Abstract

From advanced research platforms to Unmanned Aerial Vehicles (UAVs), Micro Turbojet Engines (MTEs) have grown to be essential parts in many different kinds of applications. Extensive testing, encompassing analysis, alternative fuel suitability, performance characterization, and control system validation, supports their development. This survey examines the current state of MTE experimentation, along with information on experimental methods, sensor technologies, and new directions in corresponding research. Measurement techniques, alternative fuel effects, characterization of gaseous and particle emissions, and the utilization of experimental data to validate control systems and sophisticated engine models are among the recent advances in test bed design discussed here. Presenting an overall view, the aim is to highlight current challenges and inspire more MTE technology advancement.

1. Introduction

From niche hobbyist applications to critical components in unmanned aerial vehicles (UAVs) [1], micro-turbojet engines (MTEs), distinguished by their small size, high power-to-weight ratios, and operational simplicity, have become critical components in [2] target drones, auxiliary power units, and advanced experimental research platforms. A robust experimental investigation is essentially necessary to accelerate the advancement of MTEs and broaden their application spectrum; it helps to validate designs [3,4], characterize performance [5], explore new operational regimes, and assess environmental impacts. With a focus on the development of sensor technologies used in MTE, the various experimental techniques employed, and the emerging research trends that influence the field, this comprehensive analysis aims to consolidate and critically examine the terrain of MTE experimentation. The identification of best practices, the recognition of the present constraints, and the planning of the future research direction in MTE technology are dependent on the knowledge of this experimental framework [6].

Traditionally focused on thrust generation, fuel economy, and thermal efficiency, the core of MTE research is based on the detailed characterization of engine performance. From simple setups [7] to highly instrumented facilities, including new thrust measurement systems, such as those employing inclined plate load cells [8], experimental test beds have grown increasingly sophisticated. Accurate sensing of parameters, including exhaust gas temperature (EGT), rotational speed (RPM), pressures at various stages, and fuel flow, is paramount [9]. Additionally, the literature provides an ample discussion of the basis for transient analysis [10] and detailed component studies, including compressor upgrades [11] and effects on the geometry of the exhaust nozzle [12]. Furthermore, thermodynamic assessments involving energy and exergy investigations [13] depend mainly on correct experimental data to uncover irreversibilities and paths for efficiency enhancement [12].

The global need for sustainable aviation has led to a research trend focusing on alternative fuels, which is producing numerous tests to evaluate their effect on MTEs [14]. Often referencing established fuel standards [15], methods for testing fuels, including propane, various biokerosene formulations [16,17], and waste cooking oil [18], often involve comparative performance mapping against conventional kerosene. Advanced experimental designs are required in these studies to identify modest changes in engine operability and combustion properties. Dedicated laboratory test rigs [19] have helped in controlled studies on the combustion mechanisms of different fuels [20].

Concurrently, the environmental effects of MTEs (especially their exhaust emissions) have grown to be a major focus of study requiring specific sensor technologies and collection techniques. Nowadays, experimental studies frequently incorporate measurements of gaseous emissions [21,22], and increasingly thorough characterizations of particulate matter (PM), including mass, number concentrations, and even toxicity [23,24]. Active areas of research are methodological issues, such as probe position for representative sampling [25]. Furthermore, particular experimental setups are required to operate under specific circumstances, including water intake, which affects engine performance and emissions [26].

The evolution and validation of current control systems [27,28] and diagnostic tools largely depend on experimental data and hardware-in-loop simulations [29,30]. The path toward more intelligent engines is marked by validation of complicated engine models, machine learning applications using experimental data [31,32], and the inclusion of sensors for the sensing of quantities outside of the basic performance criteria [33].

This survey will thus navigate these related domains, closely evaluating the sensor technologies, experimental techniques, and general trends in MTE experimentation. Through the synthesis of current knowledge, this work aims to highlight modern challenges and gaps in experimental procedures, provide a helpful resource for academics and engineers, and encourage continuous innovation in the field of micro-turbojet engines.

Recent years have seen measurable advances in micro-turbojet engine (MTE) experimentation across multiple groups. Bartasevicius et al. [8] introduced a pylon-plate load-cell architecture that improves low-thrust measurement fidelity. Tărăbîc et al. [9] reported a fully instrumented test bed with high-rate DAQ for transient characterization. Cican [10] quantified fuel-dependent transient behavior using diesel and kerosene. Authors in [11] demonstrated compressor-stage upgrades that increased pressure ratio and efficiency, while Sundararaj et al. [12] mapped the effect of nozzle geometry on thrust and SFC. Emissions work progressed in parallel: Kurzawska-Pietrowicz [23] provided particle characterization for miniature turbojets, and Gawron et al. [21,24] assessed VOC emissions and exhaust toxicity.

Despite progress, important gaps remain. First, small-scale and packaging constraints limit sensor access for in-situ measurements such as TIT and inter-stage pressures, complicating the validation of component efficiencies and loss models [5,13]. Second, the absence of standardized MTE test protocols hinders cross-lab comparison for fuel and emissions data [15,21]. Third, high-bandwidth transient dynamics are not yet consistently captured by models used for control development and validation, which limits the robustness of ECU strategies and diagnostic logic [27,28,31]. Finally, although sustainable aviation fuels and other alternatives are increasingly tested [14,18], long-duration studies on durability, deposits, cold-start performance, and operability envelopes remain scarce.

To address these issues, this review consolidates recent methods and sensor technologies, evaluates experimental practices across steady and transient regimes, and enumerates open problems that define a research agenda for reliable, comparable, and environmentally responsible MTE experimentation.

2. Fundamentals of Micro-Turbojet Engine and Experimental Requirements

Compact, air-breathing jet engines, micro-turbojet engines (MTEs), generate thrust by expanding a high-velocity gas stream. Notwithstanding their small scale, they run on the same basic thermodynamic concept as their larger counterparts: the Brayton cycle [3,4]. In its optimal form for a turbojet, this cycle consists of isentropic compression of ambient air, constant pressure heat addition (combustion), isentropic expansion through a turbine (which drives the compressor), and additional expansion through a nozzle to generate thrust.

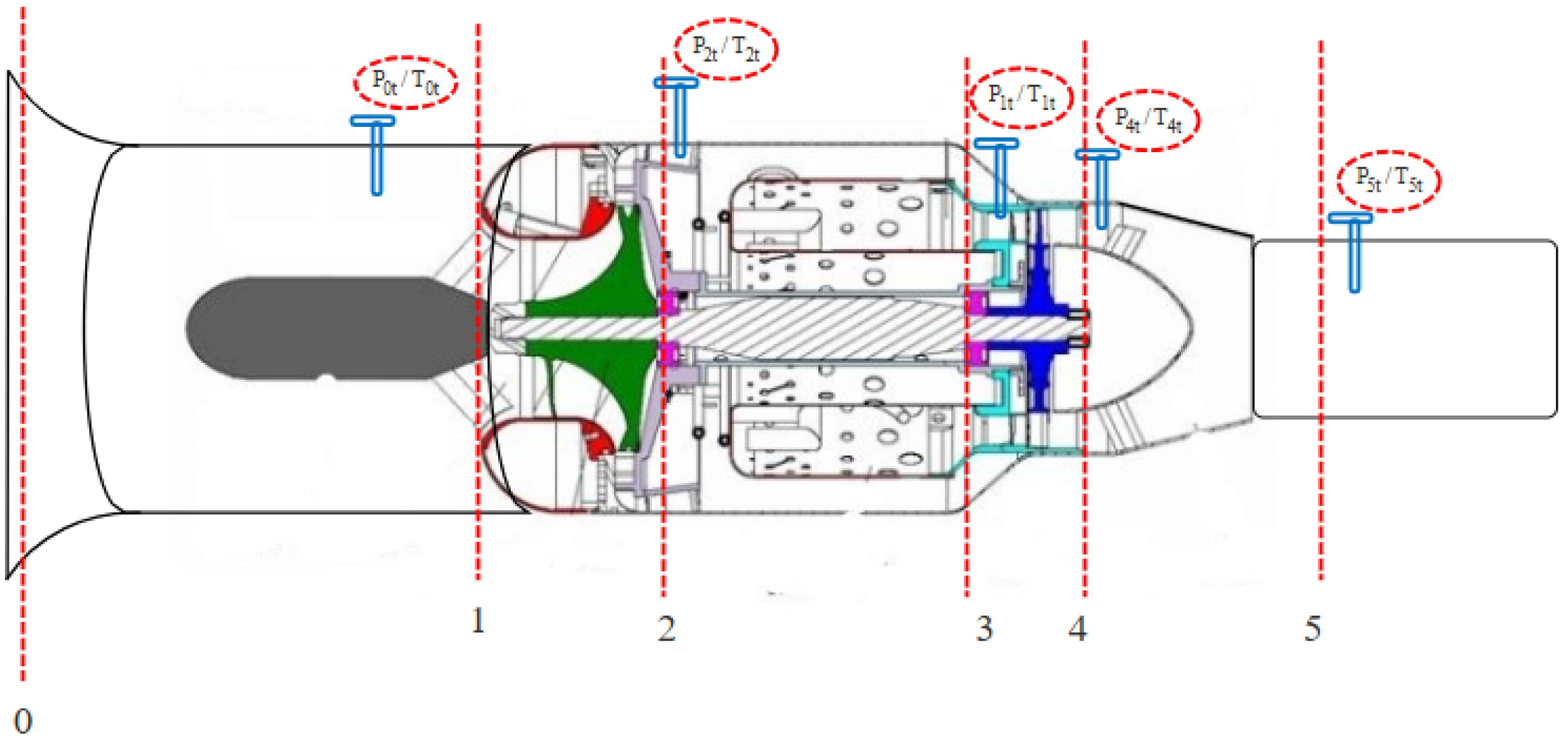

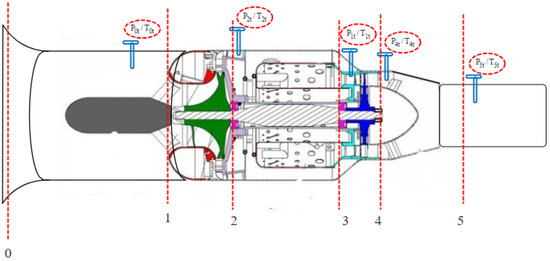

As shown in Figure 1, a normal MTE consists primarily of:

Figure 1.

Conceptual diagram illustrating major components of MTE: (0–1) Inlet system and starter motor, (1–2) Centrifugal compressor, (2–3) Annular combustor, (3–4) Axial Turbine, (4–5) Convergent Exhaust Nozzl. Key performance parameters for MTE and typical sensor locations. : Ambient pressure/temperature; : Compressor exit/combustor inlet, : Turbine inlet, : Turbine exit (often termed EGT), : free stream exit temperature.

- 1.

- Inlet with starter motor: gathers ambient air and effectively directs it with low pressure loss to the compressor. The starter motor is responsible for starting the engine until it reaches its ideal operational speed. The starter motor can also restart the engine in flight.

- 2.

- Compressor: A single-stage centrifugal (radial) compressor is usually used in MTEs because of its simplicity of manufacturing, the high pressure ratio per stage at a small scale, and the resilience [5,11]. It raises the pressure and temperature of the entering air.

- 3.

- Combustor: responsible to increase the gas temperature at almost constant pressure [2,19]. An annular or can-annular combustor, where fuel is fed, mixed with compressed air, and ignited, achieves continuous combustion.

- 4.

- Turbine: Usually a single-stage axial-flow turbine is used in MTEs. Its main purpose is to drive the compressor utilizing the hot combustion gases by extracting enough energy. It is mechanically connected by a shaft with the compressor [3].

- 5.

- Nozzle: Newton’s second and third laws allow a convergent (or occasionally convergent-divergent) nozzle to accelerate the remaining hot, high-pressure gases to a high exhaust velocity, hence producing thrust [12].

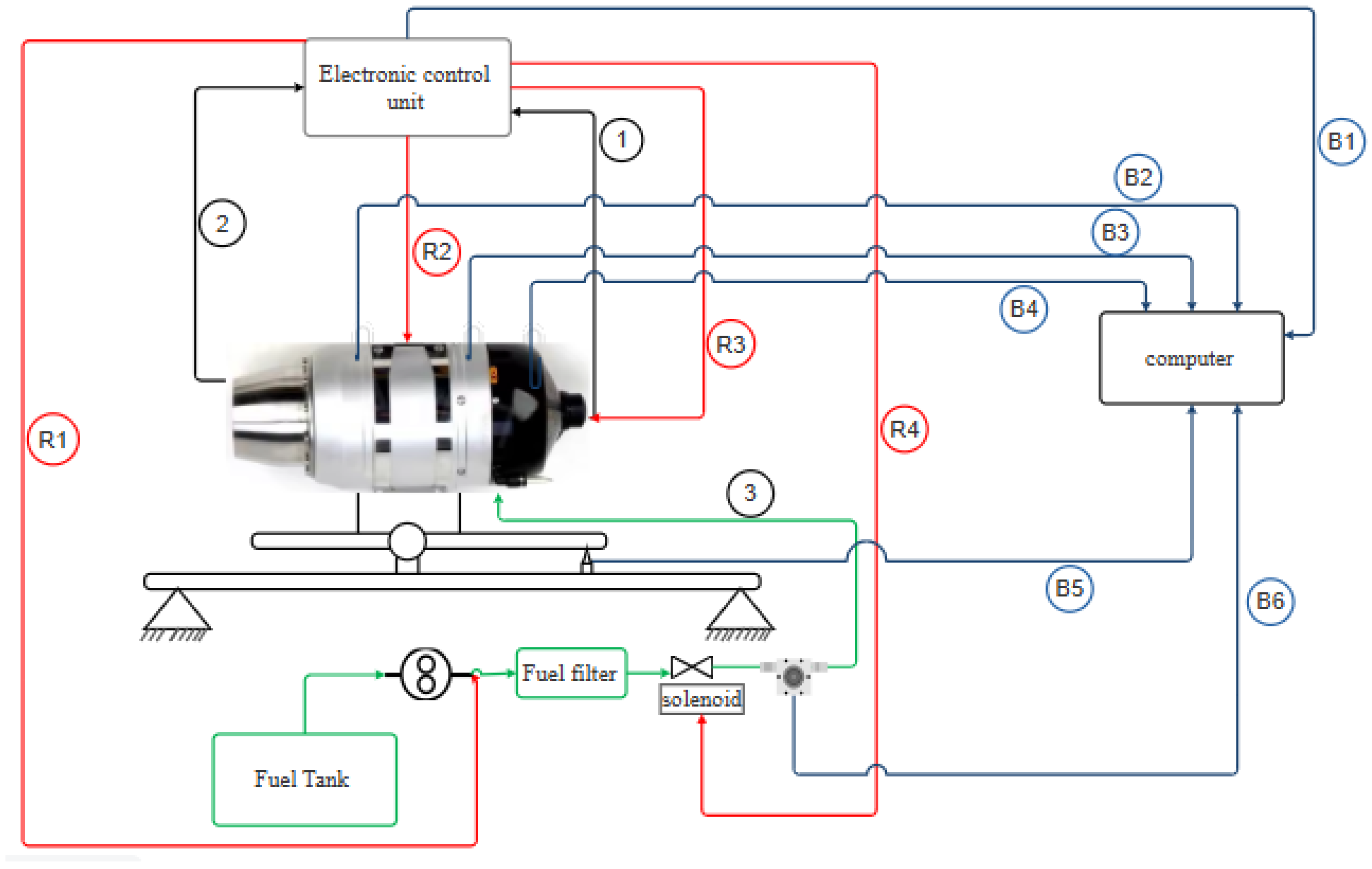

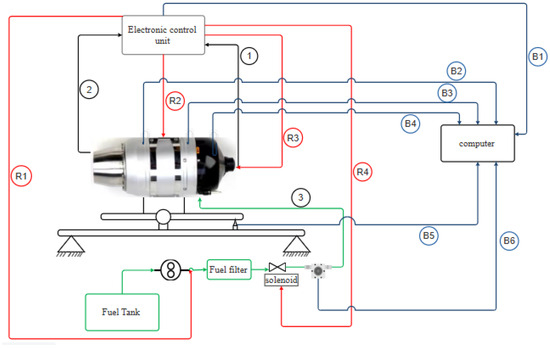

MTE characterization and comparison depend on key performance criteria. As seen in Figure 2 they consist of:

Figure 2.

Typical micro-turbojet engine (MTE) experimental test stand and wiring for instrumentation and control. Control signal: R1: Fuel pump, R2: Ignition plug, R3: Electric starter motor, R4: Fuel solenoid Control feedback signal: 1: RPM, 2: Exhaust gas temperature Visualization signal: B1: Control unit readings, B2: Turbine inlet temperature and pressure reading, B3: Compressor exit temperature and pressure reading, B4: Compressor inlet temperature and pressure reading, B5: Thrust measurement, B6: Fuel flow meter reading.

- Thrust (F): Measured in Newtons (N) or pounds-force (lbf), the net force generated by the engine. Most MTE test beds have as their main goal accurate thrust measurement [8,9].

- Specific Fuel Consumption (SFC): defined as the fuel flow rate per unit of thrust (kg/h.N or lb/h.lbf), a gauge of engine fuel efficiency. Extending flight range and endurance depends on minimizing SFC [17].

- Exhaust Gas Temperature (EGT): The gases’ temperature leaving the turbine or nozzle. This is often closely watched to minimize overheating and turbine component damage, it is a vital limiting factor for engine operation [10,34].

- Rotational speed (RPM): Usually expressed in revolutions per minute, the speed of the primary shaft connecting the compressor and turbine. It is an indication of the mechanical load of the engine and in engine modeling, the RPM is the output from the model and indicate the output power from the engine. MTEs run at very high RPMs often over 100,000 RPM.

- Efficiencies: Measured characteristics that allow one to derive various efficiencies, including thermal efficiency, propulsive efficiency, and component efficiencies (compressor, combustor, turbine) [13].

There are several criteria in the MTEs that affect the engine operation and engine life. The experiment is established to display some of these criteria. The different MTE experiments’ objectives are listed below:

- Evaluation of Design: [2,11] can confirm that a new engine design or component modification performs in line with theoretical calculations and numerical simulation, such as computational fluid dynamics (CFD).

- Performance Map: There are several academic research programs on micro gas turbines aimed at enhancing their performance. This involves changes to the design of the MGTs compressor and turbine stages, new combustor designs, and combustion analysis. These studies have yielded improved engine performance by controlling specific fuel consumption, pressure ratio, cycle peak temperature, system pressure losses, turbine and compressor efficiencies, and required power [5].

- Understanding off-design behavior: Essential for operability and control system design, it aids in assessing the engine’s performance beyond its ideal design point [10].

- Component Interaction: To investigate how various engine components interact with each other under different running situations and their compatibility.

- Fuel Effects Assessment: To measure performance, operability, and durability, which may include traditional kerosene, diesel, biofuels, and synthetic fuels [16,17].

- Emissions Characterization: To measure and analyze gaseous and particle emissions to assess environmental impact and ensure compliance with any existing or future regulations [21,23,24].

Using MTEs presents particular challenges, unlike those of their larger gas turbine counterparts:

- Higher Rotational Speeds: The high RPMs call for high-frequency data capture for transient events, strong rotor dynamic design, and specialized bearings.

- Tip Clearance Effects: Small turbomachinery with relative tip clearances larger as a percentage of blade height will create increased leakage losses.

- Lower mass flow rates: This affects not just accuracy and sensor choice but also presents an additional challenge to correctly measure air and fuel flow.

- Accessibility of instrumentation: Installing large internal instrumentation (e.g., inter-stage pressure and temperature sensors) without appreciably upsetting the flow or engine integrity is challenging, given the small size.

- Relative heat losses: from the engine casing can be more important due to a greater surface area-to-volume ratio, hence possibly influencing thermal efficiency and EGT values [13].

- Engineering Tolerances: MTE performance may be substantially affected by small production differences.

The fundamental theory for gas engines, such as the Brayton cycle, including its performance indices (KPIs), is applicable to MTE and can therefore be used to study it at a smaller scale. Micro-scale effects can cause problems, such as those caused by a relatively large tip clearance, casing heat loss, tight packaging that makes it difficult to use TIT and inter-stage probes, and low mass flow, which makes metering more challenging. Some of the solutions are verified recovery/heat-loss corrections, the use of reference bellmouth coefficients with known uncertainties, and compact access hardware that keeps the flow from being disturbed. Additionally, some of the current gaps are a standardized uncertainty analysis for thrust, SFC, and temperature across the rig measurements. Managing these difficulties calls for specific experimental techniques, meticulous test rig designs, and suitable sensor choices, which will be discussed in the next sections.

3. Sensor Technologies in MTE Experimentation

Any significant experimentation with MTEs depends on accurate and consistent measurement of many physical quantities [35]. The particular needs of MTEs, including their small physical scale, high operational speeds, wide temperature and pressure ranges, and the need for both steady-state and transient data acquisition [2,5] determine the suitable sensor technologies.

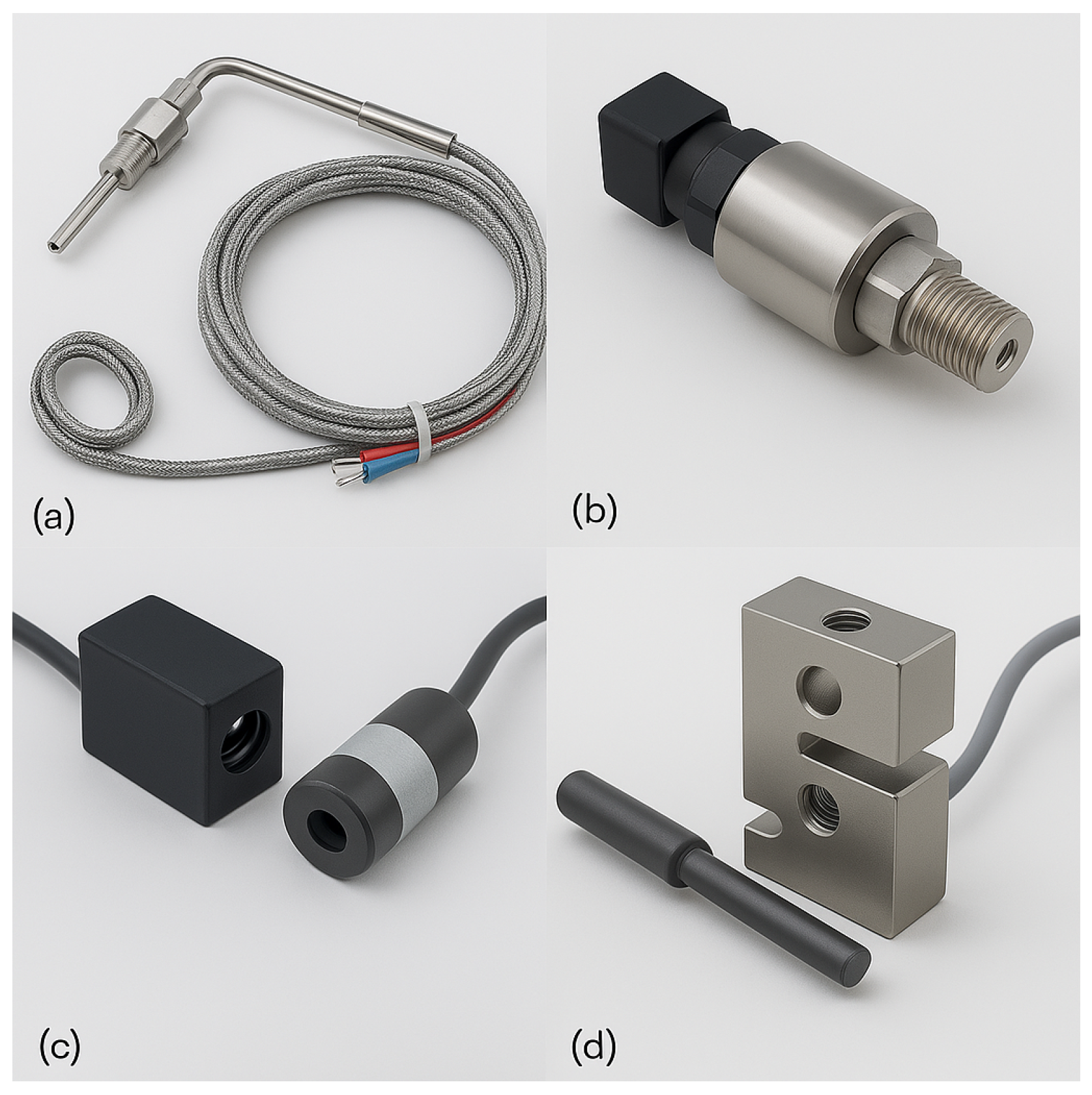

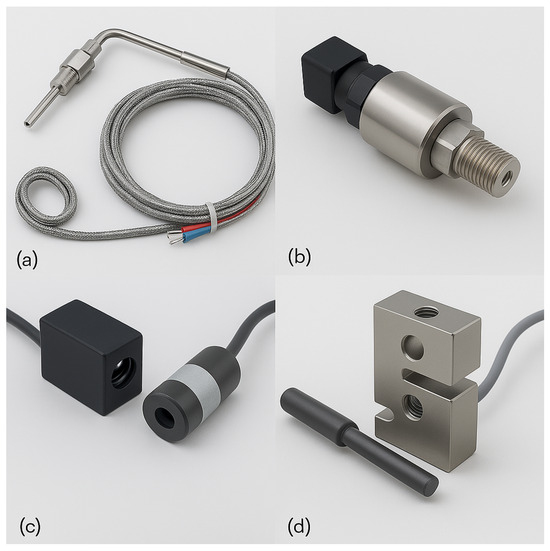

Common and sophisticated sensor types used in MTE research are reviewed in this section together with their concepts, uses, and related difficulties. While an instance of an instrumented test stand is shown in Figure 2, a montage of often-used sensors is shown in Figure 3.

Figure 3.

Montage of common sensors used in MTE experimentation (clockwise from top left, examples): (a) K-type thermocouple probe for EGT, (b) Piezoresistive pressure transducer, (c) Optical tachometer sensor with reflective tape on shaft, (d) S-type load cell for thrust measurement.

3.1. Pressure Measurement

The determination of component performance, cycle efficiency, and guaranteeing safe operation [3,9] depends on pressure measurements at several stations inside the MTE (e.g., compressor inlet/outlet, combustor, turbine outlet). Commonly carried out are static and total (stagnation) pressure measurements. Whereas total pressure is usually measured using probes such as Pitot tubes (for subsonic flow) or Kiel probes, which are less sensitive to misalignment with the flow direction [4,5], static pressure is usually measured using wall taps flush with the surface. Pressure transducers turn detected pressure into an electrical signal. Piezoresistive transducers, generally used due to their good linearity, accuracy, and reasonably small size, are suitable for limited MTE installations [9]. Capacitive transducers, which offer high accuracy and good stability, are beneficial for baseline performance mapping and are among the dominant types of sensors. The application determines which of the dynamic and stationary pressure readings to use. Time-averaged static pressures are often enough for steady-state performance mapping. However, dynamic pressure sensors with high-frequency responses are essential for detecting transient events such as compressor surge, stall, or combustion instabilities [10,28].

3.2. Temperature Measurement

In MTEs, temperature is a fundamental parameter; the main operational limit is the Exhaust Gas Temperature (EGT) [10]. To evaluate the compressor performance [11], temperatures are also recorded at the compressor intake (T0/T2) and outlet (T3). Table 1 provides a useful comparison of temperature sensor properties and their usual application contexts in MTE research. Resistance Temperature Detectors (RTDs) are generally used for higher accuracy at lower temperatures (e.g., ambient, fuel, compressor I/O [16]). Thermocouple (TC) placement is rather difficult for EGT, where frequently circumferential averaging [12] and measurement of Direct Turbine Inlet Temperature (TIT) in MTEs [5] are used. Measurement challenges include radiation errors and connection errors [4], ensuring suitable response time for transients [10], and accounting for recovery factor in high-velocity flows. Optical pyrometry [4,32] is one non-intrusive method mostly applied in specialized research facilities with optical [36].

Table 1.

Illustrative Comparison of Temperature Sensor Characteristics and MTE Application Contexts.

3.3. Rotational Speed (RPM) Measurement

MTEs run at rather high rotating speeds. Performance mapping, control, and monitoring [27] depend on accurate RPM measuring. Common are optical tachometers—reflective film on the shaft [2,9] and magnetic (Hall effect or variable reluctance) sensors. Particularly when interfacing with ECUs in noisy MTE situations [29], a clean signal capture from their frequency output is critical.

3.4. Thrust Measurement

A good gauge of MTE propulsive performance is direct thrust measurement [8]. Often utilized for this measurement are strain gauge-based load cells [9]. Friction minimization [2], exact alignment, vibration isolation, and accounting for tares and inlet momentum constitute critical thrust stand design issues. Excellent and consistent calibration is necessary [8]. Furthermore, currently investigated are new systems such as inclined plate load cells.

3.5. Fuel Flow Measurement

Determining SFC [17] and combustion efficiency [19] depends on accurate fuel flow measurements. Commonly used along with density correction—depending on fuel temperature—are volumetric flow meters, including turbine [2] and gear types for viscous fuels [18]. Designed for exact research, Coriolis mass flow meters provide direct, highly accurate mass flow measurement. Especially with biofuels, fuel compatibility is a major factor [16,18].

3.6. Air Flow Measurement

The direct measurement of the core air mass flow rate in MTEs is difficult [5] and is often inferred or measured using a calibrated bellmouth input with pressure taps [3,11]. The key problems arising from this type of measurement [2] are ensuring consistent input and precise discharge coefficients.

3.7. Vibration and Acoustic Sensors

MTE health monitoring and the study of combustion instabilities make growing use of accelerometers. Studies emphasizing noise characteristics utilizing microphones relevant for UAVs operating in noise-sensitive surroundings [37,38].

3.8. Advanced and Specialized Sensors

In-depth investigation of MTE combustion dynamics and instabilities depends on in-combustor dynamic pressure sensors [19,28]. Particularly with alternative fuels [23]. Optical diagnostics (e.g., PLIF, LII) require some level of optical access and may offer necessary data for CFD validation that may provide for validation for understanding of events such as soot generation. Advancement of MTE knowledge and performance depends on continuous development and implementation of these sensor technologies and their understanding and performance.

Nowadays, work on micro-turbojets utilizes thrust load cells, sensors to capture the rotational speed in revolutions per minute (RPM), pressure/temperature chains, and early optical methods. However, fast events within the engine are under-resolved, and additionally, electromagnetic interference (EMI) has the tendency to corrupt the measurement of the RPM near the engine control unit (ECU). The measurement of the exhaust gas temperature (EGT) suffers from radiation and recovery-factor bias; the commonly used thrust stands often tear and suffer from alignment problems. Some of the solutions can be found by adding inlet systems, modification of the thrust stands, and vibration compensation. Useful fixes are key performance indicator (KPI)–level uncertainty propagation computations, the use of high-temperature (high-T) dynamic sensors, and non-intrusive diagnostics when practical. Some gaps remain in high-bandwidth pressure sensing within small combustors and for traceable in-situ turbine inlet temperature (TIT) measurements. In practice, analyzers, heated lines, and other replacement parts account for the majority of experimental costs and the environmental footprint.

4. Experimental Methodologies for Performance and Operational Characterization

Beyond the choice of suitable sensors, the approaches used during experimentation are essential for generating consistent and complete data on Micro-Turbojet Engine (MTE) performance and operational characteristics. From steady-state mapping to dynamic response analysis, component characterization, operability testing, and basic elements of test bed design and data validation, the following summarizes standard experimental techniques.

4.1. Steady-State Performance Mapping

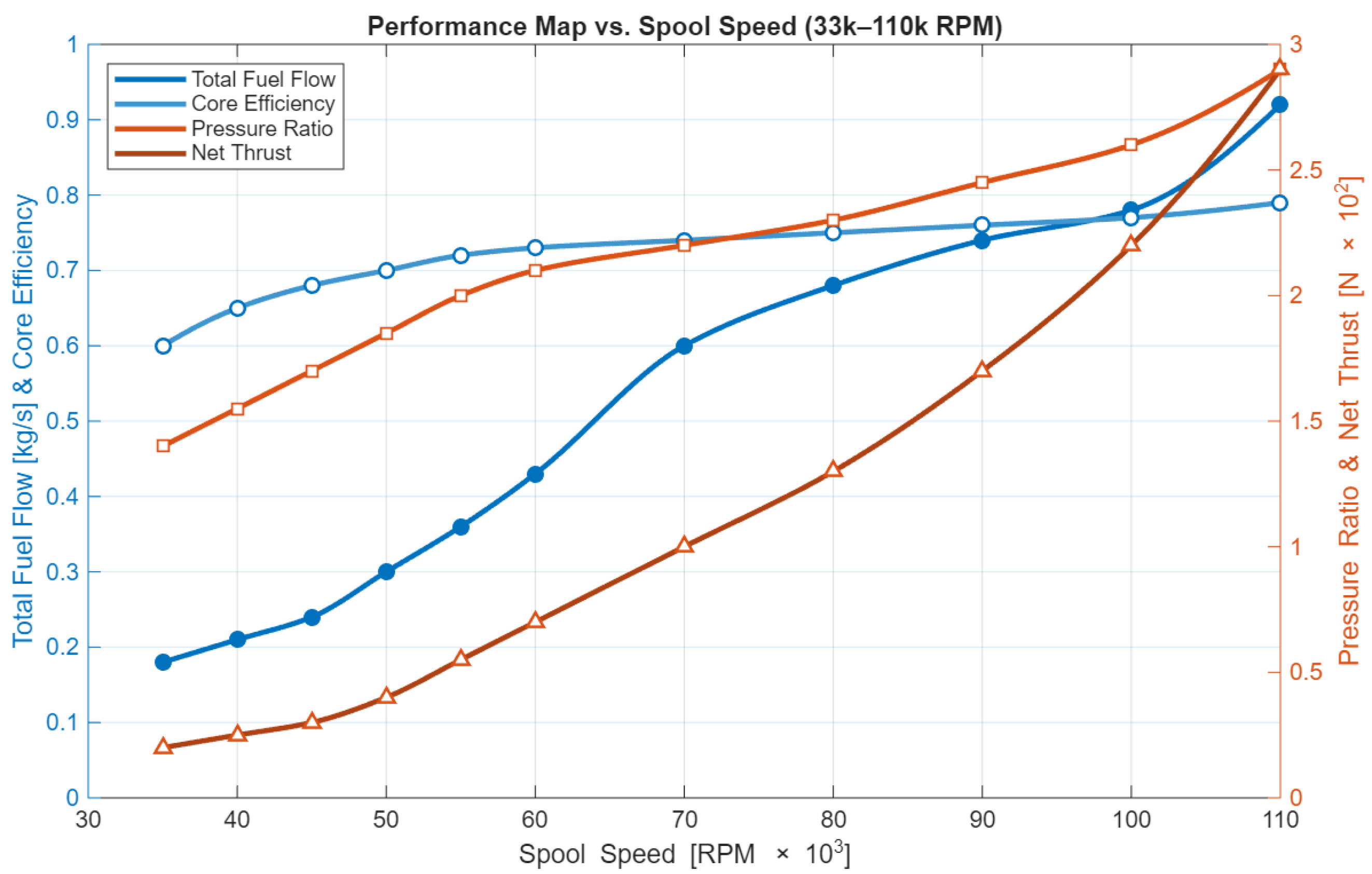

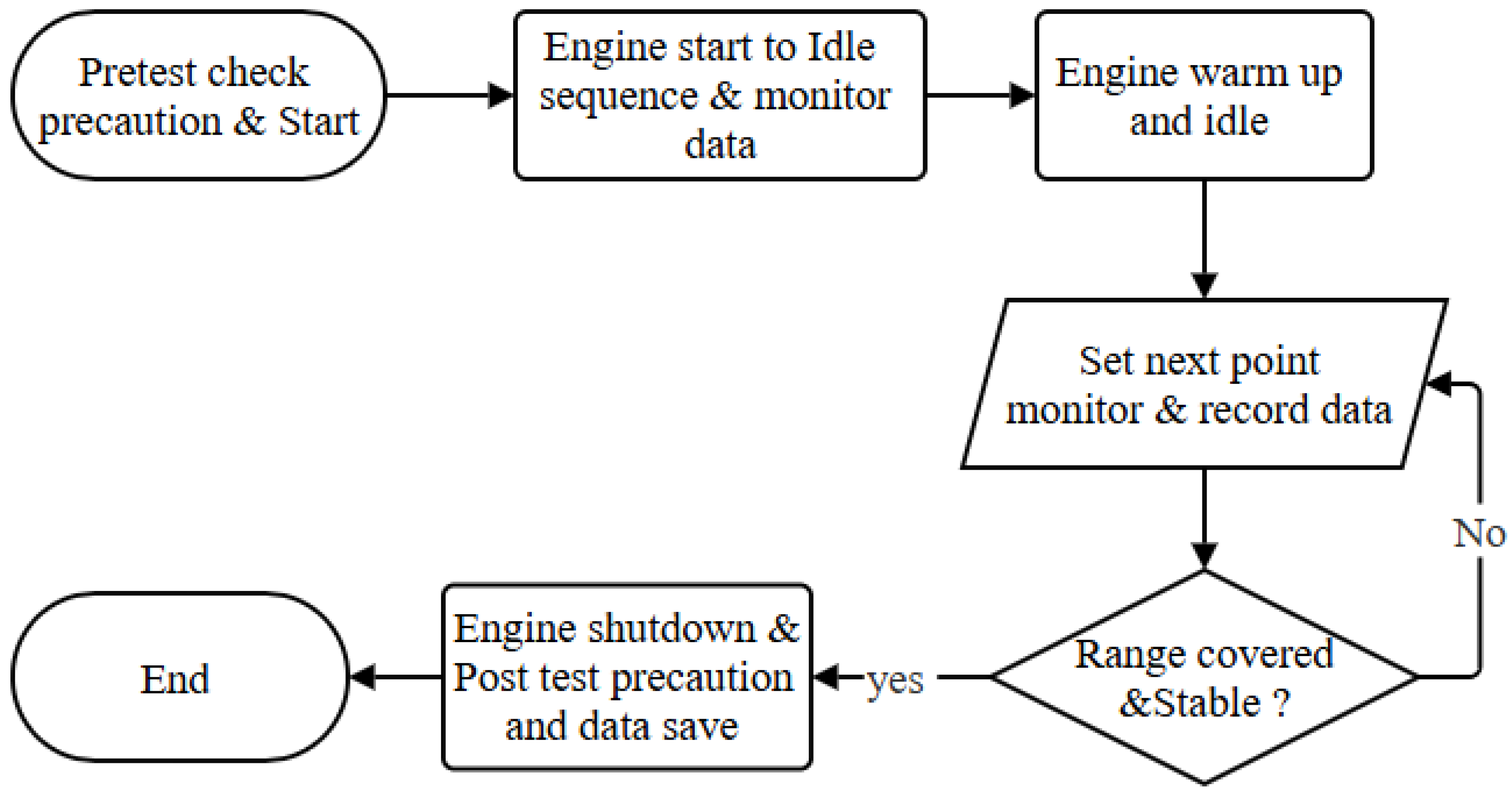

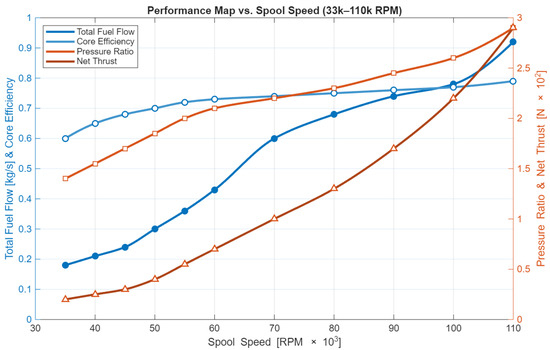

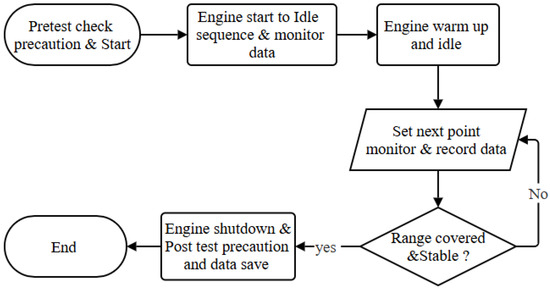

A fundamental experimental technique used to describe the baseline performance of an MTE over its operational range [5] is steady-state performance mapping [39]. Usually, the approach is given by setting the engine throttle to a specific level, allowing all important parameters to stabilize within a predefined tolerance zone (e.g., RPM ±0.5 EGT ±5 °C) for a given period (e.g., 30–60 s) [17]. Data is recorded, and the process is repeated over the throttle range. Often, collected data are modified to regular day conditions. The results, commonly shown as performance maps (as shown in Figure 4), are crucial for engine selection, mission planning, and evaluation of alternative fuels or modifications [2,16]. Figure 5 shows a generalized method.

Figure 4.

Example of an MTE performance map illustrating typical trends of key engine parameters as a function of spool speed. This map displays Net Thrust ( N), total fuel flow (L/min), pressure ratio, and core efficiency against engine spool speed (RPM). Such maps are crucial for engine characterization and operational analysis.

Figure 5.

Flowchart illustrating a generalized experimental procedure for steady-state performance testing of an MTE.

4.2. Transient Performance Analysis

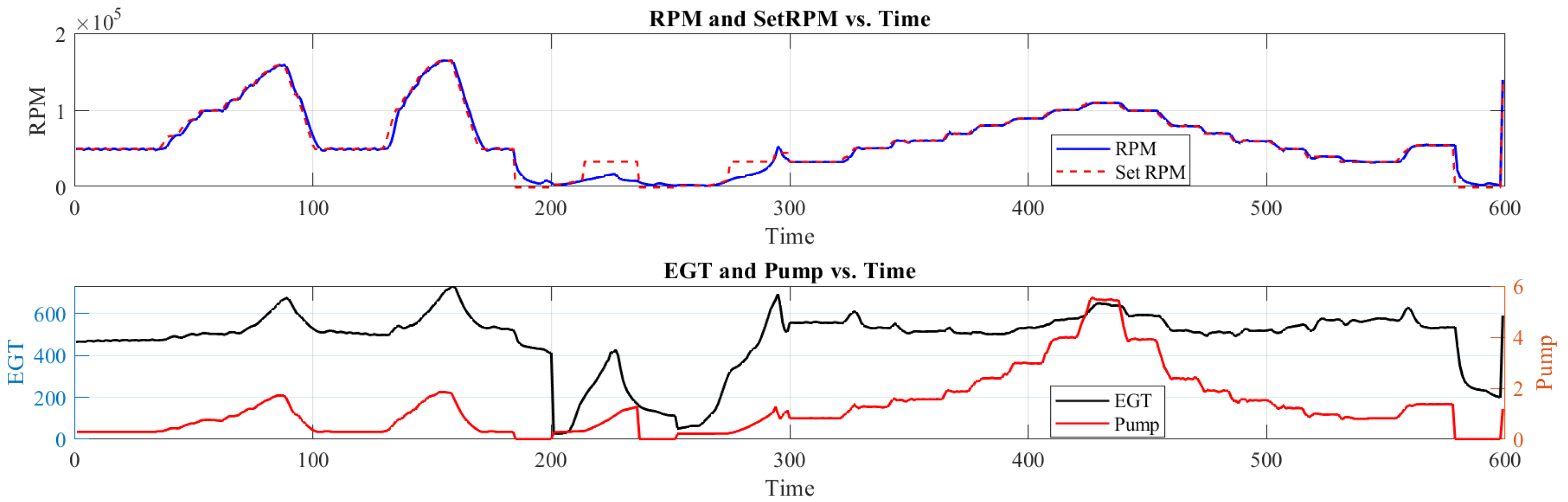

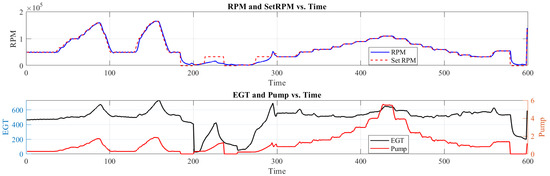

Applications needing quick changes in thrust, including UAV maneuvering or short starting sequences, and for the development of robust engine control systems [27,28] depend on an awareness of the transient behavior of MTEs [40]. Techniques call for running the engine through step changes in either throttle or slam accelerations or decelerations. Key transient parameters tracked (conceptually shown in Figure 6) include spool-up/down time, EGT overshoot/undershoot (essential for preventing damage or flame-out [10]), thrust response time, and general stability [10]. High sampling rate DAQ systems are vital [29], and the resulting data is indispensable for validating dynamic models and tweaking control parameters [10,31].

Figure 6.

Conceptual plot of a typical MTE transient response to a step increase in throttle command, showing engine RPM, fuel pump voltage, and Exhaust Gas Temperature (EGT) over time.

4.3. Component-Level Characterization

For integrated MTEs without specialized rigs, comprehensive component mapping is difficult; nevertheless, component performance (compressor/turbine pressure ratios and efficiencies [3,11], combustor efficiency, and pressure loss [17,19]) can be inferred or estimated. Usually, experimental data is combined with overall engine system models for this aim [5,32].

Component-level characterization in the cited work follows standard Brayton-cycle relations, using instrumented station pressure–temperature chains and, where required, cycle inversion [3,4]. Cican [10] reports synchronized throttle-step data that recover compressor pressure ratio, isentropic efficiency, and bound turbine efficiency from EGT overshoot. Oppong et al. [5] codify a small-rig workflow—bellmouth mass flow, wall/Kiel taps, and uncertainty-aware inversion—to obtain compressor and turbine pressure ratios and efficiencies, combustor efficiency, and combustor pressure loss. For combustors, Gawron and Białecki [19] and Badami et al. [17] use , , thrust, and metered fuel to quantify combustor efficiency and pressure loss; shifts in SFC and with alternative fuels enable back-calculated combustor efficiency at matched speed. For compressors, Authors in [11] show a stage upgrade that increases pressure ratio and reduces rise at constant corrected speed, indicating higher isentropic efficiency. For turbine/nozzle interaction, Sundararaj et al. [12] varies nozzle area and exhaust pressures to modulate back-pressure and bound turbine efficiency from thrust–EGT pairs at fixed RPM. High-rate traces in Tărăbîc et al. [9] allow time-resolved compressor/turbine pressure ratios and efficiencies during steps, while Malinowski and Lewandowska [13] provide an exergy-based consistency check on component efficiencies. In emissions-oriented campaigns, stable or shifted and SFC trends are used to assess combustor efficiency and turbine work at fixed operating points.

4.4. Operability and Stability Testing

Reliable MTE operation entails determining flameout limits (especially with alternative fuels) [18], characterizing surge/stall boundaries (often cautiously or via models), and evaluating the impact of ambient conditions such as temperature, pressure, or humidity, as well as events such as water ingestion [33].

4.5. Test Bed Design, Calibration, and Data Validation

High-quality experimental data mostly depend on the test bed design and procedural rigor. Important elements are stable fuel systems, controlled air supply, and exhaust extraction [2,9], and thorough safety measures. Crucially, ref. [8] regular calibration of all sensors and DAQ channels against traceable criteria is required. Keystones of excellent MTE experimental research include an uncertainty analysis [5] and tests for data repeatability and reproducibility [9].

The cited groups employ fixed-axis and floating thrust stands, emissions benches, and control-oriented rigs with common elements: bellmouth inlets for reference mass flow, rigid frames with low-friction guidance for thrust transmission, station pressure–temperature chains, synchronized data acquisition, safety enclosures, and exhaust extraction [2,5]. Tărăbîc et al. [9] report on a fully instrumented bench that integrates a novel thrust stand with high-rate, time-synchronized RPM/thrust logging and documented calibration/tares. Bartasevicius et al. [8] demonstrates an pylon-plate load-cell architecture with compliant mounts and vibration isolation to improve low-thrust fidelity at the micro scale. For fuel and combustor work, Gawron and Białecki [19] use taps, , metered fuel, and emissions analyzers with heated transfer lines inside a shielded cell with forced ventilation. Emissions-dedicated benches employ exhaust probes, dilution tunnels, heated lines, and particle/gas analyzers (SMPS, CPC, aethalometer/PA instruments), with attention to residence time and conditioning; probe placement is treated as a design variable to improve representativeness [23,25,41]. Aerothermal variants include adjustable nozzle modules and back-pressure control for turbine/nozzle studies [12], as well as water-ingestion hardware for operability testing [33]. Acoustic-focused stands co-locate microphone arrays with ejector/chevron modules so that thrust, SFC, and noise can be measured on the same rig [42]. Across these designs, good practice centers on bellmouth coefficient verification, deadweight calibration of load cells, thrust-line alignment checks, synchronized clocks across subsystems, and uncertainty reporting at the KPI level [5,8,9].

Throttle-step transient and steady-state maps have been established, but method variance still prevents a quantifiable comparison. Laboratories employ various dwell bands, stabilization rules, filters, clock synchronization protocols, surge/stall mapping practices, and correction chains. Having the field converge on consensus procedures, publish raw transients with synchronization markers, state bands, and filters, and report repeatability with full correction paths would benefit the entire research community. Some of the remaining gaps are multi-lab round-robins and reference scripts that make results comparable, plus qualitative techno-economic assessment (TEA) and life-cycle assessment (LCA) notes by test phase, especially for diluted emissions sequences.

5. Alternative Fuels and Emissions Characterization in MTE Experimentation

Driven toward sustainability and better logistics, research on alternative fuels for MTEs [17] closely relates to exhaust emissions characterization.

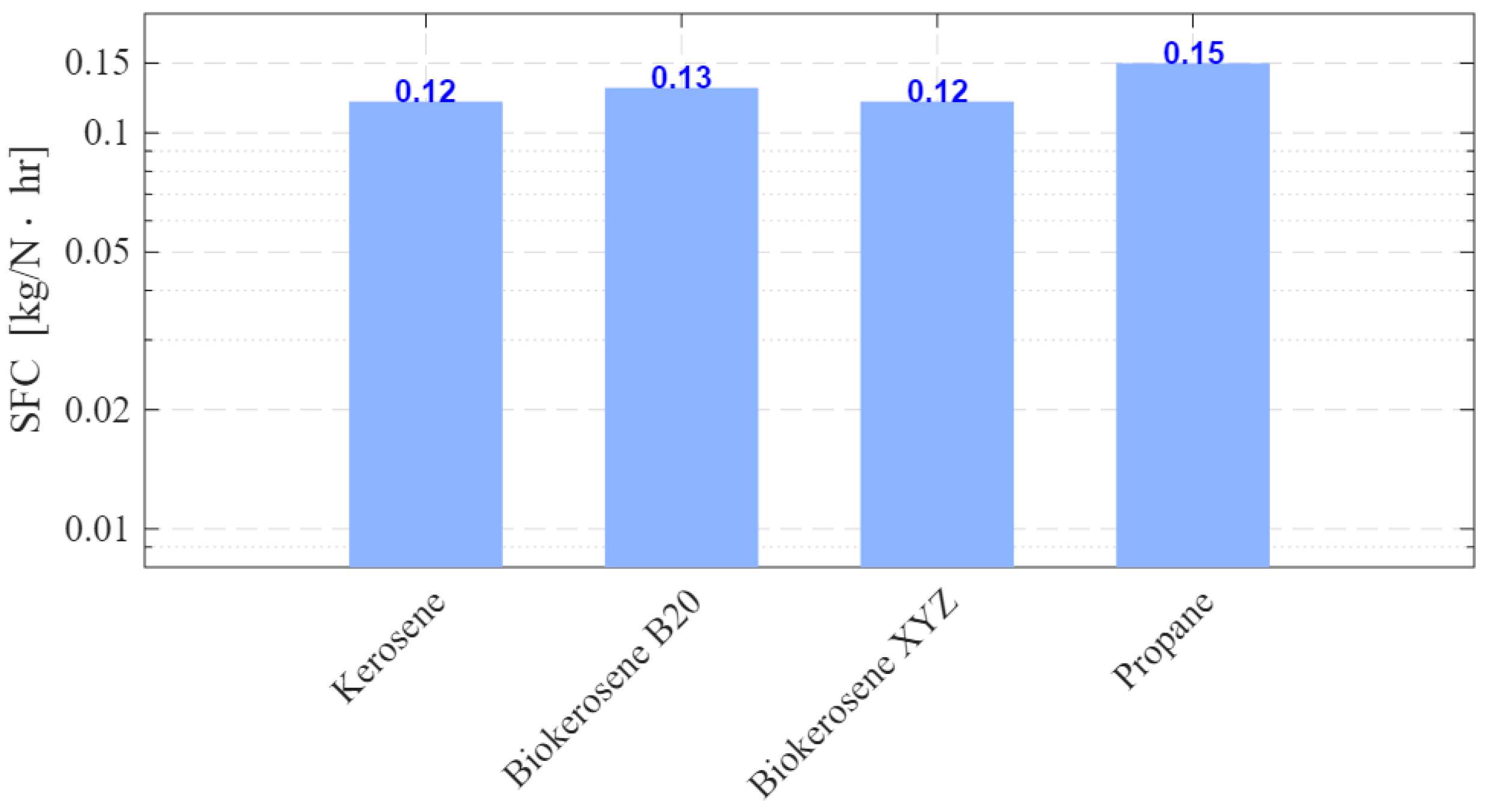

5.1. Alternative Fuels in MTEs: Motivation and Experimental Approaches

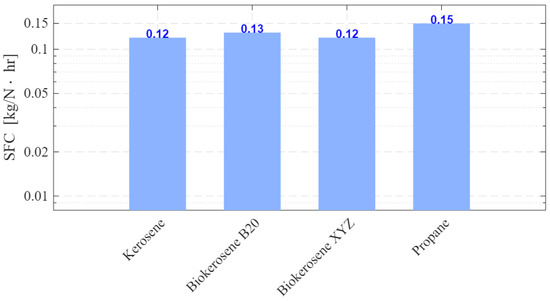

Among the reasons for the use of alternative fuels are lowering reliance on fossil fuels and emissions, as well as using specialized fuels such as propane. Among the currently tested fuels are synthetic fuels (FT fuels), biofuels (biodiesel, HEFA, and biokerosene derived from waste cooking oil), and propane and hydrogen mix fuels. Experimentation may call for fuel system changes, including preheating for viscous fuels (conceptually shown in Figure 7). The core approach is comparative testing against baseline kerosene [17], assessing thrust, SFC, EGT, operability, and emissions. Common outcomes reveal SFC changes (due to energy density), EGT variations, and altered combustion stability alongside problems such as cold start and deposits [16,18]). Reducing emissions is a basic goal for all fuel researchers.

Figure 7.

Illustrative bar chart comparing typical Specific Fuel Consumption (SFC) for an MTE operating on different fuel types. Actual values are engine and fuel-specific.

Alternative-fuel results (fuels, blends, concentrations). Reported campaigns cover drop-in biokerosene meeting the global standard specification for sustainable aviation fuel (ASTM D7566), alcohol–Jet A blends, and waste oil-derived fuels. Gawron et al. [16] evaluates biokerosene as a drop-in (tested neat or at high blend levels per pathway limits in [15]); thrust remains within baseline scatter, while SFC and shift consistently with lower LHV. Cican et al. [14] use binary Jet A blends with mid- to long-chain alcohols (C3–C8) at low-to-moderate volume fractions; the blends increase SFC at matched RPM and reduce smoke tendency, with ignition margins sensitive to chain length. Badami et al. [17] compare conventional kerosene with alternative formulations on a JetCat-class engine; alternative fuels are run as blends or neat depending on viscosity, showing small thrust deltas at set speed, modest SFC penalties, and fuel-dependent trends. Cican et al. [18] employs waste-cooking-oil–derived fuel in blended form and with fuel preheat; stable operation is reported following viscosity conditioning, with SFC above kerosene and altered start transients. At laboratory scale, Mirea and Cican [20] test biodiesel-based SAF against Jet A under controlled conditions; the SAF case maintains operability, exhibits higher SFC at equal load, and shows distinct gaseous emissions signatures. Across studies, blends are preferred when density/viscosity or volatility necessitate conditioning; neat operation is feasible for certified drop-ins within pathway limits [15], while performance shifts track expected energy-density and atomization effects.

5.2. Emissions Characterization: Sensors and Methodologies

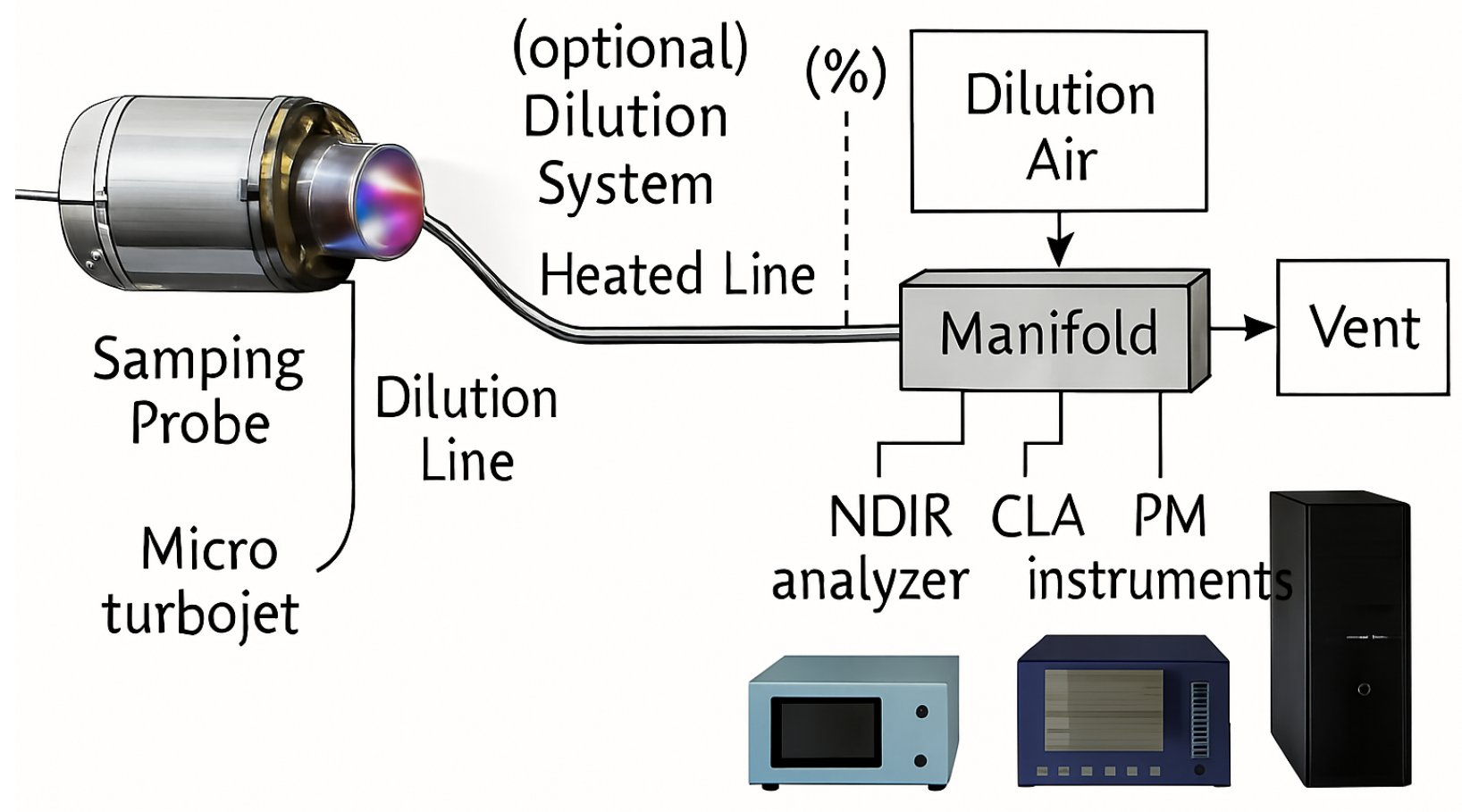

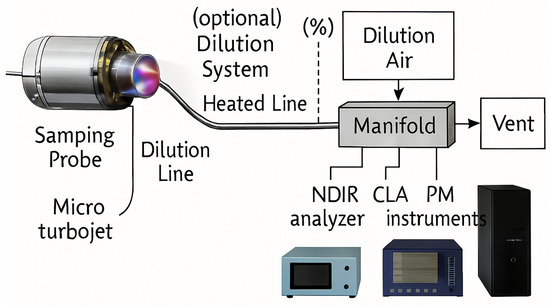

UAV proliferation and APU uses [23] are driving greater scrutiny of MTE emissions. Evaluating alternative fuels requires characterizing. Figure 8 depicts a standard measurement configuration.

Figure 8.

Conceptual schematic of an MTE exhaust gas emissions sampling and analysis train, showing the sampling probe in the exhaust, heated transfer line, optional dilution system, and connections to various gas and particulate analyzers.

- A.

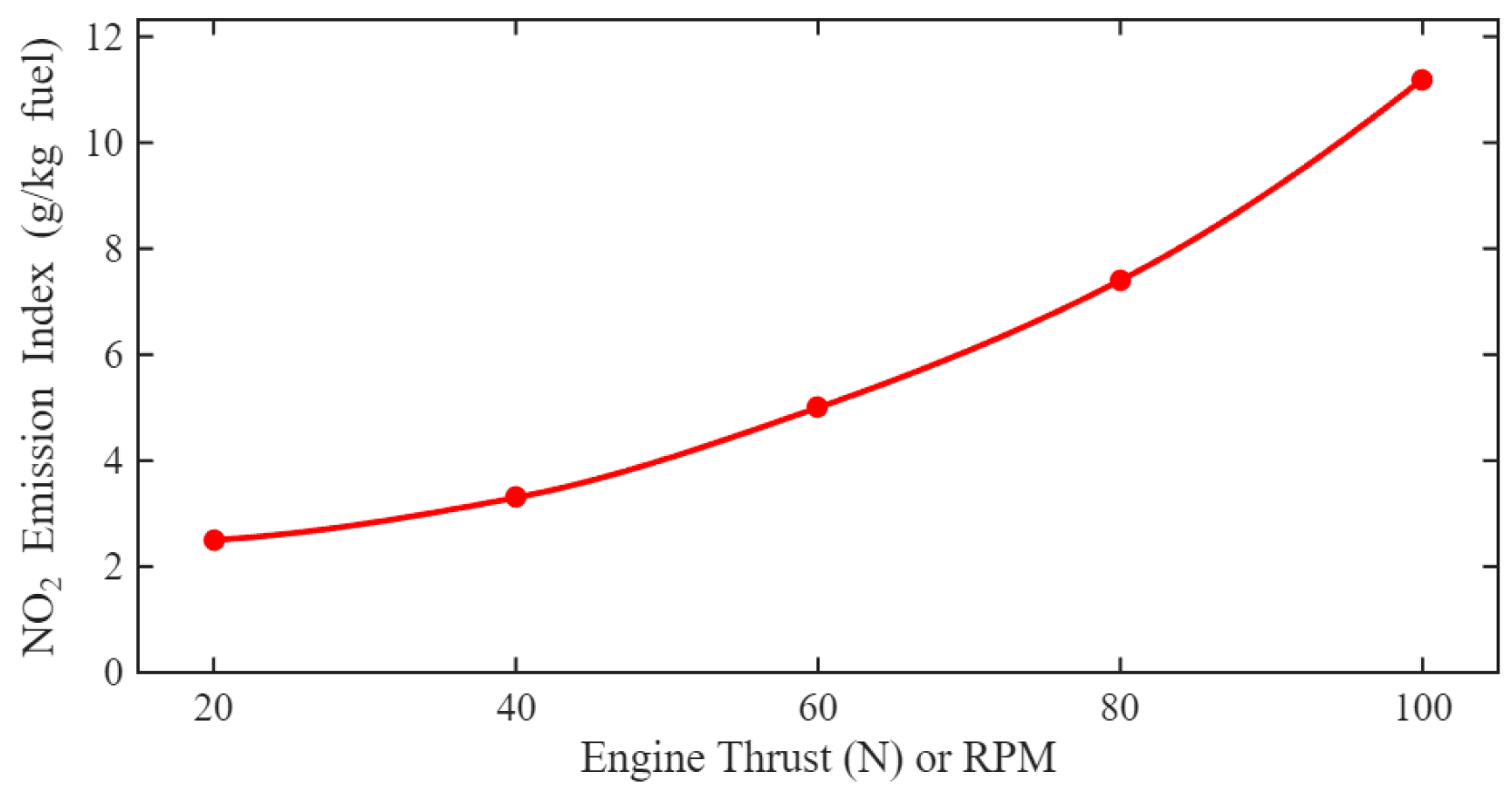

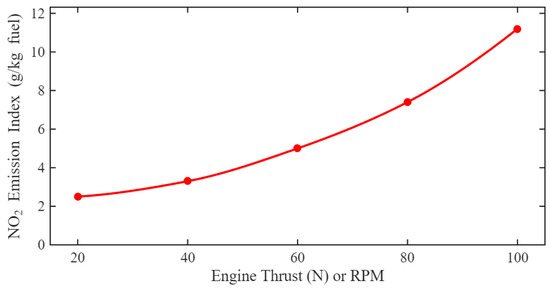

- Gaseous Emissions Measurement: Uses exhaust sampling via hot lines (probe design is crucial [25]) and NDIR (CO, CO2), CLA (NOx), and FID (THC) instrument analysis. Calculated are emission indices (EI, g/kg fuel) [21]. A typical EI trend is shown in Figure 9.

Figure 9. Example illustrative plot showing a typical trend of NOx Emission Index (EINOx) as a function of MTE thrust output or engine RPM. Actual trends depend on engine design and operating conditions.

Figure 9. Example illustrative plot showing a typical trend of NOx Emission Index (EINOx) as a function of MTE thrust output or engine RPM. Actual trends depend on engine design and operating conditions. - B.

- Particulate Matter (PM) Measurement: One of the basic concerns in emission is PM, including black carbon (BC) [41]. Among the techniques are gravimetric approaches (filters), particle size and counting (SMPS, CPCs), and real-time BC measurement (aethalometers, photoacoustic sensors). Managing high exhaust velocity/temperature presents challenges; often, this calls for dilution systems [23].

- C.

- Exhaust Toxicity Evaluation: Some studies evaluate general toxicological effects of emissions from new fuels using bioassays (such as BAT-CELL technique [24]).

- D.

- Effect on Emissions of Operating Conditions and Fuels: Engine load affects emissions; different alternative fuels [16,17] greatly change emissions. Oxygenated biofuels, for instance, may lower PM/CO but impact NOx; hydrogen can remove carbon emissions but requires NOx control.

Emissions characterization—exhaust toxicity and effects. Exhaust toxicity has been assessed using diluted-sample bioassays in conjunction with gas/particle analytics. Gawron et al. [24] expose cell systems (e.g., BAT-CELL) to exhaust from fuels containing synthesized hydrocarbons and report toxicity endpoints consistent with measured VOC speciation, indicating that reductions in aromatic content reduce cytotoxic response at matched operating points; companion VOC work [21] links lower unsaturated/oxygenated species to lower toxicity signals. Particle-focused studies emphasize sampling integrity: Kurzawska-Pietrowicz [23] use heated lines and controlled dilution to map number–size distributions across loads, while Xu et al. [41] detail PN methodology (probe geometry, residence time, line temperature) and show that protocol choices materially shift reported counts; probe placement guidance is consistent with [25].

Effect on emissions. Alternative-fuel campaigns show coherent trends tied to oxygen content and flame temperature. Alcohol–Jet A blends (C3–C8) reduce particulate number and smoke tendency and generally lower CO/THC at matched RPM, with NOx following EGT changes [14]. Biodiesel-based SAF at laboratory scale alters NOx/CO/THC ratios relative to Jet A yet maintains operability when sampling and conditioning are controlled [20]. Comparative JetCat-class tests with alternative formulations report small thrust deltas but measurable emissions shifts: CO/THC reductions are common with oxygenated fuels, while NOx varies with combustor temperature rise [17]. Certified drop-ins conforming to ASTM D7566 behave as near drop-ins for gaseous emissions, with particulate trends reflecting compositional differences rather than large combustor-efficiency changes [15,16]. Across studies, effects are robust only when dilution strategy, probe position, and analyzer drift are controlled and reported together with operating condition and uncertainty [23,25,41].

A difficult but important topic, the experimental assessment of alternative fuels and their emissions directs the evolution of more sustainable and ecologically appropriate MTE technology. Comparative fuel studies report on particulate matter (PM) and toxicity nowadays; however, comparisons are challenging due to inconsistencies in probe placements, line temperatures, dilution strategies, and analyzer drift control among these studies. PM number/size coverage is uneven, and durable evidence for sustainable aviation fuels (SAFs) is limited. The field would benefit from using non-volatile particulate matter (nvPM)–style sampling, full emission-index (EI) correction chains, mission-normalized metrics, and portable diluted sampling suitable for unmanned aerial vehicle (UAV) field tests. Some of the main gaps are long-run data on deposits, cold starts, and operability. TEA/LCA should note qualitatively about fuel type and flow, heater/pump electricity, and filter handling drive cost and impact.

6. Control System and Engine Model Experimental Validation

Safety, efficiency, and dependability depend on strong control systems and accurate dynamic models being developed for MTEs across their varied application spectrum [27,28]. From first model construction and parameter identification to control law validation and diagnostic algorithm testing, every phase of this process depends critically on experimental data and methods.

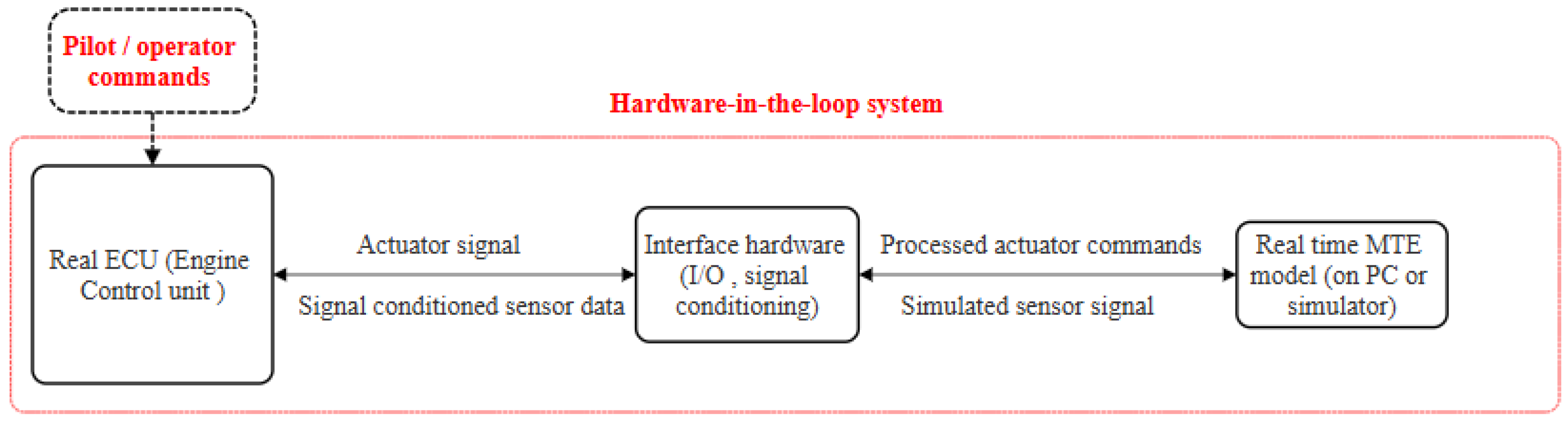

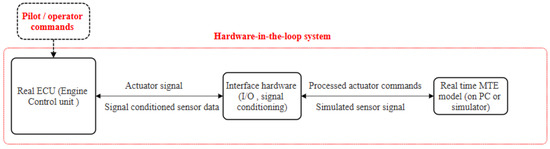

6.1. Hardware-in-the-Loop (HIL) Simulation

A potent experimental method widely utilized in the creation and testing of MTE control systems [29] is hardware-in-the-loop (HIL) simulation. The fundamental idea is integrating virtual hardware components with actual ones inside a closed loop. Two often used HIL setups for MTEs are

- ECU-within-the-Loop: Real-time dynamic models of the MTE running on a simulator are verified against the actual Engine Control Unit (ECU) hardware. This enables thorough testing of the control logic of the ECU, response to simulated sensor inputs, and fault handling features free from risk to a real engine.

- Engine-in-the-Loop (less common for whole MTEs due to complexity, but components can be): A simulated ECU or overall system model controls a real MTE or essential engine component such as a fuel pump or actuators. If a full engine test is neither practical nor safe for particular control system test phases [29], more often a specific MTE hardware simulator (a physical rig that simulates engine outputs based on ECU commands) may be employed [29].

Figure 10 shows a general block schematic of an ECU-in-the Loop HIL system. HIL simulation’s main advantages are

Figure 10.

Conceptual block diagram of a Hardware-in-the-Loop (HIL) simulation setup for MTE control system development (ECU-in-the-Loop configuration). The real Engine Control Unit interacts with a real-time simulation of the MTE and its environment.

- Rapid Control Prototyping: enables fast iteration and testing of several control strategies and parameter adjustment [43].

- Extreme Condition Safe Testing: helps to evaluate control system performance under fault conditions, extreme operating points, or environmental changes that could be hazardous or challenging to recreate on a physical engine test bed [44].

- Cost and Reduced Development Time: reduces the early to mid-stage of control system development’s requirement for thorough, expensive, and maybe dangerous physical engine testing.

- Repeatability: Simulated settings have a lot of test conditions that can be easily repeated.

To guarantee significant outcomes, HIL systems need exact real-time engine models and advanced interface hardware [31].

6.2. Experimental Data for System Identification and Model Validation

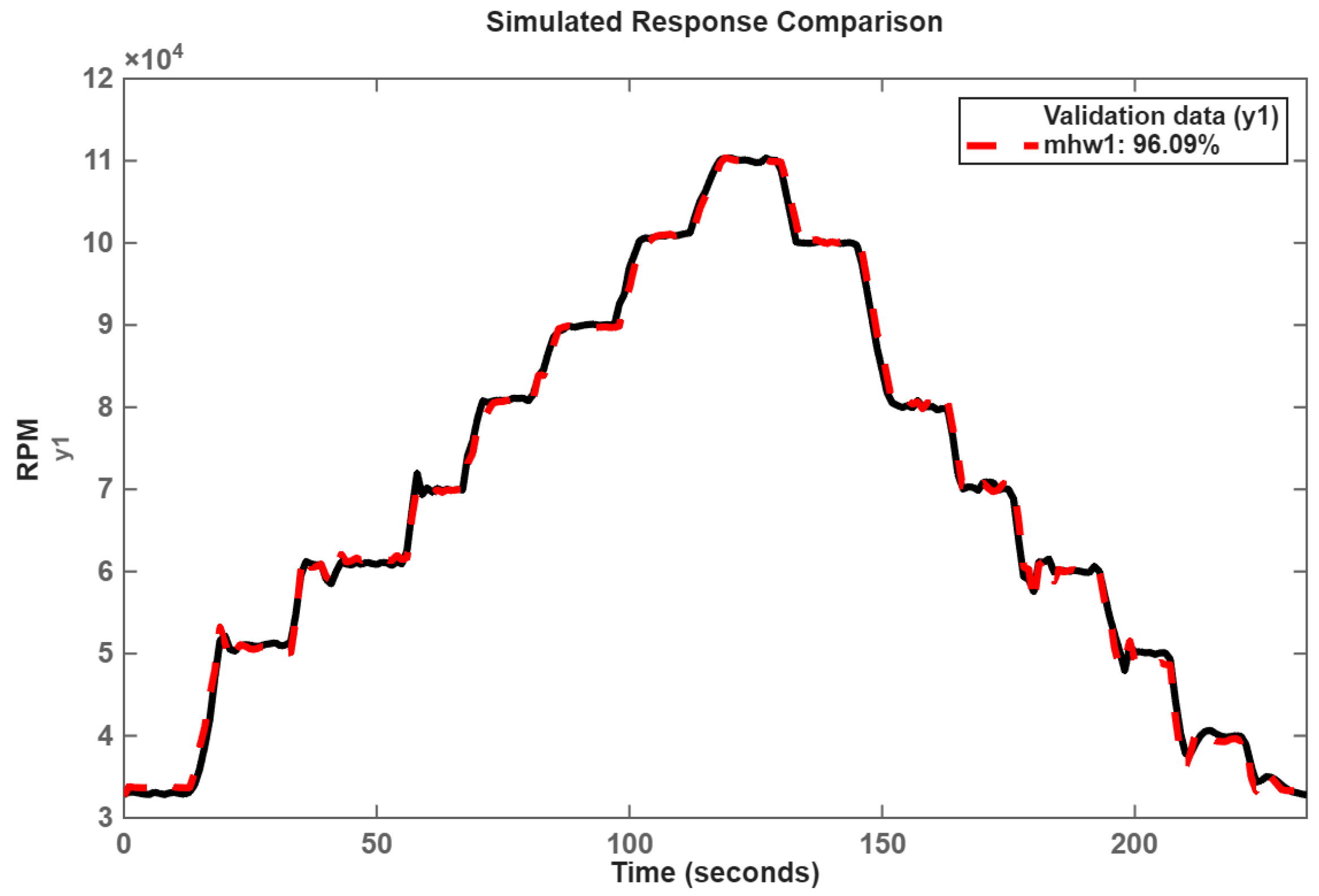

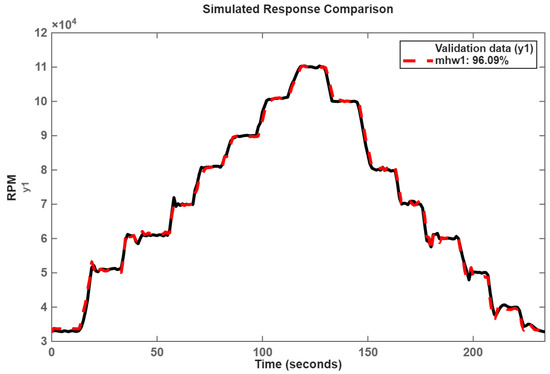

Control design, performance prediction, and health monitoring depend on accurate dynamic models of MTEs. The identification of model parameters (system identification) and validation of the accuracy of the produced models depend on experimental data, especially from transient tests (see Section 4.2).

- System Identification: Using several mathematical approaches (e.g., least squares, subspace methods), transient response data—e.g., RPM, EGT, thrust variations following throttle steps—are estimated for linear or non-linear MTE models. These models can span from basic transfer functions to sophisticated physics-based or data-driven representations [26,31],

- Verification of Model: Once a model is established, its predictive capacity is evaluated by means of a comparison between its simulated output and an additional set of experimental data not used for identification [40,45]. Accuracy in replicating steady-state operating points, transient responses (spool-up/down timings, EGT overshoots), and stability limits defines key performance indicators for validation [46]. Figure 11 provides a standard comparison between simulated and experimental RPM response [35].

Figure 11. Conceptual comparison plot of experimental MTE RPM transient data versus simulation output from a dynamic engine model, illustrating model validation. Close agreement indicates a well-parameterized model.

Figure 11. Conceptual comparison plot of experimental MTE RPM transient data versus simulation output from a dynamic engine model, illustrating model validation. Close agreement indicates a well-parameterized model.

The correctness and resilience of the found and verified engine models are much influenced by the quality and richness of the experimental dataset.

6.3. Validation of Diagnostic and Prognostic Algorithms

Research into advanced diagnostic and prognostic health management (PHM) systems is spurred by a growing demand for improved MTE dependability and lower running costs [47]. The data required to create and validate these algorithms must be produced by experimentation. Approaches consist of:

- Seeded Failure Tests: purposefully introducing controlled flaws or degradation into an engine or component (e.g., small blade damage, partially clogged fuel nozzle, sensor drift) on a test bed and tracking the engine’s response. Fault detection and isolation (FDI) methods are trained and validated using this data [31].

- Endurance Tests: Under realistic operating cycles, using an MTE for long periods helps to capture natural degradation trends. Develop and validate prognostic algorithms aiming at forecasting Remaining Useful Life (RUL) [47] using data from these tests (performance criteria, vibration, and oil debris if applicable).

- Performance degradation simulation: Simulating several degradation modes and generating synthetic data using validated engine models will help to complement experimental datasets for machine learning-based diagnostic systems [31]. Experimental evidence remains necessary for validation of these simulation-based approaches [30].

Development of robust health monitoring systems usually relies on aggregating data from numerous sensors and using advanced signal processing or machine learning techniques, both of which call for substantial experimental validation [27].

Three complementary classes of models of micro turbojets are discussed in the following.

- (i)

- Physics-based cycle and component models: station-based Brayton formulations with compressor/combustor/turbine submodels are used for steady maps and for consistency checks against experiment [3,4,5]. Implementations include engine-level models with component links [32,35], integrated analyses that account for secondary flows [45], and exergy-based partitions to bound component efficiencies [13]. These reproduce measured thrust, SFC, and T–P trends on test stands with close agreement when corrected for inlet and heat losses.

- (ii)

- Low-order gray-box dynamics: throttle-step data are fit with least-squares/subspace identification to first- to second-order transfer functions for spool speed and EGT; regression formulations capture energy and emission metrics at operating points [26,39]. Reported outputs match transient rise/settle times and steady levels under synchronized logging [9].

- (iii)

- Data-driven predictors: hybrid and purely data-driven models learn mappings from commands and station measurements to performance. Examples include extreme-learning-machine hybrids for gas-turbine states [22], deep-learning forecasters for micro-gas-turbine performance [34], and supervised learning that predicts micro-turbojet thrust, SFC, and temperatures across regimes [31,40]. These studies report lower prediction error than baseline fits and real-time inference suitable for control-design workflows. Together, the physics-based, gray-box, and machine-learning approaches provide validated steady and transient predictions, with exergy and station-balance checks used to verify plausibility.

6.4. Algorithms Used

Recently published research work can be categorized into four practical classes.

HIL/ECU-in-the-loop validation: Montazeri-Gh and Nasiri [44] exercise the electro-hydraulic fuel control unit in real time; Nasiri et al. [43] add a neural NARX Smith predictor to compensate for I/O and computation delays, reporting reduced overshoot and improved tracking in HIL. Dedicated micro-turbojet hardware simulators by Istenes-Németh et al. [29] enable closed-loop ECU testing against fast surrogate engine dynamics.

Adaptive/robust control: Zhang et al. [28] implement all-coefficient adaptive control on a micro-turbojet and demonstrate improved reference tracking under parameter drift; Shehata et al. [46] apply an adaptive fuzzy PID, showing lower EGT overshoot and shorter settling time than a fixed-gain PID in throttle steps; Chapman and Litt [27] report a benchmark gain-scheduled PID baseline validated on a bench rig.

Model-assisted prediction/compensation: Xu et al. [22] use an extreme-learning-machine hybrid to predict gas-turbine states for control and estimation; Aygun et al. [40] and Toraman et al. [31] train supervised predictors that supply accurate thrust/SFC/temperature estimates for feedforward and constraint handling, reducing model mismatch versus simple regressors; Kilic et al. [34] report deep forecasters for micro-turbine performance that meet real-time inference budgets.

Diagnostics/Prognostics and health management (PHM) algorithms: Wang et al. [47] develop a data-driven degradation prognostic scheme that estimates remaining useful life across operating conditions; Talebi et al. [30] formalize measurement selection for engine- and component-level diagnostics. Across these examples, reported outcomes are consistent: HIL workflows de-risk ECU logic and quantify delay sensitivity; adaptive controllers improve tracking and disturbance rejection over fixed-gain baselines; learned predictors lower one-step and multi-step errors to support control and supervision; and PHM methods provide actionable state-of-health estimates for endurance planning.

Hardware-in-the-loop (HIL) workflows, adaptive control, and data-driven models have demonstrated reliable applications, but challenges persist. Identification is often done on narrow regimes and then extrapolated; unreported actuator and sensor latencies limit achievable gains; few ECU-in-the-loop timing studies exist; prognostics and health management (PHM) datasets with seeded faults are scarce. Some of the effective steps to address these gaps are public benchmark transients with fixed train/test splits, mandatory input/output (I/O) latency logs in HIL reports, hybrid gray-box plus machine learning (ML) models validated on unseen fuels and ambient conditions, and PHM endurance or seeded-fault campaigns to test generalization.

7. Emerging Research Trends and Future Challenges

Micro-turbojet research is being reshaped by mission demands, fast diagnostics, and sustainability goals. A first advance is the wider use of non-intrusive, high-bandwidth diagnostics: Laser-Induced Incandescence (LII) for soot and Planar Laser-Induced Fluorescence (PLIF) for species/temperature fields, together with high-speed pressure/temperature sensing that resolves combustor and turbine dynamics [23,28]. These tools raise model fidelity but also expose practical limits: restricted optical access in tight flowpaths, emissivity/radiation bias in hot sections, and unsynchronized data acquisition (DAQ) streams that complicate uncertainty tracking for key performance indicators (KPIs). Practical remedies include windowed liners or optical ports, miniature flush probes, and rugged high-temperature dynamic sensors for confined passages. Additionally, strict time-base control with shared triggers and metadata ensures that KPI derivations (thrust, specific fuel consumption, emission indices) maintain a traceable uncertainty budget [48]. Remaining gaps are at the community level: benchmark cases with openly shared raw time series, calibration files, and post-processing scripts are still scarce, which slows down reproducibility.

Sustainable Aviation Fuels (SAFs) and hydrogen now drive a large share of experimentation. Comparative studies on small engines have expanded beyond performance into particulate and toxicity metrics, yet durability, deposits, cold-start behavior, and full operability envelopes are under-reported for many SAF candidates [14,15]. For hydrogen, the tailpipe carbon benefit is countered by wide flammability limits, high flame speed, flashback risk, and thermal NOx formation, which demand specific combustor concepts (e.g., micromix) and careful fuel conditioning [49,50]. Credible comparisons also require standardized sampling geometries, controlled line temperature, a robust dilution strategy, and analyzer-drift correction, ideally aligned with non-volatile particulate matter (nvPM) practices and reported as mission-normalized emission indices. The critical gap is endurance evidence: 50–100 h campaigns with weighted duty cycles and periodic borescope inspections are needed to show whether short-run advantages persist over realistic lifetimes.

Hybrid-electric roles are another active front. Micro-turbojets are explored as turbogenerators or range extenders with fast restart capability, yet three problems limit deployment: poor part-load efficiency, thermal cycling from frequent start/stop, and control handover between storage and the gas-turbine source. Experiments that operate near the engine’s best specific power while buffering transients with storage improve efficiency; start/stop schedules that cap exhaust-gas-temperature overshoot and shaft gradients reduce thermal stress; and coordinated direct-current (DC) bus control with measured actuator/sensor latencies stabilizes power sharing [51]. The gap is standardization: shared hybrid duty cycles and validated coupled electro-thermal models with declared latencies are needed for cross-lab comparability.

Noise reduction for urban or sensitive airspace is gaining priority. Chevron/ejector nozzles and passive acoustic liners have been tested at the micro scale, but thrust–noise trade-offs are not reported in a consistent way, and no agreed acoustic standard exists for micro-rigs [52]. A practical path is to fix microphone geometry, distances, bandwidth, and processing, and to pair noise metrics with thrust penalty and SFC change, all with confidence intervals. The gap is a compact, repeatable indoor/outdoor acoustic setup and a mission-weighted noise index for small engines, so incremental improvements can be compared across studies.

Additive manufacturing enables combustors, injectors, and turbine components with internal features and cooling paths that were not previously practical. Reported gains in mixing and flow control are tempered by known hot-section issues: surface roughness, anisotropy, coating adhesion, and limited life data under realistic thermo-mechanical cycles. Effective countermeasures include hot isostatic pressing (HIP), finish machining/polishing, and diffusion or ceramic coatings tailored to measured duty; matching thermal-mechanical rigs to engine profiles improves screening. What is missing is certification-grade evidence and batch-to-batch repeatability: round-robin coupon and subcomponent tests using shared duty cycles and acceptance metrics would allow convergence on reliable materials and processes [2,42].

Two cross-cutting needs anchor the roadmap. First, uncertainty and comparability: many reported differences among fuels, nozzles, or control laws are within the spread created by unreported stabilization rules, filters, clock synchronization, or correction chains; publishing raw transients with synchronization markers, declaring processing chains, and attaching KPI-level uncertainties would immediately raise the value of existing datasets [5]. Second, standardization and openness: consensus protocols for steady maps, throttle steps, emissions sampling, and micro-acoustic measurements—plus multi-lab round-robins using the same engine class and reference cycles—would turn isolated advances into cumulative progress; guidance from established fuel standards can seed this process [15,21].

8. Conclusions

The review demonstrates the reliability of thrust metrology, higher-rate pressure–temperature acquisition, and selective optical tools, which now underpin steady-state maps and transient tests. Comparative work on fuels extends into gaseous and particulate emissions, and control research increasingly validates models and algorithms with hardware-in-the-loop setups. Together, these strands define a practical toolkit for performance characterization, emissions assessment, and control verification across realistic operating regimes.

The central limitation is fragmentation, not physics. Results are difficult to compare because stabilization rules, filters, synchronization, sampling geometry, dilution practices, and correction chains vary across labs, while raw time series and calibration metadata are rarely shared. Evidence of endurance for alternative fuels is scarce, and acoustic and hybrid duty-cycle procedures remain inconsistent. The most important actions are clear: Adopt a minimum reporting set with KPI-level uncertainties; release at least one open benchmark dataset with raw signals and processing scripts; align micro-rig emissions to nvPM-style protocols with full EI corrections; run a 50–100 h endurance study on a representative fuel; and publish compact standards for hybrid cycles and micro-acoustic tests. Delivering these items will convert local advances in sensors, methods, fuels/emissions, and control into cumulative, comparable progress for MTE applications.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this review article have been gathered from previously published articles from various authors to provide a comprehensive review of the material. Original contributions include conclusions, summaries, and critical review. Any inquiry can be sent to corresponding author at schomarc@isu.edu.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| APU | auxiliary power unit |

| ASTM D7566 | standard spec for SAF containing synthesized hydrocarbons |

| BC | black carbon |

| CFD | computational fluid dynamics |

| CLA | chemiluminescence analyzer |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CPC | condensation particle counter |

| DAQ | data acquisition |

| DC | direct current |

| ECU | engine control unit |

| EGT | exhaust gas temperature |

| EI | emission index |

| EINOx | emission index of NOx |

| EMI | electromagnetic interference |

| FDI | fault detection and isolation |

| FID | flame ionization detector |

| FT | Fischer–Tropsch |

| HEFA | hydroprocessed esters and fatty acids |

| HIL | hardware-in-the-loop |

| I/O | input/output |

| KPI | key performance indicator |

| KPIs | key performance indicators |

| LCA | life-cycle assessment |

| LHV | lower heating value |

| LII | laser-induced incandescence |

| ML | machine learning |

| MTE | micro-turbojet engine |

| NDIR | non-dispersive infrared |

| NOx | nitrogen oxides |

| nvPM | non-volatile particulate matter |

| PA | photoacoustic |

| PHM | prognostics and health management |

| PID | proportional–integral–derivative |

| PLIF | planar laser-induced fluorescence |

| PM | particulate matter |

| RPM | revolutions per minute |

| RTD | resistance temperature detector |

| RUL | remaining useful life |

| SAF | sustainable aviation fuel |

| SFC | specific fuel consumption |

| SMPS | scanning mobility particle sizer |

| TC | thermocouple |

| TEA | techno-economic assessment |

| THC | total hydrocarbons |

| TIT | turbine inlet temperature |

| UAVs | unmanned aerial vehicles |

| VOC | volatile organic compounds |

| ambient pressure | |

| compressor inlet pressure | |

| compressor exit/combustor inlet pressure | |

| turbine inlet pressure | |

| turbine exit pressure | |

| ambient temperature | |

| compressor inlet temperature | |

| compressor exit/combustor inlet temperature | |

| turbine inlet temperature | |

| turbine exit temperature (EGT) |

References

- Khalatov, A.A.; Nemchin, A.F.; Shkvar, E.A.; Kuzmin, A.V.; Kobzar, S.G. Small-Size Jet-Powered Combat Unmanned Aircraft Systems; Lira LTD: Dnipro, Ukraine, 2023; ISBN 978-966-981-807-2. [Google Scholar] [CrossRef]

- Benini, E.; Giacometti, S. Design, manufacturing and operation of a small turbojet engine for research purposes. Appl. Energy 2007, 84, 1102–1116. [Google Scholar] [CrossRef]

- Mattingly, J.D. Elements of Gas Turbine Propulsion; McGraw-Hill: New York, NY, USA, 1996; ISBN 978-0-07-912196-7. Available online: https://books.google.com/books?id=lQsoAQAAMAAJ (accessed on 20 October 2025).

- Hill, P.G.; Peterson, C.R. Mechanics and Thermodynamics of Propulsion, 2nd ed.; Addison–Wesley: Reading, MA, USA, 1992; Available online: https://books.google.com/books?id=uYJTAAAAMAAJ (accessed on 20 October 2025).

- Oppong, F.; van der Spuy, S.J.; von Backström, T.; Diaby, A.L. An Overview of Micro Gas Turbine Engine Performance Investigation. R & D J. 2015, 31, 35–41. Available online: https://www.researchgate.net/publication/315476537_An_overview_of_micro_gas_turbine_engine_performance_investigation (accessed on 20 October 2025).

- Chen, L.; Wei, D.; Lv, Y.; Gao, Y.; Wu, D.; Dong, H. Design, Modeling, and Control of a Personal Aerial System. J. Field Robot. 2025, 42, 3227–3251. [Google Scholar] [CrossRef]

- Wren Turbines Ltd. MW54 Mk2 & Mk3 Turbo-Jet: Kit Assembly and Instruction Manual; Wren Turbines Ltd.: Doncaster, UK, 2004; Available online: https://energiazero.org/cartelle/disegno/MW54-Modelling.pdf (accessed on 20 October 2025).

- Bartasevicius, J.; Fleig, P.A.T.; Metzner, A.; Hornung, M. Design and Testing of an In-Flight Thrust Measurement System for a Pylon-Mounted Miniature Jet Engine. In Proceedings of the AIAA SciTech 2022 Forum, San Diego, CA, USA, 3–7 January 2022; Available online: https://mediatum.ub.tum.de/doc/1639232 (accessed on 20 October 2025).

- Tărăbîc, C.M.; Cican, G.; Olariu, C.; Dediu, G.; Catană, R.M. Test Stand for Microjet Engine Prototypes. Machines 2024, 12, 688. Available online: https://www.mdpi.com/2075-1702/12/10/688 (accessed on 20 October 2025). [CrossRef]

- Cican, G. Experimental Transient Process Analysis of Micro-Turbojet Aviation Engines: Comparing the Effects of Diesel and Kerosene Fuels at Different Ambient Temperatures. Energies 2024, 17, 1366. [Google Scholar] [CrossRef]

- van Eck, H.; van der Spuy, S.J. Upgrading the Compressor Stage of the CAT250TJ Micro Gas Turbine Engine. Aerotec. Missili Spaz. 2025, 104, 91–104. Available online: https://link.springer.com/article/10.1007/s42496-024-00221-9 (accessed on 20 October 2025). [CrossRef]

- Sundararaj, R.H.; Sekar, T.C.; Kushari, A. Effect of nozzle exit area on the performance of a turbojet engine. Aerosp. Sci. Technol. 2021, 116, 106844. [Google Scholar] [CrossRef]

- Malinowski, L.; Lewandowska, M. Analytical model-based energy and exergy analysis of a gas microturbine at part-load operation. Appl. Therm. Eng. 2013, 57, 125–132. [Google Scholar] [CrossRef]

- Cican, G.; Silivestru, V.; Mirea, R.; Osman, S.; Popescu, F.; Sapunaru, O.V.; Ene, R. Performance and Emissions Assessment of a Micro-Turbojet Engine Fueled with Jet A and Blends of Propanol, Butanol, Pentanol, Hexanol, Heptanol, and Octanol. Fire 2025, 8, 150. [Google Scholar] [CrossRef]

- ASTM D7566-20b; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Gawron, B.; Białecki, T. Impact of a Jet A-1/HEFA blend on the performance and emission characteristics of a miniature turbojet engine. Int. J. Environ. Sci. Technol. 2018, 15, 1501–1508. Available online: https://link.springer.com/article/10.1007/s13762-017-1528-3 (accessed on 20 October 2025). [CrossRef]

- Badami, M.; Nuccio, P.; Pastrone, D.; Signoretto, A. Performance of a small-scale turbojet engine fed with traditional and alternative fuels. Energy Convers. Manag. 2014, 82, 219–228. [Google Scholar] [CrossRef]

- Cican, G.; Deaconu, M.; Mirea, R.; Ceatra, L.C.; Cretu, M. An Experimental Investigation to Use the Biodiesel Resulting from Recycled Sunflower Oil, and Sunflower Oil with Palm Oil as Fuels for Aviation Turbo-Engines. Int. J. Environ. Res. Public Health 2021, 18, 5189. Available online: https://www.mdpi.com/1660-4601/18/10/5189 (accessed on 20 October 2025). [CrossRef] [PubMed]

- Gawron, B.; Białecki, T. The laboratory test rig with miniature jet engine to research aviation fuels combustion process. J. KONBiN 2015, 36, 79–90. Available online: https://www.researchgate.net/publication/295857873_The_laboratory_test_rig_with_miniature_jet_engine_to_research_aviation_fuels_combustion_process (accessed on 20 October 2025). [CrossRef]

- Mirea, R.; Cican, G. Lab Scale Investigation of Gaseous Emissions, Performance and Stability of an Aviation Turbo-Engine While Running on Biodiesel Based Sustainable Aviation Fuel. Inventions 2024, 9, 16. [Google Scholar] [CrossRef]

- Gawron, B.; Górniak, A.; Białecki, T.; Janicka, A.; Włostowski, R.; Włóka, A.; Molska, J.; Zawiślak, M. Impact of a synthetic component on the emission of volatile organic compounds during the combustion process in a miniature turbine engine. Energies 2021, 14, 8462. [Google Scholar] [CrossRef]

- Xu, M.J.; Wang, J.; Liu, J.X.; Li, M.; Geng, J.; Wu, Y.; Song, Z.P. An improved hybrid modeling method based on extreme learning machine for gas turbine engine. Aerosp. Sci. Technol. 2020, 107, 106333. [Google Scholar] [CrossRef]

- Kurzawska-Pietrowicz, P. Comprehensive analysis of particle emissions from miniature turbojet engine. Combust. Engines 2025, 200, 12–18. [Google Scholar] [CrossRef]

- Gawron, B.; Białecki, T.; Janicka, A.; Zawiślak, M.; Górniak, A. Exhaust toxicity evaluation in gas turbine engine fueled by aviation fuel containing synthesized hydrocarbons. Aircraft Eng. Aerosp. Technol. 2020, 92, 60–66. [Google Scholar] [CrossRef]

- Yakovlieva, A.V.; Boichenko, S.V.; Zaremba, J. Improvement of Air Transport Environmental Safety by Implementing Alternative Jet Fuels. In Proceedings of the 2019 Modern Safety Technologies in Transportation (MOSATT), Košice, Slovakia, 28–29 November 2019; IEEE: Washington, DC, USA; pp. 146–151. [Google Scholar] [CrossRef]

- Ezgin, H.; Kırmızı, M.; Çelik, U.; Aygün, H. Analysis of energy and emission metrics for an experimental turbojet engine by regression approach. Energy Sources Part A Recover. Util. Environ. Eff. 2025, 47. in press. [Google Scholar] [CrossRef]

- Chapman, J.W.; Litt, J.S. Control Design for an Advanced Geared Turbofan Engine; NASA Technical Memorandum NASA/TM—2017-219569; NASA Glenn Research Center: Cleveland, OH, USA, 2017. Available online: https://ntrs.nasa.gov/citations/20170011210 (accessed on 20 October 2025).

- Zhang, J.; Liang, S.; Guo, M.; Wang, H.; Du, X.; Zhang, H.; Song, W. Research on Control of Micro-Turbojet Engine Based on All-Coefficient Adaptive Control. In Proceedings of the 2024 3rd International Symposium on Aerospace Engineering and Systems (ISAES), Nanjing, China, 22–24 March 2024. [Google Scholar] [CrossRef]

- Istenes-Németh, R.; Beneda, K.; Fozo, L. Development of a Hardware Simulator for a Micro Turbojet Engine. In Proceedings of the 2022 IEEE 20th Jubilee World Symposium on Applied Machine Intelligence and Informatics (SAMI), Poprad, Slovakia, 2–5 March 2022. [Google Scholar] [CrossRef]

- Talebi, S.S.; Tousi, A.M.; Madadi, A.; Kiaee, M. A methodology for identifying the most suitable measurements for engine level and component level gas path diagnostics of a micro gas turbine. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2022, 236, 2646–2661. [Google Scholar] [CrossRef]

- Toraman, S.; Aygün, H.; Dursun, O.O. Machine Learning Application to Forecasting Performance and Thermodynamics Parameters of Small Turbojet Engine. J. Therm. Anal. Calorim. 2025, 150, 505–519. [Google Scholar] [CrossRef]

- Wessley, G.J.J.; Chauhan, S. Modeling and Performance Simulation of a Micro Turbojet Engine Using Flownex. Indian J. Sci. Technol. 2019, 12, 1–5. [Google Scholar] [CrossRef]

- Experimental Study on the Effect of Water Injection on a Micro Turbojet Engine. ResearchGate, Preprint. 2022. Available online: https://www.researchgate.net/publication/363160666_Experimental_Study_on_the_Effect_of_Water_Injection_on_a_Micro_Turbojet_Engine (accessed on 20 October 2025).

- Kilic, U.; Villareal-Valderrama, F.; Ayar, M.; Ekici, S.; Brooks, L.A.; Karakoc, T.H. Deep learning-based forecasting modeling of micro gas turbine performance projection: An experimental approach. Eng. Appl. Artif. Intell. 2024, 130, 107769. [Google Scholar] [CrossRef]

- Ashry, M.M.; Kamel, M.K.; Shehata, A.M. Modeling of Micro Turbojet Engine. In Proceedings of the AIAA Propulsion and Energy Forum, Indianapolis, IN, USA, 19–22 August 2019; p. 3911. [Google Scholar] [CrossRef]

- Lee, C.; Choi, S.M. A study on the mixing and infrared signal characteristics of a lobed mixer in a micro turbojet engine. Aeronaut. J. 2025, 129, 1579–1600. [Google Scholar] [CrossRef]

- Wang, W.H.; He, L.D.; Sun, Y.; Wang, Z.J.; Zhang, H.; Bao, Q.Q.; Jia, X.Y.; Dong, H.Y. Research on new integral squeeze film damper vibration control of micro turbojet engine at high speed. Int. J. Turbo Jet Engines 2024, 40 (Suppl. S1), s451–s462. [Google Scholar] [CrossRef]

- Antonov, D.V.; Cherkasov, R.E.; Yanovskiy, L.S. Comprehensive approach to static firing tests of micro gas turbine engines powered by liquid fuels. Energy 2024, 313, 133870. [Google Scholar] [CrossRef]

- Wu, X.H.; Hu, X.A.; Tian, F.Y. An analysis approach for micro gas turbine engine’s performance by experiment and numerical simulation. Case Stud. Therm. Eng. 2023, 49, 103305. [Google Scholar] [CrossRef]

- Aygun, H.; Dursun, O.O.; Dönmez, K.; Sahin, O.; Toraman, S. Prediction of performance characteristics of an experimental micro turbojet engine using machine learning approaches. Energy 2024, 313, 133997. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, M.H.; Li, G.Z.; Hu, X.H.; Yang, P.F.; Zhu, M.Y.; Zhang, B.; Chang, L.Y.; Chen, L.F. Experimental Investigation of Particulate Number Measurement Methodology for Micro-Turbojet Engine Emissions. Aerospace 2024, 11, 548. [Google Scholar] [CrossRef]

- Bogoi, A.; Cican, G.; Gall, M.; Totu, A.; Crunteanu, D.E.; Leventiu, C. Comparative Study of Noise Control in Micro Turbojet Engines with Chevron and Ejector Nozzles Through Statistical, Acoustic and Imaging Insight. Appl. Sci. 2025, 15, 394. [Google Scholar] [CrossRef]

- Nasiri, M.; Montazeri-Gh, M.; Salehi, A.; Bayati, E. Time Delay Compensation for Hardware-in-the-loop Simulation of a Turbojet Engine Fuel Control Unit Using Neural NARX Smith Predictor. Int. J. Control Autom. Syst. 2021, 19, 3309–3317. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Nasiri, M. Hardware-in-the-loop simulation for testing of electro-hydraulic fuel control unit in a jet engine application. Simulation 2013, 89, 225–233. [Google Scholar] [CrossRef]

- Lee, D.; Chung, H.; Rhee, D.H. A Study of an Integrated Analysis Model with Secondary Flow for Assessing the Performance of a Micro Turbojet Engine. Appl. Sci. 2024, 14, 7606. [Google Scholar] [CrossRef]

- Shehata, A.M.; Khalil, M.K.; Ashry, M.M. Adaptive Fuzzy PID Controller applied to micro turbojet engine. J. Phys. Conf. Ser. 2021, 2128, 012030. [Google Scholar] [CrossRef]

- Wang, C.S.; Zhu, Z.H.; Lu, N.Y.; Cheng, Y.H.; Jiang, B. A data-driven degradation prognostic strategy for aero-engine under various operational conditions. Neurocomputing 2021, 462, 195–207. [Google Scholar] [CrossRef]

- Yan, W.J.; Li, T.J.; Xing, X.Y.; Wang, X.B.; Liu, D. Experimental study on surface temperature and emissivity of rotating turbine blades of a micro turbojet engine. Appl. Therm. Eng. 2025, 259, 124811. [Google Scholar] [CrossRef]

- Mo, D.; Lin, Y.Z.; Liu, Y.X.; Chen, Z.J.; Han, X. Characterization and validation of low emission mechanisms in hydrogen micromix diffusion combustor. Appl. Therm. Eng. 2025, 274, 126497. [Google Scholar] [CrossRef]

- Huang, H.Z.; Chen, G.X.; Long, H.G.; Lei, B.J.; Liang, J.G. Gear-Shaped High-g Combustion Chamber for Micro Turbojet Engine Applications. ACS Omega 2024, 9, 18674–18685. [Google Scholar] [CrossRef]

- Zhang, X.B.; Ji, F.Z.; Du, F.R.; Ding, S.T.; Zhou, Y. Investigation on energy consumption of electric vehicle with micro gas turbine as a range-extender under various driving cycles. Int. J. Veh. Des. 2022, 88, 216–237. [Google Scholar] [CrossRef]

- Ma, P.W.; Wang, H.; Li, D.W.; Yuan, S.H.; Fan, X.L. Passive acoustic liners for aero-engine noise control: A review. Mech. Adv. Mater. Struct. 2024, 31, 12834–12849. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).