S-Graph-Based Reactive Scheduling with Unexpected Arrivals of New Orders

Abstract

1. Introduction

1.1. Literature Review

- Proactive approach: By modeling emerging unexpected events and uncertainties [25,26], different scenarios are solved [27]. This method can be seen as a form of capacity shortage scheduling, where robustness is sought to be maintained. In a circular economy, proactive approaches help to anticipate and mitigate disruptions, ensuring the efficient use of resources and minimizing waste.

- Reactive approach: During production, the schedule is changed in response to unexpected events. It is characterized by simple rules; therefore, the need for computation is low. Due to the use of local information, the new schedule may not provide a globally optimal solution. Reactive approaches in Industry 4.0 enable real-time adaptation to changing circumstances, allowing manufacturers to quickly respond to disruptions and maintain production efficiency.

- Proactive–reactive approach: As a first step, a timetable is created that takes into account future disruptions. In addition, reactive steps are used, but fewer modifications are required due to the robustness of the schedule. This hybrid approach combines the benefits of proactive planning and reactive adaptation, providing a balance between resource efficiency and responsiveness in a circular economy.

- Predictive–reactive approach: This method can be divided into two parts. First, an optimal schedule is generated through iterative search processes, typically using a static scheduling method. Second, the schedule changes during execution as a result of unexpected events [28]. For reactive scheduling, most approaches revise only a portion of the original schedule without rescheduling all necessary tasks [29,30]. Predictive–reactive approaches in Industry 4.0 leverage data analytics and machine learning to anticipate disruptions and proactively adapt schedules, while still maintaining the flexibility to react to unforeseen events.

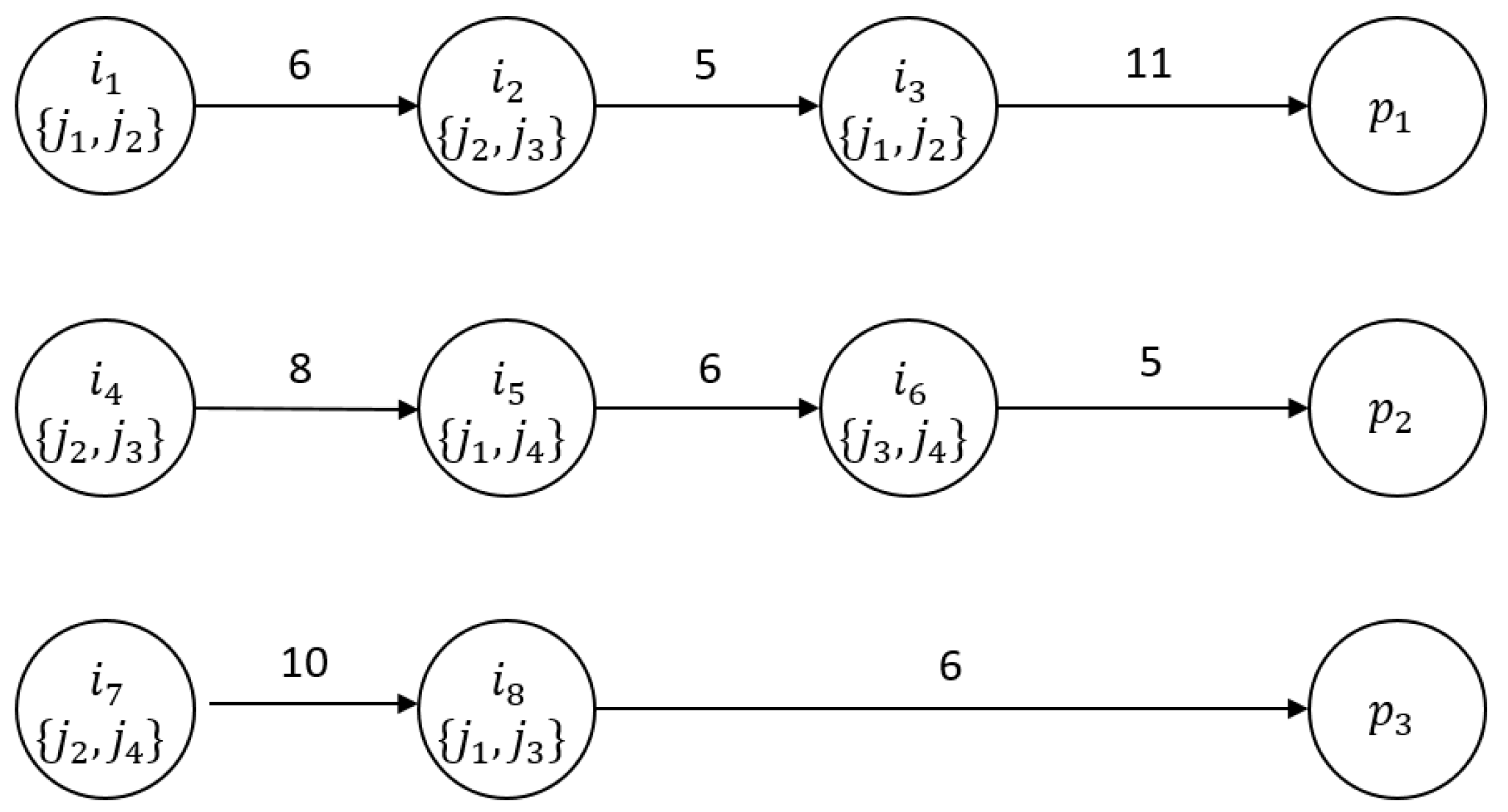

1.2. Problem Definition

- Single machine: Only one machine is available and each job consists of a single operation.

- Parallel machines: Multiple machines are available and each job consists of a single operation.

- Flow shop: Jobs have the same number of operations and the order of machine usage is consistent for all jobs.

- Flexible flow shop: Similar to the flow shop problem but multiple machines are available for each stage.

- Job shop: Jobs can have different numbers and types of operations and the order of operations can vary between jobs.

- Flexible job shop: An extension of the job shop problem with multiple machines available for performing operations.

- Open shop: The order of operations for a job is not predefined.

- is a feasible solution for the already received orders and the new order, i.e., for orders .

- , i.e., the assignments in already started before cannot be altered.

- must hold for all , i.e., no new assignment can be placed before time .

- has the minimal makespan among all schedules satisfying the above three conditions.

2. Methodology

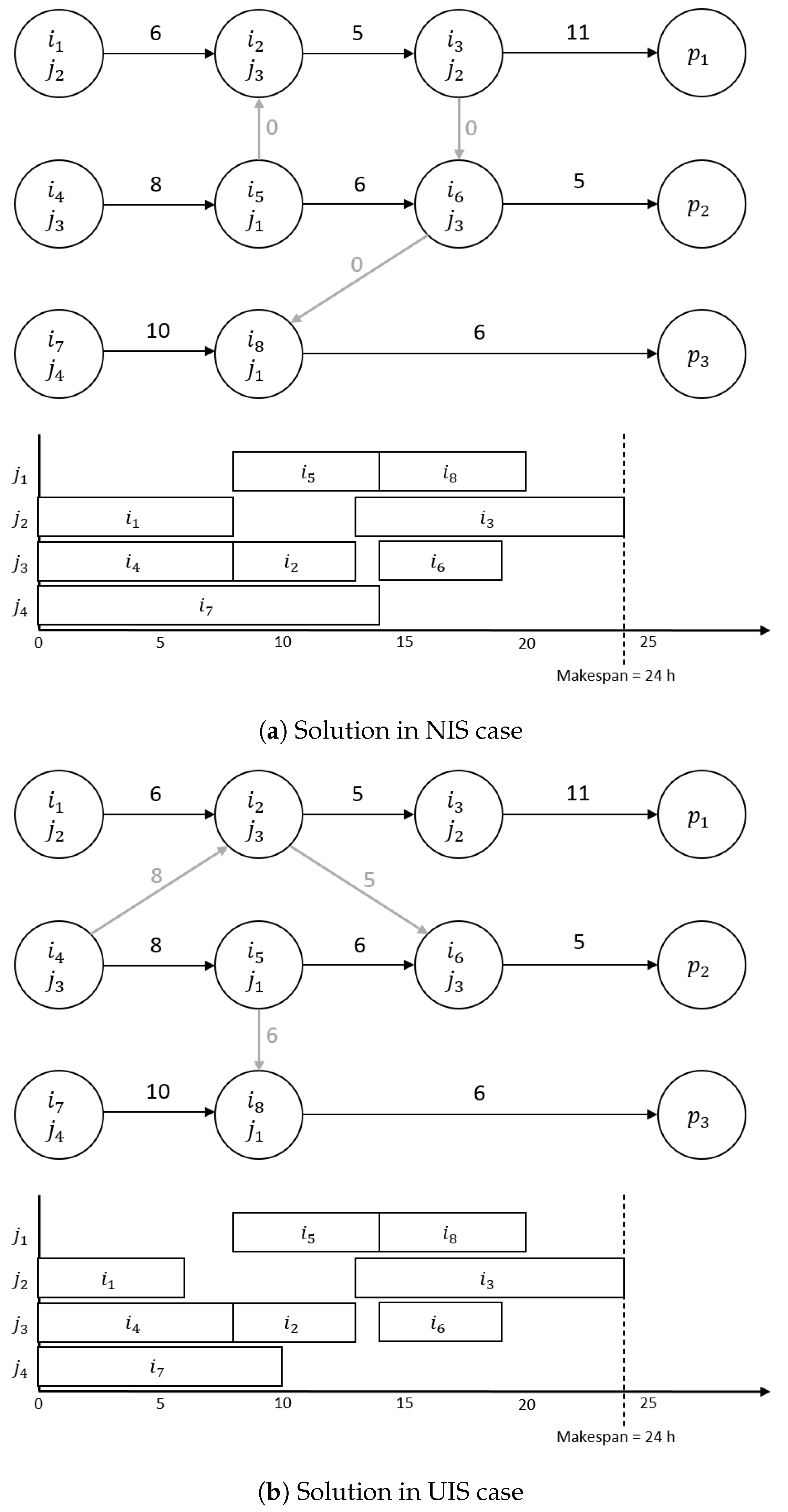

2.1. S-Graph Framework

- The sets of units have been replaced by the specific unit chosen by the algorithm to perform each task.

- Additional grey arcs expressing the activity order of units are included in the graph.

2.2. Equipment-Based and Task-Based Method

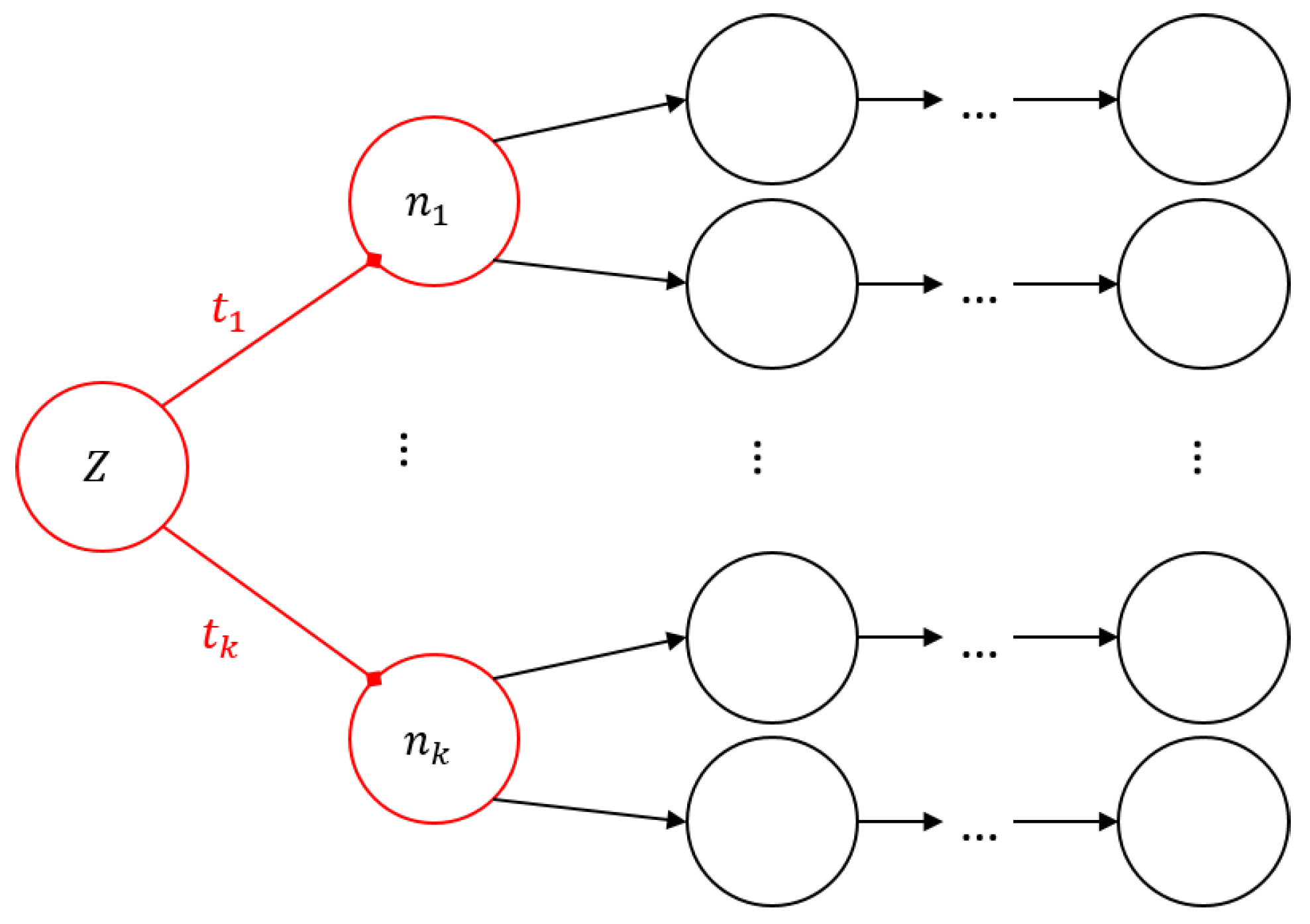

- Branching: During the generation of schedule-graphs in the B&B procedure, an S-graph and a partial assignment belong to a subproblem, i.e., to a node in the enumeration tree. The recipe-graph with no assignments serves as the root of the tree. At each partial problem, the equipment-based approach selects one equipment unit and generates child partial problems by considering all possible assignments of this equipment unit to unscheduled tasks. In contrast, the task-based approach selects one unscheduled task and generates all child partial problems by considering the possible equipment assignments to this task. In both cases, the processing time of a task may depend on the assigned equipment unit, which can modify the weight of the recipe-arcs starting from the node representing the task. The equipment-based approach ensures that if an assignment has already been made, the next assignment can only be made to the end of the sequence of tasks on the equipment, whereas the task-based approach allows for the sequence to change.

- Bounding: The bounding procedure evaluates the feasibility of a partial problem by testing whether it can be extended to a feasible schedule. If the test is positive, the algorithm determines a lower bound for the makespan of all solutions that can be derived from this partial problem. The feasibility of a partial problem is tested using a cycle search algorithm, which ensures that the schedule graph remains acyclic.

2.3. Reactive Method

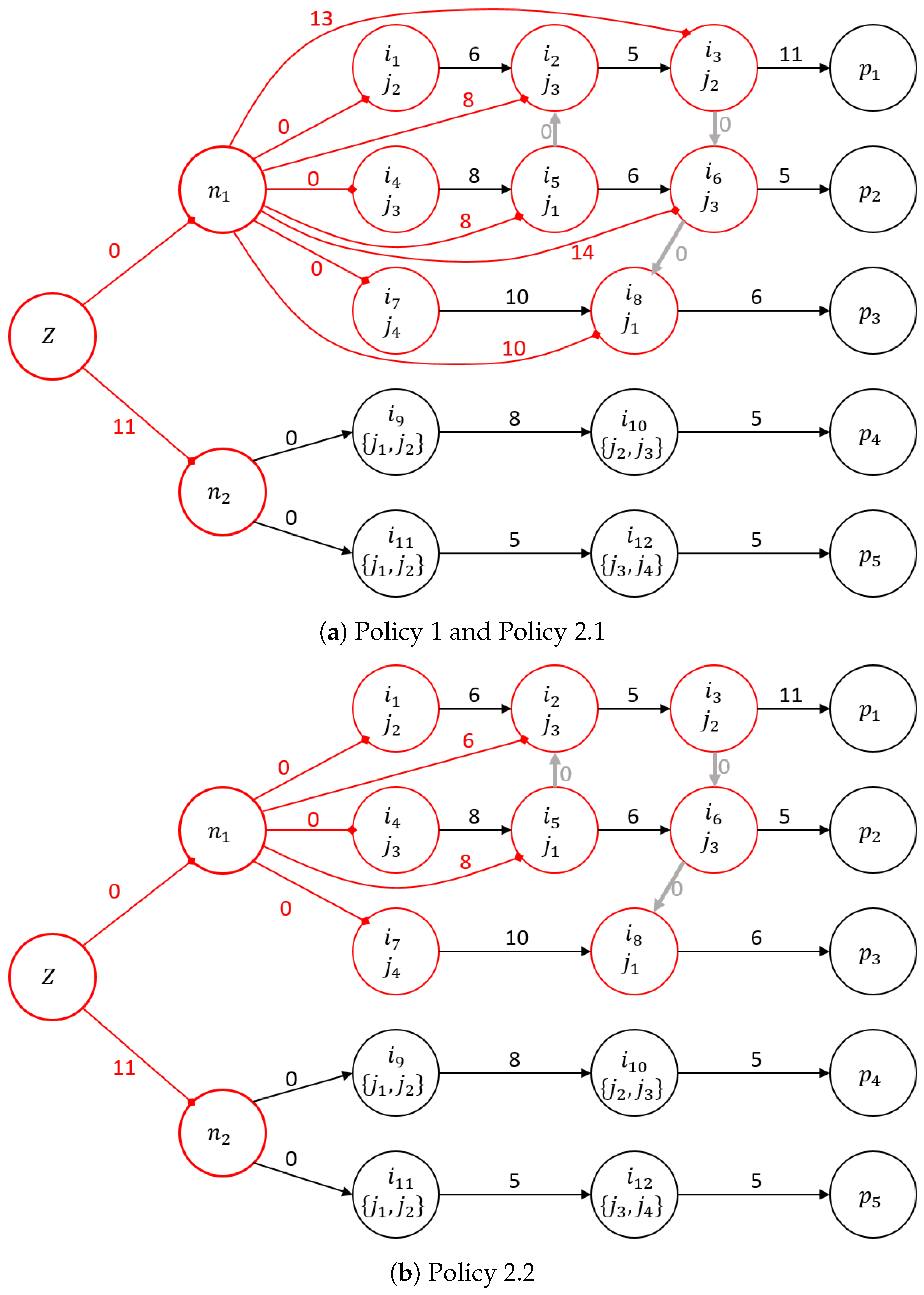

- Policy 1: None of the schedules of these tasks is allowed to be modified. It implies that the tasks of the new order can only be put to the end of the schedule.

- Policy 2: The sequence of tasks has to remain as defined in but the tasks of can be inserted between them. We can define a strict and a less strict sub-policy.

- –

- Policy 2.1: The timing of the older tasks cannot be changed, i.e., and free-time gaps are needed for inserting the new tasks.

- –

- Policy 2.2: The timing of the older tasks can be changed but their sequence and unit-task assignments must remain unchanged, i.e., they can only be delayed.

In the followings, statements referring to Policy 2 are true for both Policy 2.1 and 2.2. - Policy 3: All tasks of are free to reschedule.

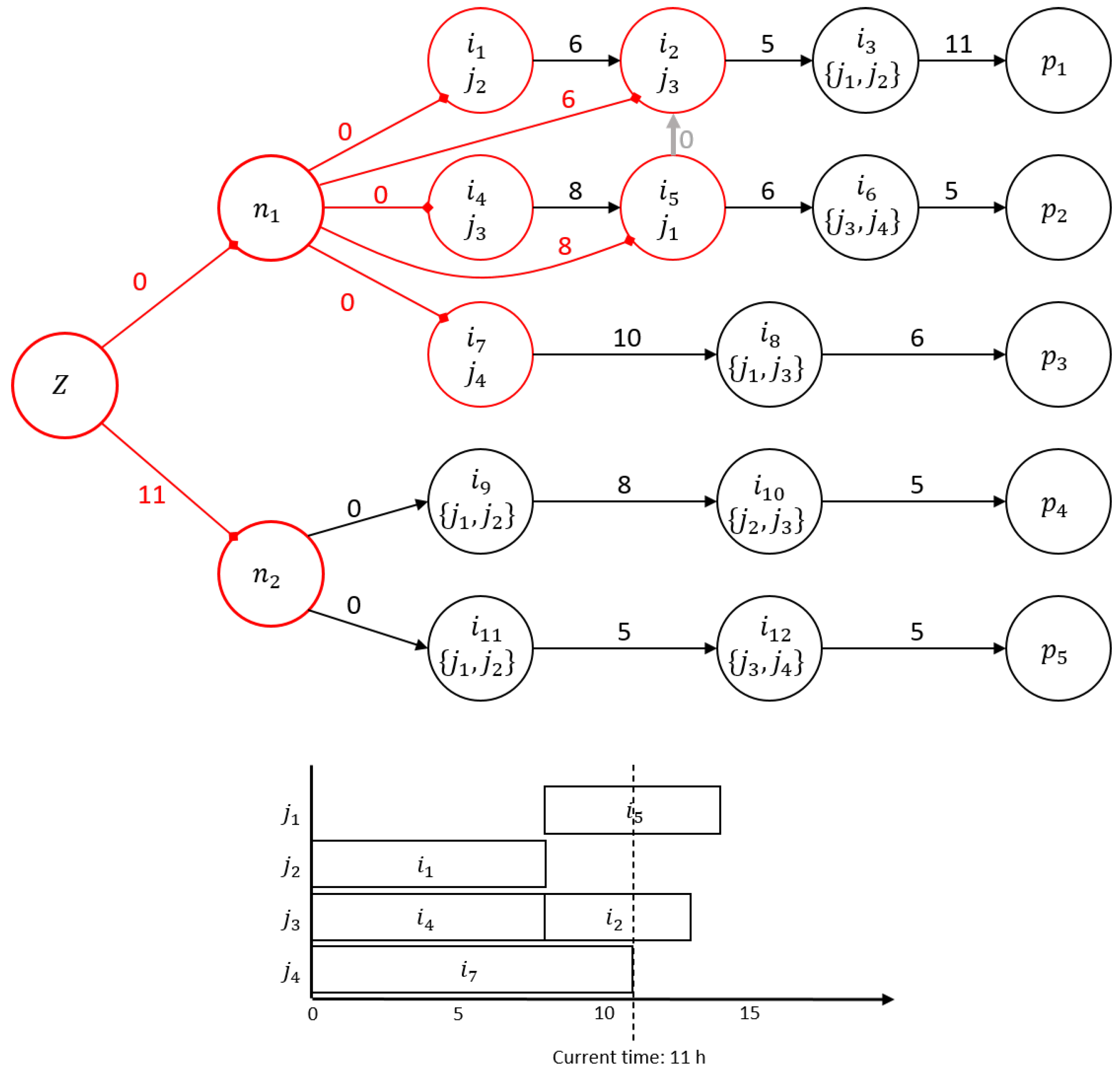

2.4. S-Graph Representation of the Current State of the Manufacturing Process

- Orders have arrived;

- Their tasks () have been scheduled, i.e., has been generated;

- Schedule is under execution;

- Order has just arrived.

- The tasks of the new order, , cannot be scheduled to start earlier than , i.e., , , .

- Some tasks of previous orders have already started, , which means that their schedule cannot be modified, i.e., .

2.5. Solution Methods

2.5.1. Initialization

- For Policy 1, the previous schedule cannot be modified, so each task of is in the ‘past’; therefore, only the tasks of order have to be scheduled, i.e., all tasks of . Using equipment-based branching, the initial set should contain the last assignment of each unit from schedule . Using task-based branching, the initial activity lists contain all tasks of according to schedule .

- For Policy 2, tasks that have already started before the arrival of order at time are considered as part of the ’past’ and cannot be modified. The initial set for equipment-based branching should include the last assignment of each unit from the past schedule . However, the original equipment-based approach lacks the capability to insert tasks into the activity list. To address this limitation, a modification is necessary to the approach to enable the insertion of new tasks between tasks that have not yet been started from previous orders . This modification allows the approach to insert new tasks without rescheduling the tasks that have not yet been started, thereby reducing the search space. The task-unit assignments for tasks have to remain as defined in schedule . The schedule-arcs of schedule ensure that the order of these tasks cannot change. As a result, only the new tasks () have to be scheduled. Using task-based branching, the initial activity lists contain all tasks of according to schedule . Because task-based branching can insert a task into an existing activity list, only the new tasks () have to be scheduled. Policy 2.1 is characterized by a stricter approach, as it permits task insertion only if a sufficient free time gap is available. Specifically, this policy ensures that the necessary completion time for the inserted task is available, thereby maintaining the integrity of the existing schedule. Policy 2.2 exhibits a more lenient characteristic as it does not enforce the availability of free time gaps. Consequently, task insertion is permitted between all tasks in the set .

- For Policy 3, all tasks, which have not started before , can be modified; therefore, all tasks of have to be scheduled. Using equipment-based branching, the initial set should contain the last assignment of each unit, which has already started (). Using task-based branching, the initial activity lists contain tasks that have started according to schedule .

2.5.2. Algorithms

- Policy 1 can be solved by the original equipment-based method after the proper initialization (see the previous section). The algorithm needs only to schedule the newly arrived tasks (), putting them after the previously scheduled tasks ().

- Policy 1 cannot be solved by the original task-based algorithm because this method cannot handle the constraint that the insertion between tasks of the original order is not allowed. Therefore, the algorithm has to be modified in such a way that, during the construction of the B&B tree, all branches where such an insertion would occur must be restricted.

- Equipment-based branching can only put tasks at the end of the activity lists of units, but Policy 2 allows tasks to be inserted into the lists. The equipment-based approach can be employed to solve Policy 2, but requires proper initialization and a necessary modification of the method, as discussed in the previous section. The initialization distinguishes the tasks of in the activity list, and using the schedule-arcs ensures that the order of these tasks remains as it was in the original list. The equipment-based approach generates branches that differ from the original method for tasks , ensuring that their order remains unchanged while allowing for the insertion of new tasks between them.

- Policy 2 can be solved by the original task-based algorithm because this approach allows for direct insertion between tasks, unlike in the case of the original equipment-based method. Therefore, the search space is smaller using the task-based method compared to using the equipment-based method.

- Policy 3 can be solved by the original equipment-based method after the initialization. The algorithm needs to schedule the newly arrived tasks () and reschedule all tasks, which have not started yet (), by adding them to the end of the activity lists.

- Policy 3 can be solved by the original task-based algorithm. However, this method inserts the tasks into the activity lists, and the structure of the S-graph (node , zero-wait arcs) ensures that none of the tasks, which have to be scheduled or rescheduled (), can start earlier than the already started tasks. Therefore, no modification of the task-based algorithm is necessary.

3. Results

3.1. Example 1

3.2. Example 2

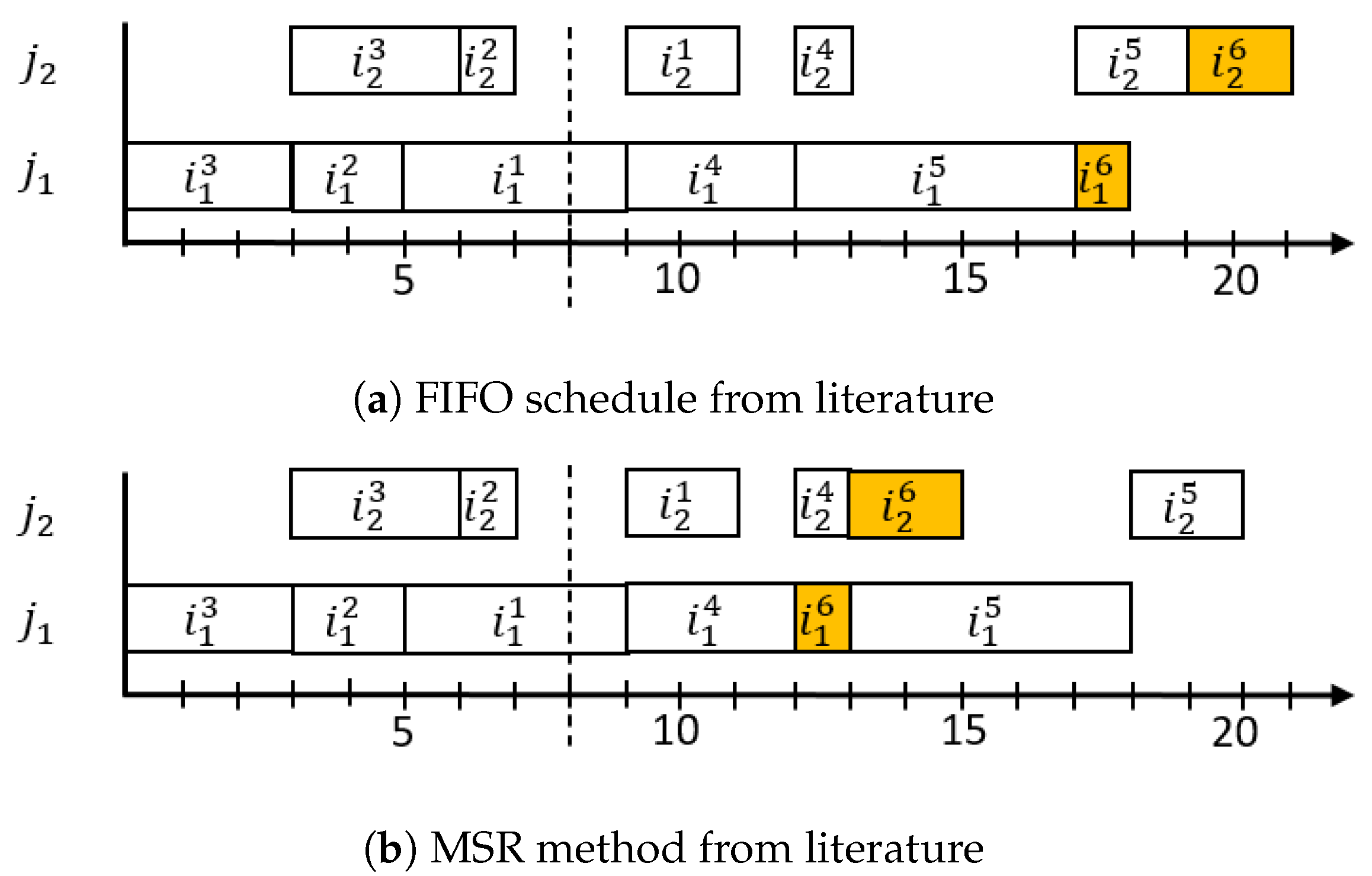

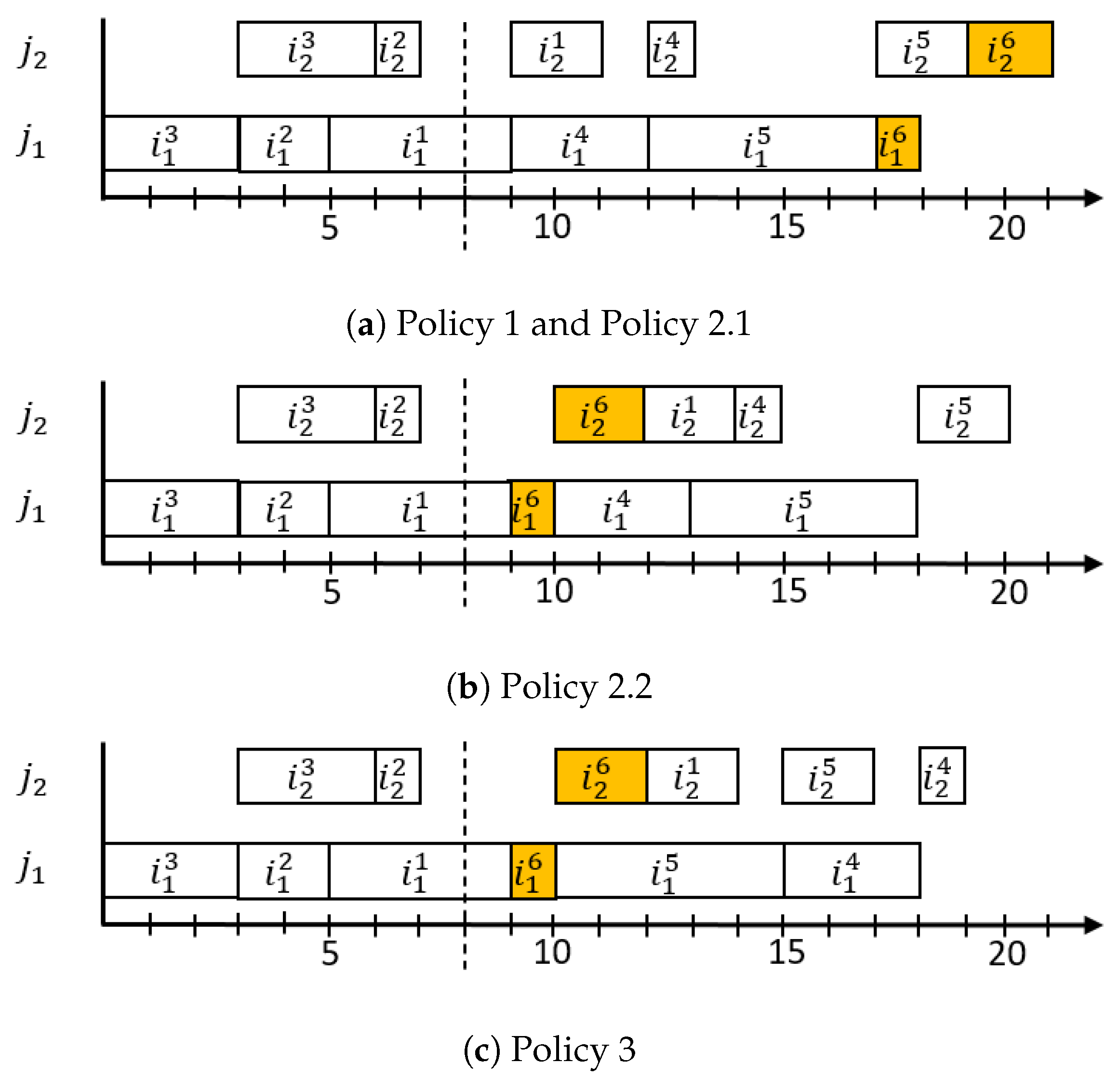

- In Strategy I, the tasks of the new order are rescheduled, while the already existing scheduling scheme remains constant. Machines are available after all assigned operations have been completed. This strategy is identical to the Policy 1 approach.

- The aim of Strategy II is to re-schedule new tasks and those that have not started yet. Therefore, the operations of existing tasks can be revised. The principle of Strategy II is identical to the proposed Policy 3 reactive approach.

- Strategy III includes an available-time block re-scheduling-based policy on the existing scheduling scheme. New tasks are scheduled on time gaps of all machines if it is possible. Therefore, if one machine is available and it has a free-time gap on the initial schedule, the machine can be employed with a new task. Finally, if all available time blocks on each machine are considered, the Strategy I scheduling scheme is employed for the remaining new tasks. Strategy III is equivalent to Policy 2.1.

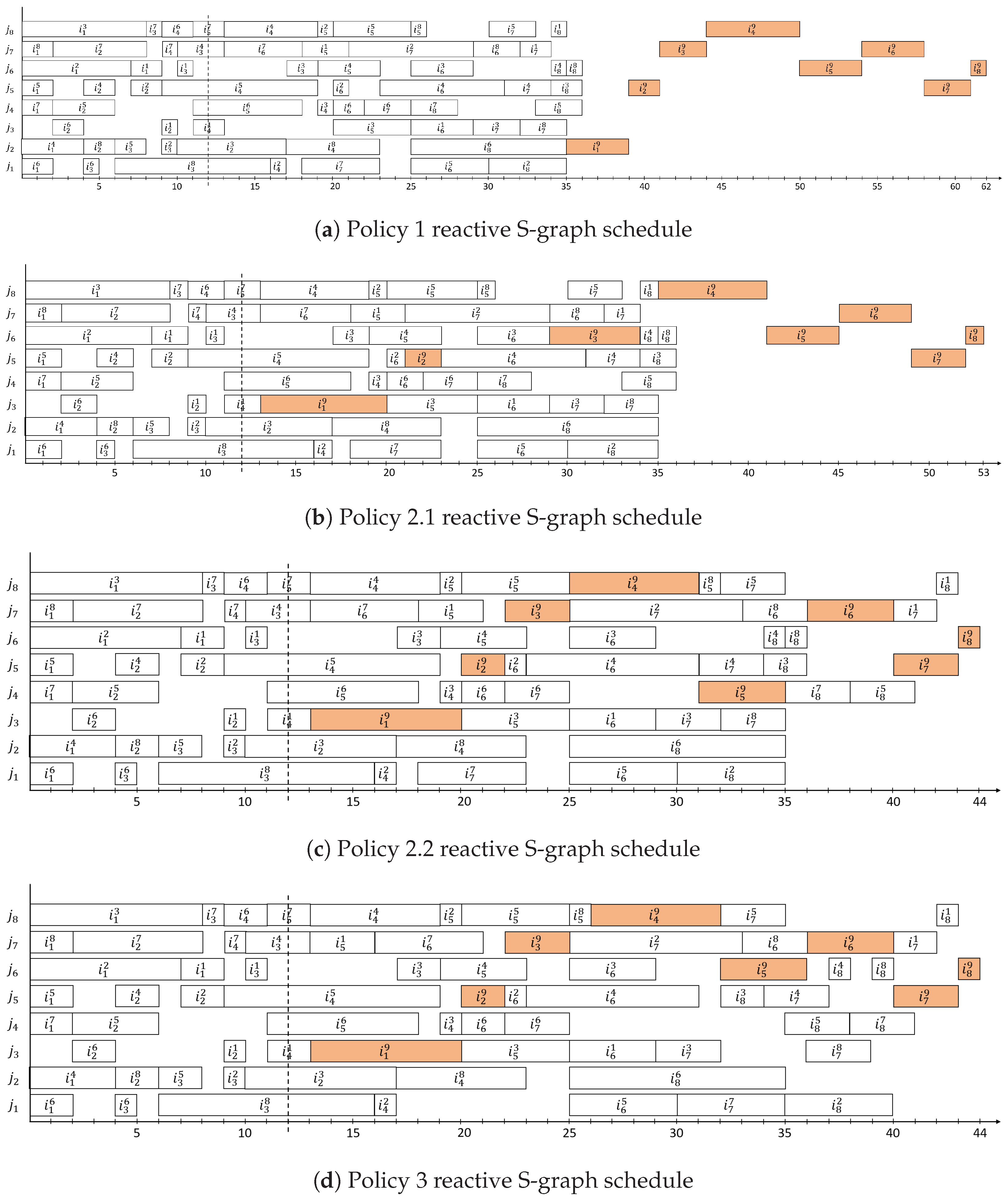

- The proposed Policy 1 approach provides a slightly better result (Figure 10a) than Strategy I, namely that the makespans are 63 and 62 for Strategy I and Policy 1, respectively. In our case, the production of product 9 starts when machine finishes its work (). In the published solution, it starts at the end of the whole initial schedule (); however, Strategy I should allow for an earlier start.

- For Policy 3, both equipment-based and task-based approaches have a makespan of 44. Compared with Strategy II, the same result is achieved, which can be explained by the consistency of the approaches. The significantly larger execution time for the task-based approach is caused by the complexity of the example (compared with the equipment-based approach) and the heuristic nature of the TABC algorithm. The Policy 3 solution is shown in Figure 10d.

- Comparing Policy 2 approaches with Strategy III, several differences can be discovered. The result of Policy 2.1, shown in Figure 10b, is equivalent to Strategy II. Using the Policy 2.2 approach, a better solution can be generated (Figure 10c) because the existing tasks can be delayed, i.e., the time gaps can be increased for longer tasks. Since there are more possibilities for Policy 2.2 than for Policy 2.1, it needs more CPU time, which can be seen clearly in the case of the equipment-based approach.

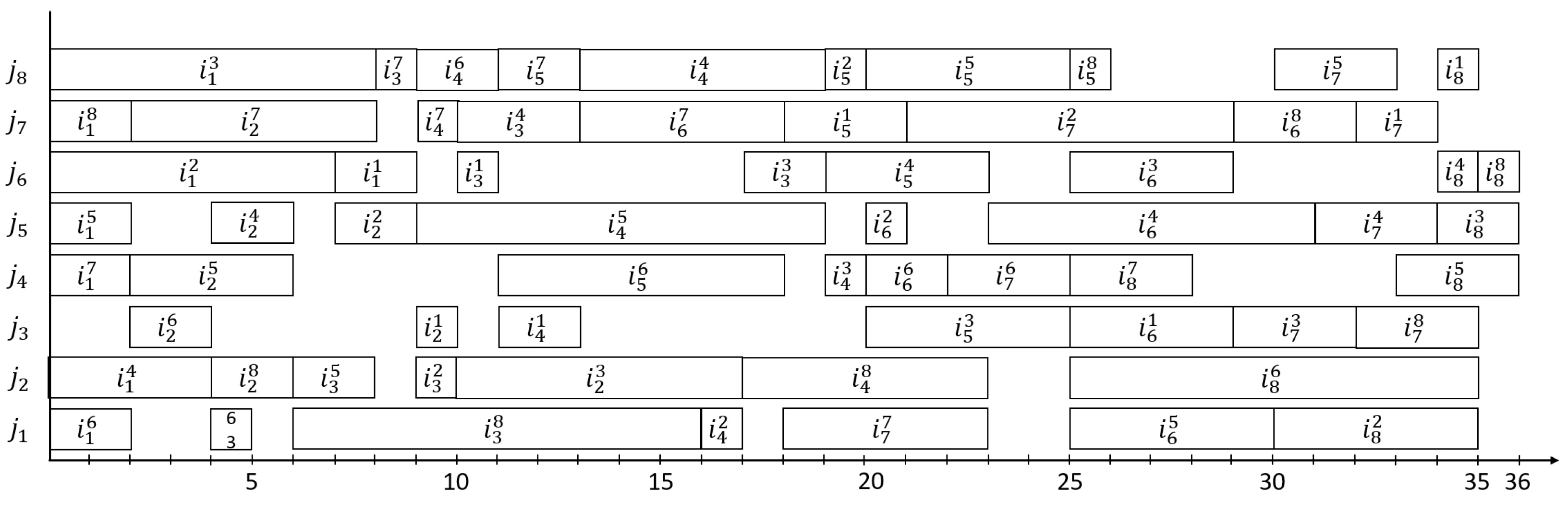

3.3. Additional Examples

- The new jobs are scheduled after the existing schedule is finished in the case of Strategy 1. Strategy 1 is more strict than Policy 1 because, despite the free capacity of machines, the new jobs cannot start before finishing the whole initial schedule.

- Using Strategy 2, each machine must complete all operations in the initial schedule before executing the new jobs. Strategy 2 is equivalent to Policy 1.

- The third strategy means simultaneously rescheduling the new jobs and the ongoing operations based on a single objective. Strategy 3 is equivalent to Policy 3.

- Strategy 4 is the same as Strategy 3 but it is based on the bi-criteria model.

- Scheduling the new jobs after the current jobs are finished (Policy 1).

- Scheduling the new jobs immediately and continuing with current jobs after new jobs are finished (rush orders).

- Inserting the new jobs into idle time while the current jobs are being finished (Policy 2.1).

- Scheduling the new jobs immediately and inserting the current jobs into idle time during completion of current jobs (rush order combined with Policy 2.2).

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| P | is a finite set of products; |

| I | is a finite set of tasks; |

| J | is a finite set of units; |

| is the set of tasks needed to be carried out to produce product ; | |

| is the set of tasks that are a prerequisite of task i; | |

| is the set of units can perform task ; | |

| is the set of tasks that can be performed by unit ; | |

| is the processing time of task performed by unit ; | |

| O | is a finite ordered set of orders, where precedes if and only if ; |

| is the arrival time of order ; | |

| is the set of tasks that have to be performed to fulfill order , where ; | |

| is a derived notation for the set of tasks that has to be performed to fulfill orders ; | |

| is a feasible schedule of orders ; | |

| is an assignment, where task is performed by unit , started at time and finished at in schedule ; | |

| is the set of assignments , where ; | |

| is the set of assignments , where ; | |

| is the set of tasks that are started before in schedule ; | |

| is the set of tasks that are not started before in schedule ; | |

| N | is the set of nodes; |

| is the set of task-nodes, where ; | |

| is the set of product-nodes, where ; | |

| is the set of recipe-arcs; | |

| is the set of schedule-arcs; | |

| is the weight of arc ; | |

| is an S-graph; | |

| is a recipe-graph; | |

| is the recipe-graph of order ; | |

| is the arrival node of order ; |

References

- Šebo, J.; Šebová, M.; Palčič, I. Implementation of Circular Economy Technologies: An Empirical Study of Slovak and Slovenian Manufacturing Companies. Sustainability 2021, 13, 12518. [Google Scholar] [CrossRef]

- Chaari, T.; Chaabane, S.; Aissani, N.; Trentesaux, D. Scheduling under uncertainty: Survey and research directions. In Proceedings of the 2014 International Conference on Advanced Logistics and Transport (ICALT), Hammamet, Tunisia, 1–3 May 2014; pp. 229–234. [Google Scholar] [CrossRef]

- Jackson, J.R. Simulation research on job shop production. Nav. Res. Logist. Q. 1957, 4, 287–295. [Google Scholar] [CrossRef]

- Riccardo Mogre, C.Y.W.; Lalwani, C.S. Mitigating supply and production uncertainties with dynamic scheduling using real-time transport information. Int. J. Prod. Res. 2014, 52, 5223–5235. [Google Scholar] [CrossRef][Green Version]

- Shen, Z.J.M.; Xie, J.; Zheng, Z.; Zhou, H. Dynamic scheduling with uncertain job types. Eur. J. Oper. Res. 2023, 309, 1047–1060. [Google Scholar] [CrossRef]

- Suresh, V.; Chaudhuri, D. Dynamic scheduling—A survey of research. Int. J. Prod. Econ. 1993, 32, 53–63. [Google Scholar] [CrossRef]

- Mohan, J.; Lanka, K.; Rao, A.N. A Review of Dynamic Job Shop Scheduling Techniques. Procedia Manuf. 2019, 30, 34–39. [Google Scholar] [CrossRef]

- Hegyháti, M.; Friedler, F. Overview of industrial batch process scheduling. Chem. Eng. 2010, 21, 895–900. [Google Scholar] [CrossRef]

- Otala, J.; Minard, A.; Madraki, G.; Mousavian, S. Graph-Based Modeling in Shop Scheduling Problems: Review and Extensions. Appl. Sci. 2021, 11, 4741. [Google Scholar] [CrossRef]

- Hojny, C.; Joormann, I.; Lüthen, H.; Schmidt, M. Mixed-integer programming techniques for the connected max-k-cut problem. Math. Program. Comput. 2021, 13, 75–132. [Google Scholar] [CrossRef]

- Sanmartí, E.; Puigjaner, L.; Holczinger, T.; Friedler, F. Combinatorial framework for effective scheduling of multipurpose batch plants. AIChE J. 2002, 48, 2557–2570. [Google Scholar] [CrossRef]

- Holczinger, T.; Romero, J.; Puigjaner, L.; Friedler, F. Scheduling of Multipurpose Batch Processes with Multiple Batches of the Products. Hung. J. Ind. Chem. 2002, 30, 263–270. [Google Scholar] [CrossRef]

- Hegyháti, M. Batch Process Scheduling: Extensions of the S-graph Framework. Ph.D. Thesis, University of Pannonia, Veszprém, Hungary, 2015. [Google Scholar]

- Adonyi, R.; Biros, G.; Holczinger, T.; Friedler, F. Effective scheduling of a large-scale paint production system. J. Clean. Prod. 2008, 16, 225–232. [Google Scholar] [CrossRef]

- Suzanne, E.; Absi, N.; Borodin, V. Towards circular economy in production planning: Challenges and opportunities. Eur. J. Oper. Res. 2020, 287, 168–190. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2022, 30, 864–898. [Google Scholar] [CrossRef]

- Berg, H.; Wilts, H. Digital platforms as market places for the circular economy-requirements and challenges. Nachhalt.|Sustain. Manag. Forum 2019, 27, 1–9. [Google Scholar] [CrossRef]

- Tatipala, S.; Larsson, T.; Johansson, C.; Wall, J. The Influence of Industry 4.0 on Product Design and Development: Conceptual Foundations and Literature Review. In Design for Tomorrow—Volume 2; Chakrabarti, A., Poovaiah, R., Bokil, P., Kant, V., Eds.; Springer: Singapore, 2021; pp. 757–768. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Industry 4.0—Challenges to implement circular economy. Benchmarking Int. J. 2019. ahead-of-print. [Google Scholar] [CrossRef]

- Hennemann Hilario da Silva, T.; Sehnem, S. The circular economy and Industry 4.0: Synergies and challenges. Rev. De Gestão 2022, 29, 300–313. [Google Scholar] [CrossRef]

- Bakajic, M.; Parvi, A. Barriers to Closing Waste Loops in the European Union. Master’s Thesis, Aalto University School of Business, Espoo, Finland, 2018. [Google Scholar] [CrossRef]

- Rossi, J.; Bianchini, A.; Guarnieri, P. Circular Economy Model Enhanced by Intelligent Assets from Industry 4.0: The Proposition of an Innovative Tool to Analyze Case Studies. Sustainability 2020, 12, 7147. [Google Scholar] [CrossRef]

- Bakon, K.; Holczinger, T.; Süle, Z.; Jaskó, S.; Abonyi, J. Scheduling Under Uncertainty for Industry 4.0 and 5.0. IEEE Access 2022, 10, 74977–75017. [Google Scholar] [CrossRef]

- O’Donovan, R.; Uzsoy, R.; McKay, K.N. Predictable scheduling of a single machine with breakdowns and sensitive jobs. Int. J. Prod. Res. 1999, 37, 4217–4233. [Google Scholar] [CrossRef]

- Liu, L.; Gu, H.y.; Xi, Y.G. Robust and stable scheduling of a single machine with random machine breakdowns. Int. J. Adv. Manuf. Technol. 2007, 31, 645–654. [Google Scholar] [CrossRef]

- Kouvelis, P.; Daniels, R.L.; Vairaktarakis, G. Robust scheduling of a two-machine flow shop with uncertain processing times. IIE Trans. 2000, 32, 421–432. [Google Scholar] [CrossRef]

- Jamili, A. Robust job shop scheduling problem: Mathematical models, exact and heuristic algorithms. Expert Syst. Appl. 2016, 55, 341–350. [Google Scholar] [CrossRef]

- Bean, J.C.; Birge, J.R.; Mittenthal, J.; Noon, C.E. Matchup scheduling with multiple resources, release dates and disruptions. Oper. Res. 1991, 39, 470–483. [Google Scholar] [CrossRef]

- Szelke, E.; Kerr, R.M. Knowledge-based reactive scheduling. Prod. Plan. Control 1994, 5, 124–145. [Google Scholar] [CrossRef]

- Pach, C.; Berger, T.; Sallez, Y.; Trentesaux, D. Reactive control of overall power consumption in flexible manufacturing systems scheduling: A Potential Fields model. Control Eng. Pract. 2015, 44, 193–208. [Google Scholar] [CrossRef]

- Nouiri, M.; Trentesaux, D.; Bekrar, A. Towards Energy Efficient Scheduling of Manufacturing Systems through Collaboration between Cyber Physical Production and Energy Systems. Energies 2019, 12, 4448. [Google Scholar] [CrossRef]

- Nowak, T.; Toyasaki, F.; Wakolbinger, T. The Road Toward a Circular Economy: The Role of Modular Product Designs in Supply Chains. In Innovative Solutions for Sustainable Supply Chains; Qudrat-Ullah, H., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 111–133. [Google Scholar] [CrossRef]

- Tolio, T.; Urgo, M.; Váncza, J. Robust production control against propagation of disruptions. CIRP Ann. 2011, 60, 489–492. [Google Scholar] [CrossRef]

- Mönch, L.; Fowler, J.W.; Mason, S.J. Production Planning and Control for Semiconductor Wafer Fabrication Facilities: Modeling, Analysis, and Systems; Springer Science & Business Media: Berlin, Germany, 2012; Volume 52. [Google Scholar] [CrossRef]

- Pinedo, M.L. Scheduling; Springer: Cham, Switzerland, 2012. [Google Scholar] [CrossRef]

- Nadeem, S.; Garza-Reyes, J.A.; Anosike, A. A C-Lean framework for deploying Circular Economy in manufacturing SMEs. Prod. Plan. Control 2023, 1–21. [Google Scholar] [CrossRef]

- Han, J.; Heshmati, A.; Rashidghalam, M. Circular Economy Business Models with a Focus on Servitization. Sustainability 2020, 12, 8799. [Google Scholar] [CrossRef]

- Ouelhadj, D.; Petrovic, S. A survey of dynamic scheduling in manufacturing systems. J. Sched. 2009, 12, 417–431. [Google Scholar] [CrossRef]

- Schönemann, M.; Herrmann, C.; Greschke, P.; Thiede, S. Simulation of matrix-structured manufacturing systems. J. Manuf. Syst. 2015, 37, 104–112. [Google Scholar] [CrossRef]

- Munavalli, J.R.; Rao, S.V.; Srinivasan, A.; van Merode, G.G. An intelligent real-time scheduler for out-patient clinics: A multi-agent system model. Health Inform. J. 2020, 26, 2383–2406. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P.; Xiao, G. Two-stage mechanism design for electric vehicle charging involving renewable energy. In Proceedings of the 2014 International Conference on Connected Vehicles and Expo, ICCVE 2014, Vienna, Austria, 3–7 November 2014; pp. 421–426. [Google Scholar] [CrossRef]

- Wu, L.; Chen, X.; Chen, X.; Chen, Q. A genetic algorithm for reactive scheduling based on real-time manufacturing information. In Proceedings of the 5th International Conference on Responsive Manufacturing—Green Manufacturing (ICRM 2010), Ningbo, China, 11–13 January 2010; pp. 375–381. [Google Scholar] [CrossRef]

- Panda, D.; Ramteke, M. Dynamic hybrid scheduling of crude oil using structure adapted genetic algorithm for uncertainty of tank unavailability. Chem. Eng. Res. Des. 2020, 159, 78–91. [Google Scholar] [CrossRef]

- Nouiri, M.; Bekrar, A.; Jemai, A.; Ammari, A.; Niar, S. A New Rescheduling Heuristic for Flexible Job Shop Problem with Machine Disruption. Stud. Comput. Intell. 2018, 762, 461–476. [Google Scholar] [CrossRef]

- Katragjini, K.; Vallada, E.; Ruiz, R. Flow shop rescheduling under different types of disruption. Int. J. Prod. Res. 2013, 51, 780–797. [Google Scholar] [CrossRef]

- Basán, N.; Cóccola, M.; Dondo, R.; Guarnaschelli, A.; Schweickardt, G.; Méndez, C. A reactive-iterative optimization algorithm for scheduling of air separation units under uncertainty in electricity prices. Comput. Chem. Eng. 2020, 142, 107050. [Google Scholar] [CrossRef]

- Shin, J.; Lee, J. Procurement scheduling under supply and demand uncertainty: Case study for comparing classical, reactive, and proactive scheduling. In Proceedings of the ICCAS 2015—2015 15th International Conference on Control, Automation and Systems, Busan, Republic of Korea, 13–16 October 2015; pp. 636–641. [Google Scholar] [CrossRef]

- Novas, J.; Henning, G. Reactive scheduling framework based on domain knowledge and constraint programming. Comput. Chem. Eng. 2010, 34, 2129–2148. [Google Scholar] [CrossRef]

- Leo, E.; Dalle Ave, G.; Harjunkoski, I.; Engell, S. Stochastic short-term integrated electricity procurement and production scheduling for a large consumer. Comput. Chem. Eng. 2021, 145, 107191. [Google Scholar] [CrossRef]

- Chen, S.I.; Su, D. A multi-stage stochastic programming model of lot-sizing and scheduling problems with machine eligibilities and sequence-dependent setups. Ann. Oper. Res. 2019, 311, 35–50. [Google Scholar] [CrossRef]

- Araki, K.; Yoshitomi, Y. Stochastic job-shop scheduling: A hybrid approach combining pseudo particle swarm optimization and the Monte Carlo method. J. Adv. Mech. Des. Syst. Manuf. 2016, 10, JAMDSM0053. [Google Scholar] [CrossRef][Green Version]

- Cao, C.; Gu, X.; Xin, Z. Stochastic chance constrained mixed-integer nonlinear programming models and the solution approaches for refinery short-term crude oil scheduling problem. Appl. Math. Model. 2010, 34, 3231–3243. [Google Scholar] [CrossRef]

- Mohammadi, M. Designing an integrated reliable model for stochastic lot-sizing and scheduling problem in hazardous materials supply chain under disruption and demand uncertainty. J. Clean. Prod. 2020, 274, 122621. [Google Scholar] [CrossRef]

- Balasubramanian, J.; Grossmann, I. Scheduling optimization under uncertainty—an alternative approach. Comput. Chem. Eng. 2003, 27, 469–490. [Google Scholar] [CrossRef]

- Zadeh, L. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Mendel, J.; John, R. Type-2 fuzzy sets made simple. IEEE Trans. Fuzzy Syst. 2002, 10, 117–127. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, Y.; Chan, F.; Xu, P.; Mahadevan, S.; Hu, Y. IFSJSP: A novel methodology for the Job-Shop Scheduling Problem based on intuitionistic fuzzy sets. Int. J. Prod. Res. 2013, 51, 5100–5119. [Google Scholar] [CrossRef]

- Liu, G.S.; Zhou, Y.; Yang, H.D. Minimizing energy consumption and tardiness penalty for fuzzy flow shop scheduling with state-dependent setup time. J. Clean. Prod. 2017, 147, 470–484. [Google Scholar] [CrossRef]

- Yang, M.; Ba, L.; Zheng, H.; Liu, Y.; Wang, X.; He, J.; Li, Y. An integrated system for scheduling of processing and assembly operations with fuzzy operation time and fuzzy delivery time. Adv. Prod. Eng. Manag. 2019, 14, 367–378. [Google Scholar] [CrossRef]

- Han, J.; Liu, Y.; Luo, L.; Mao, M. Integrated production planning and scheduling under uncertainty: A fuzzy bi-level decision-making approach. Knowl.-Based Syst. 2020, 201–202, 106056. [Google Scholar] [CrossRef]

- Torabi, S.; Sahebjamnia, N.; Mansouri, S.; Bajestani, M.A. A particle swarm optimization for a fuzzy multi-objective unrelated parallel machines scheduling problem. Appl. Soft Comput. 2013, 13, 4750–4762. [Google Scholar] [CrossRef]

- Palacios, J.J.; Puente, J.; González-Rodríguez, I.; Vela, C.R. Hybrid Tabu Search for Fuzzy Job Shop. In Natural and Artificial Models in Computation and Biology; Ferrández Vicente, J.M., Álvarez Sánchez, J.R., de la Paz López, F., Toledo Moreo, F.J., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 376–385. [Google Scholar] [CrossRef]

- Vela, C.; Afsar, S.; Palacios, J.; González-Rodríguez, I.; Puente, J. Evolutionary tabu search for flexible due-date satisfaction in fuzzy job shop scheduling. Comput. Oper. Res. 2020, 119, 104931. [Google Scholar] [CrossRef]

- Herroelen, W.; Leus, R. Project scheduling under uncertainty: Survey and research potentials. Eur. J. Oper. Res. 2005, 165, 289–306. [Google Scholar] [CrossRef]

- Liao, L.M.; Huang, C.J. Tabu search for non-permutation flowshop scheduling problem with minimizing total tardiness. Appl. Math. Comput. 2010, 217, 557–567. [Google Scholar] [CrossRef]

- Vasiljevic, D.; Danilovic, M. Handling ties in heuristics for the permutation flow shop scheduling problem. J. Manuf. Syst. 2015, 35, 1–9. [Google Scholar] [CrossRef]

- Rahman, H.F.; Sarker, R.; Essam, D. A real-time order acceptance and scheduling approach for permutation flow shop problems. Eur. J. Oper. Res. 2015, 247, 488–503. [Google Scholar] [CrossRef]

- Perez-Gonzalez, P.; Framinan, J.M. Setting a common due date in a constrained flowshop: A variable neighbourhood search approach. Comput. Oper. Res. 2010, 37, 1740–1748. [Google Scholar] [CrossRef]

- Safari, E.; Sadjadi, S.J. A hybrid method for flowshops scheduling with condition-based maintenance constraint and machines breakdown. Expert Syst. Appl. 2011, 38, 2020–2029. [Google Scholar] [CrossRef]

- Nandi, A.; Rogers, P. Using simulation to make order acceptance/rejection decisions. Simulation 2004, 80, 131–142. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Si, J. Dynamic Job Shop Scheduling Problem with New Job Arrivals: A Survey. In Proceedings of 2019 Chinese Intelligent Automation Conference; Deng, Z., Ed.; Springer: Singapore, 2020; pp. 664–671. [Google Scholar]

- Abdullah, W.N. Solving Job-Shop Scheduling Problem Using Genetic Algorithm Approach. J. Coll. Basic Educ. 2011, 17, 241–253. [Google Scholar] [CrossRef]

- Moratori, P.; Petrovic, S.; Vázquez-Rodríguez, J.A. Integrating rush orders into existent schedules for a complex job shop problem. Appl. Intell. 2010, 32, 205–215. [Google Scholar] [CrossRef]

- Perez-Gonzalez, P.; Framinan, J.M. Assessing scheduling policies in a permutation flowshop with common due dates. Int. J. Prod. Res. 2015, 53, 5742–5754. [Google Scholar] [CrossRef]

- Koch, S.; Wäscher, G. A grouping genetic algorithm for the order batching problem in distribution warehouses. J. Bus. Econ. 2016, 86, 131–153. [Google Scholar] [CrossRef]

- Kulak, O.; Sahin, Y.; Taner, M.E. Joint order batching and picker routing in single and multiple-cross-aisle warehouses using cluster-based tabu search algorithms. Flex. Serv. Manuf. J. 2012, 24, 52–80. [Google Scholar] [CrossRef]

- Albareda-Sambola, M.; Alonso-Ayuso, A.; Molina, E.; De Blas, C.S. Variable neighborhood search for order batching in a warehouse. Asia-Pac. J. Oper. Res. 2009, 26, 655–683. [Google Scholar] [CrossRef]

- Romero, J.; Puigjaner, L.; Holczinger, T.; Friedler, F. Scheduling Intermediate Storage Multipurpose Batch Plants Using the S-Graph. AIChE J. 2004, 50, 403–417. [Google Scholar] [CrossRef]

- Hegyháti, M.; Holczinger, T.; Szoldatics, A.; Friedler, F. Combinatorial approach to address batch scheduling problems with limited storage time. Chem. Eng. 2011, 25, 495. [Google Scholar] [CrossRef]

- Adonyi, R.; Holczinger, T.; Friedler, F. Novel branching procedure for S-graphs based scheduling of batch processes. In Proceedings of the 19th Polish Conference of Chemical and Process Engineering, Prague, Czech Republic, 25–29 August 2018; p. 9. [Google Scholar]

- Adonyi, R. Batch Process Scheduling with the Extensions of the S-Graph Framework. Ph.D. Thesis, Doctoral School of Information Science and Technology, University of Pannonia, Veszprém, Hungary, 2008. [Google Scholar]

- Rahmani, D.; Heydari, M. Robust and stable flow shop scheduling with unexpected arrivals of new jobs and uncertain processing times. J. Manuf. Syst. 2014, 33, 84–92. [Google Scholar] [CrossRef]

- Gao, K.Z.; Suganthan, P.N.; Chua, T.J.; Chong, C.S.; Cai, T.X.; Pan, Q.K. A two-stage artificial bee colony algorithm scheduling flexible job-shop scheduling problem with new job insertion. Expert Syst. Appl. 2015, 42, 7652–7663. [Google Scholar] [CrossRef]

- Baykasoğlu, A.; Madenoğlu, F.S.; Hamzadayı, A. Greedy randomized adaptive search for dynamic flexible job-shop scheduling. J. Manuf. Syst. 2020, 56, 425–451. [Google Scholar] [CrossRef]

- Duan, J.; Wang, J. Robust scheduling for flexible machining job shop subject to machine breakdowns and new job arrivals considering system reusability and task recurrence. Expert Syst. Appl. 2022, 203, 117489. [Google Scholar] [CrossRef]

- Fattahi, P.; Fallahi, A. Dynamic scheduling in flexible job shop systems by considering simultaneously efficiency and stability. CIRP J. Manuf. Sci. Technol. 2010, 2, 114–123. [Google Scholar] [CrossRef]

- Hao, X.; Lin, L. Job shop rescheduling by using multi-objective genetic algorithm. In Proceedings of the 40th International Conference on Computers & Indutrial Engineering, Awaji, Japan, 25–28 July 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Li, Y.; He, Y.; Wang, Y.; Tao, F.; Sutherland, J.W. An optimization method for energy-conscious production in flexible machining job shops with dynamic job arrivals and machine breakdowns. J. Clean. Prod. 2020, 254, 120009. [Google Scholar] [CrossRef]

- Moghaddam, S.K.; Saitou, K. On optimal dynamic pegging in rescheduling for new order arrival. Comput. Ind. Eng. 2019, 136, 46–56. [Google Scholar] [CrossRef]

- Muhamad, A.S.; Zakaria, Z.; Deris, S. Rescheduling for JSSP and FJSSP using Clonal Selection Principle Approach–A Theory. J. Inf. 2016, 1, 10–20. [Google Scholar]

- Caldeira, R.H.; Gnanavelbabu, A.; Vaidyanathan, T. An effective backtracking search algorithm for multi-objective flexible job shop scheduling considering new job arrivals and energy consumption. Comput. Ind. Eng. 2020, 149, 106863. [Google Scholar] [CrossRef]

| Policy | Tasks with ZW-arc | Tasks to Schedule | EQ-Based Branching | Task-Based Branching |

|---|---|---|---|---|

| Policy 1 | ✓ | stricted | ||

| Policy 2.1 | extended | stricted | ||

| Policy 2.2 | extended | ✓ | ||

| Policy 3 | ✓ | ✓ |

| Algorithm | Strategy | CPU Time [s] | Makespan |

|---|---|---|---|

| TABC algorithm [84] | Strategy I | 0.235 | 63 |

| Strategy II | 2.343 | 44 | |

| Strategy III | 0.419 | 53 | |

| Task-based | Policy 1 | 0.013 | 62 |

| Policy 2.1 | 0.083 | 53 | |

| Policy 2.2 | 0.073 | 44 | |

| Policy 3 | 487.253 | 44 | |

| Equipment-based | Policy 1 | 0.005 | 62 |

| Policy 2.1 | 0.156 | 53 | |

| Policy 2.2 | 2.307 | 44 | |

| Policy 3 | 2.270 | 44 |

| Example | S-Graph Reactive Method | ||||

|---|---|---|---|---|---|

| Paper | Approach | Objectives | Makespan | Policy | Makespan |

| [85] | Greedy randomized adaptive search | mean tardiness, instability, makespan, mean flow time | 19 | Policy 1 | 24 |

| Policy 2.1 | 24 | ||||

| Policy 2.2 | 19 | ||||

| Policy 3 | 19 | ||||

| [86] | Swarm algorithm | makespan | 22 | Policy 1 | 28 |

| Policy 2.1 | 28 | ||||

| Policy 2.2 | 27 | ||||

| Policy 3 | 22 | ||||

| [87] | Genetic algorithm | effectiveness, stability | Strategy 1: 28 | Policy 1 | 23 |

| Strategy 2: 23 | Policy 2.1 | 22 | |||

| Strategy 3: 19 | Policy 2.2 | 20 | |||

| Strategy 4: 19 | Policy 3 | 19 | |||

| [88] | Evolutionary algorithm | makespan, disruption | 117 | Policy 1 | 113 |

| Policy 2.1 | 113 | ||||

| Policy 2.2 | 113 | ||||

| Policy 3 | 113 | ||||

| [89] | Genetic algorithm | energy consumption, makespan | Policy 1 | 40.1 | |

| Strategy 1: 40.1 | Policy 2.1 | 40.1 | |||

| Policy 2.2 | 40.1 | ||||

| Strategy 2: 37.6 | Policy 3 | 37.6 | |||

| [90] | MIP model | overall idle time, makespan | Policy 1 | 25 | |

| FPFS: 24 | Policy 2.1 | 23.5 | |||

| Policy 2.2 | 23.5 | ||||

| FPRS: 24 | Policy 3 | 23.5 | |||

| [91] | Clonal selection principle | completion time | Strategy i: 24 | Policy 1 | 24 |

| Strategy ii: 25 | Policy 2.1 | 24 | |||

| Strategy iii: 24 | Policy 2.2 | 20 | |||

| Strategy iv: 22 | Policy 3 | 20 | |||

| [92] | Backtracking search algorithm | makespan, energy consumption, instability | 52 | Policy 1 | 57 |

| Policy 2.1 | 54 | ||||

| Policy 2.2 | 50 | ||||

| Policy 3 | 50 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakon, K.A.; Holczinger, T. S-Graph-Based Reactive Scheduling with Unexpected Arrivals of New Orders. Machines 2024, 12, 446. https://doi.org/10.3390/machines12070446

Bakon KA, Holczinger T. S-Graph-Based Reactive Scheduling with Unexpected Arrivals of New Orders. Machines. 2024; 12(7):446. https://doi.org/10.3390/machines12070446

Chicago/Turabian StyleBakon, Krisztián Attila, and Tibor Holczinger. 2024. "S-Graph-Based Reactive Scheduling with Unexpected Arrivals of New Orders" Machines 12, no. 7: 446. https://doi.org/10.3390/machines12070446

APA StyleBakon, K. A., & Holczinger, T. (2024). S-Graph-Based Reactive Scheduling with Unexpected Arrivals of New Orders. Machines, 12(7), 446. https://doi.org/10.3390/machines12070446