Abstract

Heating and cooling are the main concerns across a wide range of sectors, including residential buildings, industrial facilities, transportation and commercial enterprises. This being the case, a continuous rise in the cost of energy demands more effective ways to conserve energy. Heat pump (HP) systems provide the one of the best possible solutions to this problem as they offer an economical and energy-efficient system. In this review, HP systems are overviewed as energy-efficient and cost-effective solutions, focusing on their characteristic properties but also on enhancements, novel techniques and the use of heat exchangers (HXs), and microchannel heat exchangers (MCHEs) in these systems, as well as their development in recent years and their limitations. The main factors contributing to variations in the performance of HP systems are temperature and humidity in the ambient atmosphere. The present study is expected to support numerical and experimental performance analysis, and design miniaturisation via MCHEs. Unique designs or manufacturing techniques in MCHEs; various configurations in HP systems, depending on their load and environmental conditions; various nanofluids; and a comparison of nanofluids with different base metals are presented and discussed. Comparisons between various MCHEs and their respective limitations provide evidence-based guidelines for technology selection and designs for optimised operation at given environmental and load conditions.

1. Introduction

Localised heating is one of the top consumers of current energy production. Moreover, this energy is primarily produced with fossil fuels, making energy conservation a top priority due to increasing environmental concerns. Heat pump (HP) systems provide, in theory, the most efficient heating possible, and they have been the subject of research and development for more than three decades now [1]. Nevertheless, they are not employed in most of the possible situations, such as in district heating and cooling, heat pumps in agriculture, marine and offshore applications and many more. Some of the main reasons for this are the costs of the initial design, manufacturing and integration, installation and location of use. Due to these conditions, HPs have only been used by a few leading industrial applications, such in for heating, ventilation and air conditioning (HVAC) systems for large-scale applications, where significant energy conservation potential exists. It is a similar situation with microchannel heat exchangers (MCHEs); even after decades-long research, MCHEs have not been preferred for bulk manufacturing due to similar limitations. Previous studies on MCHEs being utilised in HP systems revealed several limitations, initiating a phase where all the research was focused on the development of MCHEs instead of working both on MCHEs and HP systems. This review helps to understand the advancements in both MCHEs and HP systems in their respective research fields. Furthermore, this study provides an idea of various MCHE designs and manufacturing techniques and their respective benefits and limitations, making it easier to choose an HP design for given loads and conditions.

In the early twenty first century, the focus on HP systems decreased due to research stagnation, and there were no major incentives to continue this research. However, due to increasing fuel costs, targets for a reduction in greenhouse gas emissions and other environmental reasons, energy conservation has become one of the most crucial issues at hand, making the focus on HP development greater than ever so that they can offer an efficient way to conserve energy in heating and cooling applications [1]. Numerous studies have shown that to reach the target of net-zero carbon emissions in the future, HPs are the best alternative out of all the systems used for heating and cooling or waste heat recovery. To achieve such a performance, HPs need to approach their maximum possible efficiency during their operation. A recent study by J. Famiglietti et al. [2] on the environmental performance of heat pumps highlights their growing relevance across various applications—from industrial high-temperature processes to district heating and residential systems. These studies show that heat pumps can significantly reduce greenhouse gas emissions, particularly during the use phase, which accounts for the majority of their life-cycle impact. The shift towards low-global-warming-potential refrigerants and the increasing efficiency of heat pump technologies further enhance their role in sustainable energy systems. This underscores the importance of accurate modelling and evaluation of heat pump performance under diverse operational conditions [2]. The widespread adoption of high-temperature heat pumps in industry can significantly reduce emissions and improve energy efficiency, but overcoming techno-economic barriers requires coordinated efforts from governments, utilities, manufacturers, and industry professionals through supportive policies, R&D, workforce training, financial incentives, and collaborative platforms [3].

Numerous factors can help in achieving the maximum possible efficiency, such as the development and integration of HPs into the whole system, which would make its working smoother and more refined. Research into each of the different components, such as the compressor, pump, heat exchanger (HX), of HP systems has increased their productivity or has indicated an alternative component with a higher efficiency to increase the overall functioning of the system. This study reviews the latest research on HP systems, their applications and components. Primarily, applications that break away from their conventional use, using different HXs as their components, are reviewed. One main point to be communicated with these HP system studies is that the proper design of MCHEs and their efficiency can be further advanced, but additional research is needed to achieve that and to get closer to the goal of attaining net-zero carbon emissions.

This review paper presents the characteristics of heat pump (HP) systems and their applications over recent years, a summary of HP performance with various heat exchangers (HXs) and working fluids and an introduction to heat exchangers and their types. Additionally, recent developments in microchannel heat exchangers are discussed, along with their respective limitations. Finally, a summary of the conclusions drawn from these topics, along with the identification of potential research gaps, are presented.

2. Fundamentals of and Advances in Heat Pump Systems

2.1. A Brief Introduction to Characteristics of HP Systems

HP systems are used in applications where heat is transferred from one location to another desired location. In other words, they are utilised for controlling the temperature in a designated area. The main components of an HP system are (i) a compressor, which controls the pressure, which, in turn, controls the working fluid in the system that carries heat; (ii) a condenser and an evaporator, also known as indoor and outdoor HXs, where the heat is transferred from or to working fluid; and (iii) an expansion valve, which is used to reduce the pressure of the working fluid. Additional components are added where necessary, such as a four-way valve used to control the direction of flow of working fluid, bypass valves or performance enhancers such as a high-pressure side chiller [4]. M. Yulianto et al. [5] examined the performance of a heat pump water heater (HPWH) that utilises low-global-warming refrigerants in different climate conditions, using a numerical simulator created and validated through experiments with a commercial R32 HPWH. The findings, with deviations of less than 3% between the experimental and simulated results, indicated that the system performed most efficiently in tropical climates, achieving the highest COP of about 5.4 and minimising CO2 emissions based on life-cycle climate performance (LCCP) evaluations. The performance of the HP system depends on numerous factors. These include the temperature and humidity of the environment in which the HP is working, the type and properties of the working fluid used and how the working fluid operates around the system, among many other novel methods.

2.1.1. Exergy Reduction

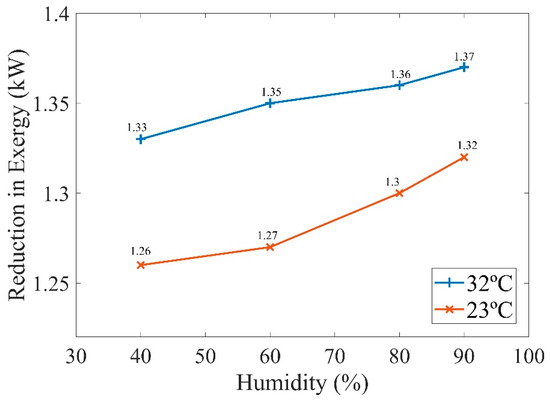

The temperature and humidity in an environment where the HP is being operated primarily affect its exergy levels. Figure 1 shows the relation between the total exergy reduction in “kW” with % humidity at different temperatures (in “°C”). E. Sahin et al. [6] experimentally investigated the effects of temperature and humidity on a heat pump system by analysing the energy and exergy performance for each component, identifying and evaluating the reduction in exergy throughout the system to improve its efficiency. In the experiment by E. Sahin et al. [6], the total reduction in exergy was synthesised for the whole system, which is summarised in Figure 1 for the reference temperatures of 23 and 32 °C, and it was observed that as the temperature and humidity increase, the total exergy level, which is the maximum amount of work performed close to the equilibrium state of the HP system, is reduced.

Figure 1.

Relation between the exergy level and humidity at different temperatures.

X. Tang et al. [7] also showed that the reduction in exergy is highest in a compressor, followed by the expansion valve, condenser and evaporator, with values of 55%, 28%, 12% and 5% respectively at −5 °C ambient temperature, a COP of approximately 3 and a heating capacity of 3.6 kW. Furthermore, it was also shown that the flow rate and the expansion valve play an essential role in exergy efficiency [7].

2.1.2. Refrigerants

Refrigerants commonly used in earlier HP systems were R132a or R410a, which have a GWP of around 1300 and 1900, respectively. Recently, due to the awareness of global warming, different refrigerants with low GWP [8] have been considered for research as an alternative to R410B; for example, R. Yildirim et al. [9] showed that R452B and R454B, which have a very low GWP, offer similar performance coefficients with a 1% higher heating capacity compared with R410A, suggesting them to be superior refrigerants compared with R410A. R744 can increase the heating capacity of the system by 80%. However, the COPs are reduced to around 2 [10]. Mixtures of more than two refrigerants with different quantities, producing new refrigerants with different properties, yield various results depending on the composition [11]. R1234yf has also been proposed as an alternative to R134a due to its low GWP of 4. Presently, with the current HP system designs, this refrigerant has an inferior performance at low ambient temperatures; however, with an improved design, it has the potential to be the best alternative in the future [12]. Table 1 shows the thermodynamic properties of a few refrigerants, based on the work by F. Afshari [13].

Table 1.

Thermodynamic properties of a few refrigerants.

2.1.3. Energy Consumption

Many new techniques are being used to reduce the energy consumed by the HP system, such as optimising allocation maps of the control input [14] or adding a dehumidifier into the system. By adding a desiccant-coated dehumidifier into the HP system, it was observed that energy consumption by the compressor was reduced by 7% on an average 20 °C inlet water temperature. It was also observed by S.I. Na et al. [15] that energy consumption was reduced by almost 20% when the temperature was raised to 30 °C [15]. In an HVAC, when an HX was replaced with a regenerative HX, it reduced the energy consumption by over 30% compared with a system in heating mode without any replacement. If the resistor is replaced, its energy consumption is reduced by around 20%, depending on geographical location, where the temperatures are especially high [16].

2.1.4. Novel Heat Pump Systems

CO2 vapour-injection HP systems, ground-source HP systems and many more have been proposed and researched for improving performance. For example, the CO2 vapour injection HP system has a 38% higher COP than an available general single-stage HP system, as shown by X. Peng et al. [17]. A hybrid subway-source HP system shows a 2% higher COP and 5% lower energy consumption [18]. By maintaining this, the overall efficiency of various HP systems specific to different operations can be maximised, advancing closer to environmental requirements. The CO2–propane autocascade is another hybrid novel HP system, with a CO2 mass fraction of 0.8 at −20 °C, a COP of 2.7 and a 12% higher heating capacity compared with the CO2 HP system [19]. Although the merits of this might appear slim, the heating capacity and COPs in vapour-injection HPs also depend on several factors such as the number of vapour inlet ports, vapour-injection port positions and intermediate pressure ratios. With optimisation of these positions, this system can show greater improvements [20,21]. The best alternative for the CO2 HP system is the propane (R290) HP system, which provides the most desired results even at high ambient temperatures. In contrast, the CO2 HP system has an extremely low COP at high ambient temperature conditions [22]. The air-cycle HP system is another novel system that is still in the developmental phase. The main factor in determining an air-cycle HP system is the position of the blower/turbocharger. The consensus of the available research data suggests that placing the turbocharger before the compressor yields better results as the heating capacity was increased by over 10% [23,24], but more data are required before such a conclusion can be accepted [25]. X. Li et al. [26] investigated CO2-based energy systems for cooling, heating and power generation, emphasising the ongoing challenges in enhancing system efficiency, reducing costs and advancing critical components such as high-temperature CO2 compressors and expanders. The paper presents a comprehensive analysis through thermodynamic evaluations, experimental investigations, and thermo-economic assessments of both standalone and cogeneration systems, offering valuable insights into the potential of CO2-based technologies and encouraging further research and development to address the existing limitations in these fields. H. Namdar et al. [27] emphasises that the integration of photovoltaic—thermal technologies with HP systems represents a promising and efficient solution for sustainable heating and hot water production, with significant potential to reduce energy consumption and carbon emissions, especially in colder climates; continued advancements in design optimisation, control strategies, and hybrid configurations will be key to their widespread adoption and real-world effectiveness.

2.2. Applications of Heat Pump Systems

Previously, HP systems were only used for HVAC purposes, but with their potential realised, they are being considered for many conditions that require a controlled atmosphere in a designated area. For instance, HPs were previously used for the cabin temperature control of a motor vehicle. However, now, it is even being used as an engine temperature control system, and with more electric vehicles being considered, the HP system has been integrated with engine temperature control and cabin temperature control as the TMS for hybrid vehicles and EVs [28]. The following section presents various applications of heat pumps across a broad range of contexts, wherein the operating conditions and working fluids may vary depending on the location and use case.

2.2.1. Residential Heat Pumps

Heat pump systems are commonly used for residential purposes such as in an HVAC system, and it has been in use for more than two decades.

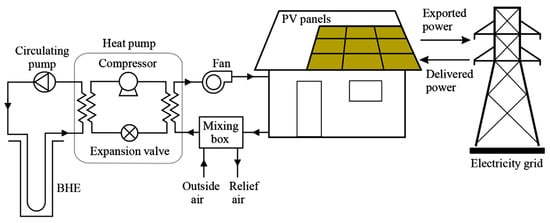

With the increased awareness for reducing energy production from fossil fuels, renewable sources for energy generation have been heavily researched. Figure 2 [29] shows a schematic diagram of a solar-powered borehole-type GSHP system that takes into account recent developments. This type of HP system provides various advantages, ranging from lower power consumption to reduced CO2 emissions. By adding energy back to the grid instead of siphoning it, power consumption can be reduced by an enormous amount [29]. The usage of materials such as metal hydrates yields significant benefits, but high material costs currently makes their use less than effective. However, as efforts are being made to reduce these costs in the future, they are highly anticipated materials [30]. One of the main goals that is always aimed for is the reduction in energy consumption irrespective of technological advancements. Heat pumps are primarily controlled with the thermostat set at a preferred temperature. However, large amounts of heat are wasted with this method, so novel methods of optimal control strategies have also been investigated, some of which have shown promising results in reducing the operational energy costs; for example, a 10% reduction was achieved using an air-sourced HP system for room temperature control [31], and for water temperature control, a reduction of 25% over an 8-week period was achieved by A. Heidari et al. [32]. Currently, air conditioning and heating are performed by different systems in residential applications, but if a single system performs both operations, there will be many benefits from this space saving. A horizontal GSHP system experiment used for both heating and cooling residential spaces was introduced in Italy by S. Bordignon et al. [33] that achieved a maximum water temperature of 65 °C, and the room temperature was maintained at a range of 18–23 °C. An integrated design of a heat pump with a different working fluid was also proposed. Use of the primarily CO2-based R290, when compared to the commonly used R410, reduced costs by 36% and emissions by 52%, but these benefits were slightly negated because of the reduced COP (by 26%) [34]. Further novel concepts, such as exhaust air recovery for HP systems, are also being considered for improving performance [35,36]. Underfloor heating system, a recent development in residential heating, has become common practice now [37]. Hybrid HP systems are also being considered to achieve more sustainable heating for old residencies to overcome the problem of poor insulation or high energy losses due to outdated practices [38].

Figure 2.

A solar-powered ground-source heat pump (GSHP) system [29].

2.2.2. Thermal Management System for an Electric Vehicle

Electric vehicles are the most viable alternative means of transport, with low operational costs and high energy efficiency at the current technological stance. However, the battery pack, the energy source of an EV, reaches high temperatures during discharge/recharge, making the TMS an important system in EVs, because the temperature around the electronics determines the life expectancy. An ideal TMS should have the ability to maintain local temperatures for all the electronics within a permitted range to obtain the maximum work out of them. This has led to further research on advanced cooling methods [39,40]. Using an HP system, it was observed that energy consumption was reduced by 40% for heating/cooling which led to an increase in the driving range for the EV of 20% by B. Yu et al. [41].

With the establishment of the HP system as an integrated TMS, the next step will be to increase the efficiency of individual components, such as HXs, to increase the overall efficiency. Research shows that heat-pipe HXs can increase the cooling capacity by 20% with no additional energy consumption, and the coefficient of heating performance was found to be around 1.3 when the ambient temperature is −20 °C and the cabin temperature is 20 °C [42]. By integrating a single evaporator into a dual parallel evaporator, the maximum mass flow can be reduced by 20% with just a small loss of around 1% in the cooling capacity, which means that a huge amount of heat transfer is possible with no increased energy consumption.

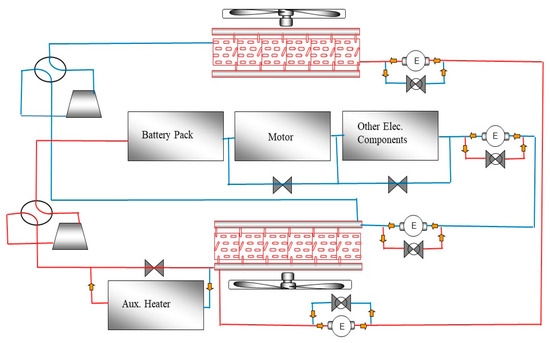

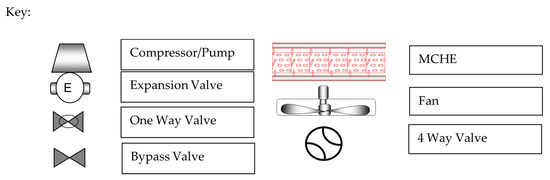

The integrated TMS design shown in Figure 3 is based on an EV design presented by Atsushi Yokoyama et al. [43], which consists of two cycles, one for cabin temperature control and one for local temperature control of on-board electronic components. Both cycles are connected to a single external crossflow MCHE. The cabin temperature control cycle has a compressor/pump, a 4-way valve, an internal MCHE, an expansion valve, a one-way valve and an internal fan as its components [44].

Figure 3.

Integrated design of a TMS for EVs.

Electronic components for the local temperature control cycle include a compressor/pump, a four-way valve, an auxiliary heater, an expansion valve, a one-way valve, a bypass valve (the number of valves depends on the number of individual circuits for the electronic components) and an external fan [45]. The two main working modes, standard in both the cycles in their design, are heating and cooling, the same as in any heat pump system.

Heating mode: In the heating mode, the interior of the system is heated as the heat is carried into the system by the working fluid. Assuming the cycle starts at the external heat exchanger, the working fluid from the external HX goes through the compressor/pump, which absorbs heat from the outside. This heated fluid is then directed towards the interior of the system by the four-way valve, where the heat of the fluid is released. Then, cold fluid is directed into the external HX, where it absorbs the heat again, and this cycle continues, resulting in the heating of the internal system [46].

Cooling mode: In the cooling mode, the interior system is cooled as the heat from the internal system is carried towards the outside by the working fluid. Assuming the cycle starts from the compressor/pump, the working fluid from the compressor is directed towards the external HX through the four-way valve, where the heat from the fluid is released. The cold fluid is directed towards the interior of the system, where it absorbs the heat. Then, hot fluid from the interior of the system enters the compressor/pump to be directed to the external HX by the four-way valve again, and the cycle continues, resulting in the cooling of the internal system [47].

The expansion valve and the one-way valve are used according to the working mode. If the working fluid goes through the expansion valve, the pressure of the fluid is decreased, and it is used before the fluid enters the HX so that it evaporates, causing it to absorb heat. When that is not needed, fluid bypasses the expansion valve through the one-way valve. The working of the proposed design can be classified further into four different working modes as follows:

- (a)

- Cabin cooling and component heating: In this mode, the cabin cycle is in the cooling mode, where heat from the cabin is conducted to the external crossflow MCHE, and the component cycle is in the heating mode, where the heat from the external crossflow MCHE is carried to the components. When a component reaches the temperature range where the maximum working efficiency can be achieved, the corresponding component can be bypassed through the bypass valve present so that the components do not exceed the temperature range and overheat. When all the components reach their respective temperature ranges, the component cycle stops working [48].

- (b)

- Cabin heating and component heating: In this mode, the cabin cycle is in the heating mode, where heat from the external crossflow MCHE is carried to the cabin. Here, the component cycle is in the heating mode, where the heat from the external crossflow MCHE is carried to the components [49].

- (c)

- Cabin cooling and component cooling: In this mode, the cabin cycle is in the cooling mode. Therein, heat from the cabin is conducted to the external crossflow MCHE, and the component cycle is in the cooling mode, where heat from the components is conducted to the external crossflow MCHE. Similarly for heating, if the temperature of any component is about to fall below the required range, that component is bypassed through the bypass valve. Particularly, the external fan is compulsory when operating in this mode, as both the cycles reject heat. In other modes, the working of the external fan depends on the amount of heat being rejected by the system and if heat is required by any part of the system [50].

- (d)

- Cabin heating and component cooling: In this mode, the cabin cycle is in the heating mode, where heat from the external crossflow MCHE is carried into the cabin. The component cycle is in the cooling mode, where heat from the components is conducted to the external crossflow MCHE.

It can be observed in Figure 3 that there is an auxiliary heater present. This is activated when frosting of the external crossflow MCHE occurs and remains active until the defrosting of the HX is complete. Therefore, it can be said that when both cycles are in a cooling mode, the auxiliary heater is in the working condition, and when it is not needed, the bypass applies [51].

2.2.3. Defrosting and Dehumidification

Defrosting is another primary consideration, as this completely negates the benefits offered by the HP system. But defrosting takes additional energy, so higher rates of defrosting are desired for greater conservation of energy consumption. At present, it is observed that with certain processes, defrosting can be conducted in 100 s in −20 °C ambient temperature and a high humidity of 80% [52]. With extremely low ambient temperatures, the discharge temperature of the compressor increases rapidly, which, in turn, reduces the heating capacity by a high margin. But when certain modifications were applied to the HP system, it was observed that the heating capacity was not reduced when the ambient temperature reached −20 °C and compressor discharge temperature reached 60 °C. In fact, it increased by almost 20% [53]. For a CO2 HP system at −20 °C ambient temperature, the COP was observed to be around 3 with a heating capacity of 3.6 kW, but this started to reduce drastically to around 1.7 kW when the inlet air temperature was increased to 20 °C and the outlet temperature was increased to 40 °C at the same ambient temperature. When an additional secondary loop was added, the heating was reduced even more, to around 1.4 kW [54]. With such a performance, a secondary loop system may not be applicable in EVs, but if fast rates of defrosting are required for a different application, then a trade-off at the cost of COP can be made to achieve the desired defrosting results [55].

2.2.4. Battery Thermal Management System

Another main application of the HP system is in a battery TMS. Instead of managing the entire system, a battery pack has its own HP system, which makes it faster at cooling/heating and more efficient compared with other systems [56]. Nevertheless, this has its own separate set of limitations depending on the kind of system, e.g., whether it is as air-cooled or force air-cooled [57]. In recent years, research on different working fluids has increased significantly. One of these working fluids is nanofluids. The current state of nanofluids shows that water is the most dependable working fluid in terms of its thermal performance compared with other nanofluids. But with further development, nanofluids could provide better performance in the future [58,59]. Microchannel aluminium tubes or liquid cold plates (LCP) with microchannels placed along the battery modules provide reasonable advantages, such as a uniform temperature distribution and lower energy consumption compared with a commonly used plate-type HX [60,61]. Research data also point to phase-change materials and thermoelectric machines as next-generation alternatives for battery management systems [62].

2.2.5. Electric Motor Temperature Control

Due to their operating conditions and structures, the temperature of both commercial electric motors and electric motors used in vehicles are comparatively harder. But a significant amount of research is being conducted into this issue by experimenting with different shapes of HXs, such as L-shaped heat pipes [63], to recover heat efficiently. Replacing the stator of an electric motor with a 3D heat-pipe casing has also been suggested, which has the potential to reduce the peak temperature at peak rating conditions by over 20% [64,65]. Direct cooling of the motor winding has also been proposed via methods such as in-slot cooling channels, oil spray cooling, forced convection cooling of laminated windings, direct cooling with ferrofluids and water-jacket cooling [66,67], and the effective integration of many other novel cooling techniques will strengthen efforts to overcome the current challenges [68,69]. This is not just confined to windings but also extends to most components of electric machines, such as conductors, permanent magnets and casings [70]. By the generic optimisation of HP systems for electric machines, their respective performances can be maximised [71].

2.2.6. Hybrid Vehicles

In a comparable situation to fully electric vehicles, hybrid vehicles also benefit from the HP system when used as the TMS rather than a conventional TMS. X.W. Tao et al. [72] observed that when an HP system was used as the TMS for hybrid vehicles, power consumption for the compression of the working fluid was reduced by 50% and cooling was reduced by 75%, but a minor drawback for these improved conditions is that exergy was also reduced by 13%. Additionally, it was also observed that the COP was reduced by the increase in ambient temperature, which ranged around 2 [73].

2.2.7. Nuclear Reactors

One of the major concerns in nuclear reactors is that having a controlled temperature environment makes the heat pump system one of the primary systems. HP systems used in nuclear reactors work under heavy heat loads of around 150 MW [74], and for the system to function at the required conditions, remarkably high-performing HXs are required. With the development of MCHEs, these are being considered as alternatives, and experiments are being conducted regarding this aspect [75]. Furthermore, for the heat to be stored, an additional secondary heat pump is used to charge and discharge the thermal energy storage devices [76,77]. The molten-salt reactor is a nuclear fission reactor that is one of the superior reactors but requires an even higher performance from the HXs [78]. Reviewing available studies, it can be summarised that HP systems with a microchannel HX have higher performance. However, this depends on numerous factors, which are further studied in the following section.

2.3. Heat Exchangers

Heat exchangers are one of the main components in the HP system where heat transfer takes place, and they can be used as a condenser, evaporator, internal heat exchanger, or regenerative heat exchanger. HXs are designed for heat transfer between multiple fluids in various states of matter and at various temperatures. Depending on the type of HX, the heat transfer may vary between different states of fluids, such as gas to gas, liquid to gas or liquid to liquid. Apart from heat transfer between fluids, no other forms of interaction between the fluids are allowed [79]. Types of fluid used in the system vary depending on the type of HX and the desired operation. They include oil, water, specific refrigerants and nanofluids [80]. Condensers are used to release the heat to condense a gaseous refrigerant or working fluid into liquid. Evaporators are used to absorb the heat from a surrounding medium such as air, water or another working fluid to convert the working fluid into liquid or gas. An internal heat exchanger enhances the refrigeration cycle efficiency by subcooling the liquid refrigerant or by superheating the gaseous refrigerant before it enters the compressor. A regenerative heat exchanger stores heat from a hot fluid and later transfers it to a cold fluid in alternating cycles. Santosa et al. [81] optimised the performance of a finned tube evaporator, focusing on the analysis of airflow dynamics within the fin gap and the air-side heat transfer coefficient. The evaporator incorporated a configuration of two aluminium wavy fins with staggered copper tubes and a 4 mm fin gap to mitigate frost formation. The findings indicate that higher turbulence intensifies the heat transfer coefficient, thus improving the evaporator’s overall efficiency.

2.4. Types of Heat Exchangers

There are different types of heat exchangers, based on their construction [82], including (i) shell and tube heat exchangers, (ii) plate heat exchangers, (iii) fin and tube heat exchangers and (iv) double-pipe heat exchangers. Recently, a new type, (v) the microchannel heat exchanger, has been reviewed and researched extensively.

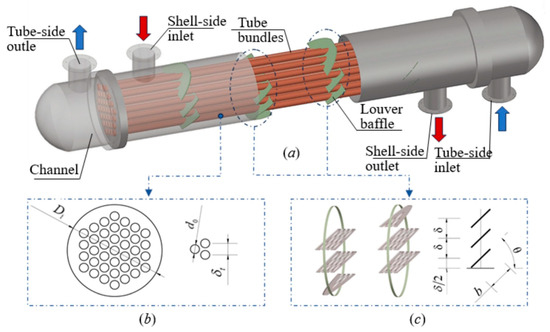

2.4.1. Shell and Tube Heat Exchanger

This type of HX consists of tube-like structures present inside a casing called the shell. One type of working fluid flows through the tubes and another working fluid flows around the tubes in the shell as shown in Figure 4 [83], where heat transfer takes place between both the working fluids. The required heat load to be dissipated or collected depends primarily upon the length, diameter and number of the tubes and the volume of the shell around the tube [84].

Figure 4.

Shell and tube heat exchanger (a) Isometric View (b) Cross-Section View (c) Louver [83].

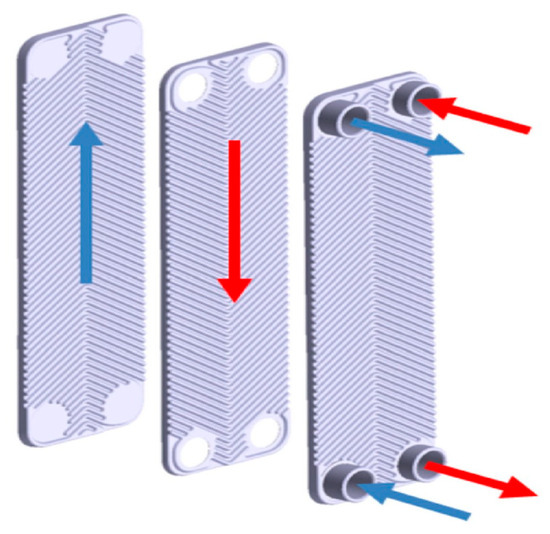

2.4.2. Plate Heat Exchanger

This type of HX consists of a working fluid flowing between plate structures. Multiple layers of plates are stacked upon each other, and these plates have grooves that act as flow paths for the fluid. Depending on the workload, the appropriate number and size of plates are incorporated. The most commonly used design is that of two plates due to its small size in height [85]. An example of a plate HX is shown in Figure 5 [86].

Figure 5.

Plate heat exchanger [86].

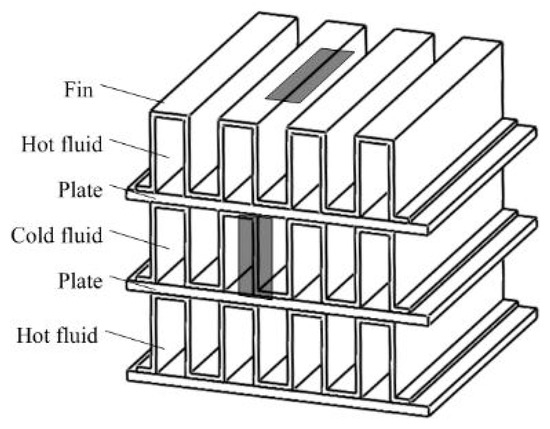

2.4.3. Plate–Fin Heat Exchanger

This type of HX is similar to that of the plate-type HX, but instead of small grooves like in the plate type, fins are present between the plates for a multi-layer design. Fins provide additional surface area, which increases the heat transfer rate. Figure 6 [87] shows a multi-layered crossflow plate–fin-type HX, in which two fluids flow in two different directions in different layers [88].

Figure 6.

Plate–fin heat exchanger [89].

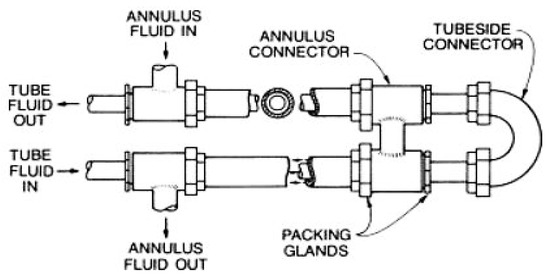

2.4.4. Double-Pipe Heat Exchanger

This type of HX is like a tube–shell HX, but instead of the number of tubes in a shell, a double-pipe HX employs concentric pipes. Fluid in the outer pipe surrounds the inner pipe in the same way as in the tube–shell type, where fluid in the shell surrounds the tubes. Figure 7 [90] shows a double-pipe HX.

Figure 7.

Double-pipe heat exchanger [91].

In parallel flow, both fluids in both pipes flow in the same direction, and in the counter flow, they flow in opposite directions [92]. The most used type is a counter type due to its superior transfer rates, where the average temperature is achieved in a short time compared with the parallel-type HX.

2.4.5. Microchannel Heat Exchanger

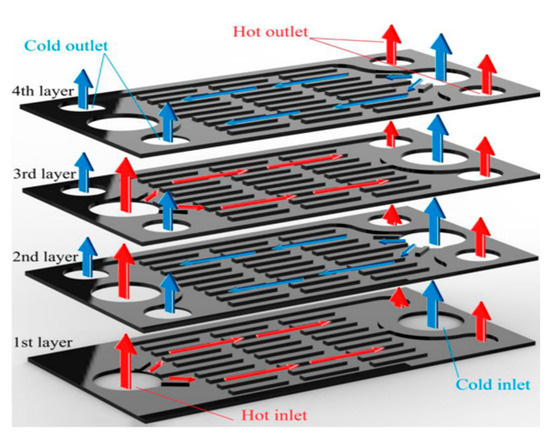

This type of HX consists of micro-sized tube-like structures called channels across the whole HX through which the working fluid passes through, transferring heat from or to the walls of the channels. MCHEs can also be a hybrid between other types of HXs such as the microchannel–fin-type HX or the microchannel–plate HX, with multiple layers of plates together containing microchannel structures within them [49]. Figure 8 [93] shows an example of an MCHE which has 4-layer design [93] or a single-phase flat plate manifold MCHE [94].

Figure 8.

Multi-layer microchannel–plate type HX [95].

3. Thermal Performance and Evaluation of Heat Pump Systems

3.1. Materials and Methods

This review was conducted through a structured literature search to ensure comprehensive coverage of the recent advancements in HP systems and MCHEs. Relevant publications were identified using various databases. Keywords used included “heat pump systems”, “microchannel heat exchanger”, “heat transfer”, and “COP evaluation”. Studies published recently were prioritised to ensure relevance. Both experimental and numerical studies were included. The selected literature was grouped based on the “type of HX used in the HP system”, “type of refrigerant used with various HXs”, “type of microchannel shapes”, and “type of material used for manufacturing MCHEs”, which are elaborated upon in subsequent sections. Key performance metrics were extracted and compared across studies to identify trends, highlight innovations and evaluate the effectiveness of different MCHE designs.

3.2. Evaluation of Heat Pump Systems

The performance of HP systems with regard to heat exchangers (HXs) and working fluids is shown in Table 2.

Table 2.

HP system performance.

Table 3 shows a comparison of the performance of different HXs with various working fluids, most of which are of innovative designs and still in the developmental phase. Even under the developmental phase of designing, many microchannel HX models show promising results, and microchannel HXs are discussed in detail in the next section.

Table 3.

Comparison of different types of heat exchangers.

3.3. Microchannel Heat Exchanger Analysis

Microchannel heat exchangers were first developed to meet the rapid growth of microelectronic machine requirements for high heat transfer rates, compactness and reduced weight, cost and loss of heat transfer [117]. They were used primarily for HVAC (heating, ventilation and air conditioning) systems [118], but in recent years, they are being researched for use in many situations that require a high heat transfer rate.

3.3.1. Microchannel Heat Exchanger Performance Parameters

When compared with a tube–fin-type HX HP system, it can be observed that a microchannel heat exchanger’s heating capacity increased by 4%, the weight of the HX reduced by 45%, the refrigerant charge reduced by 51% and the energy efficiency increased by 4% [119]. Compared with a plain-louvred design, an MCHE has a 14% higher heating capacity, while at low ambient temperatures, the frosting point was more than twice the value, and when used in an EV, by S.H. Hong et al. [120] observed that the EV’s range increased by 25%. In terms of heating capacity or energy consumption alone, there may not be a significant improvement, but when this is combined with their manufacturing and maintenance costs, MCHEs hold an overwhelming advantage. If geometric configurations are not considered carefully, a huge penalty in terms of the pressure drop (as high as twice the amount) can also be observed [121,122], and the flow distribution pattern in the channels can change, causing a maldistribution of the working fluid [123] or even a loss in the overall flow rate [124].

The existence of such undesirable properties can be related to the flawed design of microchannels and their shapes. Maldistributions lead to increased fluid flow resistance, which, in turn, causes increased power consumption and reduced thermal characteristics due to varying flow rates in the individual channels. Longer channel lengths and larger areas for fluid flow can lead to a desirable flow distribution [125], but they might also reduce the heating capacity of the HX if designed only for the best flow distribution. A proper trade-off between both properties must be found [126]. A better understanding of the flow distribution can be predicted using an artificial neural network or genetic algorithm for the whole MCHE [127,128].

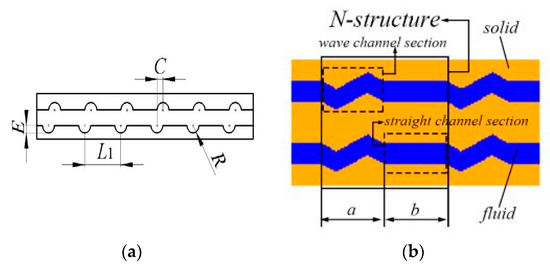

Table 4 shows the comparison of various properties for MCHEs with differently shaped microchannels. Experimenting with various shapes of microchannels is still in its initial stages but with the available data, it can be observed that even non-conventional shapes like N-shaped channels can be advantageous under appropriate conditions. Figure 9 shows a few of the novel microchannel structures that are currently being researched.

Figure 9.

(a) Fan-shaped MCHE [129]; (b) N-shaped MCHE [130].

Table 4.

MCHEs with various microchannel shapes.

Table 4.

MCHEs with various microchannel shapes.

| Shape of Microchannel | Working Fluid | ∆Tmax (K) | Heat Transfer Rate (W) | Pressure Drop (Pa) | Effectiveness | Reynold’s Number |

|---|---|---|---|---|---|---|

| Rectangular [131] | R134a | 50 | 13.25 | 800 | 0.5494 | 1943 |

| Circular [131] | R134a | 50 | 9.5 | 900 | 0.6284 | 2185 |

| Drop-shaped [132] | Water | 65 | 70 | 1200 | 0.82 | 700 |

| Fan-shaped [129] | Water | 60 | 70 | 800 | 0.85 | - |

| N- structure [130,133] | Water | 50 | 80 | 300 | - | - |

| Parallel-flow double layer [134] | Water | 65 | - | 3000 | 0.24 | 600 |

| ITRC [135] | Water | 60 | - | 150 | - | 600 |

| Trapezoidal [136] | Water | 60 | - | 250 | - | 300 |

3.3.2. Novel Designs for Microchannel Heat Exchangers

New designs have been researched in recent years that can provide better performance compared with normal MCHEs for specific applications such as precooled aero engines [137] or for nuclear reactors [75,138]. For example, by replacing MCHEs with MN-MCHXs on the cold side, the thermodynamic performance index can be increased exponentially, which leads to a huge rise in heat transfer rates [139]. By applying a desiccant coating to the microchannels of an MCHE, dehumidification by a DCMHE improved by around 190% compared with that of the MCHE, but the effectiveness of the HX was reduced by 26% [140,141]. It can be a good trade-off if the HX were to be operated in a highly humid location, but when comparing the DCMHE to the DFHE, it was observed that the DFHE was superior to the DCMHE [142]; thus, further comparison between different geometries of the DCHME is required for definitive results. High-power-density air-cooled MCHE is another design that provides promising results for systems with a high temperature difference between the working fluids [143]. PCM slurries such as RT21 are also being used for heat transfer enhancement. In this method, MCHEs are microencapsulated with a metal coating that, when combined with the PCM slurry, produces a major increase in the heat transfer rates due to the increase in thermal capacity from the metal coating and the PCM [144]. MCHEs with high-power-density air-cooling technologies used for the dissipation of heat in a closed-loop heat pump also show promising results; due to the high speeds of airflow in microchannels, good results close to optimum can be achieved, proving that high power densities can be attained even in MCHEs [145].

3.3.3. Nanofluids

All the performance characteristics depend on the working fluid used as much as it depends on the design of the HX. Research on new working fluids is being conducted, but this is still a relatively new research topic. Dialectic fluids have relatively low thermal conductivity due to the size of the channels in which the fluid flows in an MCHE; this takes full advantage of dielectric fluids, leading to exceedingly high heat transfer coefficients [146]. Liquid-metal eutectic fluids such as mixtures which have low viscosities, like 95% Ga-5% In or pure Gallium (Ga), possess good properties as alternative working fluids that enhance the thermal conductivity and heat transfer coefficients [147]. Al2O3 (aluminium oxide) nanofluid is another alternative that presents promising results by increasing the maximum outlet temperature, leading to an increase in overall efficiencies [148]. Al2O3/water nanofluid in combination with rectangular grooved microchannels was observed by X. Zeng et al. to have almost 38% higher thermal performance [149], and it was also observed that for Al2O3/water nanofluid, the heat transfer performance is enhanced with an increase in the Al2O3 concentration, with the analysis carried out up to Reynolds number (Re) = 5200 [150]. In a different study of Al2O3/water nanofluid for curved-finned microchannels, a 16% enhancement was observed [151]. Nanofluids are considered to be the most efficient alternative working fluid, depending on their application [152]. Nanofluids used with other types of HXs are not very viable, but with an MCHE, nanofluids provide good heat transfer enhancement. Specifically, carbon–acetone nanofluid, when evaluated with an MCHE, provided an enhancement of 70% to the heat transfer coefficient [153]. In an evaluation of ZrO2 nanofluids, which are modified with β-cyclodextrin, for a 0.10% concentrate nanofluid, a 37% higher thermal performance was observed [154]. In a performance evaluation of nanofluids with different liquid metals such as Ga, GaIn, EGaIn, GaSn and EGaInSn as the base fluid instead of water and Al2O3 as the nanoparticle, it was observed that GaIn displayed a thermal performance that was almost 3.4 times higher compared with nanofluids with water as the base fluid [155]. In a study of various combinations of microchannel geometries for a counter-flow MCHE, the combination of rectangular and triangular microchannel geometries was observed to have the minimum thermal resistance of 0.0625 k/W/cm2 [156], but when nanofluids were used in an MCHE with a large number of microchannels, it was also observed that the pressure dropped severely, and with an increase in the mass flow rate, the overall performance of the system decreased [93]. M.A. Hayat et al. [157] provides a comprehensive review of recent advancements in nano-enhanced materials, focusing on the enhancement of their thermal conductivity and energy storage capacity. They examine the impact of nanofillers on the thermophysical properties, including latent heat and thermal conductivity, and discuss various stability improvement methods such as dispersant addition, sonication and surface treatment. Additionally, M.A. Hayat et al. [158] explores their applications, preparation, and characterisation techniques while highlighting potential future research directions for optimising their use in thermal energy storage systems.

3.3.4. Additive Manufacturing

Additive manufacturing is considered one of the most effective alternative manufacturing techniques due to its ability to produce complex designs at a lower cost while ensuring high precision. It is being increasingly utilised across various industries. Current research is focused on the fabrication of mechanical components, such as MCHEs, using additive manufacturing methods. These components are being developed with a variety of materials, including various alloys among others, which are mentioned in Table 5. In terms of heat flux, when this is desired to be as maximal as possible, it has been determined that copper is the best material to achieve this when compared with aluminium and stainless steel [159]. Moreover, by adding pin fins to the microchannels while additively manufacturing the HXs, pressure drops can be reduced by 10%, as presented by X. Zhang et al. [160].

Table 5.

Comparison between various additively manufactured MCHEs.

3.3.5. Limitations of Microchannel Heat Exchangers

MCHEs have high heat transfer rates when compared with different HXs, but there are MCHE design limitations and difficulties in operation. In the header where the flow separation occurs, maldistribution can occur, and this is a quite common factor that reduces the overall performance of an HX. There are numerous correlations, but a single correlation is yet to be standardised; thus, more research data are required [168].

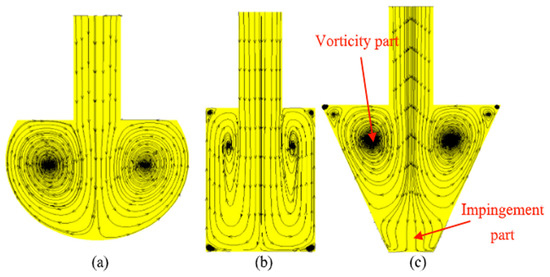

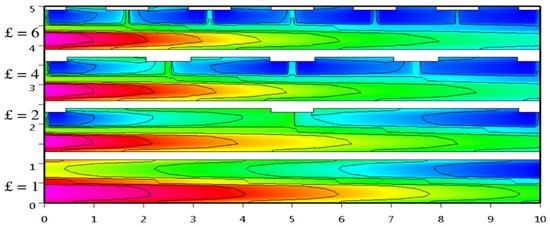

Maldistribution causes flow fluctuations, which, in turn, create different pressure zones within the HX, causing the compressor/pump to overwork; this, in turn, increases power consumption [169]. Figure 10 [170] shows an example of flow fluctuations due to different design properties, such as microchannel impingement causing vortexes in the fluid flow. The type of maldistribution depends on various properties, such as flow direction, flow rate, design characteristics and many others, which further escalate the complexity in the design of MCHEs. The height and length of microchannels also cause further limitations. If each value is high, this decreases the contact surface area, causing a reduction in the heat transfer rate. If these are low, then this causes an increment in the power consumption [171]. Figure 11 [139] shows the variations in temperature distribution at different length rations (£) of the microchannel, and it is observed that after a certain length ratio, an increase in the length ratio causes a reduction in the thermal conductivity, which can be clearly seen in Figure 10. It has been observed that maldistributions have a linear impact on the COP of about 30% [172]. Another limitation would be frosting, which can cause blockage of the microchannels, causing a reduction in the overall heat transfer rate of the system. Frosting and reduced flow rates are common issues in all types of HXs. MCHE are more affected by frosting than any other type of HX [173,174]. At low ambient temperatures, MCHEs have proven to be the most difficult to operate, while when the compressor speeds are higher, the heat transfer rate stays at a reliable range. However, at low temperatures and high compressor speeds, frosting occurs sooner, causing most of the limitations described to arise more frequently, which, in turn, reduces the overall performance [175].

Figure 10.

Flow distribution in various MCHE impingements (a) Circular shaped channel (b) Square shaped channel (c) Triangular shaped channel [170].

Figure 11.

Temperature distribution at different length ratios [139].

4. Conclusions

Heat pump (HP) systems, in conjunction with microchannel heat exchangers (MCHEs), present significant opportunities for advancing energy efficiency and environmental sustainability in heating and cooling applications. This review highlights the technological progress in these systems, including innovations in the design, material selection, and the use of novel working fluids such as nanofluids. Despite their promise, both HP systems and MCHEs face challenges that must be addressed to maximise their potential.

Key insights from the review include the following:

MCHEs demonstrate exceptional thermal efficiency and space-saving benefits compared with conventional heat exchangers, enabling reductions in the refrigerant charge of 30–45%. However, persistent issues such as flow maldistribution, excessive pressure drops and frosting at low ambient temperatures hinder their widespread application. Optimising microchannel geometries and flow distribution is essential for mitigating these challenges and for improving the system performance.

Additive manufacturing has emerged as a promising method for fabricating complex and high-precision MCHE designs cost-effectively. Aluminium alloys stand out as a balanced choice for performance and affordability, although exploring alternative materials like copper and hybrid composites could unlock other potential options, particularly in high-heat flux applications.

The integration of HP systems with advanced MCHEs has shown significant efficiency improvements across various applications, including in electric vehicles, residential HVAC systems and industrial processes. However, comprehensive studies evaluating their durability and performance in real-world conditions are required to validate these gains.

The majority of current research studies remain limited to laboratory-scale experiments and computational simulations. Expanding the research to include field trials and practical applications is crucial to bridging the gap between theory and practice. Additionally, further exploration of low-global-warming potential (GWP) refrigerants and advanced heat-transfer fluids like nanofluids could enhance their sustainability and thermal performance. Employing multi-objective optimisation frameworks can help identify ideal configurations for HP and MCHE systems, balancing trade-offs between efficiency, cost, and environmental impact.

In conclusion, the combination of HP systems and MCHEs offers transformative opportunities for addressing contemporary thermal management needs. Through targeted interdisciplinary research and technological innovation, it is possible to overcome existing limitations and fully unlock their potential. These efforts will significantly contribute to global energy conservation, environmental sustainability, and the achievement of carbon neutrality targets.

Author Contributions

Conceptualization, R.C.S. and L.L.; methodology, R.C.S. and L.L.; formal analysis, L.L.; data curation, K.S.; writing—original draft preparation, R.C.S. and L.L.; writing—review and editing, N.G. and D.R.; supervision, L.L. and H.W.; funding acquisition, L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by Brunel University of London BRIEF award and RCIF, Royal Society International Exchanges (IES\R3\183069) and Royal Society research grant (RGS\R2\222256).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| CFD | Computational Fluid Dynamics |

| COP | Coefficient of Performance |

| DCMHE | Desiccant-Coated MCHE |

| DFHE | Desiccant-Coated Fin and Tube HX |

| EV | Electric Vehicle |

| FSC | Fan-Shaped Cavities |

| GSHP | Ground-Source Heat Pump |

| GWP | Global Warming Potential |

| HP | Heat Pump |

| HVAC | Heating, Ventilation and Air Conditioning |

| HX | Heat Exchanger |

| ITRC | Isosceles Trapezoid-shaped Re-entrant Cavities |

| LCP | Liquid Cold Plate |

| MCHE | Microchannel Heat Exchanger |

| MHE-STW | MCHE with Symmetrical Triangular Wave Structure |

| MN-MCHE | Multi-Nozzle MCHE |

| PCM | Phase-Change Material |

| POE | Polyester |

| TFHE | Tube and Fin Heat Exchanger |

| TMS | Thermal Management System |

| WLTP | Worldwide Harmonised Light-Duty Vehicle Test Procedure |

References

- Chua, K.J.; Chou, S.K.; Yang, W.M. Advances in heat pump systems: A review. Appl. Energy 2010, 87, 3611–3624. [Google Scholar] [CrossRef]

- Famiglietti, J.; Acconito, L.; Arpagaus, C.; Toppi, T. Environmental Life Cycle Assessment of Industrial High-Temperature to Residential Small-Size Heat Pumps: A Critical Review. Energy Convers. Manag. X 2025, 26, 100947. [Google Scholar] [CrossRef]

- Adamo, A.; Martín, H.; de la Hoz, J.; Rubio, J. A Review of Worldwide Strategies for Promoting High-Temperature Heat Pumps. Appl. Sci. 2025, 15, 839. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Garud, K.S.; Jeon, H.-B.; Lee, H.-S. A Study on Performance Characteristics of a Heat Pump System with High-Pressure Side Chiller for Light-Duty Commercial Electric Vehicles. Symmetry 2020, 12, 1237. [Google Scholar] [CrossRef]

- Yulianto, M.; Suzuki, T.; Ge, Z.; Tsuchino, T.; Urakawa, M.; Taira, S.; Miyaoka, Y.; Giannetti, N.; Li, L.; Saito, K. Performance assessment of an R32 commercial heat pump water heater in different climates. Sustain. Energy Technol. Assess. 2022, 49, 101679. [Google Scholar] [CrossRef]

- Şahi, E.; Adigüzel, N. Experimental Analysis of the Effects of Climate Conditions on Heat Pump System Performance. SSRN Electron. J. 2021, 27. [Google Scholar] [CrossRef]

- Tang, X.; Guo, Q.; Li, M.; Jiang, M. Heating Performance Characteristics of an Electric Vehicle Heat Pump Air Conditioning System Based on Exergy Analysis. Energies 2020, 13, 2868. [Google Scholar] [CrossRef]

- Bayram, H.; Sevilgen, G.; Kılıç, M. Advances on heat pump applications for electric vehicles. Adv. Automot. Eng. 2018, 1, 79–104. [Google Scholar] [CrossRef]

- Yıldırım, R.; Güngör, A.; Kumaş, K.; Akyüz, A. Evaluation of Low GWP Refrigerants R452B and R454B as Alternative to R410a in the Heat Hump Systems. 2021. Available online: https://dergipark.org.tr/en/pub/jieas/issue/63603/947783 (accessed on 17 August 2021).

- Junqi, D.; Yibiao, W.; Shiwei, J.; Xianhui, Z.; Linjie, H. Experimental study of R744 heat pump system for electric vehicle application. Appl. Therm. Eng. 2021, 183, 116191. [Google Scholar] [CrossRef]

- Yu, B.; Ouyang, H.; Shi, J.; Guo, Z.; Chen, J. Experimental evaluation of cycle performance for new-developed refrigerants in the electric vehicle heat pump systems. Int. J. Refrig. 2021, 129, 118–127. [Google Scholar] [CrossRef]

- Li, W.; Liu, R.; Liu, Y.; Wang, D.; Shi, J.; Chen, J. Performance evaluation of R1234yf heat pump system for an electric vehicle in cold climate. Int. J. Refrig. 2020, 115, 117–125. [Google Scholar] [CrossRef]

- Afshari, F.; Comakli, O.; Karagoz, S.; Zavaragh, H.G. A thermodynamic comparison between heat pump and refrigeration device using several refrigerants. Energy Build. 2018, 168, 272–283. [Google Scholar] [CrossRef]

- Cvok, I.; Ratković, I.; Deur, J. Optimisation of Control Input Allocation Maps for Electric Vehicle Heat Pump-based Cabin Heating Systems. Energies 2020, 13, 5131. [Google Scholar] [CrossRef]

- Na, S.-I.; Chung, Y.; Kim, M.S. Performance analysis of an electric vehicle heat pump system with a desiccant dehumidifier. Energy Convers. Manag. 2021, 236, 114083. [Google Scholar] [CrossRef]

- Bellocchi, S.; Guizzi, G.L.; Manno, M.; Salvatori, M.; Zaccagnini, A. Reversible heat pump HVAC system with regenerative heat exchanger for electric vehicles: Analysis of its impact on driving range. Appl. Therm. Eng. 2018, 129, 290–305. [Google Scholar] [CrossRef]

- Peng, X.; Wang, D.; Wang, G.; Yang, Y.; Xiang, S. Numerical investigation on the heating performance of a transcritical CO2 vapor-injection heat pump syste. Appl. Therm. Eng. 2020, 166, 114656. [Google Scholar] [CrossRef]

- Mao, Z.; Hu, S.; Guan, Y.; Ji, Y.; Liu, G.; Tong, Z.; Wang, Y.; Tong, L. Performance analysis of a hybrid subway source heat pump system using capillary heat exchanger. Appl. Therm. Eng. 2021, 197, 117367. [Google Scholar] [CrossRef]

- Yu, B.; Yang, J.; Wang, D.; Shi, J.; Chen, J. Modeling and theoretical analysis of a CO2-propane autocascade heat pump for electrical vehicle heating. Int. J. Refrig. 2018, 95, 146–155. [Google Scholar] [CrossRef]

- Choi, Y.U.; Kim, M.S.; Kim, G.T.; Kim, M.; Kim, M.S. Performance analysis of vapor injection heat pump system for electric vehicle in cold startup condition. Int. J. Refrig. 2017, 80, 24–36. [Google Scholar] [CrossRef]

- Kwon, C.; Kim, M.S.; Choi, Y.; Kim, M.S. Performance evaluation of a vapor injection heat pump system for electric vehicles. Int. J. Refrig. 2017, 74, 138–150. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Gao, T.; Shi, J.; Chen, J.; Wang, T.; Pan, L. Performance evaluation of propane heat pump system for electric vehicle in cold climate. Int. J. Refrig. 2018, 95, 51–60. [Google Scholar] [CrossRef]

- Li, K.; Yu, J.; Yu, R.; Su, L.; Fang, Y.; Yang, Z. Experimental Investigation on Heating Performance of Newly Designed Air Source Heat Pump System for Electric Vehicles. J. Therm. Sci. Eng. Appl. 2021, 13, 021020. [Google Scholar] [CrossRef]

- Wang, J.; Belusko, M.; Liu, M.; Evans, M.; Alemu; Bruno, F. Preliminary Study on a Novel Transcritical CO2 High-Temperature Heat Pump. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany, 11–13 October 2021; p. 134. Available online: https://mediatum.ub.tum.de/doc/1633140/1633140.pdf (accessed on 20 February 2022).

- Li, S.; Wang, S.; Ma, Z.; Jiang, S.; Zhang, T. Using an air cycle heat pump system with a turbocharger to supply heating for full electric vehicles. Int. J. Refrig. 2017, 77, 11–19. [Google Scholar] [CrossRef]

- Li, X.; Su, W.; Xu, W.; Dai, B.; Li, J.; Li, L. Editorial: CO2-based energy systems for cooling, heating, and power. Front. Energy Res. 2022, 10, 993093. [Google Scholar] [CrossRef]

- Namdar, H.; Rossi di Schio, E.; Semprini, G.; Valdiserri, P. Photovoltaic-Thermal Solar-Assisted Heat Pump Systems for Building Applications: A Technical Review on Direct Expansion Systems. Energy Build. 2025, 334, 115516. [Google Scholar] [CrossRef]

- Tung, S.C.; Woydt, M.; Shah, R. Global Insights on Future Trends of Hybrid/EV Driveline Lubrication and Thermal Management. Front. Mech. Eng. 2020, 6, 571786. [Google Scholar] [CrossRef]

- Biglarian, H.; Abdollahi, S. Utilization of on-grid photovoltaic panels to offset electricity consumption of a residential ground source heat pump. Energy 2021, 243, 122770. [Google Scholar] [CrossRef]

- Krane, P.; Ziviani, D.; Braun, J.E.; Jain, N.; Marconnet, A. Techno-Economic Analysis of Metal-Hydride Energy Storage to Enable Year-Round Load-Shifting for Residential Heat Pumps. Energy Build. 2021, 256, 111700. [Google Scholar] [CrossRef]

- Siecker, J.; Kusakana, K.; Numbi, B.P. Optimal switching control of an air to air heat pump operating under variable time-based electricity pricing. Energy Rep. 2022, 8, 995–1002. [Google Scholar] [CrossRef]

- Heidari, A.; Marechal, F.; Khovalyg, D. An adaptive control framework based on Reinforcement learning to balance energy, comfort and hygiene in heat pump water heating systems. J. Phys. Conf. Ser. 2021, 2042, 012006. [Google Scholar] [CrossRef]

- Bordignon, S.; Carnieletto, L.; Zarrella, A. An all-in-one machine coupled with a horizontal ground heat exchanger for the air-conditioning of a residential building. Build. Environ. 2021, 207, 108558. [Google Scholar] [CrossRef]

- Vering, C.; Wüllhorst, F.; Mehrfeld, P.; Müller, D. Towards an integrated design of heat pump systems: Application of process intensification using two-stage optimization. Energy Convers. Manag. 2021, 250, 114888. [Google Scholar] [CrossRef]

- Jia, X.; Ma, G.; Zhou, F.; Liu, S.; Wu, G.; Sui, Q. Experimental study and operation optimization of a parallel-loop heat pump for exhaust air recovery in residential buildings. J. Build. Eng. 2022, 45, 103468. [Google Scholar] [CrossRef]

- Shirani, A.; Merzkirch, A.; Roesler, J.; Leyer, S.; Scholzen, F.; Maas, S. Field monitoring data on a residential exhaust air heat pump system (air-to-air heat pump). Data Brief. 2021, 38, 107386. [Google Scholar] [CrossRef]

- Göbel, S.; Schmitt, E.; Mehrfeld, P.; Müller, D. Underfloor heating system model for building performance simulations. In Proceedings of the Modelica Conferences, Lucerne, Switzerland, 8–10 September 2025; pp. 343–349. [Google Scholar] [CrossRef]

- Roccatello, E.; Prada, A.; Baratieri, M. Hybrid Heat Pump Systems as a Possible Solution for the Energy Transition Towards Sustainable Heating Systems for Buildings. In Proceedings of the Creative Solutions for a Sustainable Development: 21st International TRIZ Future Conference, TFC 2021, Bolzano, Italy, 22–24 September 2021; pp. 100–111. [Google Scholar] [CrossRef]

- Thakur, A.K.; Prabakaran, R.; Elkadeem, M.R.; Sharshir, S.W.; Arıcı, M.; Wang, C.; Zhao, W.; Hwang, J.-Y.; Saidur, R. A state of art review and future viewpoint on advance cooling techniques for Lithium–ion battery system of electric vehicles. J. Energy Storage 2020, 32, 101771. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Q.; Zhang, T.; Wang, G.; Jiang, Z.; Li, Y. Advances in Integrated Vehicle Thermal Management and Numerical Simulation. Energies 2017, 10, 1636. [Google Scholar] [CrossRef]

- Yu, B.; Yang, J.; Wang, D.; Shi, J.; Chen, J. Energy consumption and increased EV range evaluation through heat pump scenarios and low GWP refrigerants in the new test procedure WLTP. Int. J. Refrig. 2019, 100, 284–294. [Google Scholar] [CrossRef]

- Zou, H.; Wang, W.; Zhang, G.; Qin, F.; Tian, C.; Yan, Y. Experimental investigation on an integrated thermal management system with heat pipe heat exchanger for electric vehicle. Energy Convers. Manag. 2016, 118, 88–95. [Google Scholar] [CrossRef]

- Yokoyama, A.; Osaka, T.; Imanishi, Y.; Sekiya, S. Thermal Management System for Electric Vehicles. SAE Int. J. Mater. Manuf. 2011, 4, 1277–1285. [Google Scholar] [CrossRef]

- Lajunen, A.; Yang, Y.; Emadi, A. Review of Cabin Thermal Management for Electrified Passenger Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 6025–6040. [Google Scholar] [CrossRef]

- Jeffs, J.; McGordon, A.; Picarelli, A.; Robinson, S.; Widanage, W.D. System level heat pump model for investigations into thermal management of electric vehicles at low temperatures. In Proceedings of the 13th International Modelica Conference, Regensburg, Germany, 4–6 March 2019; pp. 107–116. [Google Scholar] [CrossRef]

- Peng, Q.; Du, Q. Progress in Heat Pump Air Conditioning Systems for Electric Vehicles—A Review. Energies 2016, 9, 240. [Google Scholar] [CrossRef]

- Zhang, T.; Gao, C.; Gao, Q.; Wang, G.; Liu, M.; Guo, Y.; Xiao, C.; Yan, Y.Y. Status and development of electric vehicle integrated thermal management from BTM to HVAC. Appl. Therm. Eng. 2015, 88, 398–409. [Google Scholar] [CrossRef]

- Jeffs, J.; McGordon, A.; Widanage, W.D.; Robinson, S.; Picarelli, A. Use of a Thermal Battery with a Heat Pump for Low Temperature Electric Vehicle Operation. In Proceedings of the 2017 IEEE Vehicle Power and Propulsion Conference (VPPC), Belfort, France, 11–14 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Hu, Y.; Yuill, D.P.; Ebrahimifakhar, A. The effects of outdoor air-side fouling on frost growth and heat transfer characteristics of a microchannel heat exchanger: An experimental study. Int. J. Heat Mass Transf. 2020, 151, 119423. [Google Scholar] [CrossRef]

- Torregrosa-Jaime, B.; Corberán, J.M.; Payá, J.; Delamarche, J.L. Thermal characterisation of compact heat exchangers for air heating and cooling in electric vehicles. Appl. Therm. Eng. 2017, 115, 774–781. [Google Scholar] [CrossRef]

- De Nunzio, G.; Sciarretta, A.; Steiner, A.; Mladek, A. Thermal management optimization of a heat-pump-based HVAC system for cabin conditioning in electric vehicles. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Zhou, G.; Li, H.; Liu, E.; Li, B.; Yan, Y.; Chen, T.; Chen, X. Experimental study on combined defrosting performance of heat pump air conditioning system for pure electric vehicle in low temperature. Appl. Therm. Eng. 2017, 116, 677–684. [Google Scholar] [CrossRef]

- Li, H.-J.; Zhou, G.-H.; Li, A.-G.; Li, X.-G.; Li, Y.-N.; Chen, J. Heat pump air conditioning system for pure electric vehicle at ultra-low temperature. Therm. Sci. 2014, 18, 1667–1672. [Google Scholar] [CrossRef]

- Wang, D.; Yu, B.; Hu, J.; Chen, L.; Shi, J.; Chen, J. Heating performance characteristics of CO2 heat pump system for electrical vehicle in a cold climate. Int. J. Refrig. 2018, 85, 27–41. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Liu, R.; Wang, D.; Shi, J.; Yu, Z.; Cheng, L.; Chen, J. Performance evaluation of secondary loop low-temperature heat pump system for frost prevention in electric vehicles. Appl. Therm. Eng. 2021, 182, 115615. [Google Scholar] [CrossRef]

- Ilis, G.G.; Demir, H.; Akbas, M.Y.; Mobedi, M. Recent Developments on Heat Pump Systems in Electric Vehicle and a suggestion. In Proceedings of the International Heat Transfer Symposium and Heat Powered Cycles Conference 2016, Nottingham, UK, 26–29 June 2016; Available online: https://www.researchgate.net/publication/321937922 (accessed on 18 August 2021).

- Akinlabi, A.A.H.; Solyali, D. Configuration, design, and optimization of air-cooled battery thermal management system for electric vehicles: A review. Renew. Sustain. Energy Rev. 2020, 125, 109815. [Google Scholar] [CrossRef]

- Mondal, B.; Lopez, C.F.; Mukherjee, P.P. Exploring the efficacy of nanofluids for lithium-ion battery thermal management. Int. J. Heat Mass Transf. 2017, 112, 779–794. [Google Scholar] [CrossRef]

- Wiriyasart, S.; Hommalee, C.; Sirikasemsuk, S.; Prurapark, R.; Naphon, P. Thermal management system with nanofluids for electric vehicle battery cooling modules. Case Stud. Therm. Eng. 2020, 18, 100583. [Google Scholar] [CrossRef]

- Lan, C.; Xu, J.; Qiao, Y.; Ma, Y. Thermal management for high power lithium-ion battery by minichannel aluminum tubes. Appl. Therm. Eng. 2016, 101, 284–292. [Google Scholar] [CrossRef]

- Jin, L.W.; Lee, P.S.; Kong, X.X.; Fan, Y.; Chou, S.K. Ultra-thin minichannel LCP for EV battery thermal management. Appl. Energy 2014, 113, 1786–1794. [Google Scholar] [CrossRef]

- Arora, S. Selection of thermal management system for modular battery packs of electric vehicles: A review of existing and emerging technologies. J. Power Sources 2018, 400, 621–640. [Google Scholar] [CrossRef]

- Putra, N.; Ariantara, B. Electric motor thermal management system using L-shaped flat heat pipes. Appl. Therm. Eng. 2017, 126, 1156–1163. [Google Scholar] [CrossRef]

- Fang, G.; Yuan, W.; Yan, Z.; Sun, Y.; Tang, Y. Thermal management integrated with three-dimensional heat pipes for air-cooled permanent magnet synchronous motor. Appl. Therm. Eng. 2019, 152, 594–604. [Google Scholar] [CrossRef]

- Kulikov, I.; Karpukhin, K.; Kurmaev, R. X-in-the-Loop Testing of a Thermal Management System Intended for an Electric Vehicle with In-Wheel Motors. Energies 2020, 13, 6452. [Google Scholar] [CrossRef]

- Liu, M.; Li, Y.; Ding, H.; Sarlioglu, B. Thermal management and cooling of windings in electrical machines for electric vehicle and traction application. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 668–673. [Google Scholar] [CrossRef]

- Cavazzuti, M.; Gaspari, G.; Pasquale, S.; Stalio, E. Thermal management of a Formula E electric motor: Analysis and optimization. Appl. Therm. Eng. 2019, 157, 113733. [Google Scholar] [CrossRef]

- Li, B.; Kuo, H.; Wang, X.; Chen, Y.; Wang, Y.; Gerada, D.; Worall, S.; Stone, I.; Yan, Y. Thermal Management of Electrified Propulsion System for Low-Carbon Vehicles. Automot. Innov. 2020, 3, 299–316. [Google Scholar] [CrossRef]

- Deisenroth, D.C.; Ohadi, M. Thermal Management of High-Power Density Electric Motors for Electrification of Aviation and Beyond. Energies 2019, 12, 3594. [Google Scholar] [CrossRef]

- Yang, Y.; Bilgin, B.; Kasprzak, M.; Nalakath, S.; Sadek, H.; Preindl, M.; Cotton, J.; Schofield, N.; Emadi, A. Thermal management of electric machines. IET Electr. Syst. Transp. 2017, 7, 104–116. [Google Scholar] [CrossRef]

- Michalak, A.J.; Mills, J.K. Genetic Optimization of Thermal Management Systems for EV Power Electronics via ANSYS Multiphysics. In Proceedings of the 2019 IEEE International Conference on Mechatronics and Automation (ICMA), Tianjin, China, 4–7 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 2401–2406. [Google Scholar] [CrossRef]

- Tao, X.W. Design, Modeling and Control of a Thermal Management System for Hybrid Electric Vehicles. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2016. Available online: https://tigerprints.clemson.edu/all_dissertations/1631 (accessed on 17 August 2021).

- Hamut, H.S.; Dincer, I.; Naterer, G.F. Exergy analysis of a TMS (thermal management system) for range-extended EVs (electric vehicles). Energy 2017, 46, 117–125. [Google Scholar] [CrossRef]

- Yunus, M.; Budiman, A.A.; Zhe, S.; Kiswanta; Chunlin, W.; Subekti, M.; Bakhri, S.; Jun, S. Simulation System for PeLUIt 150 MW Nuclear Reactor by using vPower. J. Phys. Conf. Ser. 2021, 2048, 012034. [Google Scholar] [CrossRef]

- Kromer, D.A.; Huning, A.J.; Garimella, S. I2S-LWR microchannel heat exchanger design and experimental validation. Ann. Nucl. Energy 2020, 145, 105710. [Google Scholar] [CrossRef]

- Ali, M.; Alkaabi, A.K.; Addad, Y. Numerical investigation of a vertical triplex-tube latent heat storage/exchanger to achieve flexible operation of nuclear power plants. Int. J. Energy Res. 2021, 46, 2970–2987. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, D.; Zhao, M.; Wang, L.; Xu, J. The Safety Analysis of the Design of the Reactor Coolant Pump Heat Shield in Qinshan Nuclear Power Plant. In Volume 3: Computational Fluid Dynamics (CFD); Verification and Validation; Advanced Methods of Manufacturing (AMM) for Nuclear Reactors and Components; Decontamination, Decommissioning, and Radioactive Waste Management; Beyond Design Basis and Nuclear Saf; American Society of Mechanical Engineers: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Lim, J.; Shin, D.; Kim, T.; Park, J.H.; Lee, J.; Cho, Y.S.; Kim, Y.; Kim, S.; Kim, S.J. Preliminary Analysis of the Effect of the Gas Injection on Natural circulation for Molten Salt Reactor Type Small Modular Reactor System Operated without a Pump, in: Transactions of the Korean Nuclear Society Virtual Autumn Meeting. 2021. Available online: https://www.kns.org/files/pre_paper/46/21A-399-임지훈.pdf (accessed on 17 August 2021).

- Ye, Q.; Li, S. Investigation on the performance and optimization of heat pump water heater with wrap-around condenser coil. Int. J. Heat Mass Transf. 2019, 143, 118556. [Google Scholar] [CrossRef]

- Yu, J.; Su, L.; Li, K.; Liu, M.; Zhang, H. Investigation on heat transfer characteristics of outside heat exchanger in an air conditioning heat pump system for electric vehicles. Int. J. Heat Mass Transf. 2021, 170, 121040. [Google Scholar] [CrossRef]

- Santosa, I.D.M.C.; Waisnawa, I.G.N.S.; Sunu, P.W.; Temaja, I.W.; Li, L. CFD Air Flow Evaluation of Finned Tube Evaporator for Refrigerated Display Cabinet Application. CFD Lett. 2024, 16, 52–63. [Google Scholar] [CrossRef]

- Ishaque, S.; Siddiqui, M.I.H.; Kim, M.-H. Effect of heat exchanger design on seasonal performance of heat pump systems. Int. J. Heat Mass Transf. 2020, 151, 119404. [Google Scholar] [CrossRef]

- Li, Y.; Lei, Y.; Li, J.; Du, B.; Song, C.; Wang, Y. Experimental Investigation on the Thermo-Hydraulic Performance and Entransy Analysis of a Shell-and-Tube Heat Exchanger with Louver Baffles. Appl. Therm. Eng. 2025, 269, 125928. [Google Scholar] [CrossRef]

- Shen, B.; Li, Z.; Gluesenkamp, K.R. Experimental study of R452B and R454B as drop-in replacement for R410A in split heat pumps having tube-fin and microchannel heat exchangers. Appl. Therm. Eng. 2022, 204, 117930. [Google Scholar] [CrossRef]

- Gherasim, I.; Taws, M.; Galanis, N.; Nguyen, C.T. Heat transfer and fluid flow in a plate heat exchanger part I. Experimental investigation. Int. J. Therm. Sci. 2011, 50, 1492–1498. [Google Scholar] [CrossRef]

- Borjigin, S.; Zhao, W.; Fu, W.; Liang, W.; Bai, S.; Ma, J.; Meng, K.; Baoyin, H. Review of Plate Heat Exchanger Utilized for Gases Heat Exchange. Renew. Sustain. Energy Rev. 2025, 210, 115224. [Google Scholar] [CrossRef]

- Bisengimana, E.; Zhou, J.; Binama, M.; Yuan, Y. Numerical investigation on the factors influencing the temperature distribution of photovoltaic/thermal (PVT) evaporator/condenser for heat pump systems. Renew. Energy 2022, 194, 885–901. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Yu, B.; Shi, J.; Chen, J. Numerical study on heat transfer performance of micro-channel gas coolers for automobile CO2 heat pump systems. Int. J. Refrig. 2019, 106, 639–649. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Dong, Q.W.; Liu, M.S.; Wang, D. Numerical study on plate-fin heat exchangers with plain fins and serrated fins at low Reynolds number. Chem. Eng. Technol. 2009, 32, 1219–1226. [Google Scholar] [CrossRef]

- Cremaschi, L.; Yatim, A.S.; Mulugurthi, S.K. Experimental study of oil retention in microchannel type evaporators of air-source heat pump systems. Int. J. Refrig. 2018, 91, 158–166. [Google Scholar] [CrossRef]

- Bell, K.J.; Exchangers, H. Encyclopedia of Physical Science and Technology; Elsevier: Amsterdam, The Netherlands, 2003; pp. 251–264. [Google Scholar] [CrossRef]

- Kong, X.; Yang, Y.; Zhang, M.; Li, Y.; Li, J. Experimental investigation on a direct-expansion solar-assisted heat pump water heater using R290 with micro-channel heat transfer technology during the winter period. Int. J. Refrig. 2020, 113, 38–48. [Google Scholar] [CrossRef]

- Glazar, V.; Trp, A.; Lenic, K. Optimization of air-water microchannel heat exchanger using response surface methodology. Int. J. Heat Mass Transf. 2020, 157, 119887. [Google Scholar] [CrossRef]

- Lavaa, A. Types of Heat Exchangers: An Introduction to All Essential About Specification. Linquip 2020. Available online: https://www.linquip.com/blog/types-of-heat-exchangers/ (accessed on 20 July 2021).

- Mazaheri, N.; Bahiraei, M.; Razi, S. Two-phase analysis of nanofluid flow within an innovative four-layer microchannel heat exchanger: Focusing on energy efficiency principle. Powder Technol. 2021, 383, 484–497. [Google Scholar] [CrossRef]

- Zohuri, B. Heat Exchanger Types and Classifications, in: Compact Heat Exchangers; Springer International Publishing: Cham, Switzerland, 2017; pp. 19–56. [Google Scholar] [CrossRef]

- Mishra, M.; Das, P.K.; Sarangi, S. Second law based optimisation of crossflow plate-fin heat exchanger design using genetic algorithm. Appl. Therm. Eng. 2009, 29, 2983–2989. [Google Scholar] [CrossRef]

- Omidi, M.; Farhadi, M.; Jafari, M. A comprehensive review on double pipe heat exchangers. Appl. Therm. Eng. 2017, 110, 1075–1090. [Google Scholar] [CrossRef]

- Chen, C.; Yang, S.; Pan, M. Microchannel structure optimization and experimental verification of a plate heat exchanger. Int. J. Heat Mass Transf. 2021, 175, 121385. [Google Scholar] [CrossRef]

- Andhare, R.S.; Shooshtari, A.; Dessiatoun, S.V.; Ohadi, M.M. Heat transfer and pressure drop characteristics of a flat plate manifold microchannel heat exchanger in counter flow configuration. Appl. Therm. Eng. 2016, 96, 178–189. [Google Scholar] [CrossRef]

- Gu, X.; Chen, W.; Chen, C.; Li, N.; Gao, W.; Wang, Y. Detailed characteristics of fluid flow and its effect on heat transfer in shell sides of typical shell-and-tube heat exchangers. Int. J. Therm. Sci. 2021, 173, 107381. [Google Scholar] [CrossRef]

- Najim, S.M.; Hussein, A.M.; Danook, S.H. Performance Evaluation of Shell and Tube Heat Exchanger by Using Fe3O4/water Nanofluid. NTU J. Eng. Technol. 2021, 9, 54–62. Available online: https://journals.ntu.edu.iq/index.php/NTU-JET/article/view/56/27 (accessed on 17 August 2021). [CrossRef]

- Gupta, S.K.; Verma, H.; Yadav, N. A review on recent development of nanofluid utilization in shell & tube heat exchanger for saving of energy. Mater. Today Proc. 2021, 54, 579–589. [Google Scholar] [CrossRef]

- Hasan, S.S.; Baqir, A.S.; Mahood, H.B. The Effect of Injected Air Bubble Size on the Thermal Performance of a Vertical Shell and Helical Coiled Tube Heat Exchanger. Energy Eng. 2021, 118, 1595–1609. [Google Scholar] [CrossRef]