Abstract

Having emerged as strategic focal points in industrial transformation and technological innovation, intelligent machine tools are pivotal in the field of intelligent manufacturing. Accurately forecasting emerging technologies within this domain is crucial for guiding intelligent manufacturing’s evolution and fostering rapid innovation. However, prevailing research methodologies exhibit limitations, often concentrating on popular topics at the expense of lesser-known yet significant areas, thereby impacting the accurate identification of research priorities. The complex, systemic, and interdisciplinary nature of intelligent machine tool technology challenges traditional research approaches, particularly in assessing technological maturity and intricate interactions. To overcome these challenges, we propose a novel framework that leverages technological communities for a comprehensive analysis. This approach clusters data into specific topics which are reflective of the technology system, facilitating detailed investigations within each area. By refining community analysis methods and integrating structural and interactive community features, our framework significantly improves the precision of emerging technology predictions. Our research not only validates the framework but also projects key emerging technologies in intelligent machine tools, offering valuable insights for business leaders and scholars alike.

1. Introduction

Intelligent machine tools, which are essential for modern manufacturing, drive significant improvements in production efficiency and precision, thereby enhancing the manufacturing sector’s competitiveness [1]. These tools are crucial in sectors such as aerospace, automotive manufacturing, and precision instrument production, where industrial automation and digitalization are advancing rapidly. By integrating computer control, sensor technology, and network communications, intelligent machine tools progressively increase manufacturing intelligence [2,3]. In this evolving landscape, emerging technologies, marked by swift development and vast commercial potential [4], are pivotal. Understanding these technologies is crucial not only for current operations, but also for shaping the future [5], as informed decision making fundamentally depends on reliable information regarding these trends.

The interdisciplinary nature of machine tool technology, characterized by complex interactions across various technological domains, poses significant challenges in predicting emerging technologies. This paper aims to concentrate on intelligent machine tools, particularly on the advanced areas where new-generation information technology deeply integrates with machine tool technology. By examining these cutting-edge developments, we aim to propose a framework that identifies potential emerging technologies via technology communities and deep learning methods, providing methodological support for capitalizing on future development opportunities in the field.

Current methods for predicting emerging technologies often focus on broad industry analyses. For instance, Zhou et al. [6] utilized a topic clustering model to identify emerging technologies in the 3D printing sector, while Wang et al. [7] applied bibliometrics to uncover emerging areas in cancer research. However, the field of intelligent machine tools is characterized by rapid changes and significant differences in the development and focus of various research topics [8]. The methodologies employed by these studies tend to spotlight emerging technologies within well-known topics, thereby neglecting potential advancements in less visible topics. Applying these traditional approaches to individual topics without accounting for the interconnectedness and mutual influences among different topics might overlook essential information, consequently diminishing the accuracy of predictions. This oversight not only hampers a comprehensive understanding of technological evolution in the realm of intelligent machine tools, but also risks leading businesses and researchers to miss crucial technological opportunities.

Another segment of emerging technology prediction methods focuses on patents or scholars. These methods identify influential patents and scholars for industry guidance using network analysis, text mining, and deep learning. For example, Zhou et al. [9] applied deep learning models to identify high-quality patents in emerging technology, based on outlier patent theory. Kong et al. [10] used a support vector machine-based classifier to extract high-quality patents representing technological innovation. Khan et al. [11] built an author collaboration network to examine the profound impact of relational structures among various participants in emerging technology development.

An important characteristic of emerging technologies is their community nature [12]. Although these approaches provide some insight into emerging technologies, they often overlook the broader community context, limiting a full understanding of technological evolution. This oversight can lead to inaccurate predictions. Current research attempts to address this by using IPC classification and cluster analysis to study patent groups while considering their community aspects. For instance, Geum et al. [13] predict emerging technologies by analyzing patent characteristics within each IPC. Kim et al. [14] use forward citations and independent claims of clustered patent groups for prediction. These methods partially consider the community aspect of technology, but lack a deep exploration of the complex interactions and subtle relationships within these communities [15]. In the field of intelligent machine tools, the interdisciplinary nature emphasizes the importance of community characteristics. Internal interactions and collaborations within these communities are crucial for technology development and innovation.

Given the capability of knowledge graphs to associate multi-source information, some researchers have started using knowledge graph technologies in predicting emerging technologies. For example, Lee et al. [16] have utilized deep learning and knowledge graphs to identify emerging technologies from three data sources. There are also studies on the technological system of intelligent machine tools, such as those by Liu et al. [17], who determined the technology system in this field through the utilization of knowledge graphs and expert interaction. This provides a foundation for combining data knowledge with domain expertise. The recent development of graph classification methods, such as Graph Convolutional Networks (GCN) [18], offers opportunities to mine and represent the complex structural characteristics of communities.

In summary, we built an emerging technology prediction model based on knowledge graphs and graph deep learning, approached from the perspective of the technology community, and comprised of patents and papers. Initially, we gather patents and papers in the field of intelligent machine tools to construct a technological knowledge graph. Subsequently, we employ community detection algorithms and reference technology systems to cluster and divide communities, achieving a balanced analysis across the topics. Following this, we utilize a community classification model based on GCN to learn the associations between community structure, various metrics, and community development. Ultimately, this relationship model is used to predict the developmental capacity of communities over the next five years, identifying communities that are likely to exert significant impacts in the future. This enables us to forecast emerging technologies within the intelligent machine tools sector.

2. Literature Review

2.1. The Development of Intelligent Machine Tools

The development of intelligent machine tools has undergone a remarkable journey based on a new generation of information technology, deeply integrating the latest developments in artificial intelligence and advanced manufacturing technologies. This evolution can be divided into three main stages [19]. Initially, the era of CNC (Computer Numerical Control) machine tools represented the first stage, where automation in machining was achieved via computer control. This was followed by the Smart Machine Tool phase, where machines were equipped with sensing and feedback systems, thus enabling the real-time monitoring of workpieces, the environment, and adjustments in order to enhance processing efficiency and quality. The final stage, the Intelligent Machine Tool [20], is characterized by high-level autonomous decision-making capabilities, allowing machines to automatically adjust processing parameters based on complex workpiece requirements and production environments, leading to more flexible and efficient production. Accelerating the development of intelligent machine tools is not only an urgent need for the transformation and upgrading of the machine tool industry, but also a crucial foundation for building a strong manufacturing nation [1].

Forecasting emerging technologies is vital. It helps machine tool manufacturers and research institutions to identify and introduce new technologies with potential at an early stage. This significantly accelerates the evolution and improvement of intelligent machine tools [8].

2.2. Emerging Technology Forecasting

Emerging technologies, characterized by their robust development momentum and significant commercial potential, profoundly impact the economy and society [4]. In the initial stages of predicting emerging technologies, reliance is typically placed on the subjective assessments of experts, involving expert panel discussions, surveys, the Delphi method [21], and analytic hierarchy processes [22]. These methods focus on qualitative analysis from experts, supplemented by scoring mechanisms for a quantitative summary of technology trends. For instance, Rotolo et al. [12] proposed four key attributes of emerging technologies, novelty, persistence, community, and growth, designing an indicator system to reflect these attributes, and, in the process, successfully uncovering emerging technologies in the field of nanomedicine. Song et al. [23] developed a system comprising seven patent indicators, which includes the scope of rights and application range, to measure technology characteristics, and thereby discover technological opportunities.

Predictions of emerging technologies based on bibliometrics focus on analyzing publicly available scientific papers and patent literature to reveal technological development trends and research hotspots. This method quantifies indicators such as the frequency of research publications, citations, and collaborative networks to unveil the dynamics and directions of technological development. For example, researchers like Tu [24] analyzed the publication trends of journal and conference papers to determine emerging technology themes in specific fields. Zhou et al. [25] identified knowledge convergence and recognized emerging technologies via the combination of topological clustering analyses of paper citation networks.

Predictions based on text mining, meanwhile, emphasize extracting key technological terms, concepts, and trends from vast textual data, using natural language processing to identify and forecast new technological directions. Zhou et al. [26], for instance, proposed a framework that combines natural language processing techniques with expert knowledge to analyze multi-source heterogeneous text data in order to identify technological opportunities. Dong et al. [27] utilized extensive paper abstract data, applying the LDA model for topic discovery and categorization, and successfully predicted emerging technologies in the field of robotics via the use of the ARIMA model. However, these traditional methods of technology identification tend to focus on macro-level research, potentially overlooking emerging technologies in less popular directions, which may be overshadowed by mainstream research literature. Additionally, traditional methods often neglect the importance of analyzing from a community perspective. Considering the community viewpoint, inter-technological relationships and interaction networks, particularly when identifying emerging technologies, can provide more comprehensive and profound insights.

Machine learning is being increasingly applied in emerging technology prediction, continuously learning and extracting features from vast datasets to unearth hidden information, and thus enhancing the understanding and forecasting of technological development trends. Lee et al. [28] employed a feedforward multilayer neural network to capture the complex nonlinear relationships between input and output indicators for predicting emerging technologies in their early stages. Zhou et al. [29] proposed a novel approach integrating data augmentation and deep learning methods to overcome the issue of lacking training samples in predicting emerging technologies. This paper builds upon the ideas of predecessors and analyses from a community perspective, incorporating the structural and interaction characteristics of communities, as well as predicting emerging technologies through graph representation using deep learning models.

2.3. Community Detection and Classification

Approaching technology evolution and emerging technology prediction from a community perspective resolves the inadequacies of traditional metric analyses and prevents the potential inaccuracies and misclassifications which are inherent in the current classification systems used by patent authorities, thereby improving consistency and stability [15]. Communities are defined as groups of non-overlapping nodes with internal connections being denser than external connections [30]. The most prevalent community detection approach is optimization based, maximizing a quality function called modularity for superior community division, as seen in the Louvain [31] and Girvan–Newman [32] algorithms. Statistical inference-based methods are considered another varient, which probabilistically model the network structure to find the most plausible communities, such as the SBM [33] algorithm. The third class of algorithms relies on the relationship between community structure and network dynamics, particularly random walks, with InfoMap [34] being a standout method within this category.

For a deeper understanding of the attributes of community structures and node properties post-partitioning, we have introduced graph classification algorithms. These algorithms classify graphs according to their structural and nodal features. Our objective is to use graph classification algorithms to distinguish communities identified as either emerging or non-emerging technological communities. Graph Convolutional Networks (GCNs) are an effective graph classification tool, and are extensively used for processing graph data [35]. GCNs apply convolution concepts to handle graph-structured data, capturing intricate node interrelations. This method enables the network to learn feature representations of nodes, taking into account their neighbors’ features. Another benefit of the GCN method is adaptability; GCNs can be integrated with other machine learning methods like deep learning and unsupervised learning to boost model performance. Our model combines GCNs with a deep learning classifier to predict emerging technologies.

3. Methods

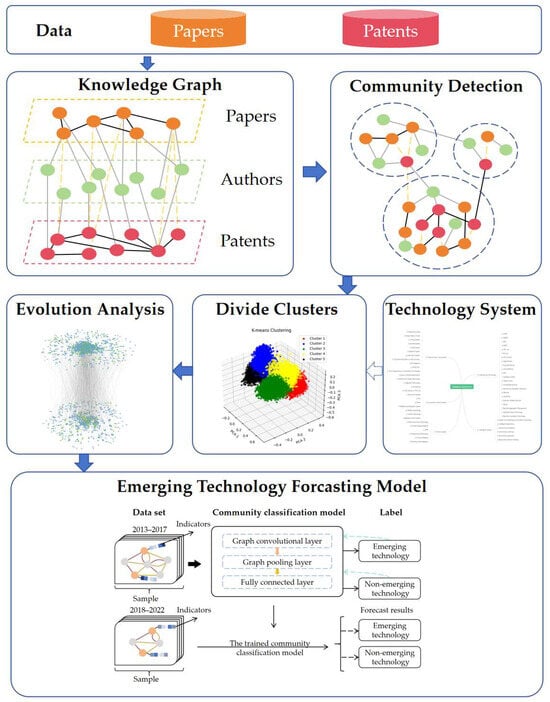

Figure 1 illustrates our proposed framework for predicting emerging technologies, which can be broken down into the following steps:

Figure 1.

Framework for predicting emerging technologies in intelligent machine tools.

- Collect patent and paper data in the field of intelligent machine tools.

- Process this data to extract relationships and construct a technological knowledge graph.

- Use community detection algorithms to identify technology communities, and divide them based on the technology system.

- Extract early features of these communities from the knowledge graph and analyze their evolution to assess their development potential.

- Build a graph deep learning model to correlate community attributes with their future growth, thereby predicting emerging technologies.

3.1. Data Collection

In our research, which aims to forecast emerging technologies in the intelligent machine tool sector, we gathered data from academic papers and patents, considering their significance in indicating theoretical advancement and practical application, respectively. The search formula is derived from the “Green Paper on Technological Innovation in Key Fields of China’s Manufacturing Industry, Technology Roadmap: 2019” [36]. We meticulously selected the Web of Science as our core academic database, and Derwent Innovation for our patents.

3.2. Knowledge Graph Construction

3.2.1. Entities Text Representation

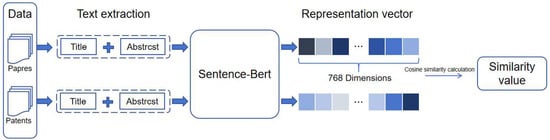

In this section, we describe our approach for the text representation of entities, which is crucial for subsequent analyses. We employed Sentence-BERT [37], an extension of the well-known BERT model, specifically designed for sentence embeddings. This choice was driven by Sentence-BERT’s ability to capture contextual nuances within texts, a critical aspect for our analysis of papers and patents. The process begins with the preprocessing of text data, where we remove irrelevant information, such as non-textual elements, and standardize the text format. Subsequently, each preprocessed text entity is converted into a high-dimensional vector using Sentence-BERT. These vectors effectively encapsulate the semantic essence of the texts, enabling accurate and nuanced similarity comparisons and clustering in the later stages of our analysis. The process is shown in Figure 2.

Figure 2.

Text representation and similarity calculation process.

3.2.2. Links

In our comprehensive analysis of the intricate relationships between patents and academic papers in intelligent machine tools, we recognize the necessity to construct a technical knowledge graph. This graph is integral for unraveling the complex web of interactions that propel technological advancements. Central to this endeavor are three pivotal types of relationships: citations, publications, and textual similarities. The citation relationship highlights the mutual progression of knowledge and innovation, providing insights into the evolution of technology. The publication linkage elucidates individual contributions to knowledge creation, revealing key figures and trends within the field. Textual similarity analysis bridges academic research and technological innovations, uncovering thematic overlaps and divergences.

By integrating these relationships into a knowledge graph, we gain a comprehensive view of the technological landscape. This integration is not just about mapping connections, but about understanding the dynamics of the flow of ideas and innovation. Our approach enables the effective tracking and prediction of emerging technologies. More importantly, it facilitates community detection within this knowledge graph, thus allowing us to identify and analyze distinct clusters of interrelated technologies and research areas.

Citation and publication relationships can be extracted from the downloaded document. For the similarity relationship, we employ cosine similarity measures on text representation vectors, using the detailed process depicted in Figure 2.

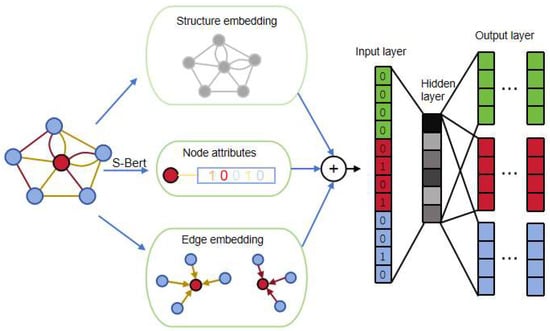

3.2.3. Knowledge Graph Representation

The process of representing a knowledge graph involves transforming the graph’s elements into vector representations in mathematical terms. This transformation allows the nodes to encompass a wider range of semantic properties, aiding subsequent classification tasks. The GATNE [38] algorithm is particularly effective at extracting complex nodes and relationships within the knowledge graph, and it also accommodates the initial input of node attribute vectors. This feature ensures that while the nodes assimilate complex semantic information, they also preserve a significant amount of their textual characteristics. Therefore, we utilize the GATNE algorithm to represent our knowledge graph, converting each node into a 768-dimensional vector. These vectors are then stored and used as the attributes of the nodes. The principle of GATNE is shown in Figure 3. In this figure, different colors are used to underscore the attention given to distinct features during the graph representation process. Green highlights a focus on structural features, red emphasizes attention to attribute features, and blue marks the emphasis on edge features.

Figure 3.

GATNE algorithm principle for knowledge graph representation.

3.3. Community Detection and Evolution Analysis

Aligned with Rotolo’s theory [12], a key characteristic of emerging technologies is their formation and development within communities. Therefore, this research predicts future technologies by focusing on the communities formed around patents and papers, employing the Louvain [31] algorithm for efficient community detection in large-scale graphs. The identification of densely linked communities is completed via the optimization of modularity.

In the intelligent machine tool sector, diverse topics garner varying interest levels. This study segments data for an in-depth, balanced analysis across these topics. Following the technology system outlined by Liu et al. [17], we aim to investigate emerging technologies in intelligent machine tools across five topics. We employ the K-means [39] algorithm, an established method in unsupervised learning, to categorize communities into five separate clusters, representing distinct topics within the intelligent machine tool sector. Each cluster’s vector is calculated through averaging the knowledge graph representation vectors of all patents and paper nodes within that community.

To acknowledge the faster growth rate of emerging technology communities as per the technology lifecycle curve, we analyze these communities in five-year intervals. By analyzing the growth rates of technology communities from 2013 to 2017, we can ascertain their developmental potential. Communities exhibiting high developmental potential are considered emerging technology communities, and will be key labels in subsequent model training. The formula for growth rate is as indicated in Formula (1).

where is the growth rate, is the total number of papers and patents published by the community between 2013 and 2017, and is the total published between 2018 and 2022.

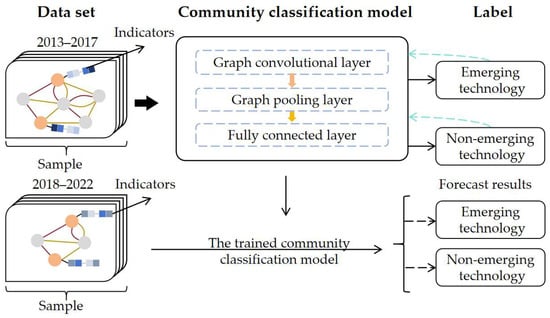

3.4. Train Model and Forecasting Emerging Technology

We aim to use the emerging and non-emerging technology communities identified between 2013 and 2017 as a training set for a community classification model. This model will be applied to data from 2018 to 2022 to predict emerging technologies, as illustrated in Figure 4.

Figure 4.

Training model and forecasting process for emerging technology.

Our objective is to utilize a graph deep learning model to correlate the initial traits of communities with their potential for future development. The future developmental capacity of these communities is as outlined in Section 3.3. Following Kong’s research [40], we have identified several indicators for community nodes. ‘Prior Knowledge’ [41] signifies the depth of research grounded in existing literature—a robust indicator of a field’s maturity and focus. ‘Technology Cycle Time’ [42] provides insight into the relevance and currency of the community’s knowledge, which is vital in rapidly advancing tech sectors. ‘Collaboration’ [43] underscores the importance of cooperative efforts for innovation and knowledge sharing.

To enhance our model, we have integrated new indicators like ‘Betweenness Centrality’ and ‘Degree Centrality’, which provide perspective regarding a node’s influence and connectivity within the knowledge network, thus denoting any potential for knowledge spread and impact. ‘Total Knowledge Contributions’ illustrate the community’s research output and innovative strength, indicative of its dynamism and productivity. ‘Scope and Coverage’ measure the community’s participation and impact on external knowledge areas, reflecting its reach and interdisciplinary nature.

Collectively, these indicators are instrumental in providing a holistic understanding and prediction of the future development of technological communities through the encapsulation of both the internal and external factors that drive technological evolution.

Each node’s features are derived from both its own characteristics and those of its community. In total, 14 indicators have been established to capture the early features of community nodes, which are key for assessing a community’s development potential, as shown in Table 1.

Table 1.

Indicators for Community Classification Model.

The model inputs are communities, which can also be understood as graphs. Specifically, these include the nodes within the community, their connections, and the attributes of each node, which are defined by 14 indicators. This comprehensive input captures both the structural and individual characteristics of each community, forming the basis for the model’s analysis and predictions. The output identifies whether a community represents an emerging technology. Communities are labeled as emerging technologies if they show high developmental potential; otherwise, they are labeled as non-emerging.

The model’s architecture includes graph convolutional layers, graph pooling layers, and fully connected layers, all specially designed to extract the structural and attribute features of the graph. The graph convolutional layers, utilizing GCN principles, accumulate features from neighboring nodes. This enables nodes to learn from both their own attributes and their position within the wider network. Graph pooling layers reduce the node count while retaining key structural information, thus aiding in computational efficiency. They focus on the graph’s most critical nodes and structures for more effective feature extraction. Finally, the fully connected layer merges features from the convolutional and pooling layers, culminating in the final classification of the graph. This layer captures intricate relationships between various features, facilitating the prediction of emerging patterns and trends within the graph data.

4. Results and Discussion

4.1. Data Collection and Knowledge Graph Construction

According to the previous method, the overall information of collected papers and patents in the field of intelligent machine tools is shown in Table 2.

Table 2.

Data collection overview for intelligent machine tools.

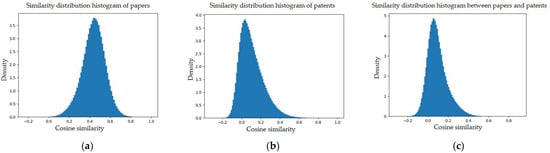

Our knowledge graph is composed of three entity types: patents, papers, and authors. We extract citation and publication relationships by analyzing the reference and author fields in papers and patents. To recognize the inherent textual structural differences between papers and patents, we plotted their probability similarity distribution curves separately, as illustrated in Figure 5. The horizontal axes represent the cosine similarity values between the pairs of text vectors, while the vertical axes indicate the density of the text pair counts at each level of similarity. The distributions observed show that the similarity scores roughly conform to a normal distribution. Significantly, the peak of the similarity distribution within papers is observed at around 0.05; for patents, it reaches nearly 0.5, and between papers and patents, the peak is approximately 0.1, showcasing substantial differences.

Figure 5.

Probability similarity distribution curves for (a) papers; (b) patents; and (c) papers and patents.

Acknowledging these textual structural differences, we established separate thresholds for similarities between patents and papers. This was accomplished through calculating the mean and standard deviation for each, adhering to the three-standard-deviation principle. Text pairs exceeding these thresholds were classified as similar links. Detailed information regarding these connections is presented in Table 3. These links offer a new lens for understanding and analyzing the flow of knowledge in the technology community.

Table 3.

Summary of links in knowledge graph.

4.2. Community Detection and Evolution Analysis

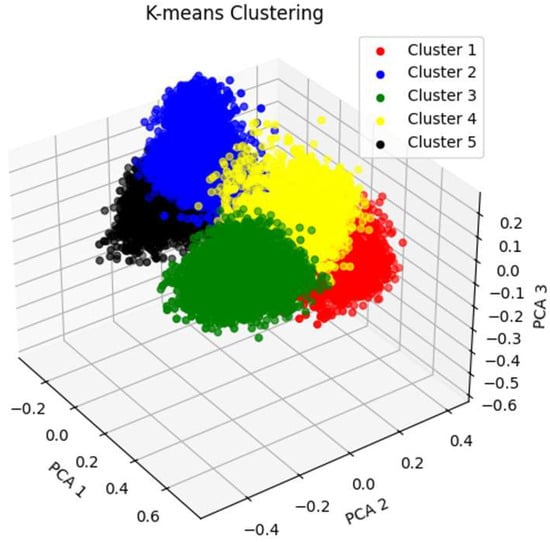

We applied the Louvain algorithm for community detection in our knowledge graph, and then, following Liu’s research, we set the number of clusters for K-means clustering to 5. The visualization of the clustering outcome is presented in a three-dimensional space using principal component analysis (PCA) in Figure 6. This PCA projection captures the largest variances, with PCA1, PCA2, and PCA3 representing the axes, thereby reducing the original 768-dimensional space for a comprehensible visual interpretation. The clusters are differentiated by color: red for Cluster 1, blue for Cluster 2, green for Cluster 3, yellow for Cluster 4, and black for Cluster 5. The dispersion of data points within each cluster reveals the density and core regions of the clusters, while the spatial separation between the clusters highlights the effectiveness of the clustering process. The clear demarcation between clusters suggests a high degree of intra-cluster similarity and inter-cluster dissimilarity, which indicates that the clustering has successfully captured distinct knowledge domains within our graph. The number of communities in each cluster following clustering is detailed in Table 4.

Figure 6.

A 3D PCA visualization of community clustering.

Table 4.

Community counts in each cluster.

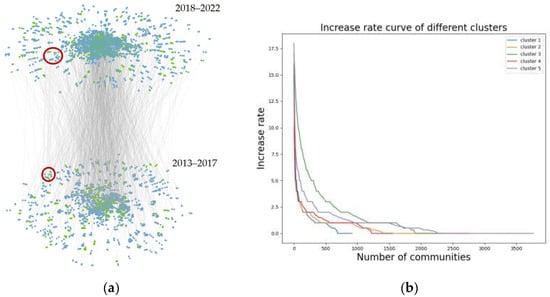

Following this, we segmented each technology community in our knowledge graph into two time periods, 2013–2017 and 2018–2022, in order to conduct an evolutionary analysis. As depicted in Figure 7a, we partially displayed our knowledge graph to demonstrate the evolution of these technology communities. This is due to the large number of nodes in the graph, which makes a full display impractical. In the graph, blue nodes represent patents and green nodes signify papers. We observe that the community highlighted by the red circle published 12 papers and patents between 2013 and 2017, and 24 papers and patents between 2018 and 2022, indicating a growth rate of 2.0 for this technology community.

Figure 7.

Technology community evolution and growth rate analysis. (a) Technology community evolution analysis; (b) technology community growth rate curve.

We calculated the growth rate for each community and plotted the distribution curves of community growth rates within each cluster, as shown in Figure 7b. It is evident that the development pace of communities varies across clusters. Consequently, we set different growth rate thresholds based on the inflection points of the growth rate curves. Communities exceeding these thresholds are considered to have high development potential and rapid growth, thus marking them as emerging technology communities. By setting these varied thresholds, we can conduct a balanced analysis of the topics corresponding to each cluster, ensuring that our approach is comprehensive and nuanced. The detailed results of the community evolution analysis are shown in Table 5.

Table 5.

Overview of the datasets.

4.3. Indicator Calculation and Model Training

Utilizing the knowledge graph, we have calculated the indicators listed in Table 1. Table 6 presents the descriptive statistical results of these indicators.

Table 6.

Descriptive statistical results of indicators.

From the growth rate curves, it is apparent that only a minority of the technology communities have significant development potential for becoming emerging technological communities. In Section 4.2 of our paper, the ratio of high-potential/low-potential technology communities is merely 1:7. This results in a highly imbalanced dataset for training our model, preventing it from adequately learning the characteristics of communities with high development potential. Therefore, after dividing the data into a training set and a test set in a 7:3 ratio, we duplicated the positive samples in the training set to achieve a more balanced representation of positive and negative samples.

The model for predicting emerging technologies was built using Python, Torch-Geometric, and Scikit-learn. Through multiple rounds of experimentation, we determined that the model should consist of two graph convolutional layers, one pooling layer, and two fully connected layers. We used the Adam optimizer with a learning rate of 0.0001. Additionally, we evaluated our model’s performance against that of a conventional deep neural network (DNN) model that does not take into account the features of the community structure. The comparative results are presented in Table 7.

Table 7.

Comparative results of predictive models.

The comparative results presented in Table 7 illustrate that our model excels in the task of predicting emerging technologies, outperforming the DNN model across all evaluation metrics. This demonstrates that considering community structural features via Graph Convolutional layers effectively captures the complex non-linear relationships between indicators and community development, thereby enhancing the accuracy of emerging technology predictions. Upon the detailed analysis of the model’s performance, we observed a recall rate of 86.84%, indicating a comprehensive detection of emerging technologies with minimal omissions. Although the F1 score is 79.85%, which is slightly lower than the accuracy rate of 81.25%, this discrepancy may be attributed to a data imbalance; however, the high F1 score suggests that this impact is not significant. Overall, these results validate the effectiveness of our model in fitting relationships.

4.4. Emerging Technology Forecasts and Analysis

The community classification model trained with communities from 2013–2017 is used to evaluate the development potential of communities from 2018–2022. Communities with high potential were identified as emerging technology communities, while those with lower potential were classified as non-emerging. In the period from 2018 to 2022, a total of 11,847 communities were identified, with 1168 predicted to be emerging, representing 9.9% of the total sample. Detailed predictions are outlined in Table 8.

Table 8.

Forecasting results for technology communities.

For our in-depth analysis of the identified technology communities, we employed the ToPMine [44] algorithm, renowned for its efficient extraction and clustering of key phrases from texts. For each cluster, we collected titles and abstracts from the nodes of each emerging technology community. Utilizing ToPMine, we extracted high-frequency keywords and performed thematic analyses. The comprehensive results of this procedure are detailed in Table 9.

Table 9.

Topics and keywords of emerging technology communities.

Based on the keyword extraction analysis, the emerging technologies in the field of intelligent machine tools are primarily intelligent control systems, intelligent applications, intelligent data-driven manufacturing, intelligent precision machining, and structural optimization. In intelligent control systems, the emphasis is on using machine learning and neural networks for data-informed decisions and learning [45], as well as applying adaptive control and sensor networks for autonomous perception and operation [46]. In the field of intelligent applications, the focus is on enhancing automated welding and robotics. This aims to improve the flexibility and automation of welding operations, leading to increased production efficiency, cost reduction, and improved welding quality [47]. Intelligent data-driven manufacturing optimizes the efficiency and connectivity of intelligent machine tools using advanced data analysis [48], with a strong focus on ensuring data security and privacy [49]. Intelligent precision machining is centered around enhancing machining process efficiency, surface quality, and energy efficiency via the utilization of advanced manufacturing and intelligent control for high precision and optimization [50]. Structural optimization and performance enhancement both focus on improving the structure and components of CNC machine tools to achieve higher precision and speed [51], thus effectively advancing the intelligence of machine tools.

The forecasted emerging technologies offer useful insights into the forthcoming innovations in intelligent machine tools. Initially, innovation in intelligent machine tool technology encompasses two dimensions: the body of intelligent machine tools, including intelligent control systems, structural optimization, and intelligent data-driven manufacturing, and their applications, such as in intelligent welding and precision machining. Importantly, innovations in intelligent machine tools extend beyond merely enhancing their intelligence. The forecasts indicate that structural optimization is also a key focus. This suggests that new methods and applications in structural optimization are emerging and deserve equal attention. We believe that while emphasizing smart innovation, attention must also be paid to key foundational technologies and emerging application domains, as a robust foundation is essential for the development of intelligent machine tools. Therefore, governments and corporations should consider their specific situations, including technological bases and application areas, for making informed decisions and planning strategically. Ultimately, the decision of whether the forecasted emerging technologies merit pursuit within an organization should be made following thorough evaluation by domain experts who are equipped with knowledge in the relevant technological areas.

To facilitate a more comprehensive exploration of the development of intelligent machine tools, this study has also conducted a brief analysis of five large non-emerging technology communities, as shown in Table 10.

Table 10.

Topics and keywords of non-emerging technology communities.

Through this analysis, we have identified several traditional technologies that remain current research focal points, including hydraulic systems and power transmission, motion and guidance mechanisms, automation and control technology, clamping mechanism optimization, and automatic feeding systems. These findings underscore the necessity of continuing to research these traditional technologies, as they still play a crucial role in the further development of intelligent machine tools. Maintaining research on these technologies not only helps us to deeply understand the foundations of intelligent machine tools, but also provides a solid base for future innovations.

5. Conclusions

This study introduces a systematic framework to forecast emerging technologies in the intelligent machine tool domain. This is achieved via community detection, evolutionary analysis methods, and graph deep learning models. The central tenet of the framework is a GCN-based community classification model, tailored to establish the relationship between the development potential of technological communities and the 14 chosen static indicators. Moreover, the framework conducts a balanced analysis of various prominent topics by clustering communities in accordance with the technology system. Our results underscore the framework’s efficacy, evidenced by the classification model’s 81% accuracy rate. When applied to the latest data, this study precisely identifies five emerging technologies within the extensive community of the intelligent machine tool domain. These encompass intelligent control systems, intelligent applications, intelligent data-driven manufacturing, intelligent precision machining, and structural optimization. Additionally, the study provides detailed emerging keywords within each technological direction, thus offering a granular view of the innovative aspects driving these fields forward.

This research delivers two principal contributions. Firstly, from an academic perspective, this study proposes a novel framework which utilizes machine learning and other quantitative analysis methods to forecast emerging technologies in the intelligent machine tools sector. These quantitative approaches guarantee the framework’s objectivity and credibility, with its effectiveness being empirically validated. This framework can be customized and applied by researchers to meet their specific objectives. Within this framework, the research segments the field based on the technological systems of intelligent machine tools, identifying emerging technologies across diverse topics, thus enhancing the comprehensiveness of forecasts. The core of this framework is the analysis of the evolution of technological communities. This begins with the establishing of a comprehensive set of indicators that capture both the internal and external factors that influence the development of technology communities. Subsequently, a graph classification model is developed to accurately model the complex relationships between these factors and the evolution of communities, greatly enhancing the accuracy of the predictions.

Secondly, from a practical perspective, the framework proposed in this research efficiently analyzes and forecasts emerging technologies in the field of intelligent machine tools within acceptable ranges of both time and cost. The insights into forthcoming trends from these predictions enable industry professionals to strategically align their planning and resources towards areas which are ripe for growth and innovation. This foresight is essential for sustaining a competitive advantage and advancing the industry. Moreover, this supports governments and businesses in making informed decisions and formulating strategic plans, thereby accelerating intelligent and rapid development in the intelligent machine tool sector.

While this study makes meaningful contributions, it is not without its limitations, which future research will need to address. The proposed quantitative analysis framework, effective in ensuring objectivity and credibility, could be further improved by integrating qualitative analysis to enhance the robustness of the findings. Future efforts could gain from integrating expert knowledge into labeling technology communities, either through manual expert reviews of labels, or by developing a label library from the emerging technologies that have already been recognized and documented by experts. Moreover, the study primarily relies on analyzing technical literature to forecast emerging technologies. However, the advent of emerging technologies is influenced by a broad array of factors. Incorporating multidimensional data, including funding, policy, supply chain data [52], and market knowledge [53], could uncover new insights, albeit at the risk of overshadowing some forecasts derived from the technical literature.

Author Contributions

Conceptualization, Y.L. (Yufei Liu); methodology, Y.L. (Yufei Liu) and C.H.; software, validation, data curation, writing—original draft preparation, visualization, C.H.; resources, project administration, Y.L. (Yufei Liu); writing—review and editing, Y.L. (Yufei Liu) and Y.L. (Yuhan Liu); supervision, Y.L. (Yufei Liu); funding acquisition, Y.L. (Yufei Liu). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China [grant numbers 72104224, 71974107, L2224053, L2224059, L2124002, 91646102, L1924058]; the Construction Project of China Knowledge Center for Engineering Sciences and Technology [grant number CKCEST-2023-1-7].

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to copyrights.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Appendix A

TS = (Machin* tool* or NC machin* or CNC or numerical control or pocket machin* or (tool life and predict*) or ((condition* monitor* and tool wear) or tool condition* monitor* or spindle condition* monitor* or Machin* condition* monitor* or *ing process* monitor* or machin* health monitor*) or Tool* magazine* or Electric* Spindle* or Motor* Spindle* or High Frequency Spindle* or high speed spindle* or Direct Drive Spindle* or FIVE-AXIS* or Thermal error or ((Quality improvement or surface quality or optimiz*) and (Machin* process* or *lling process*)) or ((tool path* or toolpath*) and (optimiz* or planning or generation) not (link* or diamond or Additive manufacturing or Incremental form*)) or (free-form surface*and machin*) or ((Quality improvement or surface quality or optimiz*) and (Machin* process* or *lling process*)) or ((Adaptive-Control or adaptive planning) and *ing Process*) or (Dynamic simulation and machining process) or (EDM and (process* or machine*)) or ((three-axis or Triaxial or Three-Axes or multi-axis or multi-axes) and machin*) or (machin* center* or machin* centre* or milling center* or milling centre* or grinding center* or grinding centre* or turing center* or turing centre*) or (precision grinder or precision lathe*) or (Fieldbus and industr*) or (Intelligent motion control or Intelligent process control) or Process knowledge base or (intelligent servo* not Holographic Data Storage System*) or ((Flexible Manufactur* or Machin* Process* or industr*) and (Remote operation or Remote service* or Remote monitor* or Remote control* or Production management or human–machine collaboration or augmented reality or Health protection or Health Care)) or (sensor* and Integrat* technology) or ((CAD or CAE) and Integrat* technology) or (Integrat* technology and PLC) or (Integrat* technology and robot*) or (Integrat* technology and network*) or (drilling process* or drilling machin*) or (boring process* or boring machin*) or (reaming process* or reaming machin*) or (slotting process* or slotting machin*) or (broaching process* r broaching machin*) or (gear process* or gear machin*) or (Worm gear and (process* or machin*)) or (screw thread and (process* or machin*)) or rough machin* or Semi-finishing or finishing process* or (forming tool and (process* or machin*)) or digital twin)not TS = (link* or Additive manufacturing or Incremental form* or clinical or NANO* or Agricultur* or Bio* or Cell* or Ecolog* or Chemi* or Medic* or Civil* or Geo* or Energ* or Marine* or Ocean* or Petroleum* or Food* or Photograph* or Physic* or Nuclear or Water* or Transport* or Telecommunication* or Education* or Aerospace or Vehicle* or rock* or Transportation or soccer or air-condition* or Aircraft) and SU = (Automation & Control Systems or Green & Sustainable Science & Technology or Robotics or Engineering) not SU = (Agricultur* or Bio* or Cell* or Ecolog* or Chemi* or Medic* or Civil* or Geo* or Energ* or Marine* or Ocean* or Petroleum* or Food* or Photograph* or Metal* or Physic* or Nuclear or Water* or Transport* or Optic* or Telecommunication* or Acoustic* or Education* or Aerospace or Material* or Mathematic* or Instruments & Instrumentation or Mathematic* or Material* or Business or Management or Planning & Development).

TS = Smart machine tool or (TS = Cyber Physical System or TS = CPS) or TS = Internet of Things machine tool or TS = Internet + machine tool or TS = Sensor machine tool or (TS = Big data collection or TS = Big data storage or TS = Bid data analysis and TS = machine tool) or (TS = Remote monitoring and TS = maintenance) or TS = Unmanned factory or TS = MT-connect Machine tools or TS = NC-link Machine tools or TS = Fieldbus Machine tools or (TS = Cloud computing and TS = Machine tools) or (TS = Parallel computing and TS = Machine tools).

TS = Machine learning and TS = Machine tools or (TS = Machine learning and TS = Machine tools) or (TS = Artificial intelligence and TS = Machine tools) or (TS = Advanced manufacturing Machine tools) or (TS = Adaptive control and TS = Machine tools) or (TS = Autonomous perception and TS = (Machine tools or Manufacturing)) or (TS = Autonomous learning and TS = (Machine tools or Manufacturing)) or (TS = Autonomous decision-making and TS = (Machine tools or Manufacturing)) or (TS = Self-regulation and TS = (Machine tools or Manufacturing)) or (TS = Machining knowledge and TS = (Machine tools or Manufacturing)).

Appendix B

(ALLD = ((Machine ADJ design ADJ technology) or (spindle adj system) or (Electric adj Spindle) or (Motor adj Spindle) or (high adj speed adj spindle) or (High adj Frequency adj Spindle) or (Direct adj Drive adj Spindle) or (Mechanical adj spindle) or (Hydraulic adj spindle) or (Pneumatic adj spindle) or (Tool adj magazine) or ((fieldbus) and (protocols)) or (3-axis) or (three-axis) or (5-axis) or (five-axis) or ((edge) and (intelligent adj module)) or (MACHINE adj TOOL*) or (CNC) or (numerical adj control ADJ machine) or (FIVE-AXIS*) or (machining adj center) or (machining adj centre) or (milling adj center) or (milling adj centre) or (grinding adj center) or (grinding adj centre) or (turing adj center) or (turing adj centre)) and IC = ((B22F) or (B23) or (B24B) or (B26F) or (F16F) or (G01B) or (G01M) or (G01N) or (G01P) or (G01R) or (G01S) or (G02B) or (G03F) or (G05B) or (G06F) or (G06T) or (G08C) or (H02K) or (H03M) or (H04J) or (H04L))) or (ALLD = ((machine ADJ bed) or ((accuracy or stiffness or vibration adj resistance or thermal adj deformation or low-speed adj motion adj stability) and (machine ADJ process)) or (Structural adj process adj design or processing adj technology or assembly adj processability or maintenance adj processability or Support ADJ design) or (spindle adj Bearing) or (feed adj system) or (slide adj rail) or (Linear adj Motor) or (Torque adj motor) or (Screw adj nut) or (gear adj rack) or (Turbine and worm) or (Hydraulic adj system) or (Spindle adj lubrication or oil adj mist adj lubrication or grease adj lubrication) or (Chip adj removal) or (Spindle ADJ cooling) or (screw adj cooling) or (Tool ADJ changer) or (Arc ADJ cam) or (Rotary ADJ Table or turntable) or (robots ADJ integration) or (Networked adj integration) or ((open adj loop) or (closed adj loop) or (semi-closed adj loop) or (half adj closed adj loop)) or (fieldbus or profibus) or (motion adj control adj card) or (((pulse adj string) or (pulse adj train)) and (control)) or (Intelligent adj servo) or (Data adj validation) or (optical-electricity adj encoder) or (optical adj encoder) or (linear adj grating) or (MCA-BTA) or (voice adj sensor) or (on-machine adj test) or (on adj machine adj verification) or (OMV) or (slotting adj machine) or (broaching adj machine) or (Gear adj processing) or (Gear adj machining) or (worm-and-worm adj wheel) or (Screw adj Machining) or (rough adj machining) or (fine adj machining) or (fine adj finishing) or (finish adj machining) or (tool adj path adj machining) or (tool adj path adj processing) or (Forming adj tool adj machining) or (Forming adj tool adj processing) or (Computer adj Aided adj Process adj Planning) or (CAPP) or (computer adj simulation adj technology) or (program adj optimization) or (Tool adj path adj generation) or (process adj database) or (workshop and ((video adj monitoring) or (video adj surveillance))) or (CoAP) or (Data ADJ Distribution ADJ Service) or (MQTT) or (OPC-UA) or (NC-Link) or (Edge adj Computing) or (Fog adj Computing) or (cloud ADJ platform) or (data adj compression) or (signal adj source adj separation) or (Distributed ADJ Control ADJ System) or (feedback ADJ control) or (Ethernet) or (internet) or (3G or 4G or 5G) or (wifi) or (wireless ADJ network) or (cluster and management) or (hub and management) or (workflow and management) or ((data ADJ process*or ADJ data ADJ access*or ADJ data ADJ deliver*or ADJ time-domain or frequency-domain) and service) or (distribut*adj ADJ comput*) or (user ADJ interface) or (data adj analy*) or (Dynamic adj visualization)) and IC = ((B23) or (G05B001918)));

(ALLD = (Machine adj tool*) and ALLD = (Cyber ADJ Physical ADJ System or Internet ADJ Of ADJ Things or Sensor or Big ADJ data or Remote ADJ monitoring and maintenance or Unmanned ADJ factory or MT-connect or NC-link or Fieldbus or Cloud ADJ computing or Parallel ADJ computing));

(ALLD = (Machine adj tool*) and ALLD = (Machine adj learning or Artificial adj intelligent adj 2.0 or Advanced adj manufacturing or Adaptive adj control or Autonomous adj perception or Autonomous adj learning or Autonomous adj decision-making or Self-regulation or Machining adj knowledge)).

References

- Zhou, J. Intelligent Manufacturing—Main Direction of “Made in China 2025”. China Mech. Eng. 2015, 26, 2273–2284. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Ullah, A.S.; Teti, R.; Kubo, A. Developing sensor signal-based digital twins for intelligent machine tools. J. Ind. Inf. Integr. 2021, 24, 100242. [Google Scholar] [CrossRef]

- Lou, P.; Liu, S.; Hu, J.; Li, R.; Xiao, Z.; Yan, J. Intelligent Machine Tool Based on Edge-Cloud Collaboration. IEEE Access 2020, 8, 139953–139965. [Google Scholar] [CrossRef]

- Porter, A.L.; Roessner, J.D.; Jin, X.Y.; Newman, N.C. Measuring national ‘emerging technology’ capabilities. Sci. Public Policy 2002, 29, 189–200. [Google Scholar] [CrossRef]

- Chen, X.; Tang, X.; Xu, X. Digital technology-driven smart society governance mechanism and practice exploration. Front. Eng. Manag. 2023, 10, 319–338. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, H.; Liu, Y.; Ding, W. A novel method to identify emerging technologies using a semi-supervised topic clustering model: A case of 3D printing industry. Scientometrics 2019, 120, 167–185. [Google Scholar] [CrossRef]

- Wang, X.; Guo, J.; Gu, D.; Yang, Y.; Yang, X.; Zhu, K. Tracking knowledge evolution, hotspots and future directions of emerging technologies in cancers research: A bibliometrics review. J. Cancer 2019, 10, 2643–2653. [Google Scholar] [CrossRef]

- Asif, M.; Shen, H.; Zhou, C.; Guo, Y.; Yuan, Y.; Shao, P.; Xie, L.; Bhutta, M. Recent Trends, Developments, and Emerging Technologies towards Sustainable Intelligent Machining: A Critical Review, Perspectives and Future Directions. Sustainability 2023, 15, 8298. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, F.; Liu, Y.; Ran, L. A deep learning framework to early identify emerging technologies in large-scale outlier patents: An empirical study of CNC machine tool. Scientometrics 2021, 126, 969–994. [Google Scholar] [CrossRef]

- Kong, D.; Zhou, Y.; Liu, Y.; Xue, L. Using the data mining method to assess the innovation gap: A case of industrial robotics in a catching-up country. Technol. Forecast. Soc. Chang. 2017, 119, 80–97. [Google Scholar] [CrossRef]

- Khan, G.F.; Wood, J. Information technology management domain: Emerging themes and keyword analysis. Scientometrics 2015, 105, 959–972. [Google Scholar] [CrossRef]

- Carley, S.F.; Newman, N.C.; Porter, A.L.; Garner, J.G. An indicator of technical emergence. Scientometrics 2018, 115, 35–49. [Google Scholar] [CrossRef]

- Geum, Y.; Kim, C.; Lee, S.; Kim, M.-S. Technological Convergence of IT and BT: Evidence from Patent Analysis. ETRI J. 2012, 34, 439–449. [Google Scholar] [CrossRef]

- Kim, G.; Bae, J. A novel approach to forecast promising technology through patent analysis. Technol. Forecast. Soc. Chang. 2017, 117, 228–237. [Google Scholar] [CrossRef]

- Yuan, G.; Zhen, Z.; Raja, K.; Massimo, R. Community evolution in patent networks: Technological change and network dynamics. Appl. Netw. Sci. 2018, 3, 26. [Google Scholar] [CrossRef]

- Lee, M.; Kim, S.; Kim, H.; Lee, J. Technology Opportunity Discovery using Deep Learning-based Text Mining and a Knowledge Graph. Technol. Forecast. Soc. Chang. 2022, 180, 121718. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Y.; Chu, H.; Tang, J. Expert Interaction Technology Roadmapping Approach:Driven by Engineering Science and Technology Knowledge Graph. Sci. Sci. Manag. S. T. 2021, 42, 29–47. [Google Scholar]

- Kipf, T.N.; Welling, M. Semi-Supervised Classification with Graph Convolutional Networks. arXiv 2016. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J. Toward New-Generation Intelligent Manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Chen, J.; Hu, P.; Zhou, H.; Yang, J.; Xie, J.; Jiang, Y.; Gao, Z.; Zhang, C. Toward Intelligent Machine Tool. Engineering 2019, 5, 679–690. [Google Scholar] [CrossRef]

- Banuls, V.A.; Salmeron, J.L. Foresighting key areas in the Information Technology industry. Technovation 2008, 28, 103–111. [Google Scholar] [CrossRef]

- Lee, S.; Kim, W.; Kim, Y.M.; Lee, H.Y.; Oh, K.J. The prioritization and verification of IT emerging technologies using an analytic hierarchy process and cluster analysis. Technol. Forecast. Soc. Chang. 2014, 87, 292–304. [Google Scholar] [CrossRef]

- Song, K.; Kim, K.; Lee, S. Identifying promising technologies using patents: A retrospective feature analysis and a prospective needs analysis on outlier patents. Technol. Forecast. Soc. Chang. 2018, 128, 118–132. [Google Scholar] [CrossRef]

- Tu, Y.N.; Seng, J.L. Indices of novelty for emerging topic detection. Inf. Process. Manag. 2012, 48, 303–325. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, F.; Kong, D.; Liu, Y. Unfolding the convergence process of scientific knowledge for the early identification of emerging technologies. Technol. Forecast. Soc. Chang. 2019, 144, 205–220. [Google Scholar] [CrossRef]

- Zhou, Y.; Miao, Z.; Urban, F. China’s leadership in the hydropower sector: Identifying green windows of opportunity for technological catch-up. Ind. Corp. Chang. 2020, 29, 1319–1343. [Google Scholar] [CrossRef]

- Dong, F.; Liu, Y.; Zhou, Y. Prediction of Emerging Technologies Based on LDA-SVM Multi-class Abstract of Paper Classification. J. Intell. 2017, 36, 40–45. [Google Scholar] [CrossRef]

- Lee, C.; Kwon, O.; Kim, M.; Kwon, D. Early identification of emerging technologies: A machine learning approach using multiple patent indicators. Technol. Forecast. Soc. Chang. 2018, 127, 291–303. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, F.; Liu, Y.; Li, Z.; Du, J.; Zhang, L. Forecasting emerging technologies using data augmentation and deep learning. Scientometrics 2020, 123, 1–29. [Google Scholar] [CrossRef]

- Fortunato, S.; Newman, M.E.J. 20 years of network community detection. Nat. Phys. 2022, 18, 848–850. [Google Scholar] [CrossRef]

- Blondel, V.D.; Guillaume, J.-L.; Lambiotte, R.; Lefebvre, E. Fast unfolding of communities in large networks. J. Stat. Mech. Theory Exp. 2008, 2008, P10008. [Google Scholar] [CrossRef]

- Girvan, M.; Newman, M. Community structure in social and biological networks. Proc. Natl. Acad. Sci. USA 2002, 99, 7821–7826. [Google Scholar] [CrossRef] [PubMed]

- Peixoto, T.P. Parsimonious Module Inference in Large Networks. Phys. Rev. Lett. 2013, 110, 148701. [Google Scholar] [CrossRef] [PubMed]

- Rosvall, M.; Bergstrom, C.T. Maps of random walks on complex networks reveal community structure. Proc. Natl. Acad. Sci. USA 2008, 105, 1118–1123. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Wei, Z.; Wen, J.R. Convolutional Neural Networks on Graphs with Chebyshev Approximation, Revisited. Adv. Neural Inf. Process. Syst. 2022, 35, 7264–7276. [Google Scholar] [CrossRef]

- National Manufacturing Power Building Strategic Advisory Committee; Strategic Consulting Center of Chinese Academy of Engineering. Green Paper on Technoogical Innovation in Key Fields of China’s Manufacturing Industry—Technology Roadmap (2019); Electronics Industry Press: Beijing, China, 2020; pp. 53–64. [Google Scholar]

- Reimers, N.; Gurevych, I. Sentence-BERT: Sentence Embeddings using Siamese BERT-Networks. arXiv 2019. [Google Scholar] [CrossRef]

- Cen, Y.K.; Zou, X.; Zhang, J.W.; Yang, H.X.; Zhou, J.R.; Tang, J. Representation Learning for Attributed Multiplex Heterogeneous Network. In Proceedings of the KDD’19 25th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, Anchorage, AK, USA, 4–8 August 2019; pp. 1358–1368. [Google Scholar]

- Kuncheva, L.I.; Vetrov, D.P. Evaluation of stability of k-means cluster ensembles with respect to random initialization. IEEE Trans. Pattern Anal. Mach. Intell. 2006, 28, 1798–1808. [Google Scholar] [CrossRef]

- Kong, D.; Dong, F.; Chen, Z.; Liu, Y.; Zhou, Y. Prediction of Emerging Technologies from the Perspective of Outlier Patents—Based on Bert Model and Deep Neural Networks. Libr. Inf. Serv. 2021, 65, 131–141. [Google Scholar] [CrossRef]

- Haupt, R.; Kloyer, M.; Lange, M. Patent indicators for the technology life cycle development. Res. Policy 2007, 36, 387–398. [Google Scholar] [CrossRef]

- Bierly, P.; Chakrabarti, A. Determinants of technology cycle time in the U.S. pharmaceutical industry. R&D Manag. 1996, 26, 115–126. [Google Scholar] [CrossRef]

- Ma, Z.; Lee, Y. Patent application and technological collaboration in inventive activities: 1980–2005. Technovation 2008, 28, 379–390. [Google Scholar] [CrossRef]

- El-Kishky, A.; Song, Y.; Wang, C.; Voss, C.R.; Han, J. Scalable Topical Phrase Mining from Text Corpora. Proc. Vldb Endow. 2014, 8, 305–316. [Google Scholar] [CrossRef]

- Navas, C.; Yepes, A.; Abolghasem, S.; Barbieri, G. MTConnect-based decision support system for local machine tool monitoring. ISM 2020 2021, 180, 69–78. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Y.; Liu, L.; Zhang, B.; Shi, Z.; Guo, Y. Machine tool spindle vibration monitoring system based on Bluetooth wireless network and LabVIEW. Ferroelectrics 2023, 609, 137–147. [Google Scholar] [CrossRef]

- Aldalur, E.; Suárez, A.; Curiel, D.; Veiga, F.; Villanueva, P. Intelligent and Adaptive System for Welding Process Automation in T-Shaped Joints. Metals 2023, 13, 1532. [Google Scholar] [CrossRef]

- Olalere, I.; Olanrewaju, O. Optimising Turning Operation in Precision Manufacturing Using Fused IoT Devices and Machine Learning Approach. IFAC-Pap. 2022, 55, 1551–1555. [Google Scholar] [CrossRef]

- Huang, W.; Jin, Z.; Li, N.; Liu, C.; Li, M. Machine Tools Fingerprinting for Distributed Numerical Control Systems. In Proceedings of the 2019 IEEE 44th Conference on Local Computer Networks (LCN), Osnabrueck, Germany, 14–17 October 2019; pp. 348–355. [Google Scholar] [CrossRef]

- Ouerhani, N.; Loehr, B.; Rizzotti-Kaddouri, A.; Santo De Pinho, D.; Limat, A.; Schinderholz, P. Data-Driven Thermal Deviation Prediction in Turning Machine-Tool—A Comparative Analysis of Machine Learning Algorithms. Procedia Comput. Sci. 2022, 200, 185–193. [Google Scholar] [CrossRef]

- Chan, T.; Reddy, S.; Ullah, A.; Roy, B. Effect of spatial moving structure and topology optimization of the CNC turning machine tools. Int. J. Adv. Manuf. Technol. 2023, 129, 2969–2987. [Google Scholar] [CrossRef]

- Liu, W.; He, Y.; Dong, J.; Cao, Y. Disruptive technologies for advancing supply chain resilience. Front. Eng. Manag. 2023, 10, 360–366. [Google Scholar] [CrossRef]

- Sankaran, S.; Killen, C.P.; Pitsis, A. How do project-oriented organizations enhance innovation? An institutional theory perspective. Front. Eng. Manag. 2023, 10, 427–438. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).