Study on the Parameter Influences of Gear Tooth Profile Modification and Transmission Error Analysis

Abstract

1. Introduction

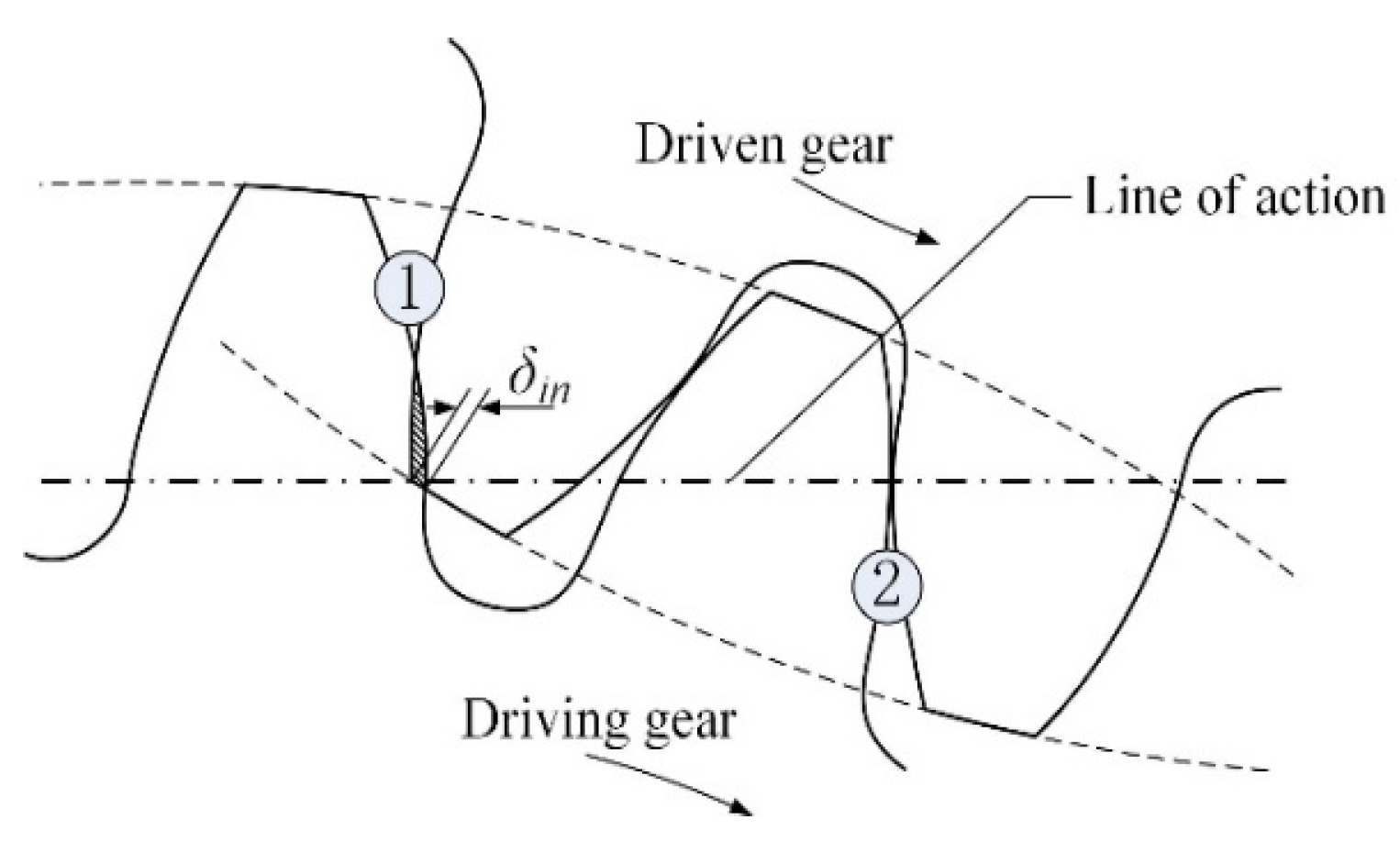

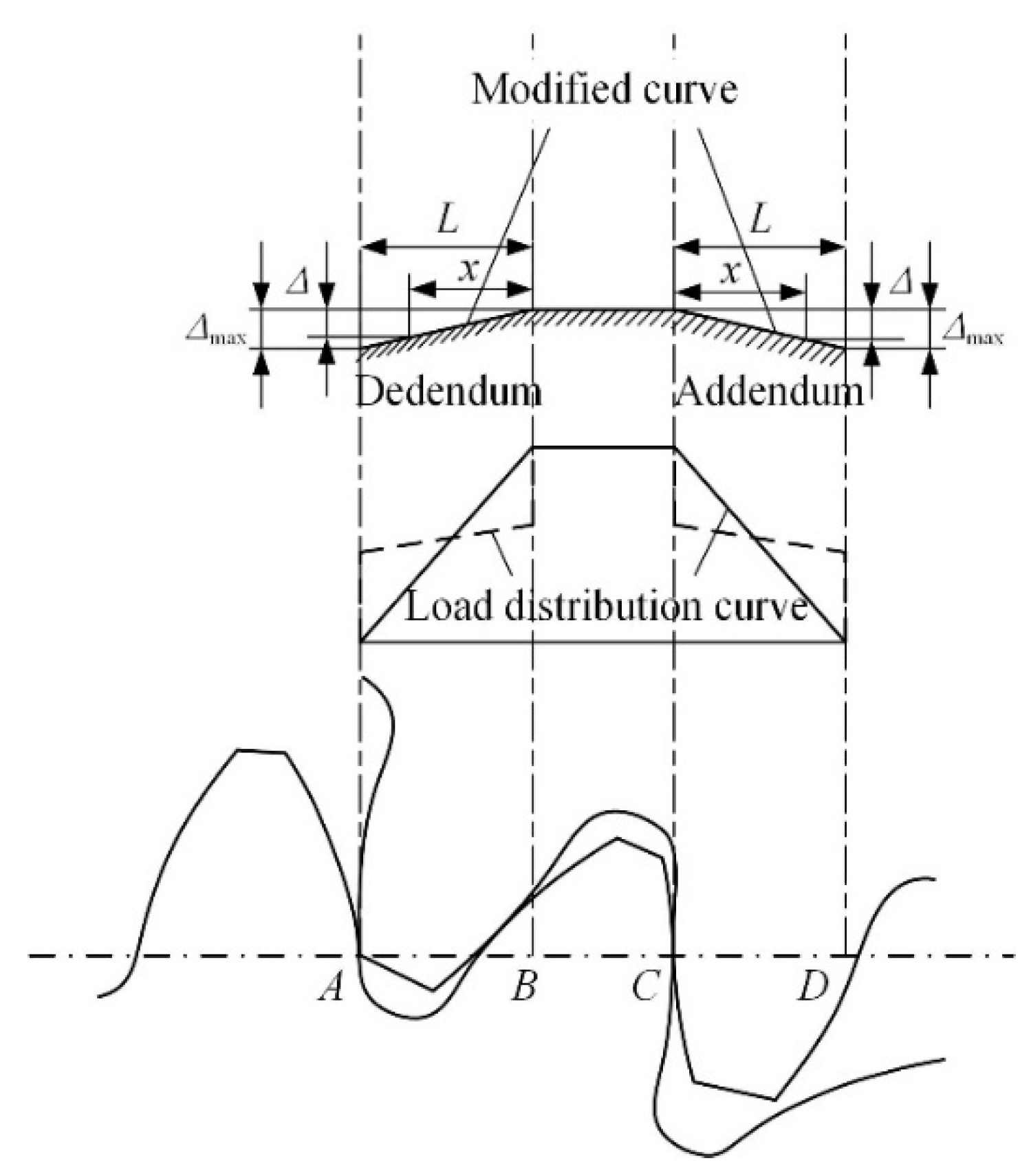

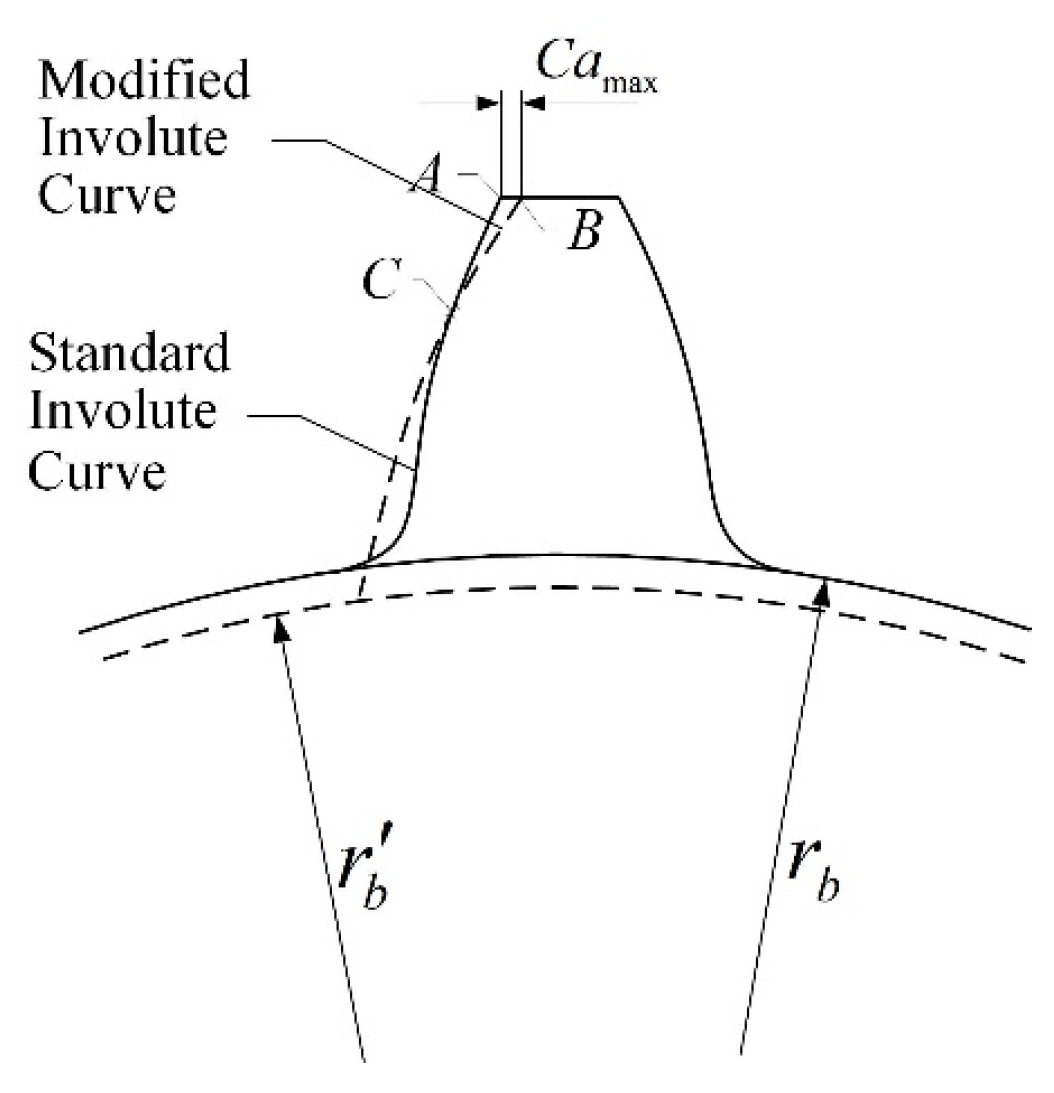

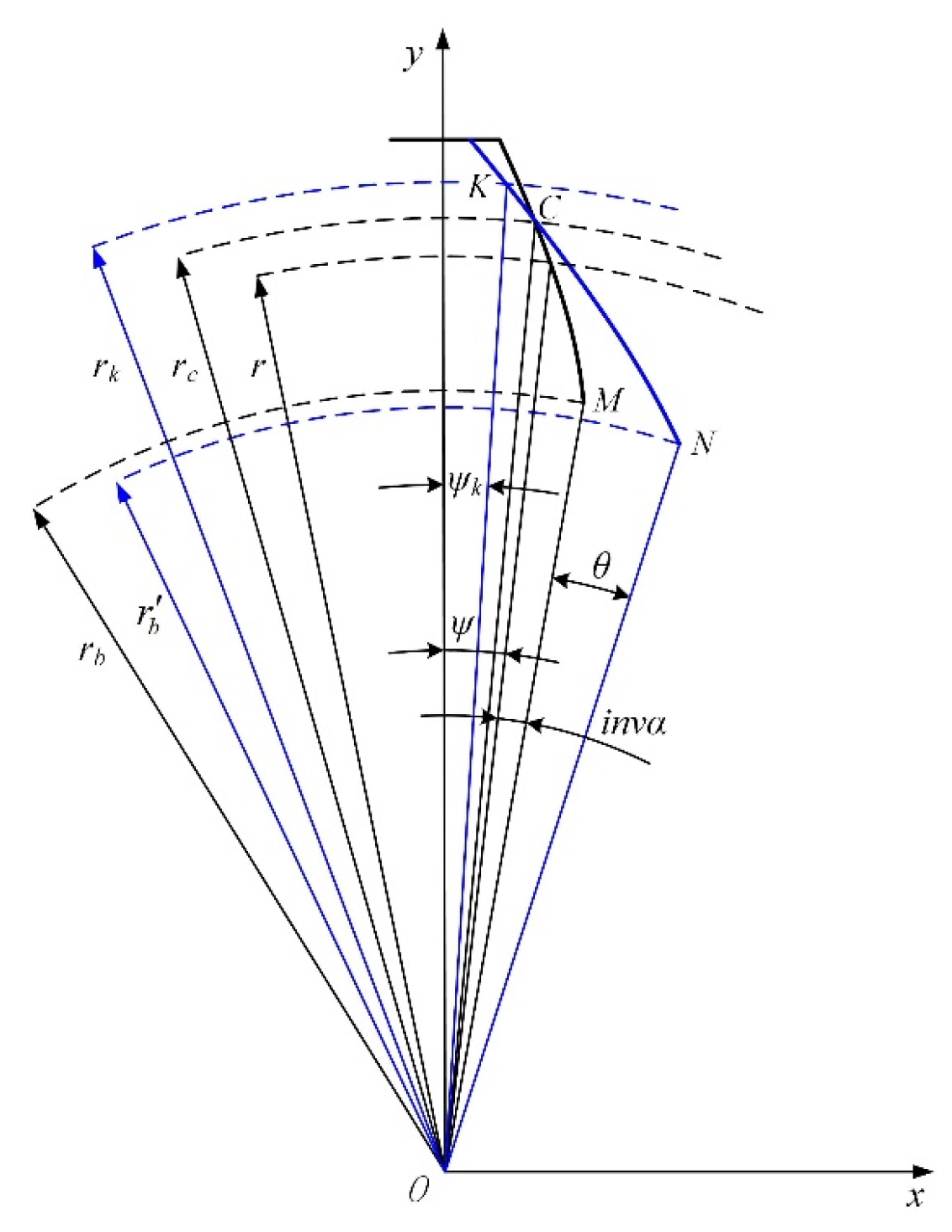

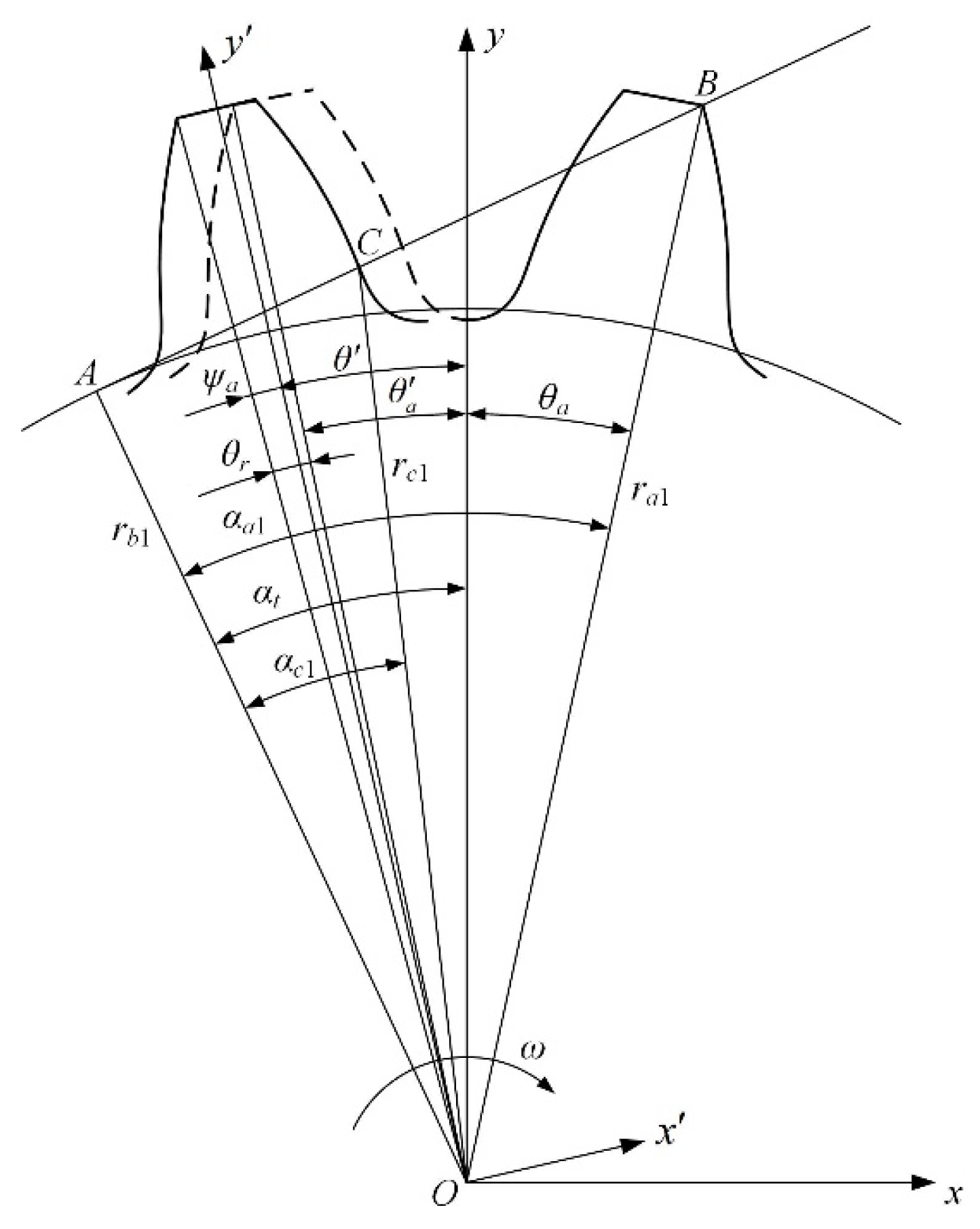

2. Gear Modification Theory

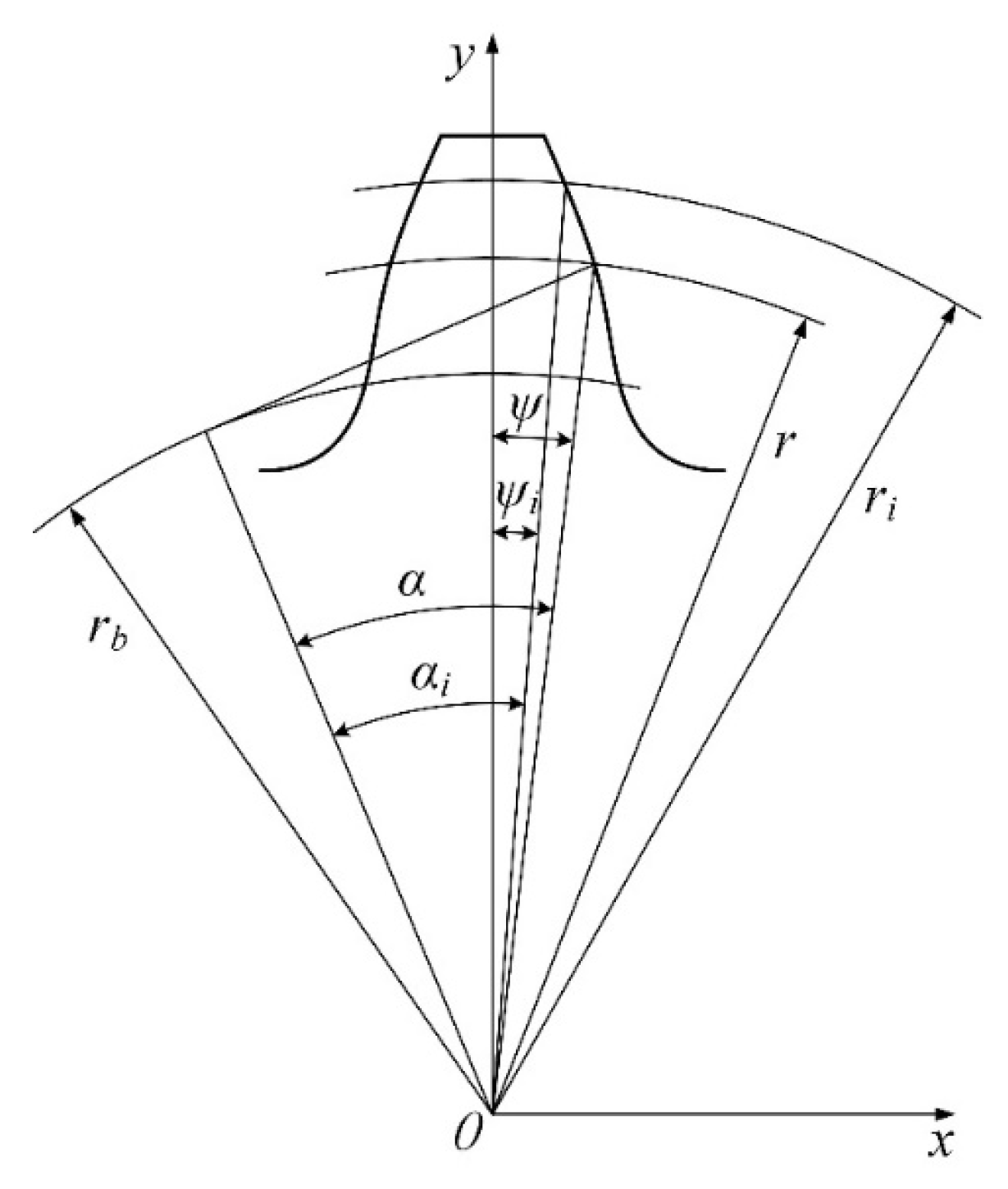

3. Parametric Model for Modified Gear

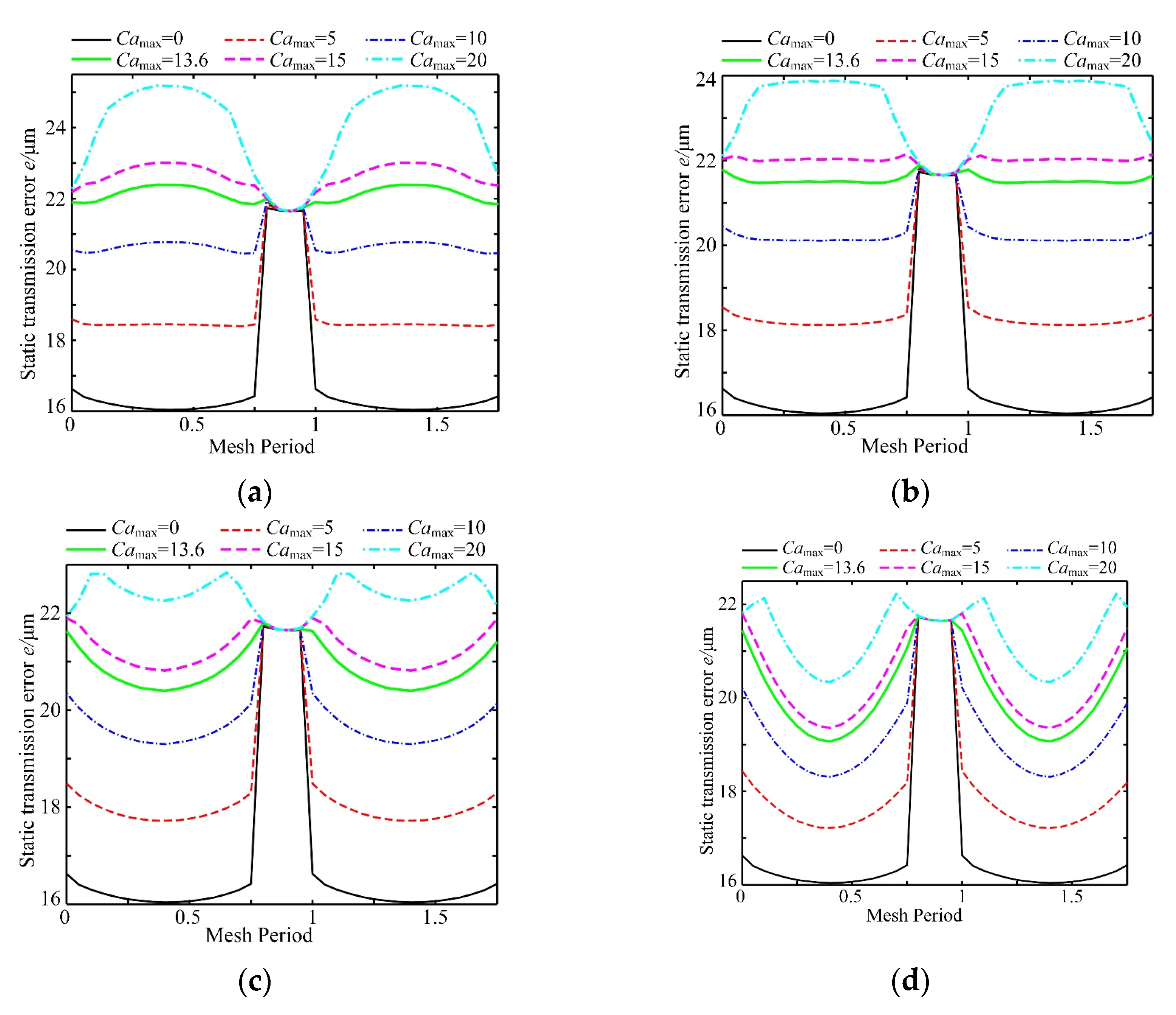

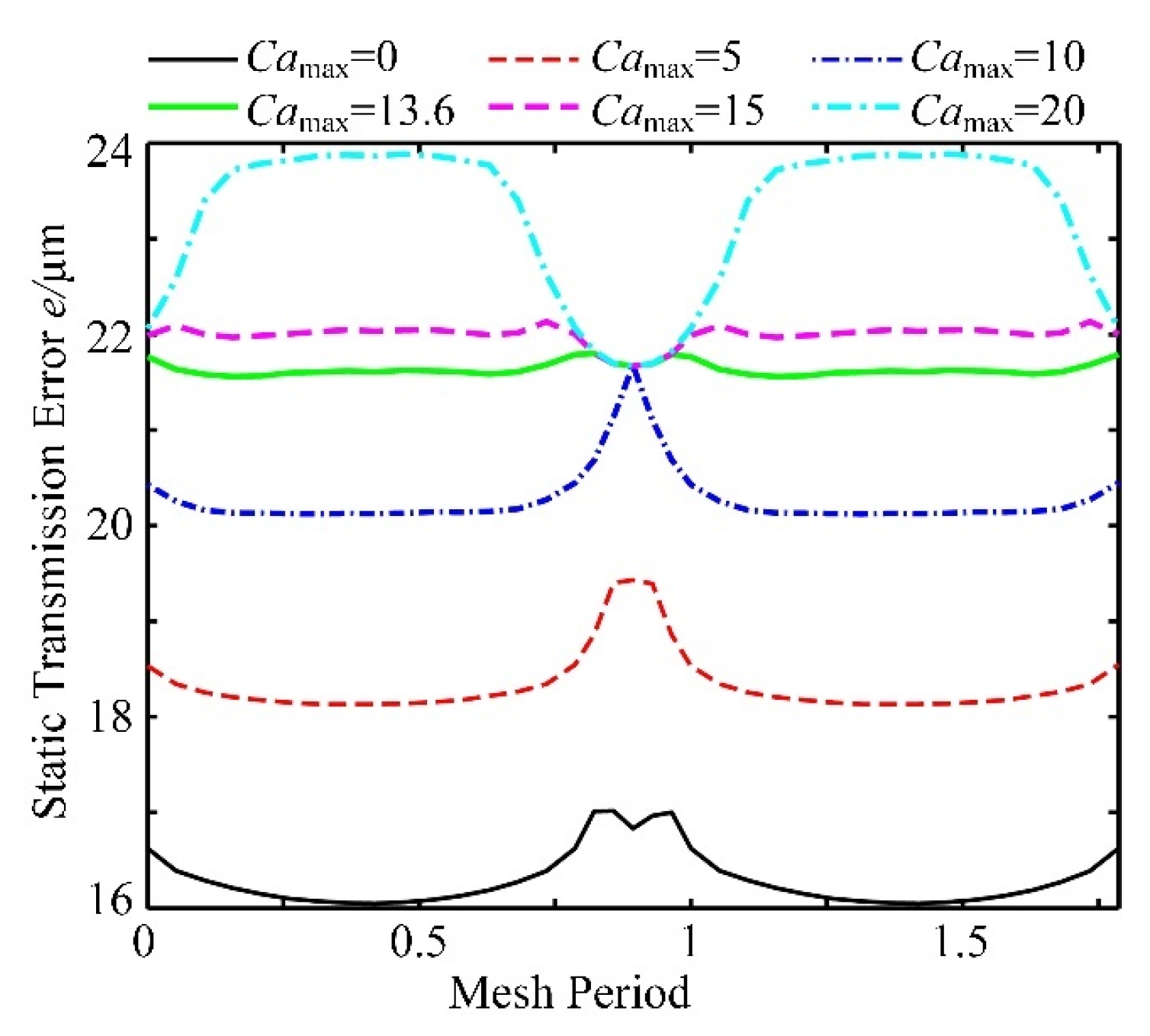

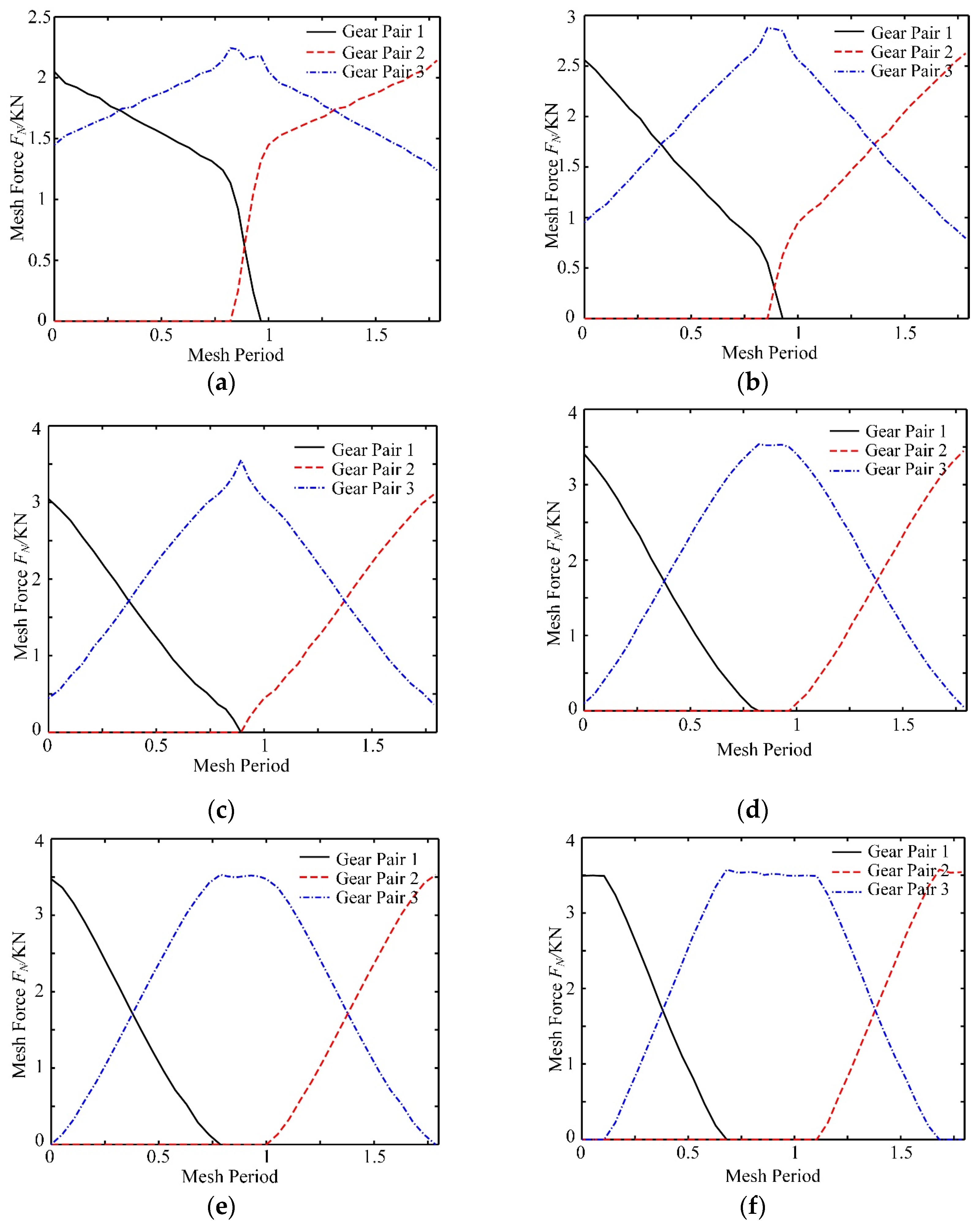

4. Influences of the Profile Modification Parameters

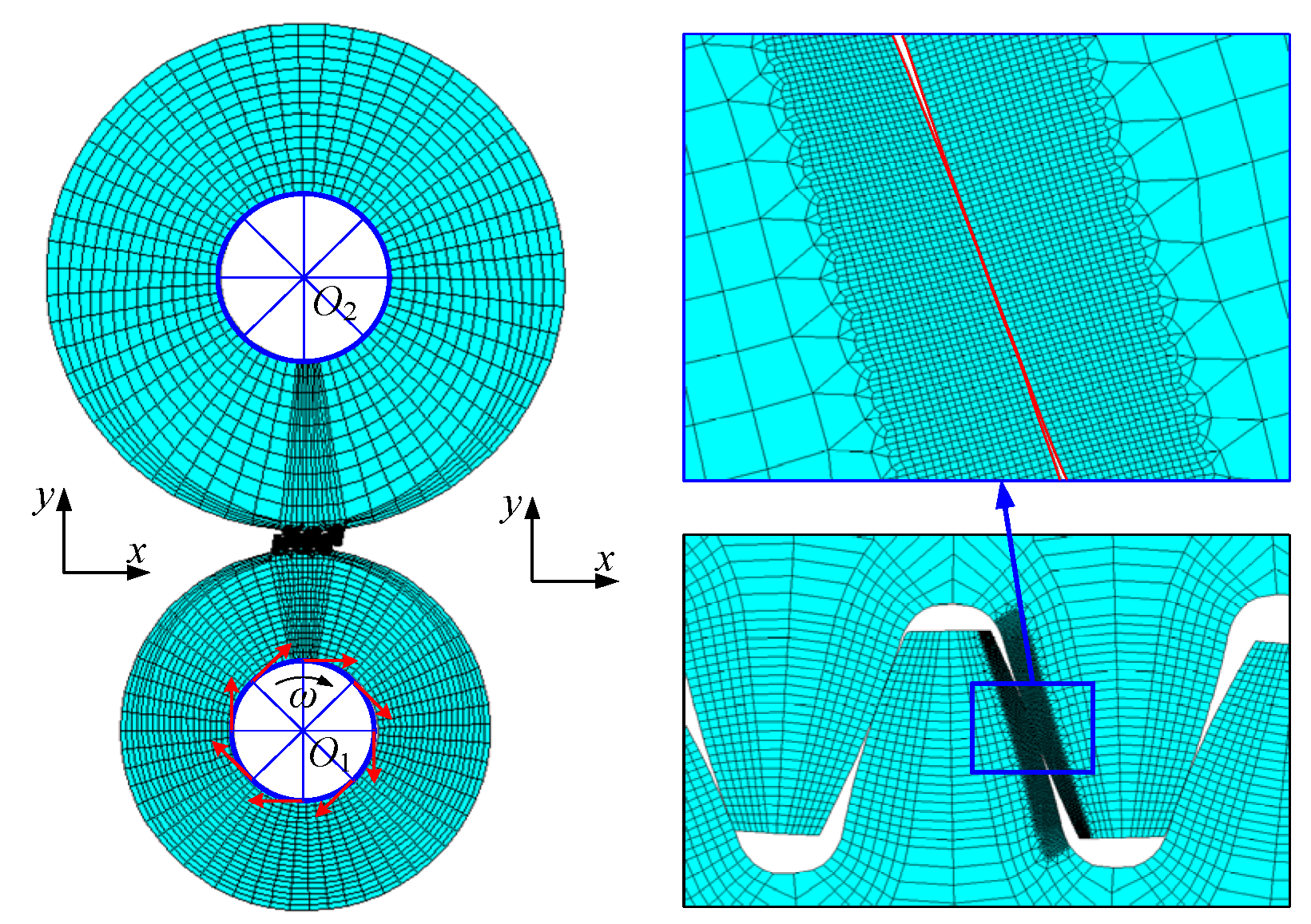

| Algorithm 1: Static transmission error for the modified gear by ANSYS | |||

| Input: Number of teeth z, Modulus m, Load T, Pressure angle α. Output: Static transmission error e. | |||

| 1: | Based on input data, parameters of the corresponding standard gear can be calculated by (3), such as ri, αi, rb and ψi. | ||

| 2: | For Camax = 0, 5,…,20 do | ||

| 3: | The base radius of modified involute curve can be computed by (2). | ||

| 4: | The angle ψk of any point K (xk, yk) in the modified involute profile can be depicted by (4). | ||

| For β = 1, 1.2, 1.5, 2.0 do | |||

| 5: | The modified value of Point K can be calculated by (6). The coordinates (xk’, yk’) of points can be depicted for the modification. | ||

| 6: | Based on coordinates, establish the finite element model of the modified spur gear by ANSYS. | ||

| 7: | Solve the static transmission error e based on load T. Mesh force FN can extracted by ANSYS. | ||

| 8: | End | ||

| 9: | End | ||

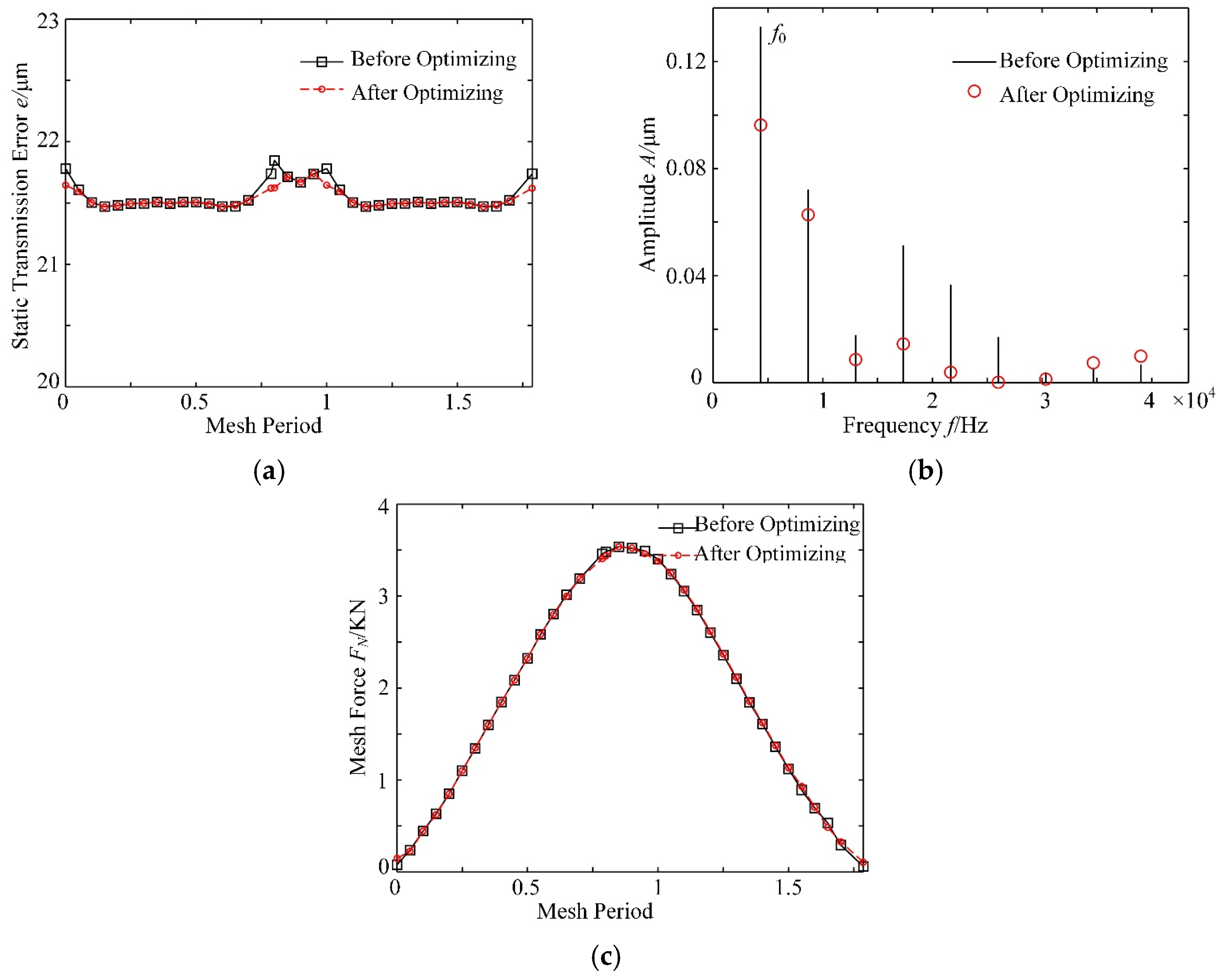

5. Influences of the Modification Gear on the Transmission Error

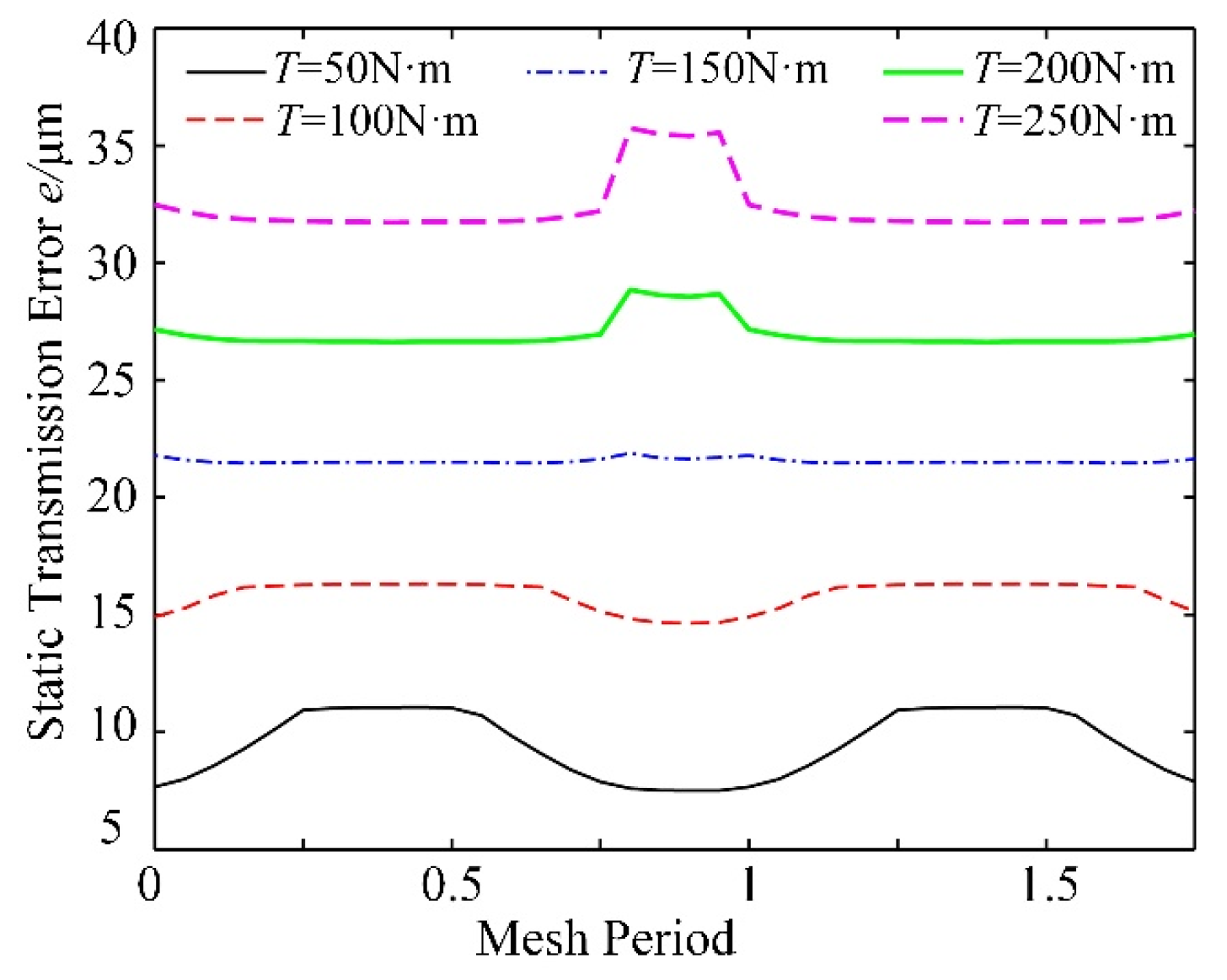

5.1. Effect of the Load

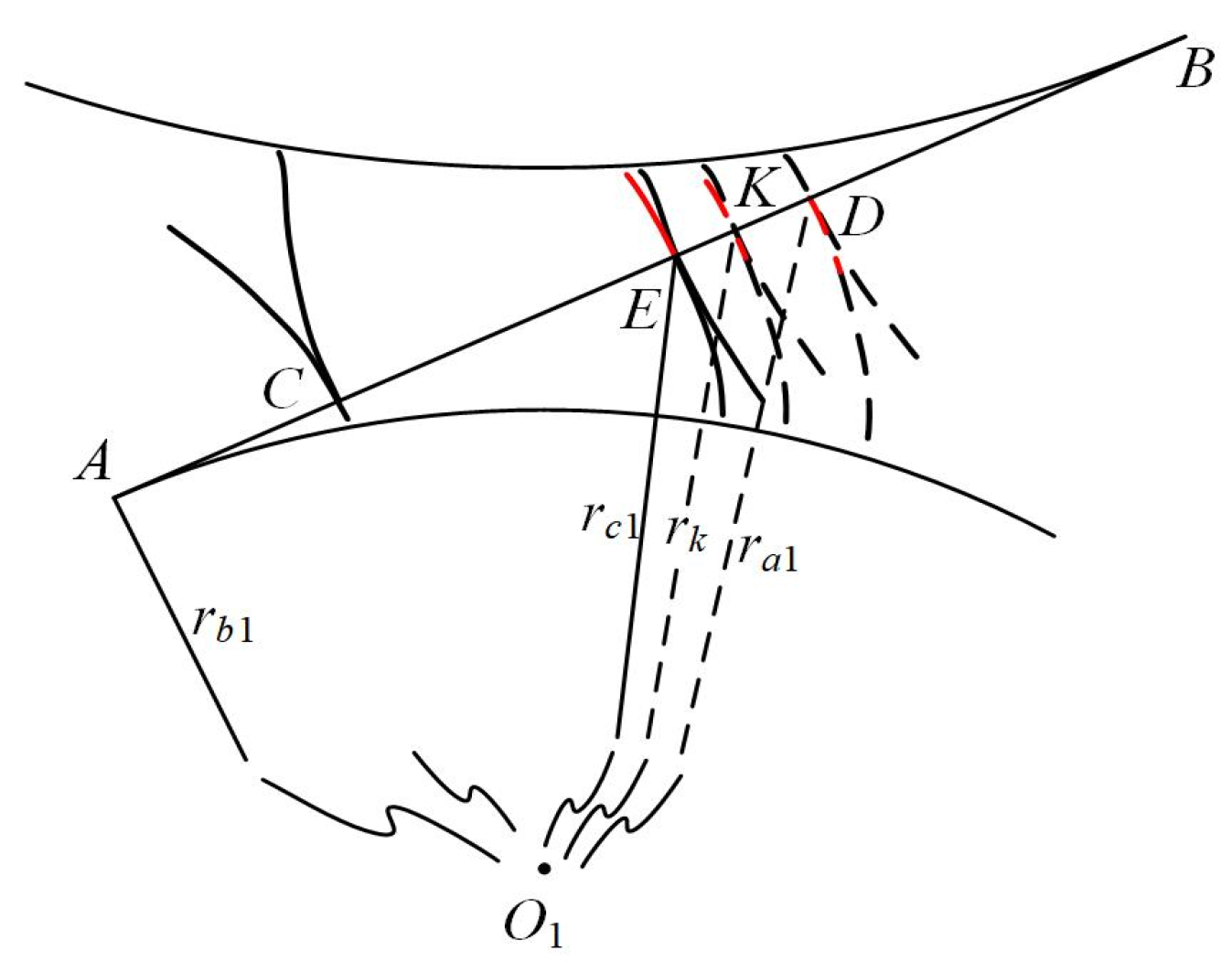

5.2. Effect of Prolonged Meshing

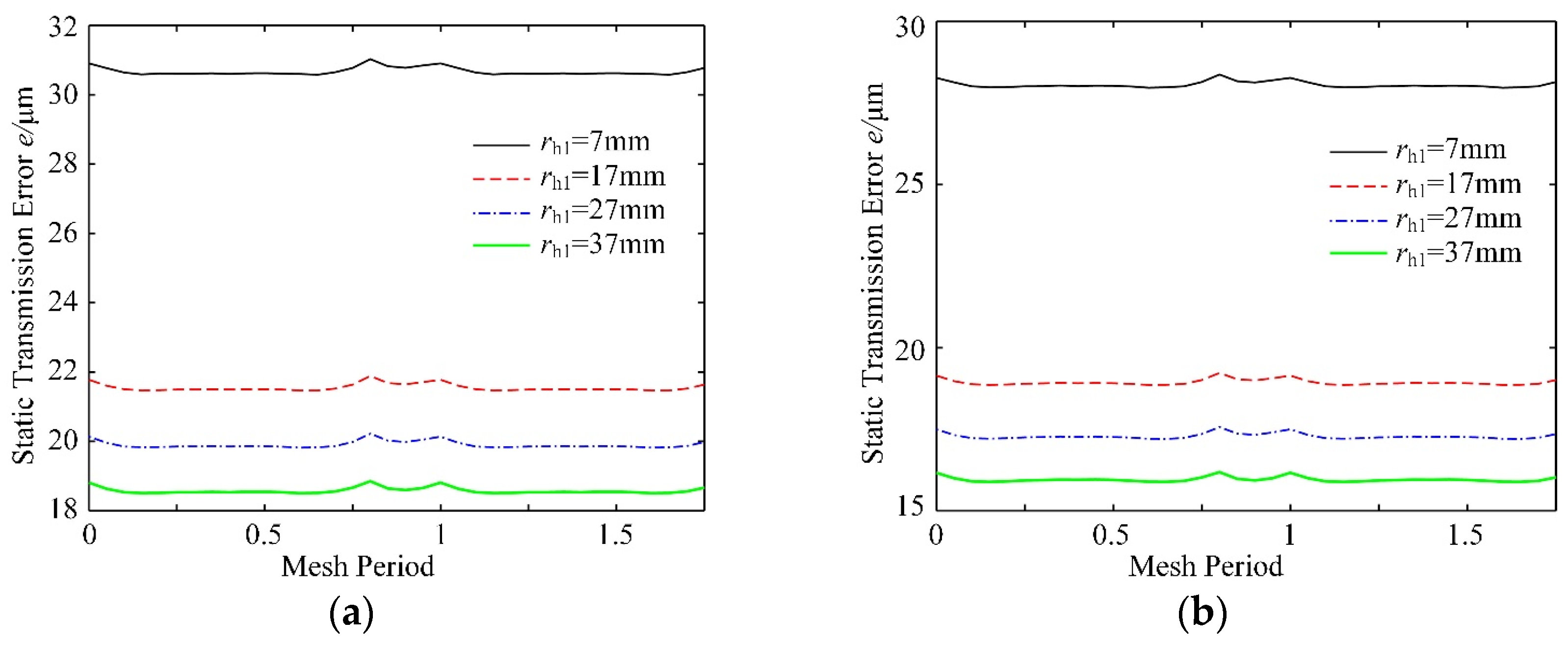

5.3. Effect of the Gear Hole Radii

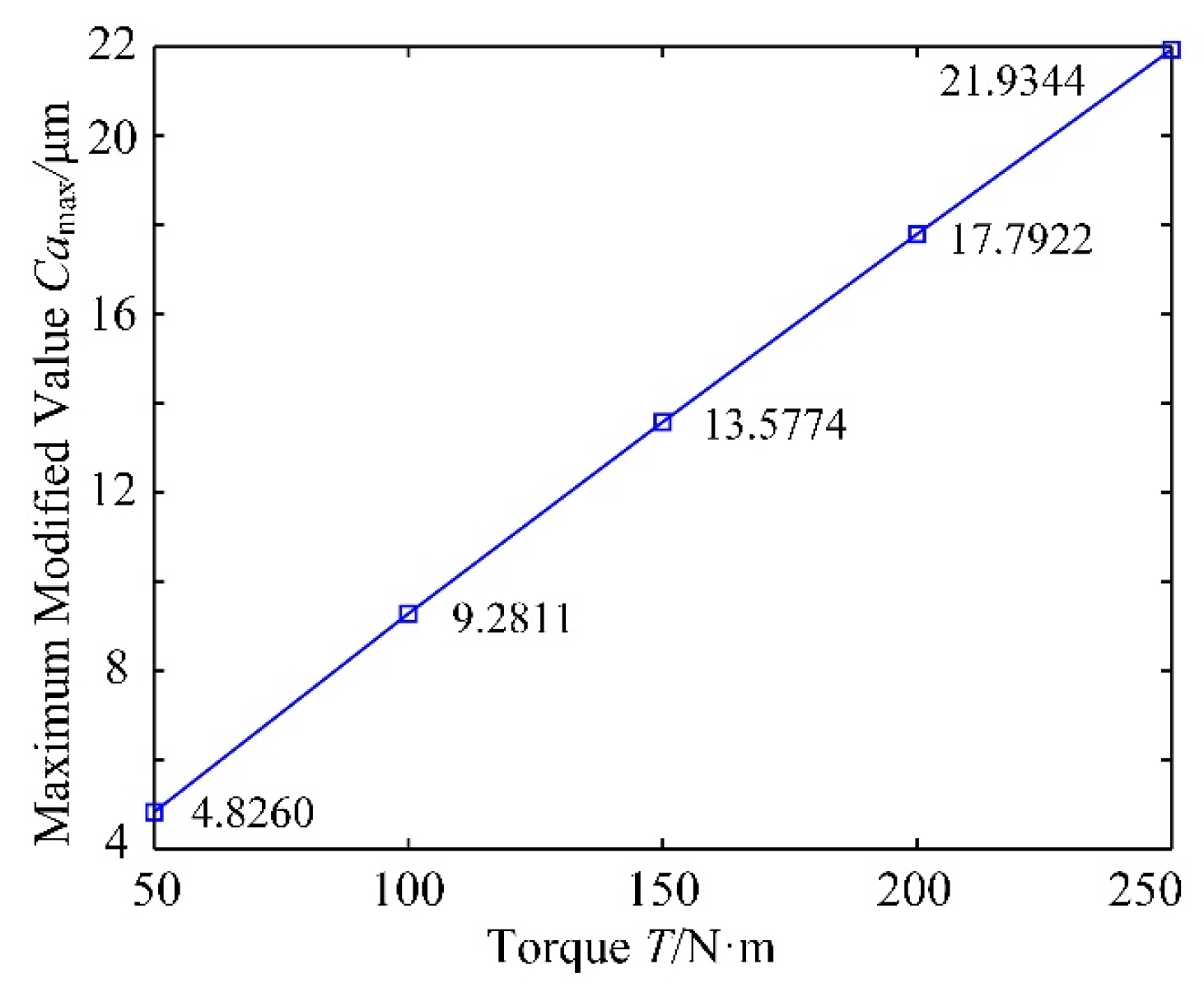

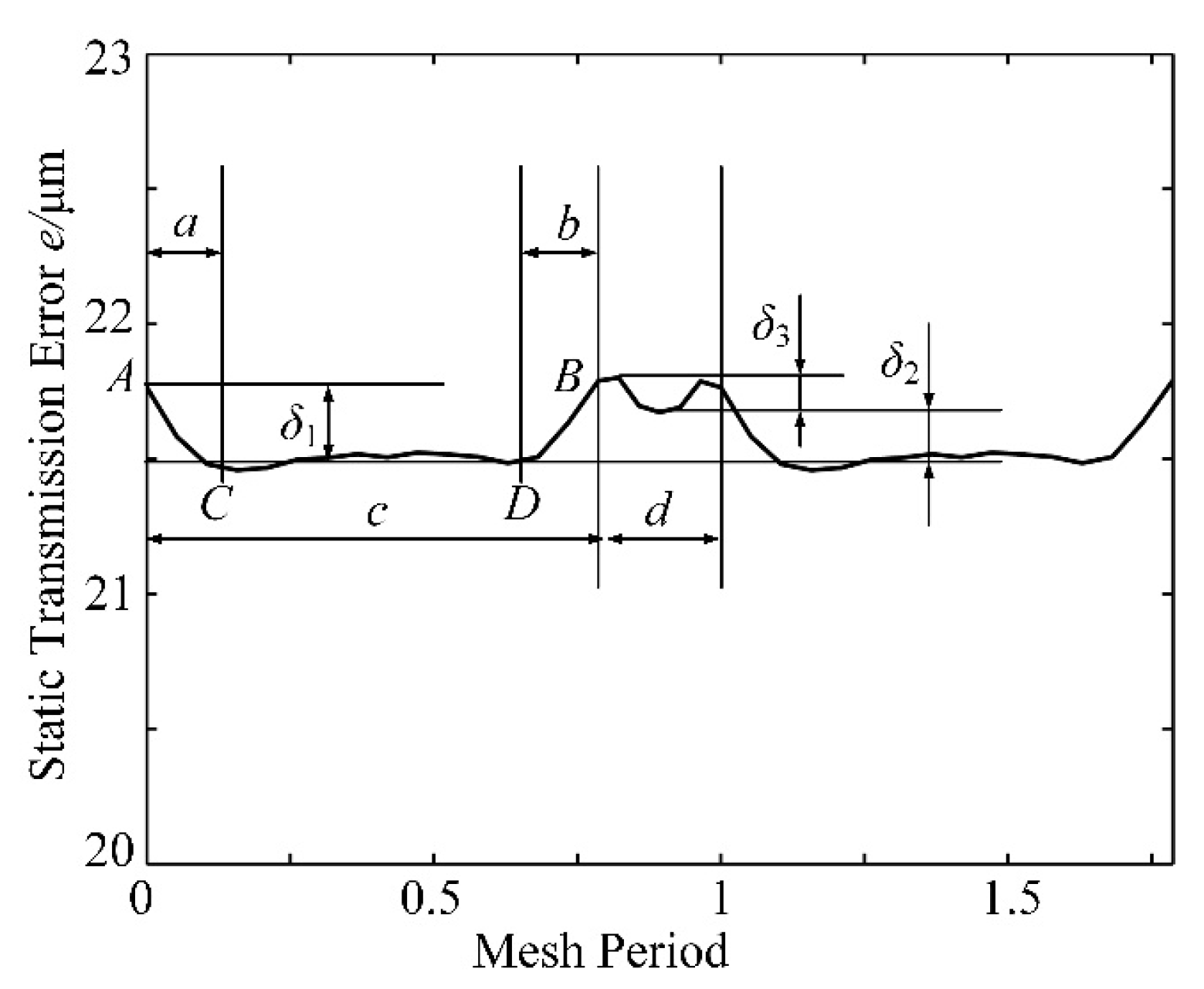

6. A Two-Stage Profile Modification Curve

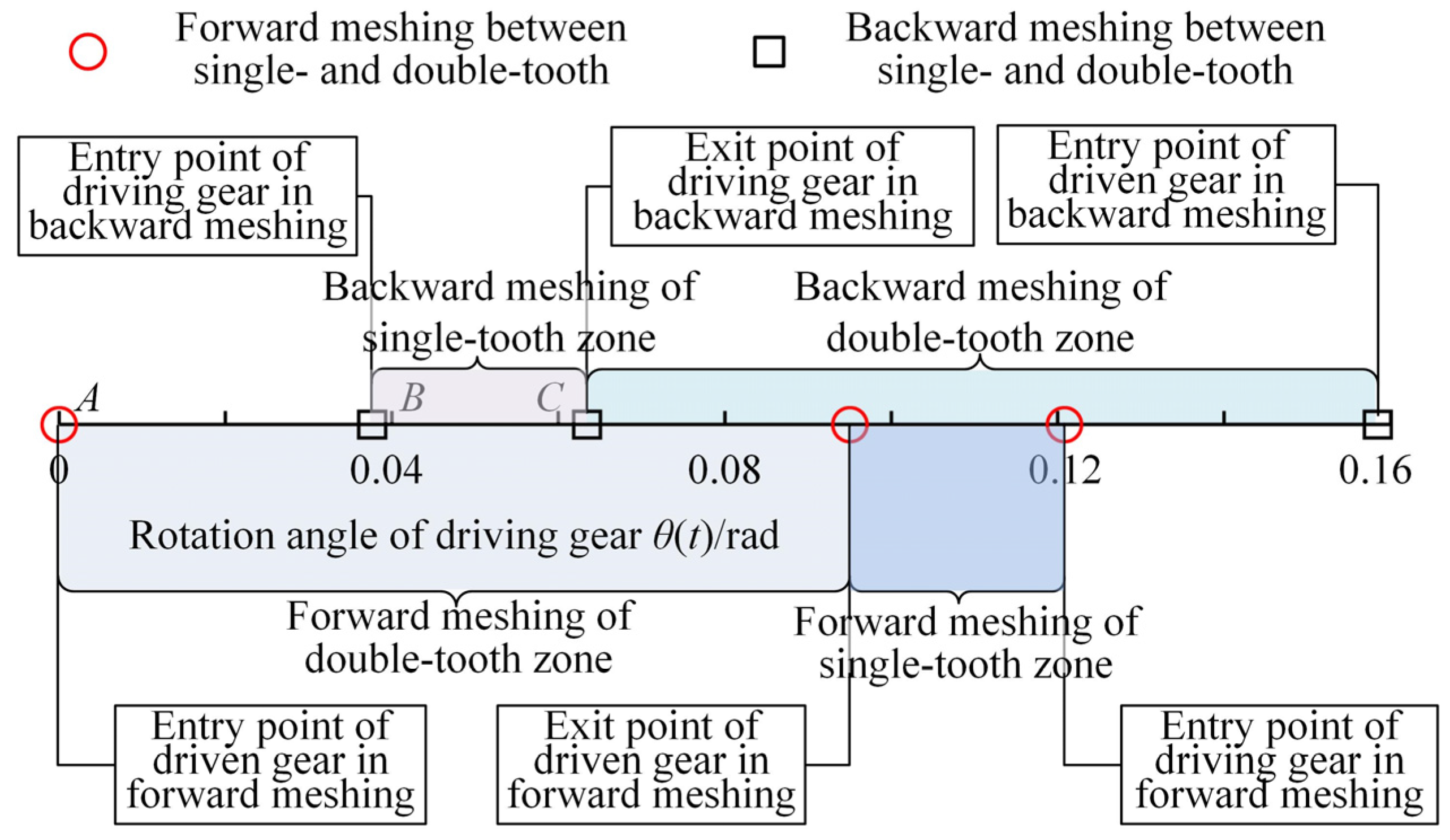

7. Dynamic Analysis of the Modified Gear System

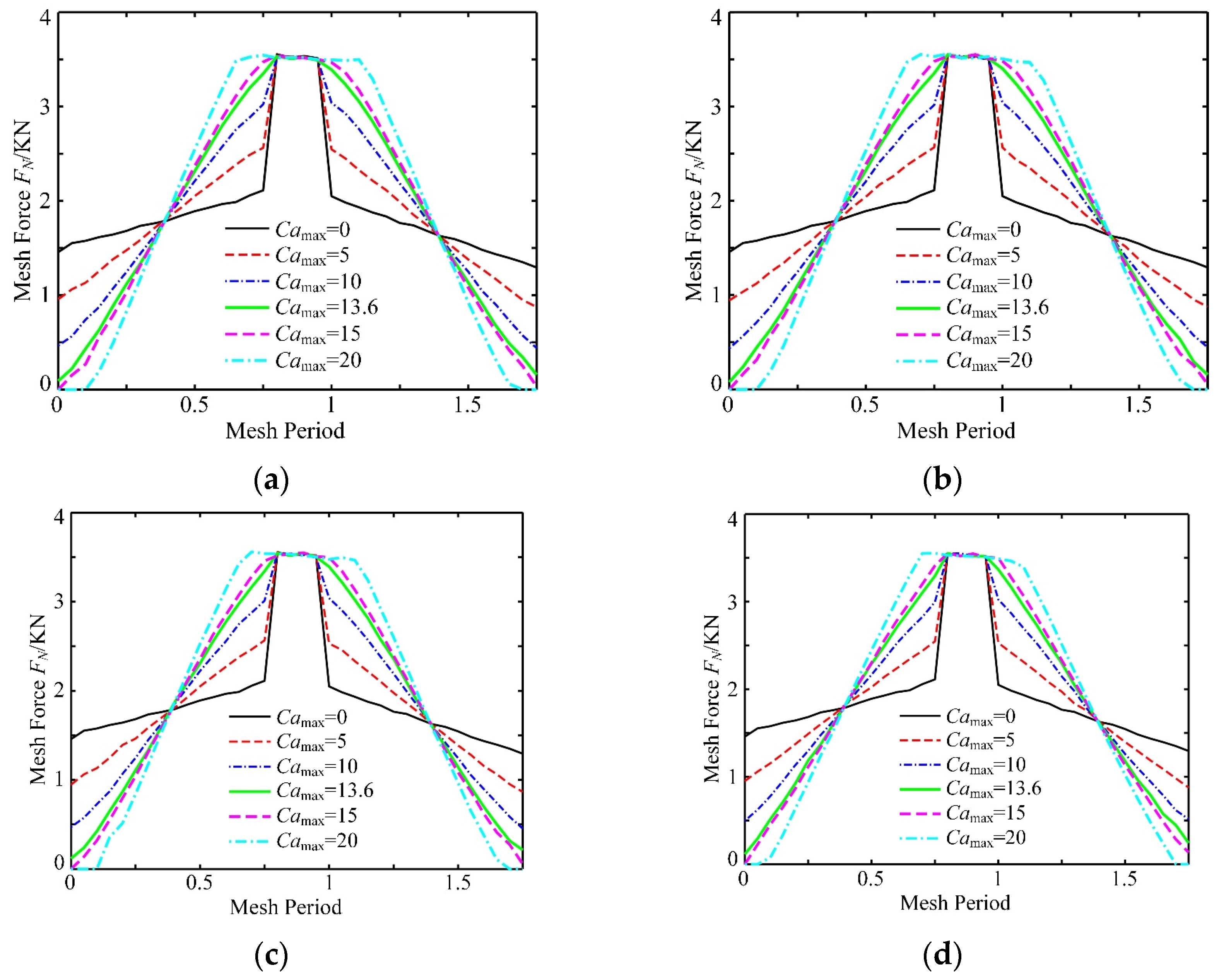

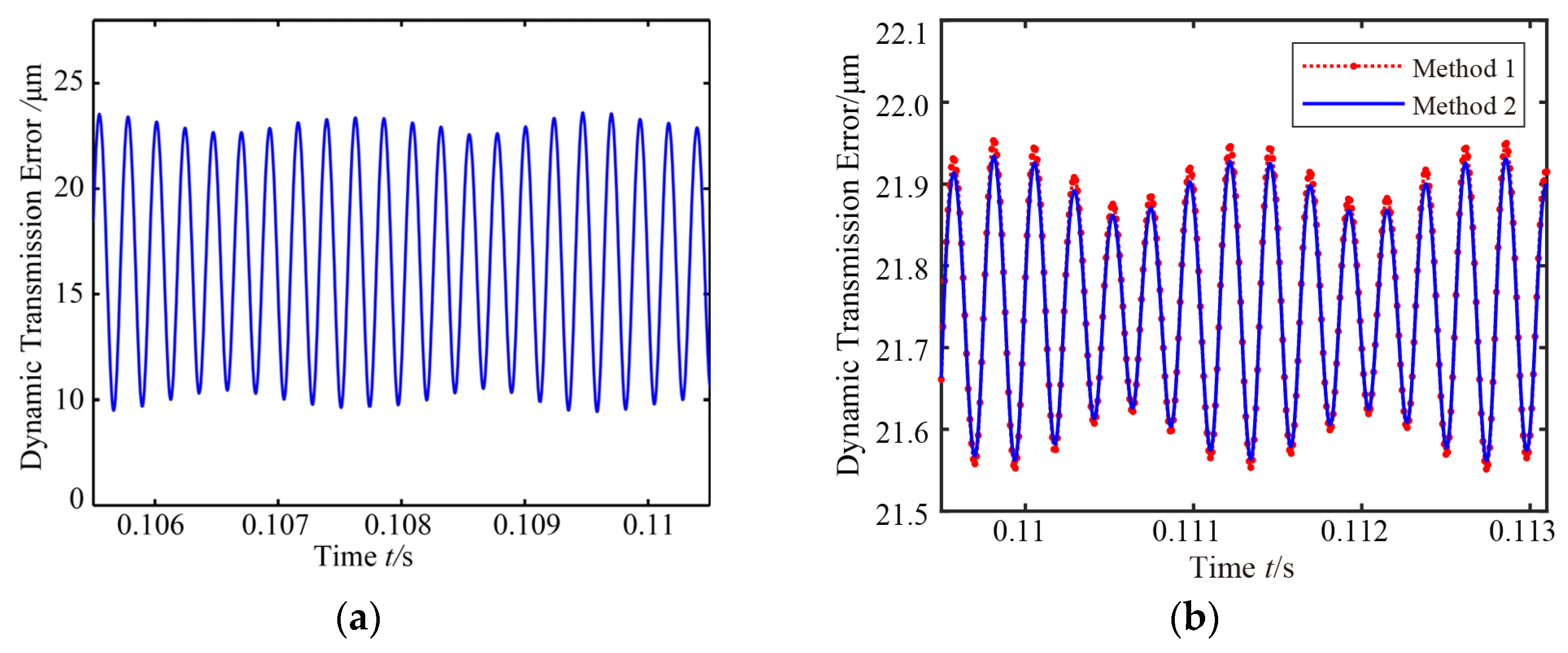

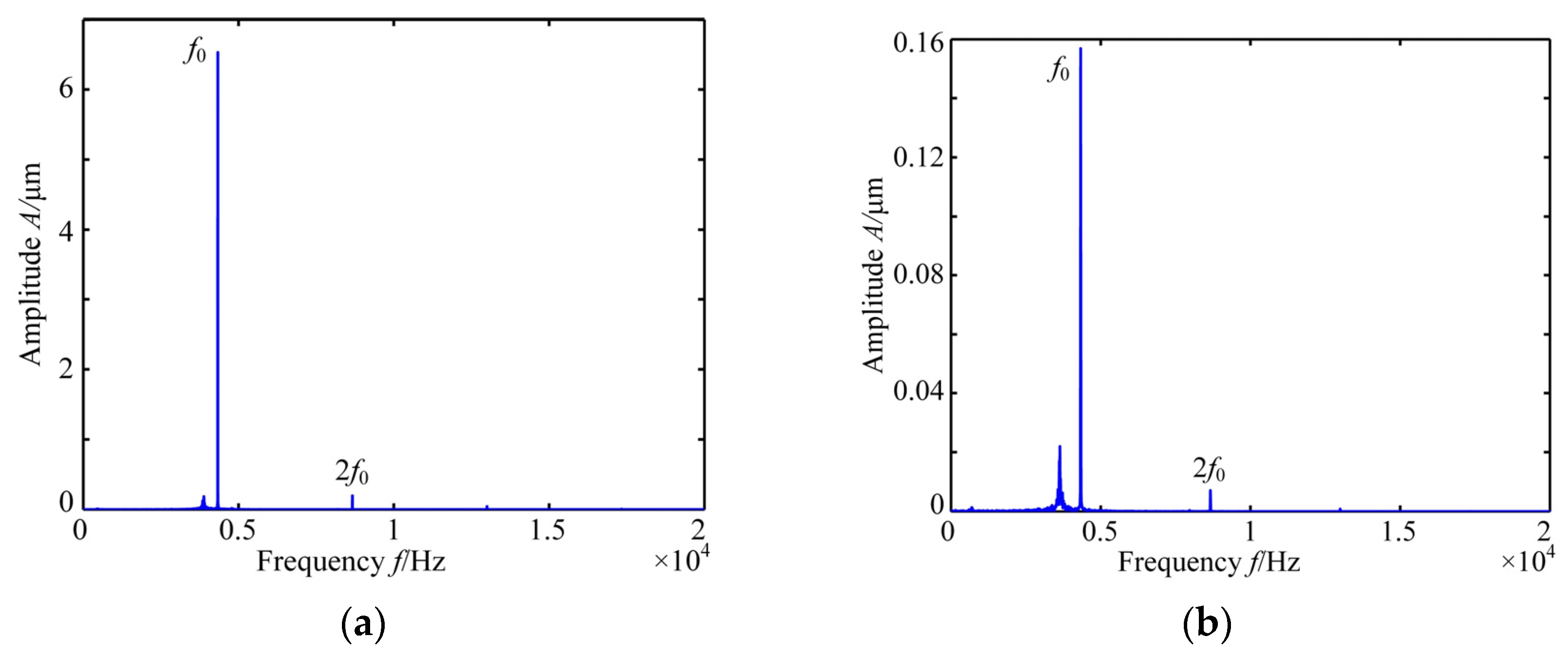

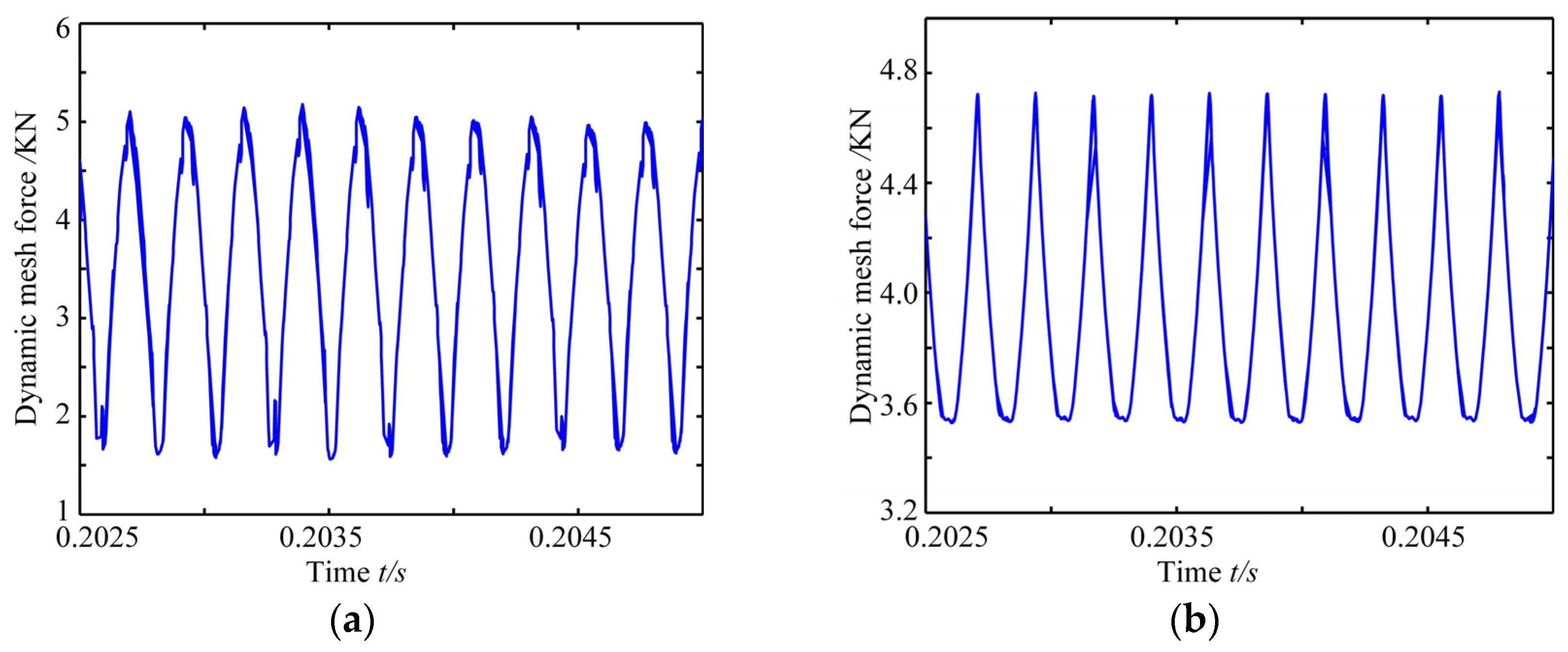

7.1. Dynamic Responses of the Modified Gear System

| Algorithm 2: Dynamic transmission error for the modified gear by the dynamic model | ||

| Input: Number of teeth z, Modulus m, Load T, Base radius rb, Moment of inertia I. Output: Dynamic transmission error e. | ||

| 1: | Establish the nonlinear backlash function by (10). | |

| 2: | For Camax = 0, 5,…,20 do | |

| 3: | Establish the relationship between backlash and angle by (11). | |

| 4: | Depict the transition location of single and double-teeth meshing by Figure 20 in the dynamic model. | |

| 5: | Mesh stiffness can be calculated by (12) and (13). | |

| 6: | Calculate the dynamic equation of gear pair by (9). | |

| 7: | Compute θ1 and θ2. Dynamic transmission error can be calculated by {rb1θ1–rb2θ2} based on Figure 18. | |

| 6: | End | |

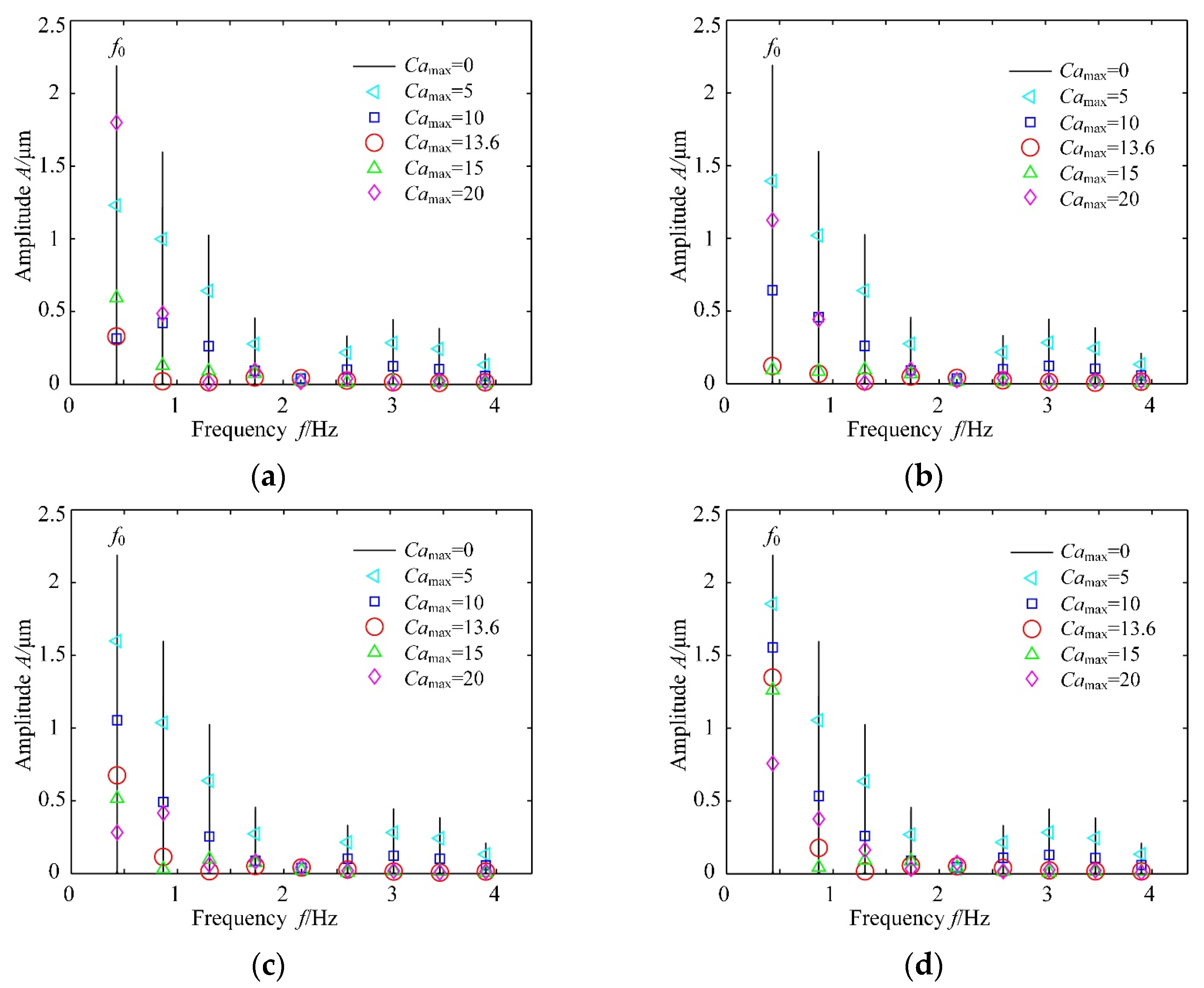

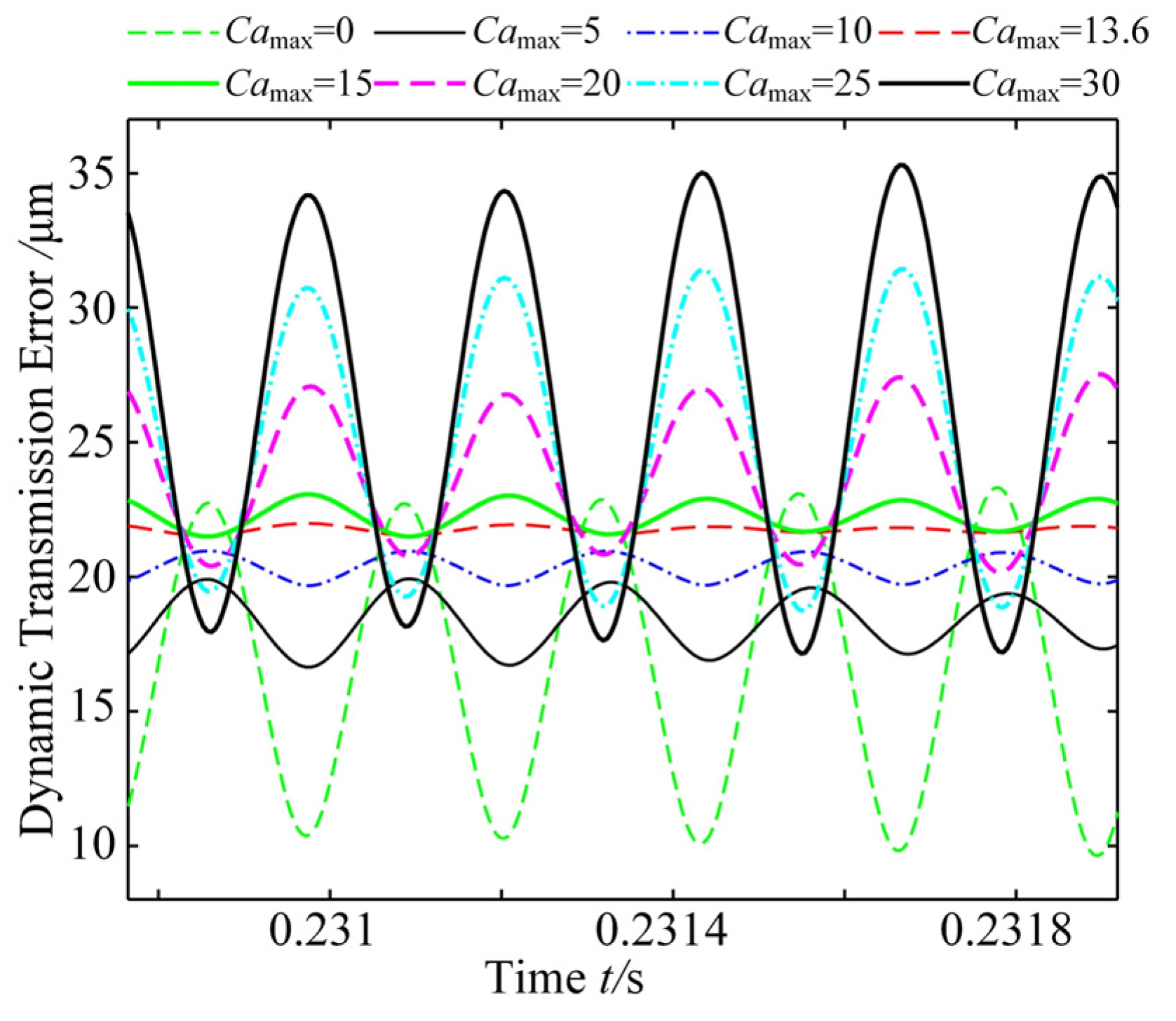

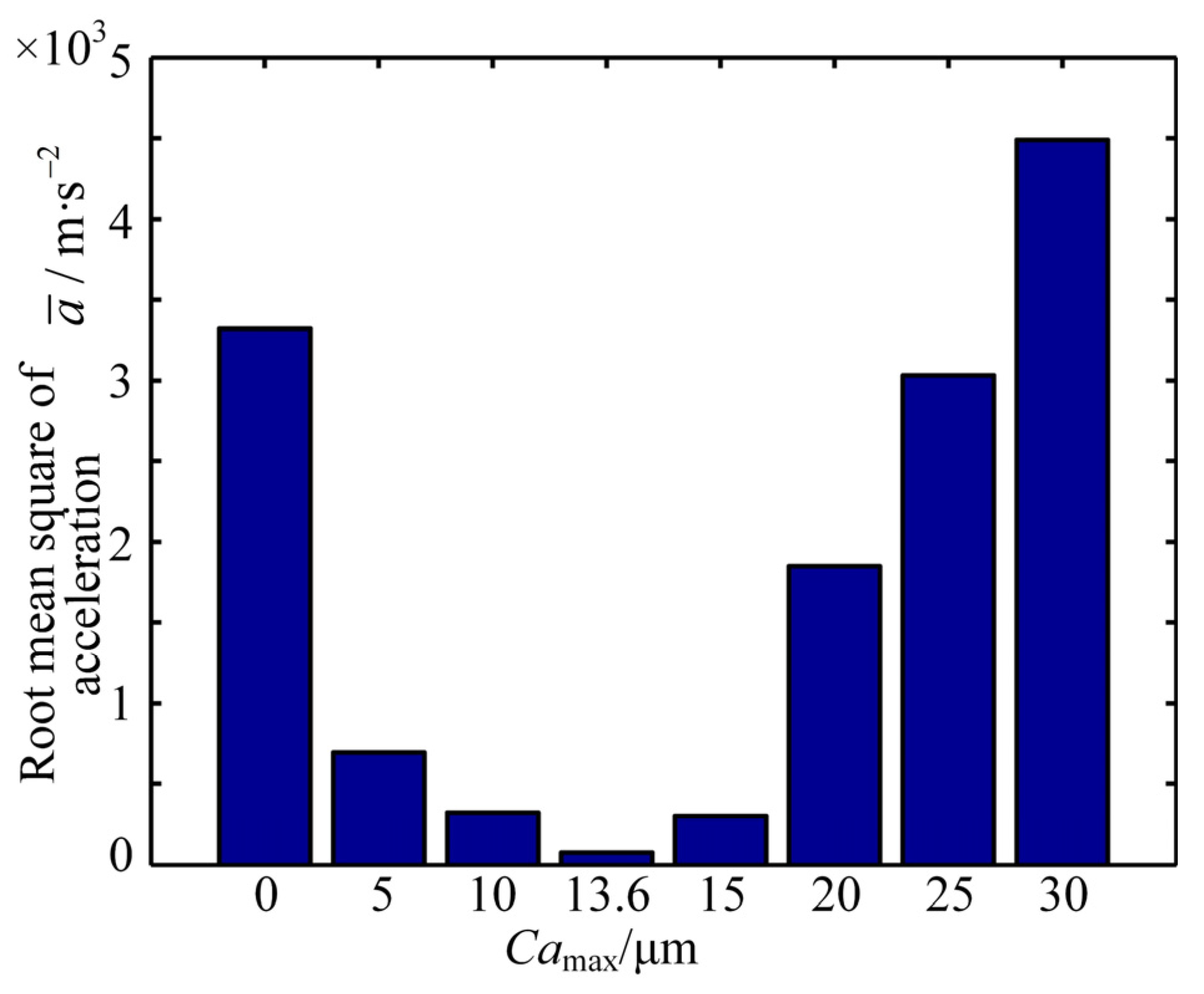

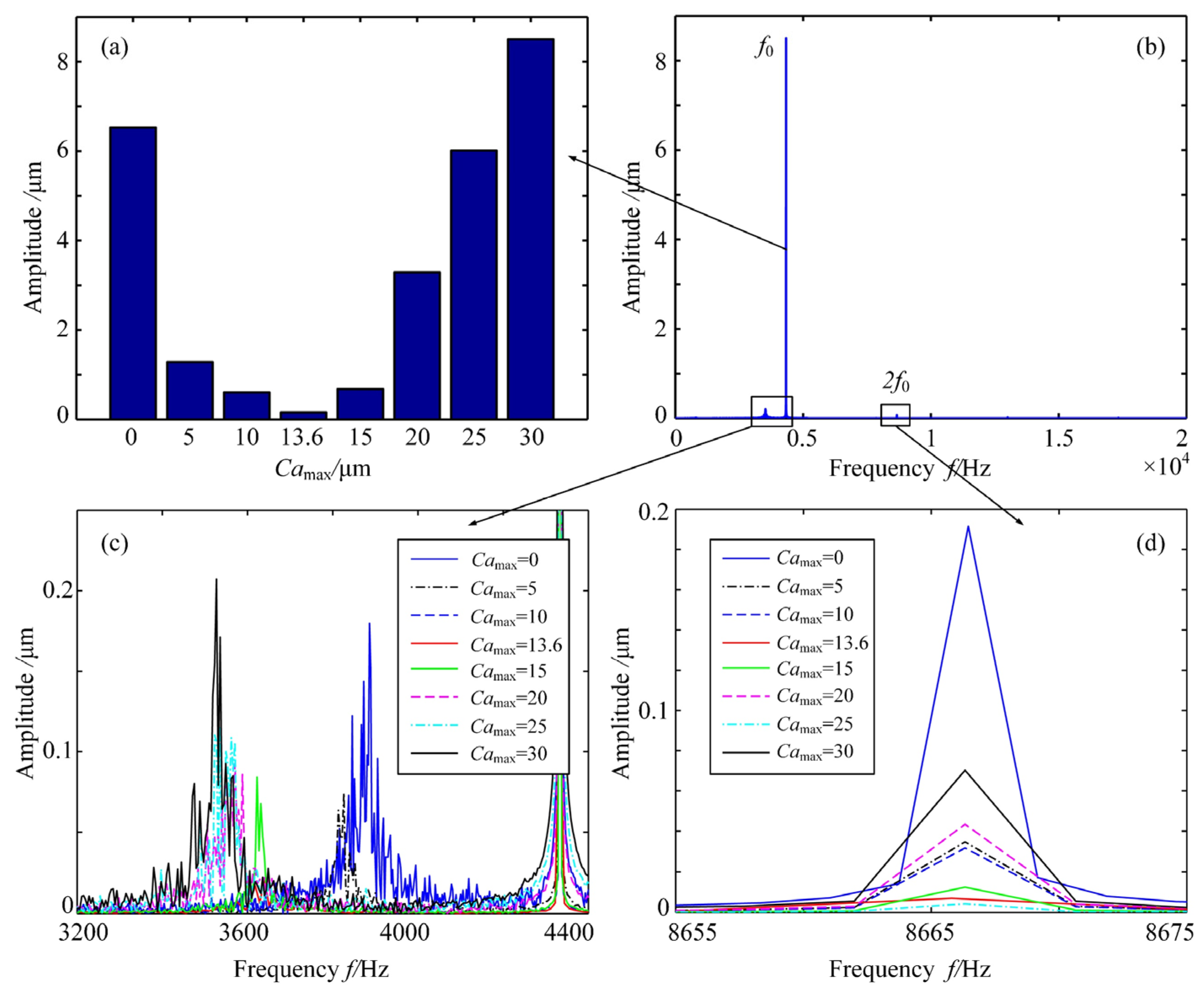

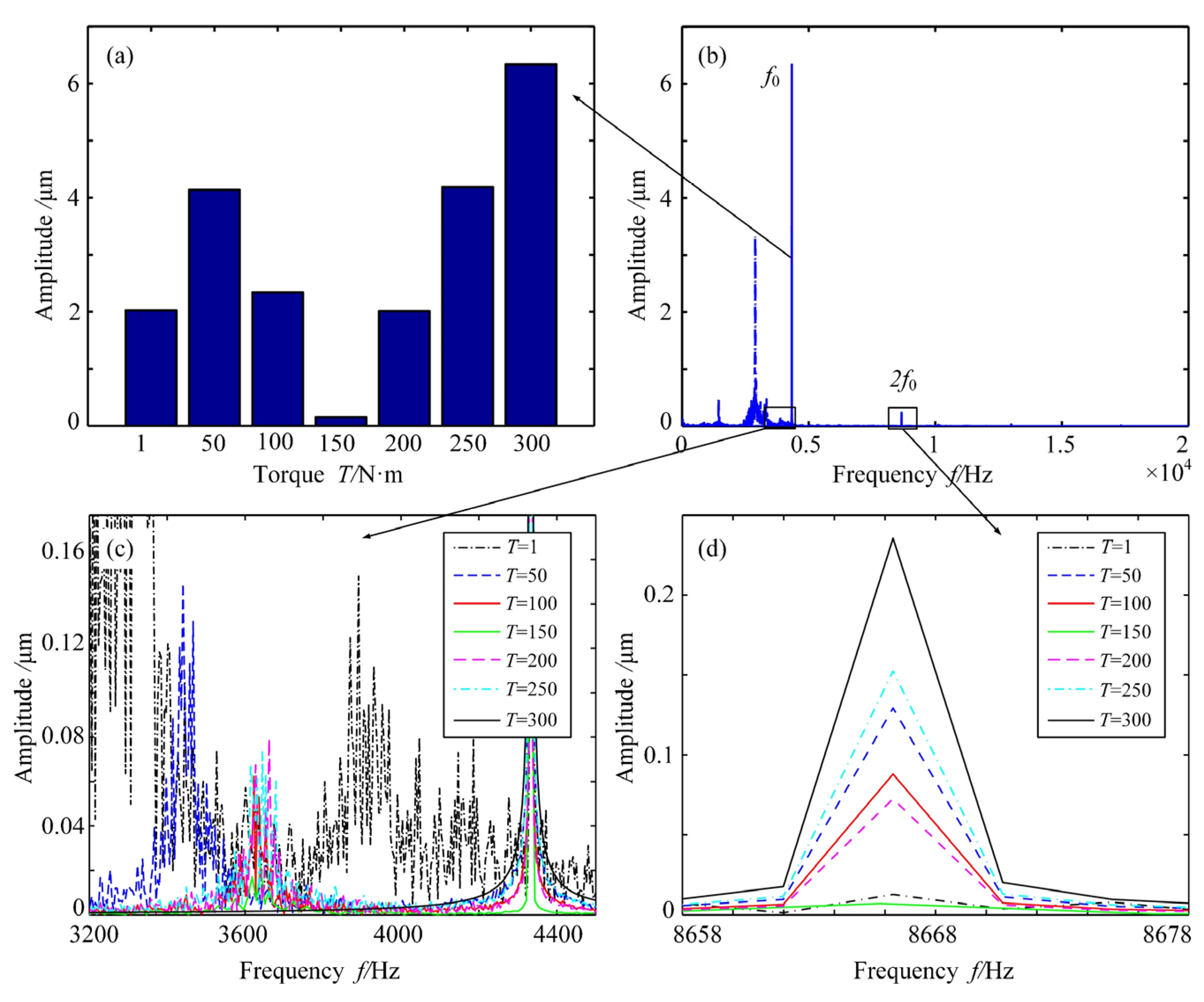

7.2. Parametric Effects on the Dynamic Responses

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| z | Number of teeth |

| r | Reference circle |

| ra | Radius of the addendum circle |

| rb | Base radius of the unmodified involute curve |

| rc | Radius of the starting point in the modified involute curve |

| Base radius of the unmodified involute curve | |

| cm | Mesh damping |

| θi | Torsional displacement |

| αa | Pressure angle of the unmodified involute curve |

| αc | Pressure angle of the modified involute curve |

| Pressure angle of the starting point in the modified involute curve | |

| Pressure angle of the tip circle in the modified gear | |

| β | Modified index |

| δin | Maximum interference value along the line of engagement |

| k(t) | Mesh stiffness |

| L | Relative coordinate of the modified length |

| Ii | Moment of inertia of Gear i |

| Ti | Torque of Gear i |

| Camax | Maximum modified value |

| Ca | Modified value corresponding to Position x |

References

- Wang, C. Multi-objective optimal design of modification for helical gear. Mech. Syst. Signal Process. 2021, 157, 107762. [Google Scholar] [CrossRef]

- Hu, Z.; Tang, J.; Zhong, J.; Chen, S.; Yan, H. Effects of tooth profile modification on dynamic responses of a high speed gear-rotor-bearing system. Mech. Syst. Signal Process. 2016, 76–77, 294–318. [Google Scholar] [CrossRef]

- Xie, C.; Shu, X. A new mesh stiffness model for modified spur gears with coupling tooth and body flexibility effects. Appl. Math. Model. 2021, 91, 1194–1210. [Google Scholar] [CrossRef]

- Chen, M.; Xiong, X.; Zhuang, W. Design and simulation of meshing performance of modified straight bevel gears. Metals 2021, 11, 33. [Google Scholar] [CrossRef]

- Wang, J.; Lv, H. Modification and optimization of cycloidal gear tooth profile based on machining error compensation. Appl. Sci. 2023, 13, 2581. [Google Scholar] [CrossRef]

- Wang, Q.B.; Xu, K.; Huai, T.; Ma, H.; Wang, K. A mesh stiffness method using slice coupling for spur gear pairs with misalignment and lead crown relief. Appl. Math. Model. 2020, 90, 845–861. [Google Scholar] [CrossRef]

- Bahk, C.; Parker, R.G. Analytical investigation of tooth profile modification effects on planetary gear dynamics. Mech. Mach. Theory 2013, 70, 298–319. [Google Scholar] [CrossRef]

- Liu, S.; Chen, X.; Song, C.; Zhu, C.; Bai, H.; Alfonso, F.A. Influence of gear-shaft interference fit assembly on the meshing characteristics of cylindrical gears considering comprehensive modifications. Mech. Mach. Theory 2023, 182, 105247. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.; Han, Q. Static/dynamic contact FEA and experimental study for tooth profile modification of helical gears. J. Mech. Sci. Technol. 2012, 26, 1409–1417. [Google Scholar] [CrossRef]

- Abruzzo, M.; Beghini, M.; Santus, C.; Presicce, F. A dynamic model combining the average and the local meshing stiffnesses and based on the static transmission error for spur gears with profile modification. Mech. Mach. Theory 2023, 180, 105139. [Google Scholar] [CrossRef]

- Gao, P.; Liu, H.; Yan, P.; Xie, Y.; Xiang, C.; Wang, C. Research on application of dynamic optimization modification for an involute spur gear in a fixed-shaft gear transmission system. Mech. Syst. Signal Process. 2022, 181, 109530. [Google Scholar] [CrossRef]

- Raut, A.S.; Khot, S.M.; Salunkhe, V.G. Optimization of Geometrical Features of Spur Gear Pair Teeth for Minimization of Vibration Generation. J. Vib. Eng. Technol. 2023, 12, 533–545. [Google Scholar] [CrossRef]

- Liu, C.; Fang, Z.; Wang, F. An improved model for dynamic analysis of a double-helical gear reduction unit by hybrid user-defined elements: Experimental and numerical validation. Mech. Mach. Theory 2018, 127, 95–111. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, Z.; Tong, S.; Li, S.; Tong, Z. Gear tribodynamic modeling and analysis considering tooth profile modification. Tribol. Int. 2023, 178, 108023. [Google Scholar] [CrossRef]

- Ghosh, S.S.; Chakraborty, G. On optimal tooth profile modification for reduction of vibration and noise in spur gear pairs. Mech. Mach. Theory 2016, 105, 145–163. [Google Scholar] [CrossRef]

- Hajjaj, A.Z.; Corrigan, K.; Mohammadpour, M.; Theodossiades, S. On the stability analysis of gear pairs with tooth profile modification. Mech. Mach. Theory 2022, 174, 104888. [Google Scholar] [CrossRef]

- Sun, Y.; Ma, H.; Huangfu, Y.; Chen, K.; Che, L.; Wen, B. A revised time-varying mesh stiffness model of spur gear pairs with tooth modifications. Mech. Mach. Theory 2018, 129, 261–278. [Google Scholar] [CrossRef]

- Pleguezuelos, M.; Sánchez, M.B.; Pedrero, J.I. Analytical model for meshing stiffness, load sharing, and transmission error for spur gears with profile modification under non-nominal load conditions. Appl. Math. Model. 2021, 97, 344–365. [Google Scholar] [CrossRef]

- Velex, P.; Chapron, M.; Fakhfakh, H.; Bruyère, J.; Becquerelle, S. On transmission errors and profile modifications minimising dynamic tooth loads in multi-mesh gears. J. Sound Vib. 2016, 379, 28–52. [Google Scholar] [CrossRef]

- Pedrero, J.I.; Pleguezuelos, M.; Sánchez, M.B. Analytical model for meshing stiffness, load sharing, and transmission error for helical gears with profile modification. Mech. Mach. Theory 2023, 185, 105340. [Google Scholar] [CrossRef]

- Jun, Z.; Wei-min, T.; Qin, C.; Tao, C. Reliability sensitivity analysis of tooth modification on dynamic transmission error of helical planetary gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 3903–3918. [Google Scholar] [CrossRef]

- Sun, Z.; Tang, J.; Chen, S.; Chen, Y.; Hu, Z.; Wang, Z.; Lu, R.; Chen, X. Mesh stiffness and dynamic response analysis of modified gear system with thin web and weight reduction holes. J. Sound Vib. 2023, 546, 117437. [Google Scholar] [CrossRef]

- Tsai, M.H.; Tsai, Y.C. A method for calculating static transmission errors of plastic spur gears using FEM evaluation. Finite Elem. Anal. Des. 1997, 27, 345–357. [Google Scholar] [CrossRef]

- Park, C.I. Tooth friction force and transmission error of spur gears due to sliding friction. J. Mech. Sci. Technol. 2019, 33, 1311–1319. [Google Scholar] [CrossRef]

- Li, H.; Chen, S.; Tang, J.; Chen, W.; Ouyang, H. A novel approach for calculating no-load static transmission error based on measured discrete tooth surfaces. Mech. Mach. Theory 2019, 138, 112–123. [Google Scholar] [CrossRef]

- Yang, Y.; Cao, L.; Li, H.; Dai, Y. Nonlinear dynamic response of a spur gear pair based on the modeling of periodic mesh stiffness and static transmission error. Appl. Math. Model. 2019, 72, 444–469. [Google Scholar] [CrossRef]

- Wang, C.; Ding, P.; Huang, X.; Gao, T.; Li, C.; Zhang, C. Reliability sensitivity analysis of ball-end milling accuracy. Int. J. Adv. Manuf. Technol. 2021, 112, 2051–2064. [Google Scholar] [CrossRef]

- Benatar, M.; Handschuh, M.; Kahraman, A. Talbot Static and dynamic transmission error measurements of helical gear pairs with various tooth modifications. J. Mech. Des. 2019, 141, 103301. [Google Scholar] [CrossRef]

- Liu, C.; Shi, W.K.; Curá, F.M.; Mura, A. A novel method to predict static transmission error for spur gear pair based on accuracy grade. J. Cent. South Univ. 2020, 27, 3334–3349. [Google Scholar] [CrossRef]

- Samani, S.; Molaie, F.; Pellicano, F. Nonlinear vibration of the spiral bevel gear with a novel tooth surface modification method. Meccanica 2019, 54, 1071–1081. [Google Scholar] [CrossRef]

- Zhou, D.; Chen, Z.; Pan, E.; Zhang, Y. Dynamic statistical responses of gear drive based on improved stochastic iteration method. Appl. Math. Model. 2022, 108, 46–65. [Google Scholar] [CrossRef]

- Huang, X.; Hu, M.; Zhang, Y.; Lv, C. Probabilistic analysis of chatter stability in turning. Int. J. Adv. Manuf. Technol. 2016, 87, 3225–3232. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, X.; Zhang, Y. Dynamic reliability analysis for planetary gear system in shearer mechanisms. Mech. Mach. Theory 2016, 105, 244–259. [Google Scholar] [CrossRef]

- Wang, G.; Chen, L.; Yu, L.; Zou, S. Research on the dynamic transmission error of a spur gear pair with eccentricities by finite element method. Mech. Mach. Theory 2017, 109, 1–13. [Google Scholar] [CrossRef]

- Feng, K.; Borghesani, P.; Smith, W.A.; Randall, R.B.; Chin, Z.; Ren, J.; Peng, Z. Vibration-based updating of wear prediction for spur gears. Wear 2019, 426, 1410–1415. [Google Scholar] [CrossRef]

- Xu, R.; Zhang, J.; Wang, J.; Li, R. Research on nonlinear dynamic model and characteristics of a spur gear pair considering the meshing state of multiple pairs of teeth. J. Adv. Mech. Des. Syst. Manuf. 2021, 15, JAMDSM0068. [Google Scholar] [CrossRef]

| Parameter | Number of Teeth z | Modulus m | Load T (N·m) | |

|---|---|---|---|---|

| A | Driving gear | 72 | 1.75 | 150 |

| Driven gear | 72 | 1.75 | ||

| B | Driving gear | 26 | 3.5 | 150 |

| Driven gear | 26 | 3.5 | ||

| C | Driving gear | 52 | 1.75 | 75 |

| Driven gear | 52 | 1.75 | ||

| D | Driving gear | 20 | 4 | 300 |

| Driven gear | 20 | 4 | ||

| Before Optimizing | After Optimizing | Amplitude | |

|---|---|---|---|

| A | 0.2417 | 0.1916 | 20.7% |

| B | 0.2853 | 0.1691 | 40.7% |

| C | 0.1408 | 0.0671 | 52.3% |

| D | 1.0288 | 0.5192 | 49.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, D.; Guo, Y.; Yang, J.; Zhang, Y. Study on the Parameter Influences of Gear Tooth Profile Modification and Transmission Error Analysis. Machines 2024, 12, 316. https://doi.org/10.3390/machines12050316

Zhou D, Guo Y, Yang J, Zhang Y. Study on the Parameter Influences of Gear Tooth Profile Modification and Transmission Error Analysis. Machines. 2024; 12(5):316. https://doi.org/10.3390/machines12050316

Chicago/Turabian StyleZhou, Di, Yonglin Guo, Jian Yang, and Yimin Zhang. 2024. "Study on the Parameter Influences of Gear Tooth Profile Modification and Transmission Error Analysis" Machines 12, no. 5: 316. https://doi.org/10.3390/machines12050316

APA StyleZhou, D., Guo, Y., Yang, J., & Zhang, Y. (2024). Study on the Parameter Influences of Gear Tooth Profile Modification and Transmission Error Analysis. Machines, 12(5), 316. https://doi.org/10.3390/machines12050316