1. Introduction

Turbomachines are widely distributed in the industry and are used in various applications at different scales. They can be not only large-sized machines, such as the turbines used in thermoelectric and hydroelectric plants, but also small-sized pumps used in medical applications, such as auxiliary blood pumps [

1]. However, the design and performance prediction of these machines remain a difficult task, mainly due to the large number of geometric parameters involved. In addition, the cost and significant time of trial-and-error methods to build prototypes reduce manufacturers’ profit margins. Numerical simulations can provide very precise information on the behavior of fluid flow in these machines, thus helping engineers to obtain a comprehensive evaluation of the performance of a particular design [

2,

3]. But, it is important to mention that this kind of solution must be combined with accelerated methods such as parallel programming to improve the time consumption of the calculation of fluid flow problems. Under this context, this article deals with parallel computing in the cloud, using the topology optimization method as a solution to the minimization of an objective’s functions.

In the literature, there are few works related to centrifugal pumps using accelerated methods. For example, Liang Dong et al. [

4] studied and verified a large-scale parallel mesh generation algorithm applied to a centrifugal pump. They used the Sutherland–Hodgman (S-H) algorithm for cropping and segmenting grid point sets on the surface mesh of a centrifugal pump that was tested using the Tianhe-2 supercomputer. The results show that the algorithm can generate 3D unstructured grid elements in 5 min, and the parallel efficiency can achieve 80%. In addition, Alessandro et al. [

5] studied the fluid flow inside a centrifugal pump in high-performance numerical simulations using GPU cards. The simulations in this work were carried out at the best-efficiency point (BEP) for single-phase flow with four different turbulence models. The comparison at the BEP showed that the integral quantity-based results were not sensitive to the turbulence model.

Some other works found in the literature are related to the optimization of these centrifugal flow machines [

6,

7,

8,

9]. Shahram Derakhshan [

6] employed a global optimization method based on artificial neural networks (ANN) and the artificial bee colony (ABC) algorithm. Derakhshan solved the Navier–Stokes equations to redesign the geometry of an impeller and improve the performance of a Berkeh brand pump 32–160. Moreover, Wen Guan Li [

7] used the singularity method to develop an inverse problem in order to design optimized impeller blades for centrifugal pumps. This work estimated the hydraulic performance using a computational fluid dynamics (CFD) code and obtained an improvement of more than 5% in its efficiency. Furthermore, Lei et al. [

8] used the direct and inverse iterative method to design an optimized pump impeller compared to the traditional design method. In addition, Gölcü et al. [

9] optimized the efficiency of a centrifugal pump by inserting splitters between the blades. The results showed that the splitter between the blades causes a negative effect on the performance of the pump impeller with six and seven blades, but when the splitter blade was added to the impeller with five blades, the efficiency was increased. This research shows that the impeller of a centrifugal pump has an important influence on the performance of these rotatory machines. In addition to these studies, there are other various works [

10,

11,

12,

13] that highlight that the study of fluid flow in centrifugal pumps is a broad research area that must be approached in three significantly ways: (a) by computational algorithms, (b) by commercial software that solves the Navier–Stokes equations, and (c) by experimental prototypes. Zhao et al. [

10] studied the optimization variables and control impeller for the optimization design. They concluded that the impeller reaches maximum efficiency when the linear segment angle is −2.886°. Wang et al. [

11] carried out an optimization process for impellers based on numerical simulation, Latin hypercube sampling (LHS), the surrogate model, and the genetic algorithm (GA) in order to improve the efficiency of residual heat-removal pump. They concluded that the optimization increased efficiency by 8.34% under the design point.

Regarding computational algorithms, topology optimization is seen as an alternative method for the optimal design of centrifugal machines [

14,

15].

Topology optimization is a mathematical method that spatially optimizes the distribution of material within a defined domain. This optimization method distributes a fluid or solid in the design domain, minimizing or maximizing a predefined objective function. A conventional method for solving an objective function and linked to topology optimization is the finite-element method (FEM).

Reviewing the literature on topology optimization for centrifugal pump design, in 2003, Borrvall and Petersson [

16] used this strategy for the first time to design the channel flow in a 2D Brinkman medium to minimize the dissipated power. However, in 2014, this technique was extended to rotatory machines by Romero and Silva [

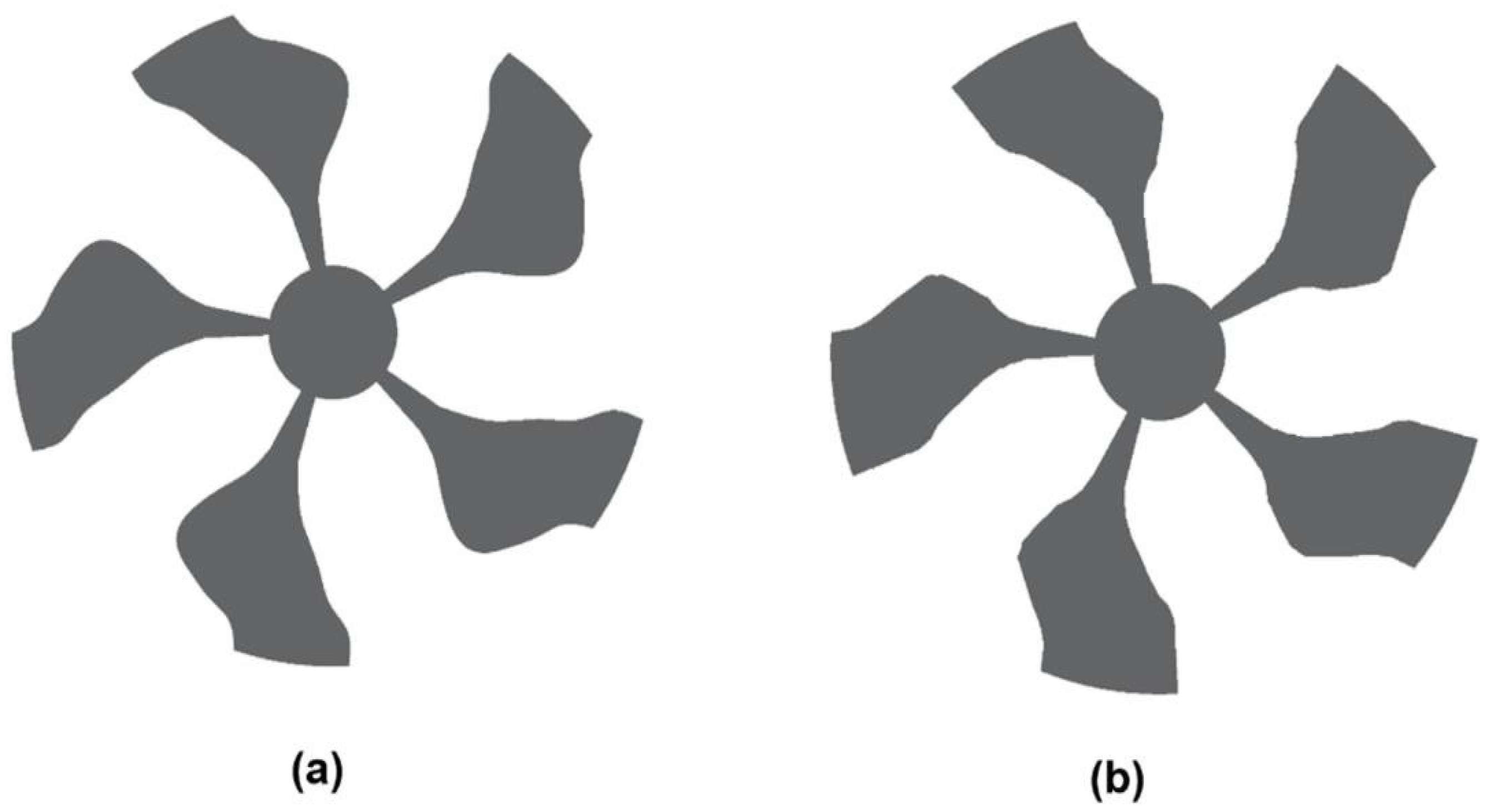

17]. They optimized the shape of the space between two blades, minimizing a multi-objective function involving the viscous dissipation, the power through the torque, and the vorticity. The results showed a dependence of the final rotor design on the initial geometry reference (straight blade, curved, or involuted blade). Moreover, Sá et al. [

18] extended the previous work by applying topology optimization based on densities for the design of small-scale centrifugal pumps. The objective functions that they considered were the viscous dissipation energy and the vorticity, obtaining similar results to those of Romero and Silva. Moreover, Chang et al. [

19] provided theoretical insights for optimizing efficiency and ensuring the smooth operation of centrifugal pumps in energy storage systems. They concluded that, as the flow rate increases, the flow separation and wake vortices reduce, leading to an efficiency improvement in the centrifugal pump under design flow conditions.

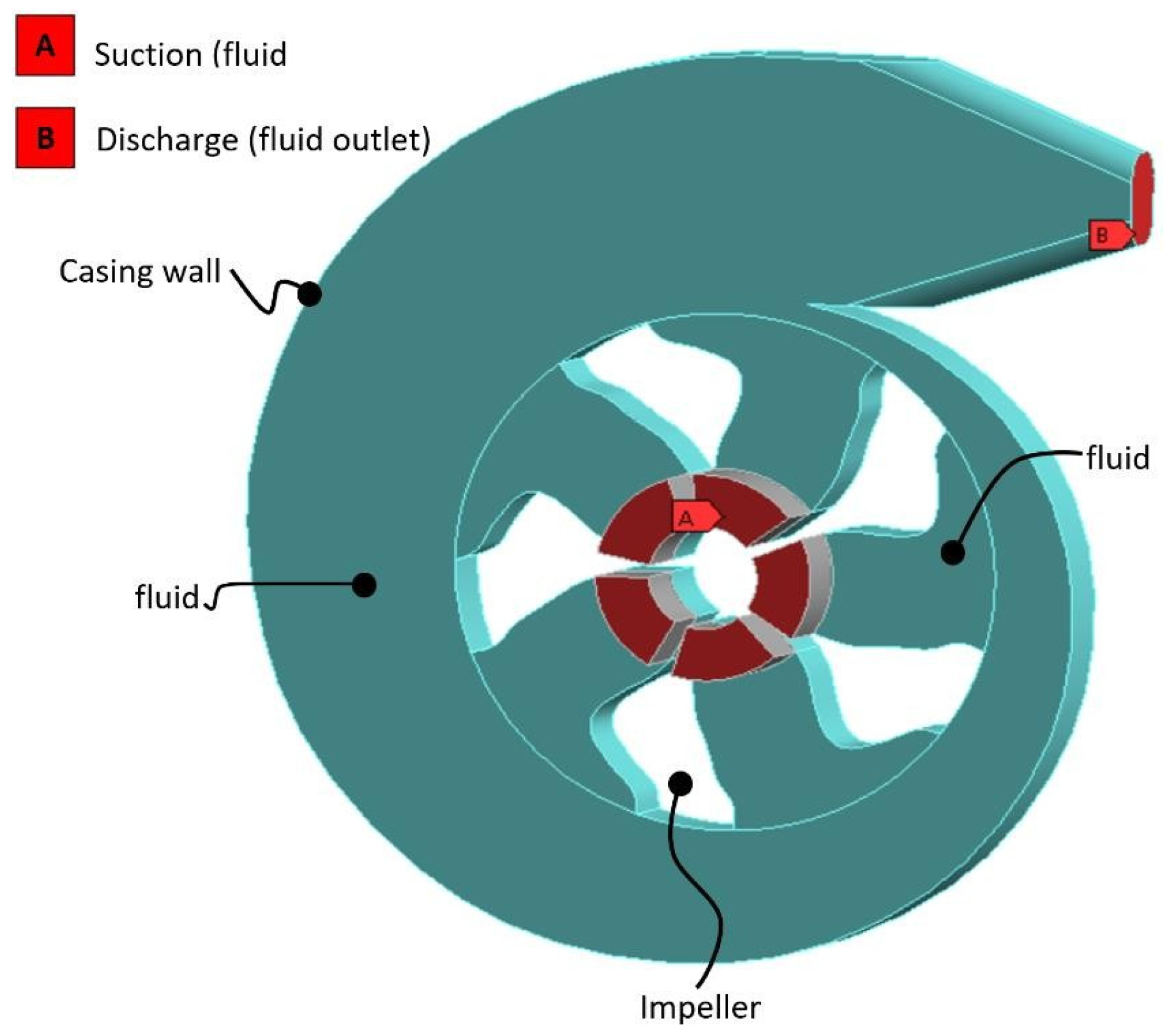

For instance, the combination of conventional numerical techniques, such as FEM, TOM, and accelerated methods, can be an efficient tool to improve the geometry of pump impellers and obtain significant enhancement in the efficiency of turbomachines. This work aims to develop a computational algorithm in MATLAB version R2020a to conceptually design the rotor of a radial flow centrifugal pump, to minimize a bi-objective function formed by the viscous dissipation energy and vorticity. Additionally, the developed algorithm is parallelized, and the code is executed with the use of several CPU cores in the cloud with two different providers, namely (a) Amazon Web Services (virtual machine) and (b) Equinix (bare-metal machine), to speed up the blade design process. Finally, the advantages and disadvantages of the different providers are analyzed, and a comparison is made between them in terms of time and computational costs.

This paper is organized as follows.

Section 2 is used to describe the finite-element method formulation applied to centrifugal pumps. In

Section 3, the implementation of topological optimization is detailed. In

Section 4, a hierarchical classification of various methods in CFD are detailed, the accelerated method used in the parallel code and the parallelized pseudocodes are explained.

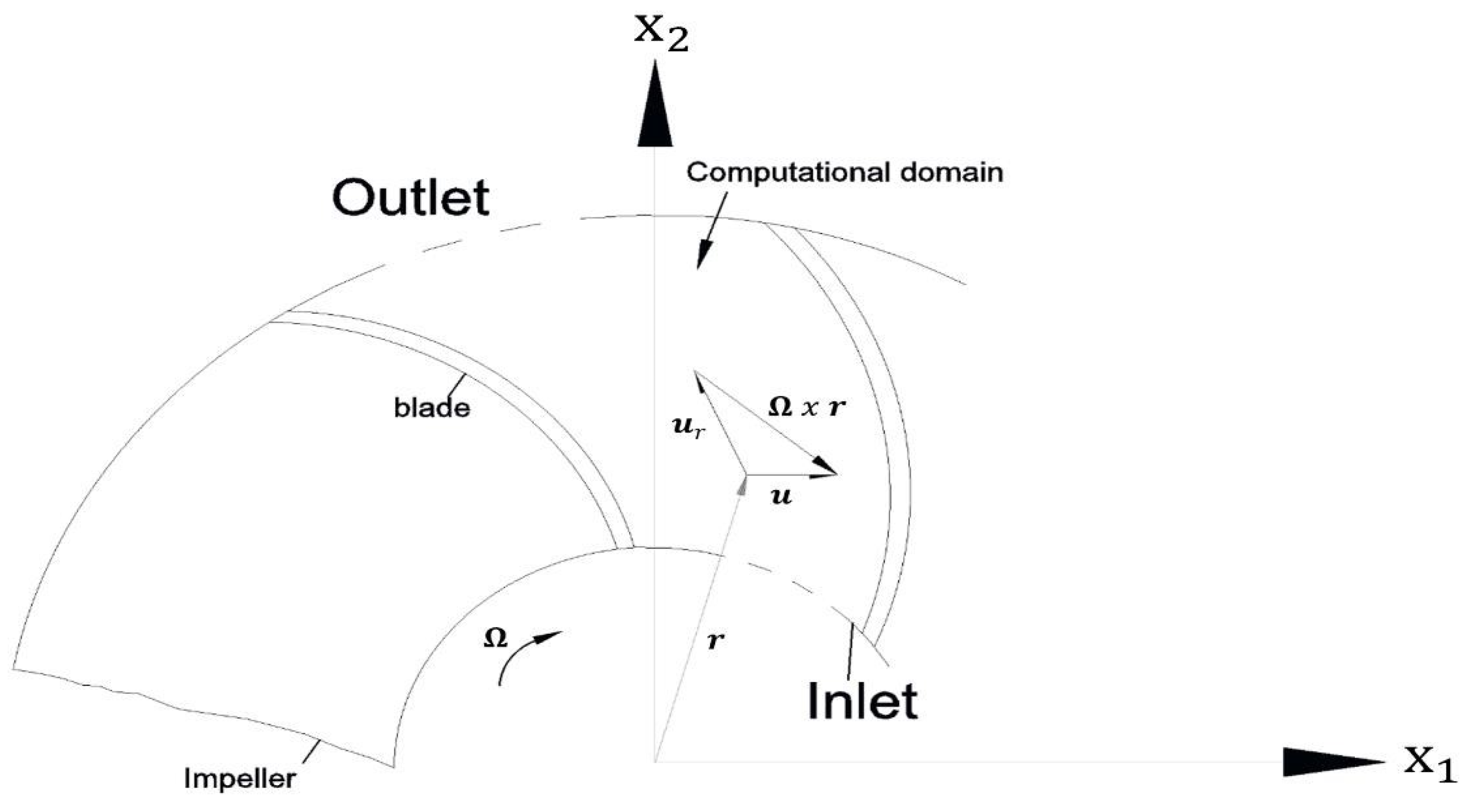

3. Topology Optimization Applied to the Radial Flow Machine Model

3.1. Material Model

The material model used in this work is the same as Borrvall and Petersson [

16] and Romero and Silva [

17]. The absorption function alpha (

α) represents the impermeability of a porous flow, dividing the domain into regions between a high permeability of the material, interpreted as a solid (

α > 1), and a low permeability of the material, represented as a fluid (

α = 0). This absorption function (Brinkman-type model) controls the distribution of the material throughout the domain, and its value depends on the optimization design variable gamma (

γ). This function is assigned by the element, and it is given by the following expression:

where:

αmax → Brinkman’s maximum penalty;

αmin → minimal Brinkman penalty;

q → permeability penalty;

γE → design variable per element.

3.2. Topology Optimization Formulation

The optimization problem in this work is a bi-objective function that includes the minimization of the energy dissipation and the minimization of the vorticity in the rotor [

17]. Thus, the optimization problem is formulated by the following expression:

The function is a bi-objective function that includes the minimization of both mentioned parameters in the rotor. The inequality constraints ≤ 0 for our specific problem is a volume constraint that defines the amount of fluid regions in the domain. Finally, the equality restrictions correspond to the fluid-modeling equations presented in the FEM for viscous flow in residual form.

3.3. Energy Dissipation

Energy dissipation is one of the objective functions in this work. At the entrance of the pump, the fluid acquires internal energy that is transmitted by the impeller of the centrifugal pump. This energy will not be the same at the exit of the rotor due to the energy losses generated by the viscous efforts in the equation of energy. This parameter represents the energy losses generated by the viscous stresses that arise from the interaction that exists between the rotor and the fluid in question, which is responsible for changing the momentum of the fluid, thus changing its direction and energy.

This energy dissipation equation is given in discrete form by the following expression [

17]:

where:

→ scalar energy dissipation;

→ design variable vector;

→ nodal values of velocities per element;

→ coefficient matrix of degrees of freedom per element.

3.4. Vorticity

Strong secondary circulatory (vortex) flows are seen in mixed-flow impellers such as axial/centrifugal pumps. These vortex flows are undesirable since they are responsible for head losses, non-uniform flows, and sliding. Backflow caused by recirculation can cause cavitation in the impeller blades [

23].

Turbomachine designers often employ disruptive elements/flow guides such as splitter vanes and other modifications (negatively impacting machine efficiency) rather than focusing on the real causes and intrinsic physical mechanics that generate secondary vortex flows. Thus, in this work, the machine flow topology is also optimized to minimize vorticity. Its equation is given in discrete form by the following expression [

17]:

where:

→ scalar vorticity;

→ vorticity matrix.

This matrix,

is obtained through the cross derivatives of the velocity in each direction (like the diffusive term in the Navier–Stokes equation) for each element, where the coefficients are explicitly detailed in the following expressions:

i = 1, 2… 8 (depending on the evaluated test function);

j = 1, 2… 8 (depending on the degree of freedom).

3.5. Bi-Objective Function

In this section, the two objective functions are combined, defining a bi-objective function based on the weighting sum method:

where:

c → scalar bi-objective function;

→ weighting coefficient associated with the energy dissipation term;

→ weighting coefficient associated with the vorticity term;

→ is a normalization factor between the vorticity and the energy dissipation;

and are energy dissipation and vorticity functions that were expressed previously.

3.6. Sensitivity Analysis

The sensitivity analysis consists of evaluating the objective function gradients to provide information on their constraints for its optimization. The derivatives of the objective functions are carried out with respect to the design variable , aiming to evaluate the partial change to our objective function in the whole domain, and thus provide the TOM algorithm the fastest way to find the minimum of our function in the domain of design.

Since the bi-objective function comes from a weighted sum, the equation for the sensitivity analysis involving the vorticity and the energy dissipation is also given from a weighted sum and is expressed as follows:

This interpretation of the sensitivity analysis can be performed either on continuous or discrete equations of the numerical method. In this paper, the sensitivities were implemented on the discrete equations and calculated by the adjoint method [

24], due to the large number of design variables.

The numerical verification of the sensitivity analysis is compared with the forward finite-difference method for the energy dissipation and for the vorticity, giving no greater relative errors to 6%. This sensitivity analysis is important for the method of moving asymptotes (MMA) because it requires the sensitivity values of all finite elements

, aiming to minimize the bi-objective function

in the whole domain.

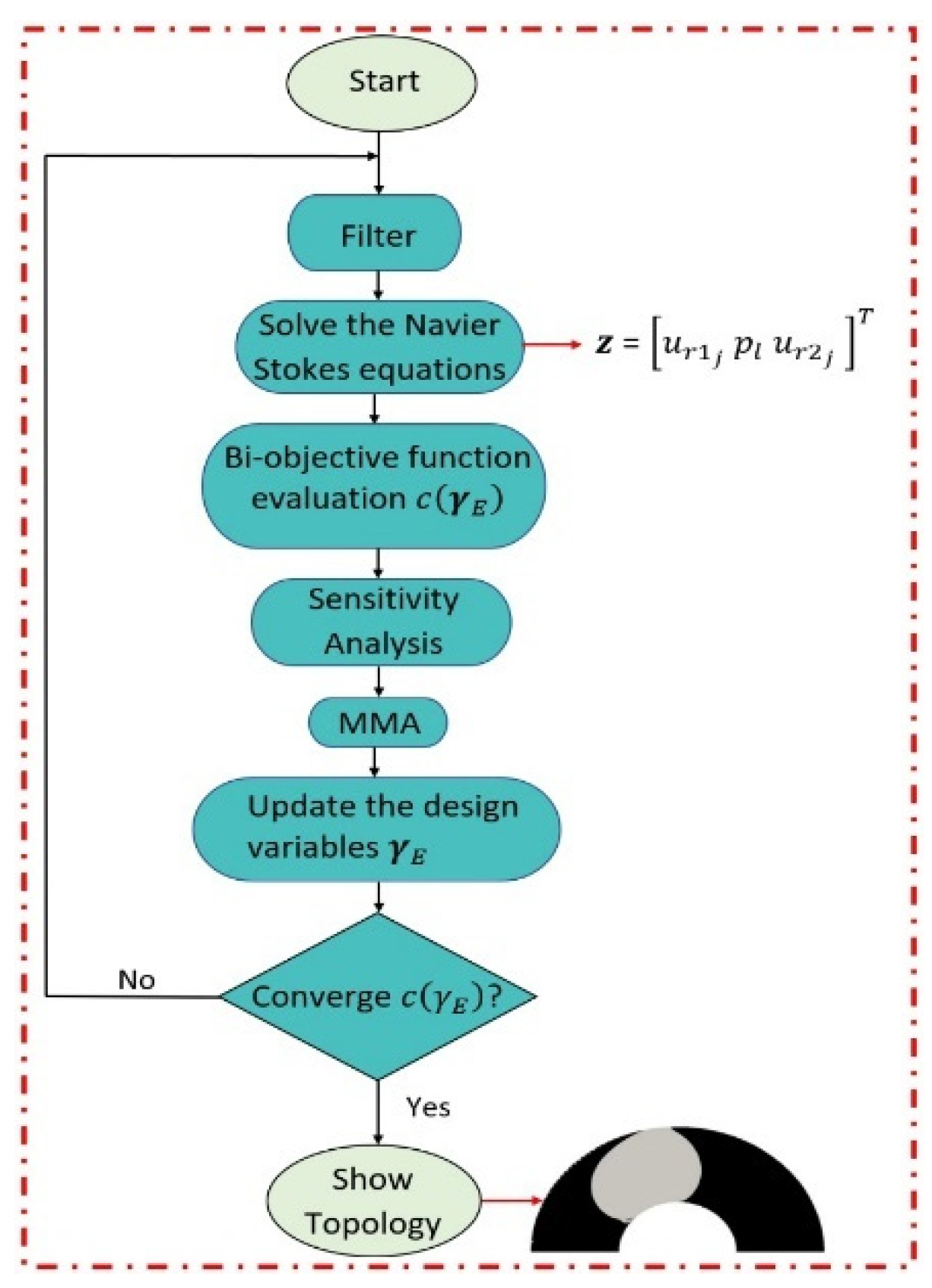

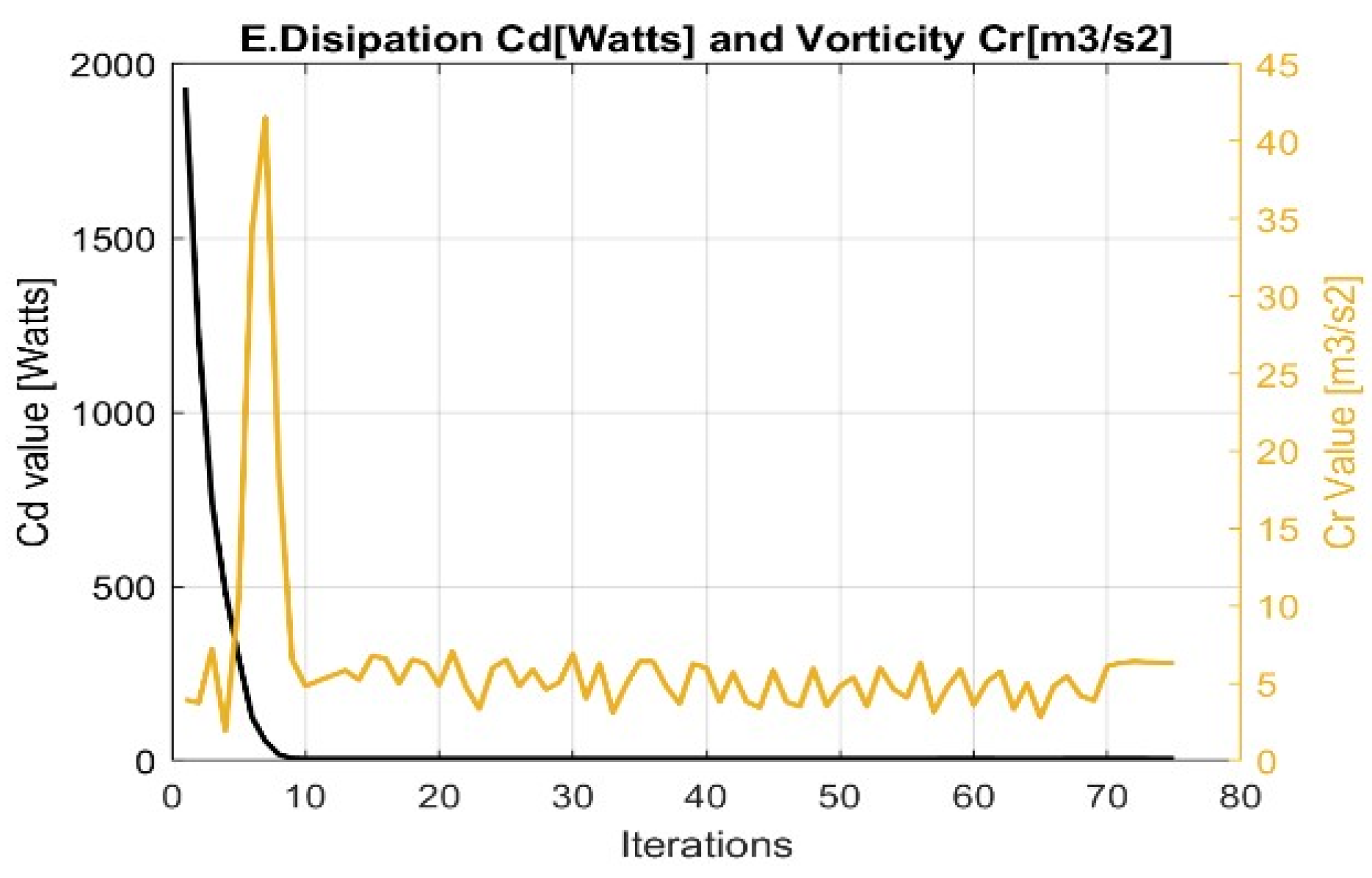

Figure 3 shows the topological optimization algorithm implemented in this research.

3.6.1. Sensitivity Analysis (E.D.)

It is also possible to analytically determine the gradient of the energy dissipation functions, as is shown in Equations (36) and (37). At this point, it is highlighted that the energy dissipation function is expanded by including the pressure state design variable through

to achieve compatibility with the resulting equation from the residual:

where:

→ vector of total derivatives;

→ state variable vector;

→ vector of explicit derivatives;

→ adjoint vector;

→ residual vector of the FEM equations.

3.6.2. Sensitivity Analysis (V)

Applying the same method in the previous section, the sensitivities of the vorticity function with respect to the design variable are also calculated, and these sensitivities are shown in Equations (38) and (39).

where:

→ vector of total derivatives of the vorticity;

→ adjoint vector of the vorticity;

→ Jacobian matrix;

→ Vorticity matrix.

The explicit derivative in Equation (38) is zero because it only depends on the diffusive terms in the Navier–Stokes equation, which do not depend on the design variable. Additionally, it should be mentioned that, to guarantee the compatibility of the left and right sides in Equation (39), the adjoint vector is calculated by direct selection. For example, for the column vector of one element, the nodal solutions of the velocities at x1 and x2 are chosen, omitting the nodal results of the pressures and generating a column vector of 16 × 1 of dimensions for the adjoint vector.

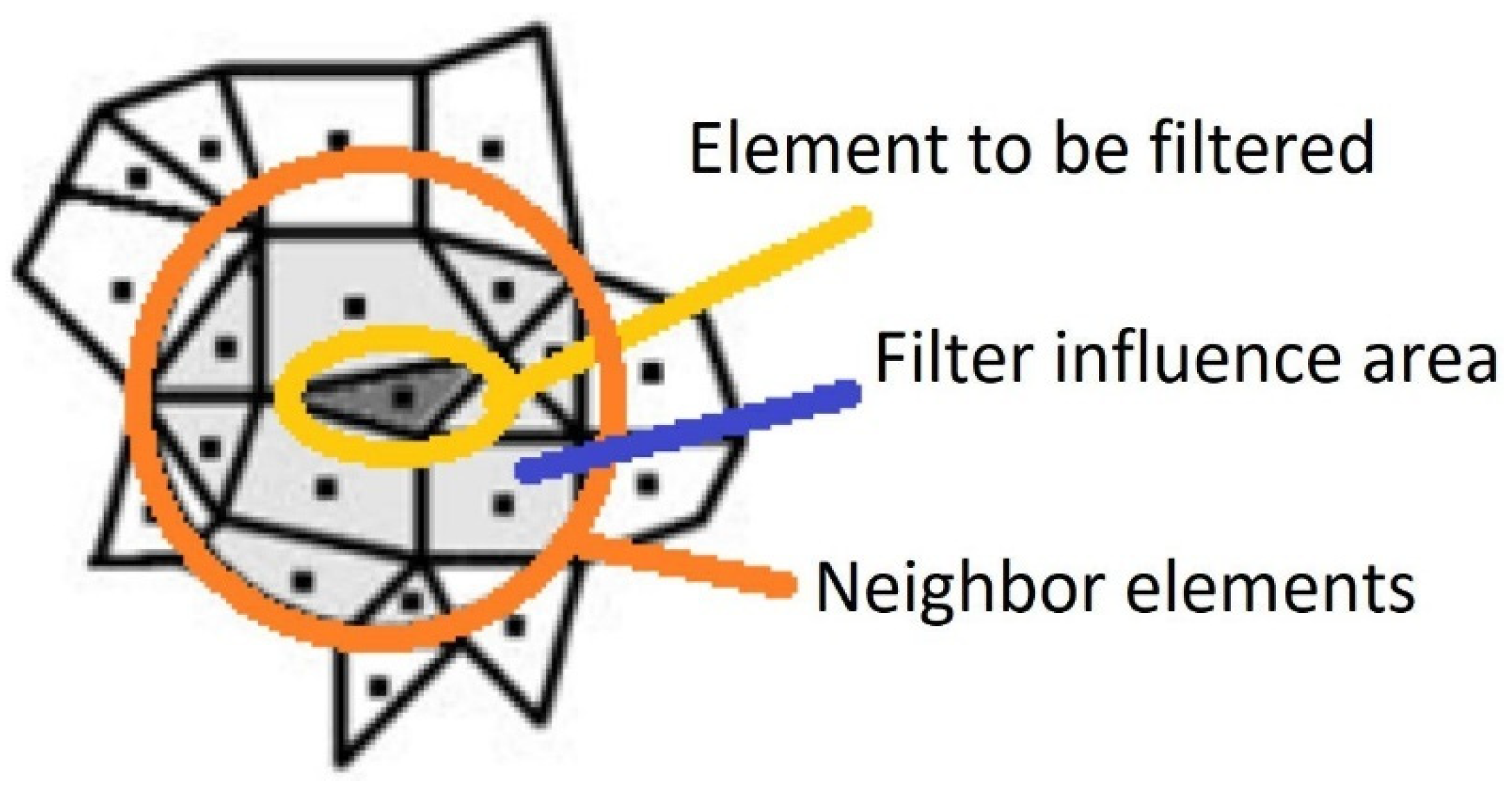

3.7. Filter

The mesh dependence problem is reduced with the application of spatial filters, since they control the area of influence from a defined radius (

Rmax), resulting in control of the topology complexity [

25].

Figure 4 illustrates the concept of a spatial filter in a two-dimensional mesh, where the element being filtered has a neighborhood selected by the radius of the filter

Rmax. Neighboring elements are those where the centroid of these elements is within the filter’s area of influence.

The filter used in this paper is the one proposed by Cardoso and Fonseca [

25]. The formulation of this filter is detailed in Equation (40), and it is called an average weight spatial filter (AWSF):

where:

is the value of the variable without filter;

is the volume of the element i;

is a weight factor;

is an average value of the weight factor;

is the radius of the filter;

is the distance between the center of element i and the center of element j;

is the number of neighboring elements.

4. Parallel Computing in the Cloud

Modern engineering requires significant computational capabilities in different areas of expertise, as engineering processes have become more complex and need frequent improvements. In this paper, parallel computing in the cloud is proposed as a platform solution to solve the TOM and FEM and applied is to flow problems in centrifugal pumps.

For decades, researchers in computational fluid dynamics have developed numerical methods to formulate and solve mathematical problems related to the physics of flow problems. These numerical methods can be classified into two main groups, such as “conventional methods” and “accelerated methods” [

27,

28,

29,

30,

31,

32,

33].

Conventional methods are the most widely used method, highly accurate, and used in most commercial packages (Ansys Fluent, Abaqus, etc.). However, conventional methods may occupy more computational memory when solving the fluid field in a certain design domain. For example, based on D. Kandhai et al. [

34], the Lattice–Boltzman method (LBM) uses 10 times less memory compared to the MEF when solving for flow in static mixer reactors, making it almost impossible to solve large problems in a reasonable time. On the other hand, accelerated methods are categorized into two main groups: advanced numerical methods and hardware techniques. The hardware techniques are generally used in conjunction with conventional and advanced numerical methods [

27]. The hardware techniques are used in this paper in conjunction with FEM as a solution technique to obtain the design of blades in turbomachinery. The interface tool chosen in this paper as a parallelization technique is the “Parallel Computing Toolbox” provided by MATLAB, which allows the user to select the number of “workers” or “cores” required to execute the algorithm.

4.1. CPU Architectures Selected in the Cloud for Execution of the Algorithm in Parallel

In this research, to accelerate the design process of the blade in a centrifugal pump, a virtual machine is used in Amazon Web Services (AWS) and a bare-metal machine in the EQUality, Neutrality and Internet eXchange (Equinix). The providers of these CPUs offer computer rental per hour to an end user, who remotely accesses these supercomputers through a personal computer and internet access. The two types of servers in the cloud (bare-metal and virtual machine) have a physical server that will be located at the provider’s facilities. The difference between these two terms lies clearly in the way the providers manage this server for the rental of these resources to the end user (s). In the bare-metal service, the entire physical server is dependent upon a single user. Therefore, the user has total control of the entire server for the proper management of the computational resources. On the other hand, in a virtual machine, the provider will virtualize this physical server (through a hypervisor) to create several virtual machines, so that several users can access these shared resources (RAM, cores, GPU, etc.) from the same server.

4.1.1. Virtual Machine in AWS

Table 1, characteristics of the type of processor used in the virtual machine for the parallelized TOM algorithm, specifies the type of processor used in the virtual machine to measure the performance of the parallelized TOM algorithm in the cloud.

The architecture of this type of processor is shown in

Figure 5. This processor offers a speed on each core of 2.2 GHz, where there is a communication channel (data/address bus) with the RAM.

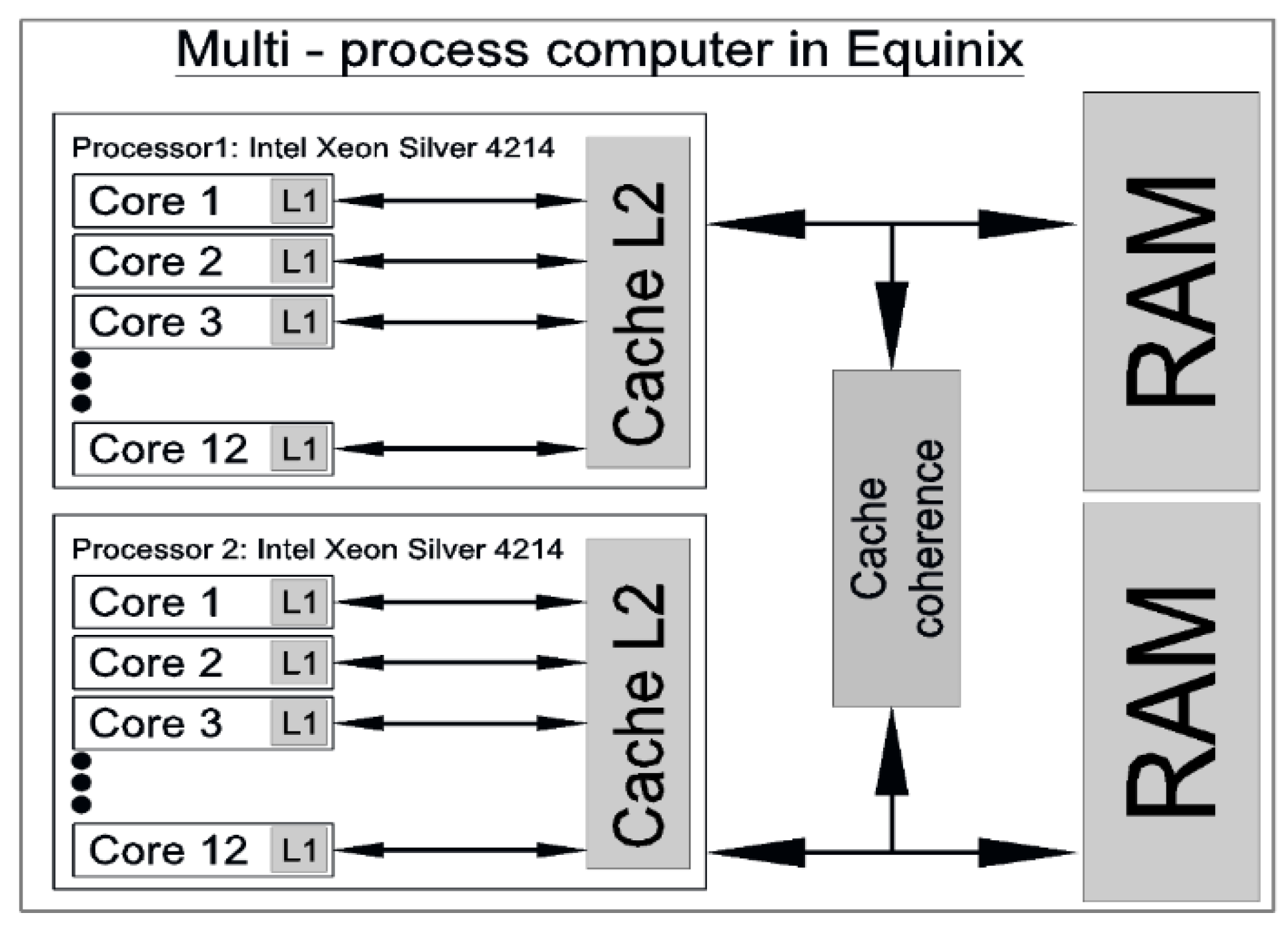

4.1.2. Bare-Metal Machine in Equinix

The provider selected for the bare-metal machine is Equinix (

Table 2). The server has two scalable processors interconnected with each other. This processor consists of 12 physical cores. That is, a total of 24 resource cores can be used in this supercomputer.

The architecture of this processor is shown in

Figure 6. This processor shows scalable technology that works with more than one multi-core processor. That is, each processor is placed in its own socket.

6. Discussions and Conclusions

Topological optimization of fluids using the finite-element method has attracted the attention of many researchers due to its ability to design optimal geometries in fluid transport and control systems. Among the pioneering works, Borrvall and Petersson (2003) developed a general framework for optimizing flow in two-dimensional systems, using formulations based on the Stokes equation [

16]. In their results, they demonstrated how it is possible to generate optimal designs to minimize energy dissipation in flow channels. Fonseca et al. extended the approach by including additional constraints related to structural robustness and fluid–structure interaction [

25]. Their studies evidenced that the integration of multiple objectives in the optimization allows for obtaining designs that not only maximize hydraulic performance but also guarantee mechanical stability. Compared to Borrvall and Petersson’s work, the optimized geometries presented more complex configurations but with a significant improvement in energy efficiency and wear resistance. On the other hand, Brenner explored topological optimization in three-dimensional systems using improved finite-element methods to handle the increased computational complexity. The results showed that optimized three-dimensional configurations allow for more precise flow control, especially in applications such as heat exchangers and microfluidic systems. Compared to two-dimensional approaches, three-dimensional designs offer advantages in specific industrial applications, although they require a higher computational cost. Hosain and Cardoso took an innovative approach by incorporating nonlinear effects in flow optimization, extending applications to the turbulent regime [

25,

27]. Their research highlighted how advanced formulations based on the Navier–Stokes equation allow systems with high velocity flows and higher complexity to be optimized. In their results, they achieved designs that improved hydraulic efficiency by 20–30% compared to traditional methods, showing the potential of topological optimization in real systems.

The purpose of this article is to show the reader that there are mathematical optimization tools that, although they take time to implement to a specific problem, can save costs and time at the design time. The result of obtaining a lower vorticity is an important issue, especially in ventricular assist devices where a minimization of this physical phenomenon is required. In this work, the minimization of energy dissipation and increased vorticity could increase the hydraulic efficiency by 38%, which is similar to what Hosain and Cardoso stated.

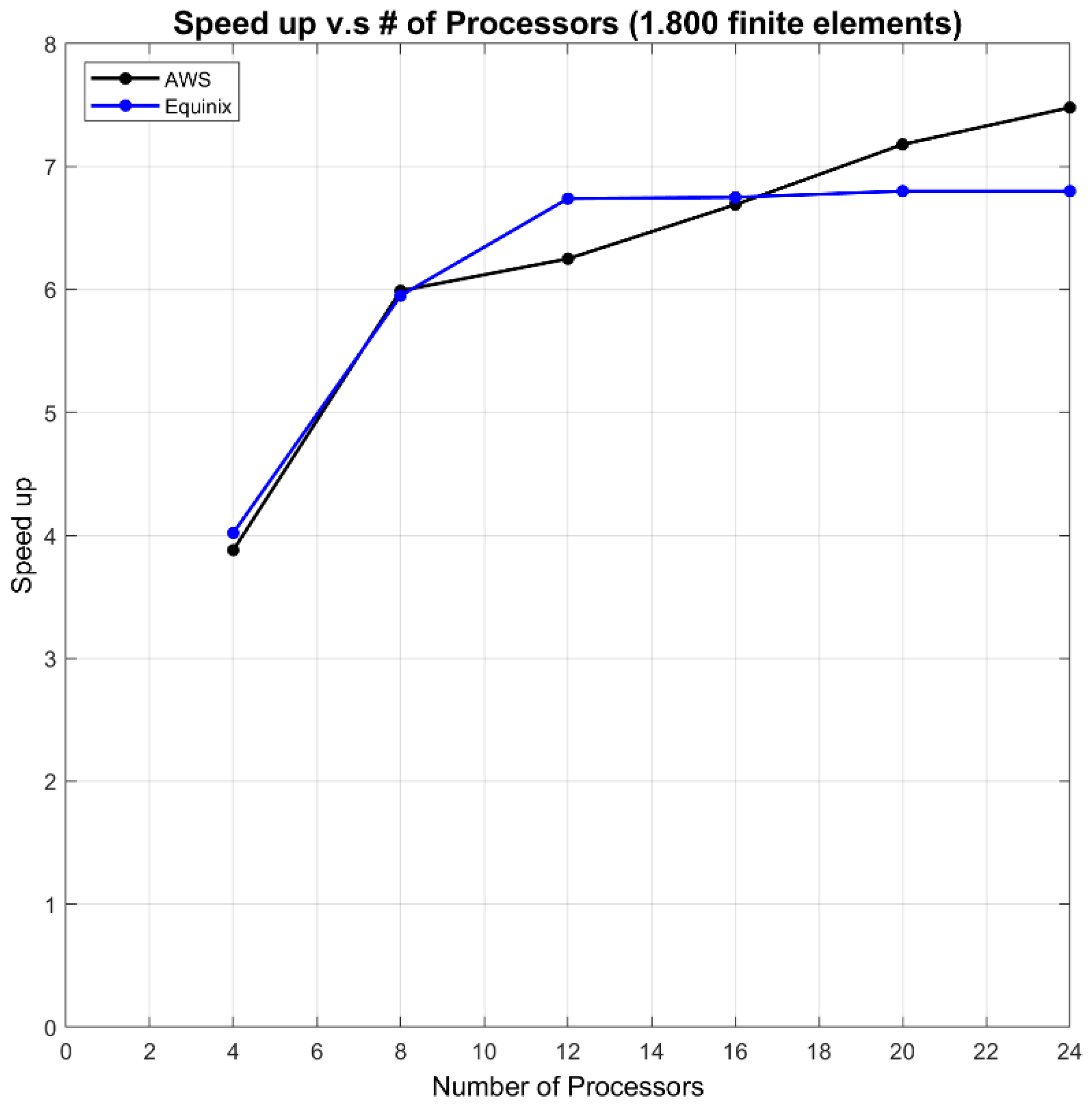

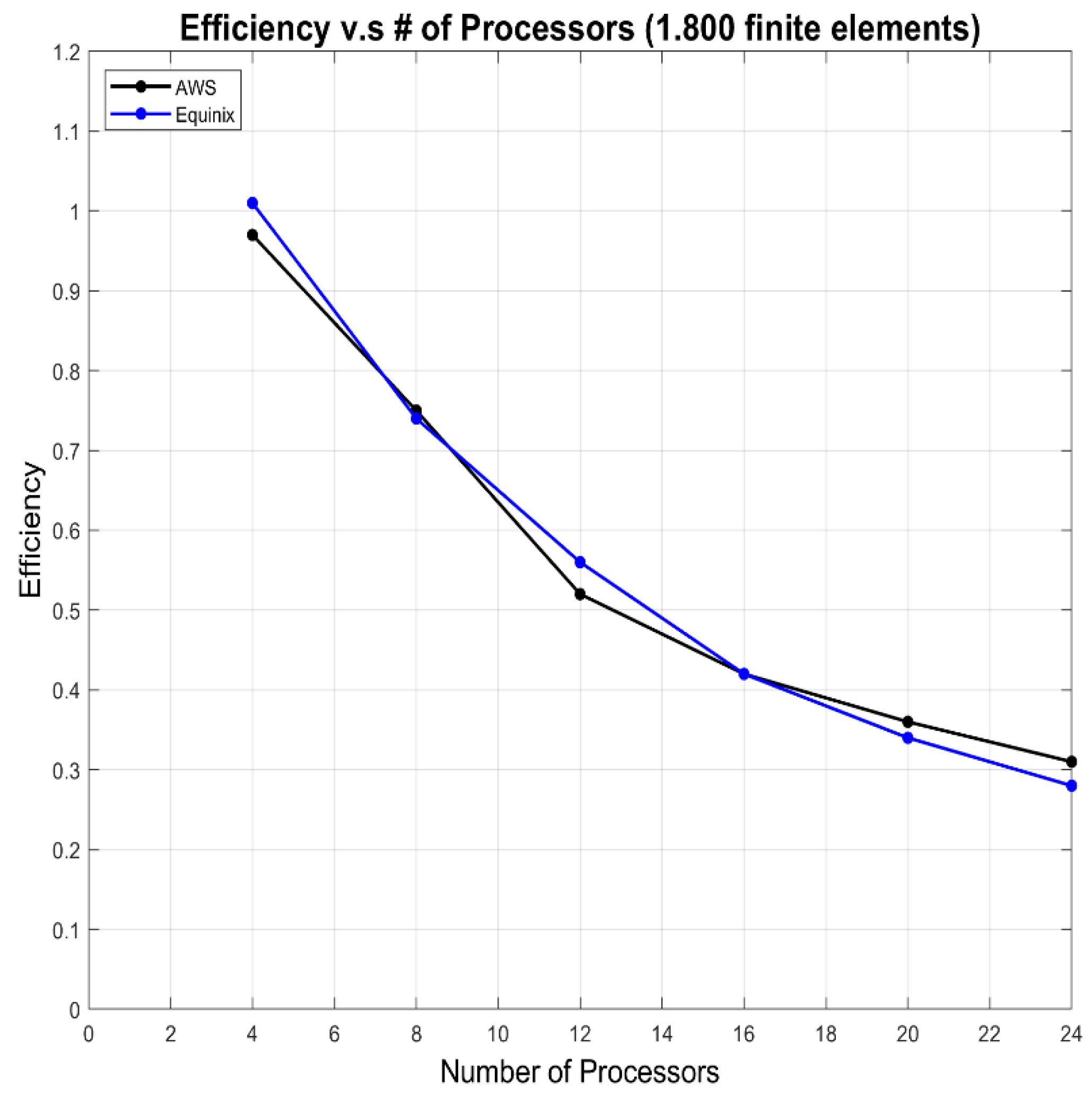

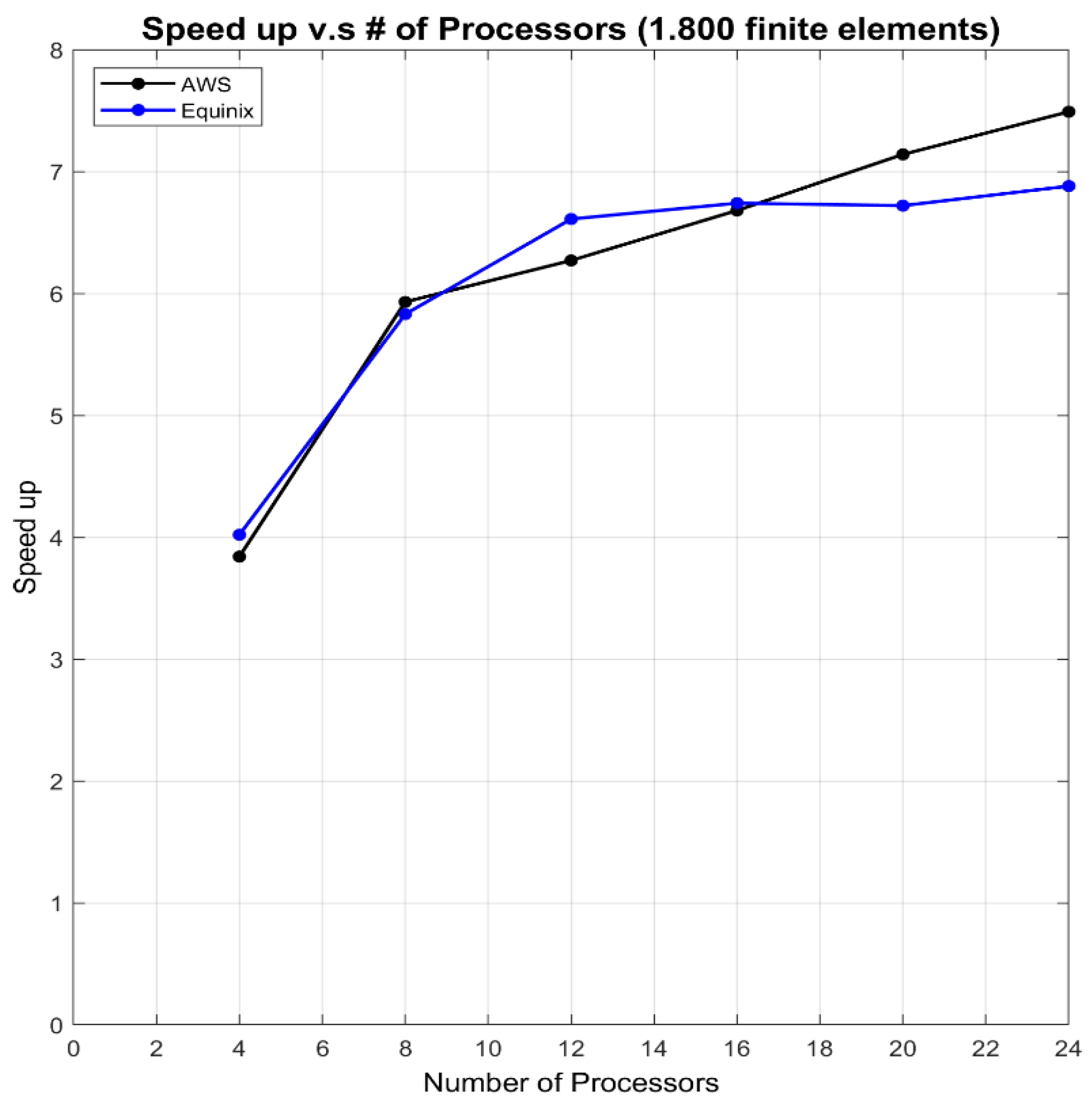

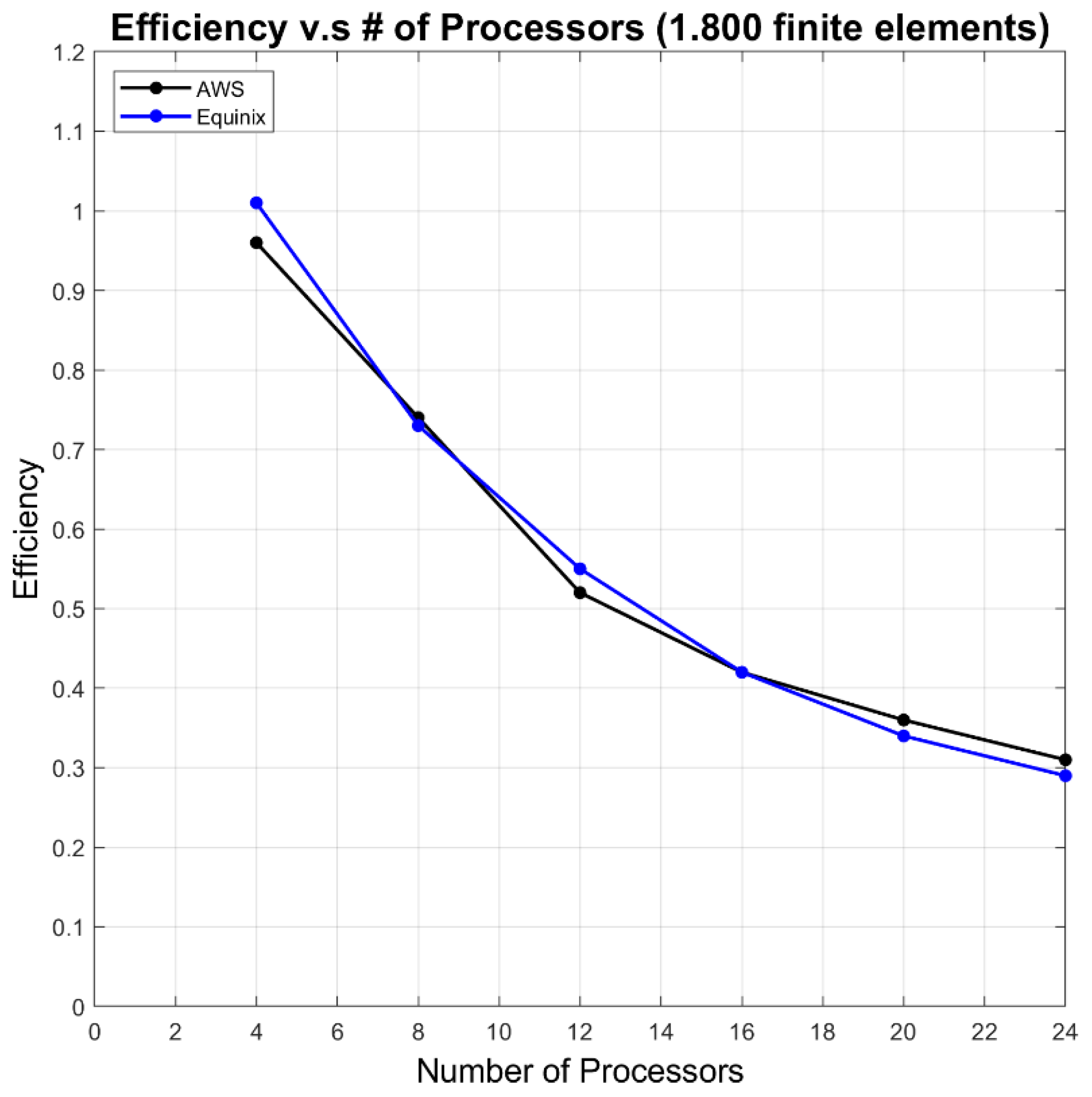

Techniques such as cloud computing allow for the development of a parallelized topological optimization algorithm, obtaining designs for turbomachinery rotors that may be non-intuitive for the designer. Similarly, the parallelization of the computational algorithm in the design model of “blades in half-rotor circumference’’ is considered successful. The fact of reducing the execution time to more than half increases the robustness of the developed algorithm. These parallelization techniques (bare metal and virtual machine) are one of the accelerated-method techniques that were studied in this paper and that motivate other readers to continue investigating new techniques to reduce the computational costs that we face today.

For this specific problem (design of rotors in half circumference), it is recommended to use AWS if it is required to execute the TOM algorithm in serial or with the use of four cores in parallel. On the other hand, for greater than four cores, it is recommended to run the algorithm in Equinix, due to the costs per hour that each provider charges for their respective services.

The Brinkman material model penalty is strong enough to represent solid and fluid zones, resulting in topologies that represent the physical minimization of the problem. The methodology used allows for extending the study of other objective functions of the turbomachine design problem. This study can go beyond hydrodynamics and, thus, be extended to objective structural functions that analyze the mechanical parts that comprise it, for example, the study of the stresses generated in the rotor of a turbomachine through interaction with the fluid.

In summary, topological optimization has proven to be a successful method for the design of rotors of radial flow machines. The work of several authors has established a solid foundation for the topological optimization of fluids using finite elements, ranging from basic formulations to advanced applications in three-dimensional contexts and with turbulence. Although each approach has specific advantages depending on the conditions of the problem, all agree that this technique offers great potential to improve the efficiency and functionality of flow systems, consolidating itself as a key tool in modern engineering.