Impact of Crown-Type Cage Eccentricity in New Energy Vehicle Motor Ball Bearings on Their Dynamic Performance

Abstract

1. Introduction

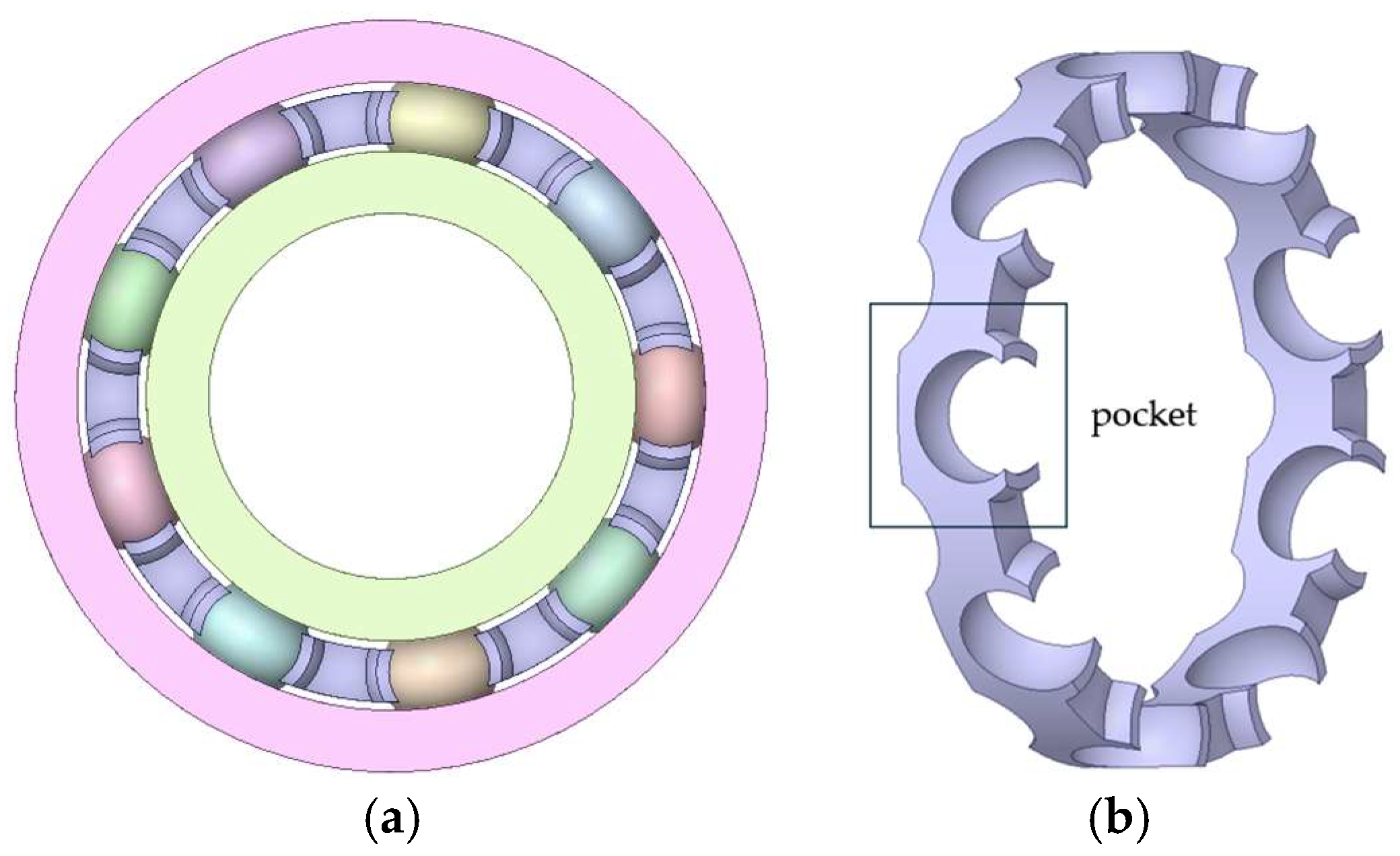

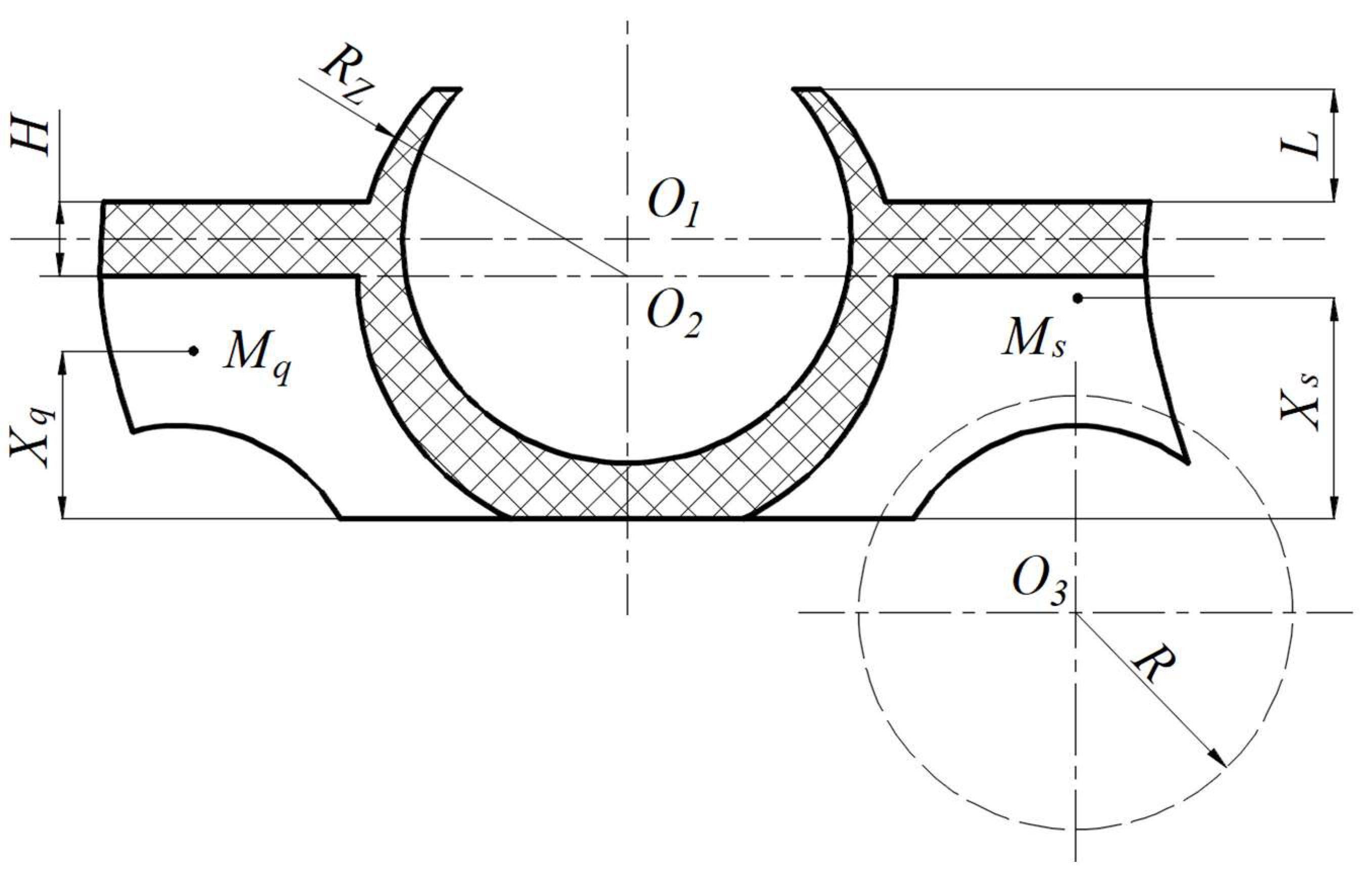

2. Geometric Structure of the Crown-Type Cage

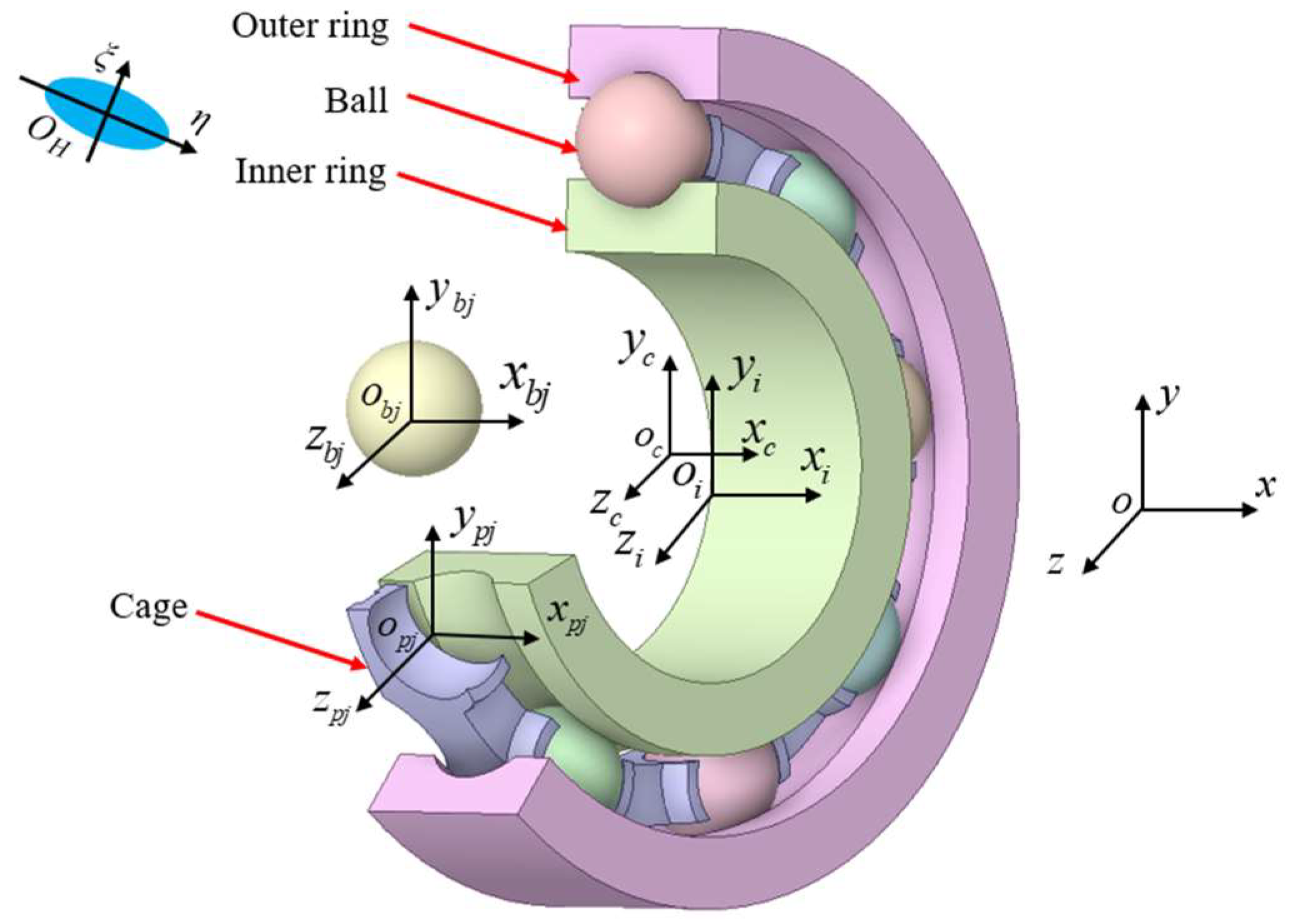

3. Deep Groove Ball Bearing Dynamics Model

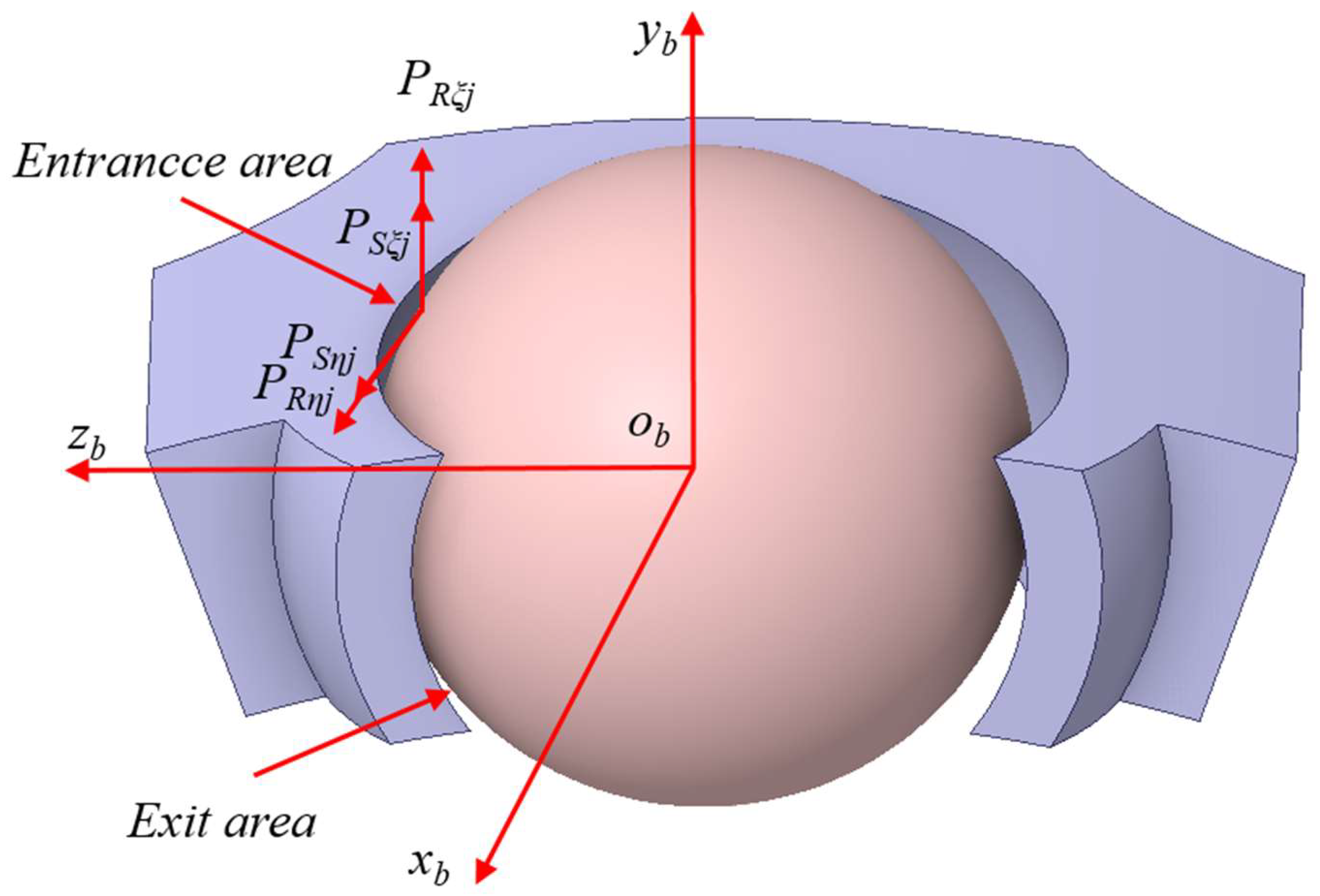

3.1. Deep Groove Ball Bearing Coordinate System

3.2. Interaction Between Cage and Balls

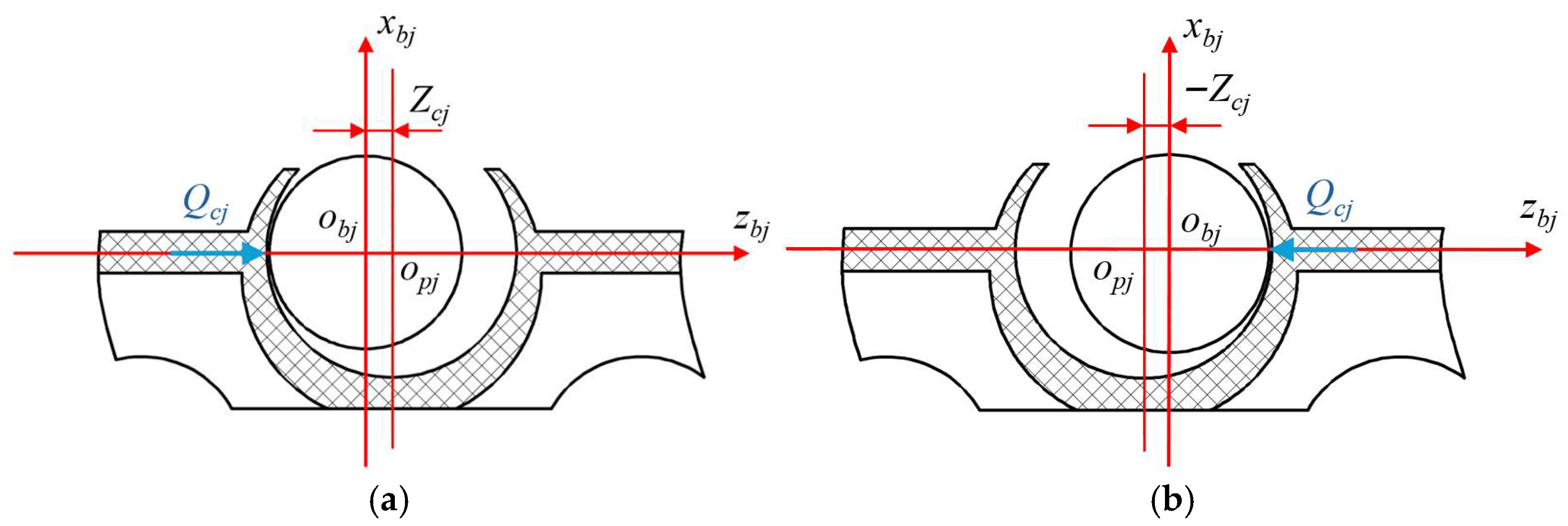

3.2.1. Normal Force Between Pocket and Ball

3.2.2. Hydrodynamic Friction Force Between Pocket and Ball

3.3. Flexible Body Dynamics Differential Equation of the Cage

3.4. Cage Vibration Acceleration Level

4. Simulation Analysis

4.1. Flexibilization of the Crown-Type Cage

4.2. Flexible Cage Strength Analysis

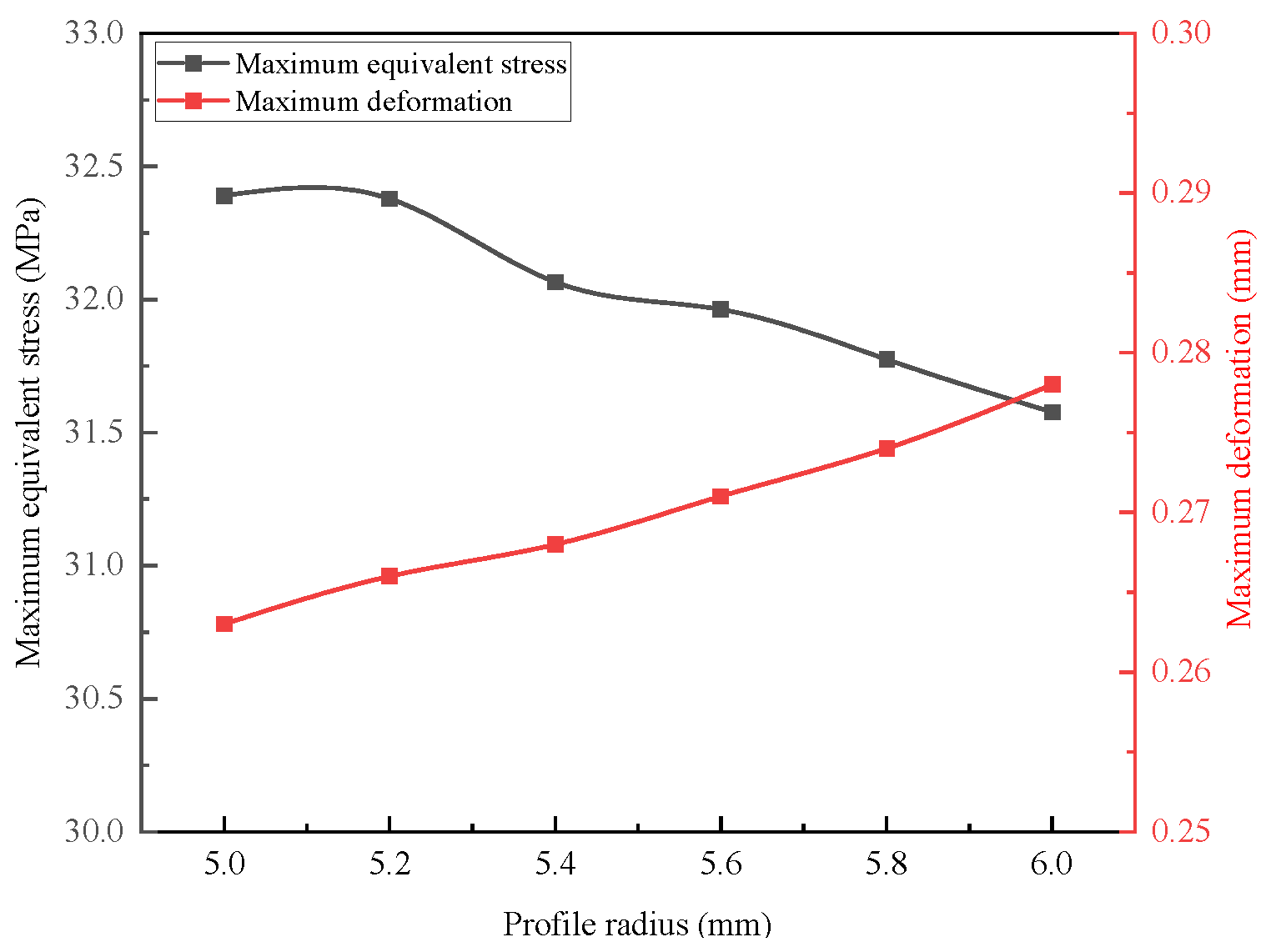

4.2.1. Influence of Profile Radius R on Cage Strength

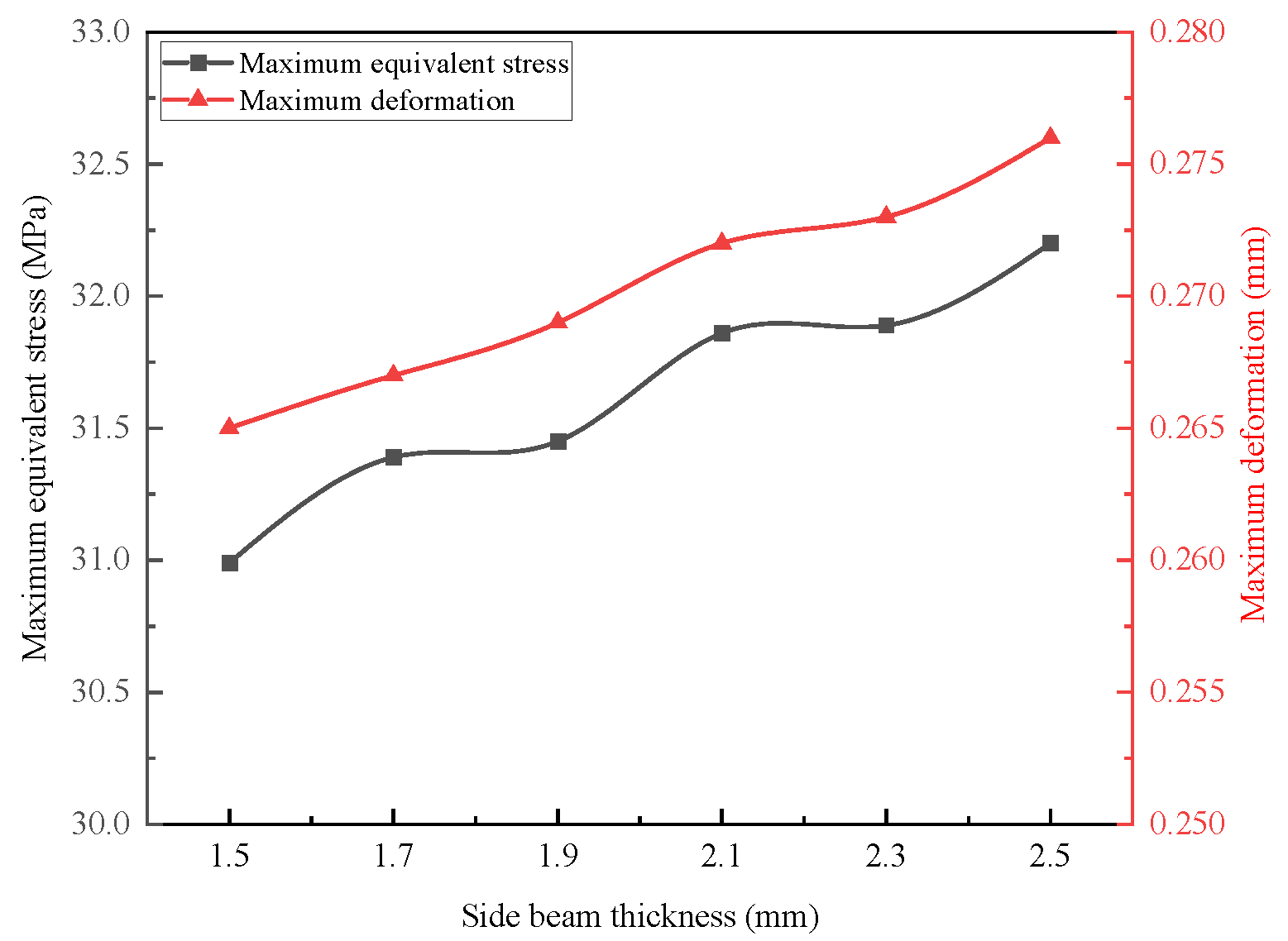

4.2.2. Influence of Side Beam Thickness H on Cage Strength

4.2.3. Influence of Claw Length L on Cage Strength

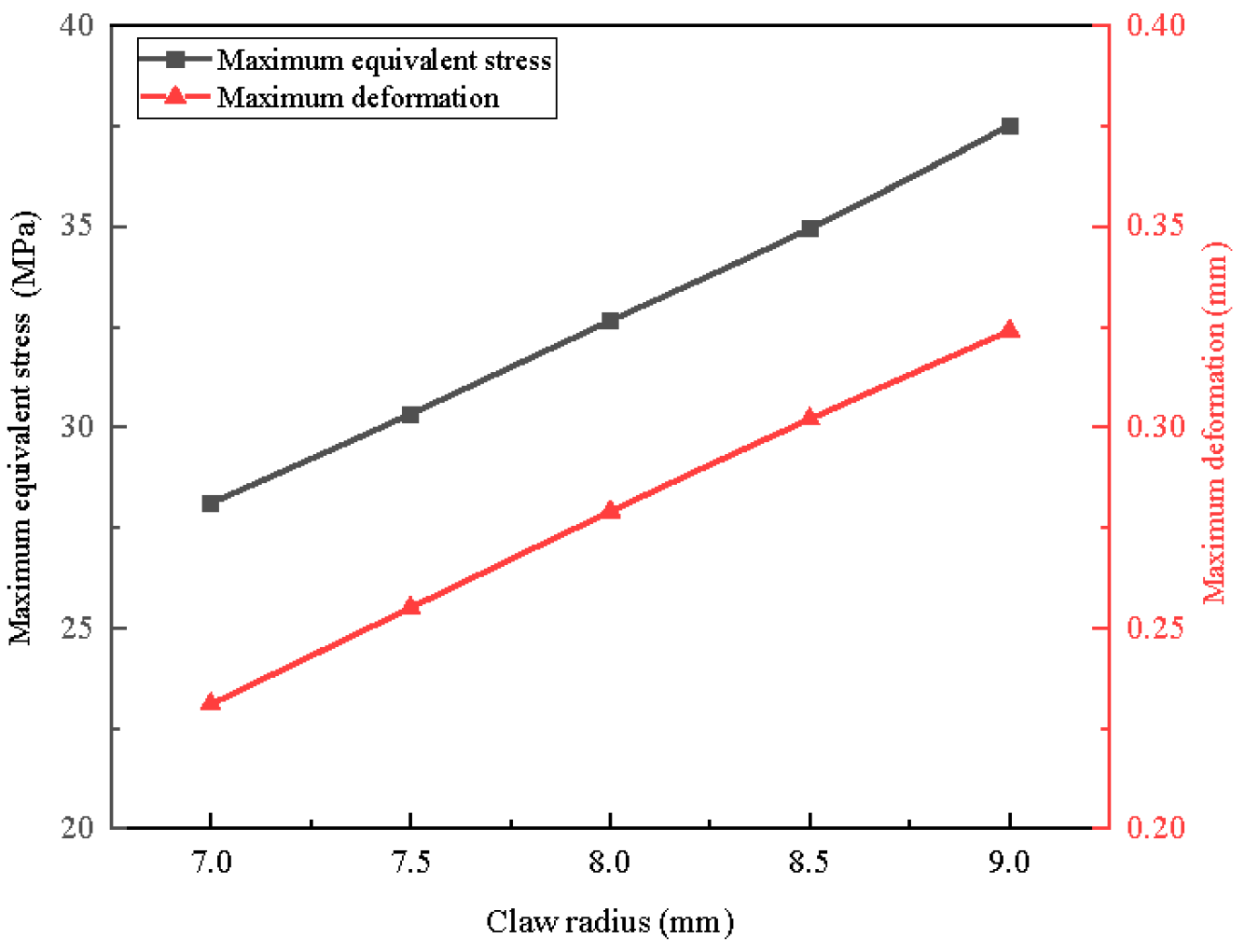

4.2.4. Influence of Claw Radius Rz on Cage Strength

4.3. Flexible Cage Stability Analysis

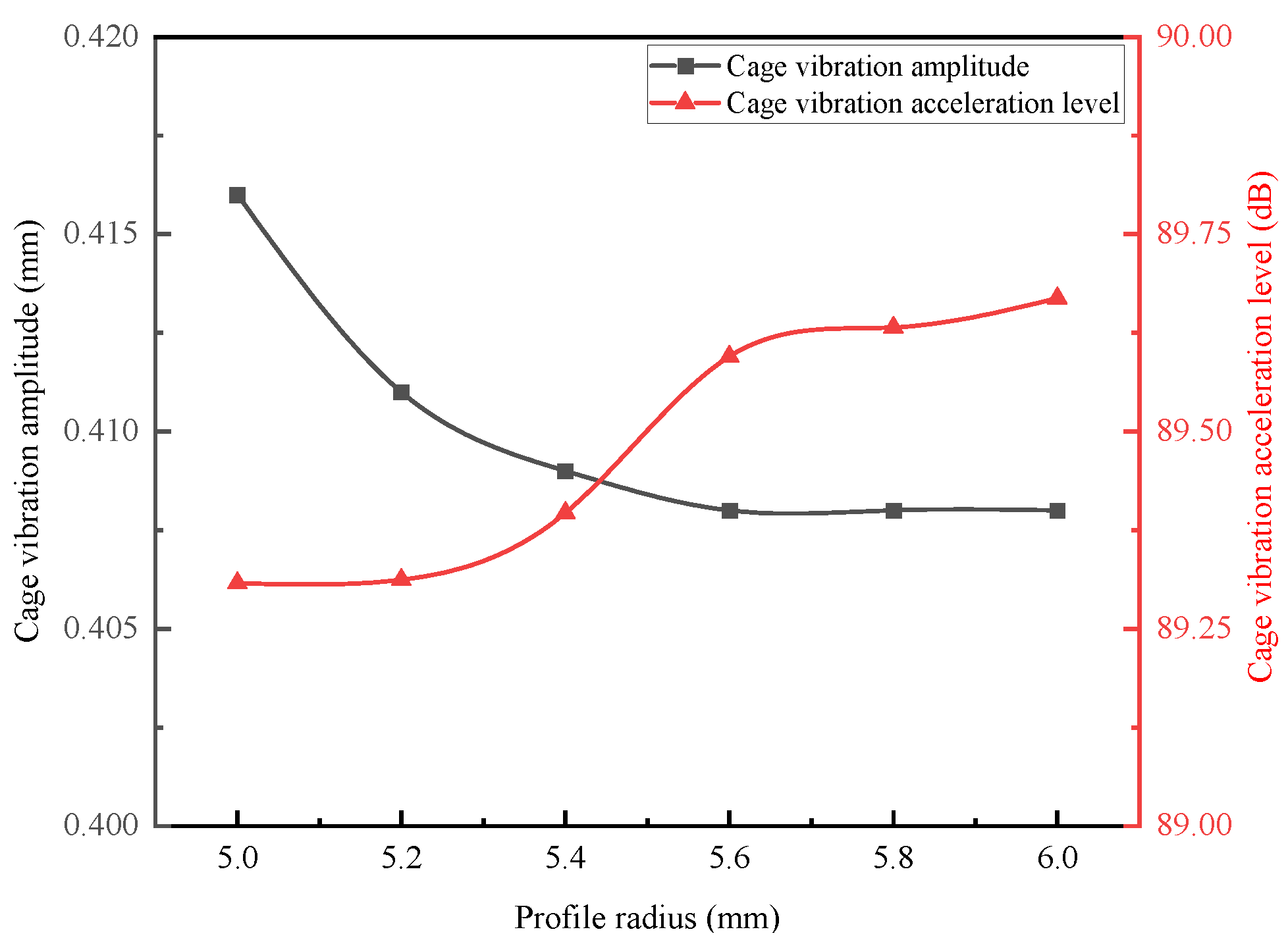

4.3.1. Influence of Profile Radius R on Cage Operational Stability

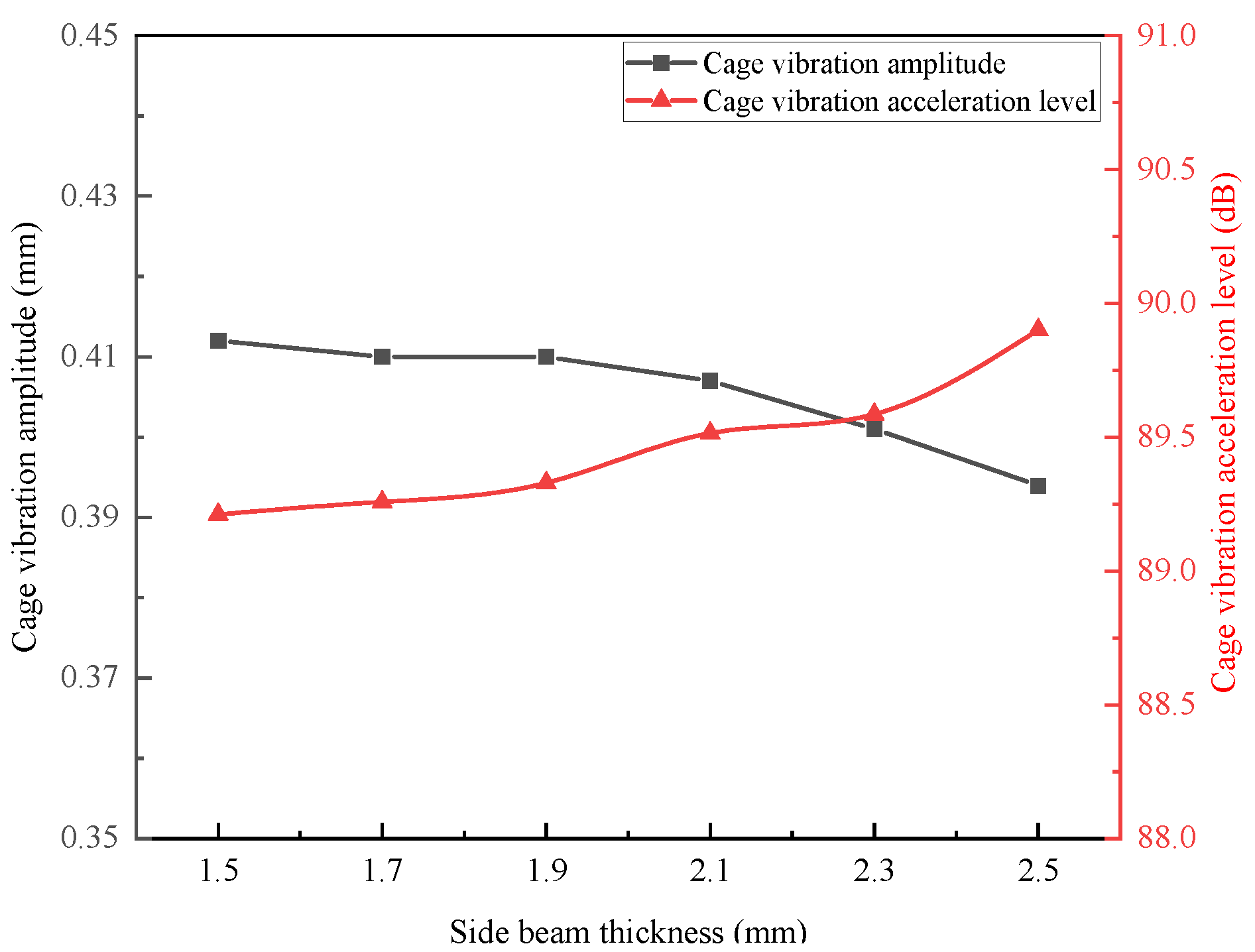

4.3.2. Influence of Side Beam Thickness H on Cage Operational Stability

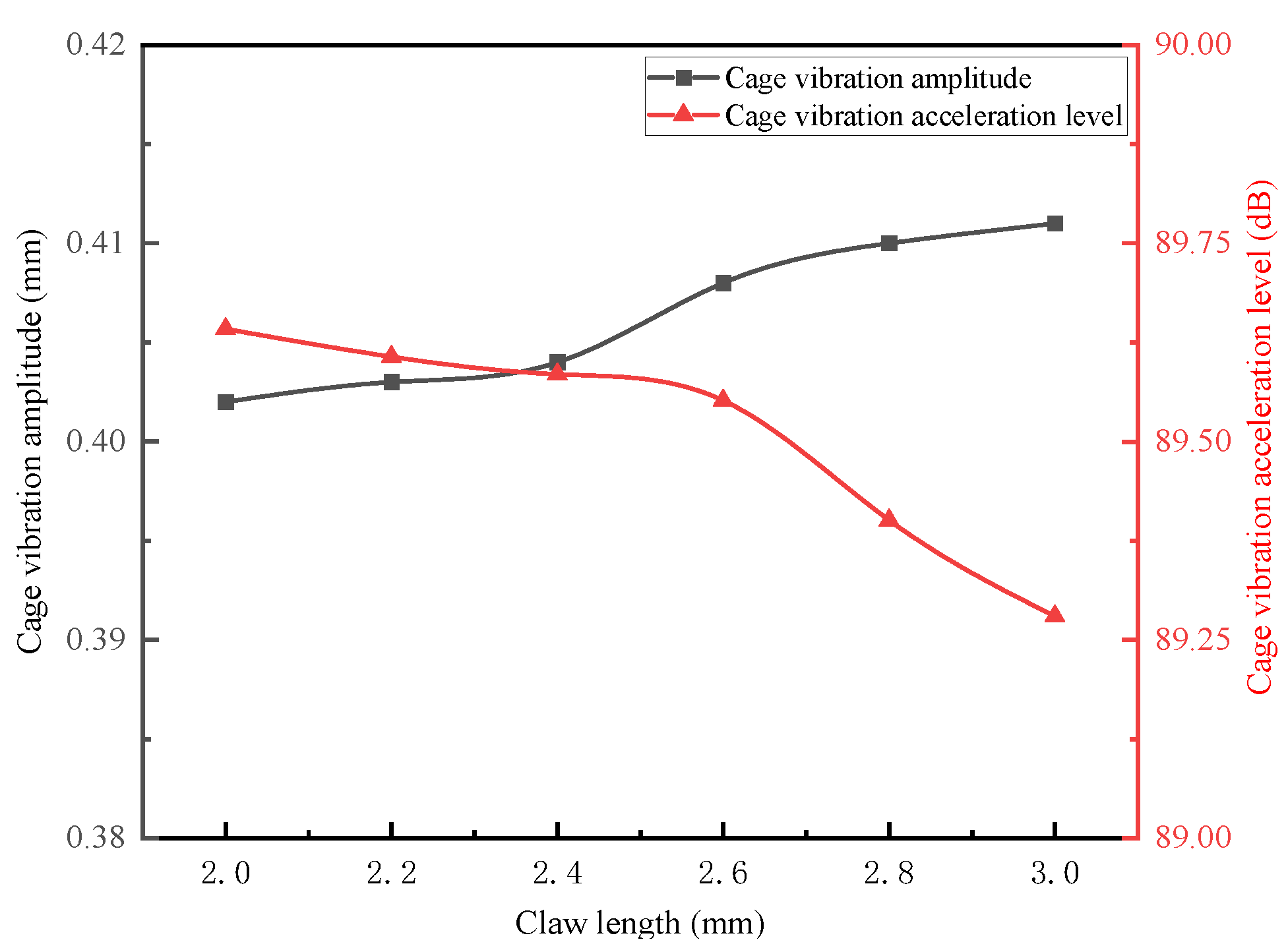

4.3.3. Influence of Claw Length L on Cage Operational Stability

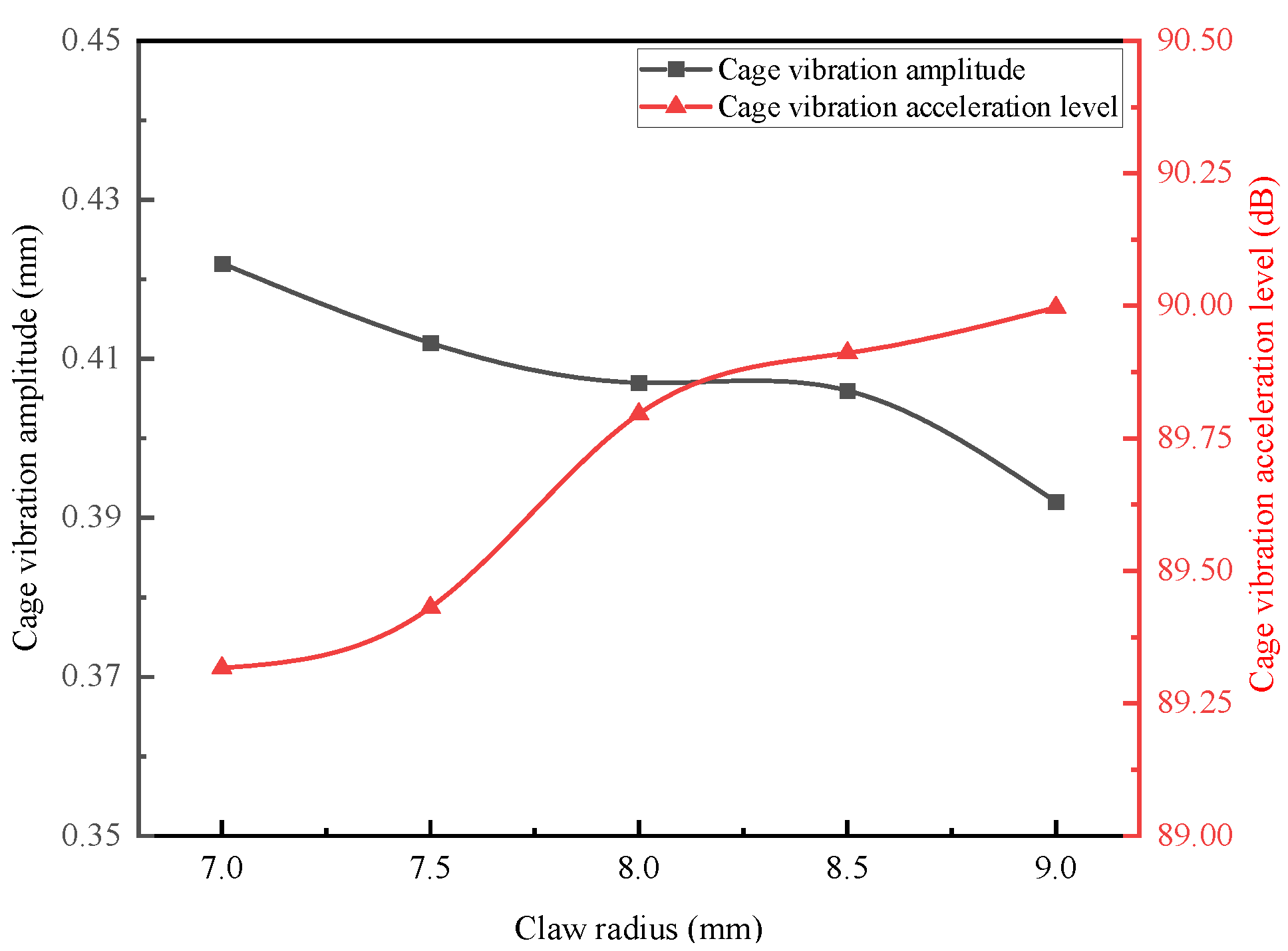

4.3.4. Influence of Claw Radius Rz on Cage Operational Stability

5. Conclusions

- Stress and Deformation Distribution: The claw ends of the crown-type cage pockets are particularly vulnerable to deformation, with the maximum equivalent stress occurring at the bottom of the pocket. This location is critical, as it represents the primary site for potential cage fracture failure.

- Influence of Eccentricity on Strength: A reduction in cage eccentricity leads to a decrease in equivalent stress, while simultaneously increasing the maximum deformation of the cage. For example, when the profile radius R increases from 5.0 mm to 6.0 mm, the eccentricity decreases by approximately 27%, resulting in an approximate 2.5% reduction in equivalent stress. However, this change also leads to a maximum deformation increase of about 5.7%. These findings indicate that in the pursuit of a lightweight cage design, structural parameters should be optimized according to specific functional requirements, carefully balancing the priorities of low stress and minimal deformation in relation to cage eccentricity.

- Influence of Centrifugal Force: An analysis of the side beam thickness and claw radius indicates that the strength of the cage is significantly affected not only by eccentricity but also by the centrifugal force exerted by the cage itself. The equivalent stress is observed to increase with the centrifugal force. For instance, when the side beam thickness (H) is increased from 1.5 mm to 2.5 mm—resulting in an increase in mass and centrifugal force—the eccentricity decreases; however, the equivalent stress still rises by approximately 3.9%.

- Influence of Eccentricity on Stability: The eccentricity of the crown-type cage significantly influences its operational stability. A decrease in cage eccentricity leads to a reduction in the collision force between the balls and the cage, as well as a decrease in the cage’s vibration amplitude. However, this reduction in eccentricity also results in an increase in the vibration acceleration level due to a decrease in the additional resistance torque caused by axial asymmetry. For instance, an increase in the profile radius (R) results in the ball–cage collision force decreasing from 5.50 N to 4.71 N (approximately a 14.4% decrease), the cage vibration amplitude decreasing from 0.416 mm to 0.408 mm, and the cage vibration acceleration level increasing from 89.308 dB to 89.669 dB. Therefore, from a stability perspective, it is not necessarily true that smaller eccentricity is always better; a targeted design is required based on functional requirements, whether aiming for lower collision force/amplitude or lower vibration acceleration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Yang, L.; Li, J.; Yu, X.K.; Yin, Y.J. Effect of Cage Pocket Geometry on Dynamic Friction Torque of High—Speed Ball Bearings. J. Bear. 2015, 7, 34–36. [Google Scholar]

- Ye, Z.H.; Li, W.; Qu, X.J.; Xiong, Z.G. Effect of Elliptical Pocket on Cage Dynamic Performance of High Speed Ball Bearings. J. Mech. Des. Manuf. 2016, 6, 184–187+191. [Google Scholar]

- Zheng, H.T.; Li, Q.L.; Yin, Y.J.; Wei, L.; Li, D.Y.; Niu, Q.B. Analysis of Impact Load Between Bearing Ball and Retainer Based on ADAMS. J. Mech. Elect. Eng. Technol. 2019, 48, 33–35. [Google Scholar]

- Choe, B.; Lee, J.; Jeon, D.; Lee, Y. Experimental Study on Dynamic Behavior of Ball Bearing Cage in Cryogenic Environments, Part I: Effects of Cage Guidance and Pocket Clearances. J. Mech. Syst. Signal Proc. 2019, 115, 545–569. [Google Scholar] [CrossRef]

- Choe, B.; Kwak, W.; Jeon, D.; Lee, Y. Experimental Study on Dynamic Behavior of Ball Bearing Cage in Cryogenic Environments, Part II: Effects of Cage Mass Imbalance. J. Mech. Syst. Signal Proc. 2019, 116, 25–39. [Google Scholar] [CrossRef]

- Hu, L.; Pueh, L.H.; Wang, D.; Wang, Z. Fatigue Failure of High Precision Spindle Bearing Under Extreme Service Conditions. J. Eng. Fail. Anal. 2024, 158, 107951. [Google Scholar] [CrossRef]

- Man, W.W.; Zhang, W.H.; Zheng, Y.W.; Deng, S.E. Influence on Traction Characteristics of Lubricating Oil on Motion Stability for Cages in High Speed Angular Contact Ball Bearings. J. Bear. 2017, 11, 31–37. [Google Scholar]

- Li, T.; Yang, L.Y.; Liu, D.L.; Zhou, M.; Jin, C. Deformation and Modal Analysis of Plastic Cage Lock of Ball Bearing. J. Coal Mine Mach. 2020, 41, 82–84. [Google Scholar]

- Ma, S.J.; Tian, C.; Yang, C.; Yan, K.; Lenci, S.; Hong, J. New Bearing Model with Flexible Cage and Study of Dynamic Behavior under Variable-speed. Mech. Syst. Signal Process. 2024, 208, 111045. [Google Scholar] [CrossRef]

- Wang, M.K.; Yan, K.; Tang, Q.; Guo, J.D.; Zhu, Y.S.; Hong, J. Dynamic Modeling and Properties Analysis for Ball Bearing Driven by Structure Flexible Deformations. Tribol. Int. 2023, 179, 108163. [Google Scholar] [CrossRef]

- Zhang, H.; Lei, X.L.; He, Y. The Effect of Geometric and Working Parameters on Dynamic Performance of Flexible Cages on Bearings. J. Flight Control Detect. 2021, 4, 73–79. [Google Scholar]

- Zhao, D.T.; Hong, J.; Yan, K.; Zhao, Q.Q.; Fang, B. Dynamic Interaction between the Rolling Element and Cage of Rolling Bearing Considering Cage Flexibility and Clearance. Mech. Mach. Theory 2022, 174, 104905. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Chen, Z.G.; Tang, L.; Zhai, W.M. Skidding Dynamic Performance of Rolling Bearing with Cage Flexibility Under Accelerating Conditions. Mech. Syst. Signal Proc. 2021, 150, 107257. [Google Scholar] [CrossRef]

- Yao, T.Q.; Xie, W.; Tan, Y. Flexible Multi-Body Dynamics Analysis on Cage of Angular Contact Ball Bearings. China Mech. Eng. 2014, 25, 117–122. [Google Scholar]

- Sadeghi, F.; Weinzapfel, N. A Discrete Element Approach for Modeling Cage Flexibility in Ball Bearing Dynamics Simulations. J. Tribol. 2009, 131, 021102. [Google Scholar] [CrossRef]

- Ma, X.M.; Wang, R.D.; Zhu, Y.T.; Li, Y.F.; Shi, L.W. Dynamic Performance Analysis of Drive Motor Bearing of New Energy Vehicle. J. Harbin Bearing 2022, 43, 3–11+21. [Google Scholar]

- Ashtekar, A.; Sadeghi, F. A New Approach for Including Cage Flexibility in Dynamic Bearing Models by Using Combined Explicit Finite and Discrete Element Methods. J. Tribol. 2012, 134, 041502. [Google Scholar] [CrossRef]

- Wang, M.K.; Yan, K.; Liu, Z.T.; Chen, F.; Hong, J. Transient Collision Behavior and Cage Instable Whirling Mechanism in Ball Bearings: Modeling Approach and Properties Investigation. Tribol. Int. 2023, 185, 108497. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, J.Q.; Zhang, W. Theoretical and Experimental Approaches for Flexible Cage Dynamic Characteristics of Four-point Contact Ball Bearing Considering Multi-point Contact Behaviors. Mech. Syst. Signal Process. 2025, 223, 111929. [Google Scholar]

- Xie, P.F.; Su, M.; Jiang, Y.H.; Liang, X.D.; Deng, S.E. Dynamic Performance Analysis on Angular Contact Ball Bearing with Two-piece Ring Based on ADAMS. J. Bear. 2010, 8, 1–4+9. [Google Scholar]

- Yao, T.Q.; Wang, L.H.; Liu, X.B.; Huang, Y.Y. Multibody Dynamics Simulation of Thin-Walled Four-Point Contact Ball Bearing with Interactions of Balls, Ring Raceways and Crown-Type Cage. Multibody Syst. Dyn. 2020, 48, 337–372. [Google Scholar] [CrossRef]

- Meng, D.Z.; Wang, Y.J.; Gao, P.Y.; Liu, L. Transient Dynamic Characteristics Analysis and Deformation Research of Thin-walled Ball bearings. J. Constr. Mach. Equip. 2021, 52, 36–42+9. [Google Scholar]

- Yang, H.S.; Liu, Q.; Deng, S.E. Dynamic Characteristic Analysis of Angular Contact Ball Bearings with Two-piece Inner Rings in Aero-Engine Main Shafts Under Unsteady-State Conditions. Lubricants 2025, 13, 249. [Google Scholar] [CrossRef]

- Zhang, W.H.; Du, S.J.; Tian, H.; Huang, L. Cage Strength Analysis and Improvement of High-Speed Deep Groove Ball Bearings. Machines 2025, 13, 241. [Google Scholar] [CrossRef]

- Jia, X.F.; Zhang, W.H.; Zhao, B.H.; Cui, Y.C.; Deng, S.E. Influence of Structural Parameters of Deep Groove Ball Bearing Crown Cage on Its Performance. J. Bear. 2021, 12, 13–19. [Google Scholar]

| Component | Material | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|

| Inner Ring | GCr15 | 7810 | 208 | 0.30 |

| Outer Ring | GCr15 | 7810 | 208 | 0.30 |

| Ball | GCr15 | 7810 | 208 | 0.30 |

| Cage | Nylon 66 | 1140 | 8.3 | 0.28 |

| Density | Elastic Modulus | Poisson’s Ratio | Natural Frequencies | Number of Modes | Meshing Method | Minimum Mesh Size |

|---|---|---|---|---|---|---|

| 1140 kg/m3 | 8.3 GPa | 0.28 | 30 | 30 | Tetrahedral | 0.02 mm |

| Profile Radius R/mm | Mass/g | Geometric Center Pos./mm | Center of Mass Pos./mm | Eccentricity/mm |

|---|---|---|---|---|

| 5.0 | 3.601 | 5.185 | 4.238 | 0.947 |

| 5.2 | 3.549 | 5.185 | 4.2837 | 0.9013 |

| 5.4 | 3.493 | 5.185 | 4.3364 | 0.8486 |

| 5.6 | 3.433 | 5.185 | 4.3839 | 0.8011 |

| 5.8 | 3.369 | 5.185 | 4.4388 | 0.7462 |

| 6.0 | 3.301 | 5.185 | 4.492 | 0.693 |

| Side Beam Thickness H/mm | Mass/g | Geometric Center Pos./mm | Center of Mass Pos./mm | Eccentricity/mm |

|---|---|---|---|---|

| 1.5 | 3.285 | 5.185 | 4.3911 | 0.7939 |

| 1.7 | 3.306 | 5.185 | 4.4045 | 0.7805 |

| 1.9 | 3.326 | 5.185 | 4.4173 | 0.7677 |

| 2.1 | 3.347 | 5.185 | 4.4284 | 0.7566 |

| 2.3 | 3.369 | 5.185 | 4.4388 | 0.7462 |

| 2.5 | 3.390 | 5.185 | 4.4471 | 0.7379 |

| Claw Length L/mm | Mass/g | Geometric Center Pos./mm | Center of Mass Pos./mm | Eccentricity/mm |

|---|---|---|---|---|

| 2.0 | 3.260 | 5.085 | 4.3454 | 0.7396 |

| 2.2 | 3.285 | 5.185 | 4.3911 | 0.7939 |

| 2.4 | 3.310 | 5.285 | 4.4371 | 0.8479 |

| 2.6 | 3.335 | 5.385 | 4.4839 | 0.9011 |

| 2.8 | 3.360 | 5.485 | 4.5314 | 0.9536 |

| 3.0 | 3.360 | 5.685 | 4.579 | 1.006 |

| Profile Radius R/mm | Mass/g | Geometric Center Pos./mm | Center of Mass Pos./mm | Eccentricity/mm |

|---|---|---|---|---|

| 7.0 | 3.137 | 5.085 | 4.1542 | 0.9308 |

| 7.5 | 3.260 | 5.085 | 4.3443 | 0.7407 |

| 8.0 | 3.379 | 5.085 | 4.5162 | 0.4588 |

| 8.5 | 3.497 | 5.085 | 4.6734 | 0.4116 |

| 9.0 | 3.613 | 5.085 | 4.8181 | 0.2669 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Zhang, J.; Zhang, R.; Shi, Z.; Dong, H. Impact of Crown-Type Cage Eccentricity in New Energy Vehicle Motor Ball Bearings on Their Dynamic Performance. Machines 2025, 13, 991. https://doi.org/10.3390/machines13110991

Yang H, Zhang J, Zhang R, Shi Z, Dong H. Impact of Crown-Type Cage Eccentricity in New Energy Vehicle Motor Ball Bearings on Their Dynamic Performance. Machines. 2025; 13(11):991. https://doi.org/10.3390/machines13110991

Chicago/Turabian StyleYang, Haisheng, Jiahang Zhang, Run Zhang, Zhanwang Shi, and Haiyang Dong. 2025. "Impact of Crown-Type Cage Eccentricity in New Energy Vehicle Motor Ball Bearings on Their Dynamic Performance" Machines 13, no. 11: 991. https://doi.org/10.3390/machines13110991

APA StyleYang, H., Zhang, J., Zhang, R., Shi, Z., & Dong, H. (2025). Impact of Crown-Type Cage Eccentricity in New Energy Vehicle Motor Ball Bearings on Their Dynamic Performance. Machines, 13(11), 991. https://doi.org/10.3390/machines13110991