Tire–Road Interaction: A Comprehensive Review of Friction Mechanisms, Influencing Factors, and Future Challenges

Abstract

1. Introduction

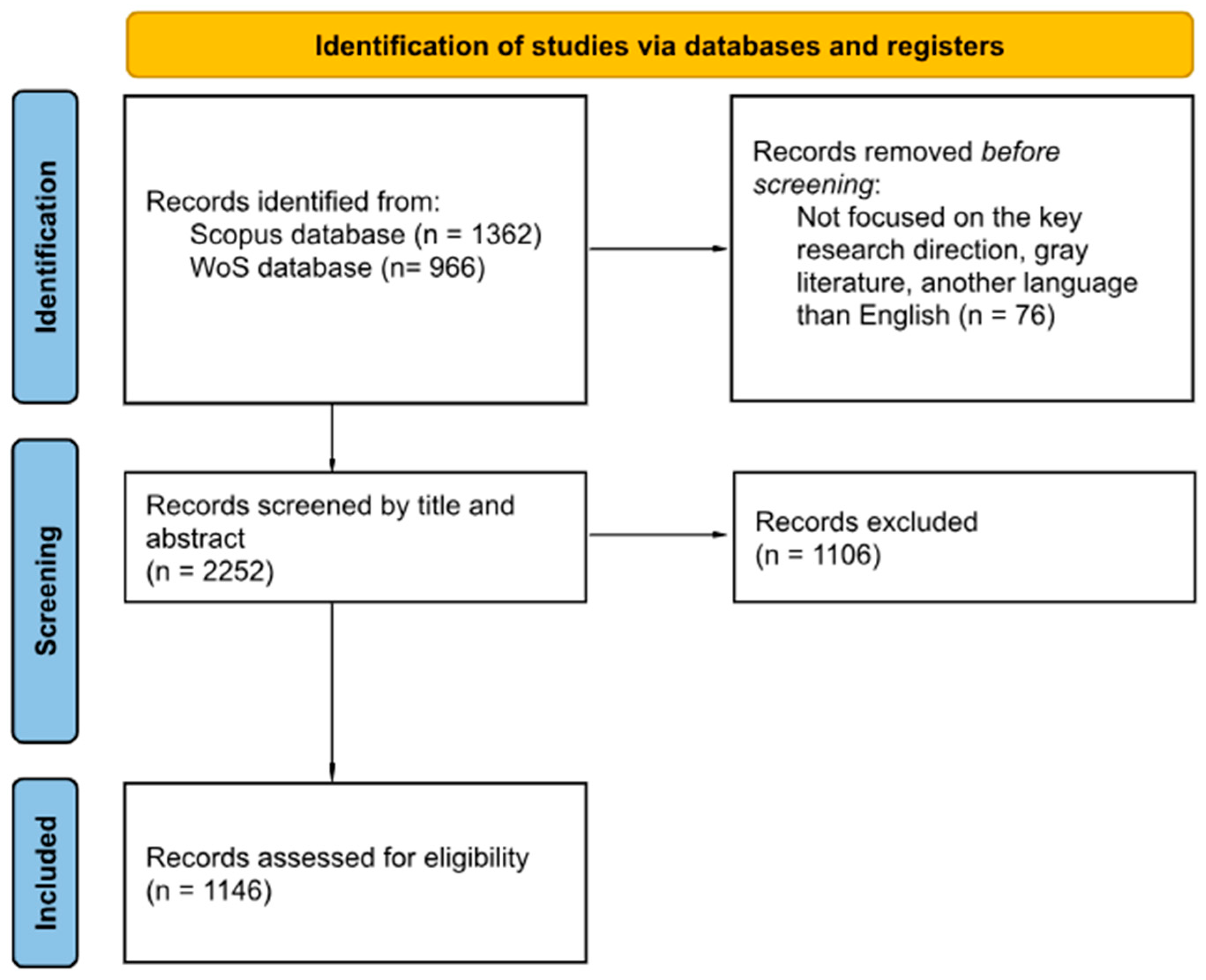

2. Bibliometric and Thematic Methods

- Publications related to the automotive sector, such as those mentioned above, including research articles, review papers, conference papers, and books;

- Studies published between 1968 and 2025 to capture the latest trends and advancements;

- Studies published in English.

- Articles not specifically focused on the key research direction;

- Non-peer-reviewed works and gray literature, excluded to ensure data quality and reliability;

- Papers published in languages other than English, or outside the specified publication window.

Review Questions

3. Results

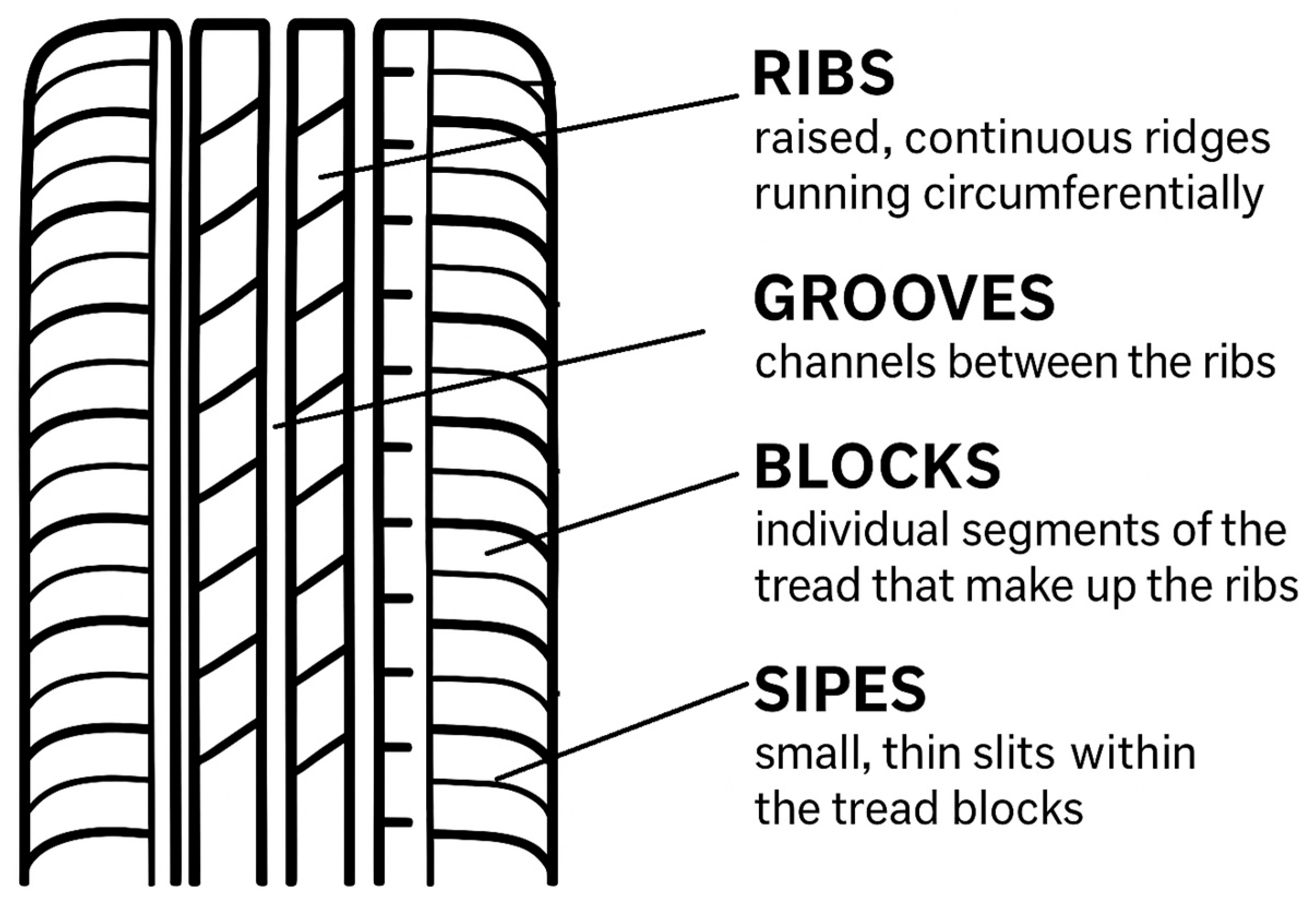

- Symmetrical patterns offer a uniform design that balances performance and longevity;

- Asymmetrical patterns combine distinct inner and outer designs, with the outer shoulder enhancing dry grip and cornering stability, while the inner shoulder improves water dispersion;

- Directional patterns, often arrow-shaped, are intended to rotate in a single direction, providing superior water evacuation and traction in snow or mud.

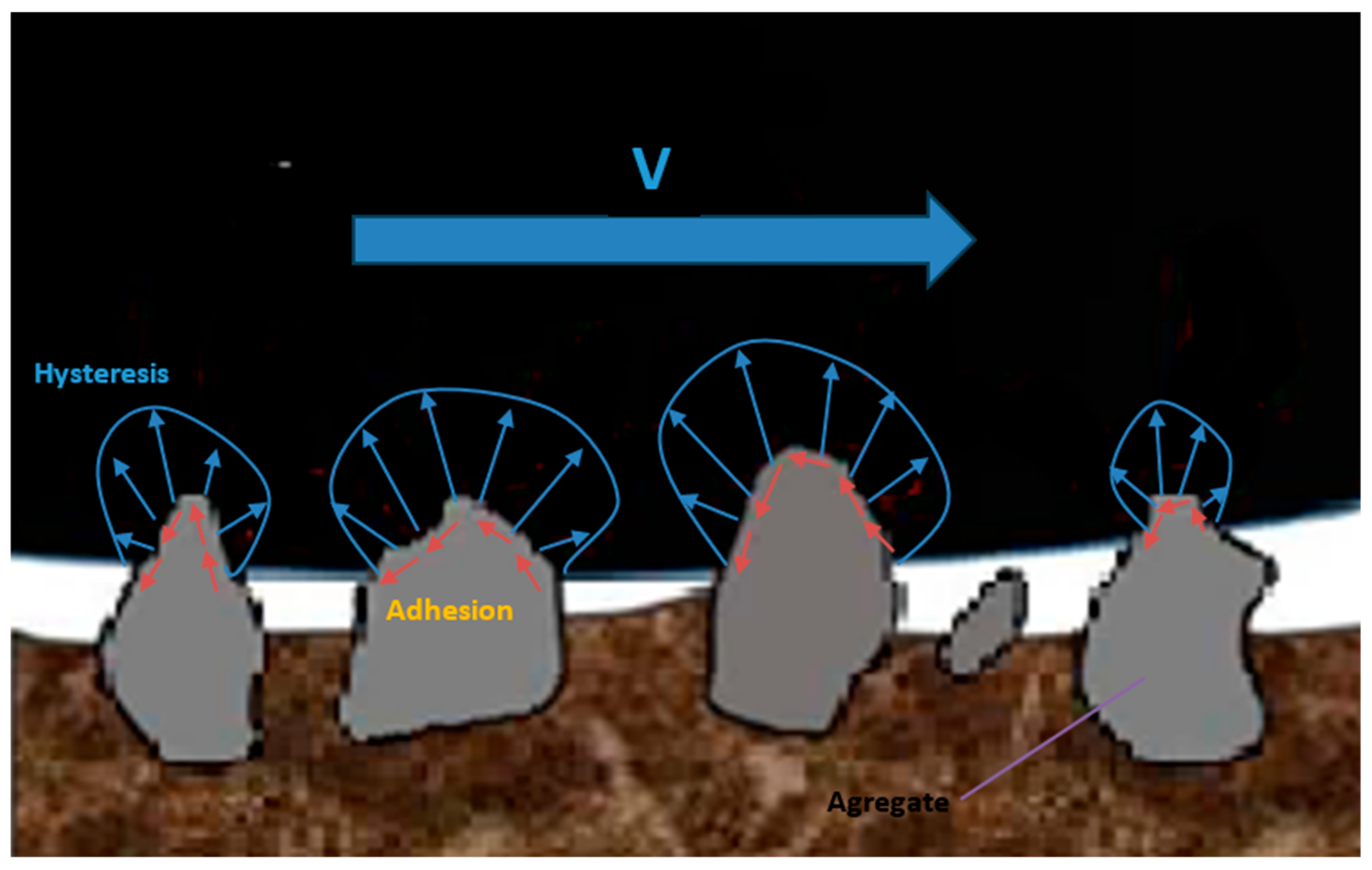

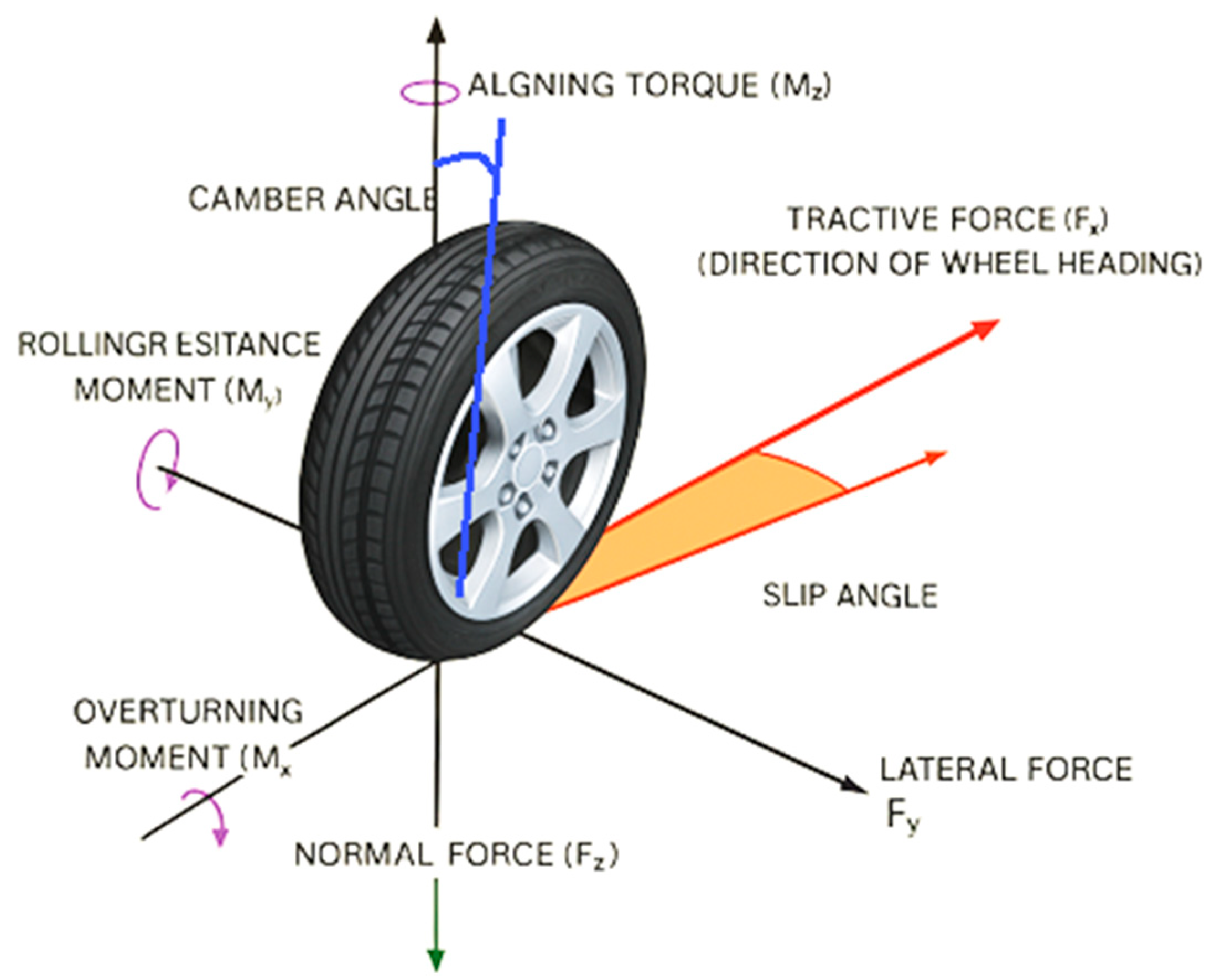

3.1. Tire–Road Friction Process

- The coefficient of static friction is the friction force that must be overcome to be able to determine the movement of the wheel from rest. This is usually greater than the coefficient of dynamic friction. Some references reviewed in this article are [55,56,57,58]. A semi-analytical model presented in [57] predicts the normal force distribution, while a beam–spring network captures the friction force and rubber deformation during stick-to-slip transitions.

- The dynamic friction coefficient represents the friction force that acts when a wheel slides on a surface [55,57]. In [59] a hybrid physical–dynamic tire–road friction model is presented for the simulation and control of vehicle motion, extending the LuGre dynamic friction model by incorporating a stick–slip partition based on the physical model of the contact patch.

3.2. Factors That Affect the Coefficient of Friction

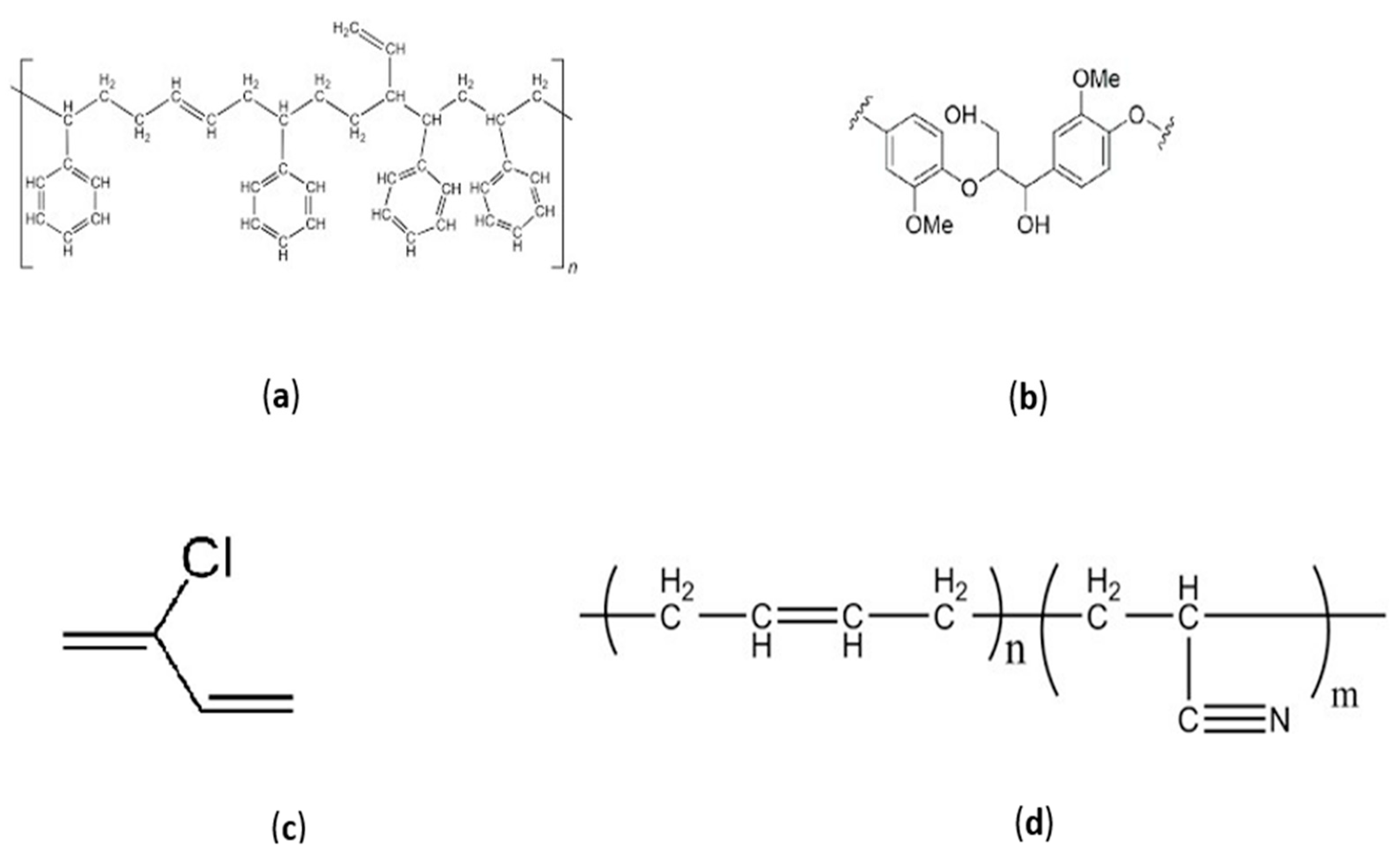

3.2.1. Tire Composition and Construction

3.2.2. Road Surface

3.2.3. Temperature

3.2.4. Tire Load and Pressure

3.2.5. New Tire Production Technology

3.3. Tire–Road Interactions Models and Methods

4. Discussion

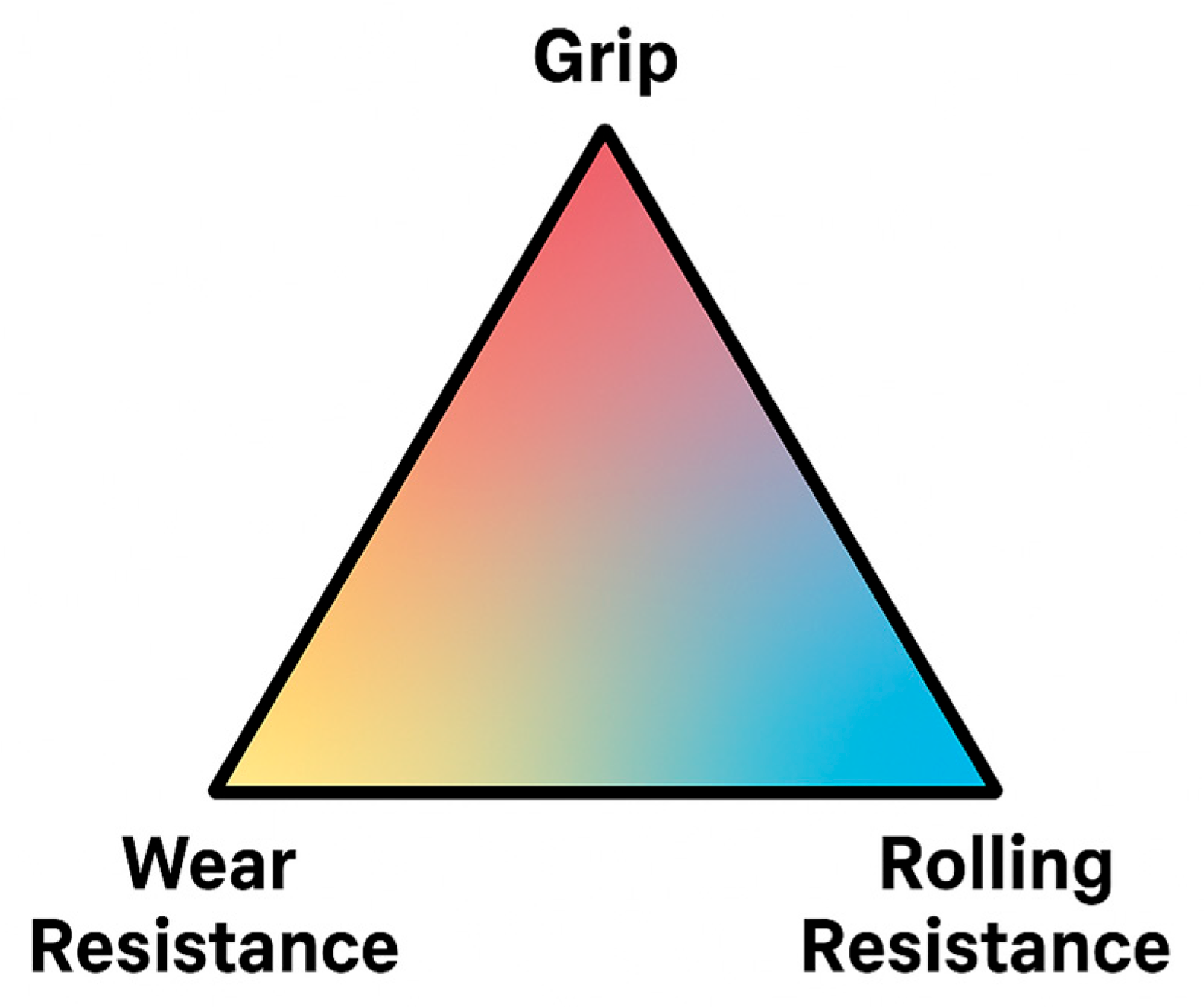

- Tire Compound: Soft rubber compounds offer better grip, thus yielding a higher coefficient of friction, but they tend to wear out more quickly and are sensitive to temperature changes. In combination with temperature, the tire compound must be selected to remain sufficiently adhesive at real operating temperatures without becoming too soft or too rigid. Although softer compounds provide increased grip, they may require higher inflation pressures to compensate for excessive deformation.

- For rubber, there is a close relation between sliding friction (especially at low speeds) and viscoelastic properties. Softer rubber (or rubber at a higher temperature, and thus more compliant) shows increased friction under relevant regimes [134].

- Enhanced formulations incorporating nanomaterials can reduce rolling resistance (RR) by 5–7% while maintaining durability.

- Tread Pattern: The tread design influences how effectively water or debris is evacuated and the extent of direct contact with the road surface. Treads with numerous grooves and protrusions perform well on wet or muddy roads but may reduce actual contact on dry asphalt, especially if combined with improper inflation pressure. In terms of surface interaction, an off-road tread on smooth asphalt may significantly reduce grip compared to a slick tire designed for that specific surface. Wet-condition treads (e.g., multiple grooves and channels) increase grip on slippery surfaces but also raise rolling resistance due to increased volume and deformation.

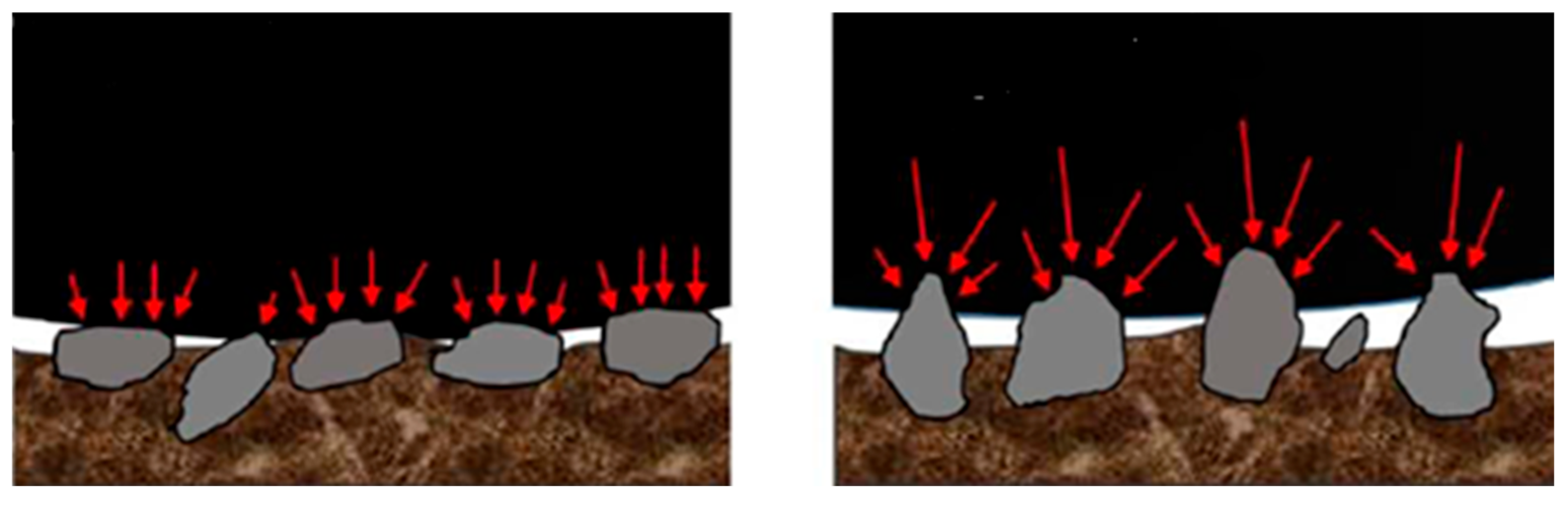

- Road Surface: The texture and material composition of asphalt mixtures significantly affect tire grip. Smooth roads provide limited roughness, making tire composition and temperature more critical. On rough-textured or wet surfaces, tread design and inflation pressure are key to maintaining effective contact. Macroscopic roughness influences hysteresis through localized deformation. Road moisture changes the adhesion mechanism—from direct bonding on dry roads to hysteresis-dominated interaction in wet conditions.

- Temperature: Temperature directly affects the elasticity of rubber: too cold and a compound becomes rigid; too hot and it becomes excessively soft. Increased temperature softens the rubber (reducing its viscoelasticity), which in turn lowers internal hysteresis and therefore the coefficient of friction. Proper inflation can help the tire reach and maintain its optimal operating temperature more efficiently. Temperature is interdependent with wheel load: excessive load increases heat buildup and accelerates wear. Theory predicts that under isothermal conditions the coefficient of friction decreases with load, which is more pronounced for the adhesion than for the hysteresis contribution. This result is found to be in fair agreement with the measured friction curves confirming the contact mechanical approach of the theory [138]. Temperature significantly influences tire–road interaction through complex thermo-viscoelastic mechanisms. As temperature increases, the rubber’s modulus decreases, allowing greater conformity to pavement micro-texture and enhancing adhesive friction at moderate levels. Elevated thermal conditions also promote molecular mobility, facilitating interfacial bonding and improving grip within an optimal viscoelastic range. However, excessive heating causes over-softening of the tread rubber, reducing shear stiffness and promoting slip. Frictional heating at asperity contacts, flash temperature, further amplifies local softening, diminishing the hysteretic component of friction and potentially inducing frictional instability [139]. At high temperatures, the viscoelastic hysteresis losses decline because the difference between storage and loss moduli narrows, reducing energy dissipation and overall friction efficiency. This thermal–mechanical feedback loop between heat generation, deformation, and slip can destabilize traction. Consequently, an optimum temperature window exists in which grip is maximized; outside this range, either excessive stiffness at low temperatures or over-softening at high temperatures leads to reduced traction, accelerated wear, and potential thermal degradation of the tread compound.

- Wheel Load: A higher wheel load generally increases the contact patch area, thereby enhancing grip—up to a certain point. When high load is combined with low inflation pressure, it can lead to excessive deformation and performance degradation. Load distribution must be analyzed in conjunction with vehicle type and road conditions. Increased load often requires higher pressure to control deformation and manage friction. Electric vehicle (EV) tires, subject to higher weights, may experience accelerated wear and contribute to particulate emissions. The use of biomaterials is being explored to mitigate these impacts.

- Tire Pressure: Inflation pressure is one of the most critical and easily adjustable parameters. It affects the size and shape of the contact patch, thus influencing the effectiveness of the tread and grip. The ideal pressure depends on temperature, load, and road surface; for instance, in racing, pressure is adjusted based on the expected track temperature. Tire wear increases with pressure, load, and friction, especially under high speed and load conditions. Higher pressure reduces lateral deformation and the contact area, leading to lower rolling resistance but potentially also to a reduced coefficient of friction due to smaller contact footprints.

| Factor | Typical Effect | Notes | References |

|---|---|---|---|

| Tire compound | Softer rubber, softer viscoelastic compounds offer higher friction coefficients, especially at low slip speeds | Softer rubber conforms better to surface asperities and has higher hysteretic and adhesive contribution; compound glass transition controls temperature sensitivity. | [10,62,63,64,65,66,67,68,69,90,144,146] |

| Tire temperature | TRFC typically increases with moderate warming toward optimal tread temperature, then can decreases if overheated | Temperature changes rubber viscoelasticity and adhesion; there is an optimal window near which hysteretic loss and adhesion produce maximum grip. | [77,78,79,90,142,143,147,148] |

| Tread pattern | Pattern that evacuates water and provides biting edges offers higher wet friction coefficient | Tread channels control water evacuation, prevent hydroplaning; tread blocks provide mechanical interlocking on rough surfaces; depth affects contact and aquaplaning threshold. | [10,48,70,146,149,150] |

| Road surface/texture | Coarser texture and high micro-roughness offer higher friction coefficient (up to a point); polished and/or contaminated surfaces offer lower friction coefficient | Tread rubber compound in the lower slip region is most prominent, which is also where vehicles operate most of the time. | [42,50,52,54,55,71,72,73,74,145,151] |

| Tire inflation pressure | Higher pressure offers smaller contact patch and often lower grip (reduced hysteretic contribution); very low pressure may generate weak lateral guidance of a vehicle | Surface roughness determines hysteretic friction (rubber deformation) and real contact area; aggregate type (porous or dense) and contamination with ice or oil change this coefficient dramatically. | [50,60,80,81,82,83,84,151] |

| Wheel load (vertical force) | Friction coefficient often decreases with increasing normal load (contact area/pressure nonlinearity); peak friction force increases, but friction coefficient often falls | Pressure changes contact area, contact pressure distribution, and tread block stiffness; both under- and over-inflation hurt effective grip vs. optimum. | [80,81,82,138,142,144,147,151,152] |

- Tire Formula (e.g., rubber type, tread, and composition): This factor establishes the intrinsic viscoelastic properties of the material. It dictates the base level of adhesion (molecular forces) and hysteresis (energy dissipation). Tires designed for lower rolling resistance, for example, typically trade off some grip due to their material composition.

- Road Surface (micro- and macro-texture): Surface texture determines the available contact points and the deformation frequency of the rubber. Micro-texture influences adhesion, while macro-texture is key to hysteresis (due to bulk deformation) and also affects water drainage, which critically reduces adhesion on wet surfaces.

- Load and Pressure: These mechanical factors define the contact patch area and the nominal contact stress. Pressure primarily controls stiffness and contact shape. Load is the vertical force. The dynamic interplay means an increase in load can increase contact but simultaneously accelerate frictional heating, leading to a complex, nonlinear effect on the final TRFC.

- Temperature: The friction mechanism itself generates heat, making temperature a dynamic output that instantly becomes a key input:

- ○

- Frictional Heat Generation: When a tire slips or deforms on the road, the energy dissipated by hysteresis generates heat.

- ○

- Thermo-Viscoelastic Change: This heat raises the temperature within the contact patch, causing a change in the rubber’s viscoelastic properties (softening or stiffening), which in turn modifies the loss modulus and thus the hysteresis component of friction.

- ○

- Feedback Loop: This change in rubber properties alters the rate of heat generation and the resulting friction coefficient, creating a constant, closed-loop feedback mechanism that determines the final friction coefficient and wear rate.

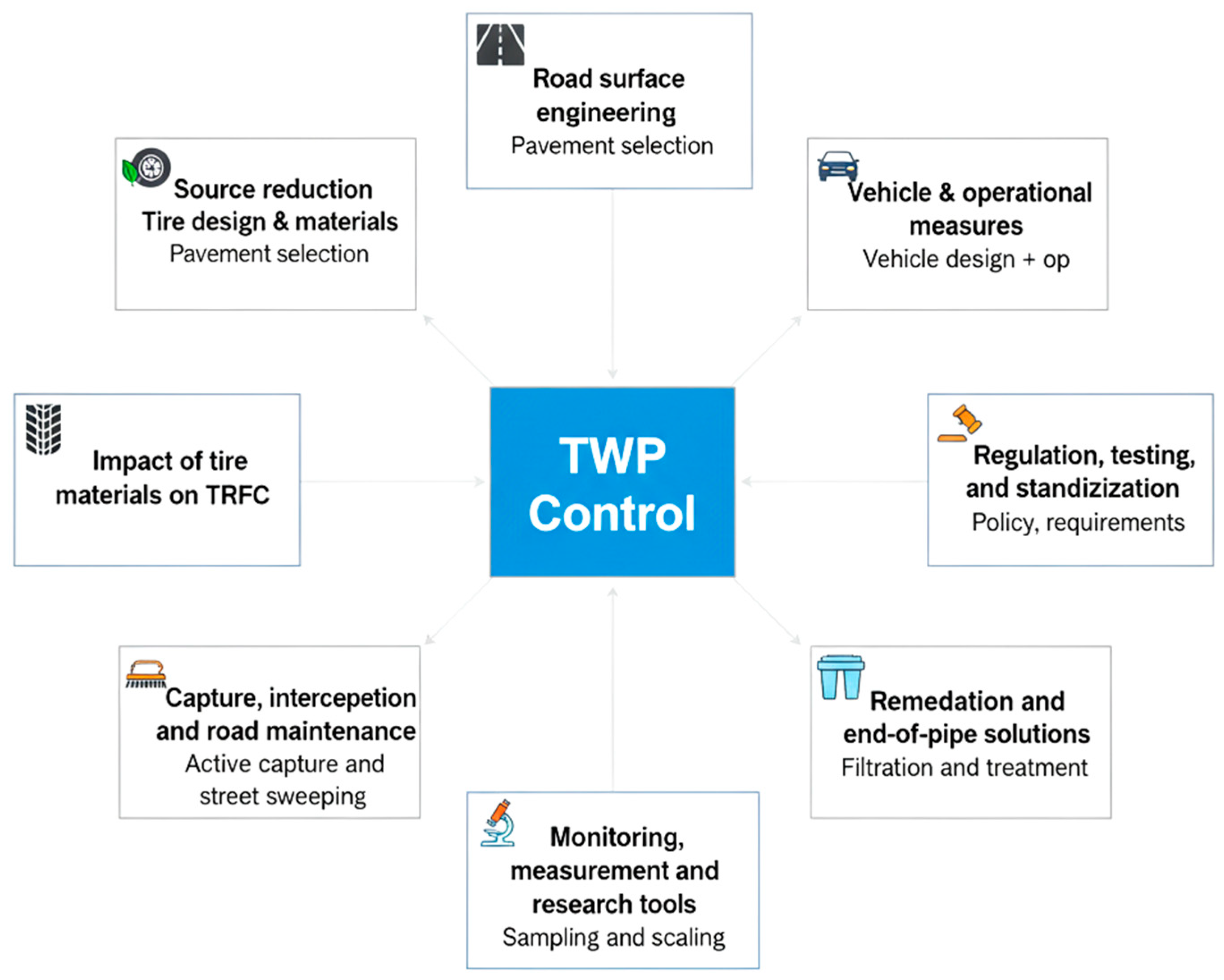

4.1. Addressing RQ1: TWP Emission Reduction Strategies to Meet Euro 7 Regulations

- Restrictions on tire wear—to be assessed through standardized measurement methods (e.g., drum testing and real-world driving conditions).

- Optimization of tire composition and design—aimed at minimizing particle emissions without compromising safety or energy efficiency.

- Rigorous testing—involving validated methodologies in both real-traffic and laboratory environments.

4.2. Addressing RQ2: Technical Pathways and Challenges for Real-Time TRFC Estimation

- Reliance on fitted parameters: Models like the Magic Formula achieve high accuracy in fitting real data. However, this accuracy is attained through a large number of empirical fitting parameters (e.g., stiffness factor, peak factor, and curvature factor) These coefficients must be determined experimentally for every specific tire–road combination, making the model a function of the experimental data rather than a universal predictor.

- Degradation and lack of generalization: Traditional analytical models depend heavily on accurate physical parameters and well-defined slip conditions. Their performance degrades significantly when environmental factors, like surface wetness, temperature variation, or uneven road textures, introduce uncertainties at the tire–road interface. Consequently, they struggle to generalize outside of the specific, well-controlled conditions under which their parameters are derived.

- Computational cost for high fidelity: Highly detailed physical models, such as the FTire model or high-fidelity FEA models, offer comprehensive realism, including thermal effects and dynamic wear modeling. However, this fidelity comes at the cost of being extremely resource-intensive and having a high computational cost, which limits their utility for real-time control applications in vehicles.

- AI-driven estimators can advance beyond conventional model-based observers by learning complex, nonlinear relationships between tire, vehicle, and environmental variables directly from noisy sensor data. This capability allows them to adaptively infer friction levels, making them superior to traditional methods that struggle with uncertainties introduced by combined environmental effects.

- The ability of AI models to learn these “complex, nonlinear relationships” leads to the “black box” problem, where the decision-making process is opaque and lacks transparency. A variant could be moving towards hybrid systems, combining data-driven learning with physical modeling constraints, producing estimators that are both adaptive and interpretable. This necessity for interpretability points directly to the lack of transparency in purely data-driven models.

- AI models, especially those using external sensors like cameras for TRFC estimation, face significant challenges in generalization across varying lighting and weather conditions.

- The need for large, labeled datasets is a continuous challenge in development. Furthermore, their robustness is highly susceptible to sensor failures, highlighting their reliance on continuous, clean data streams.

- Fully coupled multi-physics wear models (thermal–mechanical–chemical): Advanced models like FTire account for thermo-mechanical effects and predict wear based on load, pressure, and road conditions. However, these models are often computationally expensive. There is a lack of computationally efficient and generalized models that fully integrate the thermal state, mechanical deformation, and chemical aspects (e.g., oxidative degradation and filler dispersion effects on wear) over a tire’s lifespan and across a wide range of operating conditions.

- Standardized, predictive models for tire wear particle generation and diffusion: The new Euro 7 regulations impose limits on non-exhaust particle emissions, highlighting the critical nature of this gap. Strategies to mitigate TWP emissions are multi-tiered (material innovation, operational measures, and environmental management). There is a particular need for harmonized methods to quantify tire abrasion and emissions. Specifically, the lack of a standardized prediction model that accurately forecasts the rate (generation) and fate (diffusion and environmental transport) of TWPs, linking them directly to complex, real-time tribological interactions, is a persistent gap.

- Real-time, adaptive TRFC estimation under combined environmental effects: Real-time friction estimation is essential for vehicle safety systems. Progress has been made using hybrid AI-enhanced estimators and sensor-based models. Despite advancements, the modeling of combined environmental factors (e.g., water, ice, dust, and temperature variations) remains insufficiently developed, preventing robust, highly accurate real-time friction prediction under all complex and transient conditions. This is particularly challenging for new systems like electric and autonomous vehicles which have distinct loading and torque patterns.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oh, Y.; Lee, H. Characteristics of tire friction and performance of braking in high-speed driving. Adv. Mech. Eng. 2014, 6, 260428. [Google Scholar] [CrossRef]

- Cabrera, J.A.; Castillo, J.J.; Pérez, J.; Velasco, J.M.; Guerra, A.J.; Hernández, P. A procedure for determining tire-road friction characteristics using a modification of the Magic Formula based on experimental results. Sensors 2018, 18, 896. [Google Scholar] [CrossRef] [PubMed]

- Fedotov, A.I.; Markov, A.S.; Makhno, D.E.; Vikulov, M.A. Influence of tire tread pattern wear on characteristics of its longitudinal adhesion with bearing surface. IOP Conf. Ser. Mater. Sci. Eng. 2019, 632, 012026. [Google Scholar] [CrossRef]

- Kasprzak, E.; Lewis, K.; Milliken, D.; Inflation Pressure Effects in the Nondimensional Tire Model. SAE Technical Paper 2006-01-3607. 2006. Available online: https://legacy.sae.org/publications/technical-papers/content/2006-01-3607/ (accessed on 20 October 2025).

- Srirangam, S.; Anupam, K.; Scarpas, T.; Kösters, A. Influence of Temperature on Tire-Pavement Friction—I: Laboratory Tests and Finite Element Modeling. 2013. Available online: https://www.researchgate.net/publication/262419305_Influence_of_Temperature_on_Tire-Pavement_Friction-I_Laboratory_Tests_and_Finite_Element_Modeling (accessed on 20 October 2025).

- Kováč, M.; Brna, M.; Pisca, P.; Decký, M. Prediction of friction coefficient based on 3D texture characteristics of road surfaces. Appl. Sci. 2024, 14, 7549. [Google Scholar] [CrossRef]

- Klein-Paste, A.; Sinha, N.K. Comparison between rubber–ice and sand–ice friction and the effect of loose snow contamination. Tribol. Int. 2010, 43, 1145–1150. [Google Scholar] [CrossRef]

- Mayer, P.M.; Moran, K.D.; Miller, E.L.; Brander, S.M.; Harper, S.; Garcia-Jaramillo, M.; Carrasco-Navarro, V.; Ho, K.T.; Burgess, R.M.; Hampton, L.M.T.; et al. Where the rubber meets the road: Emerging environmental impacts of tire wear particles and their chemical cocktails. Sci. Total Environ. 2024, 927, 171153. [Google Scholar] [CrossRef]

- Deng, S.; Chen, R.; Duan, S.; Jia, Q.; Hao, X.; Zhang, L. Research progress on sustainability of key tire materials. SusMat 2023, 3, 581–608. [Google Scholar] [CrossRef]

- Ha, J.U.; Bae, S.H.; Choi, Y.J.; Lee, P.C.; Jeoung, S.K.; Song, S.; Choi, C.; Lee, J.S.; Kim, J.; Han, I.S. Control of tire wear particulate matter through tire tread prescription. Polymers 2023, 15, 2795. [Google Scholar] [CrossRef]

- Butilă, E.V.; Boboc, R.G. Mapping the Landscape of Romanian Automotive Research: A Bibliometric Analysis. Vehicles 2025, 7, 31. [Google Scholar] [CrossRef]

- Majcherczyk, R. Influence of the geometric roughness of a wearing course on the escape of water at the tyre/road interface and on the skidding of vehicles. Ann. Inst. Tech. Bat. Trav. Publ. 1974, 318, 37–68. [Google Scholar]

- Wang, M.-J.; Kutsovsky, Y. Effect of fillers on wet skid resistance of tires. Part I: Water lubrication vs. filler-elastomer interactions. Rubber Chem. Technol. 2008, 81, 552–575. [Google Scholar] [CrossRef]

- Yu, M.; Tong, S.-Y.; Kong, L.-Y.; Shi, L.-L. A review of tire-asphalt pavement friction measurement and skid resistance model study. J. Highw. Transp. Res. Dev. 2020, 37, 12–24. [Google Scholar] [CrossRef]

- Heinrich, G.; Klüppel, M. Rubber friction, tread deformation and tire traction. Wear 2008, 265, 1052–1060. [Google Scholar] [CrossRef]

- Lee, H.; Taheri, S. Intelligent Tires—A Review of Tire Characterization Literature. IEEE Intell. Transp. Syst. Mag. 2017, 9, 114–135. [Google Scholar] [CrossRef]

- Nishikura, S.; Usui, H.; Takematsu, K. Tractive performance analysis of part-time four-wheel-drive vehicle. JSAE Rev. 1981, 5, 39–44. [Google Scholar]

- Warner, C.Y.; Smith, G.C.; James, M.B.; Germane, G.J.; Friction Applications in Accident Reconstruction. SAE Technical Paper 830612. 1983. Available online: https://saemobilus.sae.org/papers/friction-applications-accident-reconstruction-830612 (accessed on 20 October 2025).

- Chen, H.; Gao, B.; Xu, F. Review on vehicle sideslip angle estimation. J. Mech. Eng. 2013, 49, 76–94. [Google Scholar] [CrossRef]

- Samuelraj, D.; Jaichandar, S.; Gowthama Rajan, B.; Govindan, S. Coefficient of friction in different road conditions by various control methods—An overall review. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 9–20. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, Y.; Wu, J.; Zhang, Y. A Comprehensive Review of Vehicle and Road Condition Estimation Techniques. SAE Int. J. Veh. Dyn. Stab. NVH 2025, 9, 253–283. [Google Scholar] [CrossRef]

- Sledge, N.H., Jr.; Marshek, K.M. Vehicle Critical Speed Formula—Values for the Coefficient of Friction—A Review. SAE Technical Paper 971148. 1997. Available online: https://saemobilus.sae.org/papers/vehicle-critical-speed-formula-values-coefficient-friction-a-review-971148 (accessed on 20 October 2025).

- John, S.; Pedro, J.O. Review of tyre/road friction coefficient estimation for ABS controller design. In Proceedings of the 5th South African Conference on Computational and Applied Mechanics (SACAM 2006), Cape Town, South Africa, 16–18 January 2006; pp. 432–440. [Google Scholar]

- Ahn, C.; Peng, H.; Tseng, H.E. Estimation of road friction for enhanced active safety systems: Algebraic approach. In Proceedings of the American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 1104–1109. [Google Scholar] [CrossRef]

- Li, B.; Du, H.; Li, W. Comparative study of vehicle tyre-road friction coefficient estimation with a novel cost-effective method. Veh. Syst. Dyn. 2014, 52, 1066–1098. [Google Scholar] [CrossRef]

- Rajendran, S.; Spurgeon, S.K.; Tsampardoukas, G.; Hampson, R. Estimation of road frictional force and wheel slip for effective antilock braking system (ABS) control. Int. J. Robust Nonlinear Control 2019, 29, 736–765. [Google Scholar] [CrossRef]

- Fwa, T.F. Determination and prediction of pavement skid resistance—Connecting research and practice. J. Road Eng. 2021, 1, 43–62. [Google Scholar] [CrossRef]

- Zhao, Z.; Fan, X. Review of vehicle active safety systems and their coordinated control. Recent Pat. Mech. Eng. 2021, 14, 4–17. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, J.; Wang, F.A.; Dong, H.; Yan, Y.; Ren, Y.; Zhou, C.; Yin, G. Tire Road Friction Coefficient Estimation: Review and Research Perspectives. Chin. J. Mech. Eng. 2022, 35, 6. [Google Scholar] [CrossRef]

- Qi, G.; Fan, X.; Li, H. A review on identification methods of road friction coefficient. Recent Pat. Eng. 2022, 16, e180122190907. [Google Scholar] [CrossRef]

- Preda, I. Tire-ground grip: Another perspective. Ing. Automob. 2024, 71, 5–19. [Google Scholar] [CrossRef]

- Tan, Y.; Li, J.; Xu, H.; Li, Z.; Wang, H. The mechanisms, evaluation and estimation of anti-skid performance of snowy and icy pavement: A review. J. Road Eng. 2023, 3, 229–238. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, H.; Hui, B. Driving safety analysis using grid-based water-filled rut depth distribution. Adv. Mater. Sci. Eng. 2021, 2021, 5568949. [Google Scholar] [CrossRef]

- Singh, K.B.; Arat, M.A.; Taheri, S. Literature review and fundamental approaches for vehicle and tire state estimation. Veh. Syst. Dyn. 2019, 57, 1643–1665. [Google Scholar] [CrossRef]

- Guo, H.; Yin, Z.; Cao, D.; Chen, H.; Lv, C. A review of estimation for vehicle tire-road interactions toward automated driving. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 14–30. [Google Scholar] [CrossRef]

- Ivanov, V.G. Investigation into tyre-road interaction based on fuzzy logic methods. Int. J. Veh. Auton. Syst. 2005, 3, 198–215. [Google Scholar] [CrossRef]

- Huang, Z.; Fan, X. A review on estimation of vehicle tyre-road friction. Int. J. Heavy Veh. Syst. 2024, 31, 49–86. [Google Scholar] [CrossRef]

- Xiong, Y.; Yang, X. A review on in-tire sensor systems for tire-road interaction studies. Sens. Rev. 2018, 38, 231–238. [Google Scholar] [CrossRef]

- Mohanta, B.S.; Kumar, A. A parametric analysis on the performance of vehicle tires. Mater. Today Proc. 2022, 56, 1234–1240. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Tabor, D. Tabor, Friction and adhesion. Surface forces in friction and adhesion. Faraday Spec. Discuss. Chem. Soc. 1972, 2, 7–17. [Google Scholar] [CrossRef]

- Al-Assi, M.; Kassem, E. Evaluation of adhesion and hysteresis friction of rubber–pavement system. Appl. Sci. 2017, 7, 1029. [Google Scholar] [CrossRef]

- Han, Y.; Lu, Y.; Liu, J.; Zhang, J. Research on tire/road peak friction coefficient estimation considering effective contact characteristics between tire and three-dimensional road surface. Machines 2022, 10, 614. [Google Scholar] [CrossRef]

- Zheng, B.; Tang, J.; Chen, J.; Zhao, R.; Huang, X. Investigation of adhesion properties of tire–asphalt pavement interface considering hydrodynamic lubrication action of water film on road surface. Materials 2022, 15, 4173. [Google Scholar] [CrossRef]

- Nikolić, M.; Banić, M.; Stamenković, D.; Simonović, M.; Miltenović, A.; Pavlović, V. The Influence of Rubber Hysteresis on the Sliding Friction Coefficient During Contact Between Viscoelastic Bodies and a Hard Substrate. Appl. Sci. 2024, 14, 11820. [Google Scholar] [CrossRef]

- Liu, X.; Luo, H.; Chen, C.; Zhu, L.; Chen, S.; Ma, T.; Huang, X. A technical survey on mechanism and influence factors for asphalt pavement skid-resistance. Friction 2024, 12, 845–868. [Google Scholar] [CrossRef]

- Liang, K.; Tu, Q.; Shen, X.; Dai, J.; Yin, Q.; Xue, J.; Ding, X. Modeling and verification of rolling resistance torque of high-speed rubber track assembly considering hysteresis loss. Polymers 2023, 15, 1642. [Google Scholar] [CrossRef]

- Mashadi, B.; Ebrahimi-Nejad, S.; Abbaspour, M. A rolling resistance estimate using nonlinear finite element numerical analysis of a full three-dimensional tyre model. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2019, 233, 147–160. [Google Scholar] [CrossRef]

- Lorenz, B.; Persson, B.; Fortunato, G.; Giustiniano, M. Rubber friction for tire tread compound on road surfaces. J. Phys. Condens. Matter 2013, 25, 095007. [Google Scholar] [CrossRef]

- Li, Z.; Chen, W.; Li, Y.; Wu, W. Finite element analysis of tyre contact interaction considering simplified pavement with different aggregate sizes. Appl. Sci. 2023, 13, 12011. [Google Scholar] [CrossRef]

- Chen, B.; Ding, P.; Wei, G.; Xiong, C.; Wang, F.; Yu, J.; Yu, H.; Zou, Y. A study on the contact characteristics of tires–roads based on pressure-sensitive film technology. Materials 2023, 16, 6323. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.; Li, H.; Mousavi, H.; Wang, G.; Yu, K. Evaluation and improvement of tire rolling resistance and grip performance based on test and simulation. Adv. Mech. Eng. 2020, 12, 1687814020981173. [Google Scholar] [CrossRef]

- Pacejka, H. Tire and Vehicle Dynamics, 3rd ed.; Elsevier: Oxford, UK, 2012; ISBN 9780080970165. [Google Scholar]

- Mark, J.E.; Erman, B.; Eirich, F.R. (Eds.) The Science and Technology of Rubber, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780123945846. [Google Scholar]

- Watanabe, A.; Kageyama, I.; Kuriyagawa, Y.; Haraguchi, T.; Kaneko, T.; Nishio, M. Study on the Influence of Environmental Conditions on Road Friction Characteristics. Lubricants 2023, 11, 277. [Google Scholar] [CrossRef]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics; Society of Automotive Engineers: Warrendale, PA, USA, 1992; ISBN 1560911999. [Google Scholar]

- Clark, S.K. (Ed.) Mechanics of Pneumatic Tires; NBS Monograph 122; U.S. National Bureau of Standards: Gaithersburg, MD, USA, 1971.

- Zhang, Y.; Yi, J. Static Tire/Road Stick–Slip Interactions: Analysis and Experiments. IEEE/ASME Trans. Mechatron. 2014, 19, 1865–1874. [Google Scholar] [CrossRef]

- ASTM E303-93; Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM International: West Conshohocken, PA, USA, 2013.

- Li, J.; Zhang, Y.; Yi, J. A Hybrid Physical-Dynamic Tire/Road Friction Model. J. Dyn. Syst. Meas. Control. 2013, 135, 011007. [Google Scholar] [CrossRef]

- Popp, K.; Schiehlen, W. Ground Vehicle Dynamics; Springer: Berlin/Heidelberg, Germany, 2010; p. 265. [Google Scholar] [CrossRef]

- Jazzar, R.N. Vehicle Dynamics: Theory and Application; Springer Science+Business Media: New York, NY, USA, 2008; p. 131. ISBN 978-0-387-74243-4. [Google Scholar]

- Dick, J.S. Rubber Technology: Compounding and Testing for Performance; Carl Hanser Verlag: Munich, Germany, 2020; ISBN 978-1-56990-615-6. [Google Scholar] [CrossRef]

- Mark, J.E.; Erman, B.; Eirich, F.R. (Eds.) Science and Technology of Rubber; Elsevier: Amsterdam, The Netherlands, 2005; ISBN 978-0-12-464786-2. [Google Scholar] [CrossRef]

- Wilder, C.R.; Haws, J.R. Performance of Tread Compounds in Various Tire Constructions. Rubber Chem. Technol. 1972, 45, 10–15. [Google Scholar] [CrossRef]

- Sattayanurak, S.; Noordermeer, J.W.M.; Sahakaro, K.; Kaewsakul, W.; Dierkes, W.K.; Blume, A. Silica-Reinforced Natural Rubber: Synergistic Effects by Addition of Small Amounts of Secondary Fillers to Silica-Reinforced Natural Rubber Tire Tread Compounds. Adv. Mater. Sci. Eng. 2019, 2019, 5891051. [Google Scholar] [CrossRef]

- Sarkawi, S.S.; Kaewsakul, W.; Sahakaro, K.; Dierkes, W.K.; Noordermeer, J.W.M. A Review on Reinforcement of Natural Rubber by Silica Fillers for Use in Low-Rolling Resistance Tyres. J. Rubber Res. 2015, 18, 203–233. [Google Scholar]

- Hess, W.M.; Klamp, W.K. The Effects of Carbon Black and Other Compounding Variables on Tire Rolling Resistance and Traction. Rubber Chem. Technol. 1983, 56, 390–417. [Google Scholar] [CrossRef]

- Krasnovskikh, M.; Mokrushin, I.; Novoselov, K.; Kulikova, Y.; Toderaş, M.; Bassyouni, M.; Babich, O. Recovered Carbon Black from Tires as Carbon Carrier in Metal Oxide Catalytic Systems. S. Afr. J. Chem. Eng. 2024, 49, 64–72. [Google Scholar] [CrossRef]

- Rattanasom, N.; Poonsuk, A.; Makmoon, T. Effect of Curing System on the Mechanical Properties and Heat Aging Resistance of Natural Rubber/Tire Tread Reclaimed Rubber Blends. Polym. Test. 2005, 24, 728–732. [Google Scholar] [CrossRef]

- Higuchi, M.; Suzuki, Y.; Sasano, T.; Tachiya, H. Measurement of Road Friction Coefficient Using Strain on Tire Sidewall. Precis. Eng. 2023, 84, 28–36. [Google Scholar] [CrossRef]

- Wright, P.H.; Dixon, K.K. Highway Engineering, 7th ed.; Wiley India Pvt. Ltd.: New Delihi, India, 2009; ISBN 8126524510. [Google Scholar]

- Sandberg, U.; Ejsmont, J.A.; Bergiers, A.; Goubert, L.; Zöller, M.; Karlsson, R. Road Surface Influence on Tyre/Road Rolling Resistance; (MIRIAM_SP1_04 Report); Deliverable Version: 2011-12-31; Swedish Road and Transport Research Institute (VTI): Linköping, Sweden, 2011. [Google Scholar]

- Sandberg, U. (Ed.) Models for Rolling Resistance in Road Infrastructure Asset Management Systems: Basic Information and State-of-the-Art on Measurement Methods; MIRIAM SP1; Deliverable #1; Swedish Road and Transport Research Institute (VTI): Linköping, Sweden, 2011. [Google Scholar]

- Ejsmont, J.; Sommer, S. Selected Aspects of Pavement Texture Influence on Tire Rolling Resistance. Coatings 2021, 11, 776. [Google Scholar] [CrossRef]

- ASTM E274/E274M-15; Standard Test Method for Skid Resistance of Paved Surfaces Using a Full-Scale Tire. ASTM International: West Conshohocken, PA, USA, 2020.

- Chen, D.; Han, S.; Ye, A.; Ren, X.; Wang, W.; Wang, T. Prediction of Tire–Pavement Friction Based on Asphalt Mixture Surface Texture Level and Its Distributions. Road Mater. Pavement Des. 2019, 21, 1545–1564. [Google Scholar] [CrossRef]

- Schläfle, S.; Unrau, H.-J.; Gauterin, F. Influence of Load Condition, Tire Type, and Ambient Temperature on the Emission of Tire–Road Particulate Matter. Atmosphere 2023, 14, 1095. [Google Scholar] [CrossRef]

- Anupam, K.; Srirangam, S.K.; Scarpas, A.; Kasbergen, C. Influence of Temperature on Tire–Pavement Friction: Analyses: Analyses. Transp. Res. Rec. J. Transp. Res. Board 2013, 2369, 114–124. [Google Scholar] [CrossRef]

- Angrick, C.; van Putten, S.; Prokop, G. Influence of Tire Core and Surface Temperature on Lateral Tire Characteristics. SAE Int. J. Passeng. Cars-Mech. Syst. 2014, 7, 468–481. [Google Scholar] [CrossRef]

- Clark, J.D.; Schuring, D.J. Load, Speed and Inflation Pressure Effects on Rolling Loss Distribution in Automobile Tires. Tire Sci. Technol. 1988, 16, 78–95. [Google Scholar] [CrossRef]

- Fabela-Gallegos, M.; Hernandez-Jimenez, R.; Reyes-Vidales, A. Effect of Load and Inflation Pressure on Contact Force and Pressure Distribution for Two Types of Light Duty Truck Tires. SAE Technical Paper 2007-01-4258. 2007. Available online: https://legacy.sae.org/publications/technical-papers/content/2007-01-4258/ (accessed on 20 October 2025).

- Prozzi, J.A.; Luo, R. Quantification of the Joint Effect of Wheel Load and Tire Inflation Pressure on Pavement Response. Transp. Res. Rec. 2005, 1919, 134–141. [Google Scholar] [CrossRef]

- Thombare, D. Analysis of Effect of Tire Inflation Pressure, Inflation Fluids, Load and Speed on Tire Performance. SAE Technical Paper 2019-26-0368. 2019. Available online: https://legacy.sae.org/publications/technical-papers/content/2019-26-0368/ (accessed on 20 October 2025).

- Höpping, K.; Augsburg, K.; Büchner, F. Extending the HSRI Tyre Model for Large Inflation Pressure Changes. In Proceedings of the 59th Ilmenau Scientific Colloquium, Technische Universität Ilmenau, Ilmenau, Germany, 11–15 September 2017; pp. 1–20. [Google Scholar]

- Bijina, V.; Jandas, P.J.; Joseph, S.; Gopu, J.; Abhitha, K.; John, H. Recent Trends in Industrial and Academic Developments of Green Tyre Technology. Polym. Bull. 2023, 80, 8215–8244. [Google Scholar] [CrossRef] [PubMed]

- Trellis. How Michelin and Bridgestone Are Accelerating Green Tire Innovations. Available online: https://trellis.net/article/how-michelin-and-bridgestone-are-accelerating-green-tire-innovations/ (accessed on 30 July 2025).

- European Raptors. Eco-Friendly Tires: How Green Technology Is Shaping the Tire Industry. Available online: https://europeanraptors.org/eco-friendly-tires-how-green-technology-is-shaping-the-tire-industry/ (accessed on 21 July 2025).

- Sustainable Tire Technology: The Impact of Rice Husk Silica. Available online: https://www.nbinno.com/article/reinforcing-agents/sustainable-tire-technology-the-impact-of-rice-husk-silica-pz (accessed on 20 October 2025).

- Tire Review. 5 Ways EV Tires Differ from Regular Tires. Available online: https://www.tirereview.com/5-ways-ev-tires-differ-from-regular-tires/ (accessed on 22 July 2025).

- Fathi, H.; El-Sayegh, Z.; Ren, J.; El-Gindy, M. Analysis of tire-road interaction: A literature review. Machines 2024, 12, 812. [Google Scholar] [CrossRef]

- Wikipedia. Tire Model. Available online: https://en.wikipedia.org/wiki/Tire_model (accessed on 17 September 2025).

- Pacejka, H.B.; Bakker, E. The Magic Formula Tyre Model. Veh. Syst. Dyn. 1992, 21, 1–18. [Google Scholar] [CrossRef]

- Pacejka, H.B. Modelling of Tyre Force and Moment Generation. In Rolling Contact Phenomena; Jacobson, B., Kalker, J.J., Eds.; International Centre for Mechanical Sciences: Vienna, Austria, 2000; Volume 411, pp. 143–172. [Google Scholar] [CrossRef]

- Enisz, K.; Szalay, I.; Kohlrusz, G.; Fodor, D. Tyre–Road Friction Coefficient Estimation Based on the Discrete-Time Extended Kalman Filter. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 229, 1158–1168. [Google Scholar] [CrossRef]

- Zareian, A.; Azadi, S.; Kazemi, R. Estimation of Road Friction Coefficient Using Extended Kalman Filter, Recursive Least Square, and Neural Network. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2015, 230, 52–68. [Google Scholar] [CrossRef]

- Li, K.; Cao, J.; Yu, F. Nonlinear Tire–Road Friction Control Based on Tire Model Parameter Identification. Int. J. Automot. Technol. 2012, 13, 1077–1088. [Google Scholar] [CrossRef]

- Dugoff, H.; Fancher, P.S.; Segel, L. An Analysis of Tire Traction Properties and Their Influence on Vehicle Dynamic Performance. SAE Trans. 1970, 79, 1219–1243. [Google Scholar]

- Qi, G.; Fan, X.; Li, H. A Comparative Study of the Unscented Kalman Filter and Particle Filter Estimation Methods for the Measurement of the Road Adhesion Coefficient. Mech. Sci. 2022, 13, 735–749. [Google Scholar] [CrossRef]

- Patra, N.; Datta, K. Sliding Mode Controller for Wheel-Slip Control of Anti-Lock Braking System. In Proceedings of the 2012 IEEE International Conference on Advanced Communication Control and Computing Technologies (ICACCCT), Ramanathapuram, India, 23–25 August 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 385–391. [Google Scholar] [CrossRef]

- Wang, G.; Li, S.; Feng, G. Online Estimation of Three-Directional Tire Forces Based on a Self-Organizing Neural Network. Machines 2023, 11, 344. [Google Scholar] [CrossRef]

- Patra, N.; Datta, K. Observer Based Road–Tire Friction Estimation for Slip Control of Braking System. Procedia Eng. 2012, 38, 1566–1574. [Google Scholar] [CrossRef]

- Liu, F.; Sutcliffe, M.; Graham, W.R. Prediction of Tread Block Forces for a Free-Rolling Tyre in Contact with a Rough Road. Wear 2010, 269, 672–683. [Google Scholar] [CrossRef]

- Gao, L.; Xiong, L.; Lin, X.; Xia, X.; Liu, W.; Lu, Y.; Yu, Z. Multi-Sensor Fusion Road Friction Coefficient Estimation During Steering with Lyapunov Method. Sensors 2019, 19, 3816. [Google Scholar] [CrossRef]

- Singh, K.B.; Taheri, S. Estimation of Tire–Road Friction Coefficient and Its Application in Chassis Control Systems. Syst. Sci. Control Eng. 2014, 3, 39–61. [Google Scholar] [CrossRef]

- Singh, K.B.; Ali Arat, M.; Taheri, S. An Intelligent Tire Based Tire–Road Friction Estimation Technique and Adaptive Wheel Slip Controller for Antilock Brake System. J. Dyn. Syst. Meas. Control 2013, 135, 031002. [Google Scholar] [CrossRef]

- Canudas-de-Wit, C.; Tsiotras, P.; Velenis, E.; Basset, M.; Gissinger, G. Dynamic Friction Models for Road/Tire Longitudinal Interaction. Veh. Syst. Dyn. 2003, 39, 189–226. [Google Scholar] [CrossRef]

- Romano, L.; Bruzelius, F.; Jacobson, B. An Extended LuGre-Brush Tyre Model for Large Camber Angles and Turning Speeds. Veh. Syst. Dyn. 2022, 61, 1674–1706. [Google Scholar] [CrossRef]

- Yamashita, H.; Jayakumar, P.; Sugiyama, H. Physics-Based Flexible Tire Model Integrated with LuGre Tire Friction for Transient Braking and Cornering Analysis. J. Comput. Nonlinear Dyn. 2016, 11, 031001. [Google Scholar] [CrossRef]

- Liang, W.; Medanic, J.; Ruhl, R. Analytical Dynamic Tire Model. Veh. Syst. Dyn. 2008, 46, 197–227. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Senatore, A.; Farnam, A.; Akbari, A.; Timpone, F. A Real-Time Approach to Robust Identification of Tyre–Road Friction Characteristics on Mixed-μ Roads. Veh. Syst. Dyn. 2018, 57, 1338–1362. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J. Vehicle-Longitudinal-Motion-Independent Real-Time Tire–Road Friction Coefficient Estimation. In Proceedings of the 49th IEEE Conference on Decision and Control (CDC), Atlanta, GA, USA, 15–17 December 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 2910–2915. [Google Scholar]

- Wang, X.; Gu, L.; Dong, M.; Li, X. State Estimation of Tire–Road Friction and Suspension System Coupling Dynamic in Braking Process and Change Detection of Road Adhesive Ability. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 236, 1170–1187. [Google Scholar]

- Zhang, X.; Xu, Y.; Pan, M.; Ren, F. A Vehicle ABS Adaptive Sliding-Mode Control Algorithm Based on the Vehicle Velocity Estimation and Tyre/Road Friction Coefficient Estimations. Veh. Syst. Dyn. 2014, 52, 475–503. [Google Scholar] [CrossRef]

- Xia, X.; Xiong, L.; Sun, K.; Yu, Z.P. Estimation of Maximum Road Friction Coefficient Based on Lyapunov Method. Int. J. Automot. Technol. 2016, 17, 991–1002. [Google Scholar] [CrossRef]

- Dousti, M.; Baslamisli, S.C.; Onder, E.T.; Solmaz, S. Design of a Multiple-Model Switching Controller for ABS Braking Dynamics. Trans. Inst. Meas. Control 2015, 37, 582–595. [Google Scholar] [CrossRef]

- Oertel, C.; Wei, Y. Tyre rolling kinematics and prediction of tyre forces and moments: Part I-theory and method. Veh. Syst. Dyn. 2012, 50, 1673–1687. [Google Scholar] [CrossRef]

- Miyashita, N.; Kabe, K. A New Analytical Tire Model for Cornering Simulation. Part II: Cornering Force and Self-Aligning Torque. Tire Sci. Technol. 2006, 34, 100–118. [Google Scholar]

- Fathi, H.; Khosravi, M.; El-Sayegh, Z.; El-Gindy, M. An Advancement in Truck-Tire–Road Interaction Using the Finite Element Analysis. Mathematics 2023, 11, 2462. [Google Scholar] [CrossRef]

- Taheri, S. Finite Element Modeling of Tire-Terrain Dynamic Interaction for Full Vehicle Simulation Applications. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2014. [Google Scholar]

- Di Monaco, F.; Moos, S.; Tornincasa, S.; Vezzetti, E. Guidelines for the Design of Tyre Sensor Housings. Int. J. Adv. Manuf. Technol. 2014, 75, 573–597. [Google Scholar] [CrossRef]

- Besselink, I.J.M.; Pacejka, H.B.; Schmeitz, A.J.C.; Jansen, S.T.H. The SWIFT Tyre Model: Overview and Applications. In Proceedings of the 7th International Symposium on Advanced Vehicle Control 2004, AVEC’04; Pauwelussen, J.P., Ed.; KIVI NIRIA: Den Haag, The Netherlands, 2004; pp. 525–530. [Google Scholar]

- Rajamani, R. Vehicle Dynamics and Control, 2nd ed.; Springer: New York, NY, USA, 2012; pp. 386–389. [Google Scholar] [CrossRef]

- Cosin. FTire Model Documentation. Available online: https://www.cosin.eu/wp-content/uploads/ftire_model.pdf (accessed on 22 July 2025).

- Stallmann, M.J. Cost Effective FTire Parameterisation Methods for Ride Simulations with Large Off-the-Road Tyres. Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 2018; p. 21. Available online: https://repository.up.ac.za/items/fc334464-e094-472d-922c-a1e3125b6502 (accessed on 25 September 2025).

- Fathi, H.; El-Sayegh, Z.; Ren, J.; El-Gindy, M. Modeling and Validation of a Passenger Car Tire Using Finite Element Analysis. Vehicles 2024, 6, 384–402. [Google Scholar] [CrossRef]

- Ghoreishy, M.H.R. A State of the Art Review of the Finite Element Modelling of Rolling Tyres. Iran. Polym. J. 2008, 17, 571–597. Available online: https://www.researchgate.net/publication/279900580_A_state_of_the_art_review_of_the_finite_element_modelling_of_rolling_tyres (accessed on 20 October 2025).

- Lu, D.; Zhang, Y. Research on Simplified Tire Finite Element Modeling and Simulation Method. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2025, 239, 447–463. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Li, H.Q.; Lin, F.; Wang, J.; Ji, X.W. Estimation of Road Friction Coefficient in Different Road Conditions Based on Vehicle Braking Dynamics. Chin. J. Mech. Eng. 2017, 30, 982–990. [Google Scholar] [CrossRef]

- Xu, G.; Xu, J.; Shan, H.; Gao, C.; Ran, J.; Ma, Y.; Yao, Y. The Influence of the Pavement Friction Coefficient Evolution Caused by Traffic Flow on the Risk of Motorway Horizontal Curves. PLoS ONE 2022, 17, e0266519. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.-S.; Peng, H. Road Friction Coefficient Estimation for Vehicle Path Prediction. Veh. Syst. Dyn. 1996, 25, 413–425. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, H.; Zhao, H.; Zhou, H. Road Tire Friction Coefficient Estimation for Four Wheel Drive Electric Vehicle Based on Moving Optimal Estimation Strategy. Mech. Syst. Signal Process 2020, 139, 106416. [Google Scholar] [CrossRef]

- Kelly, M.; Farhad, S. Simplified mathematical modeling and parametric study on friction coefficient of rubber materials for vehicle’s tire application. Polym. Eng. Sci. 2022, 62, 4032. [Google Scholar] [CrossRef]

- Tomer, A.; Chepyala, S.; Mukhopadhyay, R.; Ghosh, P. Influence of Tyre Rolling Resistance and Operational Parameters on Vehicle Fuel Efficiency. SAE Technical Paper 2021-26-0503. 2021. Available online: https://www.sae.org/papers/influence-tyre-rolling-resistance-operational-parameters-vehicle-fuel-efficiency-2021-26-0503 (accessed on 20 October 2025).

- Ludema, K.C.; Tabor, D. The Friction and Visco-Elastic Properties of Polymeric Solids. Wear 1966, 9, 329–348. [Google Scholar] [CrossRef]

- Jung, U.; Choi, S.-S. Classification and Characterization of Tire-Road Wear Particles in Road Dust by Density. Polymers 2022, 14, 1005. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, O.; Hwang, Y.; Yeon, G. Laboratory Evaluation of Wear Particle Emissions and Suspended Dust in Tire–Asphalt Concrete Pavement Friction. Appl. Sci. 2024, 14, 6362. [Google Scholar] [CrossRef]

- Yun, D.; Hu, L.; Tang, C. Tire–Road Contact Area on Asphalt Concrete Pavement and Its Relationship with the Skid Resistance. Materials 2020, 13, 615. [Google Scholar] [CrossRef] [PubMed]

- Lang, A.; Klüppel, M. Influences of Temperature and Load on the Dry Friction Behaviour of Tire Tread Compounds in Contact with Rough Granite. Wear 2017, 380–381, 15–25. [Google Scholar] [CrossRef]

- Persson, B.N.J. Rubber friction: Role of the flash temperature. J. Phys. Condens. Matter 2006, 18, 7789–7823. [Google Scholar] [CrossRef] [PubMed]

- Michelin. Do You Have Under-Inflated Tires?|Michelin, U.S.A. Available online: https://www.michelinman.com (accessed on 18 September 2025).

- Singh, K.B.; Sivaramakrishnan, S. Extended Pacejka Tire Model for Enhanced Vehicle Stability Control. Available online: https://www.alphaxiv.org/abs/2305.18422 (accessed on 15 September 2025).

- Liu, J.; Wang, M.; Yin, H. A Study of the Friction Characteristics of Rubber Thermo-Mechanical Coupling. Polymers 2024, 16, 596. [Google Scholar] [CrossRef]

- Meyer, W.E.; Kummer, H.W. Pavement Frictions and Temperature Effect. Available online: https://onlinepubs.trb.org/Onlinepubs/sr/sr101/101-005.pdf (accessed on 19 September 2025).

- Zhang, Y.; Gao, J.; Li, Q. Experimental Study on Friction Coefficients between Tire Tread Rubber and Ice. AIP Adv. 2018, 8, 075005. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, H.; Zhang, Y.; Jelagin, D.; Hui, B. Study of the Surface Texture Evolution and Friction Degradation in Asphalt Pavements during Wear Process. Wear 2025, 564–565, 205714. [Google Scholar] [CrossRef]

- Tolpekina, T.V.; Persson, B.N.J. Adhesion and friction for three tire tread compounds. Lubricants 2019, 7, 20. [Google Scholar] [CrossRef]

- Lang, A.; Klüppel, M. Modelling Predictions and Experimental Investigations of Rubber Friction and Tire Traction. In Proceedings of the 4th International Tyre Colloquium: Tyre Models for Vehicle Dynamics Analysis, University of Surrey, Guildford, UK, 20–21 April 2015. [Google Scholar]

- Nosko, O.; Tsybrii, Y.; Torrelio Arias, P.G.; Senatore, A. Temperature measurements at tyre tread rubber on sandpaper oscillatory sliding contacts using acicular grindable thermocouples. Tribol. Lett. 2024, 72, 75. [Google Scholar] [CrossRef]

- Zhang, M.; Unrau, H.-J.; Gießler, M.; Gauterin, F. Tire tread wear characteristics: Insights from indoor experiments and analytical modeling. Tribol. Int. 2025, 210, 110752. [Google Scholar] [CrossRef]

- Shenvi, M.N.; Verulkar, A.; Sandu, C.; Mousavi, H. Tread Rubber Compound Effect in Winter Tires: An Experimental Study. J. Terramech. 2022, 99, 57–73. [Google Scholar] [CrossRef]

- SAE J2452; Measurement of Tire-to-Road Friction Coefficient as a Function of Slip. SAE International: Warrendale, PA, USA, 2017. Available online: https://www.sae.org/standards/content/j2452_201707/ (accessed on 14 July 2025).

- Fortunato, G.; Ciaravola, V.; Furno, A.; Scaraggi, M.; Lorenz, B.; Persson, B.N.J. On the dependency of rubber friction on the normal force or load: Theory and experiment. arXiv 2015, arXiv:1512.01359. [Google Scholar] [CrossRef]

- Khaleghian, S.; Emami, A.; Taheri, S. A technical survey on tire-road friction estimation. Friction 2017, 5, 123–146. [Google Scholar] [CrossRef]

- Ayar, M.; Dalkiran, A.; Kale, U.; Nagy, A.; Karakoc, T.H. Investigation of the substitutability of rubber compounds with environmentally friendly materials. Sustainability 2021, 13, 5251. [Google Scholar] [CrossRef]

- Stolze, A.; Wanke, A.; van Deenen, N.; Geyer, R.; Prüfer, D.; Schulze Gronover, C. Development of Rubber-Enriched Dandelion Varieties by Metabolic Engineering of the Inulin Pathway. Plant Biotechnol. J. 2017, 15, 740–753. [Google Scholar] [CrossRef]

- Lee, D.; Song, S.H. Investigation of Epoxidized Palm Oils as Green Processing Aids and Activators in Rubber Composites. Int. J. Polym. Sci. 2019, 2019, 2152408. [Google Scholar] [CrossRef]

- Nasruddin; Susanto, T. The Effect of Natural-Based Oil as Plasticizer towards Physics–Mechanical Properties of NR–SBR Blending for Solid Tyres. J. Phys. Conf. Ser. 2018, 1095, 012094. [Google Scholar] [CrossRef]

- Chueangchayaphan, N.; Tarasin, M.; Phonjon, W.; Chueangchayaphan, W. Evaluating Oil Palm Trunk Biochar and Palm Oil as Environmentally Friendly Sustainable Additives in Green Natural Rubber Composites. Polymers 2025, 17, 223. [Google Scholar] [CrossRef]

- Aziz, A.K.C.; Samion, S. Friction Properties of Epoxidised Natural Rubber Based Tyre Treads. In Proceedings of the 3rd Malaysian International Tribology Conference (MITC 2020); Lecture Notes in Mechanical Engineering. SamionS., Abu Bakar, M.A., Kamis, S.L., Sulaiman, M.H., Mohd Zulkifli, N.W., Eds.; Springer: Singapore, 2022. [Google Scholar]

- Maeda, M.; Uchiyama, Y.; Iwai, T.; Amino, N. Influence of Sliding Speed on the Coefficient of Friction and Contact Areas for Silica-Filled and Carbon Black-Filled SBR. Proc. Conf. Hokuriku-Shinetsu Branch JSME 2002, 39, 39–40. [Google Scholar] [CrossRef]

- MJ Chem Trading. Scientific Magic in Tire Manufacturing: How Six Major Additives Make Driving Safer and More Comfortable. Available online: https://mjchemtrading.com/scientific-magic-in-tire-manufacturing-how-six-major-additives-make-driving-safer-and-more-comfortable/ (accessed on 18 July 2025).

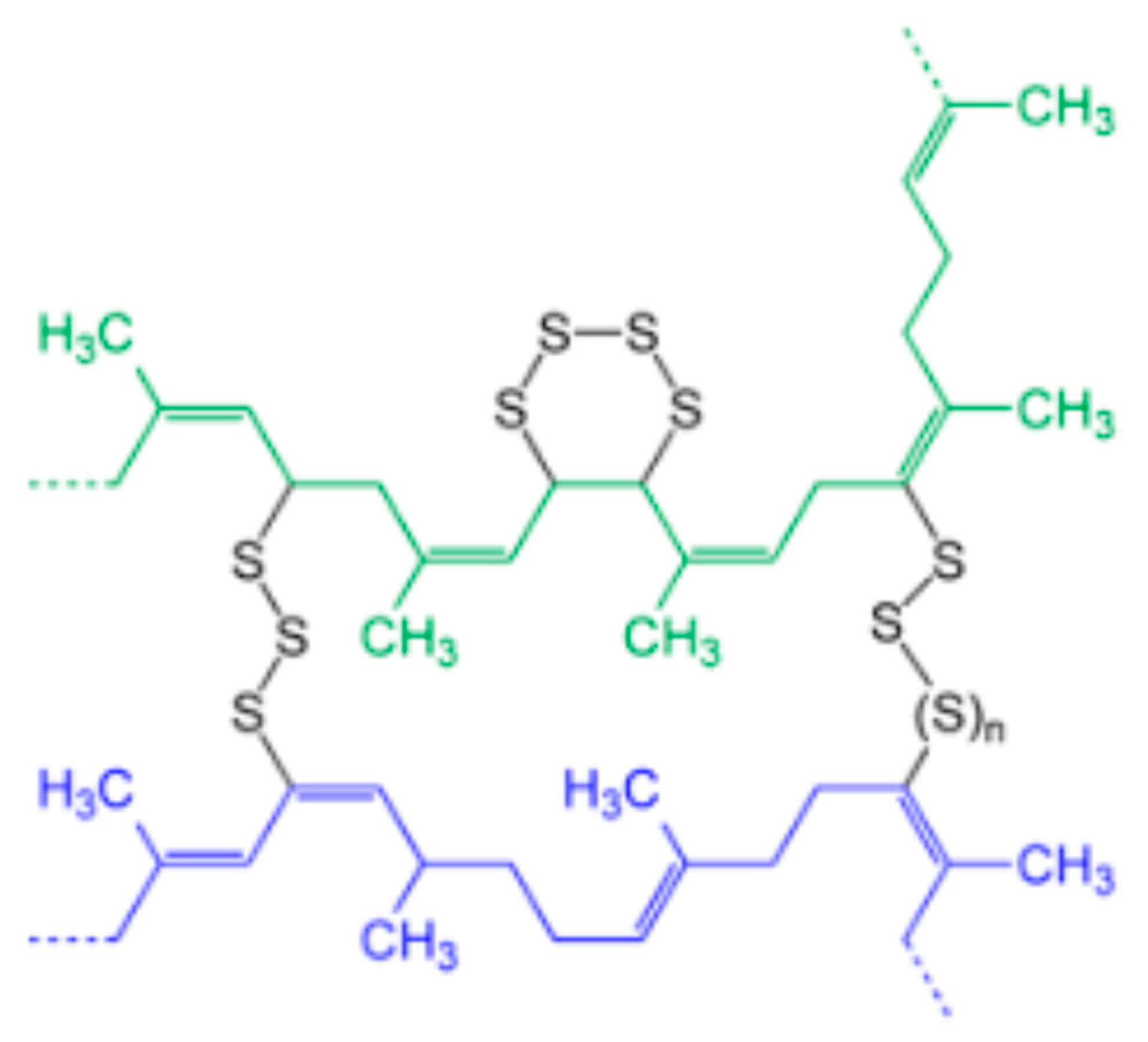

- Tang, R. Impacts of sulfur curing systems on vulcanizations and mechanical performances of elastomers: A model study based on sulfur curing systems and NR/SBR blends. In Advances in Analytical and Coordination Chemistry-Applications and Innovations; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Han, S.; Gu, B.; Kim, S.; Kim, S.; Mun, D.; Morita, K.; Kim, D.; Kim, W. Effect of Sulfur Variation on the Vulcanizate Structure of Silica-Filled Styrene–Butadiene Rubber Compounds with a Sulfide–Silane Coupling Agent. Polymers 2020, 12, 2815. [Google Scholar] [CrossRef]

- Bernal Ortega, P.; van Elburg, F.; Araujo-Morera, J.; Gojzewski, H.; Blume, A. Heading towards a fully sustainable tire tread compound: Use of bio-based resins. Polym. Test 2024, 133, 108406. [Google Scholar] [CrossRef]

- Indriasari, I.; Sattayanurak, S.; Fidyaningsih, R.; Hidayat, A.S.; Anggaravidya, M.; Arti, D.K.; Amry, A.; Utami, W.T.; Idvan, I.; Susanto, H.; et al. The Effect of Oligomeric Resins on Tire Traction of SBR/BR-Based Rubber Blends. In Proceedings of the 6th International Conference on Advanced Materials Science; Trans Tech Publications Ltd.: Zurich, Switzerland, 2024. [Google Scholar]

- Van Elburg, F.; Grunert, F.; Aurisicchio, C.; di Consiglio, M.; Talma, A.; Bernal-Ortega, P.; Blume, A. Sustainable Rubber Solutions: A Study on Bio-Based Oil and Resin Blends. Polymers 2025, 17, 2111. [Google Scholar] [CrossRef]

- He, C.; Jiang, W.; Xiao, Q.; Xing, C.; Yuan, D.; Lu, R.; Wu, W. A review of non-exhaust emissions on pavement area: Sources, compositions, evaluation and mitigation. J. Traffic Transp. Eng. (Engl. Ed.) 2024, 11, 1243–1258. [Google Scholar] [CrossRef]

- Gehrke, I.; Schläfle, S.; Bertling, R.; Öz, M.; Gregory, K. Review: Mitigation measures to reduce tire and road wear particles. Sci. Total Environ. 2024, 904, 167738. [Google Scholar] [CrossRef] [PubMed]

- Mattsson, K.; de Lima, J.A.; Wilkinson, T.; Järlskog, I.; Ekstrand, E.; Sköld, Y.A.; Gustafsson, M.; Hassellöv, M. Tyre and road wear particles from source to sea. Microplastics Nanoplastics 2023, 3, 14. [Google Scholar] [CrossRef]

- Son, C.E.; Choi, S.-S. Preparation and Characterization of Model Tire–Road Wear Particles. Polymers 2022, 14, 1512. [Google Scholar] [CrossRef] [PubMed]

- Chang, X.D.; Huang, H.B.; Jiao, R.N.; Liu, J.P. Experimental investigation on the characteristics of tire wear particles under different non-vehicle operating parameters. Tribol. Int. 2020, 150, 106354. [Google Scholar] [CrossRef]

- Cao, J.; Huang, H.; Jiao, R.; Pei, J.; Xu, Y.; Wang, Y. The study of wear particle emissions of soft rubber on rolling contact under braking conditions. Wear 2022, 506–507, 204431. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Grigoratos, T.; Dilara, P.; Franco, V. Environmental and health benefits of reducing tyre wear emissions in preparation for the new Euro 7 standard. Sustainability 2024, 16, 10919. [Google Scholar] [CrossRef]

- Müller, K.; Unice, K.; Panko, J.; Wagner, S. Tire emissions during the use phase of tires–current and future trends. Environ. Sci. Adv. 2025, 4, 1344–1363. [Google Scholar] [CrossRef]

- De Oliveira, T.; Muresan, B.; Ricordel, S.; Lumière, L.; Poirier, L.; Gasperi, J. Realistic assessment of tire and road wear particle emissions and their influencing factors on different types of roads. J. Hazard. Mater. 2023, 465, 133301. [Google Scholar] [CrossRef]

- Khardi, S. Emission factors of tyre wear particles emitted by light road vehicles in real driving conditions: A new challenge for clean road transport to improve urban air quality. Atmosphere 2024, 15, 665. [Google Scholar] [CrossRef]

- Miech, J.A.; Aker, S.; Zhang, Z.; Ozer, H.; Fraser, M.P.; Herckes, P. Tire wear emissions by highways: Impact of season and surface type. Atmosphere 2024, 15, 1122. [Google Scholar] [CrossRef]

- Wahlström, J.; Lyu, Y.; Lundberg, J.; Pagels, J.; Hjelm, R. Advancing tyre and road wear particle measurements: Balancing laboratory conditions and real-world relevance. Atmosphere 2025, 16, 588. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Ge, Y.; Wen, Y.; Luo, J.; Yin, D.; Wang, C.; Wang, C. Emission Characteristics of Tyre Wear Particles from Light-Duty Vehicles. Atmosphere 2023, 14, 724. [Google Scholar] [CrossRef]

- De Oliveira, L.; Muresan, B.; Ricordel, S.; Lumiere, L.; Poirier, L.; Gasperi, J. Realistic Evaluation of Tire Wear Particle Emissions and Their Driving Factors on Different Road Types. In Proceedings of the Goldschmidt Conference, Lyon, France, 9–14 July 2023. [Google Scholar]

- Giechaskiel, B.; Grigoratos, T.; Li, L.; Zang, S.; Lu, B.; Lopez, D.; García, J.J. Tyre Wear under Urban, Rural, and Motorway Driving Conditions at Two Locations in Spain and China. Lubricants 2024, 12, 338. [Google Scholar] [CrossRef]

- Lee, M.G.; Ryu, H.; Chung, W.; Hyun, M.; Lee, S.H.; Pak, M.; Kim, M.; Hur, J.; Kwon, J.-T.; Lee, J.; et al. Influence of road roughness and slope on the accumulation and distribution of tire-wear particles and heavy metals in road dust. Environ. Res. 2025, 282, 122079. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Wu, S.; Gao, J.; Li, Y.; An, Z.; Mao, B.; Tu, R.; Li, T. Impact of Vehicle Type, Tyre Feature and Driving Behaviour on Tyre Wear under Real-World Driving Conditions. Sci. Total Environ. 2022, 842, 156950. [Google Scholar] [CrossRef]

- Gao, Z.; Cizdziel, J.V.; Wontor, K.; Clisham, C.; Focia, K.; Rausch, J. On Airborne Tire Wear Particles along Roads with Different Traffic Characteristics Using Passive Sampling and Optical Microscopy, Single Particle SEM/EDX, and µ-ATR-FTIR Analyses. Front. Environ. Sci. 2022, 10, 1022697. [Google Scholar] [CrossRef]

- Muresan, B.; Truong, X.T.; De Oliveira, T.; Lumière, L.; Cerezo, V.; Watanabe, N.; Do, M.T. A Study of the Direct Emission of Tire Wear Particles on Different Types of Roads. Sci. Total Environ. 2025, 958, 178018. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, H.; Tan, J.; Wang, X.; Yang, Z.; Hao, L.; Du, T.; Niu, Z.; Ge, Y. A Comprehensive Review of Tyre Wear Particles. Sci. Total Environ. 2023, 857, 159375. [Google Scholar] [CrossRef]

- Papaioannou, G.; Maroof, V.; Jerrelind, J.; Drugge, L. Reducing Tyre Wear Emissions of Automated Articulated Vehicles. Transp. Res. Part D Transp. Environ. 2024, 126, 103720. [Google Scholar]

- Giechaskiel, B.; Grigoratos, T.; Mathissen, M.; Quik, J.; Tromp, P.; Gustafsson, M.; Franco, V.; Dilara, P. Contribution of Road Vehicle Tyre Wear to Microplastics. Polymers 2024, 16, 2468. [Google Scholar]

- Liu, H.; Chen, H.; Li, Y.; Gao, J.; Dave, K.; Chen, J.; Li, T.; Tu, R. Exhaust and Non-Exhaust Emissions from Conventional and Electric Vehicles. Sci. Total Environ. 2022, 851, 158057. [Google Scholar]

- Ribeiro, A.; Moutinho, A.; Fioravanti, A.; Paiva, E. Estimation of Tire–Road Friction for Autonomous Vehicles: A Neural Network Approach. arXiv 2019, arXiv:1908.00452. [Google Scholar]

- Hu, J.; Rakheja, S.; Zhang, Y. Tire–Road Friction Coefficient Estimation Based on Designed Braking Pressure Pulse. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2021, 235, 1876–1891. [Google Scholar] [CrossRef]

- Müller, S.; Uchanski, M.; Hedrick, K. Slip-Based Tire–Road Friction Estimation During Braking. In Proceedings of the ASME 2001 International Mechanical Engineering Congress and Exposition (IMECE), New York, NY, USA, 11–16 November 2001; ASME: New York, NY, USA, 2001; pp. 213–220. [Google Scholar]

- Hu, J.; Rakheja, S.; Zhang, Y. Real-Time Estimation of Tire–Road Friction Coefficient Based on Lateral Vehicle Dynamics. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 1982–1994. [Google Scholar] [CrossRef]

- Capra, D.; D’Alfio, N.; Morgando, A.; Vigliani, A. Experimental Test of Vehicle Longitudinal Velocity and Road Friction Estimation for ABS System. SAE Technical Paper 2009-01-0428. 2009. Available online: https://saemobilus.sae.org/papers/experimental-test-vehicle-longitudinal-velocity-road-frictim-estimation-abs-system-2009-01-0428 (accessed on 20 October 2025).

- Chen, L.; Bian, M.; Luo, Y.; Qin, Z.; Li, K. Tire–road friction coefficient estimation based on the resonance frequency of in-wheel motor drive system. Vehicle Syst. Dyn. 2015, 54, 1–19. [Google Scholar] [CrossRef]

- Zhang, Q.; Kong, H.; Liu, T.; Zhang, X. Adaptive model predictive control–based curved path-tracking strategy for autonomous vehicles under variable velocity. Trans. Inst. Meas. Control 2024, 47, 1624–1638. [Google Scholar] [CrossRef]

- Woo, S.; Jeon, S.; Joa, E.; Shin, D. Enhanced vehicle dynamics and safety through tire–road friction estimation for predictive ELSD control under various conditions of general racing tracks. Appl. Sci. 2024, 14, 1903. [Google Scholar] [CrossRef]

- Xiao, K.; Hui, B.; Qu, X.; Wang, H.; Diab, A.; Cao, M. Asphalt pavement water film thickness detection and prediction model: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 349–367. [Google Scholar] [CrossRef]

- Gu, T.; Li, B.; Quan, Z.; Bei, S.; Sun, X. A novel estimation method for tire-road friction coefficient using intelligent tire and tire dynamics. Mech. Syst. Signal Process. 2025, 235, 112872. [Google Scholar] [CrossRef]

- Barabás, I.; Iclodean, C.; Beleș, H.; Antonya, C.; Molea, A.; Scurt, F.B. An approach to modeling and developing virtual sensors used in the simulation of autonomous vehicles. Sensors 2025, 25, 3338. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, G.; Hang, P.; Zhao, J.; Lin, Y.; Huang, C. Fundamental estimation for tire road friction coefficient: A model-based learning framework. IEEE Trans. Veh. Technol. 2025, 74, 481–493. [Google Scholar] [CrossRef]

| Road | Static Friction Coefficient, μ0 | Dynamic Friction Coefficient, μ |

|---|---|---|

| Asphalt and concrete (dry) | 0.8–1.0 | 0.75 |

| Asphalt (wet) | 0.5–0.7 | 0.45–0.6 |

| Concrete (wet) | 0.8 | 0.7 |

| Gravel | 0.6 | 0.55 |

| Snow | 0.2 | 0.15 |

| Ice | 0.1 | 0.07 |

| Model | Characteristics | Typical Applications | Mathematical Description | No. of Papers in WoS | No. of Papers in Scopus | References |

|---|---|---|---|---|---|---|

| Magic Formula (Pacejka) | High accuracy; fits real data well; works for lateral, longitudinal, and combined slip | Vehicle dynamics, handling studies | Lateral force: where α—slip angle (rad) B—stiffness factor (slope near origin) C—shape factor D—peak factor (max force) E—curvature factor (asymmetry in curve) Extended versions include combined slip, camber, and longitudinal force. | 34 | 45 | [92,93,94,95,96] |

| Dugoff Model | Simple, computationally light, analytical form | Control design (ESC, path tracking); simplified dynamics | Longitudinal and lateral forces: where Fx, Fy—longitudinal and lateral forces s—longitudinal slip ratio α—sideslip angle Cs, Cα—longitudinal and lateral stiffness of tire µ—friction coefficient Fz—normal tire force λ—adhesion utilization factor f(λ)–saturation function | 31 | 36 | [97,98,99,100,101] |

| Brush Model | Good physical insight, handles combined slip, moderate complexity | Teaching. theoretical studies; control-oriented model | Lateral force: where a—half the contact length Cpy—lateral stiffness —tire model parameter σy = tan(α)—slip α—slip angle Fz—vertical load Μ—friction coefficient | 18 | 47 | [52,102,103,104,105,106] |

| LuGre Model and variants | Captures transient effects; can model stick–slip and hysteresis phenomena | Vehicle dynamics simulation; vehicle control design | Friction force: where z—internal bristle deflection v—relative velocity (slip speed) σ0—stiffness coefficient [N/m] σ1—damping coefficient [Ns/m] σ2—viscous friction coefficient [Ns/m] μs, μc—static and Coulomb friction coefficients vs—Stribeck velocity | 24 | 24 | [106,107,108,109,110,111,112] |

| Burckhardt Model | Less complex model than some others | Suitable for ABS/TCS, friction estimation, braking studies | Longitudinal force: where K—slip ratio Fz—normal tire force a1, a2, a3—fitting parameters | 11 | 13 | [110,113,114,115] |

| Fiala Model Stretched String | Less accurate for combined slip (braking + cornering); does not capture road condition changes | Suitable for preliminary vehicle simulations; does not provide sufficient accuracy for complex vehicle handling scenarios | Lateral force: Slip angle limit: asl = arctan(3μFz/Cα) where α—slip angle Cα—cornering stiffness Fz—vertical load μ—friction coefficient | 5 | 5 | [52,116,117] |

| FEM Models | High fidelity, detailed deformation and contact patch | Tire design, material research, structural analysis | 2 | 5 | [118,119,120] |

| Low Pressure | High Pressure |

|---|---|

| Larger but uneven contact patch | Smaller contact patch, smaller friction coefficient |

| Increased grip at low speed | Low grip, risk of skidding |

| Increased wear on the edges of the belt | Increased central tread wear |

| Increased risk of overheating | Stiffer suspension, reduced comfort |

| Strong wear of the tire and weak lateral guidance |

| Components | Influence on TRFC | Advantages/Disadvantages | References |

|---|---|---|---|

| Natural rubber (NR) | Reasonable wet performance but generally outperformed by current SSBR/silica systems designed for wet grip | Faster wear at high temperatures Epoxidized Natural Rubber (ENR) improves wet grip and friction, especially under certain loads/surface roughness. The epoxidation, filler can shift the dynamic properties/hysteresis to improve grip | [10,62,63,154,159] |

| Synthetic rubber (SBR) | SBR exhibits better tire–road friction in wet conditions than NR and maintains stability at higher operating temperatures | Durable, easily customizable, but higher fuel consumption Synthetic rubbers like (functionalized) SSBR tend to give better wet grip | [63,64] |

| Silica | Increases TRFC on wet and stable surfaces in cold conditions | Low fuel consumption, good grip; “Green Tire” silica reduces consumption by ~5% The coefficient of friction of silica-filled SBR is higher than that of carbon black-filled SBR, both in dry and lubricated sliding | [63,65,66,90,160] |

| Carbon black | Good TRFC at high temperatures, but decreases in wet conditions | Excellent abrasion resistance; ideal for off-road | [67,68,161] |

| Sulfur | Stiffness increases; affects hysteresis, particularly in dynamic contact with road surfaces; higher friction coefficient | Sulfur vulcanizates are prone to oxidative aging, especially under UV or ozone exposure As sulfur content increased, the hardness and abrasion resistance increased significantly | [69,161,162,163] |

| Biomaterials and resins | TRFC increased in wet conditions; increased wear and consumption | Bio-resins often have higher softening points compared to many oils or synthetic plasticizers. This helps raise viscoelastic loss at lower temperatures, which improves wet grip Sustainable, sensitive to wear | [65,164,165] |

| Plasticizers | Increased grip in cold weather; hysteresis and slightly higher consumption | Plasticizers affect hysteresis losses Increased energy dissipation, which is good for wet grip Improved elasticity and comfort may increase fuel consumption | [161,166] |

| Accelerators/ activators | Accelerators and activators do not directly increase or decrease the friction coefficient; they modify the crosslink network, which in turn affects viscoelastic hysteresis; results influence wet grip and rolling resistance; elastic modulus/stiffness affects dry adhesion and low-speed traction | Improves structure formation and strength | [85,161,162] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soica, A.; Gheorghe, C. Tire–Road Interaction: A Comprehensive Review of Friction Mechanisms, Influencing Factors, and Future Challenges. Machines 2025, 13, 1005. https://doi.org/10.3390/machines13111005

Soica A, Gheorghe C. Tire–Road Interaction: A Comprehensive Review of Friction Mechanisms, Influencing Factors, and Future Challenges. Machines. 2025; 13(11):1005. https://doi.org/10.3390/machines13111005

Chicago/Turabian StyleSoica, Adrian, and Carmen Gheorghe. 2025. "Tire–Road Interaction: A Comprehensive Review of Friction Mechanisms, Influencing Factors, and Future Challenges" Machines 13, no. 11: 1005. https://doi.org/10.3390/machines13111005

APA StyleSoica, A., & Gheorghe, C. (2025). Tire–Road Interaction: A Comprehensive Review of Friction Mechanisms, Influencing Factors, and Future Challenges. Machines, 13(11), 1005. https://doi.org/10.3390/machines13111005