Abstract

Industry 4.0 is an industrial paradigm that is causing changes in form and substance in factories, companies and businesses around the world and is impacting work and education in general. In fact, the disruptive technologies that frame the Fourth Industrial Revolution have the potential to improve and optimize manufacturing processes and the entire value chain, which could lead to an exponential evolution in the production and distribution of goods and services. All these changes imply that the fields of engineering knowledge must be oriented towards the concept of Industry 4.0, for example, Mechanical Engineering. The development of various physical assets that are used by cyber-physical systems and digital twins is based on mechanics. However, the specialized literature on Industry 4.0 says little about the importance of mechanics in the new industrial era, and more importance is placed on the evolution of Information and Communication Technologies and artificial intelligence. This article presents a frame of reference for the importance of Mechanical Engineering in Industry 4.0 and proposes an extension to the concept of Mechanics 4.0, recently defined as the relationship between mechanics and artificial intelligence. To analyze Mechanical Engineering in Industry 4.0, the criteria of the four driving forces that defined mechanics in the Third Industrial Revolution were used. An analysis of Mechanical Engineering Education in Industry 4.0 is presented, and the concept of Mechanical Engineering 4.0 Education is improved. Finally, the importance of making changes to the educational models of engineering education is described.

1. Introduction

Industry 4.0 is a new industrial scenario where companies, industries and businesses benefit from the implementation of new technologies in their production processes and business operations. Currently, industries are orienting their traditional operating framework toward a technology-centric operating framework, due to the technological disruptions that are modifying production systems [1]. Today’s technologies and the adoption of globalized production processes are transforming companies in such a way that the product requirements have diversified, making the analysis of product is a priority in Industry 4.0 [2]. The changes provoked by the Fourth Industrial Revolution in companies are not simple improvements due to the use of new technology but rather transformations of substance and form and are radically innovating processes in companies, businesses, organizations and administration.

The needs and requirements of customers have become more personalized, which implies that a new era has dawned in productive organizations and in the control of value chains throughout processes, that is, throughout the product life cycle [3]. The Fourth Industrial Revolution is also causing changes among suppliers and consumers and is consolidating a massive personalization that represents one of the strategies of the digitalization of companies, companies and businesses in the context of Industry 4.0. The changes and transformations taking place in the Fourth Industrial Revolution drive and promote deep digitalization, that is to say, digitalization across the whole value chain, improving and optimizing production processes. In addition, the introduction of various disruptive technologies into production systems, such as the Internet of Things (IoT), artificial intelligence (AI), Big Data, Cloud Computing and collaborative robotics, among others, has accelerated the process of change from classic or traditional factories to Smart Factories [4]. Disruptive technologies not only cause industrial revolutions but also cause changes in and have impacts of great relevance on the social and economic sphere in modern societies [5], which are characterized by their enormous differentiation and specialization. Industry 4.0 applications cover a wide range of industrial and non-industrial fields, such as textile manufacturing [6], medicine [7], the aeronautic industry [8], the automotive industry [9], agriculture [10], the petrochemical industry [11], construction [12] and the food industry [13], among others.

On the other hand, disruptive technologies are the result of research and technological advances that have developed in various fields of knowledge, such as electronics, nanotechnology, computing and mechanics, among others. In this context, Mechanical Engineering has contributed in the past and present to the development of technology and products, which makes it essential in Industry 4.0. Like any field of knowledge, Mechanical Engineering transforms, improves and adapts to new knowledge, and history has shown that it has been a factor of change and transformation in every known industrial revolution [14]. The essentiality of Mechanical Engineering in Industry 4.0 lies in the fact that it is the design platform for the development of various physical assets, such as robots, belts, actuators, mechanisms, devices and machinery, among others, which represent the basis of production systems in factories and in various companies. Mechanical Engineering synergizes with computing, electronics and control to develop various mechatronic systems and products that are essential in Industry 4.0 applications [15].

Recently, the concept of Mechanics 4.0 [16] has been proposed, which is more oriented towards the applications of the methods and algorithms of artificial intelligence to the analysis, modeling, calculation and simulation of various industrial problems in which physical systems are involved. Although artificial intelligence is a powerful tool for Mechanical Engineering, it is still a disruptive technology, so the concept of Mechanics 4.0 must be extended to cover more fields of study and applications. For example, Mechanical Engineering is related to other related fields of knowledge, such as materials, design engineering, manufacturing and maintenance, among others, and each of these fields has been integrated into Industry 4.0, giving rise to concepts such as Materials 4.0 [17], Design Engineering 4.0 [18], Maintenance 4.0 [19] and Manufacturing 4.0 [20], among others. In this way, Mechanical Engineering and its related fields or specialized fields, together with disruptive technologies, have enhanced applications in Industry 4.0; for example, they have been applied in the development of digital twins for the monitoring of wind turbines [21]; in Intelligent Reconditioning, which seeks to modernize old machinery towards the Industry 4.0 approach [22] and to evaluating the behaviors of an electromechanical cooling pump in a cyber-physical system [23], among other applications.

On the other hand, the scope of Industry 4.0 has extended to education in general, mainly to engineering education. The Fourth Industrial Revolution requires the design of new competencies for engineers that will allow them to solve the technologically specialized problems they will face. In this context, engineering education must apply modern educational models to and introduce disruptive technologies into teaching and learning processes, and in this way, engineers can be trained with the appropriate skills to face the challenges faced by Industry 4.0 and 5.0 [24]. Like other fields of study, Mechanical Engineering Education must be transformed towards the vision of Industry 4.0; otherwise, graduates will not have the knowledge and skills necessary to face various problems involving Mechanical Engineering in specialized systems and products conceived under the modern approach of the Fourth Industrial Revolution. In this sense, engineers trained in mechanics must be highly qualified and have a clear vision of technological innovation [25].

This article presents an overview of the conceptualizations and applications of Mechanical Engineering and its related fields in Industry 4.0 and its importance in previous industrial revolutions, with the purpose of identifying mechanics as an important ally of the Fourth Industrial Revolution due to the fact that most of the specialized literature pays little attention to it and focuses more on artificial intelligence and Information and Communication Technologies in the explanation of Industry 4.0. An extension of the concept of Mechanics 4.0 [16] is presented beyond the connection of mechanics with artificial intelligence. Finally, some applications of mechanics in the products and processes envisioned by Industry 4.0 are described, and the new educational approaches and disruptive digital tools that exist today for new forms of training for mechanical engineers are discussed.

2. Materials and Methods

This section describes the methodology used in this article. For the development of this study, descriptive–qualitative research methods were considered; the generalities of Mechanical Engineering in the context of Industry 4.0 were analyzed and some considerations about Mechanical Engineering Education were discussed. This work is composed of three sections: the first describes the industrial revolutions and the concepts of Industry 4.0 and disruptive technologies, as well as the importance of Mechanical Engineering in the vision of Industry 4.0. The second section describes Mechanical Engineering 4.0 and the specialized fields of knowledge that are being developed under the Industry 4.0 approach, such as Materials 4.0, Product Engineering 4.0 and Maintenance 4.0, among others, and some application examples, in particular in the development of digital twins and in the intelligent refurbishment process. The third section describes some considerations about engineering education that must be taken into account in new forms of training for mechanical engineers who will face the challenges of Industry 4.0. The following scientific databases were consulted for the literature review: Google Scholar, SpringerLink, Scopus and Web of Science.

2.1. Industrial Revolutions and Industry 4.0

This section presents a synthesis of the industrial revolutions and disruptive technologies that made revolutionary changes possible. Industry 4.0 is described with the aim of understanding technologies that are related to innovations in the production processes of companies.

2.1.1. The Industrial Revolutions

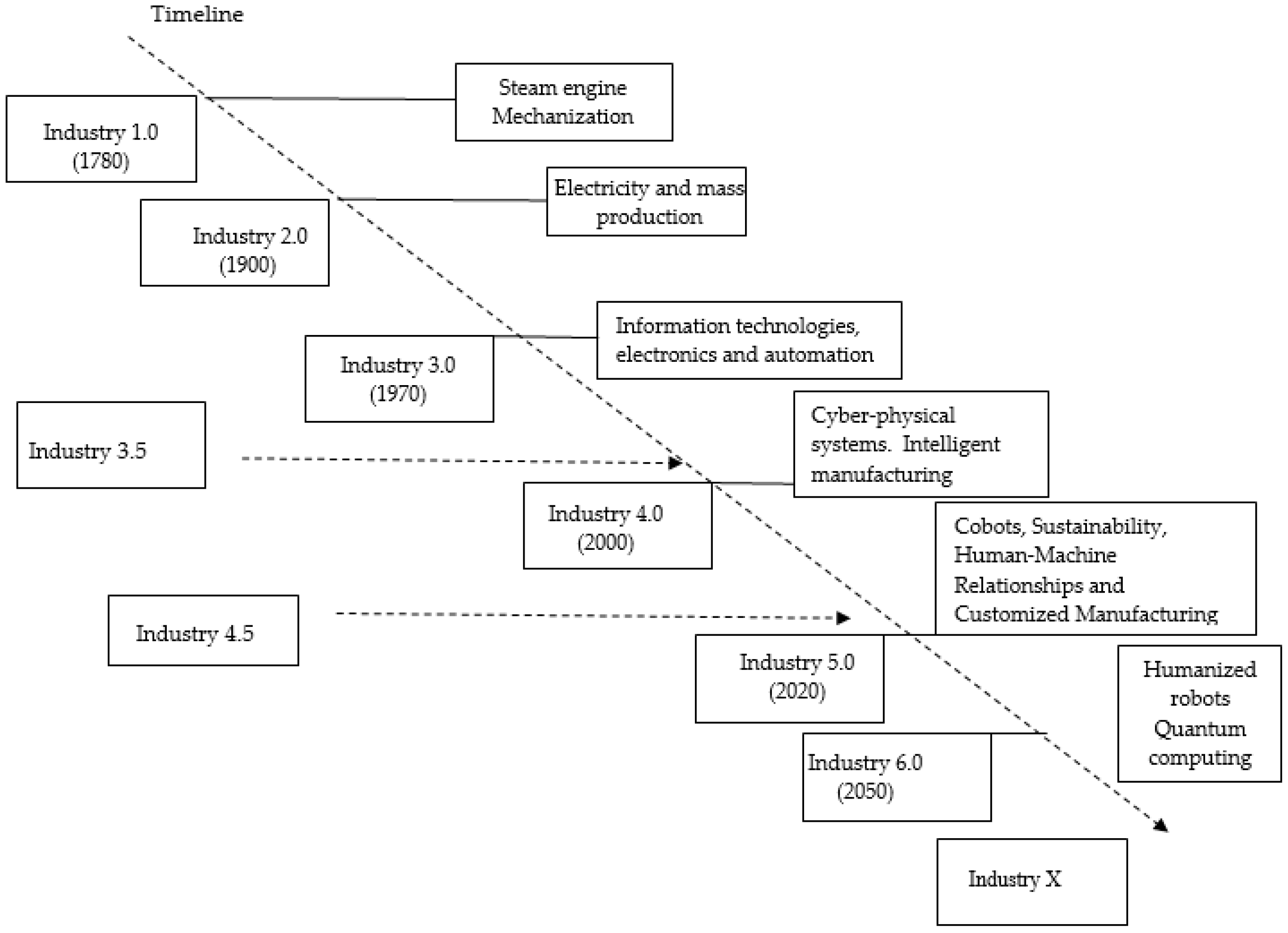

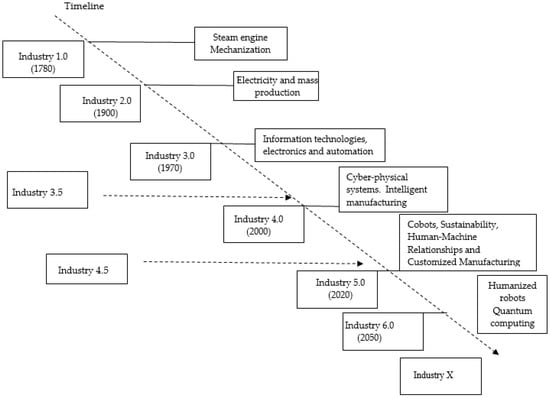

In general terms, an industrial revolution can be considered an event or occurrence of a global nature that brings about profound changes in form and substance in the industrial world and in societies due to the insertion at a given time of the disruptive technologies of the moment into the means of production and into human daily activities [26,27]. Industrial revolutions are cumulative, and for such an event to occur, new or improved technologies must be present [28,29]. Figure 1 shows a roadmap of the industrial revolutions and the disruptive technologies that characterized them [30]. Each industrial revolution has one or more major technologies associated with it.

Figure 1.

Timeline of industrial revolutions and their transitions [30].

The First Industrial Revolution, or Industry 1.0, originated in 1870 in England, and its basic technologies were the steam engine and industrial mechanization. Industry 2.0 developed around the year 1900, and its core technologies were electricity and the assembly line. Industry 3.0 began in 1970, and the technologies that led to its emergence were Information and Communication Technologies, electronics and automation. The Fourth Industrial Revolution, or Industry 4.0, originated in 2011, and its central disruptive technology was the cyber-physical system [31,32,33]. The Fifth Industrial Revolution, or Industry 5.0, had its origins in the year 2020, and Cobots and Custom Manufacturing were two of its core technologies [34]. The start of Industry 6.0 is projected for the year 2050, and its possible disruptive technologies will be Humanized Robots and Quantum Computing [35,36]. There are currently two transitions, characterized by Industry 3.5 [37] and Industry 4.5 or 4.0+ [38]. The first of these promotes the processes of globalization and offshoring and is identified as a transition between Industries 3.0 and 4.0; essentially, technological reconditioning projects are carried out. Industry 4.5 is representative of the transition from Industry 4.0 to Industry 5.0. This transition promotes and embraces digital solutions and personalization in manufacturing processes.

2.1.2. Industry 4.0

In the year 2011, Industry 4.0 was conceived in Germany [39], marking the onset of the Fourth Industrial Revolution, which has brought about changes in many aspects of human life and has had profound implications for businesses, particularly in administration, production management and labor [40]. Industry 4.0 promotes digitization in processes and supply chains, advocating for the adoption of connectivity in productive systems and businesses for survival and a competitive edge in today’s markets, characterized by being dynamic, personalized and specialized [41]. To enhance, optimize and increase productivity in companies, Industry 4.0 drives hyper-automation and hyper-connectivity in production systems. However, the adoption of highly automated machines in companies is causing a forced displacement of workers, which has concerned governments [42]. The introduction of various disruptive technologies into production processes, such as sophisticated robots, the Industrial Internet of Things, Cloud Computing and the methods and algorithms of artificial intelligence, among others, has made the concept of Smart Factories [43] or “Dark Factories” [44] possible. Disruptive technologies can be defined by their market effects [45] and customer implications [46]; they have the potential to create new markets and aim to transform companies and businesses [47]. A study identified 35 of these disruptive technologies, recognizing 13 as highly relevant and considering 9 of them the pillars of Industry 4.0 [48]: Big Data, Cybersecurity, additive manufacturing, Horizontal and Vertical Systems, augmented reality, simulation, Cloud Computing, the Internet of Things and Autonomous Robots [49,50,51].

The technological heart of Industry 4.0 is the so-called “Cyber-Physical System” (CPS) [30,32,33], which is a product of digitalization in companies and is enhanced by disruptive technologies [52]. This technology unites the physical and virtual worlds and relates the physical world to the virtual world through communication networks. A key characteristic of CPSs is that they possess software that actively engages with various physical assets [53]. It is worth mentioning that CPSs are not new technologies since there are several production systems conceived under the vision of Industry 3.0 with similar characteristics in companies, such as a CNC (Computer Numerical Control) machine. However, these systems were developed with technologies from 30 years ago and have major limitations, such as slower data transmission rates, and have problems with connectivity [54]. The applications of CPSs span agriculture, aviation, transportation, mining, manufacturing, traffic, security, energy and defense, among other things [55].

2.2. Mechanical Engineering and the Industrial Revolutions

Disruptive technologies are at the heart of the Fourth Industrial Revolution. However, many of them and their applications have foundations in disciplines such as electronics, electricity, computing, control and mechanics, among others. These disciplines do not have clear limits of application and can be combined with each other [56]; for example, a classic combination between disciplines is Mechatronics (the integration of mechanics, electronics and computing). Mechanical Engineering is essential in Industry 4.0, as many of the physical assets that are required for production are designed and developed considering the science and engineering of mechanics. The science of mechanics studies the movement of objects, while Mechanical Engineering is oriented towards the development of physical assets and technology that have a specific function for human activity. In this way, with Mechanical Engineering, various physical assets are developed in industries, such as robots, belts, actuators, mechanisms, complex mechanical systems and machinery, among others, which are responsible for performing simple, complex and specialized tasks and movements. The functions and tasks of analysis, calculation, modeling, design and manufacturing associated with Mechanical Engineering have been present in all documented industrial revolutions and will surely continue to be active in Industries 5.0 and 6.0.

2.2.1. Mechanical Engineering and the First Industrial Revolution

The First Industrial Revolution was characterized by the generation of technologies associated with Mechanical Engineering and was developed mainly in England and the United States according to the profound inventiveness of many characters of that time. A list of the most important inventions and machines from the First Industrial Revolution can be found in [57]. Some of these relevant inventions were the following: (1) the steam locomotive, invented by R. Trevithick in the year 1804; (2) the Stirling engine, invented by R. Stirling in 1816; (3) the Singer pedal sewing machine, invented by the Singer Company in 1859; (4) the mechanical computer, invented by C. Babbage in 1822, and (5) the grain thresher, invented by A. Meikle in 1784, among others. Many of the technologies that were developed at the time of the First Industrial Revolution or Industry 1.0 were emerging or disruptive as they transformed industries (textiles, manufacturing, food, etc.), agriculture, education, mining and construction, among others, which led to large-scale economic, industrial and social development in society at a global scale. In the case of the First Industrial Revolution, the base technologies considered were the steam engine and mechanization [30,31].

2.2.2. Mechanical Engineering and the Second Industrial Revolution

The period from 1870 to 1914 saw the development of the Second Industrial Revolution, the technological center of which was the introduction of electric power, mass production and the assembly line [31]. However, influential mechanical inventions were also developed in this period, such as the internal combustion engine, invented by Nikolaus August Otto in 1876, while Carl Friedrich Benz applied for a patent for his automobile in 1886 [58]. These inventions gradually became part of industrialization and began to replace other technologies; for example, the systems that worked with steam engines were replaced by electric motors and internal combustion engines [59]. Hydro turbines, precision machine tools and airplanes were also invented and developed in the Second Industrial Revolution or Industry 2.0. All these inventions and mechanical products, along with electricity and mass production, brought about disruptive changes in industries, agriculture and transportation, among other fields of development.

2.2.3. Mechanical Engineering and the Third Industrial Revolution

The Third Industrial Revolution, or Industry 3.0, began in 1970 [32], and it led to the development of countless inventions and technological developments, such as computing, which has marked a before-and-after in science and technology since its appearance and has allowed the development of many applications in all fields of knowledge. Electronics were a driving force in industrial development, and Information and Communication Technologies contributed to the development of countless applications. Industrial automation had a big boom in the Third Industrial Revolution with the introduction of the PLC (Programmable Logic Controller) and the industrial robot, accompanied by the development of electromechanical and mechatronic systems.

In Industry 3.0, Mechanical Engineering had four driving forces [60]: (1) markets became more demanding and changing with respect to mechanical products; (2) due to automation there were changes in systems and forms of production; (3) Mechanical Engineering was associated with the disruptive technologies of that time and (4) mechanics was related to the basic sciences. In this sense, markets and consumers demanded new products and designs, which motivated the integration of mechanics, electronics and computing, giving rise in Japan to the concept of Mechatronics [59], which was coined to meet the new requirements of industrial machinery. In the same way, the integration between mechanics and electricity gave rise to Electromechanics, whose applications revolutionized the forms of industrial production and allowed the construction of complex systems, such as airplanes and automobiles. The typical mode of manufacturing in the Third Industrial Revolution was mass production, and changes in markets led to more varied and smaller-quantity production. Mechanical Engineering at that time had to adapt to these changes.

On the other hand, the associations of Mechanical Engineering with the disruptive technologies of that time gave rise to a myriad of applications, such as Computer-Aided Design, the development of new materials, space applications, energy and biotechnology projects and maritime technology, among others [60]. In the same way, mechanics was related to mathematics and physics, and the applications of both were enhanced; for example, the laser was developed, advanced machines were built and computer design and simulation were promoted to solve various industrial problems. The integration of computing, mechanics, electronics, electricity and quality and material systems gave rise to the first cyber-physical systems conceived under the vision of Industry 3.0. The inventions and technologies developed in the Third Industrial Revolution, as well as the integration of applied science, helped transform society and the industrial world of that time.

2.2.4. Mechanical Engineering and the Fourth Industrial Revolution

Industry 4.0, or the Fourth Industrial Revolution, originated in 2000 [32], although other authors point out that it occurred in 2011 [39]. The processes of change and transformations brought about by this new industrial paradigm were accompanied by new scientific and technological knowledge and by diverse and varied technologies, of which 35 are considered disruptive technologies and 13 of them are of high relevance [48]. Large-scale digitalization and the use of industrial artificial intelligence in various applications are two novelties that are accelerating the processes of change and transformation in industries and businesses. Technologies such as the Industrial Internet of Things, Industrial Networks, Cloud Computing and Big Data, among others, have allowed the development of new and powerful cyber-physical systems and have made it possible to update similar systems created under the vision of Industry 3.0. In the Fourth Industrial Revolution, mass production systems are being transformed into customized manufacturing systems due to changes and new customer demands. This change in production allows consumers to have a say in the design of products, and companies must adapt their production processes to these new requirements. In Industry 4.0, cyber-physical systems and digital twin technologies enable the configuration of Smart Factories [61], in which hyper-automation and hyper-connectivity make autonomous production and manufacturing possible.

As in the previous three industrial revolutions, Mechanical Engineering makes important contributions to various fields of application of Industry 4.0. For example, mechanics is related to many physical assets of digital twins and cyber-physical systems. In addition, the properties of new materials are studied, which contributes to additive manufacturing in the design and manufacture of various products that are conceived within the vision of custom manufacturing. Collaborative robotics is another pillar of Industry 4.0 with which Mechanical Engineering is associated, and together with Mechatronics and artificial intelligence, it is responsible for the design of cooperative robots and the analysis of their movements. In the same way, mechanics and artificial intelligence have come together to model and solve various complex problems that are related to multiphysics systems [16]. Mechanical Engineering also contributes to the transition from the Third Industrial Revolution to Industry 4.0 as it is applied to performing Smart Retrofitting tasks, which consists of updating old machinery in line with Industry 4.0’s objectives [22]. This modernization process takes on relevance because many companies are in the process of technological reconversion, and intelligent retrofitting is a viable option for operating according to the vision of the Fourth Industrial Revolution using old machinery at a lower cost.

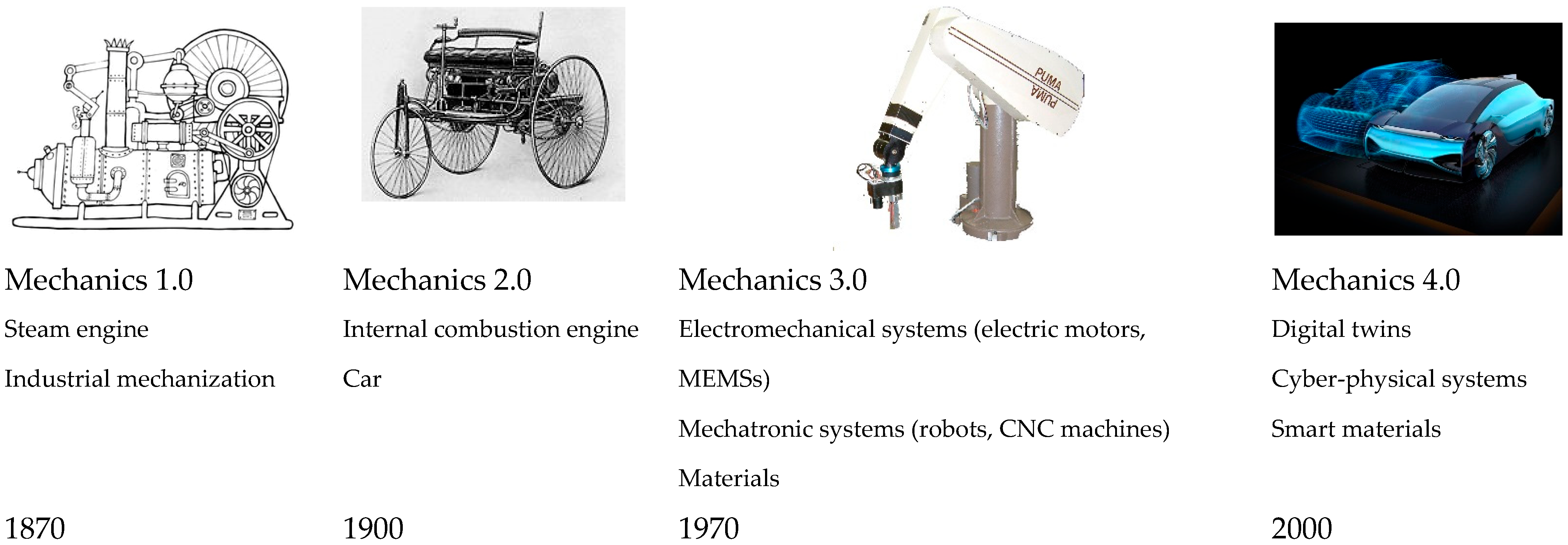

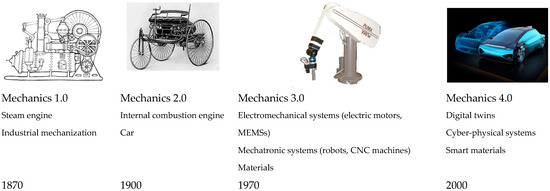

Today’s form of Mechanical Engineering follows the same process as in the Third Industrial Revolution [60], that is, it is characterized by four driving forces: (1) it is adjusting to the new requirements of the markets; (2) it is being reoriented towards the new demands of manufacturing processes; (3) it is being associated with the disruptive technologies of Industry 4.0 and (4) it is related to the basic sciences. In general terms, cyber-physical systems can be conceived as the base technology of Industry 4.0 [32] and as evolutions of Information and Communication Technologies or integrations between computing, networks and physical processes [62]. Digital twins can be interpreted as evolutions of electromechanical, mechatronic and simulation systems. Figure 2 shows the evolution of Mechanical Engineering in terms of the industrial revolutions and the technologies that have underpinned each of them.

Figure 2.

Evolutions of mechanics in the industrial revolutions and base technologies.

The potential of mechanics in Industries 3.0 and 4.0 is found in integrations, such as Electromechanics and Mechatronics conceived in the Third Industrial Revolution and in their evolutions into cyber-physical systems and digital twins in the Fourth Industrial Revolution. Therefore, the basic technologies of these two revolutions, conceived in terms of Mechanical Engineering, are the technological products that are derived from electromechanical systems, such as the electric motor and MEMSs (microelectromechanical systems), and Mechatronics (industrial robot). In the same way, in the case of Industry 4.0, the base technologies are cyber-physical systems and digital twins since both are characterized by having physical assets in which mechanics is present in an integrated way. In the same way, the development of materials has been crucial to both current and past industrial revolutions, and Mechanical Engineering takes a relevant role in their characterization, which is why it appears as one of the technologies of great importance in the evolution of mechanics.

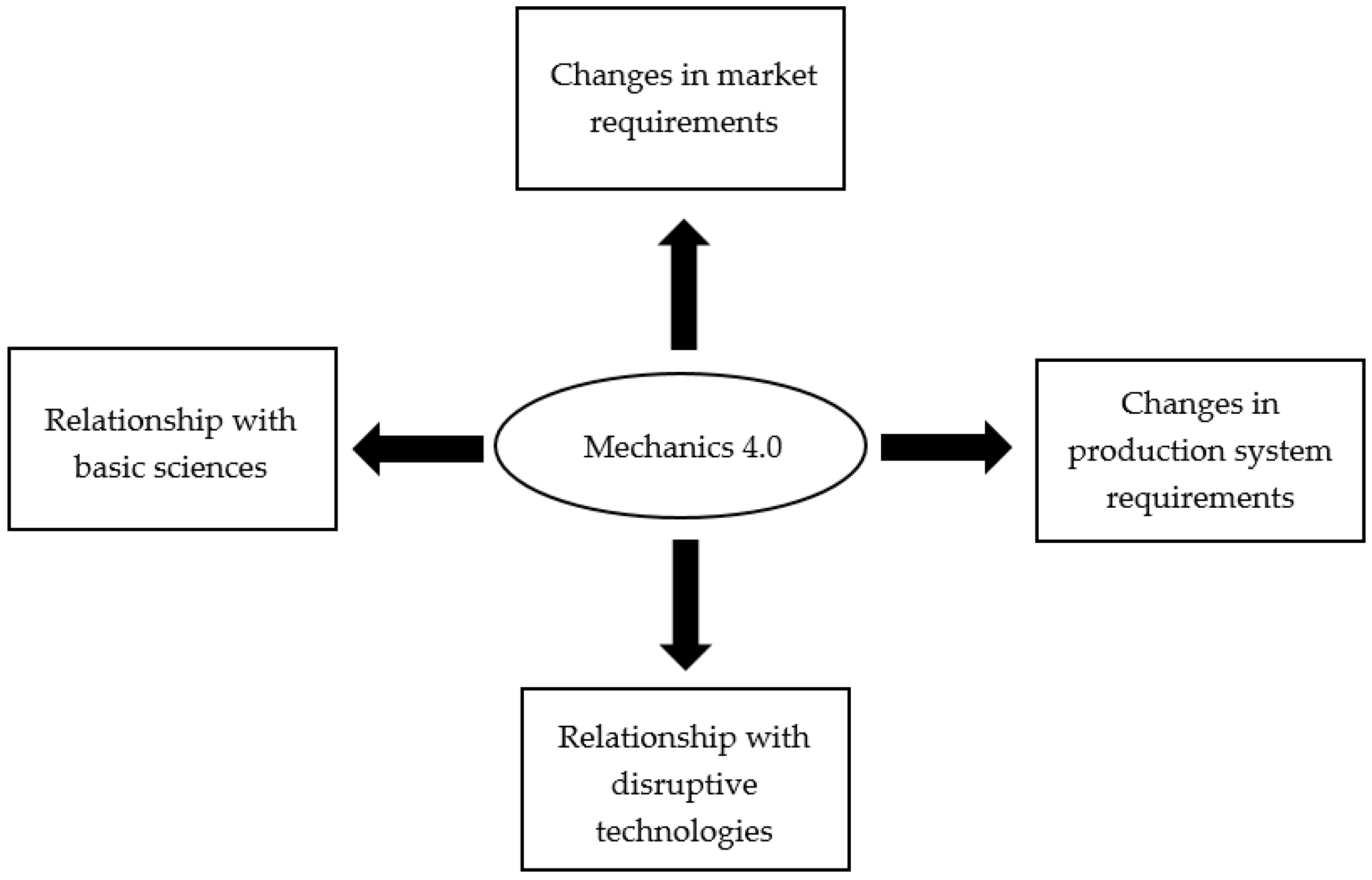

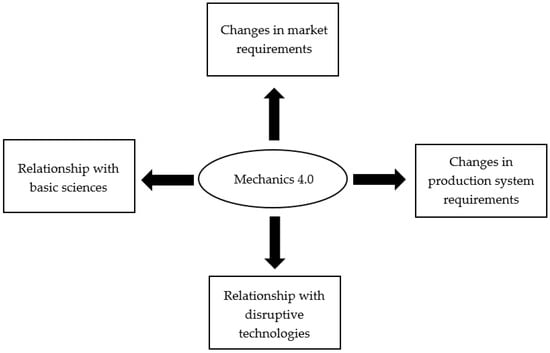

2.3. Mechanics 4.0

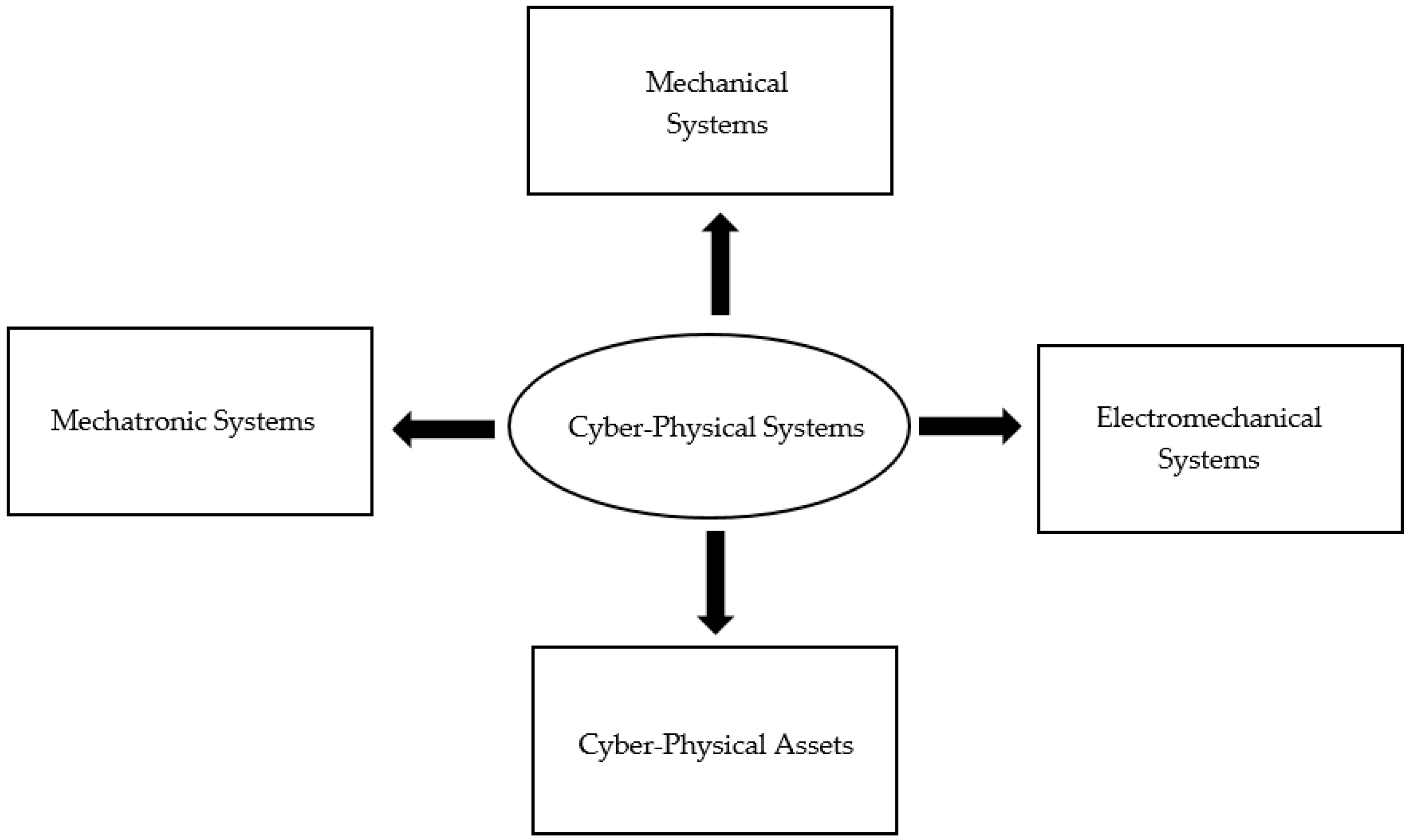

The concept of Mechanics 4.0 was proposed as the interrelation between Mechanical Engineering and artificial intelligence, whose purpose is to model and solve various problems related to multiphysics systems [16], which represent the basis of many applications in Industry 4.0. However, despite its importance, artificial intelligence is only one of the 35 disruptive technologies [48] that have accompanied the Fourth Industrial Revolution in the process of transforming the industrial world. Therefore, defining Mechanics 4.0 only in terms of disruptive technology minimizes the importance of Mechanical Engineering in Industry 4.0. It is possible to extend the concept of Mechanics 4.0 in terms of the four driving forces identified in Industry 3.0 [60], i.e., as a function of new consumer demands, new requirements in production systems and their relationships with disruptive technologies and basic sciences. Figure 3 shows a framework for Mechanics 4.0.

Figure 3.

Mechanics 4.0 framework.

2.3.1. Changes in the Market Requirements

Physical assets or products related to Mechanical Engineering, including industrial machinery and various devices for production, are currently in high demand due to the diversity of applications of companies that have aligned themselves with Industry 4.0 and those that are in transition. As in the Third Industrial Revolution, mechanical products must meet the requirements of Industry 4.0; for example, they must be precise, reliable, safe, comfortable, designed with greater accuracy and the minimum weight and environmentally friendly, among other things [60]. However, these requirements must be extended since the mechanical industrial products demanded by industries must consider integrations of Electromechanics and Mechatronics in order to be more functional; for example, they must have greater efficiency, energy efficiency, easy maintenance, availability, compactness and communication [63].

2.3.2. Changes in the Production System Requirements

Mass production was one of the most significant changes in the Second Industrial Revolution and was introduced by the Ford Company. At the beginning of the Third Industrial Revolution, the paradigm of mass production changed, and manufacturing was no longer massive, rather involving smaller quantities and a variety of forms. These changes were a consequence of the fact that the economy in the 60s and 70s was increasing, which caused and motivated greater needs for products of a greater variety [60]. In the same way, the seller’s market was transformed into a buyer’s market, due to the intensification of the market in these decades. Non-mass production and product variation were the basis for what is now known as “mass customization”, which is understood as a set of technologies and systems that make it possible to supply goods and services that meet the individual needs of customers with near-mass production efficiency [64]. This new production paradigm introduced important changes into manufacturing systems and in terms of the elements and technologies they consist of. For example, to adjust to the customized demands of today’s products, production systems must be flexible (Flexible Manufacturing Systems) and reconfigurable (Reconfigurable Manufacturing Systems), and this is possible if machinery and production systems are also flexible and reconfigurable. The reconfigurability feature allows companies to respond faster in global markets, as these types of systems adapt quickly to new product demands [65]. Therefore, Reconfigurable Manufacturing Systems very frequently change the physical configuration of the machinery on production lines.

Machines that are considered reconfigurable are designed taking into account the following considerations: (1) they are designed to operate in the environment of a Flexible Manufacturing System, specializing in a specific family of parts or products; (2) they are designed to operate under the criterion of customized flexibility; (3) the scalability of the machine is extremely important; (4) the machine must be designed under the criterion of modularity and (5) it requires that the machine can work in different places on a production line using the same basic design structure [66]. Mass customization is a new form of production in Industry 4.0 that involves designing production systems in such a way that they can be reconfigured in the face of changes in production volumes and product design. This involves the design and development of specialized, flexible and reconfigurable machines. Mass customization can be applied in four stages: (1) order securing, (2) design, (3) manufacturing and (4) supply chain coordination [67].

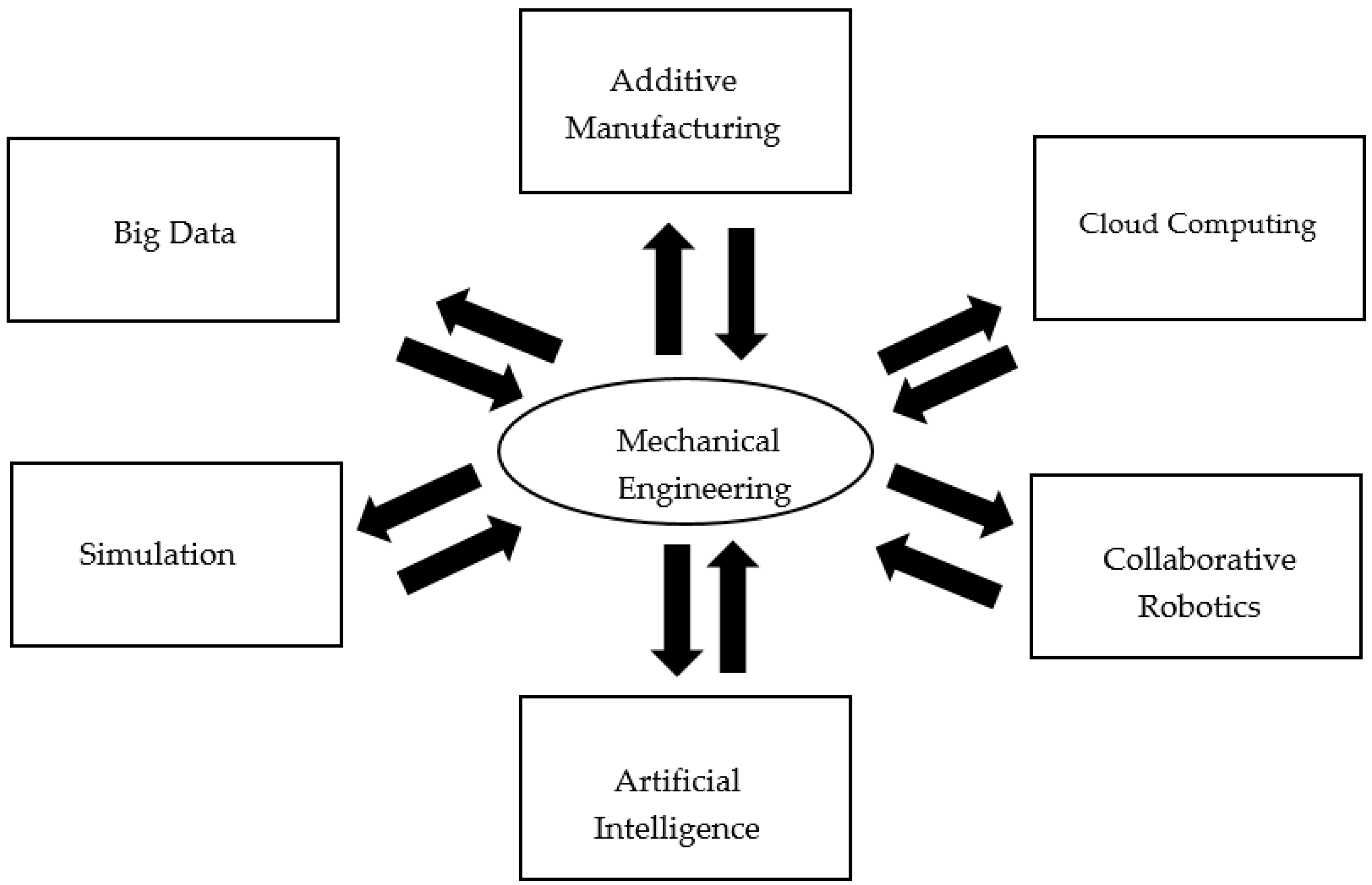

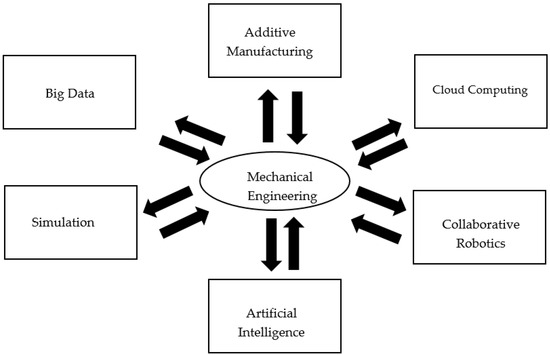

2.3.3. Relations between Mechanics and Disruptive Technologies

Mechanical Engineering has functional interactions with some of the disruptive technologies of Industry 4.0. Figure 4 shows the relationship of mechanics to just six of these disruptive technologies.

Figure 4.

Relations between Mechanical Engineering and the technologies of the new industrial revolution. Improved and adapted from [60].

According to Figure 4, the relationships between mechanics and the selected disruptive technologies are bidirectional since Mechanical Engineering provides knowledge, processes, methods, machinery and devices to disruptive technologies to achieve their objectives, and these in turn provide mechanics with theoretical knowledge, experiences and technological support for its development. For example, artificial intelligence provides mechanics with different algorithms for the solution of various complex problems related to multiphysics systems [16], while Mechanical Engineering contributes to the development of more specialized computer systems (hardware), where it is possible to solve the methods of artificial intelligence to solve all kinds of engineering problems. The same interaction is followed for Cloud Computing and Mechanical Engineering since the former provides technology for design (CAD), manufacturing (CAM), engineering (CAE) and manufacturing to improve the processes of design, production and the analysis of products, while mechanics provides, together with other areas of knowledge, the computational devices that make up the servers. Additive Manufacturing and Mechanical Engineering are also interrelated, as physical prototypes of various mechanical designs, mock-ups and final products are provided by 3D printing to improve designs and to manufacture machines, while Mechanical Engineering provides 3D printing systems with experimental methods to examine the mechanical properties and functionality of the developed prototypes. Collaborative robotics and mechanics transfer knowledge and technologies; for example, the kinematic and dynamic models that are used for the control of movements, the physical configuration of robots, the analysis of operations and the movements of people are supplied by mechanics to collaborative robotics, while the various problems that arise between robots and humans generate new challenges that are studied using mechanics. In the same way, renewable energies and mechanics support each other since the former provides new knowledge about different energies, which, in turn, are studied using mechanics. Subsequently, mechanics facilitates the development of systems for the production of non-renewable energies. Finally, mechanics and Materials Science are related since the former provides methods and knowledge for the machining of new materials while the latter provides information on the existence of new materials that mechanics is later responsible for characterizing for various applications.

2.3.4. Relation of Mechanics to the Basic Sciences

Mechanical Engineering is related to the basic sciences, but especially to mathematics and physics. Mathematics provides Mechanical Engineering with different tools for modeling and calculating various problems involving motion. Many problems in mechanics, such as the modeling of robots and mechanisms, generate systems of nonlinear equations. Numerical methods and artificial intelligence, both supported by mathematics, are used to solve the numerical models of robots [68]. In the same way, the development of the Mechanics of Continuous Mediums has given rise to modeling using partial differential equations various physical problems, such as heat, thermo-elasticity, plasticity and mechanical vibrations, among others. These problems are solved using numerical methods and through interpolation by means of the finite element method [69]. On the other hand, physics has provided valuable knowledge for Mechanical Engineering since technologies such as plasma and lasers have been fundamental for the design of cutting machinery and for manufacturing processes [70]. In the same way, mechanics has contributed to the development of complex systems such as the quantum computer and the design of accelerators with which physicists study different processes and characteristics of particles. Mechanics also contributes to the design of devices for space exploration, such as telescopes and space probes, so that physicists can study other worlds and the universe.

Mechanics 4.0, seen according to its relationships with disruptive technologies and basic sciences, and considering the market and changes in production systems, is more relevant and extensive than merely according to its association with artificial intelligence, as proposed in [16].

2.4. Mechanical Engineering and Specialized Technical Fields

Mechanics is associated with some specialized technical fields of engineering, such as industrial maintenance and materials, among others, which have evolved in parallel to Mechanical Engineering due to the introduction of the disruptive technologies of Industry 4.0 into their activities. It is possible to find in the specialized literature terms such as Tribology 4.0 [71] and Materials 4.0 [72], among others, which are a consequence of the influence of Industry 4.0.

Each specialized technical field uses disruptive technologies in its own way and delimits its application frontiers. However, Mechanics 4.0, by evolving in parallel with specialized technical fields, can be integrated with them in a more direct and systematic way, enhancing the construction of new knowledge and motivating the development of new specialized technological products. Some of the specialized fields of knowledge are described below:

Tribology 4.0 is the relationship between the disruptive technologies of Industry 4.0 and Tribology [73]. The most direct connection of Tribology is in terms of Information Technology and the Internet of Things, since the tribological data (on friction, wear and the condition of lubricants) captured by sensors can be transferred via wireless connections and the internet to devices that can process the information for different applications [71]. Another specialized technical field related to mechanics is materials. The adoption of disruptive technologies in the study and development of materials has generated the concept of Materials 4.0, whose ideal is to transform the traditional development of materials and seeks at the same time to promote a digital revolution that will accelerate the discovery, innovation and validation of new materials [74]. In the same way, industrial maintenance has evolved due to the insertion of disruptive technologies into its field of application, which has generated the concept of Maintenance 4.0, which defines the next generation of production equipment maintenance [75]. Maintenance 4.0 can be described as a subset of the smart manufacturing system represented by intelligent, self-learning machines that predict and diagnose failures and trigger maintenance actions [76].

On the other hand, modern robotics, or Robotics 4.0, is another field of knowledge that is evolving in Industry 4.0, and disruptive technologies are improving robots in terms of their collaboration, perception and autonomy [77]. In this way, robots equipped with intelligence will be able to make decisions and help workers collaboratively [78]. Another term of interest related to mechanics is Machine Tools 4.0, which describes a generation of specialized machine tools that have better connectivity, greater autonomy, a certain degree of intelligence and more efficient adaptability [79]. In addition, they have a high degree of horizontal and vertical integration, and the relationship between production and facilities at the factory level is deep and unprecedented [80]. On the other hand, the aviation industry has associated the technologies of the Fourth Industrial Revolution with its processes. The term “Aviation 4.0” refers to the use of disruptive technologies in the aviation industry [81] and refers to the design and operation of sophisticated cyber-physical systems, where one of their functions is to assist aerospace workers in operating autonomously and to make decisions and integrate with cyber-physical components into future aeronautical information systems [82].

Another important field of engineering related to mechanics is Industrial Design, whose activity is supported by some of the technologies of Industry 4.0, giving rise to the concept of Design Engineering 4.0 [83]. This is understood as an approach within Industry 4.0 that represents the human, cybernetic and physical vision of an ecosystem used for the realization of systems and provides a conducive environment for the development of complex systems [18]. Platforms have been developed in this field to assist in design, such as PDSIDES (Platform for Decision Support in the Design of Engineered Systems), which is designed to facilitate end-to-end digital integration, customization, agile collaboration networks, open innovation, co-creation, crowdsourcing and product servitization. On the other hand, Metrology, which has associated the tools of the Fourth Industrial Revolution with its applications and development, is known as Metrology 4.0 [84]. It is projected that Metrology 4.0 will revolutionize calibration processes by reducing times and costs and processing measurement information in real time [85]. Finally, another important field of engineering related to working in industries is Ergonomics, whose central axis is the adaptation of the work environment to humans [86]. Disruptive technologies are introducing changes and transformations in the safety and working conditions of workers in companies. These technologies have fostered the formation of the concept of Ergonomics 4.0 and other terms such as Operator 4.0, Safety 4.0 and Mining 4.0 [87].

2.5. Relationship of Mechanical Engineering with Background Technologies and Retrofitting

This section presents some relationships between Mechanical Engineering and three disruptive Industry 4.0 technologies with examples, called background technologies, which are (1) cyber-physical systems, (2) digital twins and (3) artificial intelligence. In addition, the importance of Mechanical Engineering in Smart Retrofitting is described.

2.5.1. Mechanical Engineering and Cyber-Physical Systems

Mechanical Engineering is related to cyber-physical systems, as they are composed of various assets, including mechanical physical assets, such as machinery, infrastructure and various devices. Cyber-physical systems represent the technological basis of Industry 4.0 [33] and are made up of physical assets and digital systems that are intertwined with each other through communication technologies and wired and wireless networks to perform various actions. There is no single definition for this technology. One of the definitions is described below: A Cyber-Physical System combines in the same frame of reference two systems, one physical and the other digital connected to the network, where the tasks and activities of the physical system can be controlled, analyzed and supervised from the networked digital system, using the communication of a feedback loop between both systems [88].

Mechanical Engineering is responsible for the design and operation of various physical systems that carry out operations in companies and provides mechanical physical models for controlling the actions of production devices and machinery. Mechanics was one area that gave rise to the mechatronic systems in the 70s that are now vital in modern machinery. In fact, today, mechanical systems have become mechatronic and electromechanical systems, and these, in turn, have become cyber-physical systems [89]. It is also possible to consider that Mechatronics was an evolution of electromechanical products and that cyber-physical systems come from an evolution of cyber systems. Cyber-physical systems and mechatronic systems have similarities and differences, which are shown in Table 1.

Table 1.

Similarities and differences between mechatronic systems and cyber-physical systems [90].

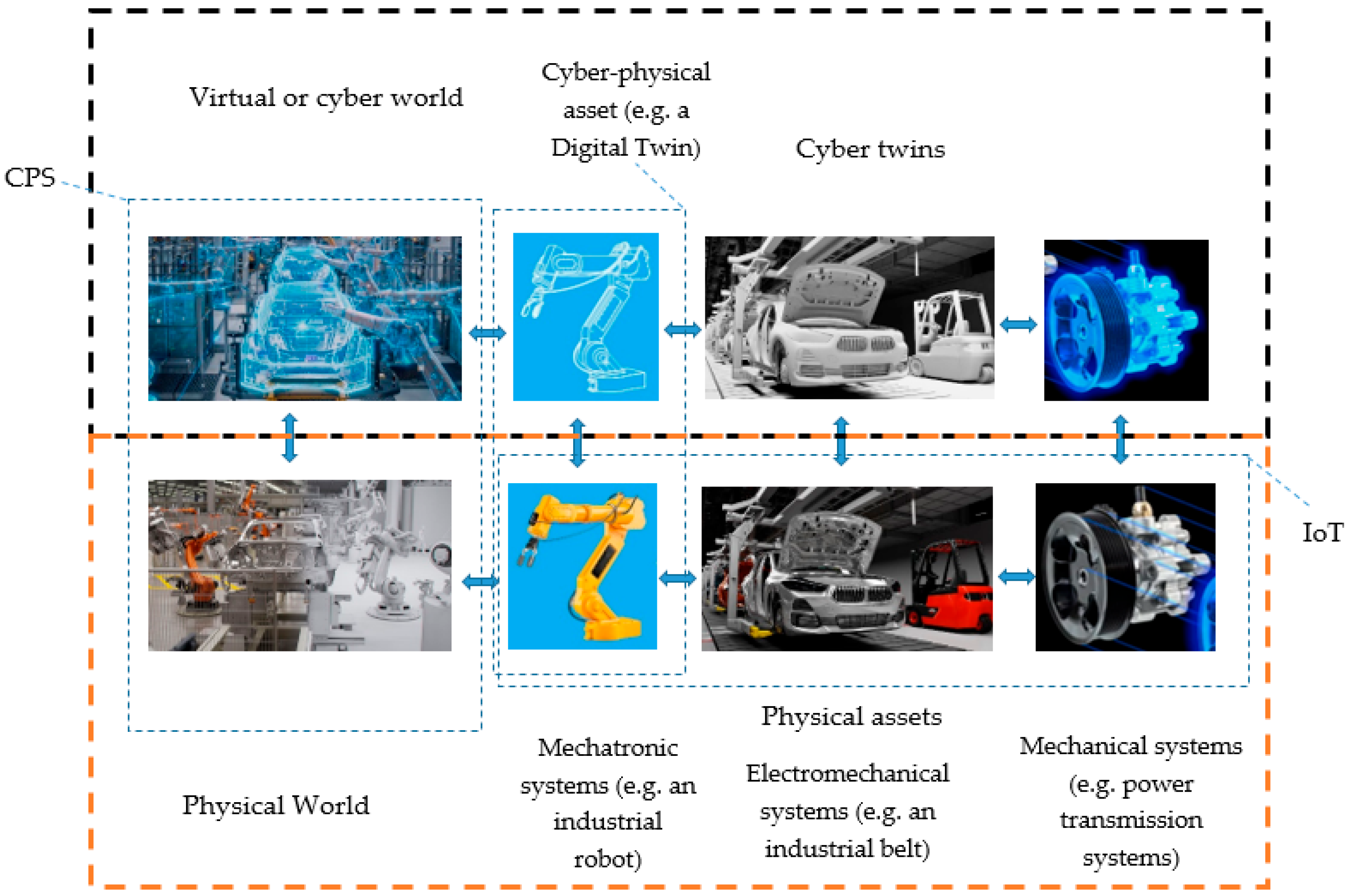

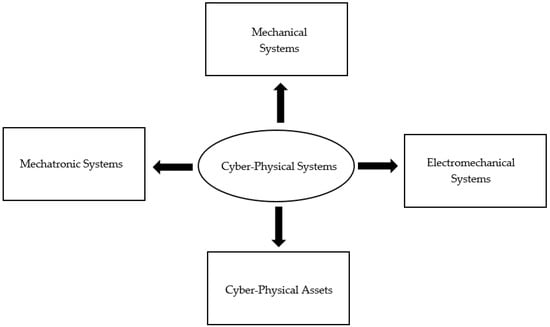

Cyber-physical systems are made up of various mechanical, electromechanical and mechatronic systems, which constitute and make up physical assets (see Figure 5). In some of these systems, it is possible to integrate digital twins, which are considered cyber-physical assets [91]. The physical assets that make up today’s cyber-physical systems, such as machines, devices, actuators, industrial belts and various mechanical devices, must meet the demands of customers, who request new and complex solutions every day. In this way, physical assets must be more operationally efficient and energy-efficient, be designed for better maintenance and have communication systems [63]. In addition, assets must be more precise, accurate, safe, reliable and nature-friendly [60].

Figure 5.

Cyber-physical systems in terms of physical assets in which Mechanical Engineering intervenes.

One technology that interacts with the physical assets of a cyber-physical system (CPS) is the Internet of Things (IoT), which is responsible for transforming machine information through sensors, processing it and sending it to cloud systems. The Internet of Things gives physical assets the characteristic of being communicable and is more closely related to physical assets [92].

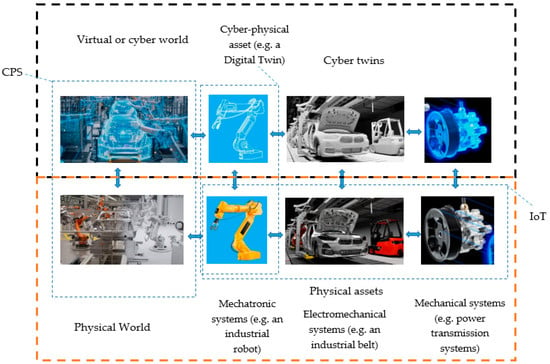

Figure 6 shows a schematic of a CPS, showing physical assets, virtual assets and cyber-physical assets, which, in this example, is a digital twin of a robot.

Figure 6.

Cyber-physical system, IoT and system assets. Taken and improved from [92].

2.5.2. Mechanical Engineering and Digital Twins

Another disruptive technology that Mechanical Engineering is related to is digital twins. These are composed of a physical asset and its virtual replica, which are interconnected with each other in a two-way relationship with real-time exchange of the evaluated data and information. The idea of the digital representation of the physical asset is that it makes it possible to have a better understanding of the dynamic and operational behavior of the asset by solving mathematical models of multiphysics systems previously programmed and fed with real-time information from sensors installed in the physical asset. Like CPSs, digital twins do not have a single definition. One definition is as follows: A Digital Twin is a non-physical model that has been designed to faithfully reflect an artificial or physical system, in which sensors are placed to acquire a series of data relating to different aspects related to the operation of the system [93]. Digital twins (DTs) represent differentiating technologies in companies, so studying them is essential in Industry 4.0.

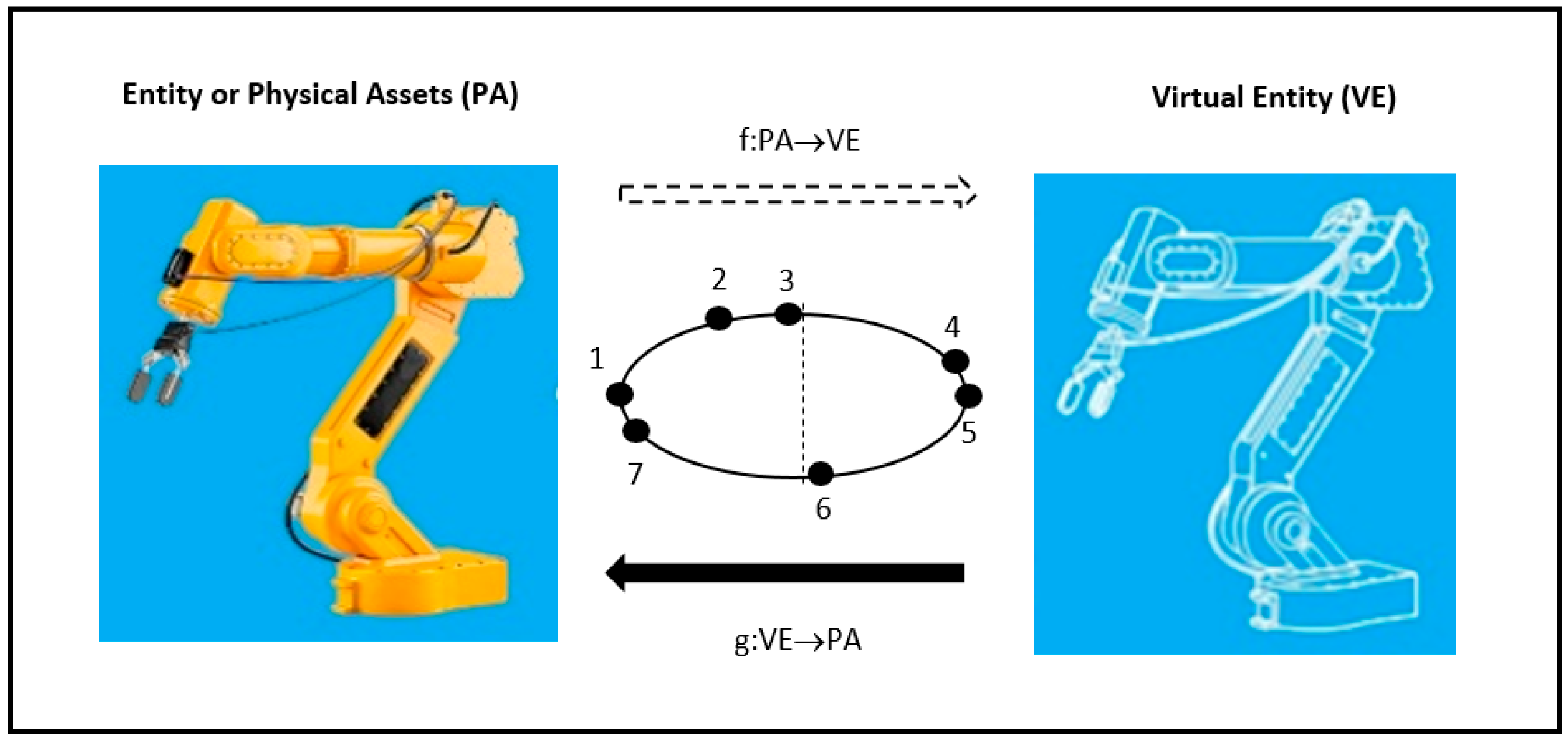

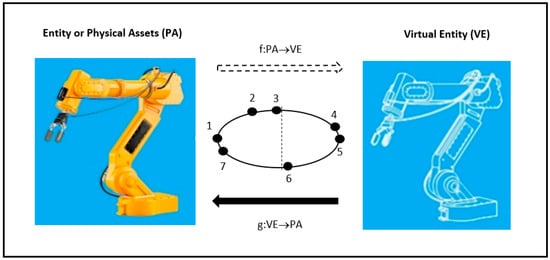

Mechanical Engineering provides physical assets, information and multiphysics models for the construction, control and operation of DTs. The operation of a digital twin is shown in Figure 7. The DT has a physical asset (PA) and a virtual entity or replica of the physical asset (VE), which are interconnected by two functions: f: PA→VE and g: VE→PA. The first function represents sending the real-time data generated by the sensors on the sensitive parts or parts of interest from the PA to the VE, and the second function represents the sending of analyzed, modeled and improved information from the VE to the PA.

Figure 7.

Operation flow of a DT. Taken and improved from [30,94].

Figure 7 shows the flow of data between the physical asset (robot) and the virtual entity (robot models) and a series of states, which are explained below: In state 1, the physical asset is believed to operate normally and to interact with the environment around it. State 2 represents the generation of signals obtained by means of sensors placed at sites of interest in or on the physical asset. State 3 is associated with sending the signals generated by the sensors to the virtual entity (f: PA→VE), and state 4 represents the information sent by the sensors and is processed by IoT elements and the operating history of the physical asset. Status 5 describes the internal processing of the data under multiphysics and prediction models, among others, using various tools such as artificial intelligence and data analytics. In this state, the processed information is generated and returned to the physical asset, and state 6 represents the transfer of the evaluated information g: VE→PA. Finally, state 7 represents the control or command elements that receive the processed information and are in charge of giving the necessary orders to execute the improvements in the physical asset.

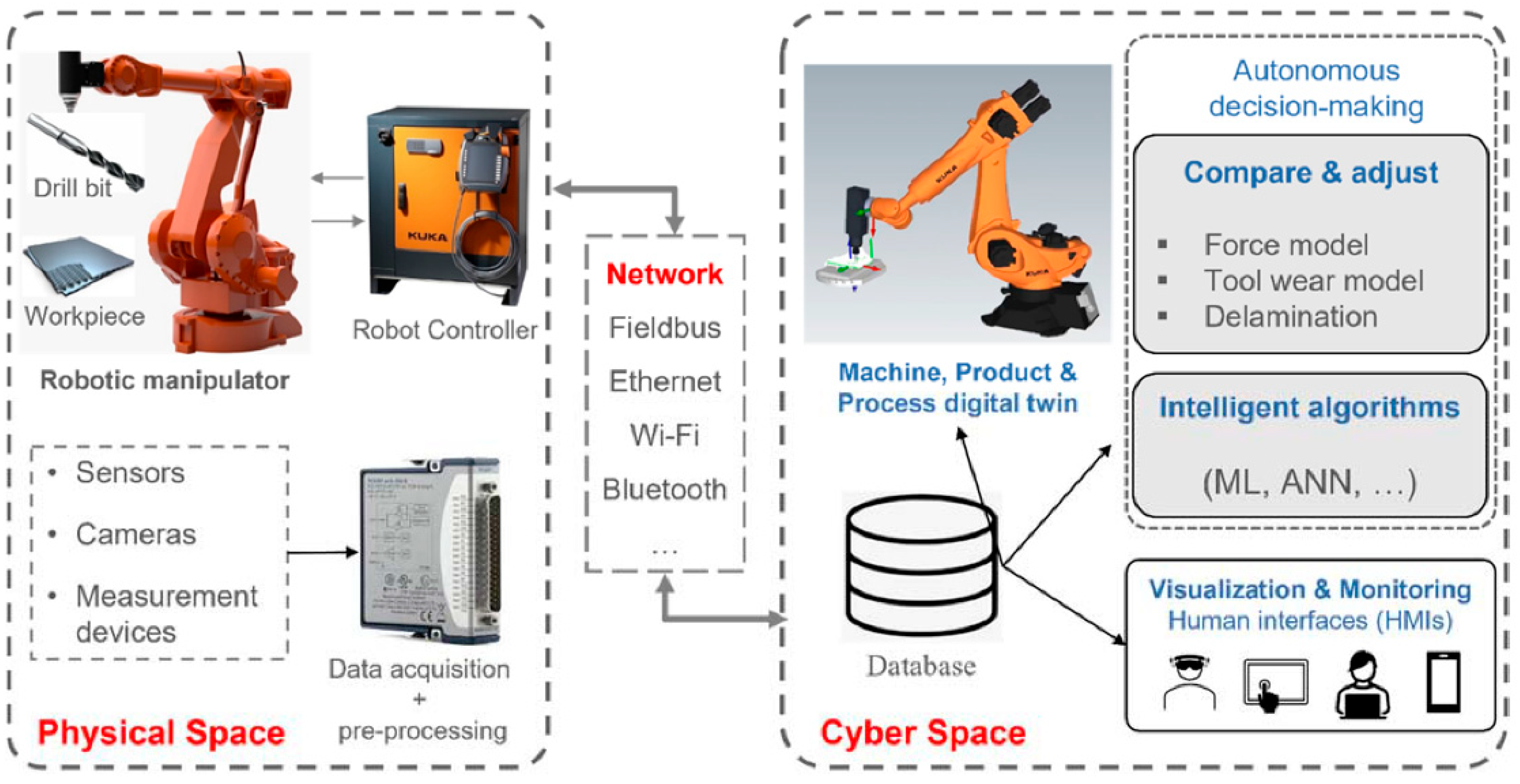

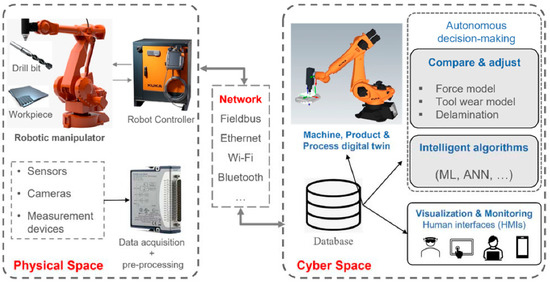

Mechanical Engineering, together with Mechatronics, provides important elements for the design, construction, control and operation of digital twins since they are two fields of knowledge responsible for providing physical assets, multiphysics models, control and relevant information on their operation and design. Therefore, Mechanical Engineering supports Industry 4.0 by being related to the design and operation of cyber-physical systems and digital twins and forms a part (real object) of the so-called “cyber-physical asset” which is defined as an object that exists in the real world and in the digital world with an end-to-end connection between the two worlds (state synchronization with a cyber-physical bridge). State changes that occur in one world are automatically reflected in the other, so that real and virtual objects are inseparably linked [91]. Digital twins and cyber-physical systems, as well as Non-Fungible Tokens (NFTs), are some examples of cyber-physical assets. Figure 8 shows an example of a robot-related digital twin that creates perforations in parts [95].

Figure 8.

Example of a DT related to a robot that punches parts. Taken from [95].

The figure above better describes some of the elements that make up a DT and the generic operating cycle shown in Figure 7. The robot is the main physical asset and is considered a mechatronic system. This system is sensorized, and the information captured by the cameras and sensors is sent to a data acquisition system and pre-processed to later be transferred to a digital or virtual entity through wired and wireless networks. In the digital world, information is integrated and processed according to pre-established mechanical and manufacturing models, and artificial intelligence systems such as machine learning (ML) and artificial neural networks, among other algorithms, are integrated. The processing of the information can be visualized by means of a Human–Machine Interface (HMI). The processed information is sent to the physical asset for adjustments and changes to be made [95].

2.5.3. Mechanical Engineering and Artificial Intelligence

Artificial intelligence is a disruptive Industry 4.0 technology [48,52] which has been partnered with Mechanical Engineering to solve a number of problems, some of them being highly complex. Decision-making and the design of physical assets are some tasks in which artificial intelligence assists mechanics in Industry 4.0 applications. In the case of decision-making, cyber-physical systems or digital twins require information on the states of mechanical systems that are characterized by physical systems in order to operate and meet objectives. The analysis of physical systems or multiphysics systems can be carried out using Artificial Intelligence methods [16]. Computational simulation is another disruptive Industry 4.0 technology that has benefited from the relationship between Mechanical Engineering and artificial intelligence; for example, human behavior has been simulated in the operation of machines and devices through artificial intelligence, and machine language (machine learning) has been applied in various problems, for example, in the development and characterization of materials, in the prediction of the mechanical behavior of parts manufactured using additive manufacturing, in the optimization of production systems, to reduce rejects, to improve product quality and to detect and reduce errors, among other important tasks [96].

Neural networks, fuzzy logic and genetic algorithms have been applied to the analysis of the movements of machines and robotic systems, especially for the solution of kinematic problems [68], and have been extended to the study of robot dynamics and control [97]. The analysis of the behavior of fluids and gases has also been studied using CFD (Computational Fluid Dynamics) and using artificial intelligence methods, such as genetic algorithms and artificial neural networks [98].

In the context of Industry 4.0, mechanical analyses of various components or machinery must be carried out quickly and efficiently. Although tools and methods have existed for decades for performing computational analysis of the mechanical behavior of elements of machinery or mechanical systems, such as finite differences or the well-known finite element method, the calculation carried out with these tools leads to thousands and millions of computational operations. In some applications, such as in manufacturing operations such as orthogonal cutting [69], the models to be solved are complex and require high computational costs and a considerably long time to reach solutions. In today’s production processes and supply chains aligned with Industry 4.0, fast and precise solutions are required in mechanical studies of the parts or components to be manufactured. Artificial intelligence is useful for developing methods of study and analysis quickly and with precise adjustments to solve and predict the behaviors of mechanical systems that make up various physical assets and that are necessary for the design, operation and control of cyber-physical systems and digital twins that are applied to different technologies for production [16].

2.5.4. Mechanical Engineering and Smart Retrofitting

Some of the equipment strategies that various companies are using to migrate from their current state to Industry 4.0 include the use of methods for technological reconversion or modernization of their production systems. This is due to the fact that the infrastructure and the new machinery equipped with systems for digitized and connected production are expensive and difficult to acquire. In the same way, some companies acquire equipment with the aim of its long operation, and due to the technology with which it was built, it is difficult to integrate it into the vision of the Fourth Industrial Revolution. Modernization or retrofitting projects for Industry 4.0, or Smart Retrofitting, are not easy to carry out because the technologies that are located on the production line do not have the same technological level, so it is necessary to design specific retrofitting methods for each machine, device or system. In fact, Smart Retrofitting can be applied to machines, production lines, cyber-physical systems and even factories and is highly dependent on the Industry 4.0 goals that the company aims to achieve [22].

A viable proposal for the introduction of companies to Industry 4.0 is to implement the so-called “smartification” of machinery, which refers to the improvement of machines or physical assets with digital technologies and services [99]. There are two methods of technological conversion: (1) intelligent retrofitting and (2) traditional retrofitting. These methods differ from each other, as the first refers to the conversion of technology oriented towards Industry 4.0 objectives and the second only seeks to expand the potentialities of a system or machine [22]. However, in practice, intelligent and traditional retrofitting are both applied in the conversion of machinery since the former depends on the latter. Mechanical Engineering is involved in both processes of technological reconversion since it is generally necessary to improve or change the elements, links, gears or mechanical systems that exist in operating machinery and even in non-operational or old machinery that is to be reconverted to enhance its performance or to meet Industry 4.0 objectives. The relationship between Mechanical Engineering and the Internet of Things (IoT) is crucial for Smart Retrofitting projects since the sensors placed in or on the improved physical assets or made part of them and the processing of the signals generated by the sensors are related to the IoT and smartification.

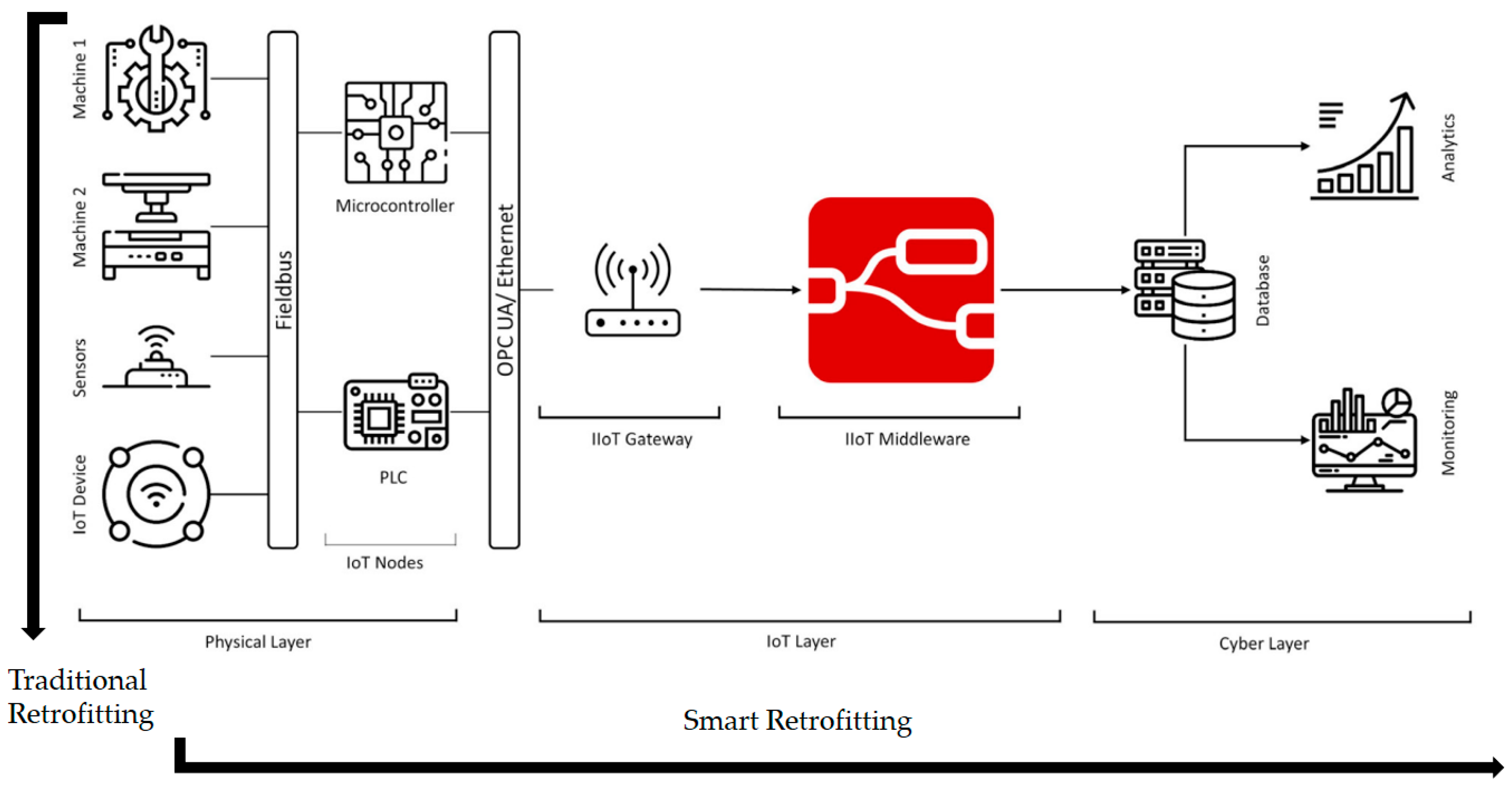

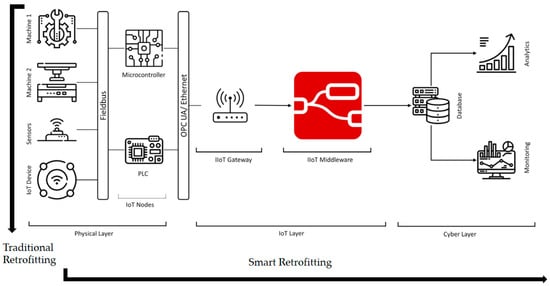

Mechanical Engineering and Mechatronics provide Smart Retrofitting with machinery improvement, mechanical system design engineering to meet new requirements, energy systems analysis, motion modeling and control, automation (PLC and microcontrollers) and sensorization of key parts of machinery, among other tools and methods, while the IoT offers communication networks, routers or gateways and communication software, among other technologies. The cloud offers applications such as monitoring, data analytics and artificial intelligence services, among others. Figure 9 shows a diagram showing the relationships between Smart Retrofitting, traditional retrofitting and the Industrial Internet of Things (IIoT).

Figure 9.

Smart Retrofitting, traditional retrofitting and the IoT. Taken and improved from [100].

Traditional retrofitting is essential for mechanical and mechatronic improvements to legacy equipment, while Internet of Things systems and elements form the basis for intelligent retrofitting. This process has three layers, as shown in Figure 9. The first is a physical layer where physical assets and signaling elements are located, and their information is communicated through an industrial protocol or a field bus to PLCs and microprocessors [100]. The second layer integrates Internet of Things elements, including OPC UA (Open Platform Communications Unified Architecture) technology, an open multi-platform industrial communication technology that offers end-to-end data transmission security, is service-oriented and relates to the standard protocol IEC 62541, considered the standard for Industry 4.0 [101]. This layer also integrates a router and middleware system (software) that allows various types of communication between the application components in a distributed network. Middleware for the IoT has been recognized as the system that can provide necessary service infrastructure and has become increasingly important for the IoT in recent years [102]. The third layer is related to virtual assets, which involve databases, processing and cloud-based services and applications. Mechanical Engineering, the Industrial Internet of Things and cloud services are essential for intelligent retrofitting.

2.6. Mechanical Engineering Education in the Context of Industry 4.0

This section presents an overview of engineering education in the context of Industry 4.0 and proposes a definition of Mechanical Engineering Education 4.0.

2.6.1. Engineering Education in Industry 4.0

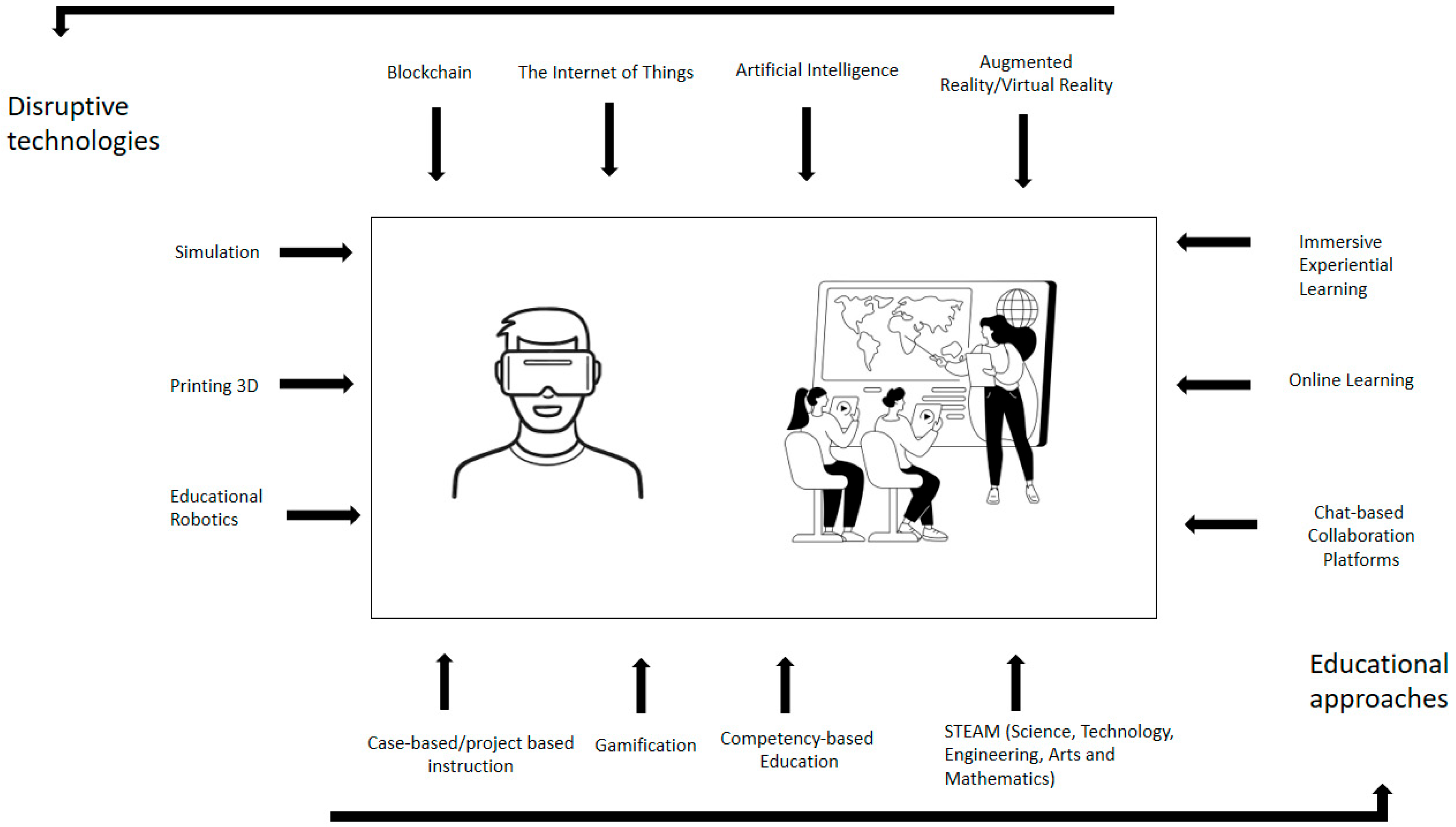

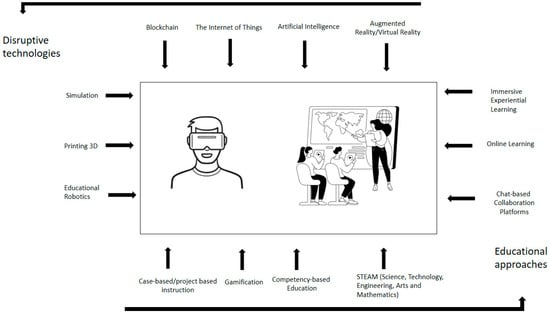

To meet the challenges brought about by Industry 4.0, the concept of Education 4.0 has been formalized, whose mission is to study the necessary changes that must occur in formal education systems in order to align educational processes with the vision of the Fourth Industrial Revolution [103]. Education 4.0 assesses the implications of disruptive technologies for learning processes and is based on four pillars: (1) technologies, (2) processes, (3) teaching methods and (4) competencies [104]. Student-centered pedagogical methods [105] and disruptive technologies are two paths studied in Education 4.0 (see Figure 10).

Figure 10.

Disruptive technologies and pedagogical methods in Education 4.0. Taken and improved from [30].

On the other hand, education related to the training of engineers oriented towards Industry 4.0 is called “Engineering 4.0 Education”. In this vision of new engineering education, the theoretical and practical applications of physical and mathematical laws or principles to design, manufacturing and maintenance tasks, among other things, are some of the activities that new engineers must master in order to align with the requirements of Industry 4.0 [106]. Engineering Education 4.0 seeks to make changes in the educational processes of students; an example is the transformation of the physical spaces of traditional classrooms into individual or shared cybernetic systems [107] Another change that is sought is the modernization of curricula in the direction of Industry 4.0, and for this, better and greater multidisciplinary and interdisciplinary collaboration between faculty members and researchers from different specialties is required, including the vision and needs of the industry [108]. Modernizing engineering laboratories is another goal of Engineering Education 4.0. For this task, disruptive technologies can help in the reconversion of academic laboratories; for example, augmented and virtual reality, when combined with the physical or remote laboratories of universities, create innovative tools for engineering education [107,109].

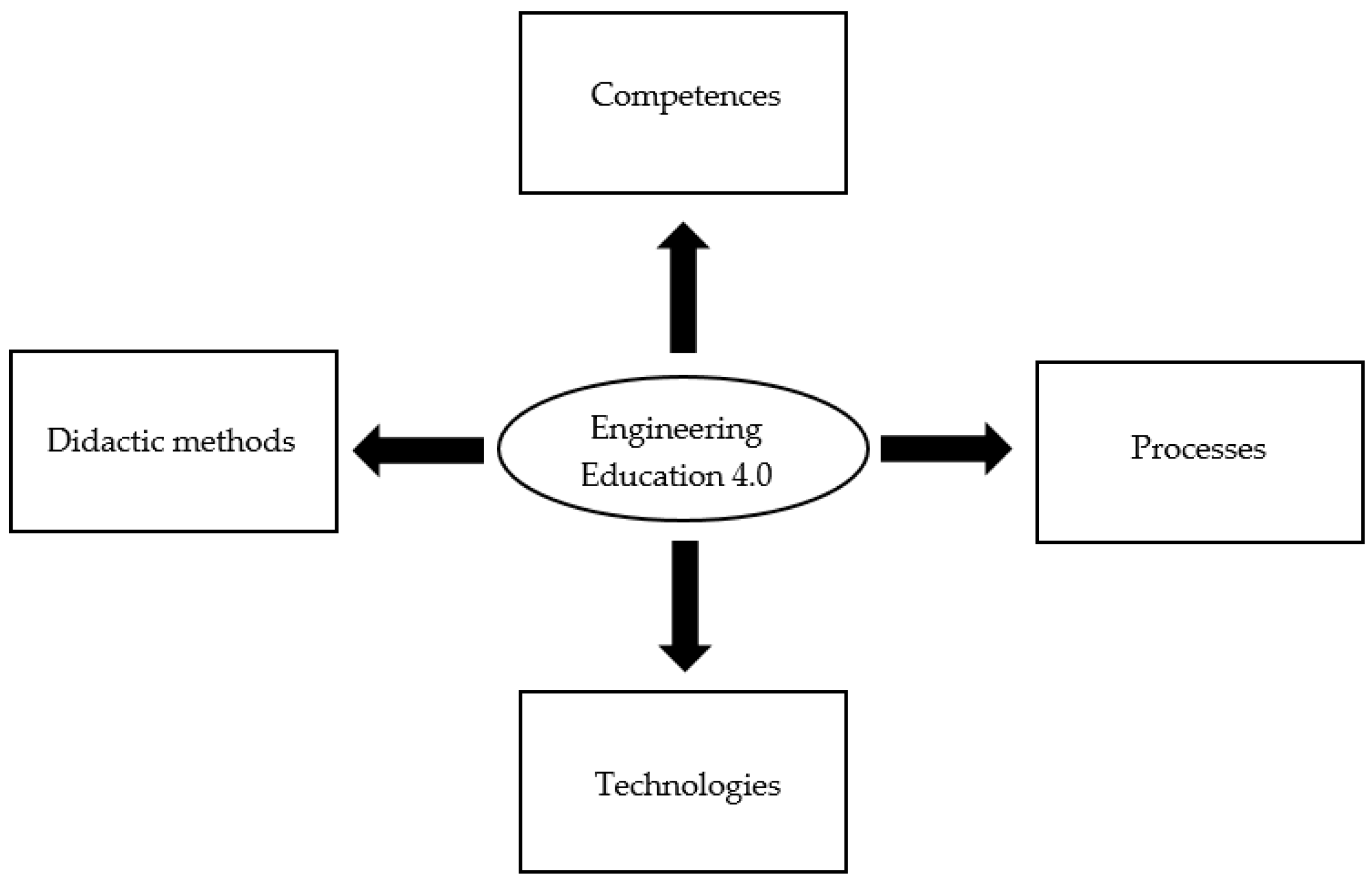

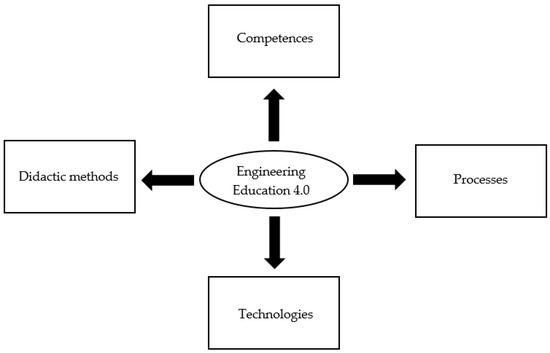

Skills training is key to the new industrial paradigm and its applications. For the design of competencies, it is of utmost importance to identify the professional profiles of factories enabled for Industry 4.0. In a recent study, a catalog of 100 new job profiles was drawn up, which were characterized and analyzed in terms of technical and soft skills and the type and level of profile, as well as the frequency of demand. The technological sectors analyzed were (1) additive manufacturing, (2) collaborative robotics, (3) Mechatronics and Machine Automation, (4) data analysis, (5) Cybersecurity and (6) Human–Machine Interfaces [110]. In addition, one of the proposals in the education of engineers is to promote the ability for them to learn continuously and without the need for companies to demand it, so it is necessary for them to have the ability to learn [111]. There are several proposals for the definitions of the skills and competencies required in Industry 4.0. One of these proposals has the following steps: (1) failure analysis, (2) forecasting, (3) adaptation to change and (4) the management of technologies, among others [112]. Finally, Engineering Education 4.0 also studies educational processes aimed at facilitating the work of teachers. Figure 11 shows the four pillars of Engineering Education 4.0.

Figure 11.

Pillars of Engineering Education 4.0. Based on [104].

2.6.2. Mechanical Engineering Education in Industry 4.0

The science of mechanics and Mechanical Engineering make important contributions to Industry 4.0 and are related to various disruptive technologies, to other areas of knowledge, such as computing and electronics, and to specialized fields of application. The strong relationship between mechanics and the Fourth Industrial Revolution makes the education of mechanical engineers a priority. The introduction of new didactic methods into teaching and learning processes, the improvement and automation of educational processes, the adoption of disruptive Industry 4.0 technologies in teaching and the development of engineering competencies are the most important guidelines that Mechanical Engineering Education must follow in order to align itself with the needs and requirements of the Fourth Industrial Revolution. Therefore, Mechanical Engineering Education should follow the guidelines of Engineering Education 4.0 and in general the vision of Education 4.0.

The tradition in engineering education until now has been that educational process continues to depend on the teacher, which complicates the insertion of new didactic proposals into teaching and student learning. From the perspective of educational approaches and teaching methods, educators in Mechanical Engineering must initiate transformations from teacher-centered teaching to student-centered learning. One educational approach that enables this transition is competency-based education [24,113]. This educational model focuses on results, integrates various proposals for teaching practice and promotes evaluation methods which focus on giving a central value to student learning and on their evaluation, promoting the application of learned knowledge and interpersonal competencies [114]. The implementation of the competency-based approach in Mechanical Engineering Education is a challenge due to the resistance to change of teachers and students. Learner-centered education requires the use of active methods to boost learning. These methods are used by teachers with the purpose of changing or transforming students’ passive processes, tasks and activities into active processes and tasks, with the aim of leading them to their own meaningful learning [115]. An active method that is naturally applied in the processes of engineering teaching and learning is Project-Based Learning [113]. This method uses projects to develop learning and encourages students to seek and find solutions to real-life situations or problems or applied projects, where it is possible to generate a product or prototype [116]. There are other active methodologies that can be used in engineering teaching and learning, such as Problem-Based Learning and the Case Method, among others. Active methodologies such as Project-Based Learning and Problem-Based Learning, as well as the competency-based approach, are applied in Education 4.0 [107] and should be promoted and applied in the teaching and learning of Mechanical Engineering.

On the other hand, with the help of disruptive technologies, it is possible to improve and automate the educational processes of teachers and students, such as the grades of exams and projects, the review of assignments, repetitive activities and checking class attendance, among others. These day-to-day tasks of teachers are often long and tedious, and they take up time. Automation can help improve the management of the activities that teachers perform and improves their attention towards students, saving valuable time and costs.

Mechanical Engineering Education must adopt the disruptive technologies of Industry 4.0 necessary to facilitate and improve the training of engineers. These technologies can be applied in two ways in the educational process: (1) in combination with a certain educational method to facilitate and improve learning and (2) as a knowledge base in the applications of Mechanical Engineering. For example, artificial intelligence can be used as pedagogical support in the search for information by using tools such as ChatGPT and virtual assistants [117], and it can also be used as a subject of study when applied to solving various multiphysics problems [16] that are necessary for applications in Industry 4.0. Virtual reality and augmented reality are two disruptive technologies that are used to motivate, facilitate and improve student learning by using electronic devices such as glasses or smartphones to perform animations and simulations in virtual environments that facilitate experimentation with educational content in an immersive way. Augmented reality has been used in conjunction with the STEAM methodology to help students improve their skills and abilities in solving math problems, particularly in the subject of geometry [118]. Augmented reality and virtual reality are applied to evaluation processes of part assembly in industries [119]. In the same way, digital twins are used in conjunction with Project-Based Learning to boost the learning of engineering students [120], and digital twins are used for applications in mechanics, for example, in aircraft maintenance [93]. The Internet of Things has also been applied in education; for example, this technology has been used in conjunction with Project-Based Learning to carry out a quantitative evaluation of learning and to understand students’ perceptions of their experiences of learning [121]. The Internet of Things is also applied for activities involving Mechanical Engineering, such as the refurbishment of machinery [100]. Robotics is another Industry 4.0 technology that has been applied in conjunction with a didactic technique called Factory Learning, which promotes learning in the workplace to develop hard and soft skills related to Industry 4.0 and creativity [122]. Robotics is a topic of conceptual and practical study in Mechanical Engineering. In this way, the disruptive technologies described in [48] are associated with pedagogical methods and with the teaching of content and applications in the training of engineers.

On the other hand, the design of competencies is another pillar of Education 4.0 and the education of mechanical engineers. The Fourth Industrial Revolution has caused a transformation and a radical change in the dimensionality or scope of engineering competencies, so it is necessary to improve, design and implement already established or new skills and competencies in mechanical engineers so that they can be incorporated into Industry 4.0. There is no consensus on defining a single class of Engineer 4.0 or Industry 4.0 engineer competencies. The following 10 competencies can be associated with Engineer 4.0: (1) social intelligence, (2) virtual collaboration, (3) resilience, (4) novel and adaptive thinking, (5) cognitive load management, (6) meaning-making, (7) new media literacy, (8) design thinking, (9) a transdisciplinary approach and (10) digital and computational skills, among others [108]. These competencies can be transferred to the training of mechanical engineers and must be complemented by the design of specific competencies, which universities and companies must unite to clearly define and apply in the workplace. The development of competencies must be directed under an educational approach, as is the case of competency-based education and active methodologies for learning, such as Project-Based Learning and Factory Learning.

Other aspects that Mechanical Engineering Education must address are the improvement and development of the topics and contents of the subjects offered in universities, as well as the improvement and modernization of laboratories. With regard to content, some subjects, such as the design and manufacture of mechanical components, must integrate aspects of additive manufacturing and 4D, 5D and 6D printing [123], as well as applications of smart materials, since several current uses are based on these technologies. In the same way, artificial intelligence should be promoted as a topic in classes on Mechanical Engineering since it has various applications to mechanics, such as, for example, the solution of various multiphysics systems [16] and the analysis of mechanisms and robots [124], among other things. Design and manufacturing topics must be taught in the context of design and digital manufacturing, for which engineering students must learn to handle different types of software and programs, such as CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), CAE (Computer-Aided Engineering), CAPP (Computer-Aided Production Planning) and CIM (Computer-Integrated Manufacturing) software, among other things [125]. Updating the class topics of engineering curricula is crucial for the training of mechanical engineers who will operate under the vision of Industry 4.0. On the other hand, the teaching laboratories of Mechanical Engineering must be modernized so that students can practice and carry out projects and so that they can improve their learning by participating remotely in projects with other universities.

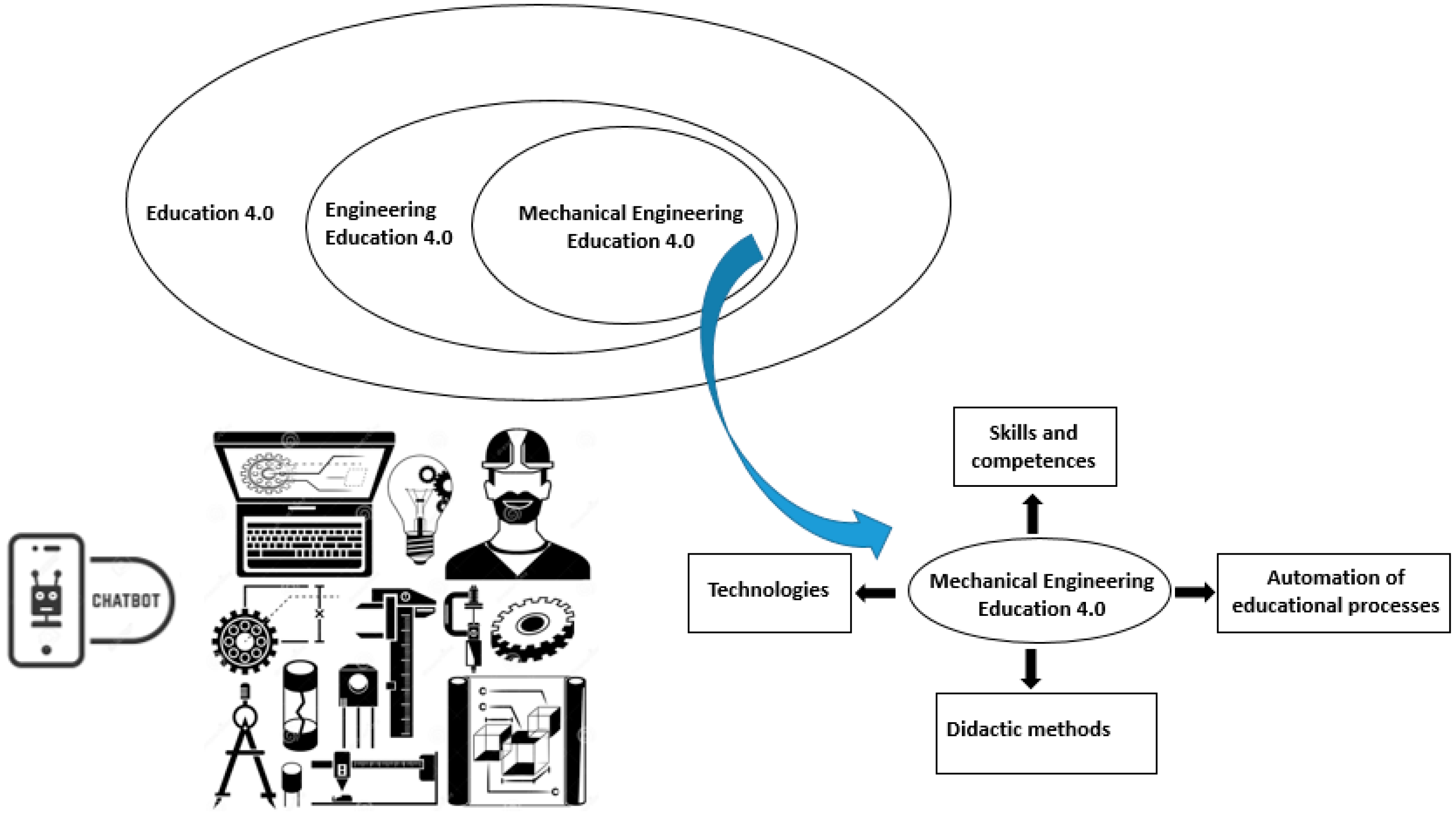

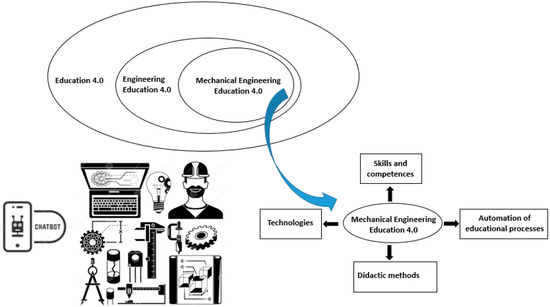

2.6.3. Mechanical Engineering Education 4.0

In order to systematize Mechanical Engineering Education in the context of Industry 4.0, the following definition is proposed in this work: Mechanical Engineering Education 4.0 can be conceived as a subsystem of Engineering Education 4.0 that adopts the disruptive technologies of Industry 4.0 and modern educational approaches to train mechanical engineers in the skills and competencies required by the Fourth Industrial Revolution and that inherits the four pillars of Education 4.0, that is, (1) competencies, (2) the automation of educational processes, (3) technologies and (4) teaching methods. Figure 12 shows a framework of Mechanical Engineering Education 4.0.

Figure 12.

Conceptualization of Mechanical Engineering Education 4.0.

2.7. Orientations of the Disciplines of Mechanics in Industry 4.0

Mechanical Engineering encompasses various disciplines, such as Materials Mechanics, Thermodynamics, Fluid Mechanics and Rigid-Body Mechanics, among others. The evolution of these disciplines in the context of Industry 4.0 does not follow a specific roadmap. For instance, experimental artificial intelligence was utilized in various mechanical applications long before the emergence of Industry 4.0. In 1996, neural networks were used in Computational Mechanics applications [126]. Artificial intelligence, considered a disruptive technology in the Fourth Industrial Revolution, has been applied in various Mechanical Engineering disciplines. For example, Fluid Mechanics, machine learning and digital twins have been used to design technology for applying drilling fluids in wells [127]. Thermodynamics, augmented reality and neural networks were used to develop a real-time augmented reality simulator that allows users to interact with deformable virtual solids [128]. There are mechanical applications that incorporate other disruptive technologies. For instance, Rigid-Body Mechanics, digital twins and virtual reality were applied to generate and control the movements of an industrial robot through a digital twin [129]. Materials Mechanics, simulation (finite element) and digital twins were used to develop a physical manufacturing testbed that bends metal into V-shaped brackets. A digital twin was used to predict the performance and process outcomes in a bending operation [130]. Additive manufacturing, Materials Mechanics and machine learning were employed to analyze the mechanical properties of polyamide 2200 used in additive manufacturing applications [131]. Engineering Design is also evolving, and the concept of Engineering Design 4.0 has been proposed. It is driven by the Internet of Things, the Internet of People, the Internet of Services and the Internet of Commerce to effectively and efficiently fulfill the promise of Industry 4.0 [18].

In this sense, the disciplines of mechanics, when used in conjunction with disruptive technologies for Industry 4.0 applications, can be considered within the vision of Mechanics 4.0, taking into account that each discipline has its own evolution both in the solution of technical problems and in Engineering Education.

3. Results and Discussion

This research has shown the importance of Mechanical Engineering and its applications within the paradigm of the Fourth Industrial Revolution. The results are summarized as follows: The main technologies of mechanics were identified in each industrial revolution of the past. It was found that the disruptive technologies of the moment have been combined with mechanics to develop projects oriented towards Industry 4.0 objectives. Digital twins and cyber-physical systems represent two disruptive technologies of Industry 4.0, and it was determined that Mechanical Engineering is related to these technologies since, together with Electromechanics and Mechatronics, they form the basis of the physical assets that are monitored and controlled from the virtual world. In the same way, artificial intelligence and Mechanical Engineering have come together for the development of various applications in Industry 4.0, including the resolution of industrial problems that involve the use of multiphysics models and the design of digital twins. This association has been called Mechanics 4.0 [16].

It was found that other specialized fields of applications related to Mechanical Engineering, such as Metrology, Ergonomics and materials development, have implemented disruptive technologies in their processes, which has given rise to terms such as Metrology 4.0 and Ergonomics 4.0, among others. In the same way, it was determined that Mechanical Engineering is related to the technological reconditioning that makes it possible to redesign inherited production systems for their incorporation into Industry 4.0 models.

It was identified that in the Third Industrial Evolution, four driving forces were taken as the basis of Mechanical Engineering to understand its importance in technological development. It was also found that the different disciplines of mechanics do not follow a roadmap in applying disruptive technologies in their processes.

On the other hand, it was found that the disruptive technologies of Industry 4.0 also have an influence on Education and that Engineering Education 4.0 has studied the training of competencies in engineers, guided the introduction of didactic methods into classes, promoted the insertion of disruptive technologies into the learning process and improved the administrative processes of teachers. The Education of Mechanical Engineers in Industry 4.0 was circumscribed within the framework of Engineering Education 4.0.

The results described above lead to the following discussion: Mechanical Engineering has been a pillar of support for each of the documented industrial revolutions, as it has been associated with or been the basis of certain disruptive technologies in each era, such as the steam engine, the mechanized development of production systems and the design of the internal combustion engine, the automobile and industrial robots, among others. In the current Industry 4.0, mechanics and its disciplines have important roles since they are the foundation of disruptive technologies such as drones, additive manufacturing, robotics and cyber-physical systems, among others. Mechanical Engineering not only contributes physical assets to digital twins and cyber-physical systems but also provides multiphysics models that are fundamental in the characterization of the mechanical states of machinery, with which predictions are made using artificial intelligence. Mechanical Engineering is also essential for various industrial applications related to the objectives of Industry 4.0, such as traditional and intelligent technological reconditioning of legacy production systems. Mechanical Engineering is responsible for improving the performance of machinery and production systems selected for conversion that need to be connected to Industry 4.0 services.

To meet the technical requirements demanded by Industry 4.0, Mechanical Engineering has been integrated with electricity, electronics and computing, forming the concepts of Electromechanics and Mechatronics, which have become new fields of knowledge. These fields of integrated knowledge are fundamental to the design of the various physical assets that make up cyber-physical systems and to the development of intelligent machinery.