The Intelligent Monitoring Technology for Machining Thin-Walled Components: A Review

Abstract

1. Introduction

2. Online Signal Acquisition Technology

2.1. Signal Acquisition Technology

2.2. Signal Processing Technology

3. Online Recognition Technology for Machining Status

3.1. Signal Feature Extraction

3.2. Machining State Recognition Technology

4. Status of Intelligent Decision Technology

5. Challenges and Prospects

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bao, Y.; Wang, B.; He, Z.; Kang, R.; Guo, J. Recent progress in flexible supporting technology for aerospace thin-walled parts: A review. Chin. J. Aeronaut. 2022, 35, 10–26. [Google Scholar] [CrossRef]

- Hou, Y.; Zhang, D.; Mei, J.; Zhang, Y.; Luo, M. Geometric modelling of thin-walled blade based on compensation method of machining error and design intent. J. Manuf. Process. 2019, 44, 327–336. [Google Scholar] [CrossRef]

- Li, B.; Deng, H.; Hui, D.; Hu, Z.; Zhang, W. A semi-analytical model for predicting the machining deformation of thin-walled parts considering machining-induced and blank initial residual stress. Int. J. Adv. Manuf. Technol. 2020, 110, 139–161. [Google Scholar] [CrossRef]

- Li, X.; Li, L.; Yang, Y.; Zhao, G.; He, N.; Ding, X.; Shi, Y.; Fan, L.; Lan, H.; Jamil, M. Machining deformation of single-sided component based on finishing allowance optimization. Chin. J. Aeronaut. 2020, 33, 2434–2444. [Google Scholar] [CrossRef]

- Li, Z.; Tuysuz, O.; Zhu, L.; Altintas, Y. Surface form error prediction in five-axis flank milling of thin-walled parts. Int. J. Mach. Tool Manf. 2018, 128, 21–32. [Google Scholar] [CrossRef]

- Lin, Y.; He, S.; Lai, D.; Wei, J.; Ji, Q.; Huang, J.; Pan, M. Wear mechanism and tool life prediction of high-strength vermicular graphite cast iron tools for high-efficiency cutting. Wear 2020, 454–455, 203319. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, C.; Li, Y.; Gao, J. A new method for inferencing and representing a workpiece residual stress field using monitored deformation force data. Engineering 2022, 22, 49–59. [Google Scholar] [CrossRef]

- Quintana, G.; Ciurana, J. Chatter in machining processes: A review. Int. J. Mach. Tool Manf. 2011, 51, 363–376. [Google Scholar] [CrossRef]

- Marousi, M.; Rimpault, X.; Turenne, S.; Balazinski, M. Initial tool wear and process monitoring during titanium metal matrix composite machining (timmc). J. Manuf. Process. 2023, 86, 208–220. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Mach. Tool Manf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Villarrazo, N.; Sáinz De La Maza, Á.; Caneda, S.; Bai, L.; Pereira, O.; López De Lacalle, L.N. Effect of tool orientation on surface roughness and dimensional accuracy in ball end milling of thin-walled blades. Int. J. Adv. Manuf. Technol. 2024, 1–13. [Google Scholar] [CrossRef]

- Tong, J.; Zhao, J.; Chen, P.; Zhao, B. Effect of ultrasonic elliptical vibration turning on the microscopic morphology of aluminum alloy surface. Int. J. Adv. Manuf. Technol. 2020, 106, 1397–1407. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Tang, Y.; Li, L.; Du, Y.; Li, L. Integrated optimization of cutting tool and cutting parameters in face milling for minimizing energy footprint and production time. Energy 2019, 175, 1021–1037. [Google Scholar] [CrossRef]

- Landwehr, M.; Kalocsay, R.; Kolvenbach, C.; Ganser, P.; Bergs, T. Preparation of papers for ifac conferences & symposia: Adaptive fixture system for reducing machining distortion caused by residual stresses in milling. IFAC-Papersonline 2022, 55, 264–269. [Google Scholar]

- Cao, X.; Yao, B.; Chen, B.; He, W.; Guo, S.; Chen, K. Intelligent tool condition monitoring based on multi-scale convolutional recurrent neural network. Ieice Trans. Inf. Syst. 2023, 106, 644–652. [Google Scholar] [CrossRef]

- Chen, T.; Li, C.; Xiao, H.; Zhu, Z.; Wang, G. A review of digital twin intelligent assembly technology and application for complex mechanical products. Int. J. Adv. Manuf. Technol. 2023, 127, 4013–4033. [Google Scholar]

- Wang, Z.; Wang, S.; Wang, S.; Zhao, Z.; Tian, Z. An intelligent prediction method of surface residual stresses based on multi-source heterogeneous data. J. Intell. Manuf. 2023, 1–17. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Wojciechowski, S.; Sharma, V.S.; Gupta, M.K.; Kuntoğlu, M. Artificial intelligence systems for tool condition monitoring in machining: Analysis and critical review. J. Intell. Manuf. 2023, 34, 2079–2121. [Google Scholar] [CrossRef]

- Siddhpura, A.; Paurobally, R. A review of flank wear prediction methods for tool condition monitoring in a turning process. Int. J. Adv. Manuf. Technol. 2013, 65, 371–393. [Google Scholar] [CrossRef]

- Mohanraj, T.; Shankar, S.; Rajasekar, R.; Sakthivel, N.R.; Pramanik, A. Tool condition monitoring techniques in milling process—A review. J. Mater. Res. Technol. 2020, 9, 1032–1042. [Google Scholar] [CrossRef]

- Cheng, Y.; Gai, X.; Guan, R.; Jin, Y.; Lu, M.; Ding, Y. Tool wear intelligent monitoring techniques in cutting: A review. J. Mech. Sci. Technol. 2023, 37, 289–303. [Google Scholar] [CrossRef]

- Xiang, J.; Yi, J. Deformation mechanism in wax supported milling of thin-walled structures based on milling forces stability. CIRP J. Manuf. Sci. Technol. 2021, 32, 356–369. [Google Scholar] [CrossRef]

- Nasir, V.; Sassani, F. A review on deep learning in machining and tool monitoring: Methods, opportunities, and challenges. Int. J. Adv. Manuf. Technol. 2021, 115, 2683–2709. [Google Scholar] [CrossRef]

- Wang, P.; Luo, M. A digital twin-based big data virtual and real fusion learning reference framework supported by industrial internet towards smart manufacturing. J. Manuf. Syst. 2021, 58, 16–32. [Google Scholar] [CrossRef]

- Lacalle, L.N.L.D.; Lamikiz, A.; Sánchez, J.A.; Bustos, I.F.D. Recording of real cutting forces along the milling of complex parts. Mechatronics 2006, 16, 21–32. [Google Scholar] [CrossRef]

- LopezdeLacalle, L.N.L.; Lamikiz, A.; Sanchez, J.A.; FernandezdeBustos, I.F. Simultaneous measurement of forces and machine tool position for diagnostic of machining tests. IEEE Trans. Instrum. Meas. 2005, 54, 2329–2335. [Google Scholar] [CrossRef]

- Artetxe, E.; Olvera, D.; de Lacalle, L.N.L.; Campa, F.J.; Olvera, D.; Lamikiz, A. Solid subtraction model for the surface topography prediction in flank milling of thin-walled integral blade rotors (IBRS). Int. J. Adv. Manuf. Technol. 2017, 90, 741–752. [Google Scholar] [CrossRef]

- Liu, D.; Liu, Z.; Zhao, J.; Song, Q.; Ren, X.; Ma, H. Tool wear monitoring through online measured cutting force and cutting temperature during face milling inconel 718. Int. J. Adv. Manuf. Technol. 2022, 122, 729–740. [Google Scholar] [CrossRef]

- Huang, P.; Zhou, J.; Xu, L. Online measurement of the elastic recovery value of machined surface in milling titanium alloy. Int. J. Adv. Manuf. Technol. 2023, 124, 4297–4305. [Google Scholar] [CrossRef]

- Guo, Q.; Mao, X.; Peng, Y.; Li, B.; Yan, R.; Yin, L.; Liao, J. Online analysis method to correlate the mode shape for forced vibration in milling thin-walled workpieces. Int. J. Adv. Manuf. Technol. 2023, 124, 329–347. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Wang, S.; Liu, N.; Zhao, Z.; Wang, Y. A novel surface residual stress monitoring method based on the power consumption of machine tool: A case study in 5-axis machining. J. Manuf. Process. 2023, 86, 221–236. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Lu, Y.; Wang, F.; Liao, Z. A novel smart toolholder with embedded force sensors for milling operations. Mech. Syst. Signal Proc. 2022, 175, 109130. [Google Scholar] [CrossRef]

- Han, J.; Liu, Z.; Cao, K.; Xu, L.; Shi, T.; Liao, G. Cutting temperature measurement in turning using fiber-optic multi-spectral radiation thermometry and its application in tool wear status recognition. Measurement 2022, 198, 111413. [Google Scholar] [CrossRef]

- Liu, H.; Chen, Q.; Li, B.; Mao, X.; Mao, K.; Peng, F. On-line chatter detection using servo motor current signal in turning. Sci. China Technol. Sc. 2011, 54, 3119–3129. [Google Scholar] [CrossRef]

- Rahimi, M.H.; Huynh, H.N.; Altintas, Y. On-line chatter detection in milling with hybrid machine learning and physics-based model. CIRP J. Manuf. Sci. Technol. 2021, 35, 25–40. [Google Scholar] [CrossRef]

- Duro, J.A.; Padget, J.A.; Bowen, C.R.; Kim, H.A.; Nassehi, A. Multi-sensor data fusion framework for cnc machining monitoring. Mech. Syst. Signal Proc. 2016, 66–67, 505–520. [Google Scholar] [CrossRef]

- Ghosh, N.; Ravi, Y.B.; Patra, A.; Mukhopadhyay, S.; Paul, S.; Mohanty, A.R.; Chattopadhyay, A.B. Estimation of tool wear during cnc milling using neural network-based sensor fusion. Mech. Syst. Signal Proc. 2007, 21, 466–479. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, X.; Niu, W. In-process cutting tool remaining useful life evaluation based on operational reliability assessment. Int. J. Adv. Manuf. Technol. 2016, 86, 841–851. [Google Scholar] [CrossRef]

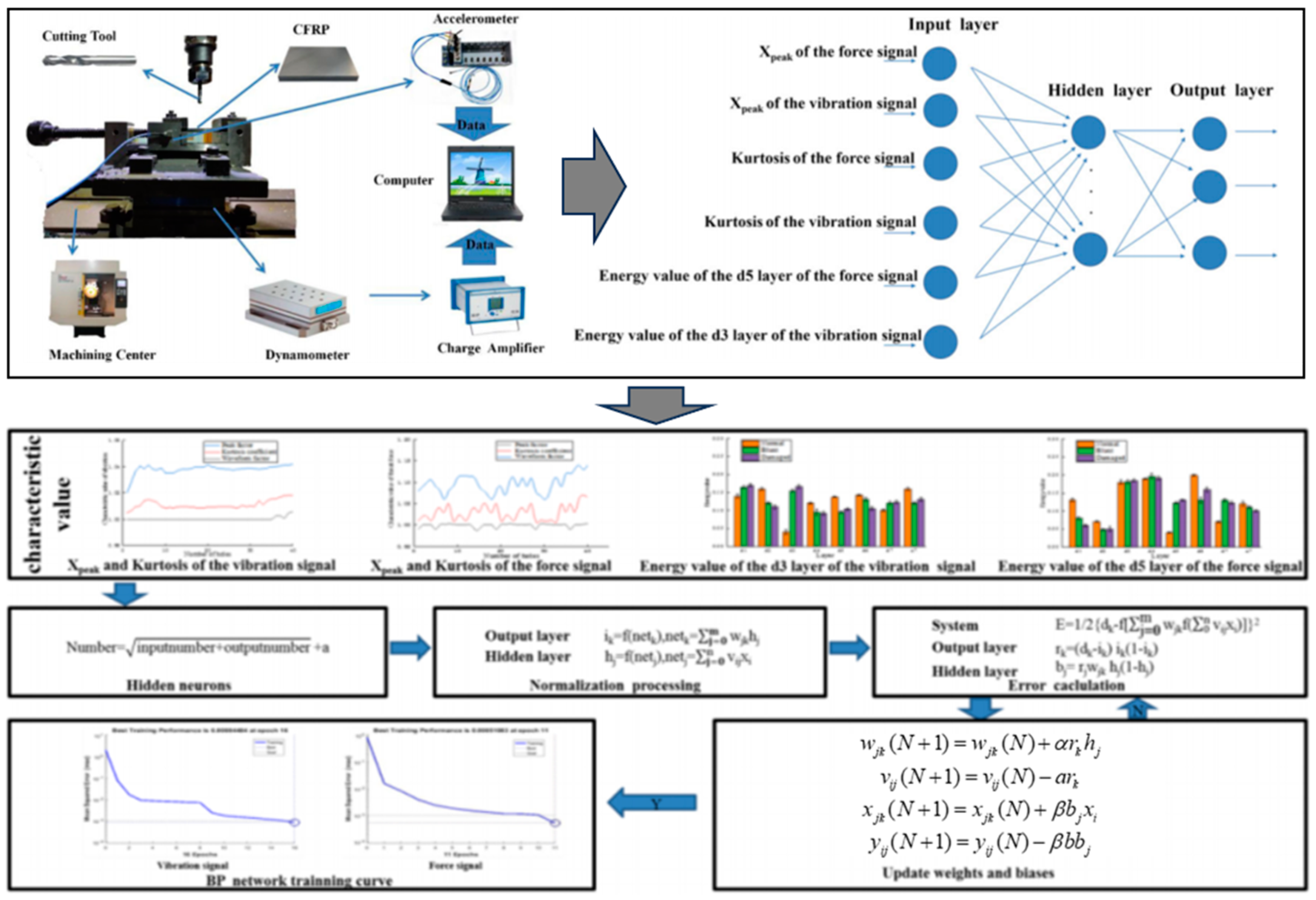

- Zhu, G.; Hu, S.; Tang, H. Prediction of tool wear in cfrp drilling based on neural network with multicharacteristics and multisignal sources. Compos. Adv. Mater. 2021, 30, 2633366X20987234. [Google Scholar] [CrossRef]

- Wang, R.; Song, Q.; Liu, Z.; Ma, H.; Liu, Z. Multi-condition identification in milling ti-6al-4v thin-walled parts based on sensor fusion. Mech. Syst. Signal Proc. 2022, 164, 108264. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Z.; Fu, Y.; Cao, S. Dynamic data-driven degradation method for monitoring remaining useful life of cutting tools. Measurement 2024, 237, 115247. [Google Scholar] [CrossRef]

- Hao, Y.; Zhu, L.; Yan, B.; Qin, S.; Cui, D.; Lu, H. Milling chatter detection with wpd and power entropy for ti-6al-4v thin-walled parts based on multi-source signals fusion. Mech. Syst. Signal Proc. 2022, 177, 109225. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Suresh, S.; Philip, J.; Jayakumar, T. Online monitoring of cutting tool temperature during micro-end milling using infrared thermography. Isight 2014, 57, 9–17. [Google Scholar] [CrossRef]

- Dit Leksir Yazid, L.; Salah, B.; Seghir, B.M.; Jurgen, B. Adaptive support vector machine-based surface quality evaluation and temperature monitoring. Application to billet continuous casting process. Int. J. Adv. Manuf. Technol. 2013, 67, 2063–2073. [Google Scholar] [CrossRef]

- Wang, L.; Qu, J.; Qian, Z. Temperature online monitoring system for aerospace manufacturing process based on gradient boosting decision tree (GBDT) algorithm. In Proceedings of the 2020 International Conference on Sensing, Measurement & Data Analytics in the Era of Artificial Intelligence, Xi’an, China, 15–17 October 2020; pp. 587–592. [Google Scholar]

- Chen, D.; Zhang, X.; Zhao, H.; Ding, H. Development of a novel online chatter monitoring system for flexible milling process. Mech. Syst. Signal Proc. 2021, 159, 107799. [Google Scholar] [CrossRef]

- Burriel-Valencia, J.; Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Bano, A.; Pineda-Sanchez, M. Short-frequency fourier transform for fault diagnosis of induction machines working in transient regime. IEEE Trans. Instrum. Meas. 2017, 66, 432–440. [Google Scholar] [CrossRef]

- Asadi, R.; Niknam, S.A.; Anahid, M.J.; Ituarte, I.F. The use of wavelet transform to evaluate the sensitivity of acoustic emission signals attributes to variation of cutting parameters in milling aluminum alloys. Int. J. Adv. Manuf. Technol. 2023, 126, 3039–3052. [Google Scholar] [CrossRef]

- Kabla, A.; Mokrani, K. Bearing fault diagnosis using hilbert-huang transform (hht) and support vector machine (svm). Mech. Ind. 2016, 17, 308. [Google Scholar] [CrossRef]

- Dar, A.H.; Abdalla, M.Z.M.; Bhat, M.Y.; Asiri, A. New quadratic phase wigner distribution and ambiguity function with applications to LFM signals. J. Pseudo-Differ. Oper. Appl. 2024, 15, 35. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, Z.; Xu, B.; Yu, Y.; Xu, J. A method to predict chatter stability accurately in milling thin-walled parts by considering force-induced deformation. J. Manuf. Process. 2023, 106, 552–563. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, X.; Zhao, W. Automatic feature extraction for online chatter monitoring under variable milling conditions. Measurement 2023, 210, 112558. [Google Scholar] [CrossRef]

- Ding, L.; Sun, Y.; Xiong, Z. Adaptive removal of time-varying harmonics for chatter detection in thin-walled turning. Int. J. Adv. Manuf. Technol. 2020, 106, 519–531. [Google Scholar] [CrossRef]

- Joseph, E.R.; Jakir, H.; Thangavel, B.; Nor, A.; Lim, T.L.; Mariathangam, P.R. Tool-emitted sound signal decomposition using wavelet and empirical mode decomposition techniques—A comparison. Symmetry 2024, 16, 1223. [Google Scholar] [CrossRef]

- Matthew, D.E.; Cao, H.; Shi, J. Advancing chatter detection: Harnessing the strength of wavelet synchrosqueezing transform and hilbert-huang transform techniques. J. Manuf. Process. 2024, 127, 613–630. [Google Scholar] [CrossRef]

- Wu, P.; Imbiriba, T.; Elvira, V.; Closas, P. Bayesian data fusion with shared priors. IEEE Trans. Signal Process. 2024, 72, 275–288. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, S.; Zhou, Y.; Huang, Y.; Zhou, D. A new reliability coefficient using betting commitment evidence distance in dempster–shafer evidence theory for uncertain information fusion. Entropy 2023, 25, 462. [Google Scholar] [CrossRef]

- Gou, H.; Zhang, X. Feature selection based on double-hierarchical and multiplication-optimal fusion measurement in fuzzy neighborhood rough sets. Inf. Sci. 2022, 618, 434–467. [Google Scholar] [CrossRef]

- Macías, A.; Muñoz, D.; Navarro, E.; González, P. Data fabric and digital twins: An integrated approach for data fusion design and evaluation of pervasive systems. Inf. Fusion 2024, 103, 102139. [Google Scholar] [CrossRef]

- Lamraoui, M.; Barakat, M.; Thomas, M.; Badaoui, M.E. Chatter detection in milling machines by neural network classification and feature selection. J. Vib. Control 2015, 21, 1251–1266. [Google Scholar] [CrossRef]

- Ye, J.; Feng, P.; Xu, C.; Ma, Y.; Huang, S. A novel approach for chatter online monitoring using coefficient of variation in machining process. Int. J. Adv. Manuf. Technol. 2018, 96, 287–297. [Google Scholar] [CrossRef]

- Wan, S.; Li, X.; Chen, W.; Hong, J. Investigation on milling chatter identification at early stage with variance ratio and hilbert–huang transform. Int. J. Adv. Manuf. Technol. 2018, 95, 3563–3573. [Google Scholar] [CrossRef]

- Li, H.; Bao, T.; Gu, C.; Chen, B. Vibration feature extraction based on the improved variational mode decomposition and singular spectrum analysis combination algorithm. Adv. Struct. Eng. 2019, 22, 1519–1530. [Google Scholar] [CrossRef]

- Segreto, T.; Teti, R. Machine learning for in-process end-point detection in robot-assisted polishing using multiple sensor monitoring. Int. J. Adv. Manuf. Technol. 2019, 103, 4173–4187. [Google Scholar] [CrossRef]

- Gonzalo, O.; Seara, J.M.; Guruceta, E.; Izpizua, A.; Esparta, M.; Zamakona, I.; Uterga, N.; Aranburu, A.; Thoelen, J. A method to minimize the workpiece deformation using a concept of intelligent fixture. Robot. Comput.-Integr. Manuf. 2017, 48, 209–218. [Google Scholar] [CrossRef]

- Wang, Y.; Bo, Q.; Liu, H.; Hu, L.; Zhang, H. Mirror milling chatter identification using Q-factor and SVM. Int. J. Adv. Manuf. Technol. 2018, 98, 1163–1177. [Google Scholar] [CrossRef]

- Rafal, R.; Pawel, L.; Krzysztof, K.; Bogdan, K.; Jerzy, W. Chatter identification methods on the basis of time series measured during titanium superalloy milling. Int. J. Mech. Sci. 2015, 99, 196–207. [Google Scholar] [CrossRef]

- Hsieh, W.; Lu, M.; Chiou, S. Application of backpropagation neural network for spindle vibration-based tool wear monitoring in micro-milling. Int. J. Adv. Manuf. Technol. 2012, 61, 53–61. [Google Scholar] [CrossRef]

- Insperger, T.; Stépán, G.; Bayly, P.V.; Mann, B.P. Multiple chatter frequencies in milling processes. J. Sound Vibr. 2003, 262, 333–345. [Google Scholar] [CrossRef]

- Jo, H.; Park, B.E.; Ji, Y.; Kim, D.; Yang, J.E.; Lee, I. Chatter detection and diagnosis in hot strip mill process with a frequency-based chatter index and modified independent component analysis. IEEE Trans. Ind. Inform. 2020, 16, 7812–7820. [Google Scholar] [CrossRef]

- Jeong, K.; Seong, Y.; Jeon, J.; Moon, S.; Park, J. Chatter monitoring of machining center using head stock structural vibration analyzed with a 1d convolutional neural network. Sensors 2022, 22, 5432. [Google Scholar] [CrossRef]

- Goharrizi, A.Y.; Sepehri, N. Internal leakage detection in hydraulic actuators using empirical mode decomposition and hilbert spectrum. IEEE Trans. Instrum. Meas. 2012, 61, 368–378. [Google Scholar] [CrossRef]

- Zhu, K.; Wong, Y.S.; Hong, G.S. Wavelet analysis of sensor signals for tool condition monitoring: A review and some new results. Int. J. Mach. Tool Manf. 2009, 49, 537–553. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, B.; Guo, K.; Liu, J.; Sun, J.; Song, G.; Zhu, S.; Sun, C.; Jiang, Z. Vibration singularity analysis for milling tool condition monitoring. Int. J. Mech. Sci. 2020, 166, 105254. [Google Scholar] [CrossRef]

- Kuljanic, E.; Totis, G.; Sortino, M. Development of an intelligent multisensor chatter detection system in milling. Mech. Syst. Signal Proc. 2009, 23, 1704–1718. [Google Scholar] [CrossRef]

- Choi, T.; Shin, Y.C. On-line chatter detection using wavelet-based parameter estimation. J. Manuf. Sci. E. 2003, 125, 21–28. [Google Scholar] [CrossRef]

- Yao, Z.; Mei, D.; Chen, Z. On-line chatter detection and identification based on wavelet and support vector machine. J. Mater. Process. Technol. 2010, 210, 713–719. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, Y.; Zhou, H.; Li, D.; Liu, H.; Qiao, H.; Wang, X. Timely online chatter detection in end milling process. Mech. Syst. Signal Proc. 2016, 75, 668–688. [Google Scholar] [CrossRef]

- Ou, J.; Li, H.; Huang, G.; Yang, G. Intelligent analysis of tool wear state using stacked denoising autoencoder with online sequential-extreme learning machine. Measurement 2021, 167, 108153. [Google Scholar] [CrossRef]

- Proteau, A.; Zemouri, R.; Tahan, A.; Thomas, M. Dimension reduction and 2d-visualization for early change of state detection in a machining process with a variational autoencoder approach. Int. J. Adv. Manuf. Technol. 2020, 111, 3597–3611. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Z.; Ding, W.; Qiao, M.; Su, H. An online prediction method of three-dimensional machining residual stress field based on incepu-net. Measurement 2025, 242, 115794. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Z.; Fu, Y.; Chen, Q. A novel approach for tool condition monitoring based on transfer learning of deep neural networks using time–frequency images. J. Intell. Manuf. 2024, 35, 1159–1171. [Google Scholar] [CrossRef]

- Urbikain, G.; López De Lacalle, L.N. Monithor: A complete monitoring tool for machining data acquisition based on FPGA programming. SoftwareX 2020, 11, 100387. [Google Scholar] [CrossRef]

- Urbikain Pelayo, G.; Olvera-Trejo, D.; Luo, M.; López De Lacalle, L.N.; Elías-Zuñiga, A. Surface roughness prediction with new barrel-shape mills considering runout: Modelling and validation. Measurement 2021, 173, 108670. [Google Scholar] [CrossRef]

- Urbikain Pelayo, G.; Olvera-Trejo, D.; Luo, M.; Tang, K.; López De Lacalle, L.N.; Elías-Zuñiga, A. A model-based sustainable productivity concept for the best decision-making in rough milling operations. Measurement 2021, 186, 110120. [Google Scholar] [CrossRef]

- Zhang, M.; Tao, F.; Zuo, Y.; Xiang, F.; Wang, L.; Nee, A.Y.C. Top ten intelligent algorithms towards smart manufacturing. J. Manuf. Syst. 2023, 71, 158–171. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Z.; Wang, K.; Qian, N.; Fu, Y.; Cao, S. Active-passive hybrid feed rate control systems in CNC machining: Mitigating force fluctuations and enhancing tool life. J. Manuf. Syst. 2024, 77, 184–195. [Google Scholar] [CrossRef]

- Bagaber, S.A.; Yusoff, A.R. Multi-objective optimization of cutting parameters to minimize power consumption in dry turning of stainless steel 316. J. Clean Prod. 2017, 157, 30–46. [Google Scholar] [CrossRef]

- Hanafi, I.; Khamlichi, A.; Cabrera, F.M.; Almansa, E.; Jabbouri, A. Optimization of cutting conditions for sustainable machining of PEEK-CF30 using TiN tools. J. Clean Prod. 2012, 33, 1–9. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, X.; Ke, Q.; Dong, W.; Zhong, Y. Disassembly line balancing optimization method for high efficiency and low carbon emission. Int. J. Precis Eng Manuf-Green Technol. 2021, 8, 233–247. [Google Scholar] [CrossRef]

- Wu, Z.; Jiang, H.; Zhao, K.; Li, X. An adaptive deep transfer learning method for bearing fault diagnosis. Measurement 2020, 151, 107227. [Google Scholar] [CrossRef]

- Li, C.; Chen, X.; Tang, Y.; Li, L. Selection of optimum parameters in multi-pass face milling for maximum energy efficiency and minimum production cost. J. Clean Prod. 2017, 140, 1805–1818. [Google Scholar] [CrossRef]

- Tian, C.; Zhou, G.; Zhang, J.; Zhang, C. Optimization of cutting parameters considering tool wear conditions in low-carbon manufacturing environment. J. Clean Prod. 2019, 226, 706–719. [Google Scholar] [CrossRef]

- Duc, D.H.; Thom, D.V.; Cong, P.H.; Minh, P.V.; Nguyen, N.X. Vibration and static buckling behavior of variable thickness flexoelectric nanoplates. Mech. Based Des. Struct. Mech. 2023, 51, 7102–7130. [Google Scholar] [CrossRef]

- Salem, A.; Hegab, H.; Rahnamayan, S.; Kishawy, H.A. Multi-objective optimization and innovization-based knowledge discovery of sustainable machining process. J. Manuf. Syst. 2022, 64, 636–647. [Google Scholar] [CrossRef]

- Zhang, X.; Liao, S.; Cao, F.; Zhao, L.; Pei, J.; Tang, F. Cloning and characterization of enoate reductase with high β-ionone to dihydro-β-ionone bioconversion productivity. Bmc Biotechnol. 2018, 18, 26. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Huang, C.; Zhao, Y.; Zhao, Z. A meta-reinforcement learning method by incorporating simulation and real data for machining deformation control of finishing process. Int. J. Prod. Res. 2023, 61, 1114–1128. [Google Scholar] [CrossRef]

- Lu, F.; Zhou, G.; Zhang, C.; Liu, Y.; Chang, F.; Xiao, Z. Energy-efficient multi-pass cutting parameters optimisation for aviation parts in flank milling with deep reinforcement learning. Robot. Comput.-Integr. Manuf. 2023, 81, 102488. [Google Scholar] [CrossRef]

- Xiao, Q.; Yang, Z.; Zhang, Y.; Zheng, P. Adaptive optimal process control with actor-critic design for energy-efficient batch machining subject to time-varying tool wear. J. Manuf. Syst. 2023, 67, 80–96. [Google Scholar] [CrossRef]

- Li, C.; Zhao, X.; Cao, H.; Li, L.; Chen, X. A data and knowledge-driven cutting parameter adaptive optimization method considering dynamic tool wear. Robot. Comput.-Integr. Manuf. 2023, 81, 102491. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Zhang, S.; Zhang, Y.; Zhou, J.; Wang, Z.; Huang, B.; Huang, R. A novel method based on deep reinforcement learning for machining process route planning. Robot. Comput.-Integr. Manuf. 2024, 86, 102688. [Google Scholar] [CrossRef]

- Cao, X.; Zhao, G.; Xiao, W. Digital twin–oriented real-time cutting simulation for intelligent computer numerical control machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 5–15. [Google Scholar] [CrossRef]

- Wang, G.; Cao, Y.; Zhang, Y. Digital twin-driven clamping force control for thin-walled parts. Adv. Eng. Inform. 2022, 51, 101468. [Google Scholar] [CrossRef]

- Ward, R.; Sun, C.; Dominguez-Caballero, J.; Ojo, S.; Ayvar-Soberanis, S.; Curtis, D.; Ozturk, E. Machining digital twin using real-time model-based simulations and lookahead function for closed loop machining control. Int. J. Adv. Manuf. Technol. 2021, 117, 3615–3629. [Google Scholar] [CrossRef]

- Afazov, S.; Scrimieri, D. Chatter model for enabling a digital twin in machining. Int. J. Adv. Manuf. Technol. 2020, 110, 2439–2444. [Google Scholar] [CrossRef]

- Zhou, G.; Zhou, K.; Zhang, J.; Yuan, M.; Wang, X.; Feng, P.; Zhang, M.; Feng, F. Digital modeling-driven chatter suppression for thin-walled part manufacturing. J. Intell. Manuf. 2024, 35, 289–305. [Google Scholar] [CrossRef]

- Zhu, Z.; Xi, X.; Xu, X.; Cai, Y. Digital twin-driven machining process for thin-walled part manufacturing. J. Manuf. Syst. 2021, 59, 453–466. [Google Scholar] [CrossRef]

- Liu, S.; Lu, S.; Li, J.; Sun, X.; Lu, Y.; Bao, J. Machining process-oriented monitoring method based on digital twin via augmented reality. Int. J. Adv. Manuf. Technol. 2021, 113, 3491–3508. [Google Scholar] [CrossRef]

- Ceruti, A.; Liverani, A.; Bombardi, T. Augmented vision and interactive monitoring in 3D printing process. Int. J. Interact. Des. Manuf. 2017, 11, 385–395. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Wang, Y.; Huang, B.; Ding, W. The Intelligent Monitoring Technology for Machining Thin-Walled Components: A Review. Machines 2024, 12, 876. https://doi.org/10.3390/machines12120876

Liu G, Wang Y, Huang B, Ding W. The Intelligent Monitoring Technology for Machining Thin-Walled Components: A Review. Machines. 2024; 12(12):876. https://doi.org/10.3390/machines12120876

Chicago/Turabian StyleLiu, Gaoqun, Yufeng Wang, Binda Huang, and Wenfeng Ding. 2024. "The Intelligent Monitoring Technology for Machining Thin-Walled Components: A Review" Machines 12, no. 12: 876. https://doi.org/10.3390/machines12120876

APA StyleLiu, G., Wang, Y., Huang, B., & Ding, W. (2024). The Intelligent Monitoring Technology for Machining Thin-Walled Components: A Review. Machines, 12(12), 876. https://doi.org/10.3390/machines12120876