1. Introduction

The early 21st century witnessed an ever growing-interest in collaborative robotics. Industries have made substantial investments in the research and innovation of these machines, resulting in a swift enhancement of their capacities related to manipulation, interaction, and learning. Concurrently, there has been a relevant rise in the volume of scientific literature dedicated to this domain, underscoring the significant interest in the field. This expansion in research output has coincided with market forecasts anticipating a worldwide sales projection of almost

$8 bn by 2027 [

1].

The concept of collaborative robotics is widely recognized for its focus on creating human-centered automation processes. This approach allows humans to safely interact within the robot’s workspace, aiming to enhance workplace safety by minimizing physical labor and leveraging human cognitive skills instead [

2]. Collaborative robots (cobots) are designed with user-friendliness in mind, featuring intuitive programming interfaces that significantly lower the learning curve for users. Their simple graphical user interfaces and methods like guided or example-based programming enable even those without coding experience to easily configure and customize operations. As a result, not only is the working condition improved, but employee satisfaction is also positively impacted. Moreover, this innovative approach leads to increased productivity in industrial tasks including, but not limited to, assembly operations and material handling, which are operations common across a wide spectrum of industrial environments [

3,

4].

Over time, advancements in technology have allowed robot manufacturers to develop increasingly dependable collaborative robots with advanced safety features and improved workspace-sharing capabilities, achieving higher performance levels [

5,

6,

7]. This increased functionality and versatility have been achieved by integrating features such as safety-monitored stops, hand guidance, speed and separation monitoring, and power and force limitations by design or control [

8]. These features collectively ensure that this type of robot can operate safely alongside human workers, enhancing efficiency and flexibility without compromising safety. By adhering to these standards, cobots are designed to be inherently safe for direct interaction, eliminating the need for physical barriers and allowing for a more integrated approach to automation. Nevertheless, in the industrial scenario, human labor remains the preferred choice particularly for small-to-medium-scale batch production [

9].

Frequently, companies opt for collaborative over industrial robots primarily due to the absence of barriers, rather than fully harnessing the benefits that collaborative robotics can provide [

10]. Cobots exhibit a significantly reduced mass relative to their larger industrial counterparts, thereby providing enhanced mobility. This attribute facilitates their relocation within the manufacturing or industrial settings in which they are deployed. These machines demonstrate considerable adaptability and versatility, enabling a single unit to undertake diverse functions. Consequently, they are applicable across a broad spectrum of industrial sectors.

Enterprises encounter difficulties in pinpointing scenarios where collaborative robots can exhibit superior efficiency compared to traditional industrial robots. This challenge primarily arises from the limitations of current methodologies and tools employed in the development and design of collaborative applications, which do not guarantee the achievement of optimal outcomes [

11]. This occurrence is a result of the need to navigate significant uncertainties throughout the process, compounded by the stringent safety standards mandated by ISO 10218-1,2 [

12,

13] and ISO-TS 15066 [

14] regulations [

15]. This regulation presents a substantial hurdle for system integrator and developers tasked with designing collaborative robotic applications. However, emerging methodologies are becoming available to assist small and medium-sized enterprises in determining which collaborative solutions excel compared to traditional ones [

11,

16]. Observations indicate that simulation studies not only streamline the decision-making process but also aid in visualizing future work cell layouts and productivity outcomes. The incorporation of simulation software during the pre-implementation stage of a work cell is a highly valuable asset for enterprises. This approach facilitates the evaluation of the impact of speed and accuracy on achieving a process that is both precise and expedited. It also enables the determination and simulation of precise trajectories, thus allowing for the avoidance of fixed obstacles within the work environment [

17,

18]. Furthermore, this methodology empowers one to identify and proactively address potential issues that may arise post-installation. Consequently, it significantly reduces operational disruptions within the production cell due to unforeseen circumstances, thereby facilitating the optimization of resource allocation, which includes both human and capital resources [

19]. Moreover, organizations can continue to leverage computer simulations to explore and assess various enhancement possibilities for their cobot-driven work cells even after the initial implementation of cobots [

20].

This project was the result of a collaboration between the Polytechnic University of Marche and Techpol, a company specialized in the design and molding of plastics in the automotive sector. This study’s aim was to illustrate how the integration of collaborative robotics into small and medium-sized enterprises can efficiently address numerous business challenges, providing economic and technological benefits [

21,

22,

23]. The primary objective of this project is to illustrate how deploying a single cobot at a plastic welding station can lead to a financial benefit, but one that is of greater significance to the redirection of human labor. By doing so, human efforts can be redirected toward value-adding activities for the company, rather than expending valuable cognitive skills and flexibility on monotonous and burdensome tasks [

24,

25]. Company resources can thus be reallocated to explore new fields in which opportunities can be found.

2. Materials and Methods

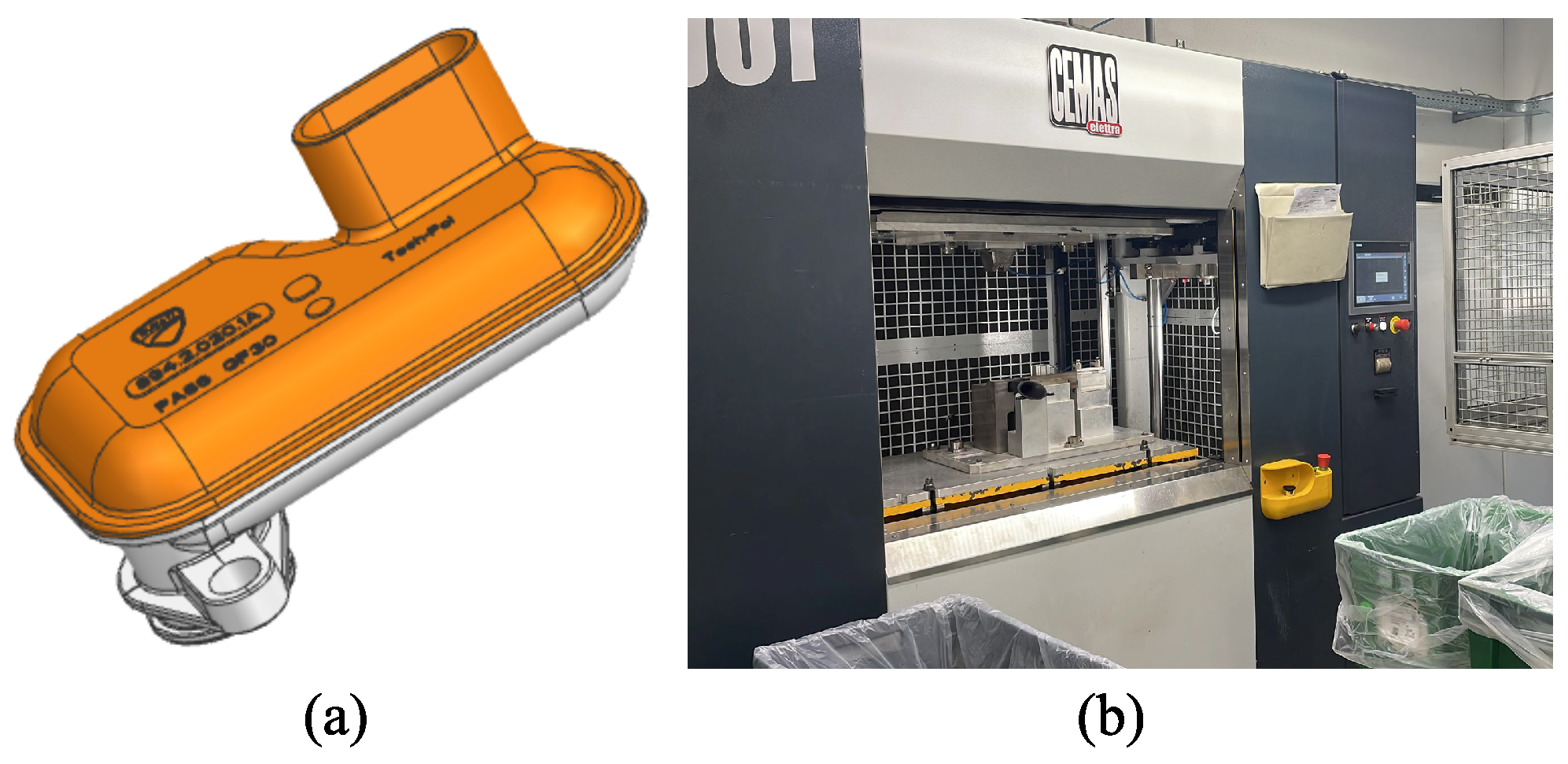

The core focus of this article centers around exploring the use of a collaborative robot (UR5e by Universal Robots, Odense, Denmark) as subservience to a vibrating welding station for automotive plastic articles. The primary objective is to automate the ’pick and place’ process of parts inside the machine to achieve the final assembled article.

Figure 1 depicts the components intended for assembly and how they are assembled, alongside the utilized machine. The assembly process involves two parts, with the lower part positioned in the lower section of the welding machine, and the upper part similarly placed, which, however, results in a non-ergonomic action. Subsequently, upon machine activation, the doors are closed to ensure operator safety, and the welding procedure commences. However, during this phase, the operator experiences idle time while waiting for the welding operation to conclude before retrieving the assembled parts and proceeding with subsequent tasks within the work cycle. The fundamental concept underpinning this project involves the creation of a parts buffer that enables the robot to operate independently until its stock is depleted. By doing so, human efforts can be redirected to value-adding activities for the company, rather than expending valuable cognitive skills and flexibility on monotonous and burdensome tasks.

The primary objective is to relieve the operator from the sole responsibility of completing the entire batch, enabling them to concentrate on assignments demanding cognitive abilities. This marks a crucial step in addressing the corporate challenge of reducing the workload on operators, freeing them from monotonous, demoralizing, and strenuous tasks. This approach not only optimizes corporate resources but also promotes a business perspective that emphasizes the human element in production, exemplifying the core principles of Industry 5.0.

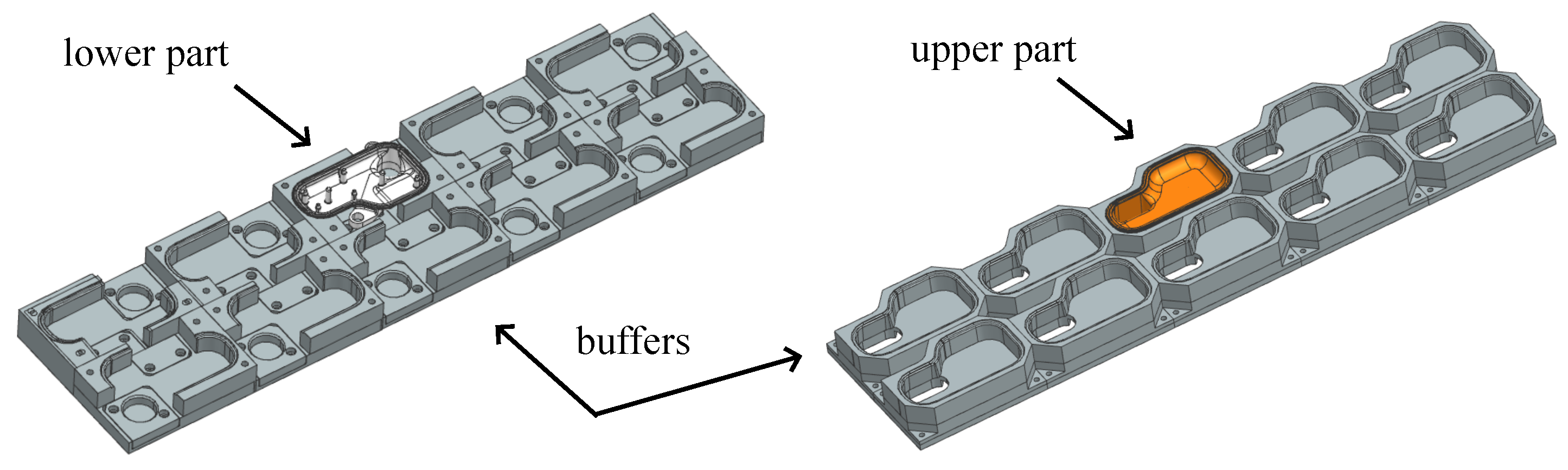

Buffers

As previously outlined, the objective was to streamline the automation process. To achieve this, a strategy was devised involving the implementation of a buffer system, as visible in

Figure 2, which the robot could utilize until it exhausted its supplies.

Negative molds for both the lower and upper parts were initially designed using NX software (version 2312.3 by Siemens, Munich, Germany) and subsequently produced for laboratory testing via additive manufacturing. The 3D printing process was chosen for mold making because it is a fast, effective, and inexpensive solution, fitting perfectly with production requirements. The decision was further facilitated by the availability of this technology directly in-house, allowing for optimal management of production time and costs, as well as offering the flexibility needed for the development of prototypes and customized products.

The negative molds were employed for laboratory feasibility testing and to craft two distinct buffers: one designated for the upper parts and another for the lower parts. These buffers were specifically developed for simulation purposes within the Process Simulate Software (version 2301 by Siemens, Munich, Germany). During this phase, it was determined that each set of buffers should include no less than 10 pairs of parts destined for assembly. The choice of this specific number is subjective, as larger buffers grant the robot greater autonomy, thereby reducing the frequency at which the operator must intervene to reload supplies.

3. Test Rig Description

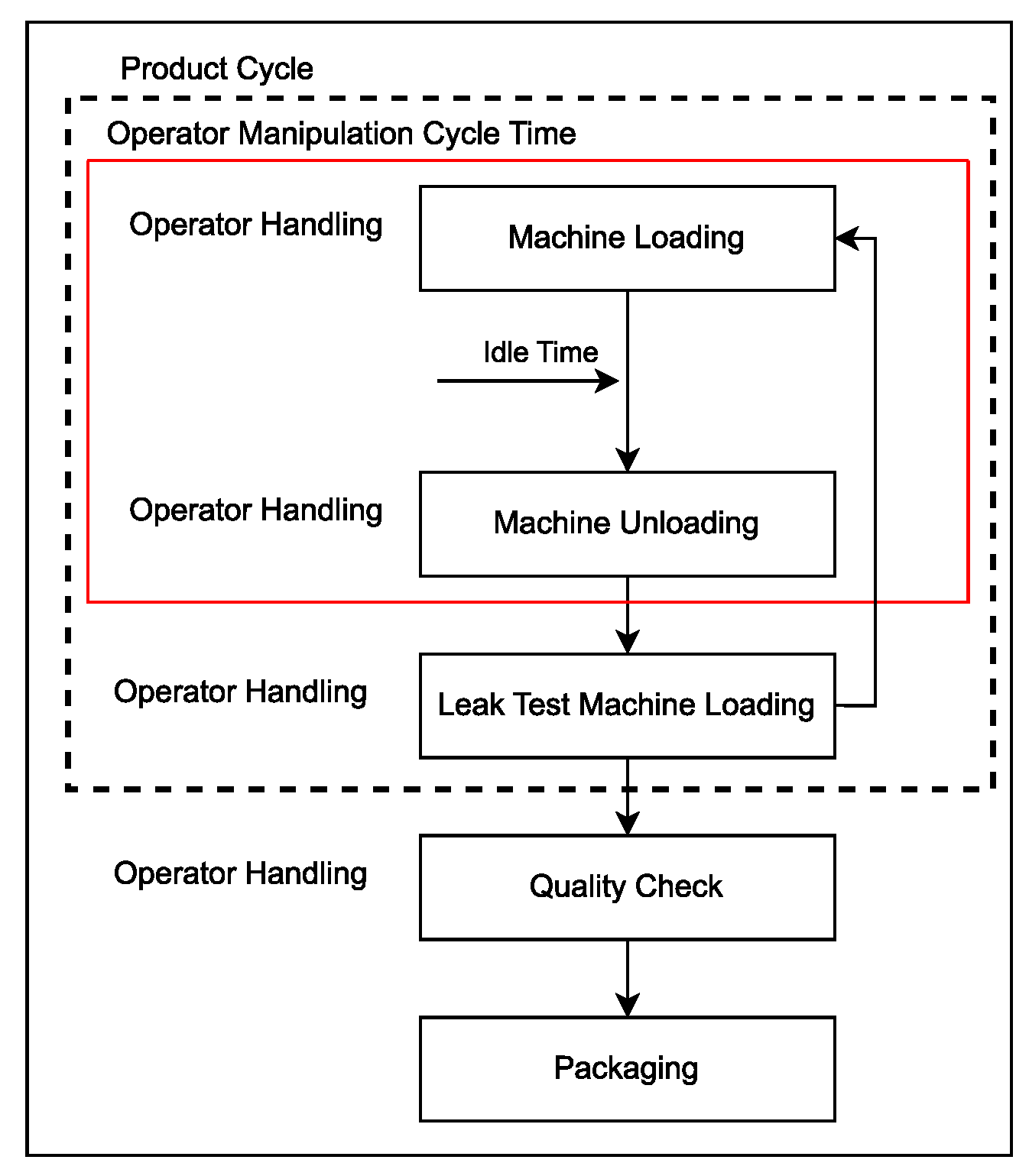

As previously stated, the primary objective of this study was the deployment of a collaborative robot to autonomously perform a task traditionally carried out by a human operator. Throughout the entire production cycle, as depicted in

Figure 3, focus was exclusively on the phase highlighted in red. This phase represents the moment when the human operator directly interacts with the product, while all other phases are automated. During the testing phases, we solely simulated this specific portion of the operation. Notably, the simulation of pieces handling within the leak test area was omitted, as it involves a predefined ’pick and place’ action with set start and end points over time, due to the workstation’s inherent nature.

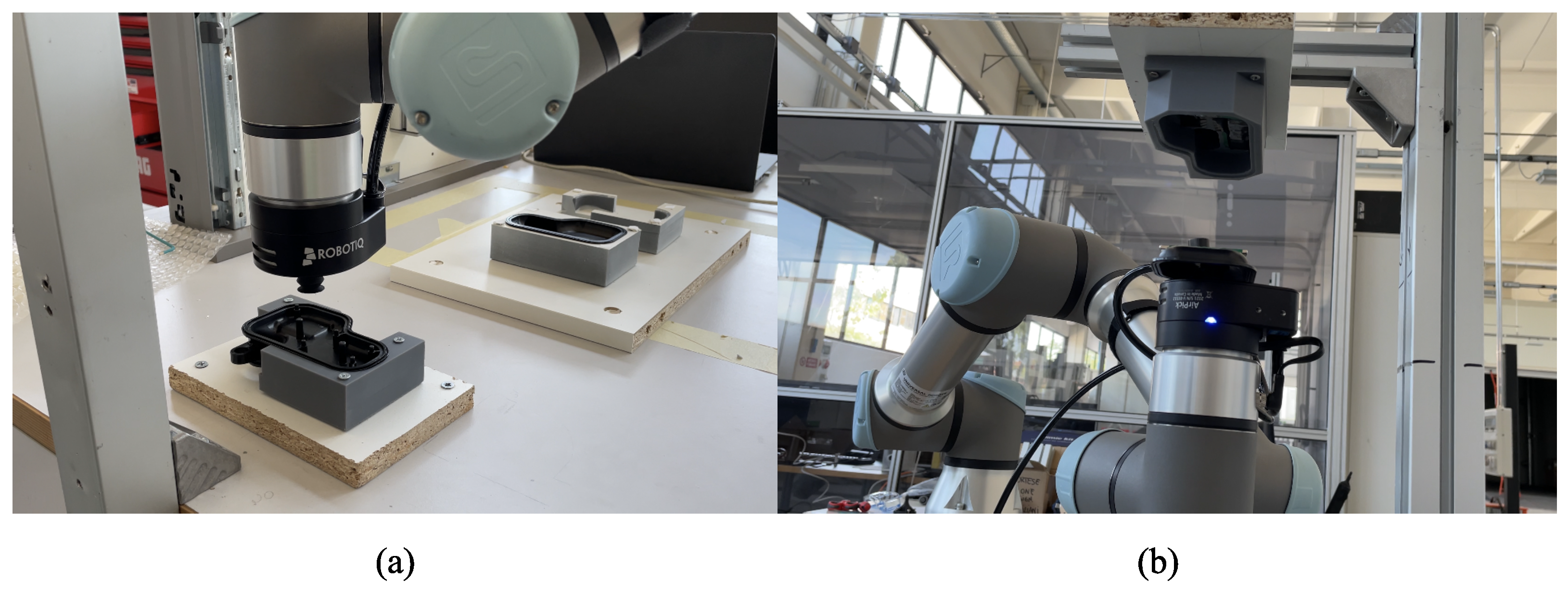

This study investigated the optimization of a single machine responsible for assembling a wide range of diverse products. To enhance the efficiency of this case study, a comprehensive analysis was conducted. This analysis encompassed an examination of all potential product variants assembled by the company’s welding machine throughout the calendar year. Robotiq’s Vacuum Gripper (version AirPick by Robotiq, Lévis, QC, Canada) emerged as the ideal choice as the end effector. This gripper exhibited remarkable flexibility, enabling seamless adaptation to various surfaces, including those with raised details. To ensure the laboratory tests closely mimicked real-world conditions and to evaluate the project’s feasibility, a structure was built to precisely replicate the distance between the upper and lower molds of the assembly machine, as visually demonstrated in the accompanying

Figure 4. To mimic the vacuum effect used by the machine to secure the upper part in place, two neodymium magnets were used: one integrated into the upper mold and the other attached to the outer surface of the component to be assembled. This magnetic arrangement has ensured a firm hold of the component in the post-insertion phase. This system effectively reproduced the vacuum system of the assembling machine, mirroring the usual operating conditions.

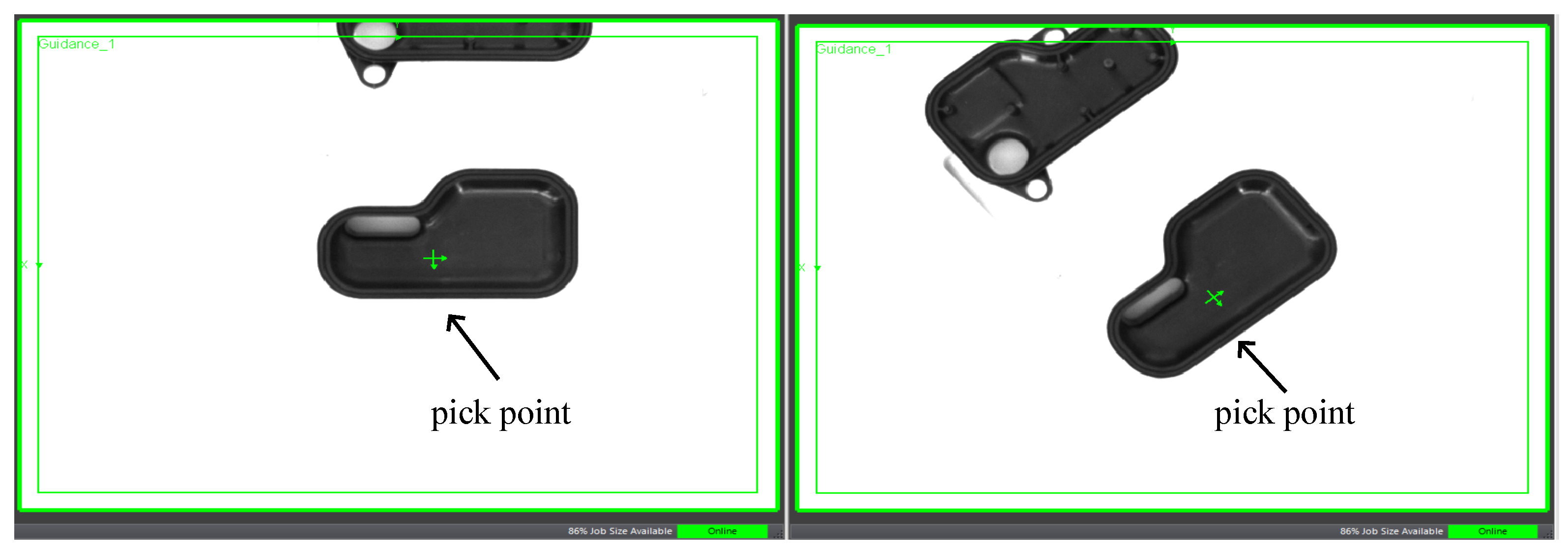

The machine, as described earlier, is responsible for assembling a diverse array of distinct products. To carry out tests, a product was randomly selected as a sample from the company’s provided list. This approach illustrates that this study does not focus on a particular product but encompasses the entire spectrum of products assembled by the machine. In the initial phase of testing, focus was directed towards machine loading operations where the pick and place points remained consistent and unaltered over time. Subsequently, in the second series of experiments, the scenario where the machine operator could potentially introduce inadvertent or deliberate alterations to the placement of buffers within the working area during the loading phase was explored. The robot was equipped with a COGNEX camera. Leveraging the capabilities of the In-Sight Explorer software (version 23.3 by Cognex, Natick, MA, USA) and proper calibration, the camera facilitated the definition of pick points for the parts. Upon activating the camera, it captured and processed images of components on the work surface. Parts were detected by search algorithms which detect edges by examining a region of interest for discontinuities in pixel polarity. Illumination in the work environment plays a key role in computer vision applications, as proper lighting ensures maximum reliability in image identification and analysis. Uniformity and adequate light intensity are essential to minimize shadows and reflections, thus improving the accuracy of object recognition and object features. Then, pickup points were defined, enabling the precise determination of where the robot should engage the components.

Subsequently, the camera supplied the robot with the necessary coordinates to reach these points with the appropriate gripping hand configuration. The camera’s advantage became apparent when changes in the buffer’s orientation or position in the workspace were detected, as visible in

Figure 5.

4. Simulation

As previously emphasized, simulations constitute a potent and indispensable tool within the realm of design to facilitate the proactive identification and mitigation of potential issues, whether they arise during the installation or production phase. The use of software proves crucial in the automation of work cells characterized by the presence of fixed, non-removable obstacles. This tool allows motion trajectories to be designed from scratch, ensuring the effective avoidance of any impediment. Subsequently, the trajectories thus defined can be further optimized, improving the operational efficiency and safety of the robotizing process.

Siemens’ Process Simulate software empowers users to generate a virtual representation of the intended work cell and execute comprehensive simulations of its operational dynamics. CAD models of the various components are imported and distributed in the work environment to create the simulation. The work cell created within the software faithfully mirrors real-world dimensions. Every component is accurately portrayed at a 1:1 scale. The precision in terms of dimensions assures the dependability of the outcomes, furnishing tangible data suitable for results analysis. In the initial stage of the simulation, efforts were focused on replicating the laboratory’s feasibility study to establish a tangible model of the robotic work cell. Upon establishing and implementing the specific trajectories for the ’pick and place’ tasks of machine loading, the primary goal was to examine and identify cycle times in correlation with the robot’s speed setting. Loading commenced with the lower part, followed by the upper part. After the welding process within the machine concluded, the robot received instructions to retrieve the fully assembled component, as depicted in

Figure 6.

In the subsequent experiment, the focus shifted towards enhancing the efficiency of the production cell’s workflow. The initial step involved the modification of the gripper’s CAD model by integrating a dual suction cup, as depicted in the accompanying figure. This modification enabled the simultaneous pickup and placement of both essential components in the machine during a single operation, thereby achieving a significant reduction in cycle time. Consequently, as visible in

Figure 7, the need for repetitive processes for each of the two parts, as observed in the initial test, was eliminated. Furthermore, an extension was made to the length of one of the gripper suction cup supports to prevent potential collisions between the robot and the machinery. Indeed, during the simulation phase, the use of the collision detection tool revealed a potential risk of contact between the robot and the machine. Through the adoption of the configuration illustrated in the figure, this collision risk was successfully mitigated. Subsequent efforts were concentrated on fine-tuning the robot’s motion trajectories and determining the optimal speed to guarantee efficient execution during the complete operational cycle.

5. Experimental Results

The cycle time of the assembly performed by the human operator was accurately recorded. Subsequently, the operating speed of the robotic work cell was adjusted to ensure a cycle time match, with the joint speed set at 45 degrees per second and the tool’s linear speed at 70 mm per second. This strategy was employed to illustrate the substantial advantages of implementing collaborative robotics, even with unchanged cycle times. The evaluation of performance across different operators was not included in this study, as the primary objective was to examine the effectiveness of substituting human labor with robotic solutions for tasks characterized by monotony and repetitiveness. Therefore, attention was not given to the variations in cycle times that might result from performance differences between the robot and human operators; the analysis was instead oriented towards evaluating the performance of the implemented automation as an alternative to human intervention. In this context, a comparative analysis of performance among various human operators was deemed irrelevant.

Subsequently, the collected data were analyzed and categorized into two distinct groups: one representing the robotic process managed by the robot, and the other reflecting the non-robotic process supervised by the human operator, as indicated in

Table 1.

Assumptions were established to ensure homogeneity in the analyzed data and facilitate their comparison, as outlined in

Table 1. These assumptions were made with the specific goal of achieving consistency in the dataset. Briefly, they can be described as follows:

The batch comprises an equal number of units in both the robotic and non-robotic cell.

Within the non-robotic batch, the operator manually assembles each unit. Conversely, in the robotic batch, the operator loads buffers capable of holding up to 10 pairs of parts. Consequently, through a single interaction with the parts, the operator, facilitated by the automated robot, is responsible for assembling 10 final products. This process is denoted in the table as human–component interaction.

The duration required for both the human operator and the robotic system to assemble the parts is equal. Furthermore, this time frame is congruent with the period taken by the human operator to replenish the buffer during the loading phase in the robotized work cell. This equivalence was established to streamline the comparative analysis of these two distinct processes.

In the context of quality control, the responsibility for its execution rests with the operator, regardless of whether it is a human operator or a robotic system handling the components. Consequently, the time allocated for this quality control task exists in both work cells and is distributed identically.

6. Results

From an economic point of view, conducting an analysis comparing the initial investment in purchasing the robot and various equipment with the resulting economic return yields clear insights. Originally, when the operator was responsible for batch production, the entire cost was attributed to the time spent on the batch. However, with the integration of the robot, the operator’s time allocated to the batch becomes inversely proportional to the buffer size, as it depends on the buffer loading interval. In the case study, a time-saving of 86%, as shown in

Table 2, was achieved, leading to substantial cost savings in the overall batch production cost.

By increasing the size of the buffers, it becomes possible to reduce the frequency at which new parts need to be loaded. This, in turn, enables a further reduction in the time allocated to operators for batch production. The parts intended for assembly are produced in-house using the injection molding process. These parts are lightweight and small, so the enlarged buffers do not pose placement challenges within the workspace. As welding machines can be employed simultaneously on different batches, the potential for integrating additional robots arises, enabling one operator to manage multiple machines. This chain mechanism has the potential to generate significant profit for the company.

As expected, the company asked for a thorough economic analysis to assess the implementation of the case study. The calculation of the investment cost took into account component expenses, regular and exceptional maintenance, and the energy consumption involved. The overall installation cost was estimated to be approximately €45,000.00. The investment was assessed using financial metrics like Return of Investment (ROI) and the Payback Period, which are commonly employed by small and medium-sized enterprises to evaluate investments. The value of the investment indicators is directly related to the size of the batch: as the size of the batches increases, the cost savings and thus the affordability of the investment increases. Conversely, small batch sizes provide financial metrics values that do not match the cost of the investment.

The correlation between production quantities and return on investment stems from their direct connection with the operational time saved, as demonstrated in the presented case study. This aspect is critically important when factoring in the hourly cost of the operator allocated to the batch, thereby highlighting the financial implications of time savings.

In

Table 3, three specific quantities of batch items are delineated: the first denotes the sample utilized in experiments, the second corresponds to the amount required to achieve the break-even point for a generic product, and the third represents the product manufactured in the highest quantities among those produced by the company that necessitates assembly at the welding machine. Each of these quantities results in a distinct return at the end of the first year, thereby influencing the decision of whether to proceed with the investment or not.

Certainly, maximizing the return within the first year is a pivotal objective for the company. In this context, it becomes imperative to design the robotic work cell specifically tailored for the product which ensures that the break-even point is not only met but also surpassed within the initial year of operation.

Nevertheless, it is crucial to acknowledge the dynamic nature of the business environment. Production quantities can fluctuate considerably across different products and over varying periods. In instances where demand exceeds the break-even point, investing in a robotic work cell proves to be highly advantageous, optimizing efficiency and profitability. Conversely, if the production quantity falls below the break-even point, the investment might not yield the anticipated returns, making it potentially unworthy of pursuit. Hence, a thorough analysis of production demands and market trends is essential to make informed decisions regarding the investment, ensuring it aligns with the company’s overarching goal of maximizing returns.

A strategic approach to address demand fluctuations is to prioritize developing the robotic work cell for the product manufactured in larger quantities, meeting the return on the investment criterion within the first year. By doing so, with minimal modifications, the same cell can be adapted to accommodate even smaller productions falling below the break-even point. This flexible strategy enables the company to maximize the utilization of collaborative robotic technology while ensuring a stable and sustainable return over a period of years. It effectively navigates the diverse production quantities of different products and adapts to fluctuating demands over time.

In this case study, the cycle time of the robotic work cell was assumed to be equivalent to the cycle time of a cell operated by a human operator. Nonetheless, the implementation of cutting-edge strategies, including the employment of a dual gripper mechanism and the application of sophisticated simulation and trajectory optimization software, as previously demonstrated, enables the attainment of reduced cycle times beyond what is typically possible through human involvement. This methodology not only elevates production efficiency but also secures a more consistent performance level over time, capitalizing on the robotic systems’ characteristic lack of susceptibility to fatigue. The work cycle formerly entrusted to the human operator is now handled by the collaborative robot, which is able to execute it in a significantly reduced time, operating non-stop, short of necessary operational stops. This transition not only allows the entire batch to be completed in less time, but also results in reduced costs for the company due to increased efficiency. The ease of programming of collaborative robots plays a key role in this context, allowing rapid changes in operating speed and trajectories if changes in the work cell are needed, increasing business competitiveness in today’s dynamic market.

7. Conclusions

This article presents a case study on the implementation of collaborative robotics in the automotive industry. The context is pertinent for all small and medium-sized enterprises aiming to embrace innovative technologies and transition their operations toward Industry 5.0. The economic benefits and efficiency gains demonstrated through this analysis showcase the viability of adopting collaborative robotics within manufacturing processes, leading to improved productivity and profitability for enterprises producing small and medium-sized batches, shifting human labor to tasks requiring mental skills.

The development and use of mobile collaborative robots in industry is indeed intended to benefit workers, not eliminate them. What is expected is a redefinition of human activities in a context of human–robot integration that will lead to higher-performance production and which is, in some ways, lighter for the worker. The collaborative dimension underlying the coming revolution will lead to a downsizing of workloads, freeing workers from the heaviest and most strenuous tasks. The operator is thus placed at the center of production according to the basic principles of Industry 5.0, reshaping the company’s perspective and propelling it towards a future empowered by novel methodologies applicable within its industry and beyond, fostering potential expansion and establishment in new domains.

One of the main limitations of this case study lies in its execution within a corporate context where assembly operations are characterized by simplicity and a limited number of steps. This approach allowed for the assessment of the benefits deriving from the use of cobots in a specific scenario, but it does not provide a complete vision of the efficiency of such technologies in more complex operations, which require a more articulated sequence of actions. Consequently, to acquire a deeper and more comprehensive understanding, it would be appropriate to conduct further research in order to explore the implementation of cobots in a wider range of assembly processes. This would allow for the identification of the most suitable situations to effectively integrate these technologies, evaluating their efficiency in more complex operational contexts.