Data–Model Integration-Driven Temperature Rise Prediction Method for New Energy Electric Drive Bearings

Abstract

1. Introduction

- Selecting an appropriate deep learning model.

- Obtaining high-quality datasets for model training. Existing research indicates that single deep learning models often struggle to maintain prediction accuracy under complex working conditions. Furthermore, there is a general lack of measured data on bearing temperature rise in practical studies, leading to insufficient accuracy of prediction models when confronted with new operating conditions.

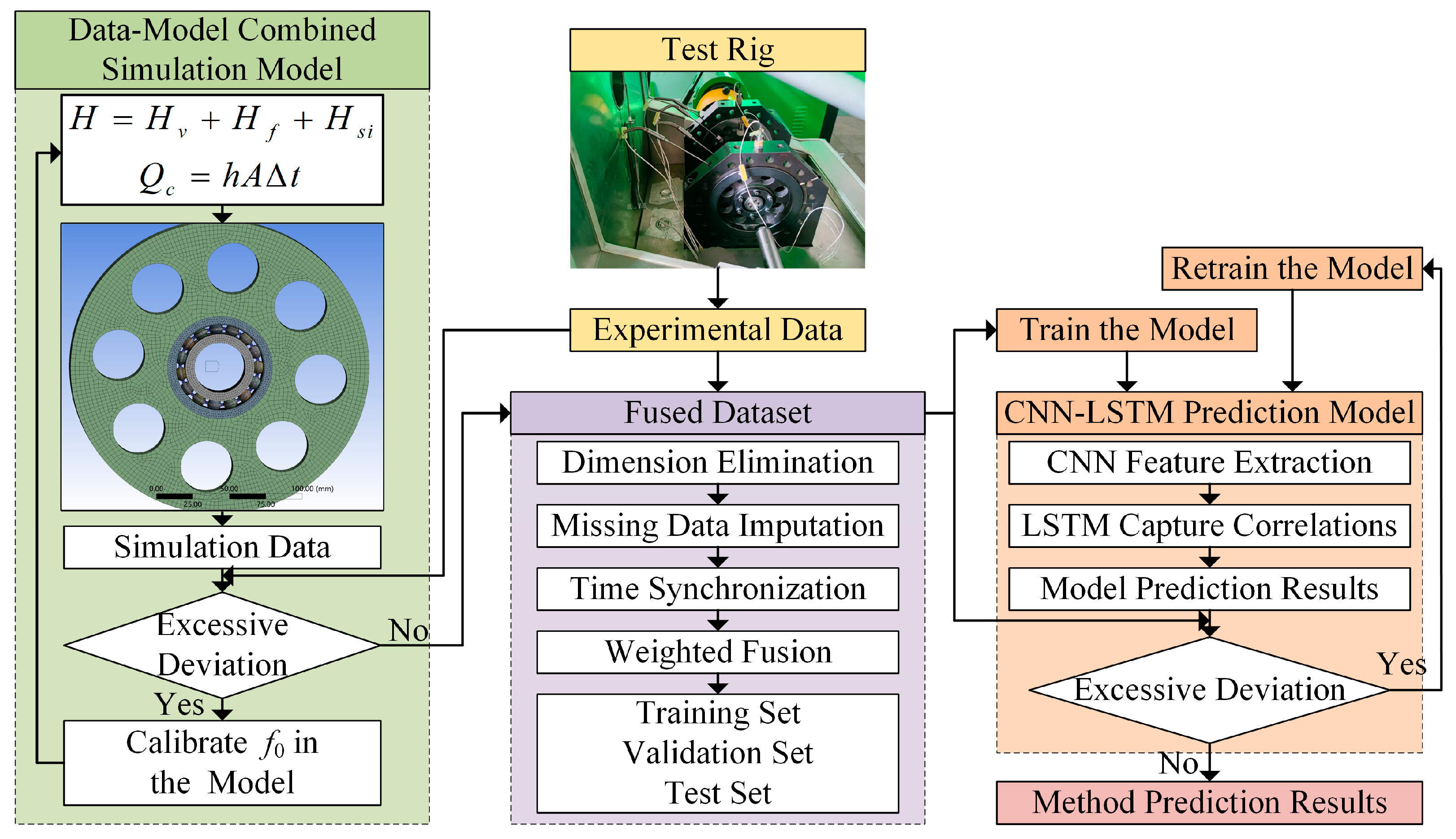

- To tackle the problems of low accuracy in mathematical models and long finite element simulation times: By combining the rapidity of mathematical calculation models with the accuracy of simulation models, a data-driven finite element simulation model is established. Measured data are introduced to correct model parameters, thereby obtaining a high-precision and rapid simulation model.

- To resolve the issue of deep learning algorithms requiring high-quality datasets while measured data are insufficient: A data–model integrated simulation model is utilized to generate bearing temperature rise simulation data covering all working conditions. The simulation data and measured data are fused through methods such as data fusion to form a hybrid dataset for new energy electric drive bearing temperature rise. A dataset update interface is provided to continuously incorporate new measured and simulation data, thereby expanding the coverage of working conditions in the dataset.

- To address the problem of single deep learning models often failing to maintain prediction accuracy under complex working conditions: A spatiotemporal feature fusion prediction model, CNN-LSTM, is developed by integrating CNN’s ability to extract spatial local features and LSTM’s expertise in processing time-series data. The hybrid dataset is used to train the model, and a model update mechanism is introduced. When the model’s prediction deviation is significant, the dataset is updated with new simulation or measured data to retrain the prediction model, ensuring its accuracy.

2. Methodology Framework

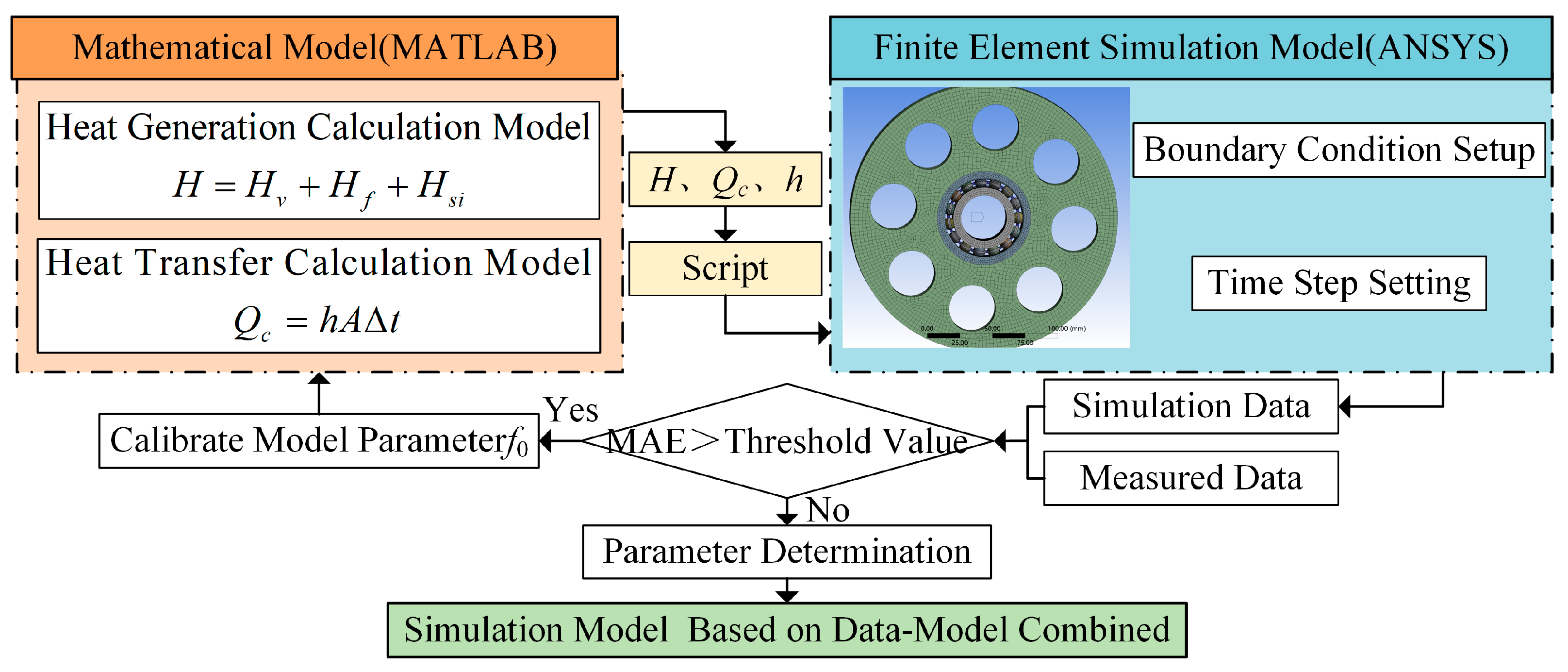

- Establishment of a Data-Driven Simulation Model: Based on the mechanisms of bearing frictional heat generation and heat transfer, a bearing heat generation calculation model and a bearing heat transfer calculation model are established. The simulation conditions are determined according to the measured data conditions. First, the frictional heat generation quantity H is calculated using the bearing heat generation model. The heat exchange quantity Qc and surface heat transfer coefficient h are calculated using the bearing heat transfer calculation model. Then, H, Qc, and h are input into the finite element simulation model. Temperature rise simulation data under the specified working conditions are obtained through finite element simulation. The MAE between the simulation data and the measured data is compared. If the MAE exceeds a critical threshold, the parameter f0 (a coefficient related to bearing type and lubrication method) in the heat generation calculation model is optimized using the gradient descent method until the MAE falls below the critical value. This process determines the model parameters and yields a simulation model that meets the required accuracy standards.

- Establishment of a Hybrid Dataset: The calibrated simulation model is utilized to generate temperature rise simulation data covering missing working conditions. This data can also guide supplementary bearing temperature rise tests to obtain corresponding measured data. Newly acquired measured data can, in turn, be used to further calibrate the simulation model, continuously enhancing its accuracy and adaptability to different working conditions, thereby improving the quality of data used for model training. Measured data and simulation data undergo normalization to eliminate dimensional differences. An interpolation method is employed to fill in missing values. Timestamps of measured and simulation data are aligned. A weight allocation strategy is applied to maximize the predictive value of the processed data, ultimately constructing a hybrid dataset comprising training, validation, and test sets. The dataset retains an update interface to continuously incorporate new measured and simulation data.

- CNN-LSTM Prediction Model and Update Mechanism: A CNN-LSTM prediction model integrating spatiotemporal features is established by combining CNN’s capability for extracting local spatial features with LSTM’s expertise in processing time-series data. The model inputs include speed, load, time, and the temperature from the previous time step, while the outputs are time and temperature. The model parameters are trained using the training set from the hybrid dataset. The validation set is utilized for hyperparameter tuning to optimize model performance. The test set is employed to evaluate the prediction accuracy of the model, ultimately yielding a prediction model that meets the required precision standards. During model application, accuracy can be monitored by comparing predictions with measured data and simulation results. When the model accuracy falls outside the predefined acceptable range, the model can be retrained using an updated dataset to recalibrate its predictive performance.

3. Model Construction

- Mathematical Calculation Model: Based on the mechanisms of bearing frictional heat generation and heat transfer, parameterized heat generation and heat transfer calculation models are established in MATLAB2023(a). Input parameters include bearing geometric parameters, material properties, thermodynamic parameters, grease-air characteristics, and operational conditions. Physical quantities such as H (heat generation), Qc (heat exchange), and h (surface heat transfer coefficient) are computed. The results are saved in text format (TXT) for use by the finite element model.

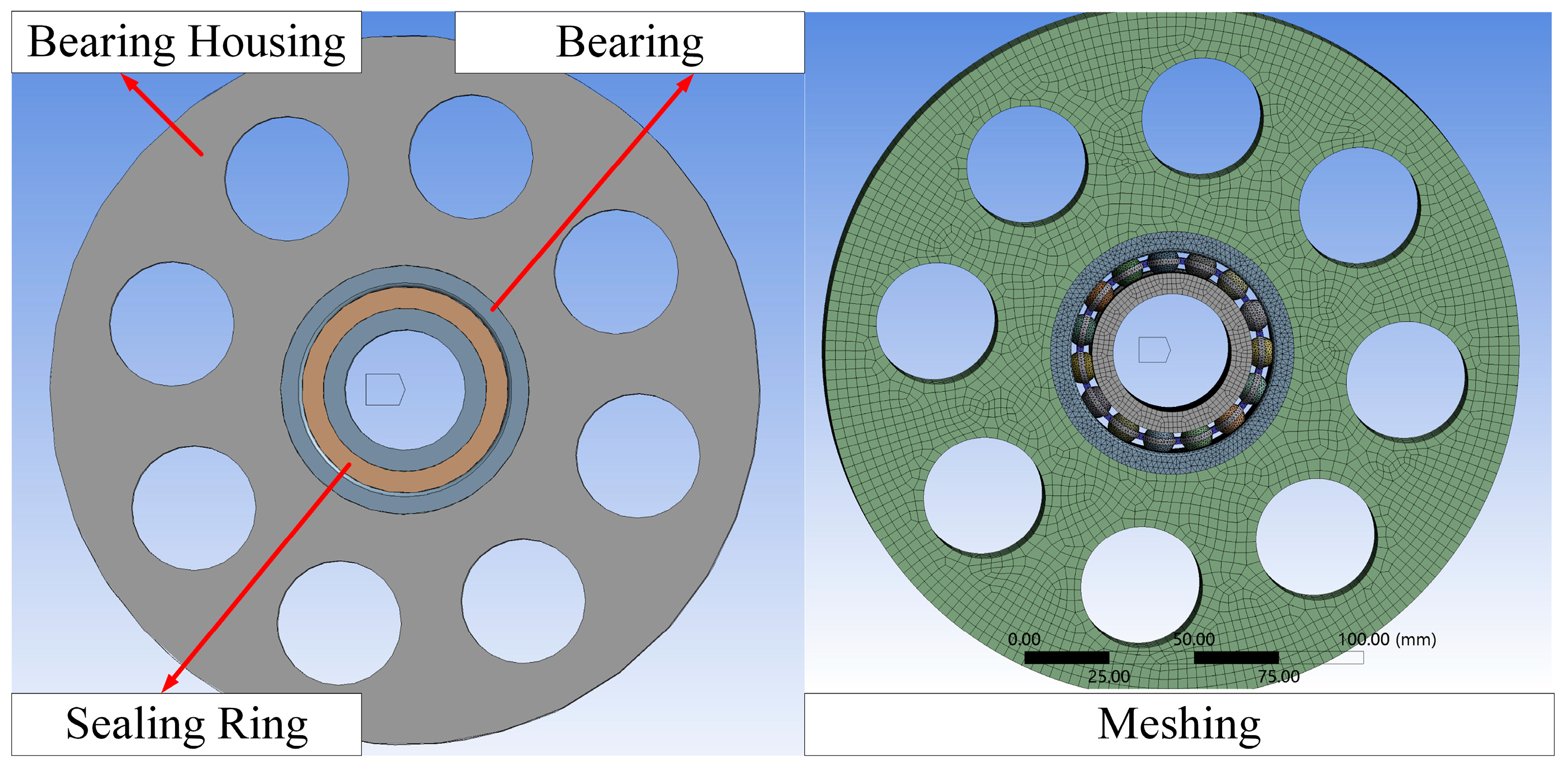

- Finite Element Simulation Model Setup: A full-scale model of the bearing is created in SOLIDWORKS, retaining key heat transfer features. Non-thermally sensitive structures such as fillets are removed to improve computational efficiency. Material properties are assigned to each part of the bearing, and the model is meshed with local refinement at contact areas to enhance simulation accuracy.

- Transient Temperature Rise Simulation: Using an APDL script in ANSYS2023.R1, the heat generation data generated by MATLAB2023(a) is read, and the bearing heat generation load is imported into the heat transfer model. Thermal boundary conditions—including heat conduction, heat convection, and thermal loads—are applied sequentially. The initial temperature and ambient temperature are set, followed by time step configuration aligned with the measured data acquisition duration to ensure temporal alignment. Complete temperature rise simulation data (including time, speed, load, and temperature) are output and saved in CSV format.

- Model Parameter Calibration: The MAE between measured and simulated data is calculated and defined as the objective function. A critical MAE threshold is set based on accuracy requirements. The parameter in the heat generation model is optimized using the gradient descent method until the MAE falls below the threshold. This process determines the final model parameters and completes the construction of the high-fidelity simulation model.

3.1. Mathematical Model

- Frictional Heat Generation Model:

- 2.

- Heat Transfer Model:

- 3.

- Model Parameter Optimization:

3.2. Finite Element Simulation Model

- Set Thermal Conduction: After creating the model, appropriate material properties need to be assigned. After importing the material library, correct material properties such as density, specific heat capacity, and thermal conductivity are assigned to the geometry to ensure accurate characterization of the model’s thermal conduction behavior.

- Define Thermal Convection: For thermal convection settings, select the appropriate mode in the “Convection” option, then choose the acting surface. Click “Details of Convection”, enter the corresponding value in the “Film Coefficient” under “Definition”, and input the ambient temperature in the “Ambient Temperature” field to complete the addition of thermal convection conditions.

- Define Thermal Loads: Based on specific operational requirements, first calculate the heat generated by each part of the bearing. Then, apply these heat values as thermal loads to the corresponding locations such as the inner ring, outer ring, balls, and cage. This step ensures accurate simulation and application of thermal loads.

- Set Time Steps: During transient analysis, appropriate time step parameters need to be defined. This includes the total simulation time, the number of time steps, and the time step size. These parameters determine the time range of the simulation and the resolution of the analysis.

4. Hybrid Dataset

- Normalize both measured and simulated data to eliminate dimensional differences between them.

- Apply interpolation to fill in missing values and ensure data completeness.

- Align timestamps of measured and simulated data to guarantee strict synchronization of bearing temperature and environmental parameters on the time scale.

- Maximize the predictive value of processed data through a weight allocation strategy. Since simulated data exhibit higher precision while measured data contain random disturbances, simulated data are assigned higher weights during fusion, whereas measured data are assigned lower weights.

- Construct a hybrid dataset comprising training, validation, and test sets based on the weighted fused data.

- The dataset retains an update interface to continuously incorporate new measured and simulated data.

5. Temperature Rise Prediction

5.1. CNN-LSTM Temperature Rise Prediction Model

5.2. CNN

5.3. LSTM

5.4. Computational Process

- (1)

- CNN Computational Process: A CNN extracts local features by applying convolution kernels through sliding window operations over the input feature maps. For each output channel, the algorithm iterates over each spatial location of the output feature map. At each location, it computes the dot product between the local input region and the convolution kernel, adds a bias term, and generates the output feature map through an activation function.

- (2)

- LSTM Computational Process: The LSTM controls information flow through gating mechanisms, addressing the gradient vanishing problem in traditional RNNs. The forget gate determines how much previous memory to retain, the input gate controls the incorporation of new information, and the output gate regulates the output of the current hidden state. The cell state acts as a memory carrier, propagating information across time steps.

6. Validation and Application

6.1. Test Equipment

6.2. Method Validation

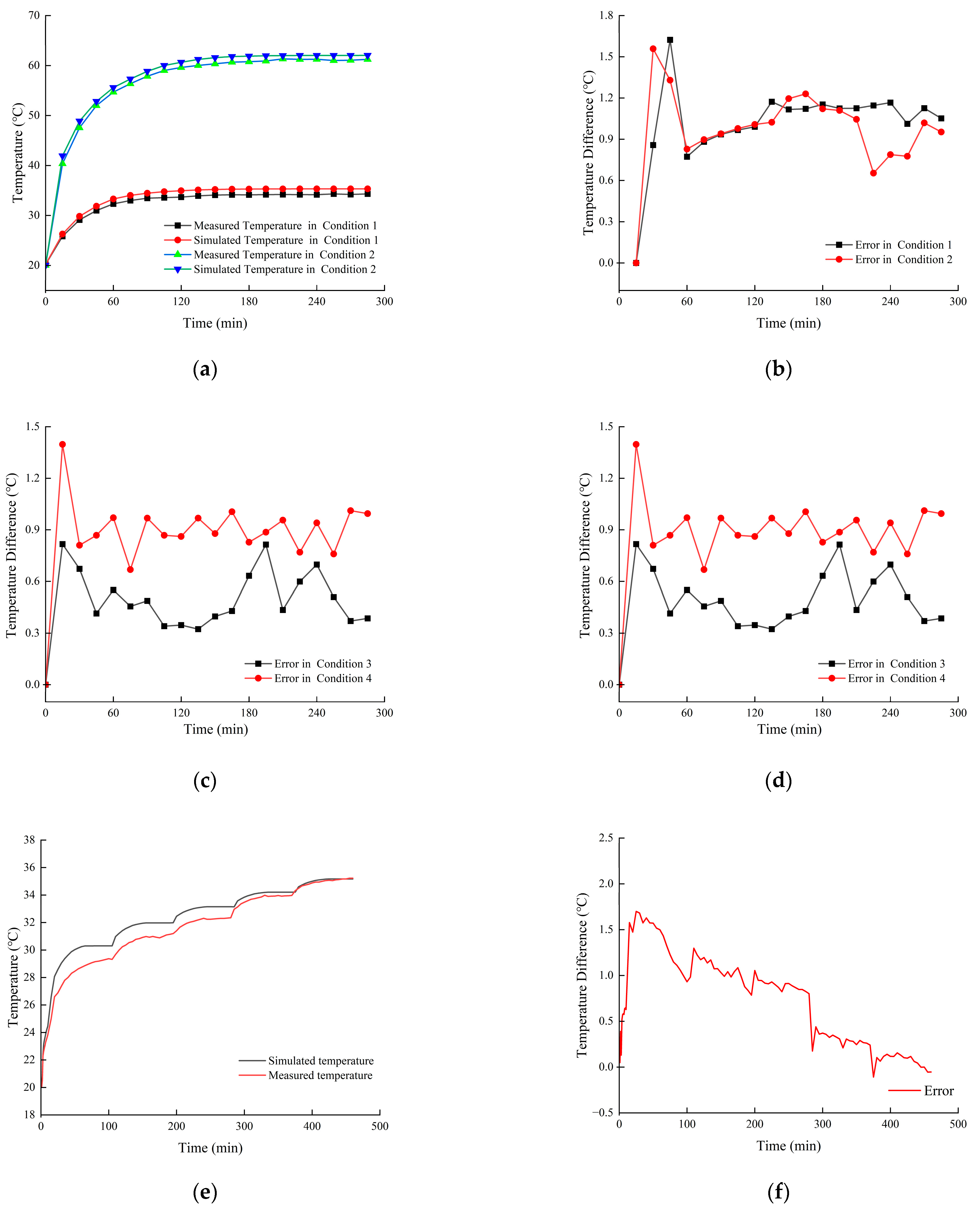

- Simulation Model

- 2.

- Hybrid Dataset

- 3.

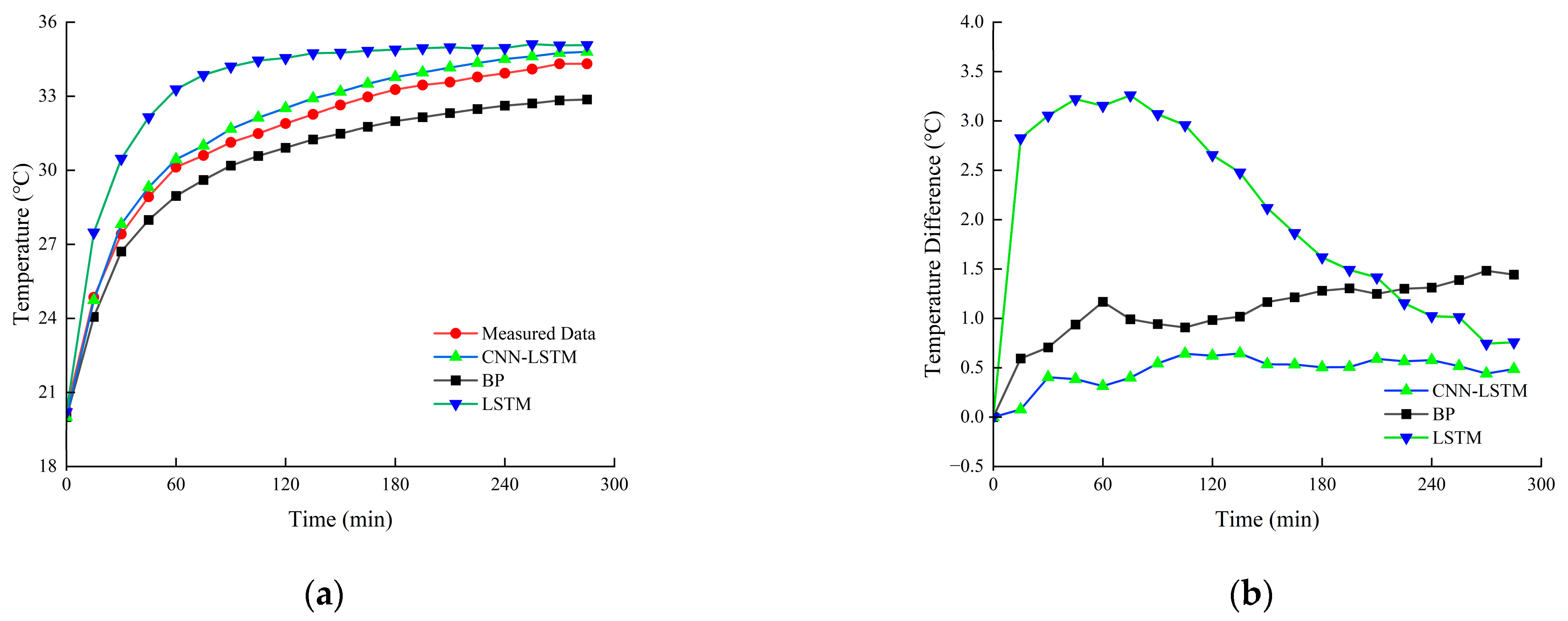

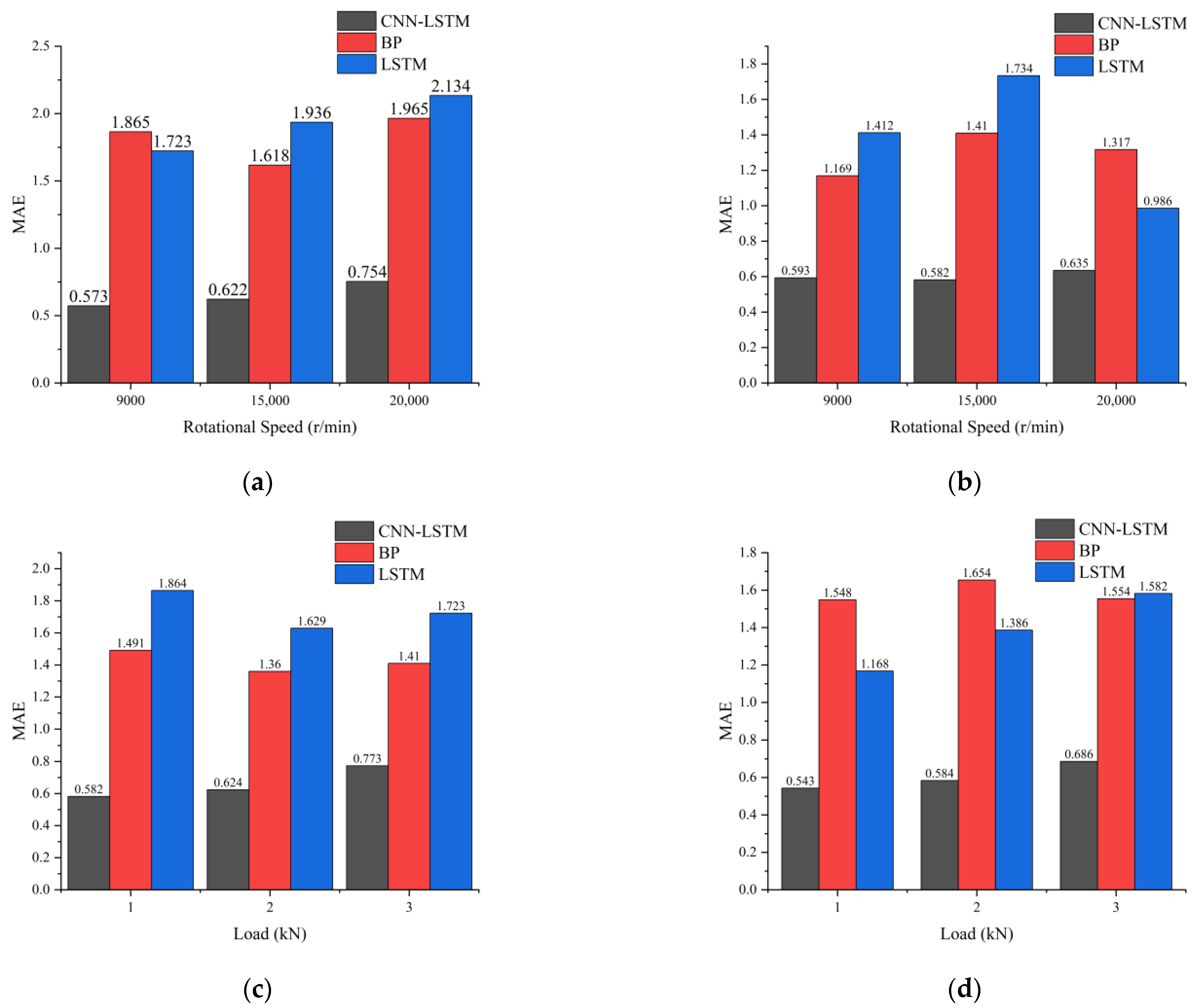

- Validation of the CNN-LSTM Method

| Algorithm 1 Computation of convolutional layers |

| Input: Input feature map: Convolutional kernel: Bias: Output: Output feature map: Steps: 1. Compute output size, 2. Initialize output feature map to zero. 3. for Traverse output channels 4. for do Traverse output height 5. for to do Traverse output width 6. Compute feature map 7. Add Bias 8. Apply activation function 9. end for 10. end for 11. end for 12. return Return output feature map End Algorithm |

| Algorithm 2 Computation of LSTM units |

| Input: Current time step input vector: Bias vector: Output: Vector concatenation is the sigmoid function 4. Compute candidate cell state: 5. Update cell state: denotes element-wise multiplication 7. Compute hidden state: Return current hidden state and cell state End algorithm |

- Comparison of Temperature Rise Prediction Results for Electric Drive Bearings under Constant Operating Conditions

- 2.

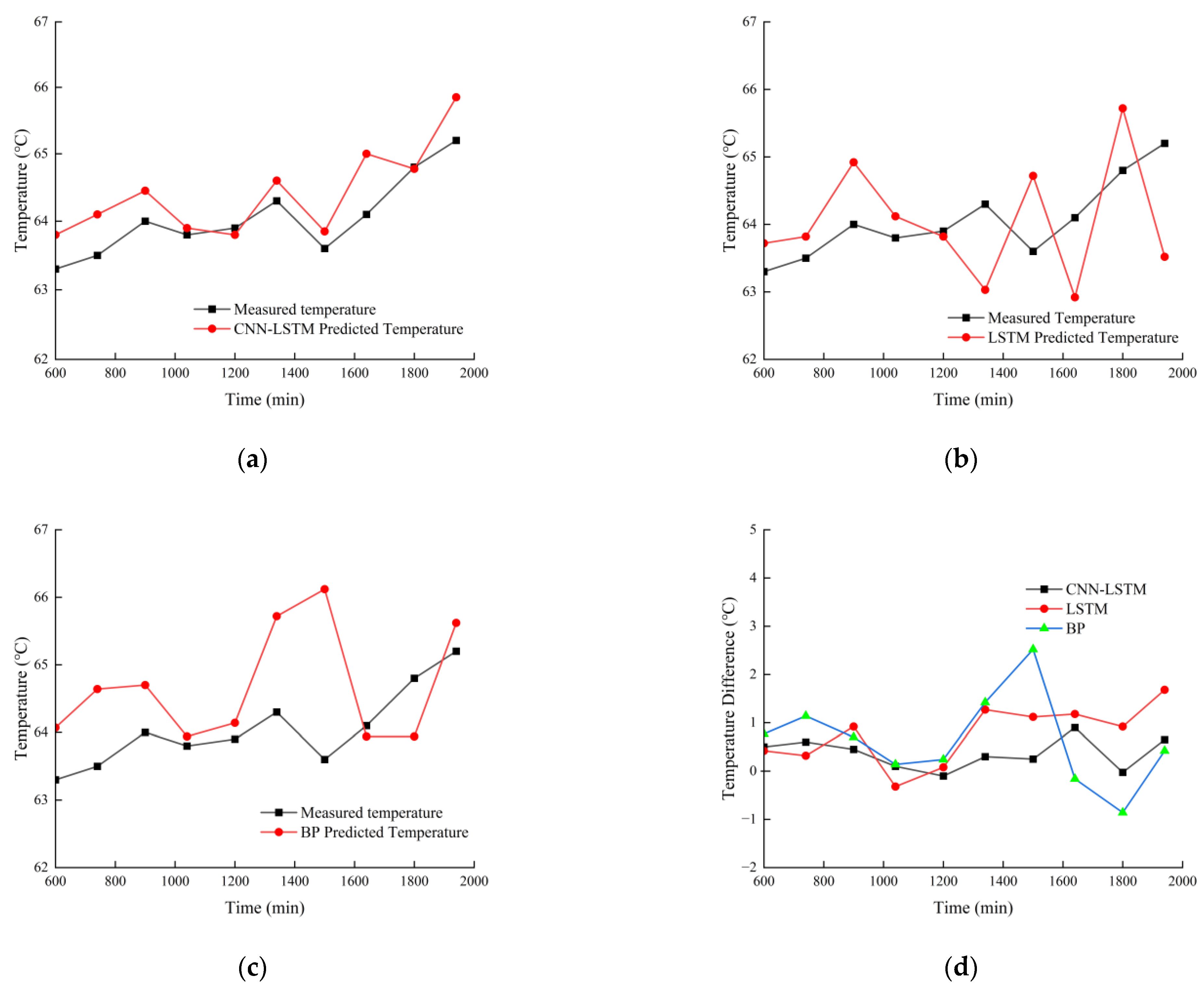

- Comparison of Temperature Rise Prediction Results for Electric Drive Bearings under Variable Operating Conditions

6.3. Analysis of Experimental Results

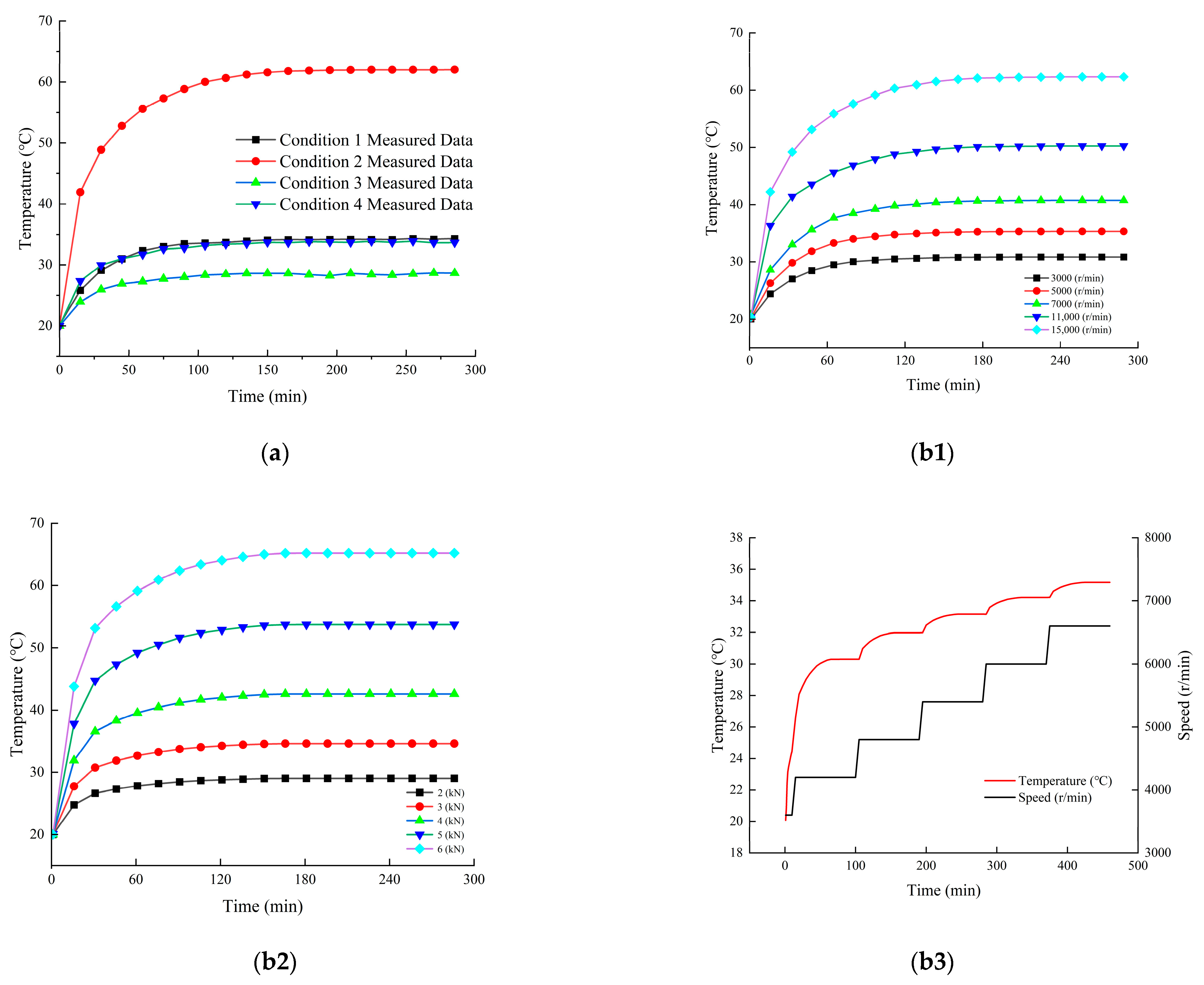

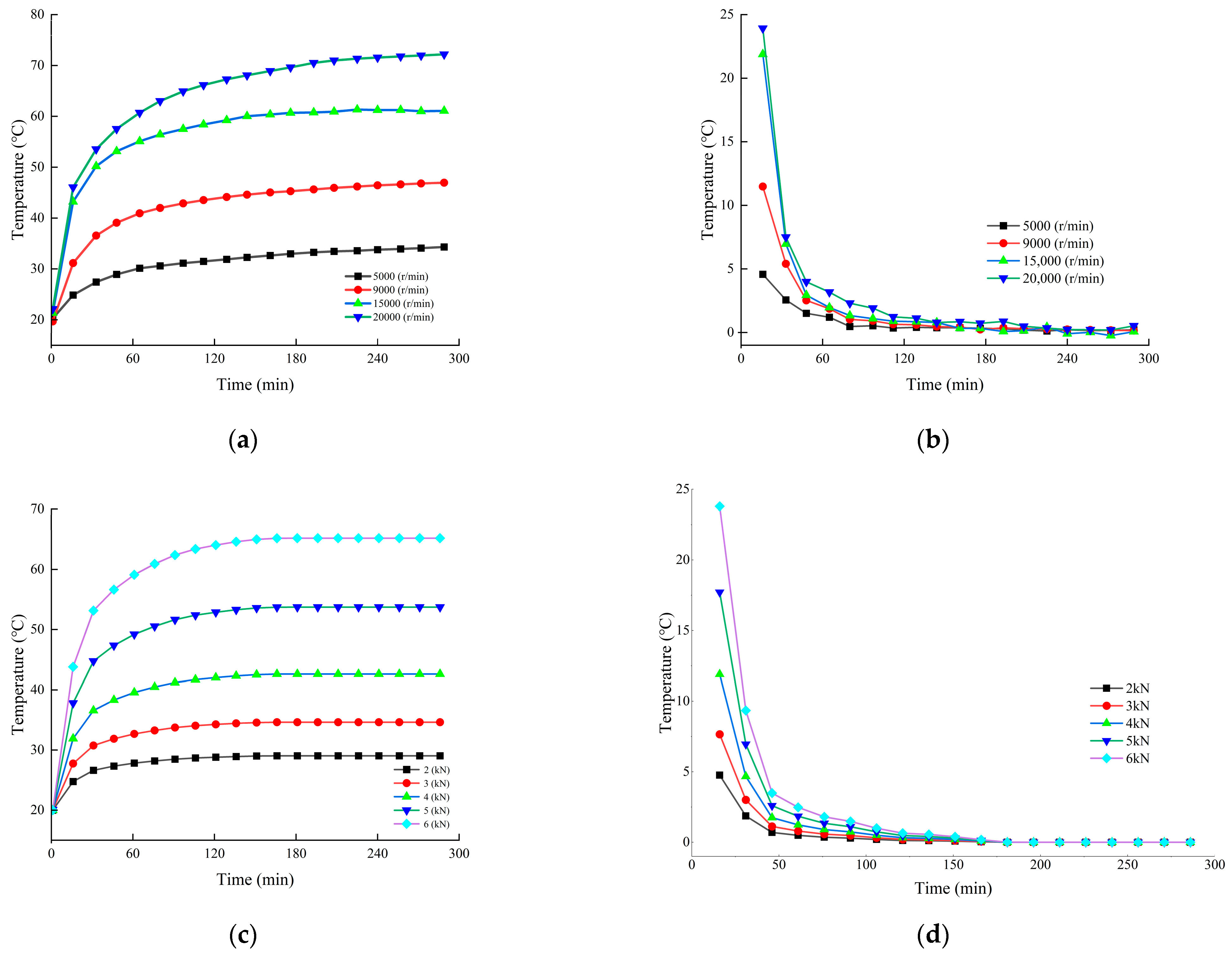

- Bearing Temperature Rise Characteristics under Constant Operating Conditions

- 2.

- Bearing Temperature Rise Characteristics under Variable-Speed Conditions

7. Conclusions

- The prediction error of the proposed method remains within 1 °C compared to the measured data. Specifically, under constant operating conditions, the maximum error during the temperature rise phase is 0.773 °C, and the maximum error during the steady-state phase is 0.686 °C. Under variable operating conditions, the maximum error during the temperature rise phase is 0.713 °C, and the maximum error during the steady-state phase is 0.764 °C. The CNN-LSTM model demonstrates superior prediction accuracy compared to the BP and LSTM models.

- The feasibility of the data–model integration-driven method for predicting the temperature rise in new energy electric drive bearings was validated, providing an important technical reference for similar studies under comparable working conditions.

- The bearing temperature rise process can be divided into a temperature rise phase and a steady-state phase, regardless of constant or variable operating conditions. The temperature changes rapidly during the temperature rise phase, while it fluctuates within a certain range during the steady-state phase. Under variable operating conditions, the temperature exhibits more pronounced fluctuations during the steady-state phase.

Limitations and Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MAE | Mean Absolute Error |

| DNN | Deep Neural Networks |

| LSTM | Long Short-Term Memory Network |

| FNN | Feedforward Neural Networks |

| GRNN | Generalized Regression Neural Networks |

| BP | Back Propagation Neural Network |

| PSO | Particle Swarm Optimization |

| CNN | Convolutional Neural Network |

| GA | Genetic Algorithm |

| RUL | Remaining Useful Life |

References

- Cheng, Y.; Wang, Z.; Zhang, W. A Novel Condition-Monitoring Method for Axle-Box Bearings of High-Speed Trains Using Temperature Sensor Signals. IEEE Sens. J. 2019, 19, 205–213. [Google Scholar] [CrossRef]

- Li, C.; Feng, Q.; Sun, B.; Gao, L.; Jia, M.; Fang, Z.; Xiong, J. Wireless Method for Measuring the Rotational Speed of Roller Bearing in a High-Temperature Environment. IEEE Sens. J. 2022, 22, 20989–20998. [Google Scholar] [CrossRef]

- Palmgren, A. Ball and Roller Bearing Engineering: Theory Design and Application, 3rd ed.; SKF Industries: Blue Bell, PA, USA, 1959; pp. 225–230. [Google Scholar]

- Goncalves, D.; Cousseau, T.; Gama, A.; Campos, A.V.; Seabra, J.H. Friction torque in thrust roller bearings lubricated with greases, their base oils and bleed-oils. Tribol. Int. 2017, 107, 306–319. [Google Scholar] [CrossRef]

- Gao, P.; Tang, W.; Cui, Y.; Wang, Y.; Mo, G.; Yin, J. Theoretical and Experimental Investigation on Thermal Characteristics of Railway Double-Row Tapered Roller Bearing. Energies 2022, 15, 4217. [Google Scholar] [CrossRef]

- Yun, X.; Xie, F.; Han, Q. Study on bearing mechanical and thermal characteristic evolvement rules affected by higher ambient temperature. J. Vibroeng. 2022, 24, 1249–1261. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.; Wang, H. Intelligent bearing structure and temperature field analysis based on finite element simulation for sustainable and green manufacturing. J. Intell. Manuf. 2021, 32, 745–756. [Google Scholar] [CrossRef]

- Cui, L.; He, Y.F.; Fu, F.W. Friction and temperature analysis of angular contact ball bearing in high speed electric spindle system. In Proceedings of the International Conference on Mechanics and Mechatronics, Changsha, China, 13–15 March 2015. [Google Scholar] [CrossRef]

- Kim, K.S.; Lee, D.W.; Lee, S.M.; Lee, S.J.; Hwang, J.H. A numerical approach to determine the frictional torque and temperature of an angular contact ball bearing in a spindle system. Int. J. Precis. Eng. Manuf. 2015, 16, 135–142. [Google Scholar] [CrossRef]

- Ye, Z.H.; Wang, L.Q.; Chen, G.C.; Tang, D. Analysis of thermo-mechanical coupling of high-speed angular-contact ball bearings. Adv. Mech. Eng. 2017, 9, 6. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, C.; Wang, J.; Wang, S.; Lv, D.; Qin, F. Research on Digital Twin Driven Rolling Bearing Model-Data Fusion Life Prediction Method. IEEE Access 2023, 11, 48611–48627. [Google Scholar] [CrossRef]

- Qin, Y.; Wu, X.; Luo, J. Data-Model Combined Driven Digital Twin of Life-Cycle Rolling Bearing. IEEE Trans. Ind. Inf. 2022, 18, 1530–1540. [Google Scholar] [CrossRef]

- Shi, H.; Song, Z.; Bai, X.; Hu, Y.; Li, T.; Zhang, K. A novel digital twin model for dynamical updating and real-time mapping of local defect extension in rolling bearings. Mech. Syst. Signal Process. 2023, 193, 110255. [Google Scholar] [CrossRef]

- Yang, J.; Palazzolo, A. Tilt Pad Bearing Distributed Pad Inlet Temperature with Machine Learning—Part I: Static and Dynamic Characteristics. J. Tribol. 2022, 144, 061801. [Google Scholar] [CrossRef]

- Yang, J.; Palazzolo, A. Tilt pad bearing distributed pad inlet temperature with machine learning—Part II: Morton effect. J. Tribol. 2022, 144, 061802. [Google Scholar] [CrossRef]

- Zhu, Y.; Cheng, J.; Liu, Z.; Zou, X.; Wang, Z.; Cheng, Q.; Xu, H.; Wang, Y.; Tao, F. Remaining Useful Life Prediction Approach Based on Data Model Fusion: An Application in Rolling Bearings. IEEE Sens. J. 2024, 24, 42230–42244. [Google Scholar] [CrossRef]

- An, Y.; Zhang, K.; Liu, Q.; Chai, Y.; Huang, X. Rolling Bearing Fault Diagnosis Method Base on Periodic Sparse Attention and LSTM. IEEE Sens. J. 2022, 22, 12044–12053. [Google Scholar] [CrossRef]

- Badawi, M.B.; Awad Taher, H.; El Fahham, I.M. Application of artificial intelligence for the prediction of plain journal bearings performance. Alex. Eng. J. 2022, 61, 9011–9029. [Google Scholar] [CrossRef]

- Zhou, E.; Zhao, Y.; Dai, Y.; Zhang, J.; Zhang, Y.; Li, H. Research on Temperature Field Prediction Model of Electric Spindle Based on Improved BP Neural Network. Res. Sq. 2021. [Google Scholar] [CrossRef]

- Li, H.; Liu, C.; Yang, F.; Ma, X.; Guo, N.; Sui, X.; Wang, X. Dynamic Temperature Prediction on High-Speed Angular Contact Ball Bearings of Machine Tool Spindles Based on CNN and Informer. Lubricants 2023, 11, 343. [Google Scholar] [CrossRef]

- Deng, C.; An, L.; Cheng, X.; Qu, J.; Gao, Z.; An, Q. A friction temperature model for dynamic bearing operation based on neural network and genetic algorithm. Tribol. Int. 2024, 191, 109057. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; An, B.; Li, R. Prediction of scuffing failure in grease-lubricated ball bearing based on GA-BP neural network. Eng. Fail. Anal. 2025, 170, 109331. [Google Scholar] [CrossRef]

- Lu, W.; Wang, Y.; Zhang, M.; Gu, J. Physics guided neural network: Remaining useful life prediction of rolling bearings using long short-term memory network through dynamic weighting of degradation process. Eng. Appl. Artif. Intell. 2024, 127, 107350. [Google Scholar] [CrossRef]

| Test Step | Speed (r/min) | Time (s) | Radial Load (kN) | Axial Load (kN) |

|---|---|---|---|---|

| 1 | 0~5400 | 3 | 1.799 | 0.257 |

| 2 | 5400 | 6 | 1.799 | 0.257 |

| 3 | 5400~18,000 | 6 | 1.799 | 0.257 |

| 4 | 18,000 | 18 | 1.799 | 0.257 |

| 5 | 18,000~5400 | 6 | 1.799 | 0.257 |

| No. | Condition | ||

|---|---|---|---|

| 1 | condition 1 | 1.599 | 1.074 |

| 2 | condition 2 | 1.588 | 1.025 |

| 3 | condition 3 | 0.816 | 0.516 |

| 4 | condition 4 | 1.397 | 0.911 |

| 5 | gradual variable-speed condition | 1.577 | 0.749 |

| Parameter Name | Parameter Value |

|---|---|

| number of convolutional layers | 2 |

| kernel size | 7 × 7/3 × 3 |

| number of kernels | 64/128 |

| LSTM hidden layers count | 1 |

| LSTM units per LSTM layer | 128 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Chen, X.; Zhong, Z.; Ye, J.; Zhang, W. Data–Model Integration-Driven Temperature Rise Prediction Method for New Energy Electric Drive Bearings. Machines 2025, 13, 925. https://doi.org/10.3390/machines13100925

Yang F, Chen X, Zhong Z, Ye J, Zhang W. Data–Model Integration-Driven Temperature Rise Prediction Method for New Energy Electric Drive Bearings. Machines. 2025; 13(10):925. https://doi.org/10.3390/machines13100925

Chicago/Turabian StyleYang, Fang, Xi Chen, Zhidan Zhong, Jun Ye, and Weiqi Zhang. 2025. "Data–Model Integration-Driven Temperature Rise Prediction Method for New Energy Electric Drive Bearings" Machines 13, no. 10: 925. https://doi.org/10.3390/machines13100925

APA StyleYang, F., Chen, X., Zhong, Z., Ye, J., & Zhang, W. (2025). Data–Model Integration-Driven Temperature Rise Prediction Method for New Energy Electric Drive Bearings. Machines, 13(10), 925. https://doi.org/10.3390/machines13100925