Research Progress and Application of Vibration Suppression Technologies for Damped Boring Tools

Abstract

1. Introduction

2. Active Damped Boring Tools

2.1. Piezoelectric-Driven Damped Boring Tools

2.2. Magnetostrictive Actuator Damped Boring Tools

2.3. Magnetorheological Fluid Damped Boring Tools

2.4. Electrorheological Fluid Damped Boring Tools

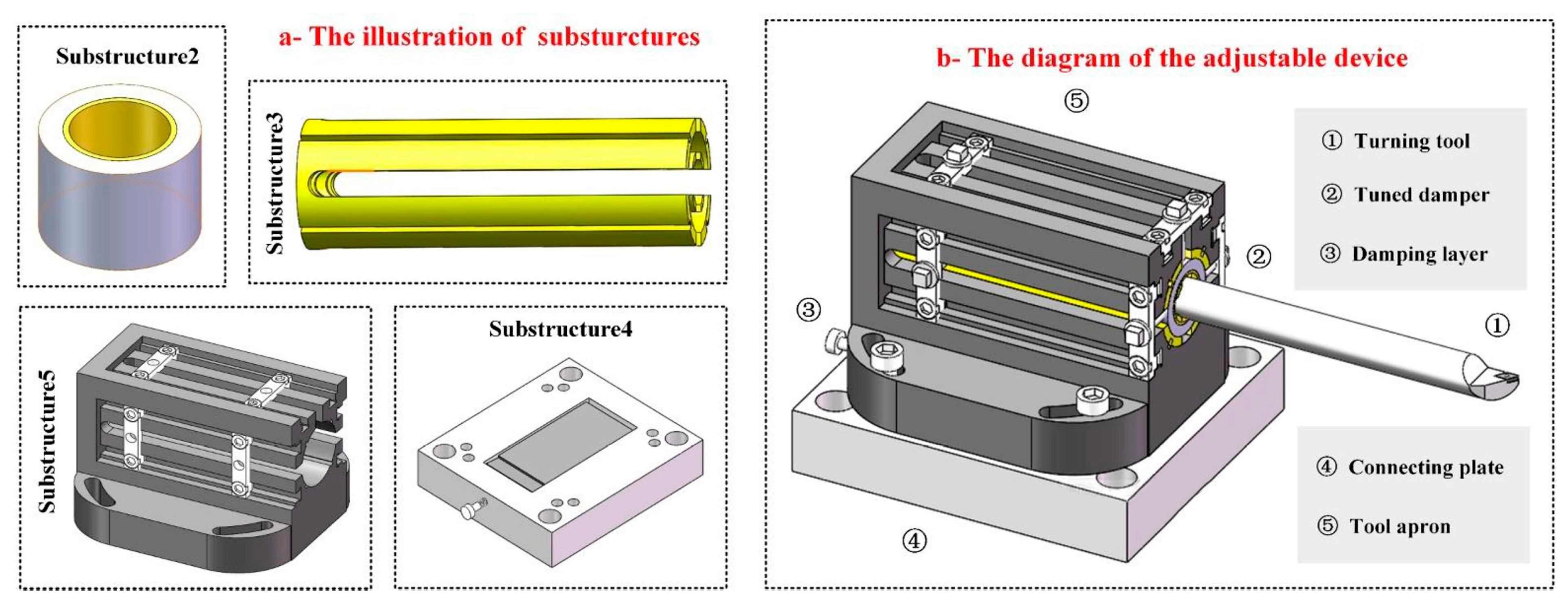

2.5. Damped Boring Tools with the Variable Parameter Dynamic Vibration Absorber

3. Passive Damped Boring Tools

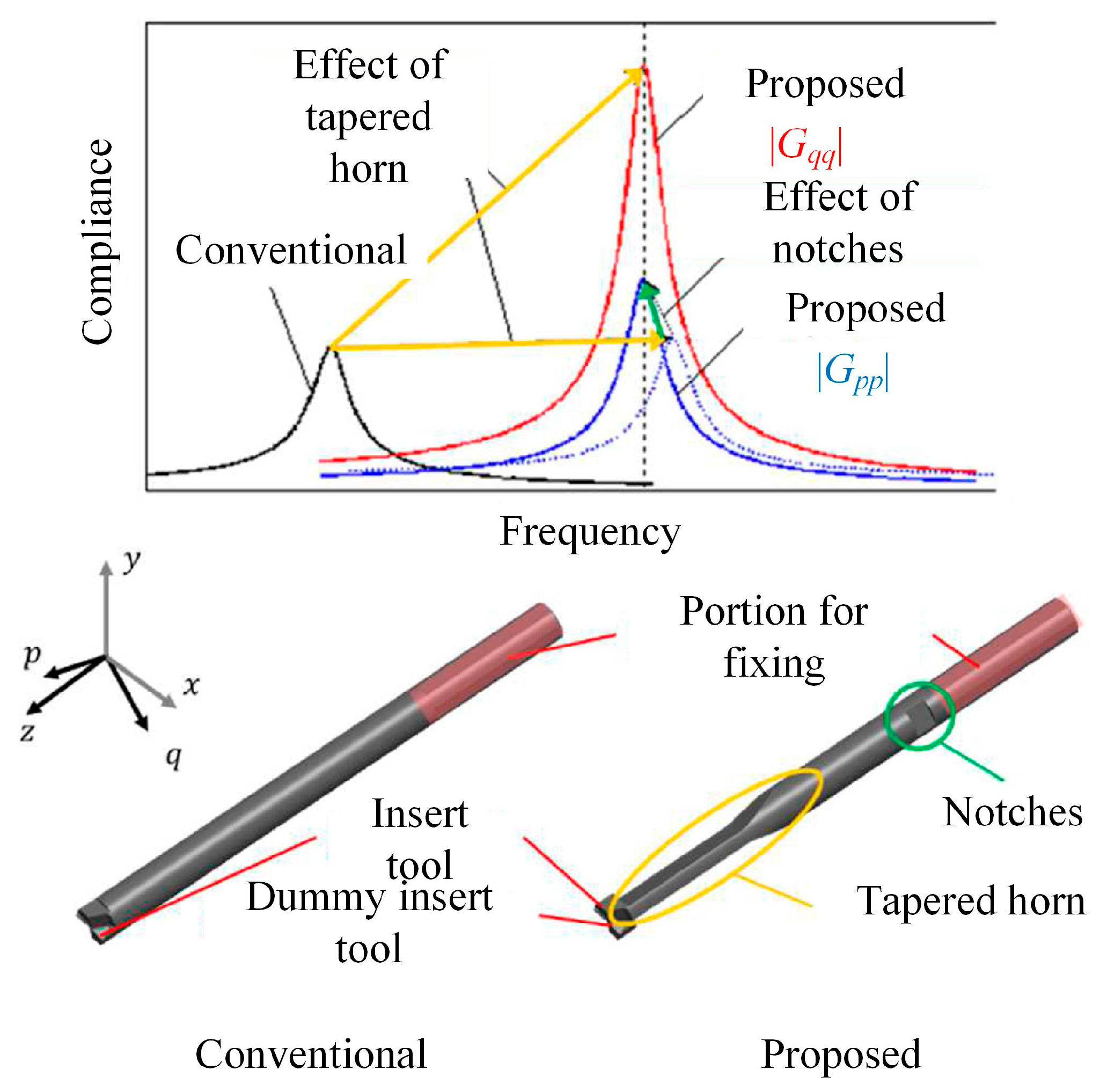

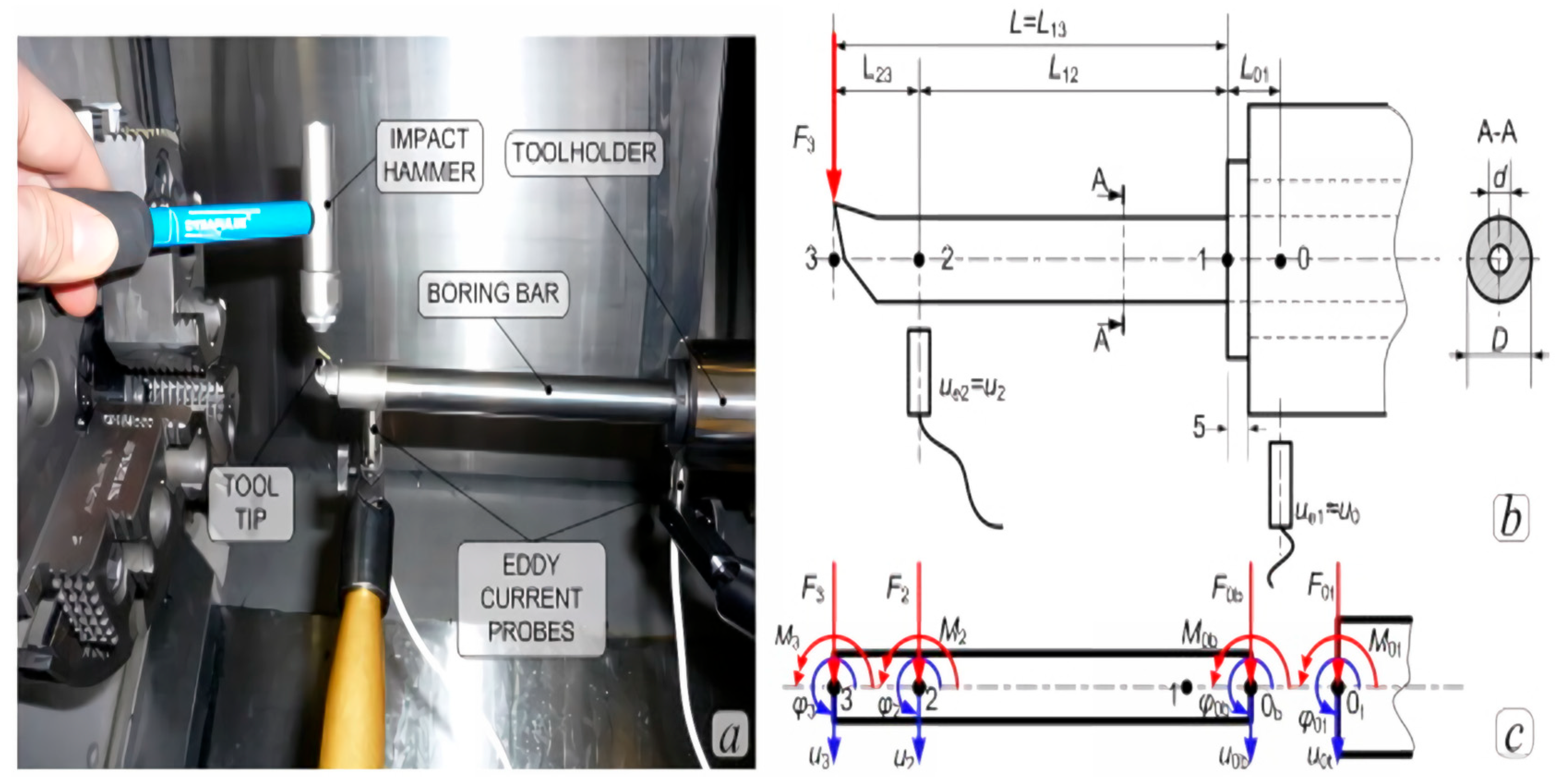

3.1. Damped Boring Tools with Structural Optimization

3.2. Damped Boring Tools with Material Optimization

3.3. Damping Boring Tools with Shock Absorbers

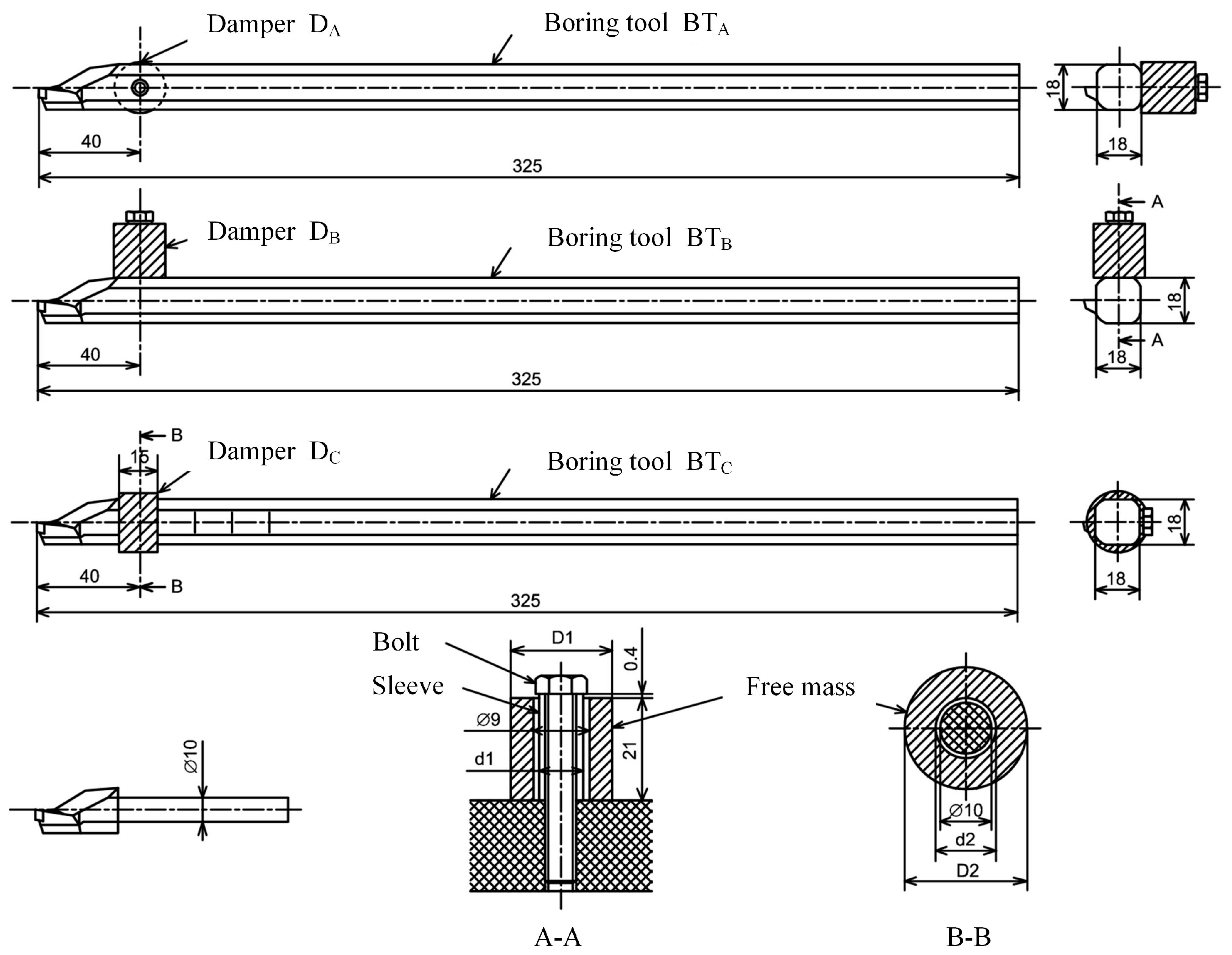

3.4. Damped Boring Tools with Friction Energy Dissipation Components

4. Conclusions

- The active damped boring tools are performed through an external driving system to achieve the effect of vibration reduction in real-time, which has strong adaptability and machining accuracy. Active vibration damped boring tools mainly include piezoelectric-driven damped tools, magnetostrictive actuator damped bars, magnetorheological damped tools, electrorheological fluid damped tools, and dynamically adjustable damped tools. The above-mentioned boring tools can be adjusted according to the frequency changes of vibration during the machining process using different driving methods, thereby improving machining stability. These technologies provide a foundation for the intelligent and functional development of vibration damped boring tools. However, the complexity and high equipment cost of active vibration damped tools limit their widespread application in the industrial field. Future research directions can be focused on the reduction in the tool preparation cost and further improvement of the machining system stability.

- Passive vibration damped boring tools are performed through structural optimization, damped material integration, and other passive methods to improve the tool damping performance and suppress machining vibration. Their advantages include a simple tool structure, low preparation cost, good stability, etc. Passive vibration damped boring tools mainly include structure-optimized damped boring tools, material-optimized damped boring tools, damped boring tools with an impact damper, and friction energy dissipation damped boring tools. Passive vibration reduction technology is suitable for various processing environments and is suitable for long-term, stable processing tasks. The main limitation for the damping effect of passive damped boring tools lies in the static characteristics and material properties of the tool design, and the damped tools cannot be adjusted in real-time according to actual machining vibration changes. Future research directions can be focused on new damping materials and structures to further improve their damping performance and adaptability.

- The rise of hybrid vibration damping technology provides new ideas for breaking through the limitations of active and passive vibration reduction methods. Through integrating passive structures and active control systems in the boring tools, closed-loop control of vibration signal sensing, processing, and responding can be achieved. It not only expands the frequency domain range of vibration reduction for the boring tools but also significantly improves the robustness and response flexibility of the machining system under complex working conditions. Hybrid damped tool systems are particularly suitable for processing tasks with variable frequencies and unstable cutting loads, which can help to improve the reliability and accuracy of the manufacturing process. However, such systems also face challenges such as high integration difficulty, high energy consumption, and complex control algorithms. Future research directions can be focused on the collaborative optimization of system miniaturization, intelligent control algorithms, and multifunctional integration, in order to promote the widespread application of hybrid vibration damping technology in various machining environments.

- The integration of artificial intelligence and digital technology is constantly expanding the functional boundaries of vibration damped boring tools. With the rapid development of sensor technology and artificial intelligence, intelligent damped boring tools can collect significant information such as vibration, temperature, and tool wear in real-time. Through machine learning and data-driven modeling, machining status can be evaluated in real-time, and damped tools can be dynamically adjusted to optimize cutting performance. At the same time, digital twin technology has shown great potential in the design of vibration damped boring bars and cutting tool status monitoring, which enables rapid iteration and tool failure prediction in virtual environments. Future research directions can be focused on the strengthening of the integrated design of damped tool software and hardware, the development of high-precision and low-latency machining data process platforms, and industrial promotion of damped boring tools in different machining scenarios.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, B.; Liu, Z.; Cai, Y.; Luo, X.; Ma, H.; Song, Q.; Xiong, Z. Advancements in material removal mechanism and surface integrity of high speed metal cutting: A review. Int. J. Mach. Tools Manuf. 2021, 166, 103744. [Google Scholar] [CrossRef]

- La Monaca, A.; Murray, J.W.; Liao, Z.; Speidel, A.; Robles-Linares, J.A.; Axinte, D.A.; Hardy, M.C.; Clare, A.T. Surface integrity in metal machining-Part II: Functional performance. Int. J. Mach. Tools Manuf. 2021, 164, 103718. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Becze, C.E.; McIntosh, D.G. Tool performance and attainable surface quality during the machining of aerospace alloys using self-propelled rotary tools. J. Mater. Process. Technol. 2004, 152, 266–271. [Google Scholar] [CrossRef]

- Zabel, A.; Heilmann, M. Deep hole drilling using tools with small diameters—Process analysis and process design. CIRP Ann. 2012, 61, 111–114. [Google Scholar] [CrossRef]

- Ahmed, A.; Lew, M.T.; Diwakar, P.; Kumar, A.S.; Rahman, M. A novel approach in high performance deep hole drilling of Inconel 718. Precis. Eng. 2019, 56, 432–437. [Google Scholar] [CrossRef]

- Kong, L.; Cao, S.; Chin, J.-H.; Si, Y.; Miao, F.; Li, Y. Vibration suppression of drilling tool system during deep-hole drilling process using independence mode space control. Int. J. Mach. Tools Manuf. 2020, 151, 103525. [Google Scholar] [CrossRef]

- Xiao, W.; Zi, Y.; Chen, B.; Li, B.; He, Z. A novel approach to machining condition monitoring of deep hole boring. Int. J. Mach. Tools Manuf. 2014, 77, 27–33. [Google Scholar] [CrossRef]

- Katsuki, A.; Onikura, H.; Sajima, T.; Mohri, A.; Moriyama, T.; Hamano, Y.; Murakami, H. Development of a practical high-performance laser-guided deep-hole boring tool: Improvement in guiding strategy. Precis. Eng. 2011, 35, 221–227. [Google Scholar] [CrossRef]

- Vopát, T.; Kuruc, M.; Pätoprstý, B.; Vozár, M.; Jurina, F.; Bočáková, B.; Peterka, J.; Görög, A.; Straka, R. The selection of cutting speed to prevent deterioration of the surface in internal turning of C45 steel by small-diameter boring bars. Machines 2024, 12, 68. [Google Scholar] [CrossRef]

- Du, W.; Wang, L.; Shao, Y. A semi-analytical dynamics method for spindle radial throw in boring process. J. Manuf. Process. 2023, 96, 110–124. [Google Scholar] [CrossRef]

- Quintana, G.; Ciurana, J. Chatter in machining processes: A review. Int. J. Mach. Tools Manuf. 2011, 51, 363–376. [Google Scholar] [CrossRef]

- Gokulu, T.; Defant, F.; Albertelli, P. Stability analysis of multi-insert rotating boring bar with stiffness variation. J. Sound Vib. 2024, 586, 118497. [Google Scholar] [CrossRef]

- Li, H.; Xia, Y.; Su, G.; Li, B.; Du, J. Ultrasonic vibration-assisted chatter suppression for deep hole boring of stainless steel. Int. J. Adv. Manuf. Technol. 2024, 131, 1691–1703. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Liu, X.; Gao, D.; Zhang, M. A review on intelligent cutting tools. J. Mech. Eng. 2021, 57, 248–268. [Google Scholar]

- Wiercigroch, M.; Wiercigroch, M.; Budak, E. Sources of nonlinearities, chatter generation and suppression in metal cutting. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2001, 359, 663–693. [Google Scholar] [CrossRef]

- Moetakef-Imani, B.; Yussefian, N.Z. Dynamic simulation of boring process. Int. J. Mach. Tools Manuf. 2009, 49, 1096–1103. [Google Scholar] [CrossRef]

- Pooja, J.; Waghmare, R.V.; Patil, G.S. Waghmare. A review on vibration mitigation of boring bar using passive damping techniques. Int. J. Res. Eng. Technol. 2015, 4, 138–141. [Google Scholar]

- Park, G.; Bement, M.T.; Hartman, D.A.; Smith, R.E.; Farrar, C.R. The use of active materials for machining processes: A review. Int. J. Mach. Tools Manuf. 2007, 47, 2189–2206. [Google Scholar] [CrossRef]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Habib, M.; Lantgios, I.; Hornbostel, K. A review of ceramic, polymer and composite piezoelectric materials. J. Phys. D Appl. Phys. 2022, 55, 423002. [Google Scholar] [CrossRef]

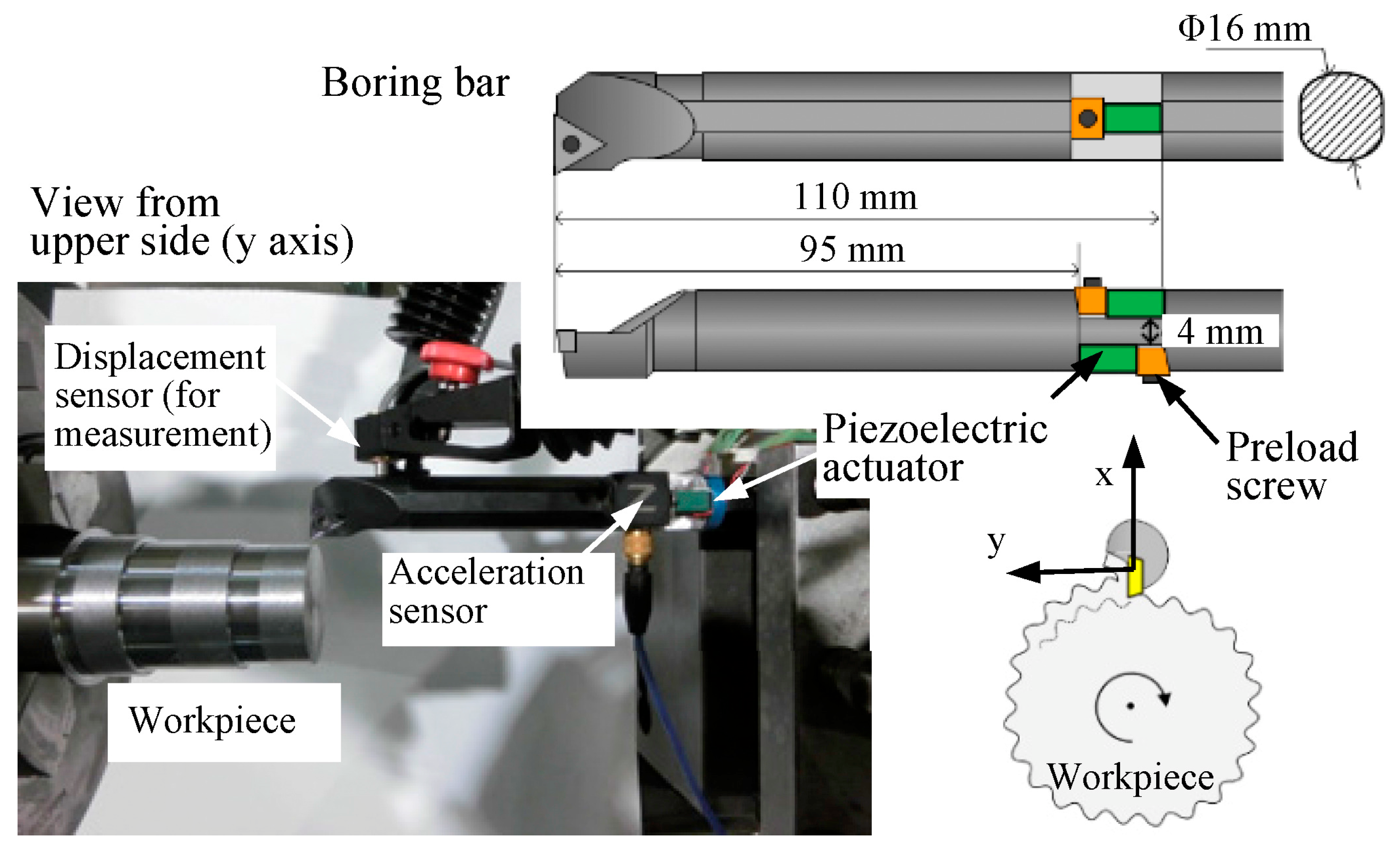

- Tanaka, H.; Obata, F.; Matsubara, T.; Mizumoto, H. Active chatter suppression of slender boring bar using piezoelectric actuators. JSME Int. J. Ser. C Dyn. Control Robot. Des. Manuf. 1994, 37, 601–606. [Google Scholar] [CrossRef]

- Chiu, W.M.; Chan, K.W. Design and testing of piezoelectric actuator-controlled boring bar for active compensation of cutting force induced errors. Int. J. Prod. Econ. 1997, 51, 135–148. [Google Scholar] [CrossRef]

- Akesson, H.; Smirnova, T.; Claesson, I.; Håkansson, L. On the development of a simple and robust active control system for boring bar vibration in industry. Int. J. Acoust. Vib. 2007, 12, 139–152. [Google Scholar] [CrossRef]

- Kong, F.; Liu, P.; Liu, C. Simulation and experimental study on active control of boring vibration based on piezoelectric intelligent structure. J. Vib. Shock. 2010, 29, 5. [Google Scholar]

- Matsubara, A.; Maeda, M.; Yamaji, I. Vibration suppression of boring bar by piezoelectric actuators and LR circuit. CIRP Ann. 2014, 63, 373–376. [Google Scholar] [CrossRef]

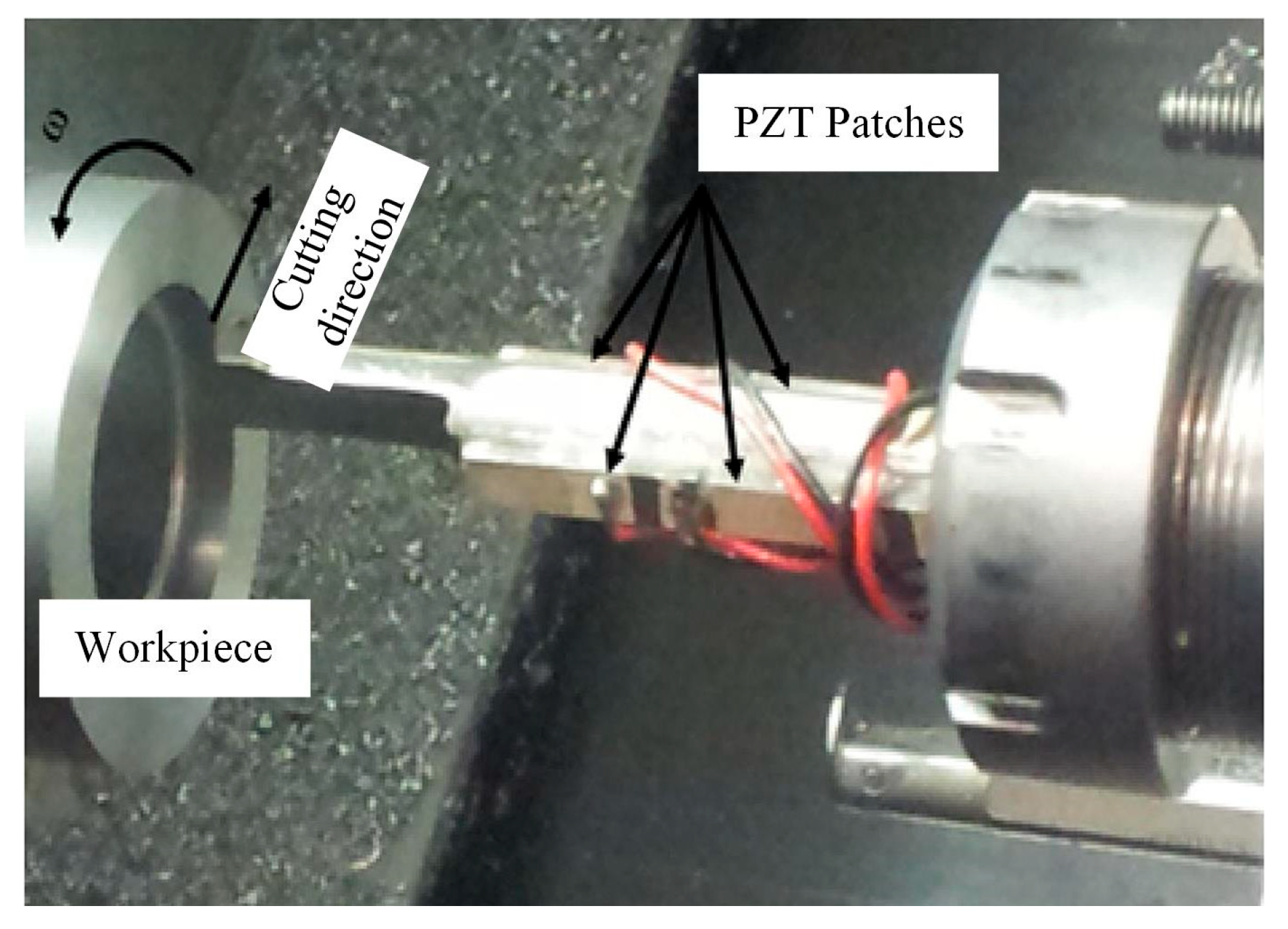

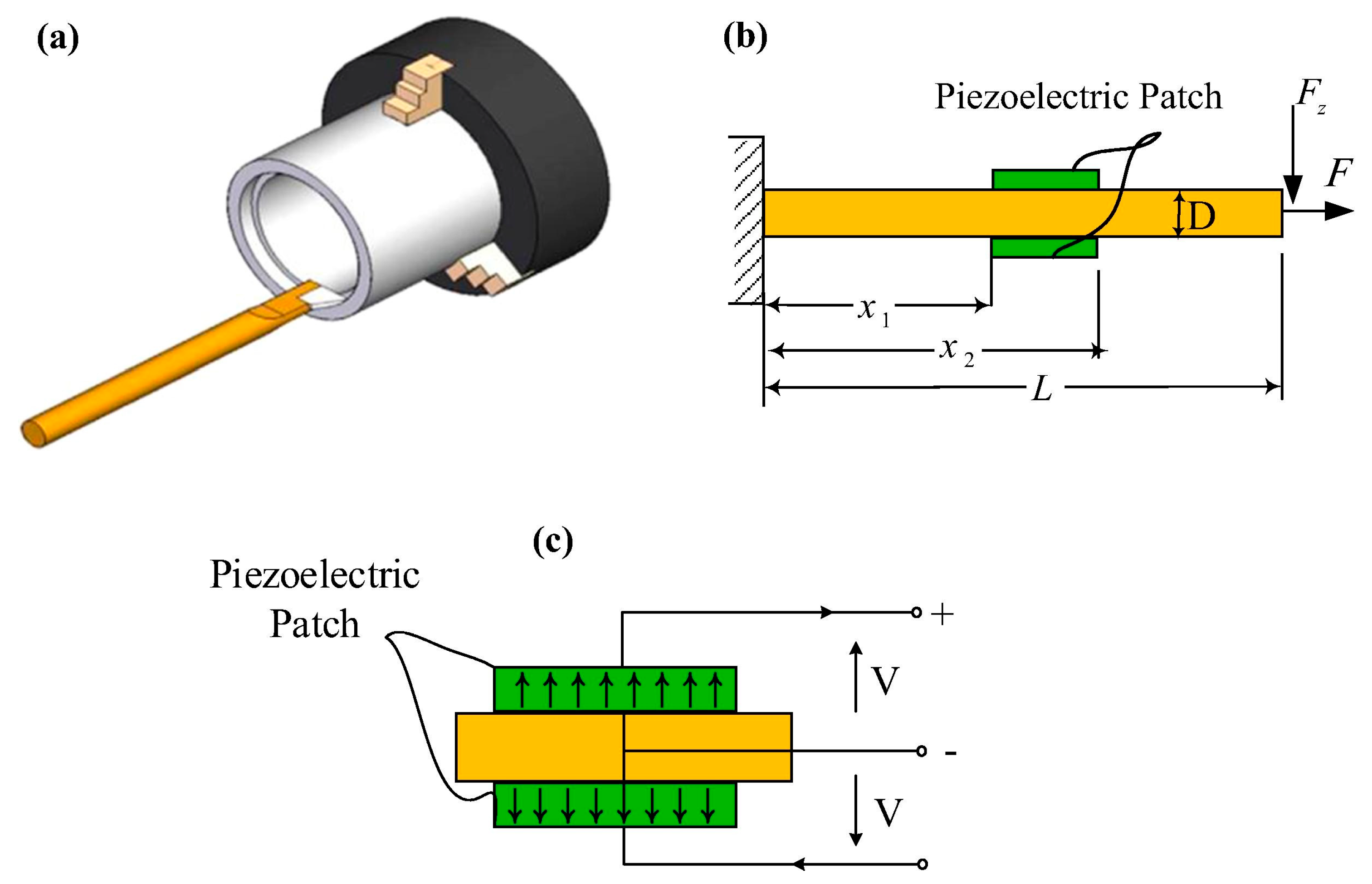

- Venter, G.S.; Silva, L.M.D.P.; Carneiro, M.B.; da Silva, M.M. Passive and active strategies using embedded piezoelectric layers to improve the stability limit in turning/boring operations. Int. J. Adv. Manuf. Technol. 2017, 89, 2789–2801. [Google Scholar] [CrossRef]

- Yigit, U.; Cigeroglu, E.; Budak, E. Chatter reduction in boring process by using piezoelectric shunt damping with experimental verification. Mech. Syst. Signal Process. 2017, 94, 312–321. [Google Scholar] [CrossRef]

- Tang, B.; Akbari, H.; Pouya, M.; Pashaki, P.V. Application of piezoelectric patches for chatter suppression in machining processes. Measurement 2019, 138, 225–231. [Google Scholar] [CrossRef]

- Aksoy, S. Magnetostrictive Actuators; Elsevier: Oxford, UK, 2022. [Google Scholar]

- Zhang, K.; Zhang, Y.; Liu, C. Study on a magnetic actuation mechanism and its performance simulations. In Proceedings of the 2006 2nd IEEE/ASME International Conference on Mechatronics and Embedded Systems and Applications, Beijing, China, 13–16 August 2006; pp. 1–5. [Google Scholar]

- Zhang, K.; Yu, J.; Li, Y.; Miao, Y. A structural analysis and optimum of a deformable unit for revolving magnetic actuation mechanism. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008; pp. 1637–1642. [Google Scholar]

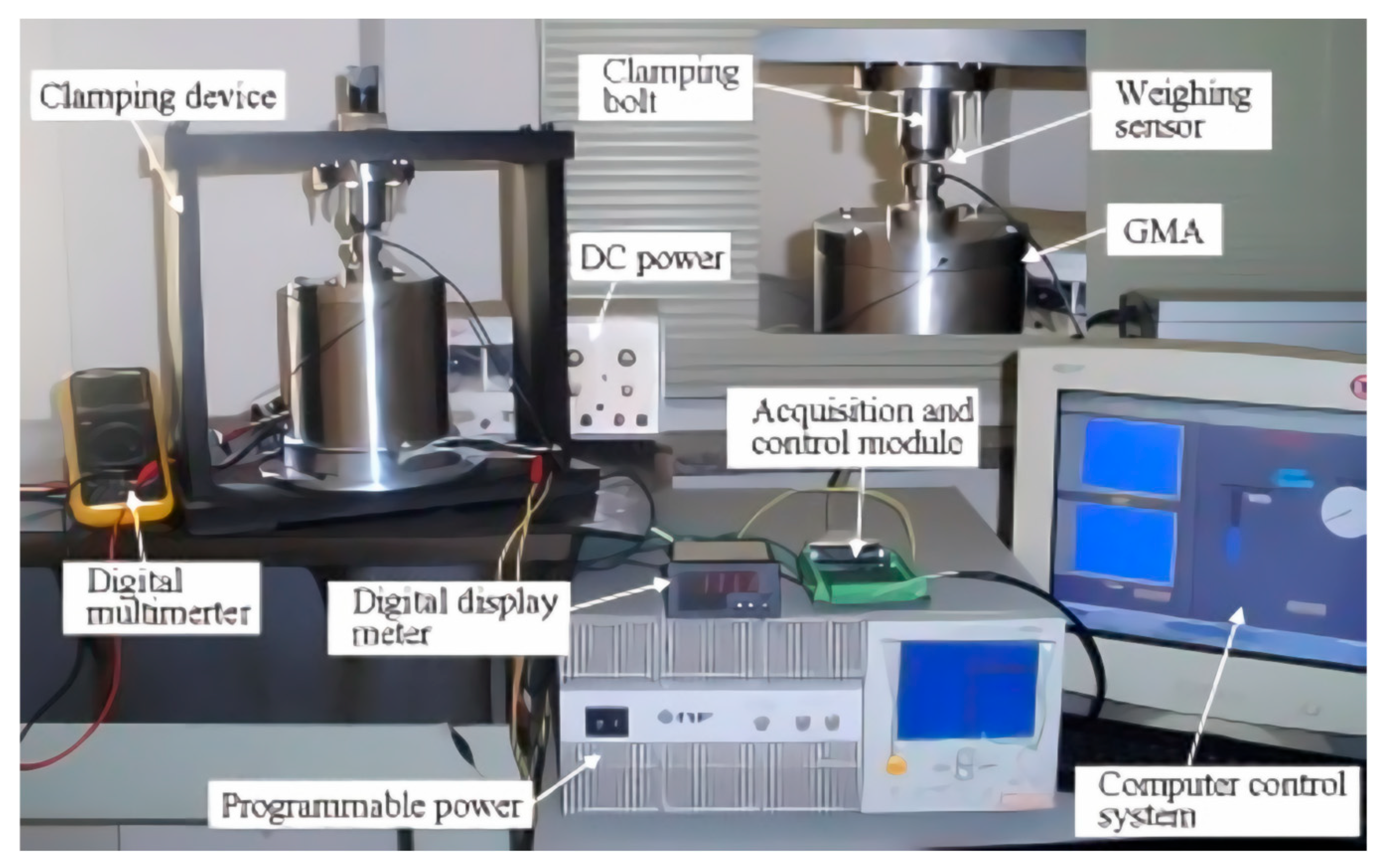

- Zhou, J.; He, Z.; Rong, C.; Xue, G. A giant magnetostrictive rotary actuator: Design, analysis and experimentation. Sens. Actuators A: Phys. 2019, 287, 150–157. [Google Scholar] [CrossRef]

- Wang, B.; Wu, Y.; Wu, X.; Liu, X.; Peng, H. Real-time measuring method to measure the micro-displacement of a rotating cutter in precise piston noncylinder pinhole boring. Int. J. Adv. Manuf. Technol. 2014, 70, 1931–1937. [Google Scholar] [CrossRef]

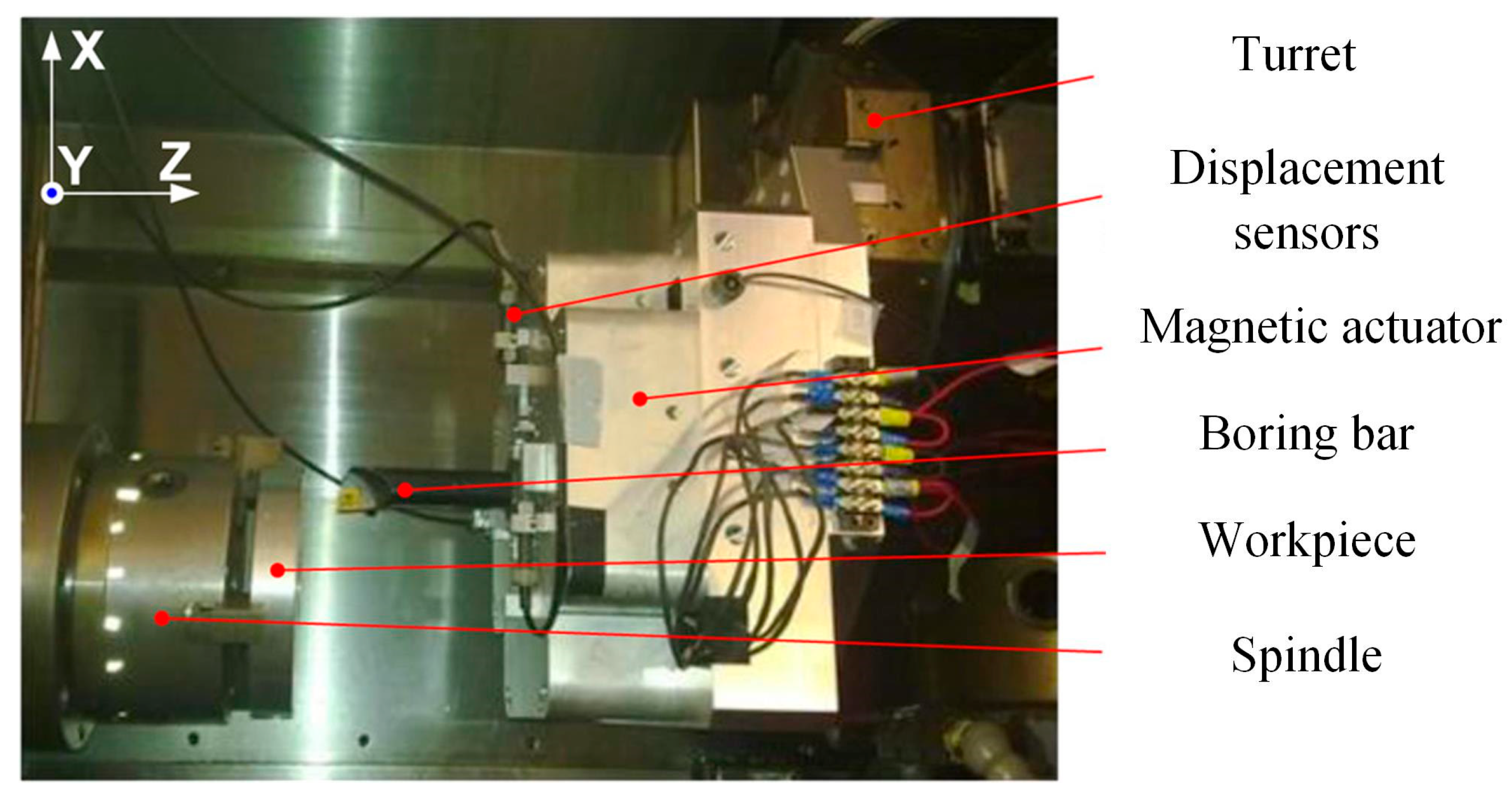

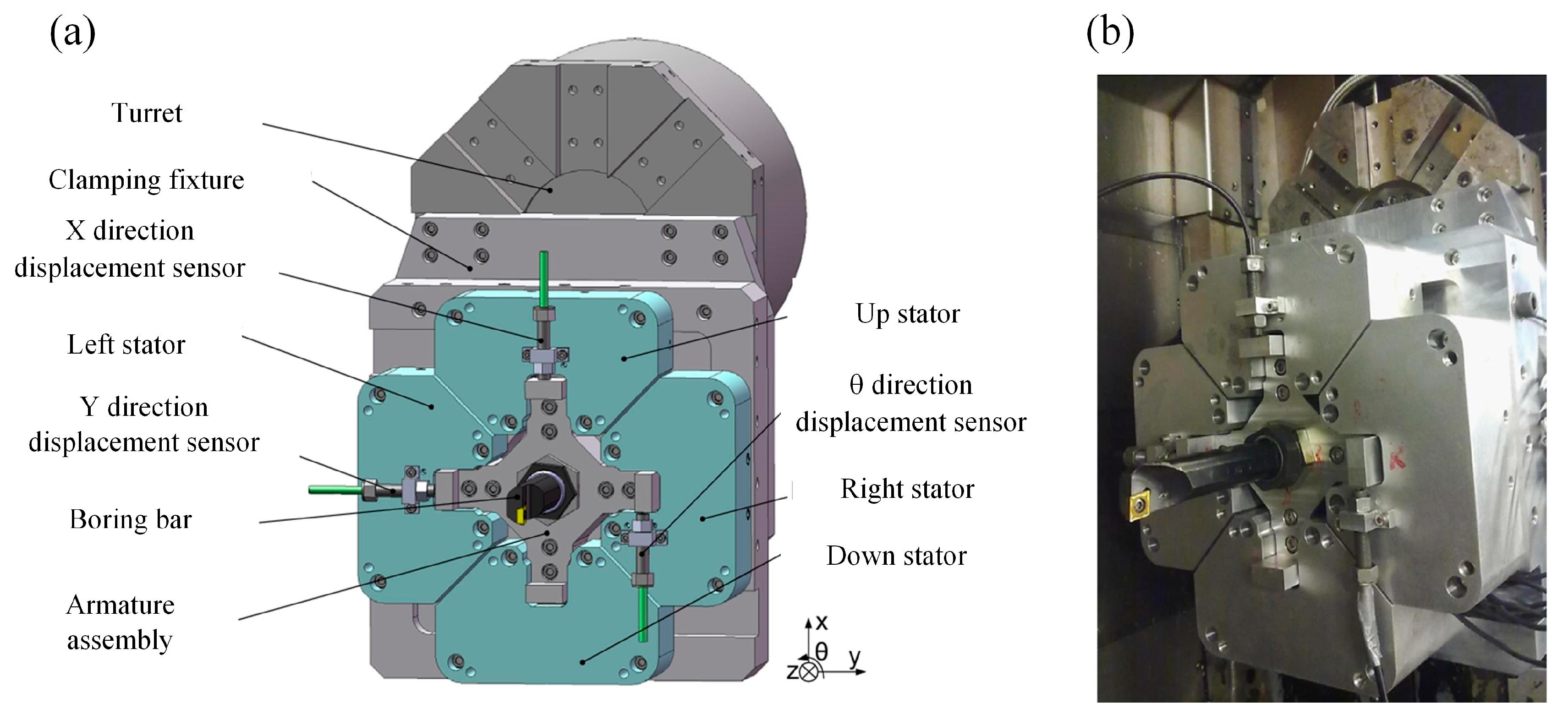

- Lu, X.; Chen, F.; Altintas, Y. Magnetic actuator for active damping of boring bars. CIRP Ann. 2014, 63, 369–372. [Google Scholar] [CrossRef]

- Chen, F.; Lu, X.; Altintas, Y. A novel magnetic actuator design for active damping of machining tools. Int. J. Mach. Tools Manuf. 2014, 85, 58–69. [Google Scholar] [CrossRef]

- Chen, F.; Hanifzadegan, M.; Altintas, Y.; Lu, X. Active damping of boring bar vibration with a magnetic actuator. IEEE/ASME Trans. Mechatron. 2015, 20, 2783–2794. [Google Scholar] [CrossRef]

- Chen, F.; Liu, G. Active damping of machine tool vibrations and cutting force measurement with a magnetic actuator. Int. J. Adv. Manuf. Technol. 2017, 89, 691–700. [Google Scholar] [CrossRef]

- Bak, C.; Son, H. Magnetostrictive actuator for chatter vibration suppression of boring bar. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; pp. 103–106. [Google Scholar]

- Liu, H.; Jia, Z.; Wang, F.; Zong, F. Research on the constant output force control system for giant magnetostrictive actuator disturbed by external force. Mechatronics 2012, 22, 911–922. [Google Scholar] [CrossRef]

- Yao, Z.; Zhang, P.; Luo, M. Extreme learning machine oriented surface roughness prediction at continuous cutting positions based on monitored acceleration. Mech. Syst. Signal Process. 2024, 219, 111633. [Google Scholar] [CrossRef]

- Isavand, J.; Kasaei, A.; Peplow, A.; Wang, X.; Yan, J. A reduced-order machine-learning-based method for fault recognition in tool condition monitoring. Measurement 2024, 224, 113906. [Google Scholar] [CrossRef]

- Pan, Y.; Kang, R.; Dong, Z.; Du, W.; Yin, S.; Bao, Y. On-line prediction of ultrasonic elliptical vibration cutting surface roughness of tungsten heavy alloy based on deep learning. J. Intell. Manuf. 2022, 33, 675–685. [Google Scholar] [CrossRef]

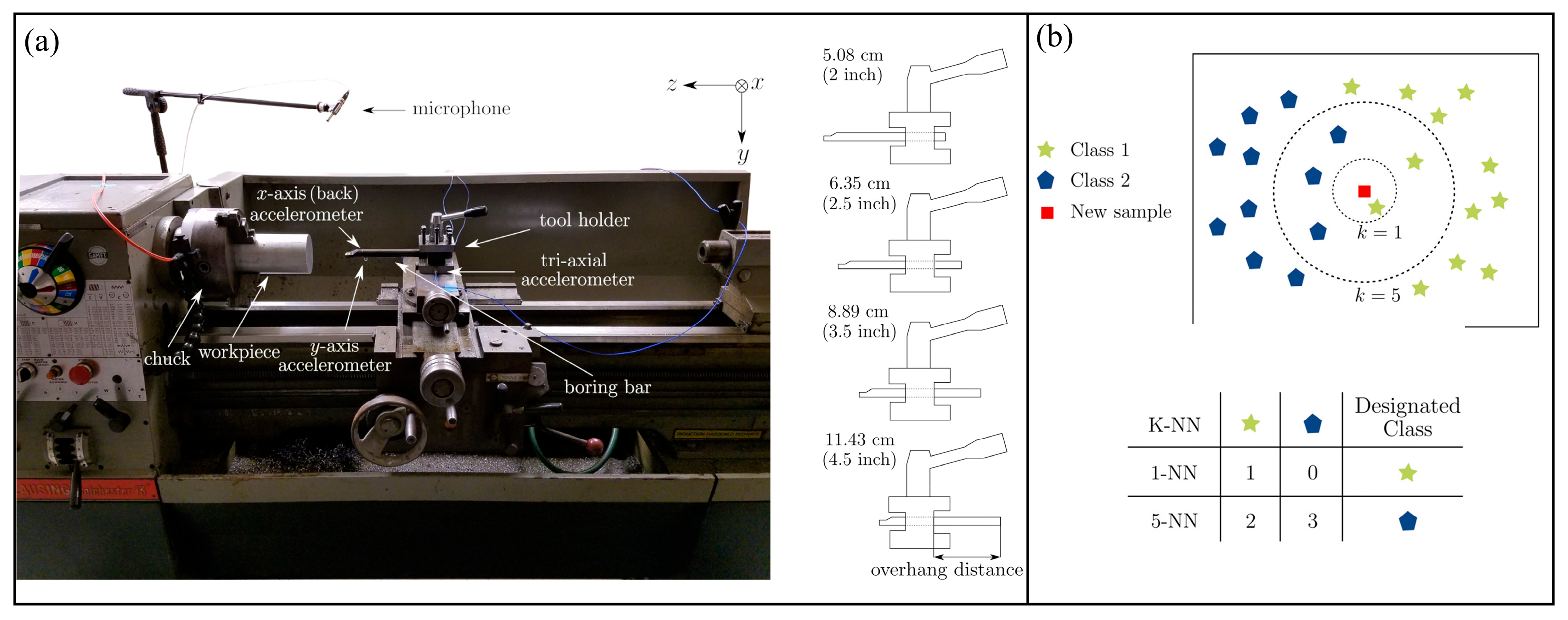

- Han, S.; Mannan, N.; Stein, D.C.; Pattipati, K.R.; Bollas, G.M. Classification and regression models of audio and vibration signals for machine state monitoring in precision machining systems. J. Manuf. Syst. 2021, 61, 45–53. [Google Scholar] [CrossRef]

- Kounta, C.A.K.A.; Arnaud, L.; Kamsu-Foguem, B.; Tangara, F. Deep learning for the detection of machining vibration chatter. Adv. Eng. Software 2023, 180, 103445. [Google Scholar] [CrossRef]

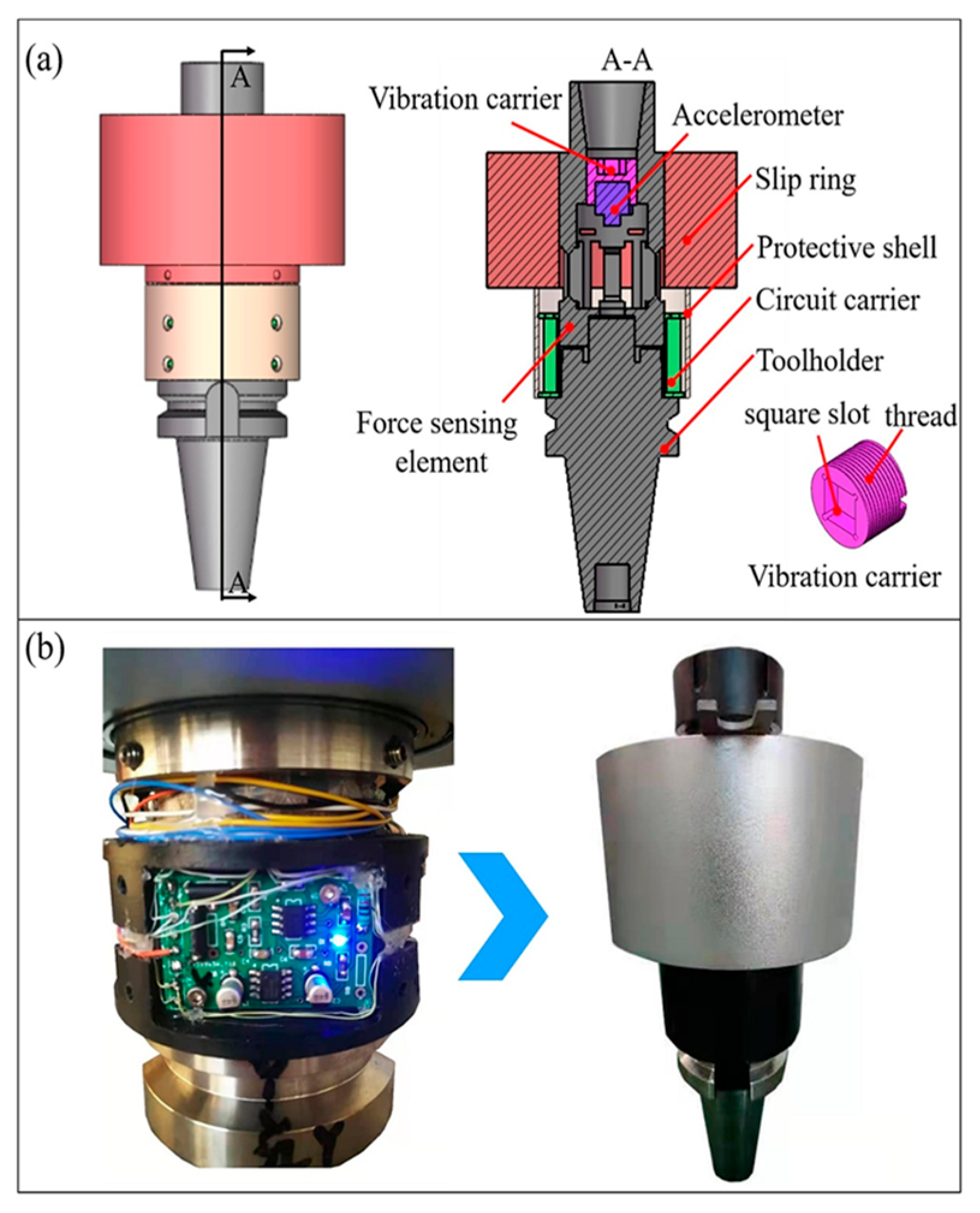

- Zhang, P.; Gao, D.; Lu, Y.; Ma, Z.; Wang, X.; Song, X. Cutting tool wear monitoring based on a smart toolholder with embedded force and vibration sensors and an improved residual network. Measurement 2022, 199, 111520. [Google Scholar] [CrossRef]

- Tama, B.A.; Vania, M.; Lee, S.; Lim, S. Recent advances in the application of deep learning for fault diagnosis of rotating machinery using vibration signals. Artif. Intell. Rev. 2023, 56, 4667–4709. [Google Scholar]

- Yesilli, M.C.; Khasawneh, F.A.; Otto, A. Chatter detection in turning using machine learning and similarity measures of time series via dynamic time warping. J. Manuf. Process. 2022, 77, 190–206. [Google Scholar] [CrossRef]

- Sun, L.-C.; Cheng, R.-C.; Chen, K.-S. Evaluation of transducer signature selections on machine learning performance in cutting tool wear prognosis. Int. J. Adv. Manuf. Technol. 2025, 119, 6451–6468. [Google Scholar] [CrossRef]

- Rahimi, M.H.; Huynh, H.N.; Altintas, Y. On-line chatter detection in milling with hybrid machine learning and physics-based model. CIRP J. Manuf. Sci. Technol. 2021, 35, 25–40. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 123001. [Google Scholar] [CrossRef]

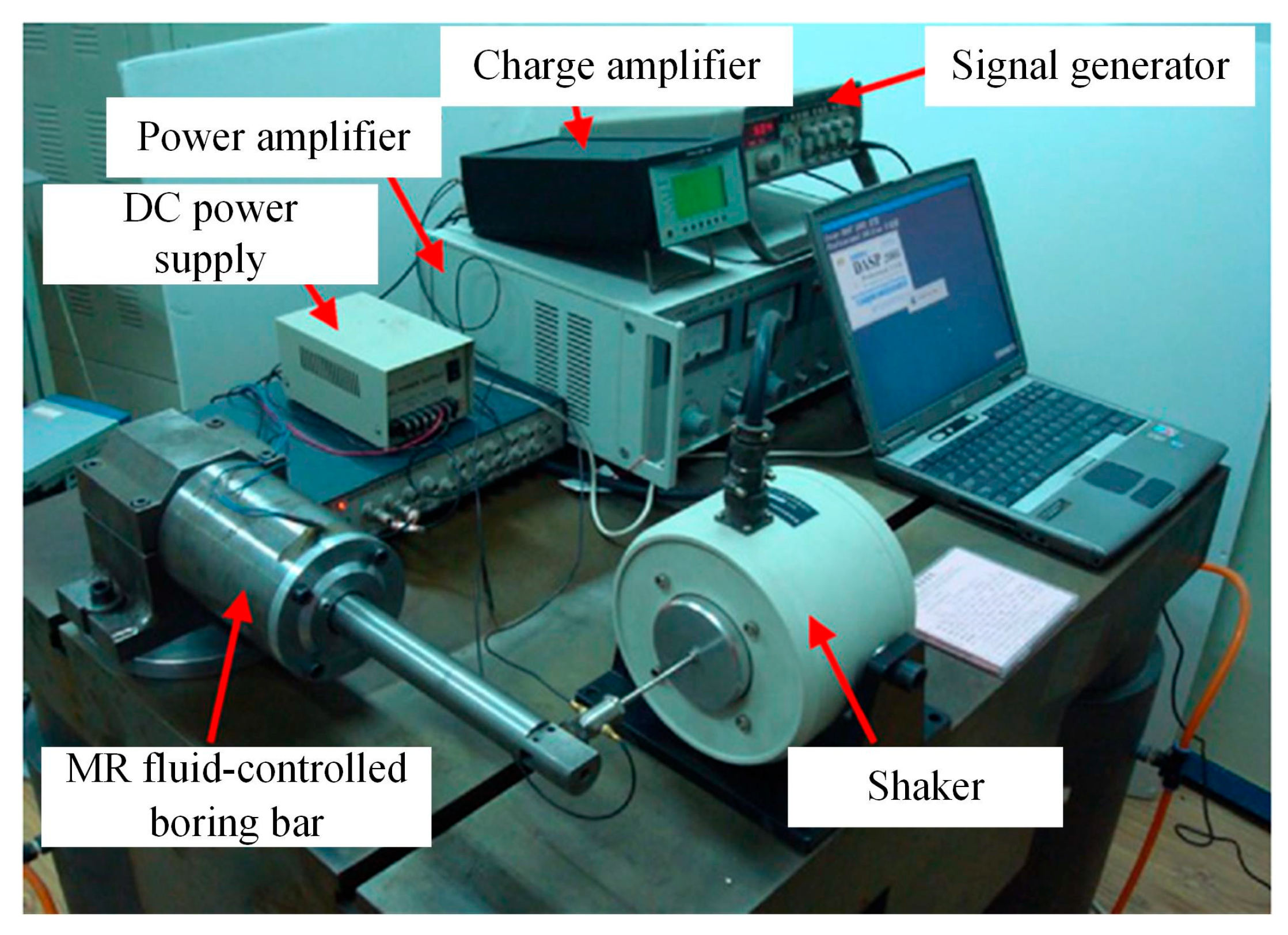

- Mei, D.; Kong, T.; Shih, A.J.; Chen, Z. Magnetorheological fluid-controlled boring bar for chatter suppression. J. Mater. Process. Technol. 2009, 209, 1861–1870. [Google Scholar] [CrossRef]

- Mei, D.; Yao, Z.; Kong, T.; Chen, Z. Parameter optimization of time-varying stiffness method for chatter suppression based on magnetorheological fluid-controlled boring bar. Int. J. Adv. Manuf. Technol. 2010, 46, 1071–1083. [Google Scholar] [CrossRef]

- Yao, Z.; Mei, D.; Chen, Z. Chatter suppression by parametric excitation: Model and experiments. J. Sound Vib. 2011, 330, 2995–3005. [Google Scholar] [CrossRef]

- Pour, D.S.; Behbahani, S. Semi-active fuzzy control of machine tool chatter vibration using smart MR dampers. Int. J. Adv. Manuf. Technol. 2016, 83, 421–428. [Google Scholar] [CrossRef]

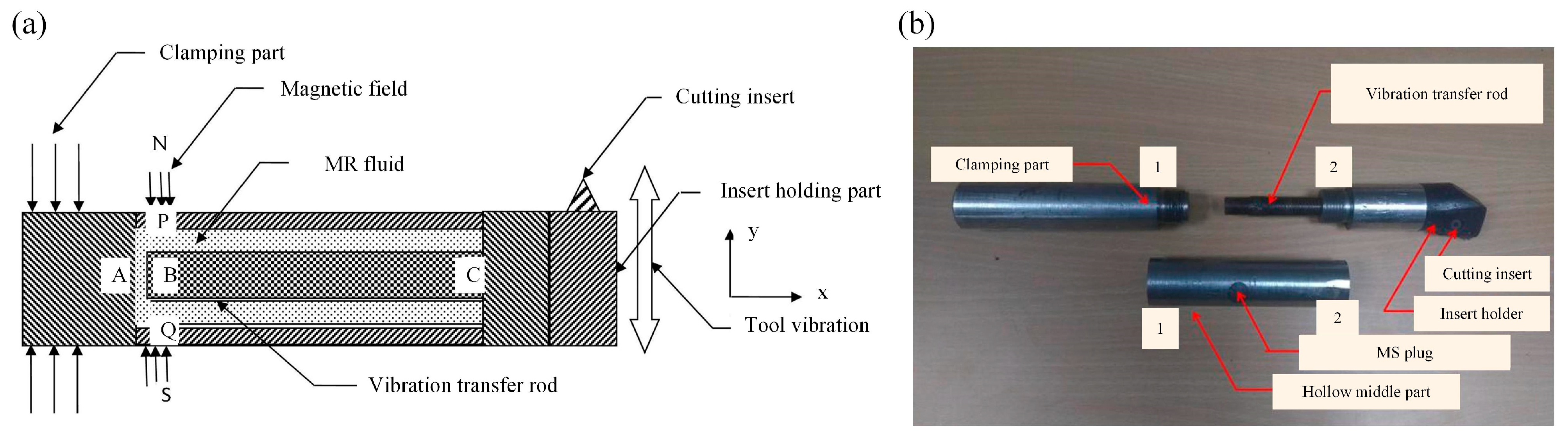

- Biju, C.V.; Shunmugam, M.S. Performance of magnetorheological fluid based tunable frequency boring bar in chatter control. Measurement 2019, 140, 407–415. [Google Scholar] [CrossRef]

- Niu, J.; Hou, J.; Shen, Y.; Yang, S. Dynamic analysis and vibration control of nonlinear boring bar with fractional-order model of magnetorheological fluid. Int. J. Nonlinear Mech. 2020, 121, 103459. [Google Scholar] [CrossRef]

- Prabhu, L.; Satish Kumar, S.; Dinakaran, D.; Jawahar, R. Improvement of chatter stability in boring operations with semi active magneto-rheological fluid damper. Mater. Today Proc. 2020, 33, 420–427. [Google Scholar] [CrossRef]

- Saleh, M.K.A.; Nejatpour, M.; Yagci Acar, H.; Lazoglu, I. A new magnetorheological damper for chatter stability of boring tools. J. Mater. Process. Technol. 2021, 289, 116931. [Google Scholar] [CrossRef]

- Saleh, M.K.A.; Ulasyar, A.; Lazoglu, I. Active damping of chatter in the boring process via variable gain sliding mode control of a magnetorheological damper. CIRP Ann. 2021, 70, 337–340. [Google Scholar] [CrossRef]

- Hou, J.; Niu, J.; Shen, Y.; Yang, S.; Zhang, W. Dynamic analysis and vibration control of two-degree-of-freedom boring bar with fractional-order model of magnetorheological fluid. J. Vib. Control 2021, 28, 3001–3018. [Google Scholar] [CrossRef]

- Aralikatti, S.S.; Puneet, N.P.; Kumar, H. Determining the optimal composition of magnetorheological fluid for a short-stroke magnetorheological damper. Sādhanā 2023, 48, 120. [Google Scholar] [CrossRef]

- Sarath, S.; Paul, P.S.; Lawrance, G. Characterization and performance analysis of magnetorheological foam damper for vibration control during boring process. Multiscale Multidiscip. Model. Exp. Des. 2024, 7, 837–854. [Google Scholar] [CrossRef]

- Stanway, R.; Sproston, J.L.; El-Wahed, A.K. Applications of electro-rheological fluids in vibration control: A survey. Smart Mater. Struct. 1996, 5, 464. [Google Scholar] [CrossRef]

- Wang, M.; Fei, R. Improvement of machining stability using a tunable-stiffness boring bar containing an electrorheological fluid. Smart Mater. Struct. 1999, 8, 511. [Google Scholar] [CrossRef]

- Wang, M.; Fei, R. Chatter suppression based on nonlinear vibration characteristic of electrorheological fluids. Int. J. Mach. Tools Manuf. 1999, 39, 1925–1934. [Google Scholar] [CrossRef]

- Wang, M.; Fei, R. On-line chatter detection and control in boring based on an electrorheological fluid. Mechatronics 2001, 11, 779–792. [Google Scholar] [CrossRef]

- Wang, M.; Fei, R. Research on online monitoring technology of chatter in cutting process based on electrorheological materials. J. Mech. Eng. 2002, 38, 5. [Google Scholar]

- Kela, L.; Vähäoja, P. Recent Studies of Adaptive Tuned Vibration Absorbers/Neutralizers. Appl. Mech. Rev. 2009, 62, 60801. [Google Scholar] [CrossRef]

- Tewani, S.G.; Rouch, K.E.; Walcott, B.L. Cutting process stability of a boring bar with active dynamic absorber. In Proceedings of the ASME 1991 Design Technical Conferences, 13th Biennial Conference on Mechanical Vibration and Noise: Vibration Analysis—Analytical and Computationa, Miami, FL, USA, 22–25 September 1991; pp. 205–213. [Google Scholar]

- Tewani, S.G.; Rouch, K.E.; Walcott, B.L. A study of cutting process stability of a boring bar with active dynamic absorber. Int. J. Mach. Tools Manuf. 1995, 35, 91–108. [Google Scholar] [CrossRef]

- Moradi, H.; Bakhtiari-Nejad, F.; Movahhedy, M.R. Tuneable vibration absorber design to suppress vibrations: An application in boring manufacturing process. J. Sound Vib. 2008, 318, 93–108. [Google Scholar] [CrossRef]

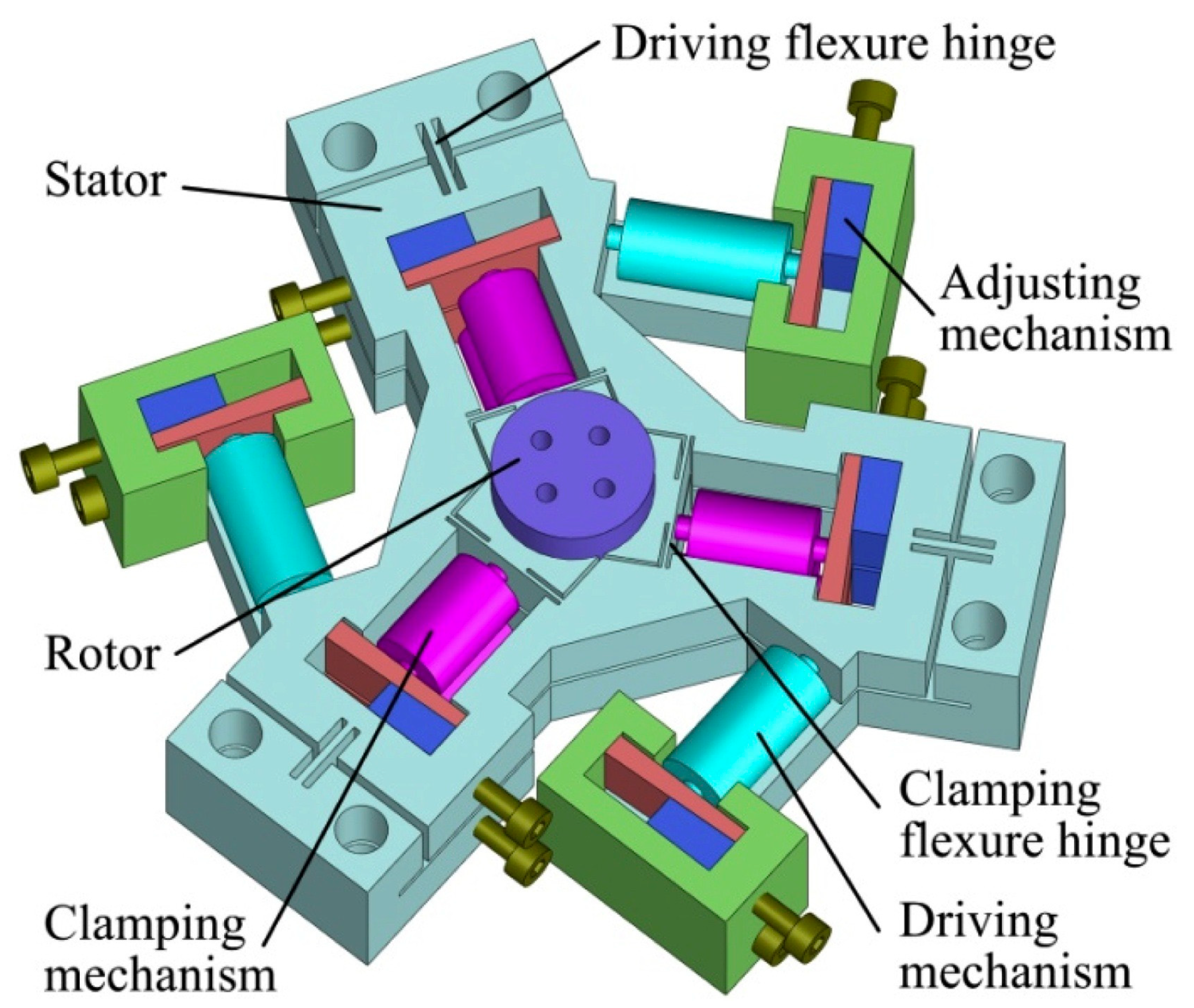

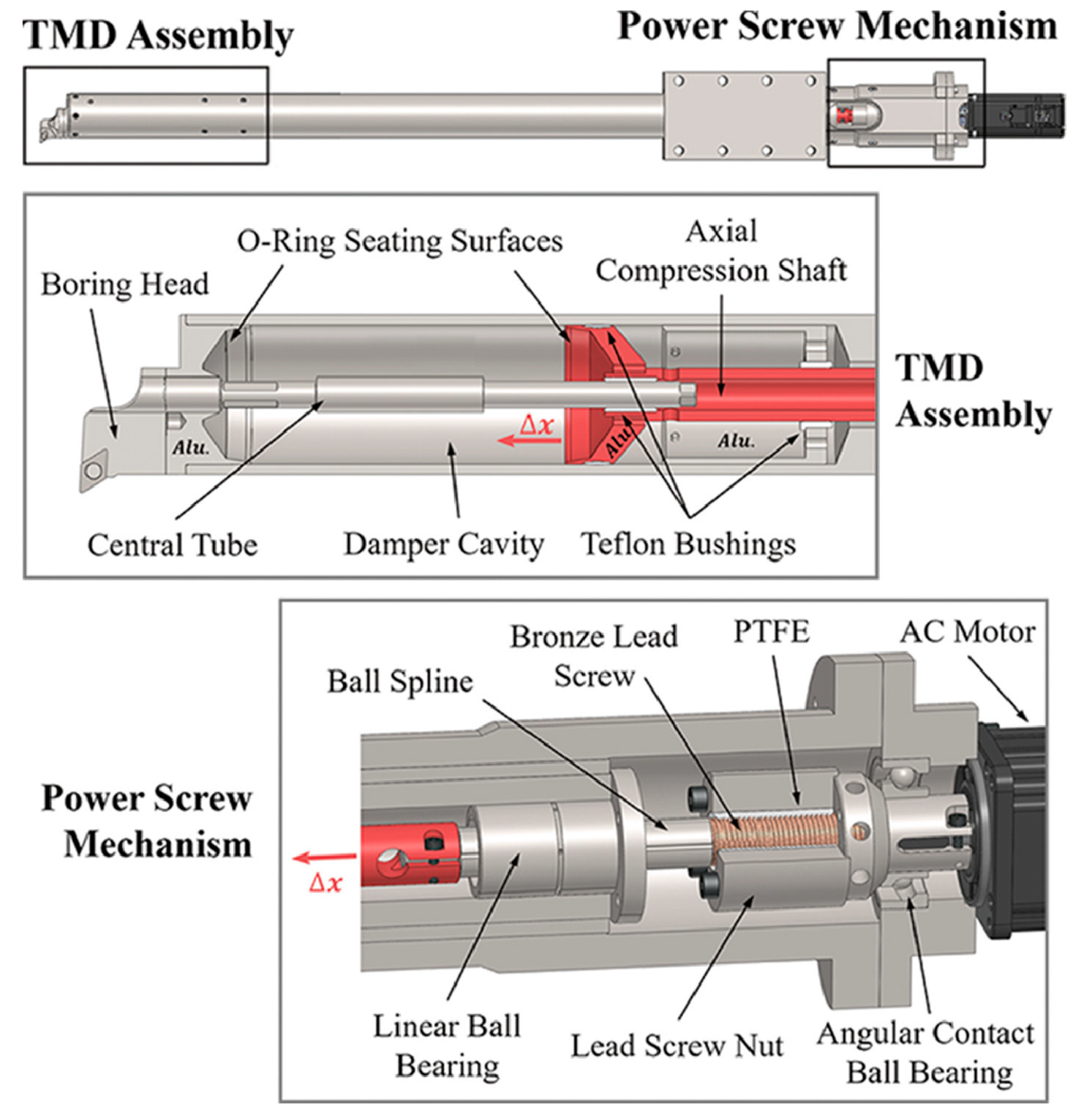

- Altintas, Y.; Lappin, D.; van Zyl, D.; Östling, D. Automatically tuned boring bar system. CIRP Ann. 2021, 70, 313–316. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Q.; Wu, S.; Li, R.; Gao, H. Analysis of the vibration characteristics and adjustment method of boring bar with a variable stiffness vibration absorber. Int. J. Adv. Manuf. Technol. 2018, 98, 95–105. [Google Scholar] [CrossRef]

- Lv, J.; Niu, J.; Shen, Y.; Yang, S. Vibration control of linear boring bar by dynamic vibration absorber combined with nonlinear energy sink. Chin. J. Theor. Appl. Mech. 2021, 53, 3124–3133. [Google Scholar]

- Liu, Q.; Li, J.; Ma, J.; Gao, D.; Han, J.; Li, J. Structure design and vibration control of vibration reduction boring bar with variable damping. Int. J. Adv. Manuf. Technol. 2024, 134, 5301–5319. [Google Scholar] [CrossRef]

- Shi, H.; Ma, C.; Li, X.; Wang, G. Equivalent linearization of hyperelastic rubber rings in dynamic vibration absorber boring bar and simulation of its dynamic properties. Eng. Res. Express 2024, 6, 015517. [Google Scholar] [CrossRef]

- Van Zyl, D.; Altintas, Y.; Ostling, D. Parametric design of boring bars with adaptive tuned mass dampers. CIRP J. Manuf. Sci. Technol. 2022, 38, 491–499. [Google Scholar] [CrossRef]

- Li, L.; Ren, Y.; Shen, Z.; Lu, J.; Tong, L. Nonlinear system optimization of cutting tools with dynamic vibration absorbers in deep hole boring: A stability analysis. Alex. Eng. J. 2025, 112, 246–253. [Google Scholar] [CrossRef]

- Li, L.; Yang, D.L.; Cui, Y.M. Optimization of machining performance in deep hole boring: A study on cutting tool vibration and dynamic vibration absorber design. Adv. Prod. Eng. Manag. 2023, 18, 371–380. [Google Scholar] [CrossRef]

- Lawrance, G.; Paul, P.S.; Varadarajan, A.S.; Vasanth, X.A.; Raj, S.B. Suppression of tool vibration in boring process: A review. J. Inst. Eng. Ser. C 2019, 100, 1053–1069. [Google Scholar] [CrossRef]

- Sun, J.; Sun, C.; Yan, Z.; Yang, W.; Zhou, C.; Zhang, P.; Shu, L. State-of-art, challenges, and outlook on deep hole boring: Chatter suppression, tool wear monitoring, and error measurement. Int. J. Adv. Manuf. Technol. 2025, 136, 2075–2105. [Google Scholar] [CrossRef]

- Åkesson, H.; Smirnova, T.; Håkansson, L. Analysis of dynamic properties of boring bars concerning different clamping conditions. Mech. Syst. Signal Process. 2009, 23, 2629–2647. [Google Scholar] [CrossRef][Green Version]

- Yan, S.; Sun, Y. Enhancing tool dynamics and stability in internal turning with an adjustable clamping device under variable cutting conditions. Mech. Syst. Signal Process. 2024, 208, 111007. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, Y.; Ji, S.; Zhang, J. Analysis of the vibration and chatter stability of a tapered composite boring bar. Shock. Vib. 2020, 2020, 4190806. [Google Scholar] [CrossRef]

- Liu, G.; Lu, L.; Su, W.; Li, J.; An, Q.; Zhang, L.; Mao, J. Design and chatter suppression of a CLD-structured CFRP boring bar for high-precision deep hole machining. Int. J. Adv. Manuf. Technol. 2025, 139, 1363–1378. [Google Scholar] [CrossRef]

- Cai, H.; Dong, Z.; Zhang, Z.B.; Cui, S. Design of a new type of deep hole boring device. J. Phys. Conf. Ser. 2021, 1748, 062038. [Google Scholar] [CrossRef]

- Takahashi, W.; Suzuki, N.; Shamoto, E. Development of a novel boring tool with anisotropic dynamic stiffness to avoid chatter vibration in cutting: Part 1: Design of anisotropic structure to attain infinite dynamic stiffness. Precis. Eng. 2021, 68, 57–71. [Google Scholar] [CrossRef]

- Nagano, S.; Koizumi, T.; Fujii, T.; Tsujiuchi, N.; Ueda, H.; Steel, K. Development of a composite boring bar. Compos. Struct. 1997, 38, 531–539. [Google Scholar] [CrossRef]

- Lee, D.G.; Hwang, H.Y.; Kim, J.K. Design and manufacture of a carbon fiber epoxy rotating boring bar. Compos. Struct. 2003, 60, 115–124. [Google Scholar] [CrossRef]

- Lee, D.G.; Lee, C.S.; Lee, H.G.; Hwang, H.Y.; Kim, J.W. Novel applications of composite structures to robots, machine tools and automobiles. Compos. Struct. 2004, 66, 17–39. [Google Scholar] [CrossRef]

- Wang, J.; Wu, F.; Han, Y.; Sun, D. Boring bar design with laminar composite structure and research on properties. China Mech. Eng. 2013, 24, 5. [Google Scholar] [CrossRef]

- Sortino, M.; Totis, G.; Prosperi, F. Modeling the dynamic properties of conventional and high-damping boring bars. Mech. Syst. Signal Process. 2013, 34, 340–352. [Google Scholar] [CrossRef]

- Khatake, P.; Nitnaware, P.T. Vibration mitigation using passive damper in machining. Int. J. Mod. Eng. Res. 2013, 3, 3649–3652. [Google Scholar]

- Akdeniz, E.; Arslan, H. A new design of boring bar using TiNi3 alloy to reduce vibration in turning operations. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2022, 237, 105–121. [Google Scholar] [CrossRef]

- Song, Q.; Shi, J.; Liu, Z.; Wan, Y.; Xia, F. Boring bar with constrained layer damper for improving process stability. Int. J. Adv. Manuf. Technol. 2016, 83, 1951–1966. [Google Scholar] [CrossRef]

- Zhang, Y.; Rong, Y.; Tian, J.; Ma, J. Chatter stability of the constrained layer damping composite boring bar in cutting process. J. Vib. Control 2019, 25, 2204–2214. [Google Scholar]

- Nanda, B.K.; Srinivas, J. Investigation of stability in internal turning using a boring bar with a passive constrained layer damping. FME Trans. 2021, 49, 384–394. [Google Scholar] [CrossRef]

- Lu, L.; Ni, C.; Liu, G.; Qian, B.; An, Q.; Cao, Z.; Zhang, L.; Li, J. Analysis and development of the CFRP boring bar for stability improvement. Fibers Polym. 2023, 24, 4413–4427. [Google Scholar] [CrossRef]

- Ghorbani, S.; Rogov, V.A.; Carluccio, A.; Belov, P.S. The effect of composite boring bars on vibration in machining process. Int. J. Adv. Manuf. Technol. 2019, 105, 1157–1174. [Google Scholar] [CrossRef]

- Singaravelu, C.; Varatharajan, P.; Ramu, G.; Alagappan, K. Investigation of damping characteristics on copper-based shape memory alloy frictional damper in boring process. Arab. J. Sci. Eng. 2021, 46, 11859–11870. [Google Scholar] [CrossRef]

- Tian, J.; Li, J.; Liu, G.; Shi, J.; Wu, Y. Design and performance study of a bionic damping boring bar based on the woodpecker. CIRP J. Manuf. Sci. Technol. 2025, 61, 308–323. [Google Scholar] [CrossRef]

- Fu, Q.; Lundin, D.; Nicolescu, C.M. Anti-vibration engineering in internal turning using a carbon nanocomposite damping coating produced by PECVD process. J. Mater. Eng. Perform. 2014, 23, 506–517. [Google Scholar] [CrossRef]

- Chockalingam, S.; Natarajan, U.; Selvam, M.; Cyril, A.G. Investigation on machinability and damping properties of nickel–phosphorus coated boring bar. Arab. J. Sci. Eng. 2016, 41, 669–676. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Y. Investigation of chatter stability of cutting process with a rotating tapered cutter bar considering internal and external damping. Int. J. Adv. Manuf. Technol. 2020, 107, 1755–1771. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, Y.; Zhang, J. Stability analysis of cutting process with internally damped rotating tapered composite cutter bar. Math. Probl. Eng. 2020, 2020, 2587820. [Google Scholar] [CrossRef]

- Wang, D. Analysis of vibration energy dissipation performance of impact dampers. J. Mech. Eng. 2014, 50, 6. [Google Scholar] [CrossRef]

- Ema, S.; Marui, E. Suppression of chatter vibration of boring tools using impact dampers. Int. J. Mach. Tools Manuf. 2000, 40, 1141–1156. [Google Scholar] [CrossRef]

- Lawrance, G.; Paul, P.S.; Varadarajan, A.S.; Praveen, A.P.; Vasanth, X.A. Attenuation of vibration in boring tool using spring controlled impact damper. Int. J. Interact. Des. Manuf. 2017, 11, 903–915. [Google Scholar] [CrossRef]

- Kumar, M.S.; Mohanasundaram, K.; Sathishkumar, B. A case study on vibration control in a boring bar using particle damping. Int. J. Eng. Sci. Technol. 2012, 3, 177–184. [Google Scholar] [CrossRef][Green Version]

- Biju, C.V.; Shunmugam, M.S. Investigation into effect of particle impact damping (PID) on surface topography in boring operation. Int. J. Adv. Manuf. Technol. 2014, 75, 1219–1231. [Google Scholar] [CrossRef]

- Devaraj, S.; Shivalingappa, D.; Jangaler, R.S. Surface quality enrichment using fine particle impact damper in boring operations. Int. J. Res. Eng. Technol. 2014, 3, 531–535. [Google Scholar] [CrossRef]

- Chockalingam, S.; Natarajan, U.; Cyril, A.G. Damping investigation in boring bar using hybrid copper-zinc particles. J. Vib. Control 2015, 23, 2128–2134. [Google Scholar] [CrossRef]

- Singh, G.; Mann, G.S.; Pradhan, S. Improving the surface roughness and flank wear of the boring process using particle damped boring bars. Mater. Today Proc. 2018, 5 Pt 2, 28186–28194. [Google Scholar] [CrossRef]

- Thomas, W.; Diniz, A.E.; Pederiva, R.; Suyama, D.I.; de Albuquerque, M.V. A new type of impact damper with long overhangs in the internal turning of hardened materials. Procedia CIRP 2019, 82, 255–260. [Google Scholar] [CrossRef]

- De Aguiar, H.C.G.; Hassui, A.; Suyama, D.I.; Magri, A. Reduction of internal turning surface roughness by using particle damping aided by airflow. Int. J. Adv. Manuf. Technol. 2020, 106, 125–131. [Google Scholar] [CrossRef]

- Lawrance, G.; Paul, P.S.; Ezhil, M.; Ashish, J.E.; Gokul, R.; Subhash, M. Influence of stainless steel impact damper on tribological properties during boring process. Mater. Today Proc. 2021, 46, 107–110. [Google Scholar] [CrossRef]

- Lawrance, G.; Paul, P.S.; Jan, N.M.; Pravin, S.S. Investigation of particle damper on tool vibration during boring process. Mater. Today Proc. 2021, 47, 4696–4699. [Google Scholar] [CrossRef]

- Thomas, W.; Peterka, J.; Szabó, T.; de Albuquerque, M.V.; Pederiva, R.; Kiss, L.P. Analytical and experimental investigation of the dynamic stability in passive damper boring bars. Procedia CIRP 2023, 117, 187–192. [Google Scholar] [CrossRef]

- Ramu, G.; Sundaramoorthy, K.; Singaravelu, C.; Prasannavenkadesan, V. A novel hybrid particle damping in boring bar for effective machining and chatter suppression. Sādhanā 2024, 49, 276. [Google Scholar] [CrossRef]

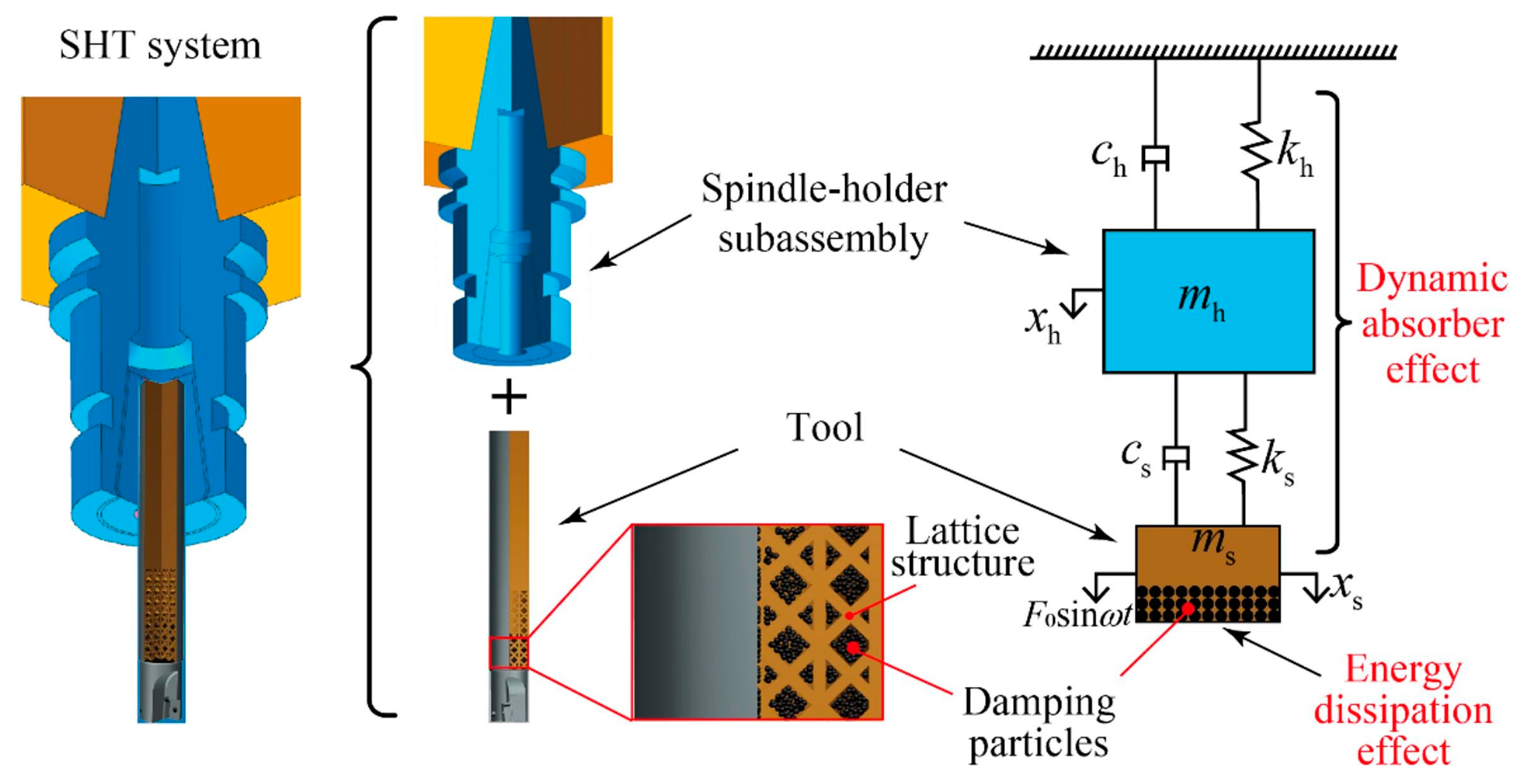

- Yang, Y.; Liu, H.-L.; Yuan, J.-W.; Kong, W.-L.; Wan, M.; Zhang, W.-H. Development of an anti-vibration cutting tool combining the lattice structures infill with damping particles. Mech. Syst. Signal Process. 2025, 228, 112425. [Google Scholar] [CrossRef]

- Tian, J.; Wu, D.; Li, J.; Shi, J.; Liu, G. Design and energy dissipation analysis of a boring bar based on particle damping. J. Vib. Eng. Technol. 2025, 13, 51. [Google Scholar] [CrossRef]

- Edhi, E.; Hoshi, T. Stabilization of high frequency chatter vibration in fine boring by friction damper. Precis. Eng. 2001, 25, 224–234. [Google Scholar] [CrossRef]

- Lu, X.D.; Zhao, J.; Mo, J.L.; Zhang, Q.; Zhang, X.; Zhou, Z.R. Improvement of dynamical and tribological properties of friction systems by introducing parallel-grooved structures in elastic damping components. Compos. Struct. 2018, 192, 8–19. [Google Scholar] [CrossRef]

- Zhao, Y.C.; Ma, F.; Yan, C.G.; Huang, H.B. Study on damping effect of liquid film in precision boring. China Mech. Eng. 2002, 13, 4. [Google Scholar]

- Zhao, Y.C.; Huang, H.B.; Yan, C.G.; Zhao, L. Simulation study of extrusion liquid film damping system in precision boring. J. Mech. Eng. 2003, 39, 4. [Google Scholar] [CrossRef]

- Shao, Q.; Zhao, Z.; Tian, X.; Wang, L. Research on effect of decreasing vibration with liquid film damping in precision boring. Wirel. Pers. Commun. 2018, 102, 1085–1094. [Google Scholar] [CrossRef]

- Wang, M.; Zan, T.; Yang, Y.; Fei, R. Design and implementation of nonlinear TMD for chatter suppression: An application in turning processes. Int. J. Mach. Tools Manuf. 2010, 50, 474–479. [Google Scholar] [CrossRef]

- Wang, M.; Zan, T.; Gao, X. Modeling and optimization of a friction damper for boring chatter control. Adv. Mech. Eng. 2015, 6, 690768. [Google Scholar] [CrossRef]

- Hayati, S.; Shahrokhi, M.; Hedayati, A. Development of a frictionally damped boring bar for chatter suppression in boring process. Int. J. Adv. Manuf. Technol. 2021, 113, 2761–2778. [Google Scholar] [CrossRef]

| Research Methods | Boring Bar Type | Working Principle | Advantages | References |

|---|---|---|---|---|

| Experiments and theoretical calculations | Piezoelectric-driven damped boring bar | Piezoelectric ceramic elements deform under the influence of an electric field | High sensitivity, fast response, high energy conversion efficiency | [20,21,22,23,24] |

| Experiments and finite element analysis | Magnetostrictive actuator damped boring tool | Material deforms under the influence of an external magnetic field | High-precision radial displacement control | [29,30,31,32,33,34] |

| Finite element analysis and experimental and dynamic modeling | Magnetorheological fluid damped boring tool | Flow characteristics of magnetorheological fluids suppress tool vibration | Reversible changes in viscosity and stiffness | [51,52,53,54,55] |

| Structural design and experiments | Rheological fluid-damped boring tool | Rheological fluids modulate damping characteristics | Precise control of electric field strength to adjust viscosity | [64,65,66] |

| Dynamic models and experiments | Variable parameter damped boring tool | Adjust internal damping and stiffness to accommodate vibration | Automatic adjustment of parameters for the motion absorber | [68,69,70] |

| Research Methods | Boring Bar Type | Structural Features | Advantages | References |

|---|---|---|---|---|

| Experiment and structural design | Structure-optimized damping boring tool | Auxiliary support or clamping device | Enhance the rigidity and vibration damping performance of boring tools | [82,83,84] |

| Finite element simulation and experiment | Material-optimized damping boring tool | High-stiffness or high-damping materials | Absorb vibration energy and reduce vibration amplitude | [88,89,90] |

| Structural design and experimentation | Damping boring tool with a shock absorber | Continuous nonlinear collisions achieve vibration reduction | Damping components absorb or dissipate vibrational energy | [107,108,109,110] |

| Structural design and experimentation | Damping boring tool for friction components | Friction material or friction damper | Simple structure and excellent dissipation capability | [122,123,124,125] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Song, J.; Zhao, J.; Ren, X.; Jiang, A.; Wang, B. Research Progress and Application of Vibration Suppression Technologies for Damped Boring Tools. Machines 2025, 13, 883. https://doi.org/10.3390/machines13100883

Zhang H, Song J, Zhao J, Ren X, Jiang A, Wang B. Research Progress and Application of Vibration Suppression Technologies for Damped Boring Tools. Machines. 2025; 13(10):883. https://doi.org/10.3390/machines13100883

Chicago/Turabian StyleZhang, Han, Jian Song, Jinfu Zhao, Xiaoping Ren, Aisheng Jiang, and Bing Wang. 2025. "Research Progress and Application of Vibration Suppression Technologies for Damped Boring Tools" Machines 13, no. 10: 883. https://doi.org/10.3390/machines13100883

APA StyleZhang, H., Song, J., Zhao, J., Ren, X., Jiang, A., & Wang, B. (2025). Research Progress and Application of Vibration Suppression Technologies for Damped Boring Tools. Machines, 13(10), 883. https://doi.org/10.3390/machines13100883