Kinematics and Dynamics Analysis of a New 5-Degrees of Freedom Parallel Mechanism with Two Double-Driven Chains

Abstract

1. Introduction

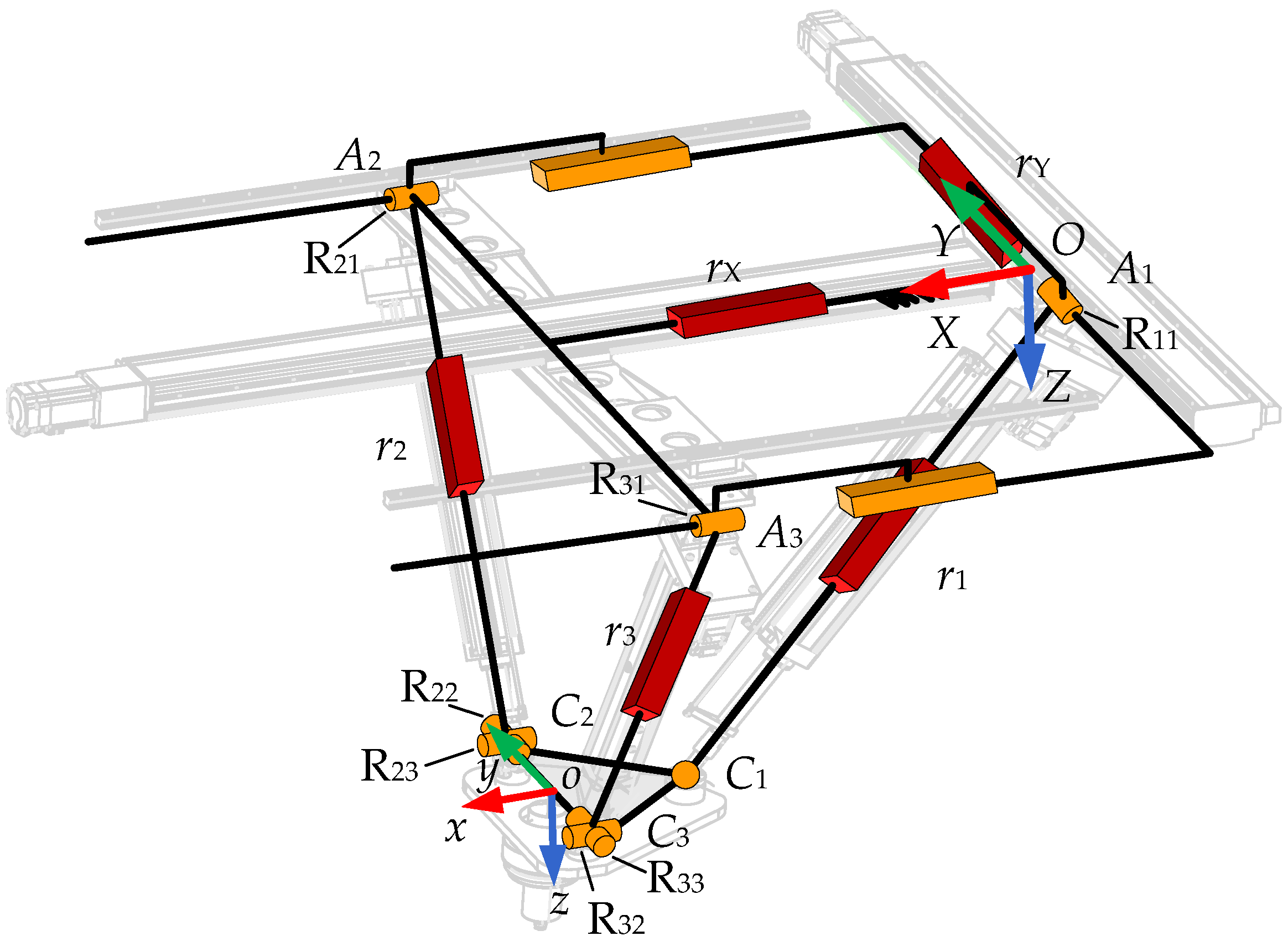

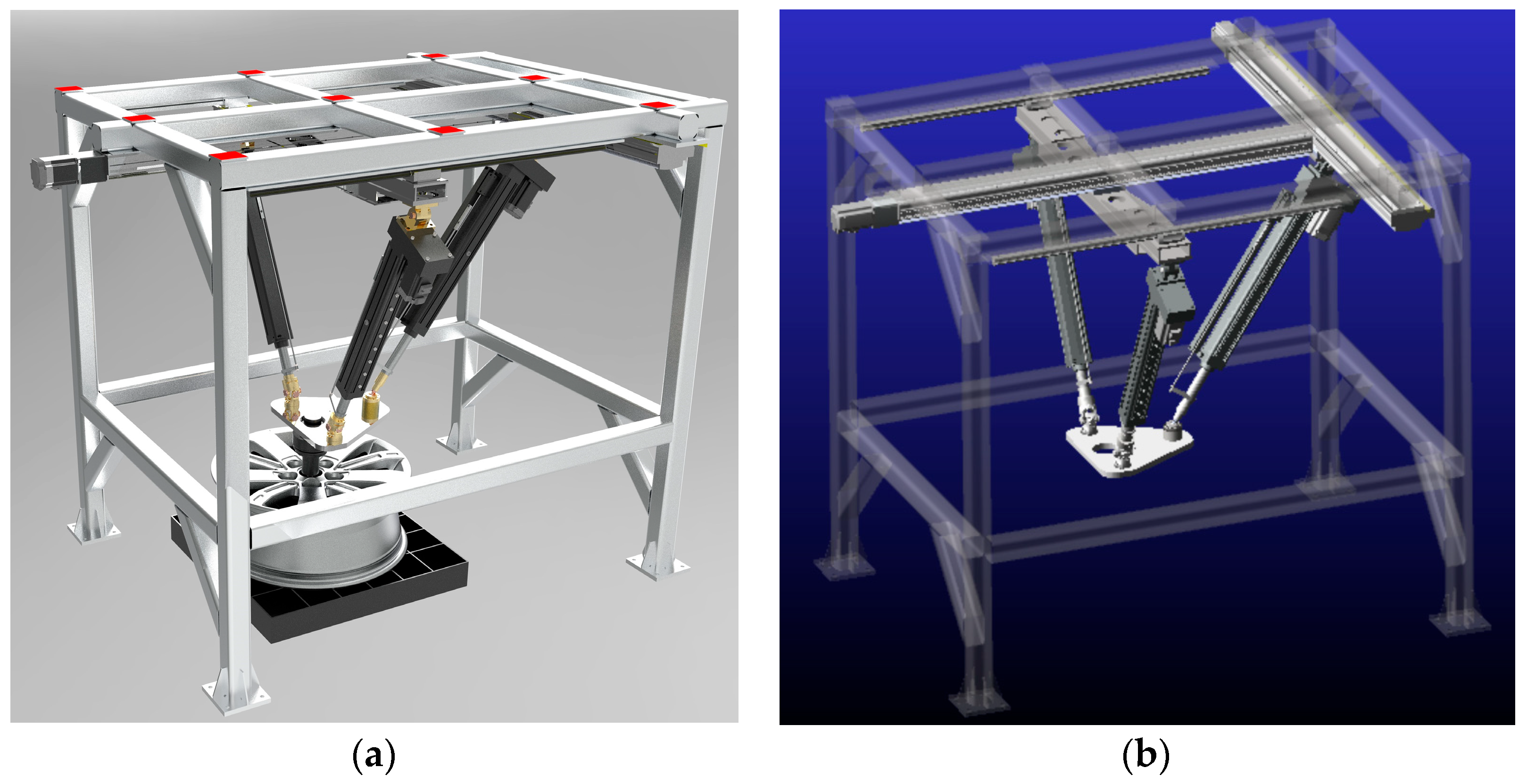

2. Structural and Kinematic Analysis

2.1. Configuration Description and Mobility Analysis

2.2. Jacobian Matrix Analysis

2.3. Kinematic Performance Analysis and Optimization

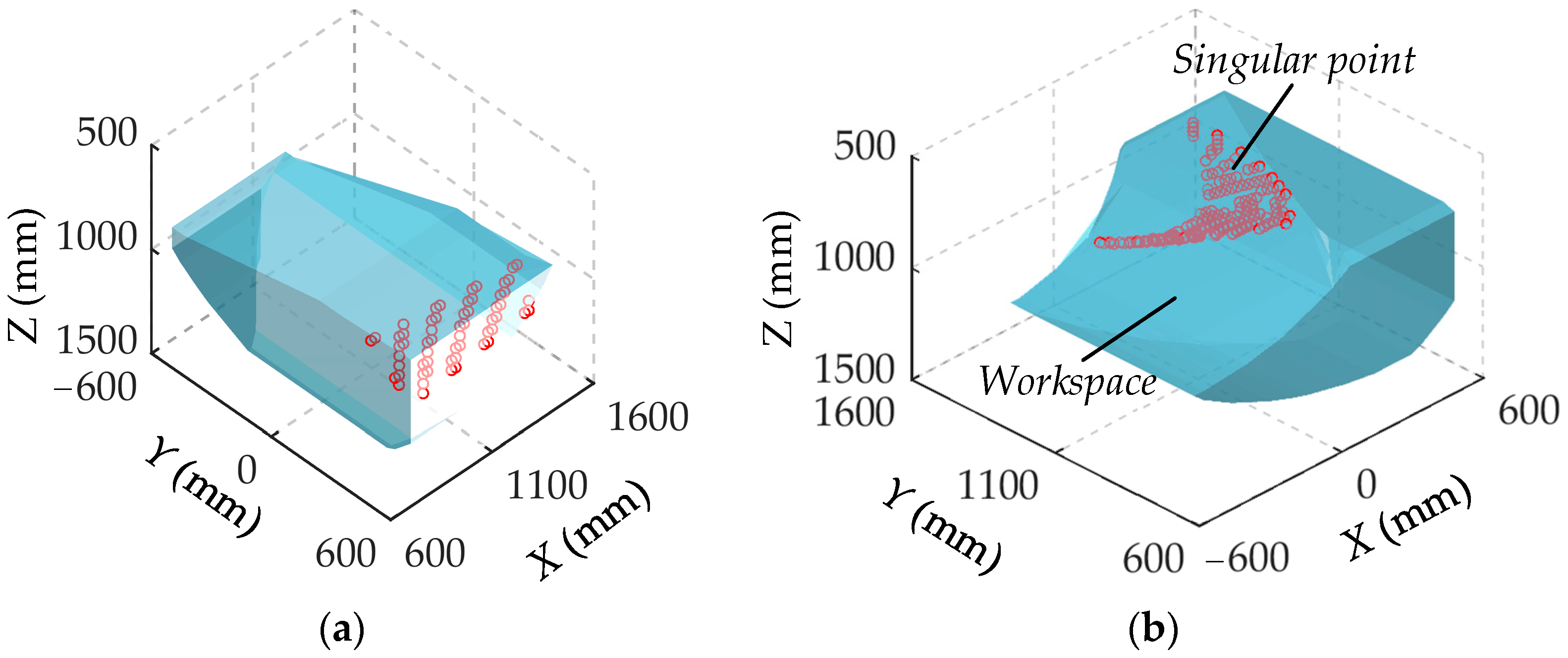

2.3.1. Singularity Analysis

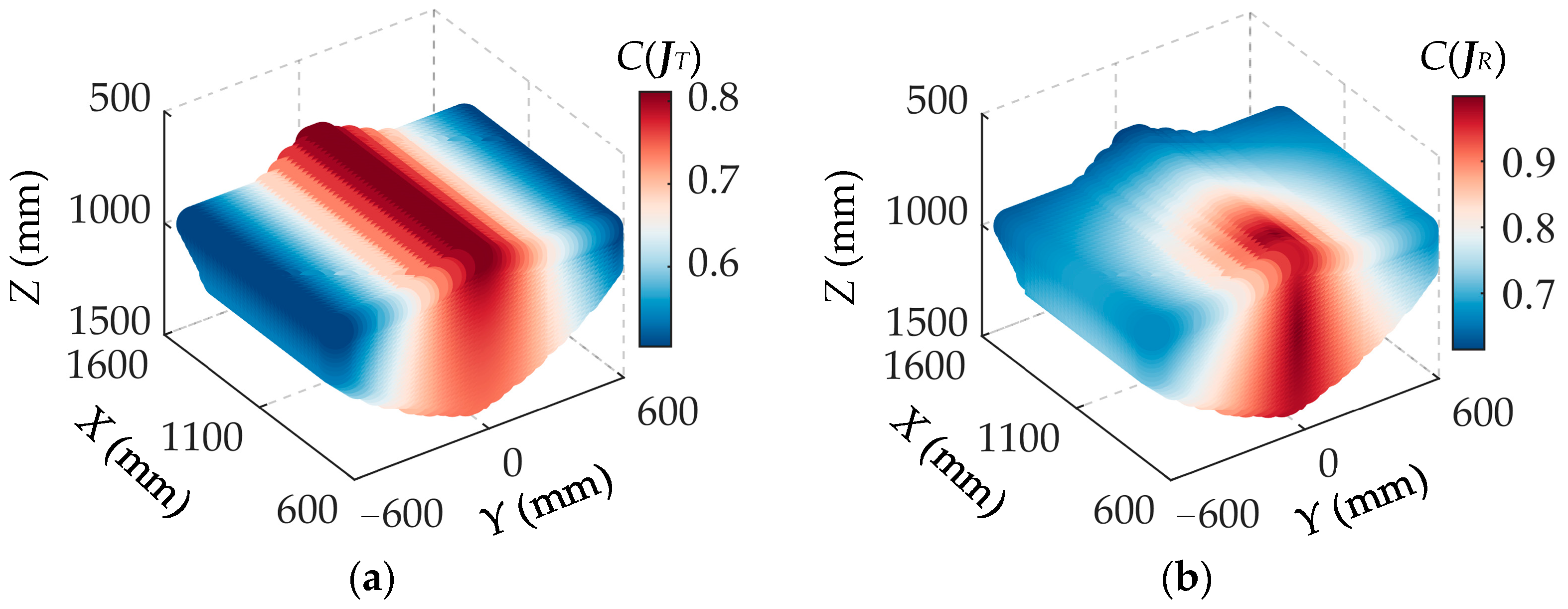

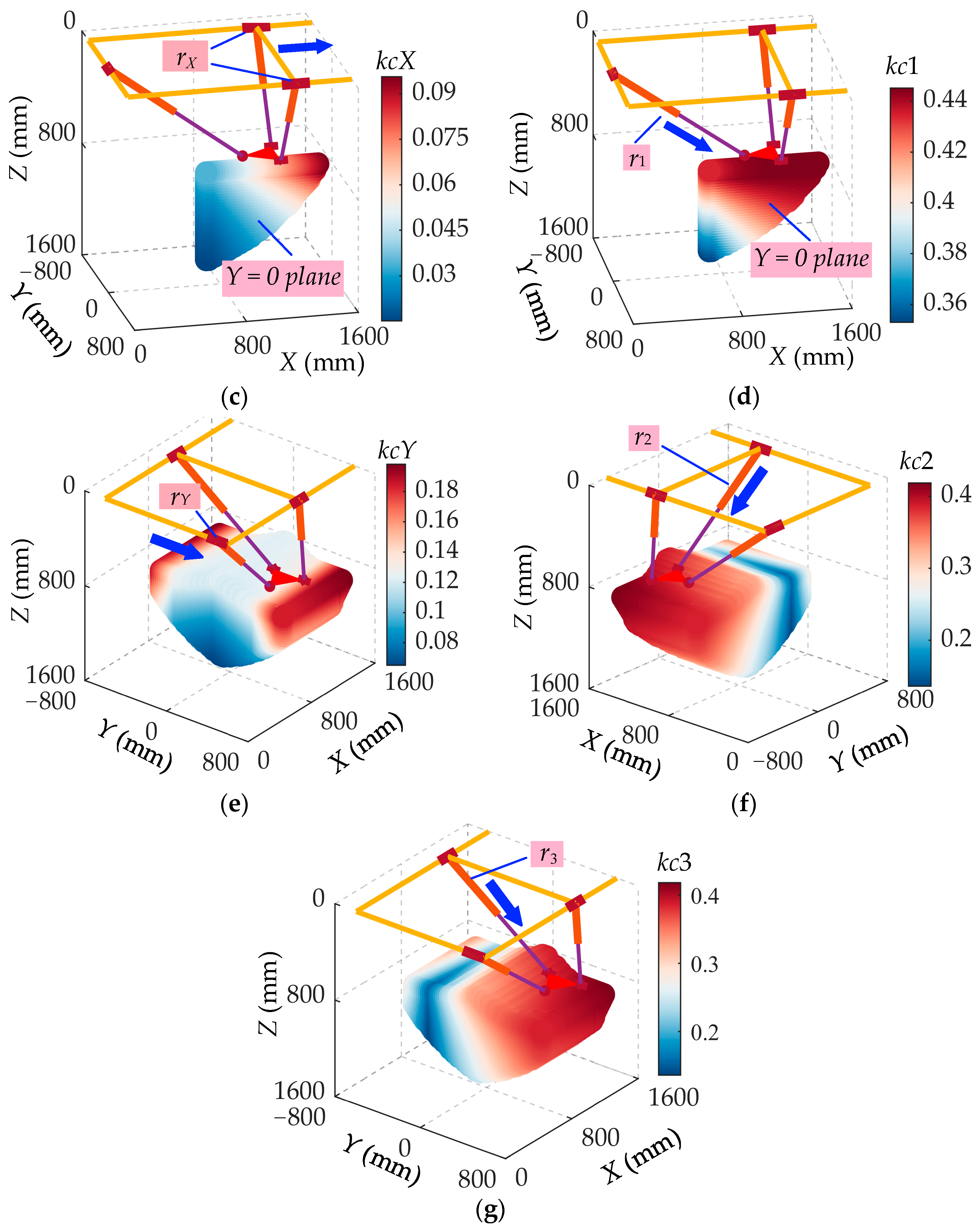

2.3.2. Dexterity Analysis

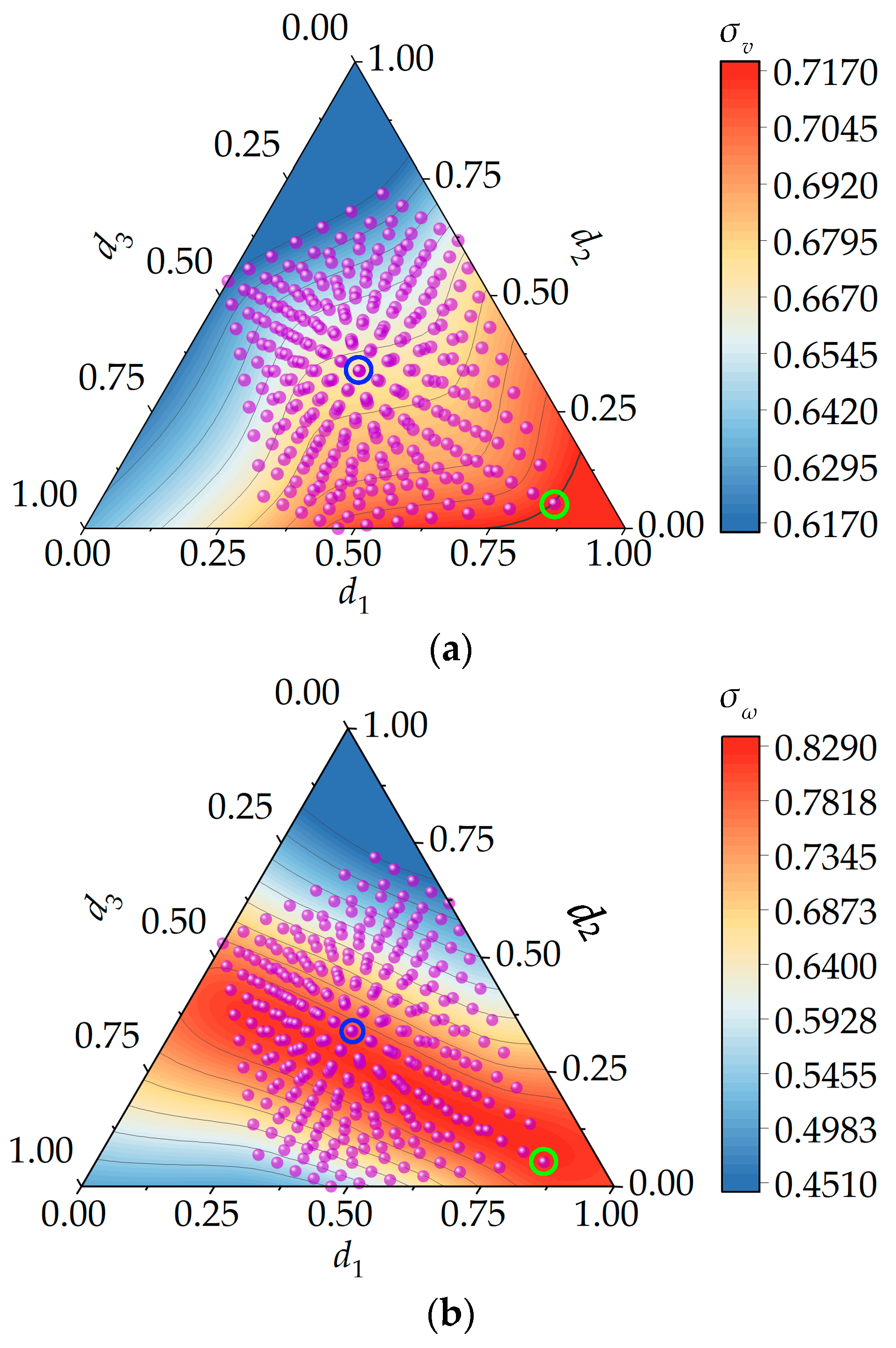

2.3.3. Optimization of Design Parameters

3. Dynamic Analysis of the P(2PRPU)/PRPS PM

3.1. Velocity and Acceleration of Branch Chains

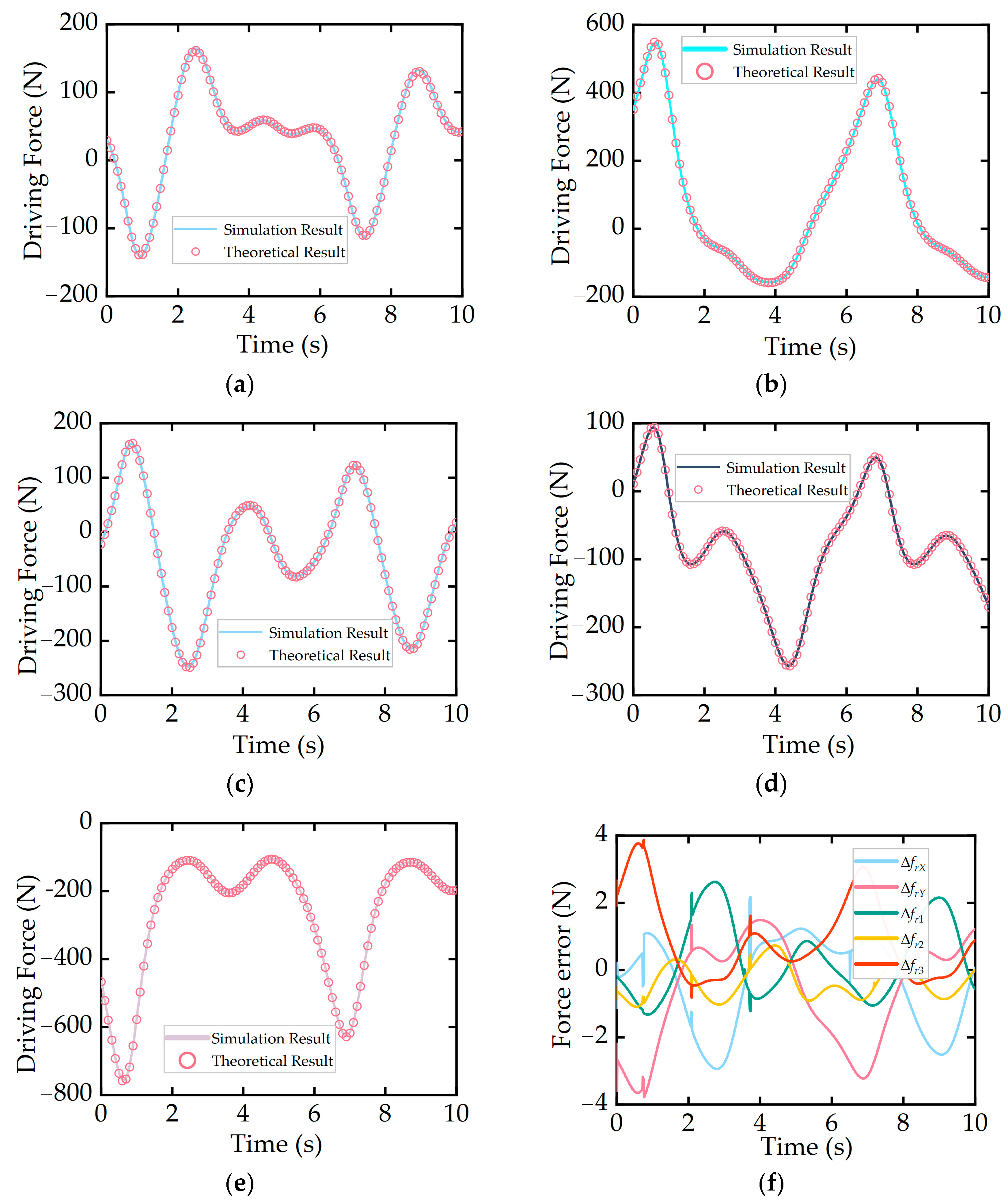

3.2. Dynamic Model of the Proposed Mechanism

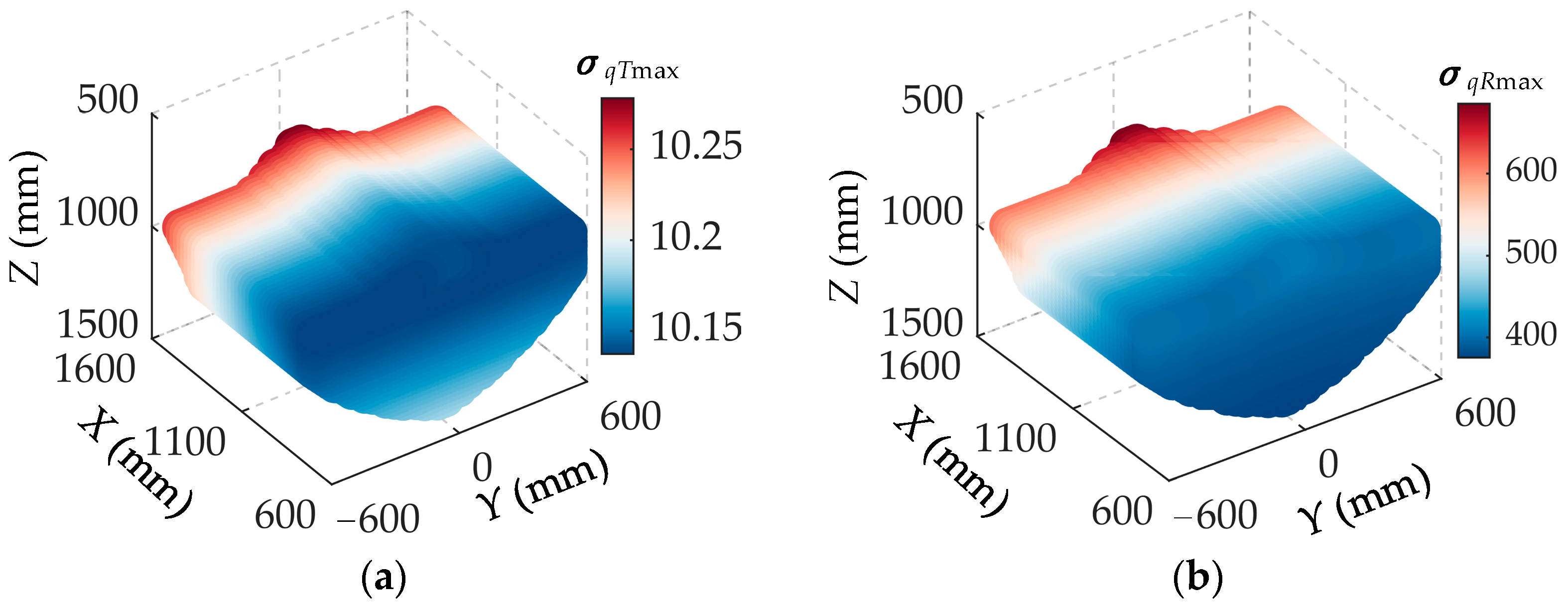

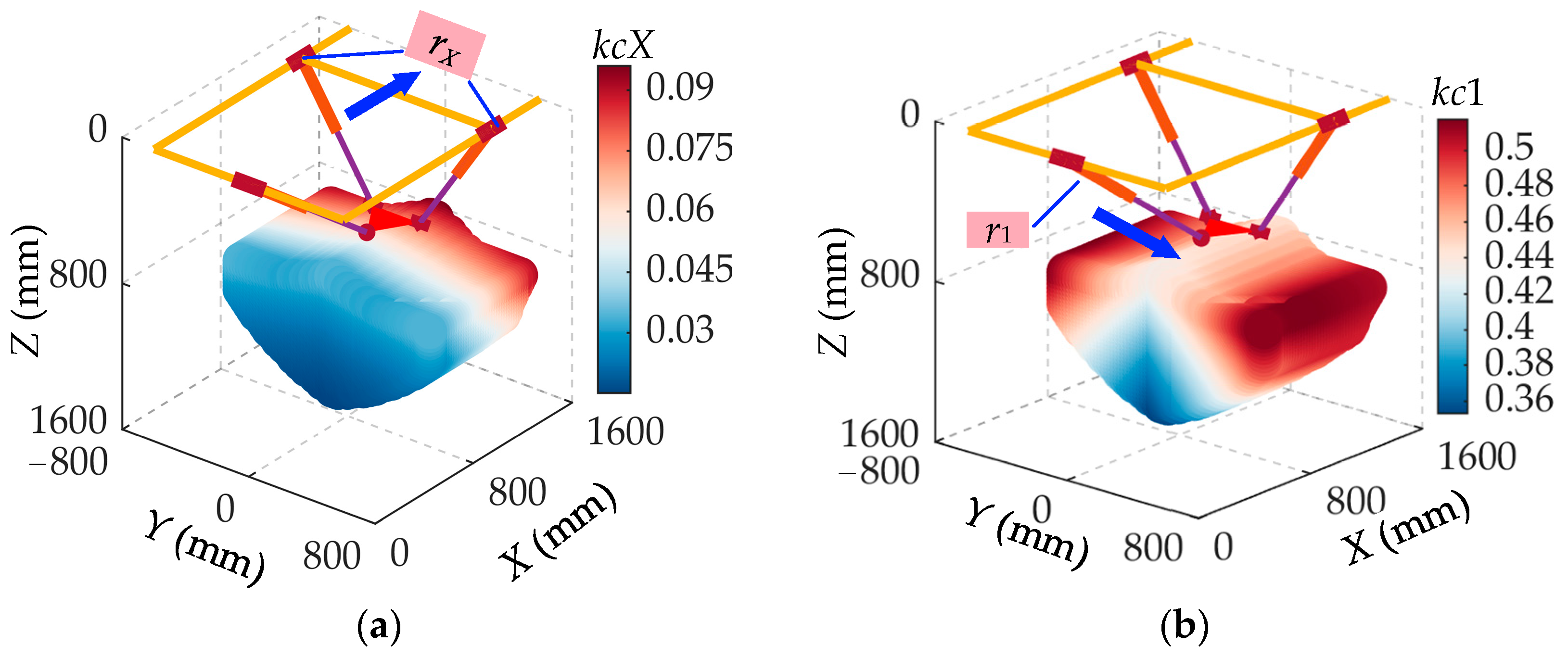

3.3. Dynamic Performance Analysis

3.3.1. Dynamic Manipulability of the P(2PRPU)/PRPS PM

3.3.2. Coupling Property of the P(2PRPU)/PRPS PM

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PM | Parallel mechanism |

| DOF | Degree of freedom |

References

- Chen, K.X.; Wang, M.; Huo, X.M.; Wang, P.F.; Sun, T. Topology and dimension synchronous optimization design of 5-DoF parallel robots for in-situ machining of large-scale steel components. Mech. Mach. Theory 2023, 179, 105105. [Google Scholar] [CrossRef]

- Zhang, D.S.; Xu, Y.D.; Yao, J.T.; Zhao, Y.S. Analysis and optimization of a spatial parallel mechanism for a new 5-DOF hybrid serial-parallel manipulator. Chin. J. Mech. Eng 2018, 31, 54. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Ding, Y. Toolpath optimization based on sequential quadratic programming for five-axis flat-end milling with hybrid robots. J. Manuf. Process. 2025, 141, 1619–1630. [Google Scholar] [CrossRef]

- Li, C.Y.; Xing, H.; Qin, P.B. Robotic arm trajectory planning based on improved Slime Mould Algorithm. Machines 2025, 13, 79. [Google Scholar] [CrossRef]

- Möller, C.; Schmidt, H.C.; Koch, P.; Böhlmann, C.; Kothe, S.-M.; Wollnack, J.; Hintze, W. Machining of large scaled CFRP-Parts with mobile CNC-based robotic system in aerospace industry. Procedia Manuf. 2017, 14, 17–29. [Google Scholar] [CrossRef]

- Garnier, S.; Subrin, K.; Arevalo-Siles, P.; Caverot, G.; Furet, B. Mobile robot stability for complex tasks in naval industries. Procedia CIRP 2018, 72, 297–302. [Google Scholar] [CrossRef]

- Zhang, X.C.; Wang, H.B.; Rong, Y.; Niu, J.Y.; Tian, J.J.; Ning, Y.S. Kinematics and stiffness analysis of a novel 4-dof over-constrained parallel mechanism with three legs. Int. J. Rob. Autom 2023, 38, 450–460. [Google Scholar] [CrossRef]

- Hu, B.; Bai, P. Research on the conditions and optimization of 3-UPU parallel manipulators that naturally realize three translational degrees of freedom. Machines 2025, 13, 265. [Google Scholar] [CrossRef]

- Zhang, X.C.; Wang, H.B.; Rong, Y.; Niu, J.Y.; Tian, J.Y.; Li, S.S. Dynamic modeling of a class of parallel-serial mechanisms by the principle of virtual work. Meccanica 2023, 58, 303–316. [Google Scholar] [CrossRef]

- Antonov, A. Parallel–serial robotic manipulators: A review of architectures, applications, and methods of design and analysis. Machines 2024, 12, 811. [Google Scholar] [CrossRef]

- Verl, A.; Valente, A.; Melkote, S.; Brecher, C.; Ozturk, E.; Tunc, L.T. Robots in machining. CIRP Ann. 2019, 68, 799–822. [Google Scholar] [CrossRef]

- Dong, C.L.; Liu, H.T.; Huang, T.; Chetwynd, D.G. A screw theory-based semi-analytical approach for elastodynamics of the tricept robot. ASME J. Mech. Rob. 2019, 11, 031005. [Google Scholar] [CrossRef]

- Alagheband, A.; Mahmoodi, M.; Mills, J.K.; Benhabib, B. Comparative analysis of a redundant pentapod parallel kinematic machine. ASME J. Mech. Rob. 2015, 7, 034502. [Google Scholar] [CrossRef]

- Shen, X.; Xie, F.G.; Liu, X.J.; Xie, Z.H. A smooth and undistorted toolpath interpolation method for 5-DoF parallel kinematic machines. Rob. Comput. Integr. Manuf. 2019, 57, 347–356. [Google Scholar] [CrossRef]

- Luo, X.; Xie, F.G.; Liu, X.J.; Xie, Z.H. Kinematic calibration of a 5-axis parallel machining robot based on dimensionless error mapping matrix. Rob. Comput. Integr. Manuf. 2021, 70, 102115. [Google Scholar] [CrossRef]

- Wang, R.Y.; Niu, Z.L.; Chen, K.X.; Sun, T. Kinematic optimization design and performance simulation of novel 5-DOF parallel machining robots with spatial layout. Machines 2022, 10, 1187. [Google Scholar] [CrossRef]

- Chen, K.X.; Wang, R.Y.; Niu, Z.L.; Wang, P.F.; Sun, T. Topology design and performance optimization of six-limbs 5-DOF parallel machining robots. Mech. Mach. Theory 2023, 185, 105333. [Google Scholar] [CrossRef]

- Zou, Q.; Zhang, D.; Luo, X.L.; Huang, G.Y.; Li, L.J.; Zhang, H.Q. Enumeration and optimum design of a class of translational parallel mechanisms with prismatic and parallelogram joints. Mech. Mach. Theory 2020, 150, 103846. [Google Scholar] [CrossRef]

- Karnam, M.K.; Baskar, A.; Srivatsan, R.A.; Bandyopadhyay, S. Computation of the safe working zones of planar and spatial parallel manipulators. Robotica 2020, 38, 861–885. [Google Scholar] [CrossRef]

- Laryushkin, P.; Antonov, A.; Fomin, A.; Essomba, T. Velocity and singularity analysis of a 5-DOF (3T2R) parallel-serial (hybrid) manipulator. Machines 2022, 10, 276. [Google Scholar] [CrossRef]

- Wang, Y.F.; Chen, Y.A.; Liu, R.M. Aircraft image recognition network based on hybrid attention mechanism. Comput. Intell. Neurosci. 2022, 2022, 4189500. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.H.; Lin, Y.F.; Cao, Y.R.; Wu, M.L.; Sun, S. Design and multi-objective Optimization of a novel 5-DOF parallel mechanism with two double-driven chains. Robotica 2023, 41, 2829–2849. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Zhao, T.S.; Xu, X.H.; Bian, H.; Ding, S.X. Kinematic analysis and dimensional synthesis of a three-degrees-of-freedom hybrid-drive parallel mechanism. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 2728–2752. [Google Scholar] [CrossRef]

- Li, W.; Angeles, J. The design of a 3-CPS parallel robot for maximum dexterity. Mech. Mach. Theory 2018, 122, 279–291. [Google Scholar] [CrossRef]

- Wang, X.H.; Sun, S.; Wu, M.L.; Cao, Y.R.; Guo, Z.Y.; Liu, Z.F. Kinematic calibration of a 5-DOF double-driven parallel mechanism with sub-closed loop on limbs. Robotica 2024, 42, 3709–3730. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, P.; Zhao, S.H.; Hu, B.; Han, J.D.; Sui, C.P. Kinematics and statics analysis of a novel 5-DoF parallel manipulator with two composite rotational/linear active legs. Rob. Comput. Integr. Manuf. 2014, 30, 25–33. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Zhao, T.S.; Wang, C.; Tian, X.; Chen, Y.H. Type synthesis and analysis of parallel mechanisms with sub-closed-loops. Mech. Mach. Theory 2018, 120, 140–165. [Google Scholar] [CrossRef]

- Niu, Z.L.; Chen, K.X.; Wang, P.F.; Sun, T. Kinematic Design and Simulation of a Novel Three Limbs 5-DOF Parallel Robot for Reconfigurable Manufacture. In Proceedings of the 2024 6th International Conference on Reconfigurable Mechanisms and Robots, Chicago, IL, USA, 23–26 June 2024. [Google Scholar]

- Rong, Y.; Zhang, X.C.; Dou, T.C.; Wang, H.B. Type synthesis of non-overconstrained and overconstrained two rotation and three translation (2R3T) parallel mechanisms with three branched chains. Mech. Sci. 2023, 14, 567–577. [Google Scholar] [CrossRef]

- Lu, S.; Li, Y.M.; Ding, B.X. Kinematics and dynamics analysis of the 3 PUS-PRU parallel mechanism module designed for a novel 6-DOF gantry hybrid machine tool. J. Mech. Sci. Technol. 2020, 34, 345–357. [Google Scholar] [CrossRef]

- Lu, S.; Ding, B.X.; Li, Y.M. Minimum-jerk trajectory planning pertaining to a translational 3-degree-of-freedom parallel manipulator through piecewise quintic polynomials interpolation. Adv. Mech. Eng. 2020, 12, 1687814020913667. [Google Scholar] [CrossRef]

- Chong, Z.H.; Xie, F.G.; Liu, X.J.; Wang, J.S. Evaluation of dynamic isotropy and coupling acceleration capacity for a parallel manipulator with mixed DoFs. Mech. Mach. Theory 2021, 163, 104382. [Google Scholar] [CrossRef]

| Symbol | Mass (kg) | Local Inertial Matrix (kg∙mm2) |

|---|---|---|

| mo | 17.83 | diag(367,124 191,975 181,594) |

| mb1, mb2, mb3 | 25.42 | diag(1,437,939 1,375,778 97,592) |

| ms1 | 2.85 | diag(118,804, 117,521 1,849) |

| ms2, ms3 | 3.79 | diag(173,612, 172,451 2,340) |

| mX | 33.57 | diag(5,541,785 5,528,349 88,156) |

| mY | 4.55 | diag(8,732 7,620 7,522) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Rong, Y.; Wang, H.; Zhang, S. Kinematics and Dynamics Analysis of a New 5-Degrees of Freedom Parallel Mechanism with Two Double-Driven Chains. Machines 2025, 13, 419. https://doi.org/10.3390/machines13050419

Zhang X, Rong Y, Wang H, Zhang S. Kinematics and Dynamics Analysis of a New 5-Degrees of Freedom Parallel Mechanism with Two Double-Driven Chains. Machines. 2025; 13(5):419. https://doi.org/10.3390/machines13050419

Chicago/Turabian StyleZhang, Xingchao, Yu Rong, Hongbo Wang, and Shijun Zhang. 2025. "Kinematics and Dynamics Analysis of a New 5-Degrees of Freedom Parallel Mechanism with Two Double-Driven Chains" Machines 13, no. 5: 419. https://doi.org/10.3390/machines13050419

APA StyleZhang, X., Rong, Y., Wang, H., & Zhang, S. (2025). Kinematics and Dynamics Analysis of a New 5-Degrees of Freedom Parallel Mechanism with Two Double-Driven Chains. Machines, 13(5), 419. https://doi.org/10.3390/machines13050419