Numerical Analysis of the Structural Parameters on the Performance of Oil-Injected Rotary Vane Compressors

Abstract

1. Introduction

2. Numerical Method

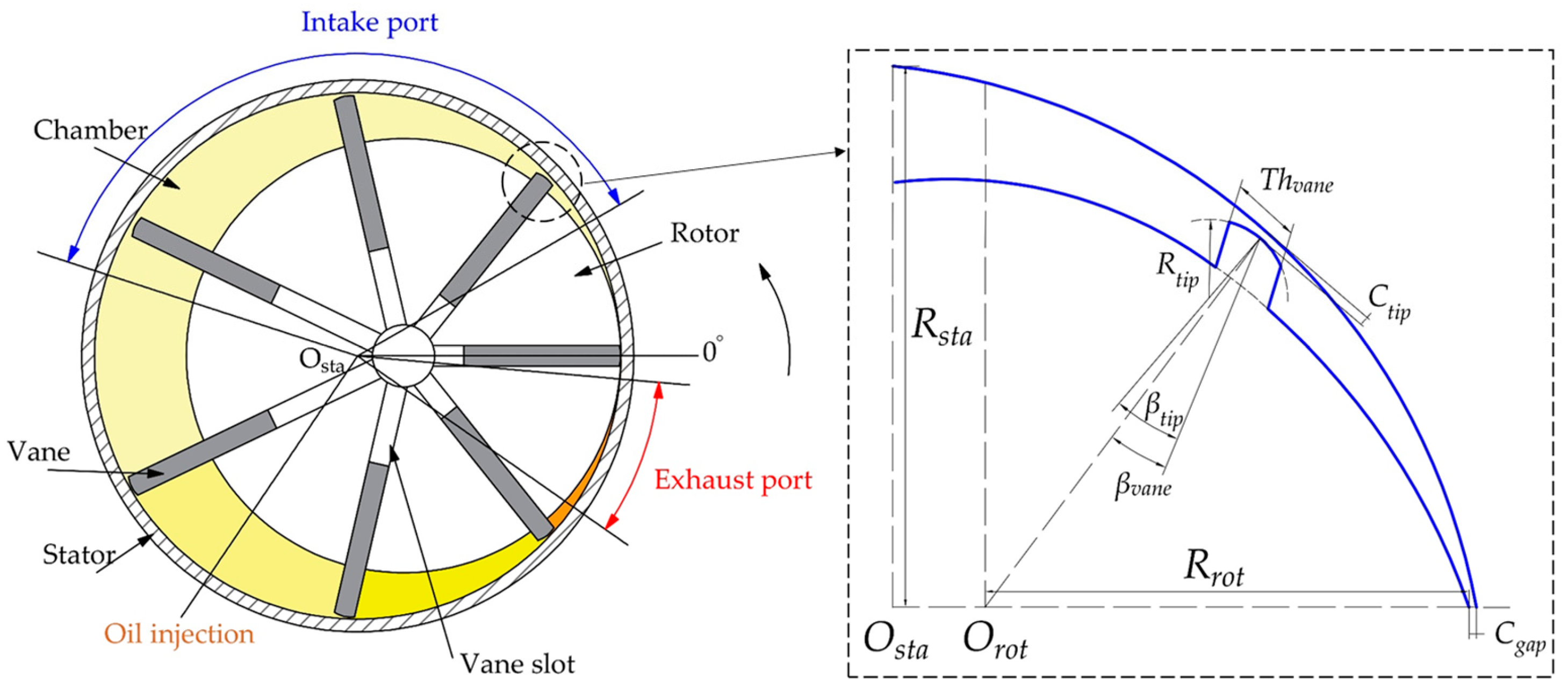

2.1. Structural Model

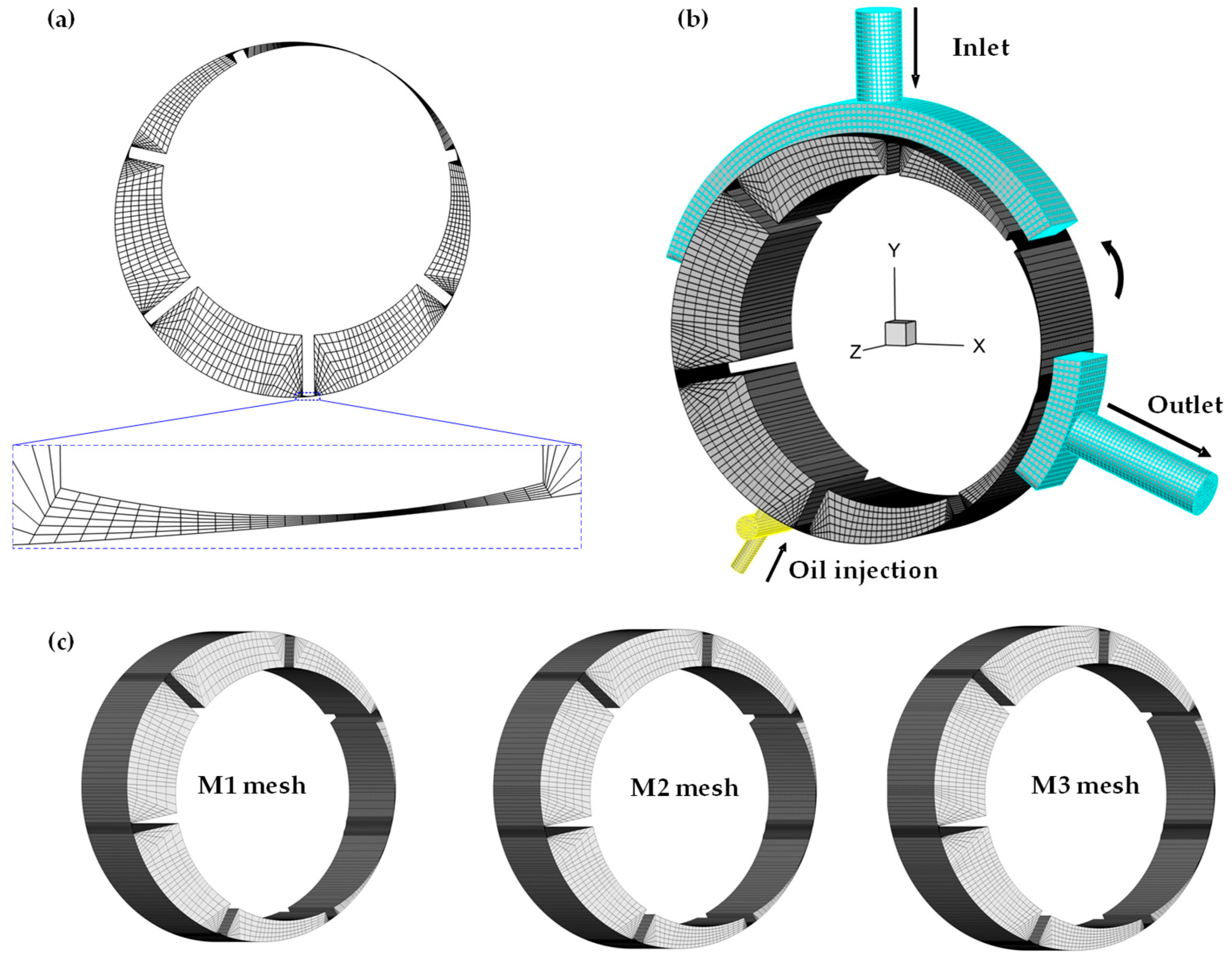

2.2. Computation Mesh

2.3. Assumptions

2.4. Multi-Phase Model

2.5. Simulation Setup

2.6. Grid Independence Test

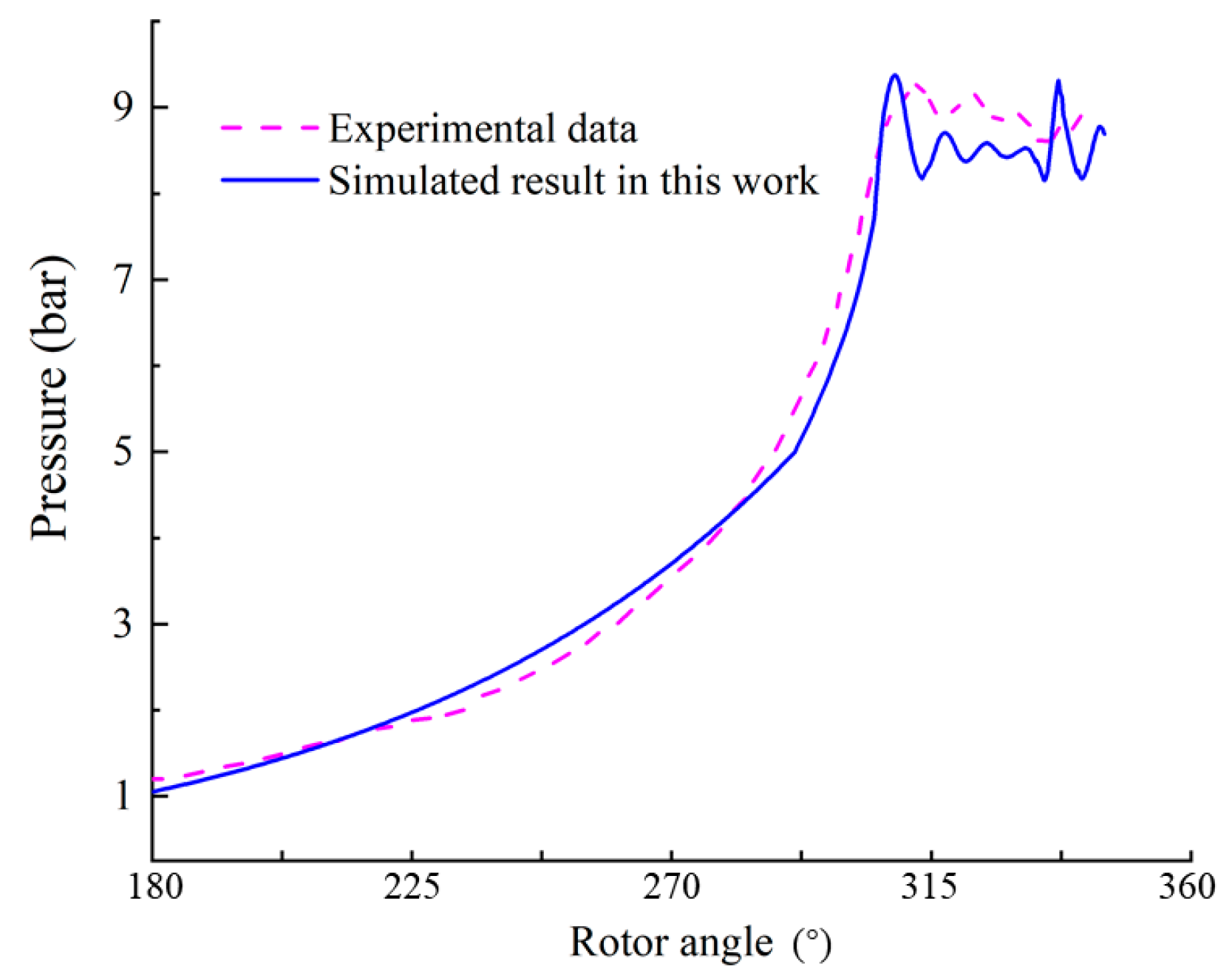

2.7. Method Validation

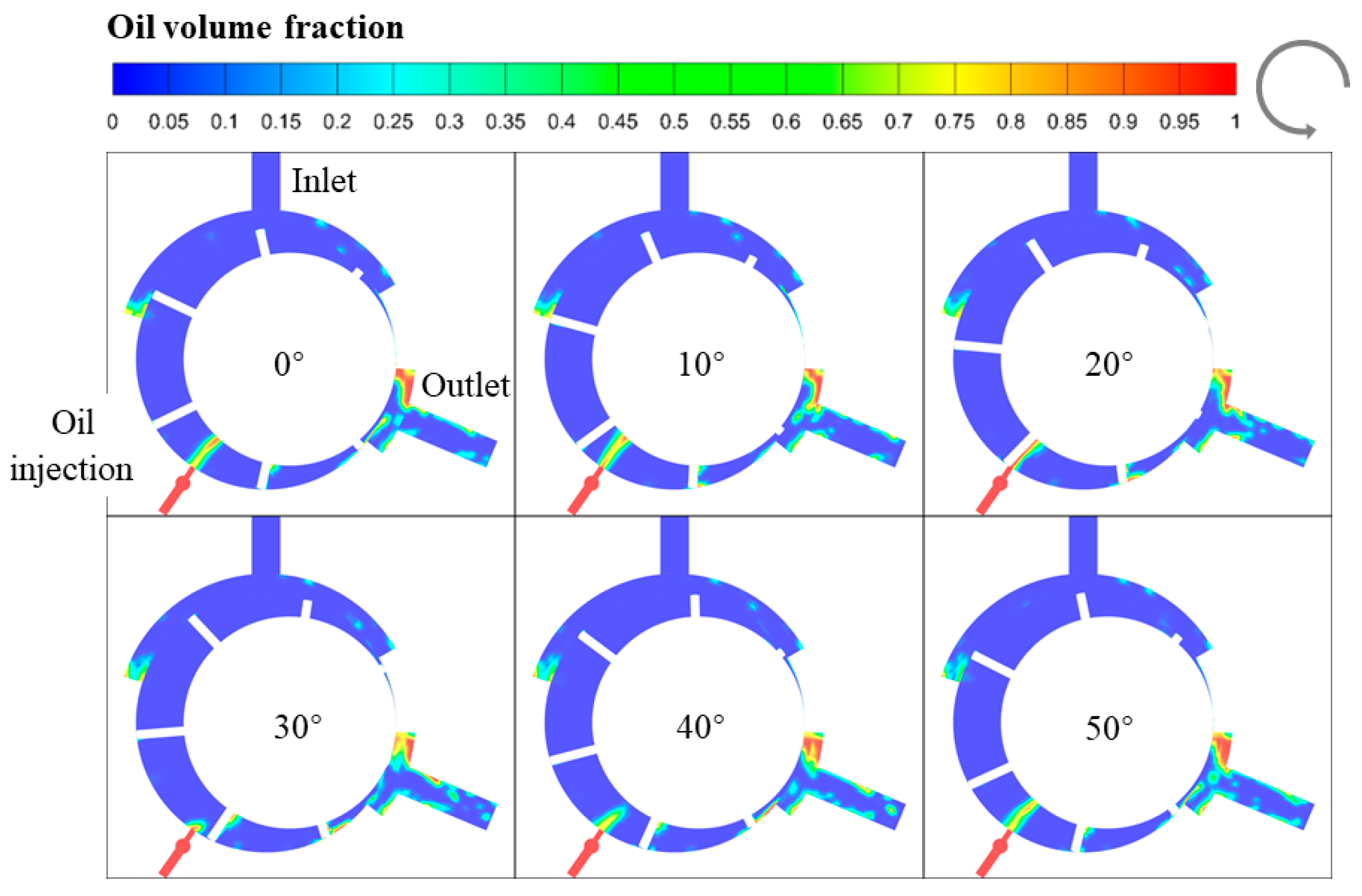

3. Oil Distribution and Comparison with Industrial Market Compressor

3.1. Oil Distribution Feature

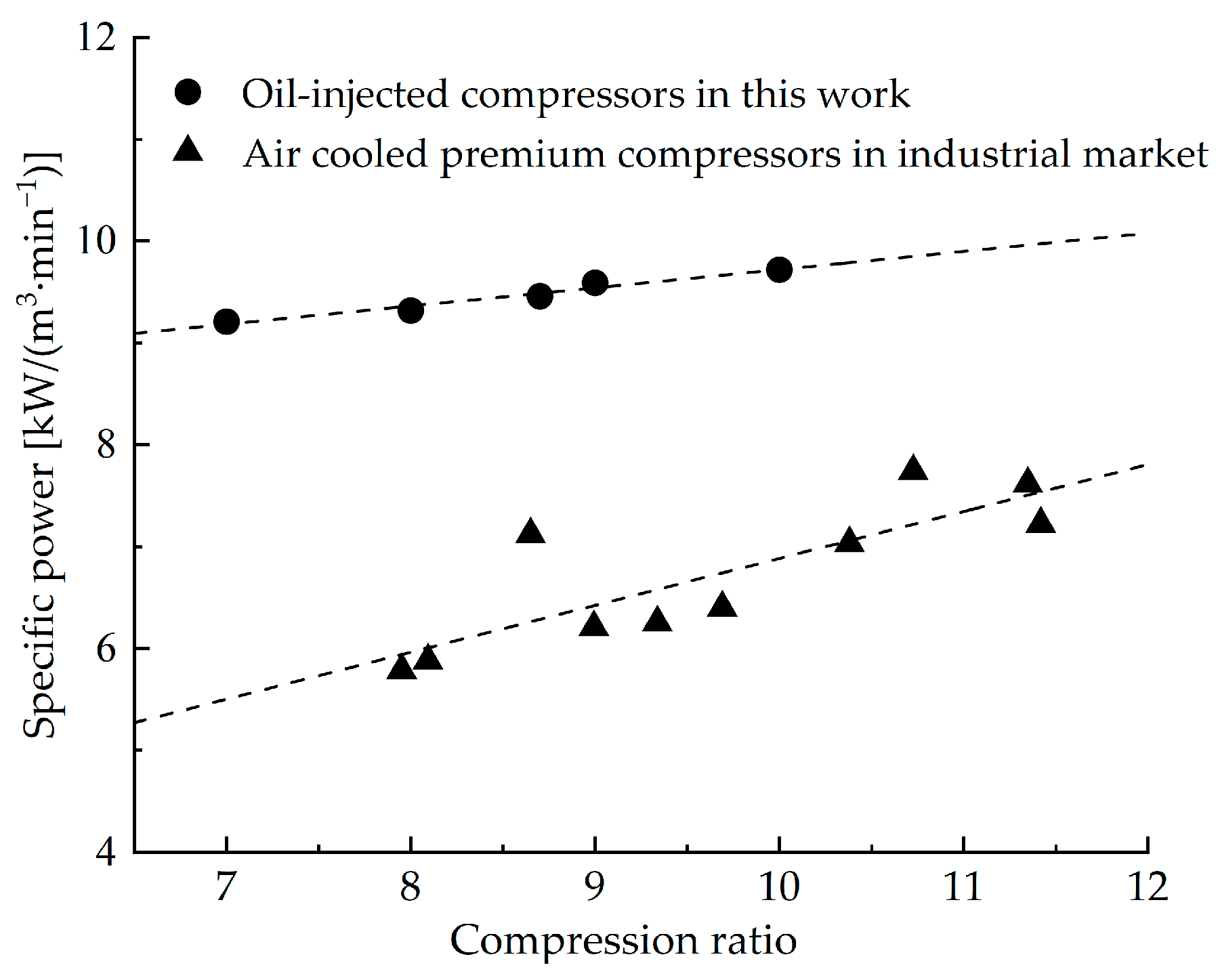

3.2. Comparison with Industrial Market Compressor

4. Influences of Vane Parameters on RVC Performance

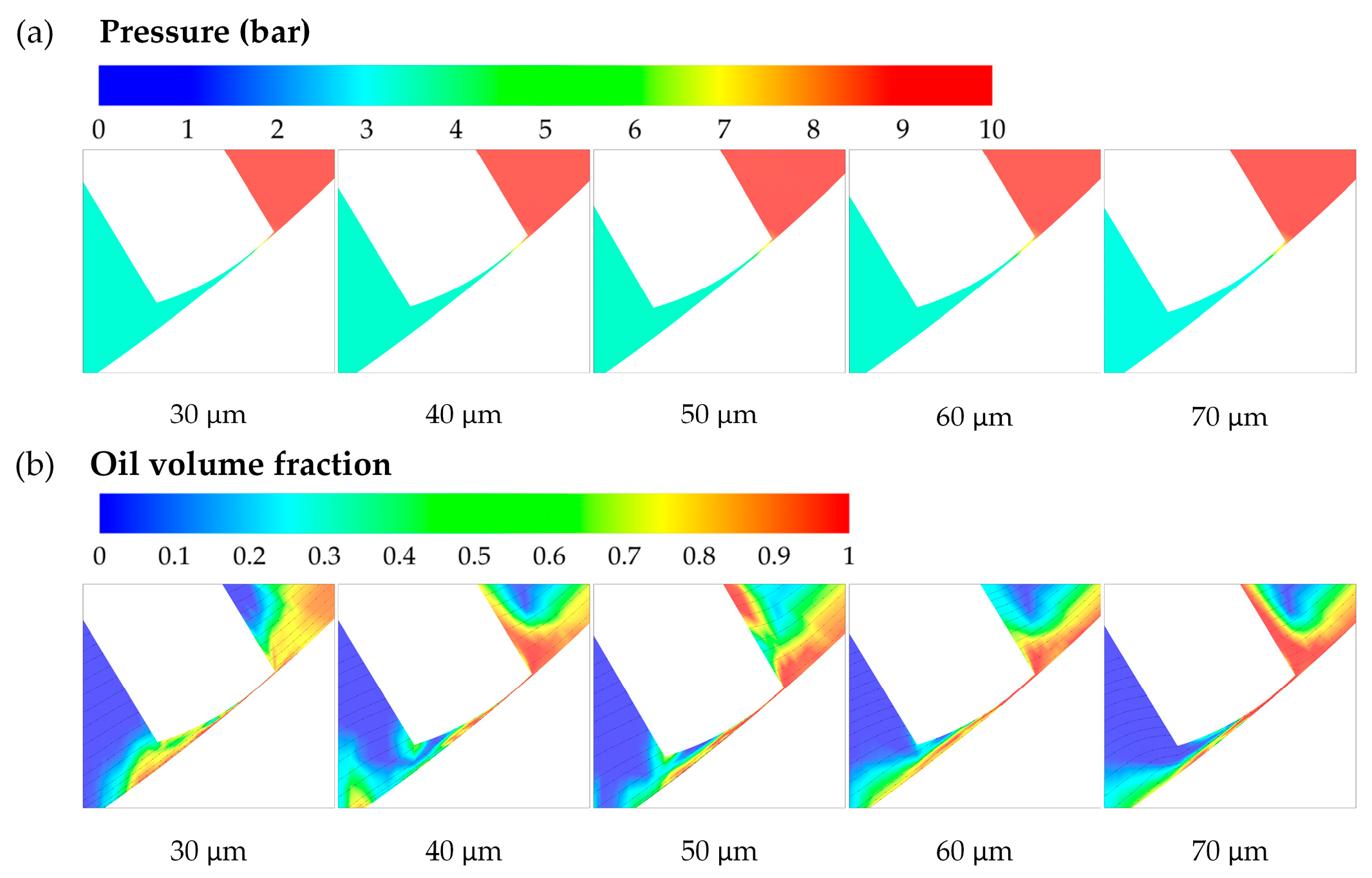

4.1. Effects of Vane Tip Clearance

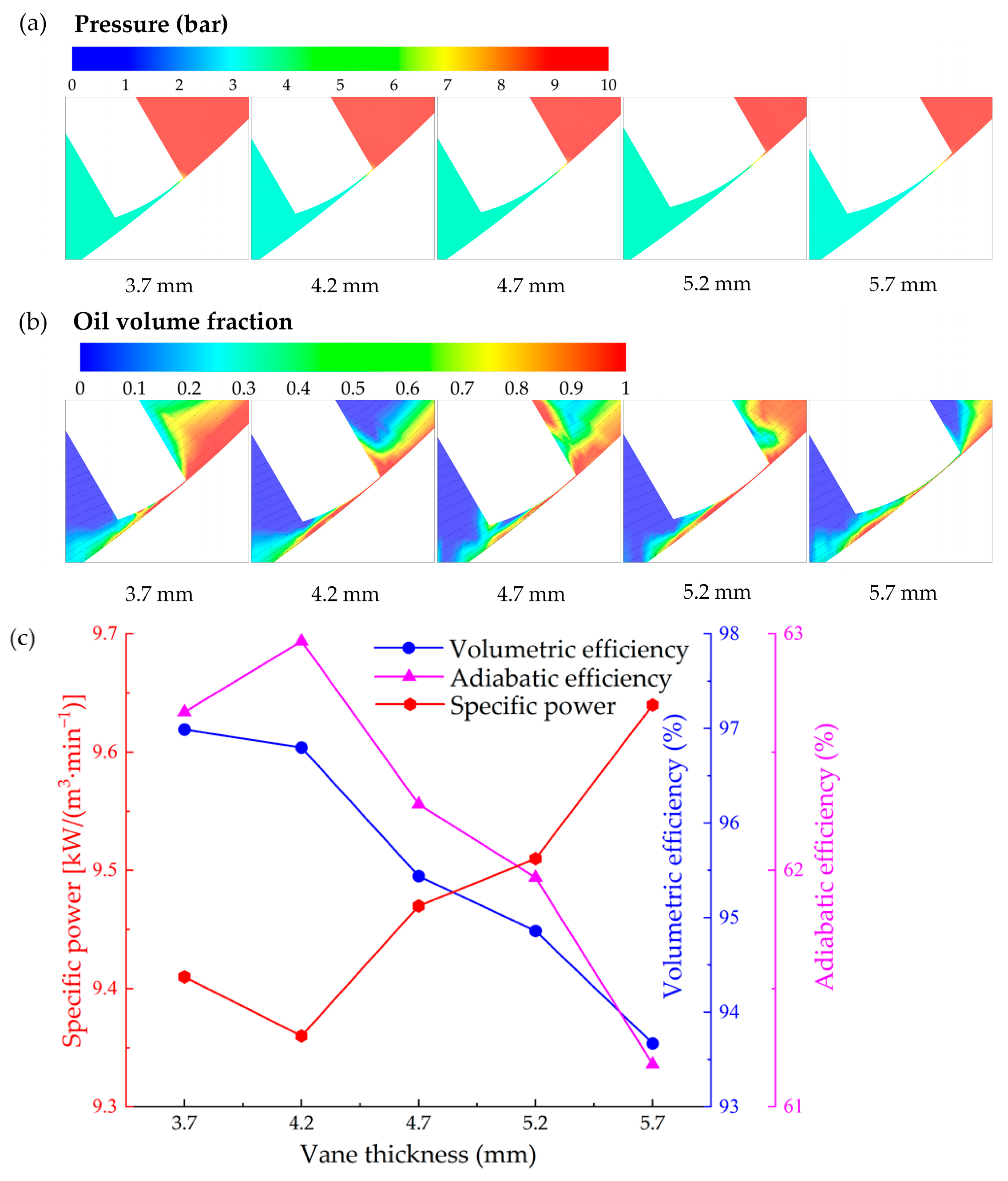

4.2. Effects of Vane Thickness

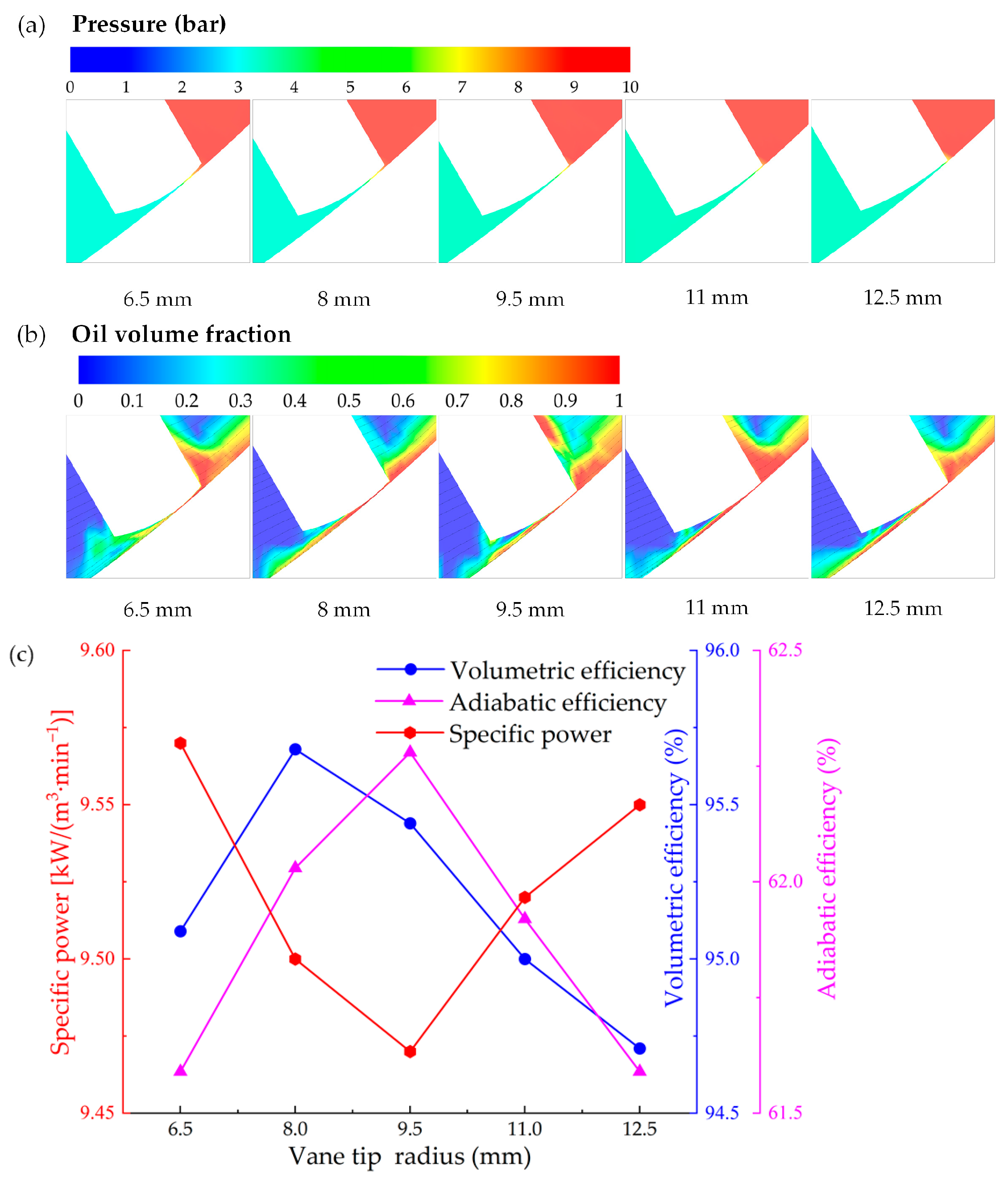

4.3. Effects of Vane Tip Radius

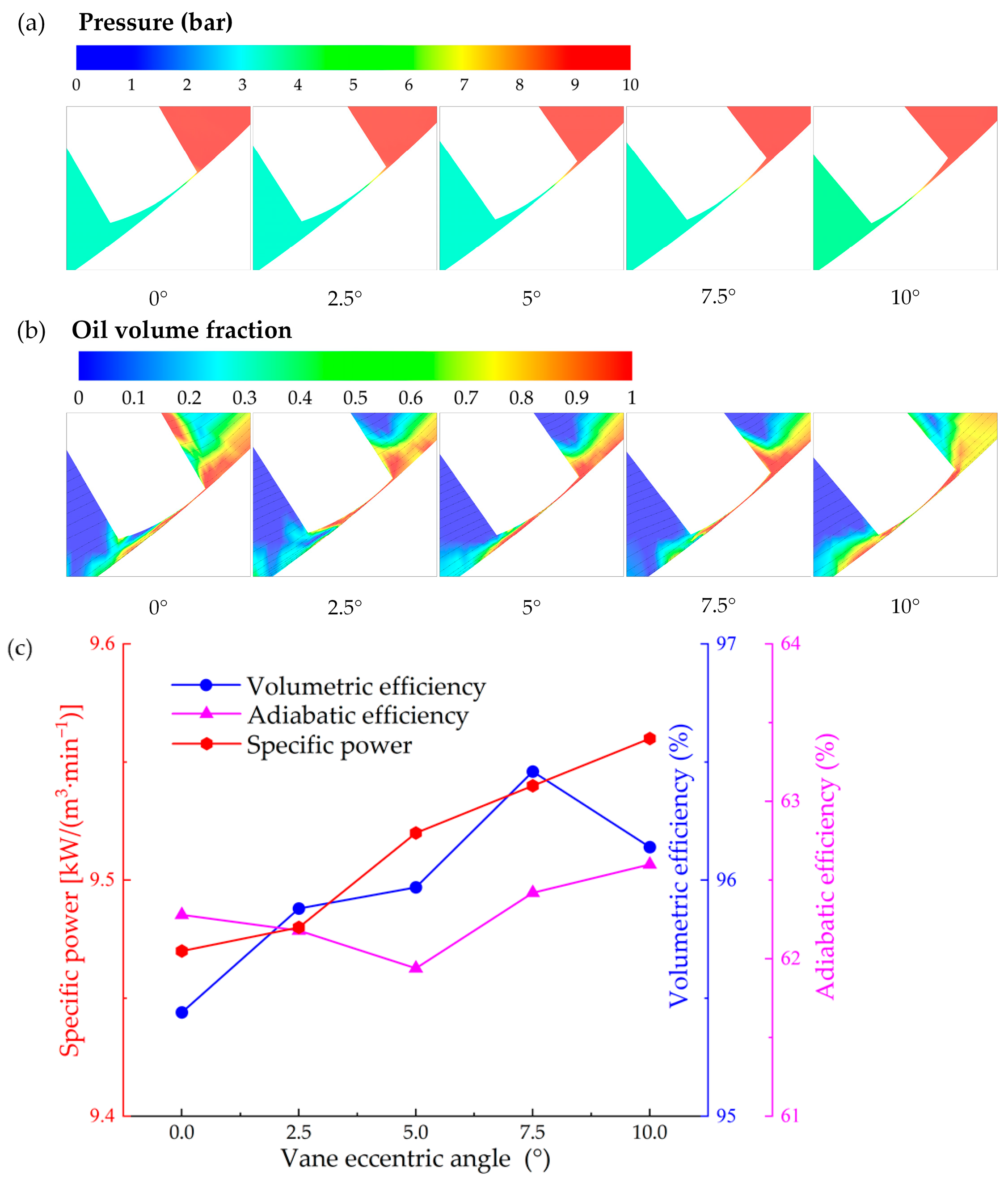

4.4. Effects of Vane Eccentric Angle

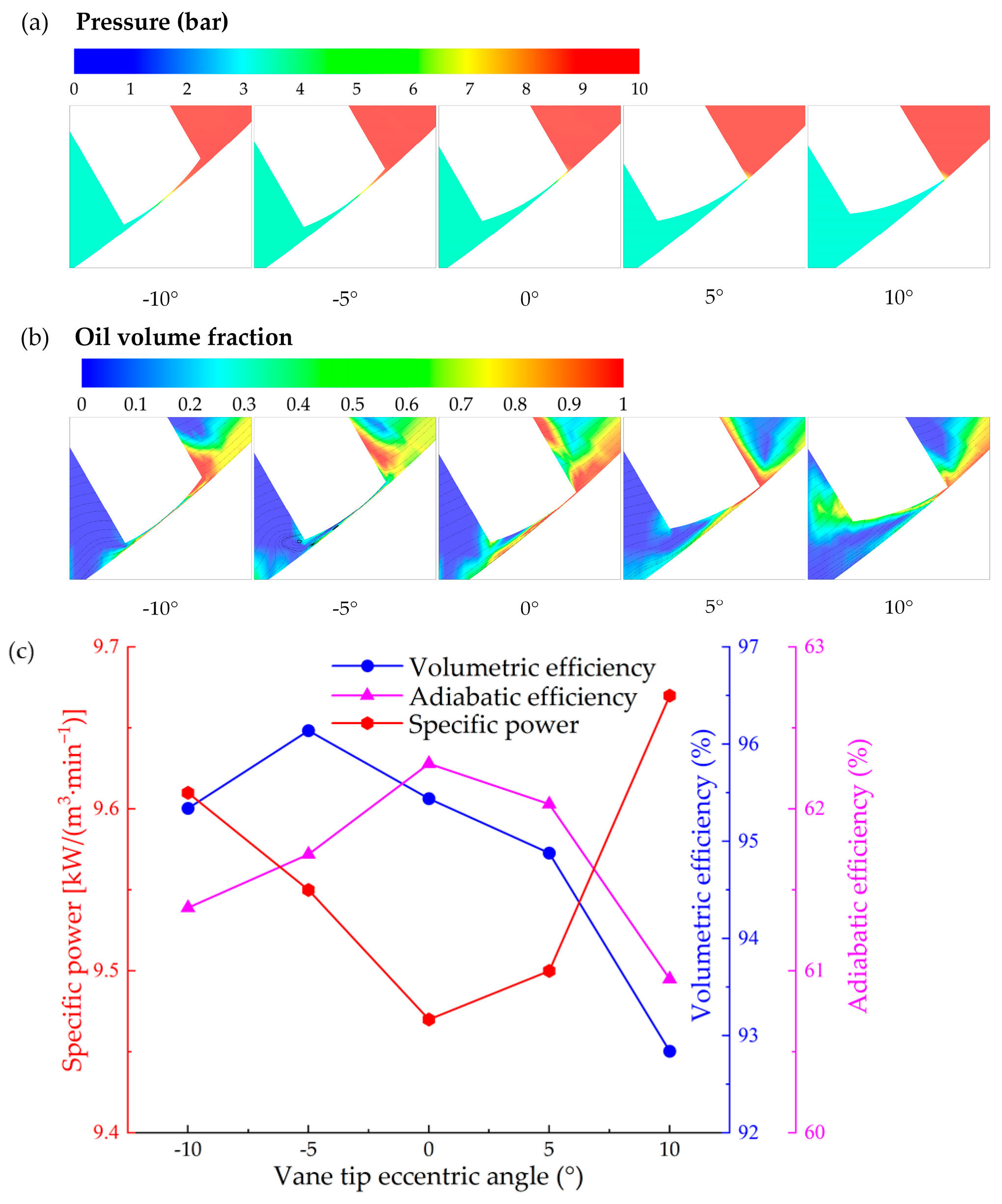

4.5. Effects of Vane Tip Eccentric Angle

5. Effects of Port Parameters on Compressor Performance

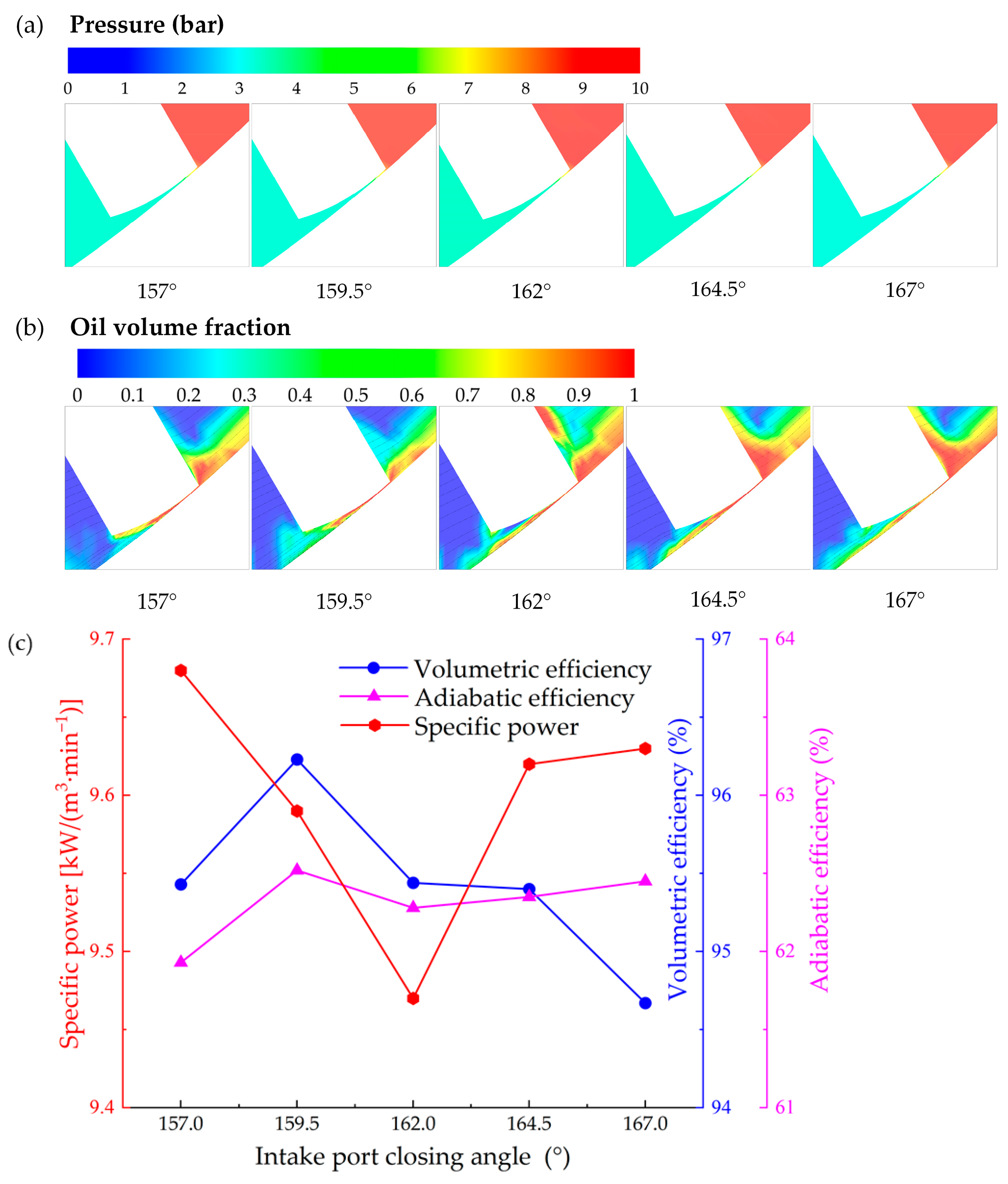

5.1. Effects of Intake Port Closing Angle (Intake Port Opening Angle = 30°)

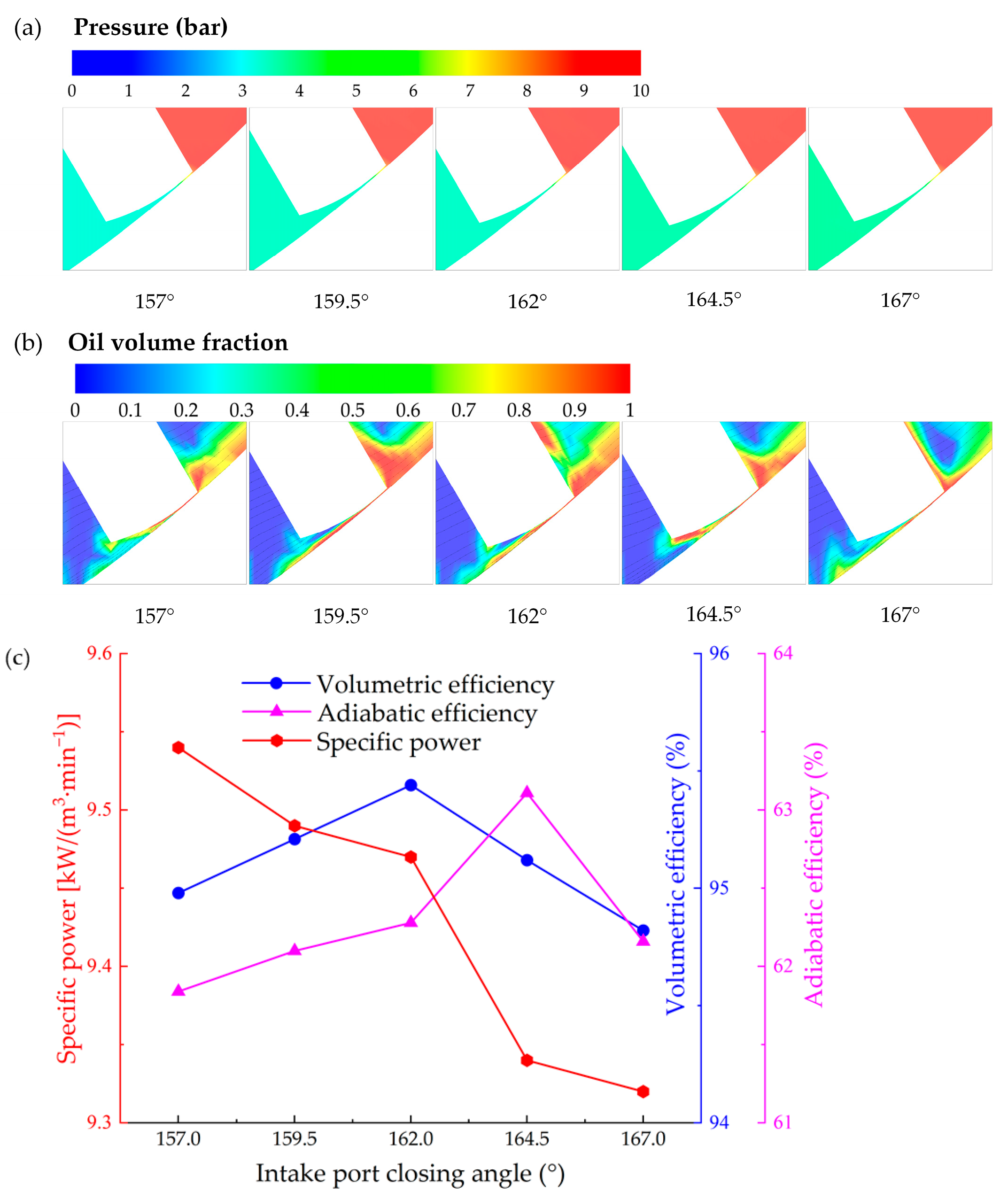

5.2. Effects of Intake Port Closing Angle (Intake Port Span Angle = 132°)

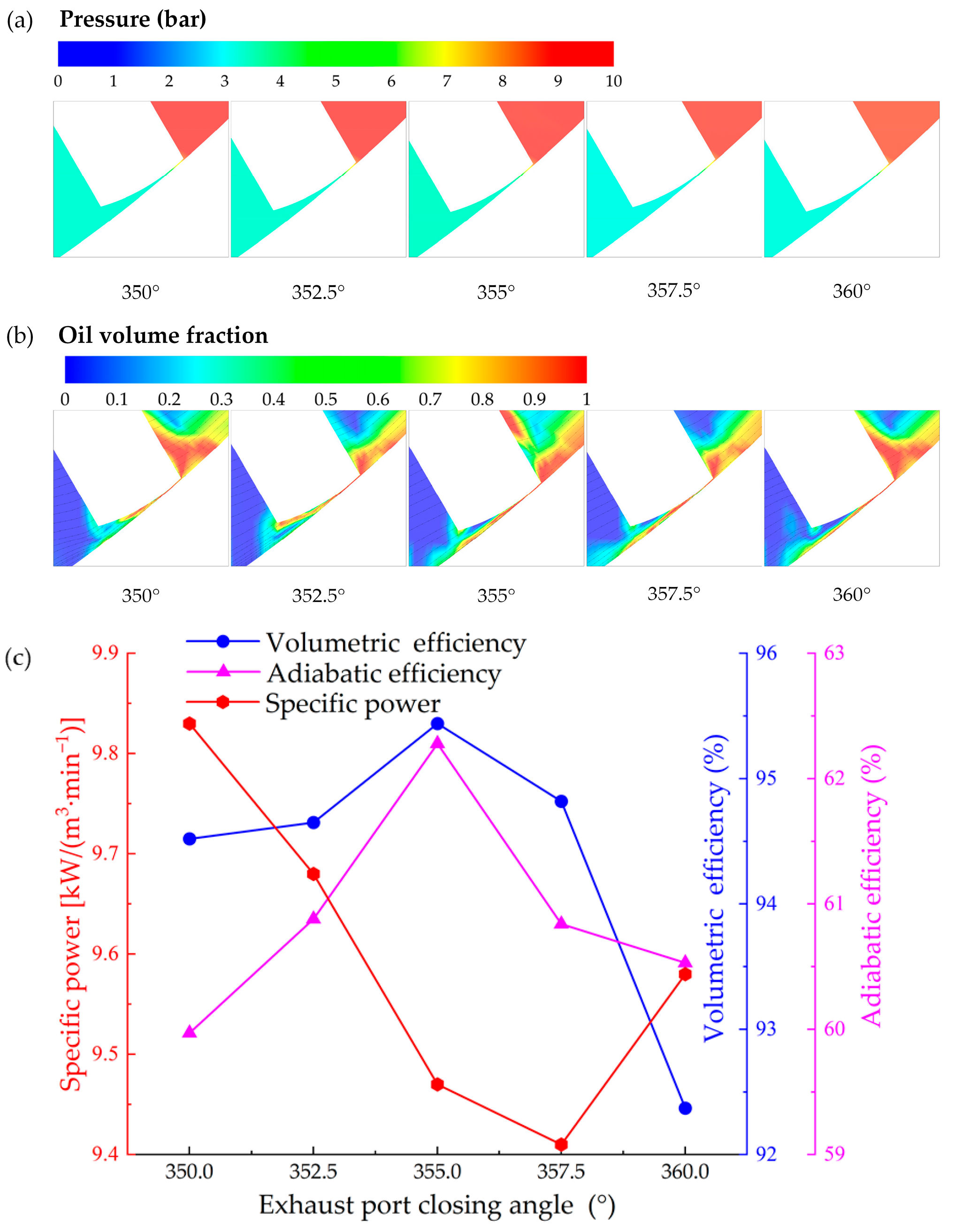

5.3. Effects of Exhaust Port Closing Angle (Exhaust Port Opening Angle = 325°)

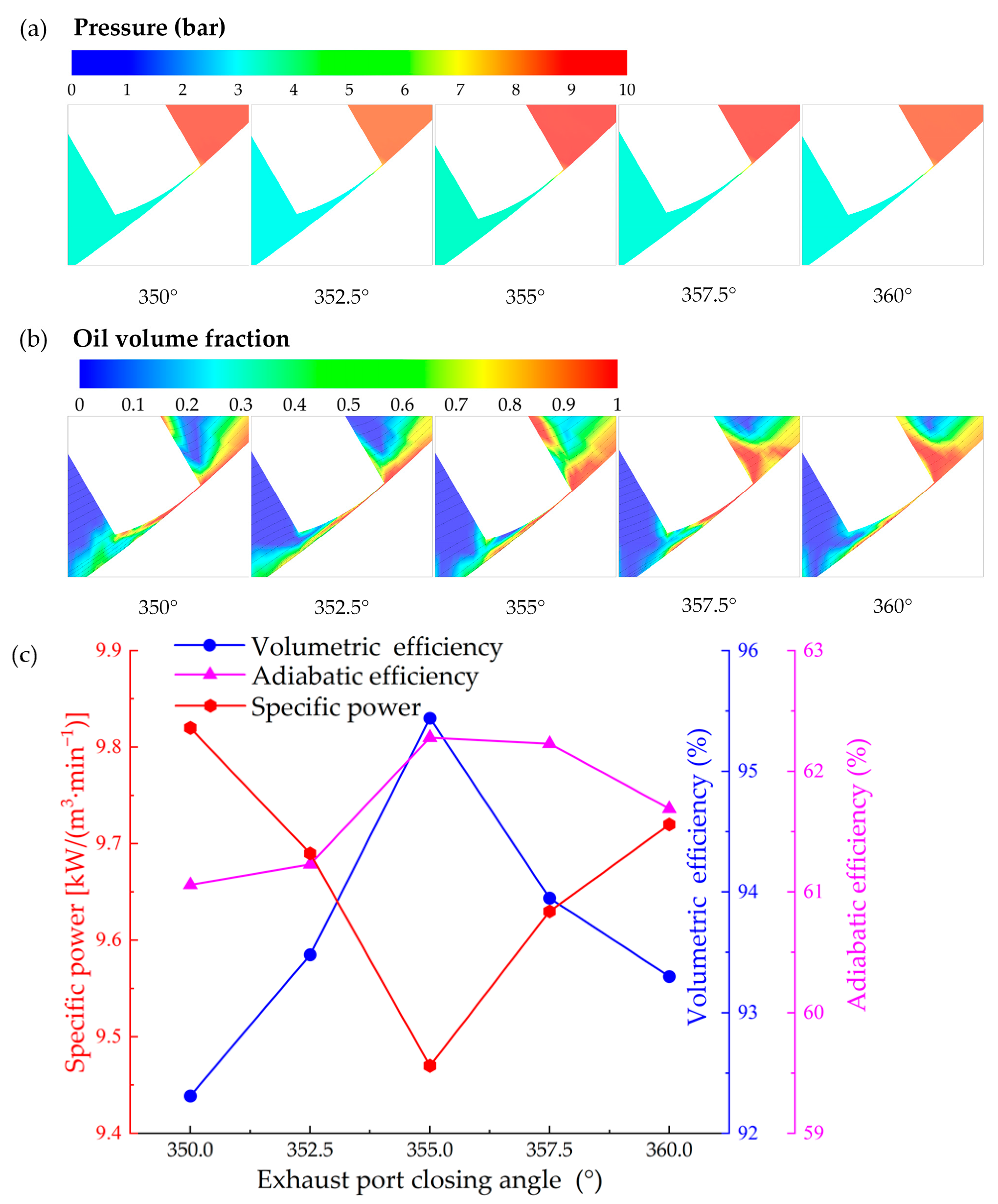

5.4. Effects of Exhaust Port Closing Angle (Exhaust Port Span Angle = 30°)

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature and Abbreviations

| α | Volume fraction [-] |

| β | Eccentric angle [°] |

| γ | Specific heat ratio [-] |

| η | Efficiency [-] |

| μ | Dynamic viscosity [Pa·s] |

| ρ | Density [kg/m3] |

| τ | Torque [Nm] |

| λ | Thermal conductivity [W/(m·k)] |

| cp | Specific heat capacity [J/(kg·K)] |

| C | Clearance [µm] |

| e | Eccentricity distance [mm] |

| F | Body force [-] |

| g | Gas phase [-] |

| G | Gravity term [-] |

| h | Specific enthalpy [J/mol] |

| l | Liquid phase [-] |

| m | Mass flow rate [kg/s] |

| n | Rotational speed [RPM] |

| p | Pressure [bar] |

| Q | Volume flow rate [m3/min] |

| R | Radius [mm] |

| t | Time [s] |

| T | Temperature [K] |

| Th | Thickness [mm] |

| v | Velocity [m/s] |

| W | Power [W] |

| Z | Axial length [mm] |

| axi | Axial |

| gap | Tangential clearance |

| rot | Rotor |

| sta | Stator |

| tip | Vane tip |

| vane | Vane |

| CFD | Computational Fluid Dynamics |

| RVC | Rotary Vane Compressor |

| VOF | Volume of Fluid |

References

- Aw, K.T.; Ooi, K.T. A review on sliding vane and rolling piston compressors. Machines 2021, 9, 125. [Google Scholar] [CrossRef]

- Liu, S.; Ma, G.; Xu, S.; Gong, Y.; Jia, X.; Wu, G. A review of reverse Brayton air cycle refrigerators. Int. J. Refrig. 2023, 150, 200–214. [Google Scholar] [CrossRef]

- Wang, C.; Wu, J.; Du, Y.; Lei, B. Lubricating condition evaluation of the rotary compressor under high ambient temperature. Int. J. Refrig. 2020, 118, 220–229. [Google Scholar] [CrossRef]

- Hosseinnia, S.M.; Amiri, L.; Poncet, S. Performance analysis of a novel air source ammonia/water cascade heat pump for heating buildings in subarctic climate. Int. J. Refrig. 2024, 164, 57–74. [Google Scholar] [CrossRef]

- Olympios, A.V.; Song, J.; Ziolkowski, A.; Shanmugam, V.S.; Markides, C.N. Data-driven compressor performance maps and cost correlations for small-scale heat-pumping applications. Energy 2024, 291, 130171. [Google Scholar] [CrossRef]

- Valenti, G.; Murgia, S.; Contaldi, G.; Valenti, A. Experimental evidence of the thermal effect of lubricating oil sprayed in sliding-vane air compressors. Case Stud. Therm. Eng. 2014, 4, 113–117. [Google Scholar] [CrossRef]

- Vittorini, D.; Cipollone, R. Financial analysis of energy saving via compressor replacement in industry. Energy 2016, 113, 809–820. [Google Scholar] [CrossRef]

- Bianchi, G.; Cipollone, R.; Murgia, S.; Contaldi, G. Development of an internal air cooling sprayed oil injection technique for the energy saving in sliding vane rotary compressors through theoretical and experimental methodologies. Int. J. Refrig. 2015, 52, 11–20. [Google Scholar] [CrossRef]

- Vittorini, D.; Cipollone, R. Energy saving potential in existing industrial compressors. Energy 2016, 102, 502–515. [Google Scholar] [CrossRef]

- Choo, W.C.; Ooi, K.T. Analysis of the novel multi-vane Revolving Vane compressor–Investigation of vane chattering phenomenon through instantaneous working chamber pressure measurements. Int. J. Refrig. 2022, 134, 207–218. [Google Scholar] [CrossRef]

- Yang, B.; Peng, X.; Sun, S.; Guo, B.; Xing, Z. Study of a rotary vane expander for the transcritical CO2 cycle—Part I: Experimental investigation. HVAC&R Res. 2009, 15, 673–688. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, B.; Pu, L.; Guo, B.; Peng, X. Improved rotary vane expander for trans-critical CO2 cycle by introducing high-pressure gas into the vane slots. Int. J. Refrig. 2011, 34, 732–741. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Battista, D.; Cipollone, R. Design improvement of volumetric pump for engine cooling in the transportation sector. Energy 2021, 231, 120936. [Google Scholar] [CrossRef]

- Fatigati, F.; Bartolomeo, M.D.; Battista, D.D.; Cipollone, R. A dual-intake-port technology as a design option for a sliding vane rotary expander of small-scale ORC-based power units. Energy Convers. Manag. 2020, 209, 112646. [Google Scholar] [CrossRef]

- Natali, C.; Battarra, M.; Proner, E.; Mucchi, E. Advantages of elliptical tip vanes on the kinematic design of balanced vane pumps. Mech. Mach. Theory 2025, 206, 105901. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.; Cui, S.; Feng, H.; Sha, R. Numerical simulation and design methodology of a novel asymmetric cylinder profile for sliding vane vacuum pumps. Vacuum 2019, 169, 108945. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Z.; Yang, S.; Li, H.; Cui, S. Geometric design and analysis of a novel sliding vane vacuum pump with three chambers. Mech. Mach. Theory 2019, 141, 52–66. [Google Scholar] [CrossRef]

- Choo, W.C.; Ooi, K.T. Analysis of the novel multi-vane Revolving Vane compressor–Theoretical modelling and experimental investigations. Int. J. Refrig. 2021, 131, 592–603. [Google Scholar] [CrossRef]

- Zhou, H.; Qu, Z.; Yang, H.; Yu, B. Dynamic model and numerical simulation for synchronal rotary compressor. ASME J. Fluids Eng. 2009, 131, 041102. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, Y.; Cao, F.; Bu, G.; Wang, Z. Simulation study on a novel vane-type expander with internal two-stage expansion process for R-410A refrigeration system. Int. J. Refrig. 2012, 35, 757–771. [Google Scholar] [CrossRef]

- Gu, H.; Zhou, X.; Chen, Y.; Wu, J.; Wu, Z.; Jiang, Y.; Sund’en, B. Analysis, modeling and simulations of an innovative sliding vane rotary compressor with a rotating cylinder. Energy Convers. Manag. 2021, 230, 113822. [Google Scholar] [CrossRef]

- Shakya, P.; Ooi, K.T. Introduction to Coupled Vane compressor: Mathematical modelling with validation. Int. J. Refrig. 2020, 117, 23–32. [Google Scholar] [CrossRef]

- Bradshaw, C.R.; Groll, E.A. A comprehensive model of a novel rotating spool compressor. Int. J. Refrig. 2013, 36, 1974–1981. [Google Scholar] [CrossRef][Green Version]

- Prasad, B.G.S. CFD for positive displacement compressors. In Proceedings of the International Compressor Engineering Conference at Purdue University, West-Lafayette, IN, USA, 15–18 July 2004; Available online: https://docs.lib.purdue.edu/icec/1689/ (accessed on 21 May 2025).

- Hieronymus, T.; Lobsinger, T.; Brenner, G. A combined CFD-FEM approach to predict fluid-borne vibrations and noise radiation of a rotary vane pump. Energies 2021, 14, 1874. [Google Scholar] [CrossRef]

- Murthy, A.A.; Krishan, G.; Shenoy, P.; Patil, I.S. Theoretical, CFD modelling and experimental investigation of a four-intersecting-vane rotary expander. Appl. Energy 2024, 353, 122145. [Google Scholar] [CrossRef]

- Rak, J.; Błasiak, P.; Kolasiński, P. Influence of the applied working fluid and the arrangement of the steering edges on multi-vane expander performance in micro ORC system. Energies 2018, 11, 892. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Chen, Z.; Tan, Q. Geometric model and pressurization analysis on a novel sliding vane compressor with an asymmetrical cylinder profile. Int. J. Refrig. 2021, 129, 175–183. [Google Scholar] [CrossRef]

- Błasiak, P.; Kolasiński, P.; Daniarta, S. Numerical analysis of heat transfer within a rotary multi-vane expander. Energies 2023, 16, 2794. [Google Scholar] [CrossRef]

- Montenegro, G.; Torre, A.D.; Fiocco, M.; Onorati, A.; Benatzky, C.; Schlager, G. Evaluating the performance of a rotary vane expander for small scale organic rankine cycles using CFD tools. Energy Procedia 2014, 45, 1136–1145. [Google Scholar] [CrossRef]

- Gu, H.; Chen, Y.; Wu, J.; Jiang, Y.; Sundén, B. Impact of discharge port configurations on the performance of sliding vane rotary compressors with a rotating cylinder. Appl. Therm. Eng. 2021, 186, 116526. [Google Scholar] [CrossRef]

- Gu, H.; Chen, Y.; Wu, J.; Sundén, B. Novel rotary sliding vane expanders with small eccentricity and guide vane ports: Numerical simulation and structural parameter analysis. Appl. Therm. Eng. 2024, 254, 123820. [Google Scholar] [CrossRef]

- Bianchi, G.; Rane, S.; Kovacevic, A.; Cipollone, R.; Murgia, S. Development of a general numerical methodology for CFD analyses in sliding vane machines and application on a mid-size oil injected air compressor. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 11–14 July 2016; Available online: https://bura.brunel.ac.uk/handle/2438/14651 (accessed on 21 May 2025).

- Dai, Y.; Zhu, H.; Bianchi, G.; Rane, S.; Ye, F. Numerical investigation on flow characteristics and working performance in oil-injected sliding vane rotary compressors. Int. J. Refrig. 2025, 171, 202–216. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, X. Numerical simulation on cavitation in a vane pump with moving mesh. In Proceedings of the 5th International Conference on Computational Methods, Cambridge, UK, 28–30 July 2014; Available online: https://www.sci-en-tech.com/ICCM2014/PDFs/401-835-1-PB.pdf (accessed on 21 May 2025).

- Lobsinger, T.; Hieronymus, T.; Brenner, G. A CFD investigation of a 2D balanced vane pump focusing on leakage flows and multiphase flow characteristics. Energies 2020, 13, 3314. [Google Scholar] [CrossRef]

- Ye, F.; Bianchi, G.; Rane, S.; Tassou, S.A.; Deng, J. Analytical grid generation and numerical assessment of tip leakage flows in sliding vane rotary machines. Adv. Eng. Software 2021, 159, 103030. [Google Scholar] [CrossRef]

- ANSYS. ANSYS Fluent Theory Guide-Release 18.0; Ansys Inc.: Washington, PA, USA, 2017. [Google Scholar]

- Vittorini, D.; Bianchi, G.; Cipollone, R. Energy Saving Potential in Existing Volumetric Rotary Compressors. Energy Procedia 2015, 81, 1121–1130. [Google Scholar] [CrossRef]

| Quantities | Values | Units |

|---|---|---|

| Number of vanes/N | 7 | - |

| Stator radius/Rsta | 68.0 | mm |

| Rotor radius/Rrot | 55.5 | mm |

| Rotor axial length/Zaxi | 40.0 | mm |

| Vane thickness/Thvane | 4.7 | mm |

| Vane tip radius/Rtip | 9.5 | mm |

| Vane tip clearance/Ctip | 50.0 | µm |

| Tangential clearance/Cgap | 50.0 | µm |

| Vane eccentric angle/βvane | 0 | ° |

| Vane tip eccentric angle/βtip | 0 | ° |

| Opening angle of intake port | 30 | ° |

| Closing angle of intake port | 162 | ° |

| Opening angle of exhaust port | 325 | ° |

| Closing angle of exhaust port | 355 | ° |

| Variables | Air | Oil (at 45 °C) |

|---|---|---|

| Fluid type | Ideal gas | Constant ρ 950 kg/m3 |

| Specific heat [J/(kg·K)] | 1004.4 | 2250 |

| Viscosity [Pa·s] | 1.7894 × 10−5 | 0.009 |

| Thermal conductivity [W/(m·K)] | 2.61 × 10−2 | 0.145 |

| Items | Specifications | Settings |

|---|---|---|

| Solver form | Pressure-based | – |

| Turbulence model | SST k-ω | – |

| Multi-phase model | Volume of fluid | Volume Fraction Parameters Formulation: Explicit Volume Fraction Cutoff: 1 × 10−6 Courant Number: 0.25 Interface modelling type: Sharp |

| Solution method | Pressure-velocity coupling | Coupled |

| Control volume gradients | Green-gauss Node-based | |

| Spatial discretisation | Pressure: PRESTO! Others: First-order upwind | |

| Transient formulation | First-order implicit | |

| Solution control | Explicit relaxation factor | 0.1 |

| Under-relaxation factor | 0.1 | |

| Residual standard | Energy: 1 × 10−6 Others: 1 × 10−3 | |

| Angular step size | 0.25° | |

| Number of angular steps | 5760 | |

| Max iterations per angular step | 500 |

| Variables | Values | Units |

|---|---|---|

| Rotating speed | 1000 | RPM |

| Intake pressure | 1.01 | bar |

| Intake temperature | 298.6 | K |

| Exhaust pressure | 8.7 | bar |

| Oil injection pressure | 6.6 | bar |

| Oil injection temperature | 338.2 | K |

| Oil injection flow rate | 0.11 | kg/s |

| Items | Cell Count of Rotor Mesh | Air-Flow Rate (g/s) | Shaft Power (kW) |

|---|---|---|---|

| M1 mesh | 109,689 | 7.227 | 3.57 |

| M2 mesh | 151,232 | 7.215 | 3.55 |

| M3 mesh | 182,592 | 7.192 | 3.54 |

| Design Parameters | Baseline | Optimal |

|---|---|---|

| Vane thickness/mm | 4.7 | 4.2 |

| Vane tip radius/mm | 9.5 | 9.5 |

| Vane eccentric angle/° | 0 | 0 |

| Vane tip eccentric angle/° | 0 | 0 |

| Intake port closing angle/° | 162 | 167 |

| Exhaust port closing angle/° | 355 | 357.5 |

| Volumetric efficiency/% | 95.44 | 96.52 |

| Adiabatic efficiency/% | 62.28 | 63.07 |

| Specific power/kW/(m3·min−1) | 9.47 | 9.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, F.; Zhu, H.; Peng, Y.; Bianchi, G.; Rane, S.; Dai, Y. Numerical Analysis of the Structural Parameters on the Performance of Oil-Injected Rotary Vane Compressors. Machines 2025, 13, 456. https://doi.org/10.3390/machines13060456

Ye F, Zhu H, Peng Y, Bianchi G, Rane S, Dai Y. Numerical Analysis of the Structural Parameters on the Performance of Oil-Injected Rotary Vane Compressors. Machines. 2025; 13(6):456. https://doi.org/10.3390/machines13060456

Chicago/Turabian StyleYe, Fanghua, Huiyang Zhu, Yexin Peng, Giuseppe Bianchi, Sham Rane, and Yuande Dai. 2025. "Numerical Analysis of the Structural Parameters on the Performance of Oil-Injected Rotary Vane Compressors" Machines 13, no. 6: 456. https://doi.org/10.3390/machines13060456

APA StyleYe, F., Zhu, H., Peng, Y., Bianchi, G., Rane, S., & Dai, Y. (2025). Numerical Analysis of the Structural Parameters on the Performance of Oil-Injected Rotary Vane Compressors. Machines, 13(6), 456. https://doi.org/10.3390/machines13060456