Coordinated Motion Control of Mobile Self-Reconfigurable Robots in Virtual Rigid Framework

Abstract

:1. Introduction

- (1)

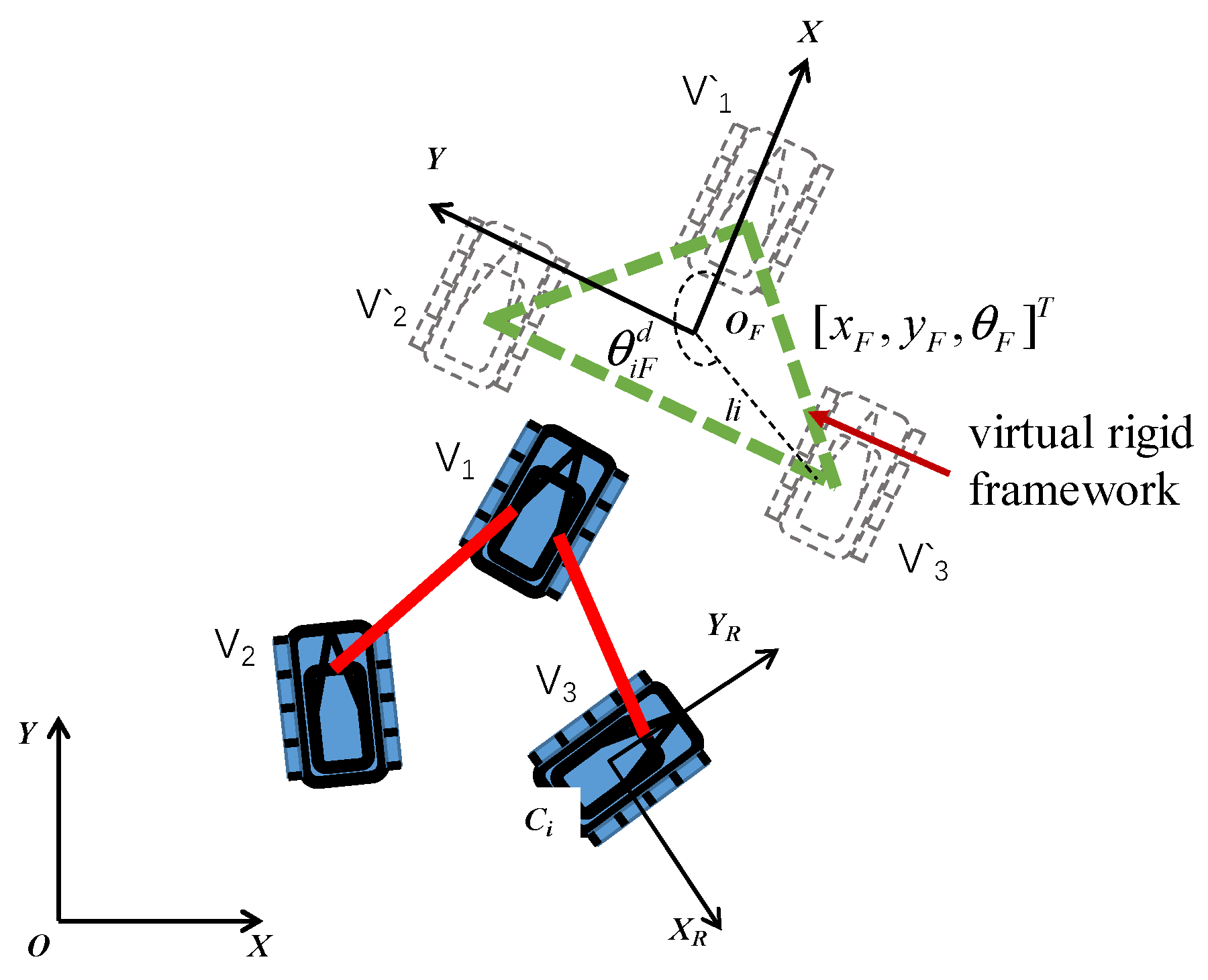

- A virtual rigid framework is created to serve as a reference for maintaining the spatial relationships between the module units. An optimized pure pursuit and PID (PPC-PID) controller for the virtual rigid structure is designed to generate the quantity of motion control needed for path-tracking.

- (2)

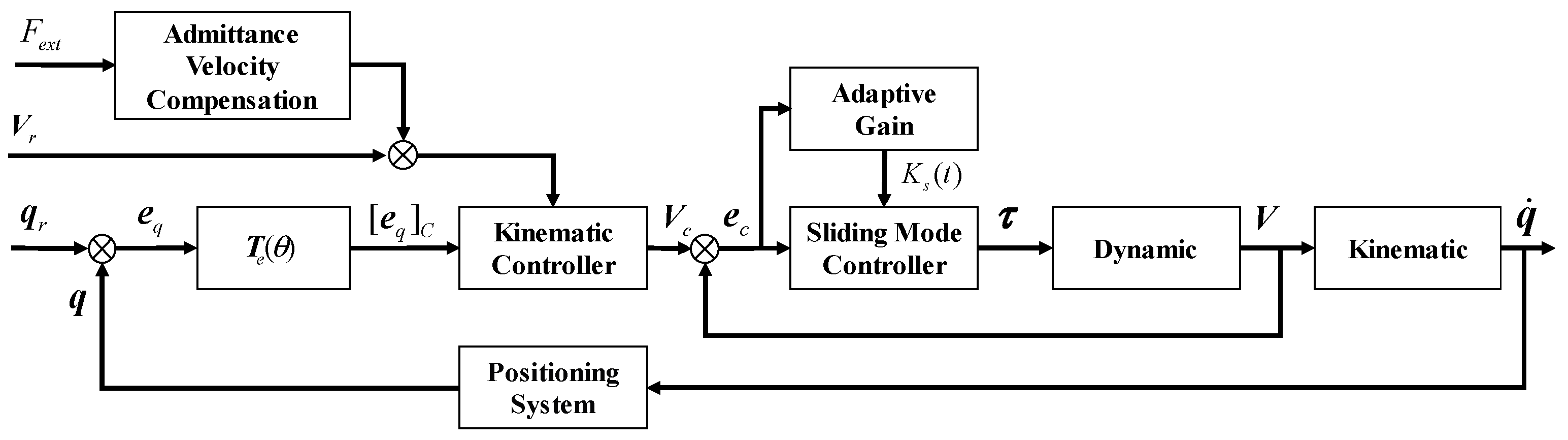

- A backstepping-based module unit motion controller that incorporates kinematic and adaptive sliding mode control is designed; this is accomplished to enable the module units to track the movement of the virtual rigid structure.

2. Virtual Rigid Structure Motion Control

2.1. Generation of the Virtual Rigid Structure Under the Virtual Rigid Framework

2.2. Optimized PPC-PID Controller for VRS

3. Coordinated Motion Controller Based on Kinematics and Adaptive Sliding Mode Control

- (1)

- Based on the kinematic model of the module unit, a velocity control input is designed. This ensures that under the desired velocity , the pose error between the module unit’s actual pose and the desired pose converges to zero.

- (2)

- Based on the velocity tracking error, a dynamic controller is designed to ensure that the module unit’s actual velocity converges to the control velocity determined by the kinematic control layer.

3.1. Kinematic Controller Based on an Error Model

3.2. Adaptive Sliding Mode Dynamic Controller

3.3. Stability Analysis

4. Simulation and Experiment Analysis

4.1. Simulation of VRS Motion

4.2. Simulation of Coordinated Motion

4.3. Experimental Verification

4.4. Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AGV | Automatic Guided Vehicle |

| MSRR | Mobile Self-Reconfigurable Robotic |

| PPC | Pure Pursuit Control |

| PID | Proportional–Integral–Derivative |

| VRS | Virtual Rigid Structure |

| ASMC | Adaptive Sliding Mode Control |

| MMRP | Modular Mobile Reconfigurable Platform |

| UWB | Ultra-Wideband |

| IMU | Inertial Measurement Unit |

| GPS | Global Positioning System |

References

- Tu, Y.; Lam, T.L. Configuration Identification for a Freeform Modular Self-reconfigurable Robot-Freesn. IEEE Trans. Robot. 2023, 39, 4636–4652. [Google Scholar] [CrossRef]

- Daudelin, J.; Jing, G.; Tosun, T.; Yim, M.; Kress-Gazit, H.; Campbell, M. An Integrated System for Perception-Driven Autonomy with Modular Robots. Sci. Robot. 2018, 3, 31. [Google Scholar] [CrossRef] [PubMed]

- O’Grady, R.; Christensen, A.L.; Dorigo, M. SWARMORPH: Multirobot Morphogenesis Using Directional Self-Assembly. IEEE Trans. Robot. 2009, 25, 738–743. [Google Scholar] [CrossRef]

- Shi, Y.; Elara, M.R.; Le, A.V.; Prabakaran, V.; Wood, K.L. Path Tracking Control of Self-Reconfigurable Robot hTetro with Four Differential Drive Units. IEEE Robot. Autom. Lett. 2020, 5, 3998–4005. [Google Scholar] [CrossRef]

- Seo, J.; Paik, J.; Yim, M. Modular Reconfigurable Robotics. Annu. Rev. Control. Robot. Auton. Syst. 2019, 2, 63–88. [Google Scholar] [CrossRef]

- O’Grady, R.; Groß, R.; Christensen, A.L.; Dorigo, M. Self-assembly strategies in a group of autonomous mobile robots. Auton. Robot. 2010, 28, 439–455. [Google Scholar] [CrossRef]

- Liu, C.; Lin, Q.; Kim, H.; Yim, M. SMORES-EP, a Modular Robot with Parallel Self-Assembly. Auton. Robot. 2023, 47, 211–228. [Google Scholar] [CrossRef]

- Zhao, D.; Lam, T.L. SnailBot: A Continuously Dockable Modular Self-Reconfigurable Robot Using Rocker-Bogie Suspension. In Proceedings of the IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 23–27 May 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022; pp. 4261–4267. [Google Scholar]

- Wei, H.; Chen, Y.; Tan, J.; Wang, T. Sambot: A self-assembly modular robot system. IEEE/ASME Trans. Mechatron. 2011, 16, 745–757. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Z.; Mateos, L.; Huang, K.W.; Schwager, M.; Ratti, C.; Rus, D. Distributed motion control for multiple connected surface vessels. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 24–29 October 2020; pp. 11658–11665. [Google Scholar]

- Parween, R.; Vega Heredia, M.; Rayguru, M.M.; Enjikalayil Abdulkader, R.; Elara, M.R. Autonomous Self-Reconfigurable Floor Cleaning Robot. IEEE Access 2020, 8, 114433–114442. [Google Scholar] [CrossRef]

- Baldassarre, G.; Trianni, V.; Bonani, M.; Mondada, F.; Dorigo, M.; Nolfi, S. Self-organized coordinated motion in groups of physically connected robots. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2007, 37, 224–239. [Google Scholar] [CrossRef]

- Trianni, V.; Nolfi, S.; Dorigo, M. Cooperative hole avoidance in a swarm-bot. Robot. Auton. Syst. 2006, 54, 97–103. [Google Scholar] [CrossRef]

- Lee, M.; Li, T.S. Kinematics, dynamics and control design of 4WIS4WID mobile robots. J. Eng. 2015, 2015, 6–16. [Google Scholar] [CrossRef]

- Hajieghrary, H.; Kularatne, D.; Hsieh, M.A. Cooperative transport of a buoyant load: A differential geometric approach. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 2158–2163. [Google Scholar] [CrossRef]

- Hajieghrary, H.; Kularatne, D.; Hsieh, M.A. Differential Geometric Approach to Trajectory Planning: Cooperative Transport by a Team of Autonomous Marine Vehicles. In Proceedings of the 2018 Annual American Control Conference (ACC), Milwaukee, WI, USA, 27–29 June 2018; pp. 858–863. [Google Scholar] [CrossRef]

- Wang, R.; Li, Y.; Fan, J.; Wang, T.; Chen, X. A novel pure pursuit algorithm for autonomous vehicles based on salp swarm algorithm and velocity controller. IEEE Access 2020, 8, 66525–166540. [Google Scholar] [CrossRef]

- AbdElmoniem, A.; Afif, Y.T.; Maged, S.A.; Abdelaziz, M.; Hammad, S. Adaptive pure-pursuit controller based on particle swarm optimization (pso-pure-pursuit). In Proceedings of the 2021 16th International Conference on Computer Engineering and Systems (ICCES), Cairo, Egypt, 15–16 December 2021; pp. 1–6. [Google Scholar]

- Nawawi, S.W.; Abdeltawab, A.A.A.; Samsuria, N.E.N. Modelling, simulation and navigation of a two-wheel mobile robot using pure pursuit controller. ELEKTRIKA-J. Electr. Eng. 2022, 21, 69–75. [Google Scholar] [CrossRef]

- AbdElmoniem, A.; Osama, A.; Abdelaziz, M.; Maged, S.A. A path-tracking algorithm using predictive Stanley lateral controller. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420974852. [Google Scholar] [CrossRef]

- Wang, L.; Zhai, Z.; Zhu, Z.; Mao, E. Path tracking control of an autonomous tractor using improved Stanley controller optimized with multiple-population genetic algorithm. Actuators 2022, 11, 22. [Google Scholar] [CrossRef]

- Sun, Y.; Cui, B.; Ji, F.; Wei, X.; Zhu, Y. The full-field path tracking of agricultural machinery based on PSO-enhanced fuzzy stanley model. Appl. Sci. 2022, 12, 7683. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Zhang, C.; Ma, K.; Yi, X.; Zeng, H. Path tracking of a four-wheel independently driven skid steer robotic vehicle through a cascaded NTSM-PID control method. IEEE Trans. Instrum. Meas. 2022, 71, 7502311. [Google Scholar] [CrossRef]

- Ammar, H.H.; Azar, A.T. Robust path tracking of mobile robot using fractional order PID controller. In Proceedings of the International Conference on Advanced Machine Learning Technologies and Applications (AMLTA2019), Cairo, Egypt, 28–30 March 2019; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; Volume 4, pp. 370–381. [Google Scholar]

- Algabri, R.; Choi, M.T. Deep-learning-based indoor human following of mobile robot using color feature. Sensors 2020, 20, 2699. [Google Scholar] [CrossRef]

- Zangina, U.; Buyamin, S.; Abidin, M.S.Z.; Azimi, M.S.; Hasan, H.S. Non-linear PID controller for trajectory tracking of a differential drive mobile robot. J. Mech. Eng. Res. Dev. 2020, 43, 255–270. [Google Scholar]

- Zuo, Z.; Yang, X.; Li, Z.; Wang, Y.; Han, Q.; Wang, L.; Luo, X. MPC-based cooperative control strategy of path planning and trajectory tracking for intelligent vehicles. IEEE Trans. Intell. Veh. 2020, 6, 513–522. [Google Scholar] [CrossRef]

- Peicheng, S.; Li, L.; Ni, X.; Yang, A. Intelligent vehicle path tracking control based on improved MPC and hybrid PID. IEEE Access 2022, 10, 94133–94144. [Google Scholar] [CrossRef]

- Yu, J.; Guo, X.; Pei, X.; Chen, Z.; Zhou, W.; Zhu, M.; Wu, C. Path tracking control based on tube MPC and time delay motion prediction. IET Intell. Transp. Syst. 2020, 14, 1–12. [Google Scholar] [CrossRef]

- Rokonuzzaman, M.; Mohajer, N.; Nahavandi, S.; Mohamed, S. Model predictive control with learned vehicle dynamics for autonomous vehicle path tracking. IEEE Access 2021, 9, 128233–128249. [Google Scholar] [CrossRef]

- Cen, H.; Singh, B.K. Nonholonomic wheeled mobile robot trajectory tracking control based on improved sliding mode variable structure. Wirel. Commun. Mob. Comput. 2021, 1, 2974839. [Google Scholar] [CrossRef]

- Azzabi, A.; Nouri, K. Design of a robust tracking controller for a nonholonomic mobile robot based on sliding mode with adaptive gain. Int. J. Adv. Robot. Syst. 2021, 18, 1729881420987082. [Google Scholar] [CrossRef]

- Abood, M.S.; Thajeel, I.K.; Alsaedi, E.M.; Hamdi, M.M.; Mustafa, A.S.; Rashid, S.A. Fuzzy Logic Controller to control the position of a mobile robot that follows a track on the floor. In Proceedings of the 2020 4th International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020; pp. 1–7. [Google Scholar]

- Abdelwahab, M.; Parque, V.; Elbab, A.M.F.; Abouelsoud, A.A.; Sugano, S. Trajectory tracking of wheeled mobile robots using z-number based fuzzy logic. IEEE Access 2020, 8, 18426–18441. [Google Scholar] [CrossRef]

- Wei, R.; Liu, Y.; Dong, H.; Zhu, Y.; Zhao, J. A Graph-Based Hybrid Reconfiguration Deformation Planning for Modular Robots. Sensors 2023, 23, 7892. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, R.; Dong, H.; Zhu, Y.; Zhao, J. A designation of modular mobile reconfigurable platform system. J. Mech. Med. Biol. 2020, 20, 2040006. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, R.; Liu, Y.; Dong, H.; Zhu, Y.; Zhao, J. Coordinated Motion Control of Mobile Self-Reconfigurable Robots in Virtual Rigid Framework. Machines 2024, 12, 888. https://doi.org/10.3390/machines12120888

Wei R, Liu Y, Dong H, Zhu Y, Zhao J. Coordinated Motion Control of Mobile Self-Reconfigurable Robots in Virtual Rigid Framework. Machines. 2024; 12(12):888. https://doi.org/10.3390/machines12120888

Chicago/Turabian StyleWei, Ruopeng, Yubin Liu, Huijuan Dong, Yanhe Zhu, and Jie Zhao. 2024. "Coordinated Motion Control of Mobile Self-Reconfigurable Robots in Virtual Rigid Framework" Machines 12, no. 12: 888. https://doi.org/10.3390/machines12120888

APA StyleWei, R., Liu, Y., Dong, H., Zhu, Y., & Zhao, J. (2024). Coordinated Motion Control of Mobile Self-Reconfigurable Robots in Virtual Rigid Framework. Machines, 12(12), 888. https://doi.org/10.3390/machines12120888