Mixed Eccentricity Fault Detection of Induction Motors Based on Variational Mode Decomposition of Current Signal

Abstract

1. Introduction

- The severity levels of eccentricity faults have not been comprehensively analyzed in some reported works.

- In many studies, eccentricity faults have been identified only under no-load or light-load conditions; however, fault detection under full-load operation remains considerably more challenging.

2. Methodology: Variational Mode Decomposition and Mixed Eccentricity Fault Detection Approach

2.1. Variational Mode Decomposition

- Each mode corresponds to an amplitude- and frequency-modulated component, which can be mathematically expressed aswhere is the phase of the mode and is its envelope.

- The modes have positive and slowly varying envelopes.

- The frequency of each mode () changes smoothly over time and tends to stay close to a particular value .

- The analytic signal corresponding to each mode is obtained through the Hilbert transform, where * denotes the convolution. This ensures that each mode possesses a spectrum confined to positive frequencies.

- The analytic signal is demodulated to its baseband representation by multiplying it with an appropriate complex exponential.

- The bandwidth is estimated by computing the squared 2-norm of the gradient of the demodulated analytic signal.

- (1)

- Modes update: the modes (ω) are updated as represented in (9). Wiener filtering is embedded to update the mode directly in the frequency domain with a filter tuned to the current center frequency .

- (2)

- The central frequency update: the center frequencies are updated as the center of gravity of the corresponding mode’s power spectrum as follows.

- (3)

- Dual ascent update: for all ω ≥ 0, the Lagrangian multiplier is updated by (11) as dual ascent to enforce exact signal reconstruction until .where τ is the update rate of the Lagrange multiplier and usually set to 0.01. A higher update rate accelerates the convergence of the algorithm; however, it also increases the risk of the optimization process being trapped in a local optimum. , , , and correspond to the Fourier transform of , , , and . The detailed algorithm of the VMD can be found in [49]. The parameters used in the VMD method are defined as follows:—Input signal to be decomposed.—k-th decomposed mode of the signal. Each mode is amplitude and frequency modulated.is the amplitude envelope of the mode.is the instantaneous phase of the mode.—Center frequency of mode , around which the mode is mostly compact.K—Total number of decomposition modes.—Penalty factor controlling the balance between data fidelity and mode smoothness (bandwidth constraint).—Lagrange multiplier used to enforce the reconstruction constraint:τ—Step size (update rate) for the dual ascent of the Lagrange multiplier. Typical value: 0.01.—Convergence tolerance for iterative updates.—Convolution operation.—Inner product of two signals, used in Lagrangian formulation.

2.2. Mixed Eccentricity Fault

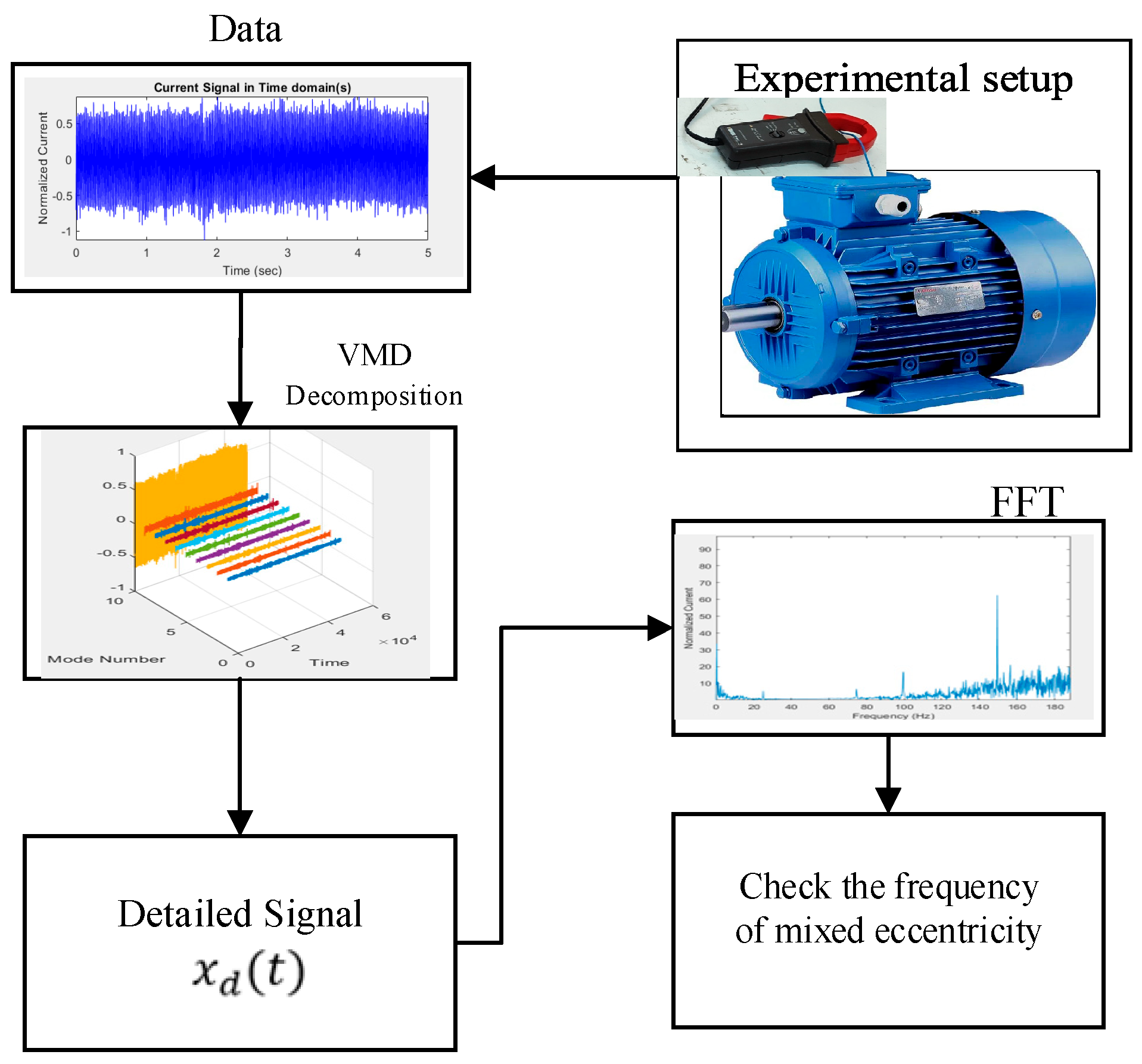

2.3. Proposed Fault Detection Algorithm

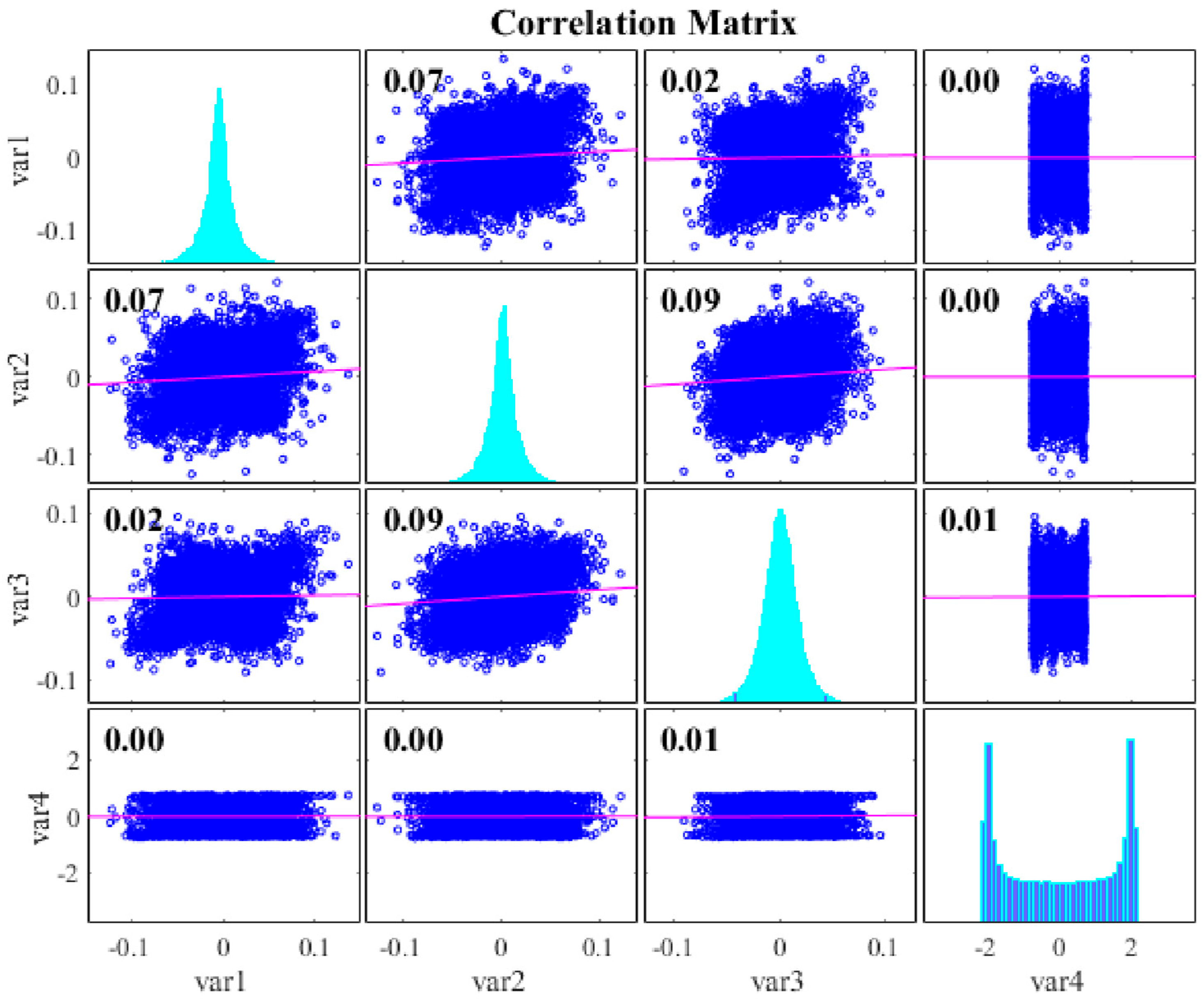

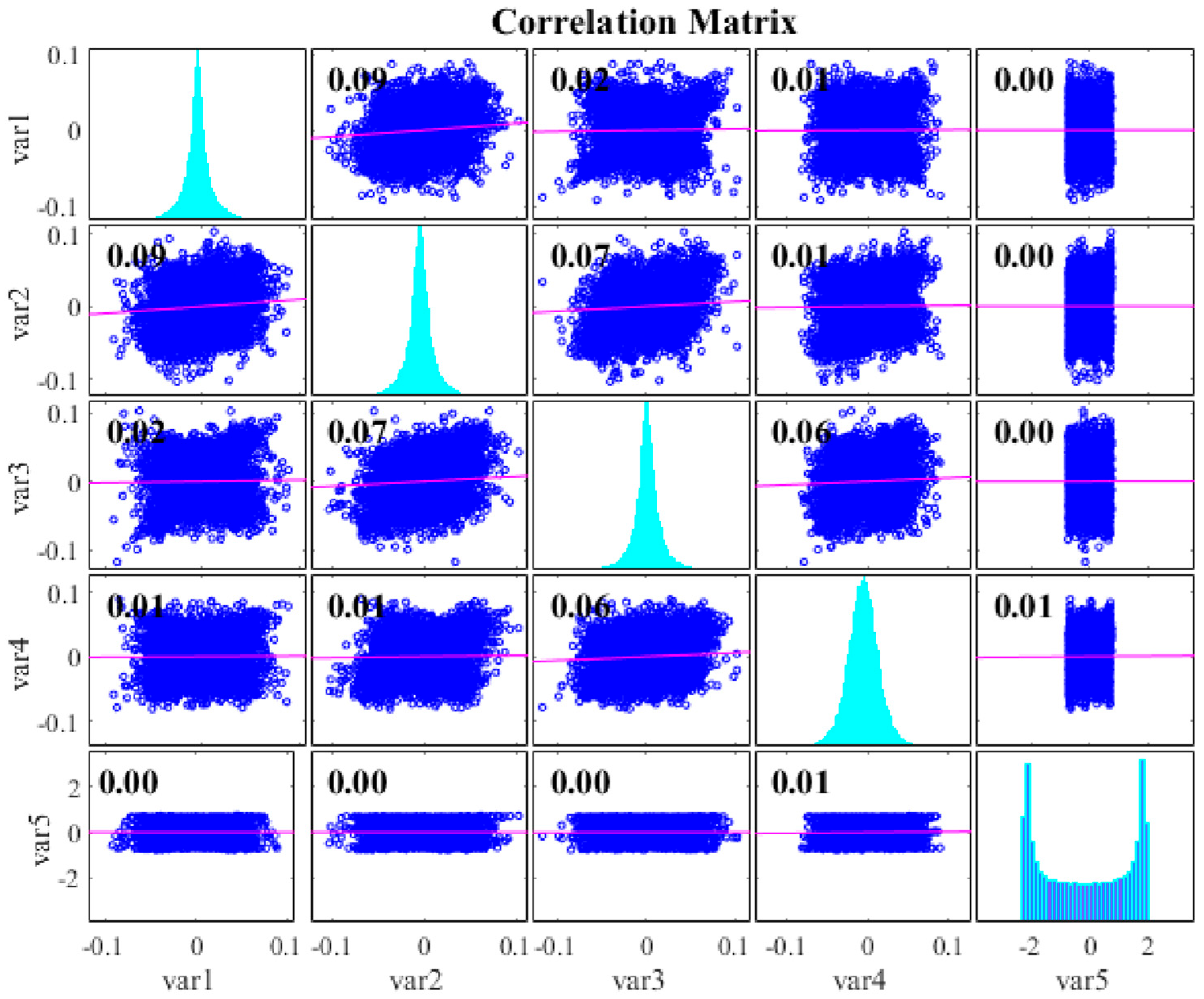

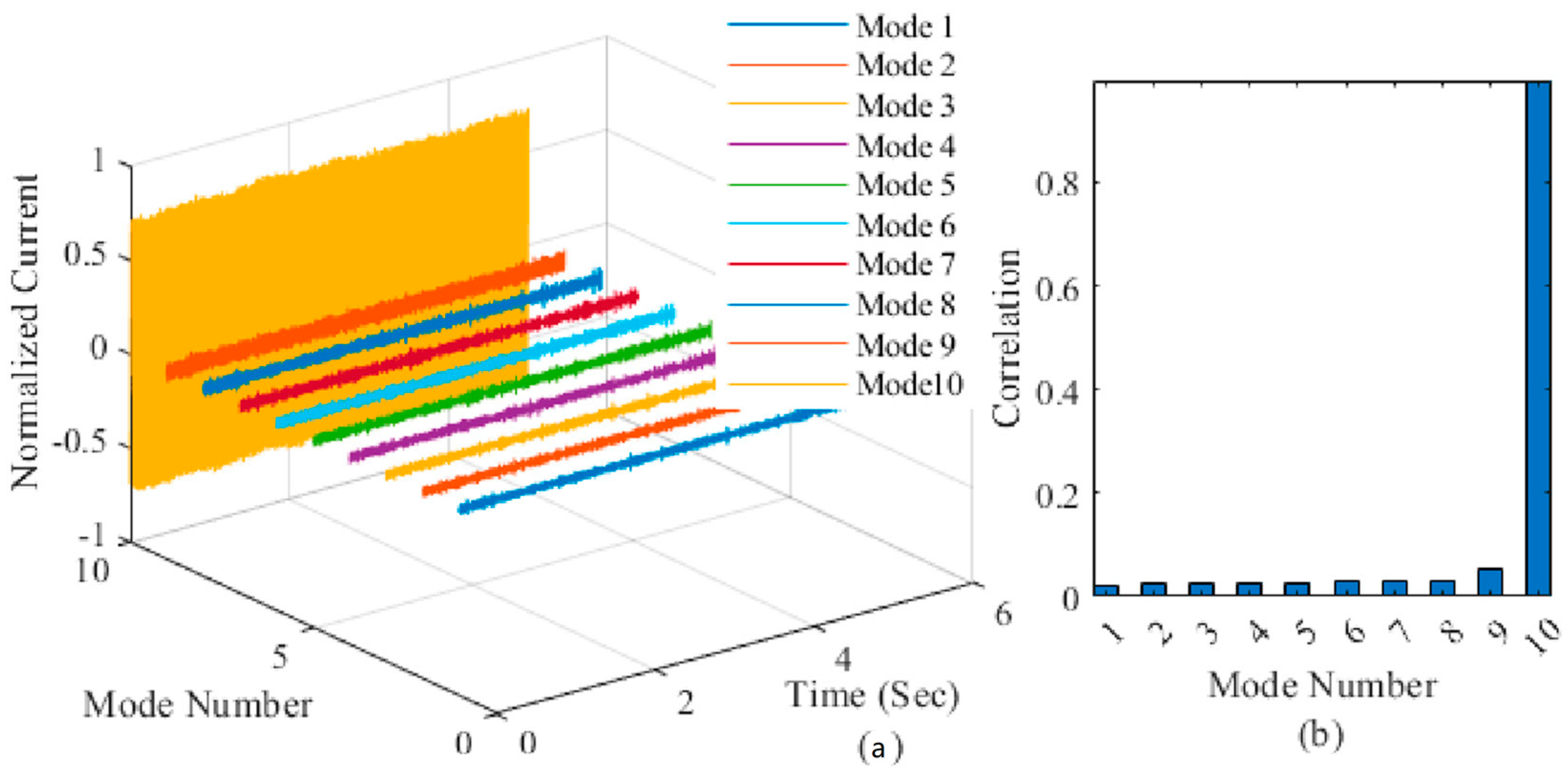

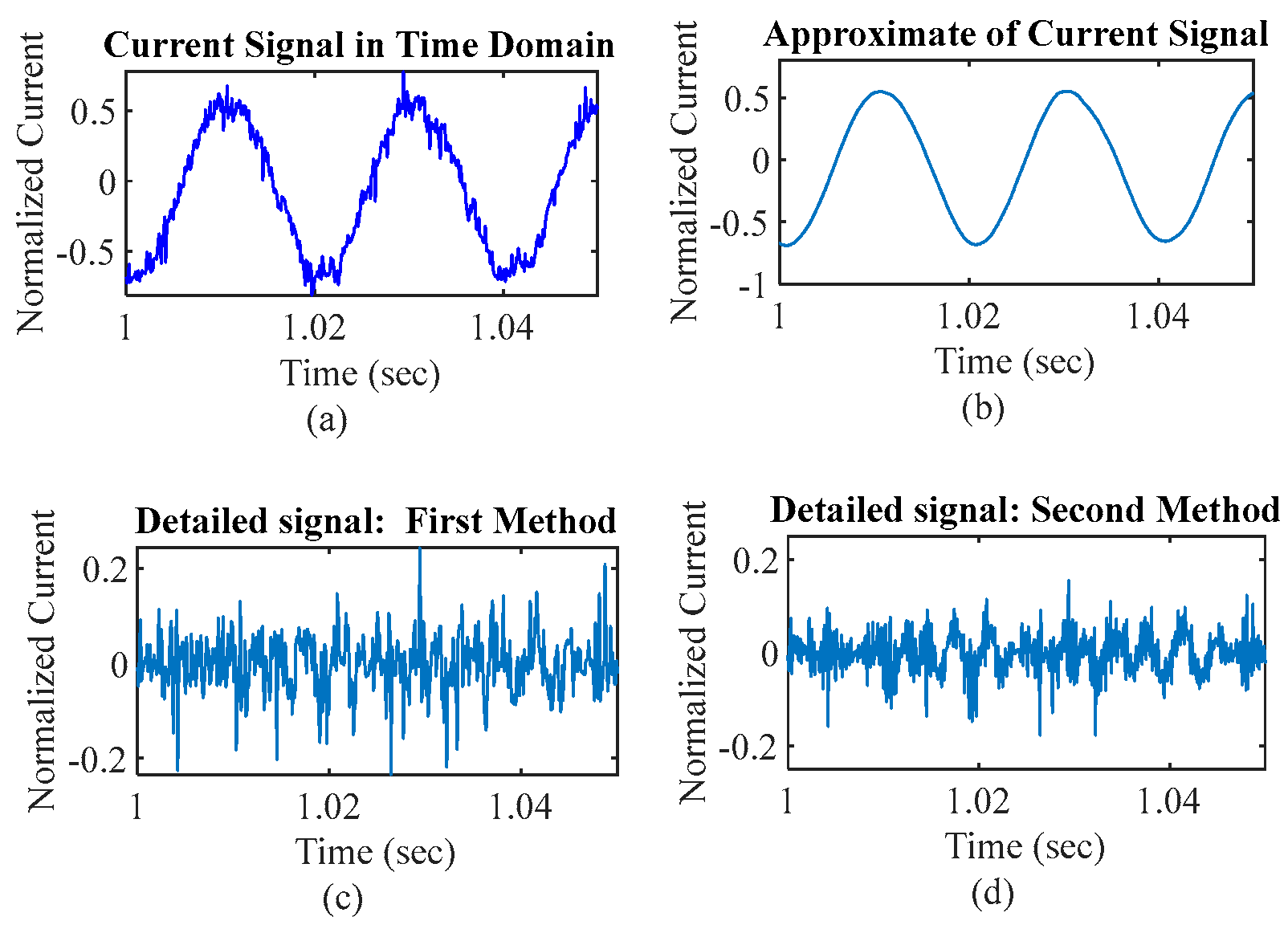

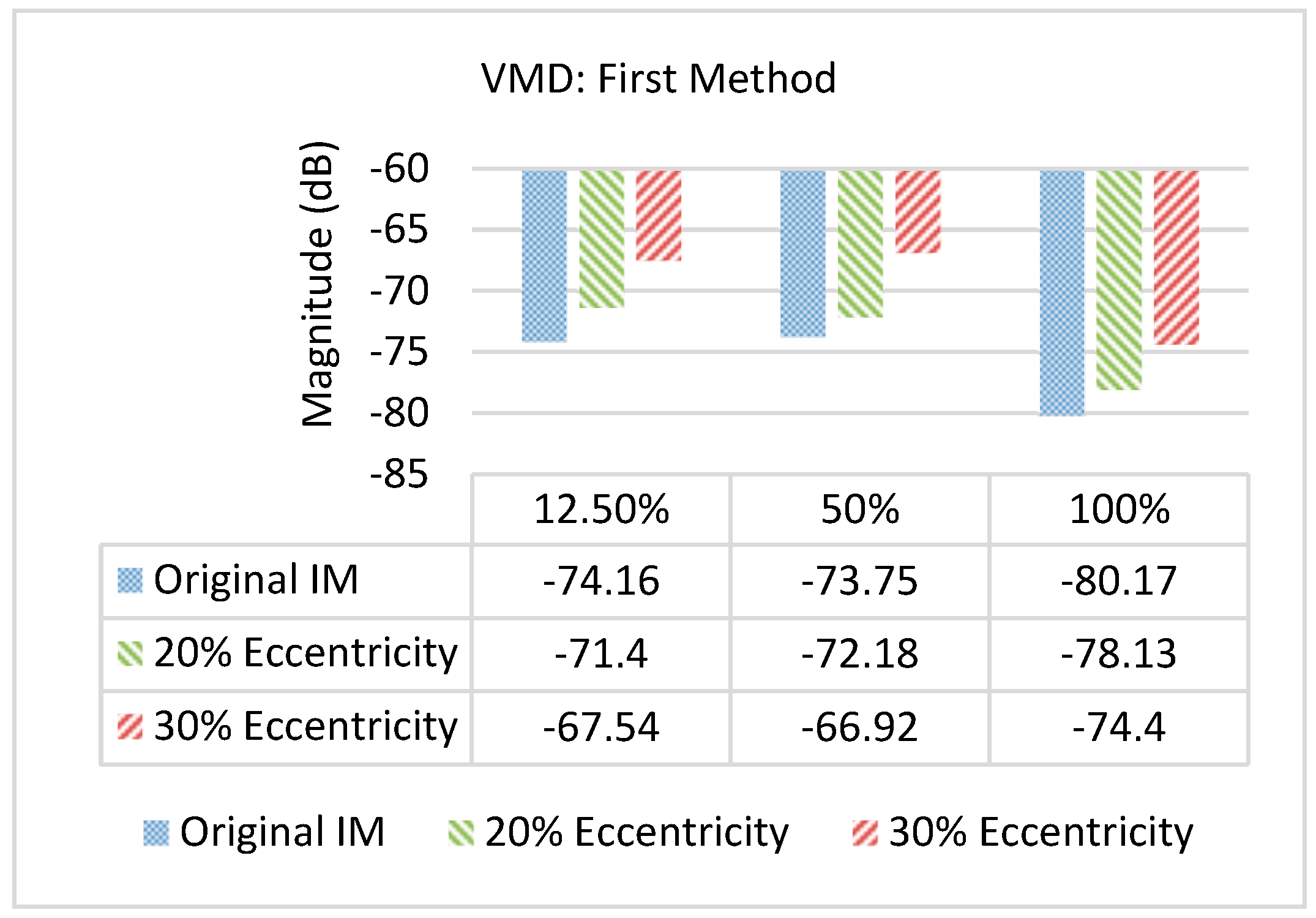

- First method: to obtain the detailed signal, i.e., , the approximated signal, , which is the sum of the modes whose correlation with the main signal is larger than 0.5, is computed based on (13). The Pearson correlation function measures the degree of similarity between two signals and identifies dominant modes in a signal by looking for modes with a similarity score exceeding 50% to the original signal. is an approximate of the original signal consisting of the main frequency component of x(t). The mixed eccentricity frequency component is distinguished in the detailed signal by removing from the original signal as represented in (14).where K is the total number of modes.

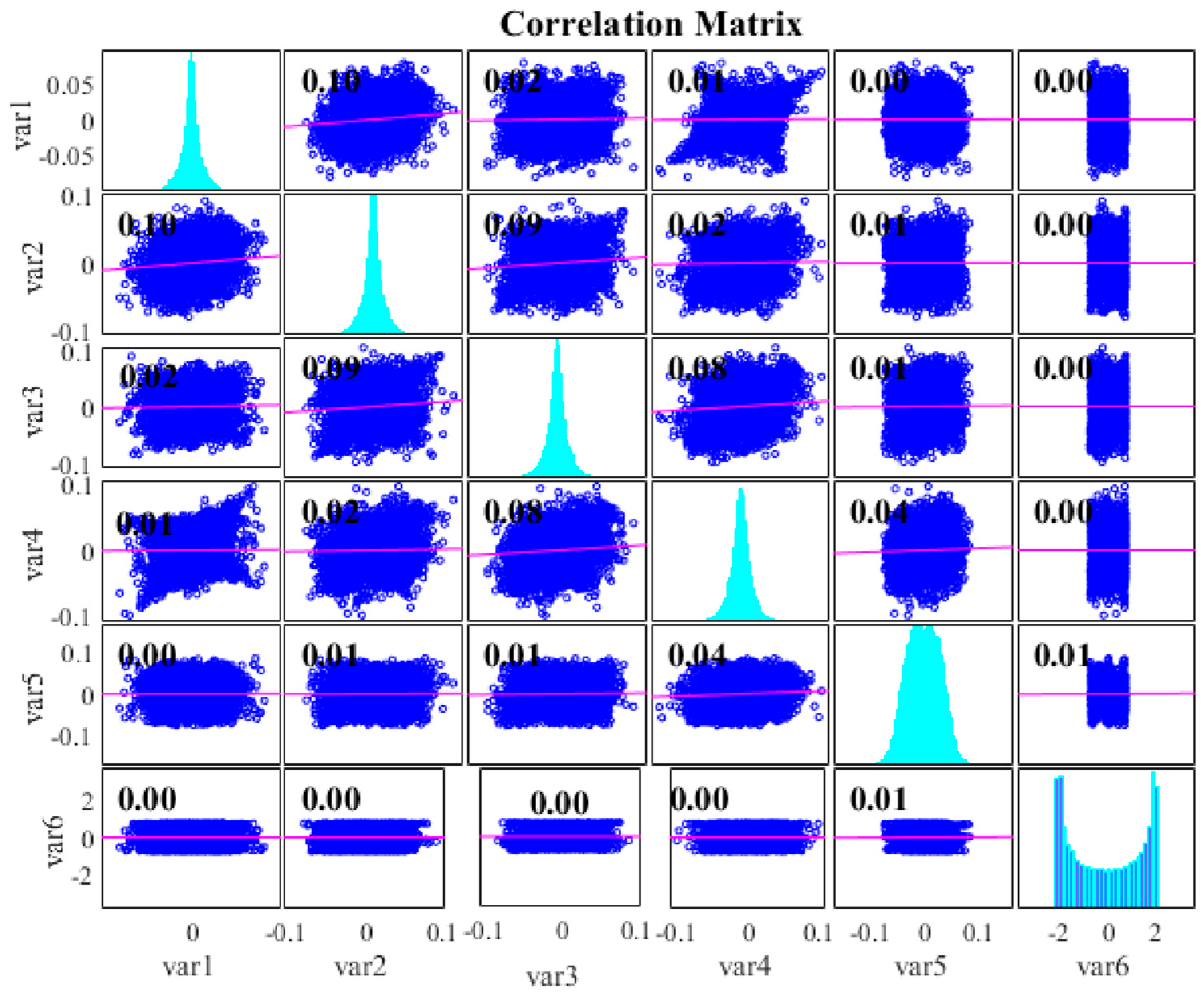

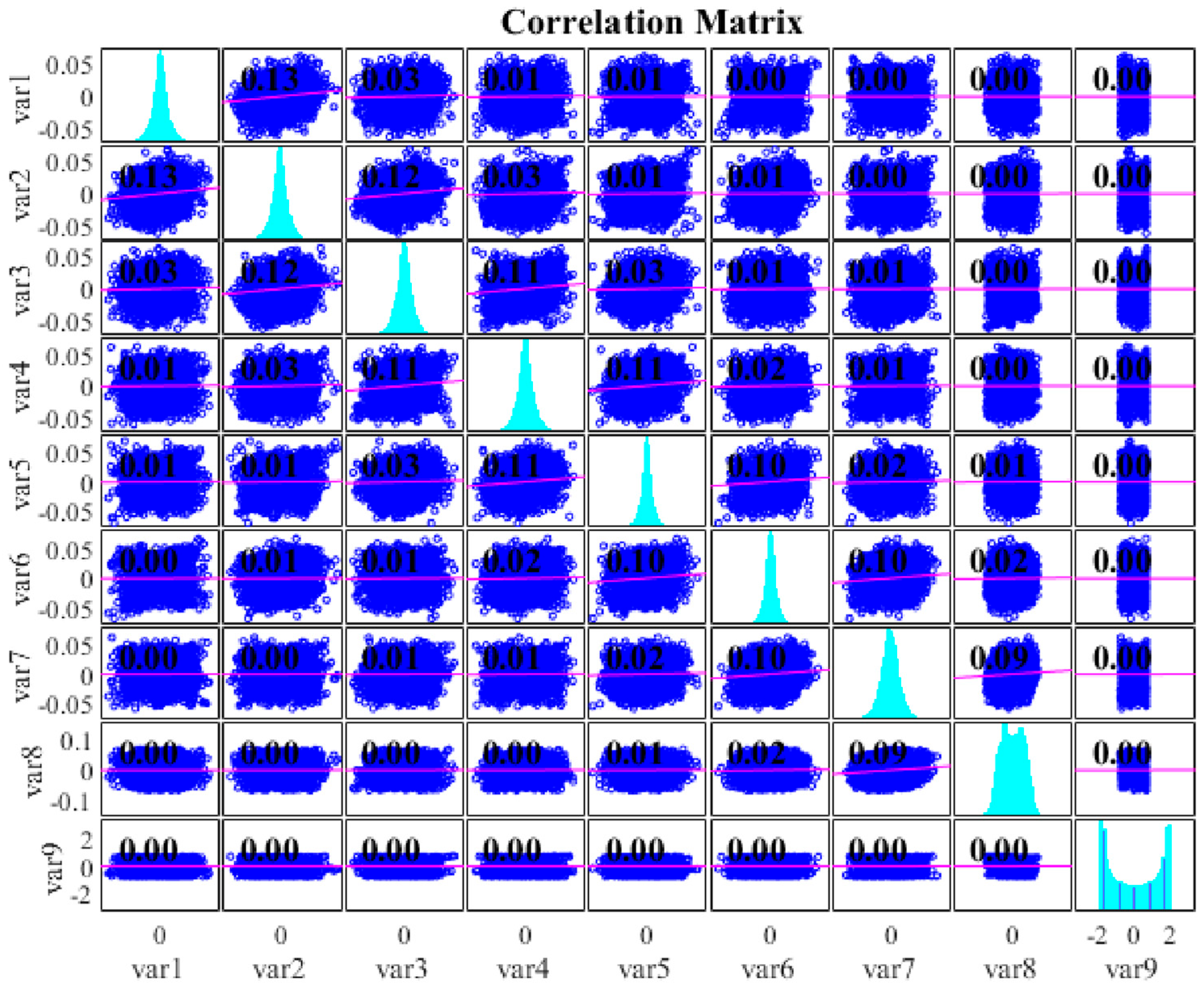

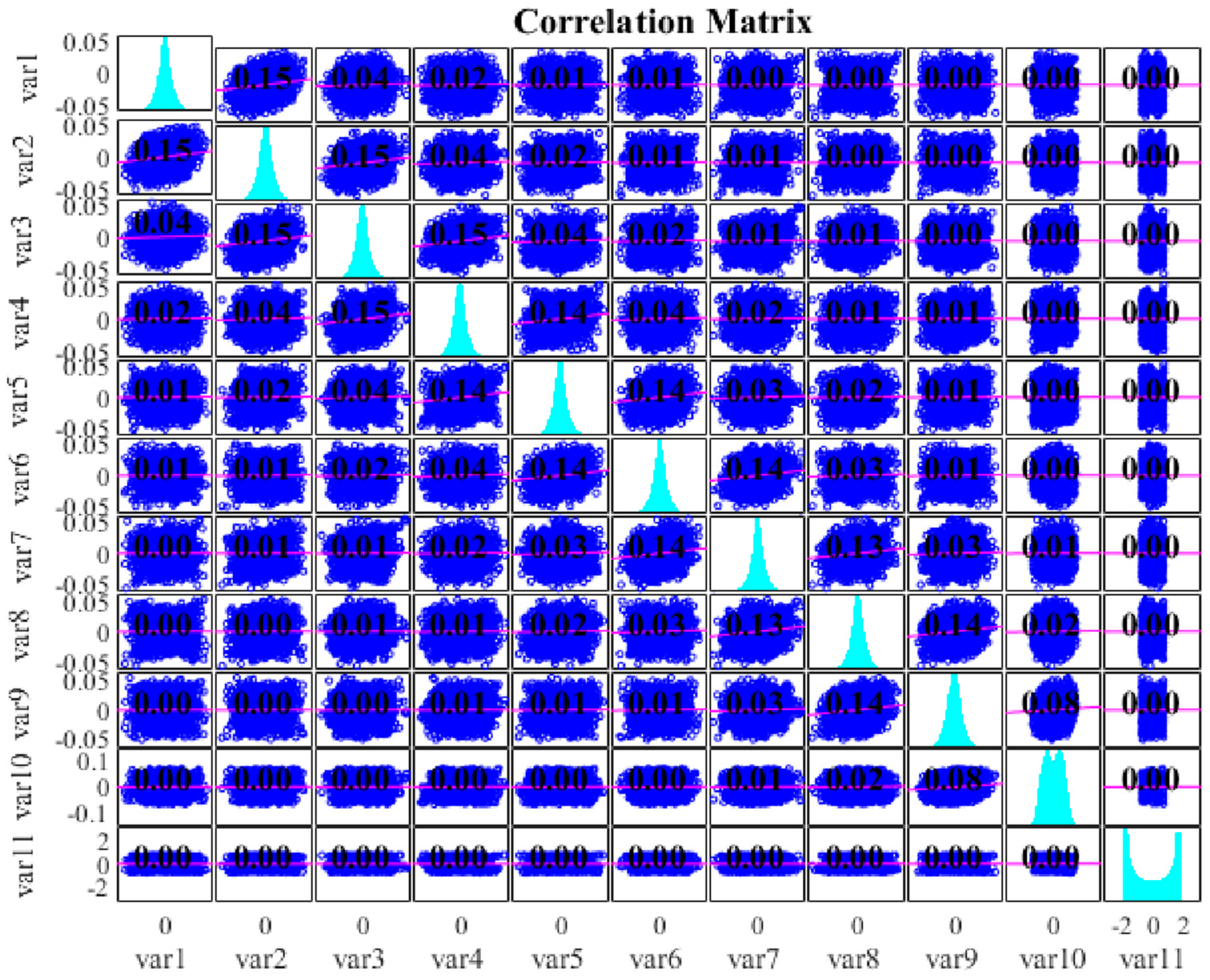

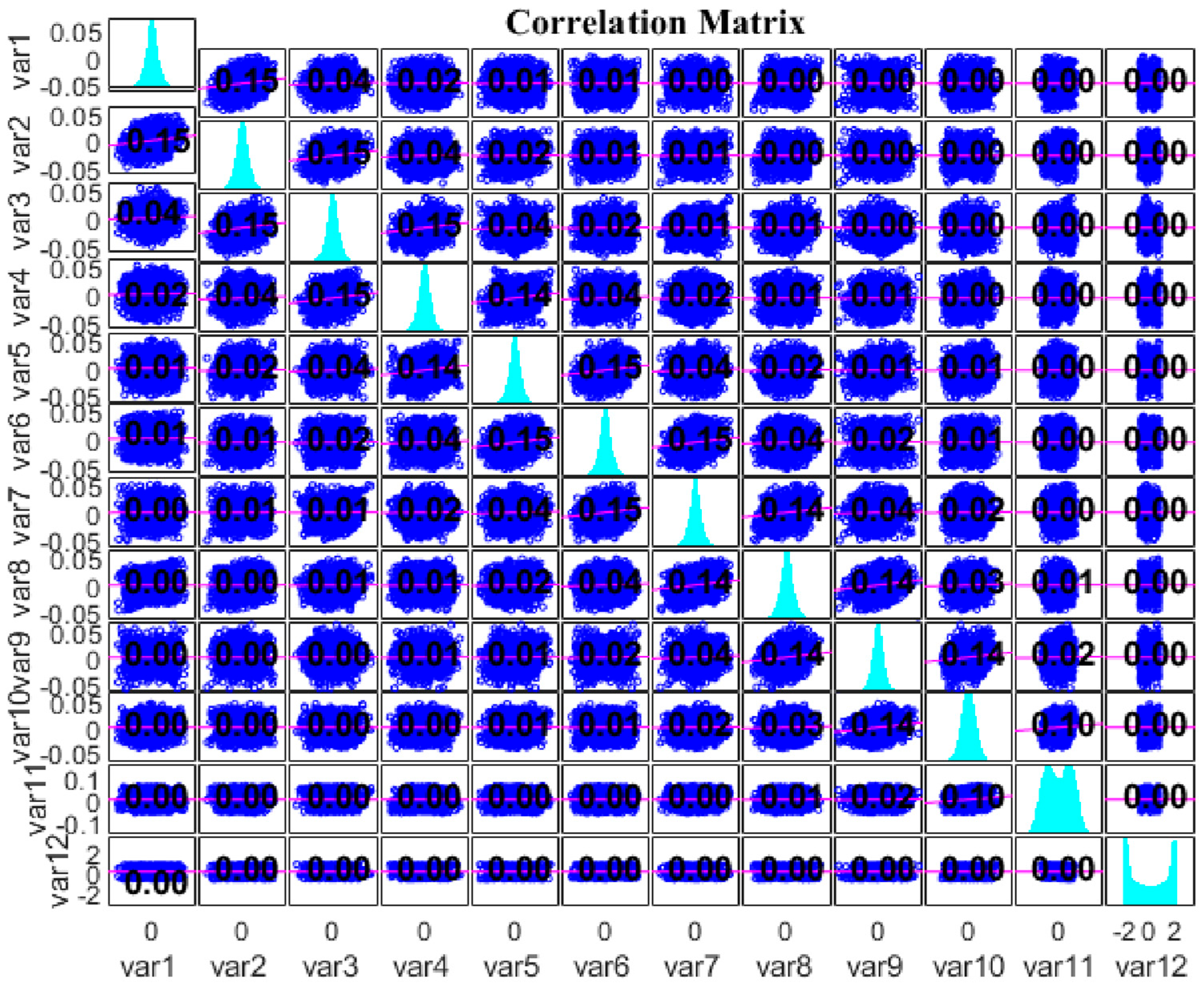

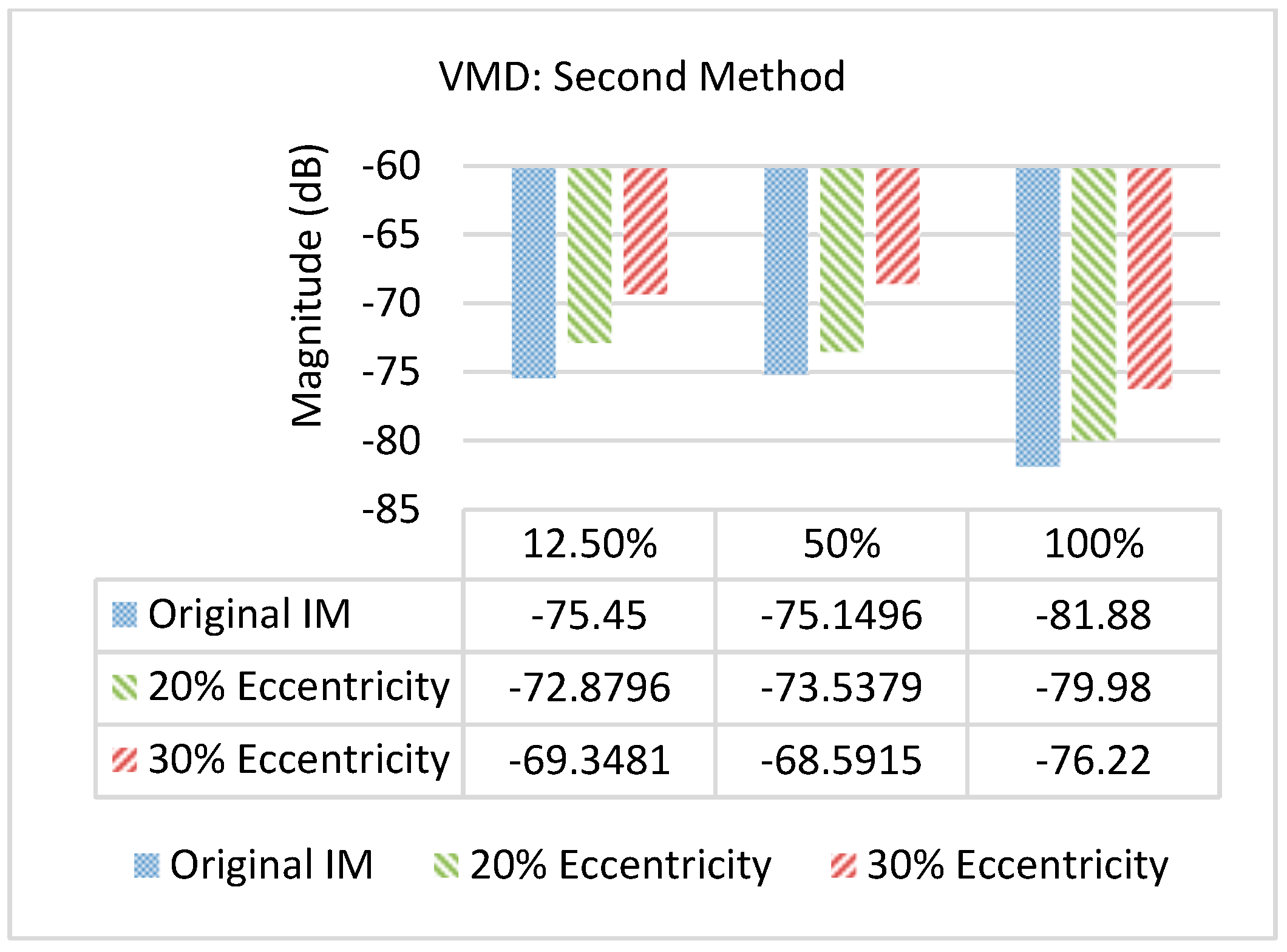

- Second method: the correlations between every two modes are computed and is obtained according to (15) in which every mode where its correlations with all other modes are less than or equal to 0.01 is included in . Based on (16), the detailed signal, , is computed. In essence, considers a group of modes “weakly interacting” if their correlation is less than or equal to a threshold (here, 0.01). This threshold depends on update rate of the Lagrange multiplier, τ.

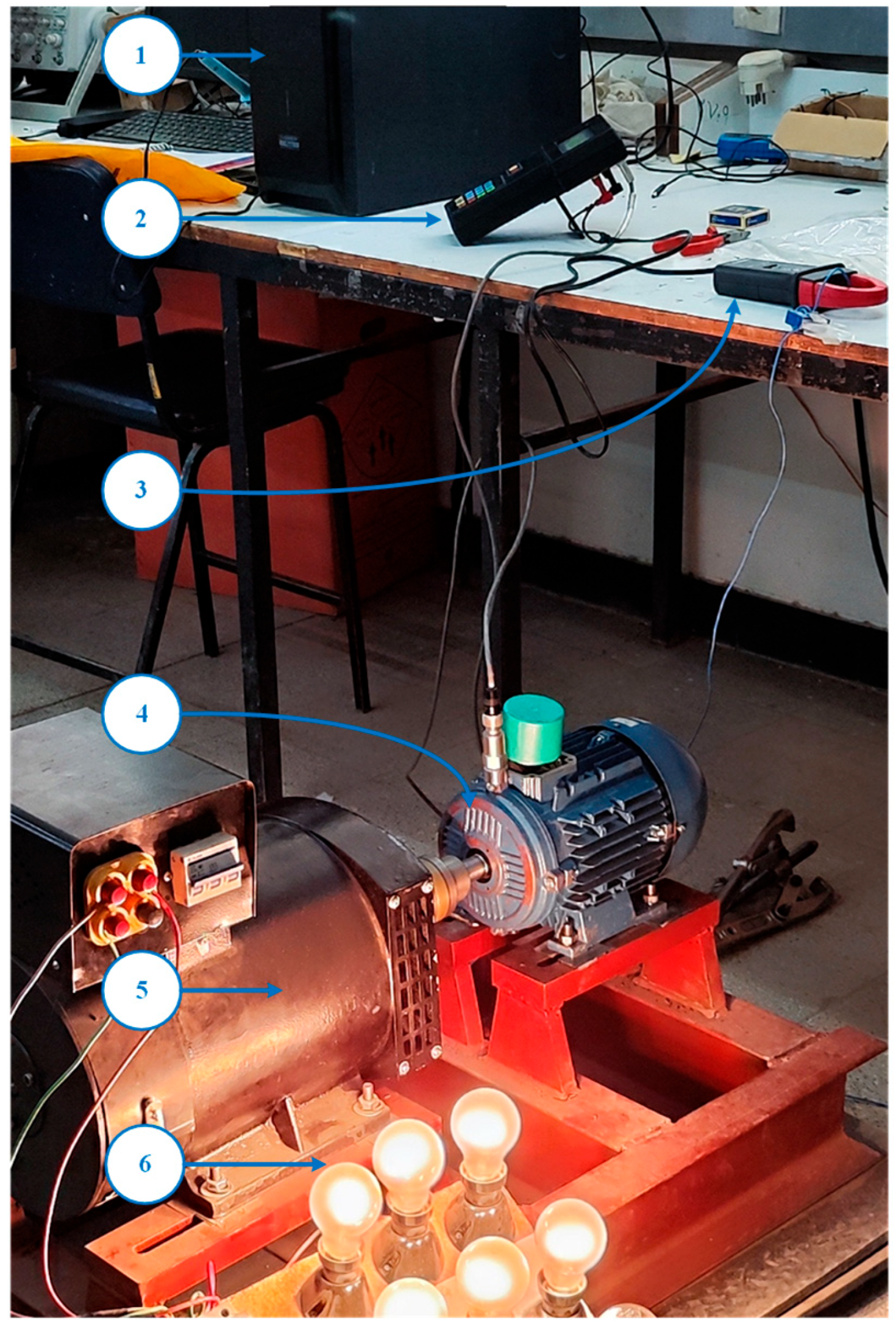

3. Experimental Validation of the Proposed VMD-Based Mixed Eccentricity Fault Detection Method

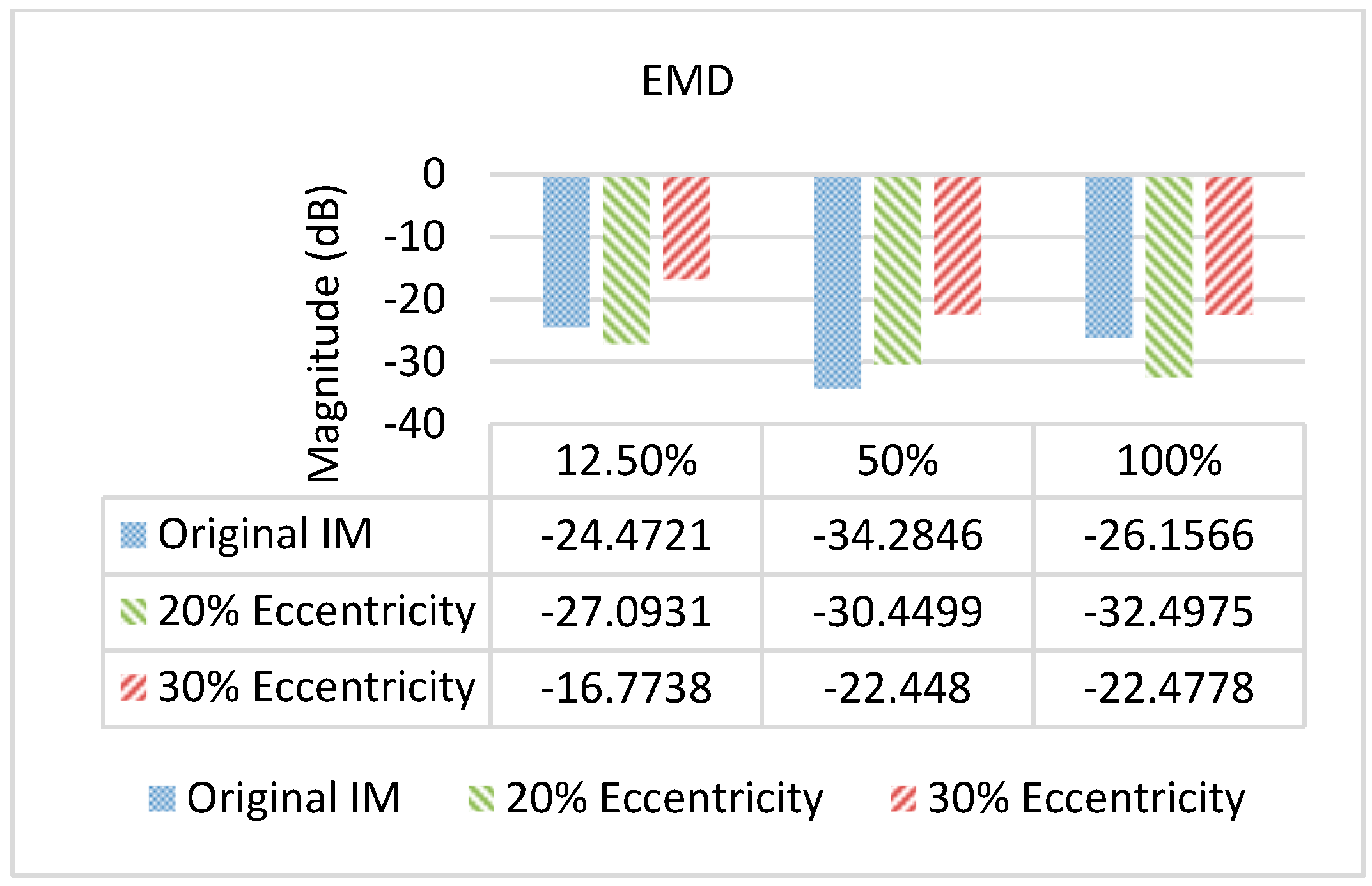

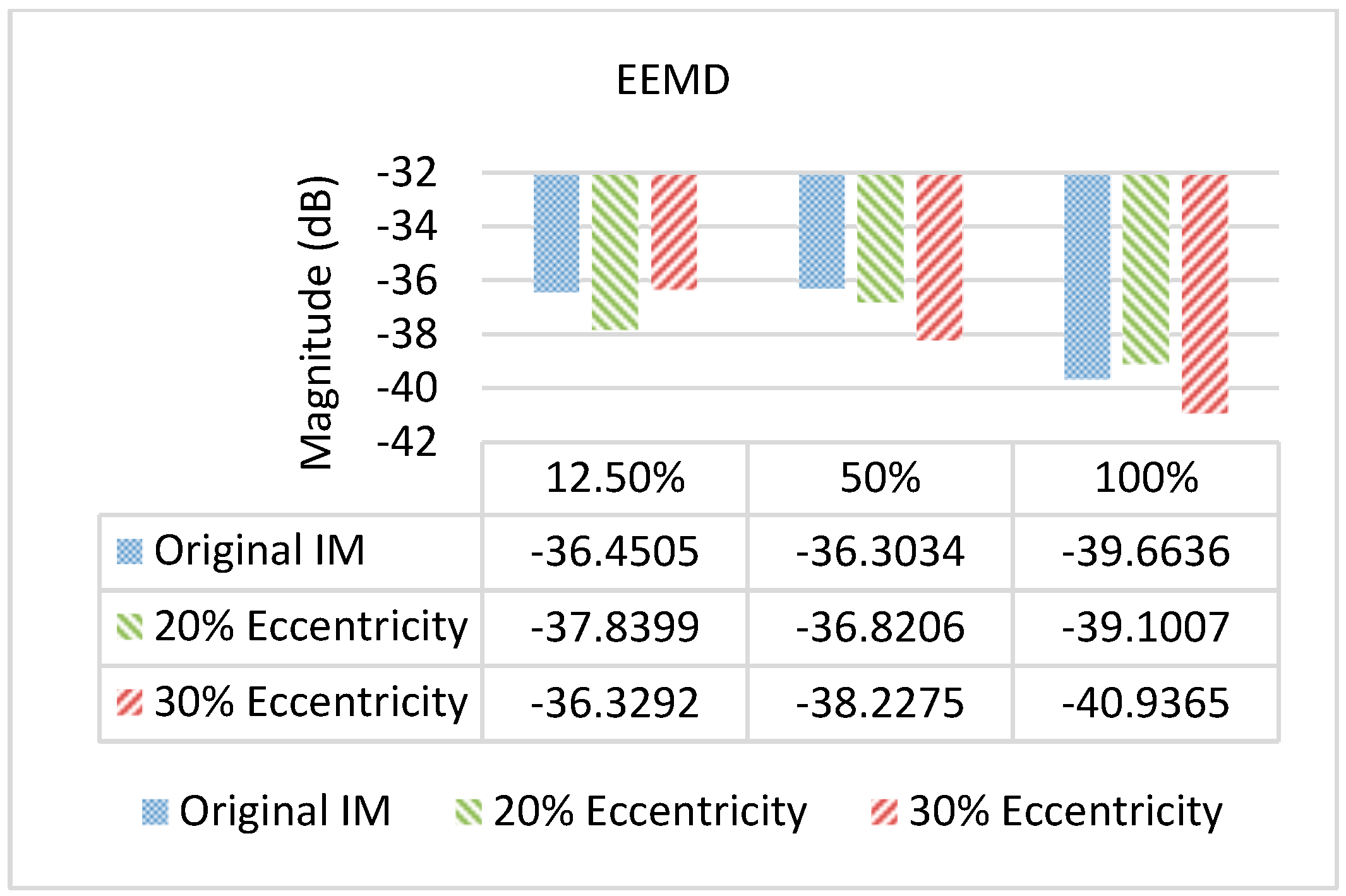

4. Discussion and Analysis of Experimental Results Using Current Signal Decomposition Methods (EMD, EEMD, and VMD)

5. Conclusions

- Superior performance of the VMD method compared to EMD and EEMD methods in noisy environments

- Consistency of fault detection variation between the healthy state and the 30% mixed eccentricity state by approximately 6 dB across various load conditions

- Fault detection based on current signal is a noninvasive method

- Only a single current sensor is required for fault detection.

- The average standard deviation was calculated as 1.297, indicating low dispersion of the data.

- The average coefficient of variation (CV) was 1.75%, reflecting minimal variability and high stability of the results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, M.; Wang, H.; Liu, P.; Long, Z.; Yang, J.; Huang, S. A Novel Data-Driven Mechanical Fault Diagnosis Method for Induction Motors Using Stator Current Signals. IEEE Trans. Transp. Electrif. 2023, 9, 347–358. [Google Scholar] [CrossRef]

- Choi, S.; Haque, M.S.; Bin Tarek, T.; Mulpuri, V.; Duan, Y.; Das, S.; Garg, V.; Ionel, D.M.; Masrur, M.A.; Mirafzal, B.; et al. Fault Diagnosis Techniques for Permanent Magnet AC Machine and Drives—A Review of Current State of the Art. IEEE Trans. Transp. Electrif. 2018, 4, 444–463. [Google Scholar] [CrossRef]

- Shin, J.; Park, Y.; Lee, S.B. Flux-Based Detection and Classification of Induction Motor Eccentricity, Rotor Cage, and Load Defects. IEEE Trans. Ind. Appl. 2021, 57, 2471–2480. [Google Scholar] [CrossRef]

- Gonzalez-Jimenez, D.; Del-Olmo, J.; Poza, J.; Garramiola, F.; Madina, P. Data-Driven Fault Diagnosis for Electric Drives: A Review. Sensors 2021, 21, 4024. [Google Scholar] [CrossRef]

- Ali, M.Z.; Shabbir, N.S.K.; Liang, X.; Zhang, Y.; Hu, T. Machine Learning-Based Fault Diagnosis for Single- and Multi-Faults in Induction Motors Using Measured Stator Currents and Vibration Signals. IEEE Trans. Ind. Appl. 2019, 55, 2378–2391. [Google Scholar] [CrossRef]

- Gadsden, S.A.; Song, Y.; Habibi, S. Novel Model-Based Estimators for the Purposes of Fault Detection and Diagnosis. IEEE-ASME Trans. Mechatron. 2013, 18, 1237–1249. [Google Scholar] [CrossRef]

- Trachi, Y.; Elbouchikhi, E.; Choqueuse, V.; El, M.; Wang, T. A Novel Induction Machine Fault Detector Based on Hypothesis Testing. IEEE Trans. Ind. Appl. 2016, 53, 3039–3048. [Google Scholar] [CrossRef]

- Martin-Diaz, I.; Morinigo-Sotelo, D.; Duque-Perez, O.; Romero-Troncoso, R.d.J. An Experimental Comparative Evaluation of Machine Learning Techniques for Motor Fault Diagnosis Under Various Operating Conditions. IEEE Trans. Ind. Appl. 2018, 54, 2215–2224. [Google Scholar] [CrossRef]

- Benninger, M.; Liebschner, M.; Kreischer, C. Fault Detection of Induction Motors with Combined Modeling- and Machine-Learning-Based Framework. Energies 2023, 16, 3429. [Google Scholar] [CrossRef]

- Kumar, R.R.; Andriollo, M.; Cirrincione, G.; Cirrincione, M.; Tortella, A. A Comprehensive Review of Conventional and Intelligence-Based Approaches for the Fault Diagnosis and Condition Monitoring of Induction Motors. Energies 2022, 15, 8938. [Google Scholar] [CrossRef]

- Pal, R.S.C.; Mohanty, A.R. A simplified dynamical model of mixed eccentricity fault in a three-phase induction motor. IEEE Trans. Ind. Electron. 2020, 68, 4341–4350. [Google Scholar] [CrossRef]

- Zare, F.; Nasiri-Gheidari, Z. Winding Function Model for Predicting Performance of 2-DOF Wound Rotor Resolver. IEEE Trans. Transp. Electrif. 2021, 8, 2062–2069. [Google Scholar] [CrossRef]

- Erős, E.; Bengtsson, K.; Åkesson, K. Fault localization for intelligent automation systems. In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Germany, 6–9 September 2022; pp. 1–8. [Google Scholar]

- Misra, S.; Kumar, S.; Sayyad, S.; Bongale, A.; Jadhav, P.; Kotecha, K.; Abraham, A.; Gabralla, L.A. Fault Detection in Induction Motor Using Time Domain and Spectral Imaging-Based Transfer Learning Approach on Vibration Data. Sensors 2022, 22, 8210. [Google Scholar] [CrossRef]

- Hammo, R. Faults Identification in Three-Phase Induction Motors Using Support Vector Machines. Master’s Thesis, Bowling Green State University, Bowling Green, OH, USA, January 2014. [Google Scholar]

- Bao, P.; Yi, W.; Zhu, Y.; Shen, Y.; Chai, B.X. STHFD: Spatial–Temporal Hypergraph-Based Model for Aero-Engine Bearing Fault Diagnosis. Aerospace 2025, 12, 612. [Google Scholar] [CrossRef]

- Bao, P.; Yi, W.; Zhu, Y.; Shen, Y.; Peng, H. A Spectral Interpretable Bearing Fault Diagnosis Framework Powered by Large Language Models. Sensors 2025, 25, 3822. [Google Scholar] [CrossRef]

- Sharma, N.R.; Bhalja, B.R.; Malik, O.P. Machine Learning-Based Severity Assessment and Incipient Turn-to-Turn Fault Detection in Induction Motors. IEEE Trans. Energy Convers. 2024, 40, 557–567. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Tsai, C.-D.; Li, T.-L. An Integrative Machine Learning Method to Improve Fault Detection and Productivity Performance in a Cyber-Physical System. J. Comput. Inf. Sci. Eng. 2020, 20, 021009. [Google Scholar] [CrossRef]

- Okokpujie, K.; Nwokolo, I.O.; Adenugba, A.V.; Awomoyi, M.E. Development of a Machine Learning Based Fault Detection Model for Received Signal Level in Telecommunication Enterprise Infrastructure. Int. J. Saf. Secur. Eng. 2024, 14, 679–690. [Google Scholar] [CrossRef]

- Dov, D.; Assaad, S.; Syedibrahim, A.; Bell, J.; Huang, J.; Madden, J.; Bentley, R.; McCall, S.; Henao, R.; Carin, L.; et al. A Hybrid Human–Machine Learning Approach for Screening Prostate Biopsies Can Improve Clinical Efficiency Without Compromising Diagnostic Accuracy. Arch. Pathol. Lab. Med. 2021, 146, 727–734. [Google Scholar] [CrossRef]

- Alimardani, R.; Rahideh, A.; Kia, S.H. Mixed Eccentricity Fault Detection for Induction Motors Based on Time Synchronous Averaging of Vibration Signals. IEEE Trans. Ind. Electron. 2024, 71, 3173–3181. [Google Scholar] [CrossRef]

- Aggarwal, A.; Allafi, I.M.; Strangas, E.G.; Agapiou, J.S. Off-Line Detection of Static Eccentricity of PMSM Robust to Machine Operating Temperature and Rotor Position Misalignment Using Incremental Inductance Approach. IEEE Trans. Transp. Electrif. 2020, 7, 161–169. [Google Scholar] [CrossRef]

- Bazghandi, R.; Marzebali, M.H.; Abolghasemi, V.; Kia, S.H. A Novel Mode Un-Mixing Approach in Variational Mode Decomposition for Fault Detection in Wound Rotor Induction Machines. Energies 2023, 16, 5551. [Google Scholar] [CrossRef]

- Abramovich, Y.I.; Johnson, B.A. GLRT-Based Detection-Estimation for Undersampled Training Conditions. IEEE Trans. Signal Process. 2008, 56, 3600–3612. [Google Scholar] [CrossRef]

- Wang, B.; Lin, C.; Inoue, H.; Kanemaru, M. Topological Data Analysis for Electric Motor Eccentricity Fault Detection. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022. [Google Scholar]

- Arifin, M.S.; Wang, W.; Uddin, M.N. A Modified EMD Technique for Broken Rotor Bar Fault Detection in Induction Machines. Sensors 2024, 24, 5186. [Google Scholar] [CrossRef]

- Wang, B.; Inoue, H.; Kanemaru, M. Motor Eccentricity Fault Detection: Physics-Based and Data-Driven Approaches. In Proceedings of the IEEE 14th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Chania, Greece, 28–31 August 2023. [Google Scholar]

- Agah, G.R.; Rahideh, A.; Khodadadzadeh, H.; Khoshnazar, S.M.; Kia, S.H. Broken rotor bar and rotor eccentricity fault detection in induction motors using a combination of discrete wavelet transform and Teager Kaiser energy operator. IEEE Trans. Energy Convers. 2022, 37, 2199–2206. [Google Scholar] [CrossRef]

- Pineda-Sanchez, M.; Puche-Panadero, R.; Riera-Guasp, M.; Perez-Cruz, J.; Roger-Folch, J.; Pons-Llinares, J.; Climente-Alarcon, V.; Antonino-Daviu, J.A. Application of the Teager–Kaiser Energy Operator to the Fault Diagnosis of Induction Motors. IEEE Trans. Energy Convers. 2013, 28, 1036–1044. [Google Scholar] [CrossRef]

- Isham, M.F.; Leong, M.S.; Lim, M.H.; Zakaria, M.K. A Review on Variational Mode Decomposition for Rotating Machinery Diagnosis. MATEC Web Conf. 2019, 255, 02017. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Z.; Yang, J. Feature Trend Extraction and Adaptive Density Peaks Search for Intelligent Fault Diagnosis of Machines. IEEE Trans. Ind. Inform. 2019, 15, 105–115. [Google Scholar] [CrossRef]

- Li, H.; Liu, T.; Wu, X.; Chen, Q. An optimized VMD method and its applications in bearing fault diagnosis. Measurement 2020, 166, 108185. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, T.; Wang, Y.; Wang, K.; Shen, Y. A parameter optimized variational mode decomposition method for rail crack detection based on acoustic emission technique. Nondestruct. Test. Eval. 2020, 36, 411–439. [Google Scholar] [CrossRef]

- Mirzaeva, G.; Saad, K.I. Advanced Diagnosis of Stator Turn-to-Turn Faults and Static Eccentricity in Induction Motors Based on Internal Flux Measurement. IEEE Trans. Ind. Appl. 2018, 54, 3961–3970. [Google Scholar] [CrossRef]

- Bessous, N.; Zouzou, S.E.; Sbaa, S.; Bentrah, W.; Becer, Z.; Ajgou, R. Static eccentricity fault detection of induction motors using MVSA, MCSA and discrete wavelet transform (DWT). In Proceedings of the 2017 5th International Conference on Electrical Engineering-Boumerdes (ICEE-B), Boumerdes, Algeria, 29–31 October 2017; pp. 1–10. [Google Scholar]

- Elbouchikhi, E.; Choqueuse, V.; Auger, F.; Benbouzid, M.E.H. Motor Current Signal Analysis Based on a Matched Subspace Detector. IEEE Trans. Instrum. Meas. 2017, 66, 3260–3270. [Google Scholar] [CrossRef]

- IGeorgakopoulos, I.P.; Mitronikas, E.D.; Safacas, A.N. Detection of Induction Motor Faults in Inverter Drives Using Inverter Input Current Analysis. IEEE Trans. Ind. Electron. 2011, 58, 4365–4373. [Google Scholar] [CrossRef]

- Gyftakis, K.N.; Kappatou, J.C. A Novel and Effective Method of Static Eccentricity Diagnosis in Three-Phase PSH Induction Motors. IEEE Trans. Energy Convers. 2013, 28, 405–412. [Google Scholar] [CrossRef]

- Hong, J.; Hyun, D.; Lee, S.B.; Kral, C. Offline Monitoring of Airgap Eccentricity for Inverter-Fed Induction Motors Based on the Differential Inductance. IEEE Trans. Ind. Appl. 2013, 49, 2533–2542. [Google Scholar] [CrossRef]

- Hyun, D.; Lee, S.; Hong, J.; Bin Lee, S.; Nandi, S. Detection of Airgap Eccentricity for Induction Motors Using the Single-Phase Rotation Test. IEEE Trans. Energy Convers. 2012, 27, 689–696. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, X.; Zhang, Z.; Chen, D.; Chen, W. Online rotor mixed fault diagnosis way based on spectrum analysis of instantaneous power in squirrel cage induction motors. IEEE Trans. Energy Convers. 2004, 19, 485–490. [Google Scholar] [CrossRef]

- Mirzaeva, G.; Saad, K.I. Advanced Diagnosis of Rotor Faults and Eccentricity in Induction Motors Based on Internal Flux Measurement. IEEE Trans. Ind. Appl. 2018, 54, 2981–2991. [Google Scholar] [CrossRef]

- Xu, Z.; Qin, C.; Tang, G. A Novel Deconvolution Cascaded Variational Mode Decomposition for Weak Bearing Fault Detection with Unknown Signal Transmission Path. IEEE Sens. J. 2020, 21, 1746–1755. [Google Scholar] [CrossRef]

- Pan, H.; Jiang, W.; Liu, Q.; Zheng, J. Multivariate Nonlinear Sparse Mode Decomposition and Its Application in Gear Fault Diagnosis. IEEE Access 2021, 9, 154265–154274. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, J. A Strategy Using Variational Mode Decomposition, L-Kurtosis and Minimum Entropy Deconvolution to Detect Mechanical Faults. IEEE Access 2019, 7, 70564–70573. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Qin, X.; Yuantao, S. Raw vibration signal pattern recognition with automatic hyper-parameter-optimized convolutional neural network for bearing fault diagnosis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 234, 343–360. [Google Scholar] [CrossRef]

- Boyd, S. Distributed Optimization and Statistical Learning via the Alternating Direction Method of Multipliers; Foundations and Trends® in Machine Learning; Now Foundations and Trends: Norwell, MA, USA, 2011; pp. 1–122. [Google Scholar]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition Monitoring using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Tian, S.; Zhen, D.; Liang, X.; Feng, G.; Cui, L.; Gu, F. Early fault feature extraction for rolling bearings using adaptive variational mode decomposition with noise suppression and fast spectral correlation. Meas. Sci. Technol. 2023, 34, 065112. [Google Scholar] [CrossRef]

- Li, Y.; Huang, D.; Qin, Z. A Classification Algorithm of Fault Modes-Integrated LSSVM and PSO with Parameters’ Optimization of VMD. Math. Probl. Eng. 2021, 2021, 6627367. [Google Scholar] [CrossRef]

- Yan, X.; Yan, W.; Yuen, K.-V.; Yang, Z.; Wang, X. An adaptive variational mode extraction method based on multi-domain and multi-objective optimization for bearing fault diagnosis. Struct. Heal. Monit. 2022, 22, 2708–2733. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble Empirical Mode Decomposition: A Noise-Assisted Data Analysis Method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, D.; Zuo, M.J. Adaptive Mode Decomposition Methods and Their Applications in Signal Analysis for Machinery Fault Diagnosis: A Review with Examples. IEEE Access 2017, 5, 24301–24331. [Google Scholar] [CrossRef]

| Method Type | Accuracy | Detection Speed | Cost-Effectiveness | Interpretability | References |

| Machine Learning | Near 100% | Real-time; up to 3h before failure | Reduces downtime & maintenance costs; scalable | Often low (black box); improved with hybrid approaches | [5,9,18,19,20,21] |

| Model-Based | High | Fast; depends on model complexity | Initial modeling cost; robust once established | High (physical models, parameter estimation) | [6,9] |

| Signal-Based | High | Fast (direct signal analysis) | Low (minimal modeling); limited for complex faults | High (direct feature-fault link) | [7,25] |

| References | Signal Type | Fault Severity | Loading Level |

|---|---|---|---|

| [35] | Flux | Not Checked | Not Checked |

| [36] | Vibration | Not Checked | No load and 75% full load |

| [36] | Current | Not Checked | No load and 75% full load |

| [37] | Current | Not Checked | Checked |

| [3] | Flux | Checked | Not Checked |

| [38] | Current | Not Checked | Up to 60% |

| [39] | Current | Checked | Not Checked |

| [40] | Current | Checked | Not Checked |

| [41] | Current | Checked | Not Checked |

| [42] | Power | Not Checked | Not Checked |

| [42] | Current | Not Checked | Not Checked |

| [43] | Flux | Not Checked | Checked |

| Reference | K Value(s) Tested | Values |

| [51] | 3–8 (adaptive) | adaptive selection recommended |

| [52] | 3–10 (empirical & adaptive) | adaptive principle validated |

| [53] | not specified | focus on vme parameters |

| Parameters | Symbols | Values | Units |

| Nominal power | Pn | 1.5 | kW |

| Nominal frequency | fn | 50 | Hz |

| Nominal voltage | Vn | 220/380 | V |

| Nominal current | In | 5.7/3.3 | A |

| Nominal speed | 1440 | RPM | |

| Nominal Power factor | PF | 0.81 | - |

| Nominal Efficiency | η | 85.3 | % |

| Number of pole-pairs | p | 2 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alimardani, R.; Rahideh, A.; Hedayati Kia, S. Mixed Eccentricity Fault Detection of Induction Motors Based on Variational Mode Decomposition of Current Signal. Machines 2025, 13, 968. https://doi.org/10.3390/machines13100968

Alimardani R, Rahideh A, Hedayati Kia S. Mixed Eccentricity Fault Detection of Induction Motors Based on Variational Mode Decomposition of Current Signal. Machines. 2025; 13(10):968. https://doi.org/10.3390/machines13100968

Chicago/Turabian StyleAlimardani, Ramin, Akbar Rahideh, and Shahin Hedayati Kia. 2025. "Mixed Eccentricity Fault Detection of Induction Motors Based on Variational Mode Decomposition of Current Signal" Machines 13, no. 10: 968. https://doi.org/10.3390/machines13100968

APA StyleAlimardani, R., Rahideh, A., & Hedayati Kia, S. (2025). Mixed Eccentricity Fault Detection of Induction Motors Based on Variational Mode Decomposition of Current Signal. Machines, 13(10), 968. https://doi.org/10.3390/machines13100968