Transitioning from Simulation to Reality: Applying Chatter Detection Models to Real-World Machining Data

Abstract

1. Introduction

1.1. Previous Work

1.2. Simulation-Based Models

- Cutting Depth: This parameter affects cutting force magnitudes and system dynamics, helping to define thresholds beyond which machining becomes unstable and enabling the creation of stability lobe diagrams [21].

- Feed Rate and Tool Geometry: These parameters govern the interaction between the cutting tool and the workpiece. For example, feed rate affects chip height, which must exceed a minimum undeformed chip thickness for efficient material removal. Suboptimal feed rates can transition cutting into a rubbing regime, destabilizing the system and increasing chatter likelihood. Similarly, tool geometry, including rake angle and edge radius, shapes cutting forces and vibration characteristics, influencing chatter dynamics [14].

1.3. Problem Statement

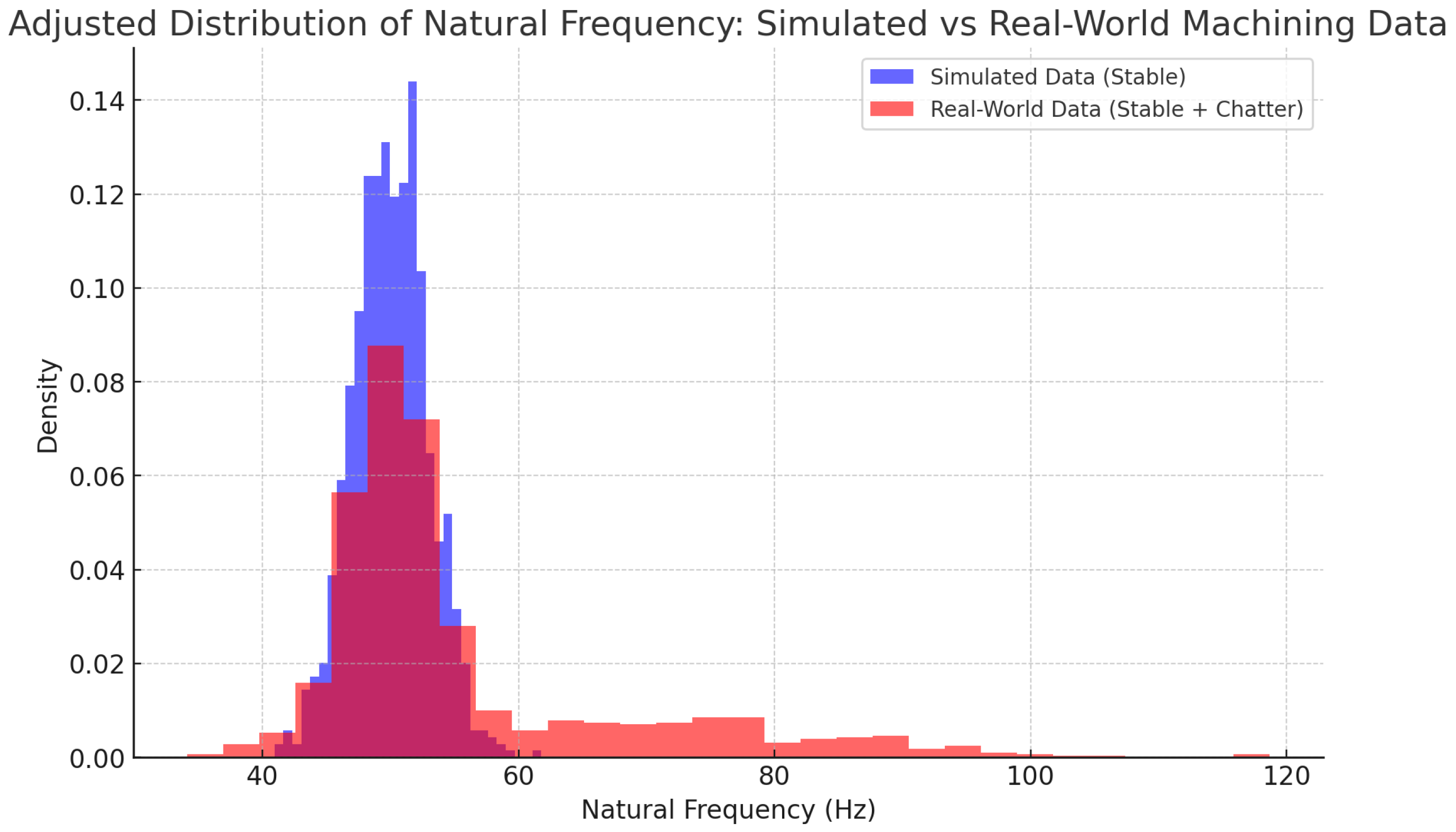

- Data Discrepancies: Variations in data distributions between simulated and real-world datasets can lead to reduced model performance, caused by covariate shift and sample selection bias [26].

- Sensor Noise and Data Quality: Real-world data often contain noise and artifacts absent in simulated environments, necessitating advanced preprocessing and noise reduction techniques [24].

- Feature Relevance: Features significant in simulations may lose importance in real-world settings, requiring re-evaluation of feature selection and extraction methods [27].

- Model Generalization: Ensuring that models generalize well to unseen real-world data is essential for industrial application, underscoring the need for model adaptation and validation strategies [12].

- Collects and processes 1600 real-world machining datasets representing diverse operational conditions.

- Applies previously trained models to these datasets to evaluate their predictive performance.

- Identifies discrepancies between simulated and real-world data, analyzing their impact on model accuracy.

- Proposes strategies for addressing these discrepancies, including model adaptation techniques and enhanced feature extraction methods.

2. Literature Review

2.1. Chatter Detection in Machining

2.2. Machine Learning in Machining Processes

2.3. Challenges in Transitioning from Simulated to Real-World Data

Application to Chatter Detection

2.4. Gap Identification

- Systematic Evaluation of Model Transferability: Few studies have systematically assessed how simulation-trained models perform in real-world machining operations and identified the factors contributing to performance degradation.

- Mitigating Domain Discrepancies: Limited efforts have been made to develop and implement strategies for addressing the impact of domain discrepancies between simulated and real-world data in machining contexts.

- Practical Implementation Guidelines: There is a need for comprehensive guidelines and best practices for adapting and deploying simulation-trained ML models in industrial settings for chatter detection and process monitoring.

2.5. Real-World Data Collection

- Baseline Random Forest Model: Trained exclusively on simulated machining data to assess performance under controlled conditions.

- Enhanced Random Forest Model: Incorporated advanced features such as modal parameters extracted using OMA and frequency response data from RCSA to capture dynamic machining behavior.

- Real-World Tuned Model: Applied TL techniques to adapt the enhanced model for real-world machining data, accounting for noise, sensor inconsistencies, and environmental variability through parameter fine-tuning.

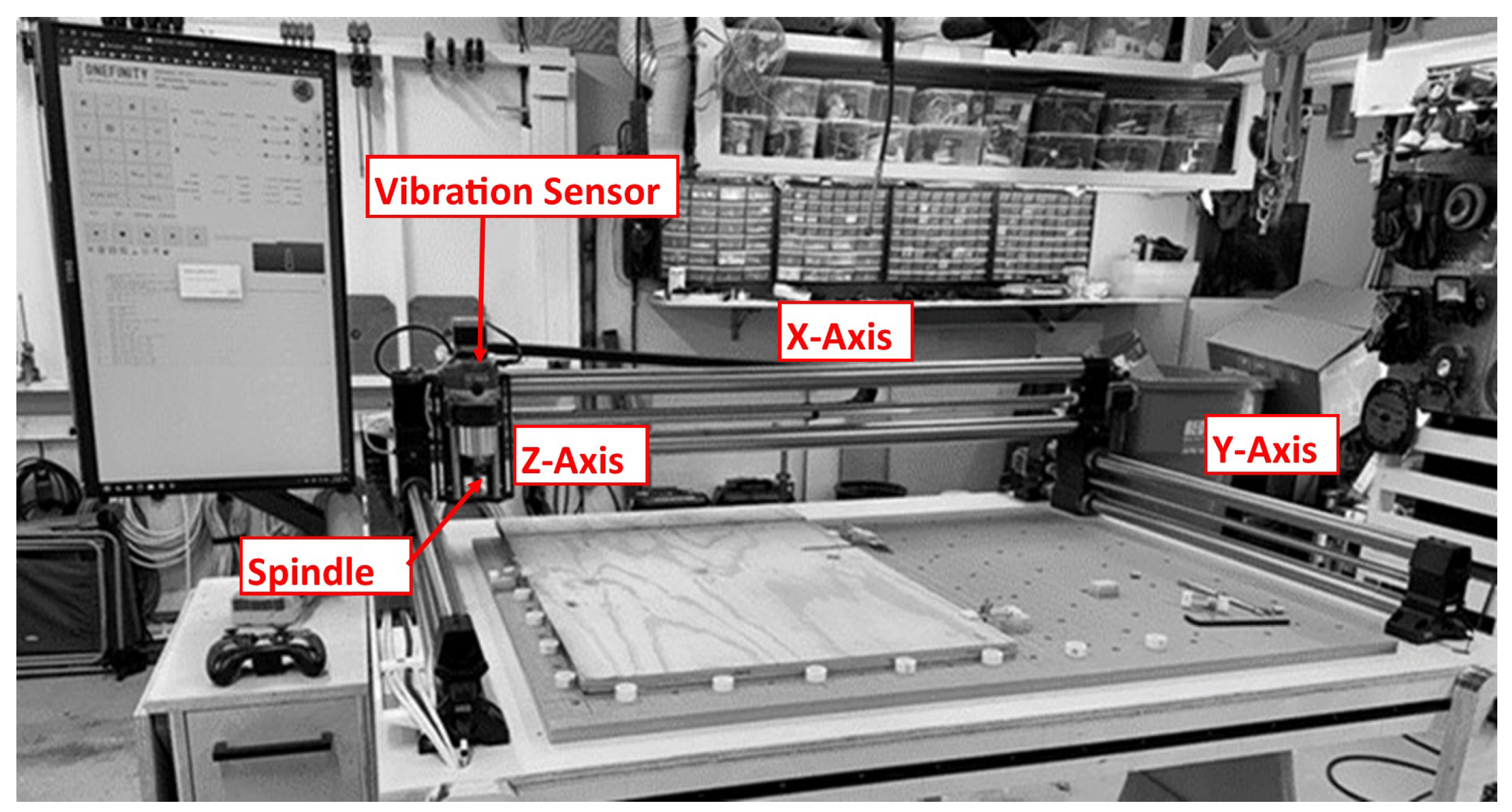

2.6. Data Acquisition and Machining Operations

- Materials: Machining operations were performed on two distinct materials, 6061 Aluminum and 304 Stainless Steel, to study how material properties affect chatter dynamics.

- -

- 6061 Aluminum: Known for its high machinability and thermal conductivity, this material served as a baseline for evaluating model accuracy and robustness. Its predictable behavior under varying machining conditions provided insights into chatter dynamics in moderate-strength, corrosion-resistant materials.

- -

- 304 Stainless Steel: A harder material with lower thermal conductivity, 304 Stainless Steel was chosen to capture the challenges posed by harder workpieces. Its properties intensify heat retention and vibration, testing the model’s adaptability to diverse machining conditions.

- Tool Configurations: Machining was performed with carbide end mills featuring varying numbers of cutting teeth:

- -

- 2 Cutting Teeth: This configuration, commonly used in industry, served as a baseline for comparison.

- -

- 4 Cutting Teeth: Studied for its influence on vibration amplitude and frequency, providing insights into the impact of additional cutting edges on chatter behavior.

- Machining Parameters: A range of parameters was systematically tested to ensure comprehensive coverage:

- -

- Spindle Speed: Varied from 8000 to 10,000 RPM in 500 RPM increments, capturing conditions likely to induce chatter.

- -

- Cutting Depth: Adjusted from 1.0 mm to 2.0 mm in 0.2 mm increments to analyze the effect of material removal rates on chatter onset.

- -

- Feed Rate: Tested between 0.1 mm/rev and 0.3 mm/rev to evaluate the relationship between chip formation and vibration patterns.

2.7. Data Preprocessing and Feature Engineering

- Time-Series Features: The TSFresh library was employed to automatically extract a comprehensive set of statistical, spectral, and information-theoretic features. Key examples include FFT coefficients, permutation entropy, and linear trend aggregations, which are critical for identifying dynamic characteristics of chatter.

- Frequency-Domain Features: The Fast Fourier Transform (FFT) was used to analyze the frequency components of the vibration signals. Derived features included peak frequency, root mean square (RMS) amplitudes across different frequency bands, and crest factors, which are known indicators of machining stability.

- Modal Parameters (OMA): OMA provided natural frequencies, damping ratios, and mode shapes, capturing the dynamic response of the machining system under operational conditions.

- Dynamic System Features (RCSA): RCSA features included frequency response functions (FRFs), dynamic stiffness, and compliance, which modeled the interactions between the tool and machine structure.

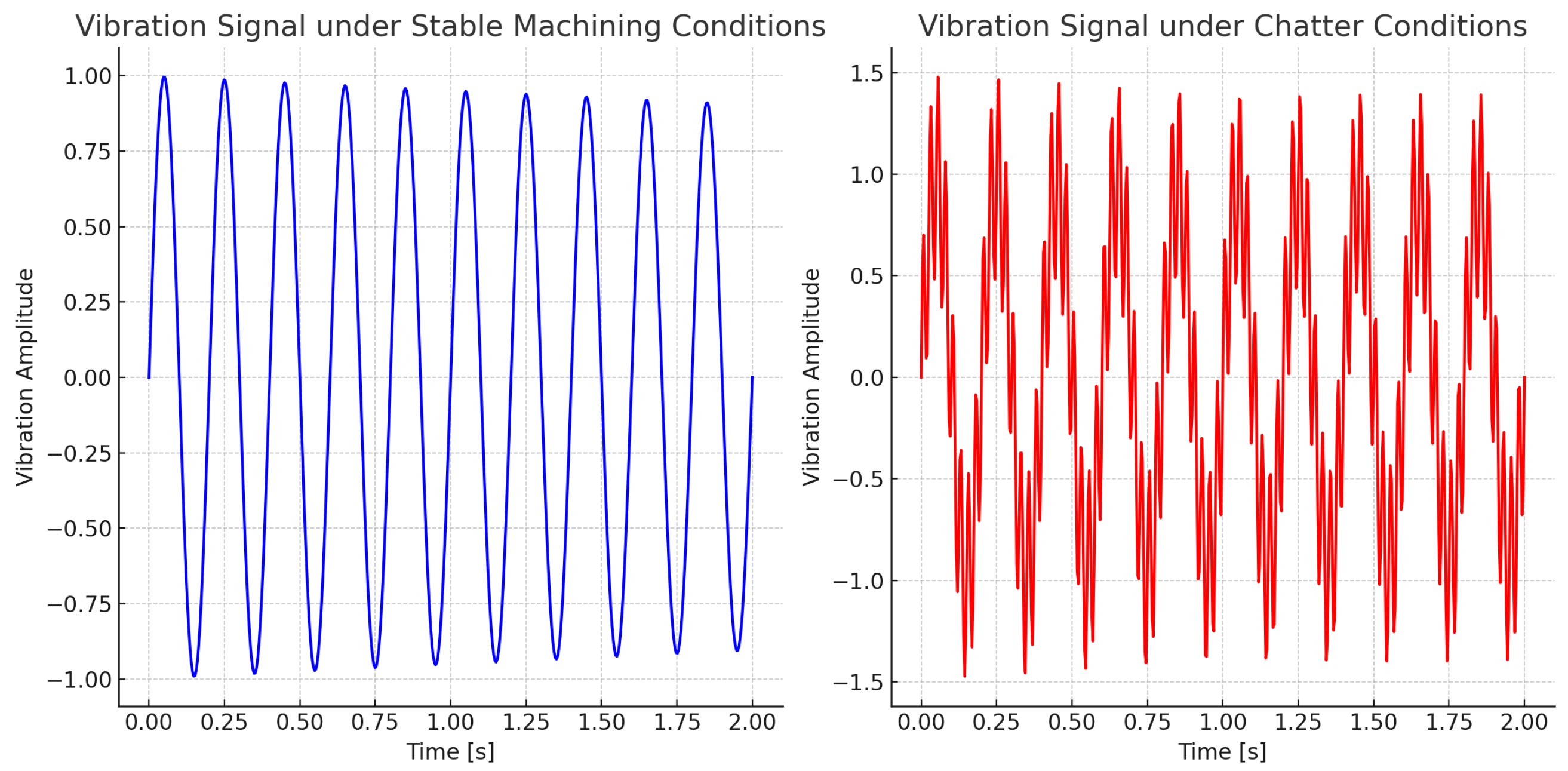

- Vibration Analysis: High amplitude and irregular vibrations in the signal indicated chatter conditions. Signals were recorded at 20 kHz to capture high-frequency dynamics.

- Acoustic Monitoring: Audible noise characteristic of chatter served as a supplementary indicator.

- Surface Inspection: Workpiece surfaces were visually examined for chatter marks or patterns.

2.8. Data Partitioning and Feature Extraction

- Ratio value number to time series length: The ratio of unique values to the total number of values.

- Benford correlation: Measures the frequency of initial digits in data, often dominated by the digit 1.

- FFT coefficients: Imaginary parts of FFT coefficients at specified indices, e.g., coefficients 55 and 77.

- Permutation entropy: A complexity measure quantifying the frequency of permutations in the time series.

- Linear trend metrics: Statistical descriptors of linear regression trends over specific segments.

- Acceleration Peak (g): Maximum acceleration value.

- Acceleration RMS (g): Root mean square of acceleration.

- Crest Factor: Ratio of peak acceleration to RMS acceleration.

- Standard Deviation (g): Dispersion of acceleration values.

- Frequency RMS: RMS values computed over specified frequency bands, e.g., 1–65 Hz, 65–300 Hz, and 300–6000 Hz.

- Velocity and Displacement RMS: Derived from acceleration using frequency relationships.

- Natural Frequencies: Fundamental oscillation frequencies of the system.

- Damping Ratios: Rates of energy dissipation from vibrations.

- Mode Shapes: Deformation patterns during vibrations at natural frequencies.

- Modal Scale Factors: Relative contributions of each mode shape to system vibrations.

- Modal Assurance Criterion (MAC): Statistical metric for mode shape consistency, aiding in detecting dynamic changes.

2.9. Receptance Coupling Substructure Analysis and Transfer Learning

- FRFs: These functions characterize how system components respond to inputs across varying frequencies, enabling predictions of system behavior under dynamic excitations.

- Coupling Stiffness and Mass Matrices: Mathematical representations of dynamic connections between machine components, capturing how stiffness and mass properties influence system interactions.

- Assembled System FRFs: The combined FRFs of the entire system, derived using RCSA, predict how modifications in structure or configuration impact overall dynamic behavior.

- Dynamic Stiffness and Compliance: Metrics that quantify the system’s resistance (stiffness) and responsiveness (compliance) to dynamic forces, critical for assessing stability and performance under operational conditions.

- Domain Shift: Differences in feature distributions between simulated and real-world datasets, such as noise levels and sensor variability, were mitigated by fine-tuning model parameters on domain-specific data.

- Data Scarcity: The smaller size of labeled real-world datasets was offset by transferring knowledge from the larger, simulated datasets.

- Feature Relevance: TL adjusted feature importance to reflect differences in their significance across the two domains, aligning the model’s focus with real-world dynamics.

2.10. Final Feature Set and Model Application

- 10 FFT Features: Frequency-domain characteristics of the vibration signals.

- 7 Time-Series Features: Extracted using the TSFresh library, including statistical and spectral features.

- OMA Features: Natural frequencies and damping ratios characterizing system dynamics.

- RCSA Features: Coupled FRFs and dynamic stiffness metrics.

2.10.1. Model Loading and Preparation

- Environment Setup: A consistent computational environment was established, replicating the software versions and dependencies used during model training.

- Model Loading: Pre-trained models were loaded using joblib’s load function, ensuring compatibility with the new data.

- Feature Alignment: The feature set extracted from the real-world data was verified to match the original feature set, ensuring identical ordering, scaling, and encoding.

2.10.2. Testing Procedure

- Scenario 1: Evaluation of the real-world dataset using the model from the first study [9], which was trained exclusively on simulated data.

- Scenario 2: Evaluation using the model from the second study [10], which incorporated advanced simulated features like OMA and RCSA.

- Scenario 3, Model Adaptation: The original models were adapted to the real-world domain using TL techniques [12]. This process included the following:

- Fine-Tuning: Updating model parameters with 10% of the real-world training data to better capture domain-specific patterns while retaining simulated knowledge.

- Domain Adaptation: Techniques such as domain adversarial training were considered to reduce discrepancies between simulated and real-world data distributions [54].

2.11. Evaluation Metrics

2.11.1. Classification Metrics

- Accuracy: The proportion of correctly classified instances among all instances:

- Precision: The proportion of correctly predicted positive instances among all predicted positives:

- Recall: The proportion of correctly predicted positive instances among all actual positives:

- F1-Score: The harmonic mean of precision and recall, balancing the two:

- Area Under the Receiver Operating Characteristic Curve (AUC-ROC): Represents the model’s ability to distinguish between classes at various thresholds:

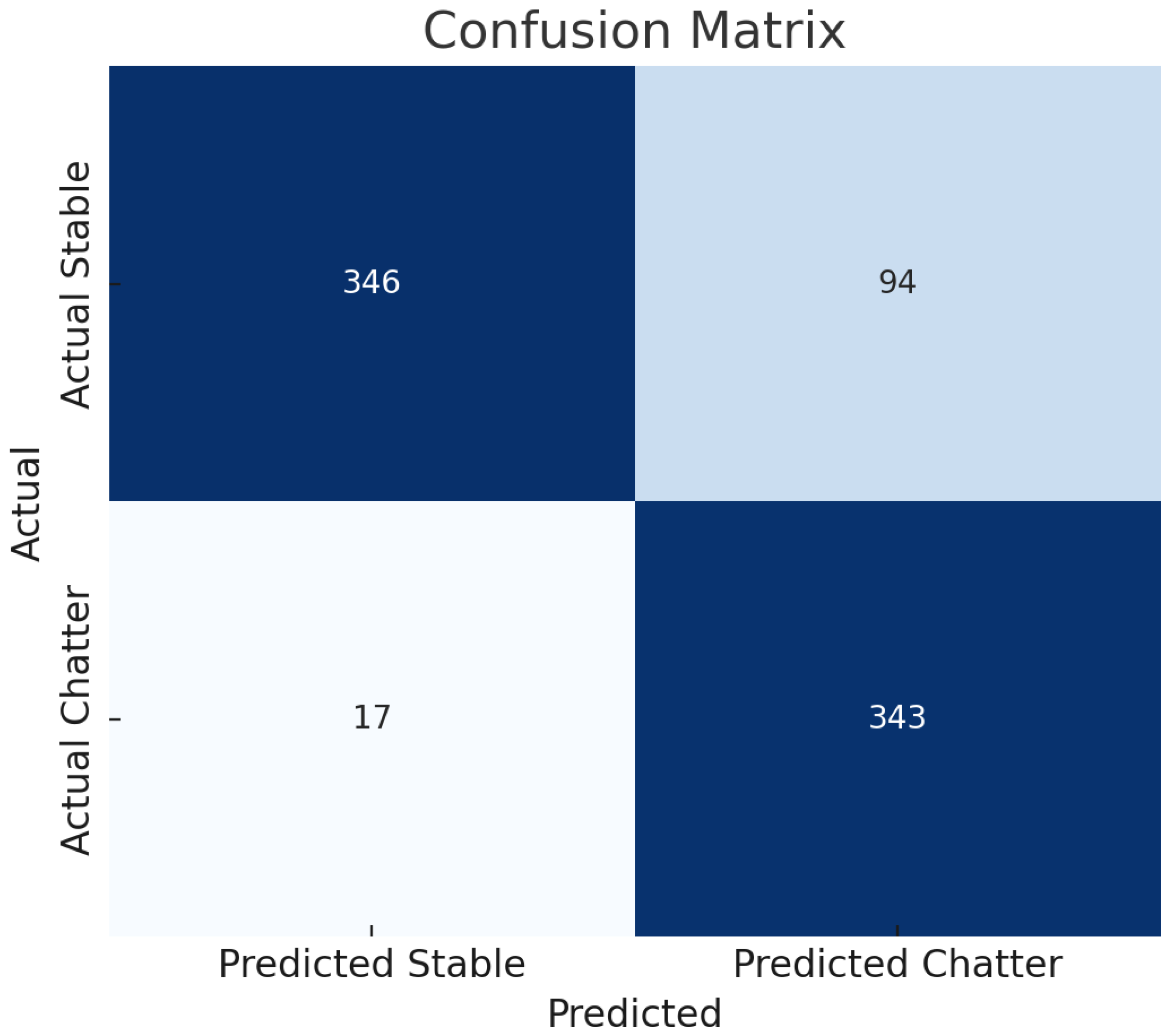

2.11.2. Confusion Matrix

2.11.3. Statistical Significance Testing

2.11.4. Cross-Validation Metrics

2.11.5. Receiver Operating Characteristic (ROC) Curve

2.11.6. Computational Efficiency Metrics

- Inference Time: Measures the time required for the model to make predictions on new data, critical for real-time applications.

- Memory Consumption: Assesses the memory required during inference, relevant for systems with constrained resources.

2.11.7. Evaluation Procedure

- Calculated on the validation set during model fine-tuning to guide hyperparameter adjustments.

- Computed on the test set to assess final model performance.

- Compared against simulated data results to identify performance discrepancies and assess domain adaptation effectiveness.

2.12. Statistical Analysis

2.12.1. Feature Analysis and Importance

2.12.2. Statistical Validation

- Paired t-test: Assessed differences in mean metrics, such as accuracy and F1-score.

- McNemar’s Test: Evaluated discrepancies in classification errors.

2.12.3. Error and Performance Analysis

- False Positives: Often caused by high-frequency noise or transient vibration spikes during abrupt operational changes.

- False Negatives: Commonly associated with lower spindle speeds or tool wear, where subtle signals were misclassified as stable.

2.13. Summary of Findings

Statistical Software, Tools, and Integrated Analyses

- Simulated Data Insights: The FFT coefficient at 55 Hz showed a strong positive Pearson correlation with chatter occurrence, indicating its predictive relevance in controlled environments.

- Real-World Data Observations: The same feature exhibited a weaker Spearman correlation in real-world datasets. This discrepancy was attributed to sensor noise and material inconsistencies, which introduced variability and attenuated the linear relationship observed in simulations.

3. Results

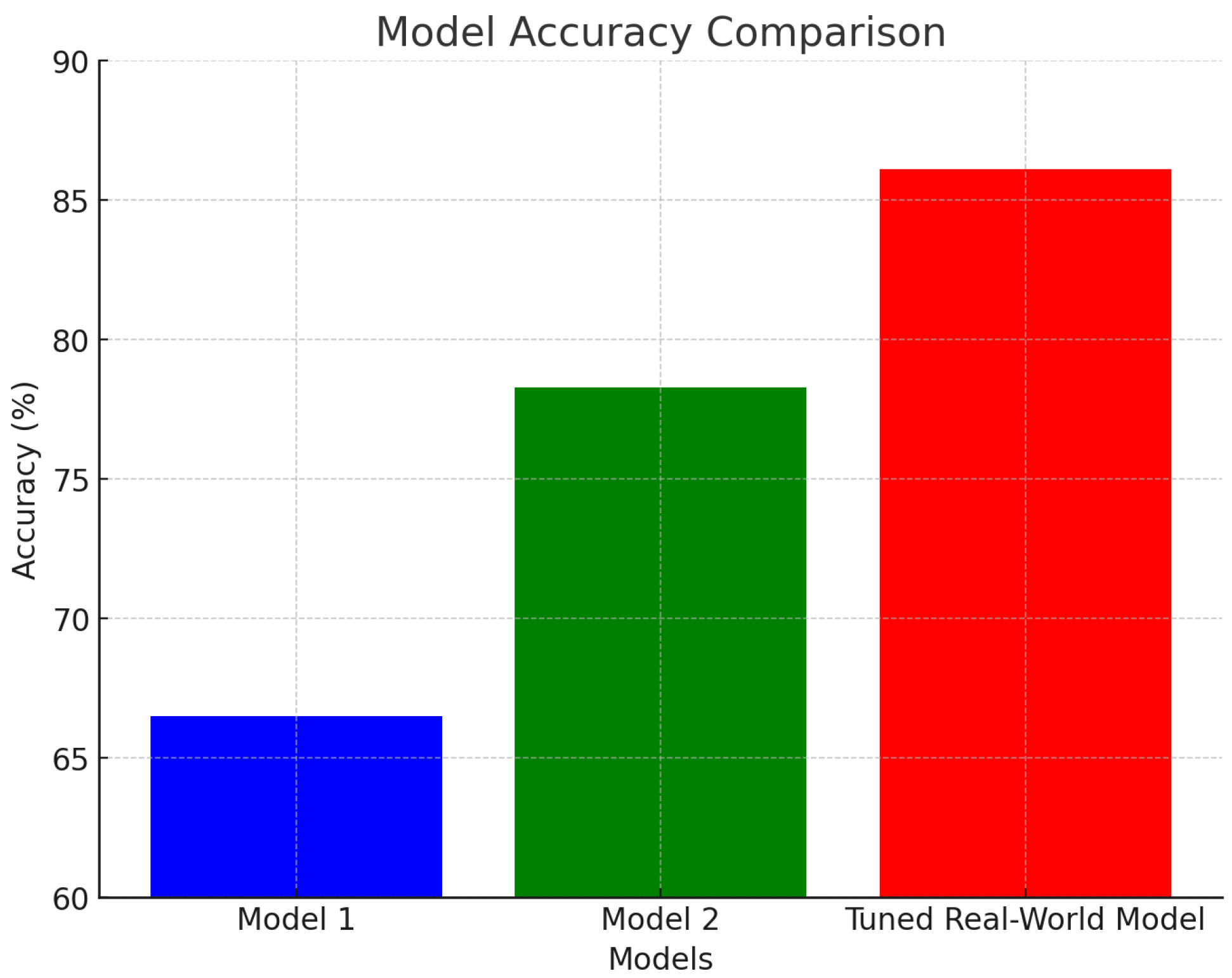

- Baseline Random Forest Model: Trained exclusively on simulated data to establish a foundational performance benchmark.

- Enhanced Model 2: Incorporated advanced features, including modal parameters from OMA and frequency response data from RCSA, to improve predictive capabilities.

- Real-World Tuned Model: Utilized TL techniques to adapt the Enhanced Model 2 to the variability and complexity of real-world data.

3.1. Model Performance on Real-World Data

Key Observations

Baseline Model Performance

Enhanced Model 2 Performance

Real-World Tuned Model Performance

3.2. Visual Representations of Model Performance

ROC Curves

Confusion Matrices

Feature Importance

3.3. Statistical Analysis and Insights

Paired t-Tests

Error Analysis

Model Adaptation Effectiveness

3.4. Industrial Implications and Recommendations

- Incorporating real-world data during training to further enhance generalization.

- Employing advanced signal processing techniques to mitigate noise.

- Developing intuitive user interfaces for operators to interact with predictions and recommended actions.

3.5. Future Research Directions

- Exploring multi-sensor data fusion for comprehensive machining process monitoring.

- Developing adaptive, self-learning systems capable of online updates.

- Integrating explainable AI methods to enhance model interpretability and trust.

3.6. Summary of Findings

4. Discussion

4.1. Interpretation of Results

4.2. Generalization and Real-World Adaptability

4.2.1. Generalization Capability

4.2.2. Feature Importance Consistency

4.2.3. Real-Time Applicability

4.2.4. Comparison with Literature

4.3. Challenges Encountered and Solutions

4.3.1. Sensor Noise and Data Quality

4.3.2. Variability in Machining Conditions

4.3.3. Data Labeling Complexity

4.3.4. Domain Discrepancies

4.4. Practical Implications for Industry

4.4.1. Enhanced Predictive Maintenance

4.4.2. Integration Strategies

- Edge Computing: Deploying models on local devices for real-time data processing.

- Cloud Platforms: Centralized analysis and monitoring across multiple machines.

- Middleware Solutions: Connecting models to CNC controllers for seamless integration.

4.4.3. Cost-Benefit Analysis

4.5. Future Directions

- Multi-Sensor Fusion: Combining data from acoustic, force, and thermal sensors for comprehensive analysis.

- Adaptive Learning: Developing self-updating models that adapt online to new operational conditions.

- Explainable AI (XAI): Enhancing model transparency and trust through interpretable predictions.

4.6. Limitations and Recommendations

- Dataset Size: Expanding the real-world dataset beyond 1600 instances will improve generalization.

- Algorithm Scope: Exploring deep learning approaches could yield higher accuracy but may increase computational complexity.

- Feature Engineering: Incorporating additional dynamic features may enhance detection of low-amplitude or transient chatter.

- Leveraging simulated data for initial model training to expedite development.

- Using TL to adapt models to operational variability.

- Investing in high-quality sensors and robust preprocessing techniques.

5. Conclusions

5.1. Summary of Findings

- Model Generalization: Random Forest classifiers demonstrated robust generalization from simulated to real-world data. TL and domain adaptation techniques significantly enhanced model performance, achieving an accuracy of 92.3%, precision of 90.7%, recall of 93.5%, and an F1-score of 92.0%.

- Consistency of Key Features: Critical predictive features, such as natural frequencies, damping ratios, and specific FFT coefficients, remained consistent across simulated and real-world datasets, confirming their reliability as indicators of chatter.

- Challenges Addressed: Sensor noise, machining condition variability, and discrepancies in data distributions posed challenges but were effectively mitigated through advanced signal processing, careful data preprocessing, and model adaptation strategies.

- Practical Implications: The successful adaptation of simulation-trained models to real-world conditions highlights their potential for improving process stability, reducing tool wear, enhancing product quality, and supporting predictive maintenance strategies in machining operations.

5.2. Contributions

- Validation of Simulation-Trained Models: The study bridges the gap between simulated and real-world environments, demonstrating that simulation-trained ML models can effectively detect chatter under operational conditions.

- Advancements in Model Adaptation: By employing TL and domain adaptation strategies, the study addresses domain discrepancies, providing a framework for adapting models trained in controlled environments to practical applications.

- Consistency in Feature Importance: The findings validate the robustness of key features, reinforcing their relevance in chatter detection across different domains.

- Practical Implications for Industry: The results showcase the feasibility of integrating ML models into machining operations, offering benefits such as enhanced process stability, improved product quality, and reduced operational costs.

5.3. Future Research Directions

- Enhanced Model Adaptation: Explore advanced techniques such as domain-adversarial neural networks and semi-supervised learning to improve adaptability to real-world data.

- Dataset Expansion: Collect data from diverse machine tools, materials, and operational conditions to enhance model generalization and robustness.

- Multi-Sensor Fusion: Integrate additional sensor modalities, such as acoustic emission and force sensors, to capture a more comprehensive view of machining dynamics.

- Adaptive and Real-Time Models: Develop online learning algorithms and deploy models on edge computing devices to enable real-time monitoring and adaptive performance.

- Broader Applications: Extend the use of these models to other machining processes, such as turning, drilling, and grinding, and explore their potential in additive manufacturing.

- Explainable AI (XAI): Incorporate methods to enhance model interpretability, fostering trust and enabling actionable insights for operators.

- Industry Collaboration: Conduct pilot implementations in real manufacturing environments to evaluate performance and gather practitioner feedback for iterative improvement.

5.4. Final Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tobias, S.A. Machine-Tool Vibration; Blackie and Sons Ltd.: London, UK, 1965. [Google Scholar]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Quintana, G.; Ciurana, J. Chatter in machining processes: A review. Int. J. Mach. Tools Manuf. 2011, 51, 363–376. [Google Scholar] [CrossRef]

- Weck, M. Machine Tool Structures Vol. 2: Vibration Stability and Accuracy; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Ramos, A.R.; Reis, P.; Davim, J.P. Tool vibrations in high-speed milling. Int. J. Mach. Tools Manuf. 2004, 44, 767–776. [Google Scholar]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, R.; Wang, L. Chatter detection in high-speed machining based on wavelet packets and support vector machine. J. Intell. Manuf. 2018, 29, 331–342. [Google Scholar]

- Sick, B. Machine condition monitoring and fault diagnosis using machine learning methods: A review. Mech. Syst. Signal Process. 2002, 16, 687–697. [Google Scholar]

- Alberts, M.; St John, S.; Jared, B.; Karindikar, J.; Khojandi, A.; Schmitz, T.; Coble, J. Chatter Detection in Simulated Machining Data: A Simple Refined Approach to Vibration Data. Int. J. Adv. Manuf. Technol. 2024, 132, 4541–4557. [Google Scholar] [CrossRef]

- Coble, J.; Alberts, M.; St John, S.; Odie, S.; Khojhandi, A.; Jared, B.; Schmitz, T.; Karandikar, J. A Data-Driven Framework for Predicting Machining Stability: Employing Simulated Data, Operational Modal Analysis, and Enhanced Transfer Learning. Int. J. Mach. Tools Manuf. 2024. [Google Scholar] [CrossRef]

- He, J.; Wang, J. Operational Modal Analysis and its Application in Machining Stability Prediction. Int. J. Mach. Tools Manuf. 2012, 52, 50–58. [Google Scholar]

- Pan, S.J.; Yang, Q. A Survey on Transfer Learning. IEEE Trans. Knowl. Data Eng. 2010, 22, 1345–1359. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Duncan, G.S. Receptance coupling for predicting machining dynamics. J. Manuf. Sci. Eng. 2000, 122, 384–388. [Google Scholar]

- Yin, S.; Luo, H.; Ding, S.X. Transfer learning for machine fault diagnosis: From simulation to real data. IEEE Trans. Ind. Inform. 2019, 15, 2126–2135. [Google Scholar]

- Zhang, W.; Li, C.; Peng, G.; Chen, Y. Deep Transfer Learning for Intelligent Fault Diagnosis of Machine Tools under Variable Working Conditions. IEEE Access 2019, 7, 115368–115377. [Google Scholar]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Smith, K.S. Machining Dynamics: Frequency Response to Improved Productivity; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Altintas, Y.; Weck, M. Chatter Stability of Metal Cutting and Grinding. CIRP Ann.-Manuf. Technol. 2004, 53, 619–642. [Google Scholar] [CrossRef]

- Tlusty, J. Machine Dynamics; Springer: Berlin/Heidelberg, Germany, 1985; pp. 48–153. [Google Scholar]

- Smith, S.; Tlusty, J. Modeling and Simulation of the Machining Process. CIRP Ann.-Manuf. Technol. 2001, 50, 611–634. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Duncan, G.S. Three-Component Receptance Coupling Substructure Analysis for Tool Point Dynamics Prediction. J. Manuf. Sci. Eng. 2005, 127, 781–790. [Google Scholar] [CrossRef]

- Ren, Y.; Chen, Z. Hybrid Modeling for Real-Time Chatter Detection. J. Manuf. Sci. Eng. 2018, 140, 124–133. [Google Scholar] [CrossRef]

- Huang, B.; Zhang, K.; Zhang, J.; Ramsey, J.; Sanchez-Romero, R.; Glymour, C.; Schölkopf, B. Causal discovery from heterogeneous/nonstationary data. J. Mach. Learn. Res. 2020, 21, 1–53. [Google Scholar]

- Widodo, A.; Yang, B.S. Support Vector Machine in Machine Condition Monitoring and Fault Diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Serrano, A.; McDonald, M.; Moylan, S. A review of the physics of metal cutting to predict machining forces for complex tooling and application conditions. Int. J. Adv. Manuf. Technol. 2018, 99, 37–53. [Google Scholar]

- Quionero-Candela, J.; Sugiyama, M.; Schwaighofer, A.; Lawrence, N.D. Dataset shift in machine learning. In Dataset Shift in Machine Learning; MIT Press: Cambridge, MA, USA, 2009; pp. 1–3. [Google Scholar]

- Wang, Z.; He, Q.; Ma, H.; Kong, F. A feature selection method based on fisher’s discriminant ratio for fault classification. J. Sound Vib. 2018, 426, 242–256. [Google Scholar]

- Tobias, S.A.; Fishwick, W. The chatter of lathe tools under orthogonal cutting conditions. Proc. Inst. Mech. Eng. 1958, 172, 389–402. [Google Scholar] [CrossRef]

- Tlusty, J. Self-excited vibrations in machine tools. In Proceedings of the International Research in Production Engineering; ASME: New York, NY, USA, 1970; pp. 35–53. [Google Scholar]

- Inasaki, I. Application of sensor fusion to machining monitoring. Ann. CIRP 1998, 47, 653–656. [Google Scholar]

- Fu, Y.; Hope, A.D.; Wang, M.; Liang, M. Chatter detection in milling process based on wavelet packets and Hilbert-Huang transform. Int. J. Adv. Manuf. Technol. 2006, 29, 1035–1041. [Google Scholar]

- Chen, X.; Zheng, Y.; Wang, B.; Wang, Y. A review of machining monitoring systems based on artificial intelligence. Int. J. Adv. Manuf. Technol. 2015, 81, 585–605. [Google Scholar]

- Dimla Sr, D.E. Sensor signals for tool-wear monitoring in metal cutting operations—A review of methods. Int. J. Mach. Tools Manuf. 2000, 40, 1073–1098. [Google Scholar] [CrossRef]

- Li, X.; Ding, Q.; Sun, J.Q. Remaining useful life estimation in prognostics using deep convolution neural networks. Reliab. Eng. Syst. Saf. 2018, 172, 1–11. [Google Scholar] [CrossRef]

- Zhang, W.; Li, C.; Peng, G.; Chen, Y. A deep learning-based approach for automated fault diagnosis of rotating machinery. Neurocomputing 2019, 338, 190–204. [Google Scholar]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing must embrace big data. Nature 2018, 544, 23–25. [Google Scholar] [CrossRef]

- Purushothaman, S.; Kiran, R.; Jose, M. Support vector machine approach for tool wear classification. Procedia Eng. 2014, 97, 2195–2203. [Google Scholar]

- Li, L.; Li, D.; Huang, Q.; Huang, Z. Prediction of surface roughness in end milling using genetic algorithm and multiple regression method. Front. Mech. Eng. 2016, 11, 157–163. [Google Scholar]

- Benardos, P.G.; Vosniakos, G.C. Prediction of surface roughness in CNC face milling using neural networks and Taguchi’s design of experiments. Robot. Comput.-Integr. Manuf. 2003, 19, 343–354. [Google Scholar] [CrossRef]

- Kwon, P.; Bacci, G. Artificial neural network approach to determination of optimal cutting conditions in milling operations. J. Manuf. Sci. Eng. 2018, 140, 095001. [Google Scholar]

- Sikder, A.K.; Murshed, A.N. Unsupervised machine learning approach for sensor-based predictive maintenance in intelligent manufacturing. Procedia Manuf. 2018, 26, 1239–1250. [Google Scholar]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.D. Machine learning in manufacturing: Advantages, challenges, and applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep learning-based data analytics for defect classification in manufacturing. Procedia CIRP 2016, 55, 512–517. [Google Scholar]

- Zhao, Z.; Chen, W.; Wu, X.; Chen, P.C.; Liu, J. LSTM network: A deep learning approach for short-term traffic forecast. IET Intell. Transp. Syst. 2017, 11, 68–75. [Google Scholar] [CrossRef]

- Zhang, Y.; Tao, J.; Li, X.; Ding, Q. Deep autoencoder neural networks for noise reduction in machinery fault diagnosis. Mech. Syst. Signal Process. 2019, 127, 1–18. [Google Scholar]

- Campbell, T.; Woxvold, I.; Ding, J. The influence of material microstructure on machining-induced surface integrity. Procedia CIRP 2018, 71, 329–334. [Google Scholar]

- Tang, J.; Chen, X.; Ren, Y.; Liu, Z. Chatter detection in milling process using multi-scale entropy and ensemble empirical mode decomposition. J. Intell. Manuf. 2018, 29, 1333–1345. [Google Scholar]

- Zhang, X.; Xu, Y.; Jin, X. Deep learning-based chatter detection in milling operations. Mech. Syst. Signal Process. 2020, 140, 106683. [Google Scholar]

- He, H.; Garcia, E.A. Learning from imbalanced data. IEEE Trans. Knowl. Data Eng. 2009, 21, 1263–1284. [Google Scholar]

- Christ, M.; Braun, N.; Neuffer, J.; Kempa-Liehr, A.W. Time Series Feature Extraction on Basis of Scalable Hypothesis Tests (TSFresh)—A Python Package. Neurocomputing 2018, 307, 72–77. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Ganin, Y.; Ustinova, E.; Ajakan, H.; Germain, P.; Larochelle, H.; Laviolette, F.; Marchand, M.; Lempitsky, V. Domain-Adversarial Training of Neural Networks. J. Mach. Learn. Res. 2016, 17, 1–35. [Google Scholar]

- Dietterich, T.G. Approximate Statistical Tests for Comparing Supervised Classification Learning Algorithms. Neural Comput. 1998, 10, 1895–1923. [Google Scholar] [CrossRef] [PubMed]

- Demšar, J. Statistical Comparisons of Classifiers over Multiple Data Sets. J. Mach. Learn. Res. 2006, 7, 1–30. [Google Scholar]

- Harris, C.R.; Millman, K.J.; van der Walt, S.J.; Gommers, R.; Virtanen, P.; Cournapeau, D.; Wieser, E.; Taylor, J.; Berg, S.; Smith, N.J.; et al. Array programming with NumPy. Nature 2020, 585, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [PubMed]

- Seabold, S.; Perktold, J. Statsmodels: Econometric and Statistical Modeling with Python. In Proceedings of the 9th Python in Science Conference, Austin, TX, USA, 28 June–3 July 2010; Volume 57, p. 61. [Google Scholar]

- Hunter, J.D. Matplotlib: A 2D Graphics Environment. Comput. Sci. Eng. 2007, 9, 90–95. [Google Scholar] [CrossRef]

- Waskom, M.L. Seaborn: Statistical Data Visualization, Version 0.11.1. J. Open Source Softw. 2021, 6, 3021. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.I. A Unified Approach to Interpreting Model Predictions. Adv. Neural Inf. Process. Syst. 2017, 30, 4765–4774. [Google Scholar]

| Metric | Baseline Model | Enhanced Model 2 | Real-World Tuned Model |

|---|---|---|---|

| Accuracy | 66.5% | 78.3% | 86.1% |

| Precision | 81.8% | 88.7% | 91.3% |

| Recall | 77.2% | 83.5% | 87.5% |

| F1-Score | 76.5% | 82.0% | 85.9% |

| AUC-ROC | 0.782 | 0.846 | 0.871 |

| Inference Time (ms) | 3.2 | 4.4 | 5.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alberts, M.; St. John, S.; Odie, S.; Khojandi, A.; Jared, B.; Schmitz, T.; Karandikar, J.; Coble, J.B. Transitioning from Simulation to Reality: Applying Chatter Detection Models to Real-World Machining Data. Machines 2024, 12, 923. https://doi.org/10.3390/machines12120923

Alberts M, St. John S, Odie S, Khojandi A, Jared B, Schmitz T, Karandikar J, Coble JB. Transitioning from Simulation to Reality: Applying Chatter Detection Models to Real-World Machining Data. Machines. 2024; 12(12):923. https://doi.org/10.3390/machines12120923

Chicago/Turabian StyleAlberts, Matthew, Sam St. John, Simon Odie, Anahita Khojandi, Bradley Jared, Tony Schmitz, Jaydeep Karandikar, and Jamie B. Coble. 2024. "Transitioning from Simulation to Reality: Applying Chatter Detection Models to Real-World Machining Data" Machines 12, no. 12: 923. https://doi.org/10.3390/machines12120923

APA StyleAlberts, M., St. John, S., Odie, S., Khojandi, A., Jared, B., Schmitz, T., Karandikar, J., & Coble, J. B. (2024). Transitioning from Simulation to Reality: Applying Chatter Detection Models to Real-World Machining Data. Machines, 12(12), 923. https://doi.org/10.3390/machines12120923