Investigation of Valve Seat Cone Angle on Small Opening Direct-Acting Relief Valve Cavitation Noise

Abstract

1. Introduction

2. Direct-Acting Relief Valve Modeling

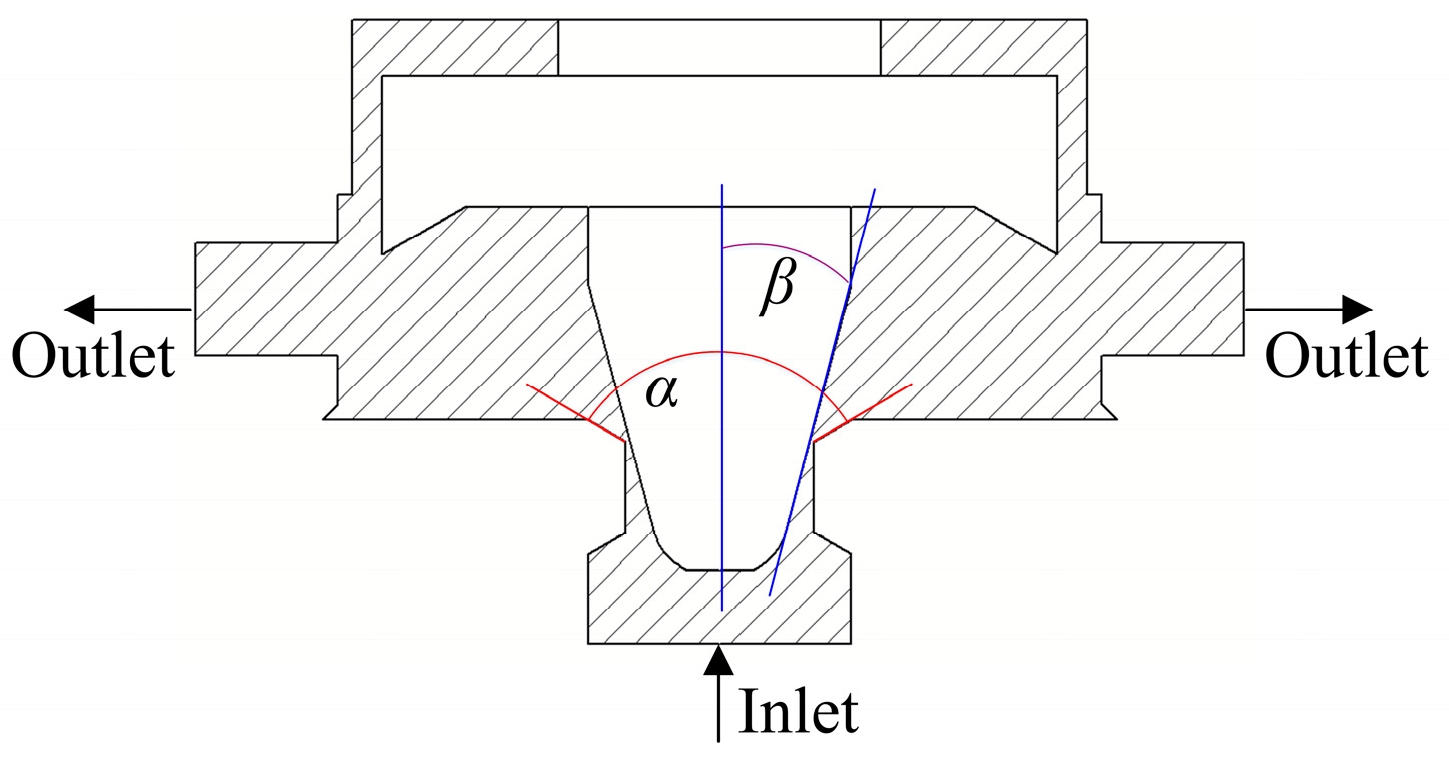

2.1. Working Principle and Configuration of Direct-Acting Relief Valves

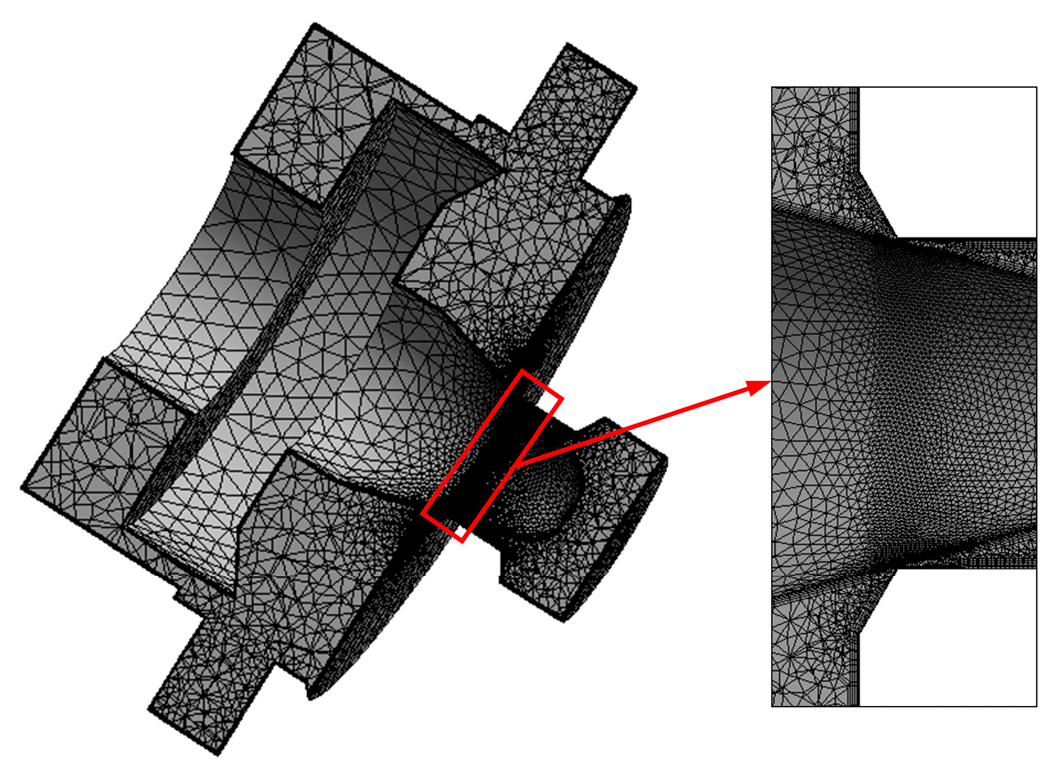

2.2. Fluid Computational Domain

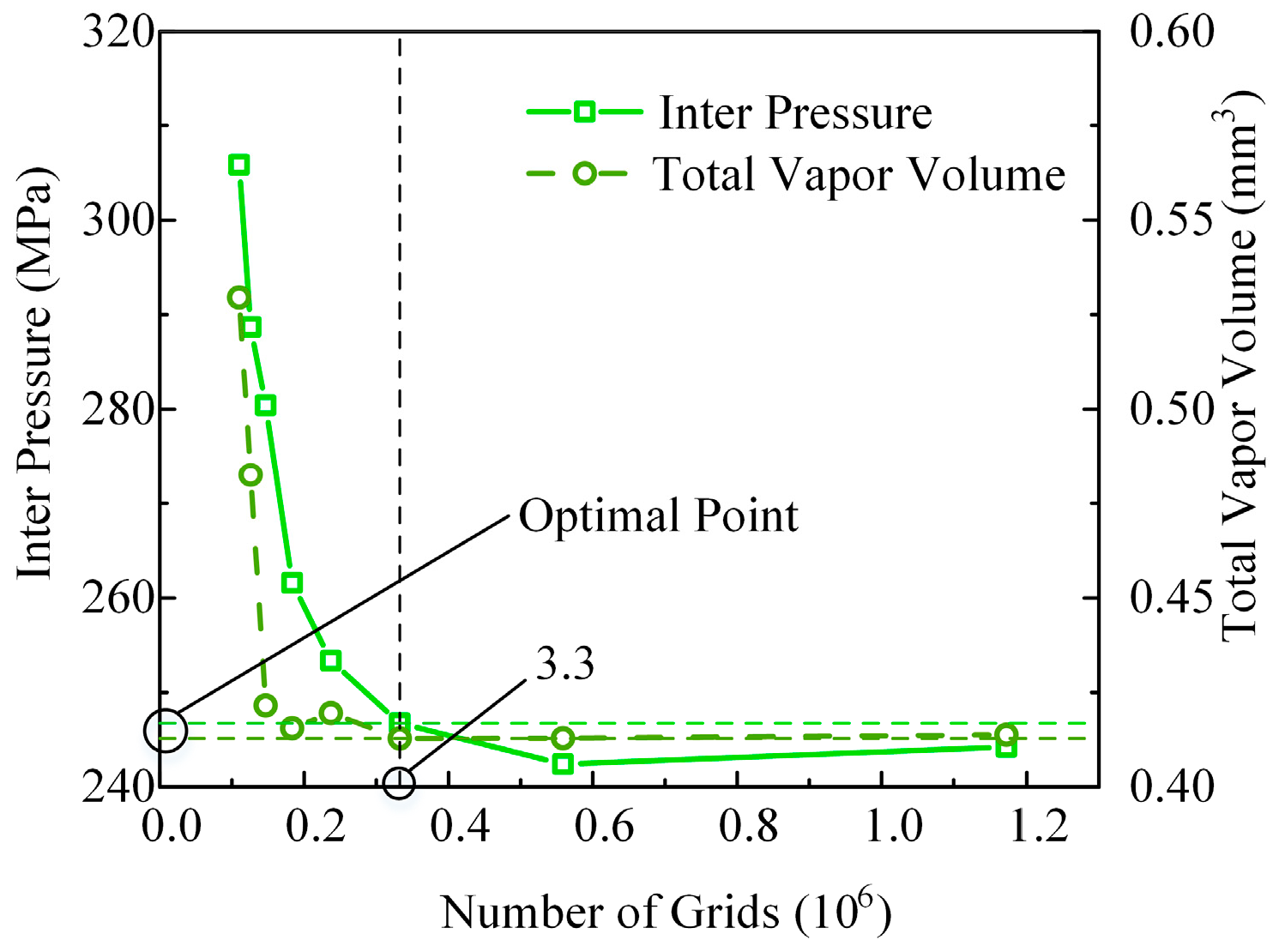

2.3. Numerical Method

2.3.1. Zwart-Gerber-Belamri Model

2.3.2. Ffowcs Williams and Hawkings Model

2.4. Numerical Strategy and Validation of Numerical Method

3. Results and Discussion

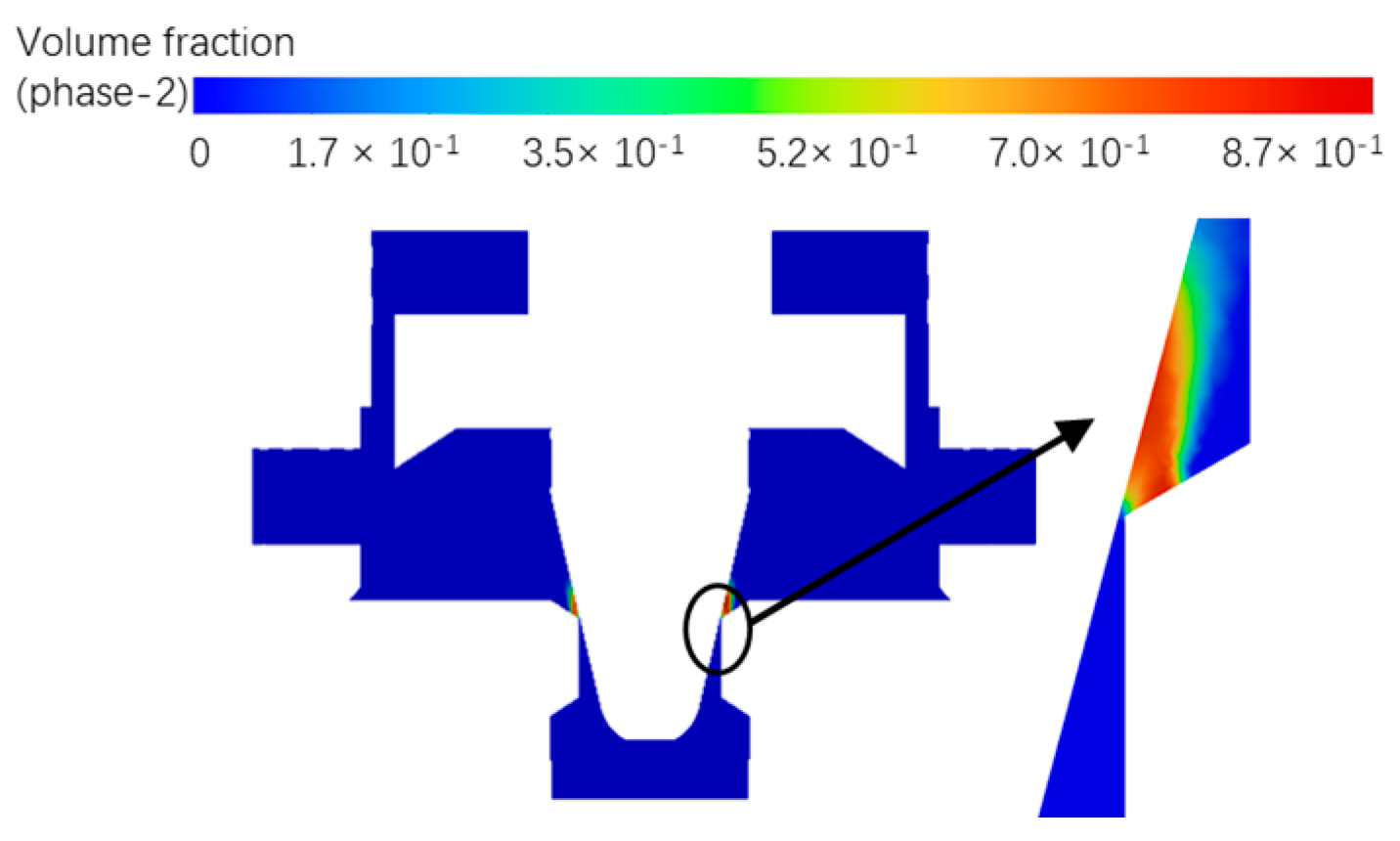

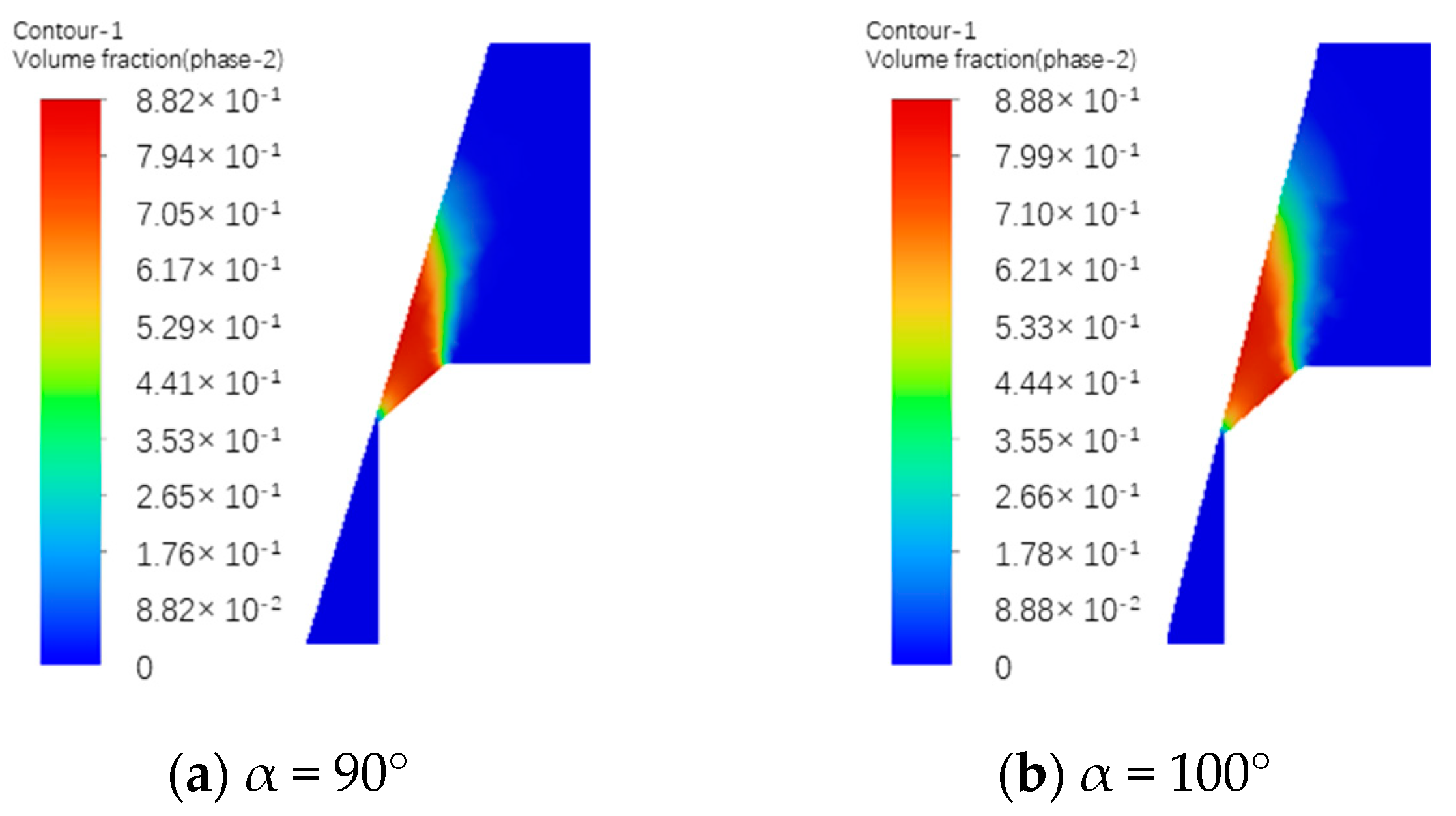

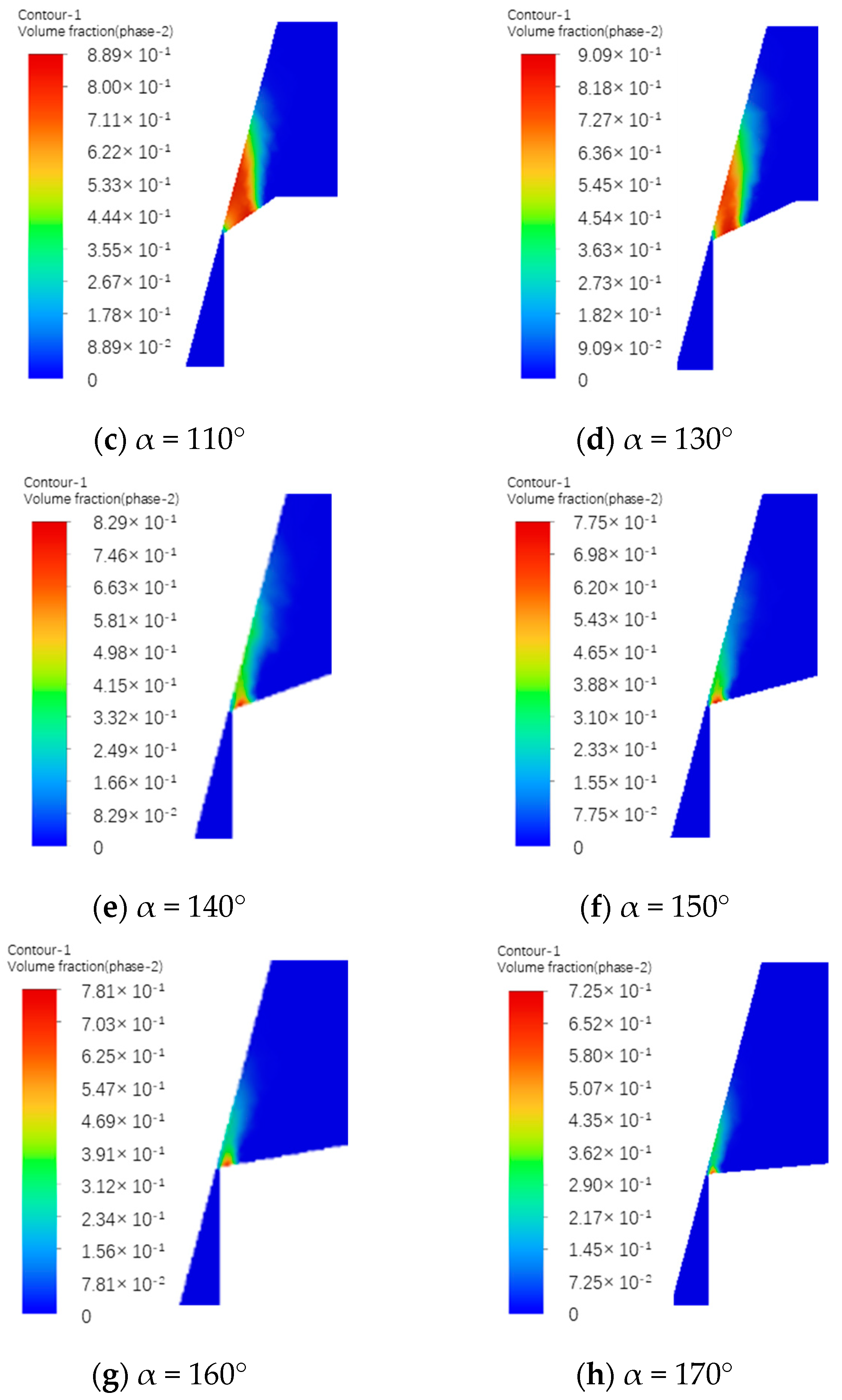

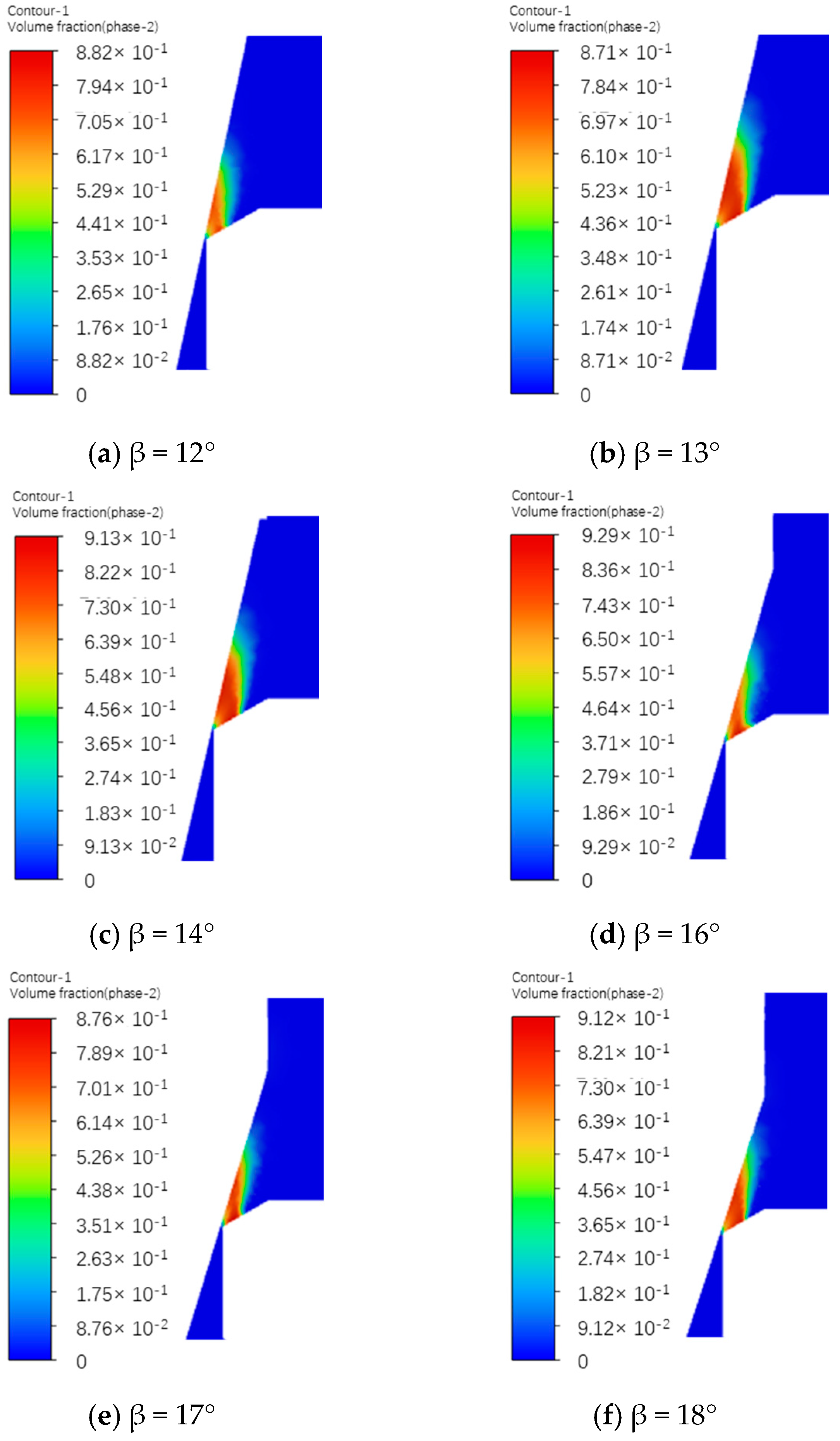

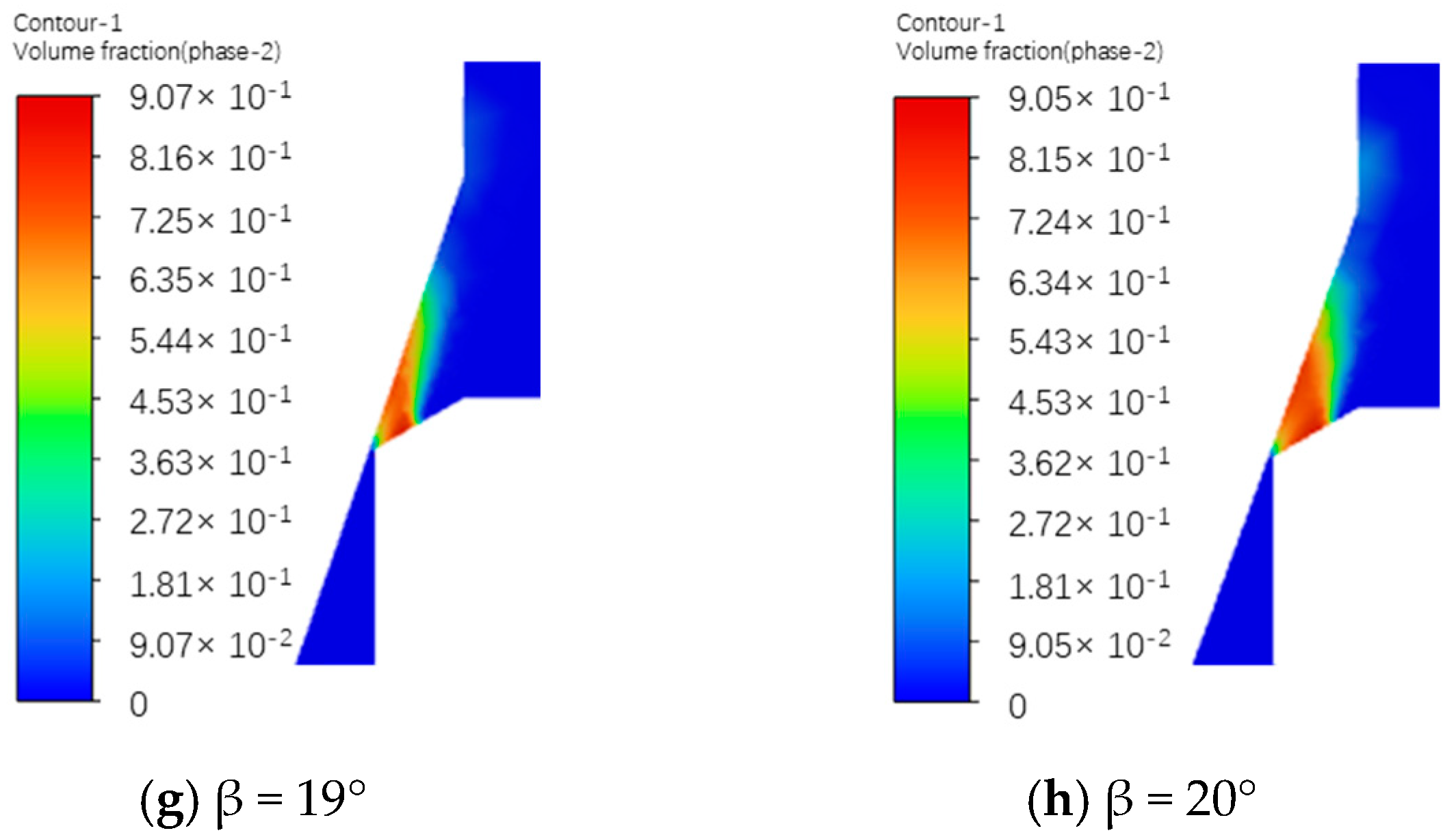

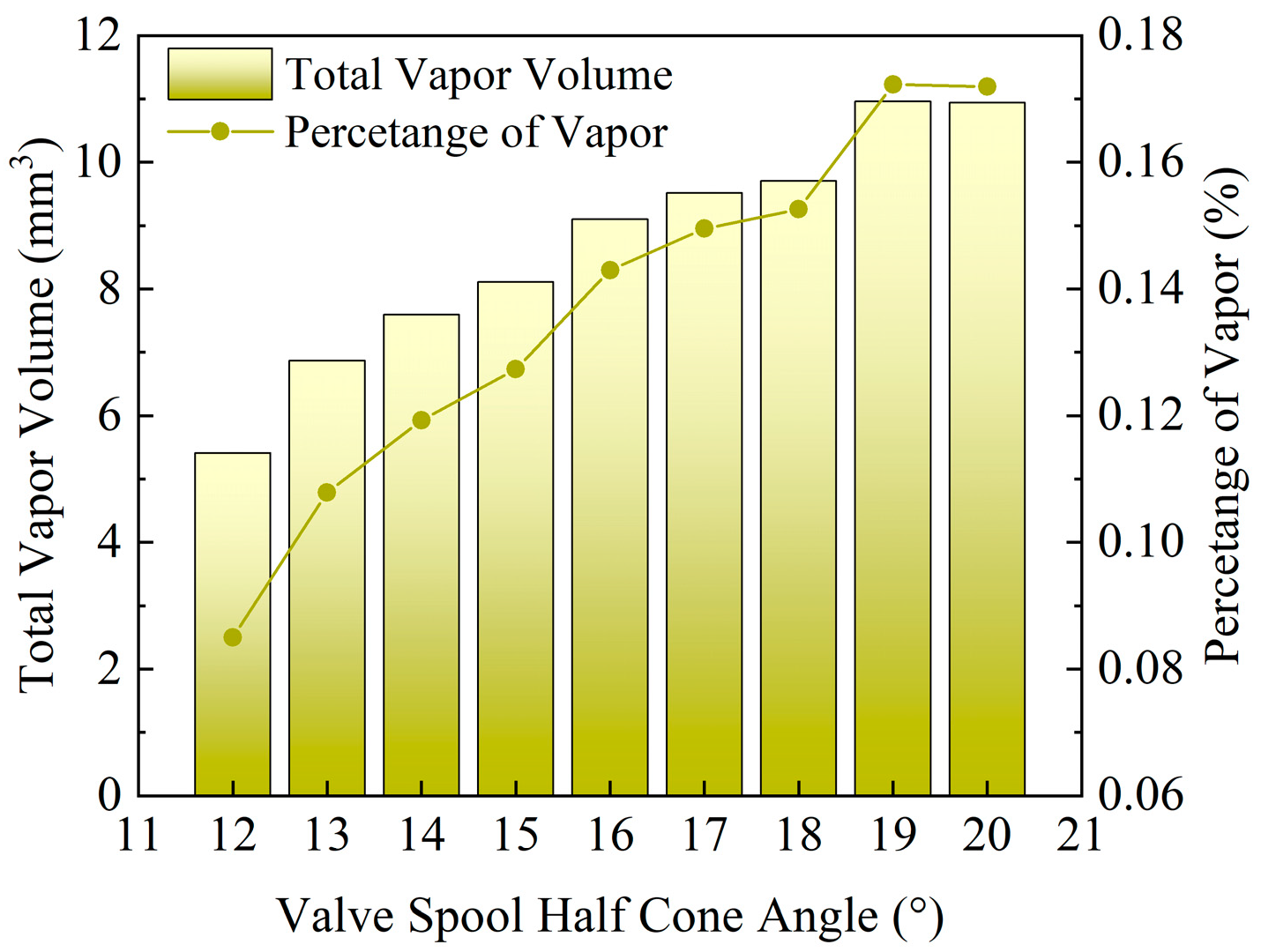

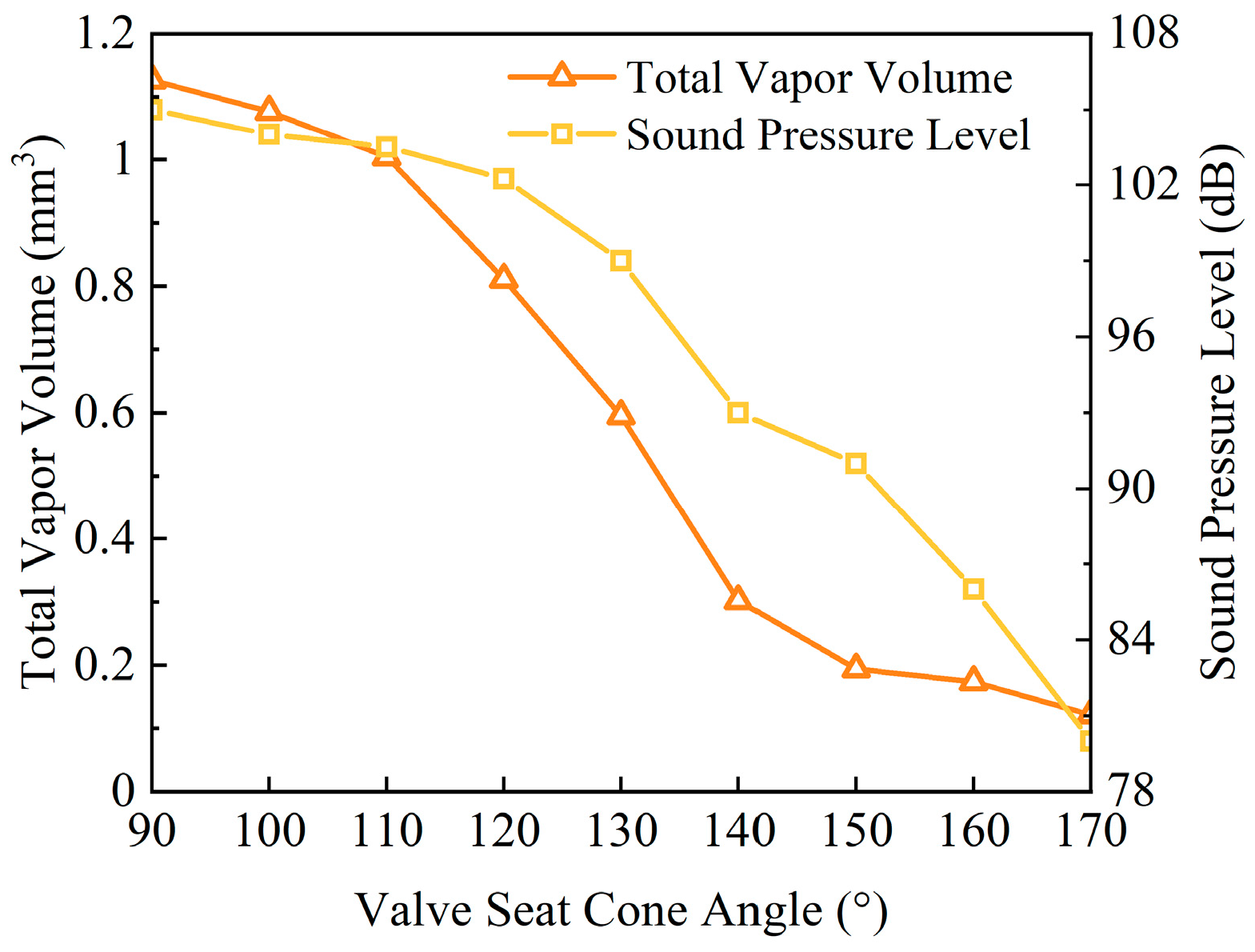

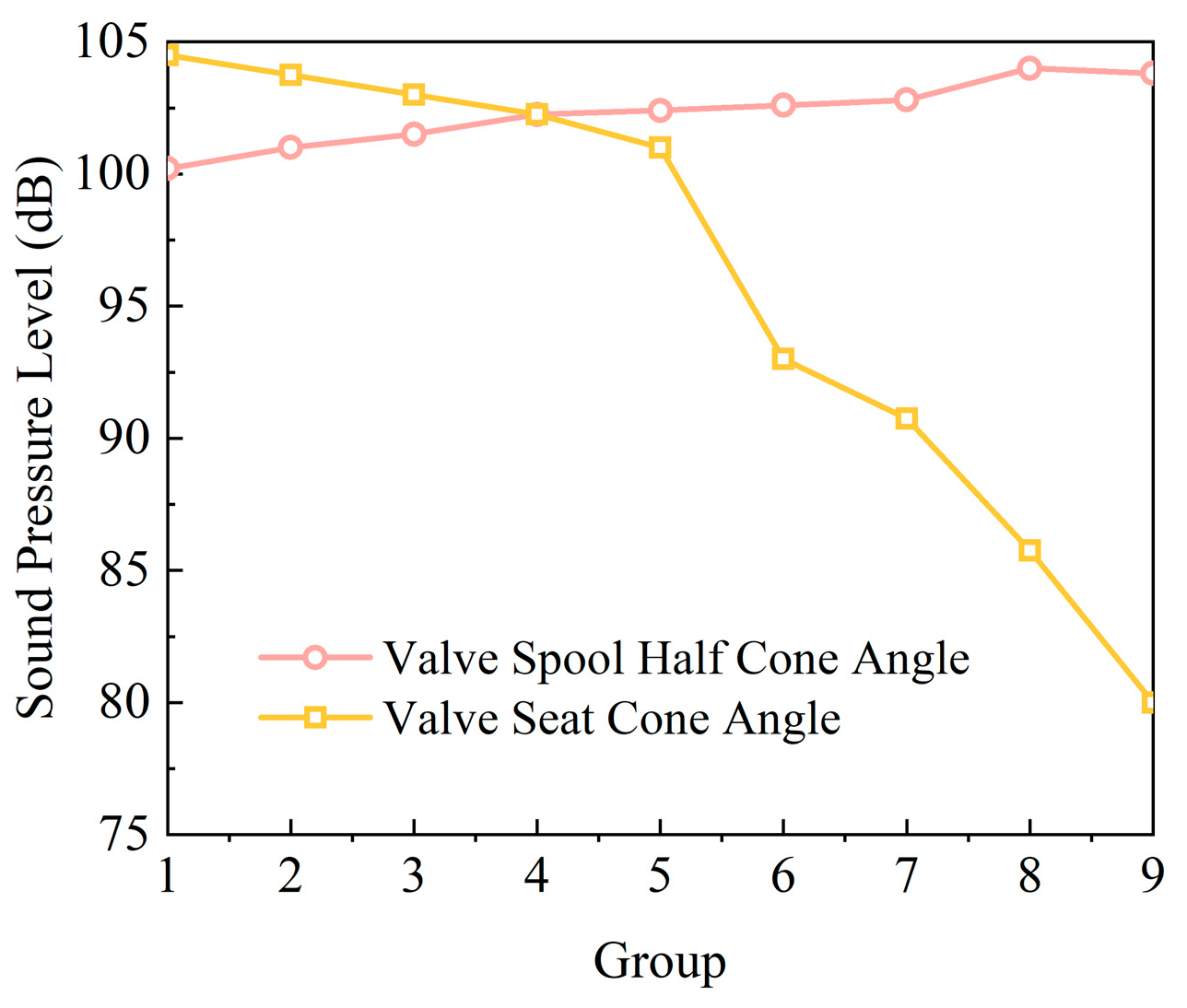

3.1. Influent of Valve Seat on the Cavitation

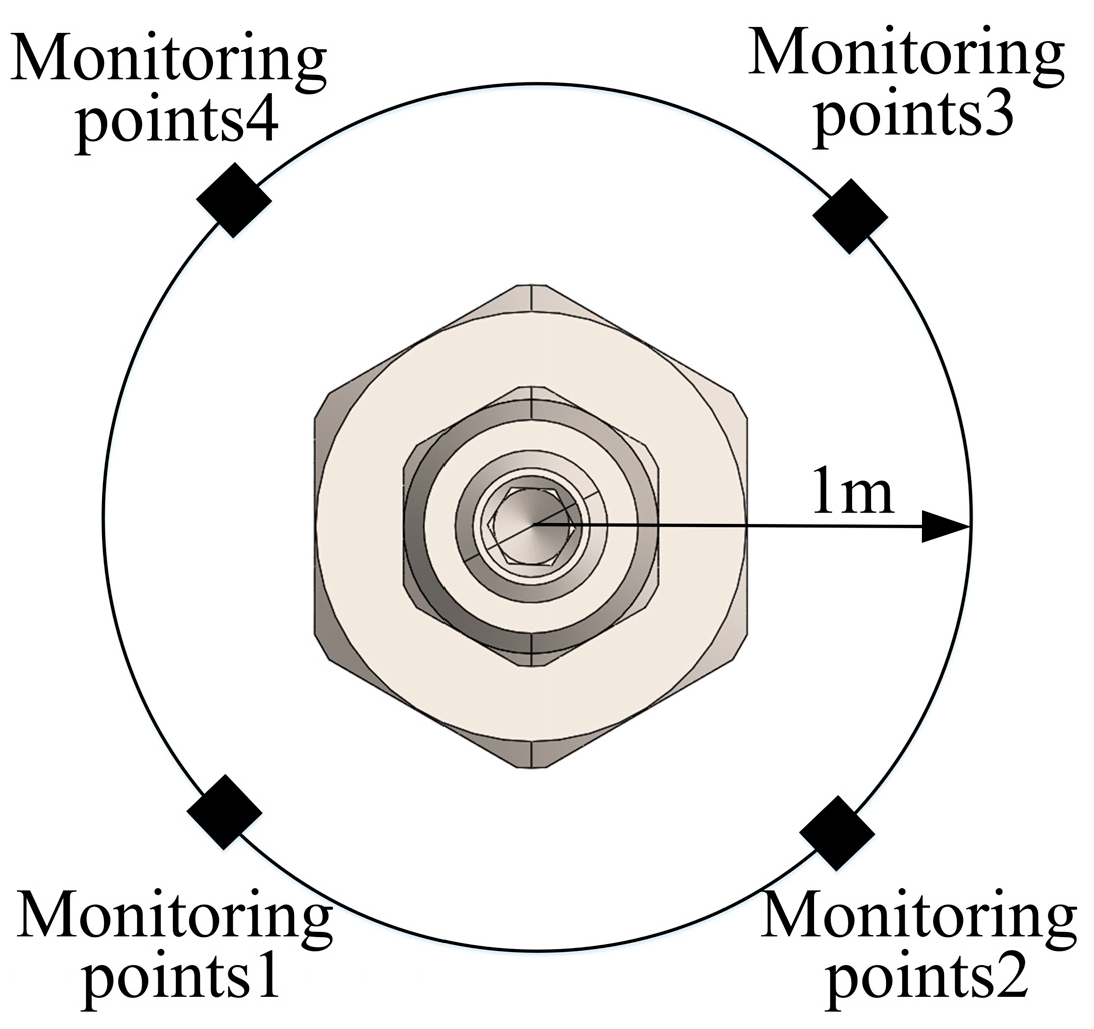

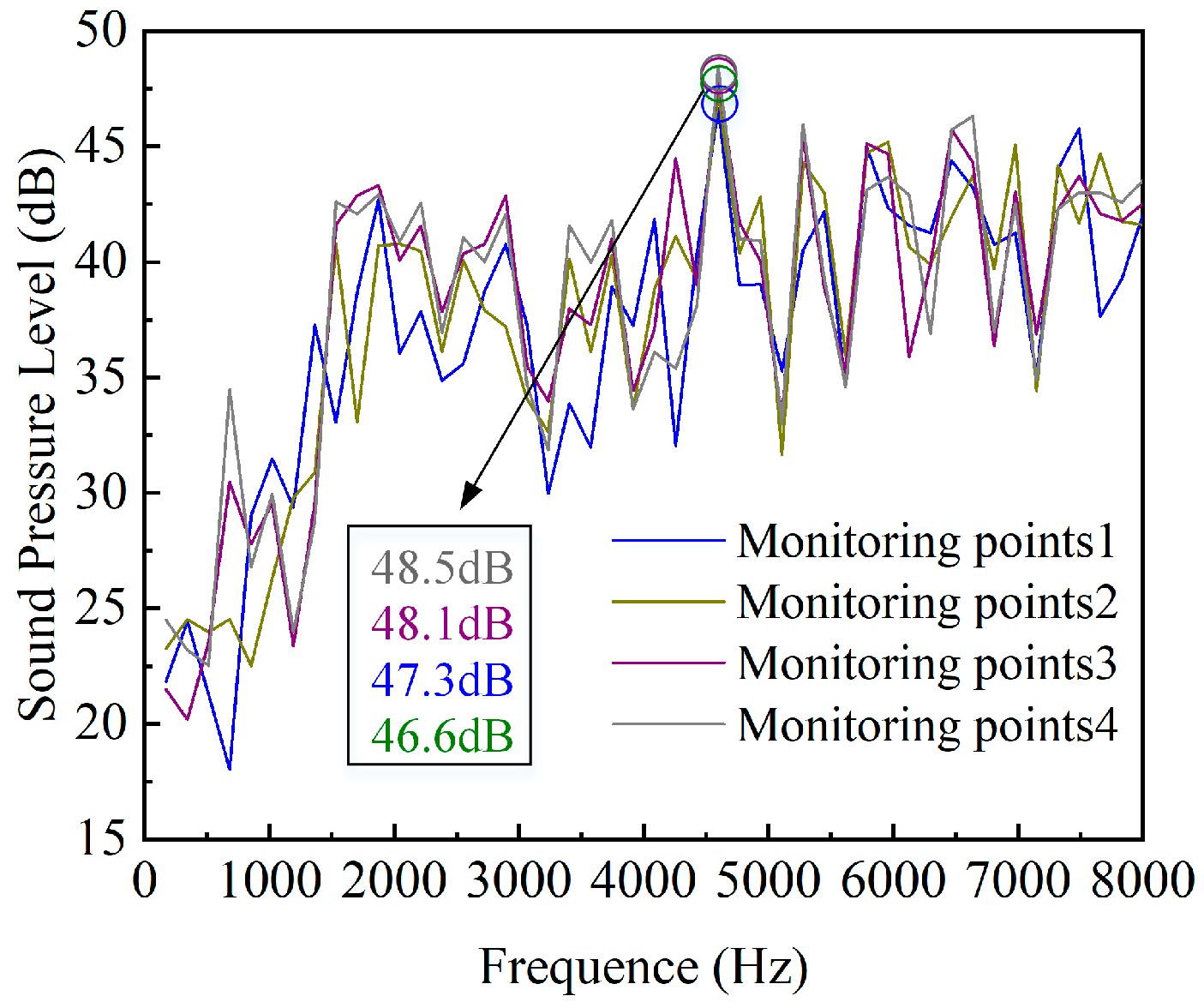

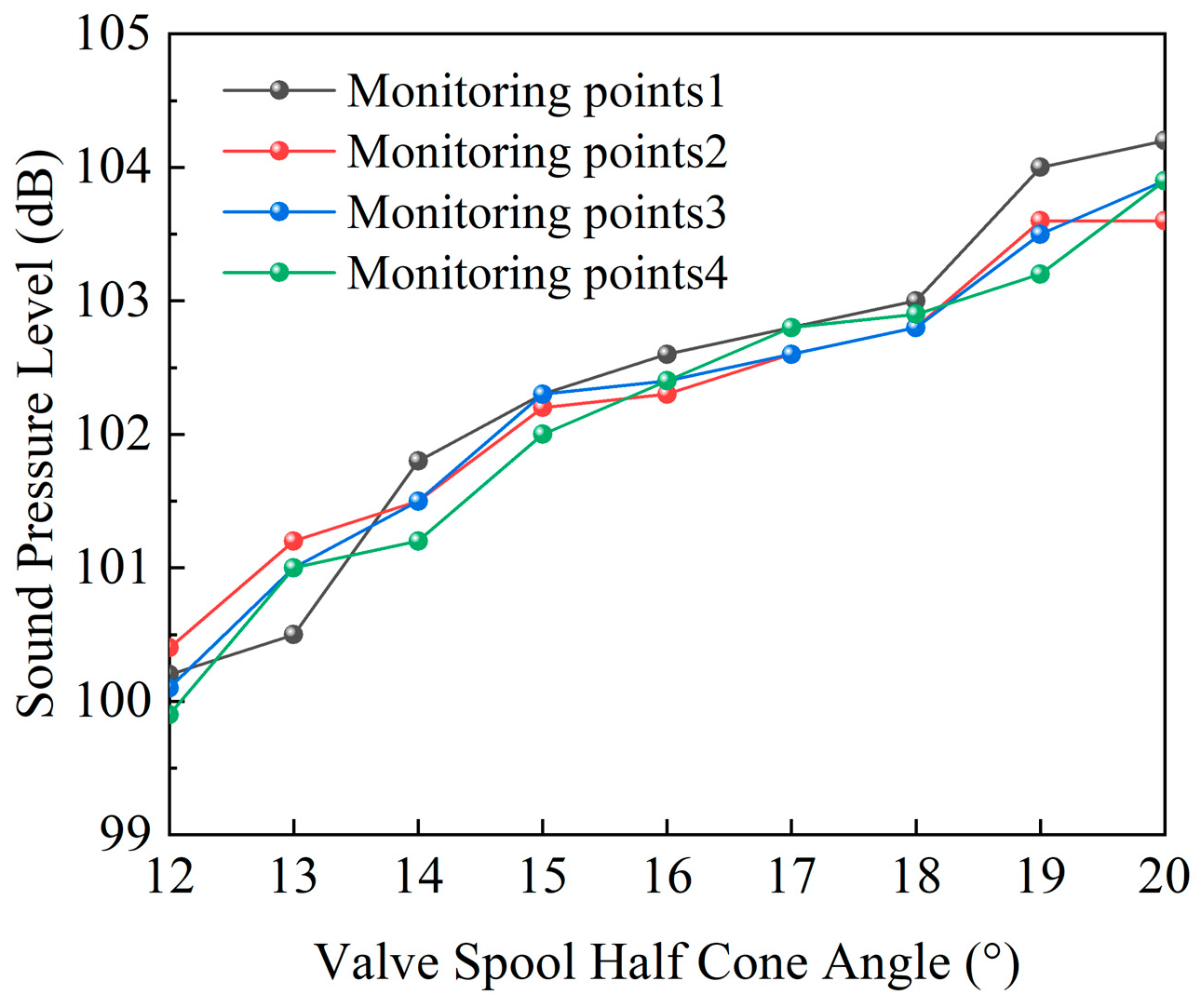

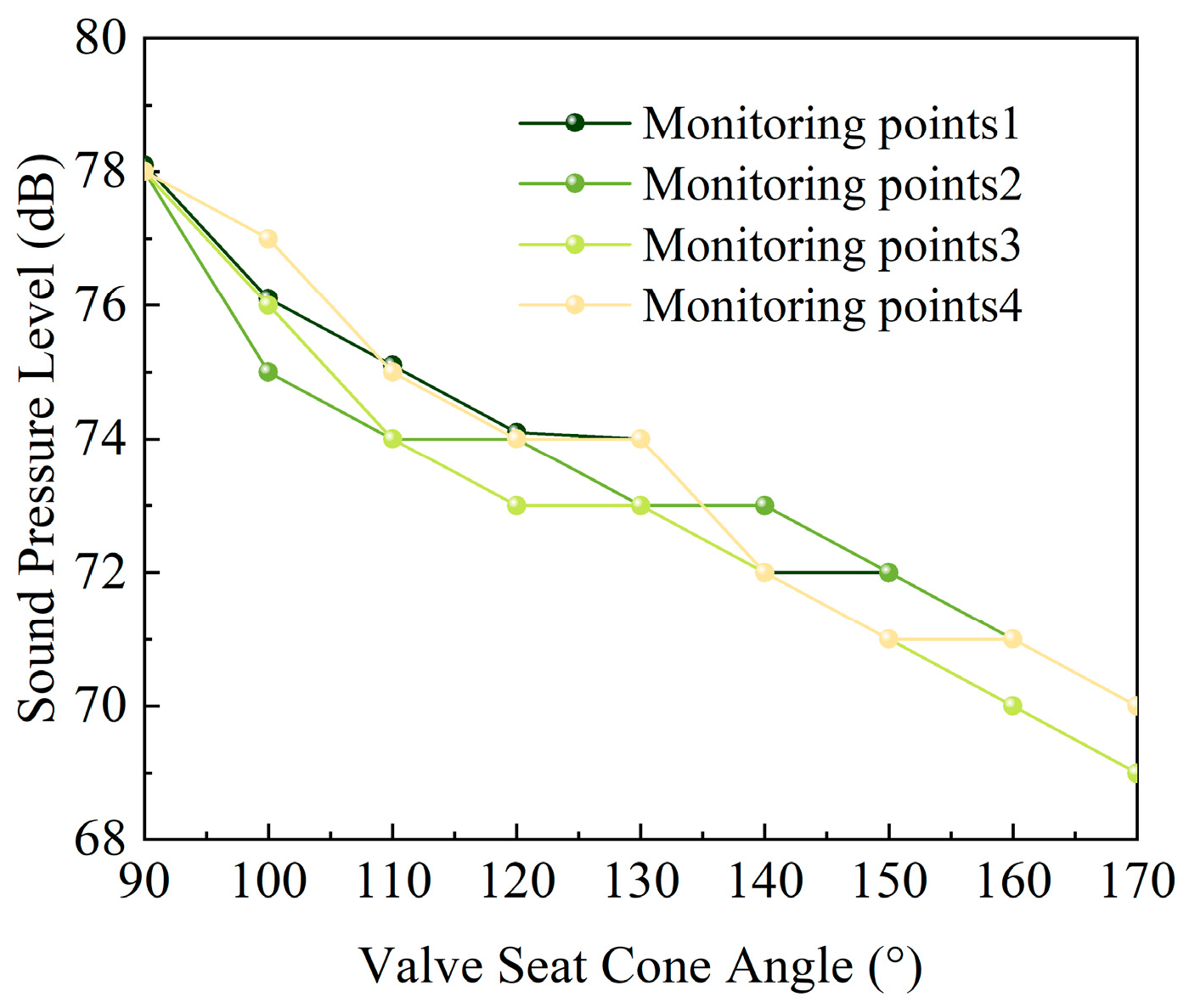

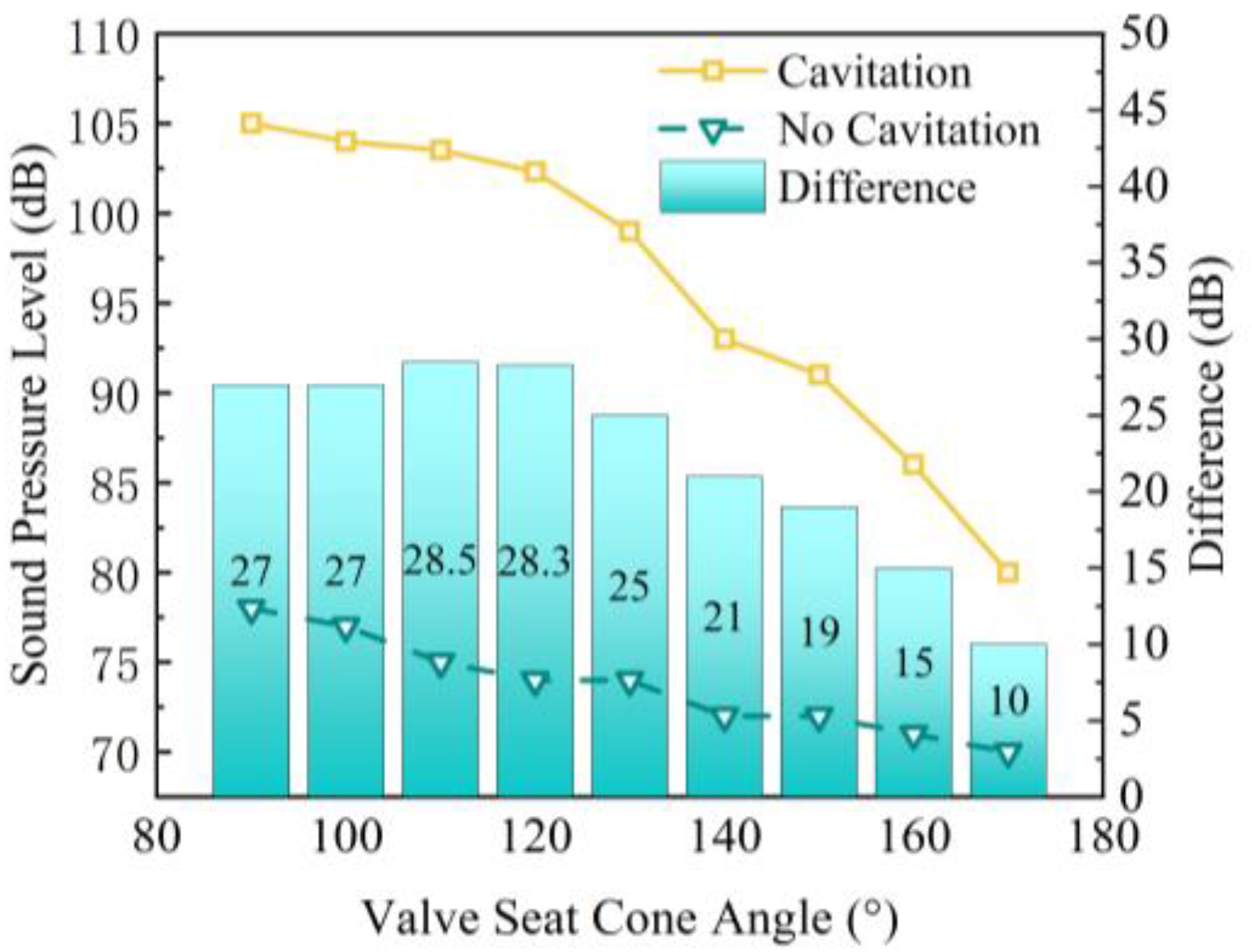

3.2. Analysis of Sound Field

4. Experimental Validation

4.1. Test Platform

4.2. Comparison of Simulation and Experiment

5. Conclusions

- (1)

- Direct-acting relief valves are prone to cavitation, particularly at the valve seat cone angle. However, increasing the seat cone angle significantly reduced the vapor volume fraction within the relief valve compared to the total vapor volume, thereby reducing the risk of cavitation.

- (2)

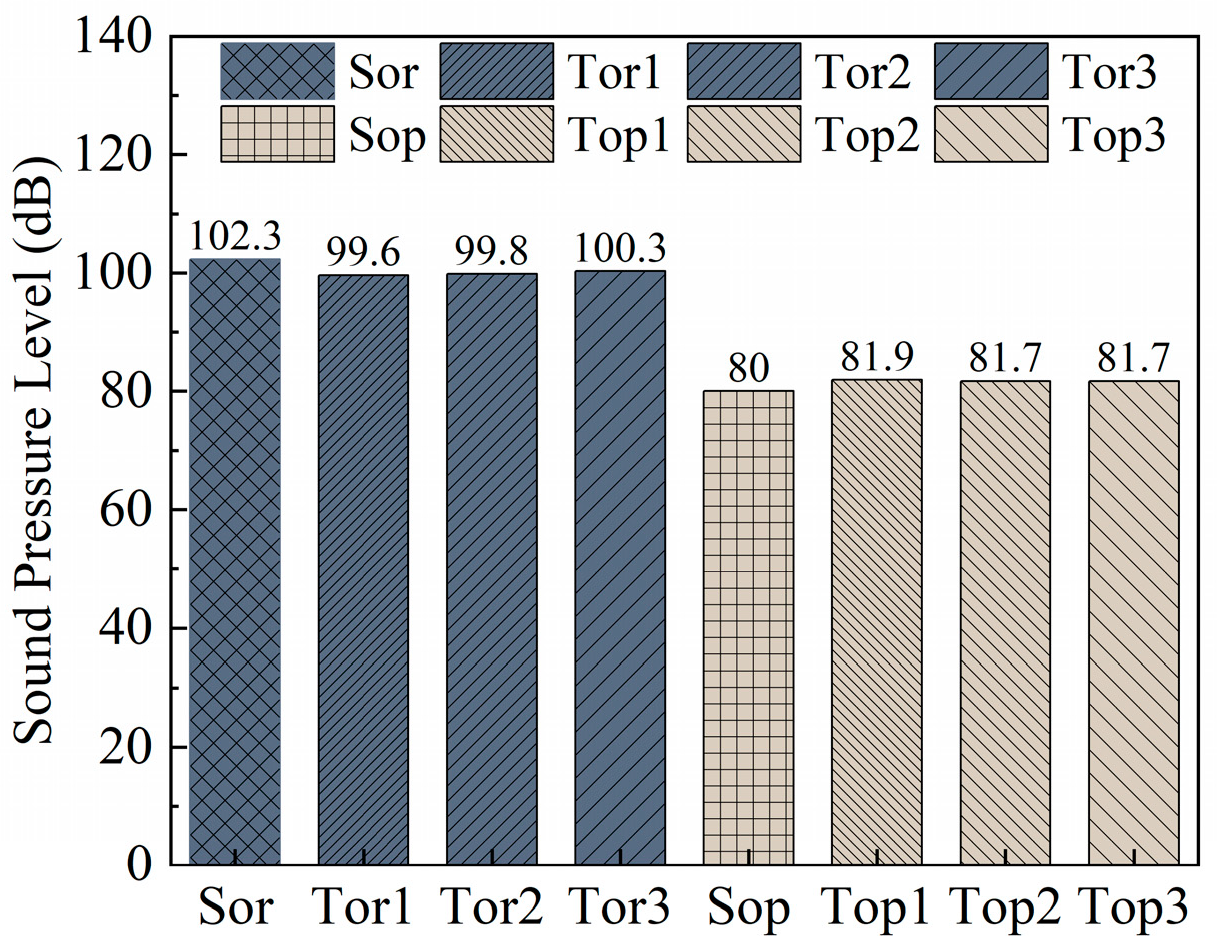

- When the relief valve spool opening is small, and cavitation is absent, the resulting noise is minimal, and a change in the valve seat cone angle has little impact on the noise. Conversely, when cavitation occurs, the generated noise is higher, suggesting that cavitation is the main cause of noise generated during relief valve operation.

- (3)

- The simulation and experimental test results exhibit similar trends, with a relative deviation of 2.4% for the simulation and 2.08% for the experimental test, validating the accuracy of each other. Optimization of the seat cone angle reduces the noise level of the relief valve by 18.2 dB.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yin, Y.B.; Wang, D.; Li, W.D.; Fu, J.Y.; He, P.F.; Zhang, X.B. Effect of the resonance suppression damping on the stability of a cartridge pilot-operated relief valve. J. Fluids Struct. 2023, 121, 103948. [Google Scholar] [CrossRef]

- Jiao, Z.X.; Zhang, H.; Shang, Y.X.; Liu, X.C.; Wu, S. A power-by-wire aircraft brake system based on high-speed on-off valves. Aerosp. Sci. Technol. 2020, 106, 106177. [Google Scholar] [CrossRef]

- Ding, R.Q.; Zhang, J.H.; Xu, B.; Cheng, M. Programmable hydraulic control technique in construction machinery: Status, challenges and countermeasures. Autom. Constr. 2018, 95, 172–192. [Google Scholar] [CrossRef]

- Ji, H.; Fu, X.; Yang, H.; Tsukiji, T. Investigation into cavitation induced noise within hydraulic relief valve. Proceedings of the JFPS International Symposium on Fluid Power. Jpn. Fluid Power Syst. Soc. 2002, 2002, 409–412. [Google Scholar]

- Yi, D.Y.; Lu, L.; Zou, J.; Fu, X. Interactions between poppet vibration and cavitation in relief valve. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1447–1461. [Google Scholar] [CrossRef]

- Xu, H.; Wang, H.H.; Hu, M.Y.; Jiao, L.Y.; Li, C. Optimal design and experimental research of the anti-cavitation structure in the water hydraulic relief valve. J. Press. Vessel. Technol. 2018, 140, 051601. [Google Scholar] [CrossRef]

- Yuan, C.; Zhu, L.S.; Du, Z.L.; Liu, S.Q. Numerical investigation into the cavitating jet inside water poppet valves with varied valve seat structures. Eng. Appl. Comput. Fluid Mech. 2021, 15, 391–412. [Google Scholar] [CrossRef]

- Wu, W.R.; Qiu, B.H.; Tian, G.T.; Liao, X.N.; Wang, T. CFD-based cavitation research and structure optimization of relief valve for noise reduction. IEEE Access 2022, 10, 66356–66373. [Google Scholar] [CrossRef]

- Kudźma, Z.; Stosiak, M. Studies of flow and cavitation in hydraulic lift valve. Arch. Civ. Mech. Eng. 2015, 15, 951–961. [Google Scholar] [CrossRef]

- Zhang, J.; Qi, N.M.; Jiang, J.H. Effect of cone throttle valve pressure on cavitation noise. J. Eng. 2020, 2020, 275–281. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Z.M.; Xu, H.C.; Li, J.L. Effects of throttling structures on cavitation flow and circumferential uniformity in a control valve. Eng. Fail. Anal. 2022, 134, 106025. [Google Scholar] [CrossRef]

- Gao, H.; Lin, W.; Tsukiji, T. Investigation of cavitation near the orifice of hydraulic valves. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2006, 220, 253–265. [Google Scholar] [CrossRef]

- Wang, G.; Deng, J.; Kou, L.Y.; Wang, W.H.; Gao, Q.F.; Zhu, X.J. Study on the influence of structural parameters on the flow and cavitation characteristics of tandem multi-stage pressure-reducing valves. Flow Meas. Instrum. 2022, 87, 102230. [Google Scholar]

- Han, M.X.; Liu, Y.S.; Wu, D.F.; Zhao, X.F.; Tan, H.J. A numerical investigation in characteristics of flow force under cavitation state inside the water hydraulic poppet valves. Int. J. Heat Mass Transf. 2017, 111, 1–16. [Google Scholar] [CrossRef]

- Qian, J.Y.; Xu, J.X.; Fang, L.; Zhao, L.; Wu, J.Y.; Jin, Z.J. Effects of throttling windows on cavitation flow of sleeve control valve. Ann. Nucl. Energy 2023, 189, 109841. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, G.R.; Qian, J.Y.; Fei, Y.; Jin, Z.J. Numerical simulation of flow-induced noise in high pressure reducing valve. PLoS ONE 2015, 10, e0129050. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Zhang, Y.J.; Liu, X.M.; Li, B.B.; Sun, S.Z.; Peng, J.J.; Liu, W.W. Experiment and simulation study on cavitation flow in pressure relief valve at different hydraulic oil temperatures. Flow Meas. Instrum. 2023, 89, 102289. [Google Scholar] [CrossRef]

- An, W.; Ren, L.; Bai, Y.Y.; Bao, G. Numerical simulation of the temperature rise and cavitation flow in a hydraulic slide valve. Flow Meas. Instrum. 2024, 96, 102553. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, W.W.; Wu, Z.Y.; Chen, D.S.; Kim, H.D.; Lin, Z. Effect of the opening degree on evolution of cryogenic cavitation through a butterfly valve. Energy 2023, 283, 128543. [Google Scholar] [CrossRef]

- Guo, P.C.; Sun, L.G.; Sun, S.H.; Feng, J.J.; Wu, K.G.; Luo, X.Q. Numerical acoustic characteristics and optimum design of the pressure reducing valve. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2016; Volume 49, p. 062022. [Google Scholar]

- Xu, B.; Hu, H.F.; Yang, K.; Wang, H.J. The role of thermodynamic effects in Cavitation: Impacts on cavitation structure and propagation of cavitation noise. Nucl. Eng. Des. 2024, 418, 112921. [Google Scholar] [CrossRef]

- Jin, H.Z.; Zhang, J.M.; Liu, X.F.; Wang, C. Study on flow-induced noise characteristics of multistage depressurization valve in the nuclear power plant. Nucl. Eng. Des. 2023, 407, 112282. [Google Scholar] [CrossRef]

- Lu, L.; Wang, J.; Li, M.R.; Ryu, S.H. Experimental and numerical analysis on vortex cavitation morphological characteristics in u-shape notch spool valve and the vortex cavitation coupled choked flow conditions. Int. J. Heat Mass Transf. 2022, 189, 122707. [Google Scholar] [CrossRef]

- Liu, H.S.; Xu, Y.; Wang, J.X. Experimental and numerical simulations to examine the mechanism of nozzle geometry affecting cavitation water jets. Geoenergy Sci. Eng. 2024, 233, 212511. [Google Scholar] [CrossRef]

- Chang, Z.B.; Zhao, L.; Mai, C.L.; Peng, Y.; Jiang, J. Study on noise induced by cavitation flow in orifice plates. Ocean Eng. 2023, 287, 115772. [Google Scholar] [CrossRef]

- Yuan, C.; Song, J.C.; Liu, M.H. Investigation of flow dynamics and governing mechanism of choked flow for cavitating jet in a poppet valve. Int. J. Heat Mass Transf. 2019, 129, 113–131. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Bai, X.R.; Long, X.P.; Ji, B.; Peng, X.X.; Farhat, M. Large eddy simulation of the tip-leakage cavitating flow with an insight on how cavitation influences vorticity and turbulence. Appl. Math. Model. 2020, 77, 788–809. [Google Scholar] [CrossRef]

- Yang, Z.P.; Wang, X.C.; Zhao, X.T.; Cheng, H.Y.; Ji, B. LES investigation of the wavy leading edge effect on cavitation noise. Ultrason. Sonochemistry 2024, 103, 106780. [Google Scholar] [CrossRef]

- Liang, J.; Luo, X.; Liu, Y.; Li, X.; Shi, T. A numerical investigation in effects of inlet pressure fluctuations on the flow and cavitation characteristics inside water hydraulic poppet valves. Int. J. Heat Mass Transf. 2016, 103, 684–700. [Google Scholar] [CrossRef]

- Zwart, P.J.; Gerber, A.G.; Belamri, T. A two-phase flow model for predicting cavitation dynamics. In Proceedings of the Fifth International Conference on Multiphase Flow, Yokohama, Japan, 30 May–3 June 2004; Volume 152. [Google Scholar]

- Yang, C.; Zhang, J.S.; Huang, Z.W. Numerical study on cavitation–vortex–noise correlation mechanism and dynamic mode decomposition of a hydrofoil. Phys. Fluids 2022, 34, 125105. [Google Scholar] [CrossRef]

| Number | Parameter Name | Unit | Value |

|---|---|---|---|

| 1 | Valve Opening | mm | 0.08 |

| 2 | Inlet pressure | MPa | 25 |

| 3 | Outlet pressure | MPa | 0 |

| Fluid | Density (kg/m3) | Viscosity (Pa·s) |

|---|---|---|

| Oil | 890 | 0.04094 |

| vapor | 1.225 | 1.7894 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, T.; Yang, L.; Zhang, J.; Wang, Z.; Song, Y.; Ai, C. Investigation of Valve Seat Cone Angle on Small Opening Direct-Acting Relief Valve Cavitation Noise. Machines 2024, 12, 434. https://doi.org/10.3390/machines12070434

Qiu T, Yang L, Zhang J, Wang Z, Song Y, Ai C. Investigation of Valve Seat Cone Angle on Small Opening Direct-Acting Relief Valve Cavitation Noise. Machines. 2024; 12(7):434. https://doi.org/10.3390/machines12070434

Chicago/Turabian StyleQiu, Tiechao, Liu Yang, Jiannan Zhang, Zhanqi Wang, Yanhe Song, and Chao Ai. 2024. "Investigation of Valve Seat Cone Angle on Small Opening Direct-Acting Relief Valve Cavitation Noise" Machines 12, no. 7: 434. https://doi.org/10.3390/machines12070434

APA StyleQiu, T., Yang, L., Zhang, J., Wang, Z., Song, Y., & Ai, C. (2024). Investigation of Valve Seat Cone Angle on Small Opening Direct-Acting Relief Valve Cavitation Noise. Machines, 12(7), 434. https://doi.org/10.3390/machines12070434