Time-Domain and Neural Network-Based Diagnosis of Bearing Faults in Induction Motors Under Variable Loads

Abstract

1. Introduction

- To demonstrate that bearing fault diagnosis under variable load conditions can be effectively performed in the time domain analysis, demonstrating that complex signal processing can be replaced.

- To verify that the machine learning algorithms of the proposed Method 2 enable accurate and rapid diagnosis under variable load conditions.

2. Theoretical Background

2.1. Statistical Features

2.2. Independent t-Test

2.3. Support Vector Machine

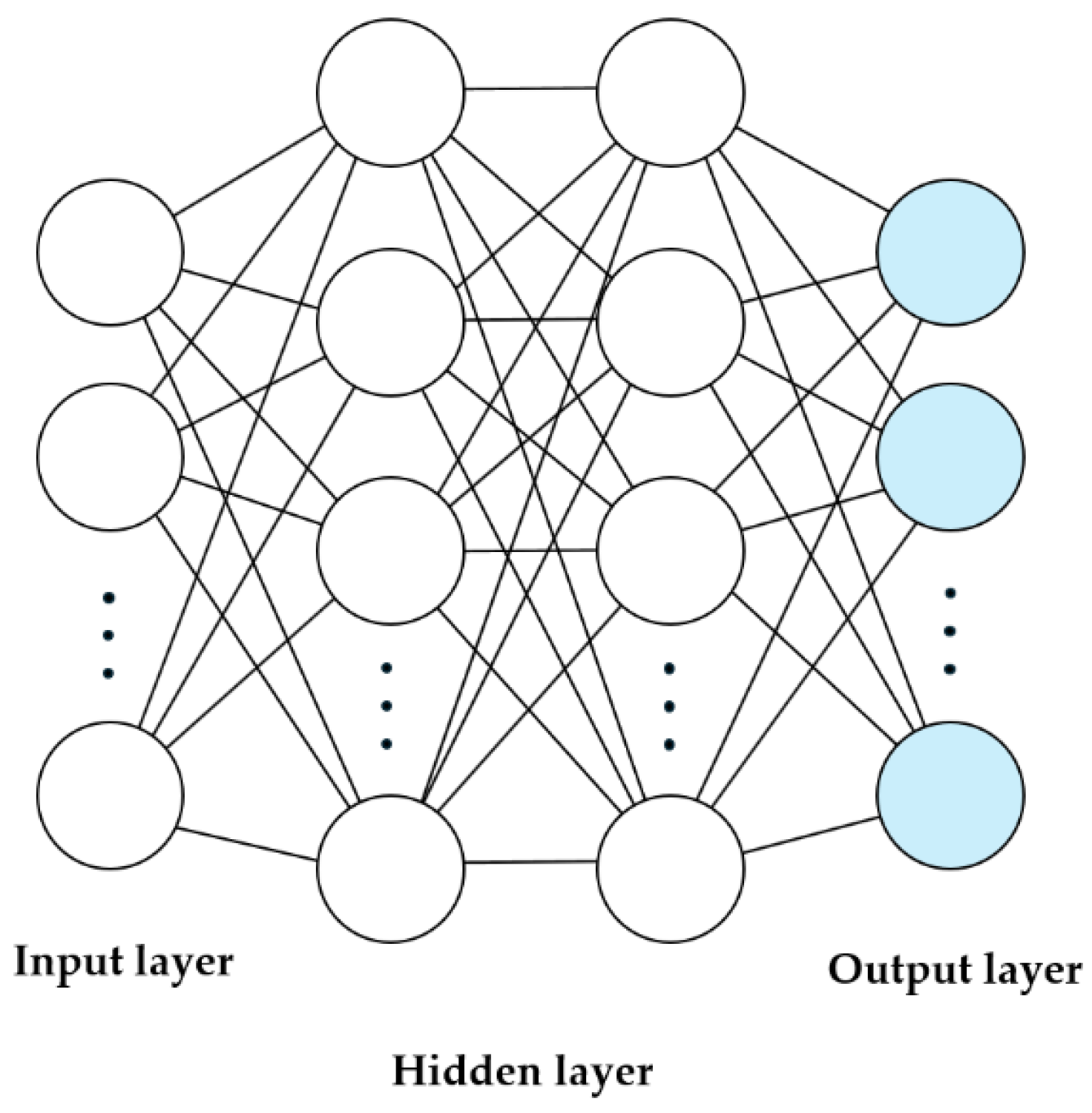

2.4. Multilayer Neural Network

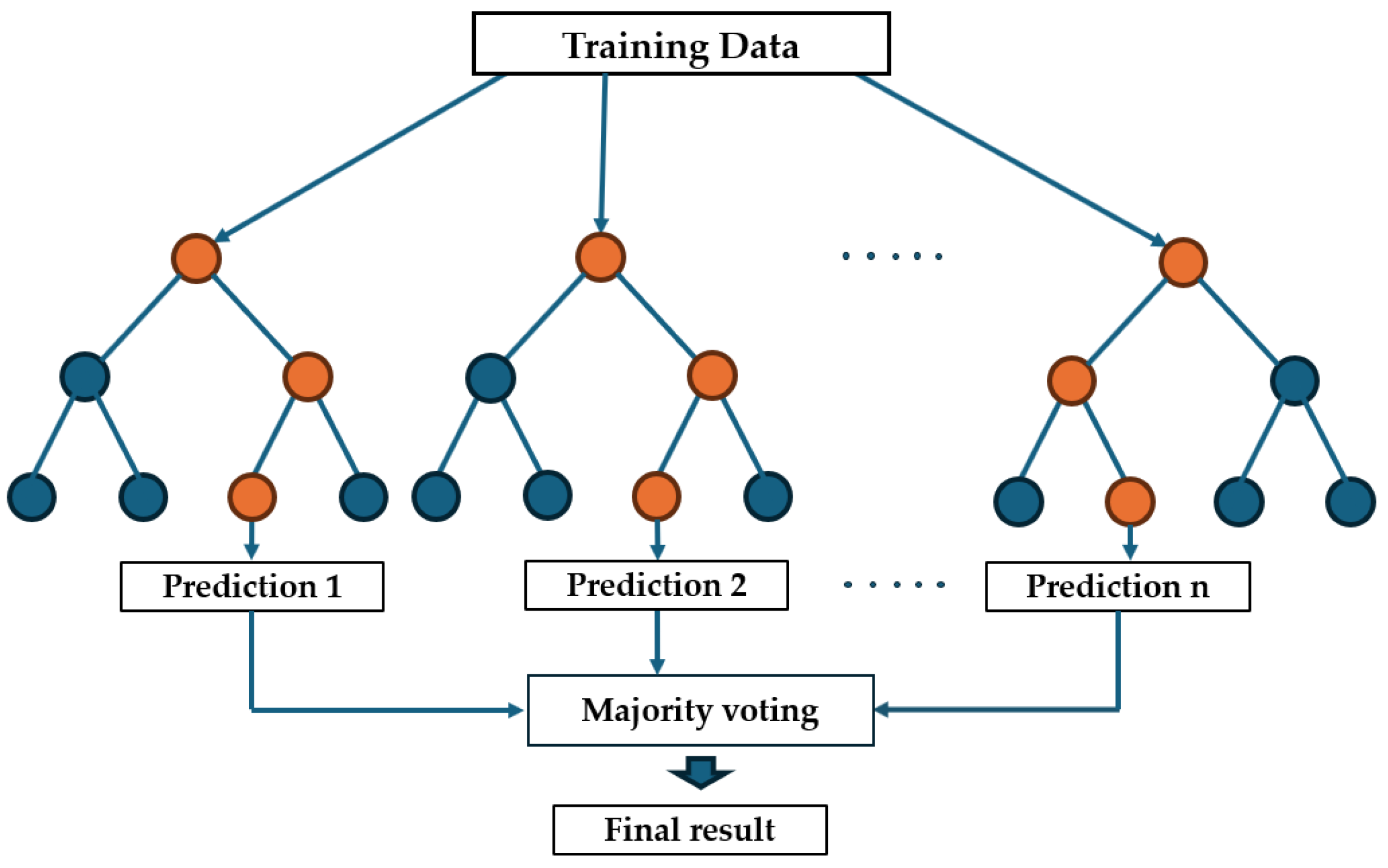

2.5. Random Forest

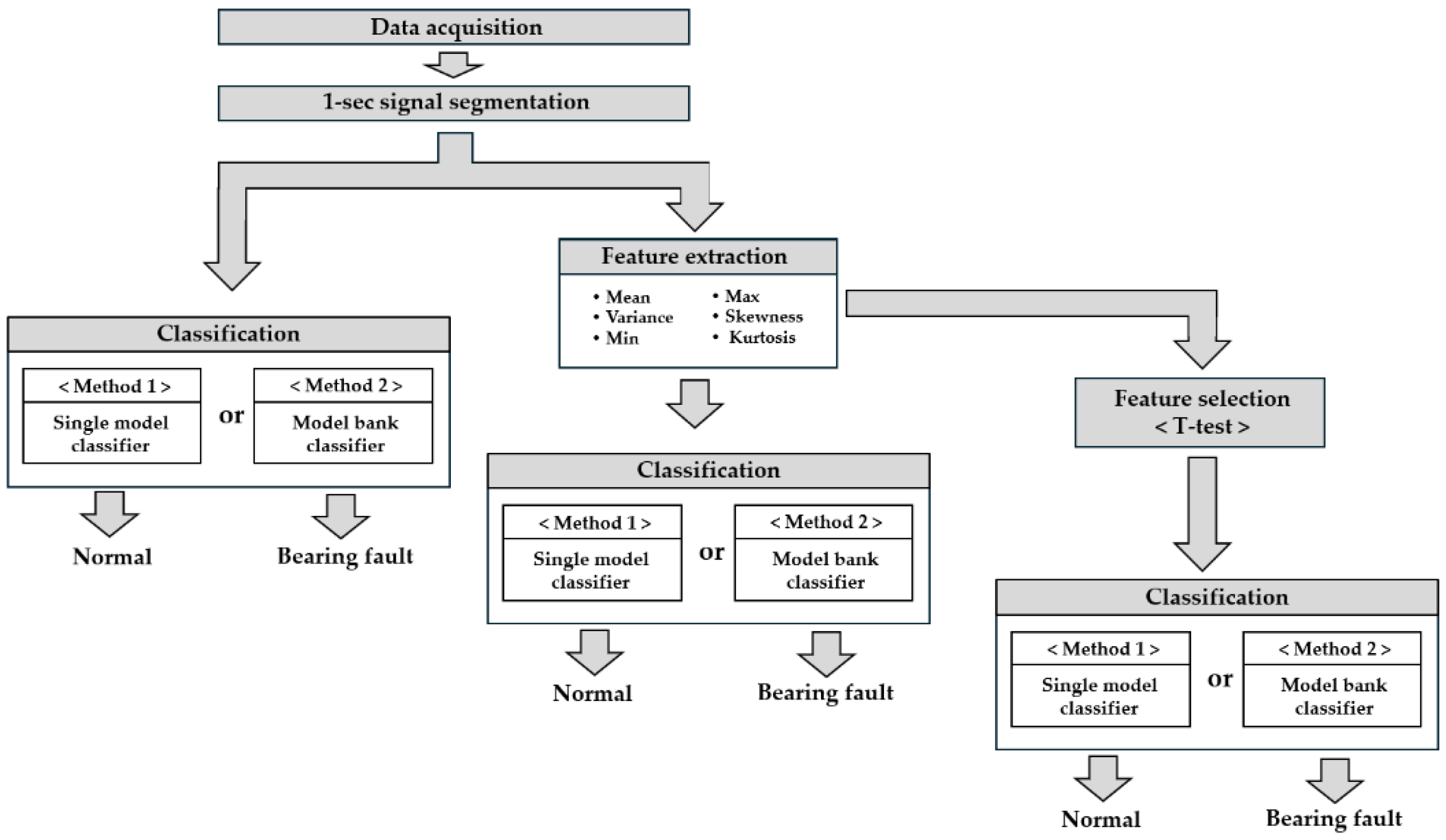

3. Proposed Fault Diagnosis Algorithm

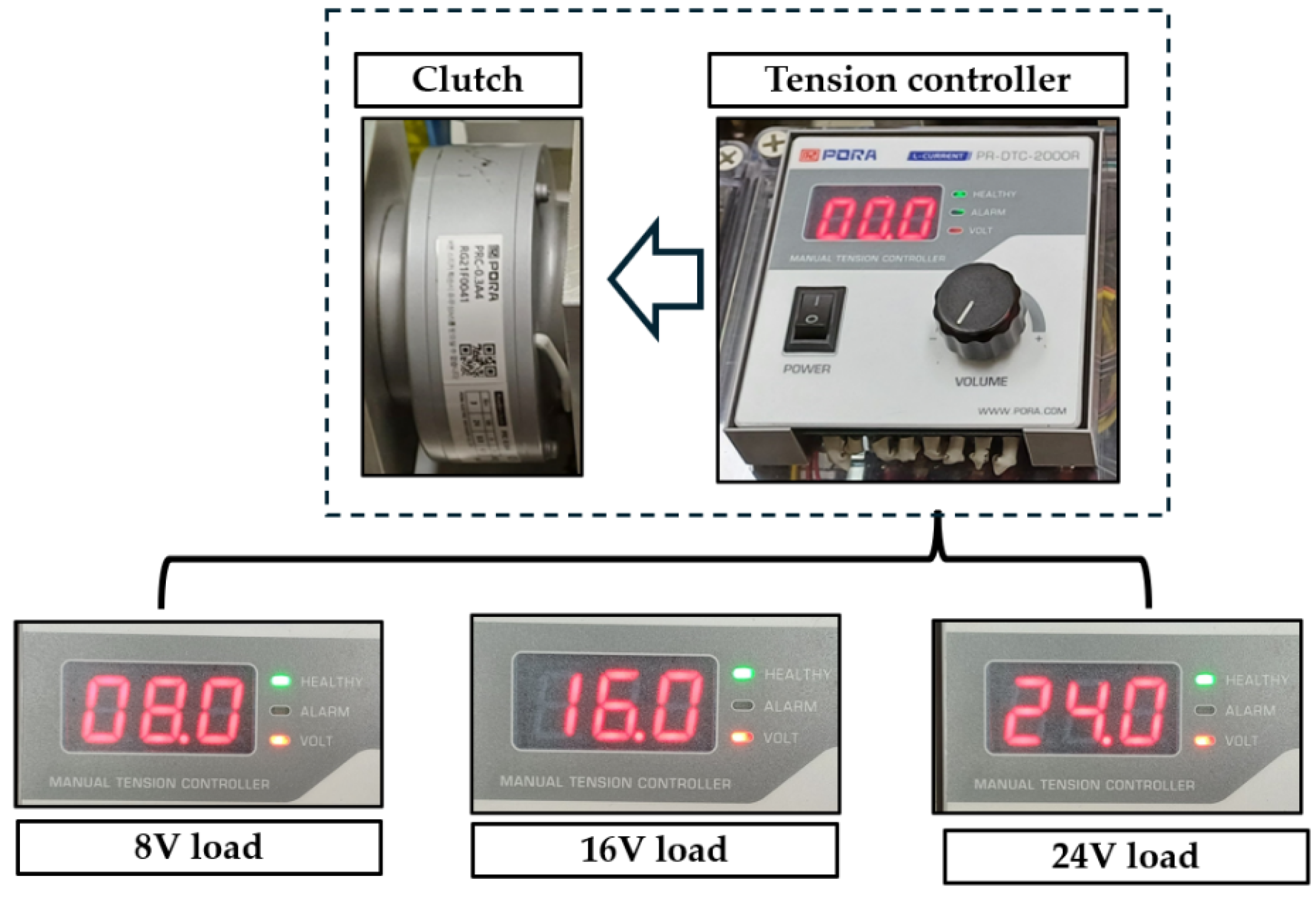

- Data acquisition: Vibration signals were collected from induction motors under both normal and bearing fault conditions. The motor operated under four load levels: no load, 8 V, 16 V, and 24 V. Data were acquired using a vibration sensor with a sampling frequency of 1024 Hz.

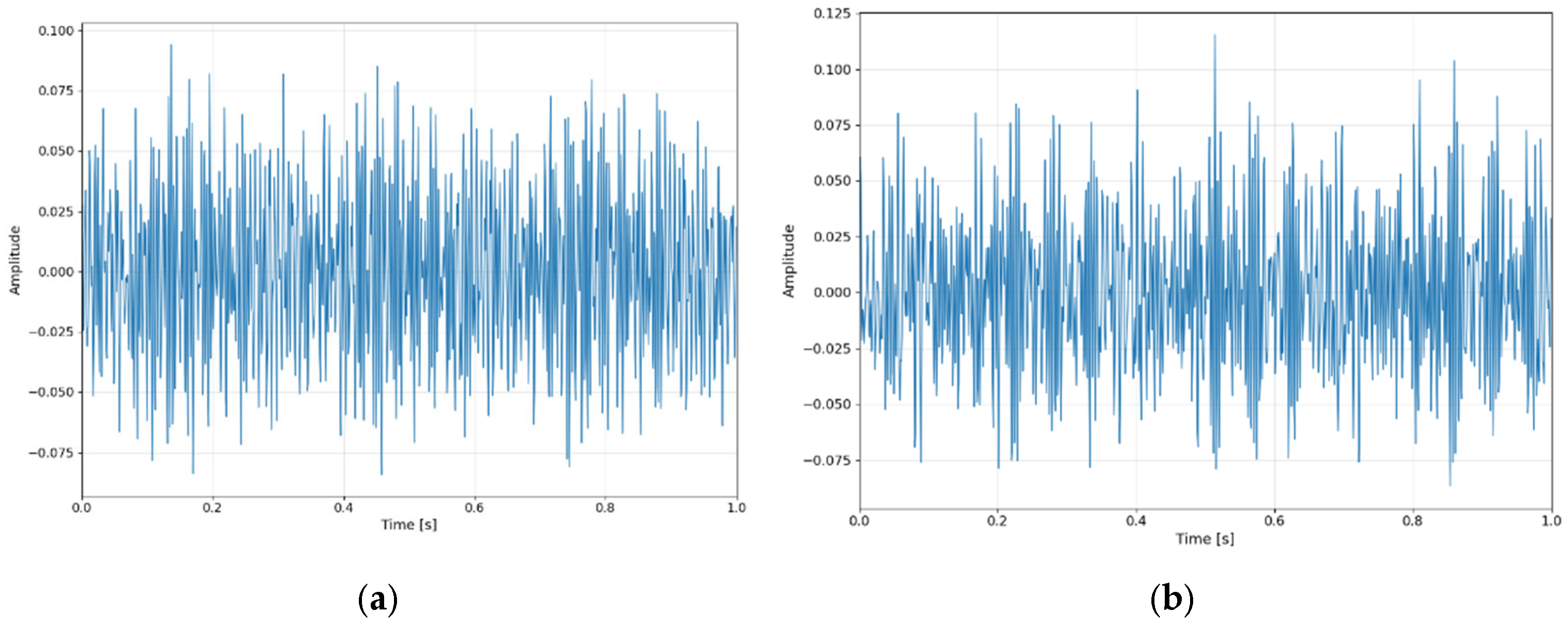

- Signal segmentation: The acquired vibration signals were divided into 1 s segments to standardize the input length.

- Feature extraction: Three categories of input data were generated from the segmented signals. The first comprised time-series signals without preprocessing, and the second included statistical features, specifically the mean, variance, minimum, maximum, skewness, and kurtosis. The third utilized three statistically significant features—kurtosis, skewness, and maximum—selected from these six variables via an independent t-test.

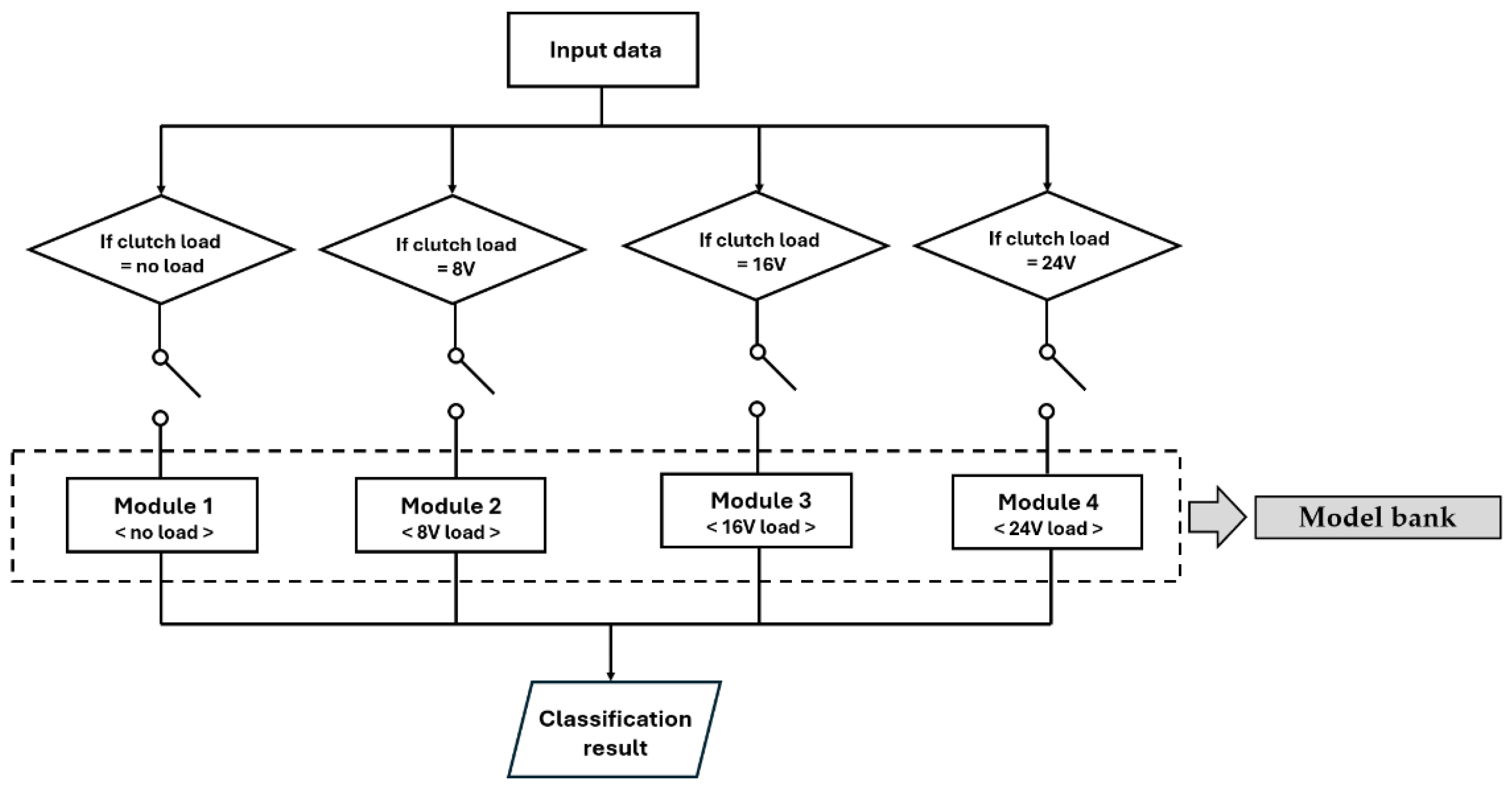

- Classification: Two diagnostic methods were compared. Method 1 was trained using data from all load conditions with a single classifier, whereas Method 2 trained independent classifiers for each load condition to distinguish between normal and fault states. For fault classification, three models were employed (SVM, MNN, and RF).

4. Experimental Setup

4.1. Simulator Configuration

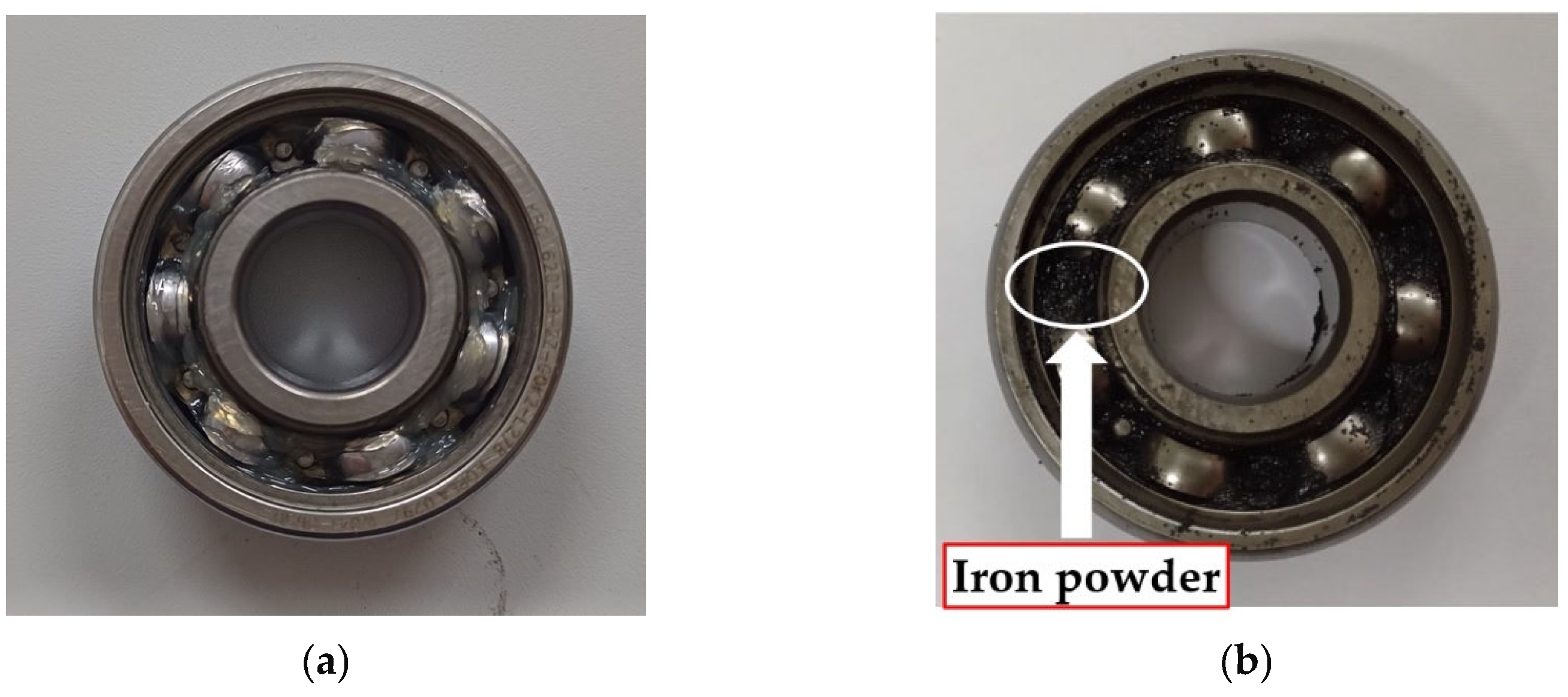

- Induction motor: Operated under both normal and bearing fault conditions; two identical motors were alternately installed for each condition.

- Powder clutch and tension controller: Regulated the clutch torque to implement four load levels (no load, 8 V, 16 V, and 24 V).

- Inverter: Two inverters were utilized—one for the normal motor and another for the faulty motor—to maintain stable control.

- Vibration sensor: A 603C01 accelerometer (IMI Sensors, New York, NY, USA) mounted on the motor housing to capture vibration signals.

- Data acquisition module: NI-9234 (National Instruments, Austin, TX, USA) for signal recording at a sampling frequency of 1024 Hz.

- Control box: Integrated all power connections, the inverter control, and safety switches for system operation.

4.2. Data Acquisition

5. Results

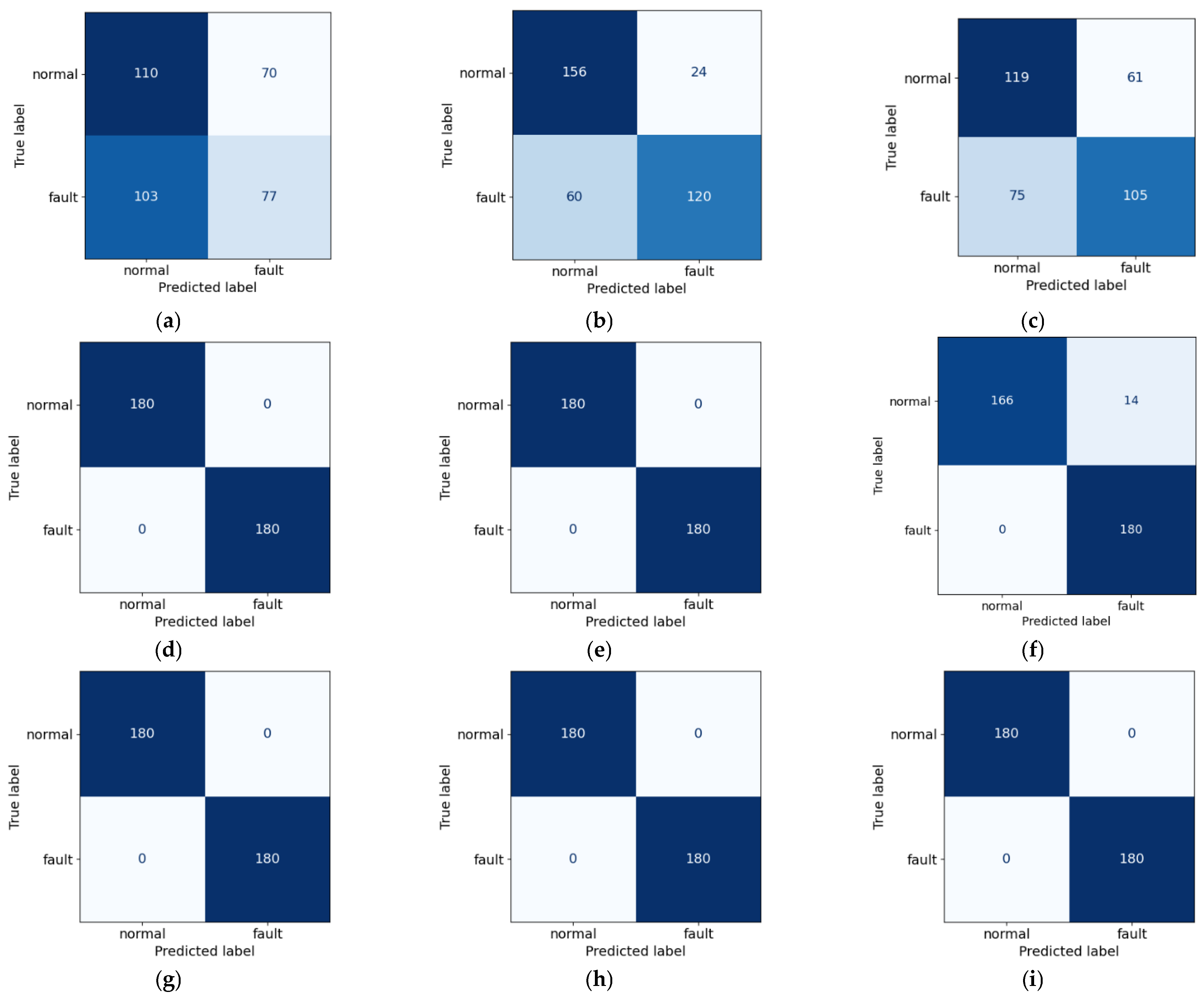

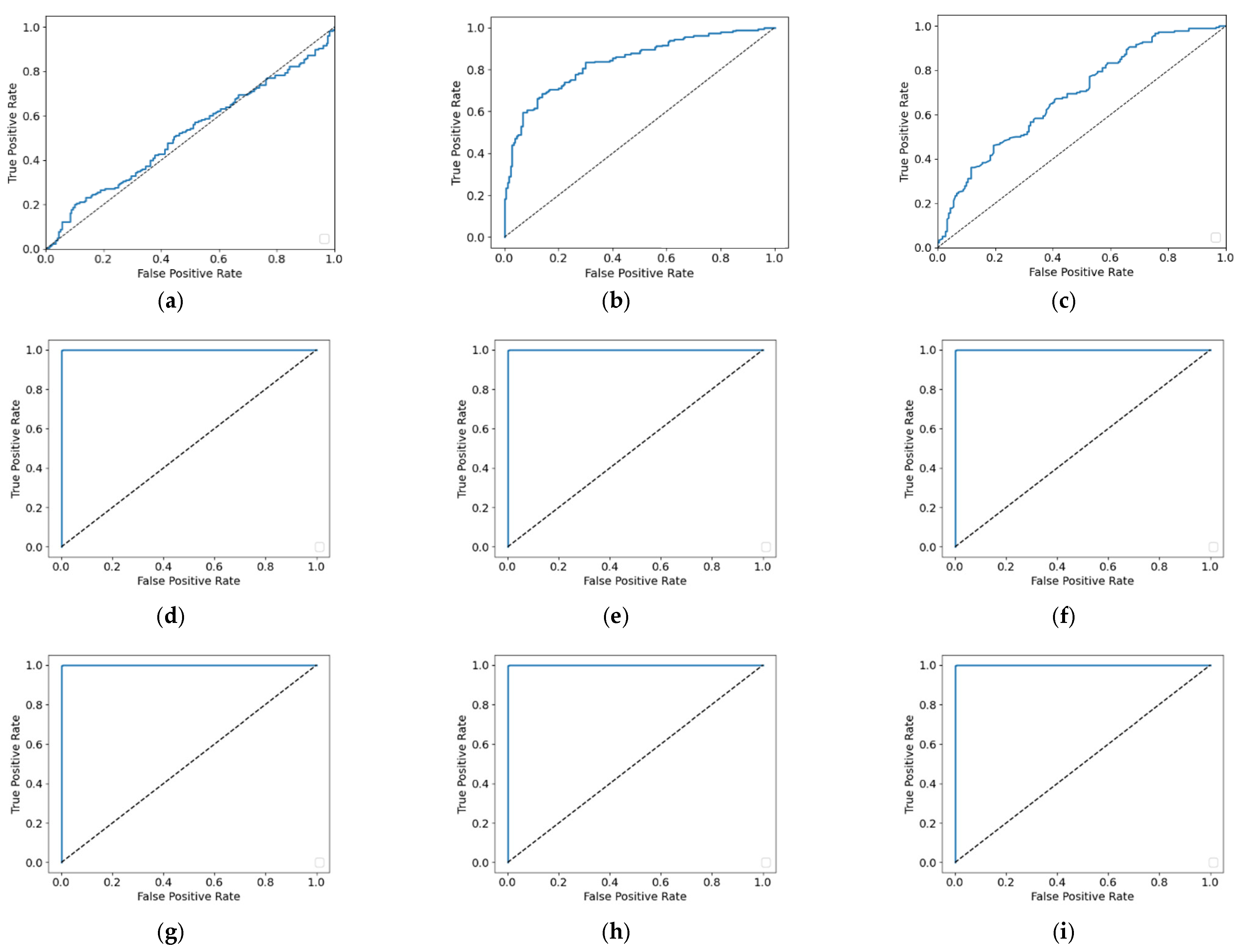

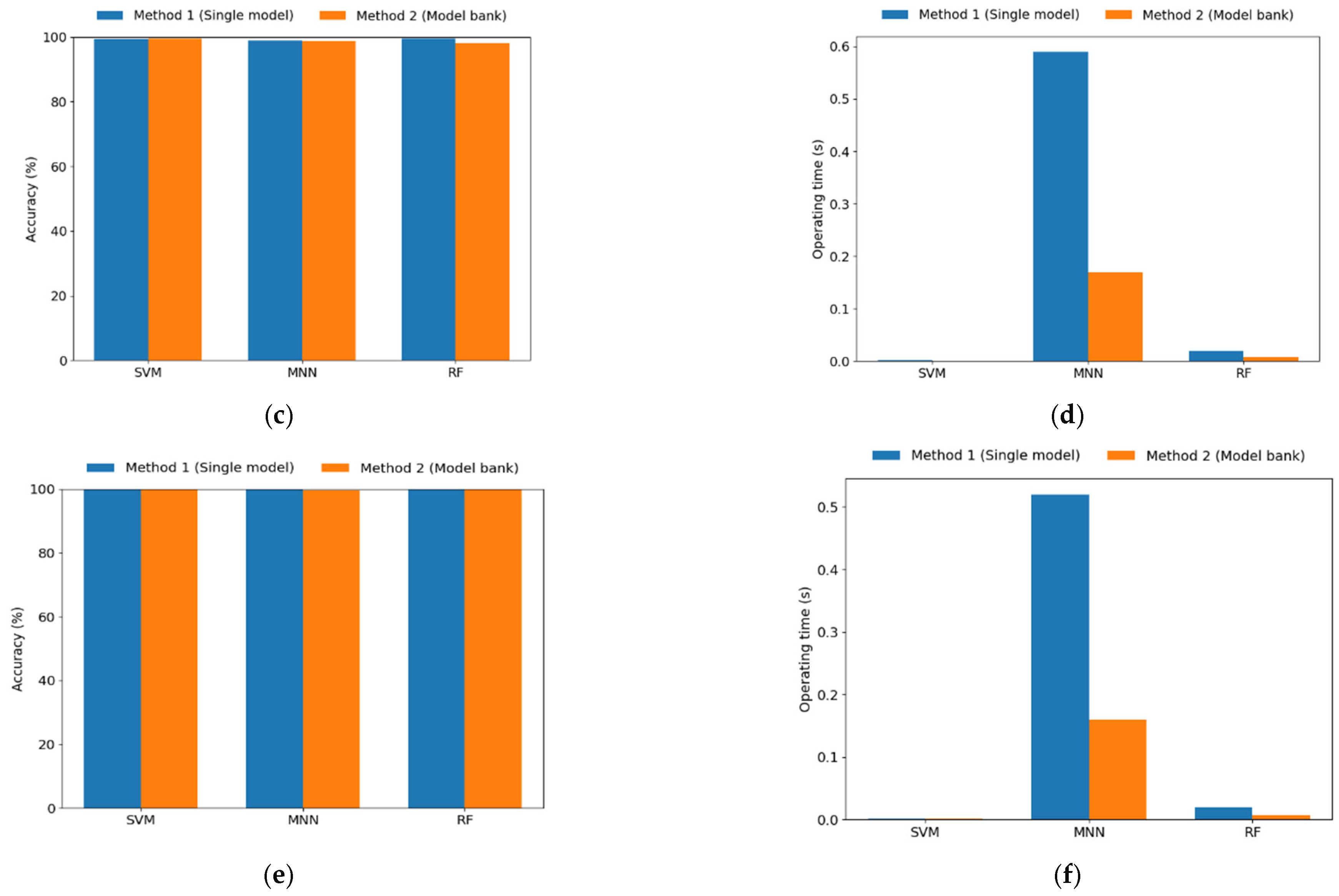

5.1. Results of Method 1

5.2. Results of Method 2

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Irfan, M.; Alwadie, A.S.; Glowacz, A.; Awais, M.; Rahman, S.; Khan, M.K.A.; Jalalah, M.; Alshorman, O.; Caesarendra, W. A Novel Feature Extraction and Fault Detection Technique for the Intelligent Fault Identification of Water Pump Bearings. Sensors 2021, 21, 4225. [Google Scholar] [CrossRef]

- Zhen, D.; Wang, T.; Gu, F.; Ball, A.D. Fault Diagnosis of Motor Drives Using Stator Current Signal Analysis Based on Dynamic Time Warping. Mech. Syst. Signal Process. 2013, 34, 191–202. [Google Scholar] [CrossRef]

- Kumar, R.R.; Andriollo, M.; Cirrincione, G.; Cirrincione, M.; Tortella, A. A Comprehensive Review of Conventional and Intelligence-Based Approaches for the Fault Diagnosis and Condition Monitoring of Induction Motors. Energies 2022, 15, 8938. [Google Scholar] [CrossRef]

- Zamudio-Ramírez, I.; Osornio-Ríos, R.A.; Antonino-Daviu, J.A.; Quijano-Lopez, A. Smart-Sensor for the Automatic Detection of Electromechanical Faults in Induction Motors Based on the Transient Stray Flux Analysis. Sensors 2020, 20, 1477. [Google Scholar] [CrossRef] [PubMed]

- Zarei, J. Induction Motors Bearing Fault Detection Using Pattern Recognition Techniques. Expert Syst. Appl. 2012, 39, 68–73. [Google Scholar] [CrossRef]

- Gundewar, S.K.; Kane, P.V. Condition Monitoring and Fault Diagnosis of Induction Motor. J. Vib. Eng. Technol. 2021, 9, 643–674. [Google Scholar] [CrossRef]

- Ruiz-Sarrio, J.E.; Antonino-Daviu, J.A.; Martis, C. Localized Bearing Fault Analysis for Different Induction Machine Start-Up Modes via Vibration Time–Frequency Envelope Spectrum. Sensors 2024, 24, 6935. [Google Scholar] [CrossRef]

- Terron-Santiago, C.; Martinez-Roman, J.; Puche-Panadero, R.; Sapena-Bano, A. A Review of Techniques Used for Induction Machine Fault Modelling. Sensors 2021, 21, 4855. [Google Scholar] [CrossRef]

- Xu, L.; Teoh, S.S.; Ibrahim, H. A Deep Learning Approach for Electric Motor Fault Diagnosis Based on Modified InceptionV3. Sci. Rep. 2024, 14, 12344. [Google Scholar] [CrossRef]

- Lucas, G.; de Castro, B.; Serni, P.; Riehl, R.; Andreoli, A. Sensors Applied to Bearing Fault Detection in Three-Phase Induction Motors. Eng. Proc. 2021, 10, 40. [Google Scholar] [CrossRef]

- Gangsar, P.; Tiwari, R. Comparative Investigation of Vibration and Current Monitoring for Prediction of Mechanical and Electrical Faults in Induction Motor Based on Multiclass-Support Vector Machine Algorithms. Mech. Syst. Signal Process. 2017, 94, 464–481. [Google Scholar] [CrossRef]

- Łuczak, D. Machine Fault Diagnosis through Vibration Analysis: Continuous Wavelet Transform with Complex Morlet Wavelet and Time–Frequency RGB Image Recognition via Convolutional Neural Network. Electronics 2024, 13, 452. [Google Scholar] [CrossRef]

- Yoo, S.M.; Lee, H.G.; Hao, W.K.; Lee, I.S. Induction Motor Fault Diagnosis Using Low-Cost MEMS Acoustic Sensors and Multilayer Neural Networks. Appl. Sci. 2025, 15, 9379. [Google Scholar] [CrossRef]

- Konar, P.; Chattopadhyay, P. Multi-Class Fault Diagnosis of Induction Motor Using Hilbert and Wavelet Transform. Appl. Soft Comput. 2015, 30, 341–352. [Google Scholar] [CrossRef]

- Zuhaib, M.; Shaikh, F.A.; Tanweer, W.; Alnajim, A.M.; Alyahya, S.; Khan, S.; Usman, M.; Islam, M.; Hasan, M.K. Faults Feature Extraction Using Discrete Wavelet Transform and Artificial Neural Network for Induction Motor Availability Monitoring—Internet of Things Enabled Environment. Energies 2022, 15, 7888. [Google Scholar] [CrossRef]

- Pandarakone, S.E.; Masuko, M.; Mizuno, Y.; Nakamura, H. Deep Neural Network Based Bearing Fault Diagnosis of Induction Motor Using Fast Fourier Transform Analysis. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 3214–3221. [Google Scholar] [CrossRef]

- El Idrissi, A.; Derouich, A.; Mahfoud, S.; El Ouanjli, N.; Chantoufi, A.; Al-Sumaiti, A.S.; Mossa, M.A. Bearing Fault Diagnosis for an Induction Motor Controlled by an Artificial Neural Network—Direct Torque Control Using the Hilbert Transform. Mathematics 2022, 10, 4258. [Google Scholar] [CrossRef]

- Tran, M.-Q.; Liu, M.-K.; Tran, Q.-V.; Nguyen, T.-K. Effective Fault Diagnosis Based on Wavelet and Convolutional Attention Neural Network for Induction Motors. IEEE Trans. Instrum. Meas. 2022, 71, 3501613. [Google Scholar] [CrossRef]

- Li, J.; Song, G.; Yan, J.; Li, Y.; Xu, Z. Data-Driven Fault Detection and Classification for MTDC Systems by Integrating HCTSA and Softmax Regression. IEEE Trans. Power Deliv. 2022, 37, 893–904. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, D.; Xu, Y.; Zhen, D.; Gu, F.; Ball, A.D. Early Rolling Bearing Fault Diagnosis in Induction Motors Based on On-Rotor Sensing Vibrations. Measurement 2023, 222, 113614. [Google Scholar] [CrossRef]

- Qiu, H.; Lee, J.; Lin, J.; Yu, G. Wavelet Filter-Based Weak Signature Detection Method and Its Application on Rolling Element Bearing Prognostics. J. Sound Vib. 2006, 289, 1066–1090. [Google Scholar] [CrossRef]

- El Bouharrouti, N.; Morinigo-Sotelo, D.; Belahcen, A. Multi-Rate Vibration Signal Analysis for Bearing Fault Detection in Induction Machines Using Supervised Learning Classifiers. Machines 2024, 12, 17. [Google Scholar] [CrossRef]

- Sobie, C.; Freitas, C.; Nicolai, M. Simulation-Driven Machine Learning: Bearing Fault Classification. Mech. Syst. Signal Process. 2018, 99, 403–419. [Google Scholar] [CrossRef]

- Matania, O.; Cohen, R.; Bechhoefer, E.; Bortman, J. Zero-Fault-Shot Learning for Bearing Spall Type Classification by Hybrid Approach. Mech. Syst. Signal Process. 2025, 224, 112117. [Google Scholar] [CrossRef]

- Snyder, Q.; Jiang, Q.; Tripp, E. Integrating Self-Attention Mechanisms in Deep Learning: A Novel Dual-Head Ensemble Transformer with Its Application to Bearing Fault Diagnosis. Signal Process. 2025, 227, 109683. [Google Scholar] [CrossRef]

- Hejazi, S.Z.; Packianather, M.; Liu, Y. A Novel Customised Load Adaptive Framework for Induction Motor Fault Classification Utilising MFPT Bearing Dataset. Machines 2024, 12, 44. [Google Scholar] [CrossRef]

- Júnior, A.M.G.; Silva, V.V.R.; Baccarini, L.M.R.; Mendes, L.F.S. The Design of Multiple Linear Regression Models Using a Genetic Algorithm to Diagnose Initial Short-Circuit Faults in 3-Phase Induction Motors. Appl. Soft Comput. 2018, 63, 50–58. [Google Scholar] [CrossRef]

- Kumar, J.P.; Chauhan, P.S.; Pandit, P.P. Time Domain Vibration Analysis Techniques for Condition Monitoring of Rolling Element Bearing: A Review. Mater. Today Proc. 2022, 62, 6336–6340. [Google Scholar] [CrossRef]

- Toma, R.N.; Prosvirin, A.E.; Kim, J.-M. Bearing Fault Diagnosis of Induction Motors Using a Genetic Algorithm and Machine Learning Classifiers. Sensors 2020, 20, 1884. [Google Scholar] [CrossRef]

- Caesarendra, W.; Tjahjowidodo, T. A Review of Feature Extraction Methods in Vibration-Based Condition Monitoring and Its Application for Degradation Trend Estimation of Low-Speed Slew Bearing. Machines 2017, 5, 21. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Su, C.-T. Distance-Based Margin Support Vector Machine for Classification. Appl. Math. Comput. 2016, 283, 141–152. [Google Scholar] [CrossRef]

- Tun, W.; Wong, J.K.-W.; Ling, S.-H. Hybrid Random Forest and Support Vector Machine Modeling for HVAC Fault Detection and Diagnosis. Sensors 2021, 21, 8163. [Google Scholar] [CrossRef]

- Ewert, P.; Kowalski, C.T.; Orlowska-Kowalska, T. Low-Cost Monitoring and Diagnosis System for Rolling Bearing Faults of the Induction Motor Based on Neural Network Approach. Electronics 2020, 9, 1334. [Google Scholar] [CrossRef]

- Kowalski, C.T.; Orlowska-Kowalska, T. Neural Networks Application for Induction Motor Faults Diagnosis. Math. Comput. Simul. 2003, 63, 435–448. [Google Scholar] [CrossRef]

- Banerjee, A.; Kumar, E.; Ravinder, M. Learning Clustered Deep Spatio-Temporal Prototypes Using Softmax Regression for Video Information Systems. Int. J. Inf. Technol. 2024, 16, 3085–3091. [Google Scholar] [CrossRef]

- Ding, B.; Qian, H.; Zhou, J. Activation Functions and Their Characteristics in Deep Neural Networks. In Proceedings of the 2018 Chinese Control and Decision Conference (CCDC), Shenyang, China, 9–11 July 2018; pp. 1836–1841. [Google Scholar] [CrossRef]

- Kingma, D.P.; Ba, J. Adam: A Method for Stochastic Optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Jiang, Z.; Söffker, D.; Shen, W. Bearing Fault Diagnosis Method Based on Deep Convolutional Neural Network and Random Forest Ensemble Learning. Sensors 2019, 19, 1088. [Google Scholar] [CrossRef] [PubMed]

- Pohakar, P.; Gandhi, R.; Hans, S.; Sharma, G.; Bokoro, P.N. Analysis of Multiple Faults in Induction Motor Using Machine Learning Techniques. e-Prime Adv. Electr. Eng. Electron. Energy 2025, 12, 101007. [Google Scholar] [CrossRef]

- Patel, R.; Giri, V. Feature Selection and Classification of Mechanical Fault of an Induction Motor Using Random Forest Classifier. Perspect. Sci. 2016, 8, 389–392. [Google Scholar] [CrossRef]

| Statistical Features | Equation |

|---|---|

| Mean | |

| Variance | |

| Max | |

| Min | |

| Skewness | |

| Kurtosis |

| Statistical Features | p-Value |

|---|---|

| Kurtosis | 0 |

| Skewness | |

| Max | |

| Min | |

| Variance | |

| Mean |

| Model | Input Data | Parameter | Value |

|---|---|---|---|

| SVM |

Time series Statistical features | C | 0.01 |

| 0.1 | |||

| MNN |

Time series Statistical features | 2 Hidden layers | 128, 64 |

| 64, 32 | |||

| RF |

Time series Statistical features | Number of trees | 300 |

| 100 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Rated power | 0.2 kW | Rated torque | 1.29/1.50 Nm |

| Rated voltage | 220 V | Rated speed | 1300/1550 rpm |

| Poles | 4 | Rated frequency | 50/60 Hz |

| Parameter | Value |

|---|---|

| Measurement range | |

| Frequency range | 0.5 to 10,000 Hz |

| Transverse sensitivity | ≤7% |

| Temperature range | −54 °C to 121 °C |

| Model | Input Data | Accuracy (%) | Operating Time (s) |

|---|---|---|---|

| SVM | Time-series | 51.7 | 0.50 |

| 6 Statistical features | 99.4 | 0.002 | |

| 3 Statistical features | 99.7 | 0.002 | |

| MNN | Time-series | 77.7 | 0.80 |

| 6 Statistical features | 99.0 | 0.59 | |

| 3 Statistical features | 99.7 | 0.52 | |

| RF | Time-series | 84.0 | 0.19 |

| 6 Statistical features | 99.6 | 0.02 | |

| 3 Statistical features | 99.7 | 0.02 |

| Model | Input Data | Accuracy (%) | ||||

|---|---|---|---|---|---|---|

| Module 1 (No Load) | Module 2 (8 V Load) | Module 3 (16 V Load) | Module 4 (24 V Load) | Average | ||

| SVM | Time-series | 53.3 | 51.9 | 55.6 | 52.5 | 53.3 |

| 6-Statistical features | 98.6 | 100.0 | 99.7 | 100.0 | 99.6 | |

| 3-Statistical features | 98.9 | 100.0 | 100.0 | 100.0 | 99.7 | |

| MNN | Time-series | 69.2 | 76.7 | 73.1 | 76.7 | 73.9 |

| 6-Statistical features | 95.0 | 100.0 | 99.7 | 100.0 | 98.7 | |

| 3-Statistical features | 98.6 | 100.0 | 99.7 | 100.0 | 99.6 | |

| RF | Time-series | 73.3 | 62.2 | 60.3 | 63.1 | 64.7 |

| 6-Statistical features | 98.3 | 96.1 | 98.3 | 99.7 | 98.1 | |

| 3-Statistical features | 98.9 | 100.0 | 100.0 | 100.0 | 99.7 | |

| Model | Input Data | Operating Time (s) | ||||

|---|---|---|---|---|---|---|

| Module 1 (No Load) | Module 2 (8 V Load) | Module 3 (16 V Load) | Module 4 (24 V Load) | Average | ||

| SVM | Time-series | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 |

| 6-Statistical features | 0.0005 | 0.0009 | 0.0009 | 0.0009 | 0.0008 | |

| 3-Statistical features | 0.0005 | 0.001 | 0.001 | 0.001 | 0.0009 | |

| MNN | Time-series | 0.26 | 0.21 | 0.19 | 0.19 | 0.21 |

| 6-Statistical features | 0.21 | 0.14 | 0.15 | 0.18 | 0.17 | |

| 3-Statistical features | 0.16 | 0.16 | 0.17 | 0.14 | 0.16 | |

| RF | Time-series | 0.03 | 0.03 | 0.03 | 0.02 | 0.03 |

| 6-Statistical features | 0.008 | 0.009 | 0.009 | 0.007 | 0.008 | |

| 3-Statistical features | 0.008 | 0.008 | 0.001 | 0.009 | 0.007 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.G.; Yoo, S.M.; Hao, W.K.; Lee, I.S. Time-Domain and Neural Network-Based Diagnosis of Bearing Faults in Induction Motors Under Variable Loads. Machines 2025, 13, 1055. https://doi.org/10.3390/machines13111055

Lee HG, Yoo SM, Hao WK, Lee IS. Time-Domain and Neural Network-Based Diagnosis of Bearing Faults in Induction Motors Under Variable Loads. Machines. 2025; 13(11):1055. https://doi.org/10.3390/machines13111055

Chicago/Turabian StyleLee, Hwi Gyo, Seon Min Yoo, Wang Ke Hao, and In Soo Lee. 2025. "Time-Domain and Neural Network-Based Diagnosis of Bearing Faults in Induction Motors Under Variable Loads" Machines 13, no. 11: 1055. https://doi.org/10.3390/machines13111055

APA StyleLee, H. G., Yoo, S. M., Hao, W. K., & Lee, I. S. (2025). Time-Domain and Neural Network-Based Diagnosis of Bearing Faults in Induction Motors Under Variable Loads. Machines, 13(11), 1055. https://doi.org/10.3390/machines13111055