Smart In-Process Inspection in Human–Cyber–Physical Manufacturing Systems: A Research Proposal on Human–Automation Symbiosis and Its Prospects

Abstract

1. Introduction

2. Background Review and Emerging Consensus

2.1. From Industry 4.0 to Industry 5.0

2.2. Inspection in Manufacturing

2.3. Human–Automation Interaction

2.4. Artificial Intelligence

2.5. Quantitative Decision-Making

2.6. Research Opportunities

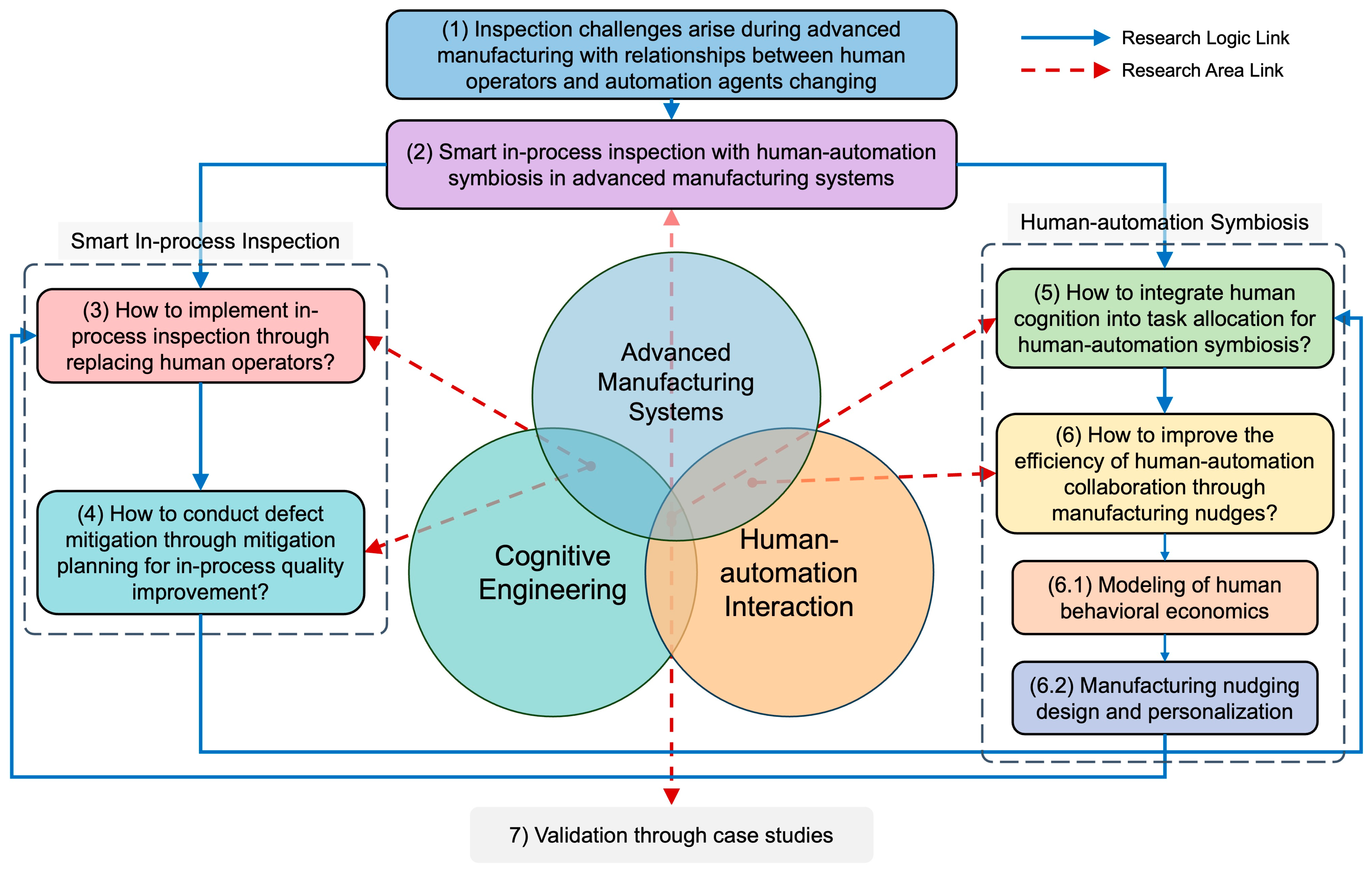

3. A Holistic Framework of Smart In-Process Inspection with Human–Automation Symbiosis

3.1. In-Process Inspection from the Manufacturing System Hierarchy Perspective

3.2. A Holistic Framework

4. A Case Example of Medical Tube Assembly In-Process Inspection

5. Fundamental Issues

- (i)

- In-Process Inspection: At the workstation level, the primary challenge is integrating inspection into the existing manufacturing process. Two key technical issues are (a) defect identification for detecting and classifying defects using appropriate vision equipment and inspection algorithms and (b) decision support for part inspection for automating decision-making activities during inspection, such as defect disposition and rework assignment.

- (ii)

- Defect Mitigation Planning for Real-Time Process Control: At the process level, the focus is on improving in-process quality through real-time adjustments. This involves (a) process modeling of the manufacturing–inspection–mitigation control loop by establishing a feedback loop to adjust configurations based on inspection results and (b) defect mitigation planning using real-time inspection data to plan process configuration adjustments to reduce defect generation.

- (iii)

- Dynamic and Adaptive Task Allocation: This aims to optimize collaboration between human operators and automation by considering human cognition in real-time. Key technical issues include: (a) modeling human cognition by quantifying human cognitive states during tasks; (b) team cognitive performance evaluation by developing new performance metrics that reflect the cognitive state of the team; and (c) trade-off between production and team cognitive performance by balancing production efficiency with cognitive performance.

- (iv)

- Behavioral Intervention Design for Human–Automation Collaboration: This issue focuses on influencing operator behavior for better collaboration. It includes: (a) human decision-making behavior modeling by quantifying decision-making behaviors in manufacturing environments; (b) nudging design for collaboration efficiency by designing interventions (nudges) to influence operator behavior; and (c) nudging personalization by tailoring nudges to fit individual operators for enhanced team synergy. These technical issues collectively support the effective integration of IPI and human–automation symbiosis in complex manufacturing environments.

5.1. In-Process Inspection

- (i)

- Data Collection (Data Layer): This involves observing and saving product data using sensing equipment, such as vision systems for visual inspection. The collected data can take the form of images or numerical values. At this level, the focus is on capturing relevant data for the subsequent stages of the inspection process.

- (ii)

- Defect Identification (Information Layer): This stage involves detecting and classifying defects using the collected product data. Several terms are associated with this process: (a) Defect detection: A binary decision, determining whether a product has a defect or not. This is often the initial step in the inspection process. (b) Defect identification: A more detailed analysis that determines the type of defect. This step can be performed manually by human operators or automatically via classification algorithms. (c) Defect recognition: An in-depth analysis that not only identifies the type of defect but also seeks to understand its potential causes. This step requires a deeper understanding of the defect. Defect identification, the core task at the information layer, uses feature extraction and classification algorithms to understand the nature and type of defects present in the product.

- (iii)

- Inspection Decision Support (Knowledge Layer): The final stage involves supporting inspection-related decision-making activities, which may include symbolic reasoning, knowledge inference, or other analytical techniques. This stage focuses on applications like defect disposition (deciding whether to rework, scrap, or continue processing a product) and root cause analysis, both of which rely on information about the defect features gathered in the previous stage.

5.2. Defect Mitigation Planning for Real-Time Process Control

5.3. Human–Automation Symbiosis Through Task Allocation and Manufacturing Nudging

5.3.1. Dynamic and Adaptive Task Allocation

5.3.2. Behavioral Intervention Design for Human–Automation Collaboration

6. A Research Roadmap and Prospects

6.1. Visual Analytics and Intelligent Reasoning

6.2. GPT-Powered Case-Based Knowledge Modeling and Reasoning

6.3. Human Cognition Modeling and Non-Cooperative Game Theoretic Optimization for Task Allocation

6.4. Conjoint Prospect Theoretic Modeling of Human Behavioral Economics

6.5. Nudging Behavioral Modeling and Optimization for Nudging Design and Personalization

7. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ross, P.; Maynard, K. Towards a 4th industrial revolution. Intell. Build. Int. 2021, 13, 159–161. [Google Scholar] [CrossRef]

- Arinez, J.F.; Chang, Q.; Gao, R.X.; Xu, C.; Zhang, J. Artificial intelligence in advanced manufacturing: Current status and future outlook. J. Manuf. Sci. Eng. 2020, 142, 110804. [Google Scholar] [CrossRef]

- Gan, Z.L.; Musa, S.N.; Yap, H.J. A Review of the High-Mix, Low-Volume Manufacturing Industry. Appl. Sci. 2023, 13, 1687. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, Y.; Wang, B.; Zang, J. Human–cyber–physical systems (HCPSs) in the context of new-generation intelligent manufacturing. Engineering 2019, 5, 624–636. [Google Scholar] [CrossRef]

- Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. [Google Scholar] [CrossRef]

- Endsley, M.R.; Kiris, E.O. The out-of-the-loop performance problem and level of control in automation. Hum. Factors 1995, 37, 381–394. [Google Scholar] [CrossRef]

- Wickens, C.D. Situation awareness: Review of Mica Endsley’s 1995 articles on situation awareness theory and measurement. Hum. Factors 2008, 50, 397–403. [Google Scholar] [CrossRef]

- Endsley, M.R. From here to autonomy: Lessons learned from human–automation research. Hum. Factors 2017, 59, 5–27. [Google Scholar] [CrossRef]

- Jacucci, G.; Spagnolli, A.; Freeman, J.; Gamberini, L. Symbiotic interaction: A critical definition and comparison to other human-computer paradigms. In Symbiotic Interaction; Springer International Publishing, Third International Workshop, Symbiotic: Helsinki, Finland, 2014; Proceedings 3; pp. 3–20. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5 January 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 3928–3937. [Google Scholar]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Xu, M.; David, J.M.; Kim, S.H. The fourth industrial revolution: Opportunities and challenges. Int. J. Financ. Res. 2018, 9, 90–95. [Google Scholar] [CrossRef]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Fast-Berglund, Å. The operator 4.0: Human cyber-physical systems & adaptive automation towards human-automation symbiosis work systems. In Proceedings of the Advances in Production Management Systems. Initiatives for a Sustainable World: IFIP WG 5.7 International Conference, APMS, Iguassu Falls, Brazil, 3–7 September 2016; pp. 677–686. [Google Scholar]

- Sanchez, J. Conceptual model of human-automation interaction. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, San Antonio, TX, USA, 19–23 October 2009; SAGE Publications: Los Angeles, CA, USA, 2009; Volume 53, pp. 1403–1407. [Google Scholar]

- Liu, Z.; Wang, J. Human-cyber-physical systems: Concepts, challenges, and research opportunities. Front. Inf. Technol. Electron. Eng. 2020, 21, 1535–1553. [Google Scholar] [CrossRef]

- Khaitan, S.K.; McCalley, J.D. Design techniques and applications of cyberphysical systems: A survey. IEEE Syst. J. 2014, 9, 350–365. [Google Scholar] [CrossRef]

- Frazzon, E.M.; Hartmann, J.; Makuschewitz, T.; Scholz-Reiter, B. Towards socio-cyber-physical systems in production networks. Procedia CIRP 2013, 7, 49–54. [Google Scholar] [CrossRef]

- Jiao, R.J.; Zhou, F.; Gebraeel, N.Z.; Duffy, V. Towards augmenting cyber-physical-human collaborative cognition for human-automation interaction in complex manufacturing and operational environments. Int. J. Prod. Res. 2020, 58, 5089–5111. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, P.; Yin, Y.; Shih, A.; Wang, L. Toward human-centric smart manufacturing: A human-cyber-physical systems (HCPS) perspective. J. Manuf. Syst. 2022, 63, 471–490. [Google Scholar] [CrossRef]

- Razaque, A.; Amsaad, F.; Abdulgader, M.; Alotaibi, B.; Alsolami, F.; Gulsezim, D.; Mohanty, S.P.; Hariri, S. A Mobility-Aware Human-Centric Cyber–Physical System for Efficient and Secure Smart Healthcare. IEEE Internet Things J. 2022, 9, 22434–22452. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.A.; Yang, S. Service innovation and smart analytics for industry 4.0 and big data environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Zhang, L.; Nee, A.Y. Advanced manufacturing systems: Socialization characteristics and trends. J. Intell. Manuf. 2017, 28, 1079–1094. [Google Scholar] [CrossRef]

- Genta, G.; Galetto, M.; Franceschini, F. Inspection procedures in manufacturing processes: Recent studies and research perspectives. Int. J. Prod. Res. 2020, 58, 4767–4788. [Google Scholar] [CrossRef]

- Mandroli, S.S.; Shrivastava, A.K.; Ding, Y. A survey of inspection strategy and sensor distribution studies in discrete-part manufacturing processes. IIE Trans. 2006, 38, 309–328. [Google Scholar] [CrossRef]

- Rezaei-Malek, M.; Mohammadi, M.; Dantan, J.Y.; Siadat, A.; Tavakkoli-Moghaddam, R. A review on optimisation of part quality inspection planning in a multi-stage manufacturing system. Int. J. Prod. Res. 2019, 57, 4880–4897. [Google Scholar] [CrossRef]

- Shi, J. In-process quality improvement: Concepts, methodologies, and applications. IISE Trans. 2023, 55, 2–21. [Google Scholar] [CrossRef]

- Wang, S.; Zou, P.; Gong, X.; Song, M.; Peng, J.; Jiao, J.R. Visual analytics and intelligent reasoning for smart manufacturing defect detection and judgement: A meta-learning approach with knowledge graph embedding case-based reasoning. J. Ind. Inf. Integr. 2024, 37, 100536. [Google Scholar] [CrossRef]

- Wickens, C.D.; Helton, W.S.; Hollands, J.G.; Banbury, S. Engineering Psychology and Human Performance; Routledge: Oxfordshire, UK, 2021. [Google Scholar]

- NSF. Future of Work at the Human-Technology Frontier. Available online: https://www.nsf.gov/news/special_reports/big_ideas/human_tech.jsp (accessed on 10 August 2024).

- Stahl, G. Theories of collaborative cognition: Foundations for CSCL and CSCW together. In Computer-Supported Collaborative Learning at the Workplace: CSCL@ Work; Computer and Systems Sciences: Kista, Sweden, 2013; pp. 43–63. [Google Scholar]

- Cuevas, H.M.; Fiore, S.M.; Caldwell, B.S.; Strater, L. Augmenting team cognition in human-automation teams performing in complex operational environments. Aviat. Space Environ. Med. 2007, 78, B63–B70. [Google Scholar]

- Cooke, N.J.; Gorman, J.C. Assessment of team cognition. Int. Encycl. Ergon. Hum. Factors 2006, 2, 270–275. [Google Scholar]

- Lee, J.D.; See, K.A. Trust in automation: Designing for appropriate reliance. Hum. Factors 2004, 46, 50–80. [Google Scholar] [CrossRef]

- Parasuraman, R.; Riley, V. Humans and automation: Use, misuse, disuse, abuse. Hum. Factors 1997, 39, 230–253. [Google Scholar] [CrossRef]

- Sadrfaridpour, B.; Saeidi, H.; Burke, J.; Madathil, K.; Wang, Y. Modeling and control of trust in human-robot collaborative manufacturing. In Robust Intelligence and Trust in Autonomous Systems; Springer: Berlin/Heidelberg, Germany, 2016; pp. 115–141. [Google Scholar]

- Andras, P.; Esterle, L.; Guckert, M.; Han, T.A.; Lewis, P.R.; Milanovic, K.; Payne, T.; Perret, C.; Pitt, J.; Powers, S.T. Trusting intelligent machines: Deepening trust within socio-technical systems. IEEE Technol. Soc. Mag. 2018, 37, 76–83. [Google Scholar] [CrossRef]

- Gebru, B.; Zeleke, L.; Blankson, D.; Nabil, M.; Nateghi, S.; Homaifar, A.; Tunstel, E. A review on human–machine trust evaluation: Human-centric and machine-centric perspectives. IEEE Trans. Hum. Mach. Syst. 2022, 52, 952–962. [Google Scholar] [CrossRef]

- Hill, C.A.; O’Hara, E.A. A cognitive theory of trust. Wash. Univ. Law Rev. 2006, 84, 1717. [Google Scholar] [CrossRef]

- Zhou, F.; Jiao, J. Quantification of Customer Perception on Airplane Cabin Lighting Design Based on Cumulative Prospect Theory. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Portland, OR, USA, 4–7 August 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 55911, p. V004T05A009. [Google Scholar]

- Hancock, P.A.; Jagacinski, R.J.; Parasuraman, R.; Wickens, C.D.; Wilson, G.F.; Kaber, D.B. Human-automation interaction research: Past, present, and future. Ergon. Des. 2013, 21, 9–14. [Google Scholar] [CrossRef]

- Kaber, D.B.; Riley, J.M.; Tan, K.W.; Endsley, M.R. On the design of adaptive automation for complex systems. Int. J. Cogn. Ergon. 2001, 5, 37–57. [Google Scholar] [CrossRef]

- Hancock, P.A.; Scallen, S.F. The future of function allocation. Ergon. Des. 1996, 4, 24–29. [Google Scholar] [CrossRef]

- Sheridan, T.B. Task analysis, task allocation and supervisory control. In Handbook of Human—Computer Interaction; Springer: Berlin/Heidelberg, Germany, 1997; pp. 87–105. [Google Scholar]

- Gorlach, I.; Wessel, O. Optimal Level of Automation in the Automotive Industry. Eng. Lett. 2008, 16, 141–149. [Google Scholar]

- Pollard, E.; Morignot, P.; Nashashibi, F. An ontology-based model to determine the automation level of an automated vehicle for co-driving. In Proceedings of the 16th International Conference on Information Fusion, Istanbul, Turkey, 9–12 July 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 596–603. [Google Scholar]

- Billings, C.E. Human-Centered Aircraft Automation: A Concept and Guidelines; National Aeronautics and Space Administration, Ames Research Center: Mountain View, CA, USA, 1991; p. 103885. [Google Scholar]

- Endsley, M.R. A systematic review and meta-analysis of direct objective measures of situation awareness: A comparison of SAGAT and SPAM. Hum. Factors 2021, 63, 124–150. [Google Scholar] [CrossRef]

- Munir, A.; Aved, A.; Blasch, E. Situational awareness: Techniques, challenges, and prospects. AI 2022, 3, 55–77. [Google Scholar] [CrossRef]

- Endsley, M.R. Designing for Situation Awareness: An Approach to User-Centered Design; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Endsley, M.R.; Kaber, D.B. Level of automation effects on performance, situation awareness and workload in a dynamic control task. Ergonomics 1999, 42, 462–492. [Google Scholar] [CrossRef] [PubMed]

- Di Flumeri, G.; De Crescenzio, F.; Berberian, B.; Ohneiser, O.; Kramer, J.; Aricò, P.; Borghini, G.; Babiloni, F.; Bagassi, S.; Piastra, S. Brain–computer interface-based adaptive automation to prevent out-of-the-loop phenomenon in air traffic controllers dealing with highly automated systems. Front. Hum. Neurosci. 2019, 13, 296. [Google Scholar] [CrossRef] [PubMed]

- Holm, M. The future shop-floor operators, demands, requirements and interpretations. J. Manuf. Syst. 2018, 47, 35–42. [Google Scholar] [CrossRef]

- Wang, S.; Song, M.; Fei, Y.C.; Zhang, D.; Gebraeel, N.Z.; Jiao, R.J. System Analysis and Design of Task Allocation for Human-Automation Symbiosis in Smart Manufacturing. In Proceedings of the 6th European International Conference on Industrial Engineering and Operations Management, Lisbon, Portugal, 18–20 July 2023. [Google Scholar]

- Licklider, J.C. Man-computer symbiosis. IRE Trans. Hum. Factors Electron. 1960, 1, 4–11. [Google Scholar] [CrossRef]

- Gerber, A.; Derckx, P.; Döppner, D.A.; Schoder, D. Conceptualization of the human-machine symbiosis–A literature review. In Proceedings of the 53rd Hawaii International Conference on System Sciences, Maui, HI, USA, 7–10 January 2020; pp. 289–298. [Google Scholar]

- Wilson, G.F.; Russell, C.A. Operator functional state classification using multiple psychophysiological features in an air traffic control task. Hum. Factors 2003, 45, 381–389. [Google Scholar] [CrossRef]

- Marquez, J.J.; Riley, V.; Schutte, P.C. Human automation interaction. In Space Safety and Human Performance; Butterworth-Heinemann: Oxford, UK, 2018; pp. 429–467. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. In Proceedings of the Advances in 25th Neural Information Processing Systems, Stateline, NV, USA, 3–8 December 2012. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. In Proceedings of the International Conference on Learning Representations, San Diego, CA, USA, 7–9 May 2015. [Google Scholar]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 8–10 June 2015; pp. 1–9. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016; pp. 770–778. [Google Scholar]

- Redmon, J. You only look once: Unified, real-time object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards real-time object detection with region proposal networks. In Proceedings of the IEEE Transactions on Pattern Analysis and Machine Intelligence, Las Vegas, NV, USA, 26 June–1 July 2016; Volume 39, pp. 1137–1149. [Google Scholar]

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask r-cnn. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 2961–2969. [Google Scholar]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Brachman, R.J.; Levesque, H.J. Knowledge Representation and Reasoning; Morgan Kaufmann: Cambridge, MA, USA, 2003. [Google Scholar]

- Chen, X.; Jia, S.; Xiang, Y. A review: Knowledge reasoning over knowledge graph. Expert Syst. Appl. 2020, 141, 112948. [Google Scholar] [CrossRef]

- Watson, I.; Marir, F. Case-based reasoning: A review. Knowl. Eng. Rev. 1994, 9, 327–354. [Google Scholar] [CrossRef]

- Riesbeck, C.K.; Schank, R.C. Inside Case-Based Reasoning; Psychology Press: London, UK, 2013. [Google Scholar]

- Zbigniew, S. An introduction to rough set theory and its applications—A tutorial. In Proceedings of the ICENCO’2004, Cairo, Egypt, 27–31 December 2004. [Google Scholar]

- Zadeh, L.A. Fuzzy logic and approximate reasoning. Synthese 1975, 30, 407–428. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Dubois, D.; Prade, H. What are fuzzy rules and how to use them. Fuzzy Sets Syst. 1996, 84, 169–185. [Google Scholar] [CrossRef]

- Achiam, J.; Adler, S.; Agarwal, S.; Ahmad, L.; Akkaya, I.; Aleman, F.L.; Almeida, D.; Altenschmidt, J.; Altman, S.; Anadkat, S. Gpt-4 technical report. arXiv 2023, arXiv:2303.08774. [Google Scholar]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention is all you need. In Proceedings of the 31st Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; p. 30. [Google Scholar]

- Brown, T.; Mann, B.; Ryder, N.; Subbiah, M.; Kaplan, J.D.; Dhariwal, P.; Neelakantan, A.; Shyam, P.; Sastry, G.; Askell, A. Language models are few-shot learners. Adv. Neural Inf. Process. Syst. 2020, 33, 1877–1901. [Google Scholar]

- Lewis, P.; Perez, E.; Piktus, A.; Petroni, F.; Karpukhin, V.; Goyal, N.; Küttler, H.; Lewis, M.; Yih, W.T.; Rocktäschel, T. Retrieval-Augmented Generation for Knowledge-Intensive NLP Tasks. In Advances in Neural Information Processing Systems; ACM: New York, NY, USA, 2020; pp. 9459–9474. [Google Scholar]

- Zhou, F. Viral Product Design for Social Network Effects. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2014. [Google Scholar]

- Thurston, D.L. A formal method for subjective design evaluation with multiple attributes. Res. Eng. Des. 1991, 3, 105–122. [Google Scholar] [CrossRef]

- Von Winterfeldt, D.; Fischer, G.W. Multi-attribute utility theory: Models and assessment procedures. In Proceedings of the Utility, Probability, and Human Decision Making: Selected Proceedings of an Interdisciplinary Research Conference, Rome, Italy, 3–6 September 1973; Springer: Dordrecht, The Netherlands, 1973; Volume 1975, pp. 47–85. [Google Scholar]

- Mullainathan, S.; Thaler, R.H. Behavioral Economics; National Bureau of Economic Research: Cambridge, MA, USA, 2000. [Google Scholar]

- Kahneman, D.; Tversky, A. Prospect theory: An analysis of decision under risk. In Handbook of the Fundamentals of Financial Decision Making: Part I; World Scientific: Singapore, 2013; pp. 99–127. [Google Scholar]

- Tversky, A. A critique of expected utility theory: Descriptive and normative considerations. Erkenntnis 1975, 9, 163–173. [Google Scholar]

- Tversky, A.; Kahneman, D. Advances in prospect theory: Cumulative representation of uncertainty. J. Risk Uncertain. 1992, 5, 297–323. [Google Scholar] [CrossRef]

- Little, J.D.; Murty, K.G.; Sweeney, D.W.; Karel, C. An algorithm for the traveling salesman problem. Oper. Res. 1963, 11, 972–989. [Google Scholar] [CrossRef]

- Gomory, R. An algorithm for the mixed integer problem; The Rand Corporation: Santa Monica, CA, USA, 1960. [Google Scholar]

- Kelley, J.E., Jr. The cutting-plane method for solving convex programs. J. Soc. Ind. Appl. Math. 1960, 8, 703–712. [Google Scholar] [CrossRef]

- Padberg, M.; Rinaldi, G. A branch-and-cut algorithm for the resolution of large-scale symmetric traveling salesman problems. SIAM Rev. 1991, 33, 60–100. [Google Scholar] [CrossRef]

- Barnhart, C.; Johnson, E.L.; Nemhauser, G.L.; Savelsbergh, M.W.; Vance, P.H. Branch-and-price: Column generation for solving huge integer programs. Oper. Res. 1998, 46, 316–329. [Google Scholar] [CrossRef]

- Wang, F.S.; Chen, L.H. Heuristic optimization. In Encyclopedia of Systems Biology; Springer: New York, NY, USA, 2013; p. 885. [Google Scholar]

- Lu, J.J.; Zhang, M. Heuristic Search. In Encyclopedia of Systems Biology; Springer: New York, NY, USA, 2013; p. 885. [Google Scholar]

- Korf, R.E. Search: A survey of recent results. In Exploring Artificial Intelligence; Morgan Kaufmann: Burlington, MA, USA, 1988; pp. 197–237. [Google Scholar]

- Glover, F.; Laguna, M. Tabu search. In Handbook of Combinatorial Optimization; Springer: Boston, MA, USA, 1998; pp. 2093–2229. [Google Scholar]

- Hansen, P.; Mladenović, N. An introduction to variable neighborhood search. In Meta-Heuristics; Springer: Boston, MA, USA, 1999; pp. 433–458. [Google Scholar]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- Dorigo, M.; Di Caro, G. Ant colony optimization: A new meta-heuristic. In Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), Washington, DC, USA, 6–9 July 1999; IEEE: Piscataway, NJ, USA, 1999; Volume 2, pp. 1470–1477. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; IEEE: Piscataway, NJ, USA, 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Whitley, D. A genetic algorithm tutorial. Stat. Comput. 1994, 4, 65–85. [Google Scholar] [CrossRef]

- Shapley, L.S. A Value for N-Person Games; Princeton University Press: Princeton, NJ, USA, 1953. [Google Scholar]

- Gillies, D.B. Solutions to general non-zero-sum games. Contrib. Theory Games 1959, 4, 47–85. [Google Scholar]

- Nash, J.F. Non-cooperative games. Annu. Math. 1950, 54, 286–295. [Google Scholar] [CrossRef]

- Nash Jr, J.F. “Equilibrium points in n-person games. Proc. Natl. Acad. Sci. USA 1950, 36, 48–49. [Google Scholar] [CrossRef]

- Von Stackelberg, H. Market Structure and Equilibrium; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Gradl, P.R.; Kimberlin, A.C.; Gaddy, D.E.; Moody, R.D. Method of Mapping Melt Pattern During Directed Energy Fabrication. U.S. Patent 10,688,560; National Aeronautics and Space Administration NASA, 23 June 2020. [Google Scholar]

- Jiao, R.J.; Commuri, S.; Panchal, J.; Milisavljevic-Syed, J.; Allen, J.K.; Mistree, F.; Schaefer, D. Design engineering in the age of Industry 4.0. J. Mech. Des. 2021, 143, 070801. [Google Scholar] [CrossRef]

- Papadopoulos, H.T.; Heavey, C. Queueing theory in manufacturing systems analysis and design: A classification of models for production and transfer lines. Eur. J. Oper. Res. 1996, 92, 1–27. [Google Scholar] [CrossRef]

- Dickins, A.; Widjanarko, T.; Lawes, S.; Leach, R.K. Design of a multi-sensor in-situ inspection system for additive manufacturing. In Proceedings of the ASPE and EUSPEN Summer Topical Meeting on Advancing Precision in Additive Manufacturing, Berkeley, CA, USA, 22–25 July 2018; pp. 152–248. [Google Scholar]

- Gamage, P.; Xie, S.Q. A real-time vision system for defect inspection in cast extrusion manufacturing process. Int. J. Adv. Manuf. Technol. 2009, 40, 144–156. [Google Scholar] [CrossRef]

- Borish, M.; Post, B.K.; Roschli, A.; Chesser, P.C.; Love, L.J.; Gaul, K.T. Defect identification and mitigation via visual inspection in large-scale additive manufacturing. JOM 2019, 71, 893–899. [Google Scholar] [CrossRef]

- Elbehiery, H.; Hefnawy, A.; Elewa, M. Surface defects detection for ceramic tiles using image processing and morphological techniques. Wolrd Acad. Sci. Eng. Technol. 2007, 1, 1488–1492. [Google Scholar]

- Neogi, N.; Mohanta, D.K.; Dutta, P.K. Review of vision-based steel surface inspection systems. EURASIP J. Image Video Process. 2014, 2014, 50. [Google Scholar] [CrossRef]

- Ngan, H.Y.; Pang, G.K.; Yung, N.H. Automated fabric defect detection—A review. Image Vis. Comput. 2011, 29, 442–458. [Google Scholar] [CrossRef]

- Phan, D.T.; Alcock, R.J. Automated grading and defect detection: A review. For. Prod. J. 1998, 48, 34. [Google Scholar]

- Huang, S.H.; Pan, Y.C. Automated visual inspection in the semiconductor industry: A survey. Comput. Ind. 2015, 66, 1–10. [Google Scholar] [CrossRef]

- Vora, H.D.; Sanyal, S. A comprehensive review: Metrology in additive manufacturing and 3D printing technology. Prog. Addit. Manuf. 2020, 5, 319–353. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, R.; Huang, B.; Liu, C.; Yu, J.; Yu, X. An automatic surface defect inspection system for automobiles using machine vision methods. Sensors 2019, 19, 644. [Google Scholar] [CrossRef]

- Chang, P.; Chen, L.; Fan, C. A case-based evolutionary model for defect classification of printed circuit board images. J. Intell. Manuf. 2008, 19, 203–214. [Google Scholar] [CrossRef]

- Czimmermann, T.; Ciuti, G.; Milazzo, M.; Chiurazzi, M.; Roccella, S.; Oddo, C.M.; Dario, P. Visual-Based Defect Detection and Classification Approaches for Industrial Applications—A SURVEY. Sensors 2020, 20, 1459. [Google Scholar] [CrossRef]

- Hornberg, A. (Ed.) Handbook of Machine Vision; John Wiley and Sons: New York, NY, USA, 2006. [Google Scholar]

- Yuk, E.H.; Park, S.H.; Park, C.S.; Baek, J.G. Feature-learning-based printed circuit board inspection via speeded-up robust features and random forest. Appl. Sci. 2018, 8, 932. [Google Scholar] [CrossRef]

- Pearson, J.M.; Shim, J.P. An empirical investigation into DSS structures and environments. Decis. Support Syst. 1995, 13, 141–158. [Google Scholar] [CrossRef]

- Shim, J.P.; Warkentin, M.; Courtney, J.F.; Power, D.J.; Sharda, R.; Carlsson, C. Past, present, and future of decision support technology. Decis. Support Syst. 2002, 33, 111–126. [Google Scholar] [CrossRef]

- De Bem Machado, A.; Secinaro, S.; Calandra, D.; Lanzalonga, F. Knowledge management and digital transformation for Industry 4.0: A structured literature review. Knowl. Manag. Res. Pract. 2022, 20, 320–338. [Google Scholar] [CrossRef]

- Huang, C.Y.; Lin, Y.H.; Tsai, P.F. Developing a rework process for underfilled electronics components via integration of TRIZ and cluster analysis. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 422–438. [Google Scholar] [CrossRef]

- Ceglarek, D.; Shi, J. Dimensional variation reduction for automotive body assembly. Manuf. Rev. 1995, 8, 235–250. [Google Scholar]

- Kim, J.; Huang, Q.; Shi, J.; Chang, T.S. Online multichannel forging tonnage monitoring and fault pattern discrimination using principal curve. J. Manuf. Sci. Eng. 2006, 128, 944–950. [Google Scholar] [CrossRef]

- Woo, J.; O’Connor, J.T. Mitigation strategies to prevent engineering design quality defects. J. Manag. Eng. 2021, 37, 04021007. [Google Scholar] [CrossRef]

- Madhvacharyula, A.S.; Pavan, A.V.S.; Gorthi, S.; Chitral, S.; Venkaiah, N.; Kiran, D.V. In situ detection of welding defects: A review. Weld. World 2022, 66, 611–628. [Google Scholar] [CrossRef]

- Fitts, P.M. Human Engineering for an Effective Air-Navigation and Traffic-Control System; National Research Council: Washington, DC, USA, 1951. [Google Scholar]

- Salas, E.; Rosen, M.A.; Burke, C.S.; Nicholson, D.; Howse, W.R. Markers for enhancing team cognition in complex environments: The power of team performance diagnosis. Aviat. Space Environ. Med. 2007, 78, B77–B85. [Google Scholar]

- Zhou, F.; Qu, X.; Helander, M.G.; Jiao, J.R. Affect prediction from physiological measures via visual stimuli. Int. J. Hum.-Comput. Stud. 2011, 69, 801–819. [Google Scholar] [CrossRef]

- Bulling, A.; Zander, T.O. Cognition-aware computing. IEEE Pervasive Comput. 2014, 13, 80–83. [Google Scholar] [CrossRef]

- Wang, S.; Song, M.; Fei, Y.; Zhang, D.; Zhou, F.; Gebraeel, N.; Jiao, R.J. Prospect-theoretic Modeling of Team Cognition for Task Allocation Towards Human-automation Symbiosis. In Proceedings of the 2023 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 18–21 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1158–1162. [Google Scholar]

- Thaler, R.H.; Sunstein, C.R. Nudge: Improving Decisions About Health, Wealth, and Happiness. In Amsterdam Law Forum; HeinOnline: Online, 2008; p. 89. [Google Scholar]

- Yang, X.; Lim, A.; Nicolaides, A.; Morkos, B. Towards the Understanding of Nudging Strategies in Cyber-Physical-Social System in Manufacturing Environments. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, St. Louis, MO, USA, 14–17 August 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 86236, p. V03BT03A011. [Google Scholar]

- Suh, N.P. Axiomatic design theory for systems. Res. Eng. Des. 1998, 10, 189–209. [Google Scholar] [CrossRef]

- Danielsson, O.; Holm, M.; Syberfeldt, A. Augmented reality smart glasses in industrial assembly: Current status and future challenges. J. Ind. Inf. Integr. 2020, 20, 100175. [Google Scholar] [CrossRef]

- Wang, S.; Jiao, C.K. Leveraging behavioural economics in smart nudge design through data-driven prospect-theoretic modelling and context-aware intelligent reasoning: Application to smart tip nudging. J. Eng. Des. 2022, 33, 896–918. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Jiao, R.J. Smart In-Process Inspection in Human–Cyber–Physical Manufacturing Systems: A Research Proposal on Human–Automation Symbiosis and Its Prospects. Machines 2024, 12, 873. https://doi.org/10.3390/machines12120873

Wang S, Jiao RJ. Smart In-Process Inspection in Human–Cyber–Physical Manufacturing Systems: A Research Proposal on Human–Automation Symbiosis and Its Prospects. Machines. 2024; 12(12):873. https://doi.org/10.3390/machines12120873

Chicago/Turabian StyleWang, Shu, and Roger J. Jiao. 2024. "Smart In-Process Inspection in Human–Cyber–Physical Manufacturing Systems: A Research Proposal on Human–Automation Symbiosis and Its Prospects" Machines 12, no. 12: 873. https://doi.org/10.3390/machines12120873

APA StyleWang, S., & Jiao, R. J. (2024). Smart In-Process Inspection in Human–Cyber–Physical Manufacturing Systems: A Research Proposal on Human–Automation Symbiosis and Its Prospects. Machines, 12(12), 873. https://doi.org/10.3390/machines12120873