Design Methods and Practices for Centrifugal Compressor Diffusers: A Review

Abstract

1. Introduction

2. Fundamentals of Compressor Diffusers

2.1. Types of Diffusers

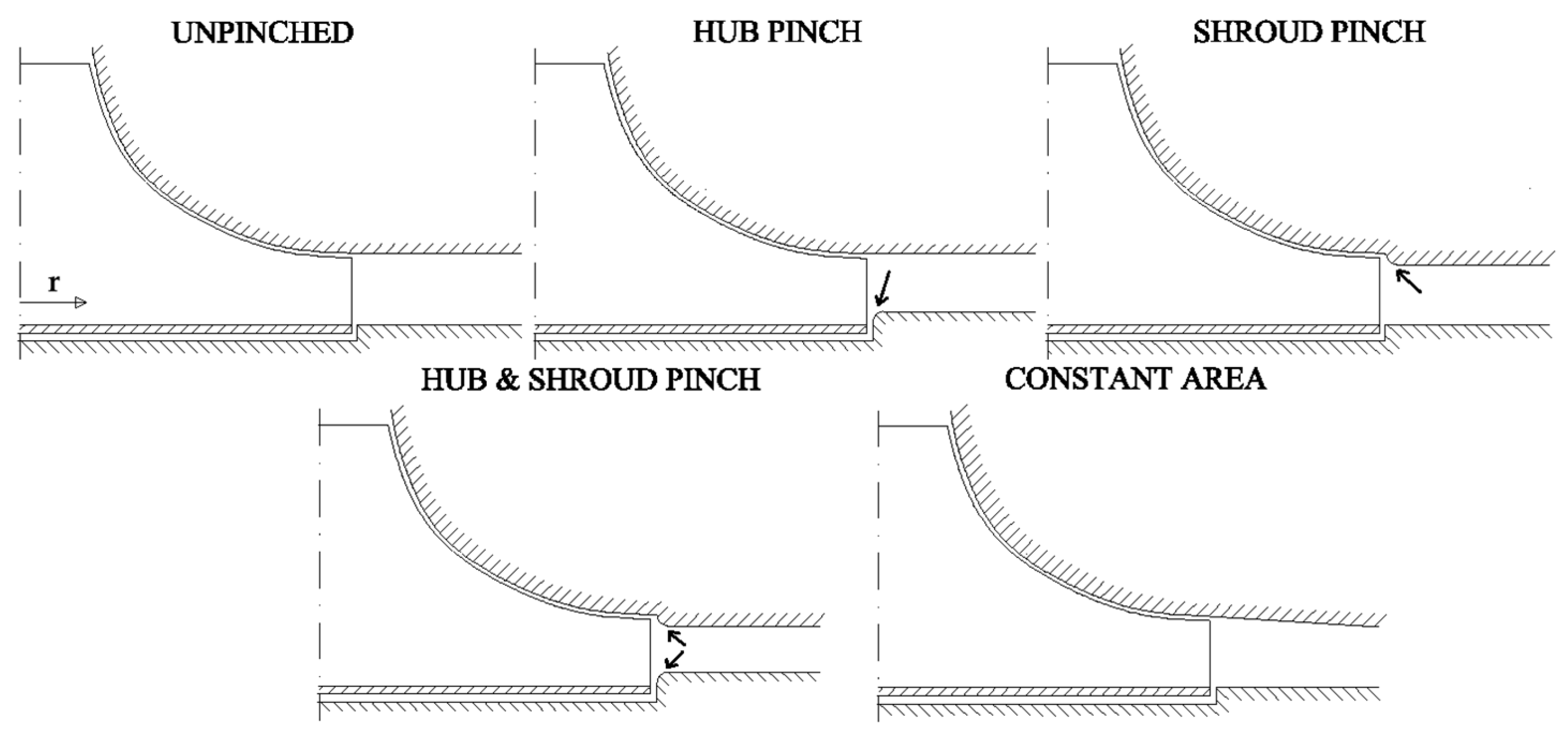

2.1.1. Vaneless Diffusers

2.1.2. Vaned Diffusers

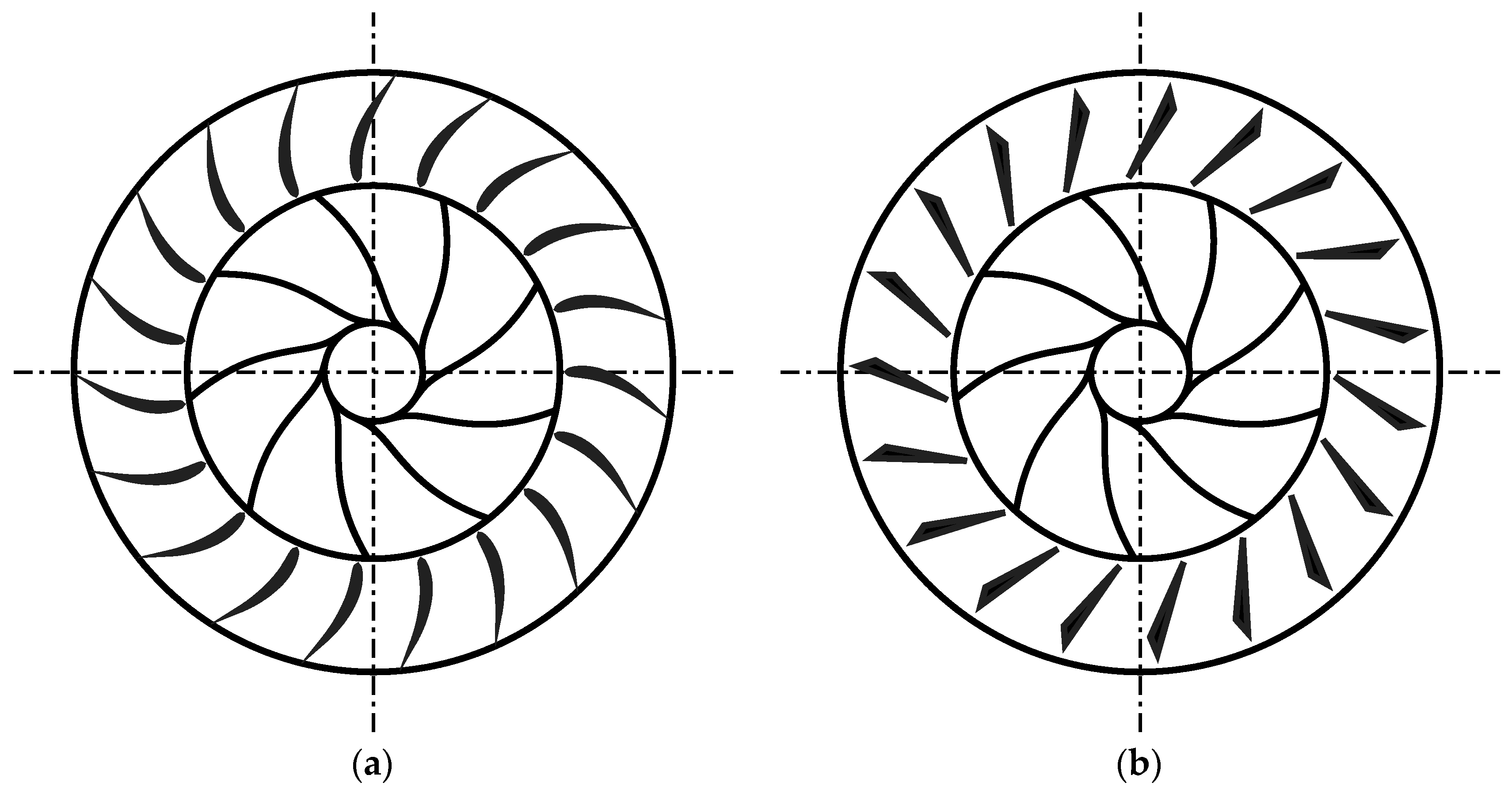

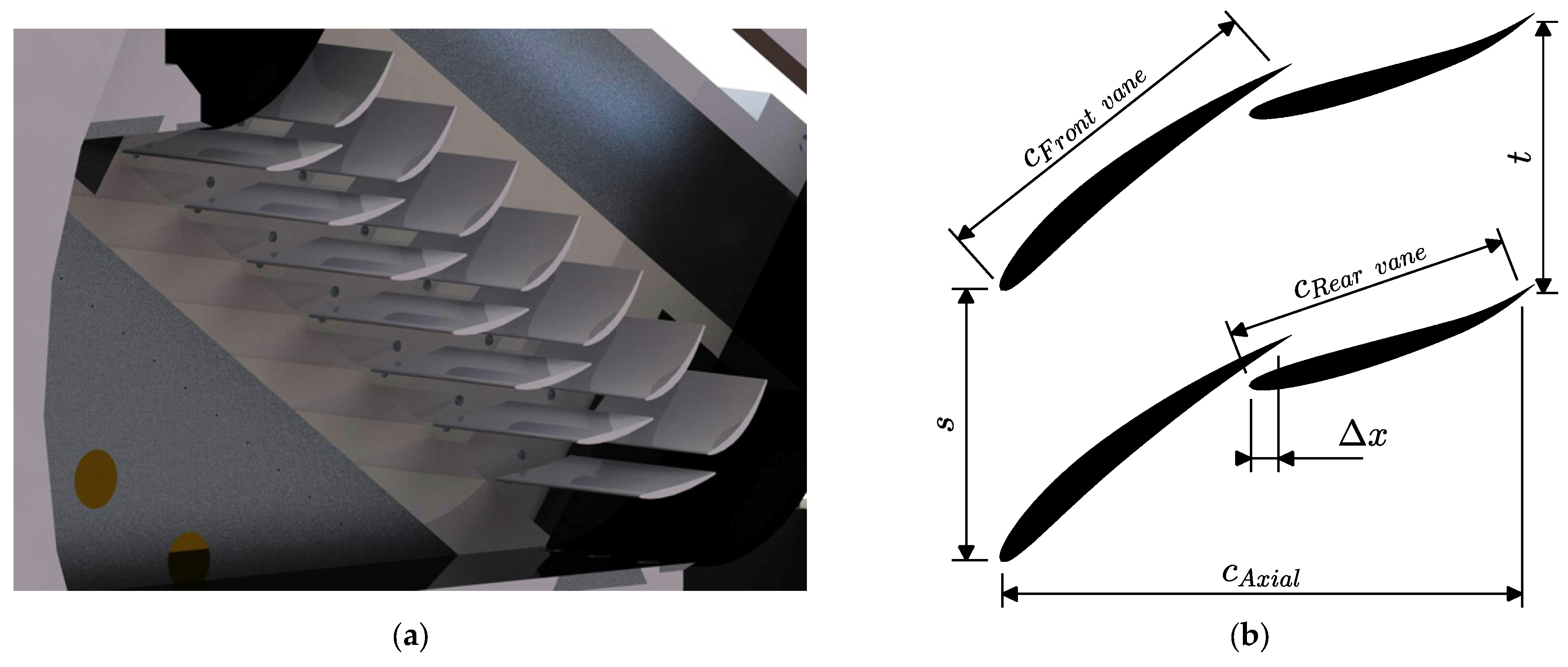

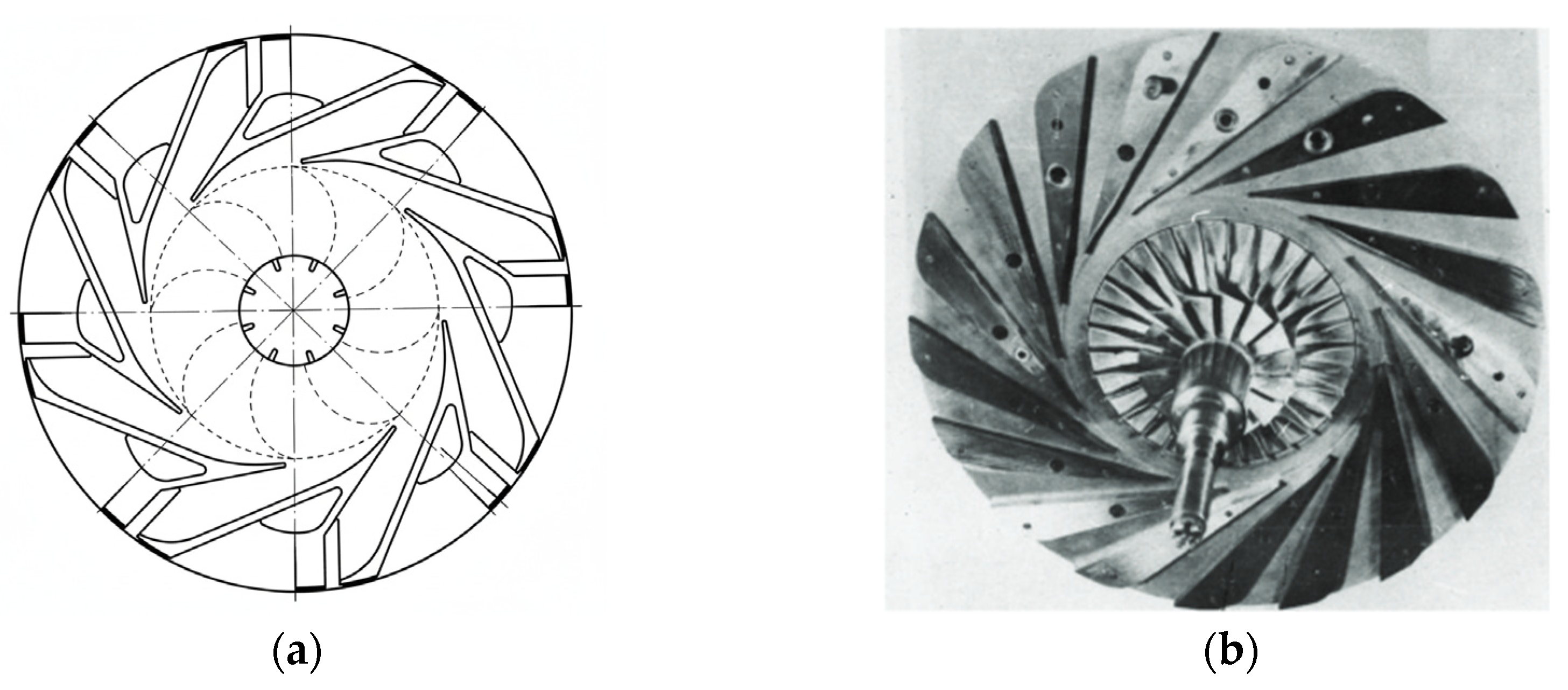

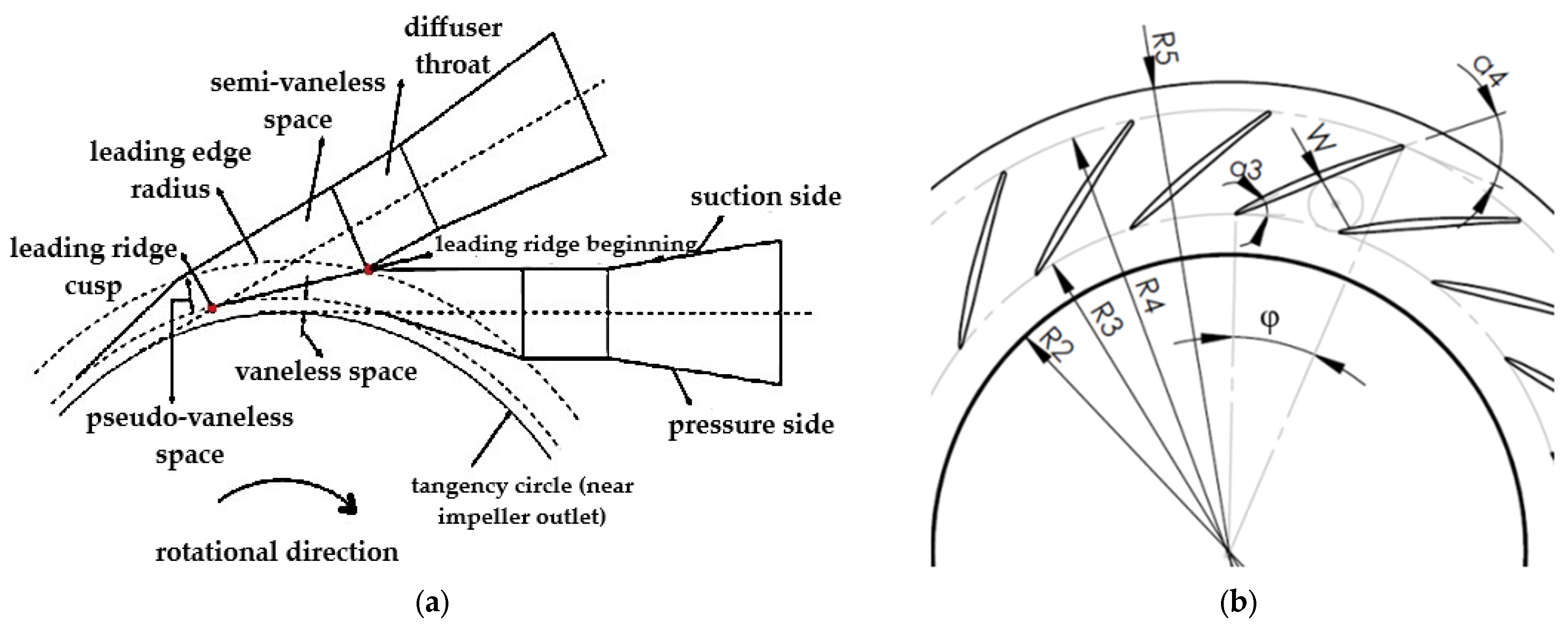

- Cascade diffusers employ thin, airfoil-shaped vanes to control flow angles with precision. They are particularly effective in subsonic regimes, where careful flow redirection is required. As shown in Figure 4a, cascade diffusers generally consist of one or more rows of airfoil vanes that redirect the flow from angle α3 to α4.

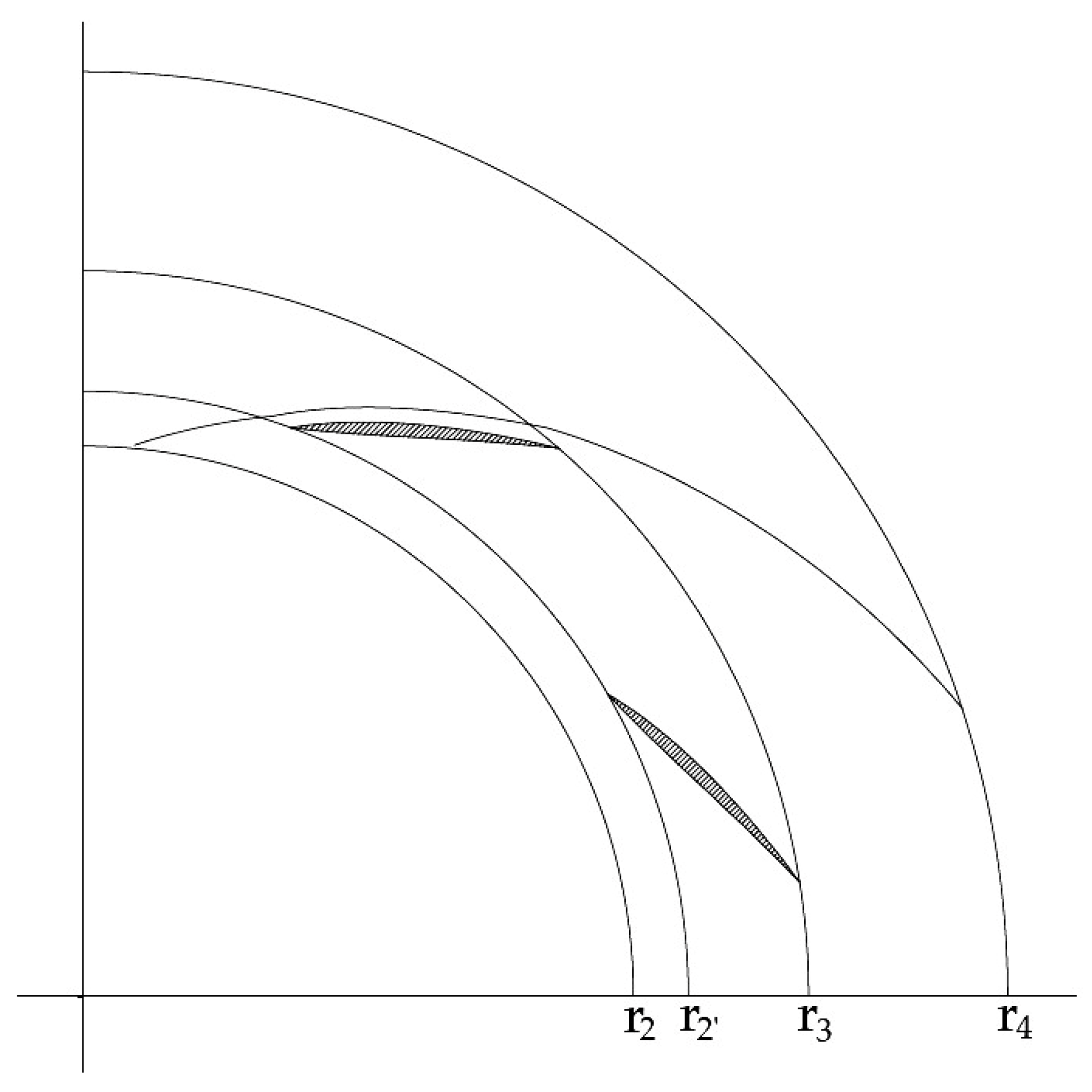

- Channel diffusers, in contrast, are designed to accommodate large area changes and higher Mach number flows. They frequently incorporate semi-vaneless logarithmic spiral profiles, making them well suited to compressible and supersonic regimes. Figure 4b illustrates such designs, which can manage substantial density variations with increasing radius.

- Low-Solidity Vaned Diffusers (LSVDs), illustrated in Figure 4c, are usually a crossover between vaned and vaneless diffusers. They have geometrical properties similar to cascade diffusers, except that the blade length and number of blades are smaller than those of conventional vaned diffusers.

- LSVDs with flat vanes are depicted in Figure 4d.

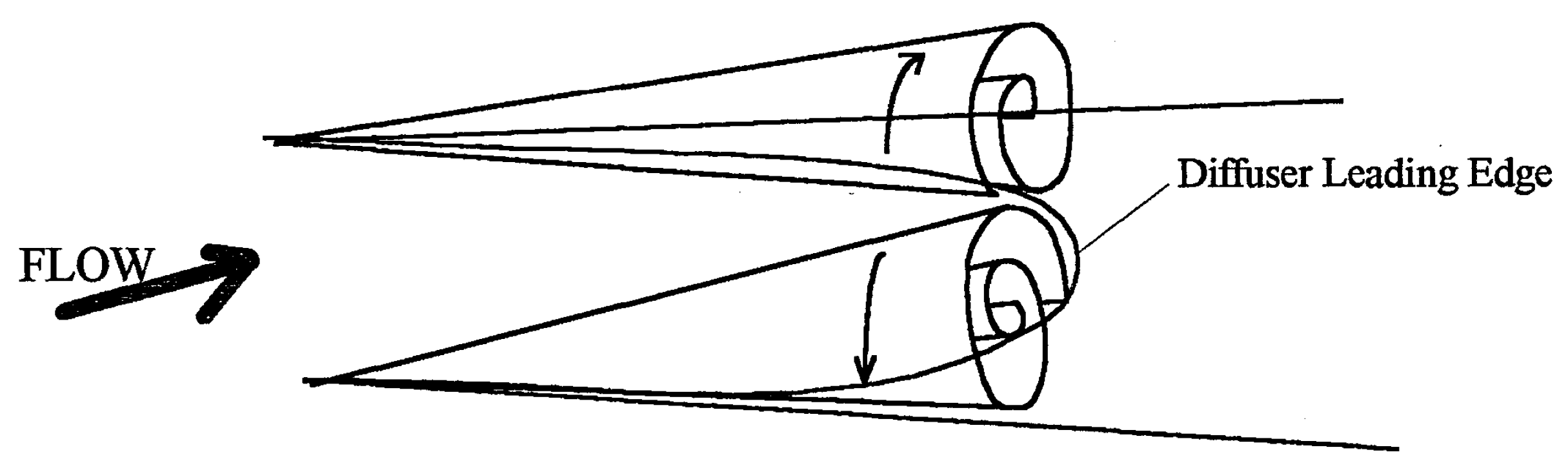

2.1.3. Pipe Diffusers

2.2. Key Aerodynamic Principles

3. Design Methodologies

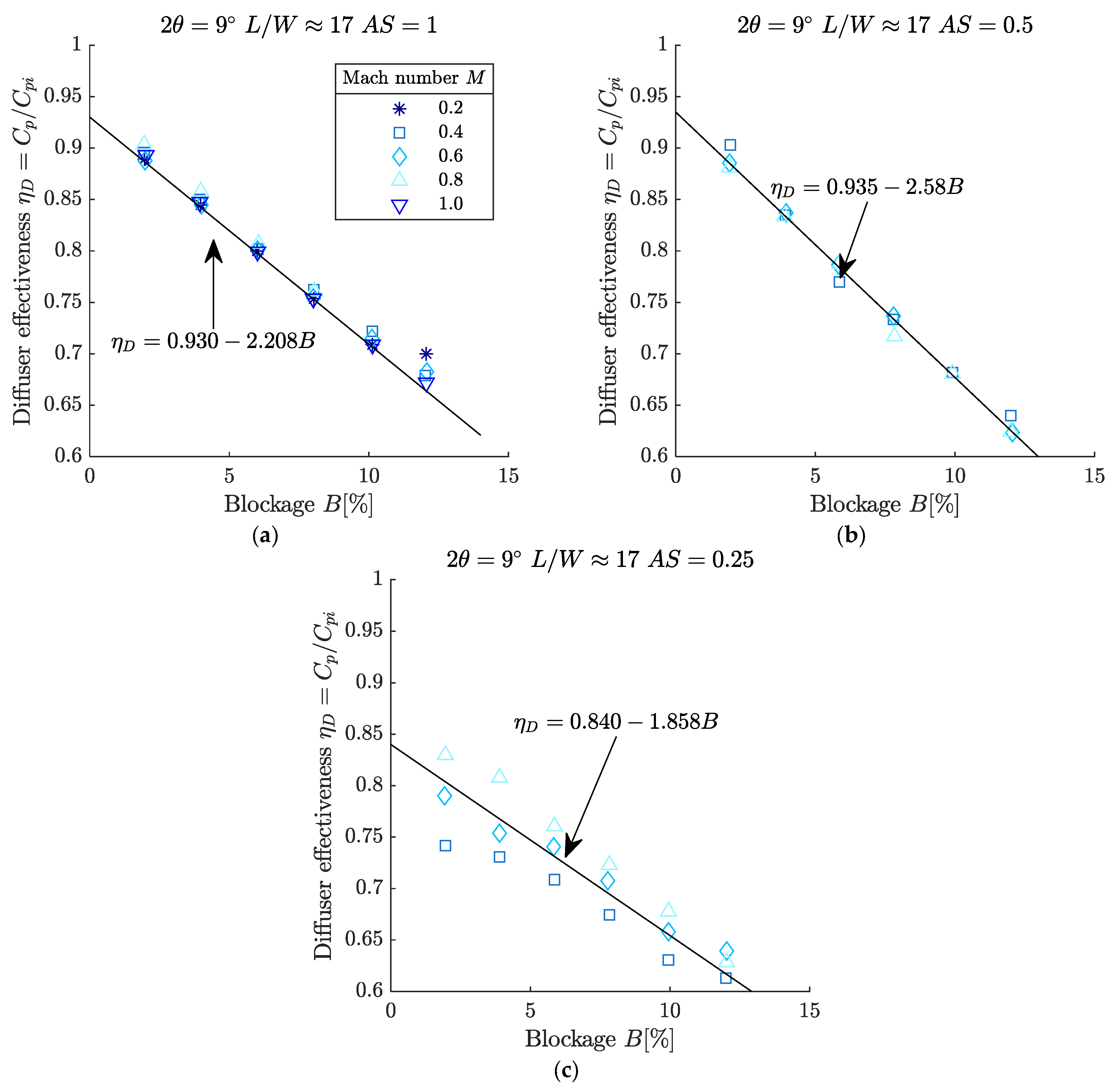

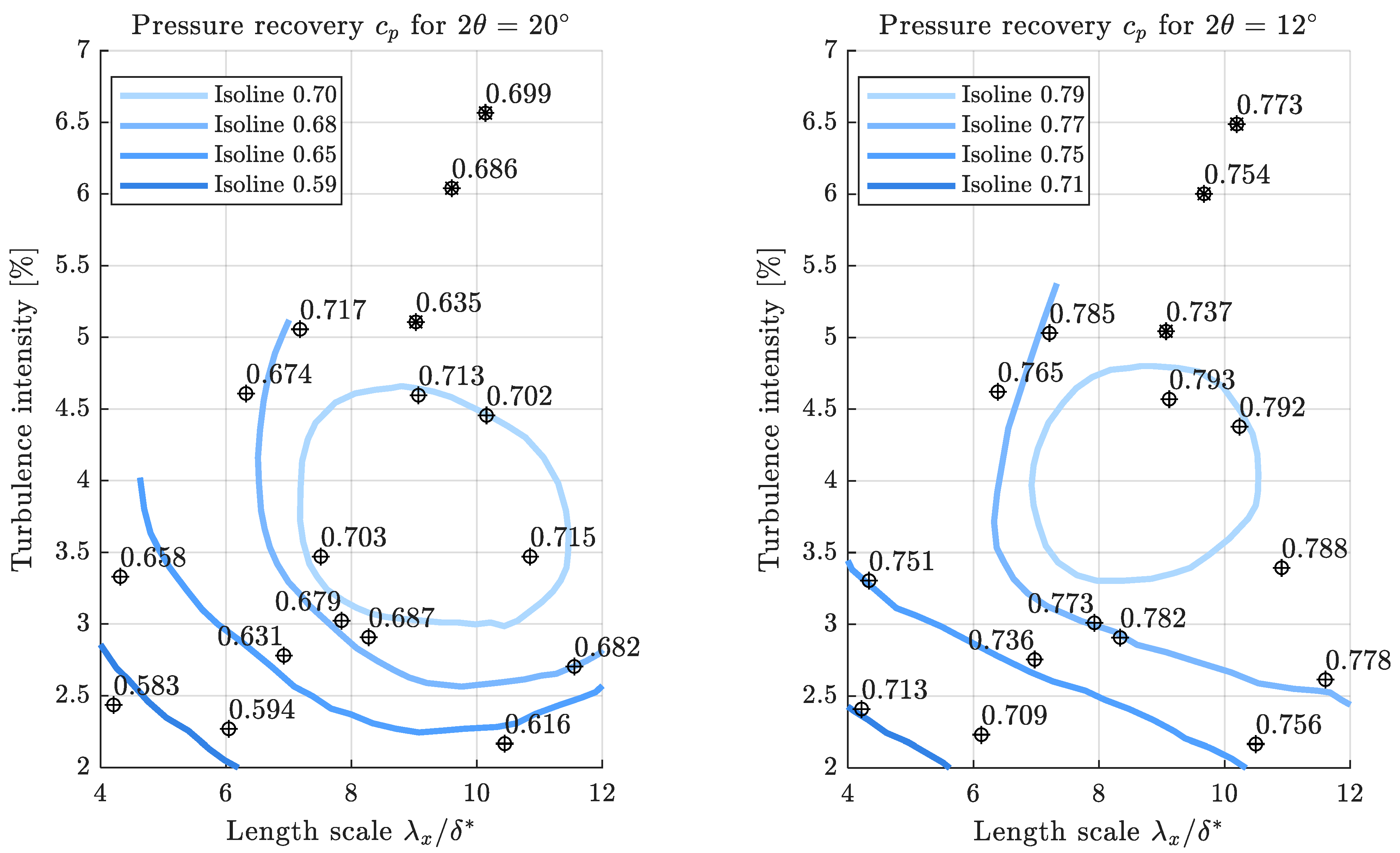

3.1. Empirical Correlations

3.2. Analytical Models

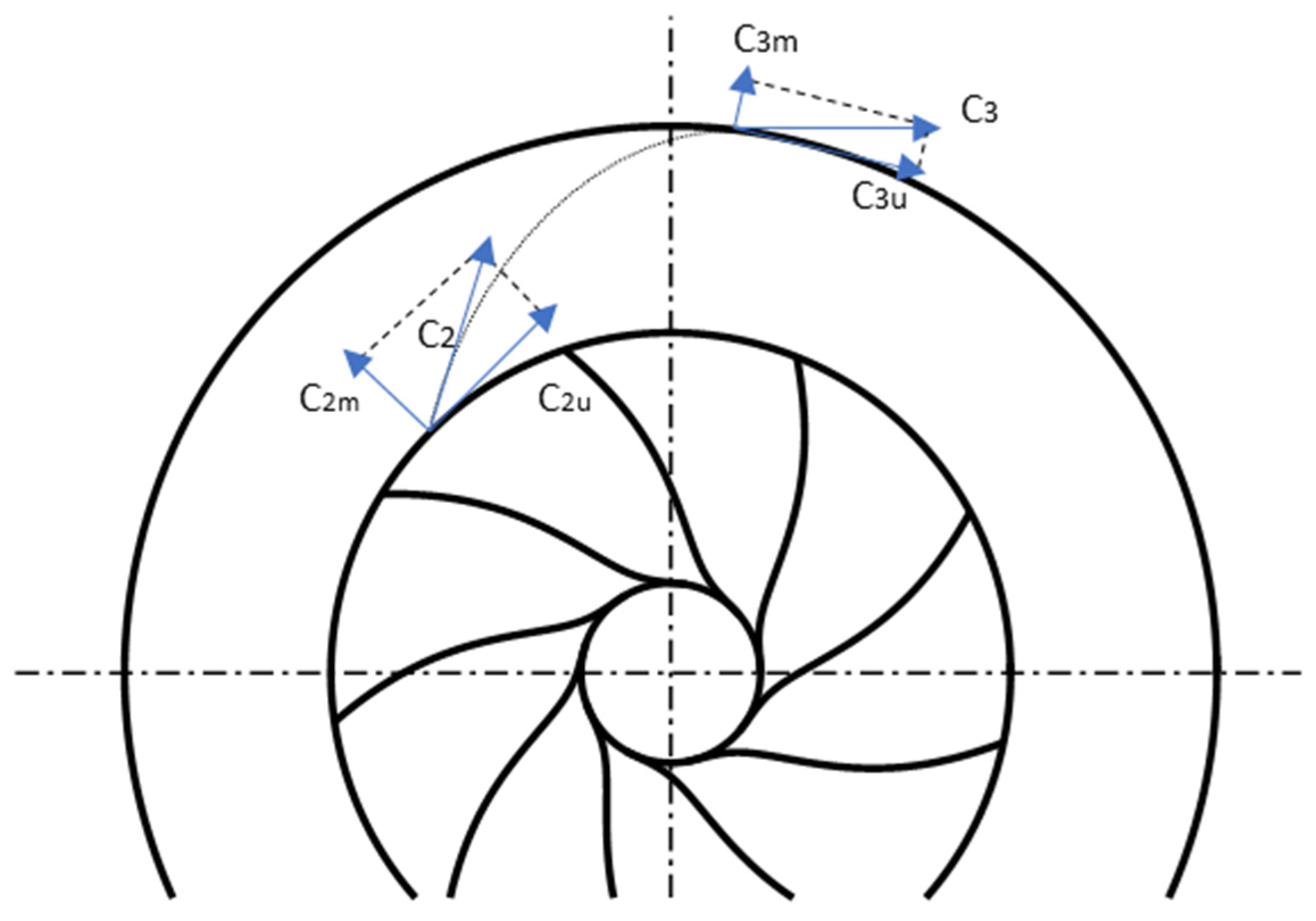

- Incidence losses—caused by the mismatch between the incoming flow angle and the vane inlet angle, which can be expressed using the flow velocity at the entrance of the diffuser (C3) and the optimum (or minimum-loss) speed defined by:in which Cm3 is the meridional velocity at the diffuser inlet, αth is the flow angle at the diffuser throat, approximated by arcsin(Ath/A3), and β3 is the blade metal angle at the diffuser inlet. The loss coefficient is given by:

- Skin friction losses—resulting from boundary layer development along the vane surfaces and endwalls.in which cf is the friction coefficient, LB is the diffuser blade mean camberline length, dH is the mean value of the throat and the tip hydraulic diameters, is the root mean square of the inlet and discharge diffuser absolute velocities, δ is the boundary layer thickness at mid-passage.

- Choking Loss—occurs when the diffuser reaches its flow capacity, limiting mass flow and increasing losses near the choke limit. To determine this pressure loss coefficient, Aungier introduces a parameter X, defined by:

- Wake Mixing Loss—caused by mixing of high- and low-momentum fluid in the wake regions behind the vanes, leading to additional entropy generation.

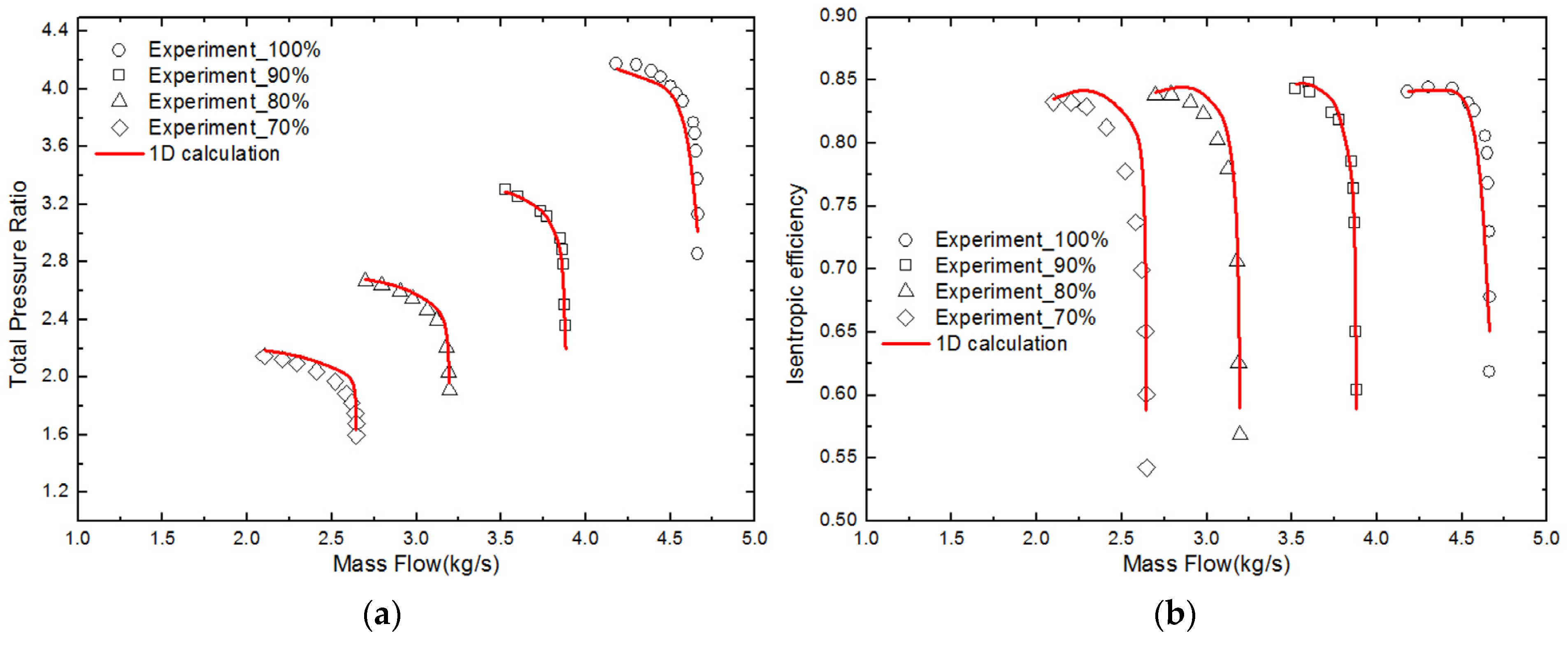

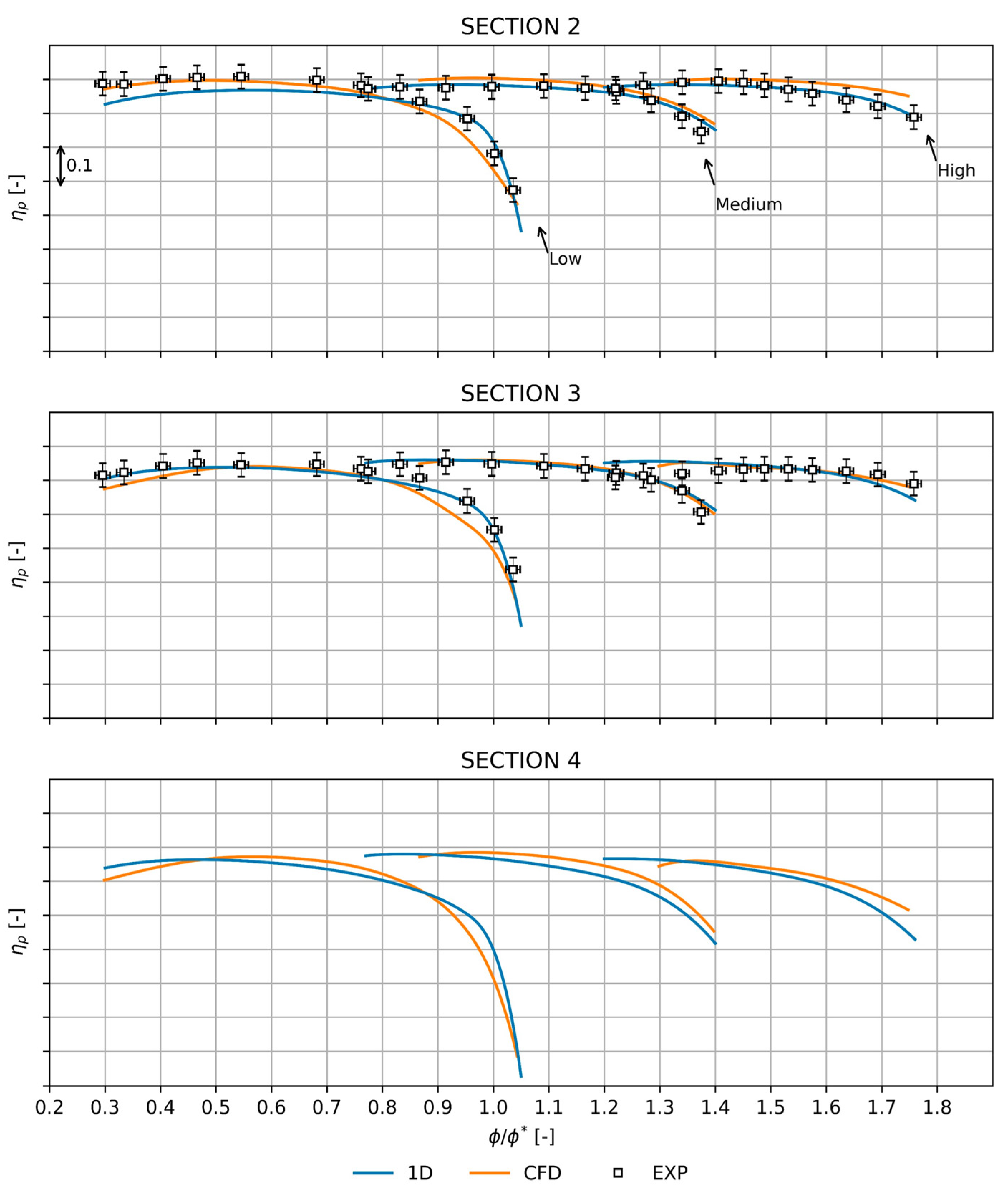

3.3. Integration of 1D and CFD Methods in Diffuser Design

4. Trade-Offs in Design

4.1. Design Constraints

- Stability Margin: Off-design operation increases the risk of flow instabilities such as rotating stall, surge and choke, which cause pressure fluctuations, loss of performance, and potential mechanical damage [147]. Ensuring sufficient surge margin across the entire operating envelope constrains diffuser geometry, blade angles, and the use of variable inlet guide vanes (VIGVs) or bleed systems to control flow and delay stall onset [148,149]. Such a safety margin, also called a safety flow range, which assures the operation of compressor stages within the surge and choke limits, is presented in [150].

- Efficiency Drop: Aerodynamic losses tend to increase under off-design conditions due to flow separation, increased secondary flows, and tip leakage effects. Compressor geometry must therefore balance aerodynamic efficiency at the design point with acceptable performance degradation at off-design conditions [151,152,153].

- Flow Range and Flexibility: A wide stable operating range requires designs that accommodate variable mass flow rates without excessive distortion or separation. Variable geometry features such as VIGVs, vaned diffusers, or active flow control devices are commonly employed to enhance flexibility and control flow behavior [99].

- Mechanical and Thermal Constraints: Off-design flow conditions can generate uneven aerodynamic loading and thermal stresses, which may impact blade life and structural integrity. The compressor design must address these mechanical limits through robust materials and structural optimization [154].

- Control System Integration: The compressor must be compatible with control strategies such as surge control systems, bleed valves, and variable geometry actuators to maintain stable and efficient operation throughout the off-design range [155].

- Stall I, at flow rates around 0.225–0.26 kg/s, involves localized impeller inlet spillage due to tip leakage vortex, causing minor flow fluctuations and reduced blade loading.

- Stall II, at flow rates below 0.225 kg/s, develops as a full annulus stall with strong mass flow oscillations, sharp drops in pressure ratio and efficiency, and intense reverse flow. This escalates vortex strength and blade loading loss, impacting the diffuser. The volute promotes the transition from localized stall I to widespread stall II, which severely disrupts compressor performance [166].

4.2. Performance Trade-Offs

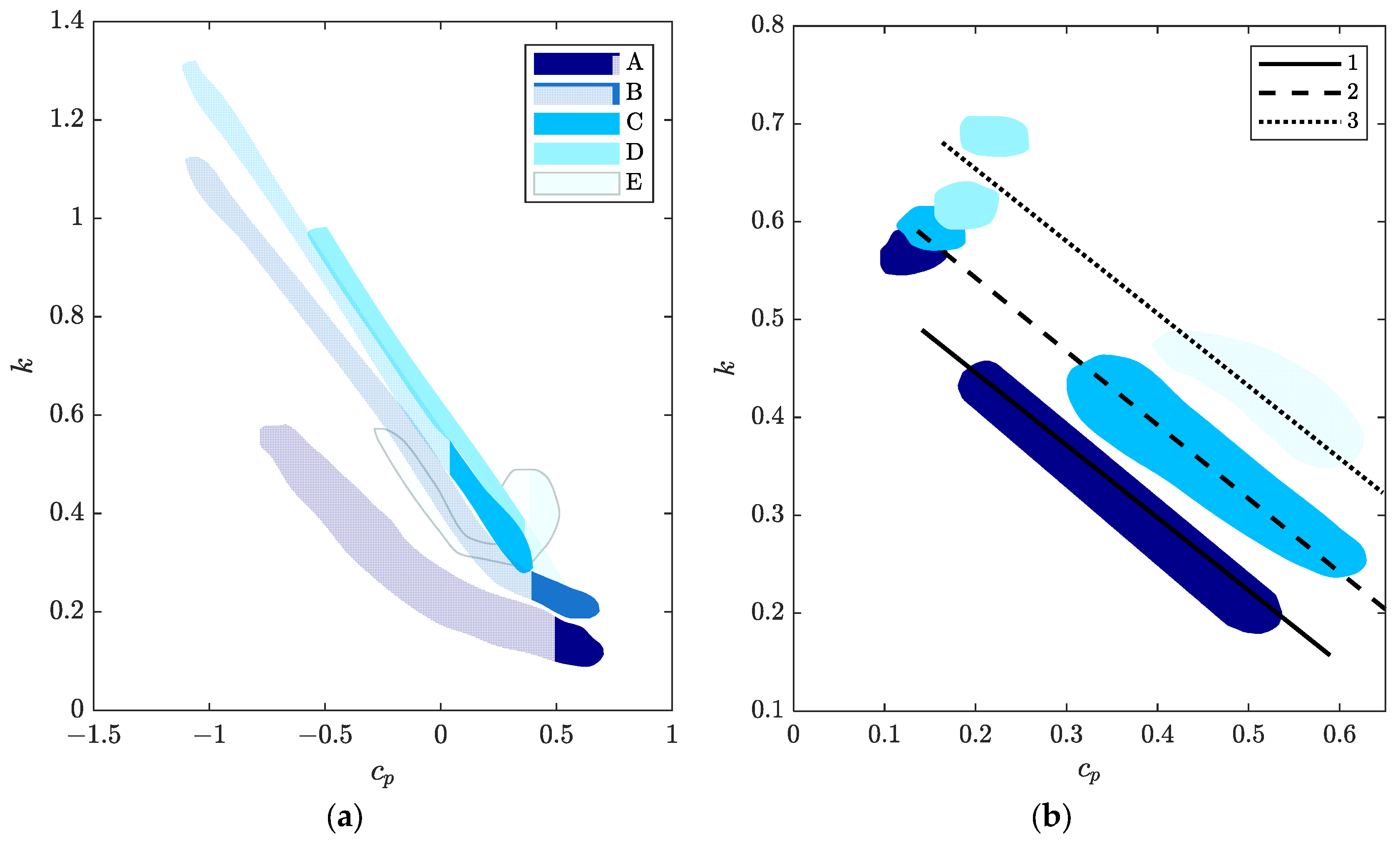

4.3. AI and Data-Driven Approach in Diffuser Design

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Networks |

| AR | area ratio |

| AS | Aspect Ratio |

| CAES | Compressed Air Energy Storage |

| CFD | Computational Fluid Dynamics |

| Cpr | pressure recovery coefficient |

| DF | diffusion factor |

| DMO | Direct Method Optimization |

| DoE | Design of Experiments |

| Ds | Specific diameter |

| FRVD | Force rotating vaneless diffuser |

| g | gravitational acceleration |

| GA | Genetic Algorithms |

| H | total stage head |

| HCF | High-cycle fatigue |

| HECC | High-Efficiency Centrifugal Compressor |

| L | Length |

| LSVD | Low-solidity vaned diffuser |

| LSD | Low-Solidity Diffusers |

| Ma | Mach number |

| n | rotational speed |

| Ns | Specific speed |

| PVD | Partial-Height Vanes |

| Q | volumetric flow rate |

| RANS | Reynolds Averaged Navier–Stokes |

| Re | Reynolds number |

| TVD | Traditional Vaned Diffusers |

| VIGS | Variable Inlet Guide Vanes |

| W | Width |

| σ | blade solidity |

References

- Blevins, R.D. Applied Fluid Dynamics Handbook; Van Nostrand Reinhold Company: New York, NY, USA, 1984; ISBN 0-442-21296-8. [Google Scholar]

- Schuldt, S.; Rosenau, K. Diffuser for Radial Compressor, Centrifugal Compressor and Turbo Machine with Centrifugal Compressor. German Patent DE102015219556A1, 2015. Available online: https://patents.google.com/patent/DE102015219556A1/en (accessed on 18 August 2025).

- Sorokes, J.M.; Kuzdzal, M.J. Centrifugal Compressor Evolution. In Proceedings of the Thirty-Ninth Turbomachinery Symposium, Houston, TX, USA, 4–7 October 2010; pp. 59–70. [Google Scholar]

- Liu, R.; Xu, Z. Numerical investigation of a high-speed centrifugal compressor with hub vane diffusers. Proc. Inst. Mech. Eng. Part A J. Power Energy 2004, 218, 155–169. [Google Scholar] [CrossRef]

- Anish, S.; Sitaram, N. Computational investigation of impeller—Diffuser interaction in a centrifugal compressor with different types of diffusers. Proc. Inst. Mech. Eng. Part A J. Power Energy 2008, 223, 167–178. [Google Scholar] [CrossRef]

- Hazby, H.R.; Xu, L.; Schleer, M. Study of the Flow in a Vaneless Diffuser at Part Speed Operating Conditions. J. Turbomach. 2014, 136, 031011. [Google Scholar] [CrossRef]

- Sorokes, J. Range Versus Efficiency: A Dilemma for Compressor Designers and Users. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2003, Washington, DC, USA, 15–21 November 2003. Paper IMECE2003-55223. [Google Scholar] [CrossRef]

- Japikse, D.; Baines, N.C. Introduction to Turbomachinery; Concepts ETI: Hartford, VT, USA, 1994; ISBN 0-933283-06-7. [Google Scholar]

- Wu, Y.A. Numerical Investigation of the Performance and Flow Behaviour of Centrifugal Compressors. Master’s Thesis, University of Manchester, Manchester, UK, 2014. Available online: https://pure.manchester.ac.uk/ws/portalfiles/portal/54552653/FULL_TEXT.PDF (accessed on 18 August 2025).

- Povey, T.; Chana, K.; Oldfield, M.; Jones, T. The Design and Performance of a Transonic Flow Deswirling System—An Application of Current CFD Design Techniques Tested Against Model and Full-Scale Experiments; IMechE Professional Engineering Publishing: London, UK, 2003; pp. 65–94. ISBN 1 8058 353 9. [Google Scholar]

- Guo, S.; Maruta, Y. Experimental Investigations on Pressure Fluctuations and Vibration of the Impeller in a Centrifugal Pump with Vaned Diffusers. JSME Int. J. Ser. B Fluids Therm. Eng. 2005, 48, 136–143. [Google Scholar] [CrossRef]

- Bilyk, D. The mechanics of vane passing frequency vibration. In Proceedings of the 11th European Fluid Machinery Congress, Edinburgh, UK, 12–15 September 2010. [Google Scholar]

- Hummel, S.; Bauer, M.; Vogt, D.M. Study of gas turbine exhaust diffuser flow and performance characteristics at off-design conditions. In Proceedings of the 14th European Conference on Turbomachinery Fluid Dynamics & Thermodynamics, Gdańsk, Poland, 12–16 April 2021. [Google Scholar] [CrossRef]

- Dixon, S.L.; Hall, C.A. Chapter 7—Centrifugal Pumps, Fans, and Compressors. In Fluid Mechanics and Thermodynamics of Turbomachinery, 7th ed.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 265–317. ISBN 978-0 12-415954-9. [Google Scholar] [CrossRef]

- Jaatinen-Värri, A.; Grönman, A.; Turunen-Saaresti, T.; Backman, J. Investigation of the Stage Performance and Flow Fields in a Centrifugal Compressor with a Vaneless Diffuser. Int. J. Rotating Mach. 2014, 10, 139153. [Google Scholar] [CrossRef]

- Bogrekci, I.; Sert, B.; Abbakar, M.; Gogebakan, A.; Demircioglu, P. Effect of Vaned and Vaneless Diffuser on the Performance of Turbo Blowers. Eng. Rev. 2024, 44, 138–147. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, J. Study of the flow characteristics in multi-row vaned diffusers of a centrifugal compressor stage. Adv. Mech. Eng. 2018, 10, 1687814018799608. [Google Scholar] [CrossRef]

- Ludtke, K. Aerodynamic Tests on Centrifugal Process Compressors—The Influence of the Vaneless Diffusor Shape. J. Eng. Power 1983, 105, 902–909. [Google Scholar] [CrossRef]

- Zhu, Y.; Sjolander, S.A. Effect of Geometry on the Performance of Radial Vaneless Diffusers. J. Turbomach. 1987, 109, 550–556. [Google Scholar] [CrossRef]

- Aungier, R.H. Centrifugal Compressors: A Strategy for Aerodynamic Design and Analysis; ASME Press: New York, NY, USA, 2000; ISBN 978-0-7918-0093-5. [Google Scholar] [CrossRef]

- Zhang, Q.; Huo, Q.; Zhang, L.; Song, L.; Yang, J. Effect of Vaneless Diffuser Shape on Performance of Centrifugal Compressor. Appl. Sci. 2020, 10, 1936. [Google Scholar] [CrossRef]

- Turunen-Saaresti, T.; Grönman, A.; Jaatinen, A. Experimental Study of Pinch in Vaneless Diffuser of Centrifugal Compressor. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Volume 7: Turbomachinery, Parts A and B, Orlando, FL, USA, 8–12 June 2009; pp. 1427–1438. [Google Scholar] [CrossRef]

- Turunen-Saaresti, T. Computational and Experimental Analysis of Flow Field in the Diffusers of Centrifugal Compressors; Lappeenranta University of Technology: Lappeenranta, Finland, 2004; ISBN 951-764-962-22. Available online: https://lutpub.lut.fi/bitstream/handle/10024/29788/isbn951764969X.pdf?sequence=1&isAllowed=y (accessed on 15 October 2025).

- Jaatinen, A. Performance Improvement of Centrifugal Compressor Stage with Pinched Geometry or Vaned Diffuser. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2009. Available online: https://lutpub.lut.fi/bitstream/handle/10024/47003/isbn%209789522148216.pdf?sequence=1&isAllowed=y (accessed on 15 October 2025).

- Jaatinen-Värri, A.; Royttä, P.; Turunen-Saaresti, T.; Grönman, A. Experimental study of centrifugal compressor vaneless diffuser width. J. Mech. Sci. Technol. 2013, 27, 1011–1020. [Google Scholar] [CrossRef]

- Adachi, Y.; Bando, K.; Miyake, Y.; Otsuki, A. Performance Improvement of a Vaneless Diffuser of Centrifugal Compressor. Trans. Jpn. Soc. Mech. Eng. Ser. B 1992, 58, 1796–1802. [Google Scholar] [CrossRef][Green Version]

- Goto, T.; Ohmoto, E.; Ohta, Y.; Outa, E. Noise reduction and surge margin improvement using tapered diffuser vane in a centrifugal compressor. J. Therm. Sci. 2010, 19, 21–25. [Google Scholar] [CrossRef]

- Abidogun, K.B. Effects of vaneless diffuser geometries on rotating stall. J. Propul. Power 2006, 22, 542–549. [Google Scholar] [CrossRef]

- Cumpsty, N.A. Compressor Aerodynamics, 2nd ed.; Krieger Publishing Company: Malabar, FL, USA, 2004; ISBN 1-57524-247-8. [Google Scholar]

- Lee, Y.; Luo, L.; Bein, T.W. Direct Method for Optimization of a Centrifugal Compressor Vaneless Diffuser. J. Turbomach. 2000, 123, 73–79. [Google Scholar] [CrossRef]

- Aalburg, C.; Simpson, A.; Schmitz, M.B.; Michelassi, V.; Evangelisti, S.; Belardini, E.; Ballarini, V. Design and Testing of Multistage Centrifugal Compressors With Small Diffusion Ratios. J. Turbomach. 2011, 134, 041019. [Google Scholar] [CrossRef]

- Jaatinen, A.; Grönman, A.; Turunen-Saaresti, T.; Röyttä, P. Effect of vaneless diffuser width on the overall performance of a centrifugal compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 225, 665–673. [Google Scholar] [CrossRef]

- Govardhan, M.; Seralathan, S. Effect of forced rotating vaneless diffusers on centrifugal compressor stage performance. J. Eng. Sci. Technol. 2011, 6, 558–574. [Google Scholar]

- Jaatinen-Värri, A.; Turunen-Saaresti, T.; Grönman, A.; Royttä, P.; Backman, J. The tip clearance effects on the centrifugal compressor vaneless diffuser flow fields at off-design conditions. In Proceedings of the 10th European Conference on Turbomachinery Fluid Dynamics & Thermodynamics (ETC10), Lappeenranta, Finland, 15–19 April 2013. [Google Scholar]

- Flete, X.; Binder, N.; Bousquet, Y.; Ciais, V.; Cros, S.; Poujol, N. Analysis and Prediction of the Stability Limit for Centrifugal Compressors with Vaneless Diffusers. Int. J. Turbomach. Propuls. Power 2024, 9, 29. [Google Scholar] [CrossRef]

- Aungier, R.H. A systematic procedure for the aerodynamic design of vaned diffusers. ASME FED 1988, 69, 27–34. [Google Scholar]

- Ziegler, K.U.; Gallus, H.E.; Niehuis, R. A study on impeller-diffuser interaction—Part I: Influence on the performance. J. Turbomach. 2003, 125, 173–181. [Google Scholar] [CrossRef]

- Murray, N.P. Effect of Impeller-Diffuser Interaction on Centrifugal Compressor Performance. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2000. Available online: https://dspace.mit.edu/bitstream/handle/1721.1/82767/54075764-MIT.pdf (accessed on 25 September 2025).

- van Eck, H. Numerical Investigation into the Effect of Vaneless Gap Size on the Performance of a MGT Mixed Flow Compressor Fitted with a Crossover Diffuser. Aerotec. Missili Spaz. 2025, 1–12. [Google Scholar] [CrossRef]

- Hosseini, M.; Sun, Z.; He, X.; Zheng, X. Effects of Radial Gap Ratio between Impeller and Vaned Diffuser on Performance of Centrifugal Compressors. Appl. Sci. 2017, 7, 728. [Google Scholar] [CrossRef]

- Shim, H.-S. Influence of Impeller-Diffuser Side-Gap Flow with a Simplified Leakage Model on the Performance and Internal Flow of a Centrifugal Pump. Energies 2025, 18, 1278. [Google Scholar] [CrossRef]

- Clements, W.W.; Artt, D.W. The Influence of Diffuser Channel Geometry on the Flow Range and Efficiency of a Centrifugal Compressor. Proc. Inst. Mech. Eng. Part A Power Process Eng. 1987, 201, 145–152. [Google Scholar] [CrossRef]

- Deniz, S.; Greitzer, E.M.; Cumpsty, N.A. Effects of Inlet Flow Field Conditions on the Performance of Centrifugal Compressor Diffusers: Part 2—Straight-Channel Diffuser. J. Turbomach. 2000, 122, 11–21. [Google Scholar] [CrossRef]

- Kalinkevych, M.; Skoryk, A. Design Method for Channel Diffusers of Centrifugal Compressors. Int. J. Rotating Mach. 2013, 2013, 589357. [Google Scholar] [CrossRef]

- Kang, J.S.; Cho, S.K.; Kang, S.H. Development of a Performance Prediction Method for Centrifugal Compressor Channel Diffusers. KSME Int. J. 2002, 16, 1144–1153. [Google Scholar] [CrossRef]

- Halawa, T.; Alqaradawi, M.; Gadala, M.S.; Shahin, I.; Badr, O. Numerical Investigation of Rotating Stall in Centrifugal Compressor with Vaned and Vaneless Diffuser. J. Therm. Sci. 2015, 24, 323–333. [Google Scholar] [CrossRef]

- Zou, W.; He, X.; Zhang, W.; Niu, Z.; Zheng, X. Roles of Vanes in Diffuser on Stability of Centrifugal Compressor. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 5380–5392. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Q.; Yuan, H.; Li, Z.; Zhou, S.; Han, G.; Lu, X. Performance Improvement of a High Loading Centrifugal Compressor with Vaned Diffuser by Hub Contour Optimization. Aerospace 2024, 11, 246. [Google Scholar] [CrossRef]

- Hunziker, R.; Gyarmathy, G. The Operational Stability of a Centrifugal Compressor and Its Dependence on the Characteristics of the Subcomponents. J. Turbomach. 1994, 116, 250–259. [Google Scholar] [CrossRef]

- Shi, L.; Ma, H.; Jin, R.; Yu, X.; Wang, T. Experimental Investigation of Evolution Characteristics of Tip Flow Instability in a Centrifugal Compressor with a Vaneless Diffuser. Proc. Inst. Mech. Eng. Part A J. Power Energy 2025, 09576509251328701. [Google Scholar] [CrossRef]

- Josuhn-Kadner, B. Flow Field and Performance of a Centrifugal Compressor Rotor with Tandem Blades of Adjustable Geometry. ASME 1994, 78835, 94-GT-13. [Google Scholar]

- Bache, G. Impeller Tandem Blade Study with Grid Embedding for Logical Grid Refinement. In Tenth Workshop for CFD Applications in Rocket Propulsion, NASA Conference Publication 3163, Part 1; NASA: Washington, DC, USA, 1992. [Google Scholar]

- Bourgeois, J.A.; Martinuzzi, R.J.; Savory, E.; Zhang, C.; Roberts, D.A. Assessment of Turbulence Model Predictions for an Aeroengine Centrifugal Compressor. J. Turbomach. 2011, 133, 011025. [Google Scholar] [CrossRef]

- Ming, Y.D.; Clinton, G.; Suresh, K.; Douglas, R. CFD Analysis of Off-Design Centrifugal Compressor Operation and Performance. In Proceedings of the 2006 International ANSYS Conference, Pittsburgh, PA, USA, 30–31 April 2006. [Google Scholar]

- Fang, J.; Ji, C.; Li, C.; Zhang, R.; Shalyaev, D. Experimental and Numerical Investigation on the Influence of the Diffuser Blade Setting Angle on the Performance of Centrifugal Compressor. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1081, 012031. [Google Scholar] [CrossRef]

- Danish, S.N.; Khan, S.U.; Umer, U.; Qureshi, S.R.; Ma, C. Performance Evaluation of Tandem Bladed Centrifugal Compressor. Eng. Appl. Comput. Fluid Mech. 2014, 8, 382–395. [Google Scholar] [CrossRef]

- Zhao, P.F.; Liu, Y.; Li, H.K.; Wang, X.F.; Yang, J.G. The Effect of Impeller—Diffuser Interactions on Diffuser Performance in a Centrifugal Compressor. Eng. Appl. Comput. Fluid Mech. 2016, 10, 565–577. [Google Scholar] [CrossRef]

- Li, Z.; Han, G.; Lu, X.; Huang, E.; Zhao, S. Improving the Operating Range Using a Centrifugal Compressor with a Tandem Impeller. Aerosp. Sci. Technol. 2020, 96, 105548. [Google Scholar] [CrossRef]

- Fang, J.; Ji, C.; Li, C.; Sun, Q. Using Tip Gaps on Tandem Diffuser to Broaden the Operation Range of a Centrifugal Compressor. J. Therm. Sci. 2021, 30, 999–1009. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, W.; Yang, S.; Lu, F.; Dou, H. Performance Enhancement of a Centrifugal Compressor by Designing a Tandem Cascade Diffuser. Energies 2022, 15, 4570. [Google Scholar] [CrossRef]

- Fan, P.; Kong, X.; Huang, T.; Liu, Y.; Wang, H. Cavity Leakage Flow on Annular Diffuser Cascades Based on Numerical Simulation and Self-Organizing Map Algorithm. Phys. Fluids 2025, 37, 035212. [Google Scholar] [CrossRef]

- Senoo, Y.; Hayami, H.; Ueki, H. Low Solidity Tandem Cascade Diffusers for Wide Range Centrifugal Blowers. ASME 1983, 79511, 83-GT-3. [Google Scholar]

- Hohlweg, W.C.; Direnzi, G.L.; Aungier, R.H. Comparison of Convectional and Low Solidity Vaned Diffusers. In Proceedings of the International Gas Turbine and Aeroengine Congress and Exposition, Cincinnati, OH, USA; 1993; p. 93-GT-98. [Google Scholar]

- Aerodynamics of Tandem Vanes. Available online: https://www.tu.berlin/en/la/research/projects/aerodynamics-of-tandem-vanes (accessed on 15 October 2025).

- Zhang, Y.C.; Kong, X.Z.; Li, F.; Sun, W.; Chen, Q.G. Performance Improvement of a Centrifugal Compressor Stage by Using Different Vaned Diffusers. IOP Conf. Ser. Mater. Sci. Eng. 2013, 52, 042003. [Google Scholar] [CrossRef]

- Chehhat, A.; Si-Ameur, M.; Boumeddane, B.; Abo-Serie, E.; Boulahrouz, S. Numerical Investigation of Diffuser Solidity Effect on Turbulent Airflow and Performance of the Turbocharger Compressor. Appl. Comput. Mech. 2016, 10, 79–96. [Google Scholar]

- Yang, C.; Liu, Z.; Liu, Y.; Wang, H.; Wang, Y.; Hu, D.; Wang, B.; Yang, J.; Chen, Y. Influence of Diffuser Vane Thickness on Centrifugal Compressor Performance. J. Phys. Conf. Ser. 2023, 2437, 012007. [Google Scholar] [CrossRef]

- Chen, S.; Zuo, S.; Wei, K. Numerical Investigation of the Centrifugal Compressor Stability Improvement by Half Vaned Low Solidity Diffusers. J. Therm. Sci. 2021, 30, 696–706. [Google Scholar] [CrossRef]

- Liang, Q.; Zuo, Z.; Zhou, X.; Tang, H.; Chen, H. Design of a Centrifugal Compressor with Low Solidity Vaned Diffuser (LSVD) for Large-Scale Compressed Air Energy Storage (CAES). J. Therm. Sci. 2020, 29, 423–434. [Google Scholar] [CrossRef]

- Han, G.; Yang, C.; Wu, S.; Zhao, S.; Lu, X. The Investigation of Mechanisms on Pipe Diffuser Leading Edge Vortex Generation and Development in Centrifugal Compressor. Appl. Therm. Eng. 2023, 219, 119606. [Google Scholar] [CrossRef]

- Sun, Z.; Linghu, Z. Flow Characteristics of a Pipe Diffuser for Centrifugal Compressors. J. Appl. Fluid Mech. 2016, 10, 143–155. [Google Scholar] [CrossRef]

- Anbarsooz, M.; Amiri, M.; Benini, E. A Numerical Investigation on the Effects of Vaned Diffusers on the Aerodynamic Performance of a Low Pressure-Ratio Methane Centrifugal Compressor. J. Appl. Fluid Mech. 2024, 17, 2545–2562. [Google Scholar] [CrossRef]

- Bennett, I.; Tourlidakis, A.; Elder, R.L. The Design and Analysis of Pipe Diffusers for Centrifugal Compressors. Proc. Inst. Mech. Eng. Part A J. Power Energy 2000, 214, 87–96. [Google Scholar] [CrossRef]

- Ishikawa, K.; Nakamura, I. Performance Chart and Optimum Geometries of Conical Diffusers with Uniform Inlet Flow and Tailpipe Discharge. JSME Int. J. Ser. 2 Fluids Eng. Heat Transf. Power Combust. Thermophys. Prop. 1990, 33, 97–105. [Google Scholar] [CrossRef][Green Version]

- Bhavsar, S.; De, S. Aerodynamic Design and Performance Evaluation of Pipe Diffuser for Centrifugal Compressor of Micro Gas Turbine. In Proceedings of the ASME 2019 Gas Turbine India, Chennai, India, 5–6 December 2019. [Google Scholar]

- Mat, A. A Comparative Study of Internal Flow Dynamic Using CFD: Simulation of Turbulent Flow in Diffuser Pipes. J. Adv. Fluid Heat Mater. Eng. 2025, 5, 10–18. [Google Scholar] [CrossRef]

- Kenny, D.P. A Novel Low-Cost Diffuser for High-Performance Centrifugal Compressors. J. Eng. Power 1969, 91, 37–46. [Google Scholar] [CrossRef]

- Reeves, G.B. Design and Performance of Selected Pipe-Type Diffusers. In Proceedings of the ASME 1977 International Gas Turbine Conference and Products Show, Philadelphia, PA, USA, 27–31 March 1977; p. 77-GT-104. [Google Scholar] [CrossRef]

- Zachau, U.; Buescher, C.; Niehuis, R.; Hoenen, H.; Wisler, D.C.; Moussa, Z.M. Experimental Investigation of a Centrifugal Compressor Stage with Focus on the Flow in the Pipe Diffuser Supported by Particle Image Velocimetry (PIV) Measurements. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; Volume 6, pp. 1705–1713. [Google Scholar] [CrossRef]

- Han, G.; Lu, X.; Zhao, S.; Yang, C.; Zhu, J. Parametric Studies of Pipe Diffuser on Performance of a Highly Loaded Centrifugal Compressor. J. Eng. Gas Turbines Power 2014, 136, 122604. [Google Scholar] [CrossRef]

- Liu, J.; Wang, D.; Huang, X. Design Methodology for Fishtailed Pipe Diffusers and Its Application to a High-Pressure Ratio Centrifugal Compressor. Aerospace 2025, 12, 746. [Google Scholar] [CrossRef]

- Han, G.; Yang, C.; Zhao, S.; Zhang, Y.; Lu, X. Investigation of a High Pressure Ratio Centrifugal Compressor with Wedge Diffuser and Pipe Diffuser. Int. J. Turbo Jet-Engines 2021, 38, 1–13. [Google Scholar] [CrossRef]

- Lakshminarayana, B. Fluid Dynamics and Heat Transfer of Turbomachinery; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1995; ISBN 9780470172629. [Google Scholar]

- Sorokes, J.M. Selecting a Centrifugal Compressor; American Institute of Chemical Engineers (AIChE) and Dresser-Rand: New York, NY, USA, 2013; Available online: https://www.aiche.org/sites/default/files/cep/20130644.pdf (accessed on 28 August 2025).

- Hajaali, A. Flow Separation Characteristics Within Rectangular and Conical Diffusers. Ph.D. Thesis, School of Engineering, Cardiff University, Wales, UK, 2020. Available online: https://orca.cardiff.ac.uk/id/eprint/142033/2/Arthur_Thesis_2020_Corrected.pdf (accessed on 28 August 2025).

- Han, G.; Lu, X.G.; Zhang, Y.F.; Zhao, S.F.; Yang, C.W.; Zhu, J.Q. Investigation of Two Pipe Diffuser Configurations for a Compact Centrifugal Compressor. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2018, 232, 716–728. [Google Scholar] [CrossRef]

- Wang, B.; Yan, M. Design and Numerical Simulation of Pipe Diffuser in Centrifugal Compressor. J. Aerosp. Power 2012, 27, 1303–1311. [Google Scholar]

- Harshavardhan Reddy, B.; Subramanian, B. Separation Control of Turbulent Developing Boundary Layer Flow in Planar Symmetric Diffuser. Phys. Fluids 2025, 37, 065117. [Google Scholar] [CrossRef]

- Mole, A.; Skillen, A.; Revell, A. The Interaction of Longitudinal Vortex Pairs with a Turbulent Boundary Layer. J. Fluid Mech. 2022, 953, A31. [Google Scholar] [CrossRef]

- Xu, C.; Amano, R.S. Study of the Flow in Centrifugal Compressor. Int. J. Fluid Mach. Syst. 2010, 3, 260–270. [Google Scholar] [CrossRef]

- Gunadal, S.M.; Govardhan, M. Performance Improvement of a Centrifugal Compressor Using Partial Vaned Diffusers. Int. J. Fluid Mach. Syst. 2020, 13, 177. [Google Scholar] [CrossRef]

- Liu, J.-N.; Huang, X. Study of a High-Pressure Ratio Centrifugal Compressor with a Wedge Diffuser and a Pipe Diffuser. In Proceedings of the Global Power and Propulsion Society, Hong Kong, China, 17–19 October 2023, ISSN 2504-4400. [Google Scholar]

- van Helvoirt, J. Centrifugal Compressor Surge, Modeling and Identification for Control; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2007; ISBN 978-90-386-1095-5. [Google Scholar]

- Lou, F.; Harrison, H.M.; Brown, W.J.; Key, N.L. Investigation of Surge in a Transonic Centrifugal Compressor with Vaned Diffuser: Part II—Correlation with Subcomponent Characteristics. J. Turbomach. 2023, 145, 051004. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Bai, H.; Zhou, X.; Lu, X. Numerical Investigation of a Centrifugal Compressor with a Pre-Compression Wedge Diffuser under High Subsonic Conditions. J. Therm. Sci. 2020, 29, 945–954. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Wang, Y.; Han, G.; Zhang, Y.; Lu, X. Numerical Investigation of the Diffuser Throat Length Effect on a Transonic Centrifugal Compressor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 3790–3803. [Google Scholar] [CrossRef]

- Wang, Y.; Han, G.; Lu, X.; Zhu, J. The Influence of Wedge Diffuser Blade Number and Divergence Angle on the Performance of a High Pressure Ratio Centrifugal Compressor. J. Therm. Sci. 2018, 27, 17–24. [Google Scholar] [CrossRef]

- Khalafallah, M.G.; Saleh, H.S.; Ali, S.M.; Abdelkhalek, H.M. CFD Investigation of Flow Through a Centrifugal Compressor Diffuser with Splitter Blades. J. Eng. Appl. Sci. 2021, 68, 43. [Google Scholar] [CrossRef]

- Gunadal, S.M.; Govardhan, M. Improvement in Stable Operating Range of a Centrifugal Compressor with Leaned Diffuser Vanes. J. Mech. Sci. Technol. 2019, 33, 5261–5269. [Google Scholar] [CrossRef]

- Zhao, Y.; Xi, G.; Zou, H.; Sun, Y.; Wang, Z. Experimental Investigation of Transient Characteristics of Mild Surge and Diffuser Rotating Stall in a Centrifugal Compressor with Vaned Diffuser. Sci. China Technol. Sci. 2020, 63, 1212–1223. [Google Scholar] [CrossRef]

- Cui, Q.; Qin, G.; Jia, C.; Wang, Y.; Lei, J. Numerical Investigation of Centrifugal Compressor Stability Enhancement Using Vaned Diffuser Endwall Contouring Technology. Energy Sci. Eng. 2022, 10, 2808–2826. [Google Scholar] [CrossRef]

- Lou, F.; Harrison, H.M.; Key, N.L. Investigation of Surge in a Transonic Centrifugal Compressor with Vaned Diffuser—Part I: Surge Signature. J. Turbomach. 2023, 145, 051003. [Google Scholar] [CrossRef]

- Li, S.; Liu, Y.; Li, H.; Omidi, M. Numerical Study of the Improvement in Stability and Performance by Use of a Partial Vaned Diffuser for a Centrifugal Compressor Stage. Appl. Sci. 2021, 11, 6980. [Google Scholar] [CrossRef]

- Wiggins, J.O. Multi-Stage Centrifugal Compressor. German Patent EP0080251A1, 1981. Available online: https://patents.google.com/patent/EP0080251A1/en (accessed on 25 September 2025).

- Mohtar, H.; Chesse, P.; Chalet, D.; Hetet, J.-F.; Yammine, A. Effect of Diffuser and Volute on Turbocharger Centrifugal Compressor Stability and Performance: Experimental Study. Oil Gas Sci. Technol. 2011, 66, 779–790. [Google Scholar] [CrossRef]

- Fischer, T.; Seume, J.R. Low-Inertia Centrifugal Compressor Wheels: Aerodynamic and Mechanical Design. Adv. Mech. Eng. 2017, 9, 1687814017690695. [Google Scholar] [CrossRef]

- Nili-Ahmadabadi, M.; Hajilouy Benisi, A.; Durali, M.; Ghadak, F. Investigation of a Centrifugal Compressor and Study of the Area Ratio and TIP Clearance Effects on Performance. J. Therm. Sci. 2008, 17, 314–323. [Google Scholar] [CrossRef]

- Sovran, G.; Klomp, E.D. Experimentally Determined Optimum Geometries for Rectilinear Diffusers with Rectangular, Conical or Annular Cross-Section. Fluid Mech. Intern. Flow 1967, 20, 270–319. [Google Scholar]

- Koch, C.C. Stalling Pressure Rise Capability of Axial Flow Compressors. J. Eng. Power 1981, 103, 645–656. [Google Scholar] [CrossRef]

- Britsch, W.; Osborn, W.; Laessig, M. Effects of Diffusion Factor, Aspect Ratio, and Solidity on Overall Performance of 14 Compressor Middle Stages; NASA Technical Paper 1523; NASA: Washington, DC, USA, 1979. [Google Scholar]

- Liu, S.; Geng, S.; Li, X.; Jin, Y.; Zhang, H. Optimization Design of Aspect Ratio and Solidity of a Heavy-Duty Gas Turbine Transonic Compressor Rotor. Machines 2023, 11, 82. [Google Scholar] [CrossRef]

- To, H.; Miller, R. The Effect of Aspect Ratio on Compressor Performance. J. Turbomach. 2019, 141, 081011. [Google Scholar] [CrossRef]

- Clements, W.W.; Artt, D.W. The Influence of Diffuser Channel Length-Width Ratio on the Efficiency of a Centrifugal Compressor. Proc. Inst. Mech. Eng. Part A Power Process Eng. 1988, 202, 163–169. [Google Scholar] [CrossRef]

- Lou, F.; Fabian, J.C.; Key, N.L. A New Approach for Centrifugal Impeller Preliminary Design and Aerothermal Analysis. J. Turbomach. 2018, 140, 051001. [Google Scholar] [CrossRef]

- Tamaki, H. A Study on Matching Between Centrifugal Compressor Impeller and Low Solidity Diffuser and Its Extension to Vaneless Diffuser. J. Eng. Gas Turbines Power 2019, 141, 041026. [Google Scholar] [CrossRef]

- Liu, Y.; Spence, S.; Horsley, J.; Mann, S.; Stuart, C. Insights into Turbocharger Centrifugal Compressor Stability Using High-Fidelity Computational Fluid Dynamics and a Novel Impeller Diffusion Factor. J. Turbomach. 2025, 147, 041003. [Google Scholar] [CrossRef]

- Lou, F.; Key, N.L. On Choosing the Optimal Impeller Exit Velocity Triangles in Preliminary Design. J. Turbomach. 2022, 144, 111011. [Google Scholar] [CrossRef]

- Japikse, D. Centrifugal Compressor Design and Performance, 3rd ed.; Concepts ETI Inc.: Wilder, TN, USA, 1996; pp. 2.26–2.81. [Google Scholar]

- Galvas, M.R. Fortran Program for Predicting Off-Design Performance of Centrifugal Compressors; NASA: Cleveland, OH, USA, 1973. [Google Scholar]

- Aungier, R.H. Mean Streamline Aerodynamic Performance Analysis of Centrifugal Compressors. J. Turbomach. 1995, 117, 360–366. [Google Scholar] [CrossRef]

- Oh, H.W.; Yoon, E.S.; Chung, M.K. An Optimum Set of Loss Models for Performance Prediction of Centrifugal Compressors. Proc. Inst. Mech. Eng. Part A 1997, 211, 331–338. [Google Scholar] [CrossRef]

- Casey, M.; Robinson, C. A New Streamline Curvature Throughflow Method for Radial Turbomachinery. J. Turbomach. 2010, 132, 031021. [Google Scholar] [CrossRef]

- Krain, H. Review of Centrifugal Compressor’s Application and Development. J. Turbomach. 2005, 127, 25–34. [Google Scholar] [CrossRef]

- Eckardt, D. Detailed Flow Investigations within a High-Speed Centrifugal Compressor Impeller. J. Fluids Eng. 1976, 98, 390–399. [Google Scholar] [CrossRef]

- Li, P.-Y.; Gu, C.-W.; Song, Y. A New Optimization Method for Centrifugal Compressors Based on 1D Calculations and Analyses. Energies 2015, 8, 4317–4334. [Google Scholar] [CrossRef]

- Aungier, R.H. Aerodynamic Performance Analysis of Vaned Diffusers. Fluid Mach. Compon. 1990, 110, 37–44. [Google Scholar]

- Caser, M. The Matching of a Vaned Diffuser with a Radial Compressor Impeller and Its Effect on the Stage Performance. J. Turbomach. 2014, 136, 121004. [Google Scholar] [CrossRef]

- Klausner, E.; Gampe, U. Evaluation and Enhancement of a One-Dimensional Performance Analysis Method for Centrifugal Compressors. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; Volume 2D: Turbomachinery, p. V02DT42A005. [Google Scholar] [CrossRef]

- Hong, E.; Ban, H.; Qi, M. Design Optimization and Analysis of a Vaned Diffuser Based on the One-Dimensional Impeller-Diffuser Throat Area Model. J. Phys. Conf. Ser. 2019, 1300, 012007. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Zhao, G. Modification and Validation of 1D Loss Models for the Off-Design Performance Prediction of Centrifugal Compressors with Splitter Blades. Machines 2023, 11, 118. [Google Scholar] [CrossRef]

- Stanitz, J.D. One-Dimensional Compressible Flow in Vaneless Diffusers of Radial and Mixed-Flow Centrifugal Compressors, Including Effects of Friction, Heat Transfer and Area Change; Technical Report for Lewis Flight Propulsion Laboratory: Cleveland, OH, USA, 1952. [Google Scholar]

- Japikse, D.; Osborne, C. Vaneless Diffuser Return Bend and Return Channel Performance Investigation; Creare: Hanover, NH, USA, 1982. [Google Scholar]

- Khoshkalam, N.; Mojaddam, M.; Pullen, K.R. Characterization of the Performance of a Turbocharger Centrifugal Compressor by Component Loss Contributions. Energies 2019, 12, 2711. [Google Scholar] [CrossRef]

- Bicchi, M.; Biliotti, D.; Marconcini, M.; Toni, L.; Cangioli, F.; Arnone, A. An AI-Based Fast Design Method for New Centrifugal Compressor Families. Machines 2022, 10, 458. [Google Scholar] [CrossRef]

- Runstadler, P.W., Jr.; Dolan, F.X. Further Data on the Pressure Recovery Performance of Straight-Channel, Plane-Divergence Diffusers at High Subsonic Mach Numbers. J. Fluids Eng. 1973, 95, 373–384. [Google Scholar] [CrossRef]

- Methel, C.-T.J. An Experimental Comparison of Diffuser Designs in a Centrifugal Compressor. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2016. Available online: https://digitalcommons.uri.edu/theses/796 (accessed on 27 August 2025).

- Hoffman, J.A. Effects of Free-Stream Turbulence on Diffuser Performance. J. Fluids Eng. 1981, 103, 385–395. [Google Scholar] [CrossRef]

- Olivero, M.; Pasquale, D.; Ghidoni, A.; Rebay, S. Three-dimensional turbulent optimization of vaned diffusers for centrifugal compressors based on metamodel-assisted genetic algorithms. Optim. Eng. 2014, 15, 973–992. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Z.; Ye, S.; Xi, G. Numerical investigations on tip leakage flow characteristics and vortex trajectory prediction model in centrifugal compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2016, 230, 757–772. [Google Scholar] [CrossRef]

- Wang, J.; Wen, S.; Wang, W.; Xi, G. Intelligence design method for three-dimensional vaned diffusers in a centrifugal compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 674–690. [Google Scholar] [CrossRef]

- Mojaddam, M.; Pullen, K.R. Optimization of a Centrifugal Compressor Using the Design of Experiment Technique. Appl. Sci. 2019, 9, 291. [Google Scholar] [CrossRef]

- Hazizi, K.; Ramezanpour, A.; Costall, A. Numerical optimisation of the diffuser in a typical turbocharger compressor using the adjoint method. Automot. Eng. Technol. 2022, 7, 179–196. [Google Scholar] [CrossRef]

- Solomon, G.R.; Rahul, R.; Balaji, R.; Selokar, A. Fluid Flow Analysis of a Rotating Vaneless Diffuser Using CFD. In Advances in Mechanical and Materials Technology; Govindan, K., Kumar, H., Yadav, S., Eds.; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Li, Q.; Sun, Z.; Lu, X.; Zhang, Y.; Han, G. Investigation of New Design Principles for the Centrifugal Compressor Vaned Diffusers. Int. J. Aerosp. Eng. 2022, 2022, 4480676. [Google Scholar] [CrossRef]

- Rao, P.; Govindaraju, V.; Venkateswarlu, K.; Kumari, M. Computational Fluid Dynamics Studies on a Centrifugal Compressor Stage with Twisted Vanes of a Low Solidity Diffuser. J. Appl. Fluid Mech. 2025, 18, 3209. [Google Scholar] [CrossRef]

- Bardelli, M.; Cravero, C.; Marini, M.; Marsano, D.; Milingi, O. Numerical Investigation of Impeller-Vaned Diffuser Interaction in a Centrifugal Compressor. Appl. Sci. 2019, 9, 1619. [Google Scholar] [CrossRef]

- Zhao, F.; Dodds, J.; Vahdati, M. Poststall Behavior of a Multistage High Speed Compressor at Off-Design Conditions. J. Turbomach. 2018, 140, 121002. [Google Scholar] [CrossRef]

- Marsan, A.; Trébinjac, I.; Moreau, S.; Coste, S. Active Flow Control in a Radial Vaned Diffuser for Surge Margin Improvement: A Multislot Suction Strategy. Int. J. Rotating Mach. 2017, 2017, 4120862. [Google Scholar] [CrossRef]

- Sundström, E.; Semlitsch, B.; Mihăescu, M. Generation Mechanisms of Rotating Stall and Surge in Centrifugal Compressors. Flow Turbul. Combust. 2018, 100, 705–719. [Google Scholar] [CrossRef]

- Amin, A.A.; Maqsood, M.T.; Mahmood-ul-Hasan, K. Surge protection of centrifugal compressors using advanced anti-surge control system. Meas. Control 2021, 54, 967–982. [Google Scholar] [CrossRef]

- Eum, H.J.; Kang, Y.S.; Kang, S.H. Tip clearance effect on through-flow and performance of a centrifugal compressor. KSME Int. J. 2004, 18, 979–989. [Google Scholar] [CrossRef]

- Kaneko, M.; Tsujita, H. Numerical investigation of influence of tip leakage flow on secondary flow in transonic centrifugal compressor at design condition. J. Therm. Sci. 2015, 24, 117–122. [Google Scholar] [CrossRef]

- Zamiri, A.; Choi, M.; Chung, J.T. Effect of blade squealer tips on aerodynamic performance and stall margin in a transonic centrifugal compressor with vaned diffuser. Aerosp. Sci. Technol. 2022, 123, 107504. [Google Scholar] [CrossRef]

- Dowell, E.H.; Curtiss, H.C.; Scanlan, R.H.; Sisto, F. Aeroelasticity in Turbomachines. In A Modern Course in Aeroelasticity; Dowell, E.H., Curtiss, H.C., Scanlan, R.H., Sisto, F., Eds.; Mechanics: Dynamical Systems; Springer: Dordrecht, The Netherlands, 1989; Volume 11. [Google Scholar] [CrossRef]

- Reynolds, B.D.; Nolcheff, N.; Bernaud, R.; Boyll, G. Systems and Methods with Distributed Bleed for Gas Turbine Engine Compressor Stabilization. U.S. Patent US20240352896A1, 26 October 2023. [Google Scholar]

- Bryan, W.B.; Fleeter, S. An Investigation of Unsteady Impeller-Diffuser Interactions in a Centrifugal Compressor. (Report No. NASA-CR-190792). NASA Lewis Research Center; U.S. Army Aviation Systems Command, 1992. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA257269.pdf (accessed on 7 October 2025).

- Spakovszky, Z.S.; Roduner, C.H. Spike and Modal Stall Inception in an Advanced Turbocharger Centrifugal Compressor. J. Turbomach. 2009, 131, 031012. [Google Scholar] [CrossRef]

- Cravero, C.; Marsano, D. Instability Phenomena in Centrifugal Compressors and Strategies to Extend the Operating Range: A Review. Energies 2024, 17, 1069. [Google Scholar] [CrossRef]

- Hewkin-Smith, M.; Pullan, G.; Grimshaw, S.D.; Greitzer, E.M.; Spakovszky, Z.S. The Role of Tip Leakage Flow in Spike-Type Rotating Stall Inception. J. Turbomach. 2019, 141, 061010. [Google Scholar] [CrossRef]

- Everitt, J.N.; Spakovszky, Z.S. An Investigation of Stall Inception in Centrifugal Compressor Vaned Diffuser. J. Turbomach. 2013, 135, 011025. [Google Scholar] [CrossRef]

- Fujisawa, N.; Ohta, Y.; Tajima, K.; Miida, H. Evolution Process of Diffuser Stall in a Centrifugal Compressor with Vaned Diffuser. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018; Volume 2A: Turbomachinery. [Google Scholar] [CrossRef]

- Fujisawa, N.; Ohta, Y. Transition Process from Diffuser Stall to Stage Stall in a Centrifugal Compressor with a Vaned Diffuser. Int. J. Rotating Mach. 2017, 2017, 2861257. [Google Scholar] [CrossRef]

- Zhang, L.; Zheng, Z.; Zhang, Q.; Zhang, L.; Li, K. Study of Rotating Stall in a Centrifugal Compressor with Wide Vaneless Diffuser. J. Therm. Sci. 2020, 29, 743–752. [Google Scholar] [CrossRef]

- Zhang, L.; He, R.; Wang, S.; Zhang, Q. A Review of Rotating Stall in Vaneless Diffuser of Centrifugal Compressor. J. Therm. Sci. 2020, 29, 323–342. [Google Scholar] [CrossRef]

- Fujisawa, N.; Tajima, K.; Miida, H.; Ohta, Y. Generation Mechanism of Diffuser Stall in a Centrifugal Compressor with Vaneless Diffuser. J. Glob. Power Propuls. Soc. 2020, 4, 190–201. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, C.; Shi, X.; Yang, C.; Chen, J. Two Stall Stages in a Centrifugal Compressor with a Vaneless Diffuser. Aerosp. Sci. Technol. 2021, 110, 106496. [Google Scholar] [CrossRef]

- Li, Z.; Lu, X.; Han, G.; Zhang, Y.; Zhao, S.; Zhu, J. The Performance of a Centrifugal Compressor with a Tandem Impeller in Off-Design Conditions. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 234, 156–172. [Google Scholar] [CrossRef]

- Sadagopan, A.; Camci, C. Viscous Flow and Performance Issues in a 6:1 Supersonic Mixed-Flow Compressor with a Tandem Diffuser. Aerosp. Sci. Technol. 2019, 88, 9–21. [Google Scholar] [CrossRef]

- Tomita, I.; Ibaraki, S.; Furukawa, M.; Yamada, K. The Effect of Tip Leakage Vortex for Operating Range Enhancement of Centrifugal Compressor. J. Turbomach. 2013, 135, 051020. [Google Scholar] [CrossRef]

- Jaatinen-Värri, A.; Tiainen, J.; Turunen-Saaresti, T.; Grönman, A.; Ameli, A.; Engeda, A.; Backman, J. Centrifugal Compressor Tip Clearance and Impeller Flow. J. Mech. Sci. Technol. 2016, 30, 5029–5040. [Google Scholar] [CrossRef]

- Brind, J. Data-Driven Radial Compressor Design Space Mapping. ASME. J. Turbomach. 2025, 147, 021001. [Google Scholar] [CrossRef]

- Agnolucci, A. Artificial Intelligence Based, Aerodynamic Optimization of Centrifugal Compressors. Ph.D. Thesis, Department of Industrial Department of Industrial Engineering, University of Engineering, University of Florence, Firenze, Italy, 2021. [Google Scholar]

- Chen, Z.; Sun, J.; Chen, Z.; Guo, Y.; Spence, S.; Peng, X.; Feng, J. Fast predesign methodology of centrifugal compressor for PEMFCs combining a physics-based loss model and an interpretable machine learning method. Int. J. Hydrogen Energy 2024, 90, 353–368. [Google Scholar] [CrossRef]

- Lottini, F.; Bicchi, M.; Agnolucci, A.; Marconcini, M.; Arnone, A. Artificial Intelligence-Based Performance Maps for Expander-Compressor Analysis in Energy Transition Applications. In Proceedings of the ASME Turbo Expo 2024: Turbomachinery Technical Conference and Exposition, London, UK, 24–28 June 2024; Volume GT2024-128901, p. V12DT35A026. [Google Scholar] [CrossRef]

- Bicchi, M.; Marconcini, M.; Bellobuono, E.F.; Belardini, E.; Toni, L.; Arnone, A. Multi-Point Surrogate-Based Approach for Assessing Impacts of Geometric Variations on Centrifugal Compressor Performance. Energies 2023, 16, 1584. [Google Scholar] [CrossRef]

- Bicchi, M.; Biliotti, D.; Toni, L.; Marconcini, M.; Grimaldi, A.; Arnone, A. A Two-Step Approach for Centrifugal Compressor Performance Mapping Based on a Reduced-Order Model and an Evolutionary Algorithm. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Boston, MA, USA, 26–30 June 2023. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, Y.; Chen, J.; Ma, H.; Liu, B. Compressor airfoil optimization method driven by data-mechanism integration based on evolutionary multi-tasking algorithm. Aerosp. Sci. Technol. 2024, 148, 108999. [Google Scholar] [CrossRef]

| Group/Diffuser Type | Description | Performance Characteristics | Main Advantages | Main Limitations |

|---|---|---|---|---|

| Baseline geometries | ||||

| Wide parallel-walled [18,27] | Constant passage width; large area ratio | Highest efficiency but poor surge margin | High efficiency; simple design | Limited stability; lower surge margin |

| Narrow parallel-walled [18,32] | Reduced width; smaller area ratio | Improved turn-down capability but lower efficiency | Compactness; improved stability | Efficiency penalty |

| Constant-area tapered [18,26] | Slightly narrowing radial passage | ~10% improved surge margin with minimal efficiency loss | Balanced trade-off between efficiency and stability | Moderate manufacturing complexity |

| Reduced-area tapered [18] | Gradual area reduction along radius | Improves turn-down, slightly reduces efficiency | Better part-load performance | Efficiency loss at design point |

| Convergent wall [19] | Wall angle < 0° (decreasing passage area) | Stabilizing slope in pressure rise; improved static pressure recovery | Better flow uniformity, higher mid-flow recovery | Limited benefit at low mass flow |

| Divergent/expansion type [15,16] | Wall angle > 0° (increasing passage area) | Reversed gradients and secondary flows | Potential higher recovery at low speed | Flow instability; low efficiency |

| Modified geometries (pinched designs) | ||||

| Shroud-pinched [20,21,22] | Local reduction in passage height near shroud | Increased isentropic efficiency and pressure ratio | Strong improvement at low flow; mitigates secondary flows | Slight volute loss increase |

| Hub-pinched [24] | Local narrowing near hub | Efficiency gain near design and choking points | Targeted performance improvement | Less effective off-design |

| Symmetrical pinching [25] | Equal narrowing at hub and shroud | Balanced performance across flow range | Uniform behavior over wide range | No peak optimization |

| Optimized geometries | ||||

| DMO-optimized diffuser [30] | Optimized width distribution via RANS-based DMO | Enhanced pressure recovery; lower energy loss | Improved design/off-design performance | Computationally intensive |

| Compact diffuser (reduced diameter) [31] | Outer diameter reduced by 8–14% | Maintains efficiency and range | Reduced stage size; efficient | Requires careful optimization |

| Configurations with Modified Flow Conditions | ||||

| Forced Rotating Vaneless Diffuser (FRVD) [33] | Rotating vaneless section | 30% shroud extension improves static pressure rise and range | Better recovery; wider operating range | Added mechanical complexity |

| Diffuser with optimized vaneless gap ratio (VGR) [36,37,38,39,40] | Ratio of diffuser inlet to impeller outlet radius (1.03–1.12) | Larger gaps → higher choke margin; smaller gaps → better stability | Tunable for desired performance | Excessive gaps increase losses |

| Side-gap/leakage-flow controlled diffuser [41] | Radial clearance 0.5–1.5 mm | Leakage direction strongly affects efficiency and flow | Better understanding of loss mechanisms | Sensitive to clearance control |

| Application-oriented variants | ||||

| Narrowed (shroud-side) [32] | Shroud width ratio ≈ 0.85 | Higher efficiency at low/design speeds; reduced impeller work | Improved low-speed operation | Lower pressure ratio at high speed |

| Constant-area diffuser with gap optimization [36,37] | Balanced vaneless gap ratio (1.06–1.12) | Improved stability; delayed choking | Robust and adaptable design | Moderate losses if gap oversized |

| Diffuser Type | Description | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| Vaneless Diffuser | Simple annular passage without vanes | Wide operating range, tolerant to incidence, avoids vane losses | Lower peak efficiency, larger frontal area, limited pressure recovery | Small turbochargers, low-cost compressors |

| Vaned Diffuser | Radial or backward-leaned vanes guide flow | High efficiency, precise flow guidance, high pressure recovery | Narrow operating range, surge-prone, sensitive to incidence | High-pressure ratio industrial and aero compressors |

| Low-Solidity Vane Diffuser (LSVD) | Vanes with low solidity (wide spacing) | Compromise between efficiency and range, mitigates flow separation | Lower efficiency than full vaned diffuser | Turbochargers, aero-engines |

| Pipe Diffuser | Multiple discrete channels replacing vaneless space | Compact design, good stability, suppresses large-scale separation | Slightly lower efficiency than airfoil vanes, complex flow with vortices | High-pressure ratio compressors, micro gas turbines |

| Wedge Diffuser | Straight wedge-shaped vanes | Simple design, robust | Susceptible to separation, lower efficiency | Legacy designs, low-cost applications |

| Hybrid (Semi-/Pseudo-Vaneless) | Combination of vaneless with partial guidance | Balances range and recovery | Moderate efficiency | Turbochargers, medium-load compressors |

| Parameter | Definition | Typical Range/Critical Values | Aerodynamic Effect | Design Implication |

|---|---|---|---|---|

| Aspect Ratio (AS) | Blade height/chord (vaned) or height/width (vaneless) | 0.8–1.4 [106] | High AS → greater turning, risk of flow separation; Low AS → better mechanical integrity, but less diffusion | Consider manufacturing constraints, structural integrity, and desired flow diffusion |

| Area Ratio (AR) | Outlet area/inlet area (A2/A1) | 1.1–1.5 (typical for vaned diffusers) [106] | High AR → more deceleration, pressure recovery; too high → risk of separation | Optimize for pressure recovery without inducing stall or loss |

| Diffuser Length-to-Width Ratio (L/w1) | Diffuser length/inlet width | ≤3.7 (beyond this, marginal gain) [113] | Longer diffusers improve recovery; very long → higher separation risk | Balance recovery vs. size; consider flow separation and compactness |

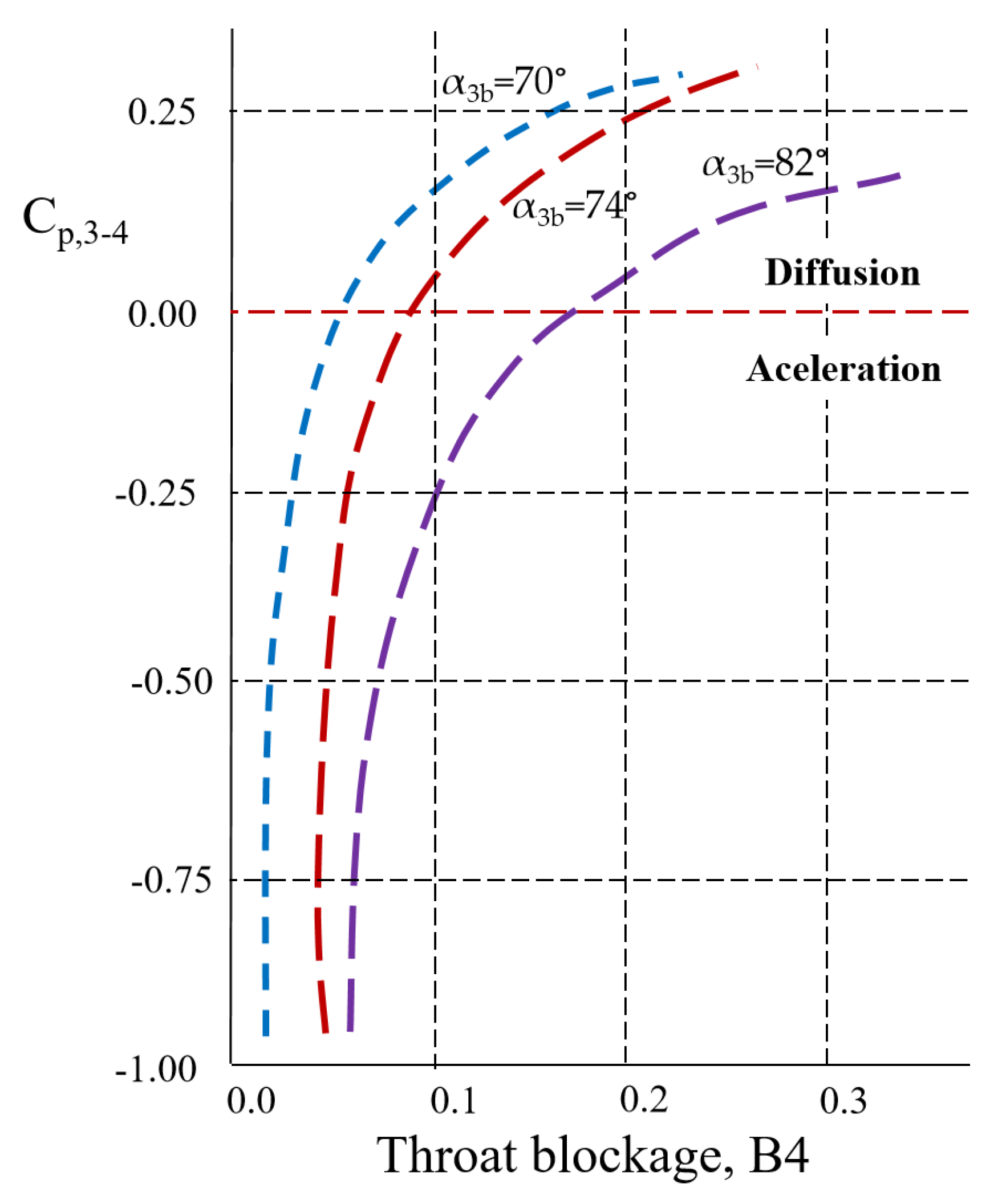

| Blockage Factor | Effective flow area/geometric throat area | 0.85–0.95 (typical) [114] | High blockage → increased losses and choking risk; low blockage → stable, but lower efficiency | Ensure optimal blade loading and clearance control |

| Blade Solidity (σ) | Blade chord/spacing (vaned) | 1.0–1.8 [115] | High σ → improved flow turning and recovery; can increase incidence sensitivity | Adjust to match turning angle and avoid high diffusion factor |

| Diffusion Factor (DF) | Measures flow deceleration | ≤0.5 [116,117] | DF > 0.4 → high separation risk | Control diffusion via geometry and solidity |

| Total Pressure Recovery Coefficient (Cpr) | (P,out − P,in)/qₜ | 0.6–0.85 [98] | Direct measure of diffuser efficiency; influenced by AR, AS, Mach, Re | Use as performance metric for empirical validation and optimization |

| Study | Diffuser Type | CFD Focus | Key Findings |

|---|---|---|---|

| Olivero et al. (2014) [138] | Vaned diffusers | CFD and genetic algorithms | Optimized vaned diffuser designs improve static pressure recovery and efficiency over a vaneless configuration, enabling more compact compressors with reduced backflow and better flow control |

| Zhao et al. (2016) [139] | Tip leakage flow modeling (impeller-based) | CFD vortex trajectory prediction | Provided models for predicting tip leakage vortex behavior in centrifugal compressors |

| Wang et al. (2018) [140] | Vaned diffuser | Numerical study | A multi-objective optimization-based intelligent design approach for the three-dimensional vaned diffuser resulted in maximized isentropic efficiency and static pressure ratio. |

| Mojaddam et al. (2019) [141] | Vaneless diffuser | Numerical study | Multi-stage optimization of impeller geometry and blade angles achieved up to 7.24% increase in pressure ratio, 2.5% improvement in efficiency initially, followed by further gains of 3.0% in pressure ratio and 0.34% in efficiency, resulting in substantial overall performance enhancement across operating conditions. |

| Hazizi, K. et al. (2022) [142] | Vaned diffuser | Numerical study | Adjoint-based numerical optimization of the turbocharger compressor diffuser achieved up to a 2.6% efficiency improvement, enhancing engine performance across real-world drive cycles. |

| Solomon et al. (2022) [143] | Vaneless diffuser | CFD across turbulence models | Compared k-ω, SST, etc.; extended shroud improved performance; demonstrated setup and mesh strategies |

| Li et al. (2022) [144] | Vaned Diffusers | Numerical study | control of tangential and meridional velocity distributions enables effective aerodynamic optimization of vaned diffusers across subsonic to supersonic inlet conditions. |

| Han et al. (2023) [70] | Pipe diffuser | CFD-based design studies | Enhancing pair vortices near the throat while suppressing corner and hub-side vortices within the diffuser passage improves pipe diffuser performance and reduces losses. |

| Wu et al. (2024) [48] | Vaned diffuser | Hub contour optimization via CFD | Addressed high-loading challenges due to supersonic exit flow; used CFD-guided hub contouring to improve diffuser performance |

| Rao et al. (2025) [145] | Low solidity diffuser | Numerical study | Twisting the diffuser vane enhances compressor efficiency and operating range, with optimal performance achieved at a 9° twist and 24° setting angle. |

| Bardelli et al. (2025) [146] | Vaned diffuser | Numerical study | The shroud-side partial vaned diffuser (SVD) enhances flow stability and reduces losses compared to the traditional full-height vaned diffuser (TVD), especially under off-design conditions. |

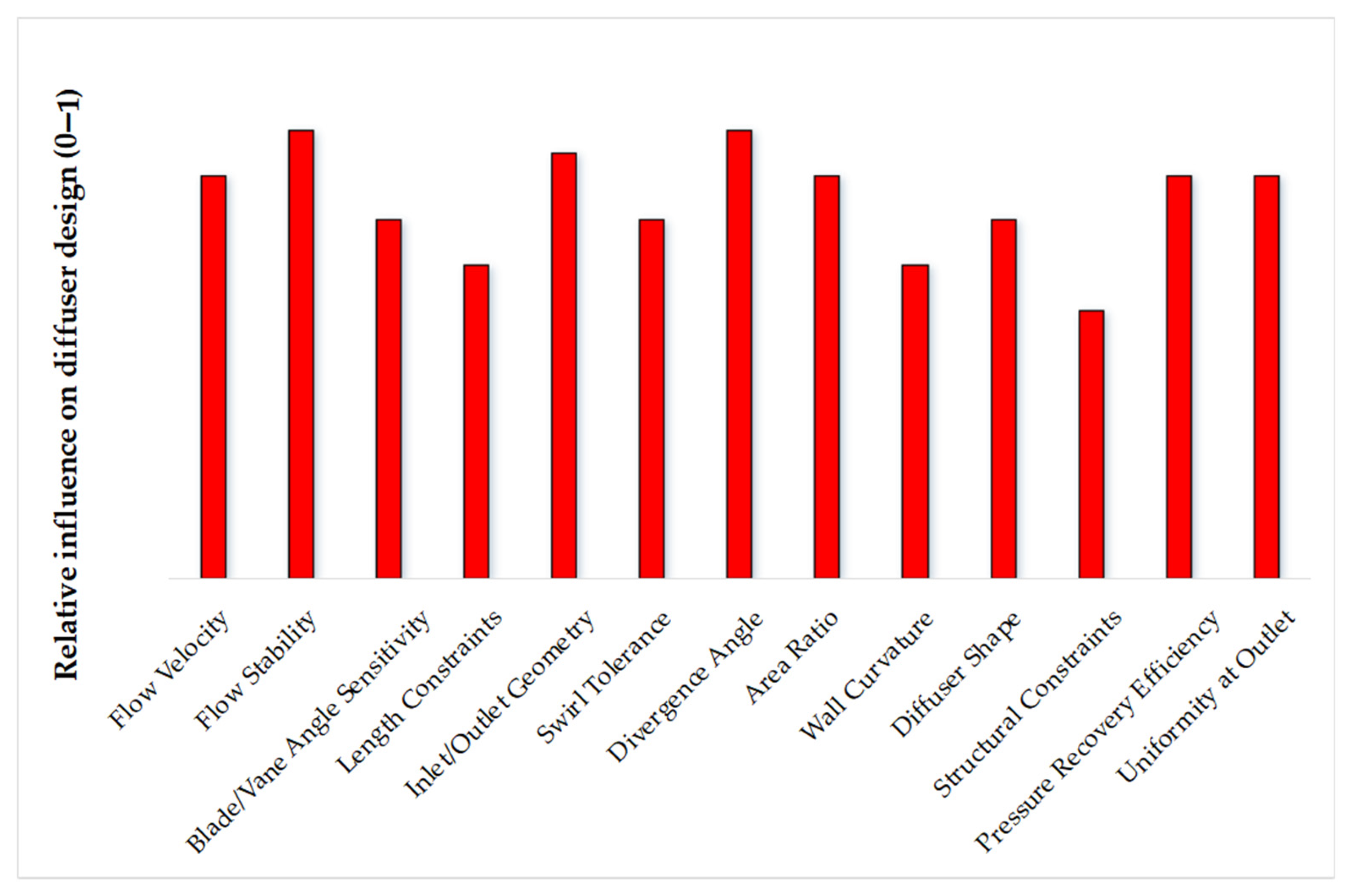

| Parameter | Description | Design Preference | Trade-Off |

|---|---|---|---|

| Flow Velocity | Influences pressure recovery and risk of separation | Moderate to low velocity | Too low reduces pressure recovery; too high increases losses |

| Flow Stability | Ensures attached flow and avoids vortices | Smooth, attached flow throughout diffuser | Longer diffuser or small divergence angles may be needed, increasing size |

| Blade/Vane Angle Sensitivity | Determines diffuser’s tolerance to upstream angle variations | Tolerant to upstream variations | High tolerance may reduce overall efficiency |

| Length Constraints | Physical limitations and effect on expansion | Long enough for pressure recovery | Too long increases weight/footprint; too short may cause separation |

| Inlet/Outlet Geometry | Shapes impact velocity distribution and pressure rise | Smooth, gradual expansion | Complex shapes can be harder to manufacture |

| Swirl Tolerance | Ability to handle upstream swirl without losses | Can handle upstream swirl | Higher tolerance may require additional design complexity |

| Divergence Angle | Too steep can cause separation, affects efficiency | Small (~5–7° for 2D diffusers) | Too small increases length; too large causes separation |

| Area Ratio | Controls expansion and pressure rise | Moderate expansion ratio | High ratios increase separation risk; low ratios reduce recovery |

| Wall Curvature | Influences boundary layer growth and separation | Gentle curvature | Complex curvature may complicate manufacturing |

| Diffuser Shape | Conical, wedge, S-shaped, multi-stage affects pressure recovery | Optimized shape for smooth expansion | Shape complexity may increase cost and weight |

| Structural Constraints | Wall thickness, vibrations, and thermal stress limits | Strong enough to handle stresses | Thicker walls increase weight, reduce efficiency |

| Pressure Recovery Efficiency | Maximizing total-to-static pressure rise | Maximize recovery | May require longer or more complex diffuser |

| Uniformity at Outlet | Ensures consistent flow for downstream components | Even velocity profile | May require shaping or guide vanes, adding complexity |

| Parameter | Flow Velocity | Flow Stability | Blade/Vane Angle Sensitivity | Length Constraints | Inlet/Outlet Geometry | Swirl Tolerance | Divergence Angle | Area Ratio | Wall Curvature | Diffuser Shape | Structural Constraints | Pressure Recovery Efficiency | Uniformity at Outlet |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Velocity | 1 | −0.7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | −0.5 | 0 |

| Flow Stability | −0.7 | 1 | −0.6 | 0 | 0 | −0.4 | −0.8 | −0.6 | 0.5 | 0 | 0 | 0.8 | 0 |

| Blade/Vane Angle Sensitivity | 0 | −0.6 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Length Constraints | 0 | 0 | 0 | 1 | 0 | 0 | −0.5 | 0 | 0 | 0 | −0.3 | 0 | 0 |

| Inlet/Outlet Geometry | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.9 |

| Swirl Tolerance | 0 | −0.4 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Divergence Angle | 0 | −0.8 | 0 | −0.5 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| Area Ratio | 0 | −0.6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| Wall Curvature | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| Diffuser Shape | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0.7 |

| Structural Constraints | 0 | 0 | 0 | −0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| Pressure Recovery Efficiency | −0.5 | 0.8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0.7 |

| Uniformity at Outlet | 0 | 0 | 0 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0.7 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dumitrescu, O.; Strătilă, S.; Drăgan, V. Design Methods and Practices for Centrifugal Compressor Diffusers: A Review. Machines 2025, 13, 990. https://doi.org/10.3390/machines13110990

Dumitrescu O, Strătilă S, Drăgan V. Design Methods and Practices for Centrifugal Compressor Diffusers: A Review. Machines. 2025; 13(11):990. https://doi.org/10.3390/machines13110990

Chicago/Turabian StyleDumitrescu, Oana, Sergiu Strătilă, and Valeriu Drăgan. 2025. "Design Methods and Practices for Centrifugal Compressor Diffusers: A Review" Machines 13, no. 11: 990. https://doi.org/10.3390/machines13110990

APA StyleDumitrescu, O., Strătilă, S., & Drăgan, V. (2025). Design Methods and Practices for Centrifugal Compressor Diffusers: A Review. Machines, 13(11), 990. https://doi.org/10.3390/machines13110990