A Critical Review of Ultrasonic-Assisted Machining of Titanium Alloys

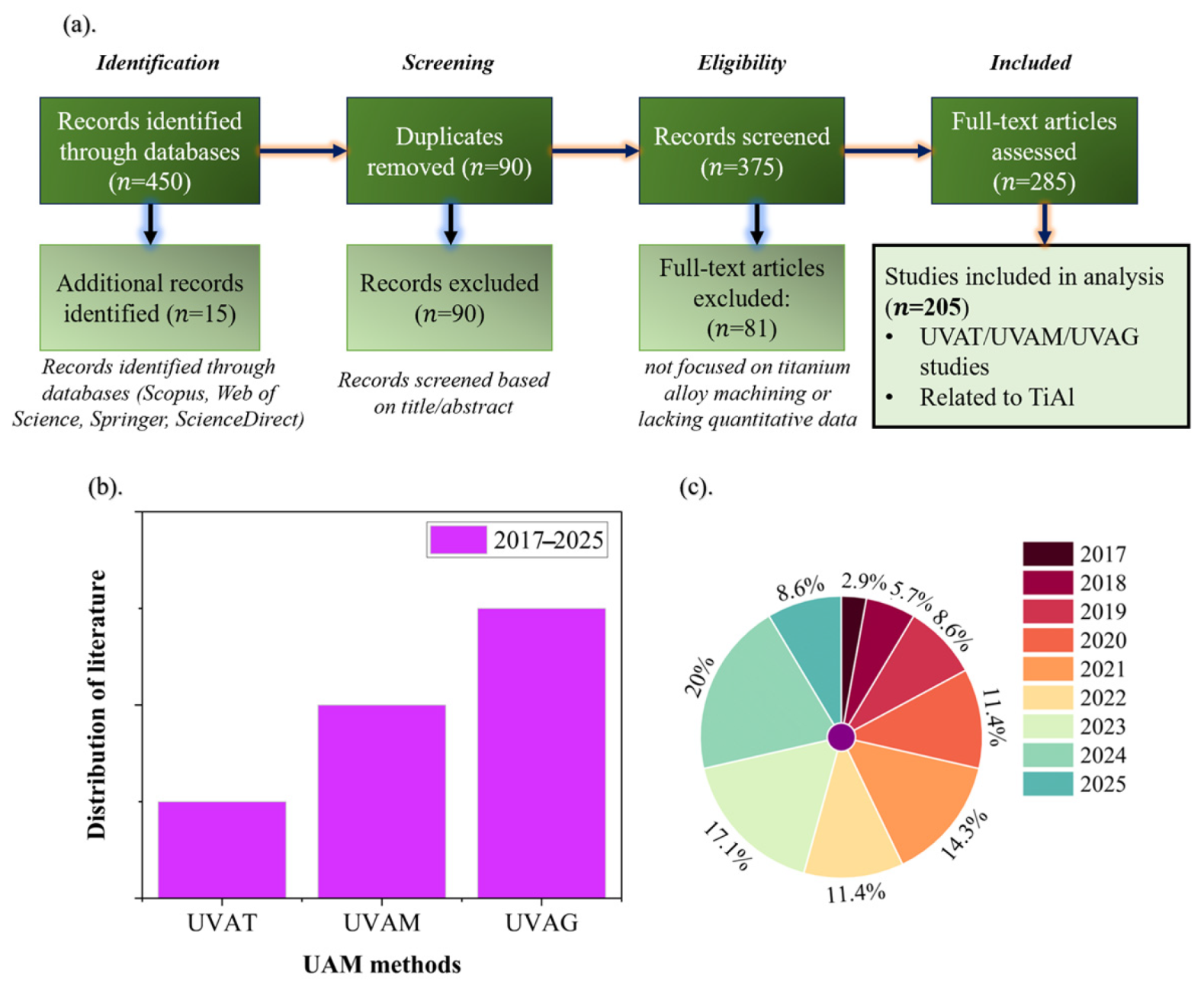

Abstract

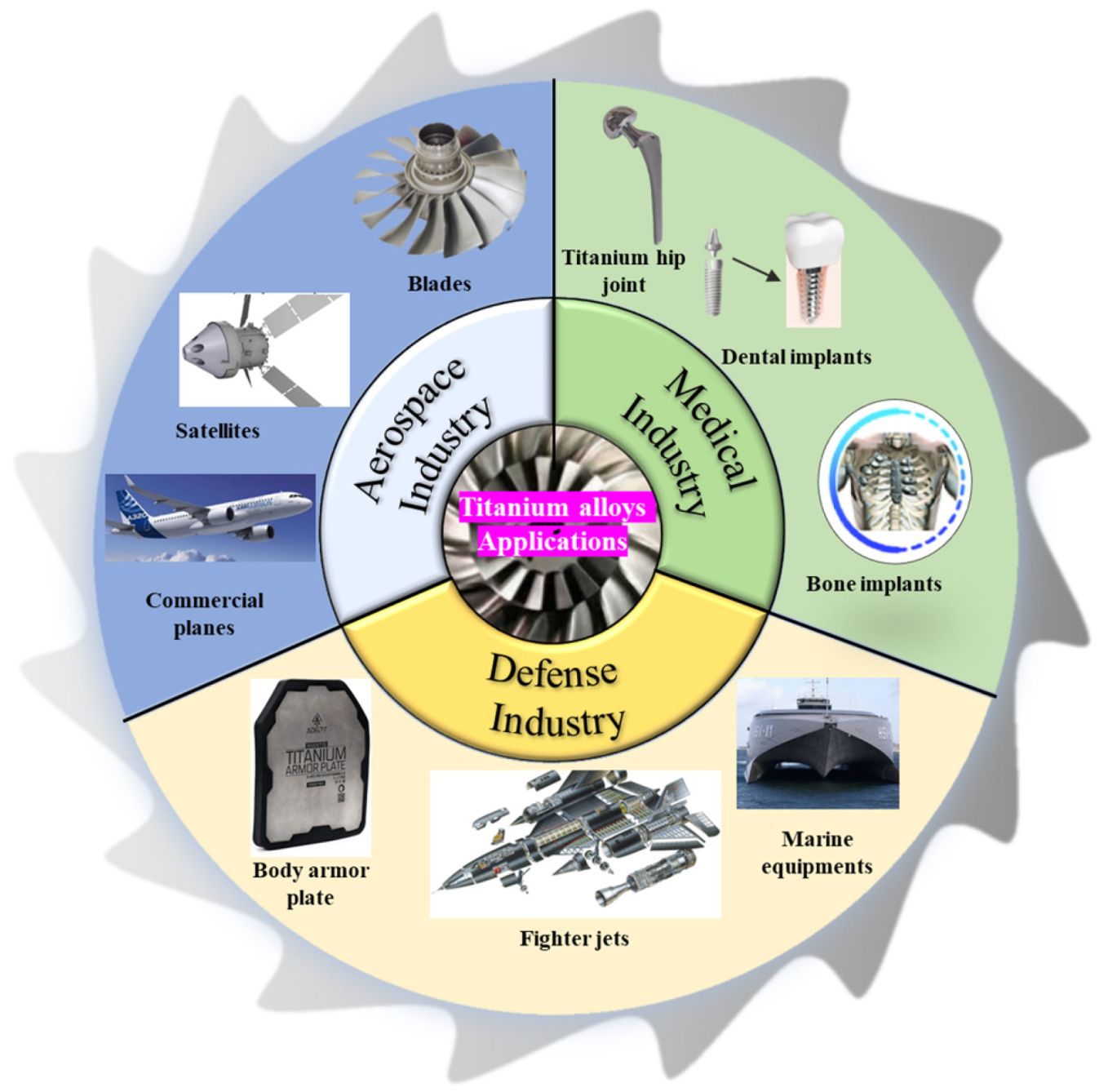

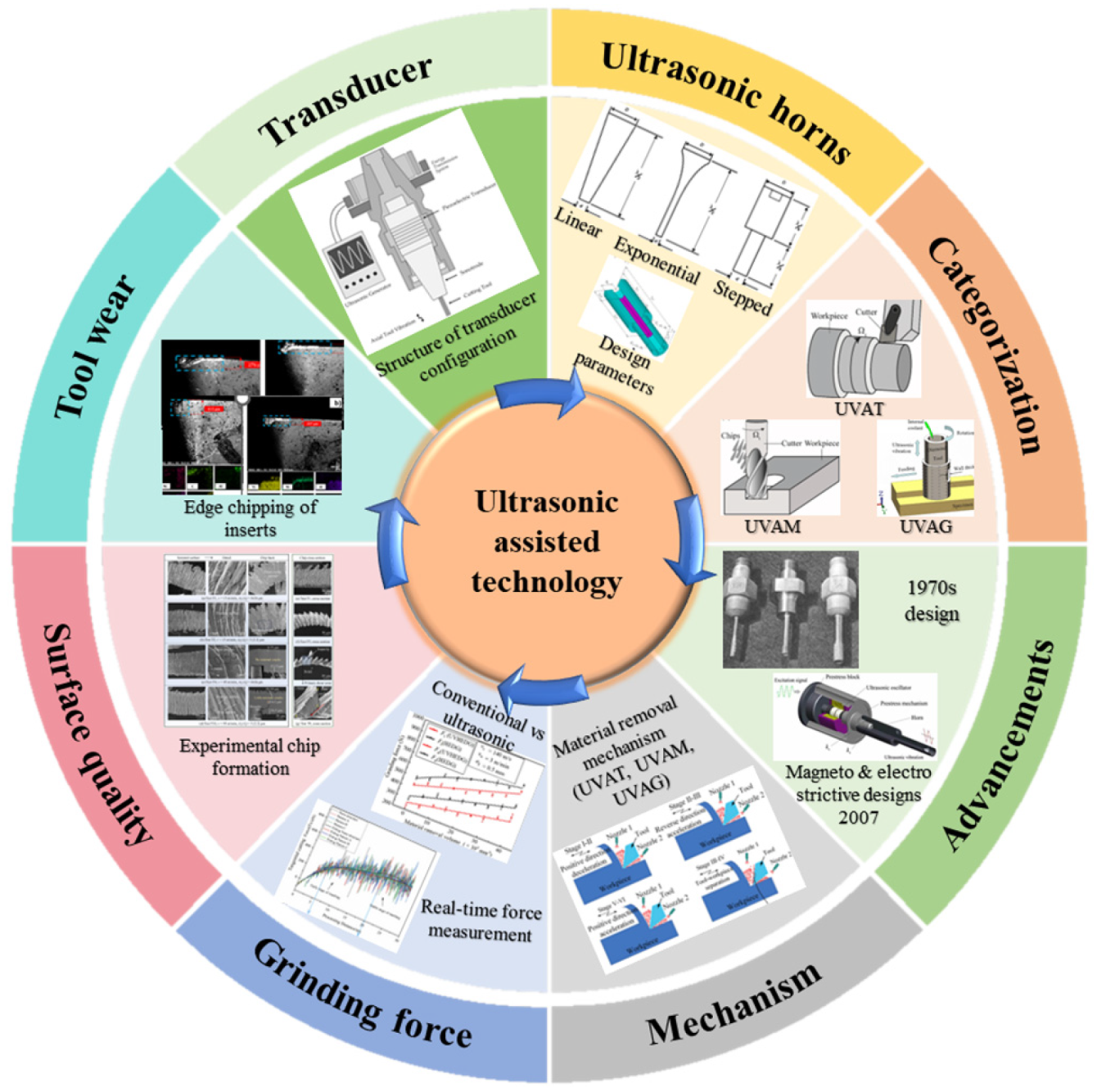

1. Introduction

2. Characterization and Processing Considerations for Titanium Alloys

2.1. Elemental Composition of Titanium Alloys

2.2. Binary and Tertiary Titanium Alloys

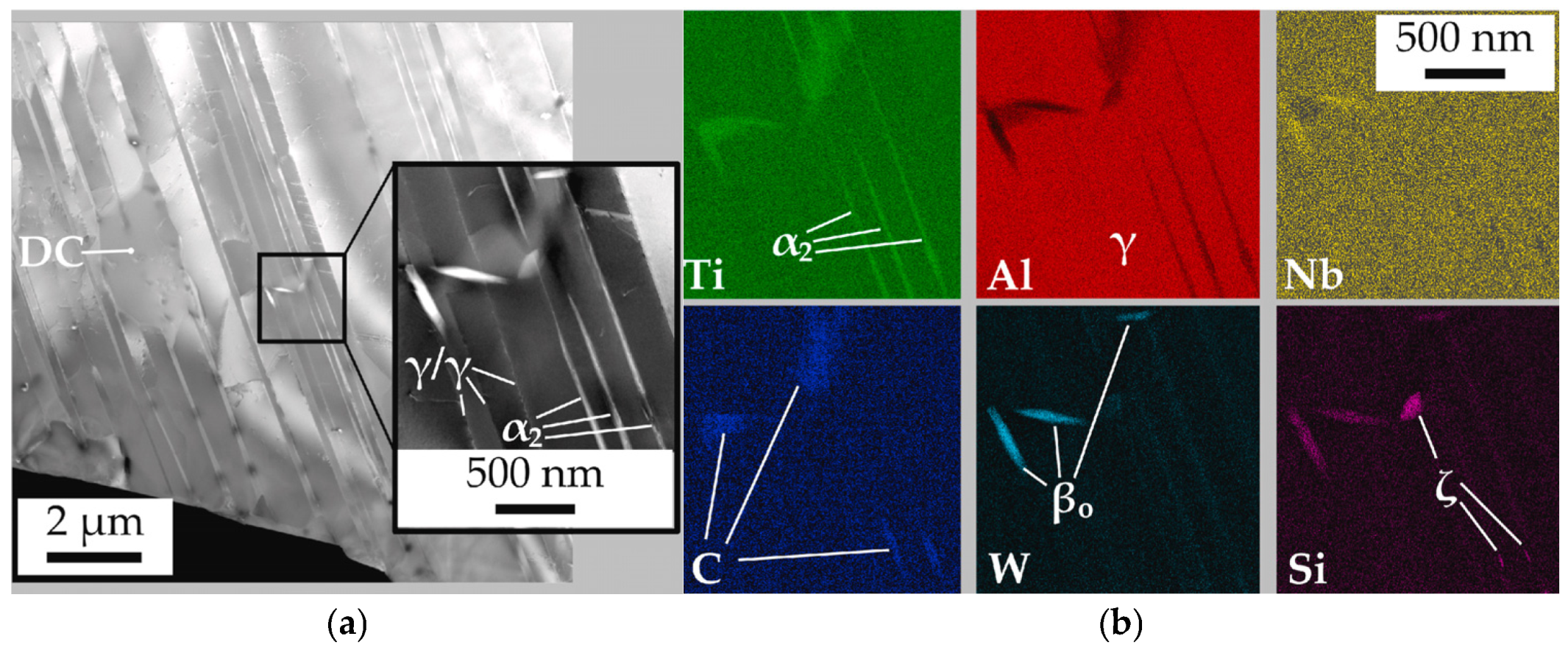

2.3. Properties of Additively Manufactured γ-TiAl Alloy

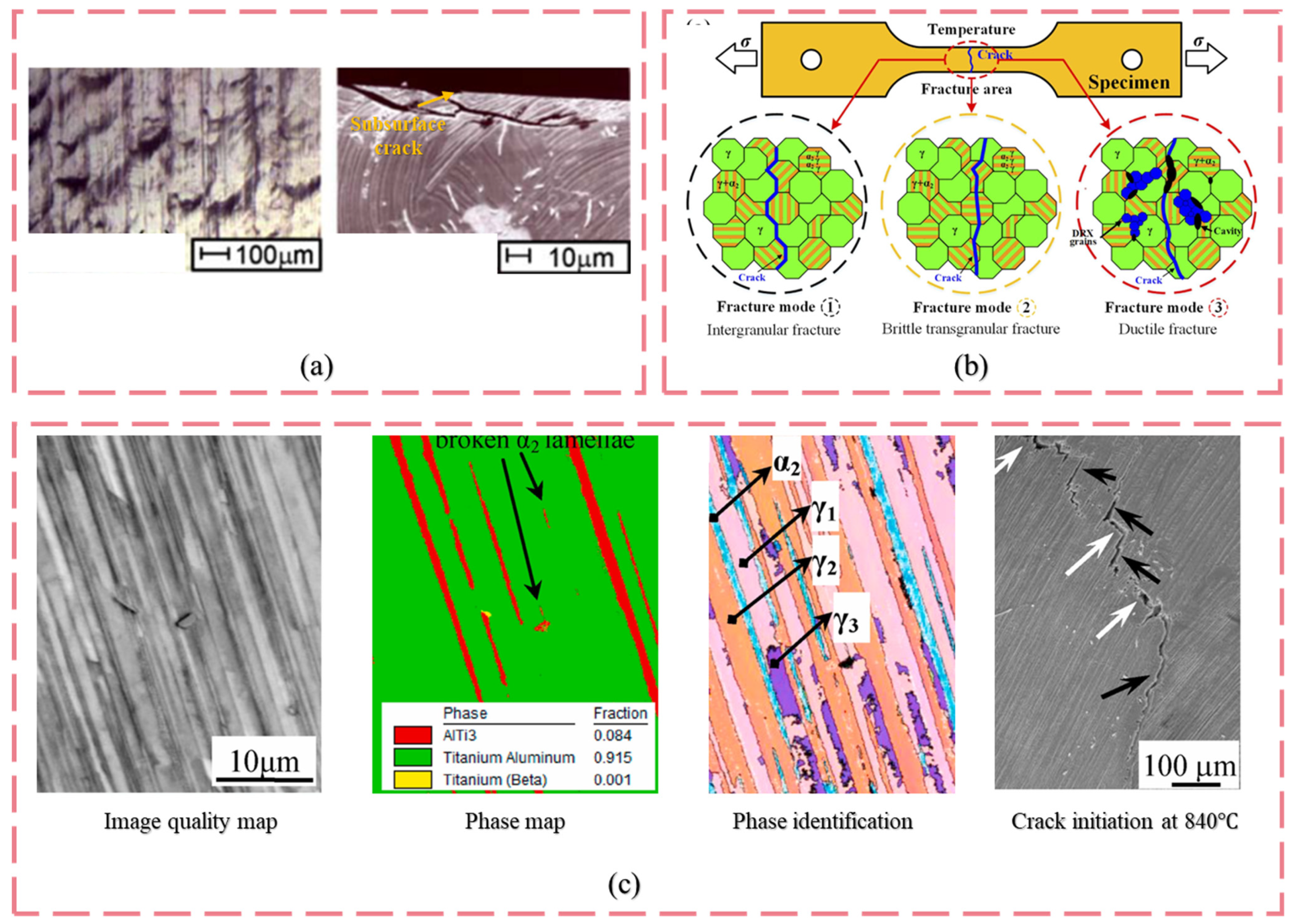

2.4. Challenges in Additively Manufactured -TiAl Alloys

3. Machining Efficiency of Titanium Alloys

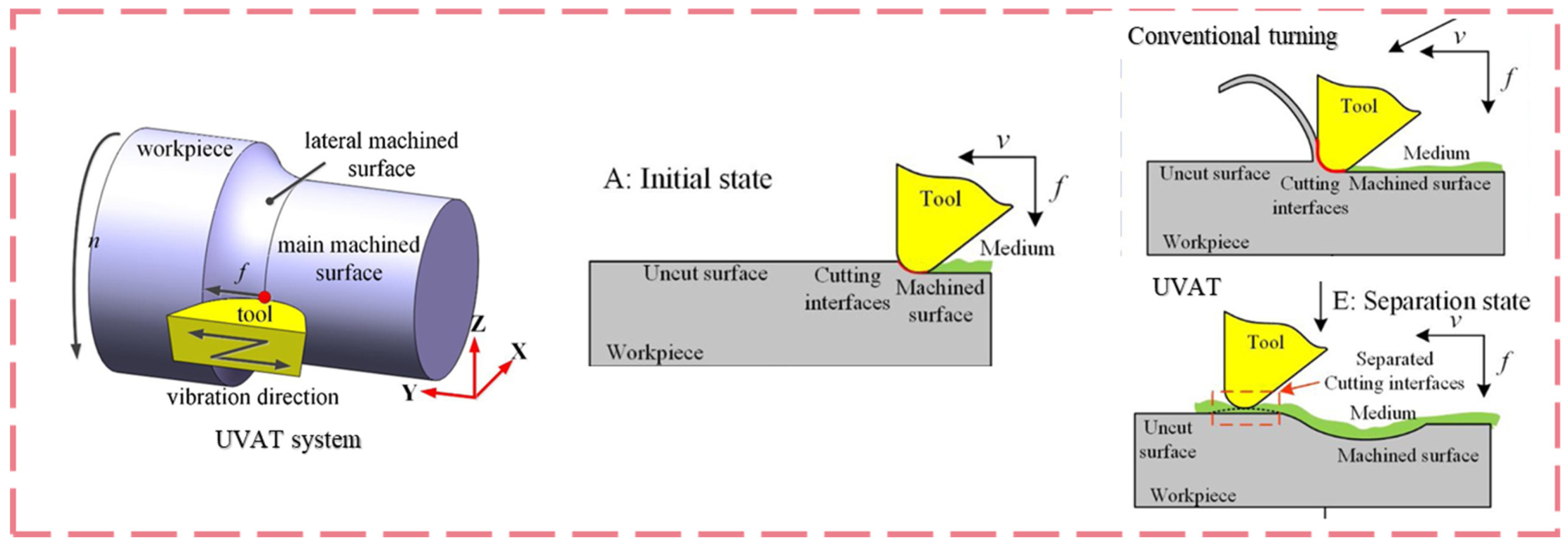

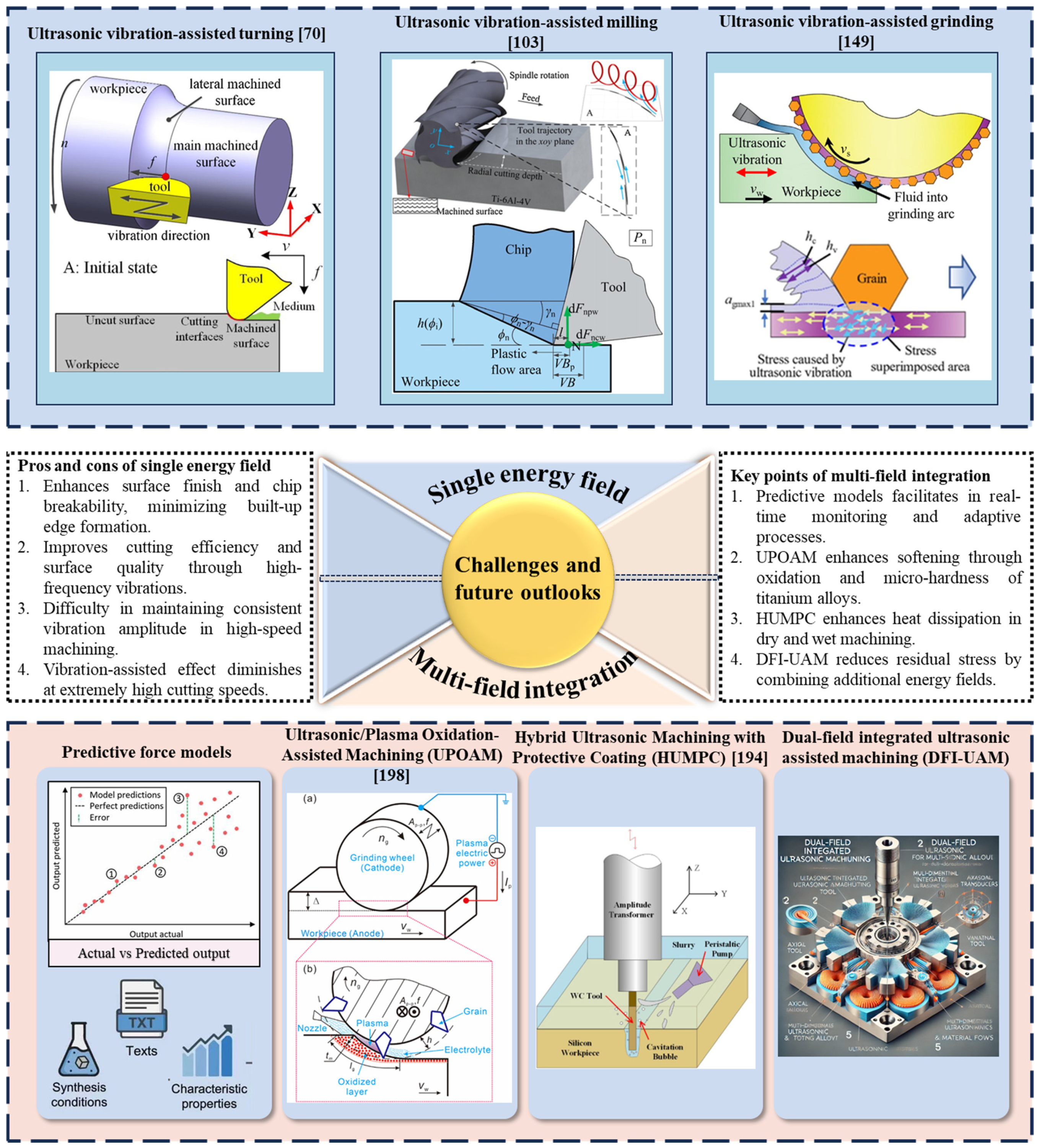

3.1. Ultrasonic Vibration-Assisted Turning (UVAT)

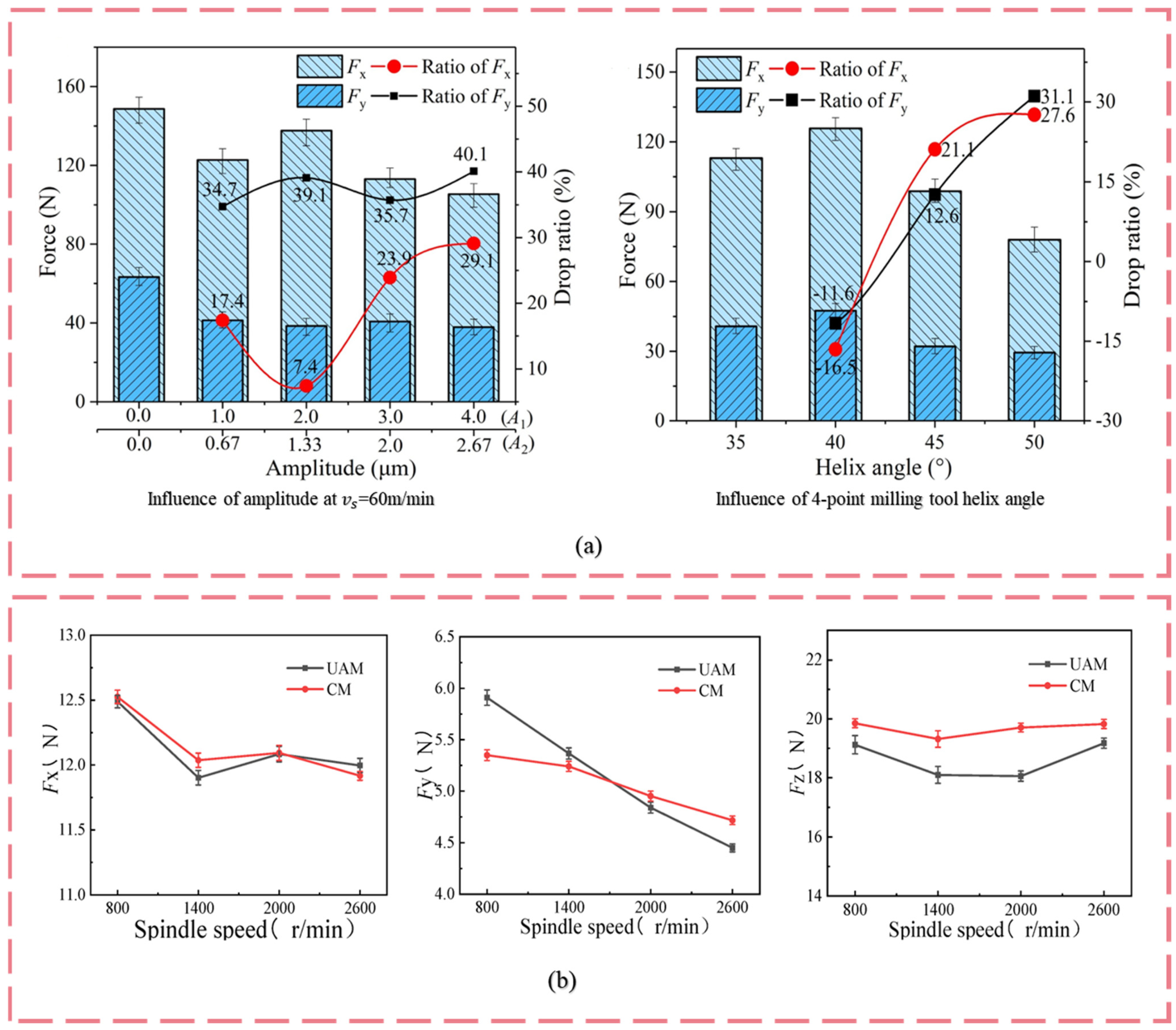

3.1.1. Influence of UVAT on Cutting Force

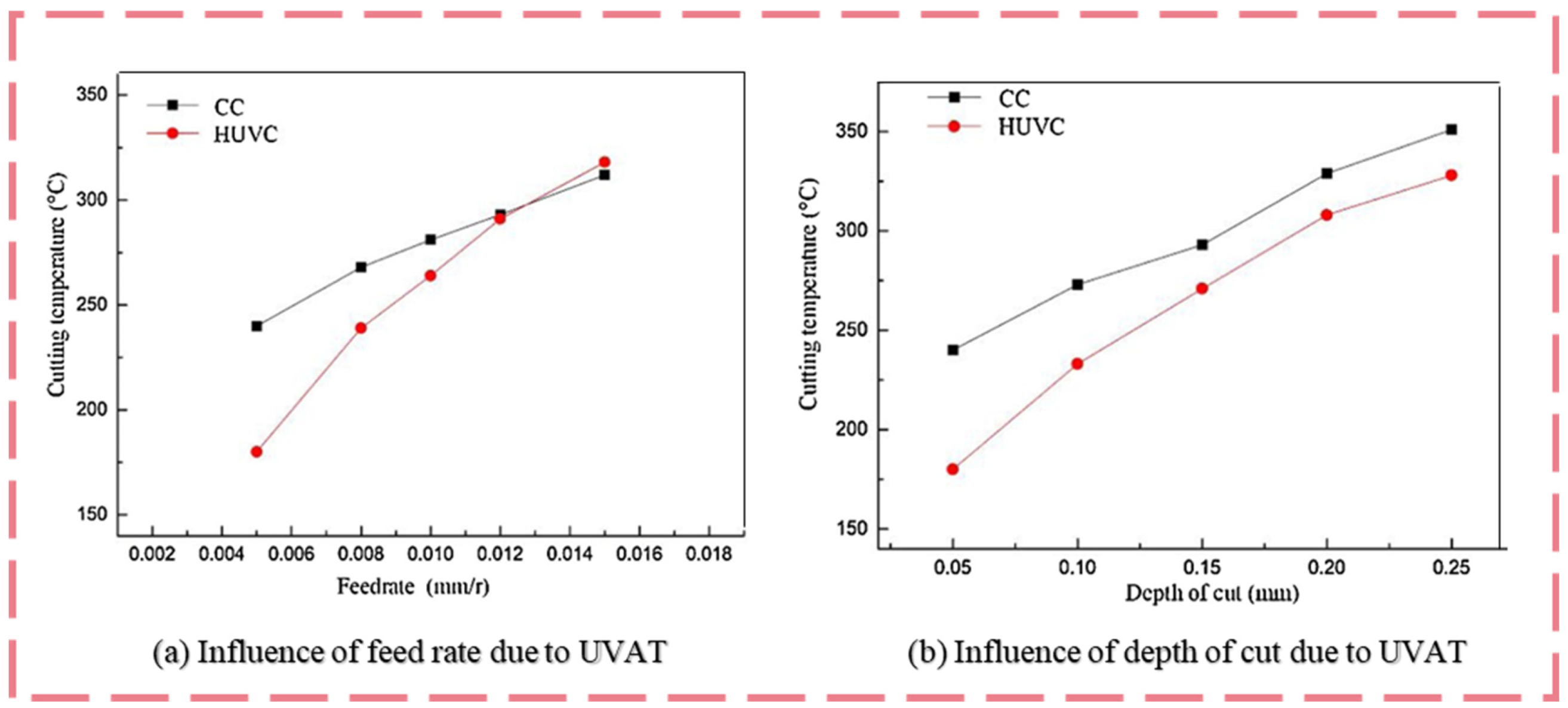

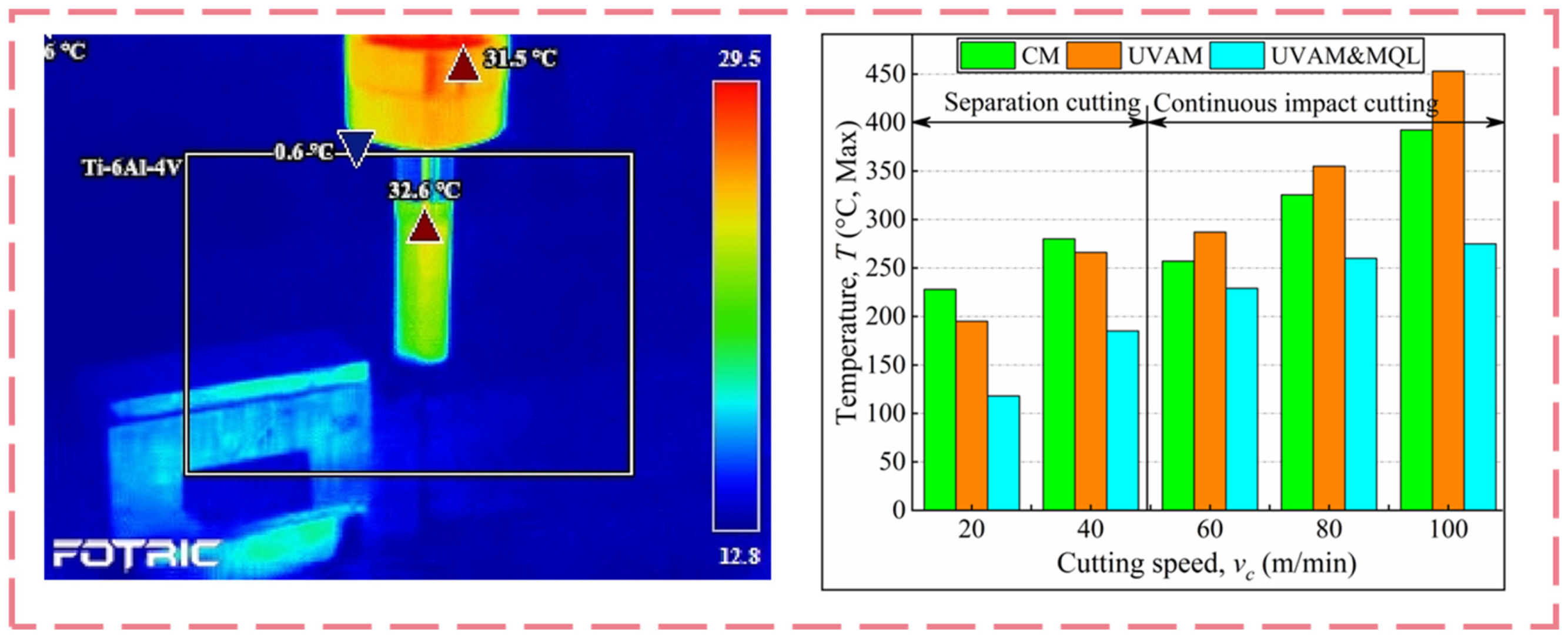

3.1.2. Influence of UVAT on Cutting Temperature

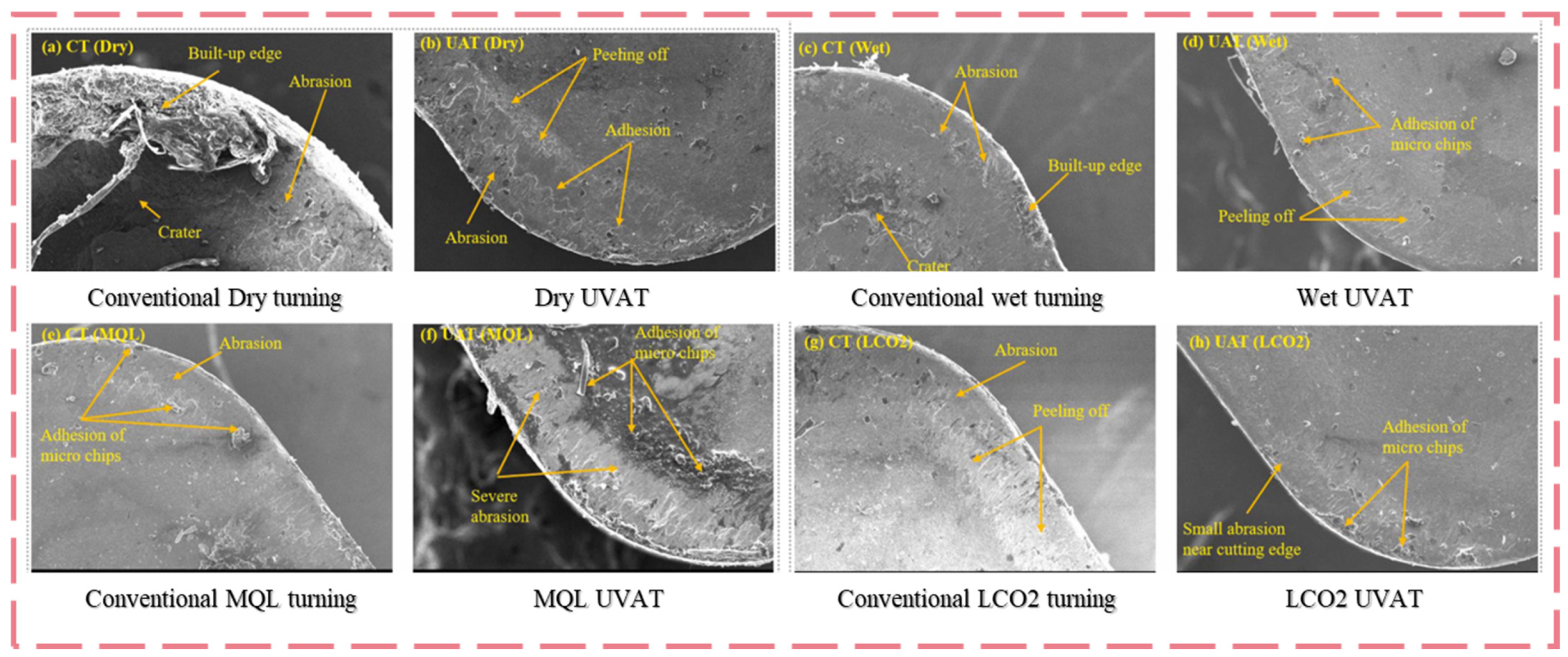

3.1.3. Influence of UVAT on Tool Wear

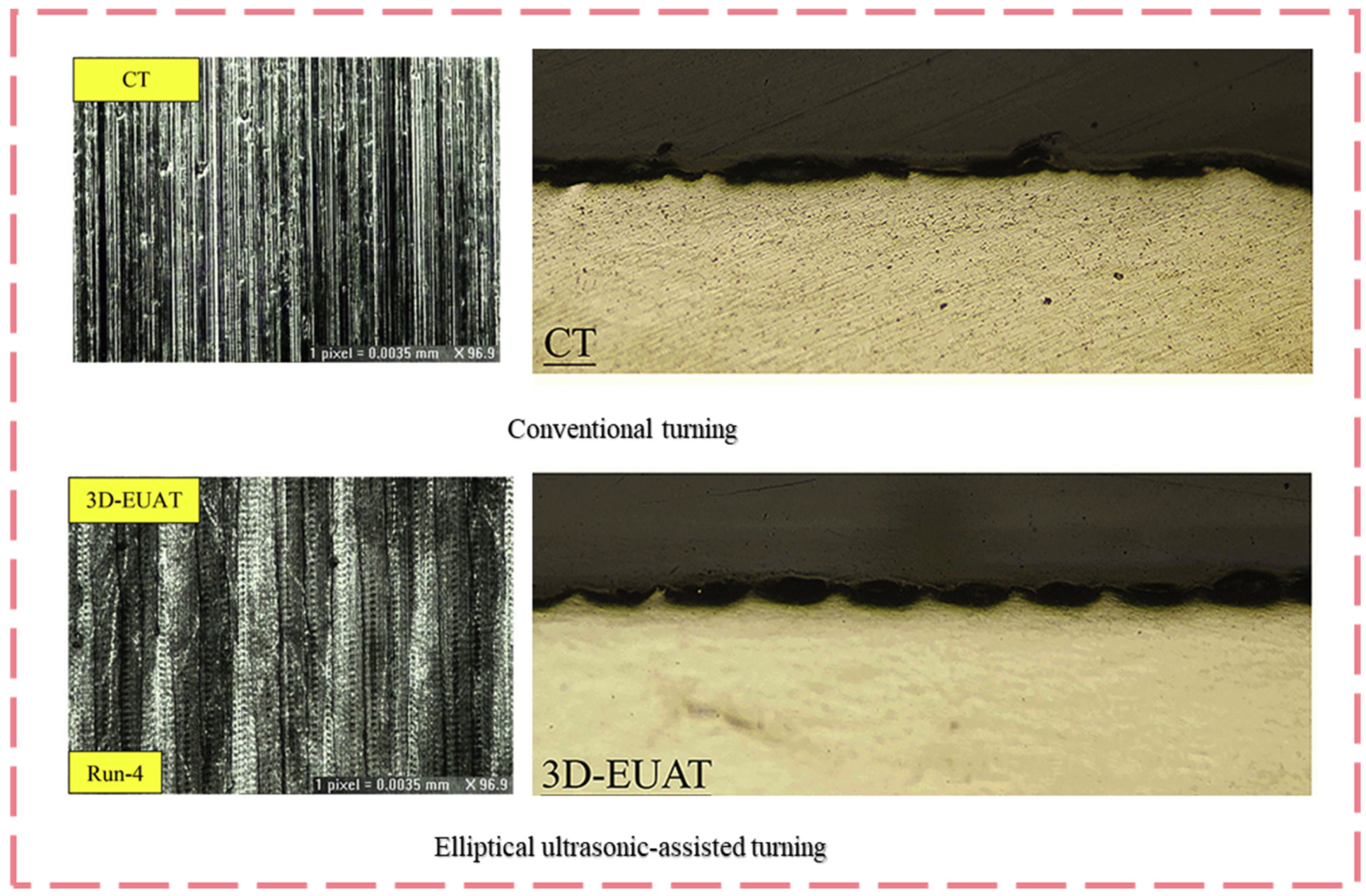

3.1.4. Influence of UVAT on Surface Integrity

3.2. Ultrasonic Vibration-Assisted Milling (UVAM)

3.2.1. Influence of UVAM on Cutting Force

3.2.2. Influence of UVAM on Cutting Temperature

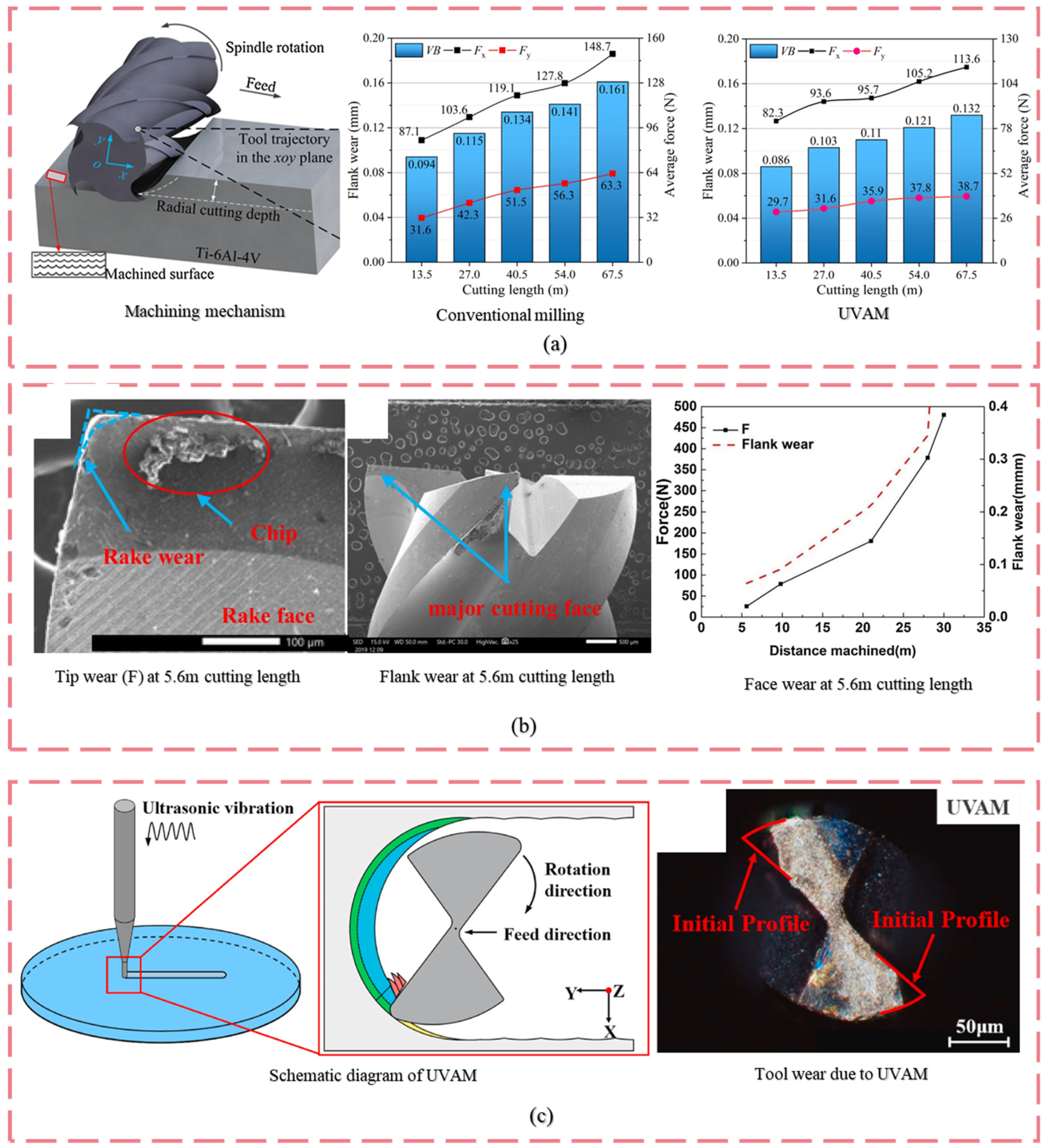

3.2.3. Influence of UVAM on Tool Wear

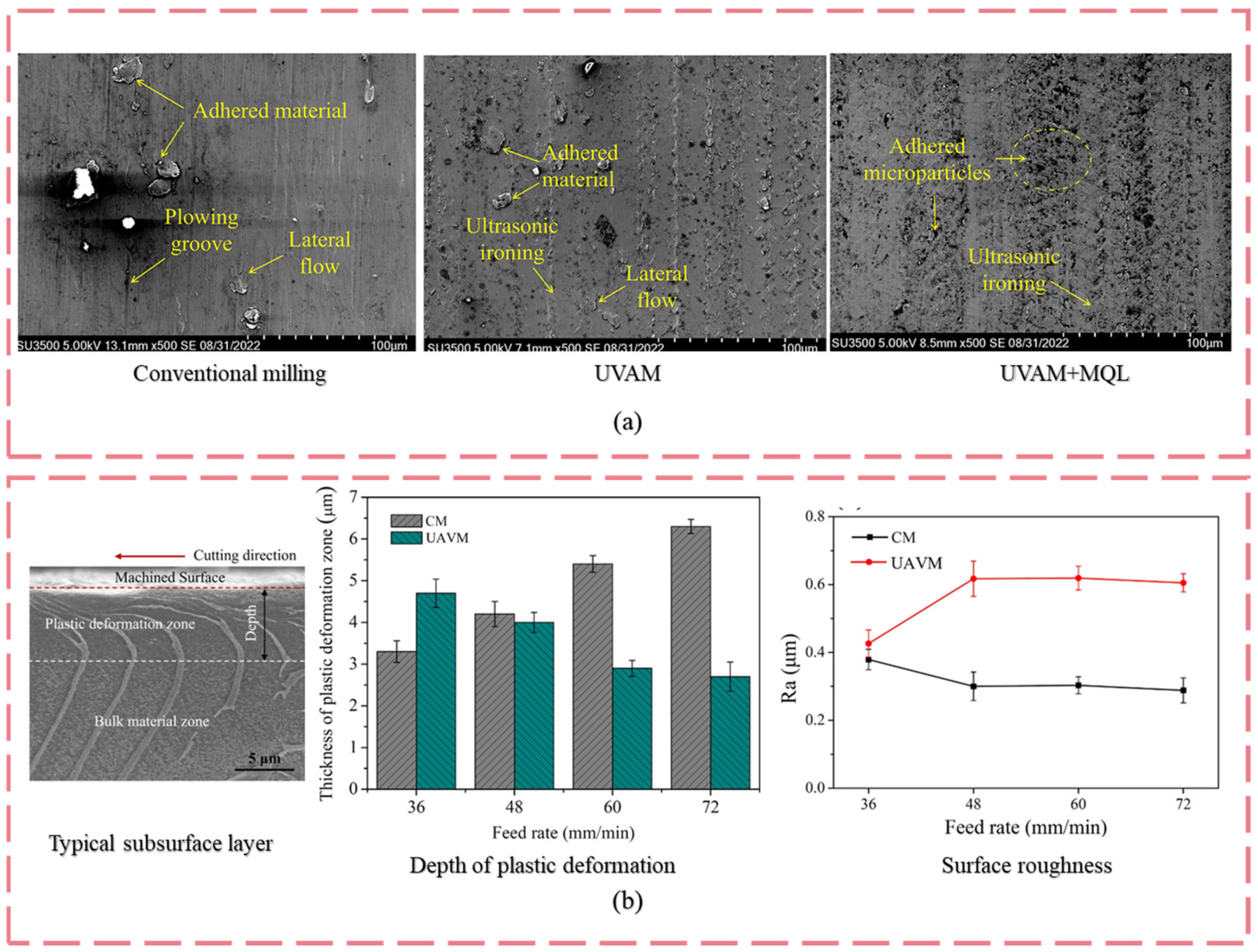

3.2.4. Influence of UVAM on Surface Integrity

3.3. Ultrasonic Vibration-Assisted Grinding (UVAG)

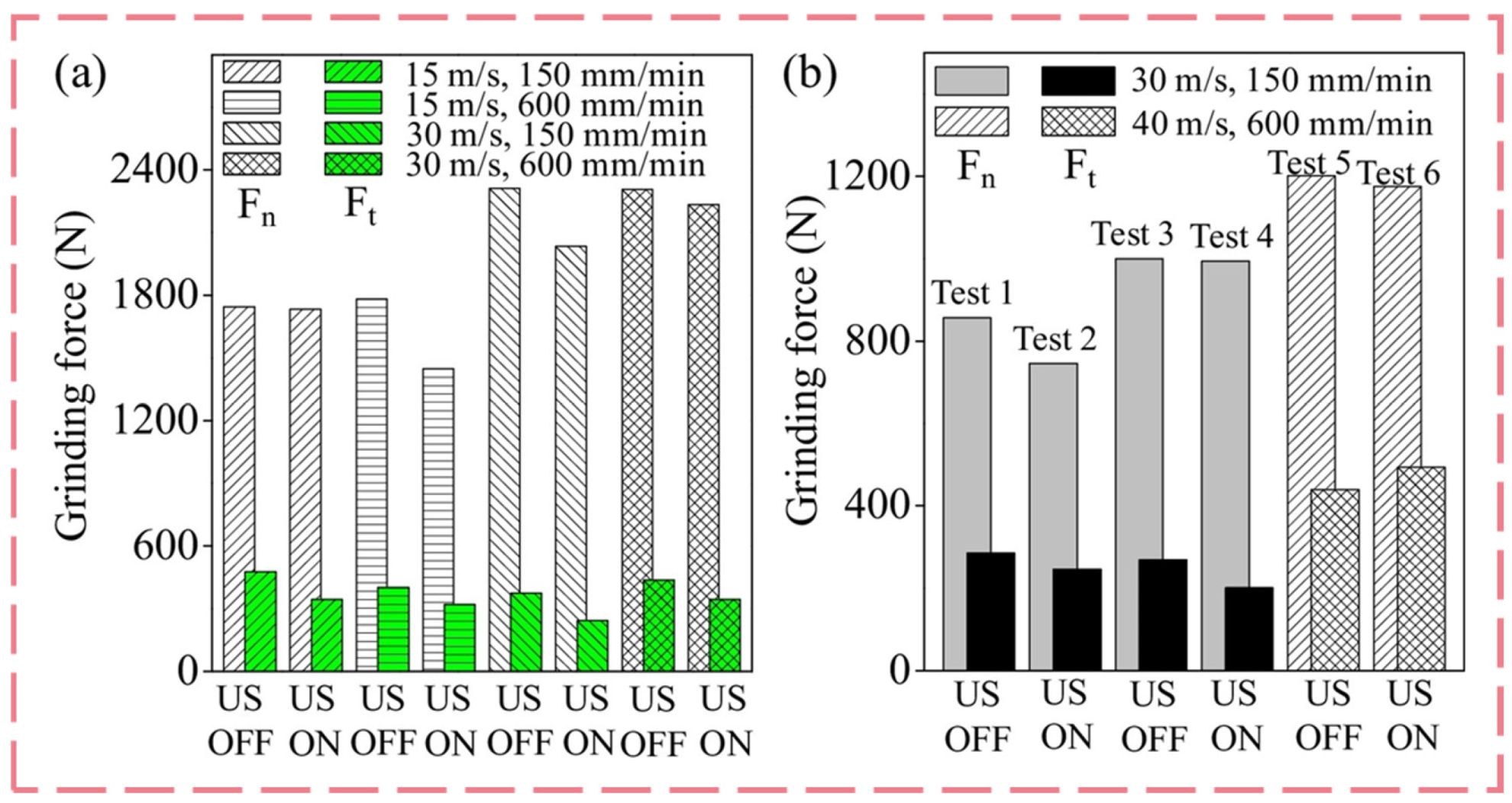

3.3.1. Influence of UVAG on Cutting Force

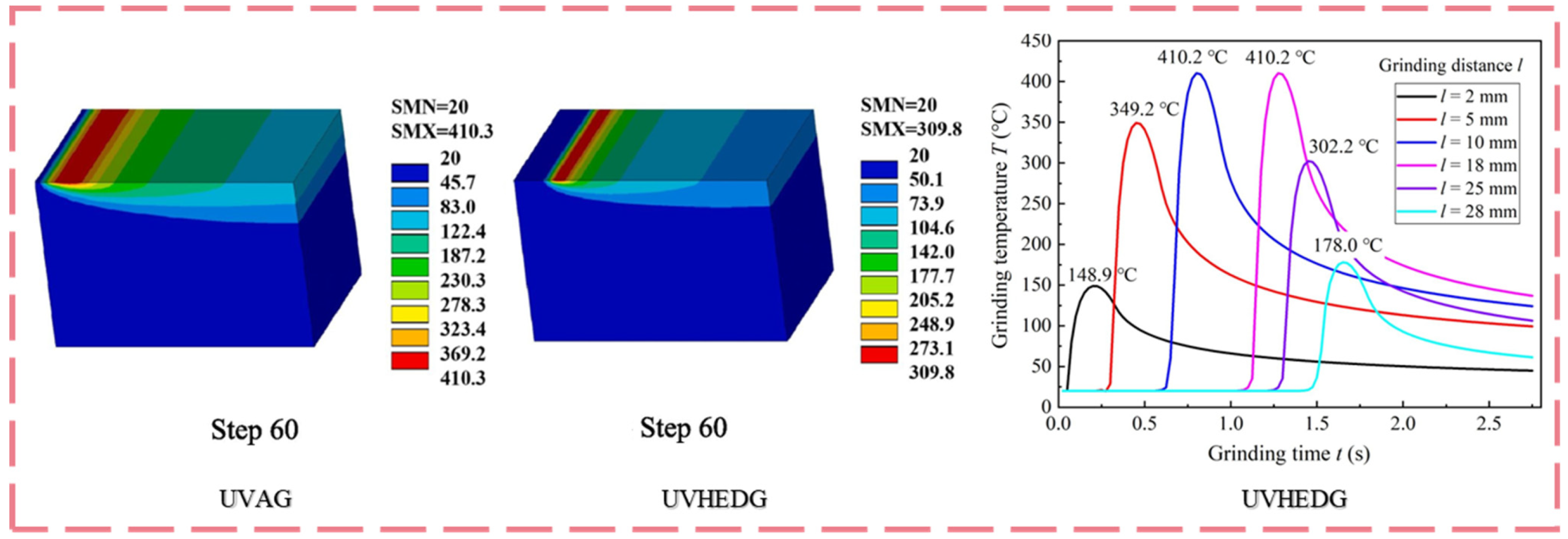

3.3.2. Influence of UVAG on Cutting Temperature

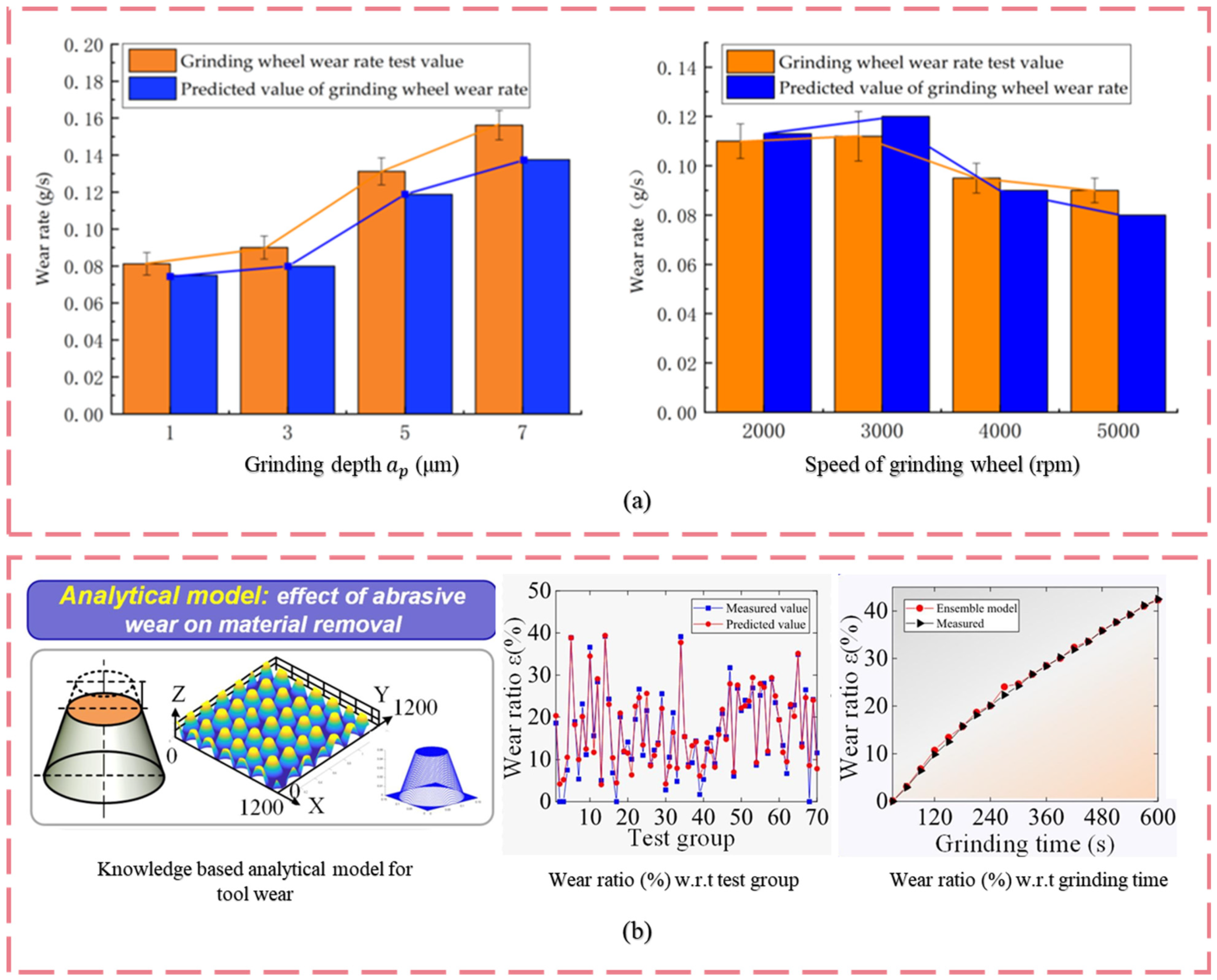

3.3.3. Influence of UVAG on Tool Wear

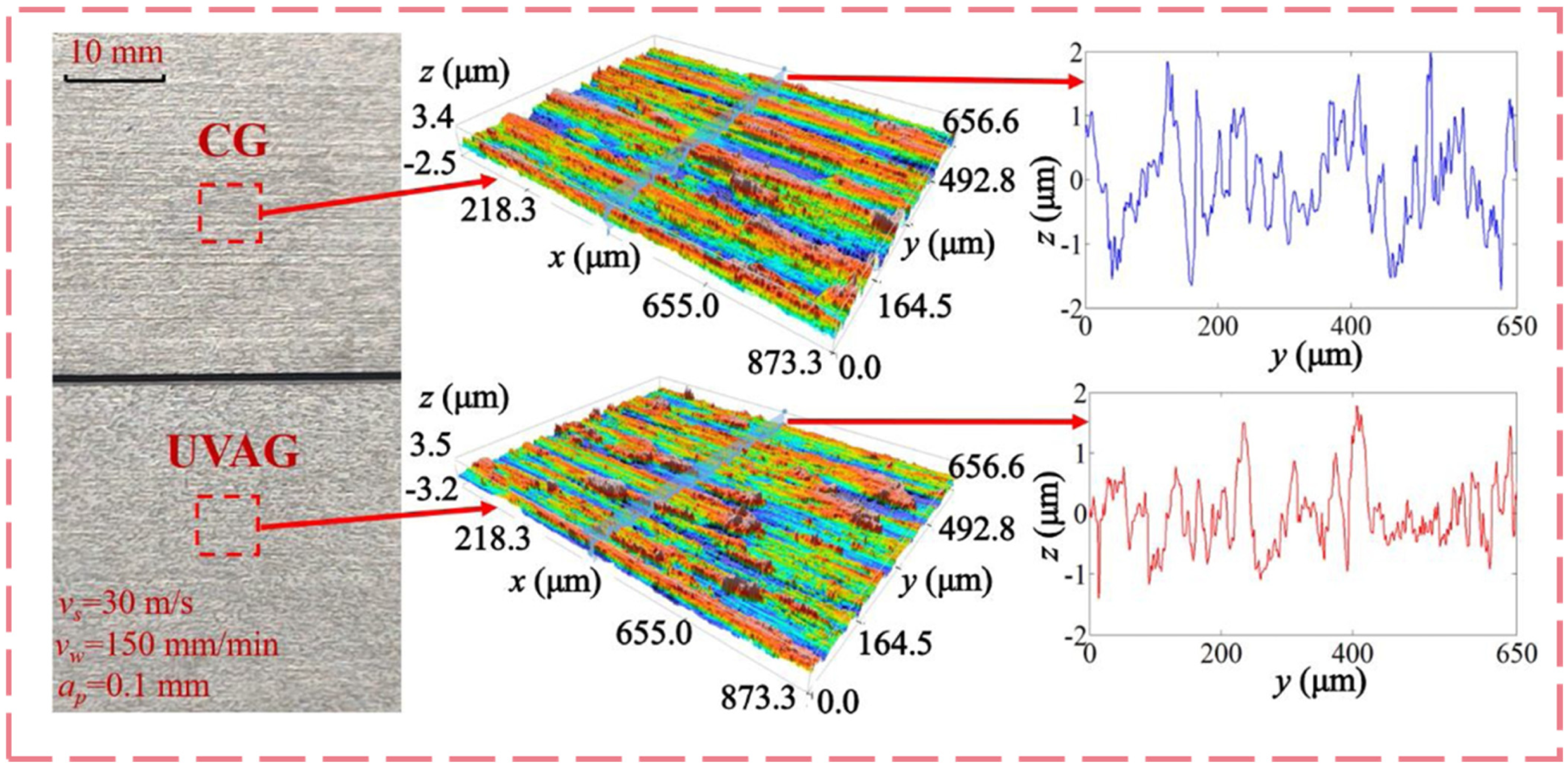

3.3.4. Influence of UVAG on Surface Integrity

3.4. Comparative Analysis of UAM Methods for Titanium Alloys

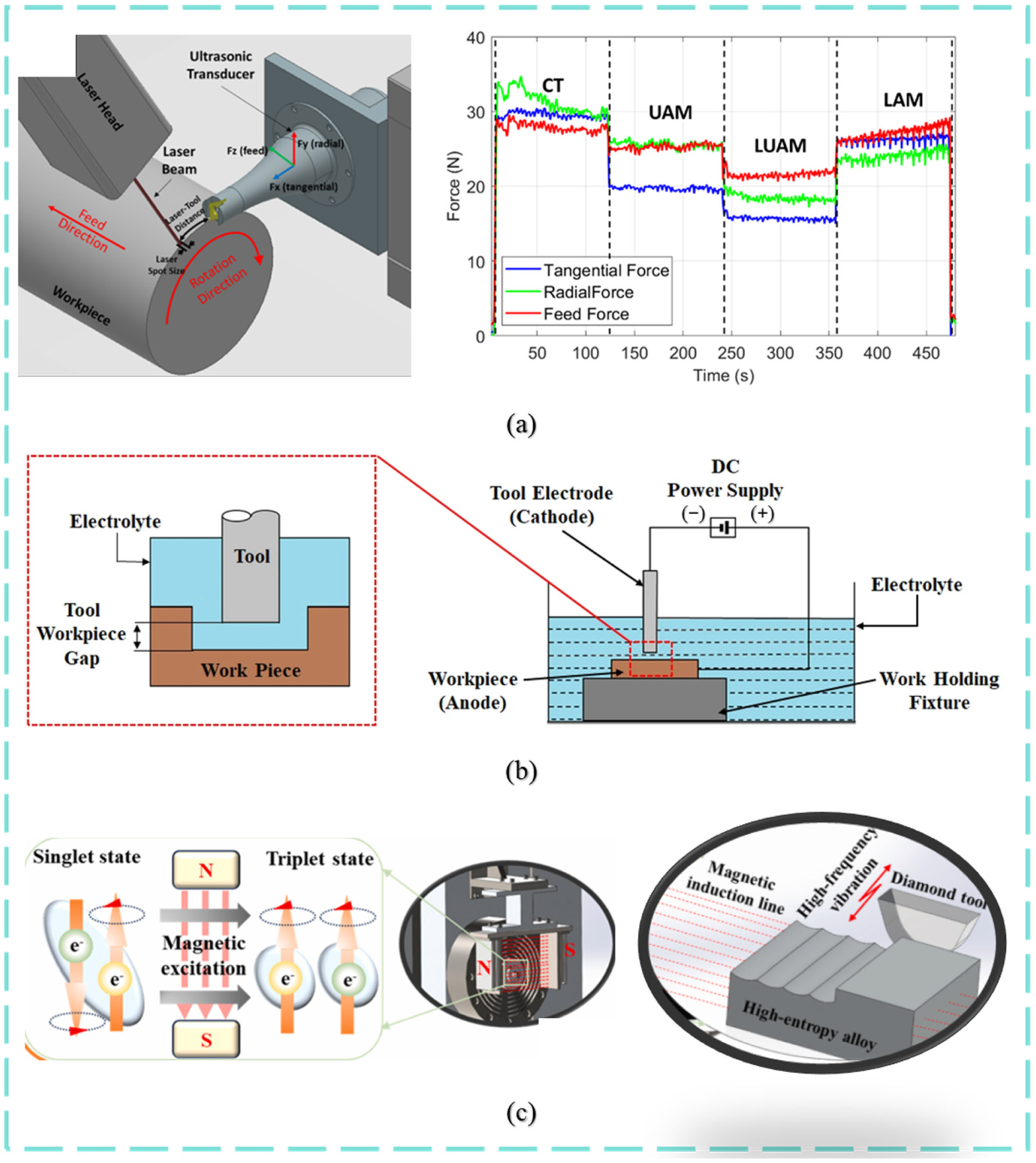

4. Emerging Frontiers of UAM

4.1. Prediction Model for UAM

4.2. Hybrid Ultrasonic Machining with Protective Coating (HUMPC)

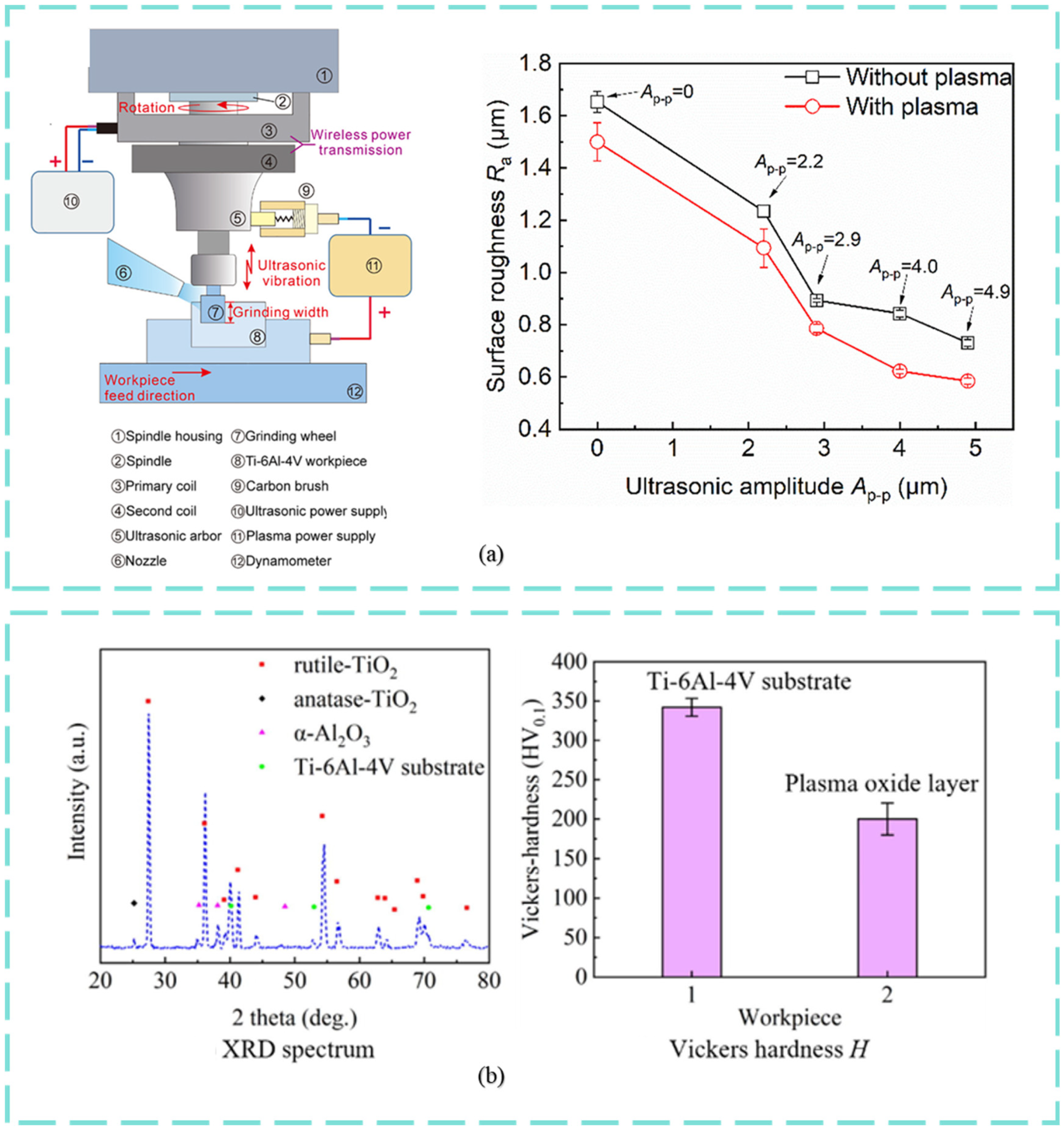

4.3. Ultrasonic/Plasma Oxidation-Assisted Machining (UPOAM)

4.4. Dual-Field Integrated Ultrasonic Assisted Machining (DFI-UAM)

5. Challenges and Future Outlook

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| UVAM | Ultrasonic-assisted machining | CM | Conventional machining |

| GMA | Gas metal arc | AUVAT | axial ultrasonic vibration assisted turning |

| UVAT | Ultrasonic vibration assisted turning | RUVAT | Radial ultrasonic vibration assisted turning |

| BUE | built-up-edge | MQL | Minimum quantity lubrication |

| LCO2 | liquid carbon dioxide | SEM | Scanning electron microscope |

| E-UVAT | Elliptical ultrasonic vibration-assisted turning | UVAM | ultrasonic vibration-assisted milling |

| MRR | Material removal rate | L-UVAM | Longitudinal ultrasonic vibration-assisted milling |

| FD-UVAM | feed direction ultrasonic vibration-assisted milling | LT-UVAM | longitudinal torsional ultrasonic vibration-assisted milling |

| UVHEDG | Ultrasonic vibration-assisted high-efficiency deep grinding | UVAG | Ultrasonic vibration-assisted grinding |

| DFI-UAM | Dual-field integrated ultrasonic assisted machining | HUMPC | Hybrid Ultrasonic Machining with Protective Coating |

| UPOAM | Ultrasonic/Plasma Oxidation-Assisted Machining | LUAM | Laser-ultrasonic assisted machining |

| EDM | Electrical discharge machining | (M-UAM) | magnetic and ultrasonic-assisted machining |

| TiAl | Titanium aluminide | AI | Artificial intelligence |

| & | Tangential and normal force (N) | Angular functions | |

| FEM | finite element method | Force in and direction (N) | |

| VB | Tool wear (mm) | Arithmetic means of 3D surface roughness | |

| Arithmetic mean of 2D surface roughness | Cutting temperature | ||

| Resultant force (N) | Tool life | ||

| Residual stress (MPa) | Feed rate | ||

| Mean force (N) | Window function | ||

| & | Material constants | Diameter (m) |

References

- Fatemi, A.; Molaei, R.; Sharifimehr, S.; Phan, N.; Shamsaei, N. Multiaxial fatigue behavior of wrought and additive manufactured Ti-6Al-4V including surface finish effect. Int. J. Fatigue 2017, 100, 347–366. [Google Scholar] [CrossRef]

- Xiao, G.; Zhang, Y.; Huang, Y.; Song, S.; Chen, B. Grinding mechanism of titanium alloy: Research status and prospect. J. Adv. Manuf. Sci. Technol. 2021, 1, 2020001. [Google Scholar] [CrossRef]

- Khan, A.; Wang, X.; Zhao, B.; Ding, W.; Jamil, M.; Khan, A.M.; Ali, S.H.; Hussain, S.; Zhang, J.; Das, R. Ultrasonic vibration-assisted cutting of titanium alloys: A state-of-the-art review. Chin. J. Aeronaut. 2024, 38, 103078. [Google Scholar] [CrossRef]

- Mi, G.; Sun, R.; Wu, M.; Tan, Y.; Qiu, Y.; Li, P. Research progress of molecular dynamic calculation on titanium alloys for aero-engine. J. Aeronaut. Mater. 2024, 44, 87–103. [Google Scholar] [CrossRef]

- Festas, A.; Ramos, A.; Davim, J.P. Machining of titanium alloys for medical application—A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 309–318. [Google Scholar] [CrossRef]

- Shu, T.; Shi, H.; Li, M.; Lin, Y.-C.; Li, A.; Pei, D. Microscale bone interlocking enhances osseointegration strength on the rough surface of 3D-printed titanium implants: Experimental and finite element analysis. BMC Oral Health 2025, 25, 208. [Google Scholar] [CrossRef] [PubMed]

- Chtioui, A.; Ouballouch, A.; Mouchtachi, A. Evolution of the chip morphology during high speed machining of titanium alloy. AIP Conf. Proc. 2024, 3241, 020001. [Google Scholar]

- Du, H.; Chen, H.; Zhu, Z.; Wang, Z.; To, S. Novel hybrid machining process of titanium alloy for texturing high-quality microstructure array surfaces. Surf. Coat. Technol. 2023, 462, 129494. [Google Scholar] [CrossRef]

- Kostov, A.; Živković, D. Thermodynamic analysis of alloys Ti–Al, Ti–V, Al–V and Ti–Al–V. J. Alloys Compd. 2008, 460, 164–171. [Google Scholar] [CrossRef]

- Duman, E.; Yapan, Y.F.; Uysal, A.; Sofuoğlu, M.A. Ultrasonic vibration-assisted machining with minimum quantity lubrication for aerospace materials. In Advances in Manufacturing for Aerospace Alloys; Springer Nature: Cham, Switzerland, 2024; pp. 47–76. [Google Scholar]

- Ellard, J.; Mathabathe, M.; Siyasiya, C.; Bolokang, A.; Vilane, V.; Rikhotso-Mbungela, R.; McDuling, C.; Masete, S. Engineering γ-TiAl alloys: The effects of Sn, Si and Mn on densification, microstructure, and mechanical properties. Intermetallics 2025, 181, 108746. [Google Scholar] [CrossRef]

- Lu, Q.; Zheng, M.; Zhu, Z.; Chen, W.; Tan, H.; Song, B. Tribological behavior of duplex titanium-aluminum alloys at the nanoscale under different vibration amplitudes. Phys. Scr. 2025, 100, 055405. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Zhang, G.; Ni, C.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tools Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

- Manikandan, P.; Venkatesan, K. Advancements in micromachining of additive manufactured materials: A comprehensive review. Mater. Manuf. Process. 2024, 39, 1469–1520. [Google Scholar] [CrossRef]

- Hémery, S.; Naït-Ali, A.; Smerdova, O.; Tromas, C. Deformation mechanisms in the α phase of the Ti-6Al-2Sn-4Zr-2Mo titanium alloy: In situ experiments and simulations. Int. J. Plast. 2024, 175, 103947. [Google Scholar] [CrossRef]

- Duan, B.; Yang, Y.; He, S.; Feng, Q.; Mao, L.; Zhang, X.; Jiao, L.; Lu, X.; Chen, G.; Li, C. History and development of γ-TiAl alloys and the effect of alloying elements on their phase transformations. J. Alloys Compd. 2022, 909, 164811. [Google Scholar] [CrossRef]

- Feng, L.; Li, B.; Li, Q.; Gao, Y.; Pei, Z.; Liang, C. Enhancement of mechanical properties and oxidation resistance of TiAl alloy with addition of Nb and Mo alloying elements. Mater. Chem. Phys. 2024, 316, 129148. [Google Scholar] [CrossRef]

- Huang, S.; Lin, Y.-C.; Chung, R.-J. A Review of the State of Art of Fabrication Technologies of Titanium Aluminide (Ti-Al) Based on US Patents. Metals 2024, 14, 418. [Google Scholar] [CrossRef]

- Najafizadeh, M.; Yazdi, S.; Bozorg, M.; Ghasempour-Mouziraji, M.; Hosseinzadeh, M.; Zarrabian, M.; Cavaliere, P. Classification and applications of titanium and its alloys: A review. J. Alloys Compd. Commun. 2024, 3, 100019. [Google Scholar] [CrossRef]

- Xue, H.; Song, Y.; Tong, X.; Liang, Y.; Peng, H.; Wang, Y.; Shang, S.-L.; Liu, Z.-K.; Lin, J. Enhancing strength and ductility in high Nb-containing TiAl alloy additively manufactured via directed energy deposition. Addit. Manuf. 2024, 86, 104194. [Google Scholar] [CrossRef]

- Xu, S.-H.; Lan, J.-J.; Han, M.; Zhang, H.-B.; Shen, K.-J.; Lin, J.-P.; Cao, H.-Z.; Zheng, G.-Q. Effect of rhenium addition on microstructure and mechanical properties of Ti−48Al−2Cr−2Nb alloys. Trans. Nonferrous Met. Soc. China 2025, 35, 474–485. [Google Scholar] [CrossRef]

- Xiong, J.; Liu, G.; Zhang, G. Influence of interlayer temperature on microstructure and mechanical properties of TiAl alloys in wire and arc additive manufacturing. J. Manuf. Process. 2023, 94, 278–288. [Google Scholar] [CrossRef]

- He, T.; Yi, B.; Zheng, M.; Song, B.; Qu, D.; Chen, J.; Zhu, Z. Molecular dynamics for nanoindentation in the γ/α2 interfacial strengthening mechanism of a duplex full lamellar TiAl alloy. Mater. Today Commun. 2024, 38, 107965. [Google Scholar] [CrossRef]

- Wang, X.; Guo, R.; Liu, G.; Li, T.; Yang, Y.; Chen, Y.; Xin, M.; Wang, Z. Microstructure Characteristics and Elevated Temperature Mechanical Properties of a B Contained β-solidified γ-TiAl Alloy. J. Wuhan Univ. Technol. Sci. Ed. 2024, 39, 738–746. [Google Scholar] [CrossRef]

- Wang, X.; He, Q.-L.; Zhao, B.; Ding, W.-F.; Liu, Q.; Xu, D.-D. Effects of tool coating and tool wear on the surface and chip morphology in side milling of Ti2AlNb intermetallic alloys. Adv. Manuf. 2025, 13, 155–166. [Google Scholar] [CrossRef]

- Wang, X.; Qu, F.; Qiu, C. On the Microstructural Evolution and Cracking Behavior of a Titanium Aluminide Alloy During Selective Laser Melting. 3D Print. Addit. Manuf. 2024, 11, 40–49. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Yu, H.; Guo, C.; Chen, X.; Zhong, S.; Zhou, L.; Osman, A.; Lu, J. Review on fatigue of additive manufactured metallic alloys: Microstructure, performance, enhancement, and assessment methods. Adv. Mater. 2024, 36, e2306570. [Google Scholar] [CrossRef]

- Polishetty, A.; Shunmugavel, M.; Goldberg, M.; Littlefair, G.; Singh, R.K. Cutting force and surface finish analysis of machining additive manufactured titanium alloy Ti-6Al-4V. Procedia Manuf. 2017, 7, 284–289. [Google Scholar] [CrossRef]

- Wimler, D.; Lindemann, J.; Kremmer, T.; Clemens, H.; Mayer, S. Microstructure and mechanical properties of novel TiAl alloys tailored via phase and precipitate morphology. Intermetallics 2021, 138, 107316. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, N.; Liang, H.; Liu, Y. Phase transformation and microstructure control of Ti2AlNb-based alloys: A review. J. Mater. Sci. Technol. 2021, 80, 203–216. [Google Scholar] [CrossRef]

- Illarionov, A.G.; Stepanov, S.I.; Naschetnikova, I.A.; Popov, A.A.; Soundappan, P.; Thulasi Raman, K.H.; Suwas, S. A review—Additive manufacturing of intermetallic alloys based on orthorhombic titanium aluminide Ti2AlNb. Materials 2023, 16, 991. [Google Scholar] [CrossRef]

- Cebi, A.; Nesli, S.; Aslan, M.T.; Yilmaz, O.; Demirtas, H.; Subasi, L.; Gunaydin, A.; Bilgin, G.M.; Orhangul, A.; Akbulut, G. Surface characteristics of additively manufactured γ-TiAl intermetallic alloys post-processed by electrochemical machining. Surfaces Interfaces 2024, 49, 104381. [Google Scholar] [CrossRef]

- Kalita, D.; Rogal, Ł.; Czeppe, T.; Wójcik, A.; Kolano-Burian, A.; Zackiewicz, P.; Kania, B.; Dutkiewicz, J. Microstructure and mechanical properties of Ti-Nb alloys prepared by mechanical alloying and spark plasma sintering. J. Mater. Eng. Perform. 2020, 29, 1445–1452. [Google Scholar] [CrossRef]

- Chen, H.; Hu, S.; Wang, L.; Deng, L. Directional design and preparation of Ti-Nb based alloys with predicted high strength and low modulus for biomedical applications: Insights from first-principles calculations. Intermetallics 2025, 177, 108580. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Gesang, Y.; Pan, M.; Liang, Y. Tribological properties of γ-TiAl alloy fretting against nickel-based superalloy at elevated temperature. Tribol. Trans. 2024, 67, 259–269. [Google Scholar] [CrossRef]

- Bugvi, S.A.; Mughal, K.H.; Jamil, M.F.; Kazim, A.H.; Shabbir, A.; Shahid, M.U.; Dar, M.U.; Asif, M.M.; Imran, H. Evaluating the work design readiness for industry 4.0 based on personal characteristics of production workers. Int. J. Ind. Eng. 2024, 31, 2. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, G.; Xiao, G. Parameter optimization for ultrasonic-assisted grinding of γ-TiAl intermetallics: A gray relational analysis approach with surface integrity evaluation. Rev. Adv. Mater. Sci. 2024, 63, 20240045. [Google Scholar] [CrossRef]

- Ahmad, N.; Irfan, S.; Maleki, E.; Lee, S.; Liu, J.P.; Shao, S.; Shamsaei, N. Determining critical surface features affecting fatigue behavior of additively manufactured Ti-6Al-4V. Int. J. Fatigue 2025, 197, 108956. [Google Scholar] [CrossRef]

- Assis, J.O.M.; Lauro, C.H.; Pereira, R.B.D.; Brandão, L.C.; Arruda, É.M.; Davim, J.P. A Chip Formation Study of the Micro-Cutting of Commercially Pure Titanium. Metals 2024, 14, 851. [Google Scholar] [CrossRef]

- Attar, H.; Bermingham, M.; Ehtemam-Haghighi, S.; Dehghan-Manshadi, A.; Kent, D.; Dargusch, M. Evaluation of the mechanical and wear properties of titanium produced by three different additive manufacturing methods for biomedical application. Mater. Sci. Eng. A 2019, 760, 339–345. [Google Scholar] [CrossRef]

- Li, G.; Chandra, S.; Rashid, R.A.R.; Palanisamy, S.; Ding, S. Machinability of additively manufactured titanium alloys: A comprehensive review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Zhang, H.; Dang, J.; Ming, W.; Xu, X.; Chen, M.; An, Q. Cutting responses of additive manufactured Ti6Al4V with solid ceramic tool under dry high-speed milling processes. Ceram. Int. 2020, 46, 14536–14547. [Google Scholar] [CrossRef]

- Zhang, P.; Zhou, H.; Ge, S.; Sun, Y.; Zhang, J. Research on nanocutting mechanism of polycrystalline γ-TiAl alloy at different temperatures. Vacuum 2024, 230, 113734. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, H.; Xin, J.; Zhang, Y.; Zhu, Z.; Tian, S. The investigation of high-temperature shear deformation mechanism in Ti-44Al-4Nb-1.5Mo-0.1B alloy. Mater. Sci. Eng. A 2025, 934, 148298. [Google Scholar] [CrossRef]

- Zhou, Y.; Cao, H.; Zhou, B.; Li, H.; Chen, W.; Lei, C.; Feng, R. Molecular dynamics simulation of the effect of tool parameters on nano-cutting of polycrystalline γ-TiAl alloys. Model. Simul. Mater. Sci. Eng. 2024, 32, 065005. [Google Scholar] [CrossRef]

- Aspinwall, D.; Dewes, R.; Mantle, A. The machining of γ-TiAI intermetallic alloys. CIRP Ann. 2005, 54, 99–104. [Google Scholar] [CrossRef]

- Liu, X.; Liu, H.; Shi, S.; Tang, Y.; Zhang, J. On revealing the mechanisms involved in brittle-to-ductile transition of fracture behaviors for γ-TiAl alloy under dynamic conditions. J. Alloys Compd. 2025, 1010, 177614. [Google Scholar] [CrossRef]

- Zhang, S.; Tian, N.; Li, D.; Li, J.; Jin, F.; Wang, G.; Tian, S. Microstructure evolution and fracture mechanism of a TiAl–Nb alloy during high-temperature tensile testing. Mater. Sci. Eng. A 2022, 831, 142094. [Google Scholar] [CrossRef]

- Zhang, P.; Zhou, H.; Sun, Y.; Zhang, J.; Yue, X.; Wang, Y. Investigation on the surface damage mechanism of single-crystal γ-TiAl alloy with pore defects based on nanocutting. Vacuum 2024, 229, 113613. [Google Scholar] [CrossRef]

- Sahto, M.P.; Wei, W.; Jamil, M.F.; Mehmood, A.; Sattar, M.; Raza, A.; Rahman, M.U.; Qaisrani, M.A. Integrating experimental and theoretical investigations of porous graphite materials with scanning electron microscope image processing. Results Eng. 2024, 24, 102893. [Google Scholar] [CrossRef]

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, B.; Zhu, H.; Li, H.; Feng, R.; Cao, H.; Lei, C. Effect of UEVC parameters on cutting surface quality and subsurface damage of single crystal γ-TiAl alloy via atomic simulation. Model. Simul. Mater. Sci. Eng. 2024, 32, 065032. [Google Scholar] [CrossRef]

- Gupta, M.K.; Korkmaz, M.E.; Yılmaz, H.; Şirin, Ş.; Ross, N.S.; Jamil, M.; Królczyk, G.M.; Sharma, V.S. Real-time monitoring and measurement of energy characteristics in sustainable machining of titanium alloys. Measurement 2024, 224, 113937. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Pruncu, C.I.; Mia, M.; Singh, G.; Lozano, J.A.; Carou, D.; Khan, A.M.; Jamil, M.; et al. Machining characteristics based life cycle assessment in eco-benign turning of pure titanium alloy. J. Clean. Prod. 2020, 251, 119598. [Google Scholar] [CrossRef]

- Yip, W.S.; To, S.; Zhou, H.; Ren, J. Sustainable Machining and Micro-Machining; Springer Nature: Dordrecht, The Netherlands, 2025. [Google Scholar] [CrossRef]

- Wang, X.; Song, J.; Xiao, H.; Liang, Z.; Qin, X.; Chen, T.; Ding, W.; Zhao, B. Wear behavior and material removal mechanism during ultrasonic vibration-assisted grinding γ-TiAl materials using a single CBN grain. Int. J. Adv. Manuf. Technol. 2025, 137, 1581–1598. [Google Scholar] [CrossRef]

- Mughal, K.H.; Ahmad, N.; Hayat, N.; Qureshi, M.A.M.; Bugvi, S.A.; Jamil, M.F.; Khan, M.A. Design and performance evaluation of a novel ultrasonic welding sonotrode for Langevin transducer using finite element approach. Int. J. Ind. Eng. 2023, 30, 4. [Google Scholar] [CrossRef]

- Mughal, K.H.; Bugvi, S.A.; Jamil, M.F.; Qureshi, M.A.M.; Khalid, F.A.; Qaiser, A.A. Tubular cubic polynomial sonotrode for green and sustainable ultrasonic welding technology. Green Manuf. Open 2023, 1, 14. [Google Scholar] [CrossRef]

- Mughal, K.H.; Jamil, M.F.; Qureshi, M.A.M.; Qaiser, A.A.; Khalid, F.A.; Maqbool, A.; Raza, S.F.; Ahmad, S.; Zhang, J.; Abbas, S.Z. Investigation of rotary ultrasonic vibration assisted machining of Nomex honeycomb composite structures. Int. J. Adv. Manuf. Technol. 2023, 129, 5541–5560. [Google Scholar] [CrossRef]

- Mughal, K.H.; Qureshi, M.A.M.; Jamil, M.F.; Ahmad, S.; Khalid, F.A.; Qaiser, A.A.; Maqbool, A.; Raza, S.F.; Zhang, J. Investigation of hybrid ultrasonic machining process of Nomex honeycomb composite using a toothed disc cutter. Ultrasonics 2024, 141, 107343. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, L.; Li, H.; Zhou, B.; Cao, H.; Feng, R. Effect of repetitive nano-cutting tool parameters on surface quality and subsurface damage of γ-TiAl alloy. Model. Simul. Mater. Sci. Eng. 2024, 32, 045005. [Google Scholar] [CrossRef]

- Jiang, Q.; Hua, Y.; Liu, X.; Li, L.; Zhang, J.; Li, F.; Han, J.; Li, Z. Cutting mechanism of laser-ultrasonic-vibration assisted machining of Ti6Al4V under two chip states based on FEM model. Int. J. Adv. Manuf. Technol. 2025, 137, 2267–2291. [Google Scholar] [CrossRef]

- Namlu, R.H.; Lotfi, B.; Kılıç, S.E. Enhancing machining efficiency of Ti-6Al-4V through multi-axial ultrasonic vibration-assisted machining and hybrid nanofluid minimum quantity lubrication. J. Manuf. Process. 2024, 119, 348–371. [Google Scholar] [CrossRef]

- Nasr, M.M.; Anwar, S. Developing an intelligent approach based on ANFIS and advanced NSGA-III for improving the turning performance of additively manufactured γ-TiAl alloy. Int. J. Adv. Manuf. Technol. 2025, 137, 3333–3358. [Google Scholar] [CrossRef]

- Wei, S.; Zou, P.; Fang, L.; Duan, J. Theoretical and experimental study of 3D ultrasonic vibration-assisted turning driven by two actuators. Measurement 2023, 215, 112865. [Google Scholar] [CrossRef]

- Sui, H.; Zhang, L.; Wang, S.; Gu, Z. Transient separation cutting characteristic of axial ultrasonic vibration–assisted cutting. Int. J. Adv. Manuf. Technol. 2020, 110, 2407–2425. [Google Scholar] [CrossRef]

- Kurniawan, R.; Ahmed, F.; Ali, S.; Park, G.C.; Ko, T.J. Analytical, FEA, and experimental research of 2D-Vibration Assisted Cutting (2D-VAC) in titanium alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2021, 117, 1739–1764. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K.; Bertolini, R.; Krolczyk, G.M.; Khanna, N. Sustainable cooling strategies to reduce tool wear, power consumption and surface roughness during ultrasonic assisted turning of Ti-6Al-4V. Tribol. Int. 2022, 169, 107494. [Google Scholar] [CrossRef]

- Tan, R.; Zhao, X.; Guo, S.; Zou, X.; He, Y.; Geng, Y.; Hu, Z.; Sun, T. Sustainable production of dry-ultra-precision machining of Ti–6Al–4V alloy using PCD tool under ultrasonic elliptical vibration-assisted cutting. J. Clean. Prod. 2020, 248, 119254. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, Z.; Li, Z.; Sui, H.; Zhang, D. Influences of machining parameters on tool performance when high-speed ultrasonic vibration cutting titanium alloys. J. Manuf. Process. 2020, 60, 188–199. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K. Machinability of Ti-6Al-4V and Nimonic-90 in ultrasonic-assisted turning under sustainable cutting fluid. Mater. Today Proc. 2022, 62, 7396–7400. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, Q.; Yu, J. Effects of continuous minimum quantity lubrication with ultrasonic vibration in turning of titanium alloy. Int. J. Adv. Manuf. Technol. 2018, 98, 827–837. [Google Scholar] [CrossRef]

- Silberschmidt, V.V.; Mahdy, S.M.; Gouda, M.A.; Naseer, A.; Maurotto, A.; Roy, A. Surface-roughness improvement in ultrasonically assisted turning. Procedia CIRP 2014, 13, 49–54. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Liu, L.; Xu, G.; Wang, G.; Zhao, M. Effect of high-speed ultrasonic vibration cutting on the microstructure, surface integrity, and wear behavior of titanium alloy. J. Mater. Res. Technol. 2023, 24, 3870–3888. [Google Scholar] [CrossRef]

- Chen, F.; Wang, D.; Wu, S. Influence of ultrasonic vibration-assisted cutting on ploughing effect in cutting Ti6Al4V. Arch. Civ. Mech. Eng. 2021, 21, 42. [Google Scholar] [CrossRef]

- Chen, D.; Chen, J.; Zhou, H. The finite element analysis of machining characteristics of titanium alloy in ultrasonic vibration assisted machining. J. Mech. Sci. Technol. 2021, 35, 3601–3618. [Google Scholar] [CrossRef]

- Lotfi, M.; Amini, S.; Akbari, J. Surface integrity and microstructure changes in 3D elliptical ultrasonic assisted turning of Ti–6Al–4V: FEM and experimental examination. Tribol. Int. 2020, 151, 106492. [Google Scholar] [CrossRef]

- Ingle, S.; Raut, D. Evaluation of tool wears mechanism considering machining parameters and performance parameters for titanium alloy in turning operation on CNC. Adv. Mater. Process. Technol. 2024, 10, 1380–1400. [Google Scholar] [CrossRef]

- Qiu, W.; Pan, D.; Li, J.; Guo, P.; Qiao, Y.; Wang, X. Chip formation mechanism in cryogenic machining of high temperature alloy-Inconel 718 and Ti-47.5Al-2.5V-1.0Cr. J. Manuf. Process. 2023, 97, 35–47. [Google Scholar] [CrossRef]

- Agrawal, C.; Khanna, N.; Gupta, M.K.; Kaynak, Y. Sustainability assessment of in-house developed environment-friendly hybrid techniques for turning Ti-6Al-4V. Sustain. Mater. Technol. 2020, 26, e00220. [Google Scholar] [CrossRef]

- Hassan, A.; Khan, M.A.; Younas, M.; Jaffery, S.H.I.; Khan, M.; Ahmed, N.; Awang, M. Impact of dry and cryogenic cutting medium on shear angle and chip morphology in high-speed machining of titanium alloy (Ti-6Al-4V). Int. J. Automot. Mech. Eng. 2024, 21, 11316–11331. [Google Scholar] [CrossRef]

- Li, K.; Shao, W.; Tang, J.; Huang, W.; Li, X. Feasibility study of high feed axial ultrasonic vibration turning of Ti6Al4V. Arch. Civ. Mech. Eng. 2024, 24, 137. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K.; Outeiro, J.; Khanna, N. Surface integrity in ultrasonic-assisted turning of Ti6Al4V using sustainable cutting fluid. Procedia CIRP 2022, 108, 55–60. [Google Scholar] [CrossRef]

- Kandi, R.; Sahoo, S.K.; Sahoo, A.K. Ultrasonic vibration-assisted turning of Titanium alloy Ti–6Al–4V: Numerical and experimental investigations. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 399. [Google Scholar] [CrossRef]

- Pei, L.; Wu, H. Effect of ultrasonic vibration on ultra-precision diamond turning of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2019, 103, 433–440. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D. Investigations of tangential ultrasonic vibration turning of Ti6Al4V using finite element method. Int. J. Mater. Form. 2019, 12, 257–267. [Google Scholar] [CrossRef]

- Sui, H.; Zhang, X.; Zhang, D.; Jiang, X.; Wu, R. Feasibility study of high-speed ultrasonic vibration cutting titanium alloy. J. Mech. Work. Technol. 2017, 247, 111–120. [Google Scholar] [CrossRef]

- Sivareddy, D.V.; Krishna, P.V.; Gopal, A.V. Experimental investigation on flank wear of the tool in ultrasonic vibration-assisted turning of Ti6Al4V alloy. Smart Sustain. Manuf. Syst. 2021, 5, 101–112. [Google Scholar] [CrossRef]

- Olt, J.; Maksarov, V.V.; Efimov, A.E. Improving the surface quality of titanium-alloy components in machining. Russ. Eng. Res. 2023, 43, 195–198. [Google Scholar] [CrossRef]

- Liu, X.; Shan, C.; Xiong, Y.; Zhou, C. Modeling and simulation for orthogonal cutting force in ultrasonic vibration–assisted machining in situ TiB2/Al MMCs. Int. J. Adv. Manuf. Technol. 2025, 137, 1667–1682. [Google Scholar] [CrossRef]

- Du, P.; Han, L.; Qiu, X.; Chen, W.; Deng, J.; Liu, Y.; Zhang, J. Development of a high-precision piezoelectric ultrasonic milling tool using longitudinal-bending hybrid transducer. Int. J. Mech. Sci. 2022, 222, 107239. [Google Scholar] [CrossRef]

- Baraya, M.; Yan, J.; Hossam, M. Improving and predicting the surface roughness and the machining accuracy in ultrasonic vibration-assisted milling. J. Vib. Eng. Technol. 2024, 12, 127–140. [Google Scholar] [CrossRef]

- Wang, X.; Zhuang, B.; Wu, T.; Su, H.; Chen, Y.; Zhao, B.; Ding, W. Microstructure evolution characterization of Ti2AlNb intermetallic alloys subjected to side milling. Mater. Today Commun. 2025, 42, 111257. [Google Scholar] [CrossRef]

- Sun, J.; Li, P.; Zhang, S.; Chen, Y.; Lu, H.; Chen, G.; Shao, D. Experimental study of surface integrity in ultrasonic vibration–assisted milling of GH4169 nickel-based superalloy. Int. J. Adv. Manuf. Technol. 2023, 129, 5047–5058. [Google Scholar] [CrossRef]

- Gu, G.; Wu, S.; Wang, D.; Zhou, S.; Zhu, L.; An, Q.; Guo, H.; Li, C. A review of the research on the variation of tool’s motion trajectory and its influence on the formation mechanism of surface quality in ultrasonic vibration machining. J. Manuf. Process. 2023, 107, 294–319. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Huang, L. Study on surface quality and tool wear of TiAl alloy in ultrasonic longitudinal torsion assisted milling. Manuf. Technol. Mach. Tool 2024, 2, 31–37. [Google Scholar] [CrossRef]

- Gao, G.; Xiang, Y.; Qiao, H.; Wei, C.; Wang, G.; Xiang, D. Modeling on cutting force considering tool flank wear in ultrasonic vibration-assisted milling Ti3Al. Wear 2025, 566–567, 205761. [Google Scholar] [CrossRef]

- Wang, B.; Tang, M.; Song, C.; Wang, H.; Long, Z.; Xu, R. Effects of shear thickening fluid preparation on tool performance in the milling of Ti6Al4V titanium alloy. J. Manuf. Process. 2024, 113, 95–104. [Google Scholar] [CrossRef]

- Wang, F.; Pang, Q.; Yang, Q.; Han, H. Effect of cryogenic cooling on micro-milling properties of titanium alloy. J. Mater. Eng. Perform. 2024, 34, 6472–6483. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X.; An, Q.; Chen, M.; Guo, H.; He, Y. Research on cutting performance and tool life improvement methods of titanium alloy ultra-high speed milling tools. J. Manuf. Process. 2024, 131, 38–51. [Google Scholar] [CrossRef]

- Xie, W.; Wang, X.; Liu, E.; Wang, J.; Tang, X.; Li, G.; Zhang, J.; Yang, L.; Chai, Y.; Zhao, B. Research on cutting force and surface integrity of TC18 titanium alloy by longitudinal ultrasonic vibration assisted milling. Int. J. Adv. Manuf. Technol. 2022, 119, 4745–4755. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, L.; Yang, Z. Comparative investigation of tool wear mechanism and corresponding machined surface characterization in feed-direction ultrasonic vibration assisted milling of Ti–6Al–4V from dynamic view. Wear 2019, 436, 203006. [Google Scholar] [CrossRef]

- Gao, G.; Xia, Z.; Su, T.; Xiang, D.; Zhao, B. Cutting force model of longitudinal-torsional ultrasonic-assisted milling Ti-6Al-4V based on tool flank wear. J. Mech. Work. Technol. 2021, 291, 117042. [Google Scholar] [CrossRef]

- Xie, W.; Zhao, B.; Liu, E.; Chai, Y.; Wang, X.; Yang, L.; Li, G.; Wang, J. Surface integrity investigation into longitudinal-torsional ultrasonic vibration side milling for a TC18 titanium alloy—Part I: The effects of cutting speed on cutting force and surface integrity. Int. J. Adv. Manuf. Technol. 2022, 120, 2701–2713. [Google Scholar] [CrossRef]

- Hu, W.; Du, P.; Qiu, X.; Zhao, X.; Hu, Z.; Zhang, J.; Liu, Y. Enhanced dry machinability of TC4 titanium alloy by longitudinal-bending hybrid ultrasonic vibration-assisted milling. J. Clean. Prod. 2022, 379, 134866. [Google Scholar] [CrossRef]

- Ren, W.; Xu, J.; Lin, J.; Yu, Z.; Yu, P.; Lian, Z.; Yu, H. Research on homogenization and surface morphology of Ti-6Al-4V alloy by longitudinal-torsional coupled ultrasonic vibration ball-end milling. Int. J. Adv. Manuf. Technol. 2019, 104, 301–313. [Google Scholar] [CrossRef]

- Ying, N.; Feng, J.; Bo, Z. A novel 3D finite element simulation method for longitudinal-torsional ultrasonic-assisted milling. Int. J. Adv. Manuf. Technol. 2020, 106, 385–400. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, J.; Yu, H. Experimental study of tool wear and its effects on cutting process of ultrasonic-assisted milling of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2020, 108, 2917–2928. [Google Scholar] [CrossRef]

- Su, Y.; Li, L. Surface integrity of ultrasonic-assisted dry milling of SLM Ti6Al4V using polycrystalline diamond tool. Int. J. Adv. Manuf. Technol. 2022, 119, 5947–5956. [Google Scholar] [CrossRef]

- Chen, P.; Tong, J.; Zhao, J.; Zhang, Z.; Zhao, B. A study of the surface microstructure and tool wear of titanium alloys after ultrasonic longitudinal-torsional milling. J. Manuf. Process. 2020, 53, 1–11. [Google Scholar] [CrossRef]

- Zheng, K.; Liao, W.; Dong, Q.; Sun, L. Friction and wear on titanium alloy surface machined by ultrasonic vibration-assisted milling. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 411. [Google Scholar] [CrossRef]

- Lu, W.; Ni, C.; Wang, Y.; Zong, C.; Liu, D. Micromachining performance of additively manufactured titanium alloys in synergistic application of ultrasonic elliptical machining and textured tool methods. Int. J. Adv. Manuf. Technol. 2025, 136, 2707–2729. [Google Scholar] [CrossRef]

- Chang, B.; Yi, Z.; Cao, X.; Duan, J.-A. Surface feature and material removal in ultrasonic vibration-assisted slot-milling of Ti–6Al–4 V titanium alloy. Int. J. Adv. Manuf. Technol. 2022, 122, 2235–2251. [Google Scholar] [CrossRef]

- Niu, Q.; Rong, J.; Jing, L.; Gao, H.; Tang, S.; Qiu, X.; Liu, L.; Wang, X.; Dai, F. Study on force-thermal characteristics and cutting performance of titanium alloy milled by ultrasonic vibration and minimum quantity lubrication. J. Manuf. Process. 2023, 95, 115–130. [Google Scholar] [CrossRef]

- Li, G.; Xie, W.; Wang, H.; Chai, Y.; Zhang, S.; Yang, L. Optimizing processing parameters and surface quality of TC18 via ultrasonic-assisted milling (UAM): An experimental study. Micromachines 2023, 14, 1111. [Google Scholar] [CrossRef] [PubMed]

- Lü, Q.; Yang, S.; Yang, L.; Liu, E.; Li, G.; Xiang, D. Optimization milling force and surface roughness of Ti-6Al-4V based on ultrasonic-assisted milling (UAM): An experimental study. Micromachines 2023, 14, 1699. [Google Scholar] [CrossRef] [PubMed]

- Qin, S.; Zhu, L.; Wiercigroch, M.; Ren, T.; Hao, Y.; Ning, J.; Zhao, J. Material removal and surface generation in longitudinal-torsional ultrasonic assisted milling. Int. J. Mech. Sci. 2022, 227, 107375. [Google Scholar] [CrossRef]

- Gao, H.; Ma, B.; Zhu, Y.; Yang, H. Enhancement of machinability and surface quality of Ti-6Al-4V by longitudinal ultrasonic vibration-assisted milling under dry conditions. Measurement 2022, 187, 110324. [Google Scholar] [CrossRef]

- Ming, W.; Cai, C.; Ma, Z.; Nie, P.; Li, C.; An, Q. Milling mechanism and surface roughness prediction model in ultrasonic vibration-assisted side milling of Ti–6Al–4 V. Int. J. Adv. Manuf. Technol. 2024, 131, 2279–2293. [Google Scholar] [CrossRef]

- Rinck, P.M.; Gueray, A.; Zaeh, M.F. Modeling of cutting forces in 1-D and 2-D ultrasonic vibration-assisted milling of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2022, 119, 1807–1819. [Google Scholar] [CrossRef]

- Outeiro, J.; Cheng, W.; Chinesta, F.; Ammar, A. Modelling and optimization of machining of Ti-6Al-4V titanium alloy using machine learning and design of experiments methods. J. Manuf. Mater. Process. 2022, 6, 58. [Google Scholar] [CrossRef]

- García-Martínez, E.; Miguel, V.; Martínez-Martínez, A. Economic analysis of eco-friendly lubrication strategies for the machining of Ti48Al2Cr2Nb aluminide. J. Clean. Prod. 2024, 435, 140541. [Google Scholar] [CrossRef]

- García-Martínez, E.; Miguel, V.; Martínez-Martínez, A. Effect of minimum quantity of lubricant on carbide tools and surface integrity in the machining of titanium aluminides. Metals 2024, 14, 399. [Google Scholar] [CrossRef]

- Feng, R.; Shao, Z.; Yang, S.; Cao, H.; Li, H.; Lei, C.; Zhang, J. Material removal behavior of nanoscale shear cutting and extrusion cutting of monocrystalline γ-TiAl alloy. Int. J. Adv. Manuf. Technol. 2022, 119, 6729–6742. [Google Scholar] [CrossRef]

- Rauf, A.; Khan, M.A.; Jaffery, S.H.I.; Butt, S.I. Effects of machining parameters, ultrasonic vibrations and cooling conditions on cutting forces and tool wear in meso scale ultrasonic vibrations assisted end-milling (UVAEM) of Ti–6Al–4V under dry, flooded, MQL and cryogenic environments—A statistical analysis. J. Mater. Res. Technol. 2024, 30, 8287–8303. [Google Scholar] [CrossRef]

- Khan, A.A.; Ahmed, M.I. Improving tool life using cryogenic cooling. J. Mech. Work. Technol. 2008, 196, 149–154. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.; Ross, N.S.; Sivalingam, V. Implementation of green cooling/lubrication strategies in metal cutting industries: A state of the art towards sustainable future and challenges. Sustain. Mater. Technol. 2023, 36, e00641. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Palanisamy, S.; Dargusch, M.S. Effect of cryogenic compressed air on the evolution of cutting force and tool wear during machining of Ti–6Al–4V alloy. J. Mech. Work. Technol. 2015, 221, 243–254. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Mu, J.; Xu, J.; Zhao, J.; Li, P.; Liu, Z. Analysis of machinability in milling of high-strength brittle thin plates of γ-TiAlNb intermetallic compound. J. Mech. Sci. Technol. 2024, 38, 4085–4095. [Google Scholar] [CrossRef]

- Li, H.; Zhu, H.; Zhou, B.; Chen, Y.; Feng, R.; Cao, H.; Lei, C. Effect of structure tool on nano-cutting surface integrity of single crystal γ-TiAl alloy via atomic simulation. Mater. Today Commun. 2024, 40, 110034. [Google Scholar] [CrossRef]

- Bermingham, M.; Palanisamy, S.; Kent, D.; Dargusch, M. A comparison of cryogenic and high pressure emulsion cooling technologies on tool life and chip morphology in Ti–6Al–4V cutting. J. Mech. Work. Technol. 2012, 212, 752–765. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, J.; Chen, H.; Xiao, G.; Chen, Z.; Yi, M.; Xu, C.; Fan, L.; Li, G. Analysis of tool wear of TiAlN coated tool, machined surface morphology and chip during titanium alloy milling. Tribol. Int. 2024, 197, 109751. [Google Scholar] [CrossRef]

- Zareena, A.; Veldhuis, S. Tool wear mechanisms and tool life enhancement in ultra-precision machining of titanium. J. Mech. Work. Technol. 2012, 212, 560–570. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, J.; Geng, X.; Wang, Z. Simulation Study on Cutting Titanium Alloy with Micro-Textured tool. In Proceedings of the 2024 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Zhongshan, China, 29 July–2 August 2024; IEEE: New York, NY, USA; pp. 24–28. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Y.; Jiao, F.; Cui, X.; Zhang, D.; Ren, L.; Zhao, B.; Pang, X. Dynamic milling force model considering vibration and tool flank wear width for monitoring tool states in machining of Ti-6AI-4V. J. Manuf. Process. 2024, 124, 1519–1540. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y. Study of surface integrity of milled gamma titanium aluminide. J. Manuf. Process. 2020, 56, 806–819. [Google Scholar] [CrossRef]

- Priarone, P.C.; Rizzuti, S.; Rotella, G.; Settineri, L. Tool wear and surface quality in milling of a gamma-TiAl intermetallic. Int. J. Adv. Manuf. Technol. 2012, 61, 25–33. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Q.; Zhao, J.; Zhu, Y.; Fu, X.; Yang, C.; Chen, Y. Ultrasonic vibration assisted milling of titanium alloy microchannel. Precis. Eng. 2024, 88, 251–265. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, G.; Zhang, K.; Wang, Y.; Wang, X.; Xiang, D. Modelling of tribological behavior and wear for micro-textured surfaces of Ti2AlNb intermetallic compounds machined with multi-dimensional ultrasonic vibration assistance. Tribol. Int. 2024, 191, 109167. [Google Scholar] [CrossRef]

- Wu, S.; Chen, F.; Wang, D.; Wang, G.; Li, C.; Lu, J. Machining mechanism and stress model in cutting Ti6Al4V. Int. J. Adv. Manuf. Technol. 2024, 131, 2625–2639. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Oiu, W.; Niu, J.; Fu, X.; Qiao, Y. Material removal mechanism and surface integrity of cutting titanium aluminum alloy under different cooling conditions. Acta Aeronaut. Astronaut. Sin. 2024, 45, 629471. [Google Scholar] [CrossRef]

- Yang, P.; Li, X.; Zhang, X.; Yao, Z.; Shivpuri, R. Improved dynamic recrystallization modeling in the high-speed machining of titanium alloy. Int. J. Adv. Manuf. Technol. 2024, 130, 2563–2586. [Google Scholar] [CrossRef]

- Hussain, A.; Layegh, S.E.; Lazoglu, I.; Arrazola, P.-J.; Lazcano, X.; Aristimuño, P.-X.; Subasi, O.; Yigit, I.E.; Öztürk, Ç.; Yavaş, Ç. Mechanics of milling 48-2-2 gamma titanium aluminide. CIRP J. Manuf. Sci. Technol. 2020, 30, 131–139. [Google Scholar] [CrossRef]

- Hukkerikar, A. Milling of Gamma titanium aluminides. ebiltegia 2022, 1–225. [Google Scholar] [CrossRef]

- Guo, S.; Du, W.; Jiang, Q.; Dong, Z.; Zhang, B. Surface integrity of ultrasonically-assisted milled Ti6Al4V alloy manufactured by selective laser melting. Chin. J. Mech. Eng. 2021, 34, 67. [Google Scholar] [CrossRef]

- Yin, J.; Sun, R.; Ming, C.; Chen, C.; Zeng, S. Investigation of single grain grinding of Titanium Alloy using Diamond Abrasive Grain with positive rake Angle. Machines 2024, 12, 451. [Google Scholar] [CrossRef]

- Li, Z.; Yang, S.; Liu, X.; Xiao, G.; San, H.; Zhang, Y.; Wang, W.; Yang, Z. Grinding force model for ultrasonic assisted grinding of γ-TiAl intermetallic compounds and experimental validation. Rev. Adv. Mater. Sci. 2024, 63, 20230167. [Google Scholar] [CrossRef]

- Ni, M.J.; Liu, R.C.; Zhou, H.H.; Yang, C.; Ge, S.Y.; Liu, D.; Shi, F.L.; Cui, Y.Y.; Yang, R. Influence of Grinding Depth on the Surface Integrity and Fatigue Property of γ-TiAl Alloy. Acta Metall. Sin. 2022, 60, 261–272. [Google Scholar] [CrossRef]

- Chen, T.; Wang, X.; Zhao, B.; Ding, W.; Xiong, M.; Xu, J.; Liu, Q.; Xu, D.; Zhao, Y.; Zhu, J. Material removal mechanisms in ultrasonic vibration-assisted high-efficiency deep grinding γ-TiAl alloy. Chin. J. Aeronaut. 2024, 37, 462–476. [Google Scholar] [CrossRef]

- Wang, X.; Tang, Y.; Zhao, B.; Chen, T.; Ding, W.; Xu, J. Grindability of γ-TiAl intermetallic compounds during ultrasonic vibration-assisted high efficiency deep grinding process. Int. J. Adv. Manuf. Technol. 2023, 128, 1127–1138. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, X.; Chen, T.; Ding, W.; Qian, N.; Xu, J. Simulation and experimental thermal analysis of ultrasonic vibration-assisted high-efficiency deep grinding of γ-TiAl blade tenon. Appl. Therm. Eng. 2025, 258, 124629. [Google Scholar] [CrossRef]

- Bhaduri, D.; Soo, S.L.; Aspinwall, D.K.; Novovic, D.; Bohr, S.; Harden, P.; Webster, J.A. Ultrasonic assisted creep feed grinding of gamma titanium aluminide using conventional and superabrasive wheels. CIRP Ann. 2017, 66, 341–344. [Google Scholar] [CrossRef]

- Cao, Y.; Zhu, Y.; Li, H.N.; Wang, C.; Su, H.; Yin, Z.; Ding, W. Development and performance of a novel ultrasonic vibration plate sonotrode for grinding. J. Manuf. Process. 2020, 57, 174–186. [Google Scholar] [CrossRef]

- Nik, M.G.; Movahhedy, M.R.; Akbari, J. Ultrasonic-assisted grinding of Ti6Al4 V alloy. Procedia CIRP 2012, 1, 353–358. [Google Scholar] [CrossRef]

- Wu, H.; Ye, X.; Chen, Z.; Zhang, S.; Zeng, J.; Wang, Q.; Wu, Y. Reducing wheel loading in the grinding of titanium alloys through ultrasonic-assisted plasma oxidation modification. Lubricants 2023, 11, 397. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.; Yan, Y.; Wang, X. Study on the CBN wheel wear mechanism of longitudinal-torsional ultrasonic-assisted grinding applied to TC4 titanium alloy. Micromachines 2022, 13, 1480. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Guo, X.; Bie, W.; Chang, B.; Zhao, C. Thermo-mechanical coupling effect on surface residual stress during ultrasonic vibration-assisted forming grinding gear. J. Manuf. Process. 2020, 59, 19–32. [Google Scholar] [CrossRef]

- Li, B.; Dai, C.; Ding, W.; Yang, C.; Li, C.; Kulik, O.; Shumyacher, V. Prediction on grinding force during grinding powder metallurgy nickel-based superalloy FGH96 with electroplated CBN abrasive wheel. Chin. J. Aeronaut. 2021, 34, 65–74. [Google Scholar] [CrossRef]

- Song, J.; Zhao, B.; Ding, W.; Zhao, Y.; Zhu, J.; Cui, H. Wear mechanism of aggregated cBN grains during single-grain ultrasonic vibration-assisted grinding of γ-TiAl alloys. Int. J. Adv. Manuf. Technol. 2024, 135, 4749–4764. [Google Scholar] [CrossRef]

- Prastyo, D.T.; Andoko; Puspitasari, P.; Prasetya, R. Recent progress and applications of coolant-lubricants in titanium machining: A review. AIP Conf. Proc. 2024, 2991, 020032. [Google Scholar]

- Ramírez-Ramírez, J.H.; Pineda-Arriaga, K.Y.; Gaona-Martínez, M.J.; Benavides-Treviño, J.R.; Pérez-González, F.A.; Colás, R.; Garza-Montes-De-Oca, N.F. The Role of Heat Treatment in the Wear Behavior of a γ-TiAl Alloy under Dry Sliding Conditions. J. Mater. Eng. Perform. 2025, 34, 1–12. [Google Scholar] [CrossRef]

- Ren, Z.; Feng, R.; Cao, H.; Zhou, B.; Li, H.; Lei, C. Wear mechanism of diamond-cutting tool in nano-cutting polycrystalline γ-TiAl alloy based on molecular dynamics simulation. J. Manuf. Process. 2024, 119, 118–129. [Google Scholar] [CrossRef]

- Vashishtha, G.; Chauhan, S.; Gupta, M.K.; Korkmaz, M.E.; Ross, N.S.; Zimroz, R.; Krolczyk, G.M. Configuration of tool wear and its mechanism in sustainable machining of titanium alloys with energy signals. Int. J. Adv. Manuf. Technol. 2024, 134, 3561–3573. [Google Scholar] [CrossRef]

- Kuo, C.; Hsu, Y.; Chung, C.; Chen, C.-C.A. Multiple criteria optimisation in coated abrasive grinding of titanium alloy using minimum quantity lubrication. Int. J. Mach. Tools Manuf. 2017, 115, 47–59. [Google Scholar] [CrossRef]

- Zhu, L.; Qin, S.; Hao, Y.; Yan, T.; Yang, Z.; Yong, J.; Shu, X. Knowledge-based intelligent ensemble monitoring method of grit wear in ultrasonic assisted grinding. Adv. Eng. Inform. 2025, 64, 103043. [Google Scholar] [CrossRef]

- Chen, T.; Wang, X.; Zhao, B.; Ding, W.; Xu, J. Surface integrity evolution during creep feed profile grinding of γ-TiAl blade tenon. Chin. J. Aeronaut. 2024, 37, 496–512. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, Q.; Ma, Q.; Yuan, D. Research of the surface residual stress of TC4 titanium alloy under longitudinal-torsional ultrasonic grinding and nanofluid minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2024, 138, 2297–2311. [Google Scholar] [CrossRef]

- Xia, Z.; Shan, C.; Zhang, M.; Liu, W.; Cui, M.; Luo, M. Machinability of elliptical ultrasonic vibration milling γ-TiAl: Chip formation, edge breakage, and subsurface layer deformation. Chin. J. Aeronaut. 2025, 38, 103096. [Google Scholar] [CrossRef]

- Rotella, G.; Imbrogno, S.; Candamano, S.; Umbrello, D. Surface integrity of machined additively manufactured Ti alloys. J. Mech. Work. Technol. 2018, 259, 180–185. [Google Scholar] [CrossRef]

- Schneider, F.; Lohkamp, R.; Sousa, F.; Müller, R.; Aurich, J. Analysis of the surface integrity in ultra-precision cutting of cp-titanium by investigating the chip formation. Procedia CIRP 2014, 13, 55–60. [Google Scholar] [CrossRef]

- Shen, J.; Wang, L.; Cao, Z.; Hu, L. Synergistically enhanced strength and ductility in TiAl/Nb composites via core-shell structure design. Mater. Sci. Eng. A 2024, 918, 147417. [Google Scholar] [CrossRef]

- Paillard, M.; Rossi, F.; Elias-Birembaux, H.; Poulachon, G.; Ritou, M.; Maury, N. Effects of the Tool Microgeometry on Thermo-Mechanical Loads for Ti-6Al-4V Finishing Cutting Operations. Procedia CIRP 2025, 133, 442–447. [Google Scholar] [CrossRef]

- Malkin, S.; Guo, C. Grinding technology: Theory and Application of Machining with Abrasives; Industrial Press Inc.: New York, NY, USA, 2008. [Google Scholar]

- Singh, R.; Dureja, J.; Dogra, M.; Gupta, M.K.; Jamil, M.; Mia, M. Evaluating the sustainability pillars of energy and environment considering carbon emissions under machining ofTi-3Al-2.5 V. Sustain. Energy Technol. Assess. 2020, 42, 100806. [Google Scholar] [CrossRef]

- Liang, Y.; Lin, J. Fabrication and properties of γ-TiAl sheet materials: A review. JOM 2017, 69, 2571–2575. [Google Scholar] [CrossRef]

- Sitharaj, A.; Arulmurugan, B.; Balaji, D.; Idhayaraja, S. Additive Manufacturing of Titanium-based Alloys by Wire Arc Directed Energy Deposition (WA-DED): A Review. In Advances in Solid-State Welding and Processing of Metallic Materials; Taylor & Francis: London, UK, 2025. [Google Scholar] [CrossRef]

- Soori, M.; Jough, F.K.G. Internal cooling system effects to heat transfer and tool wear in turning operations of titanium alloys Ti6Al4V. Trans. Can. Soc. Mech. Eng. 2024, 49, 118–127. [Google Scholar] [CrossRef]

- Li, A.; Zhang, X.; Chen, J.; Shi, T.; Wen, L.; Yu, T. Review of ultrasonic vibration-assisted milling technology. Precis. Eng. 2024, 91, 601–616. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Huang, C.K.; Wu, C.Y. Milling of MAR-M247 nickel-based superalloy with high temperature and ultrasonic aiding. Int. J. Adv. Manuf. Technol. 2007, 34, 857–866. [Google Scholar] [CrossRef]

- Wang, B.S.; Zuo, J.M.; Wang, M.L.; Hou, J.M. Prediction of milling force based on numerical simulation of oblique cutting. Mater. Manuf. Process. 2012, 27, 1011–1016. [Google Scholar] [CrossRef]

- Aydın, M.; Uçar, M.; Cengiz, A.; Kurt, M.; Bakır, B. A methodology for cutting force prediction in side milling. Mater. Manuf. Process. 2014, 29, 1429–1435. [Google Scholar] [CrossRef]

- Palanikumar, K.; Boppana, S.; Natarajan, E. Analysis of chip formation and temperature measurement in machining of titanium alloy (Ti-6Al-4V). Exp. Tech. 2023, 47, 517–529. [Google Scholar] [CrossRef]

- Niu, Y.; Jiao, F.; Zhao, B.; Gao, G. Investigation of cutting force in longitudinal-torsional ultrasonic-assisted milling of Ti-6Al-4V. Materials 2019, 12, 1955. [Google Scholar] [CrossRef]

- Bao, W.; Tansel, I. Modeling micro-end-milling operations. Part I: Analytical cutting force model. Int. J. Mach. Tools Manuf. 2000, 40, 2155–2173. [Google Scholar] [CrossRef]

- Bissacco, G.; Hansen, H.; Slunsky, J. Modelling the cutting edge radius size effect for force prediction in micro milling. CIRP Ann. 2008, 57, 113–116. [Google Scholar] [CrossRef]

- Chen, N.; Li, L.; Wu, J.M.; Qian, J.; He, N.; Reynaerts, D. Research on the ploughing force in micro milling of soft-brittle crystals. Int. J. Mech. Sci. 2019, 155, 315–322. [Google Scholar] [CrossRef]

- Werner, G. Influence of work material on grinding forces. Ann. CIRP 1978, 27, 243–248. [Google Scholar]

- Chiu, N.; Malkin, S. Computer simulation for cylindrical plunge grinding. CIRP Ann. 1993, 42, 383–387. [Google Scholar] [CrossRef]

- Guo, M.; Li, B. A frequency-domain grinding force model-based approach to evaluate the dynamic performance of high-speed grinding machine tools. Mach. Sci. Technol. 2016, 20, 115–131. [Google Scholar] [CrossRef]

- Guo, M.; Li, B.; Ding, Z.; Liang, S.Y. Empirical modeling of dynamic grinding force based on process analysis. Int. J. Adv. Manuf. Technol. 2016, 86, 3395–3405. [Google Scholar] [CrossRef]

- Guo, M.; Jiang, X.; Ding, Z.; Wu, Z. A frequency domain dynamic response approach to optimize the dynamic performance of grinding machine spindles. Int. J. Adv. Manuf. Technol. 2018, 98, 2737–2745. [Google Scholar] [CrossRef]

- Lindvall, R.; Lenrick, F.; Andersson, J.M.; M’SAoubi, R.; Bushlya, V. On wear of TiAlN coated tools with and without NbN overlayer in machining titanium alloys. Int. J. Mach. Tools Manuf. 2024, 198, 104148. [Google Scholar] [CrossRef]

- Cao, H.; Huang, Q.; Xu, H.; Zhou, B.; Chen, W.; Yu, M.; Feng, R. Effect of aqueous layer thickness on nano-scratching of single-crystal γ-TiAl alloys. Mol. Simul. 2024, 50, 1076–1091. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, J.; Xiang, Y.; Wang, R.; Xu, X.; Ji, S.; Hang, W. Effect of a protective coating on the surface integrity of a microchannel produced by microultrasonic machining. J. Manuf. Process. 2021, 61, 280–295. [Google Scholar] [CrossRef]

- Lan, T.; Feng, P.; Zhang, J.; Zhang, X.; Zheng, Z.; Wang, J. Experimental investigation on the combined effects of mechano-chemical and ultrasonic vibration in titanium alloy grinding. J. Manuf. Process. 2024, 121, 382–393. [Google Scholar] [CrossRef]

- Yoon, H.-S.; Kwon, S.B.; Kim, J.-H.; Ahn, S.-H.; Min, S. Effects of surface coating materials on cutting forces and ductile-to-brittle transition in orthogonal cutting of monocrystalline sapphire. J. Manuf. Process. 2022, 84, 375–382. [Google Scholar] [CrossRef]

- Wu, H.; Duan, W.; Sun, L.; Zeng, J.; Li, S.; Wang, Q.; Wu, Y.; Chen, Y. Effect of ultrasonic vibration on the machining performance and mechanism of hybrid ultrasonic vibration/plasma oxidation assisted grinding. J. Manuf. Process. 2023, 94, 466–478. [Google Scholar] [CrossRef]

- Wu, H.; Ye, X.; Liao, Z.; Li, S.; Xiao, C.; Zeng, J.; Zhang, S.; Wu, Y. Machinability improvement of titanium alloy in face grinding by ultrasonic assisted jet plasma oxidation. Chin. J. Aeronaut. 2025, 38, 103130. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, Y.; Jiao, F.; Wang, J. Research on cutting force characteristics of laser ultrasonically assisted turning of cemented carbide. Int. J. Refract. Met. Hard Mater. 2024, 122, 106726. [Google Scholar] [CrossRef]

- Dominguez-Caballero, J.; Ayvar-Soberanis, S.; Kim, J.; Roy, A.; Li, L.; Curtis, D. Hybrid simultaneous laser- and ultrasonic-assisted machining of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2023, 125, 1903–1916. [Google Scholar] [CrossRef]

- Goiogana, M.; Sarasua, J.; Ramos, J.; Echavarri, L.; Cascón, I. Pulsed ultrasonic assisted electrical discharge machining for finishing operations. Int. J. Mach. Tools Manuf. 2016, 109, 87–93. [Google Scholar] [CrossRef]

- Bhargav, K.V.J.; Balaji, P.S.; Sahu, R.K.; Leblouba, M. Experimental investigation on machining characteristics of titanium processed using electrolyte sonicated µ-ECDM system. Sci. Rep. 2022, 12, 15540. [Google Scholar] [CrossRef]

- Xing, Y.; Liu, Y.; Yin, T.; Li, D.; Sun, Z.; Xue, C.; Yip, W.S.; To, S. Magnetic and ultrasonic vibration dual-field assisted ultra-precision diamond cutting of high-entropy alloys. Int. J. Mach. Tools Manuf. 2024, 202, 104208. [Google Scholar] [CrossRef]

- Fan, T.; Yao, C.; Tan, L.; Cao, Y.; Sun, Y.; Tang, W. The influence of induction-assisted milling on the machining characteristics and surface integrity of γ-TiAl alloys. J. Manuf. Process. 2024, 118, 215–227. [Google Scholar] [CrossRef]

- Yip, W.; To, S. Sustainable manufacturing of ultra-precision machining of titanium alloys using a magnetic field and its sustainability assessment. Sustain. Mater. Technol. 2018, 16, 38–46. [Google Scholar] [CrossRef]

- Zhuang, K.; Wan, L.; Weng, J.; Wu, Z.; Zhang, Y.; Tian, C.; Yang, Y. A new elastic abrasive jet machining method for post–treatment of tool coatings: A case study on TiAlN coated tools for titanium machining. Tribol. Int. 2023, 185, 108533. [Google Scholar] [CrossRef]

- Jamil, M.F.; Sahto, M.P.; Mehmood, A. Comprehensive study on high-performance machining (HPM) of Inconel-718: A review. Int. J. Adv. Manuf. Technol. 2025, 139, 5305–5337. [Google Scholar] [CrossRef]

| Performance | γ-TiAl | Ti2AlNb | -Ti3Al | TC4 |

|---|---|---|---|---|

| Density (g·cm−3) | 3.7–3.9 | 5–5.8 | 4.1–4.7 | 4.54 |

| Elastic modulus (GPa) | 160–180 | 102–134 | 110–145 | 96–110 |

| Yield strength (MPa) | 400–800 | 1030–1292 | 700–1150 | 380–1150 |

| Tensile strength (MPa) | 450–900 | 1245–1413 | 750–1200 | 480–1200 |

| Room temperature ductility (%) | 1–4 | 3.5–10 | 2–10 | 5–20 |

| Thermal conductivity (W·(m·K)−1) | 22–24 | 7.87 | 7 | 6.8–7.95 |

| Method | Materials | Percentage Reductions | Ref. | Year | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AUVAT | Ti6Al4V | ↓40% | [66] | 2020 | |||||||

| UVAT | Ti6Al4V | ↓16% | ↑166% | [67] | 2021 | ||||||

| UVAT | Ti6Al4V | ↓18.5% | ↓70% | [68] | 2022 | ||||||

| UVAT | Ti6Al4V | ↓57% | [69] | 2020 | |||||||

| AUVAT | Ti6Al4V | ↓50% | ↓15% | ↑102% | [70] | 2020 | |||||

| UVAT | Ti6Al4V | ↑12% | [71] | 2022 | |||||||

| RUVAT | Ti6Al4V | ↓47% | ↓33% | [72] | 2018 | ||||||

| UVAT | Ti6Al4V | ↓43.5% | ↓49% | [73] | 2014 | ||||||

| AUVAT | Ti6Al4V | ↓14.2% | ↓25% | ↑22.5% | [74] | 2023 | |||||

| RUVAT | Ti6Al4V | ↓51.1%/↓68.3% | ↓9.4% | [75] | 2021 | ||||||

| TUVAT | Ti6Al4V | ↓13%/↓21.3% | [76] | 2021 | |||||||

| UVAT | Ti6Al4V | ↓30%/↓70% | ↓30% | [77] | 2020 | ||||||

| Without Vibration | Vibration in Cutting Direction | Vibration to Normal to Surface | Vibration Normal to Cutting Direction | Compound Vibration |

|---|---|---|---|---|

|  |  |  |  |

| Tool trajectory equations | ||||

| ) | ) | |||

| Trajectory plots | ||||

|  |  |  |  |

| Method | Materials | Percentage Reductions | Ref. | Year | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LUVAM | TC18 | - | ↓34.1% | ↑85% | - | ↓19.5% | - | ↑50% | - | [101] | 2022 |

| FDUVAM | Ti6Al4V | - | - | - | ↓30% | - | - | - | - | [102] | 2019 |

| LTUAM | Ti6Al4V | ↓29.1% /↓34.7% | - | - | - | - | ↓18% | - | - | [103] | 2021 |

| UVAM | TC18 | ↓16.1% | ↓45.7 | [104] | 2022 | ||||||

| LBUAM | TC4 | ↓32.3%/31%/6.6% | ↓35% | ↑166% | [105] | 2022 | |||||

| LTUAM | Ti6Al4V | ↓40% | ↓74.6% | [106] | 2018 | ||||||

| LTUAM | Ti6Al4V | ↓36% | ↓25% | ↑25% | [107] | 2020 | |||||

| LUVAM | Ti6Al4V | ↓55% | ↓15% | ↓17% | [108] | 2020 | |||||

| LUVAM | Ti6Al4V | ↓24% | [109] | 2022 | |||||||

| LTUAM | Ti6Al4V | ↓14% | ↓30% | [110] | 2020 | ||||||

| LUVAM | Ti6Al4V | ↓67% | ↓26% | [111] | 2018 | ||||||

| UVAM | Ti6Al4V | ↓56.5% | [112] | 2022 | |||||||

| LUVAM | Ti6Al4V | ↓12.2% | ↑27.9% | [113] | 2022 | ||||||

| LUVAM | Ti6Al4V | ↓18.6% | ↓24% | ↓15% | [114] | 2023 | |||||

| LUVAM | TC18 | ↓15.6% | ↓44% | ↓42% | ↑40% | [115] | 2023 | ||||

| LUVAM | Ti6Al4V | ↓15% | ↓72% | [116] | 2023 | ||||||

| LTUAM | Ti6Al4V | ↓45.1% | ↓28.9% | [117] | 2022 | ||||||

| LUVAM | Ti6Al4V | ↓14.6%/-/↓30.2% | ↓35.1% | ↓25.9% | [118] | 2022 | |||||

| Method | Materials | Reductions | Ref. | Year | ||||

|---|---|---|---|---|---|---|---|---|

| UVHEDG | γ-TiAl | ↓38.7% | ↓19.5% | ↓39.1% | [150] | 2023 | ||

| UVAG | γ-TiAl | ↓20.1% | [37] | 2024 | ||||

| UVHEDG | γ-TiAl | ↓39.1% | [151] | 2025 | ||||

| UVAG | γ-TiAl | ↓35%/↓19% | ↓10% | [152] | 2017 | |||

| UVAG | Ti6Al4V | ↓35%/↓39% | [153] | 2020 | ||||

| UVAG | Ti6Al4V | 14.2%/13.5% | ↓10% | [154] | 2012 | |||

| UVHEDG | γ-TiAl | 16.2%/14.7% | ↓46.5% | ↓15.4% | [149] | 2024 | ||

| UVAG | γ-TiAl | ↓25% | ↓45.9% | [155] | 2023 | |||

| UVAG | TC4 | ↓25.2% | [156] | 2022 | ||||

| UVAG | γ-TiAl | ↓40.5% | ↓38.7% | [157] | 2020 | |||

| Parameter | UVAT | UVAG | UVAM |

|---|---|---|---|

| Surface roughness (Ra, µm) | Improved over conventional | Excellent finish | Moderate to good |

| Material removal rate (MRR) | Moderate | Low to Moderate | Moderate |

| Tool wear | Significantly reduced | Reduced (abrasive tool wear controlled) | Reduced (especially in intermittent cuts) |

| Dimensional accuracy | High | Very high | Moderate to high |

| Thermal effects | Minimal (due to lower cutting forces) | Very low | Low |

| Energy consumption | Moderate | Low to moderate | Moderate |

| Geometric complexity handling | Low to Moderate | Limited | High (due to milling path flexibility) |

| Suitability for γ-TiAl | Very effective for finishing and precision | Excellent for final surface conditioning | Effective for shallow features and slots |

| Process | Prediction Model | Ref. |

|---|---|---|

| Milling (2D-force model) | [183] | |

| Whereas, g(ϕ_j (t)) is the window function. | ||

| Milling (2D-force model) | [184] | |

| Milling (3D-force model) | [185] | |

| Milling (3D-force model) | [186] | |

| Grinding (cutting) | [187] | |

| Grinding (Cutting, plowing, Rubbing) | [188] | |

| Grinding (Cutting, plowing, Rubbing) | [189,190,191] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamil, M.F.; Li, Q.; Keymanesh, M.; Feng, P.; Zhang, J. A Critical Review of Ultrasonic-Assisted Machining of Titanium Alloys. Machines 2025, 13, 844. https://doi.org/10.3390/machines13090844

Jamil MF, Li Q, Keymanesh M, Feng P, Zhang J. A Critical Review of Ultrasonic-Assisted Machining of Titanium Alloys. Machines. 2025; 13(9):844. https://doi.org/10.3390/machines13090844

Chicago/Turabian StyleJamil, Muhammad Fawad, Qilin Li, Mohammad Keymanesh, Pingfa Feng, and Jianfu Zhang. 2025. "A Critical Review of Ultrasonic-Assisted Machining of Titanium Alloys" Machines 13, no. 9: 844. https://doi.org/10.3390/machines13090844

APA StyleJamil, M. F., Li, Q., Keymanesh, M., Feng, P., & Zhang, J. (2025). A Critical Review of Ultrasonic-Assisted Machining of Titanium Alloys. Machines, 13(9), 844. https://doi.org/10.3390/machines13090844