1. Introduction

A pump is a fluid power device that converts mechanical energy into fluid kinetic energy to transport or pressurize fluids. It plays an irreplaceable role in both production and daily life, finding wide applications in agriculture, the chemical industry, the food industry, the automotive sector, aerospace, and many other fields. It is often referred to as the heart of modern industry [

1,

2,

3]. Common volumetric pumps include gear pumps, piston pumps, vane pumps, rotor pumps, reciprocating piston pumps, and screw pumps [

4,

5]. The advantages of reciprocating piston and piston pumps are reliable sealing, minimal fluid leakage, and the ability to generate high pressure. However, their complex structures, numerous components, and significant vibration and noise during operation make them unsuitable for many lightweight, miniaturized, and high-reliability applications [

6,

7]. Gear, rotor, screw, and vane pumps have relatively simple structures, but their drawbacks include poor self-sealing, difficulty in achieving high pressure, and lower efficiency [

8,

9,

10,

11]. Particularly for gear pumps, internal leakage can sometimes be an issue. Under high pressure, the casing may deform, leading to an increase in leakage and a subsequent reduction in the volumetric efficiency of the pump. Cieślicki and Karpenko demonstrated that deformation significantly affects the circumferential clearance height in external gear pumps, thereby influencing their volumetric efficiency. Their study highlights the necessity of accounting for leakage associated with variations in the internal groove height when accurately modeling the flow generated by the pump [

12]. As global demands for energy conservation and emission reduction continue to rise, the rational utilization of energy has become a mainstream focus of world development. Thus, exploring superior new principles for volumetric power machinery has become increasingly important.

With the advancement of science and technology and the extreme application demands in various countries, new types of volumetric pumps will inevitably continue to emerge. Zhang et al. used AMESim to model and simulate a new variable displacement oil pump, comparing the simulation curves with test data. Subsequently, ADAMS was used to identify redundant forces in the device, leading to proposed improvements for the pump [

13]. Guan et al. proposed a quiet spherical pump, analyzing its working mechanism and conducting a kinematic analysis. They then experimentally studied the sound and vibration characteristics of the pump. The quiet spherical pump boasts numerous advantages, making it a viable alternative to other pumps with a broad range of applications [

14]. Li et al. proposed a new energy-saving hydraulic pumping unit utilizing a balanced mechanical structure where the weight of the sucker rods is counterbalanced through a symmetrical arrangement. This new pump achieves continuous pumping, enhances pumping rate, and significantly improves energy efficiency [

15]. Shim et al. proposed a novel rotary clap pump, describing its working principle through kinematic analysis. Compared to traditional pumps, this new design exhibits reduced vibration, lower power loss, and higher flow rates, making it suitable for high-viscosity fluids [

16]. Cheng et al. addressed common issues such as low pump efficiency and high energy consumption by developing a small displacement pump. They derived the efficiency calculation formula for the pump and analyzed various factors affecting its efficiency. This small displacement pump exhibits excellent energy-saving performance and efficiency [

17].

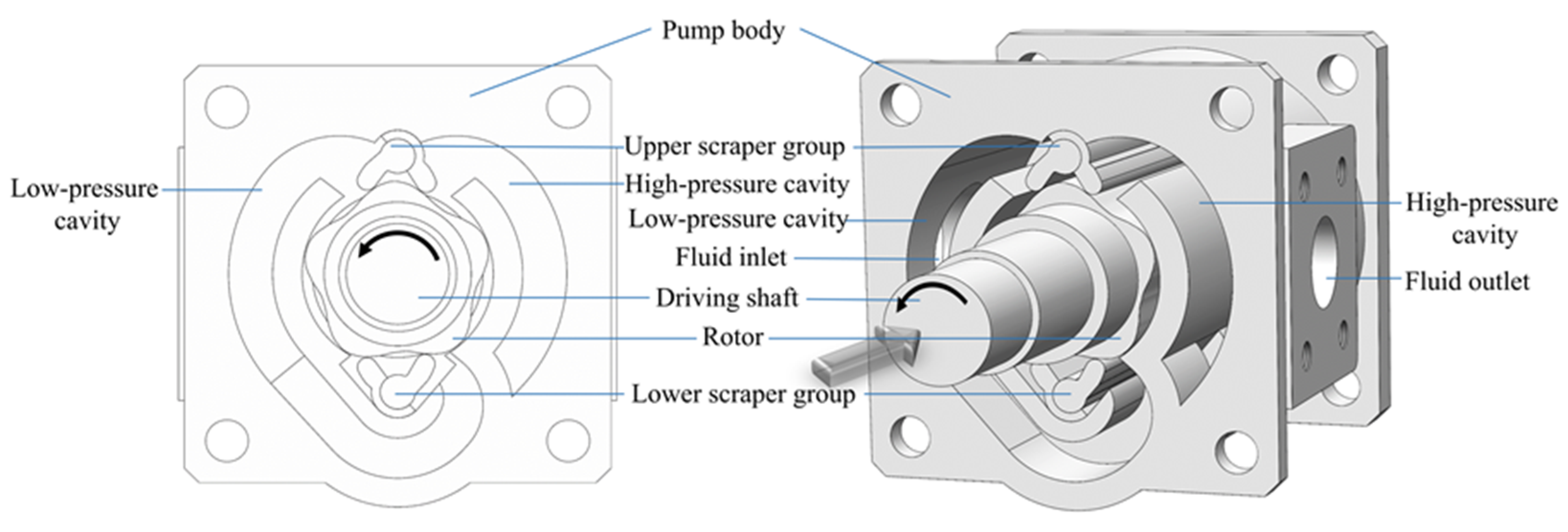

Most of the studies above focus on improvements to existing pumps and do not introduce fundamental innovations in principles. Addressing the main issues of volumetric pumps, Qingdao University proposed a swing scraper-type volumetric pump and conducted preliminary research on it. Li et al. employed various optimization methods to determine the coordinated motion between the scraper and rotor, deriving the equations for coordinated action. They conducted computational fluid dynamics simulations of the ERSP, confirming its feasibility and advantages in enhancing fluid pressure and flow rate [

18]. To further enhance the working efficiency and reduce fluid pulsation of the scraper pump, this paper proposes a double-acting five-blade rotor swing scraper pump. This pump utilizes two pairs of swinging scrapers to replace one gear in a gear pump or one rotor in a rotor pump, effectively converting the mechanical energy of the pump into fluid pressure energy. Compared to other volumetric pumps, it features a compact structure, small size, and excellent sealing. The FRSSP achieves fluid intake and discharge by making the scraper swing in response to the profile of the rotor, thereby varying the pump chamber volume and transporting the medium.

Kinematic analysis of mechanical devices is one of the indispensable steps in the research and development of mechanical devices. Mechanical structures can only realize functional requirements if they meet kinematic requirements [

19,

20,

21,

22,

23]. Peng et al. proposed a novel approach for predicting the pressure and flow rate of flexible electrohydrodynamic (EHD) pumps using a Kolmogorov–Arnold Network (KAN). KAN offers exceptional accuracy and interpretability, making it a promising alternative for predictive modeling in EHD pumping applications [

24]. Battarra et al. analyzed the kinematics of the vane–cam ring mechanism in a balanced vane pump, exploring the relationship between vane geometry and pump performance. They proposed a new design method to enhance the efficiency and performance of the pump [

25]. Guerra et al. analyzed the kinematics of the twin lip vanes used in balanced vane pumps, deriving the trajectories, velocities, and accelerations of the vanes. They detailed how the twin lip configuration affected the kinematics of the machine and validated the feasibility of the mechanism [

26]. Hou et al. proposed a kind of triplex single-function reciprocating pump driven by linear motor technology, deriving its motion laws and phase differences. They found that the pump can theoretically achieve a “constant discharge rate”, providing a theoretical basis for developing new reciprocating pumps [

27]. Yuan et al. proposed a single-stage horizontal self-priming pump system composed of roots and centrifugal pumps. They conducted modeling and kinematic simulation analysis, laying the groundwork for the next steps in prototype fabrication and experimentation [

28].

Through the kinematic study of the FRSSP, the scraper swing angle, angular velocity, and angular acceleration can be precisely determined. This deepens the understanding and description of the scraper pump’s motion laws and characteristics, providing a theoretical basis for the subsequent design of a kinematic pulsation-free scraper pump. Given the unique structure of the swing scraper pump, this paper proposes a kinematic analysis method for the companion trajectory of the FRSSP. The method involves deriving the rotor’s comparing theoretical from the cam profile and using this trajectory to derive the analytical equations of the scraper pump’s motion. The accuracy of this method is verified by comparing theoretical calculations with simulation results. This method is also applicable to cam mechanisms with similar swinging followers. It provides a disciplinary analysis tool for the high-precision design and optimization of rotor and scraper profiles. It offers displacement–following boundary conditions for future complex fluid–structure interaction analyses.

Section 2 describes the structural principles of the FRSSP.

Section 3 establishes the rotor’s comparing theoretical equation based on the cam profile equation.

Section 4 develops the kinematic model of the scraper pump based on the comparing theoretical.

Section 5 conducts simulations of the FRSSP using ADAMS, comparing theoretical calculations with simulation results. A sensitivity analysis is performed on the companion trajectory kinematic analysis method for the FRSSP.

Section 6 presents flow field simulation analysis and experimental validation of the FRSSP.

Section 7 provides a summary of the content discussed in this study.

3. The Companion Trajectory of the Rotor Cam

The rotor profile consists of a combination of five identical curves, which can be regarded as a superposition of a circle and a sinusoidal curve of five times the intrinsic frequency, and the parametric equation of the rotor profile is:

where

rb = 29.3 mm is the base circle radius of the rotor profile;

Ac = 2.8 mm is the amplitude of the enclosing sine curve; and

t is the parameter in the parametric equation of the rotor profile.

The parametric equations of the rotor profile are transformed into polar coordinate equations:

where

ρ is the polar diameter;

θ is the polar angle.

The scraper swing center is fixed, and the overall movement of the scraper key in determining the scraper and rotor contact with one end of the profile (can be designed as an arc) of the curvature of the center relative to the rotor rotation center of the position of the rule of change, i.e., the rotor profile of the companion trajectory, the corresponding analysis method is named as the companion trajectory kinematics analysis method.

Methods for determining the companion trajectory include vector projection and the cosine rule of triangles. This paper uses the vector projection method to derive the trajectory of the curvature circle center of the scraper’s contact end profile from the polar coordinate equation of the five-blade rotor profile. This trajectory, known as the companion trajectory, is essentially an equidistant outward offset line from the rotor profile. Assuming the polar coordinates of the rotor profile are (

θk,

ρk), and designing the contact portion between the scraper and the rotor as an arc with a radius

R0. Take the center of the rotor as the origin of the coordinate system, take the line between the center of the rotor and the swing center of the scraper as the

Y-axis, make a straight line perpendicular to the

Y-axis at the center of the rotor as the

X-axis, and set up the coordinate system shown in

Figure 3, and determine the companion trajectory by the profile of the five-blade rotor cam. In the figure,

A is the center of the rotor;

B is the swinging center of the scraper; point

C indicates the contact point between the swinging scraper and the rotor; point

D is the center of curvature of the contact end profile of the scraper with the rotor.

TT is tangent to the rotor profile at the contact point

C. Correspondingly,

NN is normal at that point;

ρk,

θk are the polar diameters and polar angles of the rotor profile, respectively;

rk,

ψk are the polar diameters and polar angles of the companion trajectories, respectively;

μk is the angle between the polar diameter

ρk of the rotor profile at the contact point

C and its tangent line

TT at point

C;

λk is the angle between the tangent

TT of the rotor profile at point

C and the

X-axis in the positive direction;

ηk is the angle between the normal

NN of the rotor profile at point

C and the positive

X-axis.

From

Figure 3, it can be observed that:

. The projections onto the

X-axis and

Y-axis are:

Based on the vector relationship, the polar radius

rk and polar angle

ψk of the companion trajectory of the five-blade rotor cam can be derived as follows:

After a straightforward derivation, the expressions for

μk,

λk, and

ηk are, respectively:

where

.

4. Kinematic Modeling Based on the Companion Trajectory

In order to describe more clearly the process of deducing the scraper pump kinematics from the companion trajectory of the five-blade rotor cam, the rotor profiles in

Figure 3 were removed. The positional relationship between the companion trajectory and the center of curvature

D of the profiles at the contact end of the scraper with the rotor was used to form

Figure 4, which was used to determine the parameters. In the figure,

T1T1 is tangent to the companion trajectory at point

D, and

NN is normal at point

D;

r0 is the radius of the base circle of the companion trajectory;

D0 is the intersection of the arc drawn with a radius of the length of

BD and the base circle;

β0 is the initial position angle of the scraper;

βk is the swing angle of the scraper; point

P represents a point on the companion trajectory and base circle.

Bp is the position of the center of the swing of the scraper at the moment of the initial position angle determined by the inverse method; point

E is the intersection of the normal

NN with the

Y-axis; a perpendicular line is drawn from point

E to

BD, intersecting the extension of

BD at point

F;

VD represents the velocity direction at point

D.

4.1. Determine the Swing Angle and Pressure Angle of the Scraper

Figure 4 shows the relationship between the five-blade rotor cam companion trajectory and the swinging scraper motion pattern. In order to show more clearly the derivation process between the rotor companion trajectory and each motion characteristic of the scraper,

Figure 4 is decomposed into

Figure 5a,b.

As shown in

Figure 5a, to determine the oscillation angle of the scraper when the curvature center of the scraper profile at the contact end with the rotor is at point

D, it is necessary to know the lowest position of the scraper. The reverse method is used to ascertain the scraper’s lowest position. The rotor cam is known to rotate counterclockwise. Draw a circle with

A as the center and the length of

AB as the radius to represent the circle of the trajectory of the pump body. Take

P point as the center of the circle, take the length of

BD as the radius, draw a circle, and intersect with the trajectory circle of the pump body at two points. According to the reverse method,

Bp is the center of the scraper’s swing when it is in the lowest position. Connect

ABp and

BpP, then ∠

ABpP is the initial position angle of the scraper.

βk = ∠

ABD − ∠

ABpP, which is the swing angle of the scraper. Take

B as the center of the circle,

BD as the radius to draw a circular arc, and intersect with the base circle at point

D0; connect

BD0 and

AD0, and get △

ABD0 and △

ABpP are congruent, so

β0 = ∠

ABpP, and thus

βk = ∠

ABD −

β0.

Based on trigonometric relationships and the law of cosines, the specific expression for

βk can be derived as follows:

where

h is the distance from the rotor rotating center to the swinging center of the scraper;

l is the length of the scraper;

β0 is the initial position angle of the scraper and its specific expression is:

As shown in

Figure 5b, the acute angle

αk formed by the velocity at point

D on the scraper and the normal

NN at point

D on the companion trajectory of the rotor cam is the pressure angle of the scraper, and the magnitude of the pressure angle can be deduced from the above figure. From the figure,

BD is perpendicular to the direction of velocity at point D; the normal

NN at point

D is perpendicular to the tangent

T1T1, so the magnitude of the acute angle subtended by the tangent and

BD is equal to the angle of pressure, which can be derived directly from the angular relationship in the figure. So, the specific expression for the scraper pressure angle is:

where

τ is the angle between the scraper

BD and the pole diameter

AD, and its expression is:

4.2. Determine the Rotation Angle of the Rotor Cam

Take the starting position of the companion trajectory of the rotor cam as a reference and apply the reverse method to find the rotation angle of the rotor cam. As shown in

Figure 6,

D1 is the position of the start point of the companion trajectory at

θk = 0,

r1 is the polar diameter at that point, and

ψ1 is the polar angle at that point.

AB1 is the starting position of the pump body when the scraper is in position

D1. The rotor cam rotates counterclockwise, and when a certain instantaneous scraper is located at the

BD position, it is known by the inverse method that the pump body rotates clockwise from

AB1 to the

AB position at the angle turned is the rotation angle

φk of the cam.

Based on trigonometric relationships and the cosine theorem, the specific expression for

φk can be derived.

4.3. Determine the Angular Velocity of the Scraper

Let the angular velocity of the scraper be

Ωk when the rotor rotation angle is

φk. Point

E is the intersection of the normal

NN and

BA, as shown in

Figure 5b. From the three-center theorem, point

E is the instantaneous center of the relative velocity of the rotor and the scraper, so the rotor and the scraper have the same linear velocity at point

E; thus:

where

ω is the angular velocity of the rotor.

Make the plumbline

EF of

BD at point

E. Then ∠

DEF =

αk. From the right triangle

DEF, the following can be obtained:

By combining Equations (13) and (14), the angular velocity of the scraper can be determined:

4.4. Determine the Angular Acceleration of the Scraper

The angular velocity of the scraper has been derived from

Section 4.3, but since the independent variable of the angular velocity in this text is not time

t, directly differentiating with respect to time

t will not yield the angular acceleration. The differentiation equation needs to be transformed to determine the angular acceleration of the scraper:

where

ε is the angular acceleration of the scraper,

Ω is the angular velocity of the scraper,

φ is the rotation angle of the rotor.

From Equation (16), it can be seen that to require the angular acceleration of the scraper, it is necessary to first find the derivative of the angular velocity of the scraper with respect to the rotor rotation angle. The angular velocity of the scraper and the rotor rotation angle are derived from the companion trajectory of the rotor cam. Numerical analysis can be used to fit the calculated scraper angular velocity data with the rotor rotation angle data to obtain an approximate relationship curve. Different fitting methods to obtain the curve results are different; using the appropriate method for fitting the curve can be a more realistic response to the relationship between the scraper angular velocity and the rotor rotation angle, which is extremely important. This paper uses MATLABR2021b software to calculate the scraper angular velocity and the rotor rotation angle, using the software’s curve fitting toolbox, the choice of sum of sine method to fit the relationship between

Ω and

φ curve. The fitting formula is:

where

a1,

b1,

c1,

a2,

b2,

c2, …are the coefficients derived from the software MatlabR2021b, and the specific magnitudes are shown in

Table 1 below.

The derivative of the scraper angular velocity with respect to the rotor angle dΩ/dφ:

By combining Equations (16) and (18), the angular acceleration of the scraper can be determined.

6. FRSSP Flow Field Simulation and Experiments

This section conducts a flow field analysis of the FRSSP to validate its feasibility and explore its flow field characteristics. Advanced CFD software is utilized for fluid simulation of the FRSSP. The flow field characteristics of the scraper pump are simulated at a rotor speed of 1500 r/min, followed by experiments to compare and discuss the experimental and simulation data.

6.1. FRSSP Flow Field Simulation Analysis

In this study, XFlow software is utilized for flow field simulation of the FRSSP. XFlow 2022 adopts a numerical solution scheme based on the Lattice Boltzmann Method (LBM), which is well-suited for simulating complex flow problems. Moreover, XFlow efficiently leverages multi-core CPUs and GPUs, significantly enhancing computation speed for large-scale simulations. Additionally, XFlow’s automatic mesh generation and adaptive mesh refinement features dynamically optimize mesh resolution according to flow field variations, avoiding the challenges of mesh division in complex geometries and flow conditions often encountered with traditional CFD software. This characteristic eliminates the need for mesh independence testing, thereby improving simulation efficiency. To simulate the boundary layer, XFlow uses a unified nonequilibrium wall function. This wall model is universally applicable, eliminating the need to select between different algorithms, thus improving simulation efficiency.

Before conducting the fluid simulation for the scraper pump, the simulation parameters must be configured. The 3D model of the FRSSP is imported into XFlow software. The rotor speed is set to 1500 r/min, and the angular velocity of the scrapers obtained from ADAMS kinematic simulations is imported into XFlow. Hydraulic oil is selected as the fluid medium, with a density of 865 kg/m³ and a dynamic viscosity of 0.01 Pa·s. The outlet load pressure is set to 2 MPa, and the inlet load pressure to 0.1 MPa. The simulation time is 0.04 s, with a time step of 2 × 10⁻⁶ s. Using these parameters, a single-phase fluid simulation of the scraper pump is carried out.

When the rotor completes one full rotation, the upper and lower oil chambers of the scraper pump each perform five cycles of oil intake and discharge. Specifically, for every 72° of rotor rotation, the scraper pump conducts two cycles of oil intake and discharge. To provide a clearer visualization of the pressure field, planes were established within three flow channels to better observe the pressure variations across each channel. Key positions of the scraper pump were selected to analyze the pressure field distribution within the pump chamber.

Figure 13 illustrates the pressure field distribution inside the pump chamber of the FRSSP at a rotor speed of 1500 r/min. Panels (a) to (d) depict the process of the rotor completing a 72° rotation, during which the upper and lower oil chambers of the scraper pump each perform one cycle of oil intake and discharge. The fluid enters through the inlet, passes through the low-pressure channel into the sealed chamber, where the pressure rises, and then flows through the high-pressure channel and exits at the fluid outlet. During this process, the inlet pressure remains around 0.1 MPa, the pump chamber pressure connected to the outlet ranges between 1.6 and 2 MPa, and the outlet pressure stabilizes at approximately 2.1 MPa.

Figure 14 illustrates the distribution of the velocity vectors within the pump chamber of the FRSSP at a rotor speed of 1500 r/min. Panels (a) to (d) show the process of the rotor completing a 72° rotation. The simulation results reveal that the velocity variation is minimal on the front and rear sides of the scraper pump, with significant changes in velocity concentrated in the middle section of the pump. To better visualize the velocity vector distribution, the images on the right side of the figure display the velocity variations at the middle cross-section. From the figure, it can be observed that the fluid velocity in the low-pressure channel is relatively low, ranging from approximately 0.5 to 1.5 m/s. As the fluid enters the sealed chamber, the velocity increases due to the rise in pressure. Under the influence of gravity and the high-pressure channel’s location, when the fluid enters the upper high-pressure channel, it must overcome gravity, resulting in a lower velocity. The velocity reaches its maximum as the fluid enters the lower high-pressure channel, with a peak speed of 24.3 m/s.

The simulation results show that at a rotor speed of 1500 r/min, the instantaneous maximum flow rate at the outlet of the scraper pump is 6.74 kg/s, with an average flow rate of 4.75 kg/s. To later validate the accuracy of the simulation through experimentation, multiple flow field simulations were conducted at different rotor speeds. At a rotor speed of 1200 r/min, the scraper pump’s outlet exhibits an instantaneous maximum flow rate of 4.55 kg/s and an average flow rate of 3.94 kg/s. At a rotor speed of 1667 r/min, the instantaneous maximum flow rate is 7.83 kg/s, with an average flow rate of 5.28 kg/s.

6.2. Experiment

Based on theoretical analysis, model construction, kinematic analysis, and flow field analysis, a prototype of the scraper pump was manufactured, as shown in

Figure 15d,e. To validate the feasibility of the scraper pump and the accuracy of the simulation results, experiments were conducted. The experiment involved measuring the outlet flow rate of the scraper pump at different operating speeds using the YST400W hydraulic (The manufacturer of the YST400W hydraulic test rig is Jinan Highland Hydraulic Pump Co., Ltd., located in Jinan, China.) test rig. The ultimate aim was to validate the feasibility of the scraper pump’s working principle and the accuracy of the simulation results.

The YST400W hydraulic test rig is a specialized platform for testing and inspecting hydraulic pumps and motors. It is designed for comprehensive testing of hydraulic pumps and motors and consists primarily of a motor power unit, a main fuel tank valve console, and an operation console. The experimental setups for each part are shown in

Figure 15a–c.

The rotor shaft of the experimental prototype is connected to the motor, which is set to a constant rotational speed. After the pump reaches a stable operating state, the oil supply system is activated. The flow rate is displayed on the control panel, and the value is recorded once it stabilizes. To facilitate comparison with the flow field simulation results, the motor speeds are set to 1200 r/min, 1500 r/min, and 1667 r/min, respectively. To enhance the accuracy of the experimental data, three sets of experiments are conducted for each speed, and the average of these sets is used as the final data. The structure of the experimental prototype is largely consistent with the three-dimensional model used in the flow field simulation; however, due to engineering design issues, there are minor discrepancies that may affect the experimental results. As a result, some deviation is expected between the simulation data and the experimental data. Nevertheless, as long as the error between the two remains within 5%, they can be considered mutually corroborative. The experimental results are presented in

Table 7 and compared with the flow field simulation results.

The results indicate that the flow field simulation results of the scraper pump show an error within 5% of the experimental results, validating both the feasibility of the scraper pump’s structural principles and the accuracy of the flow field simulation. Since the scraper angular velocity used in the flow field simulation was derived from the ADAMS simulation, this experiment indirectly confirms the accuracy of the ADAMS kinematic simulation. In turn, this serves as indirect evidence for the accuracy of the companion trajectory kinematic analysis method proposed in this study.