Abstract

The growing adoption of modular robotic systems presents new challenges in ensuring ease of assembly, deployment, and reconfiguration, especially for end-users with varying technical expertise. This study proposes and validates an Assembly Complexity Index (ACI) framework, combining subjective workload (NASA Task Load Index) and task complexity (Task Complexity Index) into a unified metric to quantify assembly difficulty. Twelve participants performed modular manipulator assembly tasks under supervised and unsupervised conditions, enabling evaluation of learning effects and assembly complexity dynamics. Statistical analyses, including Cronbach’s alpha, correlation studies, and paired t-tests, demonstrated the framework’s internal consistency, sensitivity to user learning, and ability to capture workload-performance trade-offs. Additionally, we propose an augmented reality (AR) and virtual reality (VR) integration workflow to further mitigate assembly complexity, offering real-time guidance and adaptive assistance. The proposed framework not only supports design iteration and operator training but also provides a human-centered evaluation methodology applicable to modular robotics deployment in Industry 4.0 environments. The AR/VR-assisted workflow presented here is proposed as a conceptual extension and will be validated in future work.

1. Introduction

With the increasing adoption of robotics and automation in industry, it has become evident that future factories will increasingly rely on robotic solutions. However, despite the wide availability of off-the-shelf manipulators, certain industries, particularly those dealing with lower payload capacities, remain hesitant to adopt such systems. For instance, the Food and Beverage sector contributed to only 3% of global annual installations of industrial robots, with no increase in installation rates compared to previous years according to Müller [1]. Many commercial robotic systems are primarily optimized for heavy-duty, high-payload tasks, making them ill-suited for flexible, lightweight, or highly specialized applications. In addition to the mismatch of technical specifications, off-the-shelf manipulators often introduce operational challenges such as vendor lock-in as per Markl et al. [2], dependence on original equipment manufacturers (OEMs) for servicing, and substantial downtime during repairs or task reconfiguration, such as in Bard [3]. As reported by Chen and Yim [4], these challenges are magnified when re-deployment is required to accommodate evolving shop-floor tasks, as fixed degrees-of-freedom (DoF), predefined workspaces, and rigid manipulator specifications create high costs associated with decommissioning, reconfiguration, and acquisition of replacement systems.

Task-agnostic, modular manipulator solutions therefore offer a highly attractive alternative. Research into modular robotic architectures has been ongoing since the early days of industrial robotics, with numerous approaches exploring unit-based reconfigurable designs. Historic developments include the Martonair Modular System by Harrison et al. [5], the Stuttgart Modular Robot by Wurst [6], the Reconfigurable Modular Manipulator System [7], the Dynamically Reconfigurable Robotic System [8], Structural Modules [9], remote-actuation modular joints [10], and the Toshiba Modular Manipulator System, TOMMS [11]. While these early approaches demonstrated modularity principles, they were often limited by actuator weight and control system constraints due to the technological limitations of their time.

Contemporary research continues to refine modular robot designs, enabled by advances in lightweight motors, off-the-shelf electronics, integrated software interfaces, and modern manufacturing processes. In this context, the presented research focuses on the development of a modular manipulator that allows reconfiguration to meet bespoke end-user task requirements while remaining accessible to non-expert operators. A design-to-fit methodology was applied, leveraging Generative Design [12] and Additive Manufacturing [13] to optimize both structural design and manufacturing efficiency. The resulting system aims to minimize complexity across its lifecycle—from assembly and integration to deployment, operation, repair, and eventual disassembly—thereby enhancing accessibility, sustainability, and flexibility for end-users.

However, the technical design of a modular system is only part of the challenge. A critical consideration remains the cognitive and physical demands placed on operators during assembly and reconfiguration. While intrinsic system complexity may not always be reducible, evaluating subjective assembly complexity becomes essential to optimize user training, task allocation, and safety. Prior research indicates that operator performance often follows an inverted U-shaped curve, where excessive workload can impair accuracy and efficiency [14].

To address this challenge, this study introduces and validates a comprehensive Assembly Complexity Index (ACI) framework, combining the NASA Task Load Index (NASA-TLX) [15] and a customized Task Complexity Index (TCI) [16,17] into a unified evaluation model. This framework enables designers to quantify assembly complexity through both cognitive workload and task structure, supporting data-driven design iterations and effective user training strategies.

To validate the proposed ACI framework, an experimental study was conducted involving participants from both industry (PepsiCo) and academia (NTU Engineering). Participants performed supervised and unsupervised assembly tasks, providing workload and complexity ratings while also offering qualitative feedback to inform system improvements. Statistical analyses confirmed the framework’s reliability, sensitivity to learning effects, and ability to capture how prior experience influences perceived complexity and task performance.

Building upon this foundation, the present study further proposes a conceptual integration of Augmented Reality (AR) and Virtual Reality (VR) technologies as an extension of the ACI framework. Emerging AR/VR tools have demonstrated considerable potential to support complex assembly tasks through immersive, adaptive guidance, potentially reducing both workload and task ambiguity for novice and expert operators alike. A conceptual AR/VR-assisted assembly workflow is introduced, outlining its prospective role in minimizing assembly complexity, accelerating learning, and enhancing operator safety within modular robotic deployment environments.

2. Materials and Methods

To rigorously assess the ease of assembly and the impact of design decisions or modifications on assembly complexity, it was essential to establish a systematic and quantifiable evaluation workflow. The proposed methodology integrates two established subjective assessment tools—the NASA Task Load Index (NASA-TLX) and the Task Complexity Index (TCI)—which were adapted for the context of modular robotic assembly. These tools collectively form the basis for calculating the Assembly Complexity Index (ACI), offering a comprehensive metric that captures both cognitive workload and perceived task difficulty.

2.1. NASA Task Load Index

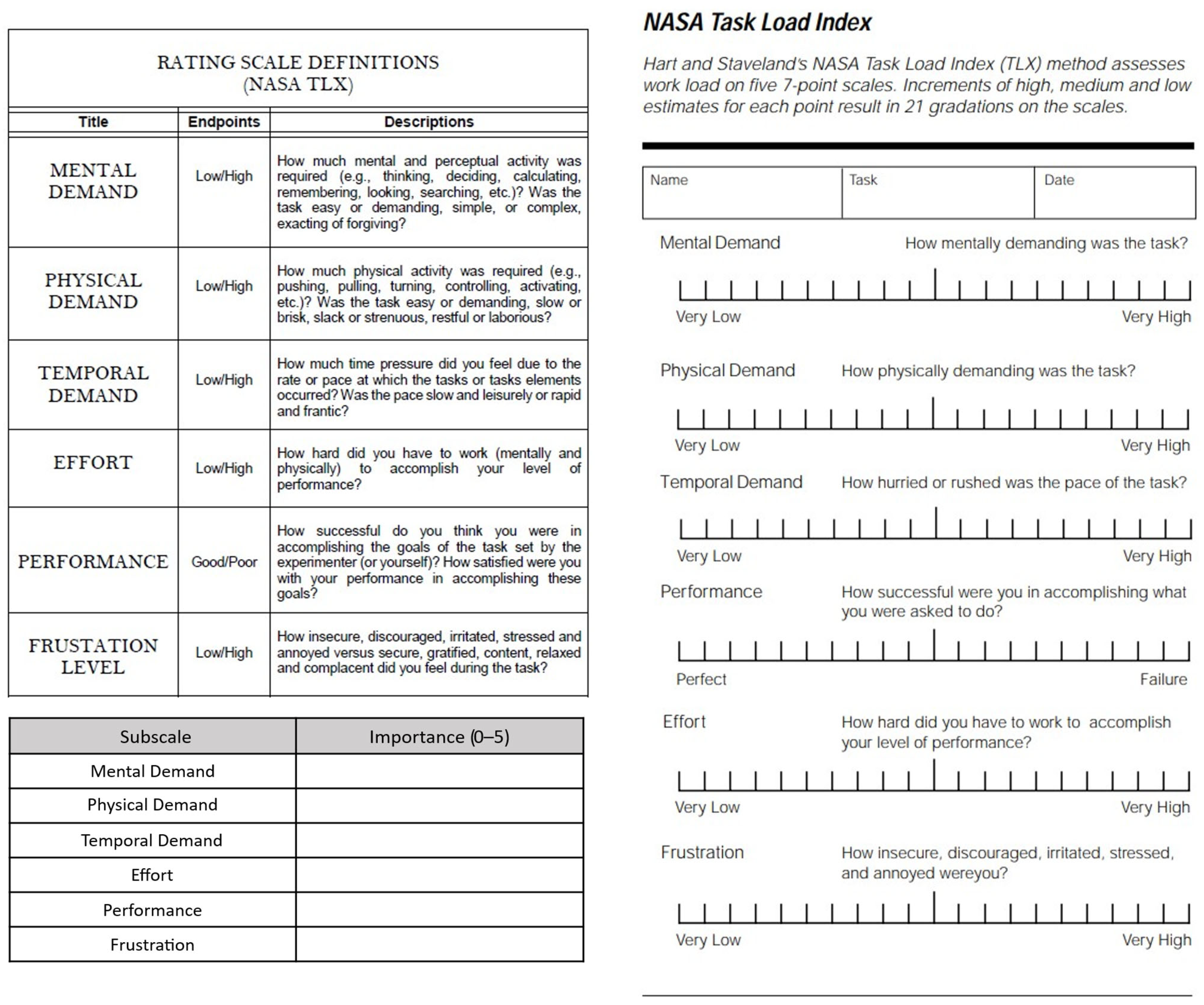

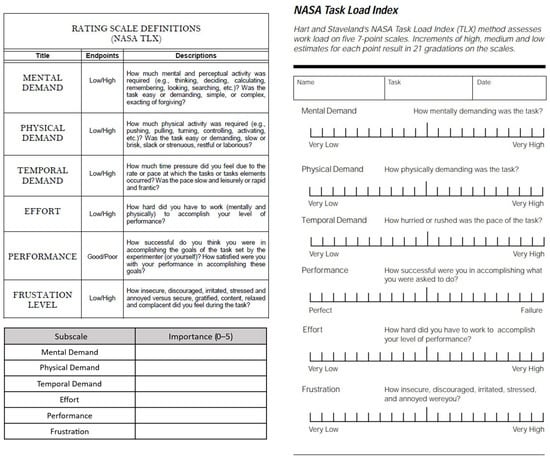

The NASA-TLX (as shown in Figure 1) is a widely recognized instrument for evaluating subjective workload [9] across six dimensions: Mental Demand, Physical Demand, Temporal Demand, Performance, Effort, and Frustration. Participants in this study rated each dimension on a 21-point scale, providing a granular view of the workload experienced during assembly tasks. The overall workload score for each participant (denoted as ) was calculated as a weighted average of the individual dimension scores:

where represents the rating for the -th subscale, is its assigned weight, m is the participant number and n is the number of subscales.

Figure 1.

NASA Task Load index (NASA-TLX) Questionnaire.

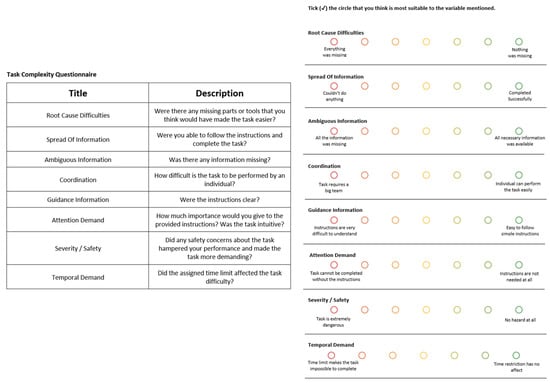

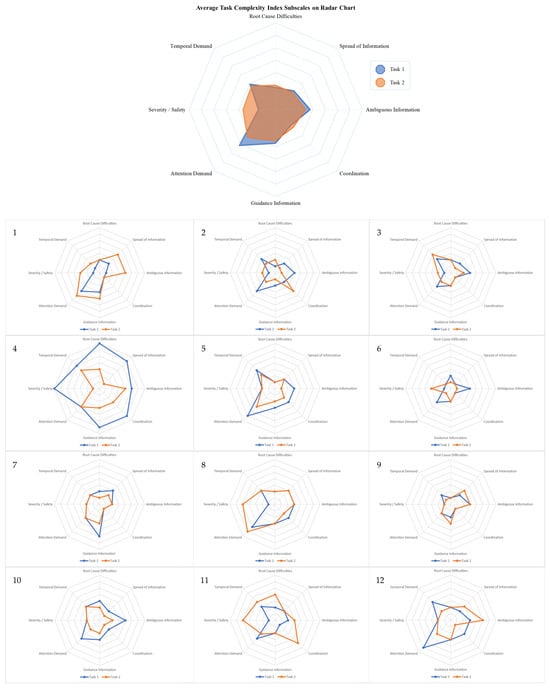

2.2. Task Complexity Index

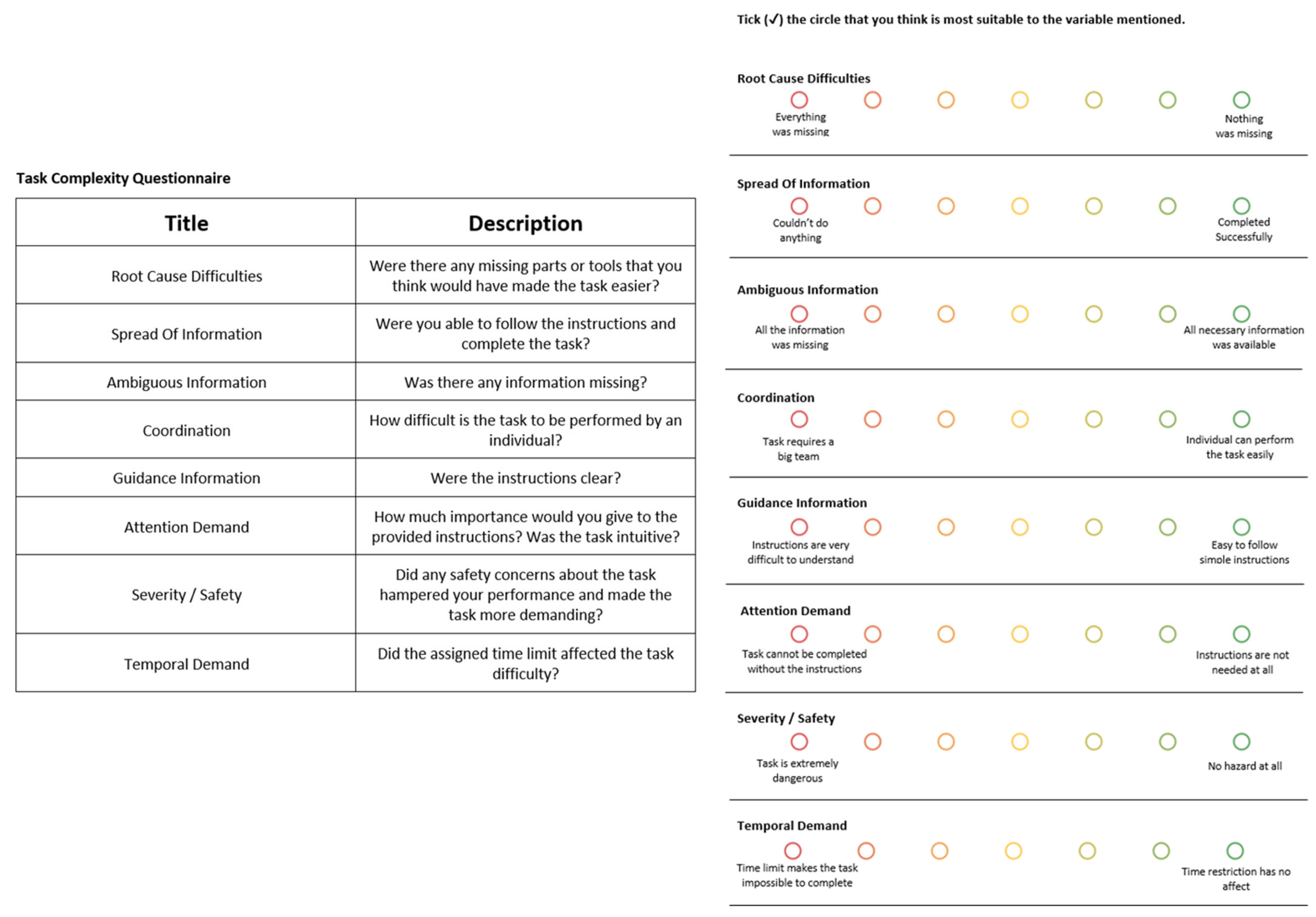

To assess task complexity, a bespoke questionnaire (as shown in Figure 2) was developed based on prior work [16,17]. This instrument evaluates eight key complexity factors: root cause difficulties, information spread, ambiguity, coordination needs, guidance clarity, attention demand, safety-criticality, and temporal demand. Each factor was rated using a 7-point Likert scale, and the overall TCI score (bn) was derived using the area ratio of an octagonal radar chart:

where represents the transformed score for each complexity factor (8-score for the nth indicator by the ith participant).

Figure 2.

Bespoke Task Complexity Index (TCI) Questionnaire.

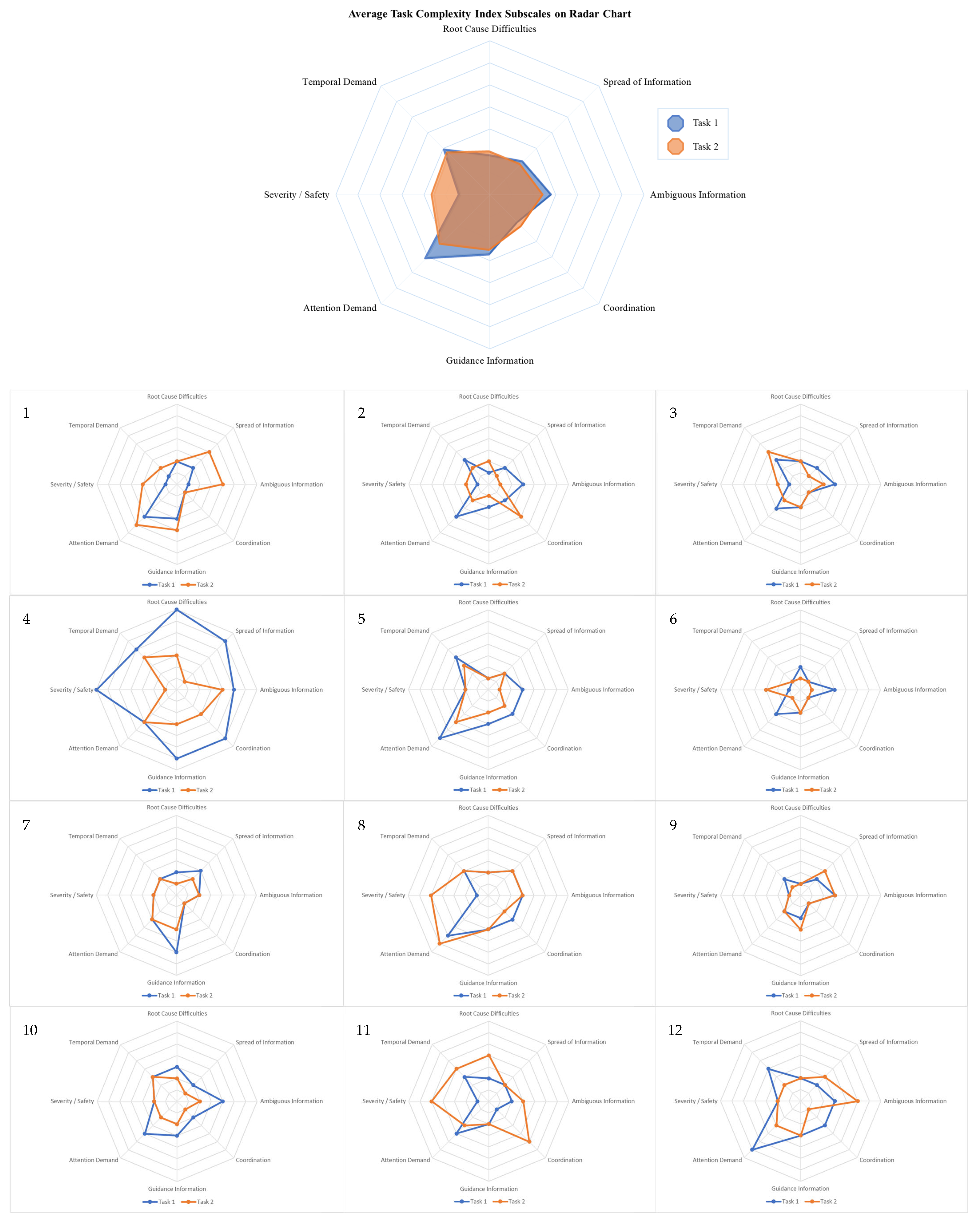

TCI involved the linearization of the area ratio plotted on an octagonal radar chart as shown in Figure 3.

Figure 3.

(Task Complexity Index) TCI Indicators on an Octagonal Radar Chart. Values are derived from participant Likert-scale ratings using Equation (2).

2.3. Data Normalization and Assembly Complexity Index

Both NASA-TLX and TCI values were normalized to a 5-point scale to ensure comparability:

where 18.67 and 7 represent the maximum achievable weighted scores for TLX and TCI, respectively.

The final Assembly Complexity Index (ACI, ) was computed as

where and are weights reflecting the relative importance of workload and complexity, normalized so . These weights were determined by averaging participant input on the perceived importance score (Figure 4) of each dimension.

Figure 4.

Normalized Weights for TLX and TCI.

2.4. Experimental Study

Twelve participants took part in two experimental sessions (Figure 5), each lasting approximately two hours, spaced two weeks apart. No prior information was provided about the specific assembly tasks. Participants were instructed to assemble the manipulator following a step-by-step manual in Task 1, with success defined as achieving functional joint control. In Task 2, no manual was provided, and participants relied on prior knowledge.

Figure 5.

Some participants performing tasks during the Experimental Study. (The study was conducted in accordance with the Declaration of Helsinki, and the protocol was approved by the Institutional Review Board of Nottingham Trent University’s School of Science and Technology (Project identification code: 1628348) on 28 February 2023. All participants provided informed consent prior to taking part.)

- Session 1 (Task 1): Participants were given up to 90 min to study an illustrated assembly manual (See Appendix A) and complete the assembly of a modular robotic joint, integrating 3D-printed structural parts, electronics, and standard tools. Success was defined by achieving functional joint control via a graphical interface.

- Session 2 (Task 2): Participants assembled a 2-DoF manipulator configuration without access to the assembly manual or time constraints, using the same parts and tools.

After each task, participants completed the NASA-TLX and TCI assessments. Completion times were recorded, and TLX, TCI, and ACI scores were computed for each individual, shown in Table 1

Table 1.

Summary of participant completion times and computed ACI components.

The study was conducted in accordance with the Declaration of Helsinki, and the protocol was approved by the Institutional Review Board of Nottingham Trent University’s School of Science and Technology (Project identification code: 1628348) on 28 February 2023. All participants provided informed consent prior to taking part.

3. Results

This section presents the outcomes of the experimental study, combining both statistical analysis and observational insights to evaluate the Assembly Complexity Index (ACI) and its components across two robotic assembly tasks.

3.1. Internal Consistency and Reliability

To assess the reliability of participant ratings, Cronbach’s alpha was computed for both the Task Complexity Index (TCI) and the NASA Task Load Index (TLX).

- TCI showed acceptable internal consistency with alpha values of 0.707 (Task 1) and 0.724 (Task 2), consistent with thresholds for moderate reliability [18].

- TLX demonstrated strong reliability with alpha values of 0.831 (Task 1) and 0.777 (Task 2), validating the use of this workload scale in assembly assessment.

3.2. Statistical Analysis

- Completion time: Mean completion time for Task 1 was 62 min (SD = 14), while Task 2 averaged 58 min (SD = 9), despite Task 2’s higher complexity. A paired t-test indicated that Task 2 was completed significantly faster (p = 0.026), suggesting a positive learning effect from the first task.

- TCI and TLX correlations: In Task 1, TLX showed a moderate positive correlation with completion time (r = 0.40), indicating that higher workload perception was associated with longer task duration. TCI correlation with time was weaker (r = 0.13). In Task 2, TCI and time showed a mild negative correlation (r = –0.22), suggesting that participants perceiving higher complexity did not necessarily take longer, possibly due to prior exposure to assembly steps.

- ACI progression: The ACI increased in Task 2 (p = 0.046), driven primarily by elevated workload ratings, even though task completion time decreased. This reflects the cognitive demands of assembling without instructions, despite procedural familiarity.

- Internal consistency: Cronbach’s alpha for TCI was acceptable at 0.71 (Task 1) and 0.72 (Task 2); for TLX, alpha was 0.83 (Task 1) and 0.78 (Task 2), confirming reliable participant responses.

3.3. Observational Findings

Qualitative observations revealed that while participants generally found the physical manipulation of parts intuitive, challenges arose in identifying the correct assembly sequence and the type of fasteners required—especially in Task 2 where no manual was provided. Participants expressed a strong preference for visual aids and more guided feedback, reinforcing the potential of integrating immersive technologies such as AR and VR for real-time, context-sensitive instruction.

Some participants noted that although Task 2 was technically more complex, they completed it faster because of familiarity with subassemblies, indicating that procedural memory can compensate for missing external guidance. These findings highlight the need for adaptable support systems that respond dynamically to user expertise and evolving task conditions.

4. Discussion and Conclusions

This study presented and validated a human-centered Assembly Complexity Index (ACI) framework for evaluating modular robotic system assembly tasks. The integration of NASA-TLX and Task Complexity Index (TCI) provided a comprehensive means to quantify both cognitive workload and perceived task complexity, supporting data-driven design decisions and operator training strategies.

4.1. Learning and ACI Dynamics

The results revealed clear evidence of learning effects: participants completed the more complex Task 2 faster than Task 1, despite reporting higher workload. This suggests that early exposure to assembly steps contributes to procedural knowledge, which helps offset cognitive demands in subsequent tasks. However, the elevated ACI in Task 2 illustrates that perceived workload remains an important factor, even when task familiarity increases. This underscores the value of supporting operators not only through design simplification but also through enhanced training and guidance mechanisms.

4.2. Conceptual Framework for Future AR/VR Integration

To further reduce assembly complexity, particularly for novice operators, this study proposes an Augmented Reality (AR) and Virtual Reality (VR) extension to the ACI framework. These technologies can provide immersive, adaptive guidance, enhancing assembly accuracy, reducing workload, and accelerating skill acquisition [19,20].

4.2.1. AR/VR Workflow for Assembly Assistance

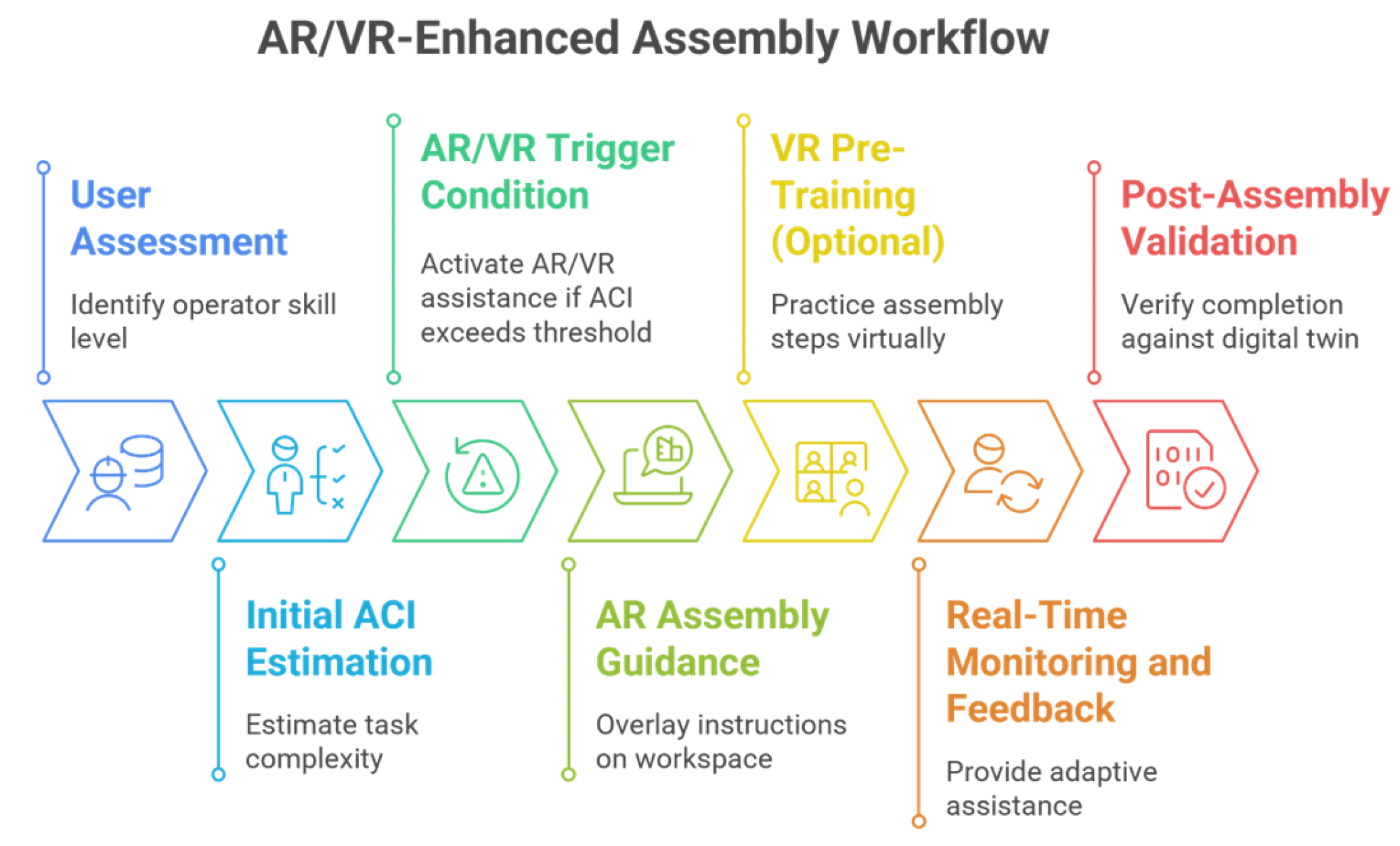

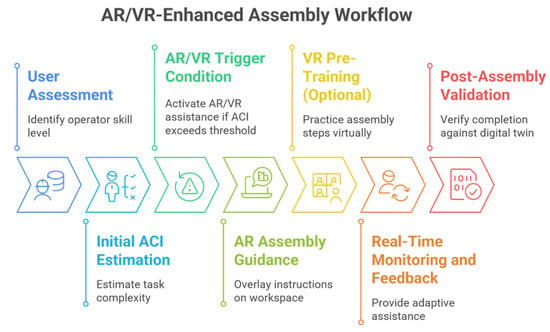

The envisioned workflow incorporates AR/VR at key decision and execution points:

- User Assessment—Identify the operator’s skill level through self-reporting or automated detection (e.g., prior experience, task history).

- Initial ACI Estimation—Estimate task complexity based on system configuration and user profile.

- AR/VR Trigger Condition—If estimated ACI exceeds a defined threshold, activate AR or VR assistance. The trigger condition illustrated here (activation of AR/VR assistance when ACI exceeds a threshold) is currently conceptual. Determining quantitative thresholds will require future experimental validation.

- AR Assembly Guidance—AR headsets (e.g., HoloLens, Magic Leap) overlay part placement, alignment cues, fastener types, and sequence instructions directly onto the physical workspace [21,22].

- Optional VR Pre-Training—VR environments simulate the assembly task, allowing users to practice steps virtually before attempting physical assembly [23].

- Real-Time Monitoring and Feedback—Dynamic ACI estimation adjusts as the user progresses, providing adaptive assistance (e.g., highlighting missed steps, correcting errors) [24].

- Post-Assembly Validation—Completion of assembly is verified against digital twin models; performance data are stored for training refinement [25].

4.2.2. Visual Concept of AR/VR Workflow

The proposed AR/VR-enhanced assembly process as illustrated in Section 4.2.1 and Figure 6, which presents a flowchart detailing the decision points and stages of the assisted assembly workflow. The diagram highlights how operator assessment and initial ACI estimation determine whether immersive assistance is activated. The workflow integrates AR overlays for real-time assembly guidance and VR environments for pre-task simulation, both feeding into dynamic ACI monitoring and post-task validation.

Figure 6.

Conceptual flowchart of the AR/VR-assisted assembly workflow showing user assessment, ACI estimation, AR/VR activation, interactive guidance, and feedback loop.

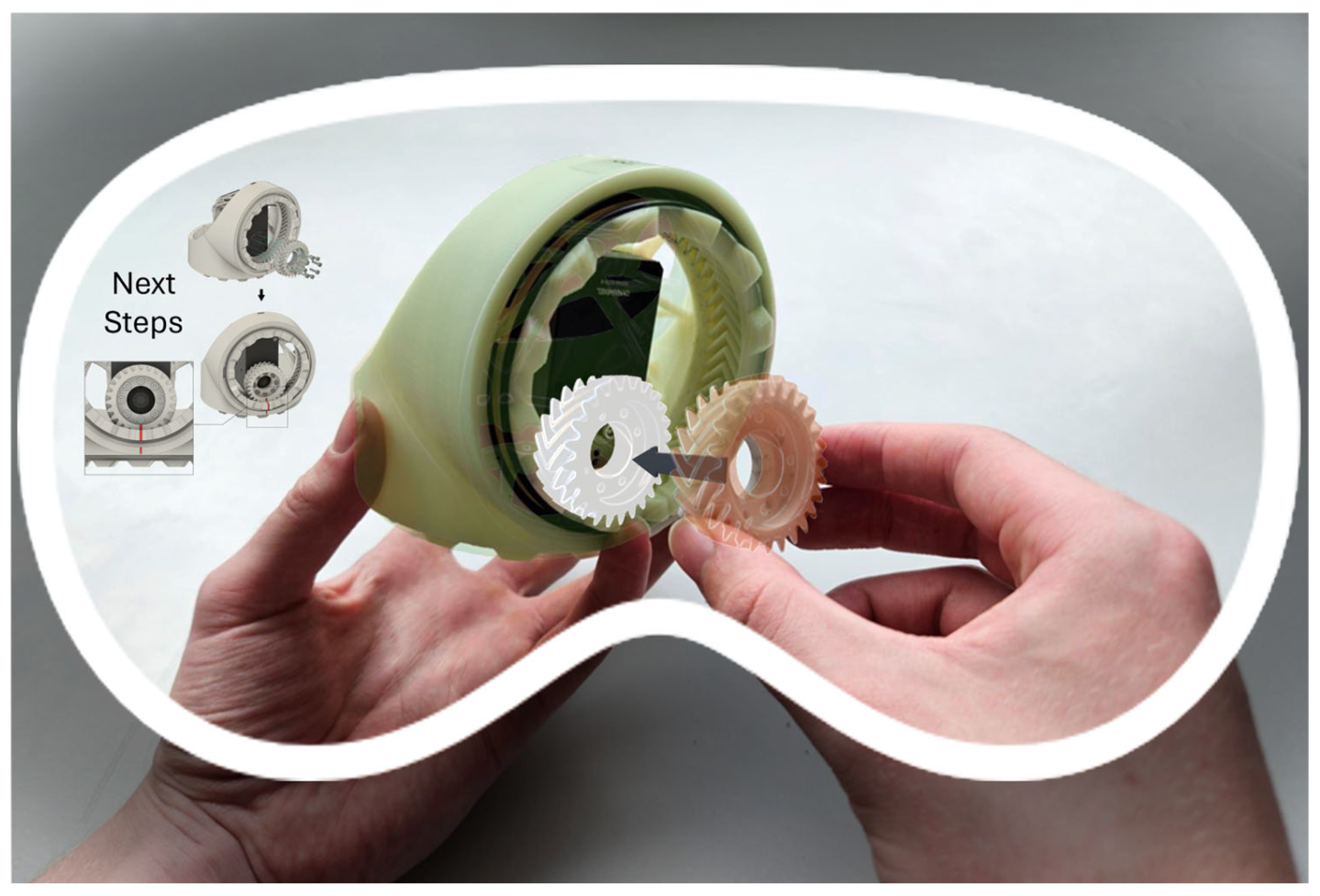

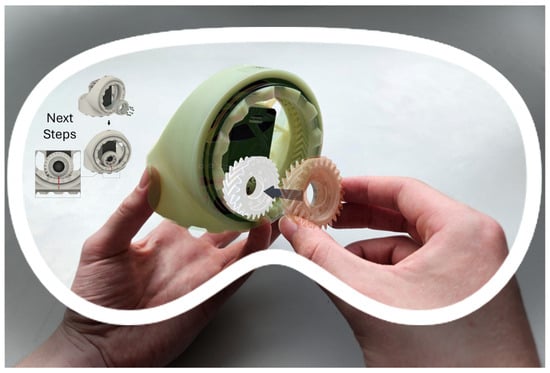

To provide a clearer vision of how AR would assist the operator during assembly, Figure 7 depicts a hypothetical view through an AR headset. The visual overlay includes part alignment indicators (e.g., highlighted in green when correctly positioned), overlay in orange if part not in correct place, white for the final position for successful assembly, and arrows showing the sequence of operations. This contextual, real-time guidance aims to reduce ambiguity, consolidate instruction delivery, and minimize attention demand by bringing critical information directly into the user’s field of view [20].

Figure 7.

Example AR headset view mock-up illustrating real-time visual overlays for part alignment and task sequence cues during assembly of a modular joint.

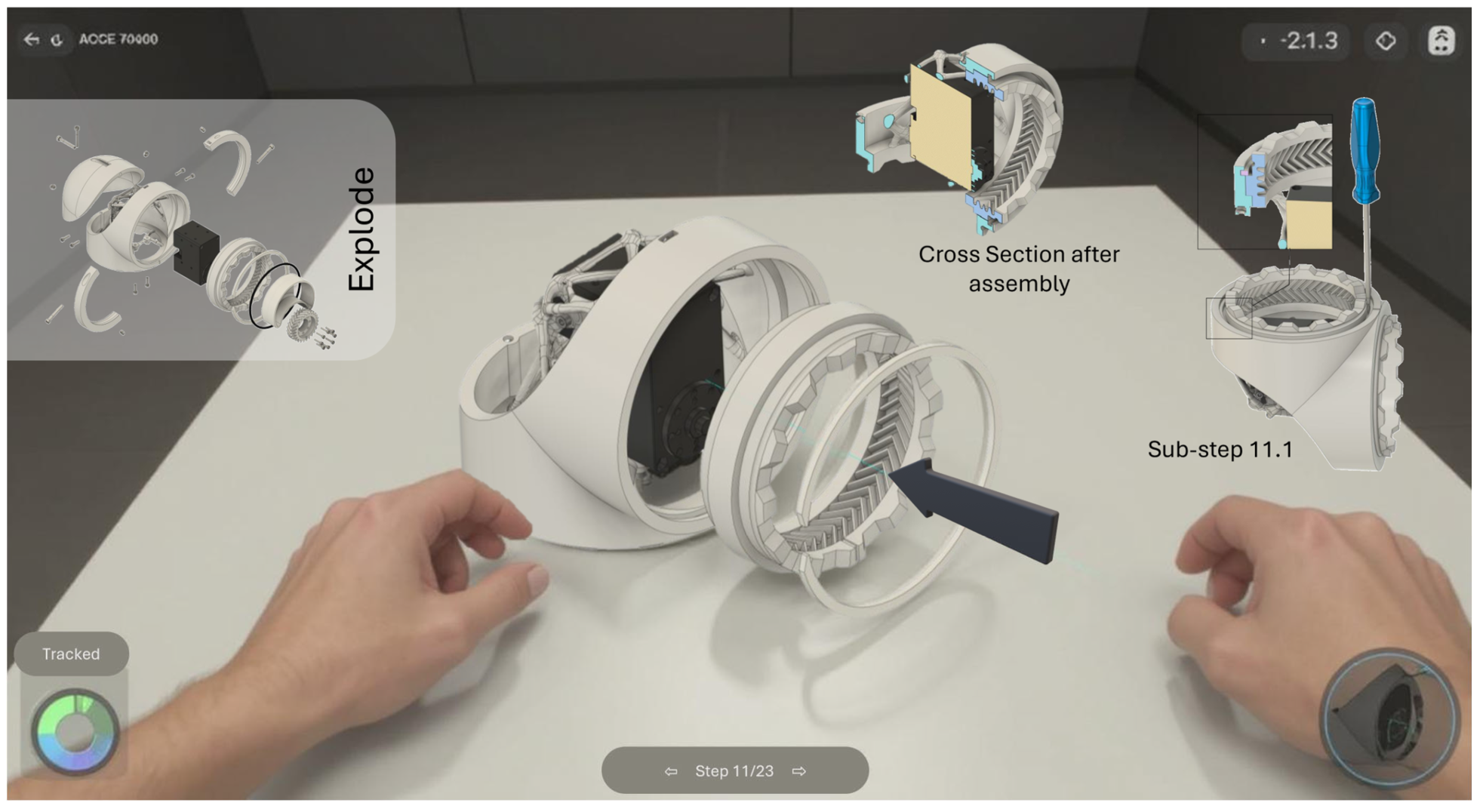

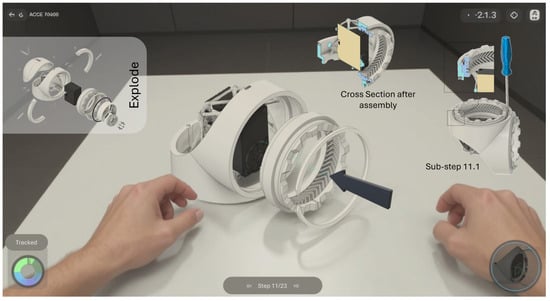

Additionally, Figure 8 shows a conceptual snapshot of a VR training environment designed to familiarize users with the assembly task before engaging with physical components. The virtual environment provides exploded views of the modular robotic joint, allowing users to interactively practice assembly steps, identify components, and understand the sequence of operations without material costs or assembly risks [23,26].

Figure 8.

Example VR training interface screenshot depicting assembly steps of the modular joint (Patent Published: WO2025040883) with interactive part selection and step-by-step assembly simulation.

Together, these figures illustrate how AR and VR can be seamlessly integrated into the ACI methodology, providing immersive, adaptive support to minimize complexity and improve assembly outcomes.

This conceptual framework provides a foundation for integrating AR/VR into the ACI methodology. Future experimental validation will quantify the actual reductions in workload and complexity achievable through these technologies, helping to refine both hardware requirements and software interfaces for modular robot assembly in industrial settings [24,25].

The conceptual AR/VR integration proposed aims to address these residual cognitive challenges. Building on the foundational Assembly Complexity Index framework developed in previous work [27], the current expansion proposes immersive real-time visual overlays, interactive prompts, and pre-task simulations. These AR/VR technologies have the potential to reduce ambiguity, consolidate information delivery, and lower attention demand—key contributors to elevated ACI scores. Although the current work did not experimentally validate AR/VR assistance, the workflow outlined provides a foundation for future studies. These studies will aim to quantify the impact of immersive guidance on ACI components, assembly time, error rates, and user satisfaction.

It should be noted that AR/VR integration was not tested in this study. The AR/VR workflow is proposed as a conceptual extension, to be empirically validated in future experiments by comparing assembly tasks performed with and without immersive assistance.

4.3. Implications for Modular Robotics Deployment

The ACI framework, particularly when extended with AR/VR support, offers a versatile tool for managing human factors in the deployment of modular robotic systems. Applications include operator onboarding, maintenance and repair training, and the safe reconfiguration of manipulators on dynamic shop floors. The framework’s adaptability to different levels of system complexity and operator expertise makes it well suited for Industry 4.0 manufacturing environments.

4.4. Limitations and Future Work

This study provides strong initial validation of the ACI framework, but it also has limitations that shape the next steps. The sample size was relatively small and limited in demographic diversity, which constrains generalizability. Future work will therefore expand to larger and more varied participant groups. The assembly tasks examined here focused on a single joint and a simple 2-DoF manipulator, which served well for early validation but did not fully capture the complexity of real-world modular robotic systems. To address this, future studies will include more complex assemblies and fault-injection scenarios to evaluate scalability and robustness. In addition, the observation that Task 2 resulted in faster completion times, but higher ACI scores reflects the cognitive load introduced when participants worked without a manual. While accuracy was maintained, future work will incorporate error tracking to provide deeper insights into performance trade-offs. Finally, the AR/VR workflow presented remains conceptual and will require empirical validation. Future studies will evaluate immersive assistance in real settings, directly comparing assembly performance with and without AR/VR support, while also addressing practical implementation challenges such as hardware requirements, system latency, and user training.

5. Patents

The modular joint designs illustrated in the AR/VR conceptual mockup figures are the original intellectual property of the corresponding author and are protected under the following published patent:

- WO2025040883: Modular Robotic Joint Assembly and Method of Use.

This patent covers the generatively designed housing, integration of internal herringbone gear systems, and modular connection architecture depicted in the assembly sequences and visual overlays used in this study.

Author Contributions

Conceptualization, K.W.; methodology, K.W.; writing—original draft preparation, K.W.; writing—review and editing, K.W. and P.B.; supervision, P.B.; funding acquisition, K.W. and P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Connected Everything Network through the Early Career Researcher Placement Scheme (EP/S036113/1) (https://connectedeverything.ac.uk/early-career-researcher-placement-scheme-2/ (accessed on 17 August 2024)) to support the initial Play Days; by the UK-RAS Network (EP/Y010523/1) (AdHoc 2024) to support participation in the AHFE Hawaii Conference and the first engagement visit to UCLA; and by the Nottingham Trent University International Partnerships Fund (Internal Funding) (IPF 2024–25) to support the ongoing collaboration with UCLA on the further development of the modular robotic housings.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and the protocol was approved by the Institutional Review Board of Nottingham Trent University’s School of Science and Technology (Project identification code: 1628348) on 28 February 2023.

Informed Consent Statement

All participants provided informed consent prior to taking part.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The author acknowledges the support of the PepsiCo R&D team and the volunteers from Nottingham Trent University’s School of Science and Technology for their participation in the experimental study. The author also gratefully acknowledges Philip Breedon for his supervision during the author’s PhD, during which the foundational research was conducted. Appreciation is extended to Nottingham Trent University for supporting this work through the International Partnerships Fund (IPF), and to Jonathan Hopkins (UCLA) for his kind support and ongoing collaboration in the continued development of modular robotic systems and compliant actuator housings.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ACI | Assembly Complexity Index |

| AM | Additive Manufacturing |

| AR | Augmented Reality |

| CAD | Computer-Aided Design |

| DoF | Degrees of Freedom |

| GD | Generative Design |

| GUI | Graphical User Interface |

| NASA-TLX | NASA Task Load Index |

| OEM | Original Equipment Manufacturer |

| TCI | Task Complexity Index |

| TLX | Task Load Index |

| VR | Virtual Reality |

Appendix A

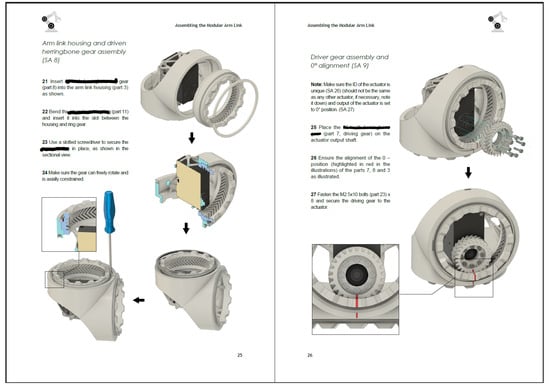

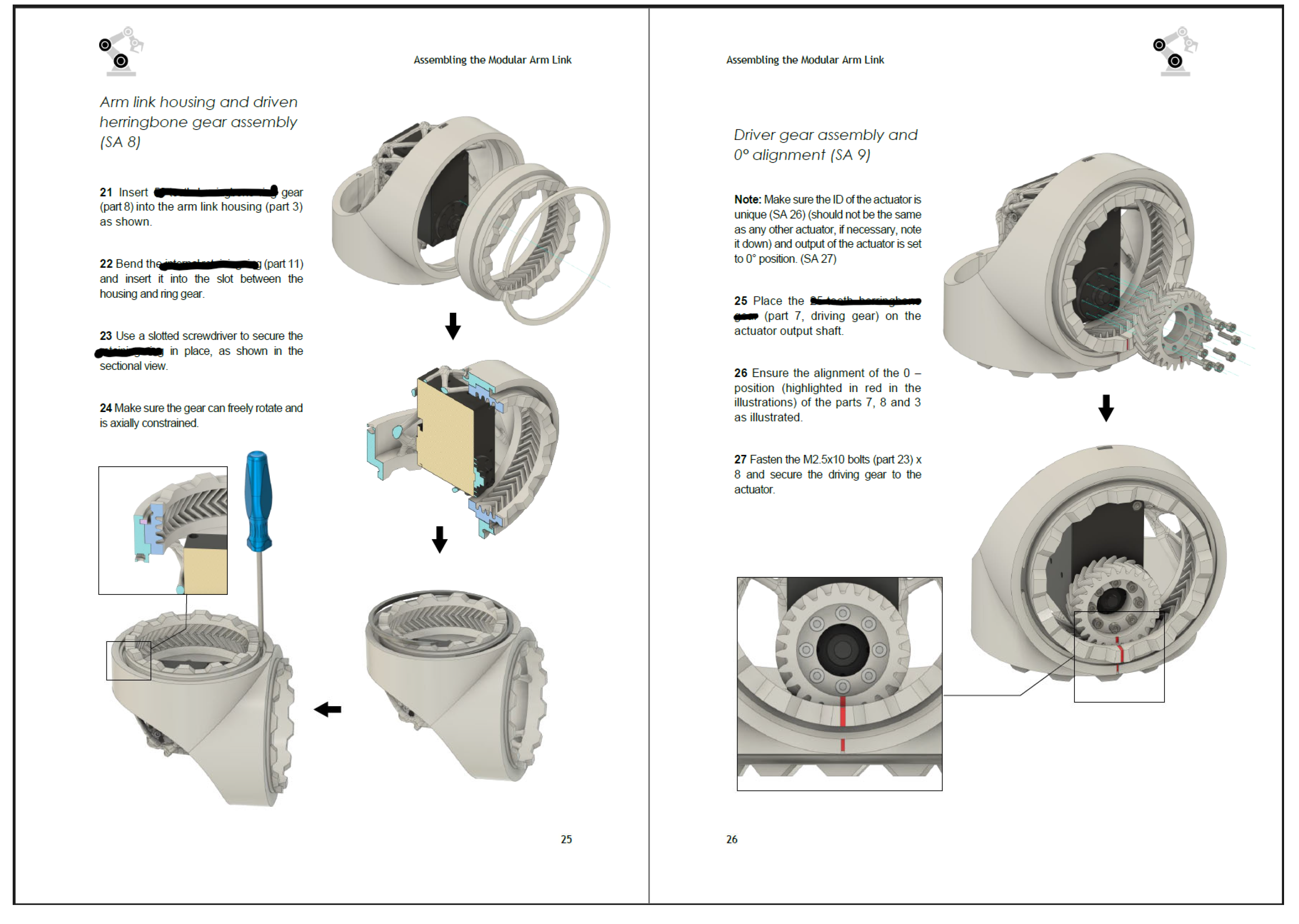

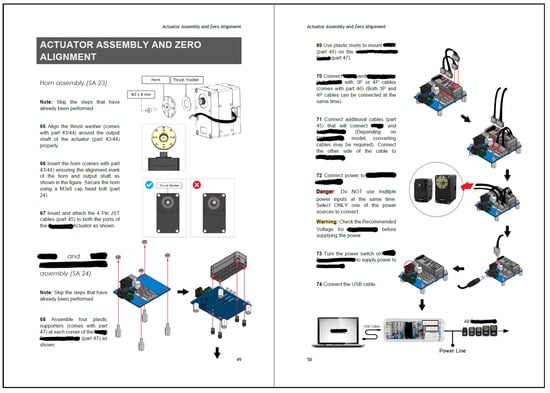

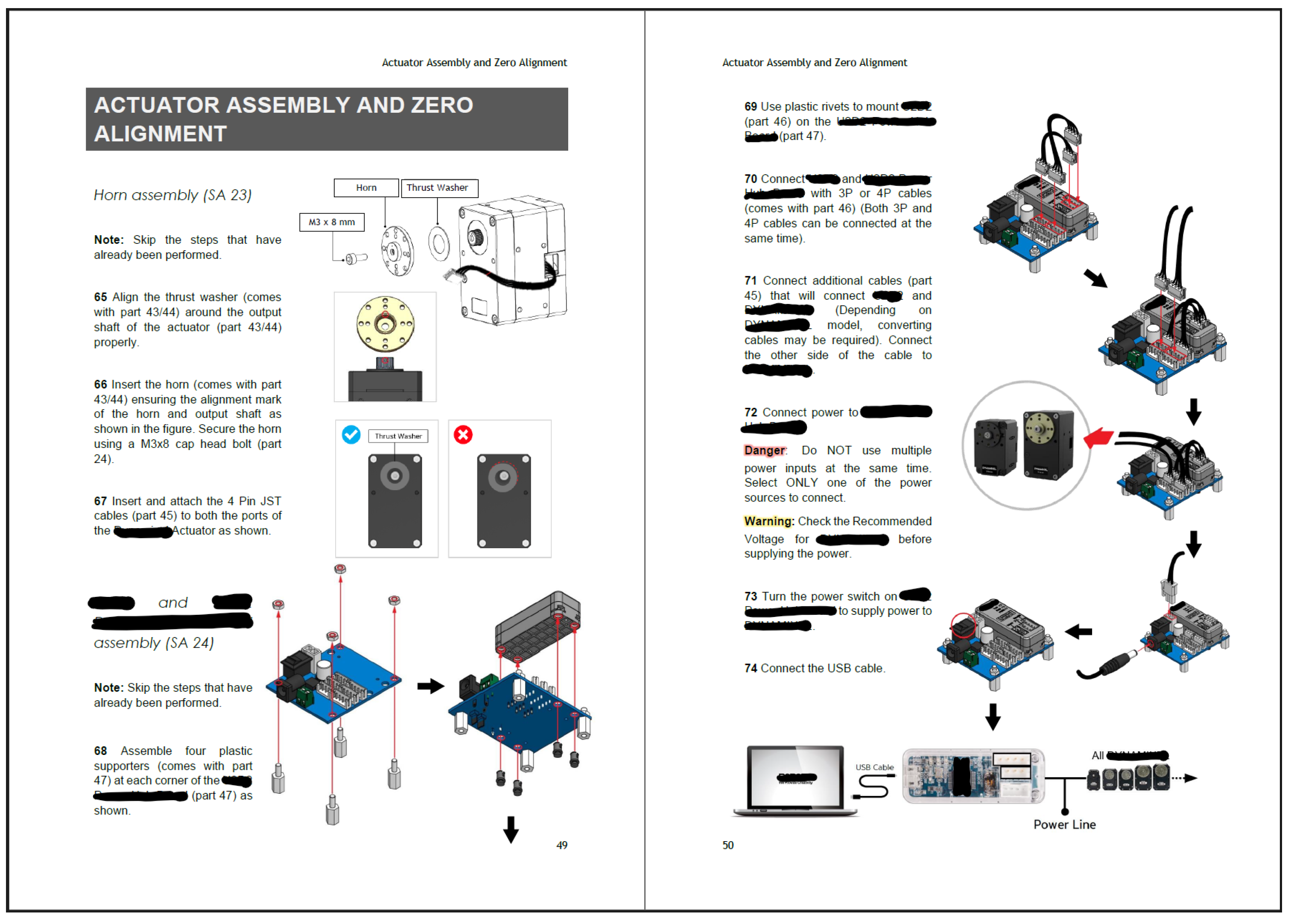

This section presents selected sample pages (Figure A1 and Figure A2) from the illustrated assembly manual that participants used during Task 1 of the experimental study. The manual provided step-by-step instructions, annotated diagrams, and visual cues to support participants in completing the modular joint assembly within the allotted time.

Figure A1.

Assembly Manual Sample Page-1 © 2025, Authors’ own work.

Figure A1.

Assembly Manual Sample Page-1 © 2025, Authors’ own work.

Figure A2.

Assembly Manual Sample Page-2 © 2025, Authors’ own work.

Figure A2.

Assembly Manual Sample Page-2 © 2025, Authors’ own work.

Please note that certain details have been intentionally redacted to protect intellectual property and due to licensing and pending patent considerations. The images are provided solely for illustration of the type and style of guidance available to participants, rather than as a comprehensive reproduction of the manual.

References

- Müller, C. World Robotics 2023—Industrial Robots; IFR Statistical Department, VDMA Services GmbH: Frankfurt am Main, Germany, 2023. [Google Scholar]

- Markl, E.; Bauer, J.M.; Riepl, D.; Steiner, T. Logic control of an industrial automation cell with ros as part of smes and industry 4.0 interconnection. In Digital Conversion on the Way to Industry 4.0: Selected Papers from ISPR2020; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 210–221. [Google Scholar]

- Bard, J.F. An assessment of industrial robots: Capabilities, economics, and impacts. J. Oper. Manag. 1986, 6, 99–124. [Google Scholar] [CrossRef]

- Chen, I.M.; Yim, M. Modular Robots. Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer Handbooks; Springer: Cham, Germany, 2016. [Google Scholar] [CrossRef]

- Harrison, R.; Weston, R.H.; Moore, P.R.; Thatcher, T.W. Industrial application of pneumatic servo-controlled modular robots. In Advances in Manufacturing Technology: Proceedings of the First National Conference on Production Research; Springer US: New York, NY, USA, 1986; pp. 229–236. [Google Scholar]

- Wurst, K.H. The conception and construction of a modular robot system. Proc. 16th ISIR 1986, 37. [Google Scholar]

- Schmitz, D.; Khosla, P.K.; Kanade, T. The CMU Reconfigurable Modular Manipulator System; Carnegie Mellon University, The Robotics Institute: Pittsburgh, PA, USA, 1988; pp. 473–488. [Google Scholar]

- Fukuda, T.; Nakagawa, S. Approach to the dynamically reconfigurable robotic system. J. Intell. Robot. Syst. 1988, 1, 55–72. [Google Scholar] [CrossRef]

- Tesar, D.; Butler, M.S. Modularity in robotic systems. In Proceedings of the NASA Conference on Space Telerobotics, Pasadena, CA, USA, 31 January–2 February 1989; Volume 1. [Google Scholar]

- Benhabib, B.; Dai, M.Q. Mechanical design of a modular robot for industrial applications. J. Manuf. Syst. 1991, 10, 297–306. [Google Scholar] [CrossRef]

- Matsumaru, T. Design and control of the modular robot system: TOMMS. In Proceedings of 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; Volume 2, pp. 2125–2131. [Google Scholar]

- Walia, K.; Khan, A.; Breedon, P. The generative design process for robotic design applications. J. Addit. Manuf. Technol. 2021, 1, 528. [Google Scholar]

- Walia, K.; Khan, A.; Breedon, P. Polymer-based additive manufacturing: Process optimisation for low-cost industrial robotics manufacture. Polymers 2021, 13, 2809. [Google Scholar] [CrossRef]

- Lysaght, N.R.J.; Hill, S.G.; Dick, A.O.; Plamondon, B.D.; Linton, P.M.; Wierwille, W.W.; Bittner, A.C., Jr. Operator Workload: Comprehensive-Review and Evaluation of Operator co Norkloaed Methodologies. 1989. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA212879.pdf (accessed on 19 September 2025).

- Hart, S.G.; Staveland, L.E. Development of NASA-TLX (Task Load Index): Results of empirical and theoretical research. Adv. Psychol. 1988, 52, 139–183. [Google Scholar]

- Braarud, P.Ø. Complexity Factors and Prediction of Crew Performance (HWR-521); OECD Halden Reactor Project: Halden, Norway, 1998. [Google Scholar]

- Collier, S. Development of a Diagnostic Complexity Questionnaire. 1998. Available online: https://www.osti.gov/etdeweb/biblio/20442103 (accessed on 19 September 2025).

- Murphy, K.R.; Davidshofer, C.O. Psychological testing. In Principles, and Applications; Prentice Hall: Upper Saddle River, NJ, USA, 1988; Volume 18. [Google Scholar]

- Wang, X.; Ong, S.K.; Nee, A.Y. A comprehensive survey of augmented reality assembly research. Adv. Manuf. 2016, 4, 1–22. [Google Scholar] [CrossRef]

- Henderson, S.J.; Feiner, S. Evaluating the benefits of augmented reality for task localization in maintenance of an armored personnel carrier turret. In Proceedings of the 2009 8th IEEE International Symposium on Mixed and Augmented Reality, Orlando, FL, USA, 19–22 October 2009; pp. 135–144. [Google Scholar]

- Magic Leap, Inc. Magic Leap 2: Developer Guide. 2023. Available online: https://developer.magicleap.com (accessed on 19 September 2025).

- Microsoft Corporation. HoloLens 2 Technical Specifications. 2020. Available online: https://www.microsoft.com/en-us/hololens/hardware (accessed on 19 September 2025).

- Bock & Linner. Robot-Oriented Design: Design and Management Tools for the Deployment of Automation and Robotics in Construction; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Nee, A.Y.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Ann. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Walia, K. Modular Robotic Joint Assembly and Training System; Patent No. WO2025040883, World Intellectual Property Organization: Geneva, Switzerland, 2025. [Google Scholar]

- Walia, K.; Breedon, P. Assembly Complexity Index (ACI): A Framework to Evaluate Assembly Process for Validating a Modular Robotic Design. In Proceedings of the AHFE International Conference on Human Factors in Design, Engineering and Computing (AHFE 2024 Hawaii Edition), Honolulu, Hawaii, USA, 8–10 December 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).