The Effect of a Ferromagnetic Steel Enclosure on Magnetic Shielding Systems: Analysis, Modeling, and Experimental Validation

Abstract

1. Introduction

2. Modeling and Simulation Methods for Steel Enclosures in Magnetic Shielding Applications

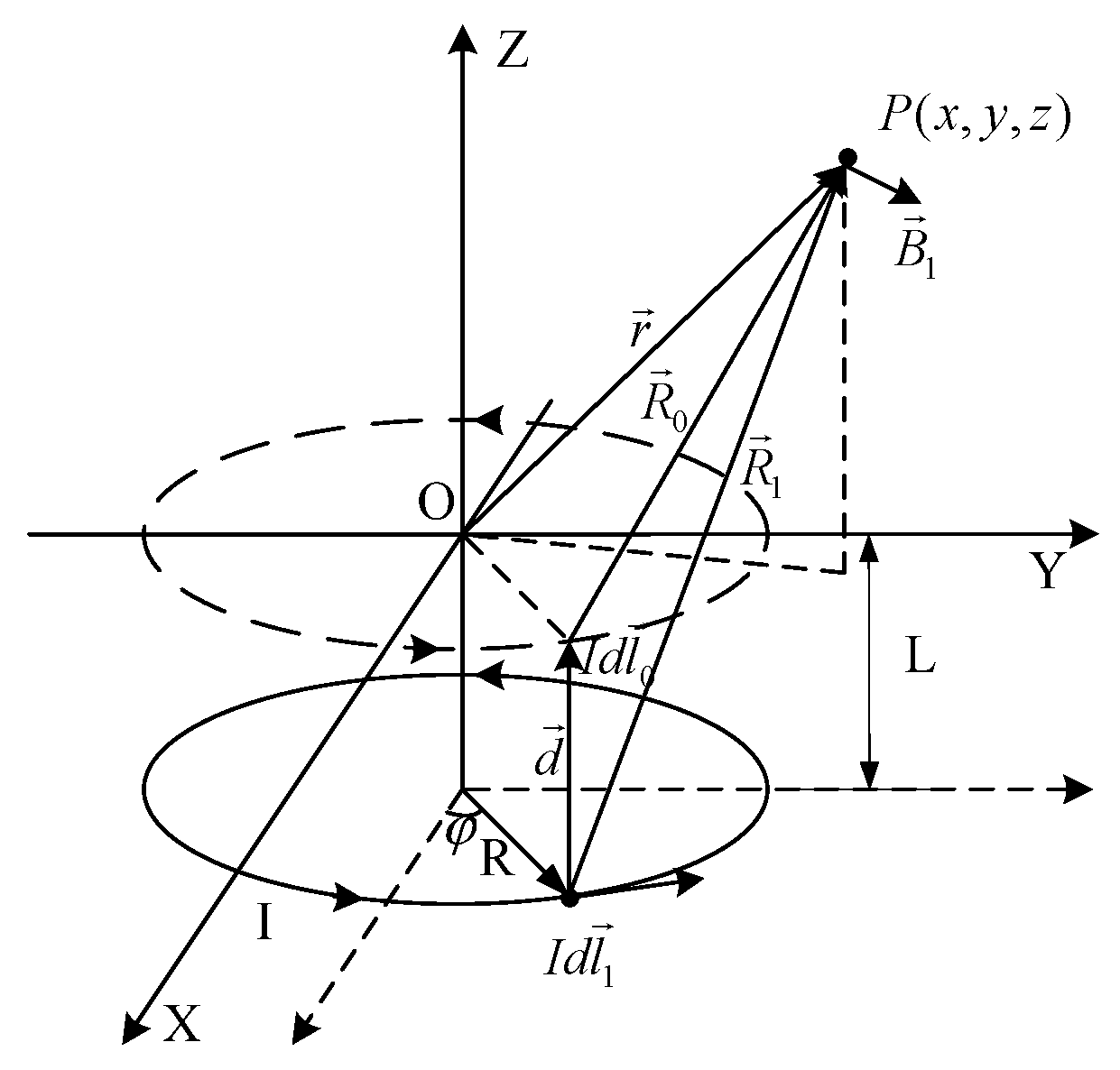

2.1. The Theoretical Analysis of Magnetic Fields in Helmholtz Coils

2.2. Simplified Model of a Steel Enclosure

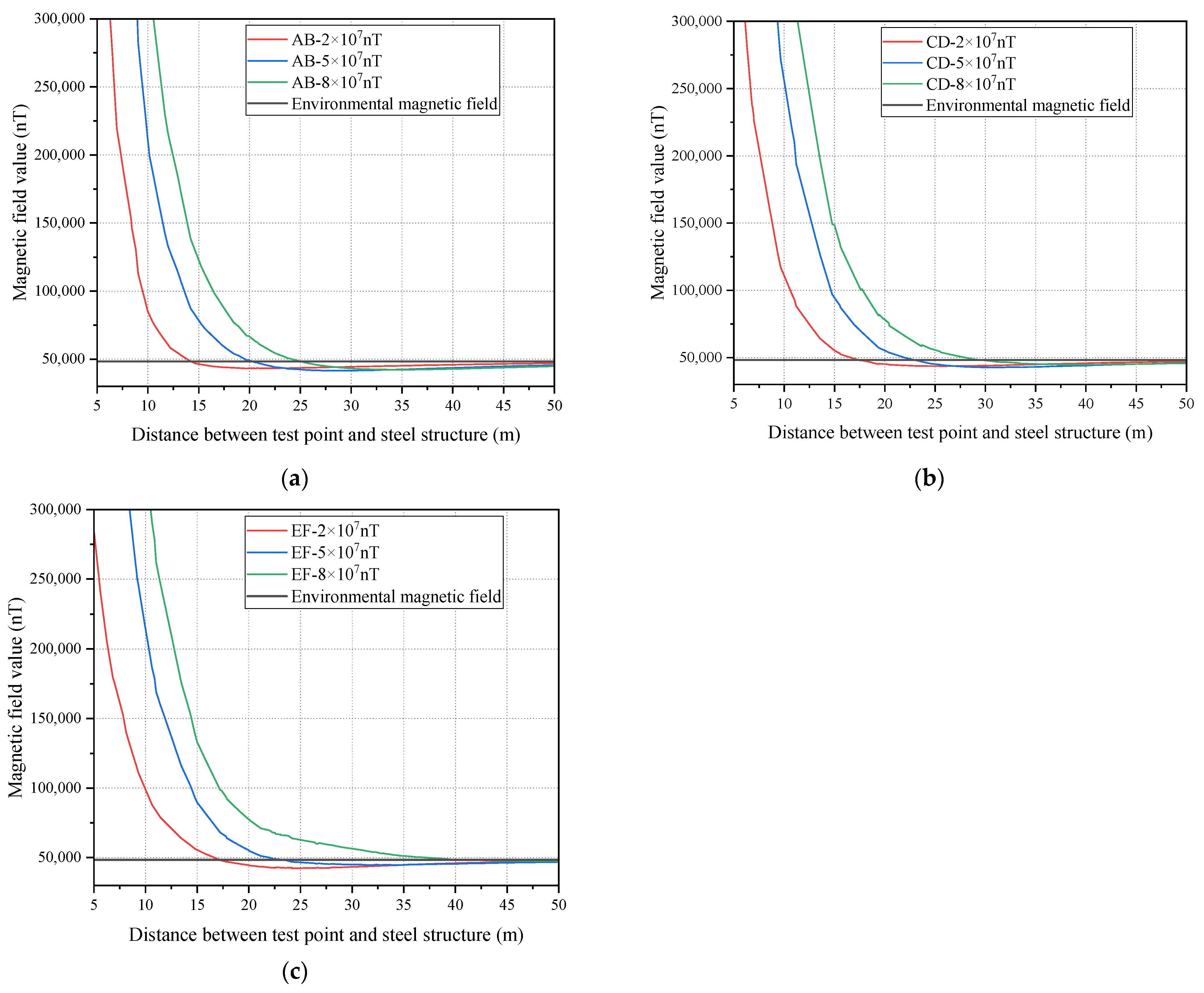

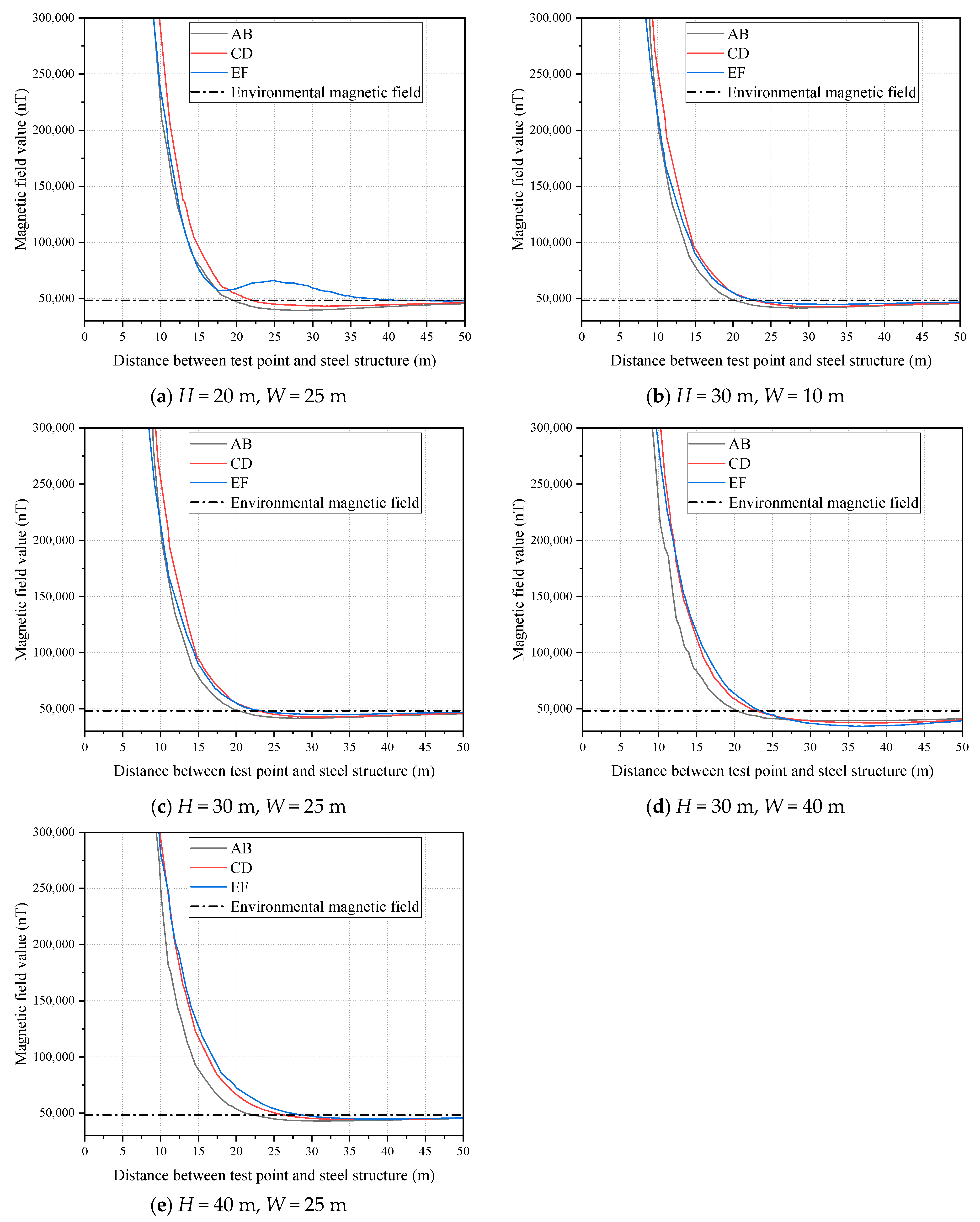

2.3. Simulation Analysis

3. Test Method and Discussion of Test Results

3.1. Principle and Method of Measurement

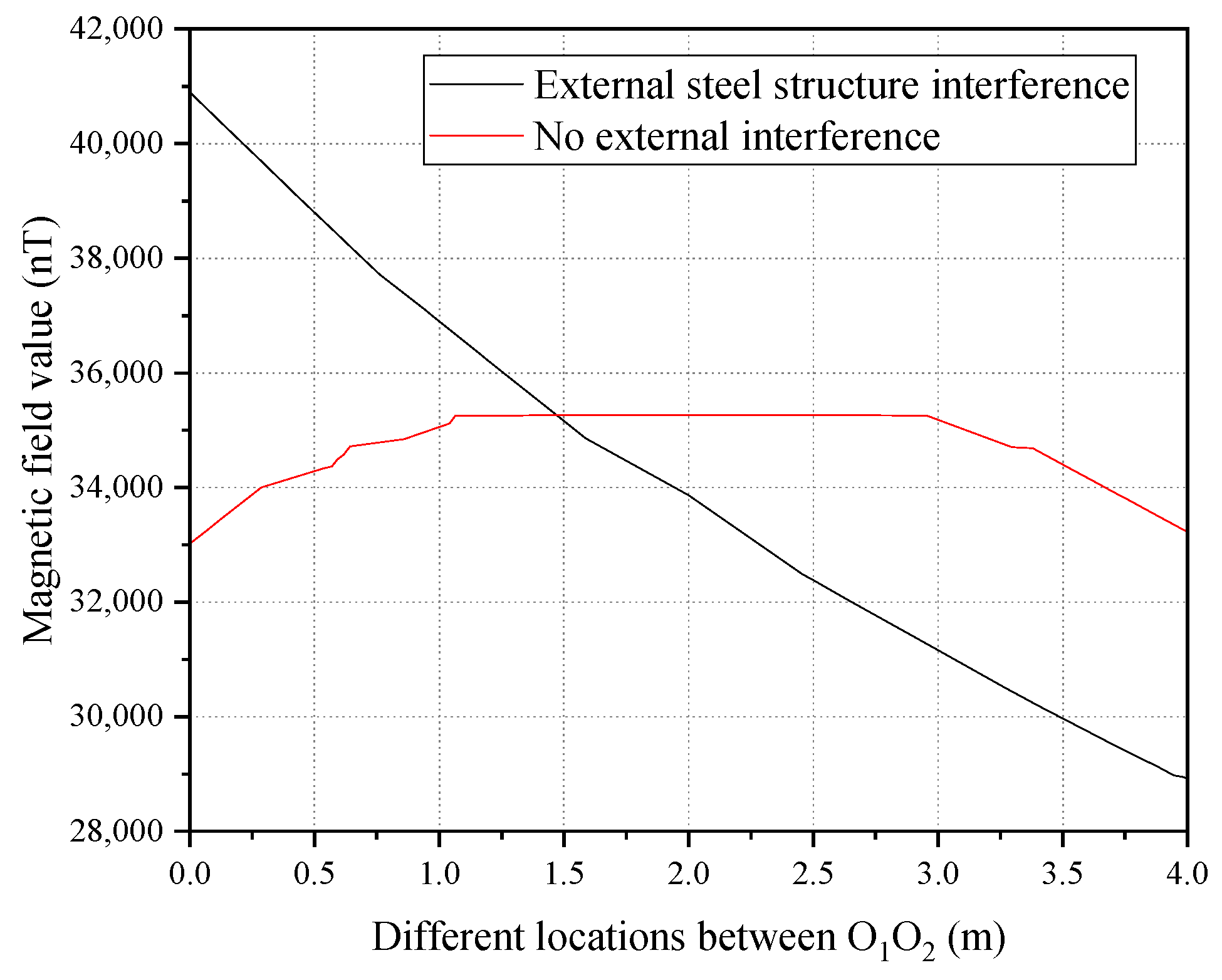

3.2. Analysis of Measurement Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holmes, N.; Rea, M.; Chalmers, J.; Leggett, J.; Edwards, L.J.; Nell, P.; Pink, S.; Patel, P.; Wood, J.; Murby, N.; et al. A lightweight magnetically shielded room with active shielding. Sci. Rep. 2022, 12, 13561. [Google Scholar] [CrossRef] [PubMed]

- Zhu, K.; Kiourti, A. A Review of Magnetic Field Emissions from the Human Body: Sources, Sensors, and Uses. IEEE Open J. Antennas Propag. 2022, 3, 732–744. [Google Scholar] [CrossRef]

- Roth, B.J. Biomagnetism: The First Sixty Years. Sensors 2023, 23, 4218. [Google Scholar] [CrossRef] [PubMed]

- Holmes, N.; Leggett, J.; Boto, E.; Roberts, G.; Hill, R.M.; Tierney, T.M.; Shah, V.; Barnes, G.R.; Brookes, M.J.; Bowtell, R. A Bi-Planar Coil System for Nulling Background Magnetic Fields in Scalp Mounted Magnetoencephalography. Neuroimage 2018, 181, 760–774. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Zhang, X.; Han, B.; Wang, J.; Wang, L. Design of Biplanar Coils for Degrading Residual Field in Magnetic Shielding Room. IEEE Trans. Instrum. Meas. 2021, 70, 6010110. [Google Scholar] [CrossRef]

- Yang, K.; Wu, D.; Gao, W.; Ni, T.; Zhang, Q.; Zhang, H.; Huang, D. Calibration of SQUID Magnetometers in Multichannel MCG System Based on Bi-Planar Coil. IEEE Trans. Instrum. Meas. 2022, 71, 1002209. [Google Scholar] [CrossRef]

- Afach, S.; Bison, G.; Bodek, K.; Burri, F.; Chowdhuri, Z.; Daum, M.; Fertl, M.; Franke, B.; Grujic, Z.; Helaine, V.; et al. Dynamic Stabilization of the Magnetic Field Surrounding the Neutron Electric Dipole Moment Spectrometer at the Paul Scherrer Institute. J. Appl. Phys. 2014, 116, 084510. [Google Scholar] [CrossRef]

- Chupp, T.E.; Fierlinger, P.; Ramsey-Musolf, M.J.; Singh, J.T. Electric dipole moments of atoms, molecules, nuclei, and particles. Rev. Mod. Phys. 2019, 91, 015001. [Google Scholar] [CrossRef]

- Kuchler, F.; Babcock, E.; Burghoff, M.; Chupp, T.; Degenkolb, S.; Fan, I.; Fierlinger, P.; Gong, F.; Kraegeloh, E.; Kilian, W.; et al. A New Search for the Atomic EDM of 129Xe at FRM-II. Hyperfine Interact. 2016, 237, 95. [Google Scholar] [CrossRef]

- Tashiro, K.; Wakiwaka, H.; Matsumura, K.; Okano, K. Desktop Magnetic Shielding System for the Calibration of High-Sensitivity Magnetometers. IEEE Trans. Magn. 2011, 47, 4270–4273. [Google Scholar] [CrossRef]

- Long, T.; Han, B.; Song, X.; Suo, Y.; Jia, L. Fast In-Situ Triaxial Remanent Magnetic Field Measurement for Single-Beam SERF Atomic Magnetometer Based on Trisection Algorithm. Photonic Sens. 2023, 13, 230311. [Google Scholar] [CrossRef]

- Fan, W.F.; Quan, W.; Liu, F.; Pang, H.Y.; Xing, L.; Liu, G. Performance of Low-Noise Ferrite Shield in a K-Rb-Ne-21 Co-Magnetometer. IEEE Sens. J. 2020, 20, 2543–2549. [Google Scholar] [CrossRef]

- Kajiwara, G.; Harakawa, K.; Ogata, H.; Kado, H. High-performance magnetically shielded room. IEEE Trans. Magn. 1996, 32, 2582–2585. [Google Scholar] [CrossRef]

- Ayres, N.J.; Ban, G.; Bison, G.; Bodek, K.; Bondar, V.; Bouillaud, T.; Clement, B.; Chanel, E.; Chiu, P.-J.; Crawford, C.B.; et al. The very large n2EDM magnetically shielded room with an exceptional performance for fundamental physics measurements. Rev. Sci. Instrum. 2022, 93, 095105. [Google Scholar] [CrossRef] [PubMed]

- Packer, M.; Hobson, P.J.; Davis, A.; Holmes, N.; Leggett, J.; Glover, P.; Hardwicke, N.L.; Brookes, M.J.; Bowtell, R.; Fromhold, T.M. Magnetic Field Design in a Cylindrical High-Permeability Shield: The Combination of Simple Building Blocks and a Genetic Algorithm. J. Appl. Phys. 2022, 131, 093902. [Google Scholar] [CrossRef]

- Allmendinger, F.; Brauneis, B.; Schmidt, U. Degaussing procedure and performance enhancement by low-frequency shaking of a 3-layer magnetically shielded room. Rev. Sci. Instrum. 2023, 94, 115105. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Zhang, Z.; Wu, B.; Wang, H.; Kong, X.; Wang, M. A Study of Enclosed Magnetic Shielding Room by Simulation. IEEE Trans. Appl. Supercond. 2021, 31, 2500404. [Google Scholar] [CrossRef]

- Ren, Z.; Qin, X.; Zhang, Q.; Sun, Y. Damage Evolution Characterization of Low Carbon Alloy Steel Based on Multiaxial Fatigue Test and DIC. In Proceedings of the IEEE International Conference on Prognostics and Health Management (ICPHM), Montreal, QC, Canada, 5–7 June 2023; pp. 239–245. [Google Scholar] [CrossRef]

- Chen, D.F.; Zhang, J.T.; Xiao, H.Y. Design of an instrument of magnetic measurement for steel structures. In Proceedings of the 12th IEEE International Conference on Electronic Measurement and Instruments (ICEMI), Qingdao, China, 16–18 July 2015; pp. 718–721. [Google Scholar]

- Kim, J.-W.; Park, S. Magnetic Flux Leakage Sensing and Artificial Neural Network Pattern Recognition Based Automated Damage Detection and Quantification for Wire Rope Non-Destructive Evaluation. Sensors 2018, 18, 109. [Google Scholar] [CrossRef] [PubMed]

- Weng, G.Y.; Wang, J.T.; Liu, Y.; Zhu, X.Y.; Dai, J.B. Magnetic Stress Sensing System for Nondestructive Stress Testing of Structural Steel and Steel Truss Components Based on Existing Magnetism. Sensors 2020, 20, 4043. [Google Scholar] [CrossRef]

- Matsumoto, T.; Uchimoto, T.; Takagi, T.; Dobmann, G.; Ducharne, B.; Oozono, S.; Yuya, H. Investigation of electromagnetic nondestructive evaluation of residual strain in low carbon steels using the eddy current magnetic signature (EC-MS) method. J. Magn. Magn. Mater. 2019, 479, 212–221. [Google Scholar] [CrossRef]

- Nichipuruk, A.P.; Stashkov, A.N.; Shchapova, E.A.; Kazantseva, N.V.; Makarova, M.V. Structure and Magnetic Properties of 09G2S Steel Obtained by the Selective Laser Melting Method. Phys. Solid State 2022, 64, 148–153. [Google Scholar] [CrossRef]

- Ferrandez, D.; Moron, C.; Saiz, P.; Moron, A. Magnetic variation in construction steels under tensile stress. Empirical research with Helmholtz coils. Mater. Constr. 2021, 71, e243. [Google Scholar] [CrossRef]

- Amoskov, V.; Bazarov, A.; Belyakov, V.; Gapionok, E.; Gribov, Y.; Kaparkova, M.; Kukhtin, V.; Lamzin, E.; Lyublin, B.; Ovsyannikov, D.; et al. Calculation of magnetic field from steel rebar of building with machine producing high stray field. Fusion Eng. Des. 2018, 135, 165–173. [Google Scholar] [CrossRef]

- Pang, H.Y.; Duan, L.H.; Quan, W.; Wang, J.; Wu, W.F.; Fan, W.F.; Liu, F. Design of Highly Uniform Three-Dimensional Spherical Magnetic Field Coils for Atomic Sensors. IEEE Sens. J. 2020, 20, 11229–11236. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Huang, J.; Luo, Y.; Lu, F. The Effect of a Ferromagnetic Steel Enclosure on Magnetic Shielding Systems: Analysis, Modeling, and Experimental Validation. Machines 2024, 12, 317. https://doi.org/10.3390/machines12050317

Cheng Y, Huang J, Luo Y, Lu F. The Effect of a Ferromagnetic Steel Enclosure on Magnetic Shielding Systems: Analysis, Modeling, and Experimental Validation. Machines. 2024; 12(5):317. https://doi.org/10.3390/machines12050317

Chicago/Turabian StyleCheng, Yuan, Jiang Huang, Yaozhi Luo, and Feng Lu. 2024. "The Effect of a Ferromagnetic Steel Enclosure on Magnetic Shielding Systems: Analysis, Modeling, and Experimental Validation" Machines 12, no. 5: 317. https://doi.org/10.3390/machines12050317

APA StyleCheng, Y., Huang, J., Luo, Y., & Lu, F. (2024). The Effect of a Ferromagnetic Steel Enclosure on Magnetic Shielding Systems: Analysis, Modeling, and Experimental Validation. Machines, 12(5), 317. https://doi.org/10.3390/machines12050317