Validation Challenges in Data for Different Diesel Engine Performance Regimes Utilising HVO Fuel: A Study on the Application of Artificial Neural Networks for Emissions Prediction

Abstract

1. Introduction

- To construct an advanced tool with a user-friendly interface for data input and output facilities to provide simulations and predictions of exhausts in outcomes.

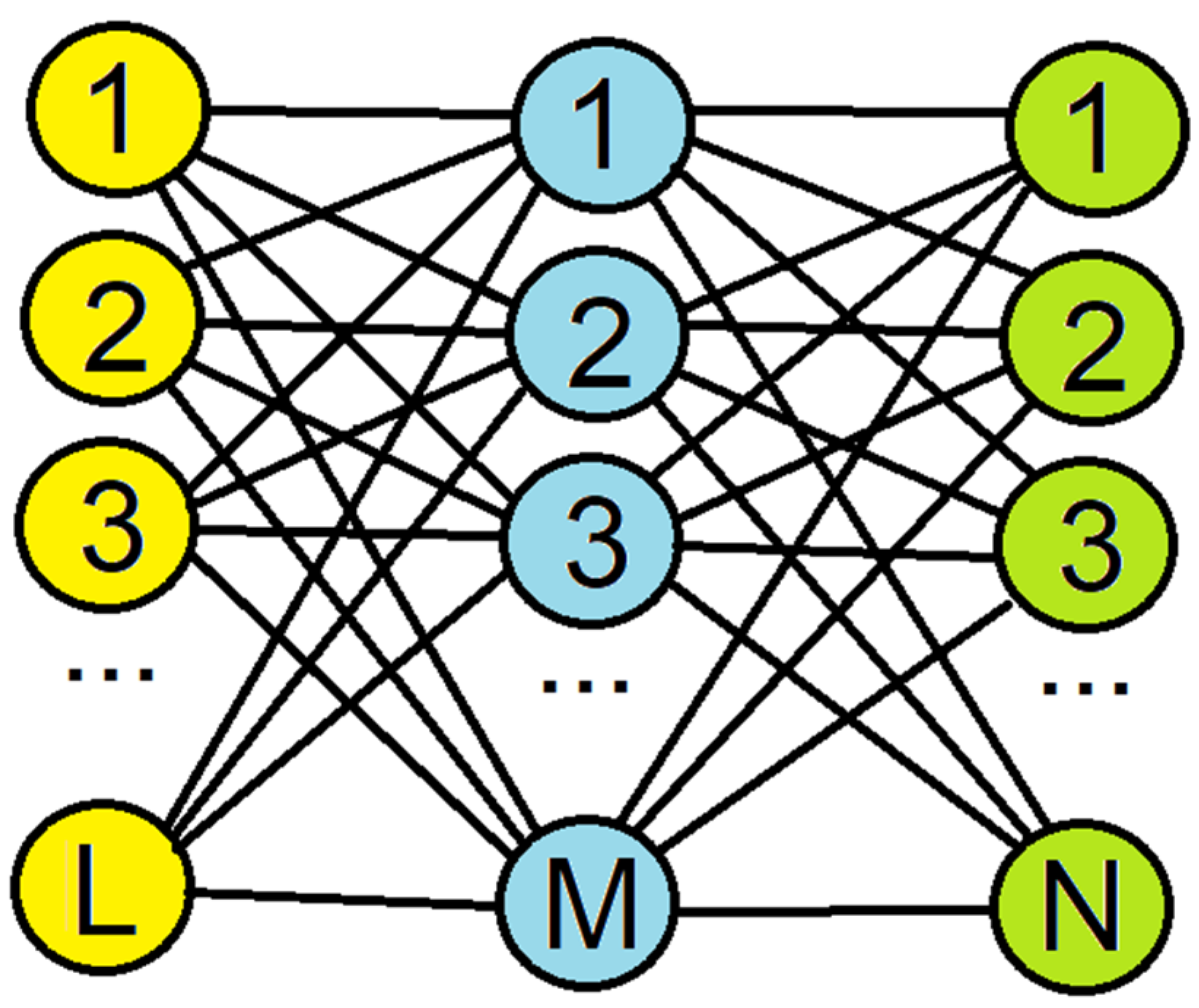

- For an artificial neural network, construct the interfaces for input the layer and output layer (number of parameters, intervals) according to the general working principles of a diesel engine.

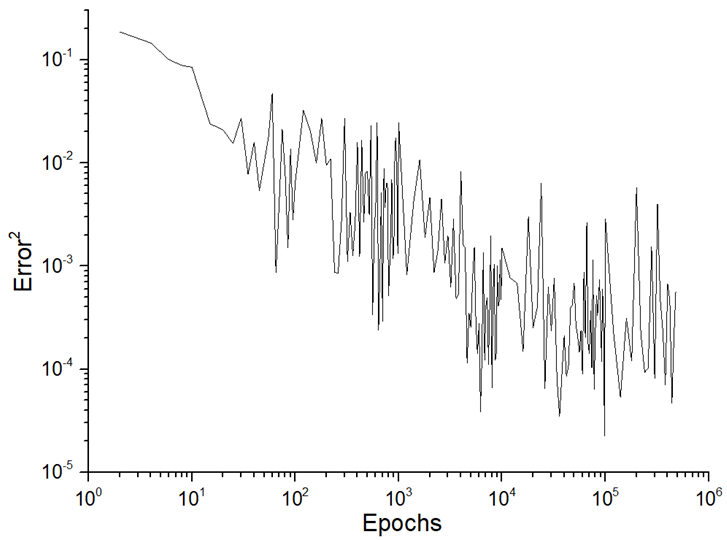

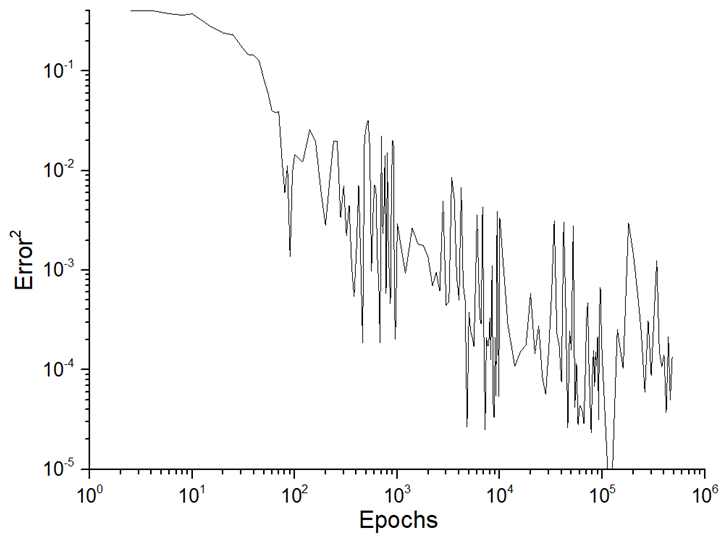

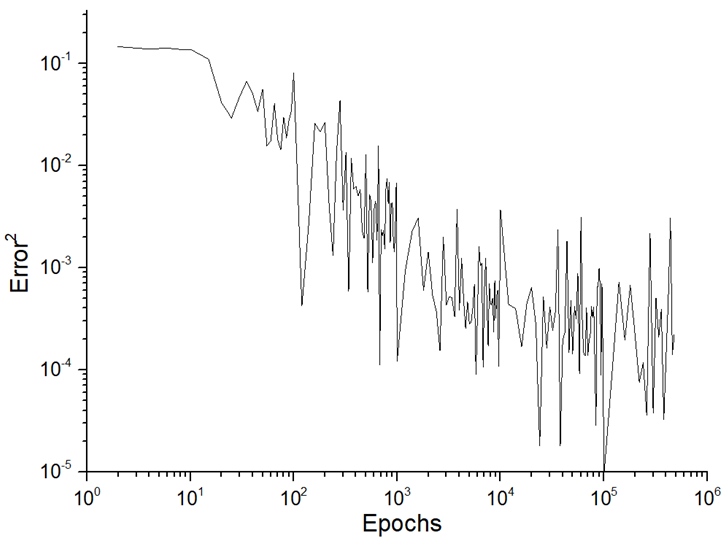

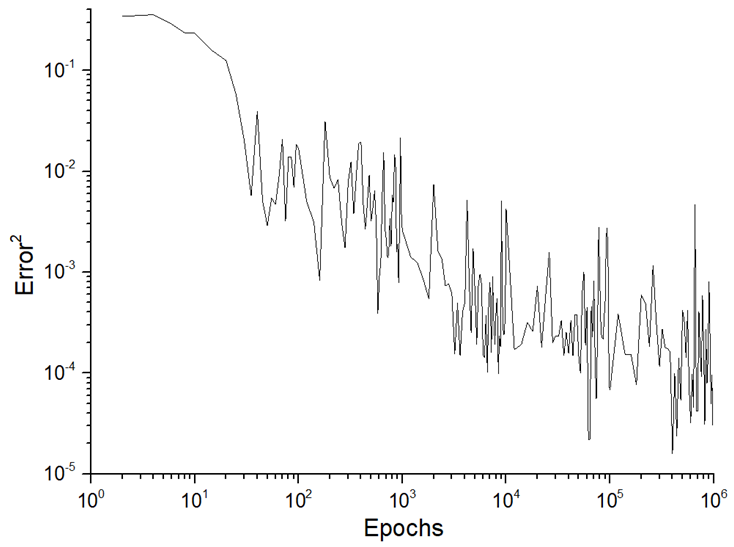

- To establish the suitable parameters of ANN (number of hidden layers, amount of perceptron in the hidden layer), the number of training epochs must be chosen, which allows for the smallest deviation of the simulated value from the experimental value.

- To provide the simulations and estimate simulated values within the framework of statistical distribution.

2. Materials and Methods

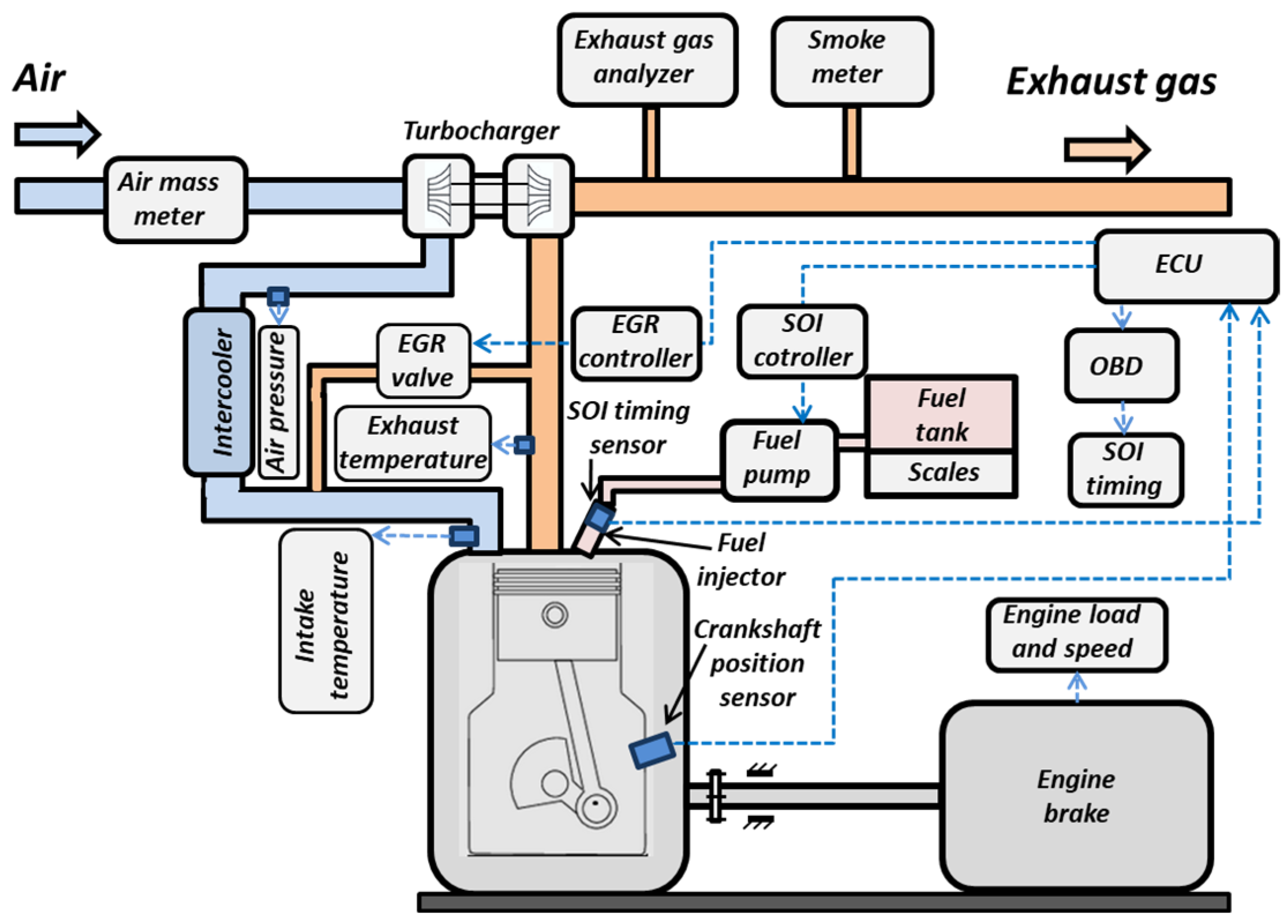

2.1. Experimental Test Equipment and Materials

2.2. Data Collection

2.3. Principal Scheme of Tool VALLUM01

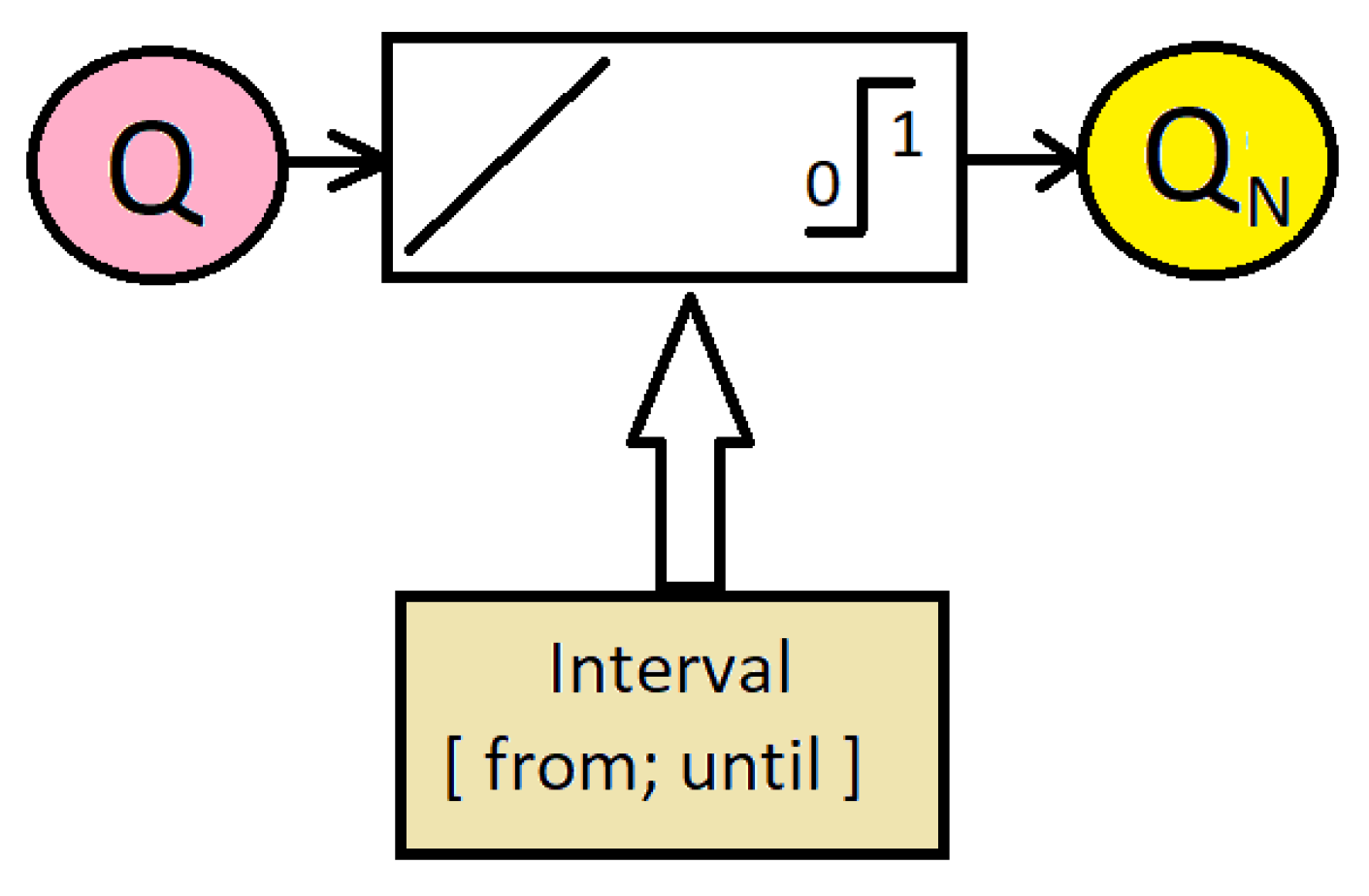

2.4. Organization of Data Input/Output

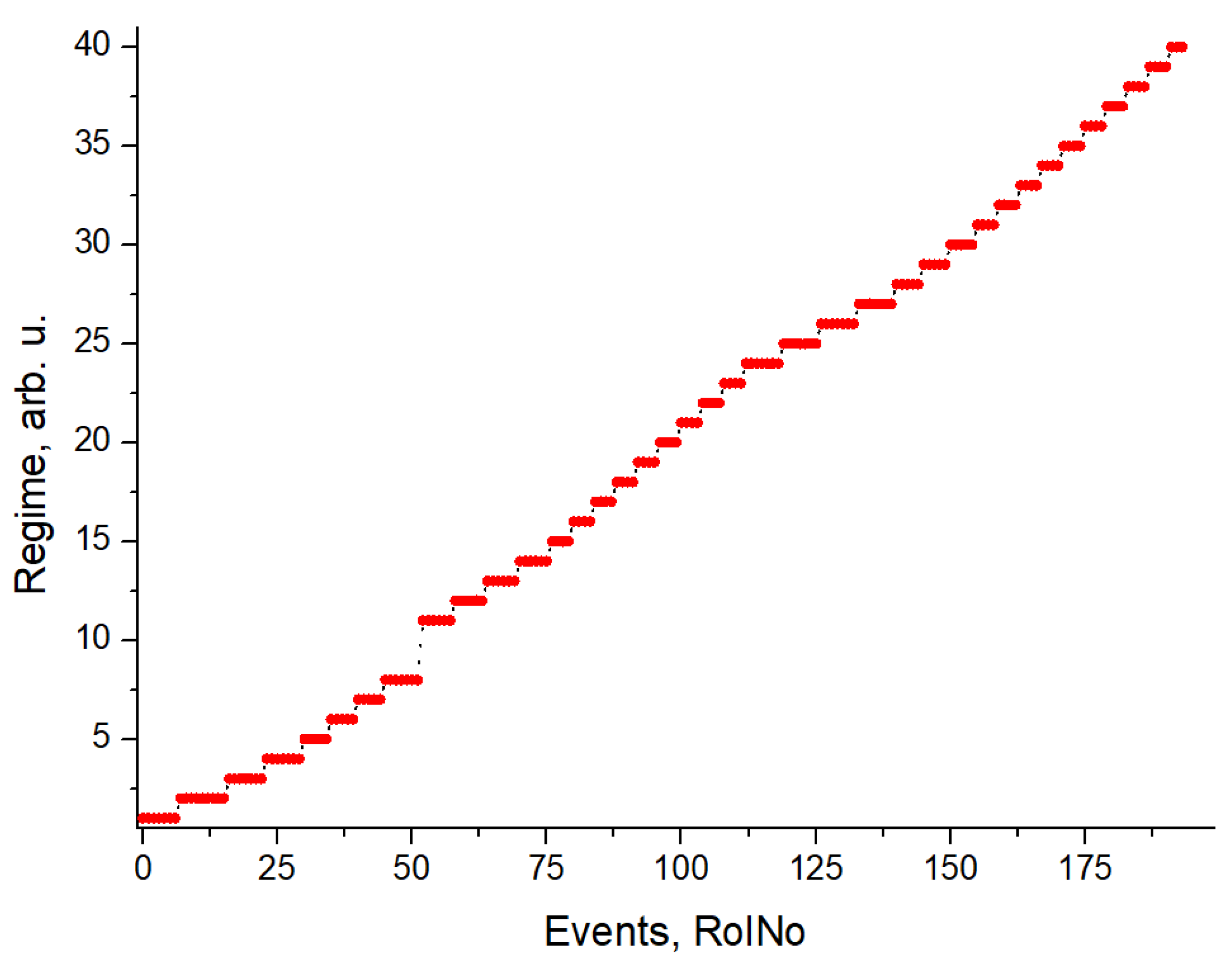

2.5. Test Campaign

- In the I stage (regimes 1–4, events, 1–30), the engine speed was set at 2000 rpm and the load was set at 30 Nm, 60 Nm, 90 Nm, and 120 Nm; the EGR was switched off, and the SOI (2–5 CAD bTDC) was controlled by the ECU.

- In the II stage (regimes 5–8, events 31–52), the engine speed was set at 2500 rpm and the load was set at 30 Nm, 60 Nm, 90 Nm, and 120 Nm; the EGR was switched off, and the SOI (5–12 CAD bTDC) was controlled by the ECU.

- In the III stage (regimes 11–14, events 53–76), the engine speed (2000 rpm) and load (60 Nm) were fixed, the EGR ratio was changed (0.05; 0.10; 0.15 and 0.20) using an EGR controller, and the SOI (3–4 CAD bTDC) was controlled by the ECU.

- In the IV stage (regimes 15–23, 77–112), the engine speed (2000 rpm) and load (60 Nm) were fixed, EGR = 0.15 was set by the EGR controller, and fuel injection was changed by the SOI controller in the range of −3–15 CAD bTDC.

- In the V stage (regimes 24–27, 113–140), the engine speed was set at 2500 rpm and the load was set at 30 Nm, 60 Nm, 90 Nm, and 120 Nm; the EGR ratio (0.35–0.05) and the SOI (5–10 CAD bTDC) were controlled by the ECU.

- In the VI stage (regimes 28–31, 141–159), the engine speed was set at 2500 rpm and the load was set at 30 Nm, 60 Nm, 90 Nm, and 120 Nm; the EGR ratio (0.45–0.20) and the SOI (2–5 CAD bTDC) were controlled by the ECU.

- In the VII stage (regimes 32–40, 160–195), the engine speed (2000 rpm) and load (60 Nm) were fixed, the controller set to EGR = 0.2, and the SOI controller varied the start of injection in the range of −3–15 CAD bTDC.

3. Results

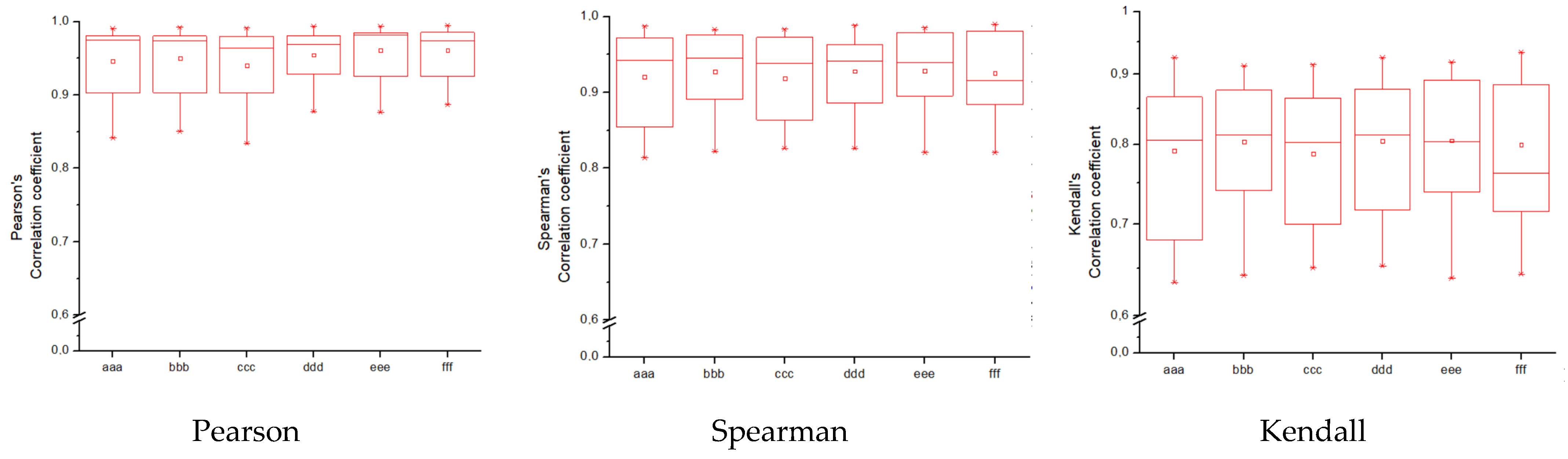

| Project | One Hidden Layer | Training | Validation | |||||

|---|---|---|---|---|---|---|---|---|

| Name | M | Routine | File | Events | Epochs | TNE2 | File | Events |

| aaaa | 500 | T1 | abc1.csv | 194 | 500,000 | Table 7, Table 8, Table 9, Table 10, Table 11 and Table 12 | abc1.csv | 194 |

| bbbb | 500 | T2 | bcd1.csv | 38 | 500,000 | Table 7, Table 8, Table 9, Table 10, Table 11 and Table 12 | abc1.csv | 194 |

| cccc | 1000 | T3 | abc1.csv | 194 | 500,000 | Table 7, Table 8, Table 9, Table 10, Table 11 and Table 12 | abc1.csv | 194 |

| dddd | 1000 | T4 | bcd1.csv | 38 | 500,000 | Table 7, Table 8, Table 9, Table 10, Table 11 and Table 12 | abc1.csv | 194 |

| eeee | 1000 | T5 | abc1.csv | 194 | 1,000,000 | Table 7, Table 8, Table 9, Table 10, Table 11 and Table 12 | abc1.csv | 194 |

| ffff | 1000 | T6 | bcd1.csv | 38 | 1,000,000 | Table 7, Table 8, Table 9, Table 10, Table 11 and Table 12 | abc1.csv | 194 |

4. Discussion

5. Conclusions

- The advanced tool VALLUM01 (with ANN implementation) containing a user-friendly interface for data input and output facilities was created, designed, and tested to provide simulations and predictions of exhausts in motor outcomes. A user-friendly input/output interface was created and used for solving the specific task of diesel motor efficiency using ANN. The set of input parameters (12) and output parameters (10) was estimated to be significant and sufficient for training, validation, and prediction. Intervals of values were recognized as suitable for fuzzification for input/output to ANN.

- Training sessions for ANN (1,000,000 epochs, 1000 perceptrons in a single-hidden layer) could be titled as the most successful. For training, the use of averaged values instead of real experimental values is acceptable.

- Following the development of a user-friendly input/output interface, the appropriateness of the input values for the artificial neural network (ANN) was verified (Table 3).

- The first cluster, which includes volumetric O2 concentration, SNOx, and SHC, and the third cluster, which includes SCO, CO2 concentration, and SCO2, yielded the best predictions. However, the second cluster, including smoke, brake specific fuel consumption, and brake thermal efficiency, showed significant deviations from experimental values, mainly due to measurement error and extreme conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| λ | The excess air ratio |

| AI | Artificial intelligence |

| ANN | Artificial neural networks |

| BMEP | Brake mean effective pressure |

| BTE | Brake thermal efficiency |

| BSFC | Brake specific fuel consumption |

| CO2 | Carbon dioxide |

| CO | Carbon monoxide |

| D100 | Pure fossil diesel fuel |

| ECU | Engine control unit |

| EGR | Exhaust gas recirculation |

| HC | Hydrocarbons |

| HVO100 | Hydrotreated Vegetable Oil |

| l0 | Stoichiometric air to fuel ratio |

| LHV | Lower heating value |

| ML | Machine Learning |

| MLP | Multilayer perceptron |

| MLPNN | Multilayer perceptron neural network |

| NOx | Nitrogen oxides |

| RSM | Response surface methodology |

| SCO2 | Recalculated CO2 value |

| SCO | Recalculated CO value |

| SHC | Recalculated HC value |

| SO | Smoke opacity |

| SOI | Start of injection |

| SNOx | Recalculated NOx value |

| TNE | Total network error |

| H2O | Water |

References

- Ulbrich, D.; Selech, J.; Kowalczyk, J.; Jóźwiak, J.; Durczak, K.; Gil, L.; Pieniak, D.; Paczkowska, M.; Przystupa, K. Reliability Analysis for Unrepairable Automotive Components. Materials 2021, 14, 7014. [Google Scholar] [CrossRef]

- Oulmelk, A.; Srati, M.; Afraites, L.; Hadri, A. An Artificial Neural Network Approach to Identify the Parameter in a Nonlinear Subdiffusion Model. Commun. Nonlinear Sci. Numer. Simul. 2023, 125, 107413. [Google Scholar] [CrossRef]

- Borucka, A.; Kozłowski, E.; Antosz, K.; Parczewski, R. A New Approach to Production Process Capability Assessment for Non-Normal Data. Appl. Sci. 2023, 13, 6721. [Google Scholar] [CrossRef]

- Žvirblis, T.; Hunicz, J.; Matijošius, J.; Rimkus, A.; Kilikevičius, A.; Gęca, M. Improving Diesel Engine Reliability Using an Optimal Prognostic Model to Predict Diesel Engine Emissions and Performance Using Pure Diesel and Hydrogenated Vegetable Oil. Eksploat. I Niezawodn.–Maint. Reliab. 2023, 25, 174358. [Google Scholar] [CrossRef]

- Sindhu, T.N.; Çolak, A.B.; Lone, S.A.; Shafiq, A.; Abushal, T.A. A Decreasing Failure Rate Model with a Novel Approach to Enhance the Artificial Neural Network’s Structure for Engineering and Disease Data Analysis. Tribol. Int. 2023, 192, 109231. [Google Scholar] [CrossRef]

- Alam, M.S.; Deb, J.B.; Amin, A.A.; Chowdhury, S. An Artificial Neural Network for Predicting Air Traffic Demand Based on Socio-Economic Parameters. Decis. Anal. J. 2024, 10, 100382. [Google Scholar] [CrossRef]

- AlAlaween, W.H.; Mahfouf, M.; Omar, C.; Al-Asady, R.B.; Monaco, D.; Salman, A.D. Serial Artificial Neural Networks Characterized by Gaussian Mixture for the Modelling of the Consigma25 Continuous Manufacturing Line. Powder Technol. 2024, 434, 119296. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Artificial Neural Networks in Supply Chain Management, a Review. J. Econ. Technol. 2023, 1, 179–196. [Google Scholar] [CrossRef]

- Adedeji, B.P. Electric Vehicles Survey and a Multifunctional Artificial Neural Network for Predicting Energy Consumption in All-Electric Vehicles. Results Eng. 2023, 19, 101283. [Google Scholar] [CrossRef]

- Sahin, G.; Isik, G.; van Sark, W.G.J.H.M. Predictive Modeling of PV Solar Power Plant Efficiency Considering Weather Conditions: A Comparative Analysis of Artificial Neural Networks and Multiple Linear Regression. Energy Rep. 2023, 10, 2837–2849. [Google Scholar] [CrossRef]

- Zurada, J.M. Introduction to Artificial Neural Systems; West: St. Paul, MN, USA, 1992; ISBN 978-0-314-93391-1. [Google Scholar]

- Rabunal, J.R.; Dorado, J. (Eds.) Artificial Neural Networks in Real-Life Applications; Idea Group Pub: Hershey, PA, USA, 2006; ISBN 978-1-59140-902-1. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning. Available online: https://www.deeplearningbook.org/ (accessed on 31 December 2023).

- Torres Sospedra, J. Ensembles of Artificial Neural Networks: Analysis and Development of Design Methods; Universitat Jaume I. Departament d’Enginyeria i Ciència dels Computadors: Castellon, Spain, 2011. [Google Scholar]

- Lou, C. Artificial Neural Networks: Their Training Process and Applications; Department of Mathematics Whitman College: Walla Walla, WA, USA, 2019. [Google Scholar]

- Li, R.; Herreros, J.M.; Tsolakis, A.; Yang, W. Integrated Machine Learning-Quantitative Structure Property Relationship (ML-QSPR) and Chemical Kinetics for High Throughput Fuel Screening toward Internal Combustion Engine. Fuel 2022, 307, 121908. [Google Scholar] [CrossRef]

- Ahmad, I.; Sana, A.; Kano, M.; Cheema, I.I.; Menezes, B.C.; Shahzad, J.; Ullah, Z.; Khan, M.; Habib, A. Machine Learning Applications in Biofuels’ Life Cycle: Soil, Feedstock, Production, Consumption, and Emissions. Energies 2021, 14, 5072. [Google Scholar] [CrossRef]

- Usman, M.; Jamil, M.K.; Ashraf, W.M.; Saqib, S.; Ahmad, T.; Fouad, Y.; Raza, H.; Ashfaq, U.; Pervaiz, A. AI-Driven Optimization of Ethanol-Powered Internal Combustion Engines in Alignment with Multiple SDGs: A Sustainable Energy Transition. Energy Convers. Manag. X 2023, 20, 100438. [Google Scholar] [CrossRef]

- Deng; Jiamei; Stobart; Richard; Basti, M. The Applications of Artificial Neural Networks to Engines. In Artificial Neural Networks-Industrial and Control Engineering Applications; Suzuki, K., Ed.; InTech: Vienna, Austria, 2011; ISBN 978-953-307-220-3. [Google Scholar]

- Xing, Y.; Zheng, Z.; Sun, Y.; Agha Alikhani, M. A Review on Machine Learning Application in Biodiesel Production Studies. Int. J. Chem. Eng. 2021, 2021, 2154258. [Google Scholar] [CrossRef]

- Aliramezani, M.; Koch, C.R.; Shahbakhti, M. Modeling, Diagnostics, Optimization, and Control of Internal Combustion Engines via Modern Machine Learning Techniques: A Review and Future Directions. Prog. Energy Combust. Sci. 2022, 88, 100967. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, G.; Chao, Y.; Chen, L.; Ghanbari, A. Simultaneous Prediction of CO2, CO, and NOx Emissions of Biodiesel-Hydrogen Blend Combustion in Compression Ignition Engines by Supervised Machine Learning Tools. Energy 2023, 282, 128972. [Google Scholar] [CrossRef]

- Khac, H.N.; Modabberian, A.; Zenger, K.; Niskanen, K.; West, A.; Zhang, Y.; Silvola, E.; Lendormy, E.; Storm, X.; Mikulski, M. Machine Learning Methods for Emissions Prediction in Combustion Engines with Multiple Cylinders. IFAC-PapersOnLine 2023, 56, 3072–3078. [Google Scholar] [CrossRef]

- Venkatesh, S.N.; V, S.; Thangavel, V.; Balaji P, A.; Vijayaragavan, M.; Subramanian, B.; Josephin JS, F.; Varuvel, E.G. Efficacy of Machine Learning Algorithms in Estimating Emissions in a Dual Fuel Compression Ignition Engine Operating on Hydrogen and Diesel. Int. J. Hydrogen Energy 2023, 48, 39599–39611. [Google Scholar] [CrossRef]

- Lionus Leo, G.M.; Jayabal, R.; Srinivasan, D.; Chrispin Das, M.; Ganesh, M.; Gavaskar, T. Predicting the Performance and Emissions of an HCCI-DI Engine Powered by Waste Cooking Oil Biodiesel with Al2O3 and FeCl3 Nano Additives and Gasoline Injection—A Random Forest Machine Learning Approach. Fuel 2024, 357, 129914. [Google Scholar] [CrossRef]

- Williams, Z.; Moiz, A.; Cung, K.; Smith, M.; Briggs, T.; Bitsis, C.; Miwa, J. Generation of Rate-of-Injection (ROI) Profile for Computational Fluid Dynamics (CFD) Model of Internal Combustion Engine (ICE) Using Machine Learning. Energy AI 2022, 8, 100148. [Google Scholar] [CrossRef]

- Bekesiene, S.; Smaliukiene, R.; Vaicaitiene, R. Using Artificial Neural Networks in Predicting the Level of Stress among Military Conscripts. Mathematics 2021, 9, 626. [Google Scholar] [CrossRef]

- Jovanović, N.; Vasović, B.; Jovanović, Z.; Cvjetković, M. Neural Network Implementation in Java. Bizinfo 2020, 11, 19–30. [Google Scholar] [CrossRef]

- Godwin, D.J.; Varuvel, E.G.; Martin, M.L.J. Prediction of Combustion, Performance, and Emission Parameters of Ethanol Powered Spark Ignition Engine Using Ensemble Least Squares Boosting Machine Learning Algorithms. J. Clean. Prod. 2023, 421, 138401. [Google Scholar] [CrossRef]

- Valeika, G.; Matijošius, J.; Górski, K.; Rimkus, A.; Smigins, R. A Study of Energy and Environmental Parameters of a Diesel Engine Running on Hydrogenated Vegetable Oil (HVO) with Addition of Biobutanol and Castor Oil. Energies 2021, 14, 3939. [Google Scholar] [CrossRef]

- Rimkus, A.; Žaglinskis, J.; Stravinskas, S.; Rapalis, P.; Matijošius, J.; Bereczky, Á. Research on the Combustion, Energy and Emission Parameters of Various Concentration Blends of Hydrotreated Vegetable Oil Biofuel and Diesel Fuel in a Compression-Ignition Engine. Energies 2019, 12, 2978. [Google Scholar] [CrossRef]

- Shepel, O.; Matijošius, J.; Rimkus, A.; Duda, K.; Mikulski, M. Research of Parameters of a Compression Ignition Engine Using Various Fuel Mixtures of Hydrotreated Vegetable Oil (HVO) and Fatty Acid Esters (FAE). Energies 2021, 14, 3077. [Google Scholar] [CrossRef]

- Ross-Tech: Home. Available online: https://www.ross-tech.com/index.php (accessed on 31 December 2023).

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018; ISBN 978-1-260-11610-6. [Google Scholar]

- Gruodis, A. VALLUM01. Advanced Tool for Implementation of Artificial Neural Network Containing Tabular Interface for Input/Output 2023. Available online: https://github.com/solo51/VALLUM (accessed on 31 December 2023).

- Sonawane, S. Understanding and Implementing Neural Networks in Java from Scratch. Available online: https://towardsdatascience.com/understanding-and-implementing-neural-networks-in-java-from-scratch-61421bb6352c (accessed on 31 December 2023).

- Gruodis, A. Realizations of the Artificial Neural Network for Process Modeling. Overview of Current Implementations. Appl. Bus. Issues Solut. 2023, 2, 22–27. [Google Scholar] [CrossRef]

| Parameter | Units | Value |

|---|---|---|

| Displacement, VH | dm3 | 1.896 |

| Number of cylinders, i | - | 4/OHC |

| Number of engine strokes, τ | - | 4 |

| Compression ratio | - | 19.5 |

| Power | kW | 66 (4000 rpm) |

| Torque | Nm | 180 (2000–2500 rpm) |

| Bore | mm | 79.5 |

| Stroke | mm | 95.5 |

| Fuel injection | - | Direct injection (single) |

| Nozzle type and holder assembly | - | Hole-type, two spring |

| Nozzle opening pressure | bar | 190 |

| Properties | Units | HVO100 | EN 15940 | D100 | EN 590 |

|---|---|---|---|---|---|

| Density at 15 °C | g/mL | 0.782 | 0.765–0.800 | 0.838 | 0.820–0.845 |

| Kinematic viscosity at 40 °C | cSt | 2.876 | 2.000–4.500 | 2.9401 | 2.000–4.500 |

| Cold filter plugging point | °C | –44 | ≤+5… ≤–44 * | –22 | ≤+5… ≤–44 * |

| Pour point | °C | <–50 | ≤–10 *… ≤–34 * | –39 | ≤–10 *… ≤–34 * |

| Flash point | °C | 65.0 | > 55.0 | 74.8 | >55.0 |

| Water content | % V/V | 0.0021 | ≤0.020 | 0.0028 | ≤0.020 |

| Lubricity | µm | 344 | ≤460 | 406 | ≤460 |

| Cetane number | - | 74.3 | ≥70 | ~53 | ≥51.0 |

| Elemental composition (H) | % | 15.62 | - | 13.31 | - |

| Elemental composition (C) | % | 84.38 | - | 86.69 | - |

| C/H ratio | 5.40 | - | 6.51 | - | |

| Stoichiometric air to fuel ratio () | kg air/1 kg fuel | 15.10 | - | 14.50 | - |

| Lower heating value (LHV) | MJ/kg | 43.63 | ≈44 | 42.83 | ≈43 |

| Index | Abbr. | Parameter | Units | Interval | |

|---|---|---|---|---|---|

| XMIN | XMAX | ||||

| 0 | P10 | - | 1.0 | 10.0 | |

| 1 | P03 | MPa | 0.0 | 1.2 | |

| 2 | P02 | EGR ratio | - | 0.0 | 0.5 |

| 3 | P11 | Start of injection (SOI) | CA bTDC | −3.0 | 18.0 |

| 4 | P09 | Cetane number | - | 5.0 | 85.0 |

| 5 | P01 | Engine speed (n) | rpm | 800.0 | 4000.0 |

| 6 | P04 | Volume fraction of HVO100 | % | 0.0 | 100.0 |

| 7 | P05 | Volume fraction of D100 | % | 0.0 | 100.0 |

| 8 | P12 | C/H ratio | - | 5.0 | 7.0 |

| 9 | P06 | ) | 1 kg of air/1 kg of fuel | 10.0 | 20.0 |

| 10 | P08 | Lower heating value (LHV) | MJ·kg−1 | 18.0 | 60.0 |

| 11 | P07 | Density | kg·m−3 | 600.0 | 900.0 |

| Index | Abbr. | Parameter | Units | Interval | |

|---|---|---|---|---|---|

| YMIN | YMAX | ||||

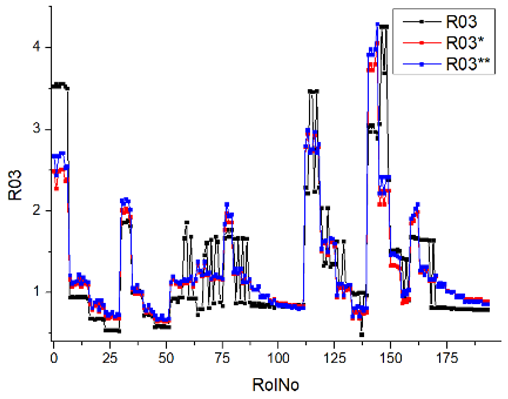

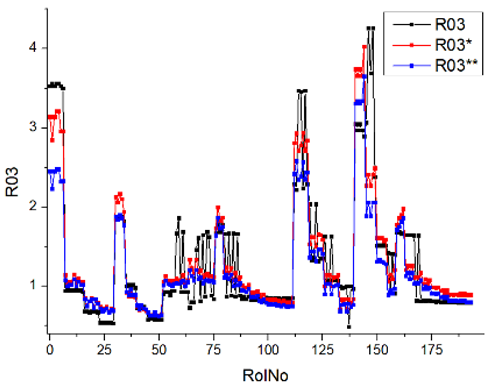

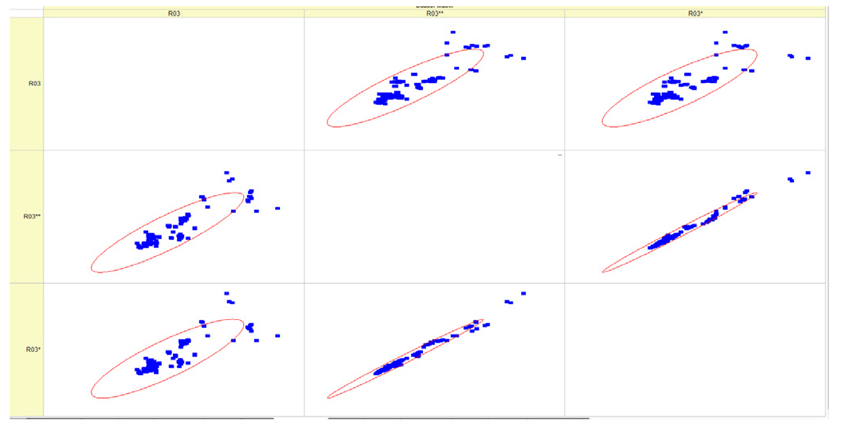

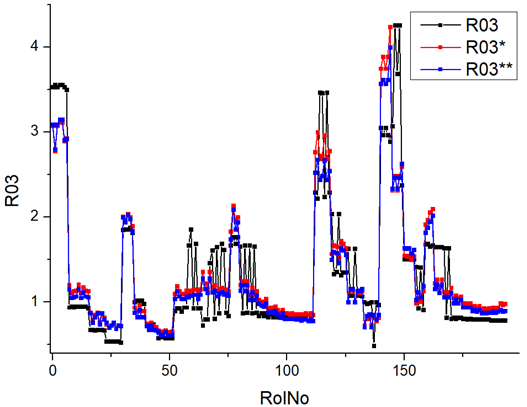

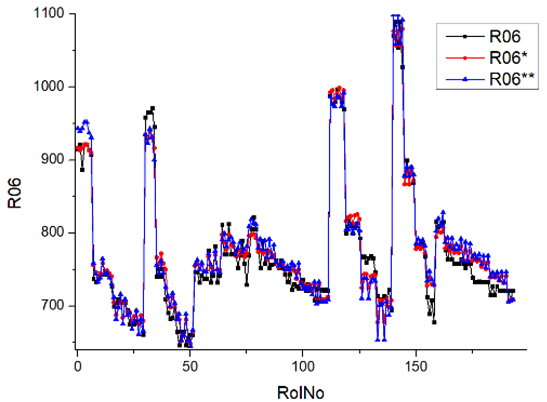

| 0 | R03 | SCO | g·kWh−1 | 0.5 | 10.0 |

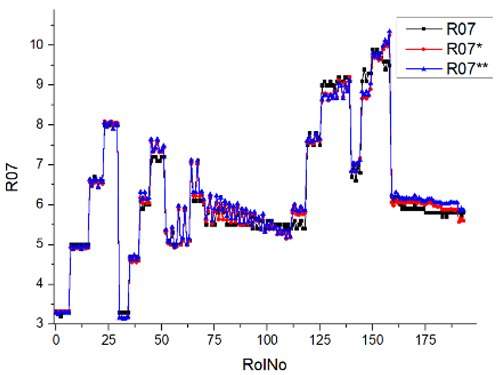

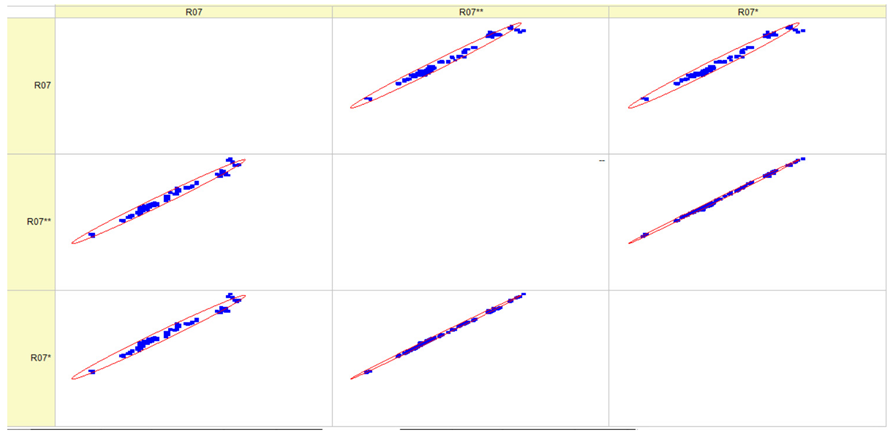

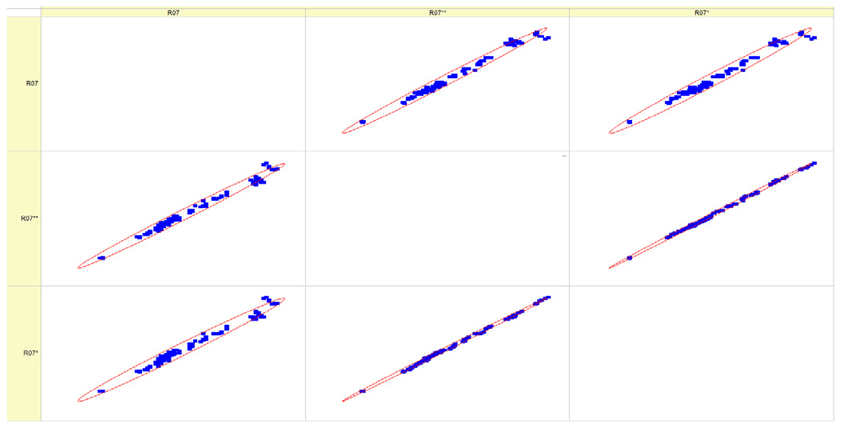

| 1 | R07 | Volumetric CO2 concentration | % | 0.1 | 15.0 |

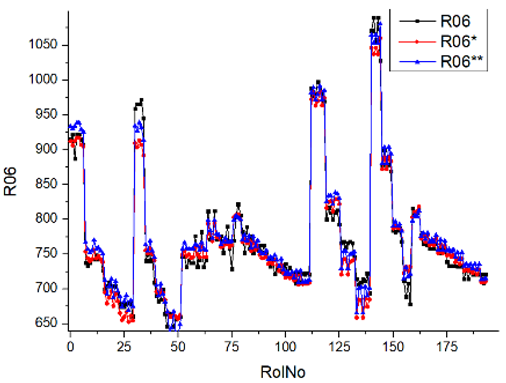

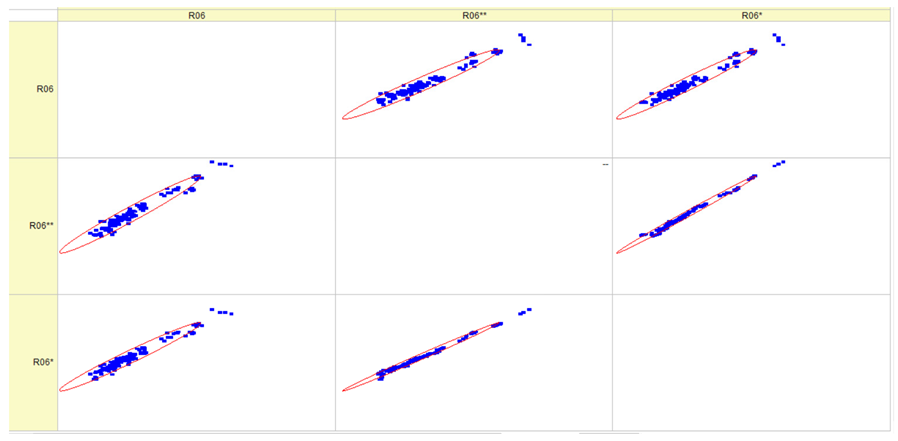

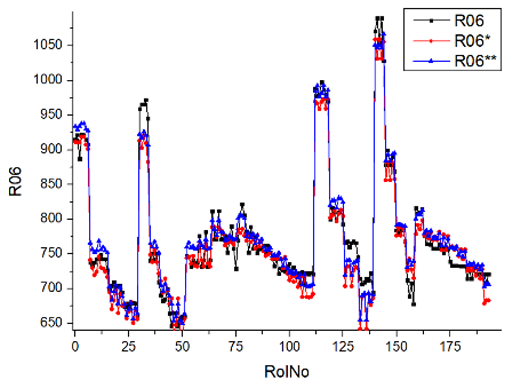

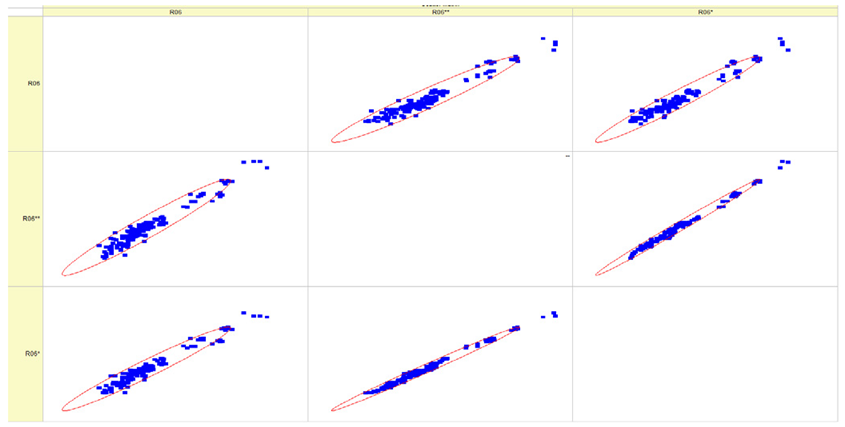

| 2 | R06 | SCO2 | g·kWh−1 | 100.0 | 2000.0 |

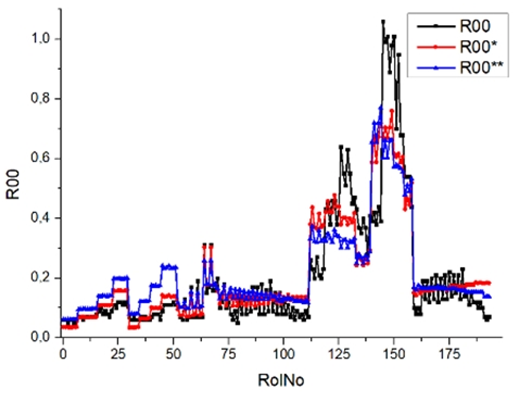

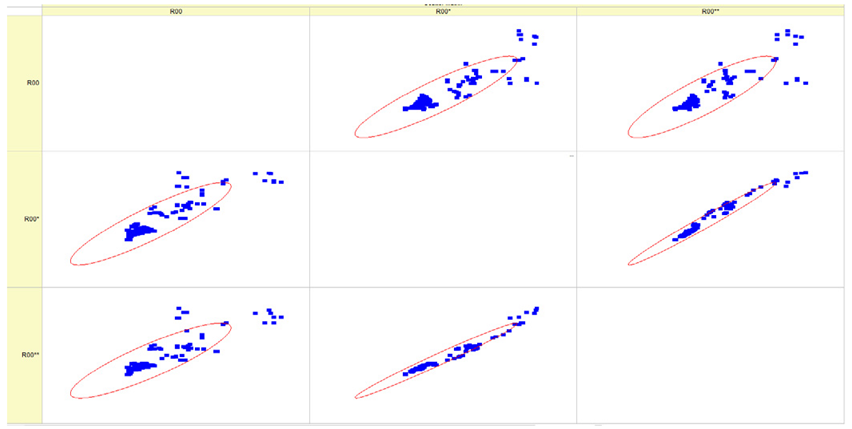

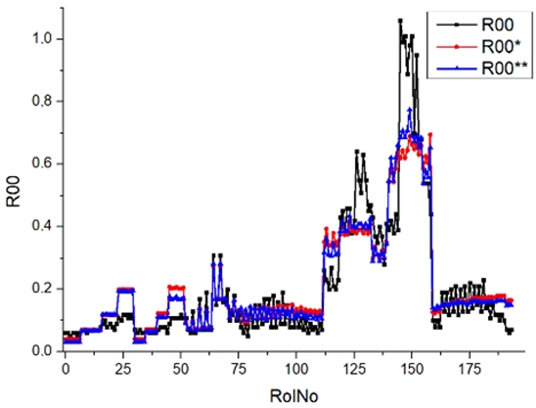

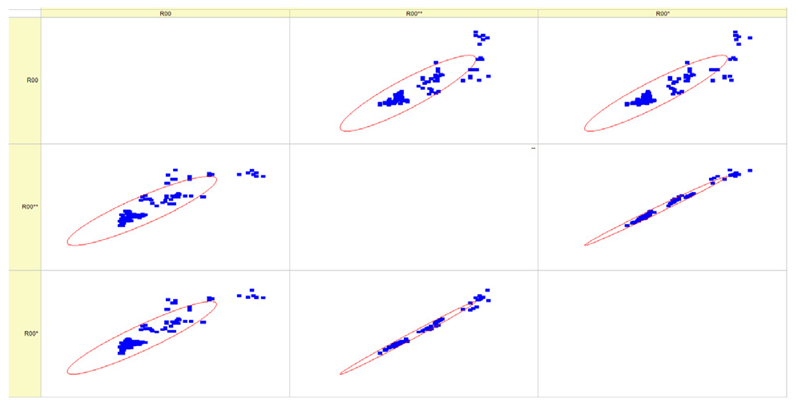

| 3 | R00 | Smokiness | m−1 | 0.001 | 100.0 |

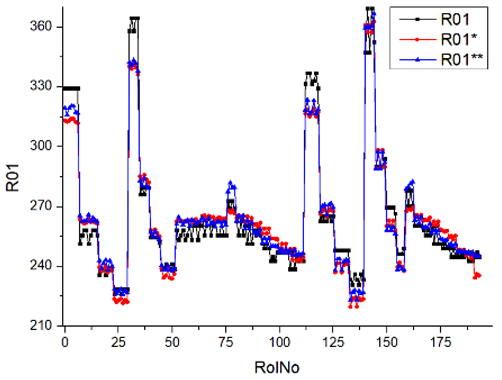

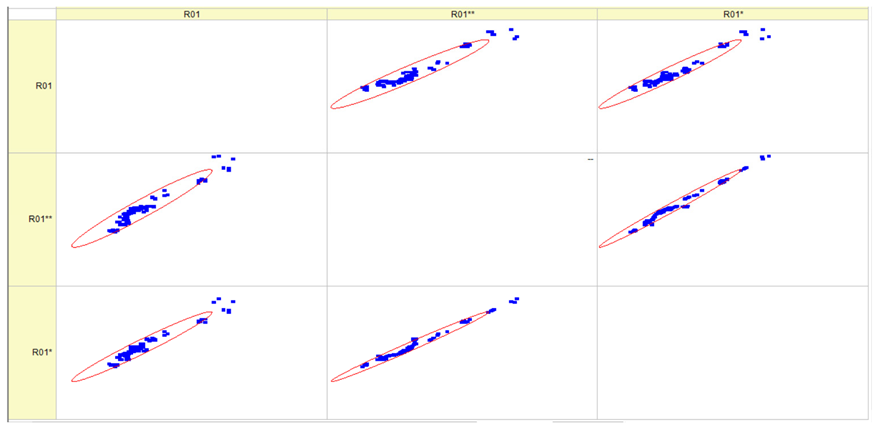

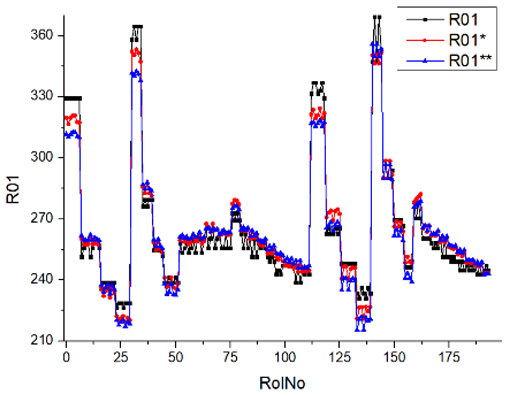

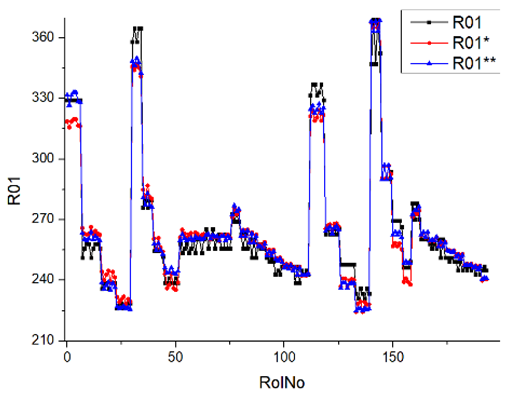

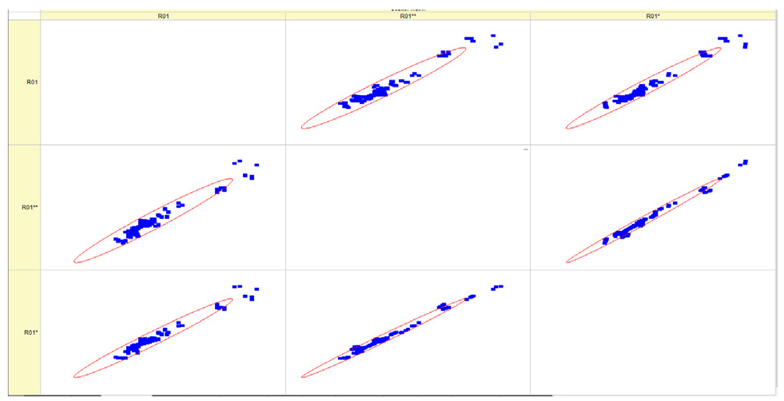

| 4 | R01 | Brake specific fuel consumption (BSFC) | g·kWh−1 | 150.0 | 3000.0 |

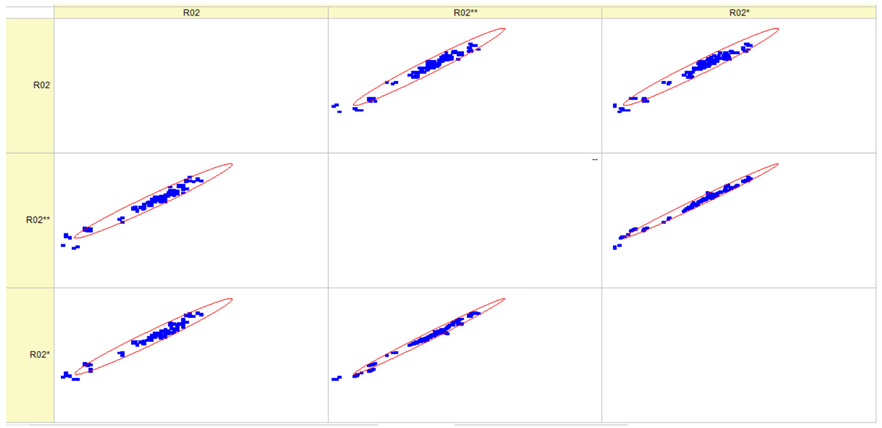

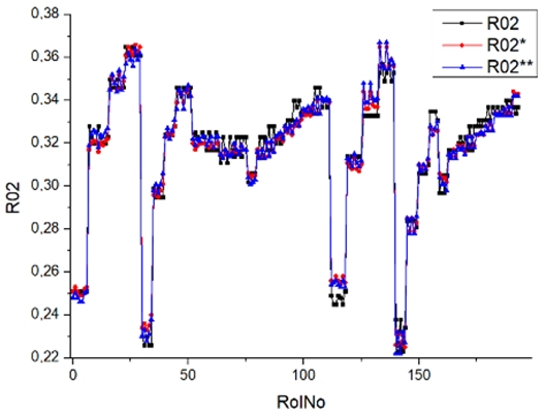

| 5 | R02 | Brake thermal efficiency (BTE) | - | 0.01 | 0.5 |

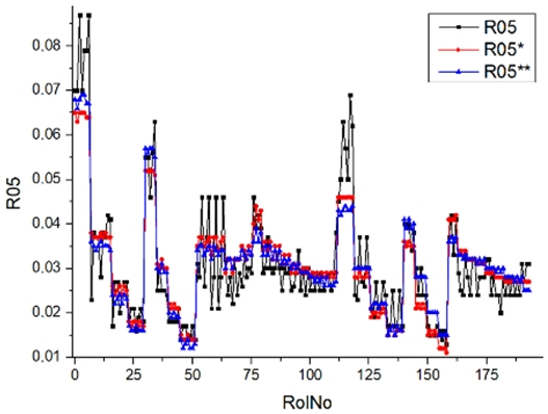

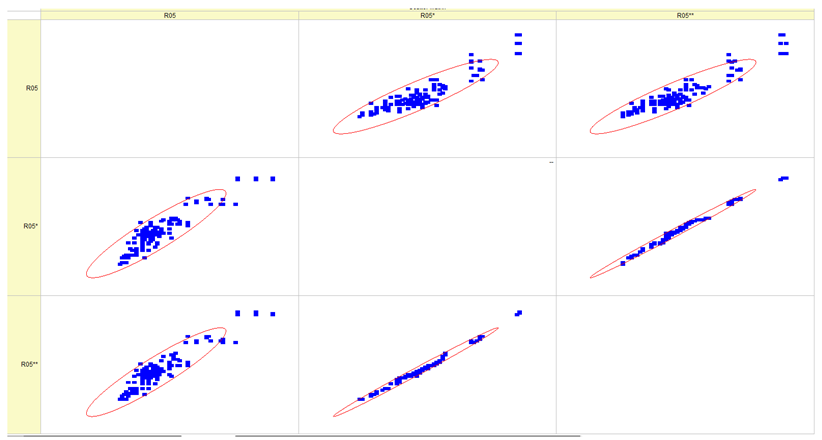

| 6 | R05 | SHC | g·kWh−1 | 0.01 | 2.0 |

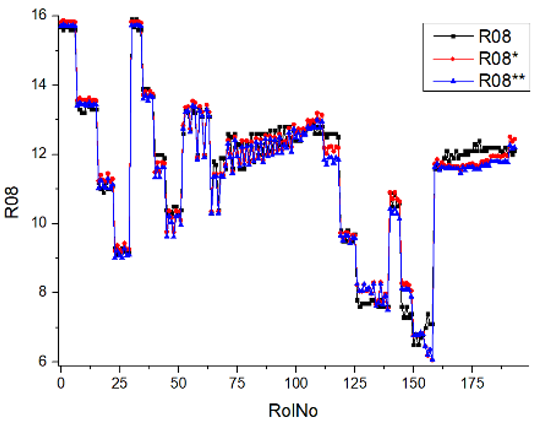

| 7 | R08 | Volumetric O2 concentration | % | 0.5 | 20.0 |

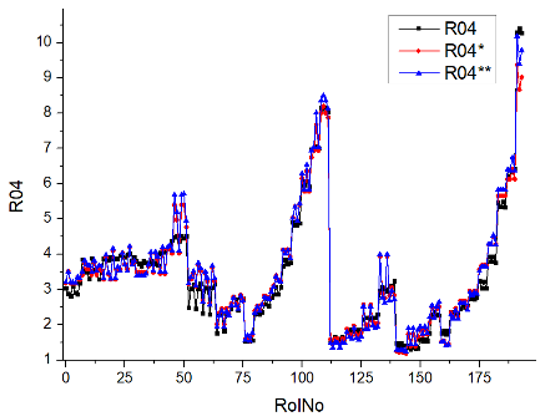

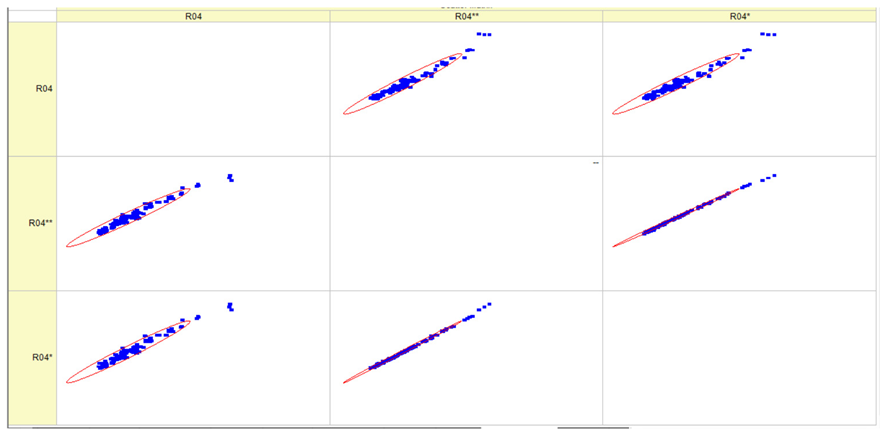

| 8 | R04 | SNOx | g·kWh−1 | 0.1 | 20.0 |

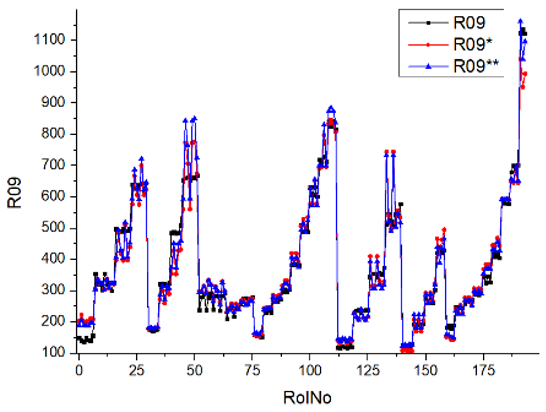

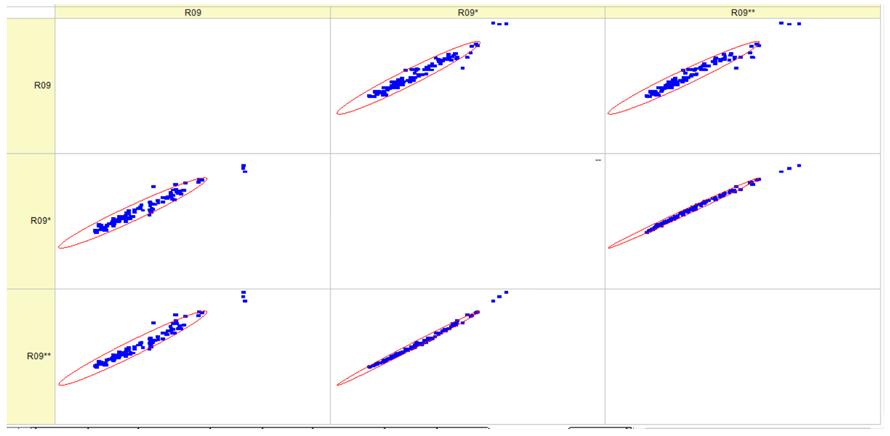

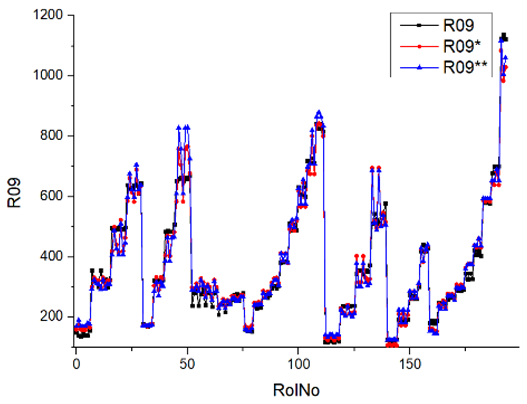

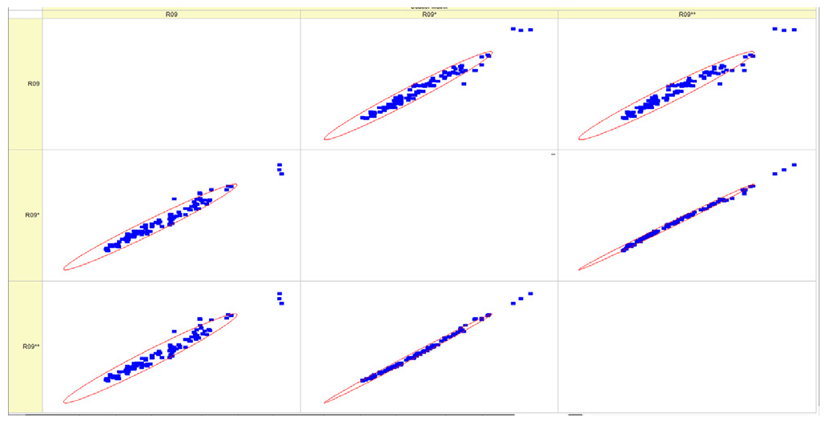

| 9 | R09 | Volumetric NOx concentration | ppm | 10.0 | 10,000.0 |

| Hidden Layer | |||

|---|---|---|---|

| Epochs | Events | M = 500 | M = 1000 |

| 500,000 | 194 |  |  |

| 500,000 | 38 |  |  |

| 1,000,000 | 194 | x |  |

| 1,000,000 | 38 | x |  |

| Abbr | Parameter | Distributions of Predicted Value | Pearson |

|---|---|---|---|

| R03 | SCO, g·kWh−1 |  |  |

| R07 | Volumetric CO2 concentration, % |  |  |

| R06 | SCO2, g·kWh−1 |  |  |

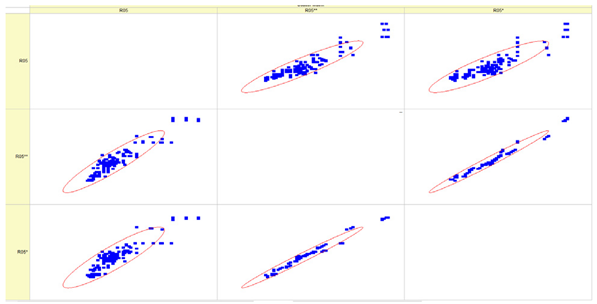

| R00 | Smokiness, m−1 |  |  |

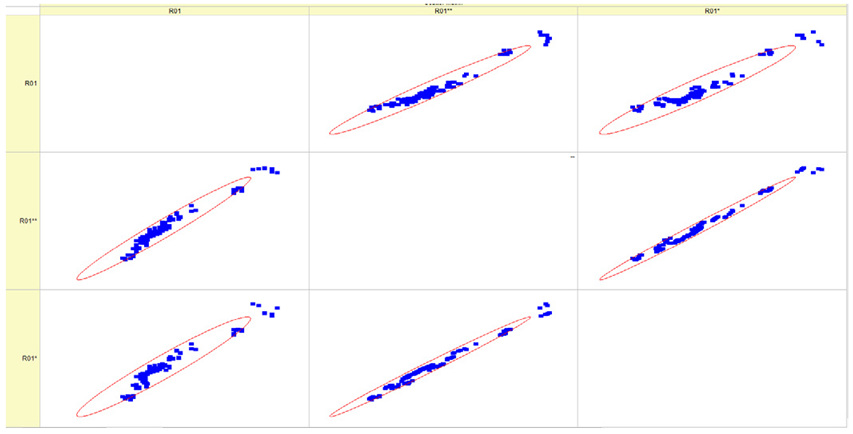

| R01 | Brake specific fuel consumption (BSFC), g·kWh−1 |  |  |

| Abbr | Parameter | Distribution of Predicted Value | Pearson |

|---|---|---|---|

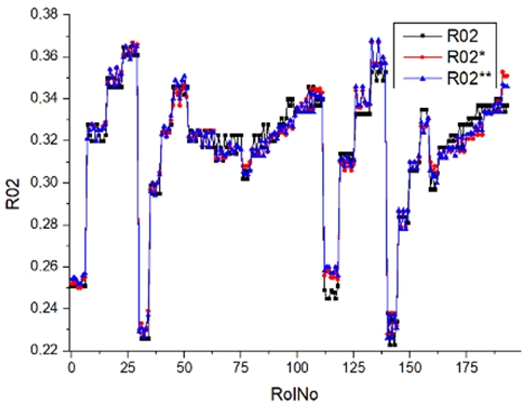

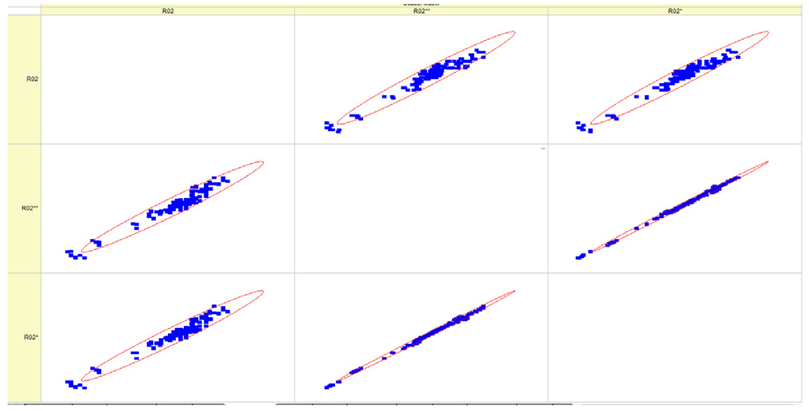

| R02 | Brake thermal efficiency (BTE) |  |  |

| R05 | SHC, g·kWh−1 |  |  |

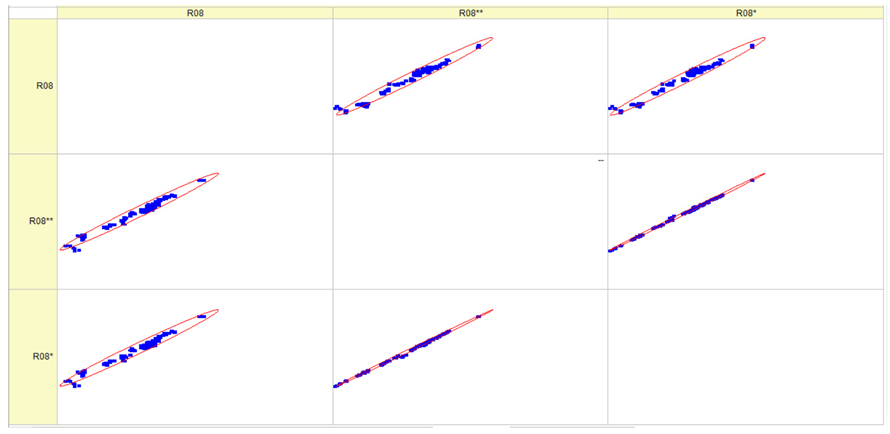

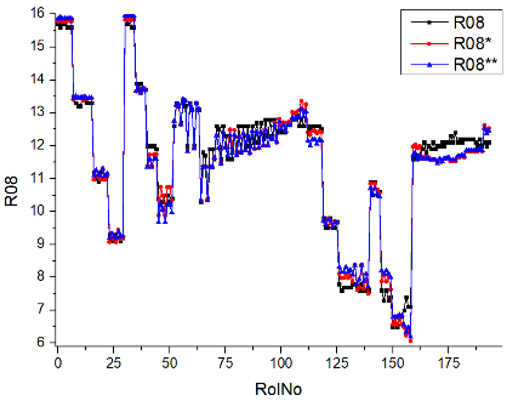

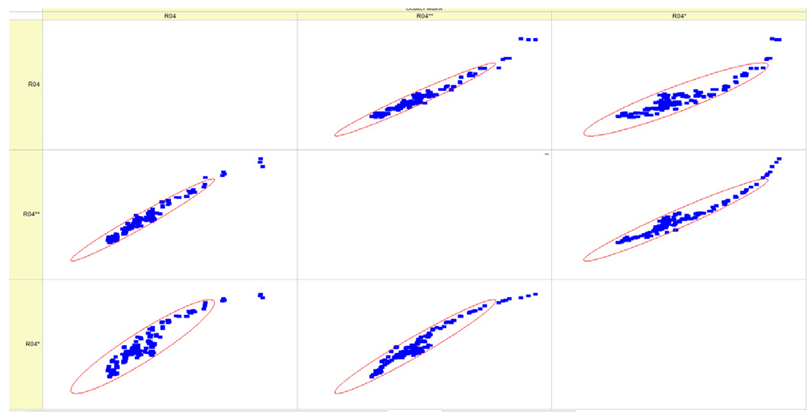

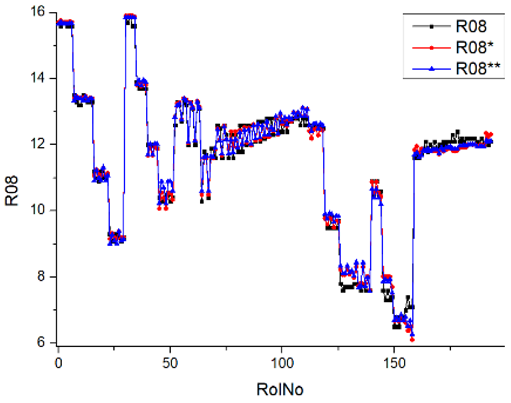

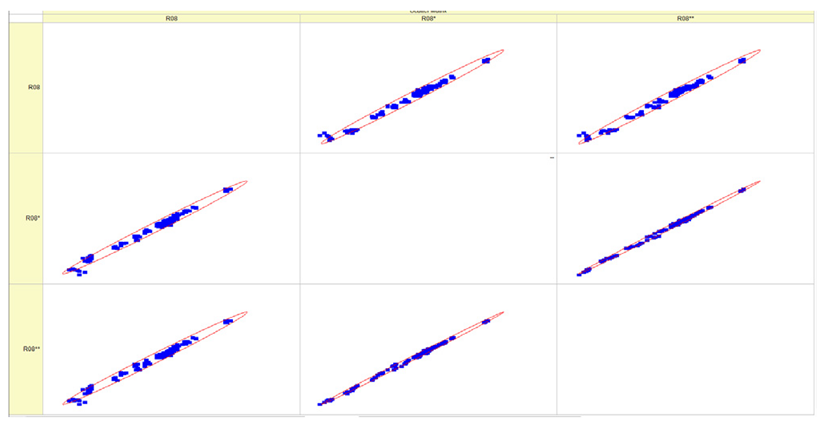

| R08 | Volumetric O2 concentration, % |  |  |

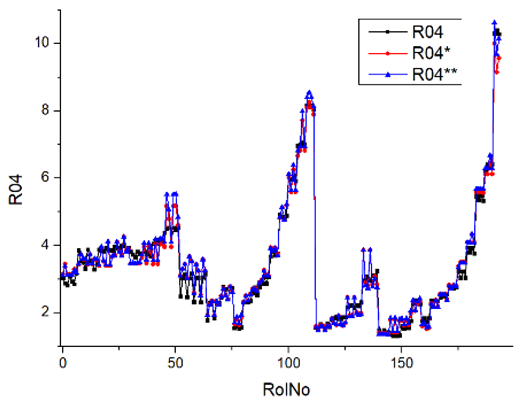

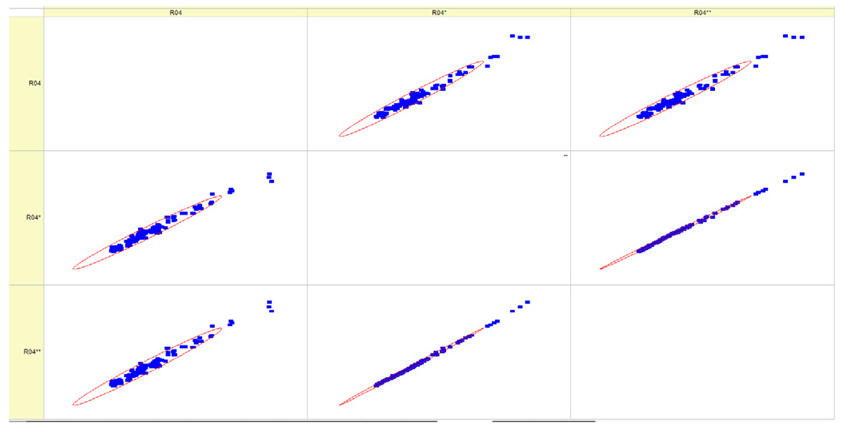

| R04 | SNOx, g·kWh−1 |  |  |

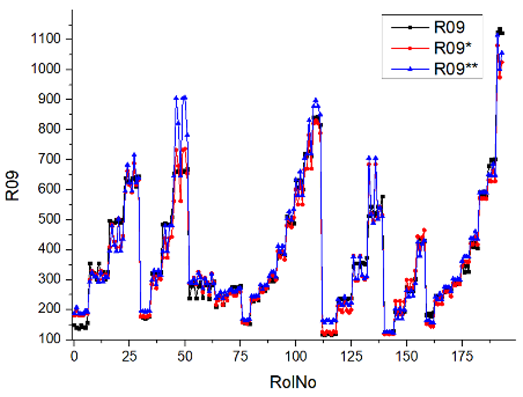

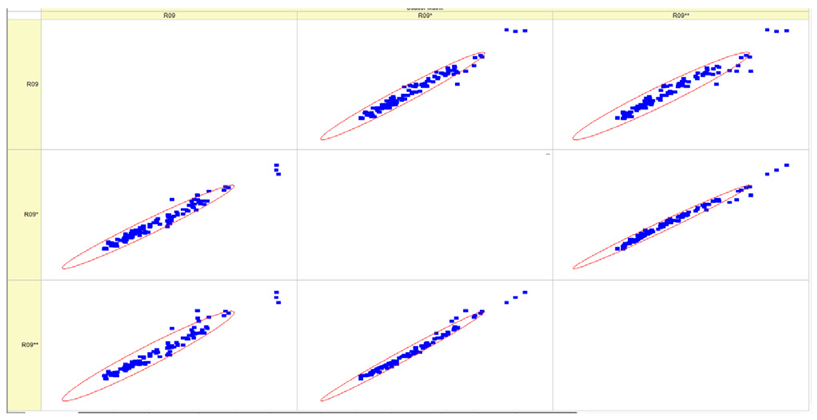

| R09 | Volumetric NOx concentration, ppm |  |  |

| Abbr | Parameter | Distributions of Predicted Value | Pearson |

|---|---|---|---|

| R03 | SCO, g·kWh−1 |  |  |

| R07 | Volumetric CO2 concentration, % |  |  |

| R06 | SCO2, g·kWh−1 |  |  |

| R00 | Smokiness, m−1 |  |  |

| R01 | Brake specific fuel consumption (BSFC), g·kWh−1 |  |  |

| Abbr | Parameter | Distribution of Predicted Value | Pearson |

|---|---|---|---|

| R02 | Brake thermal efficiency (BTE) |  |  |

| R05 | SHC, g·kWh−1 |  |  |

| R08 | Volumetric O2 concentration, % |  |  |

| R04 | SNOx, g·kWh−1 |  |  |

| R09 | Volumetric NOx concentration, ppm |  |  |

| Abbr | Parameter | Distributions of Predicted Value | Pearson |

|---|---|---|---|

| R03 | SCO, g·kWh−1 |  |  |

| R07 | Volumetric CO2 concentration, % |  |  |

| R06 | SCO2, g·kWh−1 |  |  |

| R00 | Smokiness, m−1 |  |  |

| R01 | Brake specific fuel consumption (BSFC), g·kWh−1 |  |  |

| Abbr | Parameter | Distribution of Predicted Value | Pearson |

|---|---|---|---|

| R02 | Brake thermal efficiency (BTE) |  |  |

| R05 | SHC, g·kWh−1 |  |  |

| R08 | Volumetric O2 concentration, % |  |  |

| R04 | SNOx, g·kWh−1 |  |  |

| R09 | Volumetric NOx concentration, ppm |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matijošius, J.; Rimkus, A.; Gruodis, A. Validation Challenges in Data for Different Diesel Engine Performance Regimes Utilising HVO Fuel: A Study on the Application of Artificial Neural Networks for Emissions Prediction. Machines 2024, 12, 279. https://doi.org/10.3390/machines12040279

Matijošius J, Rimkus A, Gruodis A. Validation Challenges in Data for Different Diesel Engine Performance Regimes Utilising HVO Fuel: A Study on the Application of Artificial Neural Networks for Emissions Prediction. Machines. 2024; 12(4):279. https://doi.org/10.3390/machines12040279

Chicago/Turabian StyleMatijošius, Jonas, Alfredas Rimkus, and Alytis Gruodis. 2024. "Validation Challenges in Data for Different Diesel Engine Performance Regimes Utilising HVO Fuel: A Study on the Application of Artificial Neural Networks for Emissions Prediction" Machines 12, no. 4: 279. https://doi.org/10.3390/machines12040279

APA StyleMatijošius, J., Rimkus, A., & Gruodis, A. (2024). Validation Challenges in Data for Different Diesel Engine Performance Regimes Utilising HVO Fuel: A Study on the Application of Artificial Neural Networks for Emissions Prediction. Machines, 12(4), 279. https://doi.org/10.3390/machines12040279