Engineering Innovations for Polyvinyl Chloride (PVC) Recycling: A Systematic Review of Advances, Challenges, and Future Directions in Circular Economy Integration

Abstract

1. Introduction

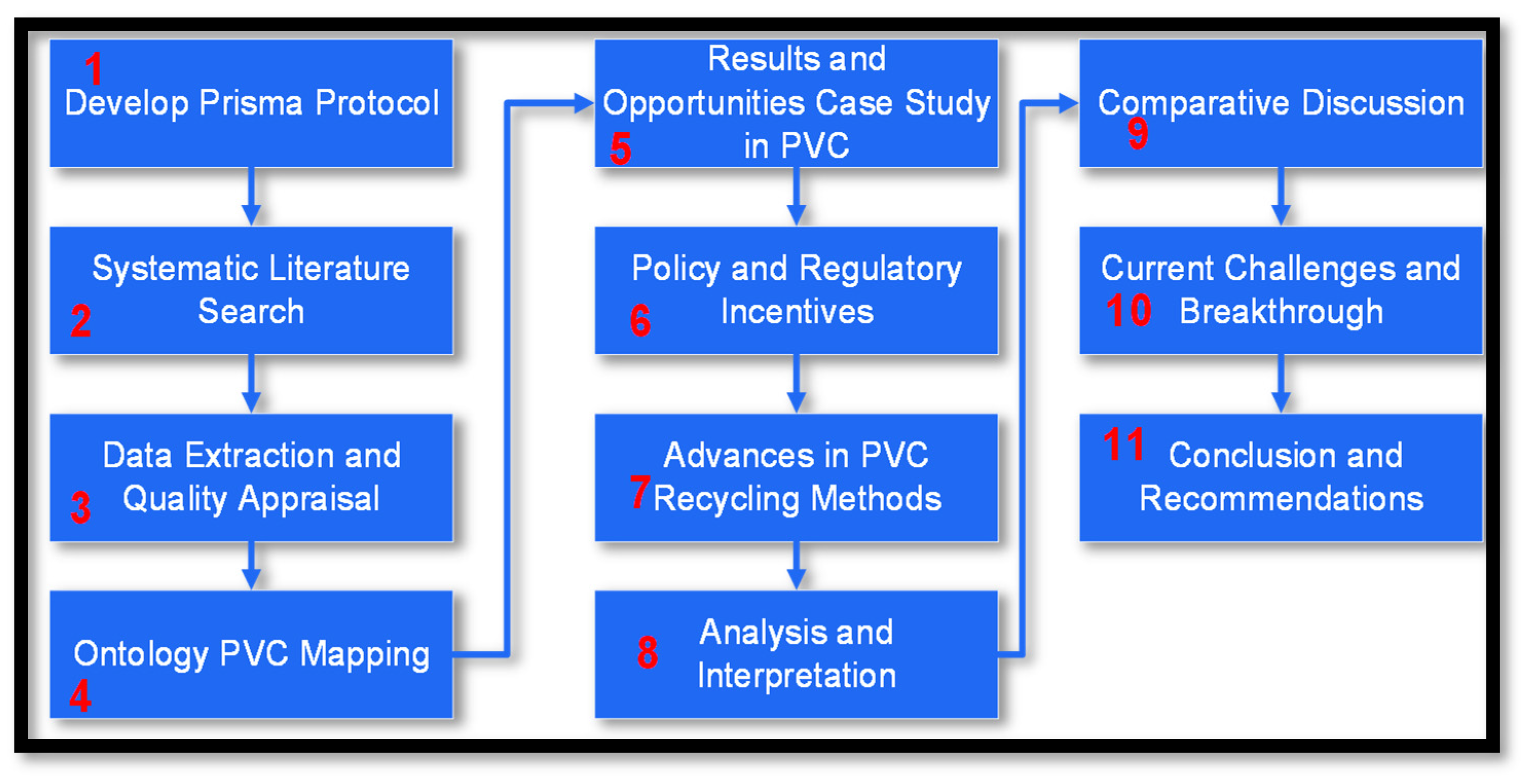

Objectives of This Study

- To trace the development of PVC recycling technologies and evaluate their environmental impacts across various historical phases.

- To analyse the integration of advanced manufacturing systems guided by PRISMA protocols within PVC recycling processes and assess their contributions to circularity and process optimisation.

- To evaluate the extent to which innovative engineering solutions improve resource efficiency and reduce waste in PVC recycling systems.

- To identify existing challenges in PVC recycling and explore engineering solutions to address them.

- To formulate evidence-based policy recommendations and outline strategic research directions that support the development of sustainable PVC recycling infrastructures.

- How have PVC recycling methods evolved over time, and what are the key technological milestones that have shaped their development?

- In what ways do advanced manufacturing technologies contribute to the efficiency and scalability of PVC recycling processes?

- To what extent do current PVC recycling strategies align with circular economy principles, and how can system integration improve lifecycle optimisation?

- What are the critical inefficiencies and environmental burdens associated with traditional PVC recycling methods, particularly regarding energy use, recovery rates, and material degradation?

- What technological and regulatory gaps remain in integrating circular economy principles into advanced manufacturing systems for PVC recycling, and what research is needed to address them?

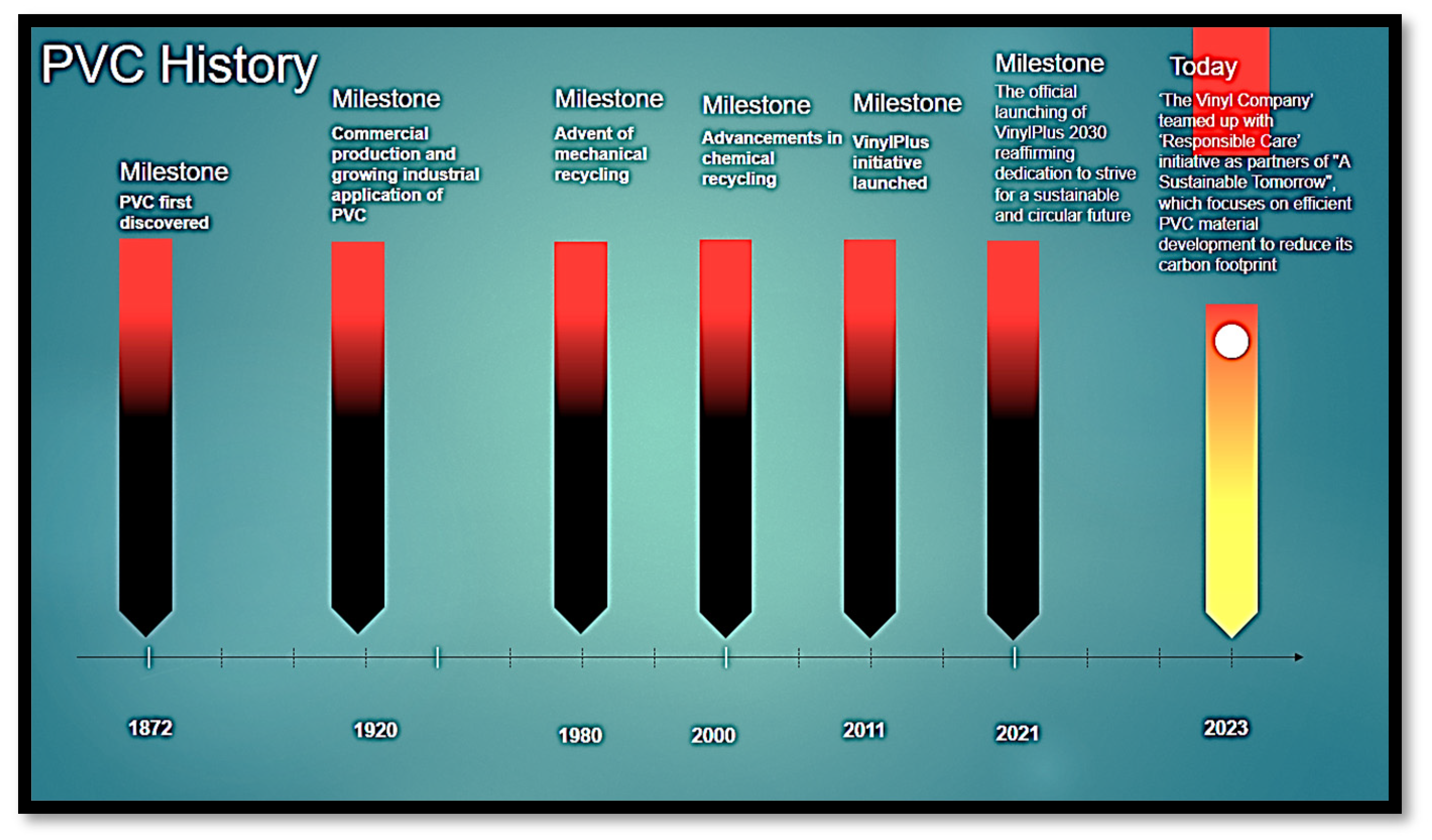

2. Background: Historical Development and Evolution of PVC Recycling

Milestones in Regulatory Frameworks for PVC Waste Management

3. Methodology

3.1. Materials and Methods

3.2. Systematic Literature Search Using PRISMA

3.3. Search Parameters

3.4. PRISMA Assessment Protocol

- PVC recycling methods and contributions to circular economy principles.

- Cutting-edge technologies, lifecycle assessment, and policy evaluation.

- Criteria for exclusion included duplicate studies, unclear results, low-quality methods, and outdated references. This step refined the selection to 120 high-quality articles.

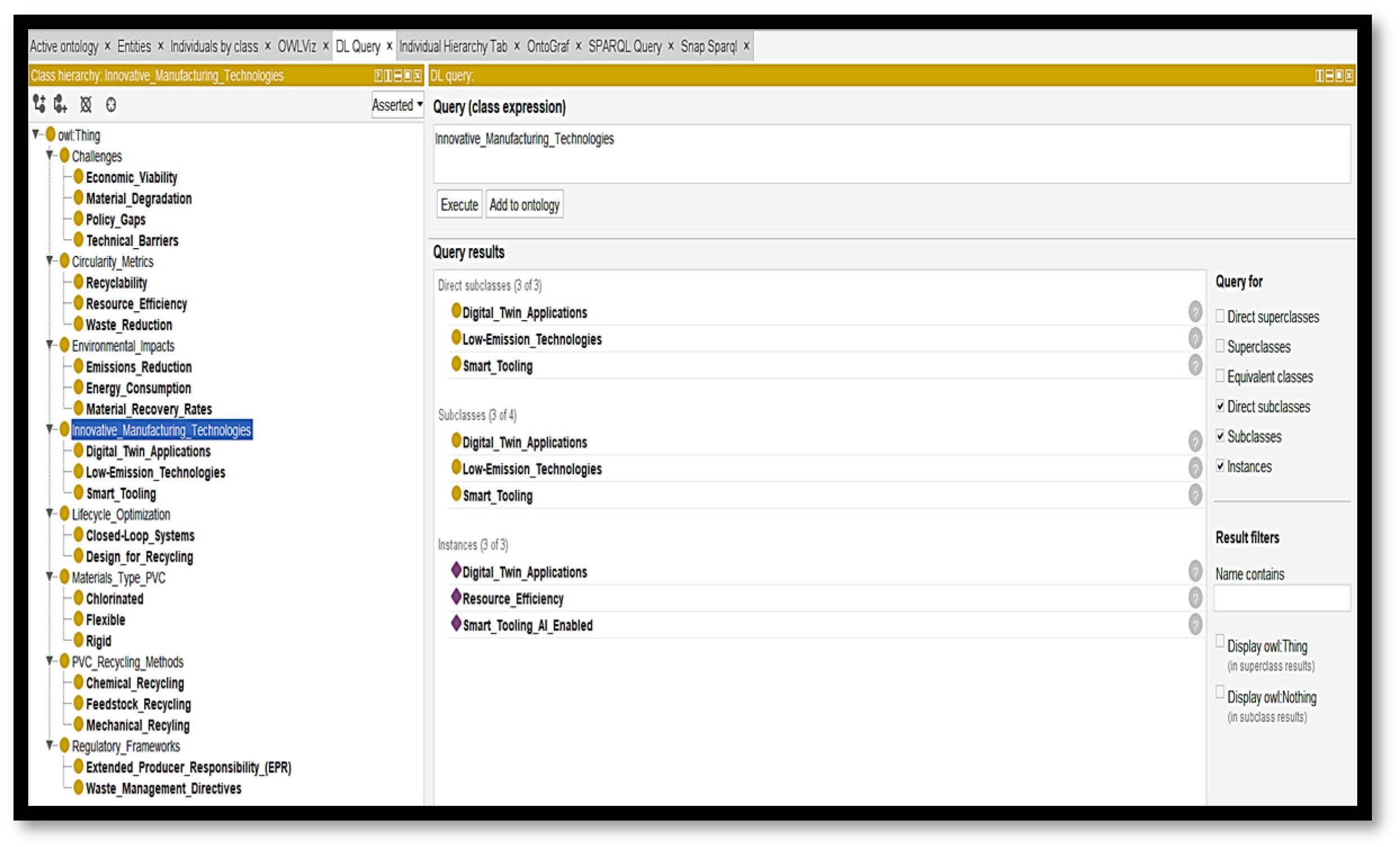

3.5. Ontological Relationships Mapping in PVC Recycling and Circular Economy

- Identifying innovation areas;

- Refining data relevance and quality’

- Visualizing links between recycling technologies, CE principles, and policy interventions;

- Operational modelling for LCM, such as supply chain LP models [14], could complement ontological mapping by quantifying optimal recycling pathways based on energy and emissions efficiency.

4. Results: Opportunities and Case Studies in PVC Recycling

4.1. Technological Innovations in PVC Recycling

- Timeline of PVC Recycling Advancements

- Chemical Recycling Techniques

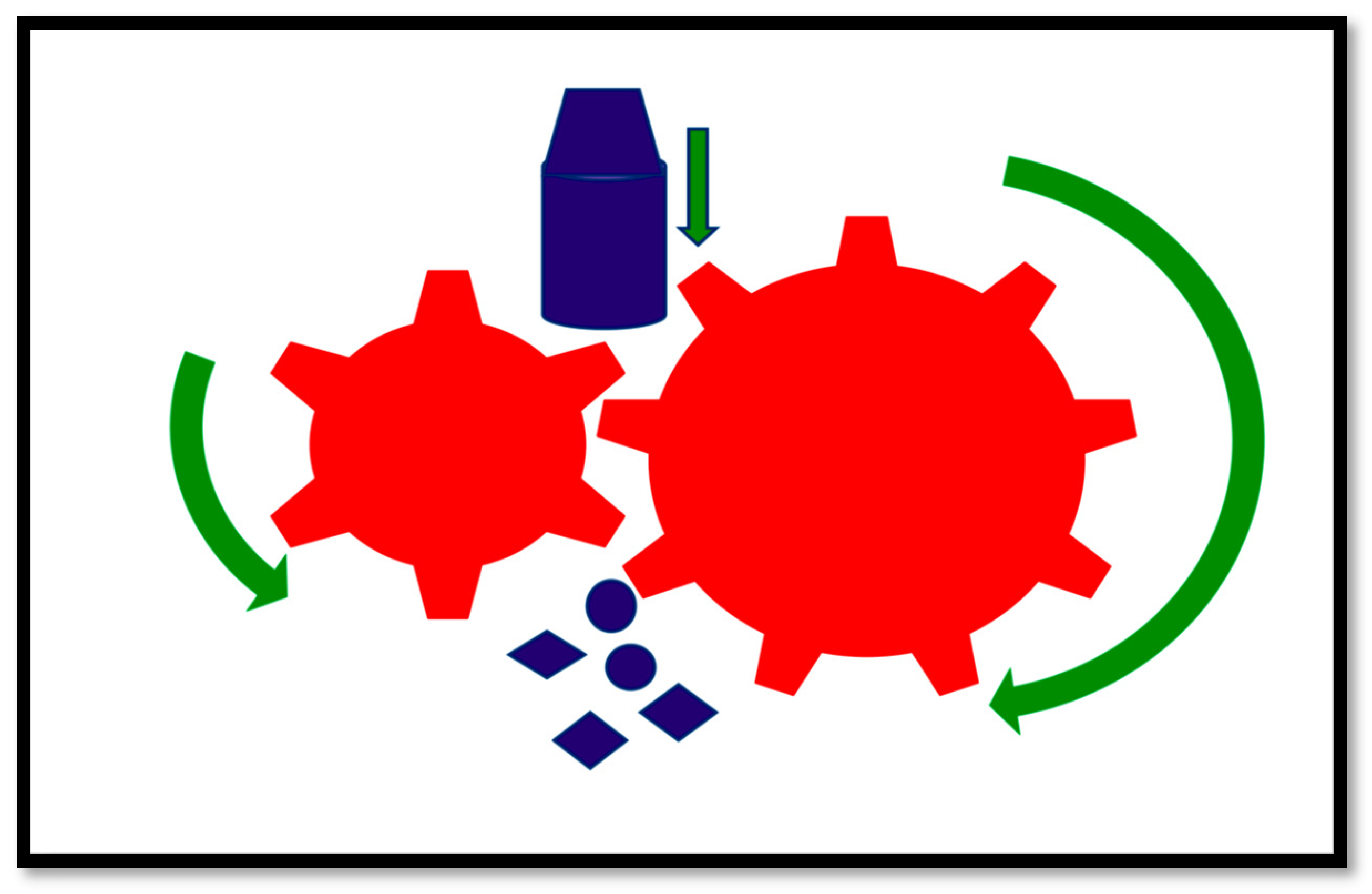

- Advances in Mechanical Recycling

4.2. Integrating Recycling Methods into Circular Economy Principles

4.3. Policy and Regulatory Incentives

4.4. Case Study: Successful PVC Recycling Initiatives

4.5. Challenges and Prospects

5. Advances in PVC Recycling: Engineering and Technology

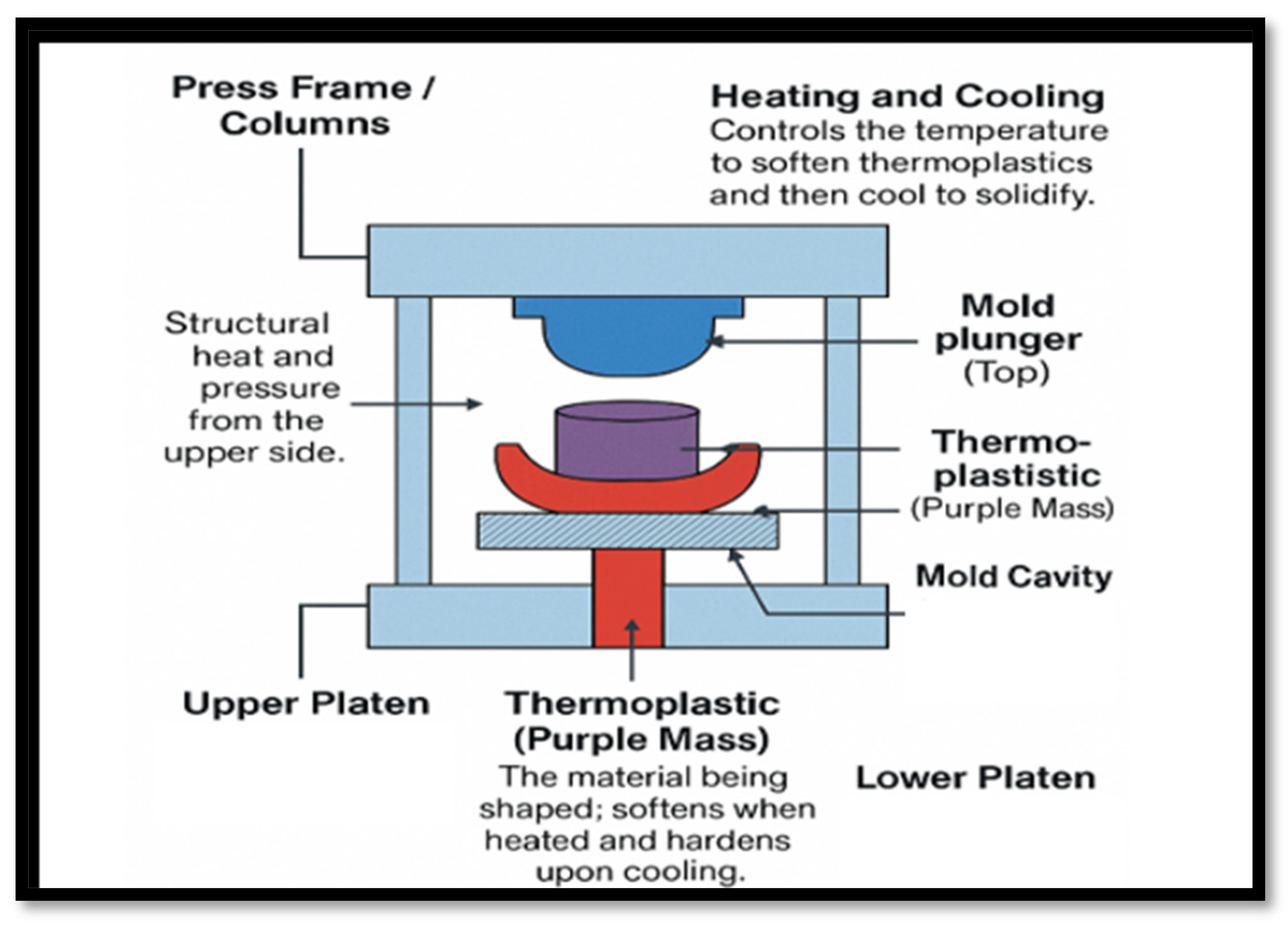

5.1. Innovative Manufacturing Processes Used in PVC Recycling

- Chemical recycling;

- Additive manufacturing (3D printing);

- Supercritical fluid extraction (SFE);

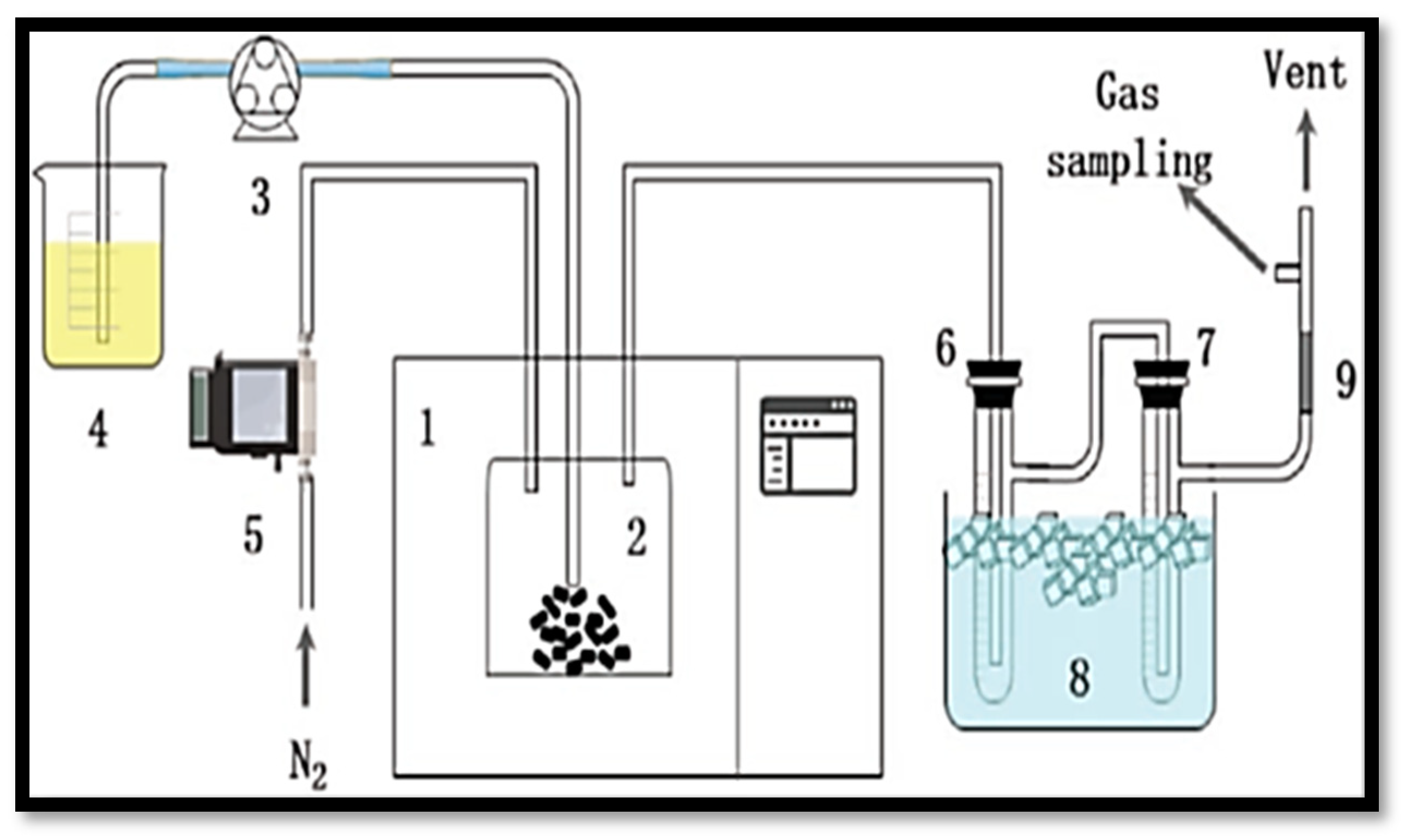

- Microwave-assisted recycling;

- Electrochemical recycling;

- Biological recycling;

- Dissolution and extraction;

- Transforming PVC into a nanostructured catalyst support;

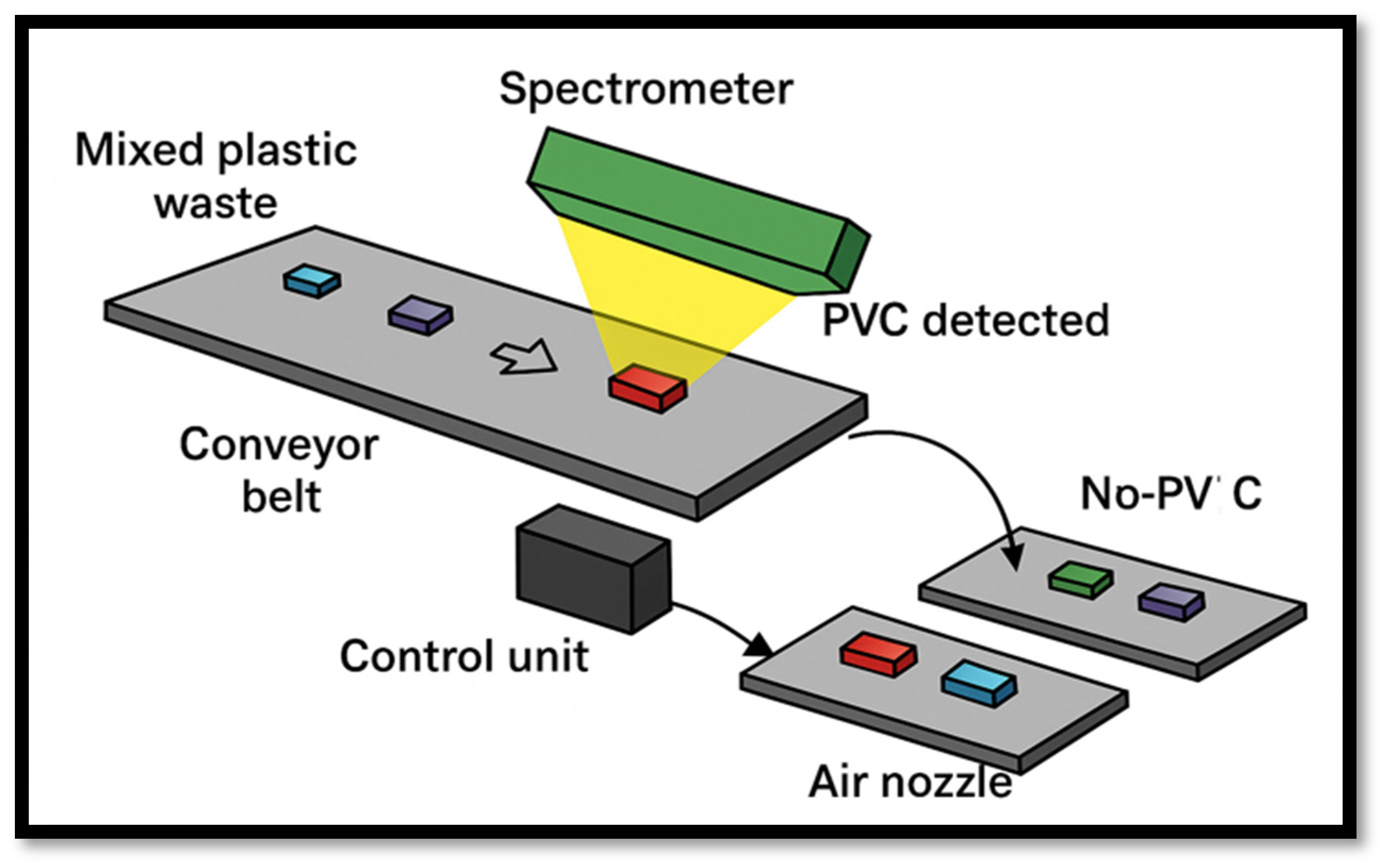

- Sorting with electromagnetic waves;

- Flotation with surfactants;

- Pre-treatment using reagents;

- Pre-treatment using Fenton reaction;

- Pre-treatment with thermal heat treatment (mild and microwave);

- Pre-treatment with corona discharge;

- Chemical Recycling

- Additive Manufacturing (3D Printing)

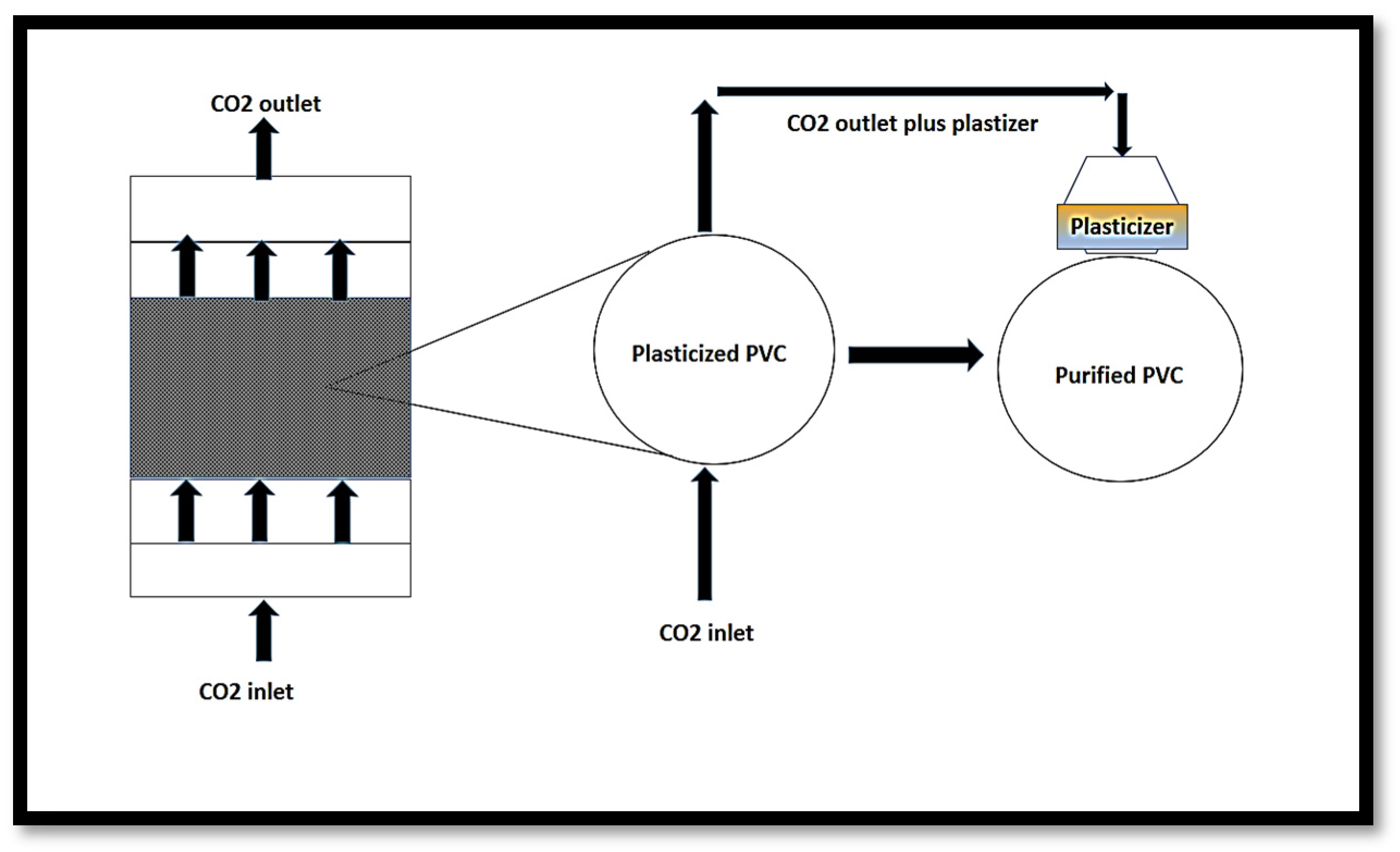

- Supercritical Fluid Extraction (SFE)

- Microwave-Assisted Recycling

- Other Innovative Recycling Techniques gaining traction are as follows:

- Electrochemical Recycling: employs electrochemical reactions for high-purity PVC recovery [60].

- Biological Recycling: Uses enzymes or microorganisms for the environmentally friendly degradation of PVC waste [61]. It is also known as ‘biodegradation’ or ‘enzymatic degradation’ process.

- Dissolution and Extraction: selectively dissolves PVC using sustainable solvents [62]. It is used to extract and purify PVC from waste streams for use in making new products.

- Advanced Sorting Technologies: employs electromagnetic waves in an advanced sensor technology to separate PVC from mixed waste streams [65].

5.2. Integration of Sustainable Practices in PVC Manufacturing

- Plasma Pyrolysis: converts PVC waste into syngas for hydrogen production and turbines [70].

- Low-Emission Manufacturing Technologies

- Material Substitution and Additives for Recyclability

5.3. Innovations in Production Machines and Tooling

- Machinery Optimized for Recyclable Materials

- Extruders: transform PVC into sheets, films, or structural parts [43].

- Smart Tooling for Sustainable Manufacturing

5.4. Systems Integration for Sustainable Outcomes

- Digital Twin and Industry 4.0 Applications in PVC Recycling

- Automation in Recycling and Manufacturing Processes

6. Analysis and Interpretation

PVC Classes on Innovative Manufacturing Technologies

- Digital twin applications;

- Low-emission technologies;

- Smart tooling.

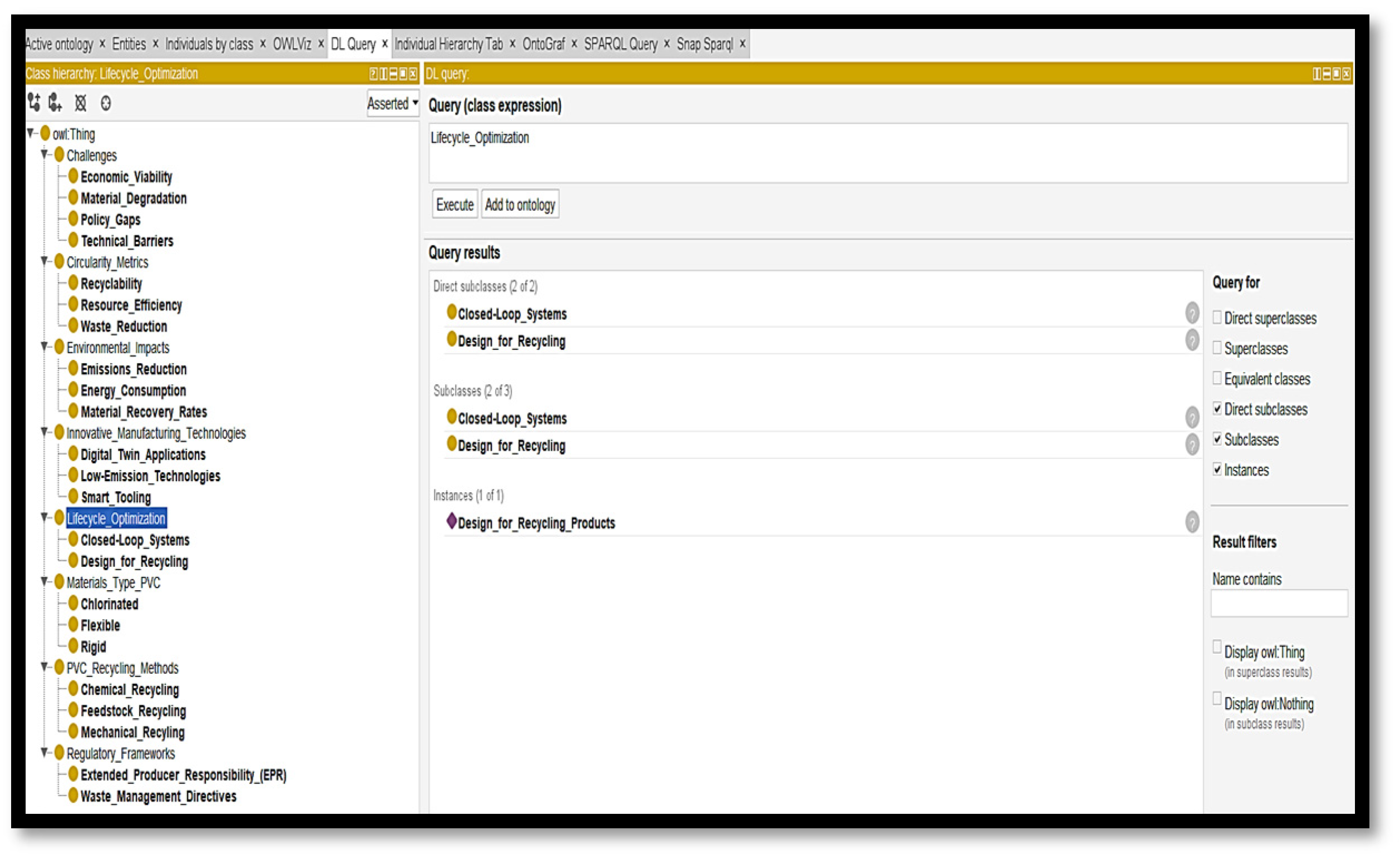

- PVC Classes on Lifecycle Optimisation

- Closed-loop systems;

- Design for recycling.

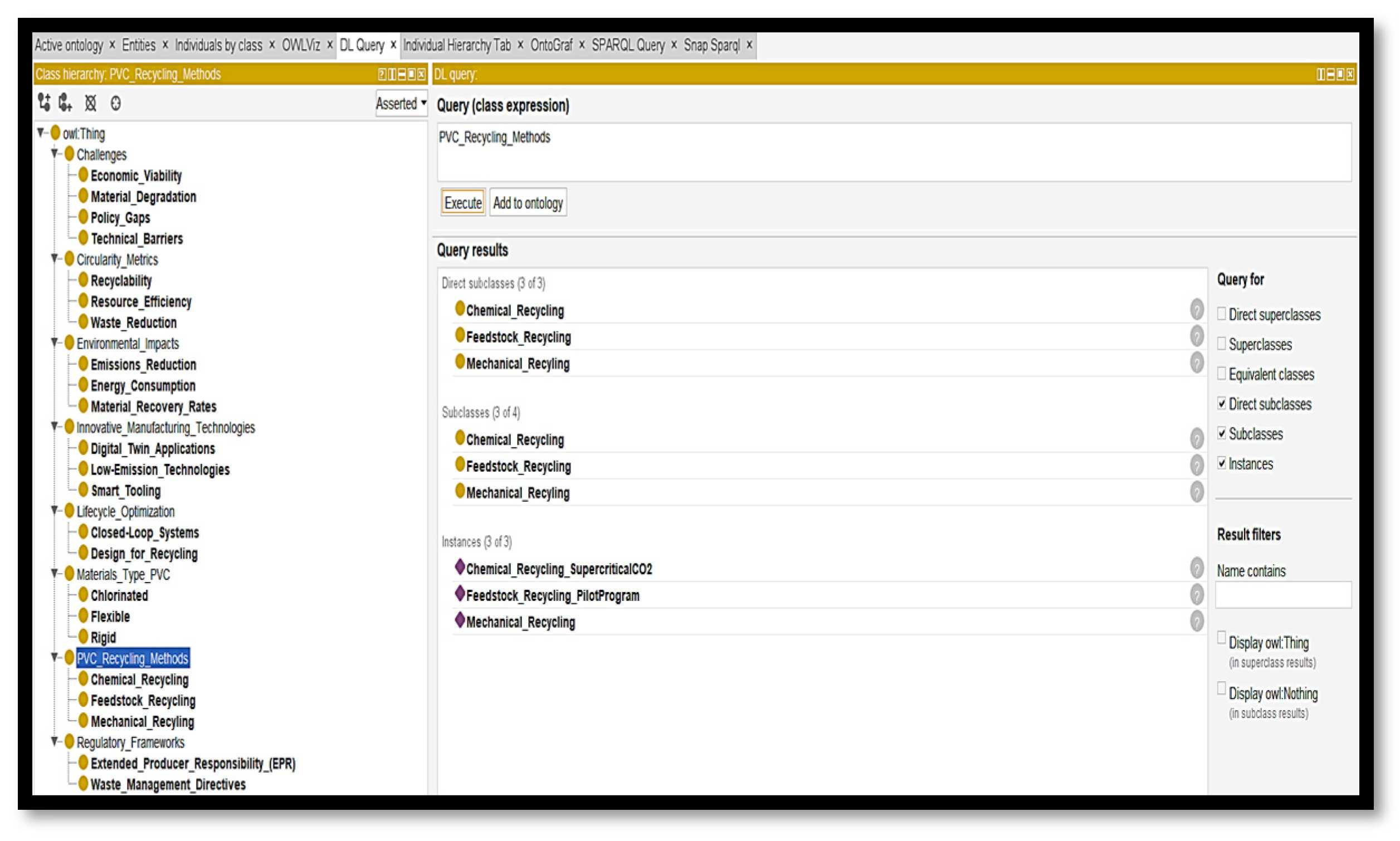

- PVC Classes on PVC Recycling Methods

- Chemical recycling;

- Feedstock recycling;

- Mechanical recycling.

7. Discussion: Circular Economy Perspectives for PVC Recycling

7.1. Transitioning PVC Recycling into a Circular Economy Framework

7.2. Strategies for Achieving a Closed-Loop System

- Design for Recycling

- Extended Producer Responsibility (EPR)

7.3. Circularity Challenges and Barriers

- Technological Barriers: Current mechanical recycling methods result in polymer degradation, limiting recycling prospects. Chemical recycling offers a solution but remains economically unscalable.

- Regulatory Variability: inconsistent global policies create inefficiencies in cross-border waste management and hinder large-scale adoption.

- Market Hesitancy: industries often resist using recycled PVC due to concerns about quality and processing stability, impacting the demand.

- Economic Constraints: high capital investment requirements for advanced recycling infrastructures pose financial risks for smaller enterprises.

7.4. Opportunities and Benefits for Circularity in PVC Product Lifecycles

7.5. Future Directions in PVC Recycling Innovations

- The integration of ontological mapping and LP-based operational models enhances the system-level understanding of energy and material flows.

- Desktop manufacturing and devolved supply systems provide viable models for decentralised PVC recycling infrastructures.

- Smart tooling and CNC energy flow analytics offer practical benchmarks for machine performance and environmental compliance.

7.6. Addressing Gaps and Future Directions in PVC Recycling Innovation

8. Current Challenges and Breakthroughs in PVC Recycling

8.1. Material Composition and Complexity

8.2. Technical Limitations in Current Methods

8.3. Economic Viability and Market Challenges

9. Conclusions

9.1. Summary of Key Findings

9.2. Policy and Practice Recommendations

9.3. Future Directions for Research and Development

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M.N. Plastic waste and its management strategies for environmental sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar] [CrossRef]

- Hossain, U.; Ng, S.T.; Dong, Y.; Amor, B. Strategies for mitigating plastic wastes management problem: A lifecycle assessment study in Hong Kong. Waste Manag. 2021, 131, 412–422. [Google Scholar] [CrossRef] [PubMed]

- Čolnik, M.; Kotnik, P.; Knez, Ž.; Škerget, M. Degradation of Polyvinyl Chloride (PVC) Waste with Supercritical Water. Processes 2022, 10, 1940. [Google Scholar] [CrossRef]

- Karlsson, T.M.; Arneborg, L.; Broström, G.; Almroth, B.C.; Gipperth, L.; Hassellöv, M. The unaccountability case of plastic pellet pollution. Mar. Pollut. Bull. 2018, 129, 52–60. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Turner, A.; Filella, M. Polyvinyl chloride in consumer and environmental plastics, with a particular focus on metal-based additives. Environ. Sci. Process. Impacts 2021, 23, 1376–1384. [Google Scholar] [CrossRef]

- Everard, M. Twenty years of the Polyvinyl Chloride Sustainability Challenges. J. Vinyl Addit. Technol. 2019, 26, 390–402. [Google Scholar] [CrossRef]

- Mirowski, J.; Oliwa, R.; Oleksy, M.; Tomaszewska, J.; Ryszkowska, J.; Budzik, G. Poly(vinyl chloride) Composites with Raspberry Pomace Filler. Polymers 2021, 13, 1079. [Google Scholar] [CrossRef]

- Li, H.; Aguirre-Villegas, H.A.; Allen, R.D.; Bai, X.; Benson, C.H.; Beckham, G.T.; Bradshaw, S.L.; Brown, J.L.; Brown, R.C.; Cecon, V.S.; et al. Expanding plastics recycling technologies: Chemical aspects, technology status and challenges. Green Chem. 2022, 24, 8899–9002. [Google Scholar] [CrossRef]

- Santos, G.; Esmizadeh, E.; Riahinezhad, M. Recycling Construction, Renovation, and Demolition Plastic Waste: Review of the status quo, challenges and opportunities. J. Polym. Environ. 2023, 32, 479–509. [Google Scholar] [CrossRef]

- Martínez-Narro, G.; Hassan, S.; Phan, A.N. Chemical recycling of plastic waste for sustainable polymer manufacturing—A critical review. J. Environ. Chem. Eng. 2024, 12, 112323. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2016, 143, 710–718. [Google Scholar] [CrossRef]

- Cheng, K.; Srai, J.S. Special issue on sustainable manufacturing and the key enabling technologies. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1603. [Google Scholar] [CrossRef]

- Tridech, S.; Cheng, K. Low Carbon Manufacturing: Characterisation, theoretical models and implementation. Int. J. Manuf. Res. 2011, 6, 110–121. [Google Scholar] [CrossRef]

- Peng, Y.; Dai, L.; Dai, A.; Wu, Q.; Zou, R.; Liu, Y.; Ruan, R.; Wang, Y. Catalytic process toward green recycling of polyvinyl chloride: A study on thermodynamic, kinetic and pyrolysis characteristics. J. Anal. Appl. Pyrolysis 2022, 168, 105719. [Google Scholar] [CrossRef]

- Sadat-Shojai, M.; Bakhshandeh, G.-R. Recycling of PVC wastes. Polym. Degrad. Stab. 2010, 96, 404–415. [Google Scholar] [CrossRef]

- Lewandowski, K.; Skórczewska, K. A brief review of Poly (Vinyl chloride) (PVC) recycling. Polymers 2022, 14, 3035. [Google Scholar] [CrossRef]

- Fagnani, D.E.; Tami, J.L.; Copley, G.; Clemons, M.N.; Getzler, Y.D.Y.L.; McNeil, A.J. 100th Anniversary of Macromolecular Science Viewpoint: Redefining Sustainable Polymers. ACS Macro Lett. 2020, 10, 41–53. [Google Scholar] [CrossRef]

- Shih, H.-S. Policy analysis on recycling fund management for E-waste in Taiwan under uncertainty. J. Clean. Prod. 2016, 143, 345–355. [Google Scholar] [CrossRef]

- Miliute-Plepiene, J.; Fråne, A.; Almasi, A.M. Overview of polyvinyl chloride (PVC) waste management practices in the Nordic countries. Clean. Eng. Technol. 2021, 4, 100246. [Google Scholar] [CrossRef]

- Department for Environment, Food and Rural Affairs. Environmental Improvement Plan: Annual Progress Report 2023 to 2024. gov.uk. Available online: https://www.gov.uk/government/publications/environmental-improvement-plan-annual-progress-report-2023-to-2024/environmental-improvement-plan-annual-progress-report-2023-to-2024 (accessed on 2 April 2025).

- Atasu, A.; Subramanian, R. Extended producer responsibility for E-Waste: Individual or collective producer responsibility? Prod. Oper. Manag. 2012, 21, 1042–1059. [Google Scholar] [CrossRef]

- Ait-Touchente, Z.; Khellaf, M.; Raffin, G.; Lebaz, N.; Elaissari, A. Recent advances in polyvinyl chloride (PVC) recycling. Polym. Adv. Technol. 2023, 35, e6228. [Google Scholar] [CrossRef]

- Elgarahy, A.M.; Priya, A.K.; Mostafa, H.Y.; Zaki, E.G.; Elsaeed, S.M.; Muruganandam, M.; Elwakeel, K.Z. Toward a circular economy: Investigating the effectiveness of different plastic waste management strategies: A comprehensive review. J. Environ. Chem. Eng. 2023, 11, 110993. [Google Scholar] [CrossRef]

- Wang, J.; Wang, F.; Duan, H.; Li, Y.; Xu, J.; Huang, Y.; Liu, B.; Zhang, T. Polyvinyl Chloride-Derived carbon spheres for CO2 adsorption. ChemSusChem 2020, 13, 6426–6432. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Mulder, K.; Knot, M. PVC plastic: A history of systems development and entrenchment. Technol. Soc. 2001, 23, 265–286. [Google Scholar] [CrossRef]

- VinylPlus. The European PVC Industry’s Commitment to Sustainable Development. 2018. Available online: https://www.pvc.at/wp-content/uploads/2020/09/VinylPlus-at-a-Glance-EN.pdf (accessed on 2 April 2025).

- VinylPlus. VinylPlus Progress Report 2020—VinylPlus; VinylPlus: Brussels, Belgium, 2020; Available online: https://www.vinylplus.eu/resources/vinylplus-progress-report-2020 (accessed on 2 April 2025).

- The Vinyl. PVC-Compounds for a Sustainable Future. 2023. Available online: https://cefic.org/responsible-care/2023-european-responsible-care-awards/pvc-compounds-for-a-sustainable-future (accessed on 1 April 2025).

- Chen, Y.; Zhang, S.; Han, X.; Zhang, X.; Yi, M.; Yang, S.; Yu, D.; Liu, W. Catalytic dechlorination and charring reaction of polyvinyl chloride by CUAL layered double hydroxide. Energy Fuels 2018, 32, 2407–2413. [Google Scholar] [CrossRef]

- Jha, R.K.; Neyhouse, B.J.; Young, M.S.; Fagnani, D.E.; McNeil, A.J. Revisiting poly (vinyl chloride) reactivity in the context of chemical recycling. Chem. Sci. 2024, 15, 5802–5813. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, Z. C, H, CL, and in element cycle in wastes: Vacuum pyrolysis of PVC plastic to recover indium in LCD panels and prepare carbon coating. ACS Sustain. Chem. Eng. 2017, 5, 8918–8929. [Google Scholar] [CrossRef]

- Lu, L.; Li, W.; Cheng, Y.; Liu, M. Chemical recycling technologies for PVC waste and PVC-containing plastic waste: A review. Waste Manag. 2023, 166, 245–258. [Google Scholar] [CrossRef]

- Wiesinger, H.; Bleuler, C.; Christen, V.; Favreau, P.; Hellweg, S.; Langer, M.; Pasquettaz, R.; Schönborn, A.; Wang, Z. Legacy and emerging plasticizers and stabilizers in PVC floorings and implications for recycling. Environ. Sci. Technol. 2024, 58, 1894–1907. [Google Scholar] [CrossRef] [PubMed]

- Sherwood, J. Closed-Loop recycling of polymers using solvents. Johns. Matthey Technol. Rev. 2019, 64, 4–15. [Google Scholar] [CrossRef]

- Boaretti, C.; Donadini, R.; Roso, M.; Lorenzetti, A.; Modesti, M. Transesterification of BiS (2-Ethylhexyl) phthalate for the recycling of flexible polyvinyl chloride scraps in the circular economy framework. Ind. Eng. Chem. Res. 2021, 60, 17750–17760. [Google Scholar] [CrossRef]

- Normand, A.T.; Wu, Y.; Régnier, T.; Fleurat-Lessard, P.; Rousselin, Y.; Théron, B.; Gendre, P.L.; Carta, M. Poly (vinyl chloride) Dechlorination Catalyzed by Zirconium. Chem. A Eur. J. 2024, 30, e202304005. [Google Scholar] [CrossRef] [PubMed]

- Luciani, V.; Serranti, S.; Bonifazi, G.; Di Maio, F.; Rem, P. Quality control in the recycling stream of PVC from window frames by hyperspectral imaging. In Proceedings of the SPIE Optics + Optoelectronics 2013, Prague, Czech Republic, 15–18 April 2013; Volume 8774, p. 87741N. [Google Scholar] [CrossRef]

- Phengsaart, T.; Julapong, P.; Manositchaikul, C.; Srichonphaisarn, P.; Rawangphai, M.; Juntarasakul, O.; Aikawa, K.; Jeon, S.; Park, I.; Tabelin, C.B.; et al. Recent Studies and Technologies in the Separation of Polyvinyl chloride for Resources Recycling: A Systematic review. Sustainability 2023, 15, 13842. [Google Scholar] [CrossRef]

- Jaidev, K.; Suresh, S.S.; Gohatre, O.K.; Biswal, M.; Mohanty, S.; Nayak, S.K. Development of recycled blends based on cables and wires with plastic cabinets: An effective solution for value addition of hazardous waste plastics. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 38, 312–321. [Google Scholar] [CrossRef]

- Kye, H.; Han, S.; Han, J.; Hong, S.; Lee, D.; Bae, J.W. Eco-friendly technologies for physical and chemical recycling of PVC-Related wasteful resources. Eng. J. 2016, 20, 19–27. [Google Scholar] [CrossRef]

- Chang, H.; Abu-Zahra, N. One step forward to a sustainable green solution for extruded foam PVC building products. J. Vinyl Addit. Technol. 2011, 17, 17–20. [Google Scholar] [CrossRef]

- Carroll, W.F. Vinyl recycling: An update. J. Vinyl Technol. 1991, 13, 96–100. [Google Scholar] [CrossRef]

- Steenblik, R. Shift the Subsidies Database Reveals $40 Billion in Fossil Fuel Funding over Last Four Years—Oil Change International; Oil Change International: Washington, DC, USA, 2011; Available online: http://priceofoil.org/shift-the-subsidies (accessed on 2 April 2025).

- Amthiou, H.; Arioua, M.; Benbarrad, T. Digital Twins in Industry 4.0: A Literature review. ITM Web Conf. 2023, 52, 01002. [Google Scholar] [CrossRef]

- Brignon, J.-M. Costs and benefits of recycling PVC contaminated with the legacy hazardous plasticizer DEHP. Waste Manag. Res. J. A Sustain. Circ. Econ. 2021, 39, 1185–1192. [Google Scholar] [CrossRef] [PubMed]

- Grigorescu, R.M.; Ghioca, P.; Iancu, L.; David, M.E.; Ion, R.; Nicolae, C.; Gabor, R.A.; Radu, E.R.; Ganciarov, M.; Spurcaciu, B.; et al. Influence of non-metallic fraction of printed circuit boards waste on recycled polyvinyl chloride from waste wires. J. Appl. Polym. Sci. 2021, 139, 51469. [Google Scholar] [CrossRef]

- Horodytska, O.; Cabanes, A.; Fullana, A. Non-intentionally added substances (NIAS) in recycled plastics. Chemosphere 2020, 251, 126373. [Google Scholar] [CrossRef] [PubMed]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A review. Macromol. Rapid Commun. 2020, 42, e2000415. [Google Scholar] [CrossRef]

- Khangale, U.; Benedictus; Ozor, P.A.; Mbohwa, C. A Review of Recent Trends and Status of Plastics Recycling in Industries. Available online: https://www.tci-thaijo.org/index.php/easr/index (accessed on 17 April 2025).

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2017, 147, 245–266. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Tamimi, Z.A.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Picchioni, F. Supercritical carbon dioxide and polymers: An interplay of science and technology. Polym. Int. 2014, 63, 1394–1399. [Google Scholar] [CrossRef]

- Arshad, H.; Sulaiman, S.A.; Hussain, Z.; Naz, Y.; Basrawi, F. Microwave assisted pyrolysis of plastic waste for production of fuels: A review. MATEC Web Conf. 2017, 131, 02005. [Google Scholar] [CrossRef]

- Versteeg, F.A.; Bollen, D.A.W.M.; Picchioni, F. Recycling PVC with scCO2: From Soft to Rigid PVC. ACS Sustain. Chem. Eng. 2024, 12, 15398–15408. [Google Scholar] [CrossRef]

- Truc, N.T.T.; Lee, B.-K. Sustainable and Selective Separation of PVC and ABS from a WEEE Plastic Mixture Using Microwave and/or Mild-Heat Treatment with Froth Flotation. Environ. Sci. Technol. 2016, 50, 10580–10587. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, W.; Zhang, X.; Qiao, J. Chemical recycling of plastics by Microwave-Assisted High-Temperature pyrolysis. Glob. Chall. 2020, 4, 1900074. [Google Scholar] [CrossRef] [PubMed]

- Bharadwaj, C.; Purbey, R.; Bora, D.; Chetia, P.; Duarah, R.; Dutta, K.; Sadiku, E.R.; Varaprasad, K.; Jayaramudu, J. A review on sustainable PET recycling: Strategies and trends. Mater. Today Sustain. 2024, 27, 100936. [Google Scholar] [CrossRef]

- Zhang, W.; Killian, L.; Thevenon, A. Electrochemical recycling of polymeric materials. Chem. Sci. 2024, 15, 8606–8624. [Google Scholar] [CrossRef] [PubMed]

- Aji, I.; Sapuan, S.; Zainudin, E.; Abdan, K. Kenaf Fibres as Reinforcement for Polymeric Composites: A review. Int. J. Mech. Mater. Eng. 2009, 4, 239–248. [Google Scholar]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Wilczewski, S.; Skórczewska, K.; Tomaszewska, J.; Osial, M.; Dąbrowska, A.; Nikiforow, K.; Jenczyk, P.; Grzywacz, H. Graphene modification by curcuminoids as an effective method to improve the dispersion and stability of PVC/Graphene nanocomposites. Molecules 2023, 28, 3383. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.-S. Catalytic pyrolysis of plastic waste: Moving toward pyrolysis based biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef]

- Masoumi, H.; Safavi, S.M.; Khani, Z. Identification and classification of plastic resins using near infrared reflectance spectroscopy. Int. J. Mech. Mechatron. Eng. 2012, 6, 5. Available online: https://publications.waset.org/11237/identification-and-classification-of-plastic-resins-using-near-infrared-reflectance-spectroscopy (accessed on 17 April 2025).

- Feng, Q.; Wang, K.; Yang, S.; Guo, J.; Chen, J.; Wang, T.; Liu, L.; Chen, Y. Non-Thermal plasma technology for further purification of flue gas in the resource utilization process of waste Mercury Catalyst: A case study in Xinjiang, China. Processes 2024, 12, 691. [Google Scholar] [CrossRef]

- Motunrayo, A.; Adegoke, J. Innovations in Recycling Technologies for the Circular Economy. Researchgate 2023. [Google Scholar]

- Integrated Waste Management. Google Books. Available online: https://books.google.com.gh/books?id=qwwCEQAAQBAJ (accessed on 17 April 2025).

- Lopez, G.; Artetxe, M.; Amutio, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Recent advances in the gasification of waste plastics. A critical overview. Renew. Sustain. Energy Rev. 2017, 82, 576–596. [Google Scholar] [CrossRef]

- Cong, R.; Fujiyama, A.; Matsumoto, T. Optimal plastic recycling system and technology development could accelerate decarbonization: A case study from Japan. Waste Manag. 2024, 175, 110–120. [Google Scholar] [CrossRef] [PubMed]

- Pourali, M. Application of Plasma Gasification Technology in Waste to Energy—Challenges and Opportunities. IEEE Trans. Sustain. Energy 2010, 1, 125–130. [Google Scholar] [CrossRef]

- Onn, M.; Suhana, H.; Razali, A.; Jasni, Z.J.; Zairul, A.A.Z. Types of Automated Recycling Machines for plastic Waste Management in Promoting Sustainability: A Short review. Chem. Eng. Trans. 2024, 113, 55–60. [Google Scholar]

- Cheon, J.; Son, J.; Ahn, Y. Economic and environmental factor-integrated optimal model for plastic-waste sorting. J. Ind. Eng. Chem. 2024, 139, 162–174. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Suman, R. Digital Twin applications toward Industry 4.0: A Review. Cogn. Robot. 2023, 3, 71–92. [Google Scholar] [CrossRef]

- Imaekhai, L. Design and fabrication of a plastic film granulating machine. J. Adv. Sci. Eng. 2018, 1, 47–54. [Google Scholar] [CrossRef]

- Buckshumiyan, A.; Babu, S.S.; Prakash, M.; Arasu, G.A. Recycling of plastic wastage by die shredder machine. Mater. Today Proc. 2023; in press. ISSN 2214-7853. [Google Scholar] [CrossRef]

- Zubair, Z.; Iqbal, M.U.; Shah, T. Polymeric Materials. In Engineering Materials; Springer Nature Switzerland: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- May, G.; Kiritsis, D. Zero defect manufacturing strategies and platform for smart factories of industry 4.0. In Proceedings of the International Conference on the Industry 4.0 Model for Advanced Manufacturing, Belgrade, Serbia, 3–6 June 2019; Lecture Notes in Mechanical Engineering. Springer: Berlin/Heidelberg, Germany, 2019; pp. 142–152. [Google Scholar] [CrossRef]

- Pires, F.; Cachada, A.; Barbosa, J.; Moreira, A.P.; Leitao, P. Digital Twin in Industry 4.0: Technologies, applications and challenges. In Proceedings of the 2022 IEEE 20th International Conference on Industrial Informatics (INDIN), Perth, Australia, 25–28 July 2022. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2015, 114, 11–32. [Google Scholar] [CrossRef]

- Akshata, P. Critical Assessment of Circular Economy Regarding Waste Reduction and Optimal Use of Resources. 2022. Available online: https://www.researchgate.net/publication/351283756 (accessed on 17 April 2025).

- King, S.; Locock, K.E.S. A circular economy framework for plastics: A semi-systematic review. J. Clean. Prod. 2022, 364, 132503. [Google Scholar] [CrossRef]

- Circular Economy Project. Ontology for Circular Economy Project. Developed Using Protégé (Version [Protégé-5.6.3]). Available online: https://zenodo.org/uploads/15292909#basic-information-section (accessed on 3 April 2025).

- Burelo, M.; Hernández-Varela, J.D.; Medina, D.I.; Treviño-Quintanilla, C.D. Recent developments in bio-based polyethylene: Degradation studies, waste management and recycling. Heliyon 2023, 9, e21374. [Google Scholar] [CrossRef] [PubMed]

- Burelo, M.; Martínez, A.; Hernández-Varela, J.D.; Stringer, T.; Ramírez-Melgarejo, M.; Yau, A.Y.; Luna-Bárcenas, G.; Treviño-Quintanilla, C.D. Recent developments in synthesis, properties, applications and recycling of Bio-Based elastomers. Molecules 2024, 29, 387. [Google Scholar] [CrossRef] [PubMed]

- Bonciu, F. Is Circular Economy Compatible with Capitalism? Is Circular Economy Compatible with Capitalism? 2020. Available online: https://www.researchgate.net/publication/342765144_IS_CIRCULAR_ECONOMY_COMPATIBLE_WITH_CAPITALISM (accessed on 17 April 2025).

- Bac, U. The role of environmental factors in the investment prioritization of facilities using recycled PVC. Pol. J. Environ. Stud. 2021, 30, 2981–2993. [Google Scholar] [CrossRef]

- Skelly, P.W.; Chang, C.F.; Braslau, R. Degradation of polyvinyl chloride by sequential dehydrochlorination and olefin metathesis. ChemPlusChem 2023, 88, e202300184. [Google Scholar] [CrossRef]

- Sheldon, R.A. Green carbon and the chemical industry of the future. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2024, 382, 20230259. [Google Scholar] [CrossRef]

- Ramle, M.S.; Romli, A.Z.; Abidin, M.H. Tensile properties of aminosilane treated rice husk/recycled PVC composite. Adv. Mater. Res. 2013, 812, 151–156. [Google Scholar] [CrossRef]

- Kassab, A.; Nabhani, D.A.; Mohanty, P.; Pannier, C.; Ayoub, G.Y. Advancing Plastic Recycling: Challenges and opportunities in the integration of 3D printing and distributed recycling for a circular economy. Polymers 2023, 15, 3881. [Google Scholar] [CrossRef]

- Windels, S.; Diefenhardt, T.; Jain, N.N.J.; Marquez, C.C.M.; Bals, S.S.B.; Schlummer, M.; De Vos, D.E. Catalytic upcycling of PVC waste-derived phthalate esters into safe, hydrogenated plasticizers. Green Chem. 2021, 24, 754–766. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

| Year | Milestone |

|---|---|

| 1872 | PVC first discovered [27] |

| 1920 | Commercial production and growing industrial applications [6] |

| 1980 | Introduction of mechanical recycling [19] |

| 2000 | Advancements in chemical recycling [23] |

| 2011 | VinyIPlus initiative launched [28] |

| 2021 | The official launching of VinylPlus 2030, reaffirming dedication to strive for a sustainable and circular future [28,29] |

| 2023 | ‘The Vinyl Company’ teamed up with the ‘Responsible Care’ initiative as partners of “A Sustainable Tomorrow”, which focuses on efficient PVC material development to reduce its carbon footprint [30]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chidara, A.; Cheng, K.; Gallear, D. Engineering Innovations for Polyvinyl Chloride (PVC) Recycling: A Systematic Review of Advances, Challenges, and Future Directions in Circular Economy Integration. Machines 2025, 13, 362. https://doi.org/10.3390/machines13050362

Chidara A, Cheng K, Gallear D. Engineering Innovations for Polyvinyl Chloride (PVC) Recycling: A Systematic Review of Advances, Challenges, and Future Directions in Circular Economy Integration. Machines. 2025; 13(5):362. https://doi.org/10.3390/machines13050362

Chicago/Turabian StyleChidara, Alexander, Kai Cheng, and David Gallear. 2025. "Engineering Innovations for Polyvinyl Chloride (PVC) Recycling: A Systematic Review of Advances, Challenges, and Future Directions in Circular Economy Integration" Machines 13, no. 5: 362. https://doi.org/10.3390/machines13050362

APA StyleChidara, A., Cheng, K., & Gallear, D. (2025). Engineering Innovations for Polyvinyl Chloride (PVC) Recycling: A Systematic Review of Advances, Challenges, and Future Directions in Circular Economy Integration. Machines, 13(5), 362. https://doi.org/10.3390/machines13050362