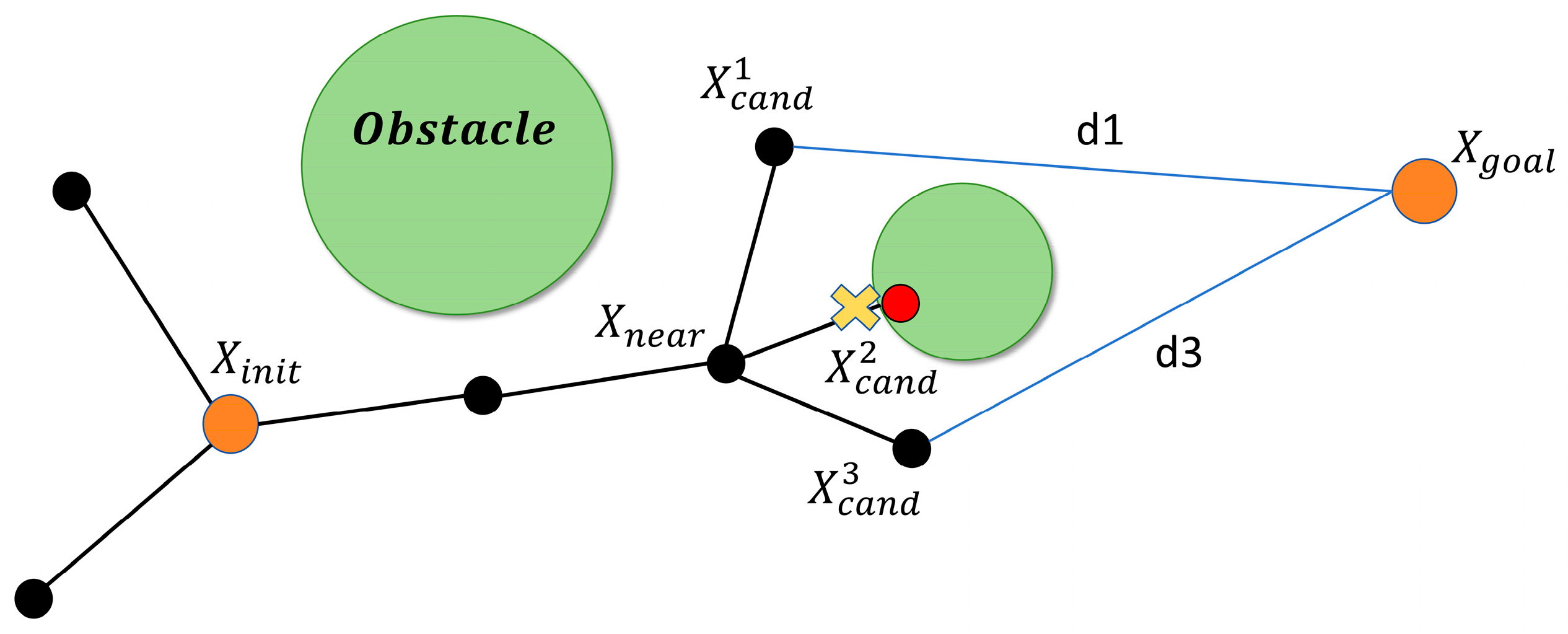

3.3. Expansion-Node Optimization Strategy

- Sampling. During Stage II, randomly sample joint-space configurations . The value of is chosen adaptively according to the density of environmental obstacles.

- Candidate generation. For each sample, combine the goal-biased direction with the random direction to obtain a new expansion direction . Using the dynamic step size , generate a corresponding set of candidate nodes, as defined by Equation (14):

- Selection. Discard any candidate nodes that collide with obstacles. For the remaining collision-free candidates, compute their Euclidean distances to the goal and insert into the tree the node with the smallest distance, denoted , according to Equation (15).

3.4. Dual-Arm Collision-Detection Model

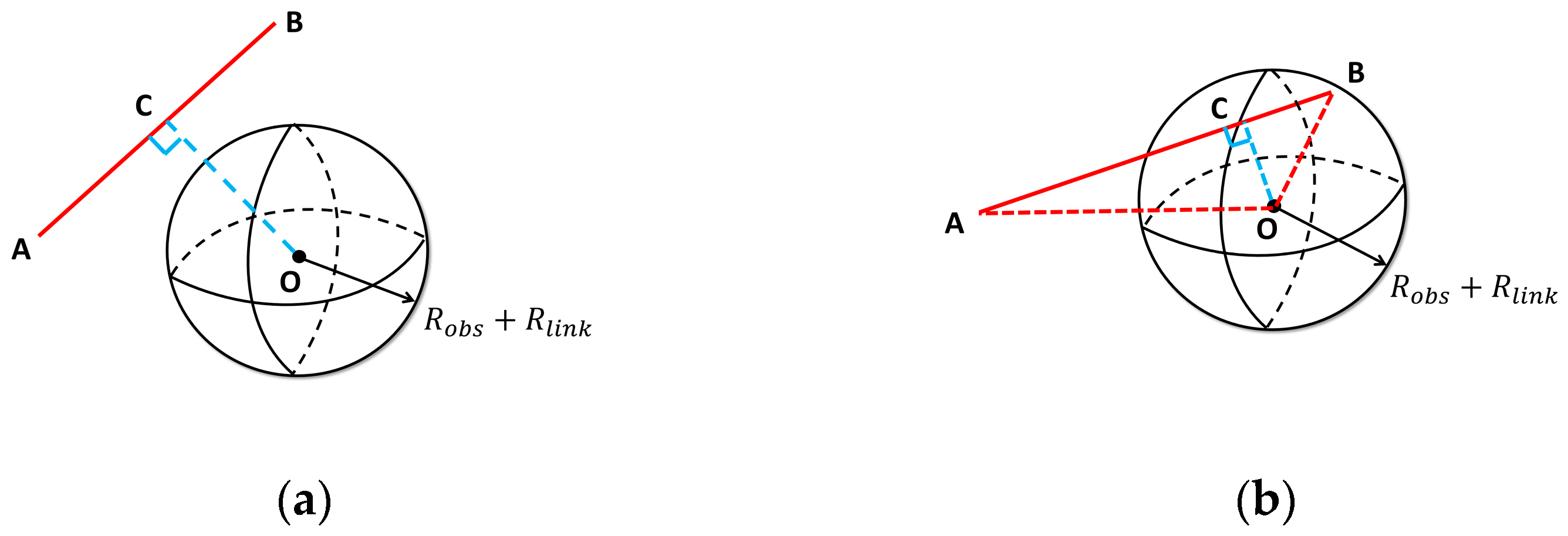

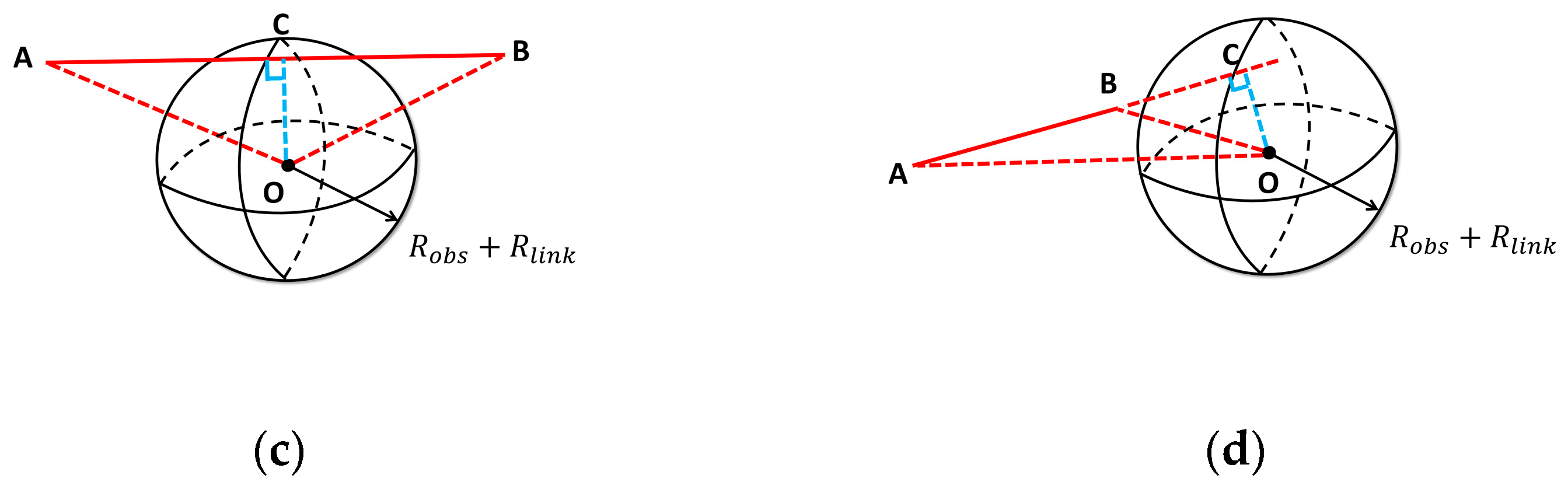

3.4.1. Link–Obstacle Collision Detection

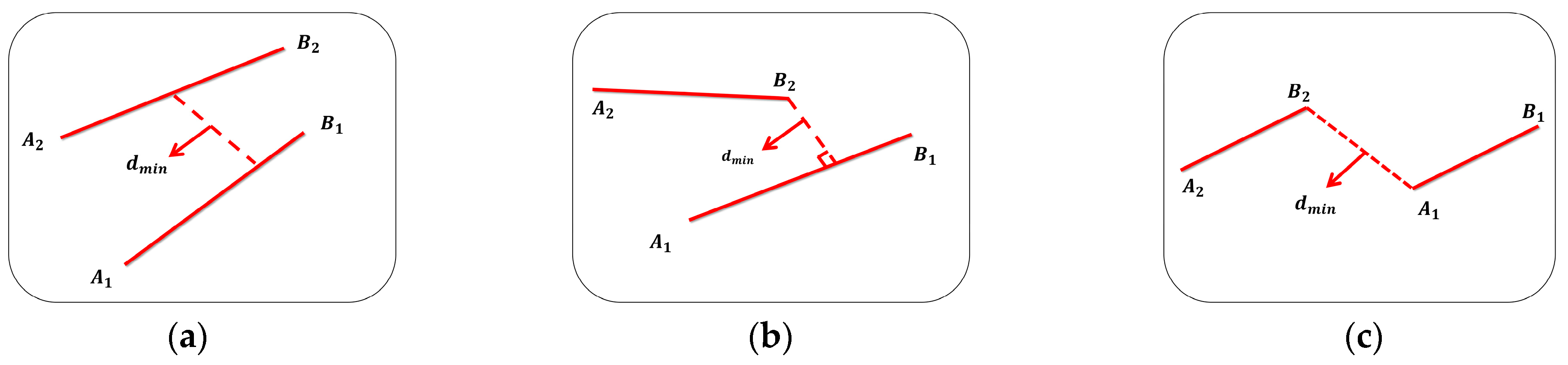

3.4.2. Link–Link Collision Detection

- 1.

- Case (a): If , the foot-points of the mutual perpendicular lie inside both segments. The solution of the optimization problem is valid, yielding .

- 2.

- Case (b): If , and, using the point-to-segment distance formula for each of the four endpoints yields the following equation:where denotes the Euclidean distance from point P to segment .

- 3.

- Case (c): If the link-to-link distance is the minimum of the four endpoint–endpoint distances, and the formula is as follows:

3.5. Path Optimization

- Forward pruning.

- 2.

- Iterative refinement.

3.6. Algorithm Implementation

- Initialization.

- 2.

- Stage I—Goal-directed expansion.

- 3.

- Stage II—Direction-optimized sampling.

- (1)

- Generate random samples in joint space.

- (2)

- For each sample, construct a goal-biased direction by combining the random vector with ; compute the adaptive step length from the angle θ between these vectors.

- (3)

- Generate the candidate node set and discard any colliding nodes.

- (4)

- Select .

- (5)

- If , record a failure; once consecutive failures exceed backtrack to the parent of and resample.

- (6)

- Add and return to Stage I.

- 4.

- Termination.

| Algorithm 1. ODSN-RRT |

| Output: T |

| do #Stage I: goal-directed growth |

| do |

| ) then |

| ) < threshold then |

| 8. return T |

| 9. end if |

| 10. else |

| 11. break #collision → switch to Stage II |

| 12. end if |

| 13. end while |

| do #Stage II: direction-optimized growth |

| = 1 to k do |

| ) |

| then |

| 25. end if |

| 26. end for |

| then |

| ) < threshold then |

| into T, return T |

| 32. end if |

| 33. else #Failure backtracking |

| + 1 |

| then |

| then |

| 38. else |

| 39. return “failure” |

| 40. end if |

| 41. end if |

| 42. end if |

| 43. break |

| 44. end while |

| 45. end for |

4. Simulation and Experimental Validation

4.1. 2-D Environment Simulation

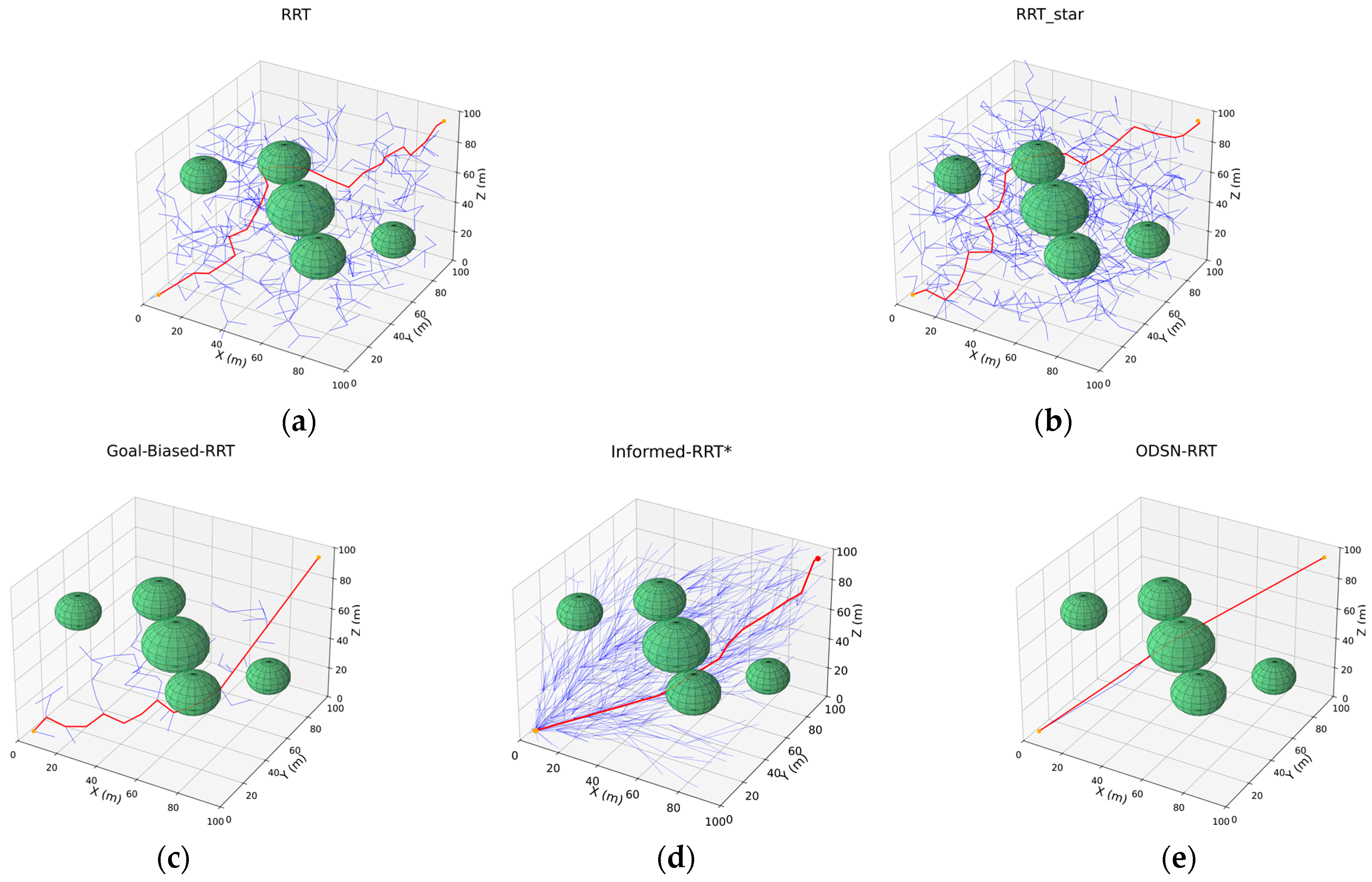

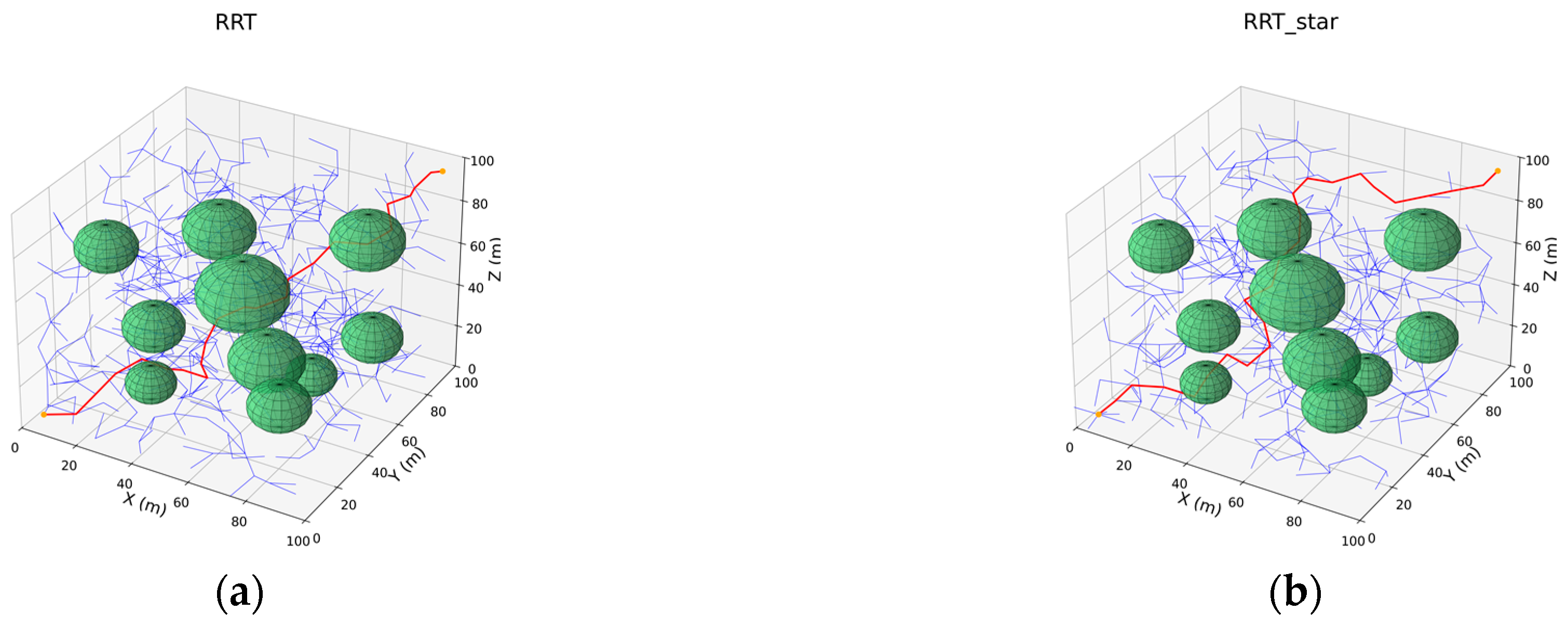

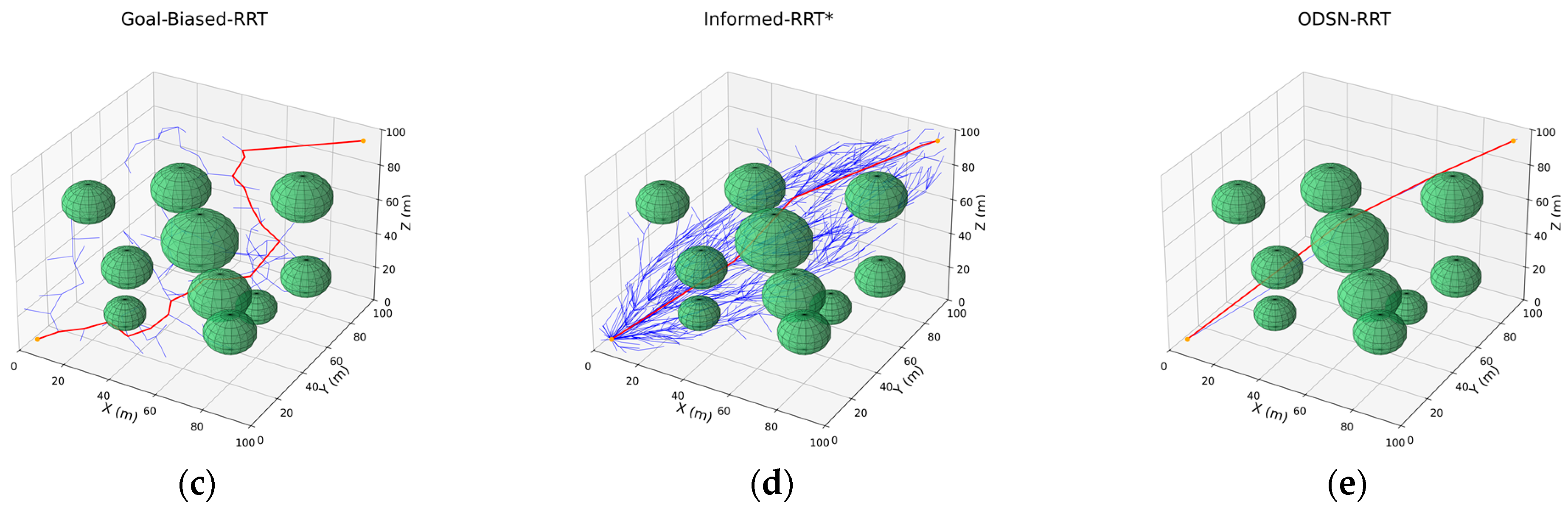

4.2. 3-D Environment Simulation

- Scenario A. Relative to the classical RRT, the average path length is shortened by 21.0%, the mean number of sampled nodes is cut by 96.5%, the path-smoothness metric is raised by 95.6%, and planning time falls 95.7%. Against RRT*, the path is 31.9% shorter, nodes fall by 96.2%, smoothness nearly doubles, and time is cut 98.9%. Relative to Goal-Biased RRT, the path is 19.6% shorter, nodes are reduced by 65.3%, smoothness improves by 26.8%, and time is slightly higher. Finally, compared with the Informed-RRT*, ODSN-RRT still trims 2.0% off the path while cutting node count from 911 to 17 (−98.1%), raising the smoothness metric from 0.85 to 0.89 and cutting planning time by 99.9%.

- The denser Scenario B. ODSN-RRT achieves the lowest mean path length and maintains a node count of only 22. This represents a 32.9% reduction in path length and a 94.6% reduction in nodes compared with RRT, together with more than double the smoothness. Versus RRT*, the path is 32.7% shorter, nodes fall by 94.5%, and smoothness again more than doubles. Compared with Goal-Biased RRT, the path shortens by 21.7%, nodes drop by 76.3%, smoothness rises by 29.9%, and planning time is 41.8% faster. Relative to Informed-RRT*, the path is 1.2% shorter, node count is reduced by 97.5%, comparable smoothness is maintained, and planning is sped up by 99.8% while preserving a 100% success rate.

4.3. Ablation Experiments

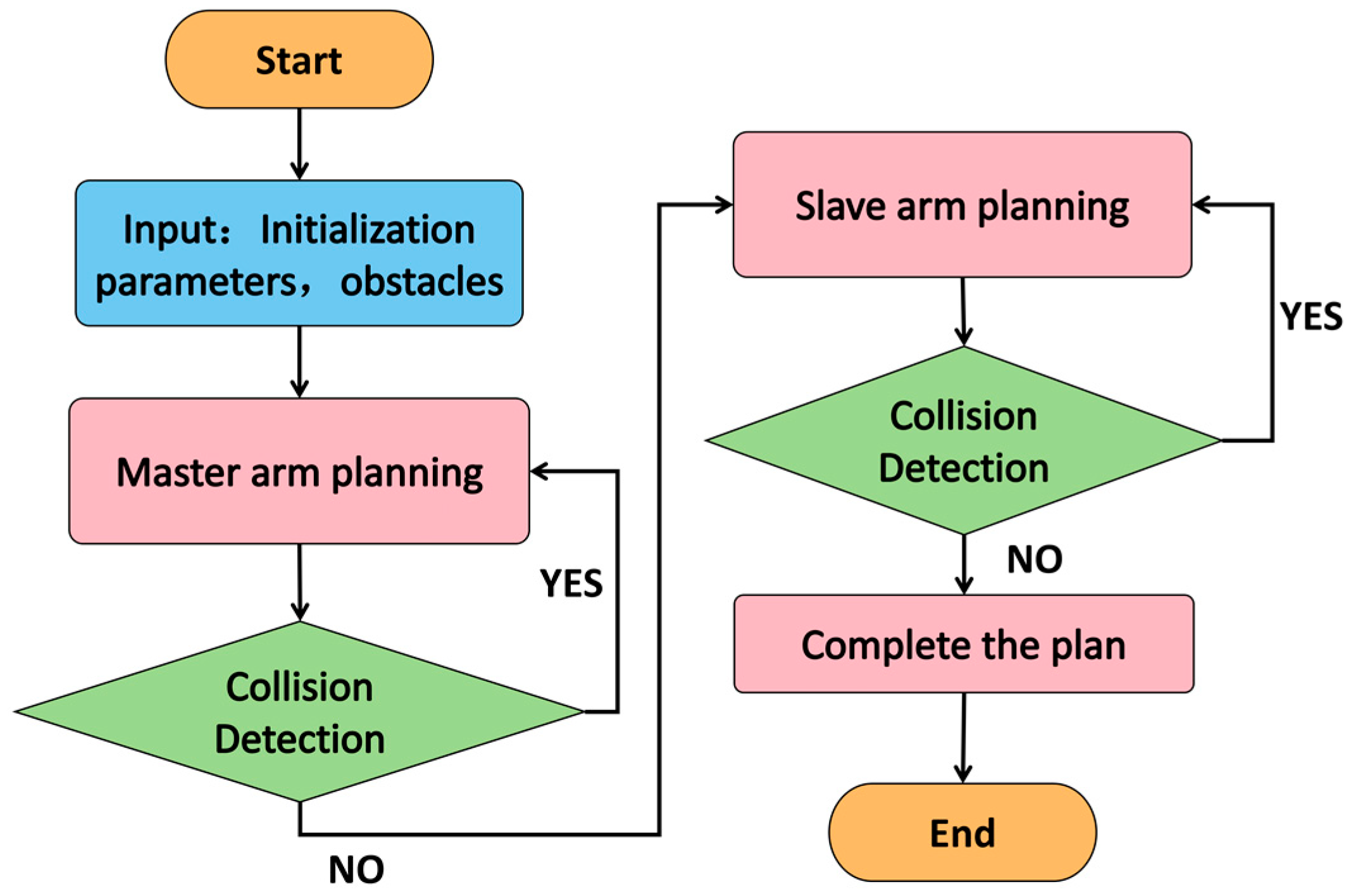

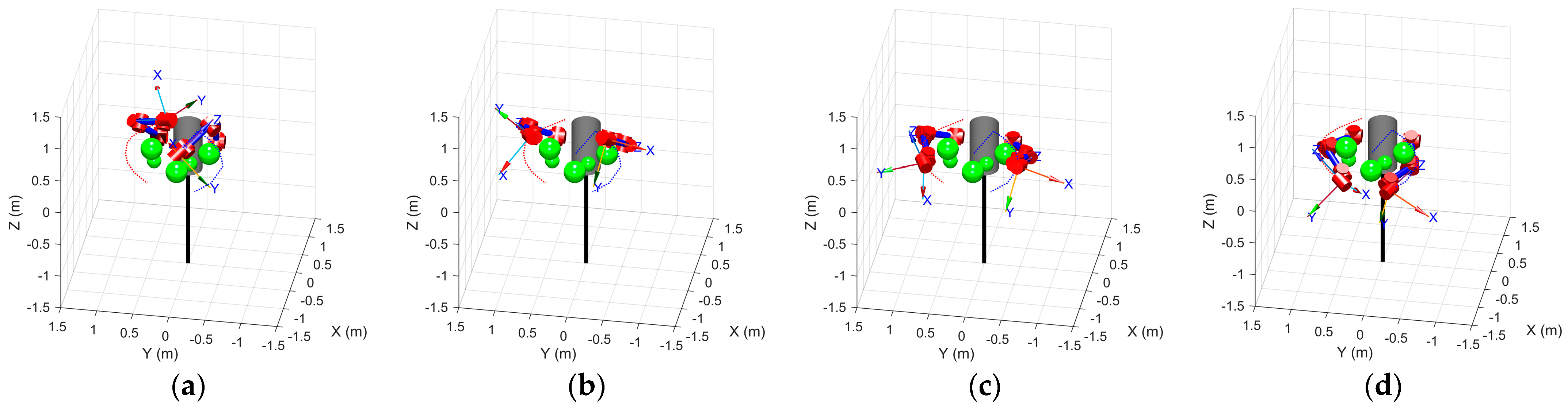

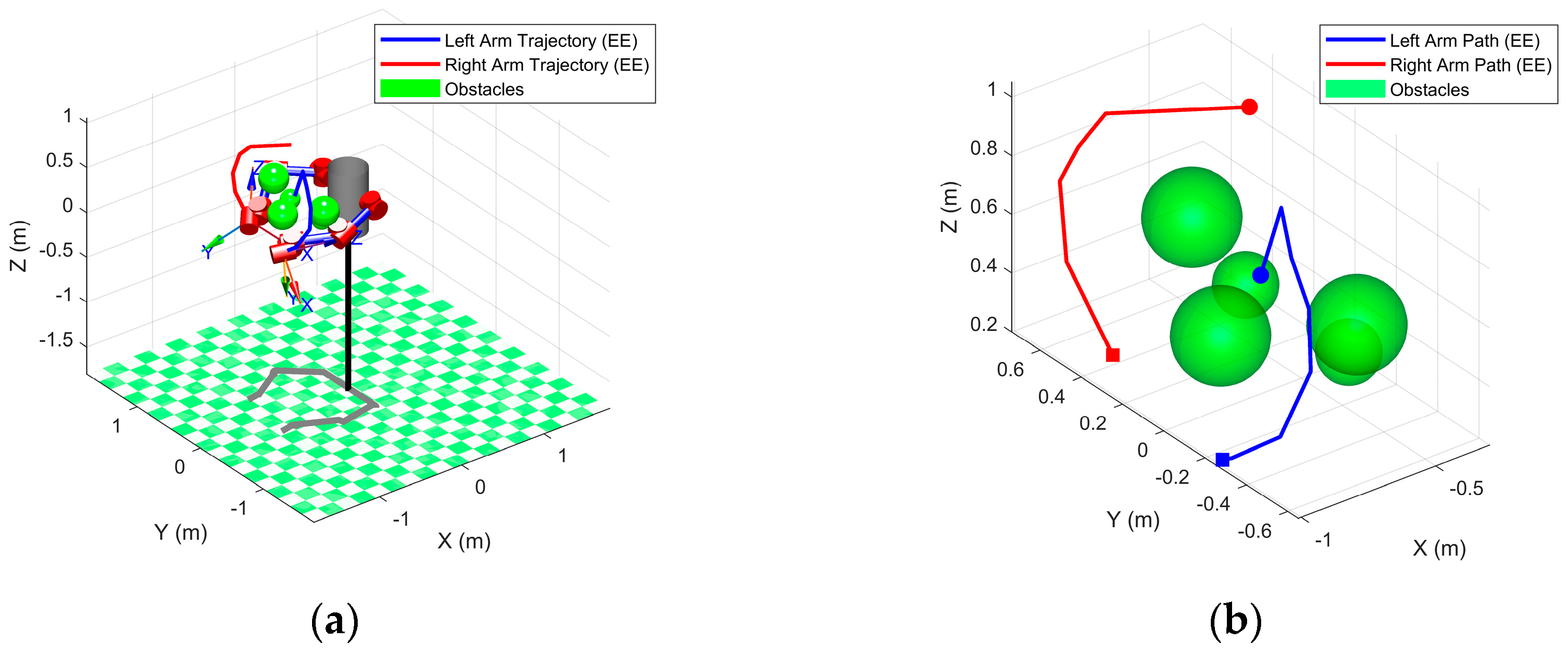

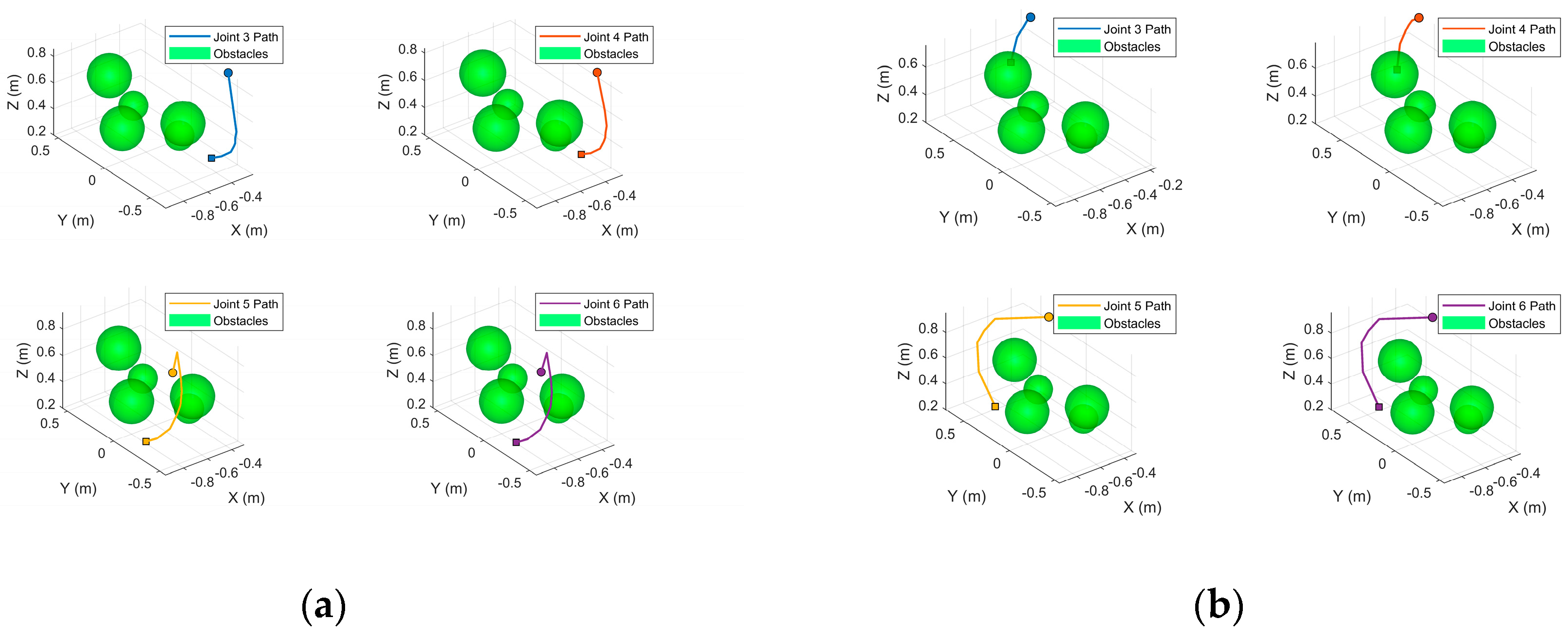

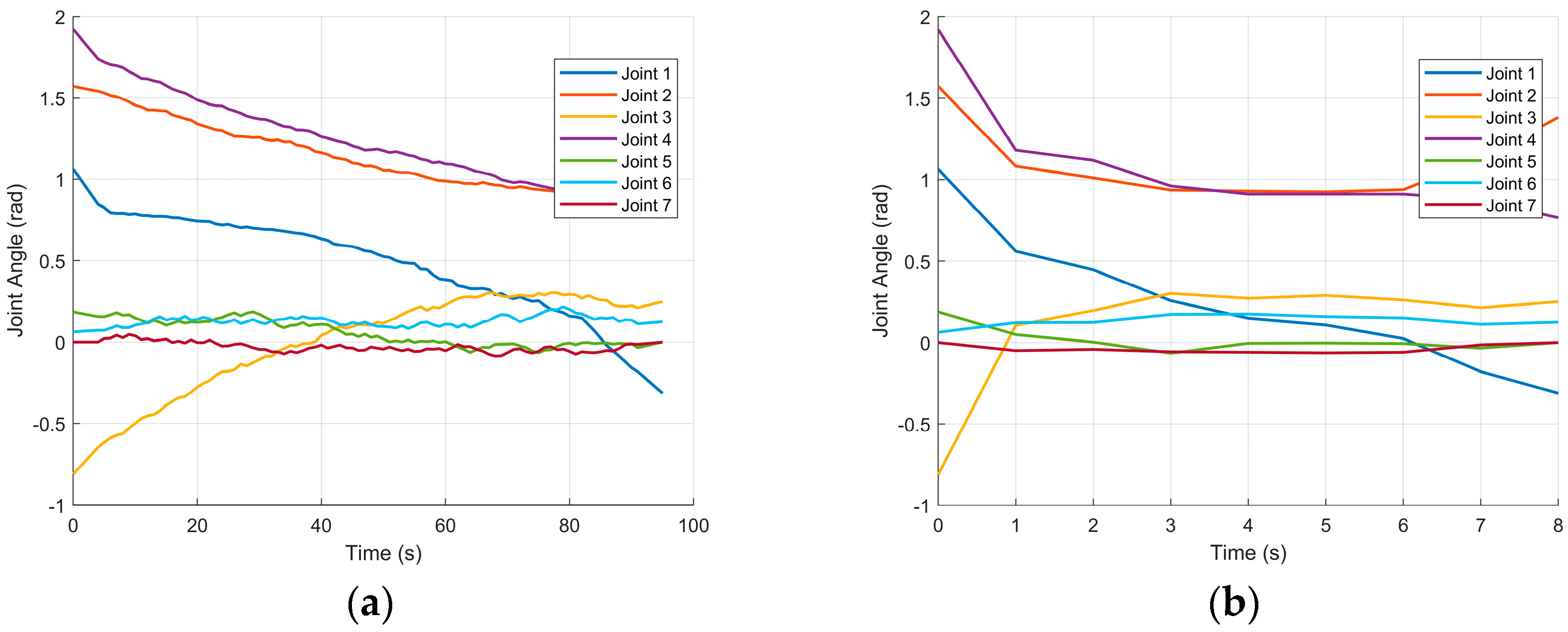

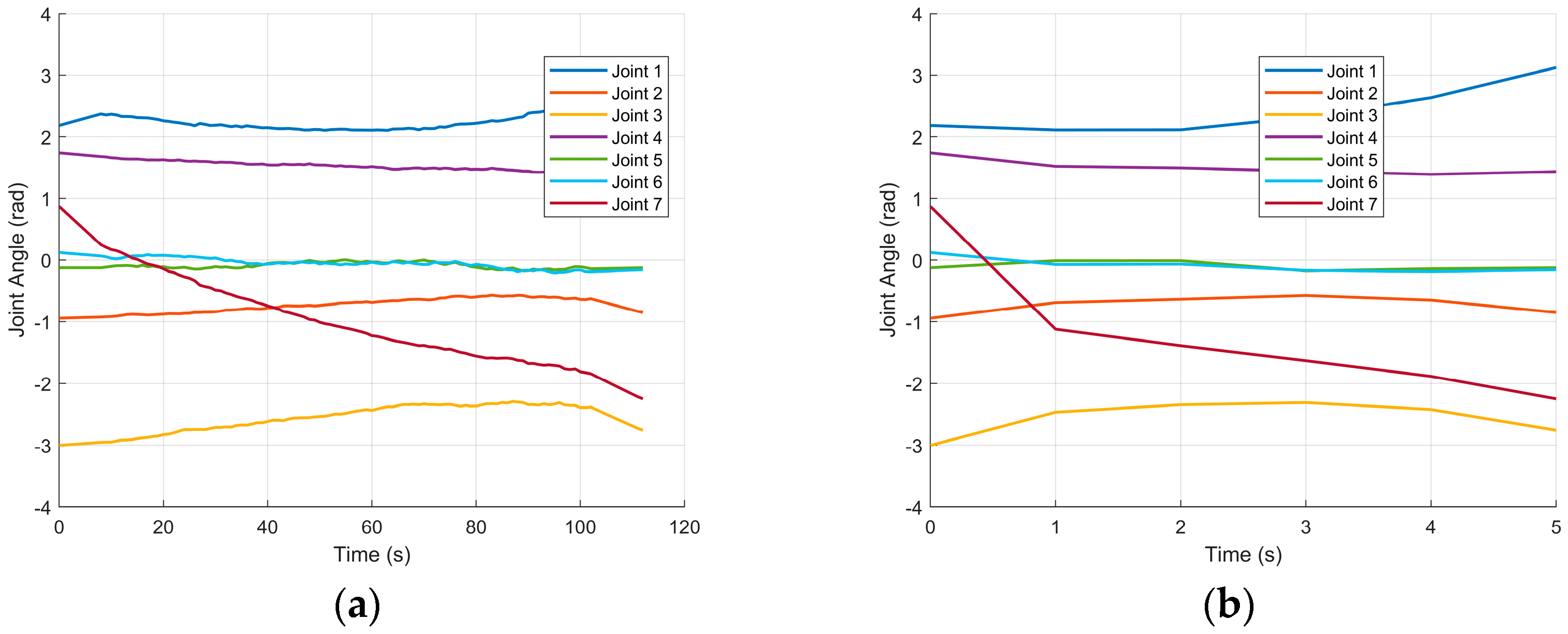

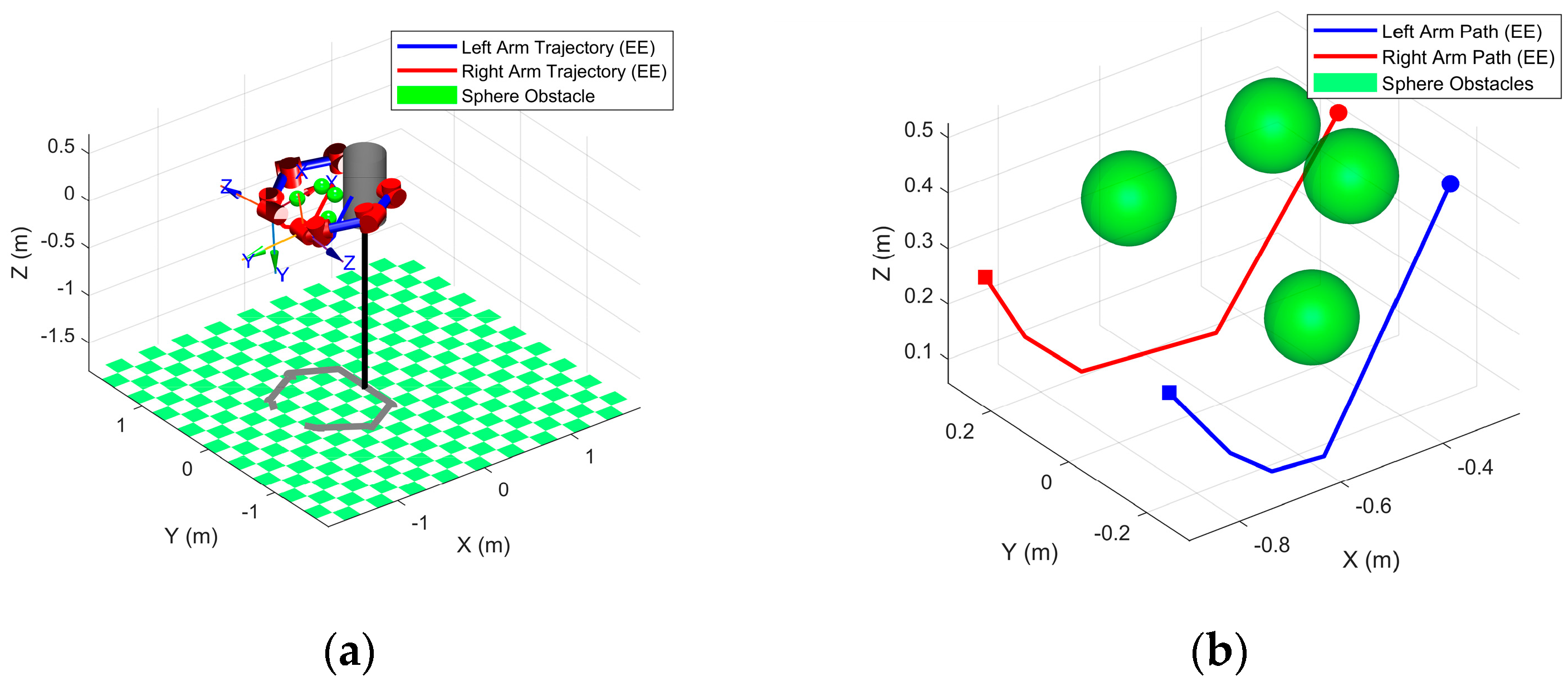

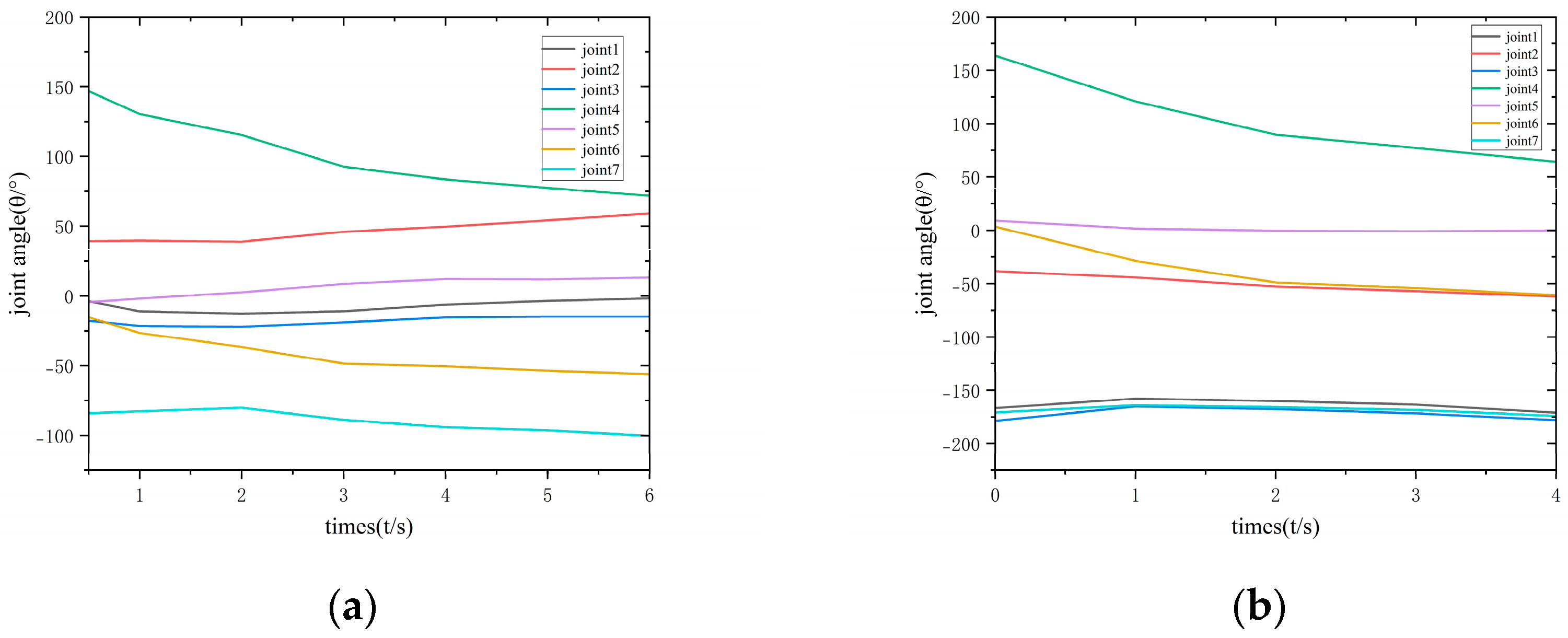

4.4. Dual-Arm Robot Simulation

- Master-arm planning: A collision-free trajectory for the master arm is generated while considering all static spherical obstacles.

- Slave-arm planning: At every time step, the instantaneous configuration of the master arm is treated as a dynamic obstacle; the slave arm is then planned so that it avoids both the environment and the moving master arm.

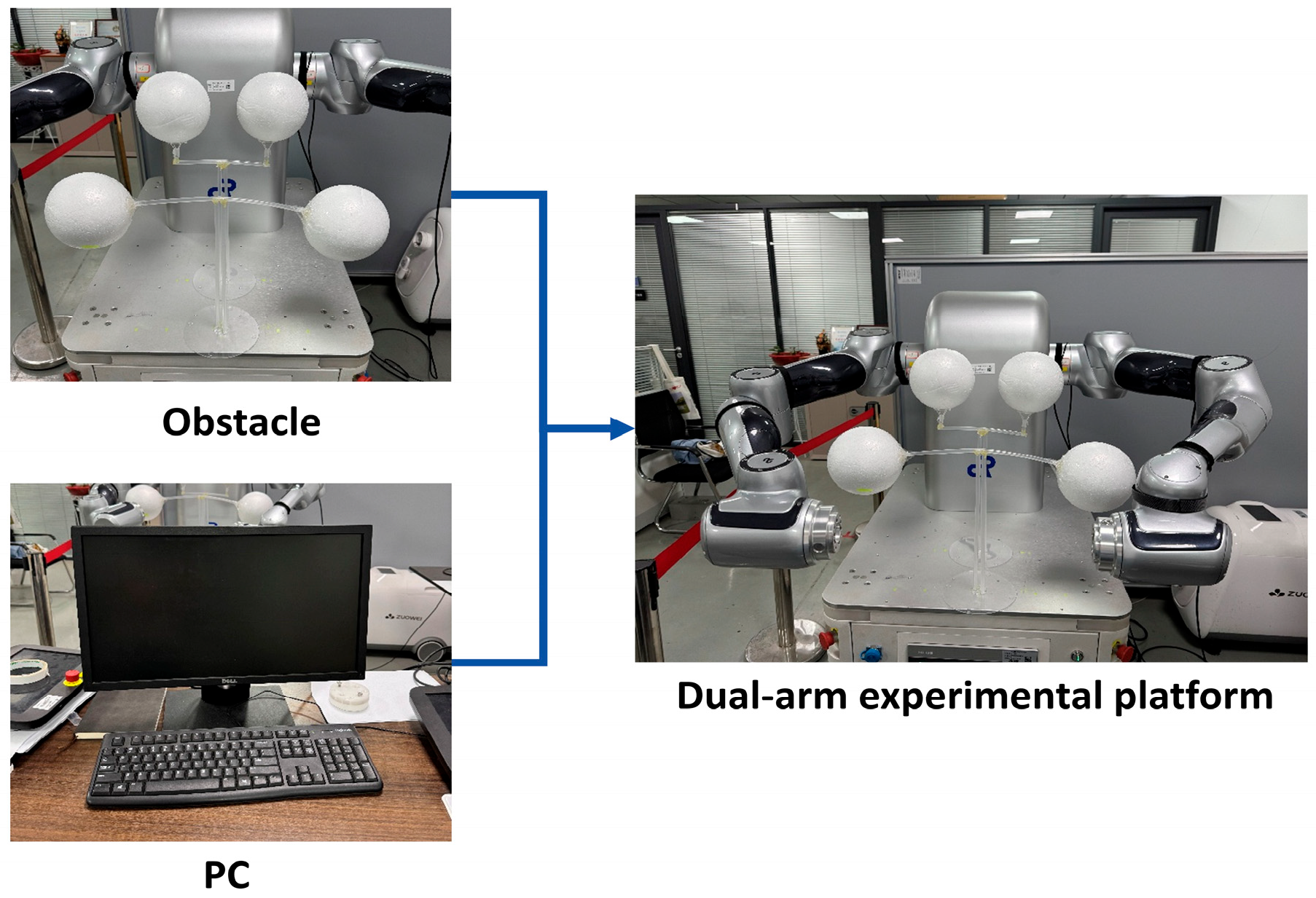

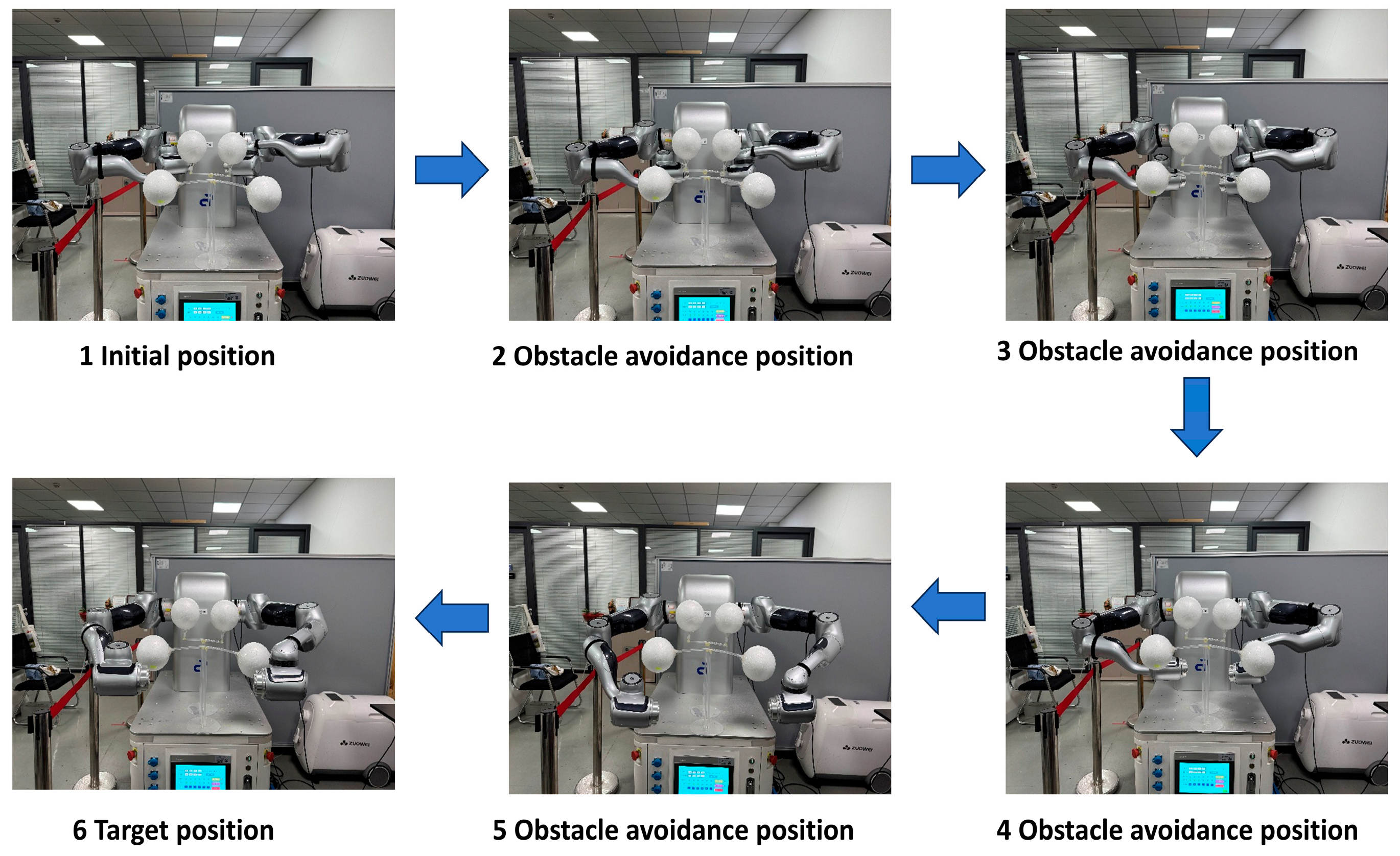

4.5. Real-Robot Experimental Validation

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Yang, S.; Zhang, Y.; Wen, H.; Jin, D. Coordinated control of dual-arm robot on space structure for capturing space targets. Adv. Space Res. 2023, 71, 2437–2448. [Google Scholar] [CrossRef]

- Peta, K.; Wiśniewski, M.; Kotarski, M.; Ciszak, O. Comparison of Single-Arm and Dual-Arm Collaborative Robots in Precision Assembly. Appl. Sci. 2025, 15, 2976. [Google Scholar] [CrossRef]

- Krüger, J.; Schreck, G.; Surdilovic, D. Dual arm robot for flexible and cooperative assembly. CIRP Ann. Manuf. Technol. 2011, 60, 5–8. [Google Scholar] [CrossRef]

- Abbas, M.; Narayan, J.; Dwivedy, S.K. A systematic review on cooperative dual-arm manipulators: Modeling, planning, control, and vision strategies. Int. J. Intell. Robot. Appl. 2023, 7, 683–707. [Google Scholar] [CrossRef]

- Jiang, Y.; Fakhruldeen, H.; Pizzuto, G.; Longley, L.; He, A.; Dai, T.; Clowes, R.; Rankin, N.; Cooper, A.I. Autonomous biomimetic solid dispensing using a dual-arm robotic manipulator. Digit. Discov. 2023, 2, 1733–1744. [Google Scholar] [CrossRef]

- Fleischer, H.; Baumann, D.; Joshi, S.; Chu, X.; Roddelkopf, T.; Klos, M.; Thurow, K. Analytical measurements and efficient process generation using a dual–arm robot equipped with electronic pipettes. Energies 2018, 11, 2567. [Google Scholar] [CrossRef]

- Fleischer, H.; Baumann, D.; Chu, X.; Roddelkopf, T.; Klos, M.; Thurow, K. Integration of Electronic Pipettes into a Dual-arm Robotic System for Automated Analytical Measurement Processes Behaviors. In Proceedings of the 2018 IEEE 14th International Conference on Automation Science and Engineering (CASE), Munich, Germany, 20–24 August 2018; pp. 22–27. [Google Scholar]

- Liu, J.; Xu, C.; Jia, X.; Wu, Y.; Li, T. Cooperative Collision Avoidance Control with Relative Velocity Information for Redundant Dual-arm Robotic Manipulators. J. Bionic Eng. 2025, 22, 1111–1125. [Google Scholar] [CrossRef]

- Lei, M.; Wang, T.; Yao, C.; Liu, H.; Wang, Z.; Deng, Y. Real-Time Kinematics-Based Self-Collision Avoidance Algorithm for Dual-Arm Robots. Appl. Sci. 2020, 10, 5893. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, Z.; Tan, Y.; Fu, H.; Min, H. Efficient TD3 based path planning of mobile robot in dynamic environments using prioritized experience replay and LSTM. Sci. Rep. 2025, 15, 18331. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Yang, X.; Liu, H.; Li, J.; Wang, P. Path planning techniques for mobile robots: Review and prospect. Expert Syst. Appl. 2023, 227, 120254. [Google Scholar] [CrossRef]

- Orthey, A.; Chamzas, C.; Kavraki, L.E. Sampling-based motion planning: A comparative review. Annu. Rev. Control Robot. Auton. Syst. 2024, 7, 285–310. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, B.; Fränti, P. A review of motion planning algorithms for intelligent robots. J. Intell. Manuf. 2022, 33, 387–424. [Google Scholar] [CrossRef]

- Szczepanski, R. Safe Artificial Potential Field—Novel Local Path Planning Algorithm Maintaining Safe Distance From Obstacles. IEEE Robot. Autom. Lett. 2023, 8, 4823–4830. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, H.; Wang, Q.; Shi, Y.; Zhao, J. An improved A* algorithm for generating four-track trajectory planning to adapt to longitudinal rugged terrain. Sci. Rep. 2025, 15, 6727. [Google Scholar] [CrossRef]

- Yuan, Q.; Sun, R.; Du, X. Path Planning of Mobile Robots Based on an Improved Particle Swarm Optimization Algorithm. Processes 2023, 11, 26. [Google Scholar] [CrossRef]

- Chen, G.; Luo, N.; Liu, D.; Zhao, Z.; Liang, C. Path planning for manipulators based on an improved probabilistic roadmap method. Robot. Comput.-Integr. Manuf. 2021, 72, 102196. [Google Scholar] [CrossRef]

- Xu, T. Recent advances in Rapidly-exploring random tree: A review. Heliyon 2024, 10, e32451. [Google Scholar] [CrossRef]

- Kuffner, J.J.; LaValle, S.M. RRT-connect: An efficient approach to single-query path planning. In Proceedings 2000 ICRA. Millennium Conference, Proceedings of the IEEE International Conference on Robotics and Automation. Symposia Proceedings (Cat. No.00CH37065), San Francisco, CA, USA, 24–28 April 2000; IEEE: New York, NY, USA, 2000; pp. 995–1001. [Google Scholar]

- Zhang, L.; Cai, K.; Sun, Z.; Bing, Z.; Wang, C.; Figueredo, L.; Haddadin, S.; Knoll, A. Motion planning for robotics: A review for sampling-based planners. Biomimet. Intell. Robot. 2025, 5, 100207. [Google Scholar] [CrossRef]

- Kang, M.; Chen, Q.; Fan, Z.; Yu, C.; Wang, Y.; Yu, X. A RRT based path planning scheme for multi-DOF robots in unstructured environments. Comput. Electron. Agric. 2024, 218, 108707. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, S.; Cui, Y.; Jiang, H. Path planning for robotic manipulator in complex multi-obstacle environment based on improved_RRT. IEEE/ASME Trans. Mechatron. 2022, 27, 4774–4785. [Google Scholar] [CrossRef]

- Armstrong, D.; Jonasson, A. AM-RRT*: Informed sampling-based planning with assisting metric. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 10093–10099. [Google Scholar]

- Shi, W.; Wang, K.; Zhao, C.; Tian, M. Obstacle avoidance path planning for the dual-arm robot based on an improved RRT algorithm. Appl. Sci. 2022, 12, 4087. [Google Scholar] [CrossRef]

- Dong, Z.; Zhong, B.; He, J.; Gao, Z. Dual-Arm Obstacle Avoidance Motion Planning Based on Improved RRT Algorithm. Machines 2024, 12, 472. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, X.; Li, J.; Yang, Z.; Cao, L. Improved RRT* Algorithm for Disinfecting Robot Path Planning. Sensors 2024, 24, 1520. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, T.; Li, B.; Meng, M.Q.H. GMR-RRT*: Sampling-Based Path Planning Using Gaussian Mixture Regression. IEEE Trans. Intell. Veh. 2022, 7, 690–700. [Google Scholar] [CrossRef]

- Fang, Y.; Lu, L.; Zhang, B.; Liu, X.; Zhang, H.; Fan, D.; Yang, H. Motion control of obstacle avoidance for the robot arm via improved path planning algorithm. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 727. [Google Scholar] [CrossRef]

- Karaman, S.; Frazzoli, E. Sampling-based algorithms for optimal motion planning. Int. J. Robot. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef]

- Gammell, J.D.; Srinivasa, S.S.; Barfoot, T.D. Informed RRT*: Optimal sampling-based path planning focused via direct sampling of an admissible ellipsoidal heuristic. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 2997–3004. [Google Scholar]

- Gammell, J.D.; Barfoot, T.D.; Srinivasa, S.S. Batch Informed Trees (BIT*): Informed asymptotically optimal anytime search. Int. J. Robot. Res. 2020, 39, 543–567. [Google Scholar] [CrossRef]

| Link | a/m | α/° | d/m | θ/° | Joint Range |

|---|---|---|---|---|---|

| 1 | 0 | 180 | −0.2856 | Q1 | [−179°, 179°] |

| 2 | 0 | 90 | 0 | Q2 | [−90°, 90°] |

| 3 | 0 | −90 | −0.4586 | Q3 | [−179°, 179°] |

| 4 | 0.065 | 90 | 0 | Q4 | [−179°, 179°] |

| 5 | −0.0528 | −90 | −0.4554 | Q5 | [−179°, 179°] |

| 6 | −0.0122 | −90 | 0 | Q6 | [−179°, 179°] |

| 7 | 0.087 | −90 | −0.1169 | Q7 | [−179°, 179°] |

| Number of Segments | Path Length | Number of Nodes | Smoothness |

|---|---|---|---|

| ) | 161.9 | 18 | 0.87 |

| 3 (α1/α2/α3) | 160.57 | 14 | 0.95 |

| ) | 161.86 | 19 | 0.86 |

| Condition | Interpretation | Collision | |

|---|---|---|---|

| (a) | Link away from obstacles | No | |

| (b) | , | Link–obstacle intersection | Yes |

| (c) | , | Link intersects obstacle at two points | Yes |

| (d) | , | No link–obstacle intersection | No |

| Algorithm | Path Length (m) | Nodes | Smoothness |

|---|---|---|---|

| RRT | 164.8 | 84 | 0.71 |

| RRT* | 149.9 | 81 | 0.84 |

| Goal-Biased RRT | 157.8 | 59 | 0.76 |

| Informed-RRT* | 142.0 | 365 | 0.89 |

| ODSN-RRT | 139.0 | 16 | 0.94 |

| Algorithm | Path Length (m) | Nodes | Smoothness | Time (s) | Search Success Rate |

|---|---|---|---|---|---|

| RRT | 240.63 | 491 | 0.46 | 0.0592 | 87% |

| RRT* | 237.35 | 453 | 0.45 | 0.2393 | 82% |

| Goal-Biased RRT | 201.31 | 49 | 0.71 | 0.0018 | 100% |

| Informed-RRT* | 164.84 | 911 | 0.86 | 3.4932 | 100% |

| ODSN-RRT | 161.54 | 17 | 0.90 | 0.0026 | 100% |

| Algorithm | Path Length (m) | Nodes | Smoothness | Time (s) | Search Success Rate |

|---|---|---|---|---|---|

| RRT | 246.36 | 405 | 0.44 | 0.0782 | 81% |

| RRT* | 245.79 | 402 | 0.44 | 0.3716 | 83% |

| Goal-Biased RRT | 210.90 | 93 | 0.67 | 0.0177 | 100% |

| Informed-RRT* | 167.31 | 886 | 0.88 | 5.9868 | 100% |

| ODSN-RRT | 165.25 | 22 | 0.87 | 0.0103 | 100% |

| Algorithm | Path Length (m) | Nodes | Smoothness | Time (s) |

|---|---|---|---|---|

| RRT | 246.36 | 356 | 0.55 | 0.047 |

| OD-RRT | 177.50 | 20 | 0.69 | 0.003 |

| ODS-RRT | 168.40 | 25 | 0.76 | 0.002 |

| ODSN-RRT | 165.25 | 22 | 0.87 | 0.003 |

| Master Arm | Slave Arm | |

|---|---|---|

| Start joint angles (°) | (61, 90, −46.5, 110, 10.7, 3.58, 0) | (125, −54, −172, 99.8, −7.16, 7, 50) |

| Goal joint angles (°) | (−17.9 79.2 14.3 43.8 0 7.16 0) | (179, −48.6, −158, 82.3, −7.16, −9, −129) |

| and radius (m) | (−0.6, 0.4, 0.6, 0.15), (−0.6, −0.4, 0.6, 0.15) (−0.4, 0.4, 0.3, 0.1), (−0.4, −0.1, 0.3, 0.1) (−0.8, 0, 0.45, 0.15) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Xiong, G.; Dang, B.; Chen, J.; Zhang, J.; Xie, H. Improved RRT-Based Obstacle-Avoidance Path Planning for Dual-Arm Robots in Complex Environments. Machines 2025, 13, 621. https://doi.org/10.3390/machines13070621

Wang J, Xiong G, Dang B, Chen J, Zhang J, Xie H. Improved RRT-Based Obstacle-Avoidance Path Planning for Dual-Arm Robots in Complex Environments. Machines. 2025; 13(7):621. https://doi.org/10.3390/machines13070621

Chicago/Turabian StyleWang, Jing, Genliang Xiong, Bowen Dang, Jianli Chen, Jixian Zhang, and Hui Xie. 2025. "Improved RRT-Based Obstacle-Avoidance Path Planning for Dual-Arm Robots in Complex Environments" Machines 13, no. 7: 621. https://doi.org/10.3390/machines13070621

APA StyleWang, J., Xiong, G., Dang, B., Chen, J., Zhang, J., & Xie, H. (2025). Improved RRT-Based Obstacle-Avoidance Path Planning for Dual-Arm Robots in Complex Environments. Machines, 13(7), 621. https://doi.org/10.3390/machines13070621