Soft Grippers in Robotics: Progress of Last 10 Years

Abstract

1. Introduction

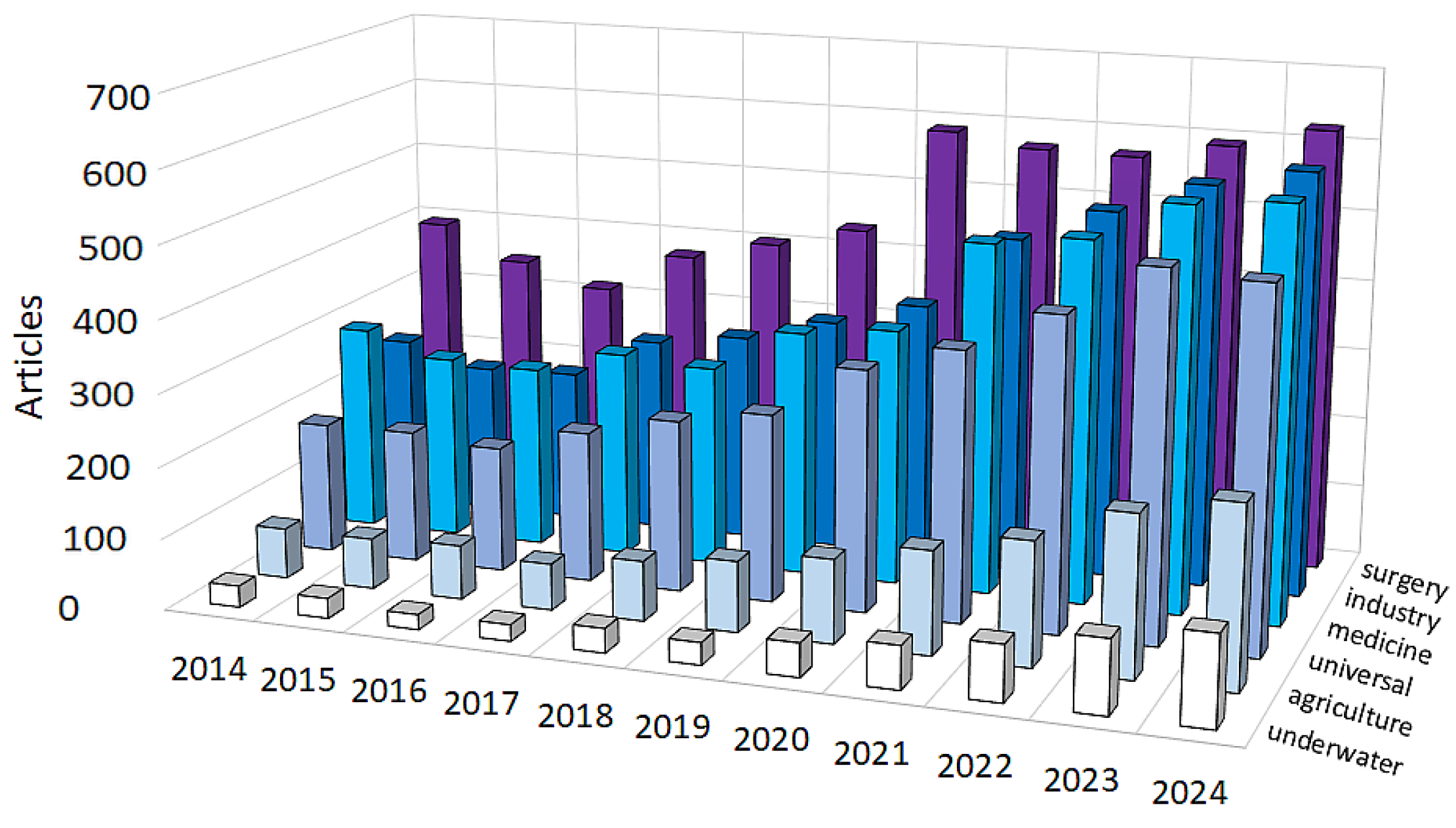

2. Methodology of Research

3. Statistical Analysis of Included Papers

4. Types of Gripper Systems

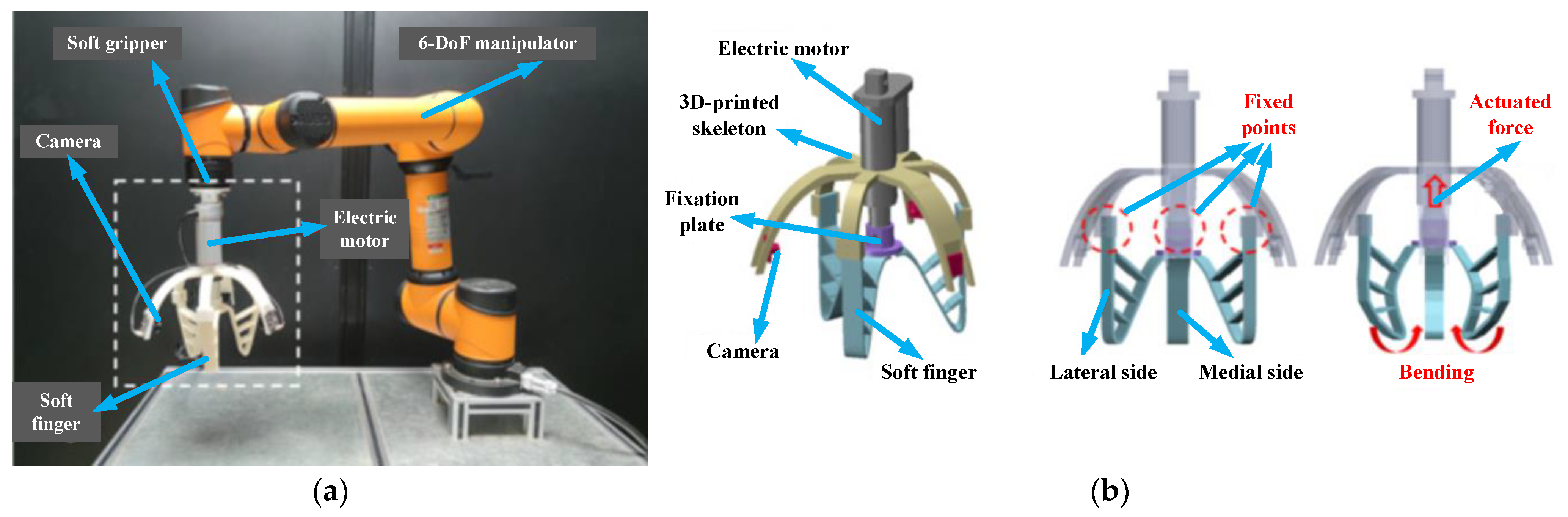

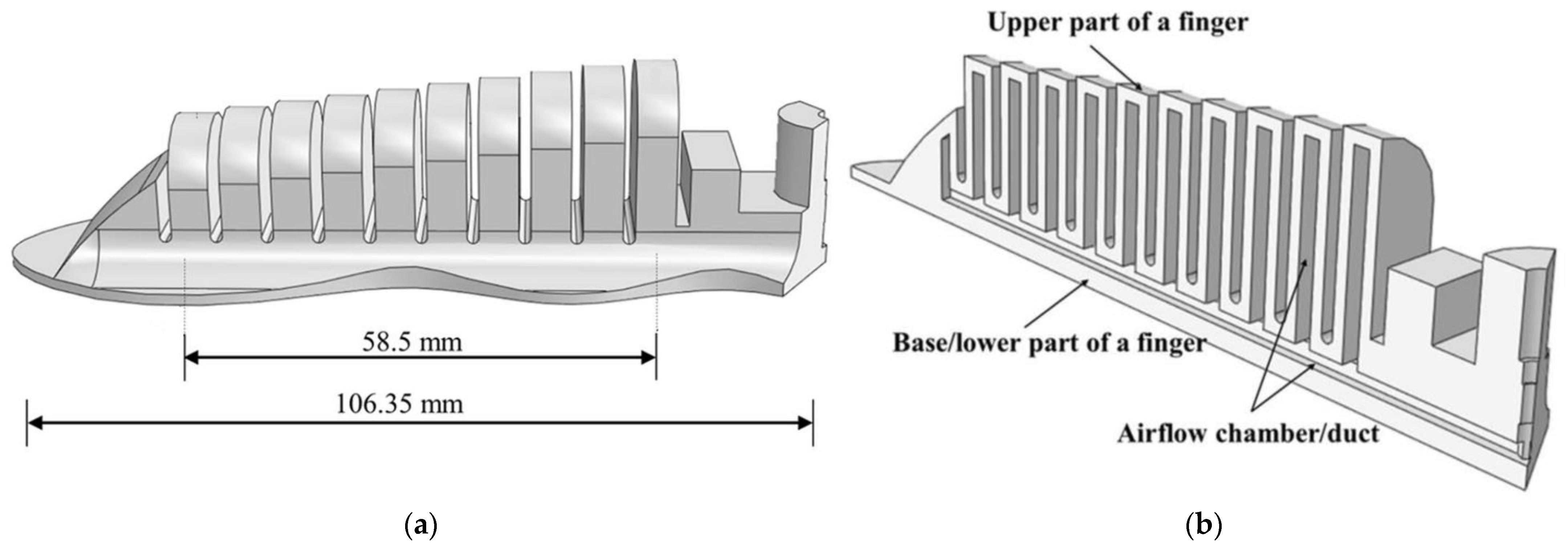

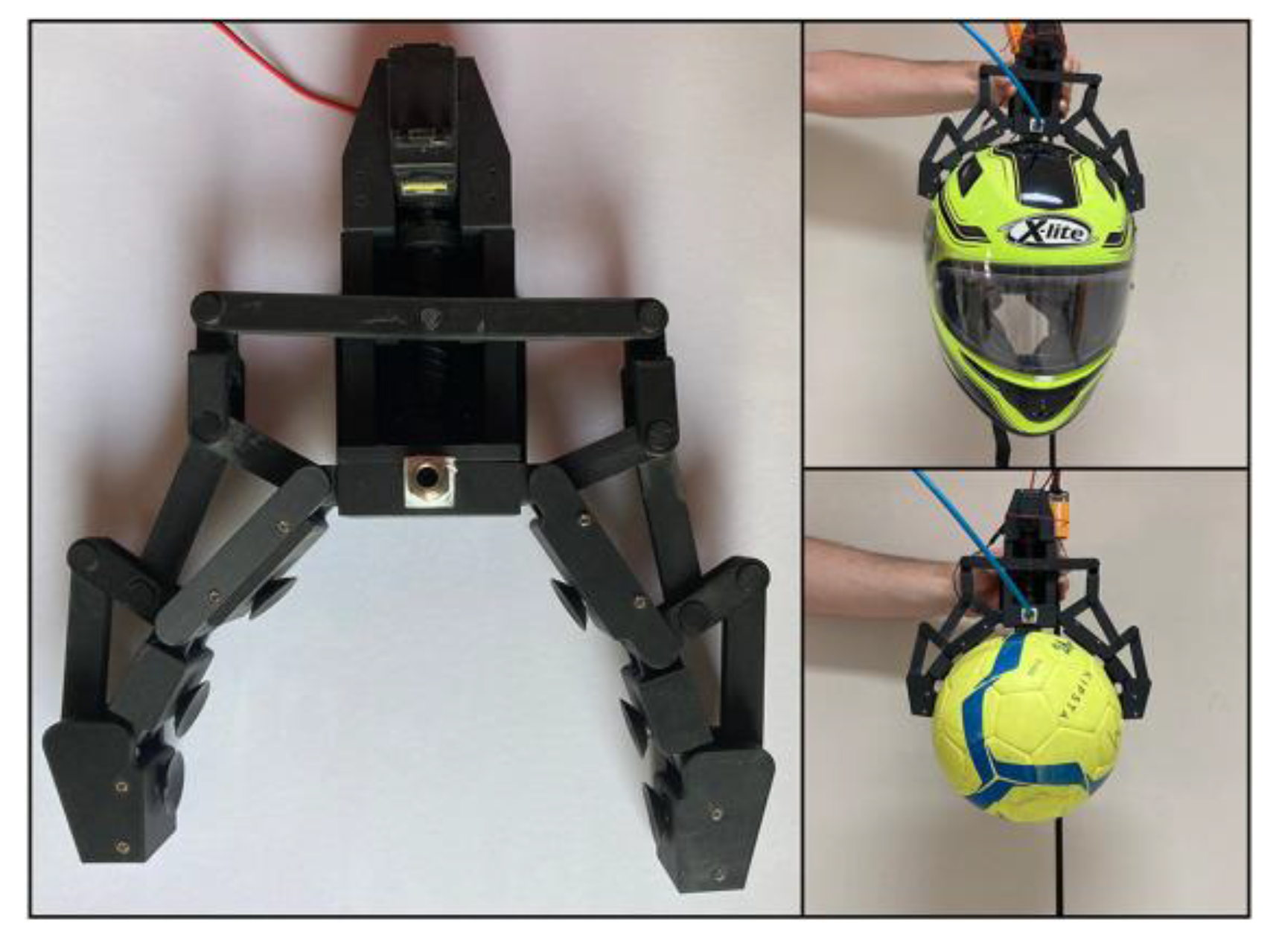

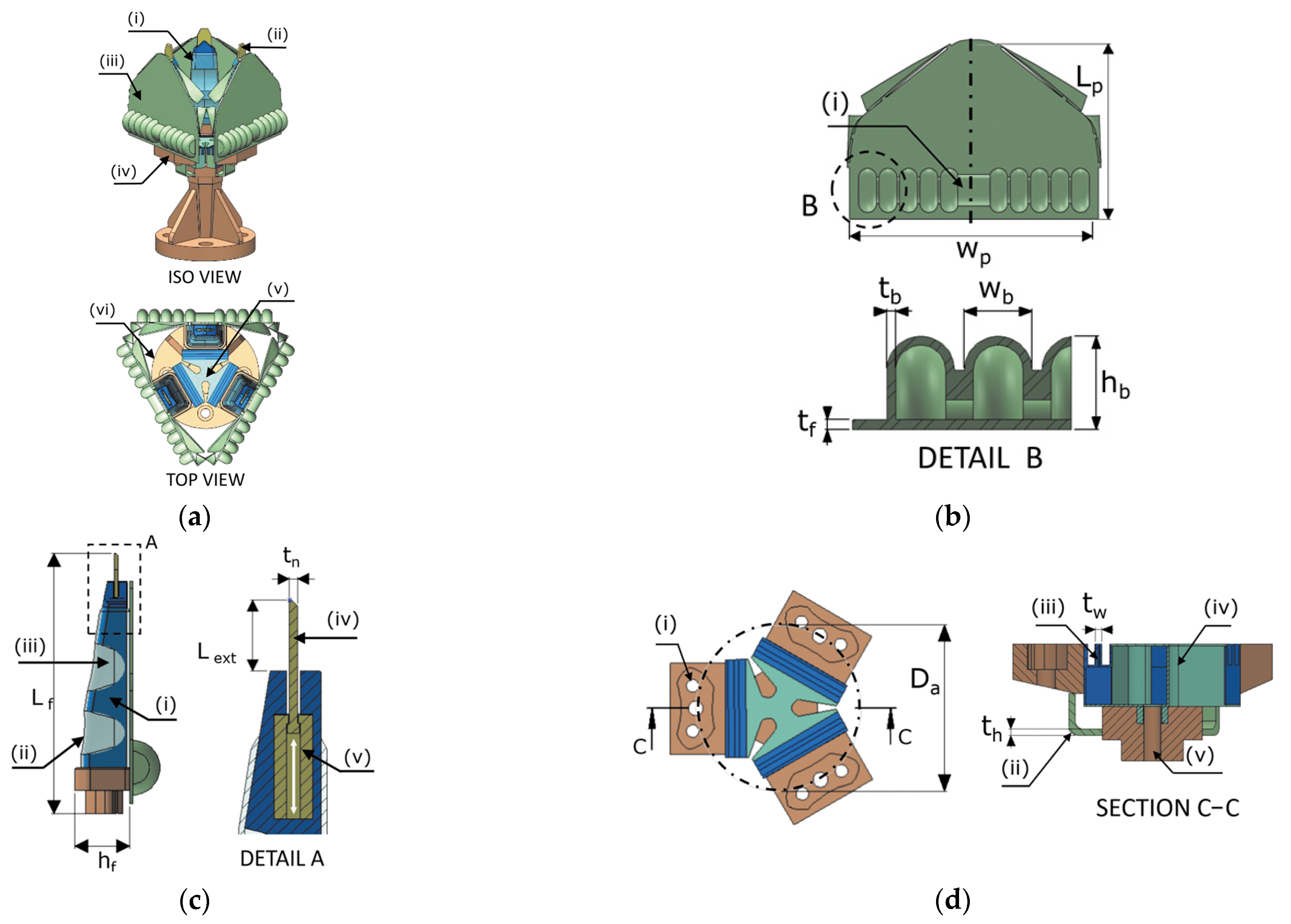

4.1. Geometric Bonding Grippers

4.2. Grippers Working with Friction Force

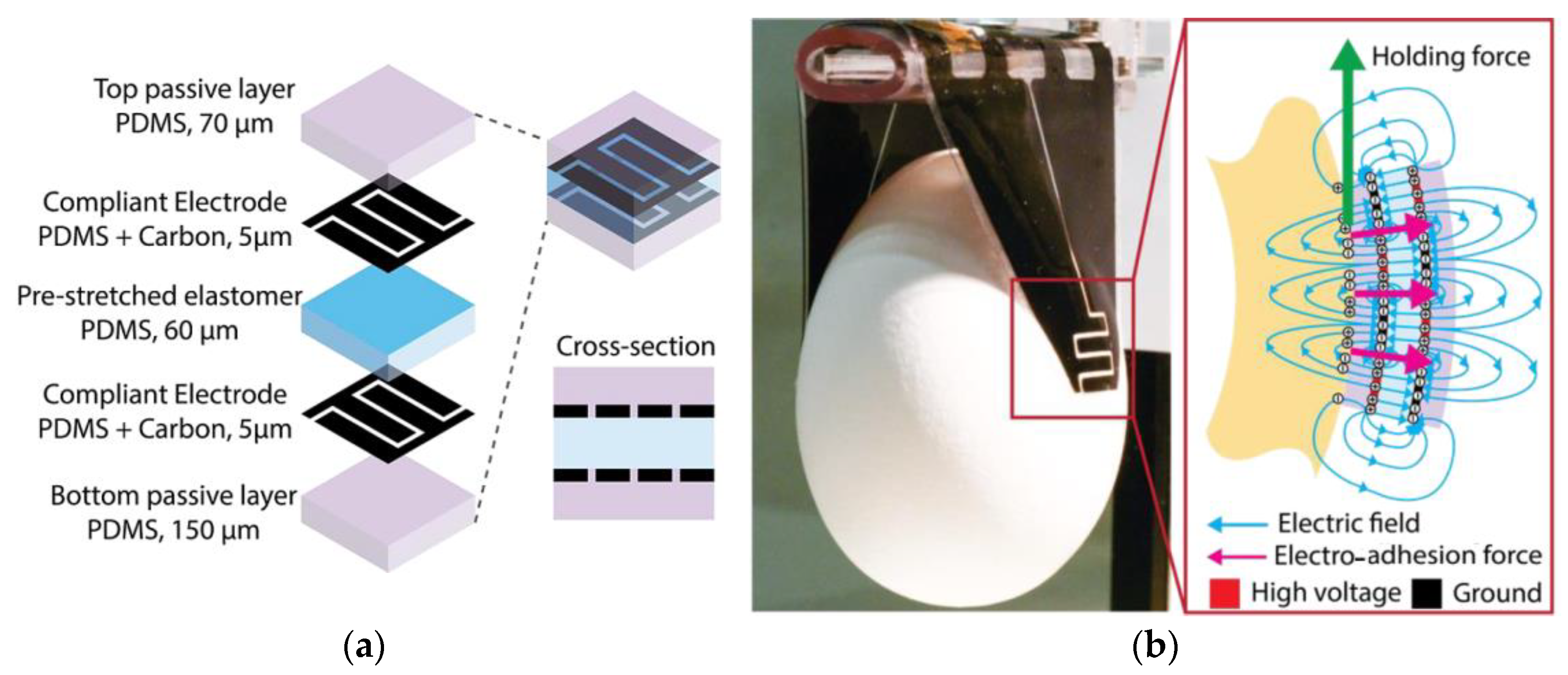

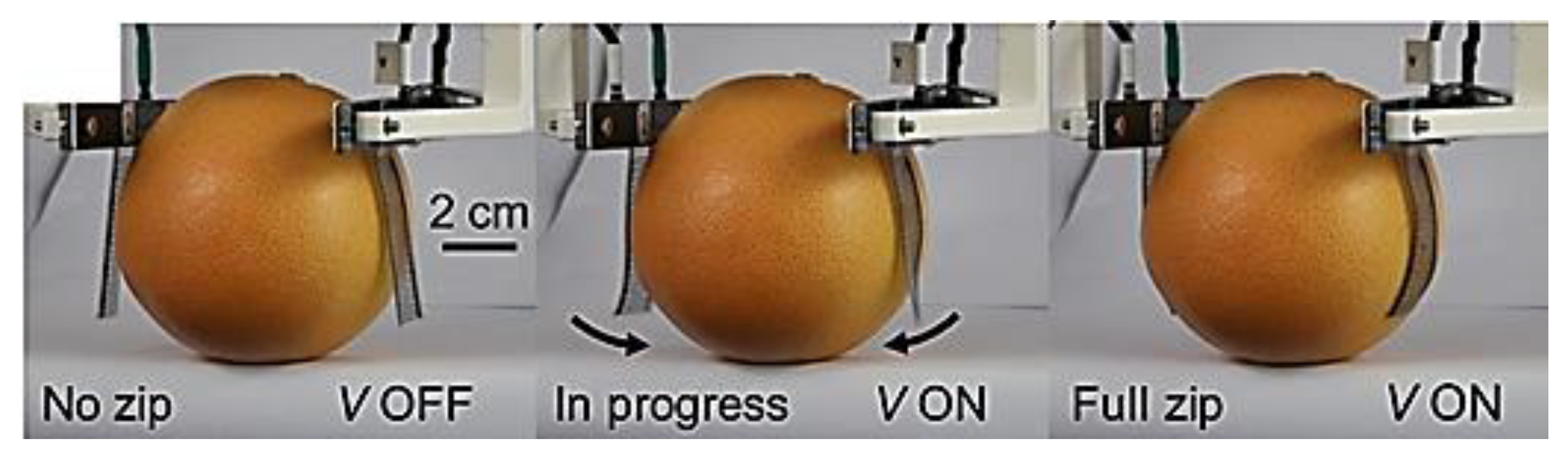

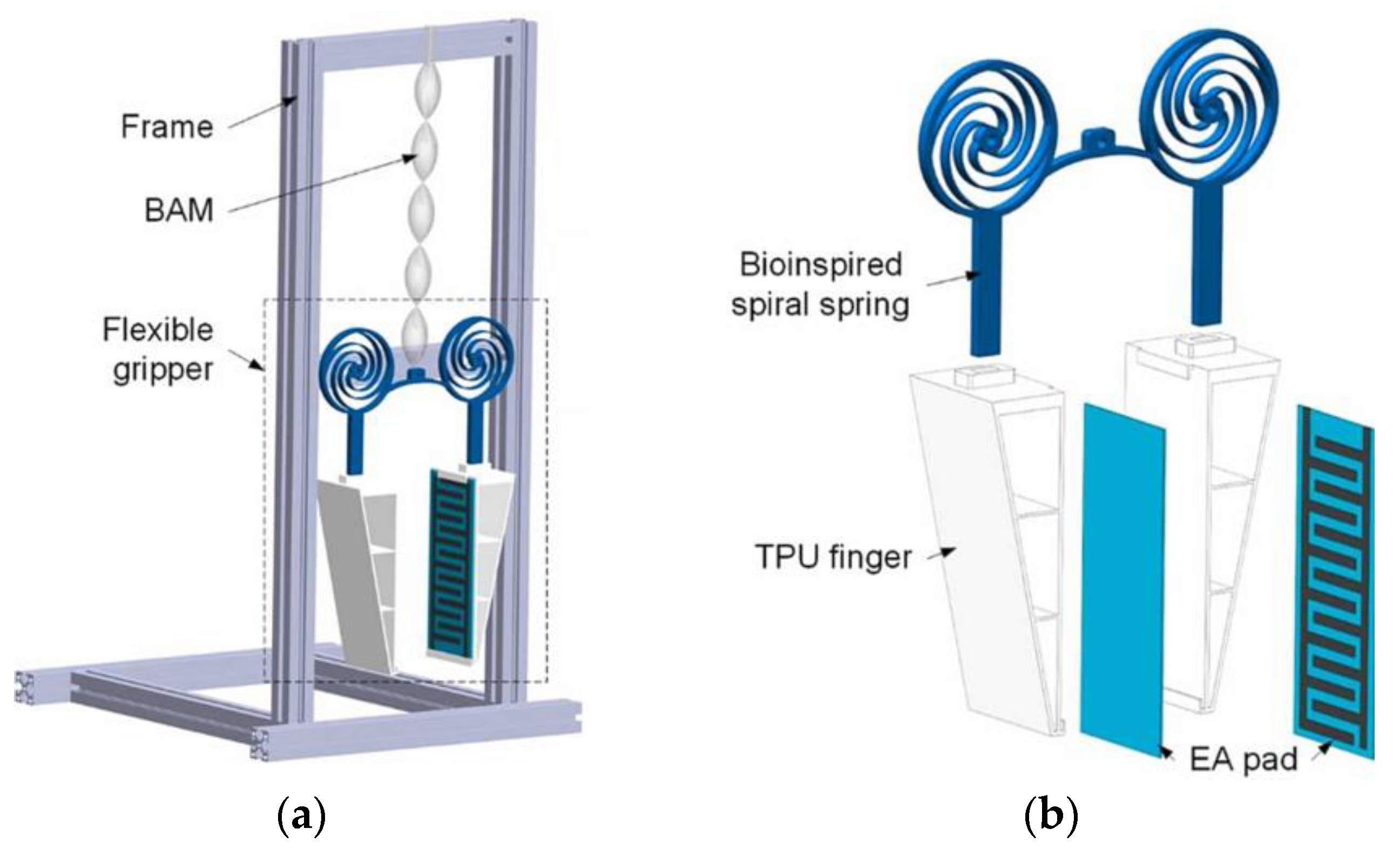

4.3. Grippers for Complex Gripping Method

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kazi, K.; Nerkar, P.; Shinde, S.S.; Kutubuddin, K.; Liyakat, S.; Desai, S.; Sayyad, S.; Kazi, L. Monitoring Fresh Fruit and Food Using Iot and Machine Learning to Improve Food Safety and Quality. Tuijin Jishu/J. Propuls. Technol. 2023, 44, 1001–4055. [Google Scholar]

- Ou Yang, C.-W.; Yu, S.-Y.; Chan, C.-W.; Tseng, C.-Y.; Cai, J.-F.; Huang, H.-P.; Juang, J.-Y. Enhancing the Versatility and Performance of Soft Robotic Grippers, Hands, and Crawling Robots Through Three-Dimensional-Printed Multifunctional Buckling Joints. Soft Robot. 2024, 11, 741–754. [Google Scholar] [CrossRef]

- Negrello, F.; Stuart, H.S.; Catalano, M.G. Hands in the Real World. Front. Robot. AI 2020, 6, 480351. [Google Scholar] [CrossRef] [PubMed]

- AboZaid, Y.A.; Aboelrayat, M.T.; Fahim, I.S.; Radwan, A.G. Soft Robotic Grippers: A Review on Technologies, Materials, and Applications. Sens. Actuators A Phys. 2024, 372, 115380. [Google Scholar] [CrossRef]

- Ghosh, A.; Yoon, C.; Ongaro, F.; Scheggi, S.; Selaru, F.M.; Misra, S.; Gracias, D.H. Stimuli-Responsive Soft Untethered Grippers for Drug Delivery and Robotic Surgery. Front. Mech. Eng. 2017, 3, 267124. [Google Scholar] [CrossRef]

- Almanzor, E.; Anvo, N.R.; Thuruthel, T.G.; Iida, F. Autonomous Detection and Sorting of Litter Using Deep Learning and Soft Robotic Grippers. Front. Robot. AI 2022, 9, 1064853. [Google Scholar] [CrossRef]

- Xie, Z.; Liang, X.; Roberto, C. Learning-Based Robotic Grasping: A Review. Front. Robot. AI 2023, 10, 1038658. [Google Scholar] [CrossRef] [PubMed]

- Pan, M.; Yuan, C.; Liang, X.; Zou, J.; Zhang, Y.; Bowen, C. Triboelectric and Piezoelectric Nanogenerators for Future Soft Robots and Machines. iScience 2020, 23, 101682. [Google Scholar] [CrossRef]

- Chubb, K.; Berry, D.; Burke, T.; Singh, K.; Khosla, A.; Gupta, S.; Day, N.; Penaloza, J.; Santos, V.J.; Tauber, F.; et al. Perspective for Soft Robotics: The Field’s Past and Future. Bioinspir. Biomim. 2023, 18, 035001. [Google Scholar] [CrossRef]

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft Manipulators and Grippers: A Review. Front. Robot. AI 2016, 3, 223168. [Google Scholar] [CrossRef]

- Elangovan, N.; Chang, C.-M.; Gao, G.; Liarokapis, M. An Accessible, Open-Source Dexterity Test: Evaluating the Grasping and Dexterous Manipulation Capabilities of Humans and Robots. Front. Robot. AI 2022, 9, 808154. [Google Scholar] [CrossRef]

- Ahmed, F.; Waqas, M.; Jawed, B.; Soomro, A.M.; Kumar, S.; Hina, A.; Khumar, U.; Kim, K.H.; Choi, K.H. Decade of bio-inspired soft robots: A review. Smart Mater. Struct. 2022, 31, 073002. [Google Scholar] [CrossRef]

- Troiano, A. Mechanical and Control Design of a Flexible Modular Gripper. Ph.D. Thesis, Politecnico di Torino, Torin, Italy, 2023. [Google Scholar]

- Zhu, M.; Mori, Y.; Wakayama, T.; Wada, A.; Kawamura, S. A Fully Multi-Material Three-Dimensional Printed Soft Gripper with Variable Stiffness for Robust Grasping. Soft Robot. 2019, 6, 507–519. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.D.; Goh, G.L.; Lyu, Z.; Ariffin, M.Z.; Yeong, W.Y.; Lum, G.Z.; Campolo, D.; Han, S.; Yee, H.; Wong, A.; et al. 3D Printing of Robotic Soft Grippers: Toward Smart Actuation and Sensing. Adv. Mater. Technol. 2022, 7, 2101672. [Google Scholar] [CrossRef]

- Xu, J.; Pan, X.; Xu, B.; Yue, H.; Lu, Y.; Ying, K.; Wang, Z.; Yang, F. Buckling-Inspired Triboelectric Sensor for Multifunctional Sensing of Soft Robotics and Wearable Devices. Nano Energy 2024, 130, 110141. [Google Scholar] [CrossRef]

- Hao, Y.; Zhang, S.; Fang, B.; Sun, F.; Liu, H.; Li, H. A Review of Smart Materials for the Boost of Soft Actuators, Soft Sensors, and Robotics Applications. Chin. J. Mech. Eng. (Engl. Ed.) 2022, 35, 1–16. [Google Scholar] [CrossRef]

- Nguyen, C.C.; Wong, S.; Thai, M.T.; Hoang, T.T.; Phan, P.T.; Davies, J.; Wu, L.; Tsai, D.; Phan, H.-P.; Lovell, N.H.; et al. Advanced User Interfaces for Teleoperated Surgical Robotic Systems. Adv. Sens. Res. 2023, 2, 2200036. [Google Scholar] [CrossRef]

- Birglen, L.; Schlicht, T. A Statistical Review of Industrial Robotic Grippers. Robot. Comput. Integr. Manuf. 2018, 49, 88–97. [Google Scholar] [CrossRef]

- Alici, G.; Huynh, N.N. Performance Quantification of Conducting Polymer Actuators for Real Applications: A Microgripping System. IEEE/ASME Trans. Mechatron. 2007, 12, 73–84. [Google Scholar] [CrossRef]

- Takeuchi, K.; Nomura, S.; Tamamoto, T.; Sakagami, N.; Koganezawa, K. Development of Multi-Joint Gripper for Underwater Operations. In Proceedings of the 2018 OCEANS—MTS/IEEE Kobe Techno-Oceans, Kobe, Japan, 28–31 May 2018. [Google Scholar] [CrossRef]

- Shih, B.; Drotman, D.; Christianson, C.; Huo, Z.; White, R.; Christensen, H.I.; Tolley, M.T. Custom Soft Robotic Gripper Sensor Skins for Haptic Object Visualization. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Vancouver, BC, Canada, 24–28 September 2017; pp. 494–501. [Google Scholar] [CrossRef]

- Palli, G.; Moriello, L.; Scarcia, U.; Melchiorri, C. An Underwater Robotic Gripper with Embedded Force/Torque Wrist Sensor. IFAC-PapersOnLine 2017, 50, 11209–11214. [Google Scholar] [CrossRef]

- Papadopoulos, E.; Aghili, F.; Ma, O.; Lampariello, R. Robotic Manipulation and Capture in Space: A Survey. Front. Robot. AI 2021, 8, 686723. [Google Scholar] [CrossRef] [PubMed]

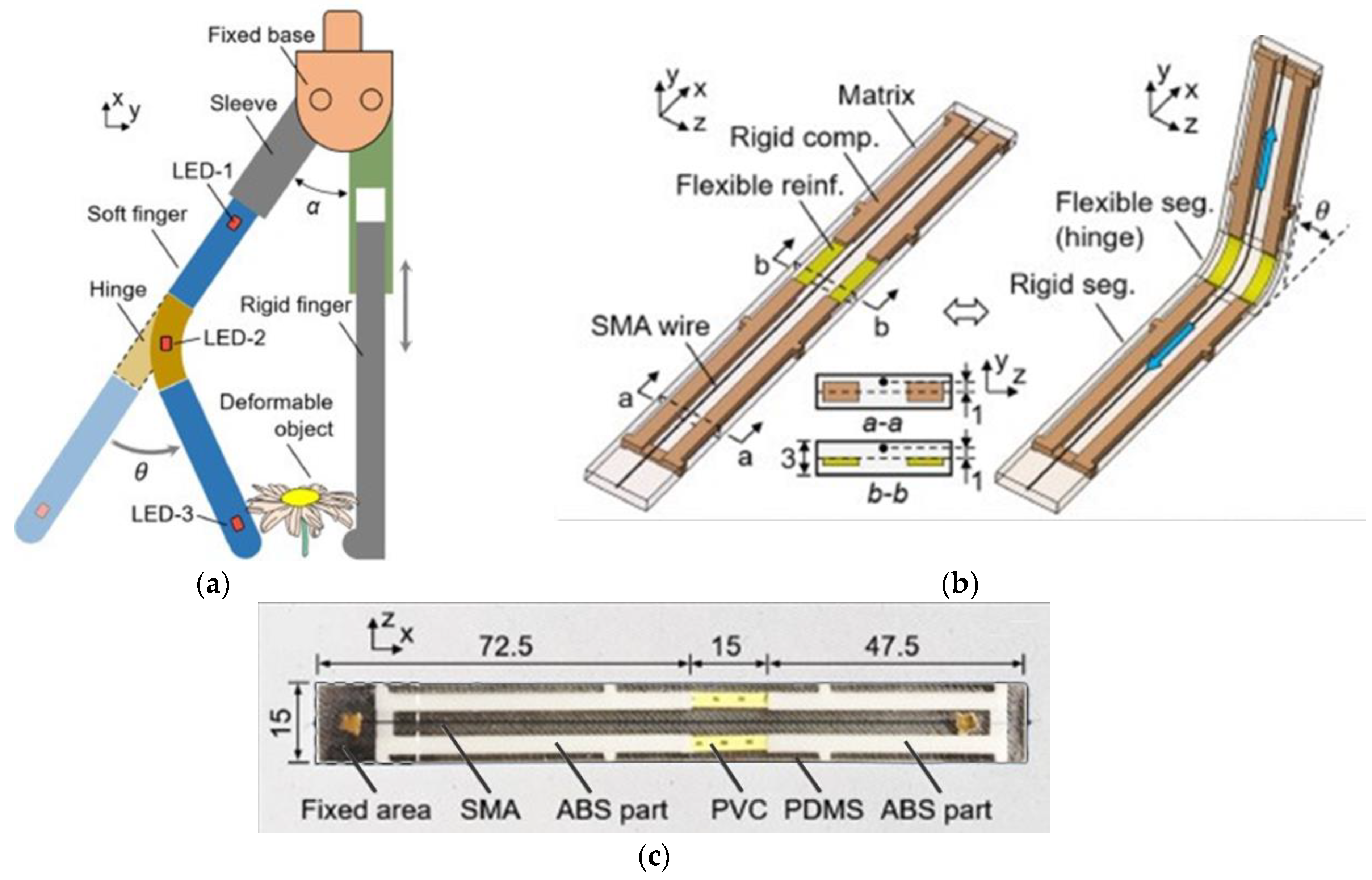

- Wang, W.; Tang, Y.; Li, C. Controlling Bending Deformation of a Shape Memory Alloy-Based Soft Planar Gripper to Grip Deformable Objects. Int. J. Mech. Sci. 2021, 193, 106181. [Google Scholar] [CrossRef]

- Amend, J.R.; Brown, E.; Rodenberg, N.; Jaeger, H.M.; Lipson, H. A Positive Pressure Universal Gripper Based on the Jamming of Granular Material. IEEE Trans. Robot. 2012, 28, 341–350. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, H.; Yuan, H.; Liang, B. A Compliant Adaptive Gripper and Its Intrinsic Force Sensing Method. IEEE Trans. Robot. 2021, 37, 1584–1603. [Google Scholar] [CrossRef]

- Zhou, L.; Ren, L.; Chen, Y.; Niu, S.; Han, Z.; Ren, L. Bio-Inspired Soft Grippers Based on Impactive Gripping. Adv. Sci. 2021, 8, 2002017. [Google Scholar] [CrossRef] [PubMed]

- Kelley, R.B.; Birk, J.R.; Martins, H.A.S.; Tella, R. A Robot System Which Acquires Cylindrical Workpieces from Bins. IEEE Trans. Syst. Man Cybern. 1982, 12, 204–213. [Google Scholar] [CrossRef]

- Liu, C.H.; Chen, T.L.; Chiu, C.H.; Hsu, M.C.; Chen, Y.; Pai, T.Y.; Peng, W.G.; Chiang, Y.P. Optimal Design of a Soft Robotic Gripper for Grasping Unknown Objects. Soft Robot. 2018, 5, 452–465. [Google Scholar] [CrossRef]

- Homberg, B.S.; Katzschmann, R.K.; Dogar, M.R.; Rus, D. Haptic Identification of Objects Using a Modular Soft Robotic Gripper. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–2 October 2015; pp. 1698–1705. [Google Scholar] [CrossRef]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal Robotic Gripper Based on the Jamming of Granular Material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Zareinia, K.; Janabi-Sharifi, F. A Brief Review on Robotic Grippers Classifications. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019. [Google Scholar] [CrossRef]

- Zaidi, S.; Maselli, M.; Laschi, C.; Cianchetti, M. Actuation Technologies for Soft Robot Grippers and Manipulators: A Review. Curr. Robot. Rep. 2021, 2, 355–369. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-De-santos, P. Soft Grippers for Automatic Crop Harvesting: A Review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Wan, W.; Harada, K. Designing a Mechanical Tool for Robots with Two-Finger Parallel Grippers. IEEE Robot. Autom. Lett. 2019, 4, 2981–2988. [Google Scholar] [CrossRef]

- Lee, J.; Lee, S.D.; Huh, T.M.; Stuart, H.S. Haptic Search With the Smart Suction Cup on Adversarial Objects. IEEE Trans. Robot. 2024, 40, 226–239. [Google Scholar] [CrossRef]

- Terrile, S.; Argüelles, M.; Barrientos, A. Comparison of Different Technologies for Soft Robotics Grippers. Sensors 2021, 21, 3253. [Google Scholar] [CrossRef]

- Peng, C.J.; Ameline, O.; Ribeiro, F.B.; Plesse, C.; Haliyo, S.; Chen, S.J.; Chassagne, L.; Cagneau, B. Electromechanical Model of a Conducting Polymer Transducer, Application to a Soft Gripper. IEEE Access 2019, 7, 155209–155218. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Pancheri, F.; Lueth, T.C. LARG: A Lightweight Robotic Gripper With 3-D Topology Optimized Adaptive Fingers. IEEE/ASME Trans. Mechatron. 2022, 27, 2026–2034. [Google Scholar] [CrossRef]

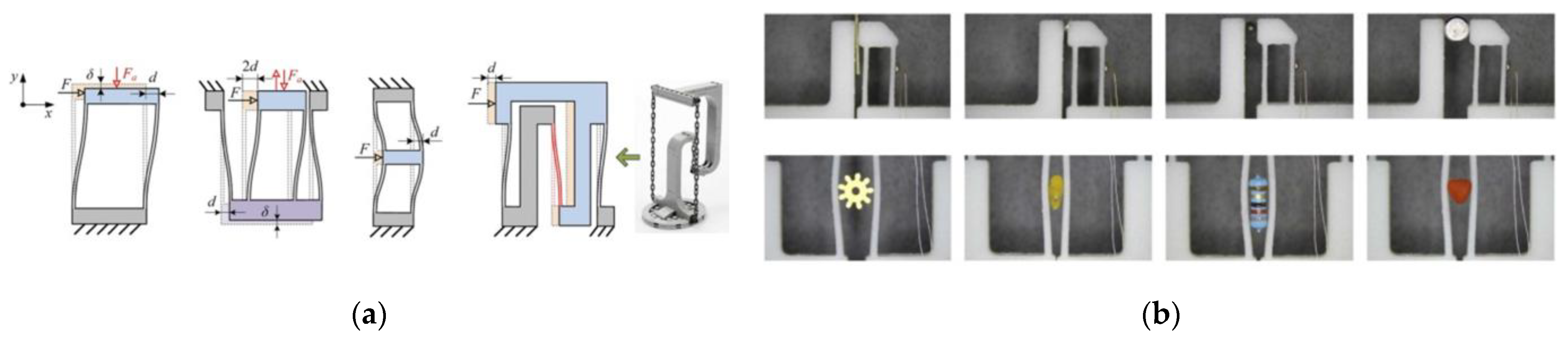

- Lee, J.Y.; Seo, Y.S.; Park, C.; Koh, J.S.; Kim, U.; Park, J.; Rodrigue, H.; Kim, B.; Song, S.H. Shape-Adaptive Universal Soft Parallel Gripper for Delicate Grasping Using a Stiffness-Variable Composite Structure. IEEE Trans. Ind. Electron. 2021, 68, 12441–12451. [Google Scholar] [CrossRef]

- Harada, K.; Nagata, K.; Rojas, J.; Ramirez-Alpizar, I.G.; Wan, W.; Onda, H.; Tsuji, T. Proposal of a Shape Adaptive Gripper for Robotic Assembly Tasks. Adv. Robot. 2016, 30, 1186–1198. [Google Scholar] [CrossRef]

- Elfferich, J.F.; Dodou, D.; Della Santina, C. Soft robotic grippers for crop handling or harvesting: A review. IEEE Access 2022, 10, 75428–75443. [Google Scholar] [CrossRef]

- Wei, Y.; Cai, L.; Fang, H.; Chen, H. Fruit Recognition and Classification Based on Tactile Information of Flexible Hand. Sens. Actuators A Phys. 2024, 370, 115224. [Google Scholar] [CrossRef]

- Fu, K.; Vougioukas, S.G.; Bailey, B.N. Computer-Aided Design and Optimization of a Multi-Level Fruit Catching System for Fresh-Market Fruit Harvesting. Comput. Electron. Agric. 2024, 225, 109334. [Google Scholar] [CrossRef]

- Dai, N.; Fang, J.; Yuan, J.; Liu, X. 3MSP2: Sequential Picking Planning for Multi-Fruit Congregated Tomato Harvesting in Multi-Clusters Environment Based on Multi-Views. Comput. Electron. Agric. 2024, 225, 109303. [Google Scholar] [CrossRef]

- Liang, J.; Bian, X.; Jia, L.; Liang, M.; Kong, R.; Zhang, J. A Method for Grasp Detection of Flexible Four-Finger Gripper. Rob. Auton. Syst. 2024, 178, 104721. [Google Scholar] [CrossRef]

- Mun, H.; Cortes, D.S.D.; Youn, J.H.; Kyung, K.U. Multi-Degree-of-Freedom Force Sensor Incorporated into Soft Robotic Gripper for Improved Grasping Stability. Soft Robot. 2024, 11, 628–638. [Google Scholar] [CrossRef] [PubMed]

- Navas, E.; Shamshiri, R.R.; Dworak, V.; Weltzien, C.; Fernández, R. Soft Gripper for Small Fruits Harvesting and Pick and Place Operations. Front. Robot. AI 2023, 10, 1330496. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, W.; Gao, P.; Zhong, X.; Pu, W. Finger-Palm Synergistic Soft Gripper for Dynamic Capture via Energy Harvesting and Dissipation. Nat. Commun. 2022, 13, 7700. [Google Scholar] [CrossRef] [PubMed]

- Crooks, W.; Vukasin, G.; O’Sullivan, M.; Messner, W.; Rogers, C. Fin Ray® Effect Inspired Soft Robotic Gripper: From the Robosoft Grand Challenge toward Optimization. Front. Robot. AI 2016, 3, 220991. [Google Scholar] [CrossRef]

- Lin, J.; Hu, Q.; Xia, J.; Zhao, L.; Du, X.; Li, S.; Chen, Y.; Wang, X. Non-Destructive Fruit Firmness Evaluation Using a Soft Gripper and Vision-Based Tactile Sensing. Comput. Electron. Agric. 2023, 214, 108256. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, C.; Tang, W.; Jiao, Z.; Wang, J.; Wang, W.; Zhong, Y.; Zhu, P.; Hu, Y.; Yang, H.; et al. A Bioinspired Stress-Response Strategy for High-Speed Soft Grippers. Adv. Sci. 2021, 8, 2102539. [Google Scholar] [CrossRef]

- Shi, L.; He, Y.; Guo, S.; Kudo, H.; Li, M.; Asaka, K. IPMC Actuator-Based a Movable Robotic Venus Flytrap. In Proceedings of the 2013 ICME International Conference on Complex Medical Engineering (CME 2013), Beijing, China, 25–28 May 2013; pp. 375–378. [Google Scholar] [CrossRef]

- Venkata, P.; Reddy, P.; Suresh, S. A Review on Importance of Universal Gripper in Industrial Robot Applications. Int. J. Mech. Eng. Rob. Res. 2013, 2, 255–264. [Google Scholar]

- Gerez, L.; Chang, C.M.; Liarokapis, M. Employing Pneumatic, Telescopic Actuators for the Development of Soft and Hybrid Robotic Grippers. Front. Robot. AI 2020, 7, 601274. [Google Scholar] [CrossRef] [PubMed]

- Dilibal, S.; Sahin, H.; Danquah, J.O.; Emon, M.O.F.; Choi, J.W. Additively Manufactured Custom Soft Gripper with Embedded Soft Force Sensors for an Industrial Robot. Int. J. Precis. Eng. Manuf. 2021, 22, 709–718. [Google Scholar] [CrossRef]

- Udupa, G.; Sreedharan, P.; Dinesh, P.S.; Kim, D. Asymmetric Bellow Flexible Pneumatic Actuator for Miniature Robotic Soft Gripper. J. Robot. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Wang, B.; Hirshikesh; Yu, T.; Ye, X.; Natarajan, S. Experimental Investigation on Adaptive Grasping of a Novel 3D-MSSPA Gripper in Complex Space. Sens. Actuators A Phys. 2024, 370, 115277. [Google Scholar] [CrossRef]

- Li, H.; Xie, D.; Xie, Y. A Soft Pneumatic Gripper with Endoskeletons Resisting Out-of-Plane Bending. Actuators 2022, 11, 246. [Google Scholar] [CrossRef]

- Zhang, Z.; Ni, X.; Wu, H.; Sun, M.; Bao, G.; Wu, H.; Jiang, S. Pneumatically Actuated Soft Gripper with Bistable Structures. Soft Robot. 2022, 9, 57–71. [Google Scholar] [CrossRef] [PubMed]

- Courchesne, J.; Cardou, P.; Rachide Onadja, P.A. A Compact Underactuated Gripper with Two Fingers and a Retractable Suction Cup. Front. Robot. AI 2023, 10, 1066516. [Google Scholar] [CrossRef]

- Lee, J.Y.; Eom, J.; Yu, S.Y.; Cho, K. Customization Methodology for Conformable Grasping Posture of Soft Grippers by Stiffness Patterning. Front. Robot. AI 2020, 7, 562612. [Google Scholar] [CrossRef]

- Amend, J.; Cheng, N.; Fakhouri, S.; Culley, B. Soft Robotics Commercialization: Jamming Grippers from Research to Product. Soft Robot. 2016, 3, 213–222. [Google Scholar] [CrossRef]

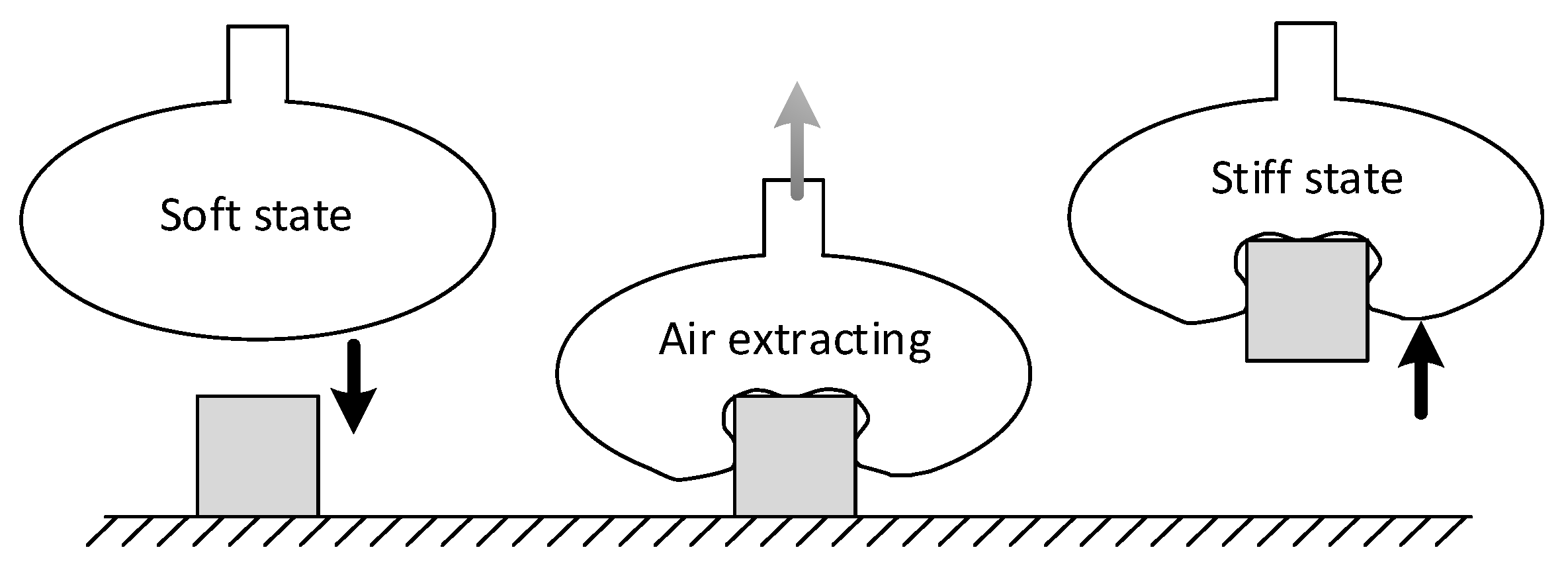

- Bamotra, A.; Walia, P.; Prituja, A.V.; Ren, H. Layer-Jamming Suction Grippers with Variable Stiffness. J. Mech. Robot. 2019, 11, 1–12. [Google Scholar] [CrossRef]

- Hou, N.; Wu, M.; Zhao, Q.; Tang, Z.; Wang, K.; Xu, X.; Zheng, X.; Xie, G. Reticular Origami Soft Robotic Gripper for Shape-Adaptive and Bistable Rapid Grasping. Soft Robot. 2024, 11, 550–560. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, Y.; Yang, Y.; Wei, Y. Passive Particle Jamming and Its Stiffening of Soft Robotic Grippers. IEEE Trans. Robot. 2017, 33, 446–455. [Google Scholar] [CrossRef]

- Ji, H.; Zhang, L.; Nie, S.; Huo, L.; Nie, S.; Wu, Z. Optimization Design and Experiment Study on a Water Hydraulic Flexible Actuator Integrating Flexible Inner Skeleton and Soft External Skin Used for Underwater Flexible Gripper. Sens. Actuators A Phys. 2024, 366, 114957. [Google Scholar] [CrossRef]

- Galloway, K.C.; Becker, K.P.; Phillips, B.; Kirby, J.; Licht, S.; Tchernov, D.; Wood, R.J.; Gruber, D.F. Soft Robotic Grippers for Biological Sampling on Deep Reefs. Soft Robot. 2016, 3, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, M.; Nishimura, T.; Watanabe, T. LCLE: A Liquid-Cooled Laminar Electromagnet for a Soft Robotic Gripper and Heavy Object Grasping. In Proceedings of the 5th IEEE International Conference on BioInspired Processing (BIP 2023), Alajuela, Costa Rica, 28–30 November 2023. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, L.; Wang, Z.; Xiang, Y.; Chen, X.; Xue, Z. Wireless Driven and Self-Sensing Flexible Gripper Based on Piezoelectric Elastomer/High-Entropy Alloy Magnetoelectric Composite. Chem. Eng. J. 2024, 498, 155415. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, Y.; Liu, Z.; Wang, J.; Xu, J.; Yu, L. Ultracompact Single-Nanowire-Morphed Grippers Driven by Vectorial Lorentz Forces for Dexterous Robotic Manipulations. Nat. Commun. 2023, 14, 3786. [Google Scholar] [CrossRef]

- Youn, J.H.; Koh, J.S.; Kyung, K.U. Soft Polymer-Actuated Compliant Microgripper with Adaptive Vibration-Controlled Grasp and Release. Soft Robot. 2024, 11, 585–595. [Google Scholar] [CrossRef]

- Nishimura, T.; Suzuki, Y.; Tsuji, T.; Watanabe, T. Single-Motor Robotic Gripper with Multi-Surface Fingers for Variable Grasping Configurations. IEEE Robot. Autom. Lett. 2024, 9, 4114–4121. [Google Scholar] [CrossRef]

- Sun, X.; Yang, S.; Li, Y.; Chen, W.; Jin, Y. A Low-Cost Underactuated Compliant Gripper with Multifunctional Jaws for Precision Manipulation. Sens. Actuators A Phys. 2024, 366, 115047. [Google Scholar] [CrossRef]

- Roberge, J.P.; Ruotolo, W.; Duchaine, V.; Cutkosky, M. Improving Industrial Grippers with Adhesion-Controlled Friction. IEEE Robot. Autom. Lett. 2018, 3, 1041–1048. [Google Scholar] [CrossRef]

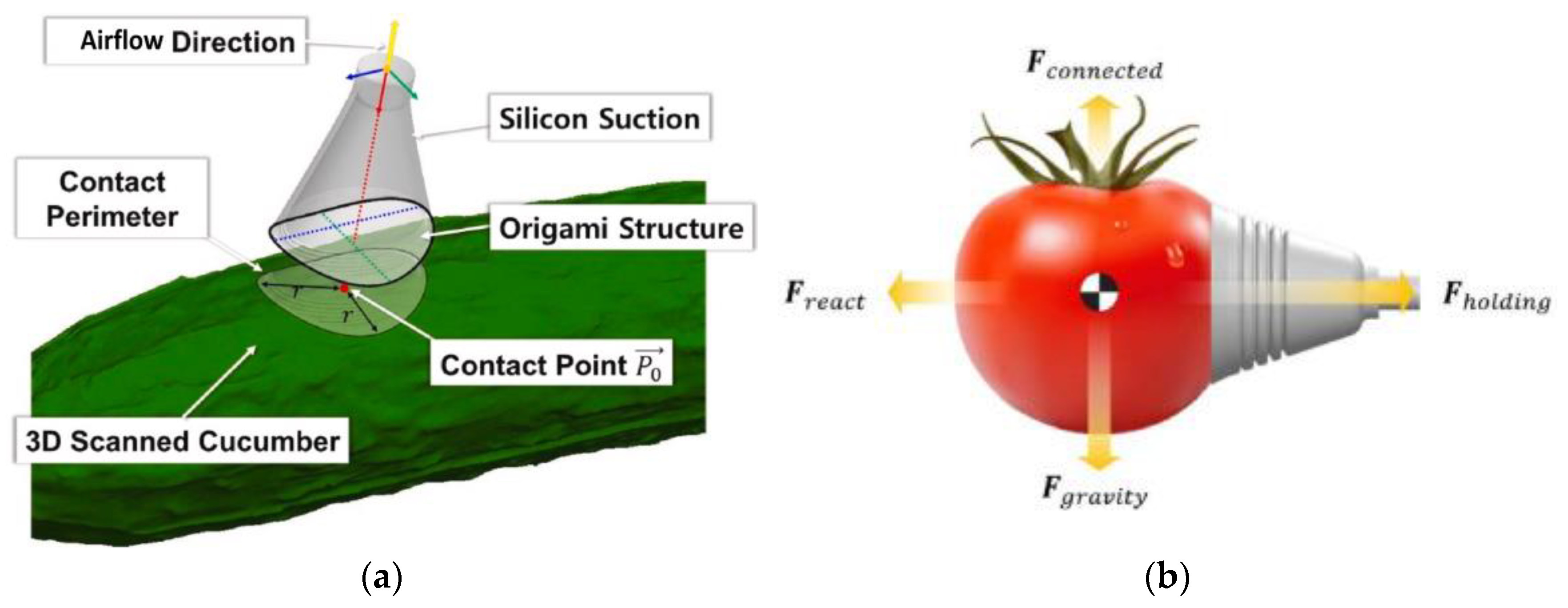

- Jo, Y.; Park, Y.; Son, H. Il A Suction Cup-Based Soft Robotic Gripper for Cucumber Harvesting: Design and Validation. Biosyst. Eng. 2024, 238, 143–156. [Google Scholar] [CrossRef]

- Visentin, F.; Castellini, F.; Muradore, R. A Soft, Sensorized Gripper for Delicate Harvesting of Small Fruits. Comput. Electron. Agric. 2023, 213, 108202. [Google Scholar] [CrossRef]

- Kang, G.; Kim, Y.J.; Lee, S.J.; Kim, S.K.; Lee, D.Y.; Song, K. Grasping through Dynamic Weaving with Entangled Closed Loops. Nat. Commun. 2023, 14, 4633. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Zhao, Y.; Berman, J.; Chi, Y.; Li, Y.; Huang (Helen), H.; Yin, J. Angle-Programmed Tendril-like Trajectories Enable a Multifunctional Gripper with Ultradelicacy, Ultrastrength, and Ultraprecision. Nat. Commun. 2023, 14, 4625. [Google Scholar] [CrossRef] [PubMed]

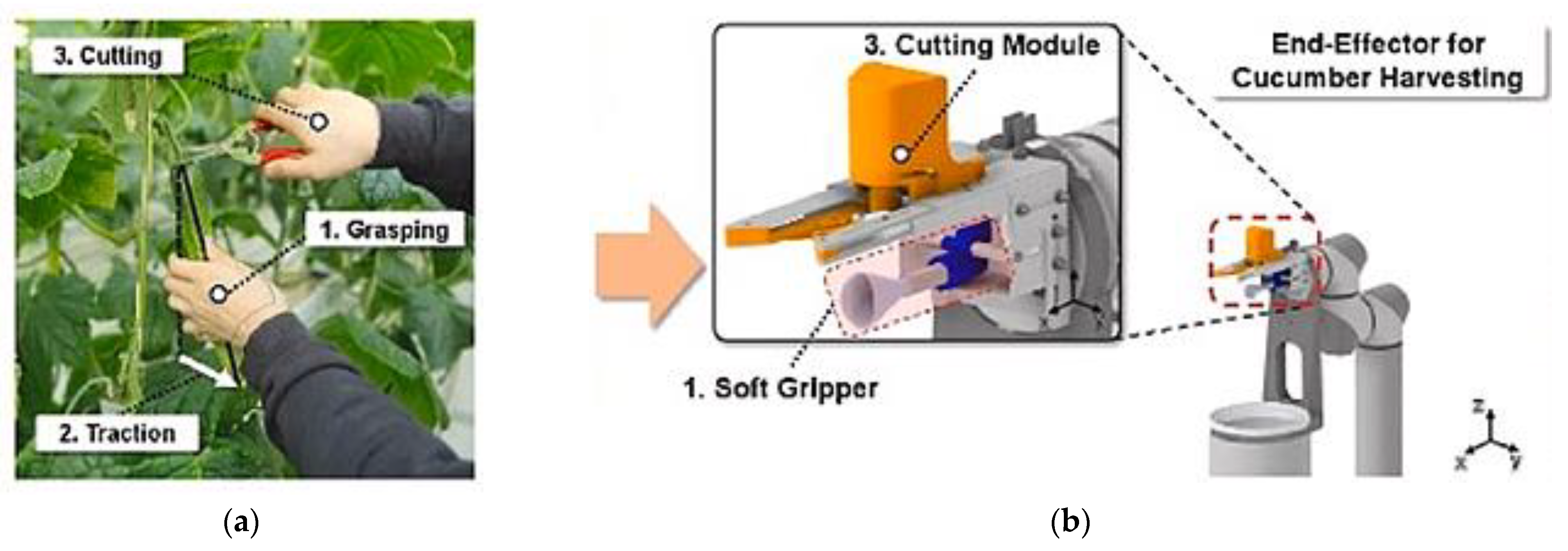

- Park, Y.; Seol, J.; Pak, J.; Jo, Y.; Jun, J.; Son, H.I. A Novel End-Effector for a Fruit and Vegetable Harvesting Robot: Mechanism and Field Experiment. Precis. Agric. 2023, 24, 948–970. [Google Scholar] [CrossRef]

- Song, S.; Drotlef, D.M.; Son, D.; Koivikko, A.; Sitti, M. Adaptive Self-Sealing Suction-Based Soft Robotic Gripper. Adv. Sci. 2021, 8, 2100641. [Google Scholar] [CrossRef]

- Maggi, M.; Mantriota, G.; Reina, G. Combining Underactuation with Vacuum Grasping for Improved Robotic Grippers. Mechatronics 2024, 102, 103211. [Google Scholar] [CrossRef]

- Li, H.; Zhou, P.; Zhang, S.; Yao, J.; Zhao, Y. A High-Load Bioinspired Soft Gripper with Force Booster Fingers. Mech. Mach. Theory 2022, 177, 105048. [Google Scholar] [CrossRef]

- Hoang, T.T.; Quek, J.J.S.; Thai, M.T.; Phan, P.T.; Lovell, N.H.; Do, T.N. Soft Robotic Fabric Gripper with Gecko Adhesion and Variable Stiffness. Sens. Actuators A Phys. 2021, 323, 112673. [Google Scholar] [CrossRef]

- Gao, D.; Thangavel, G.; Lee, J.; Lv, J.; Li, Y.; Ciou, J.H.; Xiong, J.; Park, T.; Lee, P.S. A Supramolecular Gel-Elastomer System for Soft Iontronic Adhesives. Nat. Commun. 2023, 14, 1990. [Google Scholar] [CrossRef]

- Kang, M.; Sun, K.; Seong, M.; Hwang, I.; Jang, H.; Park, S.; Choi, G.; Lee, S.H.; Kim, J.; Jeong, H.E. Applications of Bioinspired Reversible Dry and Wet Adhesives: A Review. Front. Mech. Eng. 2021, 7, 668262. [Google Scholar] [CrossRef]

- Israelachvili, J.N. Intermolecular and Surface Forces; Academic Press: Cambridge, MA, USA, 2010; 710p. [Google Scholar]

- Chandra, D.; Yang, S. Stability of High-Aspect-Ratio Micropillar Arrays against Adhesive and Capillary Forces. Acc. Chem. Res. 2010, 43, 1080–1091. [Google Scholar] [CrossRef]

- Amador, G.J.; Klaassen van Oorschot, B.; Sen, U.; Karman, B.; Leenders, R. Capillary Adhesion of Stick Insects. Ann. N. Y. Acad. Sci. 2024, 1538, 98–106. [Google Scholar] [CrossRef]

- Xiang, C.; Li, Z.; Wang, F.; Guan, Y.; Zhou, W. A 3D Printed Flexible Electroadhesion Gripper. Sens. Actuators A Phys. 2023, 363, 114675. [Google Scholar] [CrossRef]

- Glick, P.; Suresh, S.A.; Ruffatto, D.; Cutkosky, M.; Tolley, M.T.; Parness, A. A Soft Robotic Gripper with Gecko-Inspired Adhesive. IEEE Robot. Autom. Lett. 2018, 3, 903–910. [Google Scholar] [CrossRef]

- Herter, S.; Stopp, P.; Fischer, S.C.L. Soft Tactile Coil-Based Sensor for Misalignment Detection of Adhesive Fibrillary Gripping Systems. Adv. Sens. Res. 2024, 3, 2300098. [Google Scholar] [CrossRef]

- Sut, D.J.; Sethuramalingam, P. Soft Manipulator for Soft Robotic Applications: A Review. J. Intell. Robot. Syst. Theory Appl. 2023, 108, 1–23. [Google Scholar] [CrossRef]

- An, S.; Xiang, C.; Ji, C.; Liu, S.; He, L.; Li, L.; Wang, Y. Design and Development of a Variable Structure Gripper with Electroadhesion. Smart Mater. Struct. 2024, 33, 055035. [Google Scholar] [CrossRef]

- Cacucciolo, V.; Shintake, J.; Shea, H. Delicate yet Strong: Characterizing the Electro-Adhesion Lifting Force with a Soft Gripper. In Proceedings of the RoboSoft 2019—2019 IEEE International Conference on Soft Robotics, Seoul, Republic of Korea, 14–18 April 2019; pp. 108–113. [Google Scholar] [CrossRef]

- Cacucciolo, V.; Shea, H.; Carbone, G. Peeling in Electroadhesion Soft Grippers. Extrem. Mech. Lett. 2022, 50, 101529. [Google Scholar] [CrossRef]

- Mastrangelo, M.; Caruso, F.; Carbone, G.; Cacucciolo, V. Electroadhesion Zipping with Soft Grippers on Curved Objects. Extrem. Mech. Lett. 2023, 61, 101999. [Google Scholar] [CrossRef]

- Vogt, D.; Parker, K.K.; Wood, R.J.; Sinatra, N.R.; Teeple, C.B.; Vogt, D.M.; Gruber, D.F. Ultragentle Manipulation of Delicate Structures Using a Soft Robotic Gripper. Sci. Robot. 2019, 4, eaax5425. [Google Scholar] [CrossRef]

- Qu, J.; Yu, Z.; Tang, W.; Xu, Y.; Mao, B.; Zhou, K. Advanced Technologies and Applications of Robotic Soft Grippers. Adv. Mater. Technol. 2024, 9, 2301004. [Google Scholar] [CrossRef]

- Gu, G.; Zhang, N.; Xu, H.; Lin, S.; Yu, Y.; Chai, G.; Ge, L.; Yang, H.; Shao, Q.; Sheng, X.; et al. A Soft Neuroprosthetic Hand Providing Simultaneous Myoelectric Control and Tactile Feedback. Nat. Biomed. Eng. 2021, 7, 589–598. [Google Scholar] [CrossRef] [PubMed]

- Al Abeach, L.A.T.; Nefti-Meziani, S.; Davis, S. Design of a Variable Stiffness Soft Dexterous Gripper. Soft Robot. 2017, 4, 274–284. [Google Scholar] [CrossRef] [PubMed]

- Tondu, B. Modelling of the McKibben Artificial Muscle: A Review. J. Intell. Mater. Syst. Struct. 2012, 23, 225–253. [Google Scholar] [CrossRef]

- Jain, S.; Dontu, S.; Teoh, J.E.M.; Alvarado, P.V.Y. A Multimodal, Reconfigurable Workspace Soft Gripper for Advanced Grasping Tasks. Soft Robot. 2023, 10, 527–544. [Google Scholar] [CrossRef] [PubMed]

- Tawk, C.; Gillett, A.; In Het Panhuis, M.; Spinks, G.M.; Alici, G. A 3D-Printed Omni-Purpose Soft Gripper. IEEE Trans. Robot. 2019, 35, 1268–1275. [Google Scholar] [CrossRef]

- Ham, K.B.; Han, J.; Park, Y.J. Soft Gripper Using Variable Stiffness Mechanism and Its Application. Int. J. Precis. Eng. Manuf. 2018, 19, 487–494. [Google Scholar] [CrossRef]

- Huang, S.J.; Chang, W.H.; Su, J.Y. Intelligent Robotic Gripper with Adaptive Grasping Force. Int. J. Control Autom. Syst. 2017, 15, 2272–2282. [Google Scholar] [CrossRef]

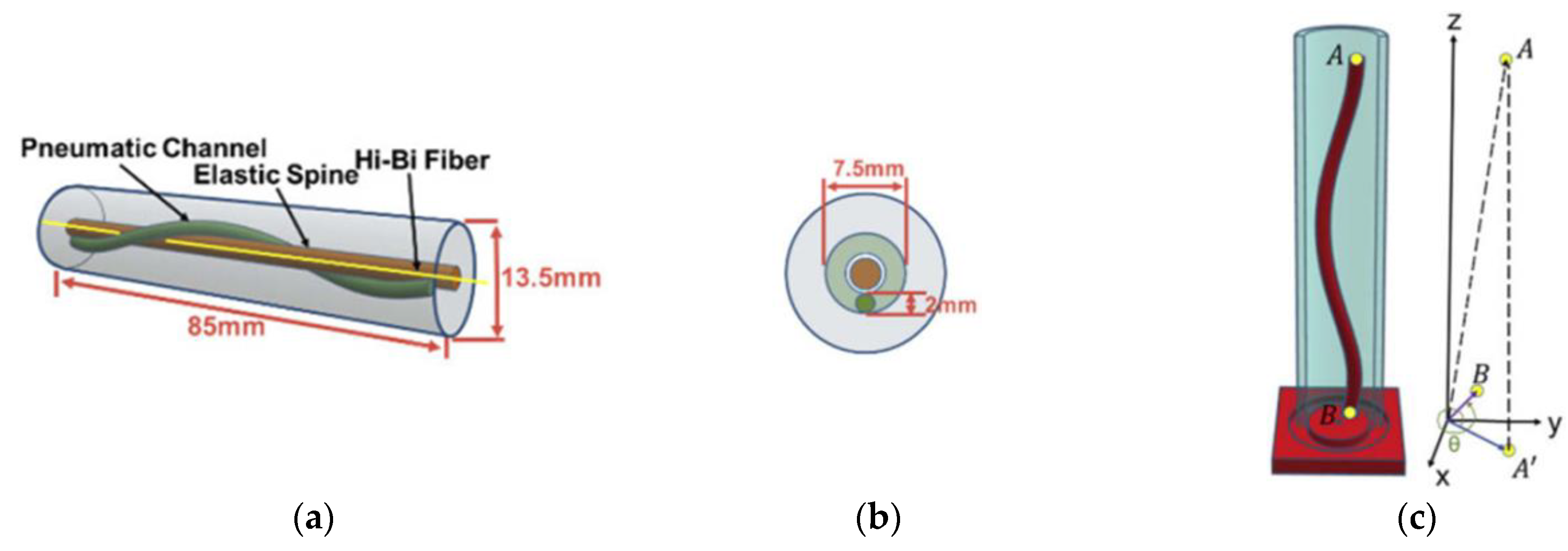

- Cooper, L.P.; Yang, M.; Liu, N.; Fok, M.P.; Wang, X. Twining Plant Inspired Pneumatic Soft Robotic Spiral Gripper with a Fiber Optic Twisting Sensor. Opt. Express 2020, 28, 35158–35167. [Google Scholar] [CrossRef]

- Raja, R.; Shoushtari, A.L. Bio-Inspired Soft Grippers for Biological Applications. arXiv 2024, arXiv:2407.14324. [Google Scholar]

- Fang, B.; Sun, F.; Wu, L.; Liu, F.; Wang, X.; Huang, H.; Huang, W.; Liu, H.; Wen, L. Multimode Grasping Soft Gripper Achieved by Layer Jamming Structure and Tendon-Driven Mechanism. Soft Robot. 2022, 9, 233–249. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Domel, A.G.; An, N.; Green, C.; Gong, Z.; Wang, T.; Knubben, E.M.; Weaver, J.C.; Bertoldi, K.; Wen, L. Octopus Arm-Inspired Tapered Soft Actuators with Suckers for Improved Grasping. Soft Robot. 2020, 7, 639–648. [Google Scholar] [CrossRef] [PubMed]

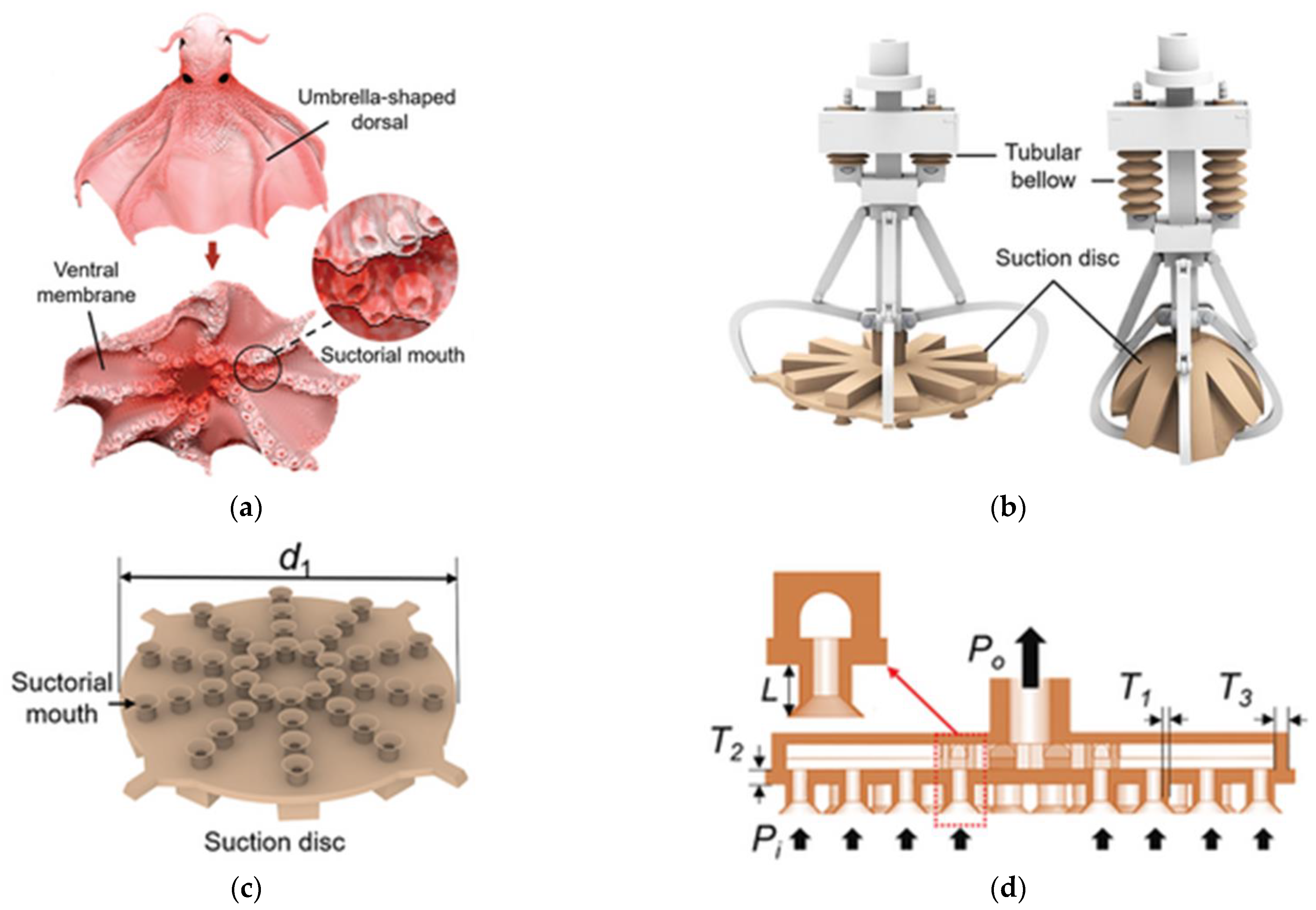

- Wu, M.; Afridi, W.H.; Wu, J.; Afridi, R.H.; Wang, K.; Zheng, X.; Wang, C.; Xie, G. Octopus-Inspired Underwater Soft Robotic Gripper with Crawling and Swimming Capabilities. Research 2024, 7, 0456. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Zheng, X.; Liu, R.; Hou, N.; Afridi, W.H.; Afridi, R.H.; Guo, X.; Wu, J.; Wang, C.; Xie, G. Glowing Sucker Octopus (Stauroteuthis Syrtensis)-Inspired Soft Robotic Gripper for Underwater Self-Adaptive Grasping and Sensing. Adv. Sci. 2022, 9, 2104382. [Google Scholar] [CrossRef] [PubMed]

- Qi, Q.; Xiang, C.; Ho, V.A.; Rossiter, J. A Sea-Anemone-Inspired, Multifunctional, Bistable Gripper. Soft Robot. 2022, 9, 1040–1051. [Google Scholar] [CrossRef]

- Wang, X.; Wang, W.; Liu, H.; Guo, Q.; Yu, H.; Yuan, Z.; Yang, W. Bionic Sea Anemone Actuator with a Double-Layered Gripper Driven by Multiple Physical Fields. ACS Appl. Polym. Mater. 2023, 5, 5582–5591. [Google Scholar] [CrossRef]

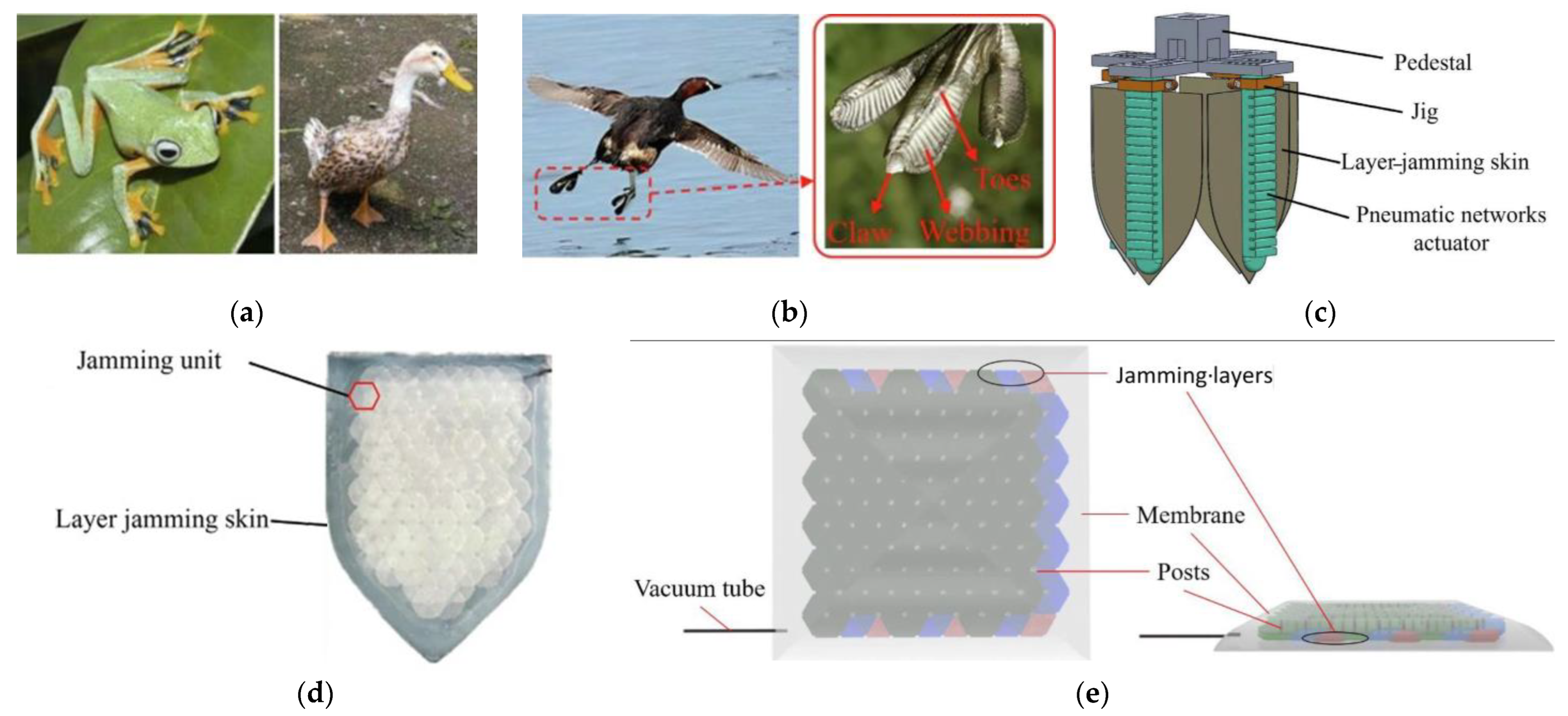

- Zhang, Z.; Li, S.; Zhou, Y.; Huang, D.; Sun, M.; Zhang, G.; Chai, H.; Jiang, S. Layer Jamming Skin-based Bionic Webbed Foot Soft Gripper with Variable Stiffness and Envelopment. Compos. Struct. 2024, 341, 118215. [Google Scholar] [CrossRef]

- Alshawabkeh, M.; Alagi, H.; Navarro, S.E.; Duriez, C.; Hein, B.; Zangl, H.; Faller, L.M. Highly Stretchable Additively Manufactured Capacitive Proximity and Tactile Sensors for Soft Robotic Systems. IEEE Trans. Instrum. Meas. 2023, 72, 1–10. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Lou, Y.; Zhang, B.; Zhou, J.; Chen, J. Soft Bionic Gripper with Tactile Sensing and Slip Detection for Damage-Free Grasping of Fragile Fruits and Vegetables. Comput. Electron. Agric. 2024, 220, 108904. [Google Scholar] [CrossRef]

- Ye, Y.; Han, C.; Kang, S.; Zhao, J.; Scharff, R.B.N.; Wang, J.; Du, D. Development of a Novel Variable-Curvature Soft Gripper Used for Orientating Broccoli in the Trimming Line. Comput. Electron. Agric. 2024, 225, 109267. [Google Scholar] [CrossRef]

- Li, H.; Bai, H.; Wang, Z.; Tan, Y.; Tang, Y. Soft Bioinspired Pneumatic Actuator for Adaptive Grasping Based on Direct Ink Writing Method. Sens. Actuators A Phys. 2024, 367, 115041. [Google Scholar] [CrossRef]

- Wu, G.-H.; Yang, Y.-L.; Wang, S.; Cui, Y.-G.; Wei, Y.-D. Dynamic Modeling and Robust Vibration Control of a High-Speed Macro-Micro Gripping System. Mech. Syst. Signal Process 2023, 204, 110801. [Google Scholar] [CrossRef]

- Gupta, U.; Qin, L.; Wang, Y.; Godaba, H.; Zhu, J. Soft Robots Based on Dielectric Elastomer Actuators: A Review. Smart Mater. Struct. 2019, 28, 103002. [Google Scholar] [CrossRef]

- Carloni, A.; Valori, M.; Bertolucci, F.; Agostini, L.; Berselli, G.; Fassi, I.; Tosatti, L.M.; Vertechy, R. Enhancing Compliant Gripper Performance: Exploiting Electro-Adhesion to Increase Lifting Force over Grasping Force. Robot. Comput. Integr. Manuf. 2025, 91, 102843. [Google Scholar] [CrossRef]

- Mouazé, N.; Birglen, L. Analyse de La Saisie d’objets Déformables Par Des Pinces Adaptatives. Ph.D. Thesis, University of Montreal, Montreal, QC, Canada, 2021. [Google Scholar]

- Webster, R.J.; Jones, B.A. Design and Kinematic Modeling of Constant Curvature Continuum Robots: A Review. Int. J. Robot. Res. 2010, 29, 1661–1683. [Google Scholar] [CrossRef]

- Mutlu, R.; Tawk, C.; Alici, G.; Sariyildiz, E. A 3D Printed Monolithic Soft Gripper with Adjustable Stiffness. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 6235–6240. [Google Scholar] [CrossRef]

- Guo, D.; Kang, Z.; Wang, Y.; Li, M. Design of Multi-Material Soft Pneumatic Modules. Smart Mater. Struct. 2021, 30, 095006. [Google Scholar] [CrossRef]

- Dafflon, M.; Lorent, B.; Clavel, R. A Micromanipulation Setup for Comparative Tests of Microgrippers. Int. Symp. Robot. 2006. No. LSRO-CONF-2006-064. [Google Scholar]

- Frank, H.; Barteit, D.; Wellerdick-Wojtasik, N.; Frank, T.; Novak, G.; Mahlknecht, S. Autonomous Mechanical Controlled Grippers for Capturing Flying Objects. In Proceedings of the IEEE International Conference on Industrial Informatics (INDIN), Vienna, Austria, 23–27 June 2007; Volume 1, pp. 431–436. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, J.; Zhang, M.; Yin, Y.; Zhao, X. Study on Ballast Test of Underwater Pile Gripper. J. Phys. Conf. Ser. 2024, 2815, 012018. [Google Scholar] [CrossRef]

- Lindborg, J. Solid Mechanics Structural Integrity Analysis of a Hydraulic Manipulator. Master’s Thesis, Lund University, Lund, Sweden, 2024. [Google Scholar]

- Li, S.; Stampfli, J.J.; Xu, H.J.; Malkin, E.; Diaz, E.V.; Rus, D.; Wood, R.J. A Vacuum-Driven Origami “magic-Ball” Soft Gripper. In Proceedings of the IEEE International Conference on Robotics and Automation, Montreal, QC, Canada, 20–24 May 2019; pp. 7401–7408. [Google Scholar] [CrossRef]

- Montambault, S.; Gosselin, C.M. Analysis of Underactuated Mechanical Grippers. J. Mech. Des. 2001, 123, 367–374. [Google Scholar] [CrossRef]

- Chen, F.Y. Gripping Mechanisms for Industrial Robots: An Overview. Mech. Mach. Theory 1982, 17, 299–311. [Google Scholar] [CrossRef]

- Chaturvedi, R.; Islam, A.; Sharma, A.; Sharma Yashwant Singh Parmar, K.; Sharma, K.; Sharma, R. Design and Analysis of Mechanical Gripper of Aristo-Robot for Welding. TEST Eng. Manag. 2020, 83, 23202–23209. [Google Scholar]

- Lee, S.C.; Moon, H.G.; Hwang, S.H.; Bin Shin, D.; Baek, I.H.; Sun, D.I.; Ryu, J.K.; Han, C.S. Development of an Assembled Gripper for a Hydraulic Cutting Machine with a Novel Design for the Stable Holding of Various Shaped Objects. Int. J. Precis. Eng. Manuf. 2021, 22, 1413–1424. [Google Scholar] [CrossRef]

- Carpenter, R.; Hatton, R.; Balasubramanian, R. Comparison of Contact Capabilities for Underactuated Parallel Jaw Grippers for Use on Industrial Robots. In Proceedings of the ASME 2014 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Buffalo, NY, USA, 17–20 August 2014. [Google Scholar] [CrossRef]

- Qi, J.; Li, X.; Tao, Z.; Feng, H.; Fu, Y. Design and Control of a Hydraulic Driven Robotic Gripper. In Proceedings of the 2021 IEEE International Conference on Robotics and Biomimetics (ROBIO 2021), Sanya, China, 27–31 December 2021; pp. 398–404. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Kumar, B. Vacuum Cup Grippers for Material Handling In Industry. IJISET-Int. J. Innov. Sci. Eng. Technol. 2017, 4, 187–194. [Google Scholar]

- Ross, S.; Korostynska, O.; Cordova-Lopez, L.E.; Mason, A. A Review of Unilateral Grippers for Meat Industry Automation. Trends Food Sci. Technol. 2022, 119, 309–319. [Google Scholar] [CrossRef]

- Savkiv, V.; Mykhailyshyn, R.; Duchon, F.; Fendo, O. Justification of Design and Parameters of Bernoulli–Vacuum Gripping Device. Int. J. Adv. Robot. Syst. 2017, 14. [Google Scholar] [CrossRef]

- Tavakoli, M.; Viegas, C.; Romao, J.C.; Neto, P.; De Almeida, A.T. Switchable Magnets for Robotics Applications. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–2 October 2015; pp. 4325–4330. [Google Scholar] [CrossRef]

- Lien, T.K.; Davis, P.G.G. A Novel Gripper for Limp Materials Based on Lateral Coanda Ejectors. CIRP Ann. 2008, 57, 33–36. [Google Scholar] [CrossRef]

- Hirano, D.; Tanishima, N.; Bylard, A.; Chen, T.G. Underactuated Gecko Adhesive Gripper for Simple and Versatile Grasp. In Proceedings of the IEEE International Conference on Robotics and Automation, Paris, France, 31 May–31 August 2020; pp. 8964–8969. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, X.; Zheng, M.; Zhang, F.; Zhang, Q.; Wang, X.; Gorb, S.N.; Dai, Z. A Gecko-Inspired Gripper with Controllable Adhesion. In Intelligent Robotics and Applications; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2018; Volume 10985, pp. 112–121. [Google Scholar] [CrossRef]

- Verotti, M.; Dochshanov, A.; Belfiore, N.P. A Comprehensive Survey on Microgrippers Design: Mechanical Structure. J. Mech. Des. 2017, 139, 060801. [Google Scholar] [CrossRef]

- Nikoobin, A.; Niaki, M.H. Describing the Effective Parameters in Grippers, and Designing the Novel Micro-Nano Gripper. In Proceedings of the 2011 2nd International Conference on Control, Instrumentation and Automation (ICCIA 2011), Shiraz, Iran, 27–29 December 2011; pp. 957–963. [Google Scholar] [CrossRef]

- Zmyślony, M.; Dradrach, K.; Haberko, J.; Nałęcz-Jawecki, P.; Rogóż, M.; Wasylczyk, P.; Zmyślony, M.; Dradrach, K.; Nałęcz-Jawecki, P.; Rogóż, M.; et al. Optical Pliers: Micrometer-Scale, Light-Driven Tools Grown on Optical Fibers. Adv. Mater. 2020, 32, 2002779. [Google Scholar] [CrossRef]

- Brecher, C.; Peschke, C.; Freundt, M.; Lange, S. Multi-Axes Micro Gripper for the Handling and Alignment of Flexible Micro Parts: Development of compact and shock resistant gripper components. In Precision Assembly Technologies for Mini and Micro Products, Proceedings of the IFIP TC5 WG5. 5 Third International Precision Assembly Seminar (IPAS’2006), Bad Hofgastein, Austria, 19–21 February 2006; Springer: Boston, MA, USA, 2006; pp. 11–19. [Google Scholar]

- Takahashi, T.; Suzuki, M.; Aoyagi, S. Octopus Bioinspired Vacuum Gripper with Micro Bumps. In Proceedings of the 2016 IEEE 11th Annual International Conference on Nano/Micro Engineered and Molecular Systems (NEMS 2016), Sendai, Japan, 17–20 April 2016; pp. 508–511. [Google Scholar] [CrossRef]

- Bučinskas, V.; Subačiūtė-Žemaitienė, J.; Dzedzickis, A.; Šutinys, E.; Morkvėnaitė-Vilkončienė, I. Robotic Micromanipulation: B) Grippers for Biological Objects. Robot. Syst. Appl. 2022, 2, 1–14. [Google Scholar] [CrossRef]

- Valchev, G.; Dantchev, D.; Kostadinov, K. On the Forces Between Micro and Nano Objects and a Gripper. Int. J. Intell. Mechatron. Robot. 2012, 2, 15–33. [Google Scholar] [CrossRef]

- Sandoval, J.A.; Xu, T.; Adibnazari, I.; Deheyn, D.D.; Tolley, M.T. Combining Suction and Friction to Stabilize a Soft Gripper to Shear and Normal Forces, for Manipulation of Soft Objects in Wet Environments. IEEE Robot. Autom. Lett. 2022, 7, 4134–4141. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, Q.; Cai, D.; Chen, C.; Zhang, J.; Duan, W. Theoretical Modelling of Soft Robotic Gripper with Bioinspired Fibrillar Adhesives. Mech. Adv. Mater. Struct. 2022, 29, 2250–2266. [Google Scholar] [CrossRef]

- Davies, J.; Phan, P.T.; Huang, D.; Hoang, T.T.; Low, H.; Thai, M.T.; Nguyen, C.C.; Nicotra, E.; Lovell, N.H.; Do, T.N. Hydraulically Actuated Soft Tubular Gripper. In Proceedings of the IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 23–27 May 2022; pp. 6144–6150. [Google Scholar] [CrossRef]

- Kumar, B.; Jaiswal, A.K.; Kumar, B. Material Compositions Affects Vacuum System in Gripping Technology. Int. J. Sci. Technol. ISSN 2017, 7, 15–23. Available online: www.ijst.co.in (accessed on 24 May 2024).

- Gabriel, F.; Fahning, M.; Meiners, J.; Dietrich, F.; Dröder, K. Modeling of Vacuum Grippers for the Design of Energy Efficient Vacuum-Based Handling Processes. Prod. Eng. 2020, 14, 545–554. [Google Scholar] [CrossRef]

- Liu, Q.; Gu, X.; Tan, N.; Ren, H. Soft Robotic Gripper Driven by Flexible Shafts for Simultaneous Grasping and In-Hand Cap Manipulation. IEEE Trans. Autom. Sci. Eng. 2021, 18, 1134–1143. [Google Scholar] [CrossRef]

- Teshigawara, S.; Tsutsumi, T.; Shimizu, S.; Suzuki, Y.; Ming, A.; Ishikawa, M.; Shimojo, M. Highly Sensitive Sensor for Detection of Initial Slip and Its Application in a Multi-Fingered Robot Hand. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 1097–1102. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Mei, D.; Zhu, L.; Chen, J. Flexible Tactile Sensor Array for Distributed Tactile Sensing and Slip Detection in Robotic Hand Grasping. Sens. Actuators A Phys. 2019, 297, 111512. [Google Scholar] [CrossRef]

- Yussof, H.; Ohka, M.; Suzuki, H.; Morisawa, N. Tactile Sensing-Based Control System for Dexterous Robot Manipulation. Lect. Notes Electr. Eng. 2009, 14 LNEE, 199–213. [Google Scholar] [CrossRef]

- Romano, J.M.; Hsiao, K.; Niemeyer, G.; Chitta, S.; Kuchenbecker, K.J. Human-Inspired Robotic Grasp Control with Tactile Sensing. IEEE Trans. Robot. 2011, 27, 1067–1079. [Google Scholar] [CrossRef]

- Goudu, S.R.; Yasa, I.C.; Hu, X.; Ceylan, H.; Hu, W.; Sitti, M.; Goudu, S.R.; Yasa, I.C.; Hu, X.; Ceylan, H.; et al. Biodegradable Untethered Magnetic Hydrogel Milli-Grippers. Adv. Funct. Mater. 2020, 30, 2004975. [Google Scholar] [CrossRef]

- Xie, H.; Meng, X.; Zhang, H.; Sun, L. Development of a Magnetically Driven Microgripper for PicoNewton Force-Controlled Microscale Manipulation and Characterization. IEEE Trans. Ind. Electron. 2020, 67, 2065–2075. [Google Scholar] [CrossRef]

- Li, X.; Fan, D.; Sun, Y.; Xu, L.; Li, D.; Sun, B.; Nong, S.; Li, W.; Zhang, S.; Hu, B.; et al. Porous Magnetic Soft Grippers for Fast and Gentle Grasping of Delicate Living Objects. Adv. Mater. 2024, 36, 2409173. [Google Scholar] [CrossRef]

- Su, Z.; Hausman, K.; Chebotar, Y.; Molchanov, A.; Loeb, G.E.; Sukhatme, G.S.; Schaal, S. Force Estimation and Slip Detection/Classification for Grip Control Using a Biomimetic Tactile Sensor. In Proceedings of the IEEE-RAS International Conference on Humanoid Robots, Seoul, Republic of Korea, 3–5 November 2015; pp. 297–303. [Google Scholar] [CrossRef]

- Mantriota, G. Optimal Grasp of Vacuum Grippers with Multiple Suction Cups. Mech. Mach. Theory 2007, 42, 18–33. [Google Scholar] [CrossRef]

- Valencia, A.J.; Idrovo, R.M.; Sappa, A.D.; Guingla, D.P.; Ochoa, D. A 3D Vision Based Approach for Optimal Grasp of Vacuum Grippers. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and their Application to Mechatronics (ECMSM 2017), Donostia, Spain, 24–26 May 2017. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, T.; Ren, Z.; Gong, Z.; Wang, H.; Yang, X.; Guan, S.; Wen, L. Modeling and Experiments of a Soft Robotic Gripper in Amphibious Environments. Int. J. Adv. Robot. Syst. 2017, 14. [Google Scholar] [CrossRef]

- Wang, T.; Sun, E.; Zhu, S. Contact Force Estimation of Hydraulic Soft Bending Actuators for Gripping. Adv. Robot. 2021, 35, 1098–1106. [Google Scholar] [CrossRef]

- Le Signor, T.; Dupre, N.; Close, G.F. A Gradiometric Magnetic Force Sensor Immune to Stray Magnetic Fields for Robotic Hands and Grippers. IEEE Robot. Autom. Lett. 2022, 7, 3070–3076. [Google Scholar] [CrossRef]

- Liu, D.; Liu, X.; Li, P.; Tang, X.; Kojima, M.; Huang, Q.; Arai, T. Magnetic Driven Two-Finger Micro-Hand with Soft Magnetic End-Effector for Force-Controlled Stable Manipulation in Microscale. Micromachines 2021, 12, 410. [Google Scholar] [CrossRef] [PubMed]

- Nica, M.; Forbrigger, C.; Diller, E. A Novel Magnetic Transmission for Powerful Miniature Surgical Robots. IEEE/ASME Trans. Mechatron. 2022, 27, 5541–5550. [Google Scholar] [CrossRef]

- Schlick, J.; Zuehlke, D. Design and Application of a Gripper for Microparts Using Flexure Hinges and Pneumatic Actuation. SPIE 2001, 4568, 1–11. [Google Scholar] [CrossRef]

- Linghu, C.; Zhang, S.; Wang, C.; Yu, K.; Li, C.; Zeng, Y.; Zhu, H.; Jin, X.; You, Z.; Song, J. Universal SMP Gripper with Massive and Selective Capabilities for Multiscaled, Arbitrarily Shaped Objects. Sci. Adv. 2020, 6, eaay5120. [Google Scholar] [CrossRef]

- Baghbani Kordmahale, S.; Qu, J.; Muliana, A.; Kameoka, J. A Hydraulic Soft Microgripper for Biological Studies. Sci. Rep. 2022, 12, 21403. [Google Scholar] [CrossRef]

- Qing, H.; Chi, Y.; Hong, Y.; Zhao, Y.; Qi, F.; Li, Y.; Yin, J. Fully 3D-Printed Miniature Soft Hydraulic Actuators with Shape Memory Effect for Morphing and Manipulation. Adv. Mater. 2024, 36, 2402517. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Onaizah, O.; Middleton, K.; You, L.; Diller, E. Reliable Grasping of Three-Dimensional Untethered Mobile Magnetic Microgripper for Autonomous Pick-and-Place. IEEE Robot. Autom. Lett. 2017, 2, 835–840. [Google Scholar] [CrossRef]

- Zhang, J.; Salehizadeh, M.; Diller, E. Parallel Pick and Place Using Two Independent Untethered Mobile Magnetic Microgrippers. In Proceedings of the IEEE International Conference on Robotics and Automation, Brisbane, Australia, 21–25 May 2018; pp. 123–128. [Google Scholar] [CrossRef]

- Thien Hoang, T.; Thien Phan, P.; Thanh Thai, M.; Lovell, N.H.; Nho Do, T.; Hoang, T.T.; Phan, P.T.; Thai, M.T.; Lovell, N.H.; Do, T.N. Bio-Inspired Conformable and Helical Soft Fabric Gripper with Variable Stiffness and Touch Sensing. Adv. Mater. Technol. 2020, 5, 2000724. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Riemer, O.; Stern, R. Machining of Precision Parts and Microstructures. In Initiatives of Precision Engineering at the Beginning of a Millennium; Springer: Boston, MA, USA, 2002; pp. 3–11. [Google Scholar] [CrossRef]

- Maggi, M.; Mantriota, G.; Reina, G. Introducing POLYPUS: A Novel Adaptive Vacuum Gripper. Mech. Mach. Theory 2022, 167, 104483. [Google Scholar] [CrossRef]

- Takahashi, T.; Nagato, K.; Suzuki, M.; Aoyagi, S. Flexible Vacuum Gripper with Autonomous Switchable Valves. In Proceedings of the IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 364–369. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, X.J.; Dong, X.; Zhou, J.; Zhao, H. Enhancing the Universality of a Pneumatic Gripper via Continuously Adjustable Initial Grasp Postures. IEEE Trans. Robot. 2021, 37, 1604–1618. [Google Scholar] [CrossRef]

- Fujita, M.; Ikeda, S.; Fujimoto, T.; Shimizu, T.; Ikemoto, S.; Miyamoto, T. Development of Universal Vacuum Gripper for Wall-Climbing Robot. Adv. Robot. 2018, 32, 283–296. [Google Scholar] [CrossRef]

- Fantoni, G.; Hansen, H.N.; Santochi, M. A New Capillary Gripper for Mini and Micro Parts. CIRP Ann. 2013, 62, 17–20. [Google Scholar] [CrossRef]

- Licht, S.; Collins, E.; Mendes, M.L.; Baxter, C. Stronger at Depth: Jamming Grippers as Deep Sea Sampling Tools. Soft Robot. 2017, 4, 305–316. [Google Scholar] [CrossRef]

| Type of the Object | Size of the Object | Gripper Type | References |

|---|---|---|---|

| Strong, unsensitive | micrometric | mechanic | [129] |

| electric | [122] | ||

| 10 … 100 mm | mechanic | [37,75,77,108,130] | |

| hydraulic | [131,132] | ||

| vacuum | [133] | ||

| pneumatic pressure | [28,29,30,31,103,104,106,126,127,128] | ||

| >100 mm | mechanic | [23,134,135,136] | |

| hydraulic | [137,138,139] | ||

| vacuum | [140,141,142] | ||

| magnetic | [71,143], | ||

| Coanda effect gripping | [144] | ||

| adhesive | [145,146] | ||

| Fragile | micrometric | mechanic | [76,147,148] |

| hydraulic | [149,150,151] | ||

| vacuum | [152] | ||

| pneumatic pressure | [153] | ||

| adhesive | [154,155] | ||

| 10 … 100 mm | mechanic | [84] | |

| hydraulic | [156] | ||

| vacuum | [157,158] | ||

| pneumatic pressure | [159] | ||

| electric | [160,161,162,163] | ||

| magnetic | [164,165,166] | ||

| biomimetic | [167] | ||

| >100 mm | vacuum | [168,169] | |

| pneumatic pressure | [170] | ||

| hydraulic | [171] | ||

| Soft and sensitive | micrometric | magnetic | [172,173,174] |

| pneumatic pressure | [175] | ||

| adhesive | [176] | ||

| hydraulic | [28,177,178] | ||

| 10 … 100 mm | magnetic | [179,180] | |

| hydraulic | [69,70,86,100,181,182] | ||

| vacuum | [32,38,78,82,111,112,113,114,115,117,183,184], | ||

| pneumatic pressure | [22,26,29,30,31,54,58,59,60,61,62,96,105,109,154] | ||

| adhesive | [91,92,97,98,99,123,124] | ||

| particle jamming, pressure | [68] | ||

| >100 mm | mechanic | [21,27,30,53] | |

| pneumatic pressure | [185] | ||

| Special case | vacuum, for climbing | [186] | |

| capillary forces | [187] | ||

| hydraulic, deep sea | [188] | ||

| electric, nanoscale | [73] | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzedzickis, A.; Petronienė, J.J.; Petkevičius, S.; Bučinskas, V. Soft Grippers in Robotics: Progress of Last 10 Years. Machines 2024, 12, 887. https://doi.org/10.3390/machines12120887

Dzedzickis A, Petronienė JJ, Petkevičius S, Bučinskas V. Soft Grippers in Robotics: Progress of Last 10 Years. Machines. 2024; 12(12):887. https://doi.org/10.3390/machines12120887

Chicago/Turabian StyleDzedzickis, Andrius, Jūratė Jolanta Petronienė, Sigitas Petkevičius, and Vytautas Bučinskas. 2024. "Soft Grippers in Robotics: Progress of Last 10 Years" Machines 12, no. 12: 887. https://doi.org/10.3390/machines12120887

APA StyleDzedzickis, A., Petronienė, J. J., Petkevičius, S., & Bučinskas, V. (2024). Soft Grippers in Robotics: Progress of Last 10 Years. Machines, 12(12), 887. https://doi.org/10.3390/machines12120887