1. Introduction

In recent decades, induction motors (IMs) have become the backbone of modern industrial applications, playing a vital role in manufacturing, energy conversion, robotics, transportation, and automation systems due to their durability, simplicity of construction, low cost, and high power-to-weight ratio [

1,

2]. Despite their reliability, induction motors are susceptible to various faults caused by harsh operating conditions, aging, poor lubrication, load variations, or environmental factors. Among these, bearing-related faults are the most prevalent, accounting for approximately 41–42% of all failures in industrial IMs according to IEEE and EPRI statistical analyses [

3]. Since rolling-element bearings ensure the smooth and efficient operation of rotating machinery, any degradation in their performance can lead to reduced efficiency, unplanned downtime, increased maintenance costs, or even catastrophic system failure [

4]. To address this critical issue, industrial stakeholders are transitioning from reactive and preventive maintenance schemes to predictive maintenance (PdM) strategies. Predictive maintenance involves real-time monitoring of equipment health and applying diagnostic algorithms to anticipate failures before they occur, optimizing resource allocation and minimizing production losses [

5]. This transition is largely driven by the emergence of Industry 4.0, which combines cyber–physical systems (CPSs), the Industrial Internet of Things (IIoT), edge computing, cloud services, and artificial intelligence (AI) [

6,

7]. These technologies enable the continuous acquisition, processing, and analysis of operational data through intelligent sensors, making real-time condition-based maintenance a feasible and scalable solution.

Vibration analysis is currently one of the most widely adopted methods for assessing the health of bearings. It enables the detection of characteristic fault frequencies associated with inner and outer race defects, ball defects, and lubrication issues [

8]. However, the effectiveness of vibration-based diagnostics depends heavily on signal quality, proper sensor placement, and the application of advanced data-driven techniques for pattern recognition and classification. Among the computational techniques, Machine Learning (ML) and Deep Learning (DL) have shown significant promise in automating the fault diagnosis process [

9]. These methods are capable of learning from complex and non-linear data distributions, offering superior accuracy over traditional signal processing techniques. Notably, Support Vector Machines (SVMs), Convolutional Neural Networks (CNNs), Multilayer Perceptrons (MLPs), and ensemble learning approaches such as Gradient Boosting and XGBoost are increasingly used in PdM systems [

10,

11,

12]. Their effectiveness has been demonstrated in both laboratory and real-world scenarios involving various types of IM faults.

This study contributes an intelligent diagnostic framework for bearing fault detection in induction motors by combining vibration signal analysis with machine learning models (SVMs and ANNs) in an IoT-enabled architecture. The framework leverages IO-Link sensors, edge computing, and cloud integration to enable scalable and real-time monitoring. Validation on an experimental dataset including multiple lubrication states and structural defect scenarios demonstrates its effectiveness and practical applicability. Several recent studies have explored machine learning-based approaches for induction motor fault diagnosis, combining methods such as SVMs, neural networks, and boosting techniques to enhance classification accuracy. For example, Kim et al. [

13] proposed a framework integrating SVMs, neural networks, and boosting methods to effectively identify various motor faults under laboratory conditions. Building upon this line of research, the present study proposes a hybrid intelligent diagnostic framework that integrates SVMs and ANNs within an Industry 4.0-compliant IoT architecture extending the approach to real-time, scalable, and industrially deployable monitoring.

The rest of this paper is structured as follows.

Section 2 provides a comprehensive review of the state-of-the-art in intelligent fault diagnosis of induction motor bearings, with emphasis on ML and DL methods.

Section 3 introduces the main characteristics of vibration signals and presents the theoretical background of fault-specific frequency patterns (BPFO, BPFI, BSF, FTF) that enable fault localization and identification in bearing systems.

Section 4 describes the experimental setup, data acquisition system, and modeling framework.

Section 5 presents the results and comparative analysis of the proposed methodology. Finally,

Section 6 concludes the paper and outlines directions for future work.

2. Fault Diagnosis Techniques

This section provides a structured literature review of existing fault diagnosis techniques for induction motor bearings. While some aspects overlap with the general background presented in the Introduction, the aim here is to offer a more detailed and systematic overview. This review highlights the strengths and limitations of prior approaches and motivates the use of SVMs and ANNs in the proposed framework. By presenting this material in a dedicated section, the Introduction is kept concise, while readers are still provided with a comprehensive technical foundation before the methodology is introduced.

Vibration analysis remains the cornerstone of bearing fault diagnosis in rotating electrical machines due to its sensitivity, diagnostic richness, and early-stage fault detection capability. Rolling element bearings produce distinct vibration signatures depending on the type and severity of defect, such as spalls or cracks in the inner/outer race, rolling elements, or cages. These signatures manifest as characteristic fault frequencies that are functions of bearing geometry and rotational speed. Over the past decades, this approach has been widely applied in both industrial and research contexts and further refined through advances in signal processing and sensor technologies [

14].

Traditional methods focus on time-domain and frequency-domain analysis. Time-domain indicators like root mean square (RMS), kurtosis, skewness, crest factor, and peak amplitude are often the first-line features for monitoring signal energy or impulsiveness [

15,

16]. However, their diagnostic reliability is limited in complex or noisy environments. Consequently, frequency-domain methods such as Fast Fourier Transform (FFT) and envelope analysis became dominant due to their capacity to isolate defect-specific frequency bands [

17,

18]. To overcome the non-stationary nature of real-world vibration signals, time–frequency representations have been employed. Short-Time Fourier Transform (STFT), Wavelet Transform (WT), and Empirical Mode Decomposition (EMD) have allowed dynamic spectral analysis, enabling the detection of transient and incipient faults in varying speed conditions [

19,

20,

21]. In particular, Wavelet Packet Decomposition (WPD) has proven effective for isolating energy components of fault-induced vibrations in specific frequency bands [

22].

Recent developments integrate advanced statistical metrics and adaptive signal decomposition methods, such as Hilbert–Huang Transform (HHT) and Variational Mode Decomposition (VMD), which exhibit higher robustness in handling non-linear and time-varying phenomena [

23,

24]. These techniques facilitate envelope extraction and demodulation of modulated signals caused by cyclic impacts—critical for early fault detection in bearings. Moreover, multisensor fusion approaches, where vibration data is combined with acoustic, current, or temperature measurements, have shown promise in increasing diagnostic accuracy and robustness [

25]. However, even standalone vibration analysis, when enhanced with adaptive filtering, denoising, and advanced time–frequency techniques, remains a practical and effective tool for predictive maintenance systems, particularly in Industry 4.0 environments.

Acoustic emission (AE) analysis has emerged as a complementary and powerful technique for detecting early-stage bearing faults, particularly those involving surface degradation, micro-cracking, or lubrication deficiencies. AE refers to the high-frequency elastic waves generated by rapid energy releases within materials, such as crack initiation or frictional slip. Unlike vibration signals, which primarily capture lower-frequency responses from macroscopic motion, AE signals contain high-frequency information (typically > 100 kHz), enabling detection of subtle incipient faults often missed by conventional methods. The main advantage of AE is its sensitivity to microscopic changes, making it ideal for early fault detection before severe damage occurs. Caesarendra et al. [

26] reviewed AE-based condition monitoring methods and their applications for low-speed slew bearings, highlighting the effectiveness of AE in capturing early fault signatures. Hemmati et al. [

27] experimentally investigated the statistical parameters of AE signals in rolling element bearings, showing that parameters such as hit count, rising time, energy, and amplitude are sensitive to fault presence and severity under varying load and speed conditions. Furthermore, Tang et al. [

28] conducted a comparative study of vibration and AE signals for fault diagnosis in low-speed bearings, demonstrating that AE event extraction using short-time autocorrelation function (STAF) enhances the identification of fault-induced pulses, providing reliable diagnostics even in challenging operational scenarios. Collectively, these studies confirm that AE analysis, especially when combined with advanced signal processing techniques, offers a robust approach for early detection and monitoring of bearing faults, complementing traditional vibration-based methods.

Recent advances in deep learning have significantly enhanced the accuracy and scalability of bearing fault diagnosis systems, especially in the context of Industry 4.0, where large volumes of heterogeneous sensor data are readily available. Hybrid multimodal fusion techniques, which integrate vibration and acoustic emission signals, have been shown to improve the robustness of diagnostic models by leveraging complementary information from multiple sensing modalities. Che et al. [

29] proposed a deep learning framework that utilizes multimodal fusion and feature extraction to achieve high diagnostic accuracy, demonstrating superior performance over single-sensor approaches. In a similar direction, Zhang et al. [

30] introduced a novel architecture based on variable pooling multiscale convolutional neural networks (VPMCNNs), which effectively captures multiscale features from raw acoustic emission signals, leading to improved classification performance under both constant and variable operating conditions. Moreover, traditional shallow learning architectures are increasingly replaced by deep neural networks that can automatically extract hierarchical features from complex time–frequency representations. He and He [

31] developed a deep learning method employing short-time Fourier transform (STFT) and a LAMSTAR neural network, which achieved reliable fault classification using acoustic signals collected from experimental bearing rigs. Zhao et al. [

32] provided a comprehensive overview of deep learning applications in machine health monitoring, emphasizing the superiority of convolutional and recurrent neural networks in extracting discriminative features from non-stationary signals. Alongside algorithmic development, sensor placement remains a critical consideration in ensuring signal quality and observability of fault characteristics. Dai et al. [

33] proposed an optimal sensor placement strategy for modal identification in rotating machinery, considering both the number and spatial configuration of sensors, thus enhancing the efficacy of monitoring systems.

Motor Current Signature Analysis (MCSA) has proven to be a non-invasive and cost-effective technique for detecting bearing faults in induction motors. However, the faint fault signatures in current signals—often buried within dominant supply harmonics—pose significant challenges. To boost diagnostic performance, recent studies have integrated advanced filtering approaches with Support Vector Machine (SVM) classifiers. A recent comprehensive review by Niu et al. [

34] systematically outlines the state-of-the-art in MCSA-based fault diagnosis, summarizing techniques ranging from traditional spectral and demodulation analyses to time–frequency and AI-driven approaches. The authors note that the successful deployment of MCSA hinges on effective noise suppression and robust feature extraction under varying load and speed conditions.

Building on this foundation, Jonjo et al. [

35] proposed a multi-stage pipeline—time-shifting to attenuate supply harmonics, optimized Variational Mode Extraction (VME) using Black Widow optimization, followed by CNN-SVM classification on 2D current representations—achieving over 95% accuracy. Similarly, Dalvand et al. [

36] introduced time-shifting combined with demodulation filters and SVMs to isolate fault-related current components, significantly improving SNR. Further advancing classifier techniques, Khadem Hosseini et al. [

37] merged Wavelet-based feature extraction and Kernel PCA with a projection-based SVMs optimized via a Projection Recurrent Neural Network (PRNN), boosting detection fidelity in bearing fault tests. These hybrid frameworks illustrate the strength of combining signal preprocessing with powerful, adaptive SVM classifiers.

Still, there’s room for improvement. Challenges such as fluctuating torque, unbalanced hosts, and supply distortions require more adaptive decomposition methods like Variational Mode Decomposition or Adaptive EMD. Moreover, dynamic SVM parameter tuning and real-time edge implementation are essential for Industry 4.0 deployment. Together, these advances spotlight a clear trend: merging advanced filtering techniques (time-shift, VME, wavelets) with SVM-based ML models substantially enhances MCSA diagnostics, aligning well with the needs of scalable, reliable, and field-deployable predictive maintenance systems.

Infrared Thermography (IRT) has emerged as a non-invasive and non-contact diagnostic technique for detecting incipient faults in induction motors, especially in situations where physical sensors might be impractical or intrusive. Recent advancements have combined IRT with machine learning (ML) and deep learning (DL) methods to extract meaningful thermal patterns associated with bearing, rotor, and lubrication-related faults. In [

38], Atif et al. proposed a hybrid approach integrating classical ML and DL techniques, achieving 98.29% classification accuracy using SVMs and 100% using a simplified CNN, thereby demonstrating high efficiency in identifying various bearing defects through statistical and GLCM-based features. Similarly, Javed et al. [

39] utilized Local Octa Pattern (LOP) features in conjunction with genetic algorithms and SVM classifiers to detect overload and fault conditions, showcasing robust real-time performance with infrared datasets. Molina et al. [

40] applied a lightweight neural network trained via the Google Teachable Machine to classify four fault types (bearing and rotor bar defects), deployed on embedded systems for live monitoring, proving the feasibility of edge deployment in industrial settings. Kulkarni et al. [

41] provided a broad survey of thermal imaging-based fault detection techniques across different machine types, emphasizing the versatility of DL algorithms such as CNNs in handling complex image-based diagnostics. Finally, Kilickaya et al. [

42] introduced a novel self-organized operational neural network (Self-ONN) architecture for fault diagnosis in squirrel-cage induction motors. The proposed model achieved comparable performance to deeper CNNs like ResNet and EfficientNet, while being significantly lighter and suitable for edge deployment scenarios with limited computational resources.

The diagnostic techniques of vibration analysis, acoustic emission, motor current signature analysis (MCSA), and infrared thermography (IRT) offer complementary insights into bearing health, each excelling under specific operating conditions and fault types. Vibration and acoustic emission provide high sensitivity to early localized defects, while, MCSA enables non-intrusive monitoring, and IRT supports contactless surface temperature assessment. Accurate fault type and severity identification, depend on extracting distinctive features—such as frequency peaks, amplitude modulations, and thermal gradients—that serve as indicators of specific fault mechanisms and are essential for reliable automated diagnosis. Despite their proven effectiveness, most existing studies either rely on controlled laboratory datasets or single diagnostic models. The novelty of this work lies in integrating a hybrid intelligent diagnostic framework, combining Support Vector Machines (SVMs) and Artificial Neural Networks (ANNs), within an Industry 4.0-compliant IoT architecture. Validated on a custom experimental dataset incorporating diverse lubrication and structural bearing faults, this framework balances interpretability with predictive accuracy and is designed for real-time industrial deployment. As feature extraction is a critical step, the following section introduces the characteristic vibration signal features and fault-specific frequency patterns forming the basis of the proposed methodology.

3. Signal Features and Fault Signatures in Bearing Diagnosis

This section provides the theoretical foundation of bearing fault frequencies and fault signatures, which are directly related to the experimental states analyzed in

Section 4. In vibration-based diagnosis of rolling element bearings, early and accurate fault diagnosis relies heavily on identifying specific frequency components generated by the dynamic interactions of defective bearing elements. These frequency components as shown in

Table 1, known as characteristic fault frequencies (CFFs), are deterministic and can be derived from the bearing’s geometry and the motor’s rotational speed. Each bearing fault—whether located on the outer race, inner race, rolling element, or the cage—produces a unique frequency signature due to the periodic impact events that arise as the defective component interacts with the rest of the system during rotation. The most used CFFs are the following:

These fault frequencies are embedded in the vibration spectrum of the motor and can be used as diagnostic indicators. The accurate calculation of CFFs enables fault localization (inner race, outer race, ball, or cage) and supports classification models by serving as ground-truth frequencies for both feature extraction and validation. When a fault is present, harmonics and sidebands around these frequencies may appear, particularly when the fault is severe or when amplitude modulation occurs due to load or speed variations.

Consequently, most signal processing and feature extraction techniques (e.g., envelope analysis, spectral kurtosis, time-frequency transforms) aim to enhance and isolate these fault frequencies from noise and non-relevant components. These frequencies manifest in real signals and they are detected and leveraged by diagnostic algorithms. The effectiveness of any intelligent fault diagnosis system for rolling element bearings critically depends on the quality of features extracted from the raw signals. These features are derived either from the time domain or the frequency domain of the vibration signal and are chosen based on their sensitivity to bearing faults and their ability to discriminate among different fault types and severities.

Time-domain features are statistical descriptors directly computed from the amplitude of the vibration signal over time. These features are straightforward to compute and do not require transformation into another domain, making them attractive for real-time and embedded diagnostic systems. Commonly used time-domain features include: Root Mean Square (RMS), Peak-to-Peak Value (P2P), Crest Factor (CF), Kurtosis (K), Skewness, Impulse Factor (IF) [

47]. These features can provide early indicators of degradation when tracked over time in a condition monitoring system. However, they may be insufficient under noisy or variable-speed conditions, where fault-induced components are buried under broadband noise.

Frequency-domain features are obtained by transforming the vibration signal using the Fast Fourier Transform (FFT) or other spectral techniques. They allow for isolation of specific frequencies associated with known fault mechanisms, such as the CFFs. The key frequency-domain features include Spectral Energy, Spectral Kurtosis (SK), Sideband Analysis, Amplitude at CFFs, Power Spectral Density (PSD), and Envelope Spectrum Peaks. Envelope analysis, typically combined with the Hilbert transform, helps extract modulated fault components from high-frequency resonance regions. Peaks in the envelope spectrum at CFFs confirm the existence of localized defects. These frequency-domain features are critical in robust fault diagnosis, particularly when the motor operates under varying load or speed. Moreover, they facilitate explainable AI models, where each frequency component has a known physical interpretation.

In bearing fault diagnosis, the visual examination of vibration signals—particularly in the time and frequency domains—provides critical insight into the underlying mechanical condition of the bearing. Different fault types, such as outer race, inner race, ball, or cage defects, exhibit distinct dynamic responses that are observable in the form of periodic impulses, sidebands, and energy concentration at specific fault frequencies. These frequencies, namely the Ball Pass Frequency Outer race (BPFO), Ball Pass Frequency Inner race (BPFI), Ball Spin Frequency (BSF), and Fundamental Train Frequency (FTF), form the diagnostic foundation for vibration-based monitoring systems. Their presence, intensity, and evolution in the recorded signals allow for the discrimination between different fault severities and locations.

In the time domain, a localized defect on the outer or inner race leads to recurrent impulsive responses as the rolling elements strike the damaged surface. These impulses, though sometimes masked by system noise or other mechanical interactions, can be revealed through techniques such as the envelope analysis or high-resolution filtering. A healthy bearing typically exhibits a low-amplitude, broadband response, while a defective bearing demonstrates sharp periodic bursts with increased amplitude and kurtosis, especially when the fault size grows. The corresponding frequency spectra show harmonics centered around the shaft rotation frequency and modulated by the bearing characteristic fault frequencies. For example, an outer race fault will produce a series of spectral peaks spaced at the BPFO, while an inner race fault leads to similar patterns around the BPFI, with modulations affected by the rotational speed of the shaft and the number of rolling elements [

21].

In the frequency domain, envelope spectra derived from demodulation techniques are particularly powerful. These representations isolate modulated high-frequency components associated with repetitive impacts. Such impacts result in prominent spectral lines at the BPFO, BPFI, or BSF, depending on the fault location. As reported in Randall and Antoni [

18], the sideband structure and the spacing between spectral lines provide an important diagnostic cue, allowing for the detection of compound or multiple defects. Antoni [

19] introduced the kurtogram as a tool to automatically select the frequency band that contains the highest impulsiveness, guiding the analyst to the frequency range where the defect signature is most pronounced.

Other studies have demonstrated the efficacy of combining statistical analysis, time–frequency transforms, and sparse signal decomposition for fault identification. Yang et al. [

20] applied basis pursuit decomposition to isolate defect-induced transients from the overall vibration response, enhancing the visibility of fault signatures. Similarly, Kankar et al. [

17] employed the wavelet transform to distinguish inner and outer race defects through transient energy concentration and localized signal behavior. These visualization techniques not only aid in fault classification but also contribute to the validation of automated diagnostic algorithms, offering a benchmark for supervised and unsupervised learning approaches.

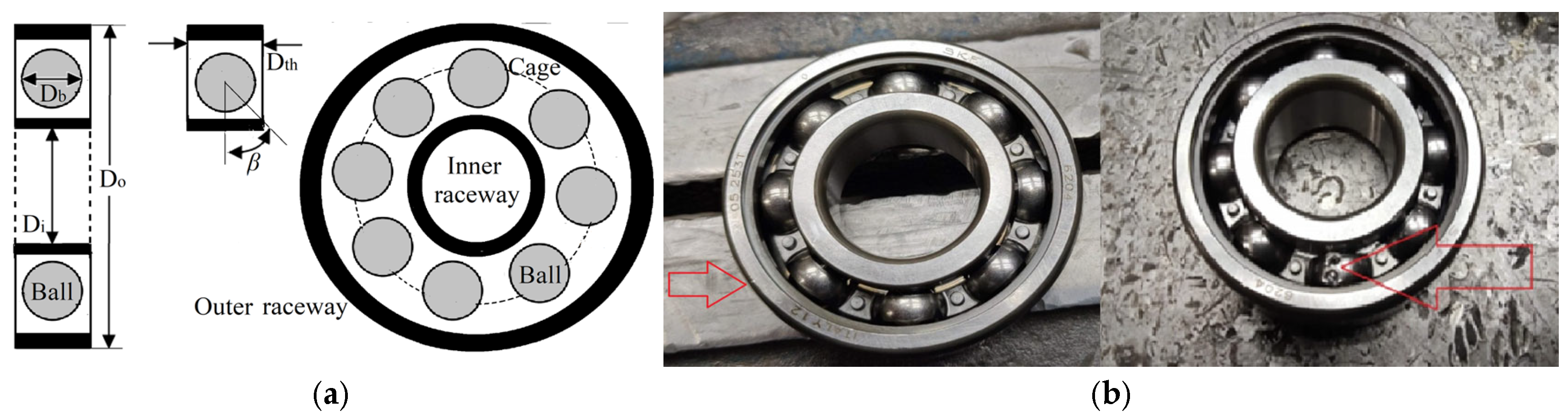

Figure 1a presents the typical schematic structure of a bearing with its individual parts while

Figure 1b illustrates various types of failures (red color arrows show the outer race and inner ball race fault) that can result from severe mechanical stress. The accuracy and reliability of each method applied depends largely on the vibration data collected by accelerometers. The placement of the sensor on both the electrical motor and the bearings plays a critical role in the post-processing signal. Research has shown that placing the vibration sensor on the

Z-axis of the machine, in the same direction as the rotor, presented the highest sensitivity to inner race fault, providing more reliable results [

48].

The inclusion of such representative vibration patterns in a diagnostic framework facilitates interpretability, especially when the system is deployed in real-time industrial environments. It enables maintenance engineers to visually confirm the classification outputs of machine learning models and enhances trust in predictive maintenance solutions, particularly when combined with sensor fusion or cloud-based monitoring architectures. Research efforts have been particularly focused on identifying both localized and distributed faults that are considered complex to locate. Incorporating a multi-sensory system collecting data through vibration, current measurements and magnetic field leakage measurements on different varieties of faults in bearings a deep machine learning (2D-CNN) model was utilized which takes as input images generated from a set of samples and the CNN identifies characteristic patterns [

49].

The extraction of features from vibration signals acquired from induction motors often results in high-dimensional datasets containing numerous descriptors from the time, frequency, and time-frequency domains. However, not all extracted features contribute equally to fault classification. Many features may be redundant, irrelevant, or noise-sensitive, which can degrade model performance and lead to overfitting. Therefore, selecting the most discriminative features and reducing the dimensionality of the input feature vector are critical steps in developing efficient and interpretable fault diagnosis systems. Utilizing an excessive number of features increases model complexity, prolongs training times, and can hinder generalization, especially when working with limited training data. Additionally, deploying diagnostic algorithms in real-time environments or on edge-computing platforms demands compact yet informative feature subsets. To address these challenges, both supervised and unsupervised feature selection methods are employed.

Principal Component Analysis (PCA) is one of the most widely used techniques for dimensionality reduction. It transforms the original features into a new orthogonal space that captures the directions of maximum variance. Although PCA effectively reduces dimensionality, its main drawback lies in the loss of interpretability, as the new principal components are linear combinations of the original features. In cases where interpretability is crucial, the Minimum Redundancy Maximum Relevance (mRMR) method is preferred. Based on mutual information theory, mRMR selects features that are highly relevant to the class labels while minimizing redundancy among them.

Relief-F is another supervised method that estimates the importance of each feature by comparing the distances between similar and dissimilar samples in the feature space. A commonly adopted approach in bearing fault diagnosis is the use of Support Vector Machine Recursive Feature Elimination (SVM-RFE), which iteratively removes the least relevant features based on the weight vector of an SVM model. Although computationally demanding, SVM-RFE yields highly optimized and compact feature subsets with excellent classification capabilities. In addition, statistical techniques such as Fisher Score and Analysis of Variance (ANOVA) are utilized to assess the discriminative power of individual features by comparing intra-class and inter-class variances. Features with high Fisher scores are considered more informative for classification tasks and are therefore retained in the final feature set.

Following feature selection, further dimensionality reduction may be applied to enable efficient model training and deployment, especially in industrial scenarios involving embedded systems and IoT devices. Advanced techniques such as autoencoders or t-distributed stochastic neighbor embedding (t-SNE) are used for non-linear data compression and visualization in reduced dimensional spaces. It is also important to emphasize the value of physically meaningful features in the context of condition monitoring and maintenance. Features such as RMS amplitude, spectral energy density, peak values in the envelope spectrum, and statistical descriptors like kurtosis or skewness provide interpretable insights into the health status of bearings. These features often correlate directly with specific types of faults such as inner race defects, outer race defects, or lubrication issues. Hence, the final feature vector used in classification is typically composed of selected metrics from the time and frequency domains that are both statistically significant and physically relevant, thereby enhancing the robustness and transparency of the diagnostic model.

In this study, vibration analysis was selected as the primary diagnostic method due to its high sensitivity and low cost, while time-domain and frequency-domain features were extracted to characterize bearing conditions. Statistical indicators—including RMS, crest factor, kurtosis, skewness, and peak-to-peak values—were computed. Additionally, spectral features obtained through Fast Fourier Transform (FFT) and envelope analysis to capture characteristic fault frequencies (BPFO, BPFI, BSF). These processed features formed the basis for training the machine learning models. Compared to other diagnostic approaches, motor current analysis offers non-invasive and economical monitoring, (infrared thermography is affected by environmental conditions, and acoustic emission is effective for detecting early microcracks but is more complex and costly). A literature search indicates that multimodal fusion of these signals can enhance diagnostic robustness, however, industrial adoption requires careful consideration of sensor layout and implementation costs [

50]. The following section details the experimental setup and methodology used to collect vibration signals and implement the proposed diagnostic framework.

4. Proposed Fault Detection Methodology

4.1. Experimental Validation

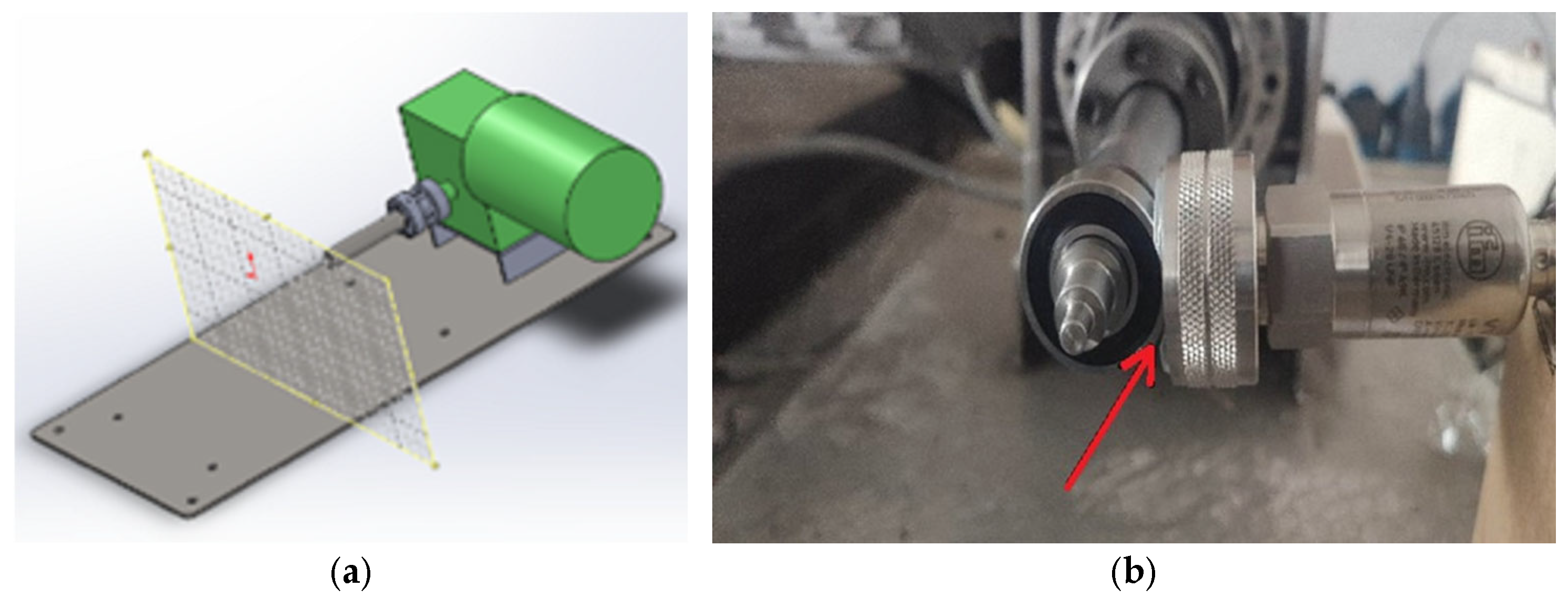

Accurate and reliable data collection requires the appropriate experimental setup built with the aim of identifying failures in bearings that have a wide range of use in industry. The experimental setup shown in

Figure 2 includes a small size and power (1) induction motor system with the basic characteristics presented in

Table 2.

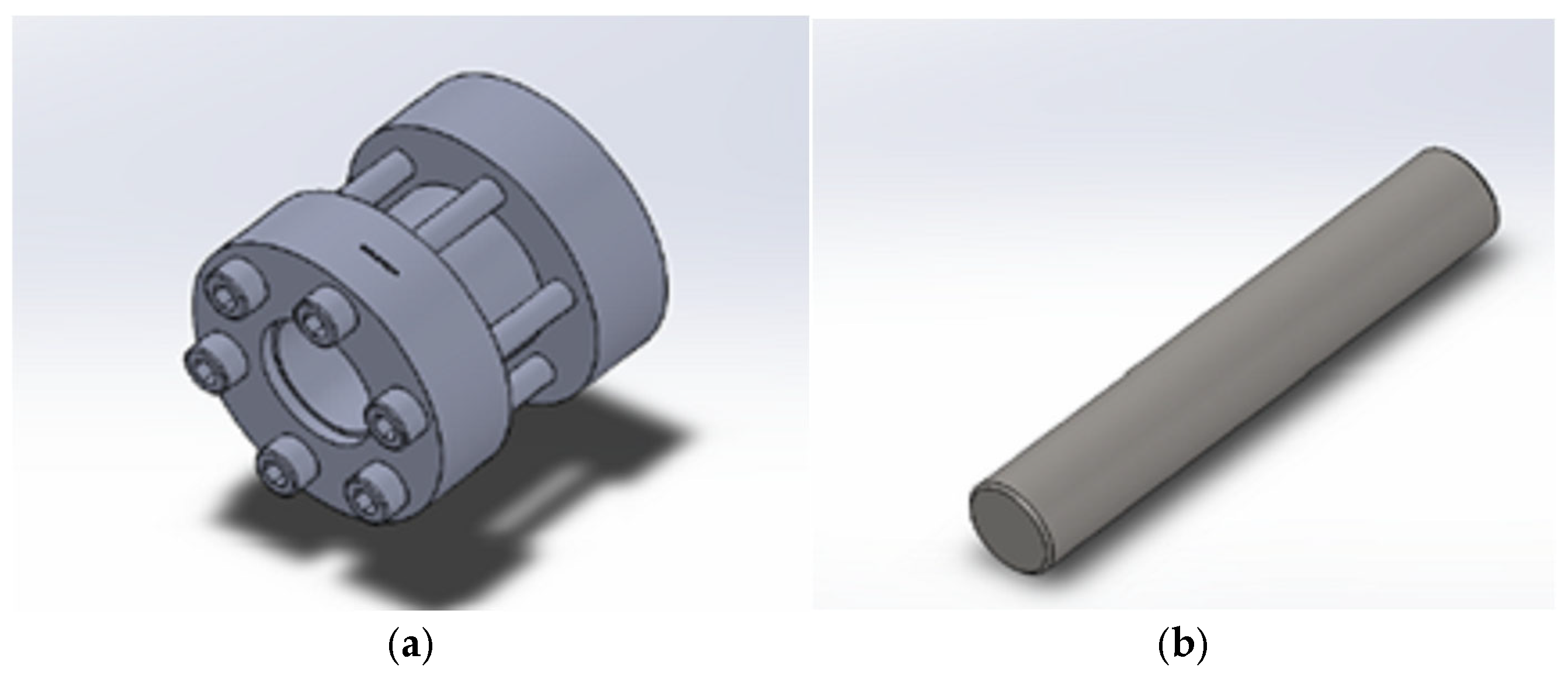

Class 6204 2RS bearings (The Timken Company, North Canton, OH, USA) have been fitted to the motor and a 1/80 reducer (shown in

Figure 3a) has been utilized for the lateral transmission while the placement of vibration sensor shown in

Figure 3b. A coupler (shown in

Figure 4a) has been fitted to the output of the reducer which has been designed and constructed to be able to mount bearings for different fault conditions. The individual basic subsystems are summarized in

Figure 4b. The (2) Vibration IO-Link Sensor VVB001 (ifm electronic GmbH, Essen, Germany) has been mounted on the bearing which sends data every ten seconds to an IO-link master. The choice to use IO-link protocol was made to have self-diagnosis of the sensor and confirmation of correct measurements as well as less measurement error because no signal conversions such as analog—digital converter are required. It is important for the analysis and the creation of correct predictive maintenance techniques to have a reliable signal source with low error.

The (3) IO-LINK Master sends the data to the (4) PLC using Profinet communication. Subsequently, the PLC collects the data and with a suitable algorithm converts the data into string variables to become MQTT JSON packets and sent from the PLC to the Raspberry. The (5) Raspberry pi is responsible for sending the data to the (6) AWS Cloud. All the data collected in the cloud is collected in specific buckets depending on the experiment being performed so that it can be easily processed.

4.2. Proposed Methodology

The proposed diagnostic methodology is a hybrid intelligent framework tailored to identify and classify bearing faults in induction motors (IMs), with a focus on real-time performance and deployment in Industry 4.0 environments. The system leverages both traditional machine learning via Support Vector Machines (SVMs) and deep learning via Artificial Neural Networks (ANNs), forming a dual-path diagnostic pipeline that enhances interpretability, accuracy, and adaptability under diverse fault scenarios. The system integrates sensor-level vibration signal acquisition with edge and cloud computing elements, enabling scalable deployment, remote monitoring, and autonomous diagnostic capabilities.

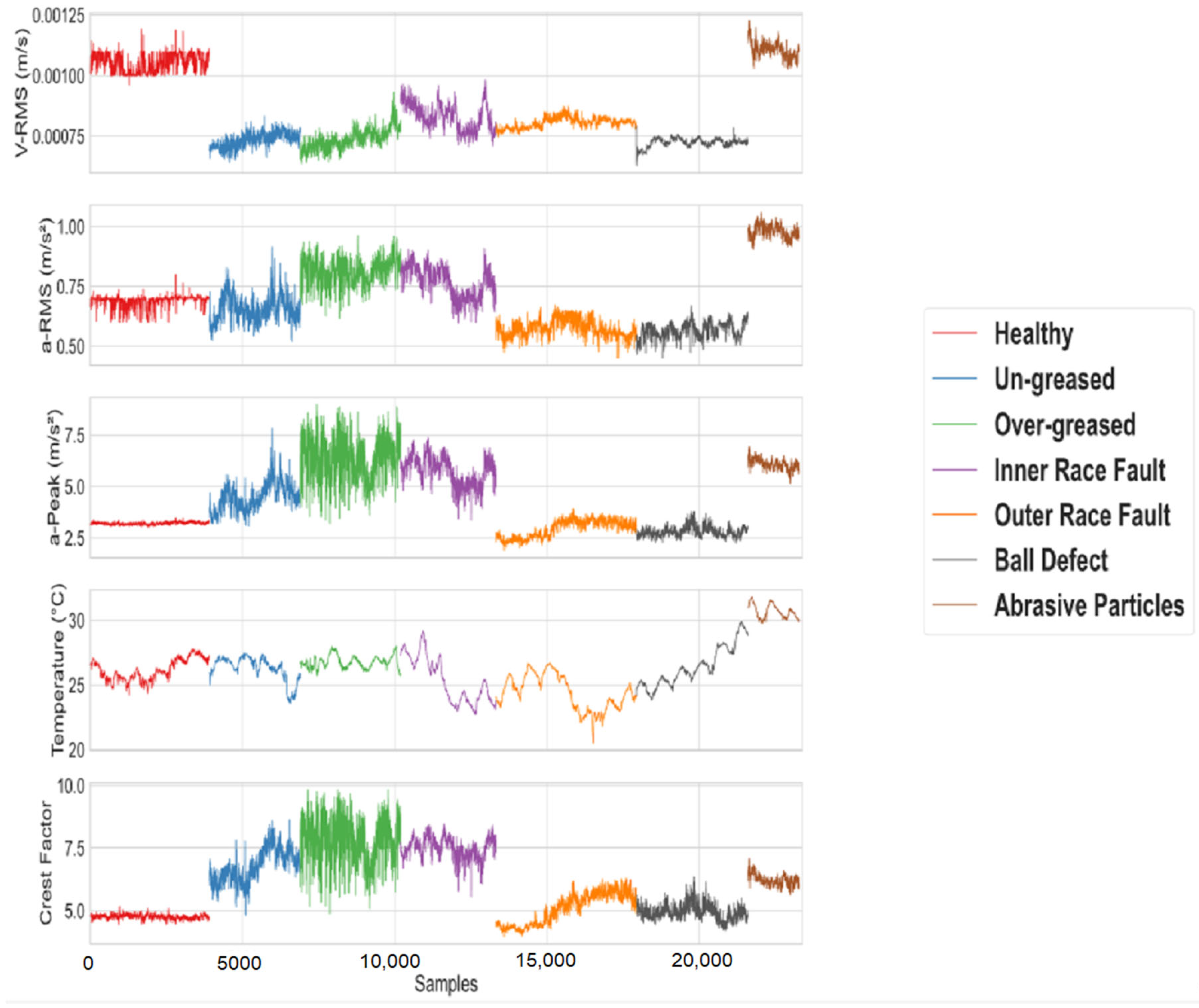

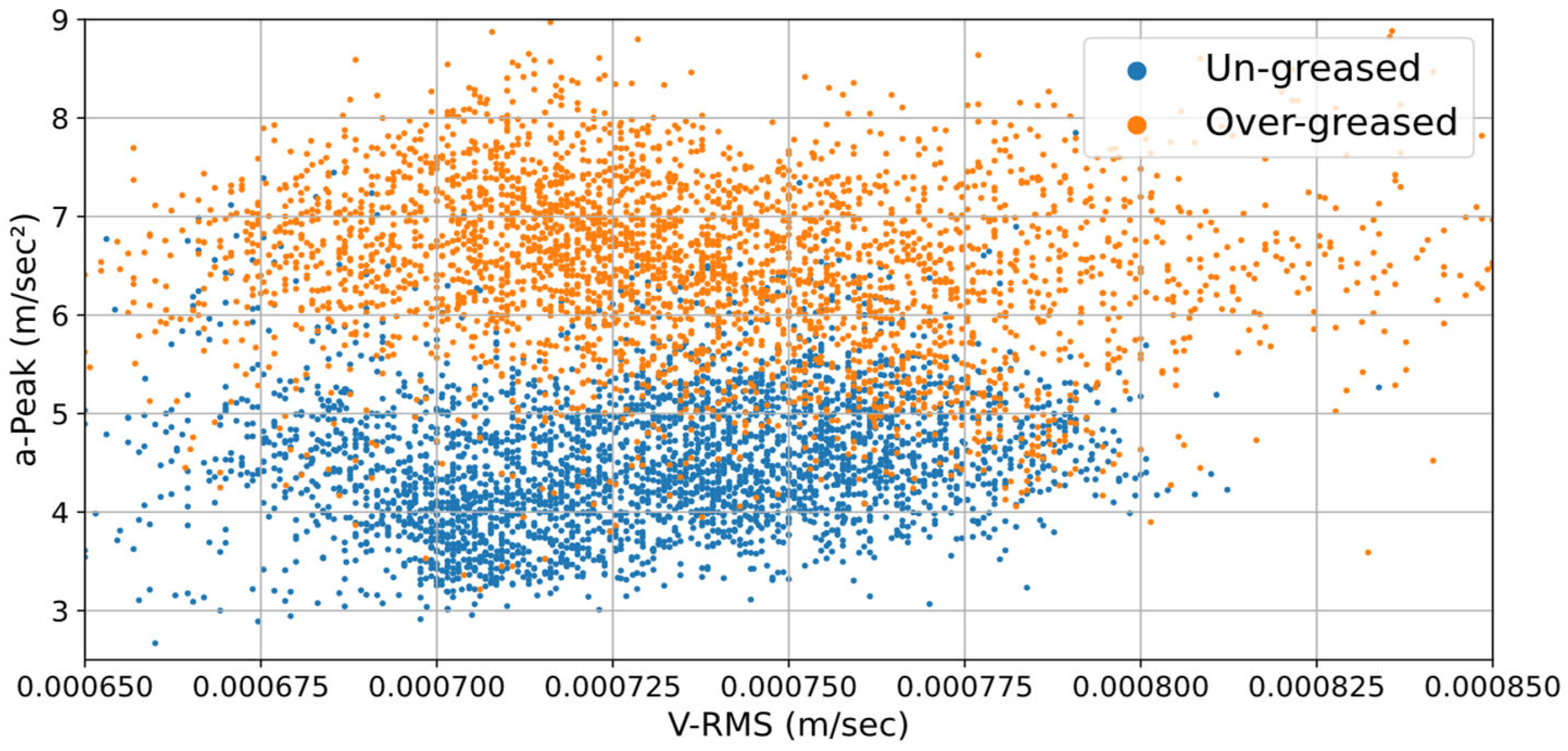

The data acquisition process begins with high-fidelity vibration signals collected from an industrial IO-Link accelerometric sensor mounted directly on the bearing housing. This sensor captures the mechanical vibrations generated by the rotating motor shaft and its interaction with the bearing assembly. These raw time-domain signals are continuously streamed to an industrial controller and forwarded to an edge device (Raspberry Pi or equivalent) via IO-Link protocol. To facilitate remote monitoring and data-driven analytics, the signals are also transmitted to a cloud server over MQTT. Each signal corresponds to one of several predefined bearing health states, including healthy, over-lubricated, unlubricated (dry), and structurally damaged bearings such as those with inner race faults, outer race faults, and ball defects.

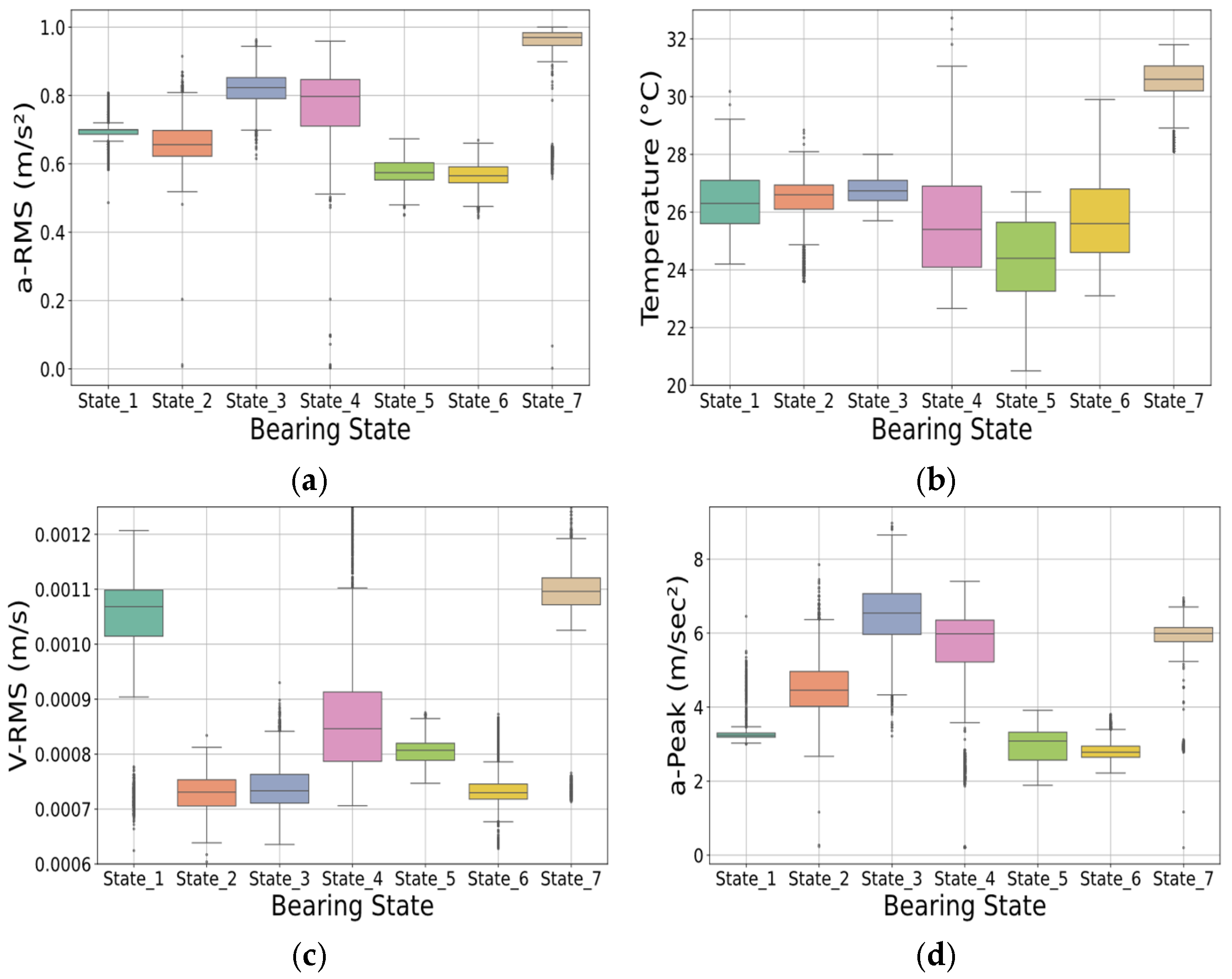

Once the signal is received, it undergoes a series of preprocessing steps designed to enhance the signal-to-noise ratio and extract diagnostic information. Initially, a Fast Fourier Transform (FFT) is applied to convert the signal into the frequency domain. This transformation allows the isolation and identification of specific fault-related frequency components, which are known to correlate with particular bearing defect types, such as the Ball Pass Frequency of Outer Race (BPFO), Ball Pass Frequency of Inner Race (BPFI), and Ball Spin Frequency (BSF). In addition to frequency-based information, statistical features are extracted from the time domain signal. These include the root mean square (RMS), crest factor, kurtosis, skewness, peak-to-peak value, and signal entropy, all of which offer quantitative descriptors of the signal’s morphology and are sensitive to impulsive or periodic signatures typical of bearing degradation.

Given the potential high dimensionality and redundancy among the extracted features, dimensionality reduction is optionally performed using Principal Component Analysis (PCA). PCA transforms the original feature space into an orthogonal basis, retaining only the components that contribute most significantly to the total variance. This step is particularly important in reducing classifier complexity and mitigating overfitting. The reduced feature vector is then normalized using z-score standardization to ensure all features have zero mean and unit variance, which is crucial for optimal SVM performance.

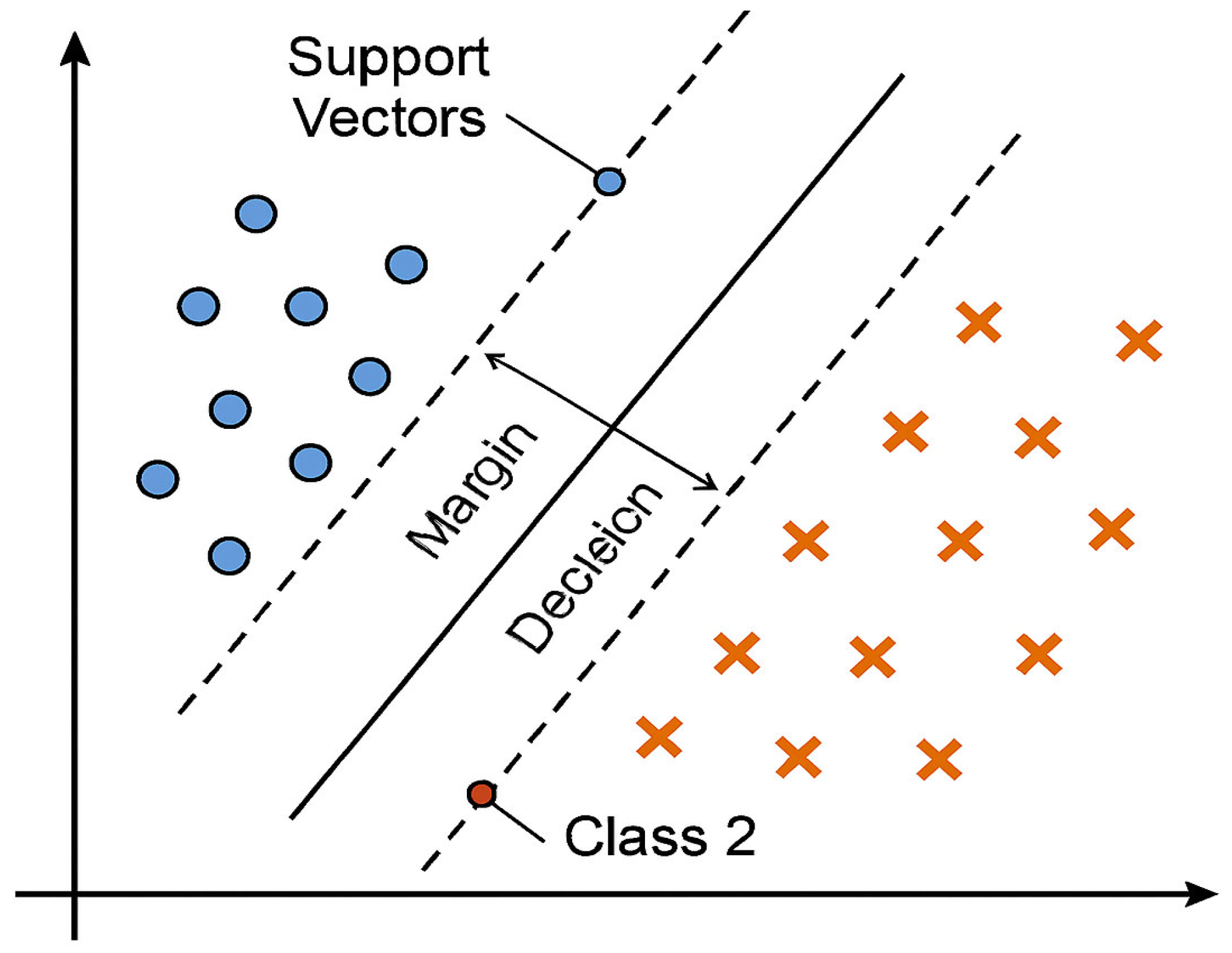

The heart of the classification process is the Support Vector Machine algorithm, which is trained on a labeled dataset of extracted features corresponding to known fault classes. The goal of SVMs is to find the optimal hyperplane that maximally separates the data points belonging to different classes.

Figure 5 shows the typical SVM model illustrating how the model separates two sets of data.

Formally, given a set of training examples

, where

represents the n-dimensional feature vector and

denotes the class label, the SVM solves the following primal optimization problem [

51]:

The modified problem becomes:

Here, is a regularization parameter that controls the trade-off between maximizing the margin and minimizing the classification error.

In this implementation, the Gaussian Radial Basis Function (RBF) kernel is adopted due to its flexibility and performance across a wide range of pattern recognition problems. The RBF kernel is defined as:

where

, is a parameter that defines the width of the Gaussian function and controls the influence of each training sample.

Using the Lagrangian method, the problem can be transformed into its dual form, where the optimization is over the Lagrange multipliers

:

Once optimized, the final decision function used to classify a new input

is:

where

are the Lagrangian multipliers obtained during training, and the support vectors

are the subset of training samples that lie closest to the decision boundary and satisfy

.

These vectors are critical to the classification decision and determine the orientation and position of the separating hyperplane. This framework enables the separation of non-linearly separable classes in high-dimensional space, making it ideal for fault classification under noisy or overlapping conditions.

Parallel to the SVM path, a shallow Artificial Neural Network is trained on the same feature set. The architecture includes:

An input layer matching the dimensionality of the feature vector (typically after PCA)

One or two hidden layers with ReLU activation

An output layer with Softmax or Sigmoid activation for binary/multi-class classification

The forward propagation for a neuron in layer

is given by:

where

is the non-linear activation function such as ReLU or sigmoid, and

is the weighted sum of inputs into neuron

in layer

. The activation introduces the required nonlinearity for learning complex patterns. The network’s training objective is to minimize a loss function

L between the predicted outputs

and the ground truth labels

. Two forms of loss are considered, depending on task type:

For binary classification (e.g., healthy vs. faulty), the Binary Cross-Entropy Loss is used:

For multi-class classification (e.g., differentiating between multiple fault types), the Categorical Cross-Entropy Loss is applied:

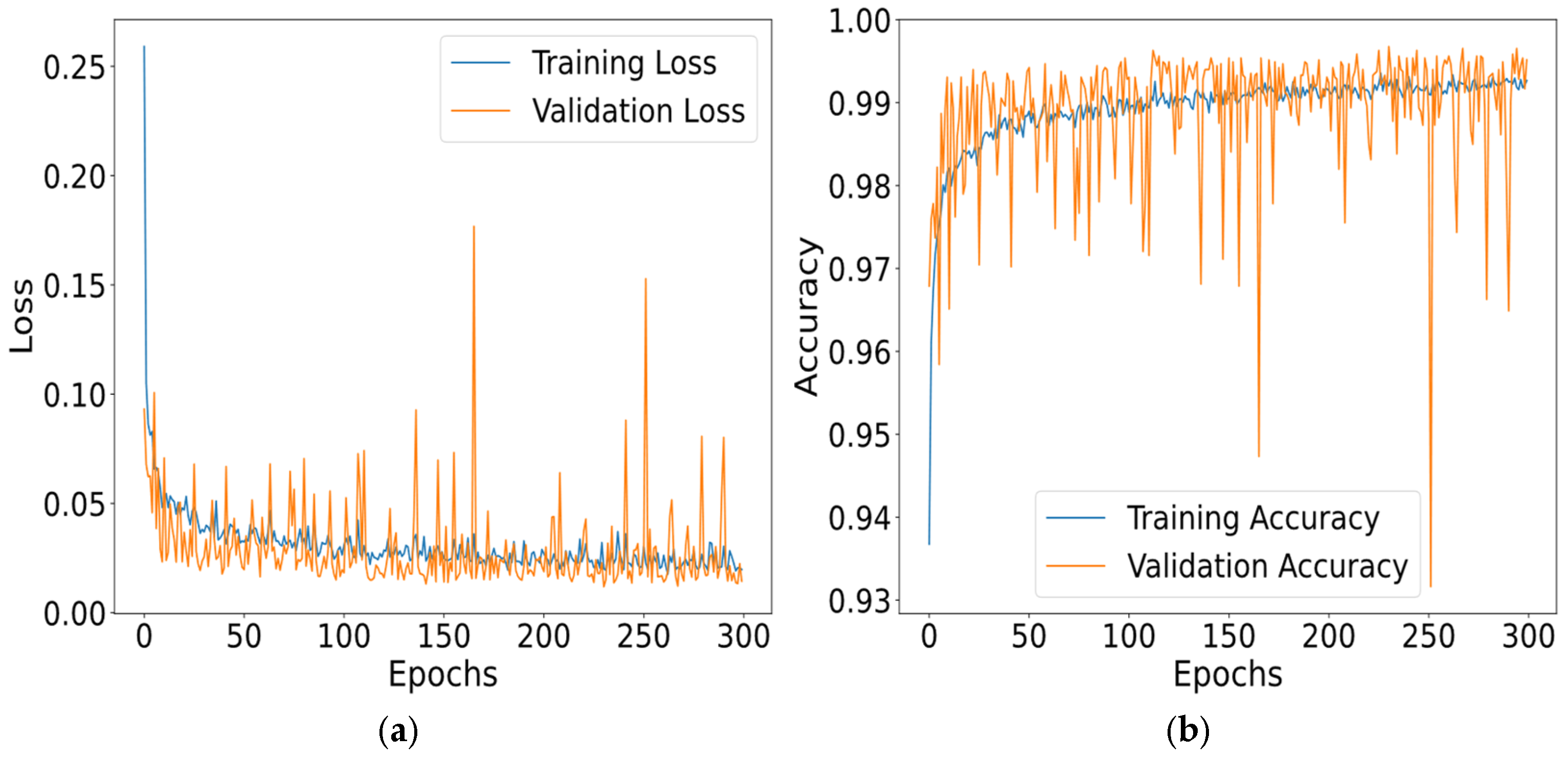

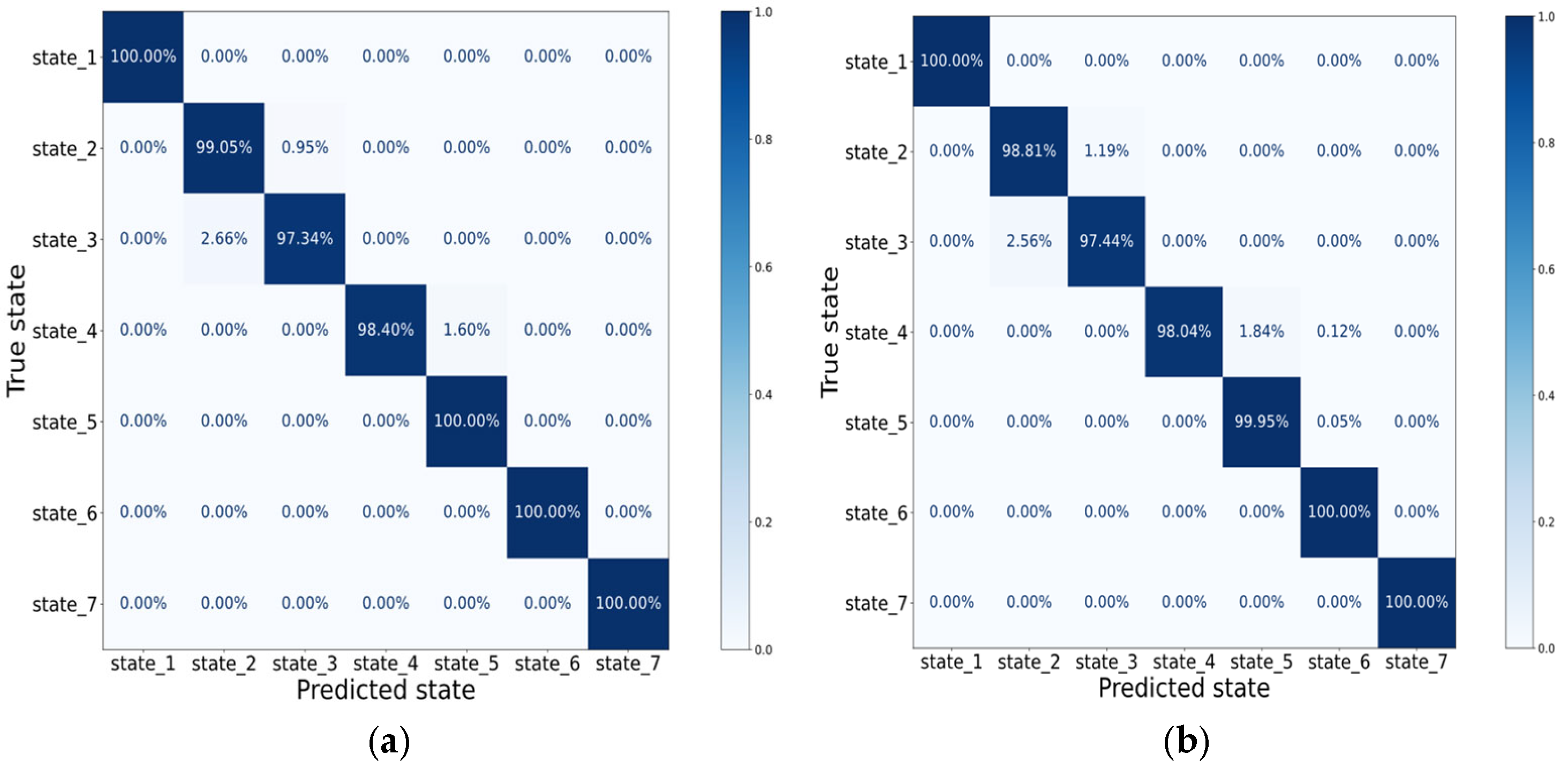

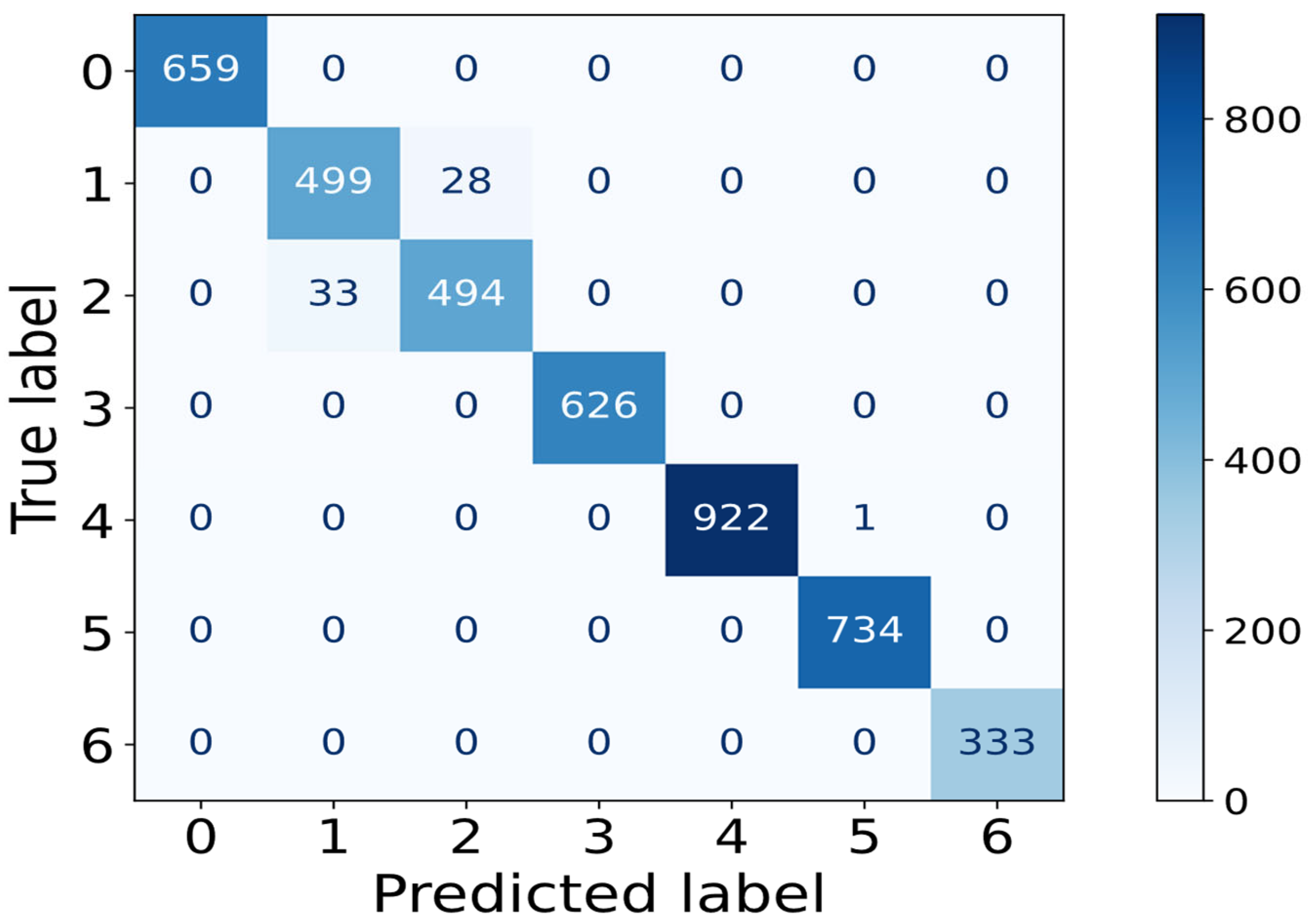

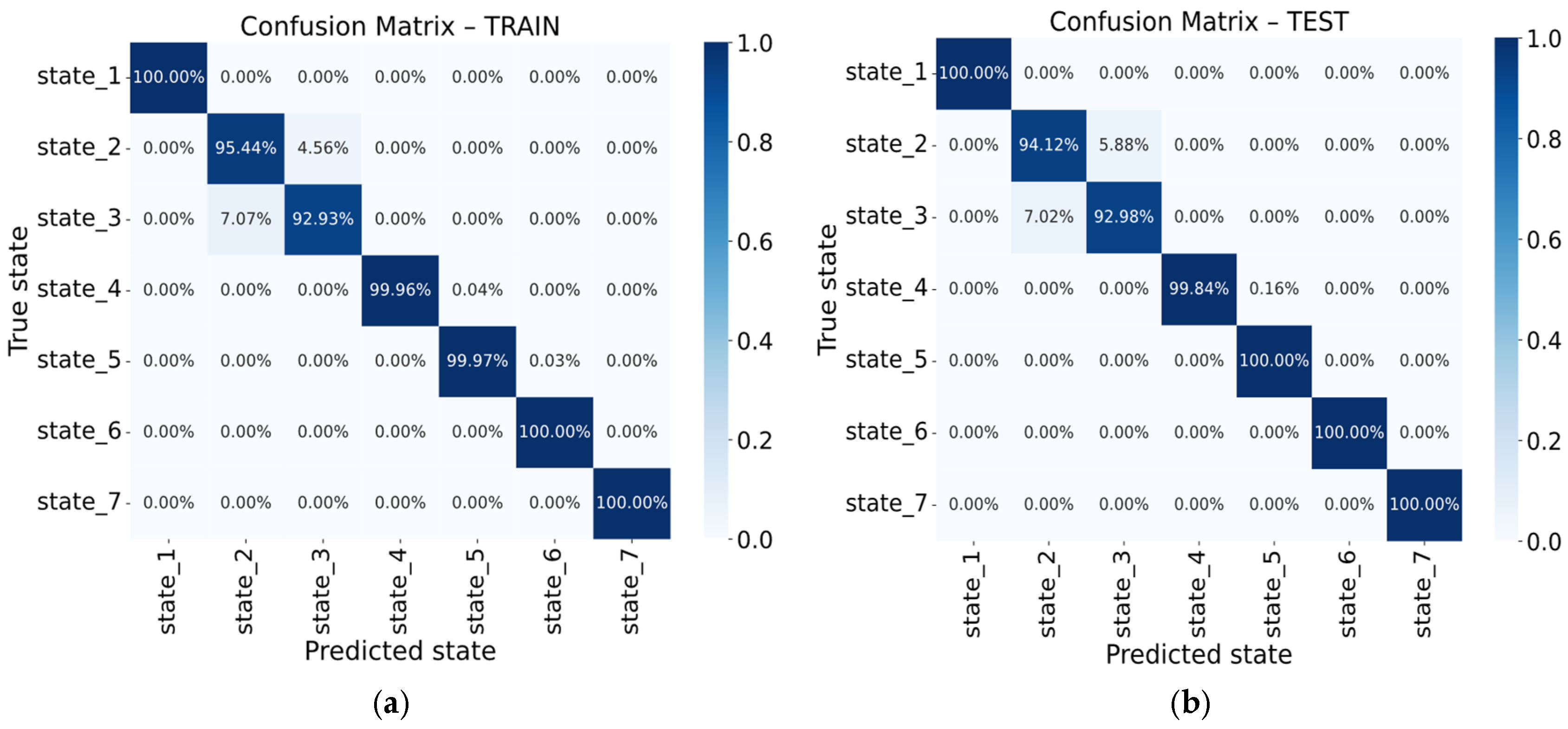

In our implementation, the categorical version is selected due to the presence of multiple bearing fault categories. The trained model is evaluated using classification metrics such as accuracy, precision, recall, and confusion matrix analysis. The ANN serves as a complementary classifier that learns from non-linear correlations in the feature space, often excelling when large annotated datasets are available.

The complete pipeline is encapsulated in a flowchart diagram (

Figure 6), which outlines each stage of the diagnostic methodology: from vibration data acquisition and signal preprocessing to feature extraction, dimensionality reduction, classification via SVMs and ANNs, result evaluation with metric indices and cloud-based decision visualization. The dual-path classification strategy leverages SVMs for lightweight edge deployment and ANNs for capturing non-linear dependencies, offering a balance between interpretability and accuracy Each bearing fault state was recorded under identical mechanical and electrical conditions to ensure dataset balance, with 70% of the samples used for training and the remaining 30% for testing and evaluation

The experimental validation of the system was performed using a laboratory setup consisting of a 0.75 kW induction motor operating at a nominal speed of 1450 rpm. Faults were artificially introduced under controlled conditions to replicate real-world failure modes while maintaining experimental reproducibility. The IO-Link sensor used was a VVB001 model capable of sampling at 1600 Hz, providing precise signal acquisition without aliasing. Multiple experimental runs were performed for each fault type to guarantee reproducibility and reduce the impact of noise and transient variations.

Each bearing fault class was repeated for multiple runs under identical mechanical and electrical conditions to build a balanced dataset. The classifier was trained using 70% of the data, while the remaining 30% was reserved for testing and performance evaluation. Preliminary results, discussed in

Section 5, indicate high classification accuracy and robustness of the SVM model across all fault categories, with a particularly strong performance in distinguishing between similar structural faults such as inner and outer race defects. Additionally, the model’s simplicity and low computational overhead make it well-suited for deployment on embedded edge devices in smart industrial environments.

The novelty of this dual-strategy diagnostic methodology lies in the integration of two complementary machine learning paradigms—SVMs for interpretable, computationally efficient decision boundaries, and ANNs for capturing complex non-linear relationships—within a unified IoT-enabled architecture. Unlike prior works that employ either a single classifier or rely solely on laboratory datasets, our study deploys the framework on an Industry 4.0-compliant edge–cloud system, processing real vibration signals acquired via IO-Link sensors in an operationally relevant setup.

Unlike conventional methods that rely solely on either rule-based logic or deep model with limited transparency, this approach maintains a balance between explainability and predictive power. Furthermore, the modular design of the pipeline enables flexible adaptation to different machine types, fault scenarios, and sensor configurations, offering a scalable and transferable solution for intelligent predictive maintenance. This comprehensive and forward-looking methodology thus sets a new benchmark in the field of data-driven diagnostics for rotating machinery.

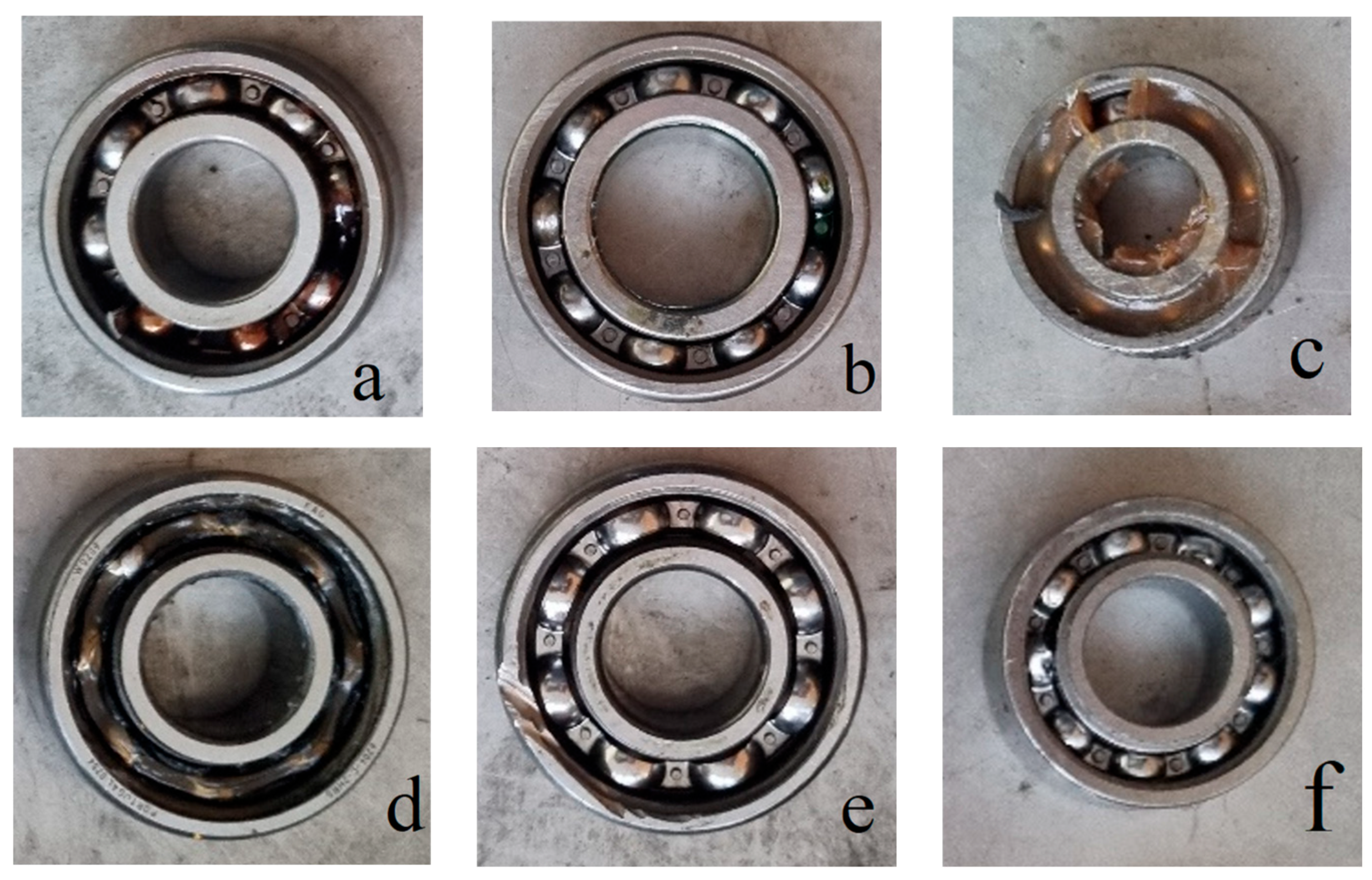

Figure 7 presents the various bearing operating conditions that were adapted to the experimental setup. As we can see in our study, the following cases were examined as: (a) Healthy, (b) Un-greased bearing, (c) Over-greased bearing, (d) inner race fault, (e) outer race fault, (f) ball defect. In the experimental part of this study, vibration signals were acquired under controlled laboratory conditions to simulate various bearing fault scenarios, as vibration analysis provides a reliable and non-invasive diagnostic source for rolling element bearings.

7. Conclusions

This study introduced and validated an intelligent diagnostic framework for induction motor bearings that integrates vibration signal analysis with machine learning classifiers (ANNs and SVMs) in an IoT-enabled architecture. The main findings confirm that the proposed models achieve high classification accuracy, precision, recall, and F1-scores across all seven considered bearing conditions, with strong robustness against noise and operational variability. The comparative evaluation highlighted the complementary strengths of ANNs and SVMs, where the ANN provided slightly higher accuracy in complex classes, while the SVM offered computational efficiency and interpretability suitable for edge deployment. The models achieved up to 98% classification accuracy, with macro-averaged precision, recall, and F1-scores consistently above 0.95, confirming the robustness of the proposed framework.

The primary contributions of this work include the design of a complete Industry 4.0-compliant pipeline that combines IO-Link vibration sensors, edge computing, and cloud services for real-time predictive maintenance, the use of a custom experimental dataset comprising diverse lubrication-related and structural bearing defects, enabling realistic validation of the methodology and the comparative application of two well-established machine learning algorithms, offering insights into their trade-offs for industrial deployment. By combining interpretability and efficiency (SVM) with non-linear learning capabilities (ANN), the proposed methodology advances the state of the art in intelligent fault diagnosis for rotating machinery. Although focused on induction motor bearings, the methodology can be transferred to other rotating machinery fault diagnosis tasks. These contributions directly support predictive maintenance by enabling early, reliable detection of bearing faults in Industry 4.0 environments.

Despite these contributions, some limitations should be acknowledged. These limitations, however, are inherent to proof-of-concept experimental validations and open the way for broader investigations in real industrial environments. The experimental validation relied on a single dataset collected under controlled laboratory conditions, which may constrain the generalizability of the results to broader industrial contexts. Additionally, the study focused exclusively on vibration signals, whereas multimodal sensor fusion (e.g., current, acoustic, or thermal data) could further improve diagnostic robustness.

Future research should extend this work by validating the framework on larger-scale industrial case studies with varying operating loads and environments, exploring multimodal fusion approaches that combine vibration with complementary sensing modalities, incorporating advanced deep learning architectures such as CNNs, LSTMs, and transformers for enhanced feature learning, and implementing adaptive and self-learning mechanisms for continuous improvement during real-world deployment. These directions will enhance the scalability, accuracy, and resilience of intelligent predictive maintenance systems for rotating machinery.