Abstract

This study investigates the impact of various auxiliary cooling techniques on machinability, energy consumption, carbon emissions, and economic factors in the drilling process of AA7075T6 aluminium alloy using TiO2 and C-reinforced composites. The study employed various cooling conditions (dry, MQL, CO2, and hybrid MQL+CO2), with different cutting speeds and feed rates, to evaluate their effects on drilling characteristics. The findings indicated that the combined MQL and CO2 cooling notably enhanced the drilling process by reducing cutting forces by 32% and surface roughness by 65% compared to dry cutting. This synergy between lubrication and cooling significantly improves machinability, resulting in higher-quality machining outputs with smoother surfaces and more precise circularity. Energy analysis revealed that the MQL+CO2 method reduces energy consumption to 64% observed under dry conditions, underscoring its efficiency through better heat dissipation and reduced friction. Furthermore, this method demonstrates a significant reduction in carbon emissions, contributing to environmental sustainability. Economically, although initial costs associated with the implementation of cooling systems are higher, they are offset by reduced tool wear and energy costs, making it a viable solution for sustainable manufacturing practices.

1. Introduction

Global climate change poses a significant threat to people across the globe. Despite its considerable contribution to global warming [1], India is expected to reduce its carbon emissions. Various measures have been implemented to reduce emissions during the operational phase of manufacturing [2]. The manufacturing industry is one of the most critical sectors that requires a requirement in energy consumption. Many countries, including China (0.723 CNY/kWh) and India (8.5 CNY/kWh), are concerned about the increasing electricity prices [3]. Drilling holes is one of the most crucial operations in the manufacturing components. It is critical to ensure that a drilled hole has precise diameter and depth in industries such as aerospace, automotive, and precision instruments. Especially drilling hard material can be costly for certain hard-to-cut materials, such as Inconel, titanium alloy, aluminium metal matrix composite, etc. [4]. In today’s advanced age of cutting-edge technologies, there is a growing fascination with metal matrix composites (MMCs) that incorporate particulate reinforcements. These innovative materials, known as hybrid MMCs, have garnered significant attention and show great promise. Al7075-T6 is commonly used as an aluminium matrix material. As a result of its exceptional machinability, formability, and castability, it is a popular choice for a wide range of applications [5]. The Al7075 base material was fabricated into MMCs utilising various oxides and ceramic reinforcements, including TiO2, C, B4C, Al2O3, TiB2, and SiC. It was found that fabricated MMCs exhibited improved hardness, impact resistance, and tensile strength [6]. A stir-cast Al7075/C/TiO2 MMC has been reported by Danappa et al. [7]. The study examined how varying weight percentages (wt%) of TiO2 particles affect the wear rate. It was found that incorporating 3–5 wt% TiO2 particles into the MMC significantly reduced the wear rate. Arunkumar et al. [8] performed work using stir-cast Al7075/TiC/Al2O3/C MMCs. Additionally, the study indicated that differences in the wt% of TiC content of manufactured MMCs were associated with significant differences in the wear rate. Nowadays, the conventional manufacturing sector is stepping into a sustainable manufacturing process due to several factors such as laws enforced by the government, environmental management systems, effective use of resources, increased productivity, labour management, waste recycling, low-cost products, and high customer satisfaction.

While dry machining is generally performed without a cutting fluid, excessive tool wear and high temperatures may occur. Making simple components is ideal for this process [8]. While flood cooling is a widely adopted practice in the metal industry, it is considered as not environmentally sustainable. The production of various machines consumes around twelve million kilograms of these coolants, contributing adversely to the environment. Coolant has to be processed and treated before it can be disposed. This method almost doubles the cost of production and the cost, covering around 7% to 17% of the total cost [9]. Even though the price of coolants is high, these substances can still generate toxic fumes, which can cause respiratory issues and even cause cancer for the operators [10]. These are issues of coolant disposal which can be readily tackled by popular methods like minimum quantity lubrication (MQL), liquid nitrogen (LN2), and carbon dioxide (CO2) [11]. It is widely known that integrating MQL and cryogenic-LN2 can improve a workpiece’s surface integrity and tool life [12]. Rahim and Sasshara [13] have explored the effect of palm oil in the MQL system for drilling titanium alloys. The study shows that palm oil replaces synthetic ester lubrication for the MQL system in high-speed drilling. Govindaraju et al. [14] have also pursued work in which LN2 was used as a cooling lubricant to drill AISI 1045 steel. It has been found that cutting temperature and tool wear are lower in dry machining compared to wet machining. Rosnan et al. [15] performed the drilling of nickel-titanium alloy under MQL + nanofluids. The cutting speed vc (10–30 m/min), feed rate of (f—0.02 mm/rev), and TiAlN coated and uncoated carbide twist drill Ø 6 mm were used for the study. The findings showed that the MQL + nano lubricants were ideal for controlling the wear rate of the tool at a range of 10–20 mm/min. This suggestion is backed up by evidence, through which Kishawy et al. [16] concluded that the MQL-nanofluid cutting test results were better than those obtained from the conventional MQL tests.

New developments in cryogenic + MQL machining have led to new strategies that are more sustainable alternatives to conventional machining processes. However, this process setup and the development costs are still higher than conventional methods. Pusavec et al. [17] conducted turning experiments on Inconel 718 alloy under dry, MQL, LN2, and LN2+MQL machining. The results showed that LN2+MQL machining significantly lowers the overall power consumption, reduces the cutting force, enhances the tool life, and increases productivity. Combining cryogenic and MQL techniques balances technical, economic, and environmental aspects, increasing the tool life by 50% and the cutting speed by 30%, contrasting with dry machining. Pereira et al. [18] conducted the cryogenic hard turning of ASP23 steel using carbon dioxide, which significantly increased tool life, reduced cutting temperature, and improved surface finish. The authors found that the machine tools energy consumption was reduced by 88% when operated at a 200 mm/min speed using cryogenic coolant [19]. Zhao et al. [20] conducted a study that examined the impact of using LN2 during the milling process of a Ti-6Al-4V alloy. vc varies from 60 to 120 m/min, with an aside constant f of 1 mm/tooth and depth of cut of 1 mm. The reduction in the residual stress under the LN2 conditions is slower than under dry milling. Additionally, their findings indicated that cryogenic milling has the potential to enhance the surface quality of Ti-6Al-4V alloy.

Jayaganth et al. [21] conducted drill tests on 410 SS with three vc values ranging from 11 to 21 m/min. Different cutting fluids, namely coconut oil, cassava oil, and kerosene, were utilised for the experiments. The results indicated that the coconut oil medium performed well in machinability even at higher vc and f. Prakash et al. [22] optimised the three levels of spindle speed, f, and wt% input machining parameters in drilling LM6 hybrid metal matrix composites (HMMCs) under HSS, carbide, and coated carbide tools. The optimal process for achieving surface roughness is obtained using a TiN-coated drill bit at an f of 50 mm/min, 3000 rpm, and 6 wt% reinforcements. Daniel et al. [23] conducted drilling experiments on Al5059/SiC (5%, 10%, and 15%)/2% of MoS2 HMMCs in another study. According to the results of the analysis of variance (ANOVA), the artificial neural network (ANN) model is the most efficient for predicting the process parameters. The mass fraction of SiC and the feed rate are the most important factors influencing the response variable. Gowtham and Senthilkumar [24] experimentally investigated the AA5052 with an aluminium metal matrix composite (AMMC) and hybrid aluminium metal matrix composite (HAMMC). The study revealed that the surface roughness of the HAMMC was lower than that of the AMMC. This is because of the presence of the MoS2 solid lubricant. This helps in reducing frictional heat and improving the surface finish.

Khanna et al. [25] compared Ti-6Al-4V machining using flood coolant, MQL, and liquid carbon dioxide (LCO2) as a cryogenic coolant. MQL machining had a lower environmental impact but showed a 75% reduction in tool life, higher cutting force, and increased surface roughness compared to flood and cryogenic machining. Pereira et al. [26] conducted drilling experiments on a CFRP-Ti6Al4V alloy in both dry and CO2 environments. Although power consumption was greater due to increased torque, a swift reduction in cutting temperature during the CO2 trial was noted. Hard turning of ASP23 steel was also carried out under dry and CO2 conditions, revealing a notable enhancement in tool life with the adoption of CO2 cryogenic technology. The recent literature has introduced novel sustainable approaches for machining hard materials.

The literature review demonstrates that selecting an appropriate coolant can significantly contribute to establishing an environmentally sustainable system. Researchers observed the absence of emissions during machining operations when employing cryogenic-assisted and MQL techniques. Researchers have recently become interested in combining CO2 and the MQL system to address machinability issues. This study investigates the impact of hybrid drilling operations (using both CO2 and MQL) on the machinability and sustainability of AA7075T6 with TiO2 and C-reinforced composite materials.

2. Materials and Methods

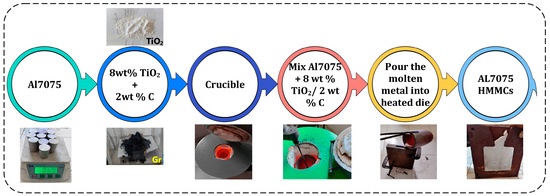

2.1. Preparation of Drilling Workpieces

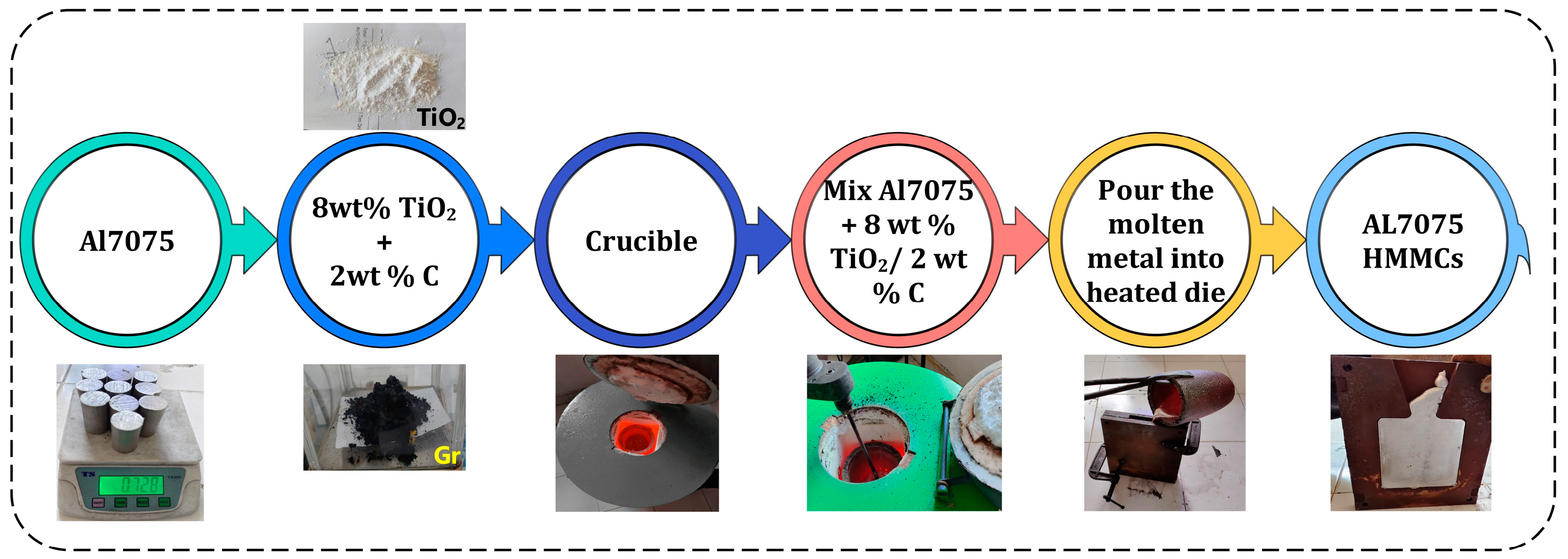

The preparation process for machined workpieces used in the experiments are shown in Figure 1. The Ø 20 mm and 100 mm long AA7075T6 rods are cut into pieces and placed in the crucible followed by heating at a rate of 750 °C. The weight fractions of TiO2 and C are 8% and 2%, respectively, and they are preheated to around 450 °C for the removal of moisture and also to improve wettability. A uniform stirring process is then performed for around 10 min at 500 rpm. A cast composite with 150 mm × 150 mm × 12 mm dimensions was then cut using wire EDM. The chemical composition for the cast aluminium 7075T6 is illustrated in Table 1.

Figure 1.

Flowchart of the preparation process for experimental samples of AL7075HMMCs.

Table 1.

Chemical composition of aluminium 7075T6 alloy.

Drilling operations were conducted on the YCM EV20 model of the CNC vertical machining centre. The indexable U drill model of the C25-3D13-42SP05 tool holder to hold the SPMX050204-YG602 insert with an ultra-dense PVD TiAlN coating is employed as the tooltip with a nose radius of 0.4 mm. Every trial was conducted using fresh cutting tools to retain the precision of the machining procedure.

2.2. Experimental Condition

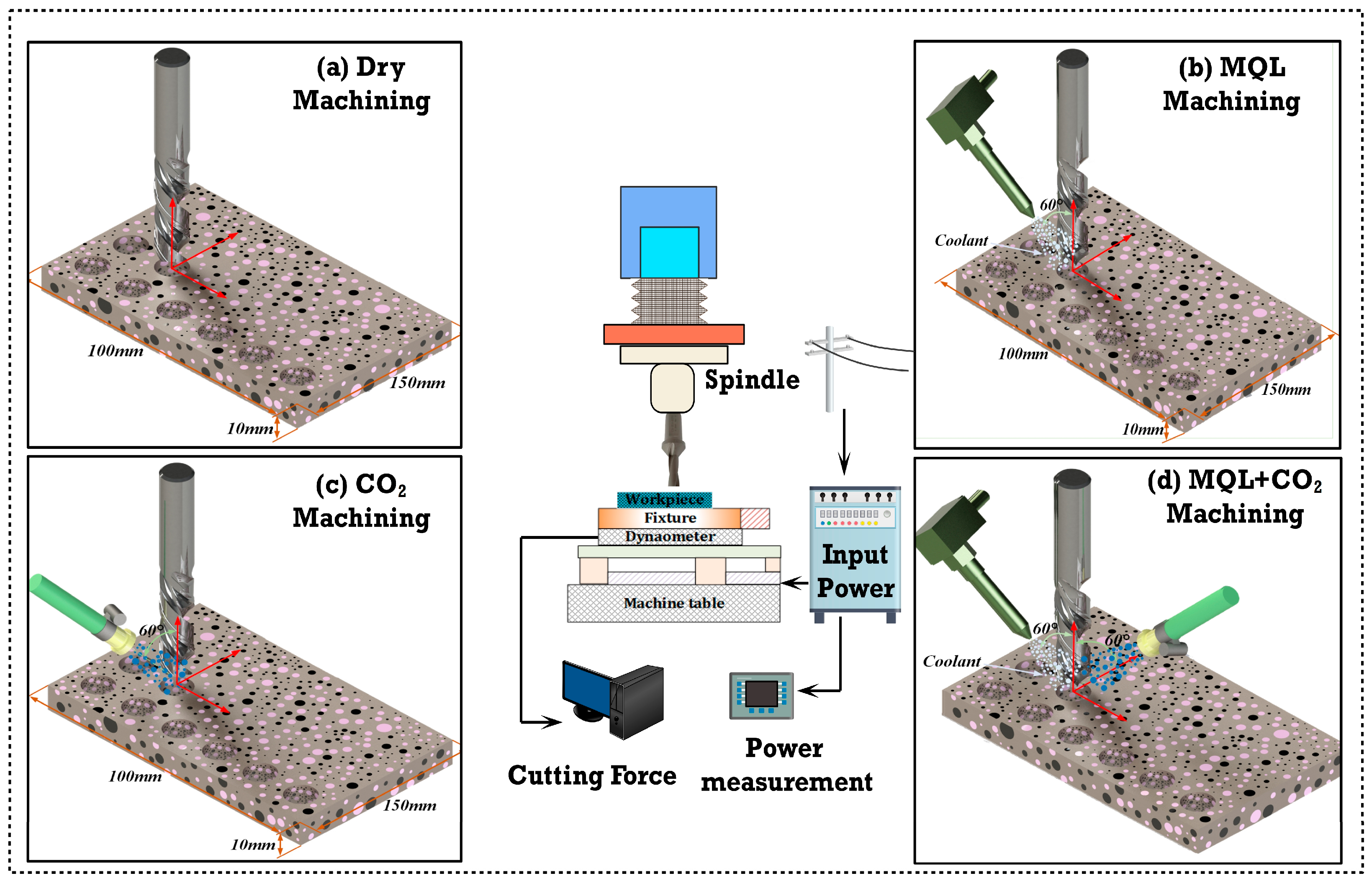

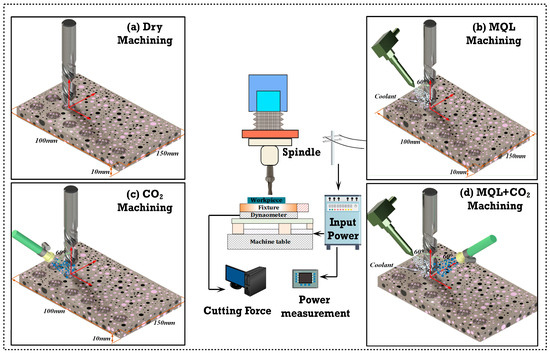

The experiments were conducted under various cooling conditions, including dry, MQL, CO2, and hybrid (MQL+CO2). Different cutting speeds of 30 m/min, 40 m/min, 50 m/min, and 60 m/min; feed rates of 0.05 mm/rev and 0.08 mm/rev; and a constant drilling depth of 10 mm were used for conducting the experiments. The setup configurations for the diverse machining conditions can be observed in Figure 2. Furthermore, Table 2 outlines the experimental design executed with different feed rates. The Kenco MQL system was employed for experiments in the MQL setting, with a vegetable oil-based (Sunflower oil) coolant flow rate of 50 mL/h and an air pressure of 4 bar. The equipment used for supplying CO2 is developed in-house. For cryogenic environments, the pressurised CO2 gas cylinder under 2.5 bar pressure was supplied through the nozzle and controlled the flow by a pressure regulator.

Figure 2.

Illustration of drilling environments (a) dry, (b) MQL, (c) CO2, (d) CO2+MQL.

Table 2.

Experimental conditions.

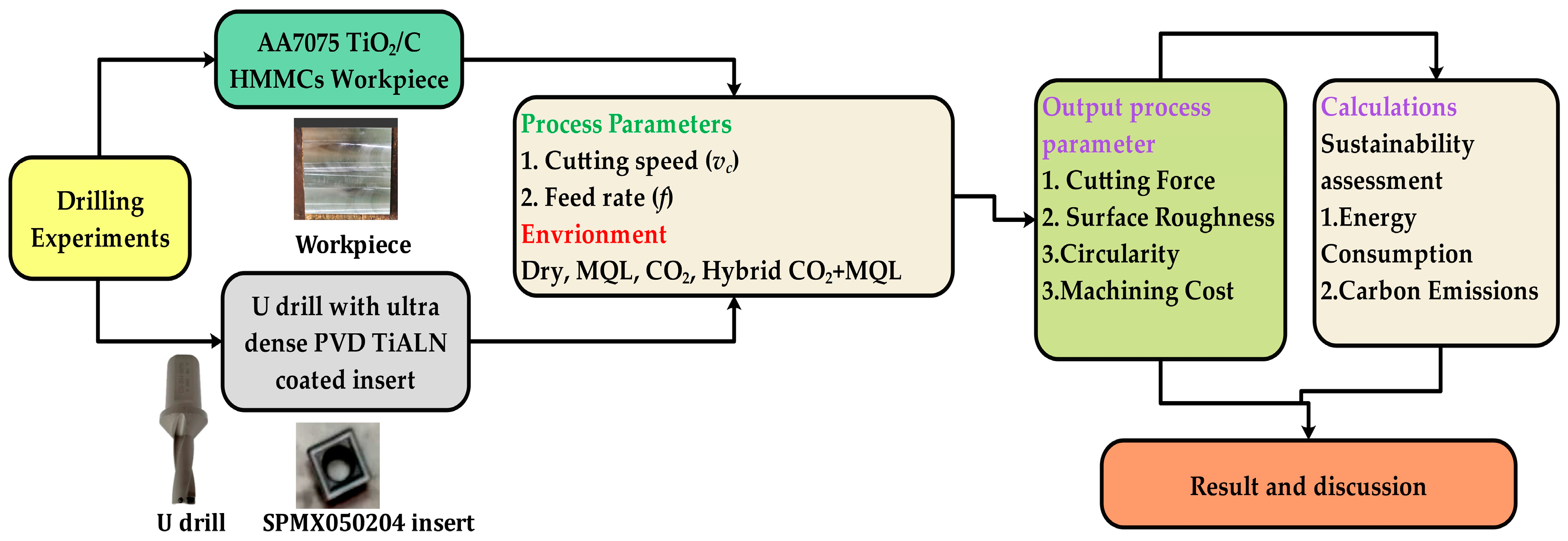

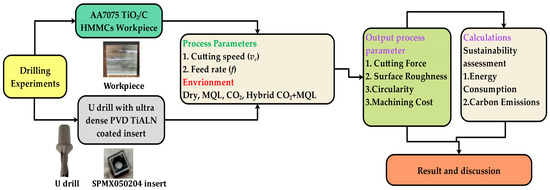

The methodology of the present work is shown in Figure 3. Experiments were carried out under different processing parameters. Indicators of machinability were obtained by direct measurement, and the generated torque and thrust force were measured using a 9272 Kistler piezoelectric dynamometer connected to a 5070A multichannel amplifier. The portable roughness tester TR200 was used to measure the roughness of the surface using a traverse length of 4 mm and a cutoff length of 0.8 mm. The energy consumption during a particular cutting operation is monitored with the help of a power clamp meter. Then, the coefficients related to the sustainability assessment were calculated. The results obtained for the processability and sustainability indicators are analysed and discussed in the next section. Experimental plan are shown in the Table 3.

Figure 3.

Methodology of current research work.

Table 3.

Experimental plan.

3. Results and Discussion

This part compares the cutting parameters, energy usage, carbon footprints, and economic aspects of drilling operations with various auxiliary cooling methods like dry cutting, MQL, CO2 cooling, and CO2+MQL. The aim is to assess each technique’s efficiency and identify the optimal auxiliary cooling approach.

3.1. Machinability Analysis

3.1.1. Cutting Force

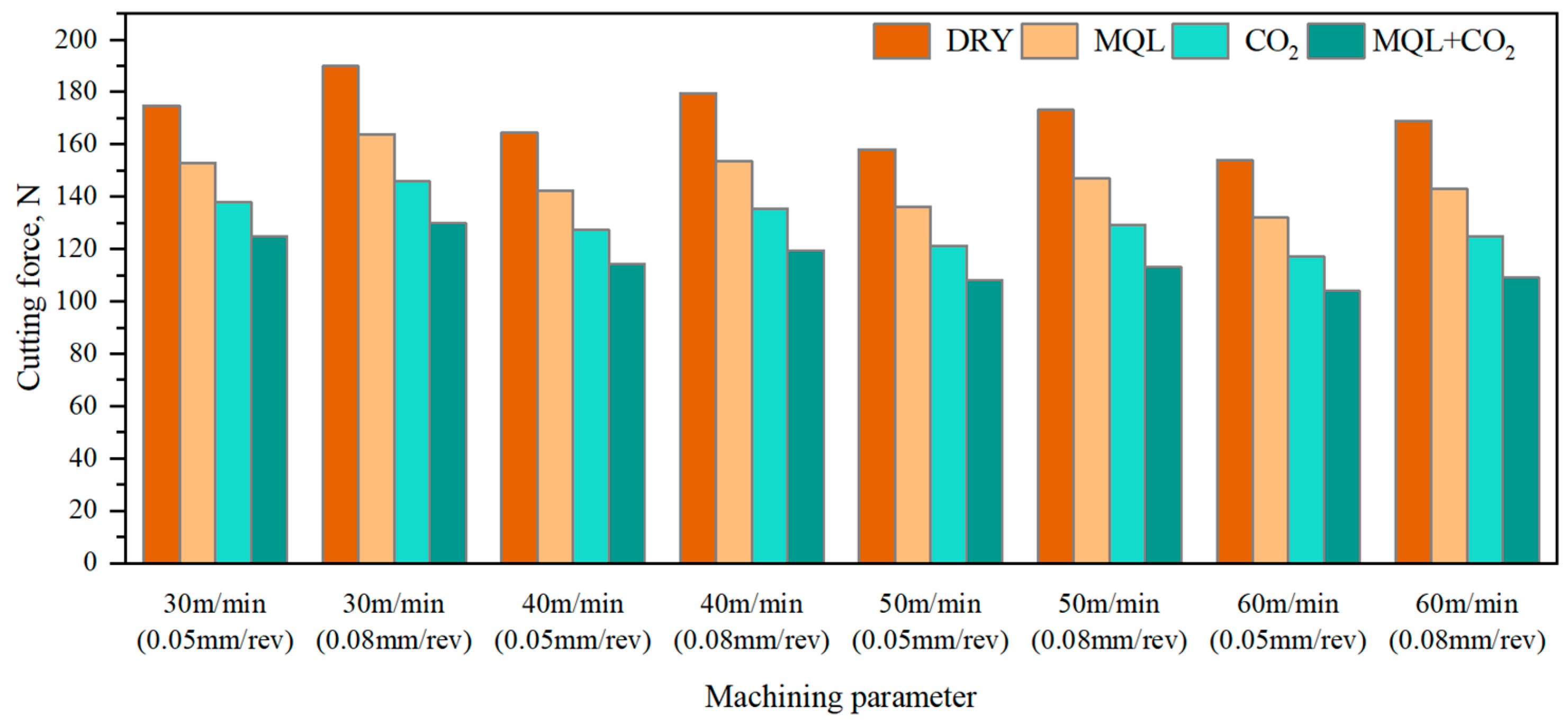

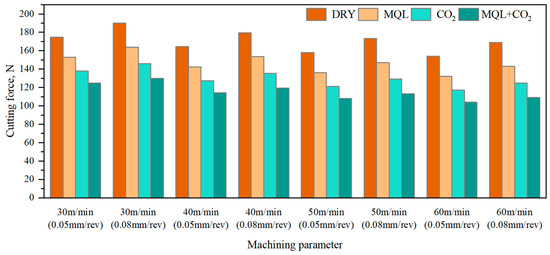

To ensure high-quality machined surfaces, it is important to prevent chips from melting and adhering to the cutting edge to produce BUE, which can cause additional friction and increase the cutting force [27]. The cutting force (Fc) reflects the difficulty of machining and directly affects the tool life [28]. Drilling experiments under different cooling conditions (dry cutting, MQL, CO2 cooling, and CO2+MQL cooling) and cutting parameters (feed rates and cutting speeds) were used to determine the most effective cooling method to reduce cutting force. The results, depicted in Figure 4, show that the drilling force decreases as the vc increases in dry conditions. When the vc is set at 30 m/min and the f is set at 0.08 mm/rev, the Fc is at its highest, measuring 190 N under dry conditions. Using MQL or CO2 cooling alone can reduce the Fc by 14% and 24% under the same machining parameters. This shows that the use of lubrication and cooling can improve machinability. When MQL is combined with CO2 mixing-assisted cooling, the Fc during the drilling process can be reduced by 32% compared to dry conditions at a measurement of 130 N. This is because MQL and CO2 provide both lubrication and cooling, which greatly reduces the negative impact of cutting heat on machining and improves the machinability of drilling.

Figure 4.

Cutting force analysis under different conditions.

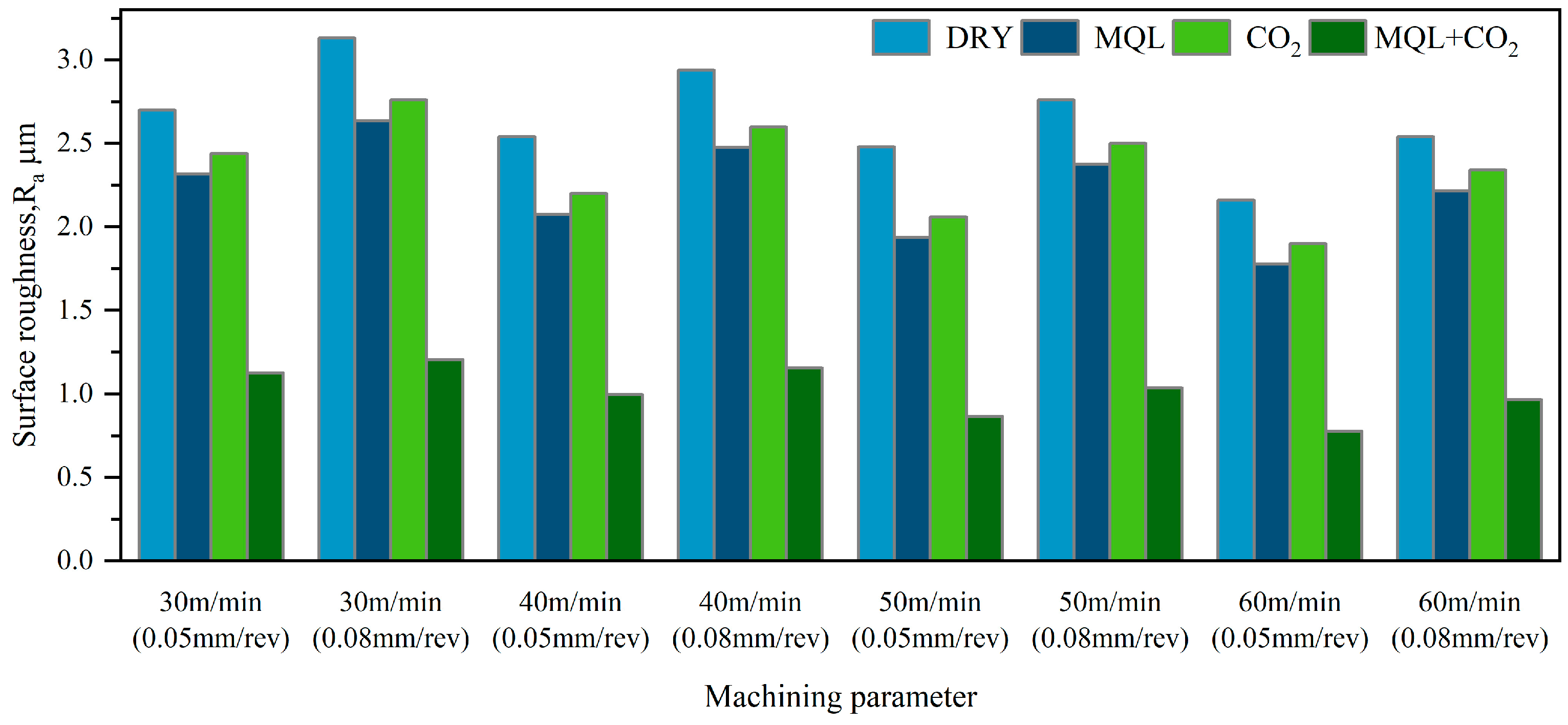

3.1.2. Surface Roughness

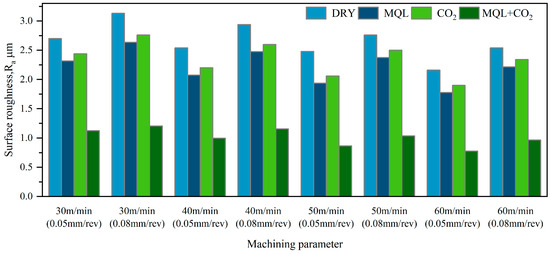

The quality of the hole surface indicates the stability of the cutting conditions and chip-breaking performance during the process to some extent [29]. The comparison of roughness (Ra) value measurements obtained from drilling under different cutting conditions is depicted in Figure 5. In drilling operations, the surface roughness of the holes decreases with an increase in vc and a decrease in f, especially in dry conditions. Comparing the drilling roughness under different cooling conditions, it can be seen that MQL cooling and CO2 cooling can reduce the Ra value to a certain extent. This may be due to the lubricating effect of MQL and the cooling effect of CO2, which helps in improving the fracture during drilling. In addition, the airflow can also enhance the ability to clean the chips [30]. The roughness of drilling can be minimized when using MQL+CO2 cooling. This reduction is due to the combined effects of low temperature and lubrication. The average roughness with CO2 is clearly below dry machining but the roughness evolution is softer with the use of the CO2 cryogenic technique than dry hard turning [18]. The adhesion ability of chip breaking is effectively reduced by using MQL+CO2 mixed cooling, which results in better cutting performance during the drilling process. Moreover, these cooling conditions can significantly improve the smoothness of drilling compared to dry conditions. For instance, at a vc of 60 m/min and an f of 0.05 mm/rev, the minimum Ra of the drilling hole is Ra 0.776 μm, representing a 65% reduction in Ra compared to the dry condition.

Figure 5.

Surface roughness analysis under different conditions.

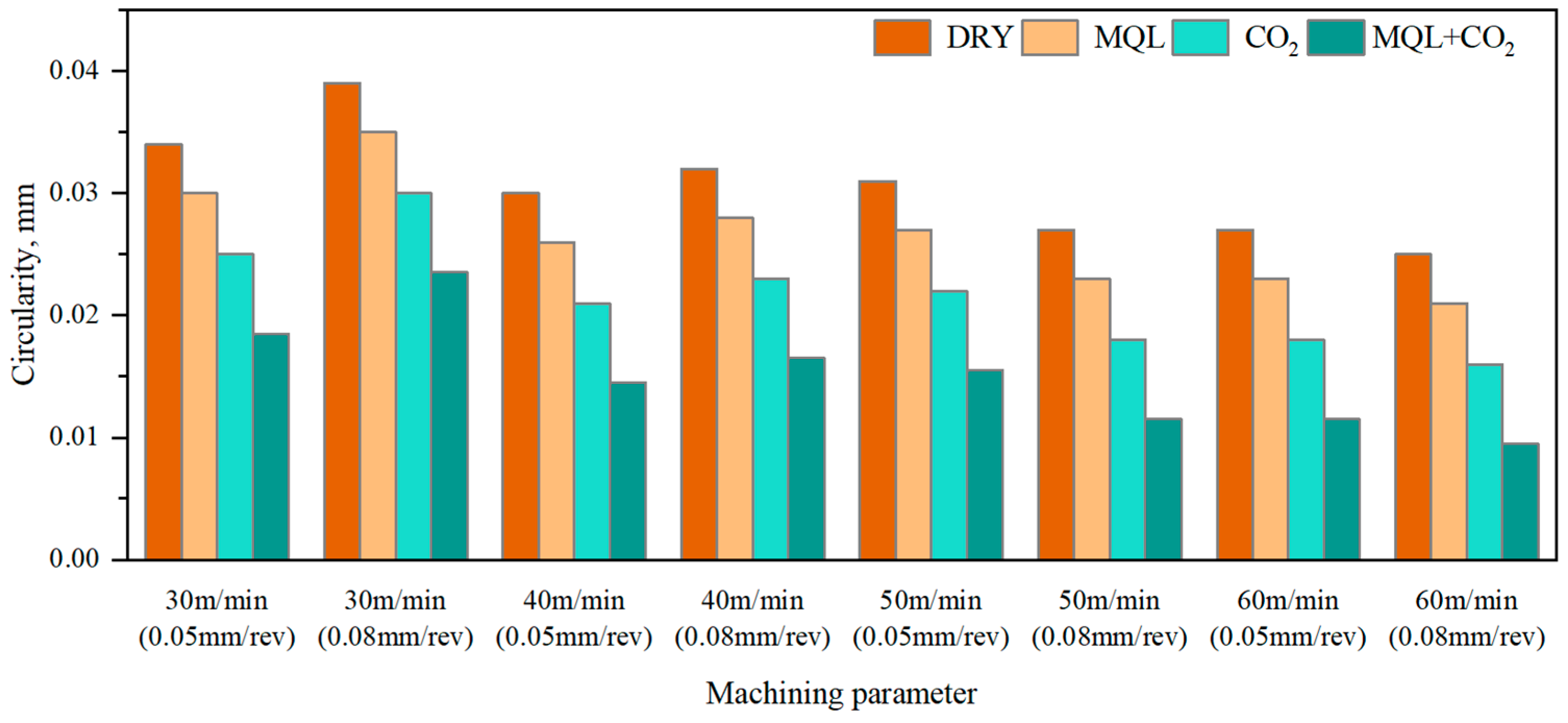

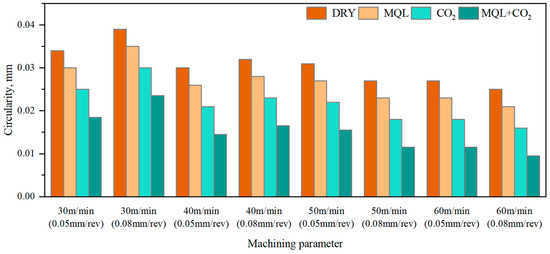

3.1.3. Circularity

It is important to ensure high surface quality while drilling holes, but the forming accuracy of drilling is equally essential. The circularity of the drilled hole can impact the assembly accuracy of parts [31]. Therefore, a three-dimensional scanning method using a Faro red laser scanner (accuracy of 15 μm) was employed to inspect and measure the circularity error of drilling for different experimental conditions. The measurement results are represented in Figure 6. The radial stiffness and the stability of the workpiece are significantly influenced by the cutting speed and feed rate [32]. The results reveal that the increased vc decreases the circularity error, which may be attributed to the increase in relative cutting times. In addition, an increase in f results in a 5–10% reduction in circularity error at the same vc. This is because the increase in f leads to a reduction in rotational disturbances. Compared to the dry conditions, the circularity of the holes has significantly improved under cooling conditions, especially when using MQL+CO2. The minimum circularity error is 0.01 mm when the vc is 60 m/min and the f is 0.08 mm/rev. This error is 60% lower than the dry conditions.

Figure 6.

Circularity analysis under different conditions.

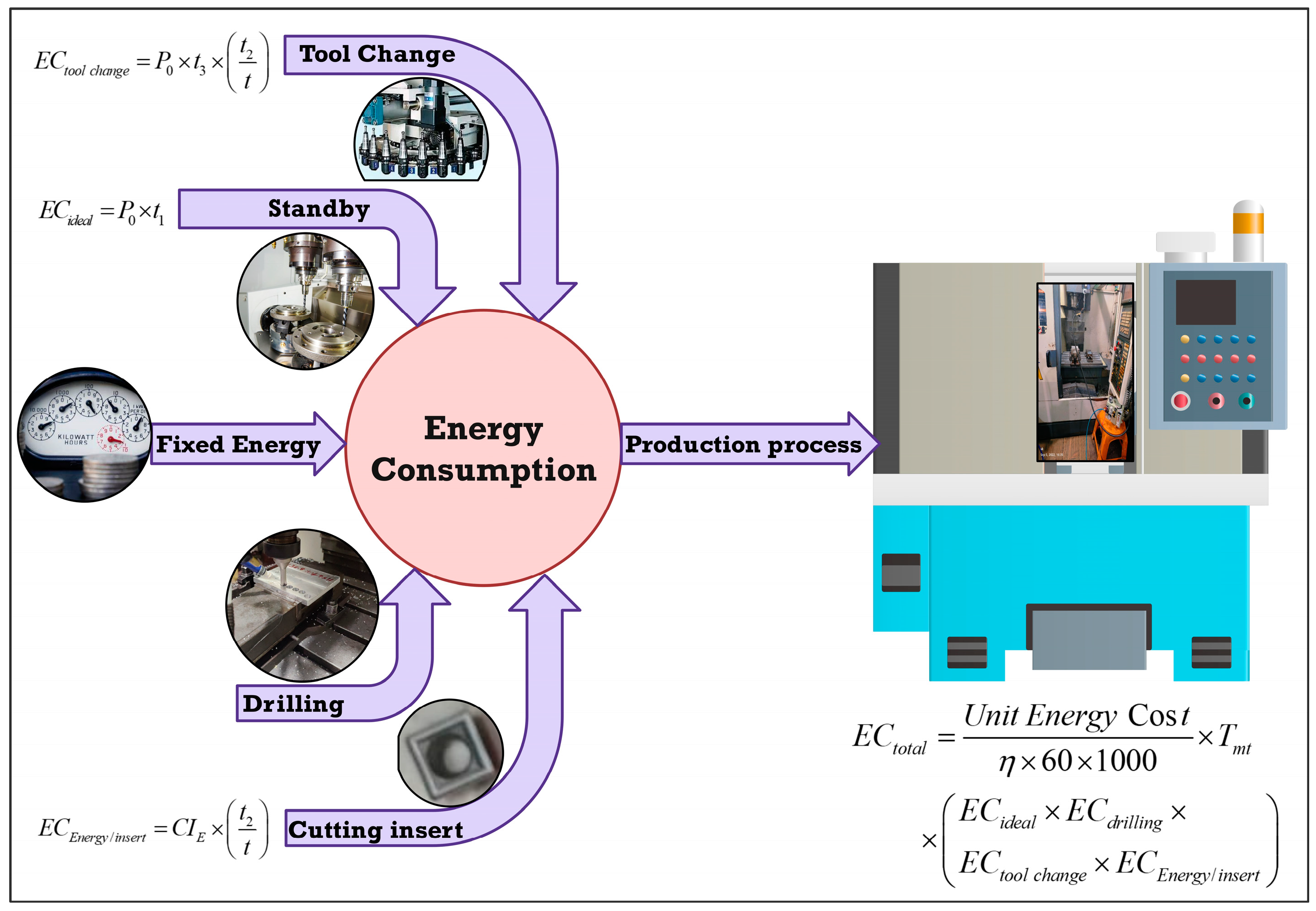

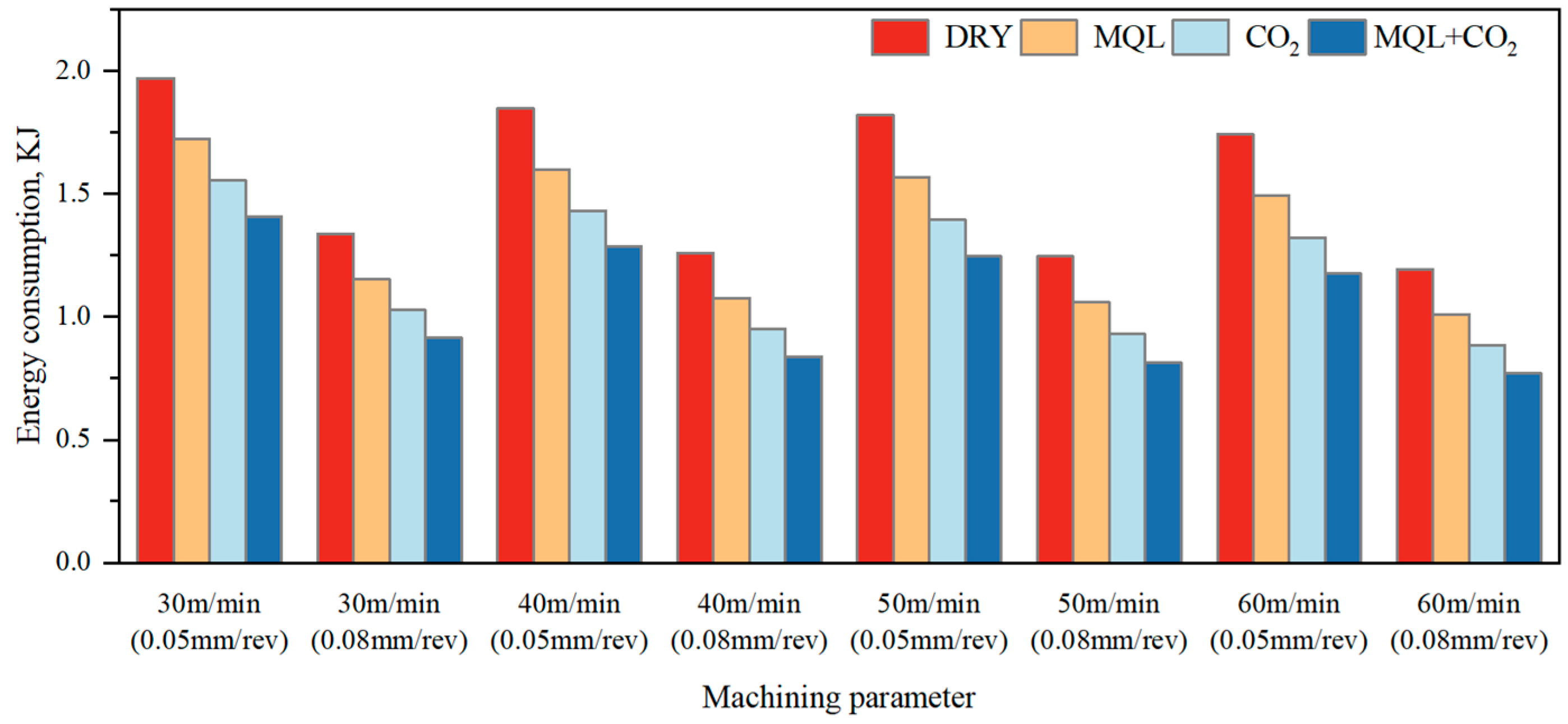

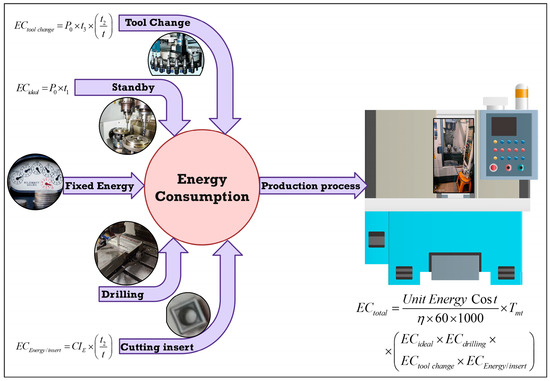

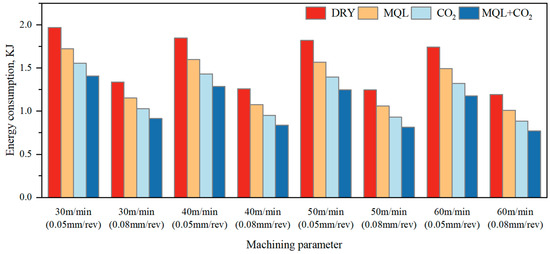

3.2. Energy Consumption Analysis

In mechanical processing, there is a greater emphasis on quality and stability. However, with the advancement of green manufacturing technology, manufacturing companies are now paying attention to the sustainability of manufacturing and processing [33]. Energy costs differ between various processing techniques; the difference in energy costs is prominent for actual high-volume manufacturing processes, so it is necessary to optimise energy consumption. During the optimisation process, the impact of processing parameters and auxiliary cooling methods on energy must be revealed through energy consumption analysis of the substantial impact.

The energy consumption of the whole drilling process is shown in Figure 7. For drilling processing, the method proposed by [34] was used to calculate the energy consumption of each process. The total energy consumption is composed of the ideal part; drilling part; tool change part and energy/insert (cutting insert—CI) part; and CEFEnergy carbon emissions factor for energy (0.7210 kg CO2/kWh); the specific calculation process is as follows:

Figure 7.

Energy consumption flow chart in the drilling process.

The specific expressions of each part in Equation (1) are as follows:

where (unit W) is the ideal power and (unit s) is the ideal time.

with

By substituting Equations (2)–(6) into Equation (1), the total energy consumption of drilling process becomes the following:

The energy consumption calculation results are shown in Figure 8. Under dry conditions, it is recommended to use a minimum vc of 60 m/min and a minimum f of 0.08 mm/rev to minimize energy consumption. Energy consumption increases as cutting time is prolonged due to the cutting parameters. Therefore, reducing the cutting time can effectively decrease energy consumption. When different auxiliary cooling conditions are used, the energy consumption of solutions with auxiliary cooling is lower than that of dry conditions. Specifically, when MQL (minimum quantity lubrication) and CO2 (carbon dioxide) are used, the heat generated is 73% and 43% of that under dry conditions, respectively. The MQL+CO2 cooling method is an efficient way to reduce energy consumption during drilling. Compared to dry drilling, the energy generated by MQL+CO2 drilling is only 64%, which means that the use of auxiliary cooling significantly impacts the machinability of the drilling process. This method reduces the dissipation of friction heat and improves the energy utilization efficiency of the processing process. Cryogenic application as a sustainable machining alternative shows high potential for enhancing the overall machining performance and the machined part quality [17].

Figure 8.

Energy consumption under different conditions.

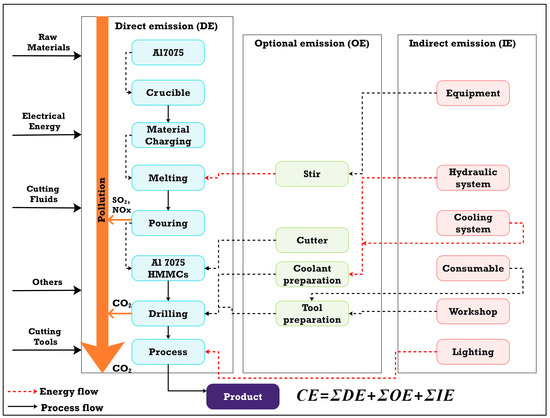

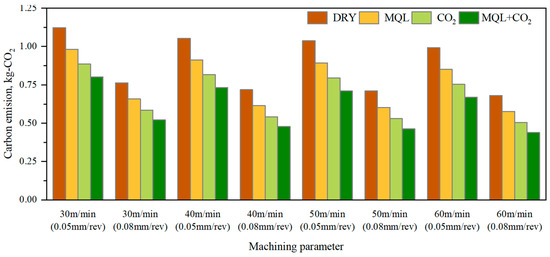

3.3. Carbon Emission Analysis

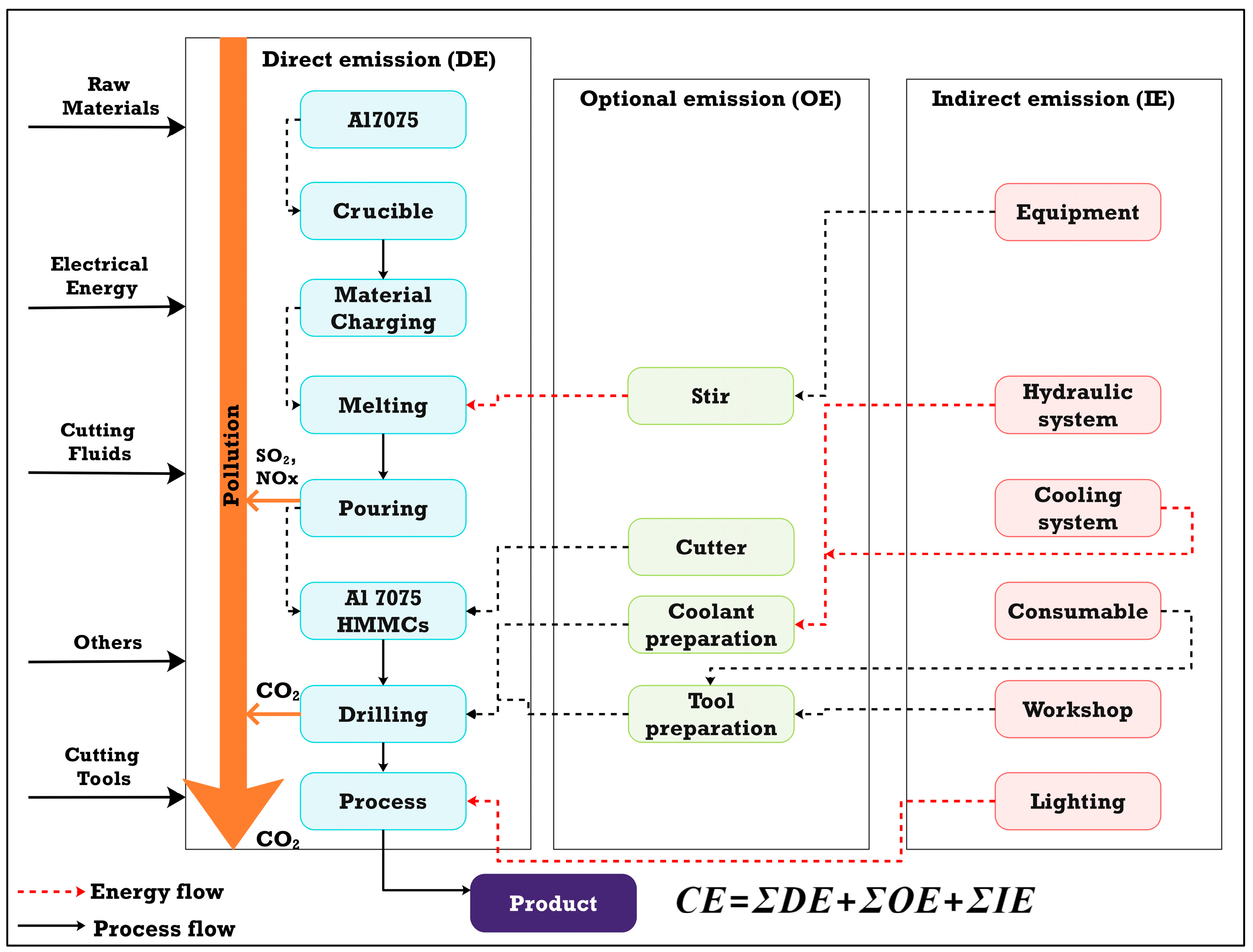

During the drilling, whether it involves dry cutting or cutting with auxiliary cooling, carbon emissions occurred within the working environment leading to the emission of the greenhouse gases that can harm the operators involved [35]. The carbon emissions reflect the negative impact of processing on the environment and the use of resources [36]. Additionally, the CO2 cooling also emits carbon into the working environment, thus further contributing to the overall carbon emissions of the process. The primary source of carbon emissions can cause more energy consumption. To comply with the requirements of green manufacturing, it is essential to analyse and control carbon emissions. The detailed flowchart of carbon emissions that occurred during the drilling process is shown in Figure 9. The carbon emissions of the drilling process can be calculated in the Equations (7) and (8).

where represents total energy consumption, is the carbon emission factor, and represents the carbon emissions of the production process and is composed of three parts: direct emission , optional emission , and indirect emission :

Figure 9.

Energy consumption related to carbon emissions during the drilling process.

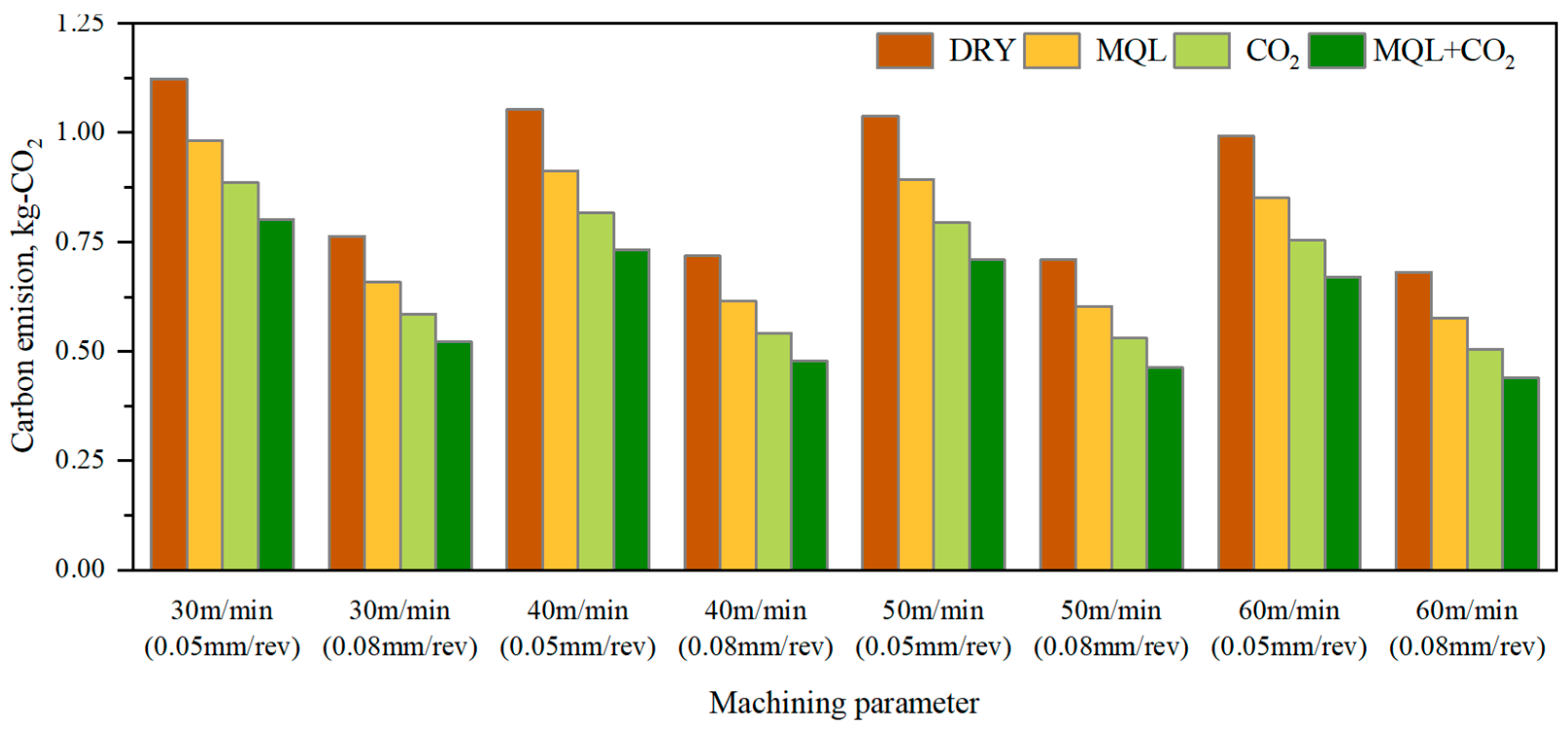

Figure 10 shows the graph representing the carbon emissions that occurred during each experiment. The feed rate has a greater impact on carbon emissions. As the feed rate increases, the carbon emissions decrease. In the case of dry conditions, when the feed rate increases from 0.05 mm/rev to 0.08 mm/rev, the carbon emissions corresponding to different cutting speeds dropped by 68% on average. The carbon emissions produced by the added cooling method are less than those of dry cutting. This means that the cooling method can effectively reduce the carbon footprint generated with respect to energy consumption. The MQL+CO2 method is environmentally friendly with the smallest carbon emissions. This mixed cooling technique reduces the energy consumption in processing and effectively controls the direct emission of CO2. In all experiments, the MQL+CO2 cooling method had the lowest carbon emission of 0.35 kg-CO2 when the cutting speed was 60 m/min and the feed rate was 0.08 mm/rev.

Figure 10.

Carbon emission under different conditions.

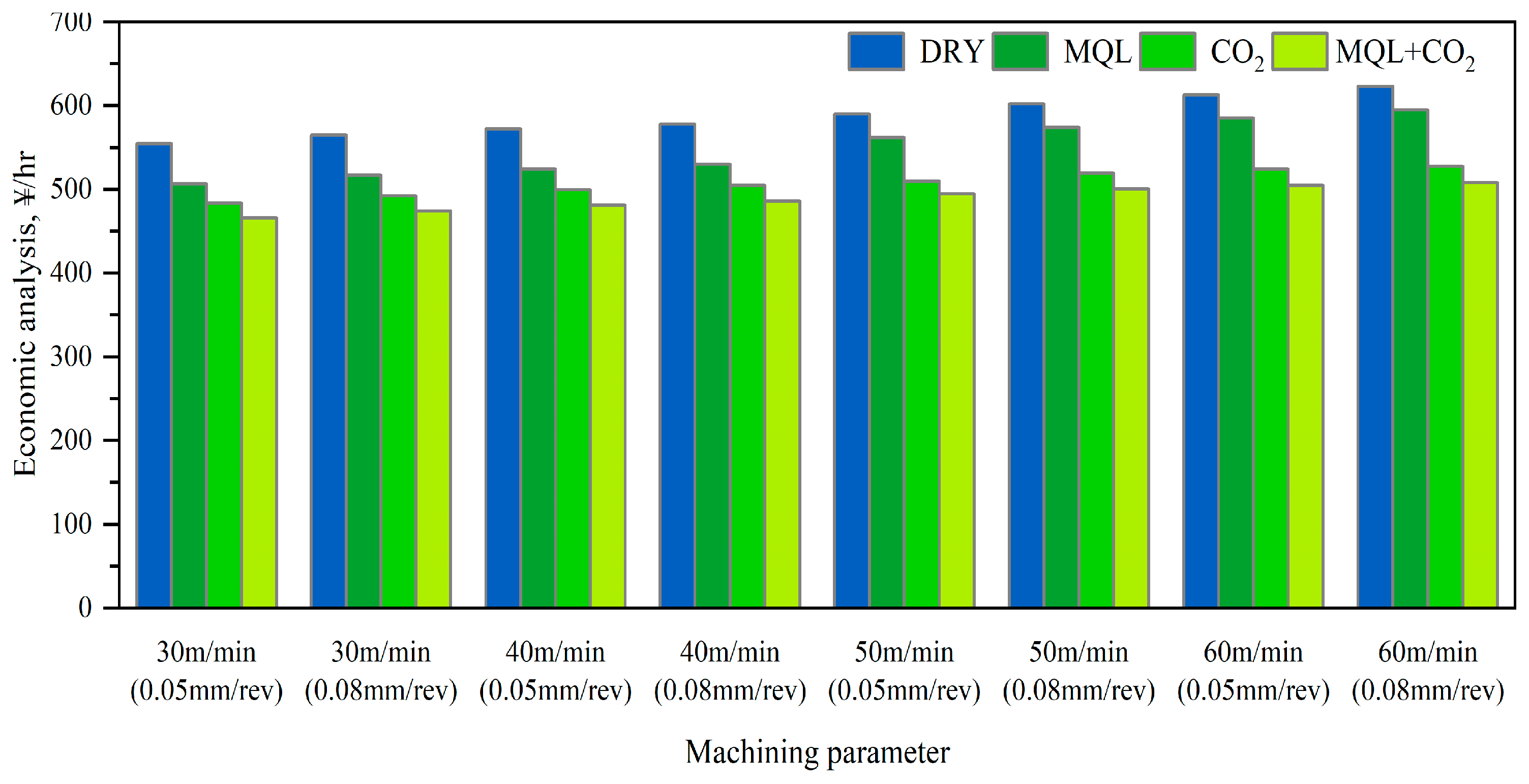

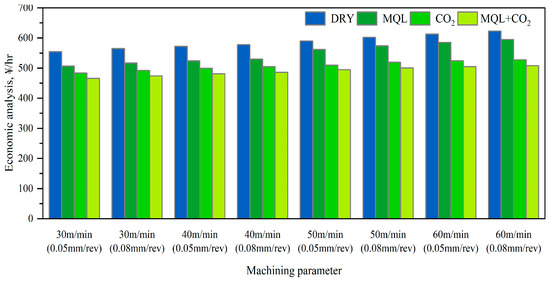

3.4. Economic Analysis

Drilling economic analysis is essential for green manufacturing to reduce production costs and enhance sustainability. The composition of the economic cost of drilling, which comprises the direct labour cost, machine cost, energy cost, cutting tool cost, cutting fluid cost, and maintenance cost, is shown in Table 4 [37].

Table 4.

Individual drilling process cost elements.

The total cost of the four different cooling methods used for the same machining task is shown in Figure 11. It is worth noting that although the cost of the machine increases when cooling is required, the overall cost is still lower than the dry conditions. This indicates that the cost of tool damage during cutting is a significant factor and that adding cooling and lubrication equipment can reduce the amount of tool damage. The newly proposed method is more aligned with the principles of sustainable manufacturing [38]. Although the amount of coolant and lubricant needed may vary depending on the cooling conditions, their cost only stands for a small portion of the total cost. Thus, the total cost does not change significantly.

Figure 11.

Economic analysis under different conditions.

Two kinds of corresponding energy-saving strategies can deal with the energy loss of the two parts. The fixed energy-saving strategy mainly focuses on energy-saving optimization for the whole stage design of the machine tool, and the variable energy-saving strategy reduces energy consumption by adjusting processing parameters according to the actual processing scene [39]. The present study targets multiple sustainable processing indicators, which can effectively reduce fixed energy loss and carbon emission and ensure processing quality [40]. It is worth noting that the addition of energy attributes in the proposed approach enhances the overall nature of the strategy.

4. Conclusions

Through a comparative analysis of the drilling process under various auxiliary cooling conditions, including dry cutting, MQL (minimum quantity lubrication), CO2 cooling, and combined CO2+MQL, several conclusions were drawn that underscore the impacts on machinability, energy consumption, carbon emissions, and economic aspects.

- (1)

- The use of combined MQL and CO2 cooling significantly reduces cutting forces by up to 32% and improves surface roughness by 65% compared to dry cutting. This suggests that the synergy between lubrication and cooling effects in the MQL+CO2 method greatly enhances the overall machinability, contributing to higher-quality machining outputs with smoother surfaces and more precise circularity.

- (2)

- The implementation of auxiliary cooling methods, particularly the MQL+CO2 combination, demonstrates a significant reduction in energy consumption during drilling. Energy consumption for this method is only 64% of that observed in dry conditions, indicating improved energy efficiency due to reduced friction and more effective heat dissipation.

- (3)

- Auxiliary cooling methods, especially MQL+CO2, improve machining performance and contribute to environmental sustainability by reducing carbon emissions. This method achieved the lowest carbon emission readings, making it an environmentally preferable option in compliance with green manufacturing principles.

- (4)

- Although the initial costs associated with implementing cooling systems might increase, the overall economic analysis reveals that the costs associated with tool wear and damage are significantly reduced. This results in a lower total cost of operation compared to dry cutting, demonstrating the economic viability of integrating advanced cooling technologies in drilling processes.

- (5)

- The analysis of circularity errors shows substantial improvements under the auxiliary cooling conditions compared to dry cutting. The minimum circularity error observed with MQL+CO2 cooling represents a 60% improvement, underscoring the benefits of auxiliary cooling in achieving higher precision and quality in machined parts.

Author Contributions

Conceptualization, Y.X.; Formal analysis, S.C. and Y.X.; Funding acquisition, Y.X.; Investigation, S.C. and G.Z.; Methodology, S.C.; Project administration, G.C.; Resources, G.Z.; Software, S.H.; Supervision, G.Z. and G.C.; Validation, S.H.; Visualization, S.H.; Writing—original draft, S.C.; Writing—review and editing, Y.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Scientific and Technological Research Projects in Henan Province (No. 242102221054), the Open Project of Henan Key Laboratory of Intelligent Manufacturing of Mechanical Equipment, Zhengzhou University of Light Industry (No. IM202312), and the Doctoral Research Fund of Zhengzhou University of Light Industry (No. 2022BSJJZK02).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jeswiet, J.; Kara, S. Carbon emissions and CES™ in manufacturing. CIRP Ann. 2008, 57, 17–20. [Google Scholar] [CrossRef]

- You, J.; Xu, X.; Wang, Y.; Xiang, X.; Luo, Y. Life cycle carbon emission assessment of large-span steel structures: A case study. Structures 2023, 52, 842–853. [Google Scholar] [CrossRef]

- Khan, A.M.; Zhao, W.; Li, L.; Alkahtani, M.; Hasnain, S.; Jamil, M.; He, N. Assessment of cumulative energy demand, production cost, and CO2 emission from hybrid CryoMQL assisted machining. J. Clean. Prod. 2021, 292, 125952. [Google Scholar] [CrossRef]

- Shokrani, A.; Huibin, S.; Dhokia, V.; Newman, S.T. High speed cryogenic drilling of grade 5 ELI titanium alloy. In Proceedings of the 26th International Conference on Flexible Automation and Intelligent Manufacturing, Seoul, Republic of Korea, 27–30 June 2016. [Google Scholar]

- Singh, N.; Belokar, R.; Walia, R. Fabrication and mechanical characterization of Al7075-T6/SiC/Gr/S-glass fiber particulate reinforced hybrid metal matrix composite using vacuum sealed stir casting technique. Trans. Indian Inst. Met. 2022, 75, 1741–1750. [Google Scholar] [CrossRef]

- Pasha, S.K.; Sharma, A.; Tambe, P. Mechanical properties and tribological behavior of Al7075 metal matrix composites: A review. Mater. Today Proc. 2022, 56, 1513–1521. [Google Scholar] [CrossRef]

- Danappa, G.; Raghavendra, C.; Swamy, R.; Naik, K. Dry sliding wear behaviour of Al7075/Gr/nano TiO2 MMC using RSM. Mater. Today Proc. 2021, 38, 2797–2802. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, A.M.; He, N.; Li, L.; Iqbal, A.; Mia, M. Evaluation of machinability and economic performance in cryogenic-assisted hard turning of α-β titanium: A step towards sustainable manufacturing. Mach. Sci. Technol. 2019, 23, 1022–1046. [Google Scholar] [CrossRef]

- Katna, R.; Suhaib, M.; Agrawal, N. Nonedible vegetable oil-based cutting fluids for machining processes—A review. Mater. Manuf. Process. 2020, 35, 1–32. [Google Scholar] [CrossRef]

- Xavior, M.A.; Adithan, M. Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J. Mater. Process. Technol. 2009, 209, 900–909. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. Cryogenic machining of titanium Ti-5553 alloy. J. Manuf. Sci. Eng. 2019, 141, 041012. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Rahim, E.; Sasahara, H. A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Tribol. Int. 2011, 44, 309–317. [Google Scholar] [CrossRef]

- Govindaraju, N.; Shakeel Ahmed, L.; Pradeep Kumar, M. Experimental investigations on cryogenic cooling in the drilling of AISI 1045 steel. Mater. Manuf. Process. 2014, 29, 1417–1421. [Google Scholar] [CrossRef]

- Rosnan, R.; Murad, M.N.; Azmi, A.I.; Shyha, I. Effects of minimal quantity lubricants reinforced with nano-particles on the performance of carbide drills for drilling nickel-titanium alloys. Tribol int. 2019, 136, 58–66. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Deiab, I.; Eltaggaz, A. Sustainability assessment during machining Ti-6Al-4V with Nano-additives-based minimum quantity lubrication. J. Manuf. Mater. Process. 2019, 3, 61. [Google Scholar] [CrossRef]

- Pusavec, F.; Deshpande, A.; Yang, S.; M’Saoubi, R.; Kopac, J.; Dillon Jr, O.W.; Jawahir, I. Sustainable machining of high temperature Nickel alloy–Inconel 718: Part 1–predictive performance models. J. Clean. Prod. 2014, 81, 255–269. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.; Barreiro, J.; de Lacalle, L.L. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.T. Energy conscious cryogenic machining of Ti-6Al-4V titanium alloy. Proc. Inst. Mech. Eng. Part B 2018, 232, 1690–1706. [Google Scholar] [CrossRef]

- Zhao, W.; Ren, F.; Iqbal, A.; Gong, L.; He, N.; Xu, Q. Effect of liquid nitrogen cooling on surface integrity in cryogenic milling of Ti-6Al-4 V titanium alloy. Int. J. Adv. Manuf. Tech. 2020, 106, 1497–1508. [Google Scholar] [CrossRef]

- Jayaganth, A.; Jayakumar, K.; Deepak, A.; Pazhanivel, K. Experimental studies on drilling of 410 stainless steel. Mater. Today Proc. 2018, 5, 7168–7173. [Google Scholar] [CrossRef]

- Prakash, J.U.; Rubi, C.S.; Palani, S.; Juliyana, S.J.; Sadhana, A.D. Optimization of machining parameters in drilling of LM6/B4C/Fly ash hybrid composites. Manuf. Rev. 2022, 9, 28. [Google Scholar] [CrossRef]

- Daniel, S.A.A.; Pugazhenthi, R.; Kumar, R.; Vijayananth, S. Multi objective prediction and optimization of control parameters in the milling of aluminium hybrid metal matrix composites using ANN and Taguchi-grey relational analysis. Def. Technol. 2019, 15, 545–556. [Google Scholar] [CrossRef]

- Gowtham, N.; Senthilkumar, N. Surface integrity in drilling AA5052+ 3% MoS2+ 9% Si3N4 HAMMC and comparing the results with AA5052+ 9% Si3N4 AMMC-experimental studies and optimization. Mater. Today Proc. 2022, 69, 1173–1178. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; de Lacalle, L.N.L.; Rodríguez, A.; Pereira, O. In pursuit of sustainable cutting fluid strategy for machining Ti-6Al-4V using life cycle analysis. Sustain. Mater. Technol. 2021, 29, e00301. [Google Scholar] [CrossRef]

- Rodríguez, A.; Calleja, A.; de Lacalle, L.L.; Pereira, O.; Rubio-Mateos, A.; Rodríguez, G. Drilling of CFRP-Ti6Al4V stacks using CO2-cryogenic cooling. J. Manuf. Prpcess. 2021, 64, 58–66. [Google Scholar] [CrossRef]

- Ahmed, Y.S.; Youssef, H.; El-Hofy, H.; Ahmed, M. Prediction and optimization of drilling parameters in drilling of AISI 304 and AISI 2205 steels with PVD monolayer and multilayer coated drills. J. Manuf. Mater. Process. 2018, 2, 16. [Google Scholar] [CrossRef]

- Bermingham, M.; Kirsch, J.; Sun, S.; Palanisamy, S.; Dargusch, M. New observations on tool life, cutting forces and chip morphology in cryogenic machining Ti-6Al-4V. Int. J. Mach. Tool. Manuf. 2011, 51, 500–511. [Google Scholar] [CrossRef]

- Liu, K.; Li, J.; Sun, J.; Zhu, Z.; Meng, H. Investigation on chip morphology and properties in drilling aluminum and titanium stack with double cone drill. Int. J. Adv. Manuf. Tech. 2018, 94, 1947–1956. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Erzincanlı, F. Tool wear and surface roughness analysis in milling with ceramic tools of Waspaloy: A comparison of machining performance with different cooling methods. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 83. [Google Scholar] [CrossRef]

- Maiorova, K.; Vorobiov, I.; Andrieiev, O.; Lupkin, B.; Sikulskiy, V. Forming the geometric accuracy and roughness of holes when drilling aircraft structures made from polymeric composite materials. East.-Eur. J. Enterp. Technol. 2022, 116, 71. [Google Scholar]

- Pramanik, A.; Basak, A.; Prakash, C.; Shankar, S.; Chattopadhyaya, S. Sustainability in drilling of aluminum alloy. Clean. Mater. 2022, 3, 100048. [Google Scholar] [CrossRef]

- Kaushal, S.; Singh, I.; Singh, S.; Gupta, A. Sustainable Advanced Manufacturing and Materials Processing: Methods and Technologies; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Sivalingam, V.; Liu, H.; Selvam, B.; Kai, G.; Kumar, P.G.; Gupta, M.K.; Korkmaz, M.E.; Sun, J. Towards sustainability assessment, energy consumption, and carbon emissions in cryogenic drilling of Alloy 20: A new approach towards sustainable future and challenges. Int. J. Adv. Manuf. Tech. 2024, 131, 1151–1165. [Google Scholar] [CrossRef]

- Lu, T.; Rotella, G.; Feng, S.; Badurdeen, F.; Dillon, O.; Rouch, K.; Jawahir, I. Metrics-based sustainability assessment of a drilling process. In Sustainable Manufacturing: Shaping Global Value Creation; Springer: Berlin/Heidelberg, Germany, 2012; pp. 59–64. [Google Scholar]

- Hoghoughi, M.; Farahnakian, M.; Elhami, S. Environmental, economical, and machinability based sustainability assessment in hybrid machining process employing tool textures and solid lubricant. Sustain. Mater. Technol. 2022, 34, e00511. [Google Scholar] [CrossRef]

- Kshitij, G.; Khanna, N.; Yıldırım, Ç.V.; Dağlı, S.; Sarıkaya, M. Resource conservation and sustainable development in the metal cutting industry within the framework of the green economy concept: An overview and case study. Sustain. Mater. Technol. 2022, 34, e00507. [Google Scholar] [CrossRef]

- Sivalingam, V.; Zhou, Q.; Selvam, B.; Sun, J.; Pandiyan, K.; Gupta, M.; Korkmaz, M.E. A mathematical approach of evaluating sustainability indicators in milling of aluminium hybrid composite by different eco-friendly cooling strategies. Sustain. Mater. Technol. 2023, 36, e00605. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Yilmaz, H.; Ross, N.S.; Boy, M.; Sivalingam, V.K.; Chan, C.K.; Raman, J. Towards specific cutting energy analysis in the machining of Inconel 601 alloy under sustainable cooling conditions. J. Mater. Res. Technol. 2023, 27, 4074–4087. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.; Ross, N.S.; Sivalingam, V. Implementation of green cooling/lubrication strategies in metal cutting industries: A state of the art towards sustainable future and challenges. Sustain. Mater. Technol. 2023, 36, e00641. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).