Review of Automated Operations in Drilling and Mining

Abstract

1. Introduction

2. Problem Statement and Motivation

3. Overview of Drilling Approaches

3.1. Cable Tool Drilling

3.2. Auger Drilling

3.3. Rotary Drilling

3.4. Diamond Drilling

3.5. Directional Drilling

- Whipstock: A special geometry that allows the drill bit to slide off its surface. The geometry’s angle is what directs the drilling bit [8].

- Bent-house PDM: The motor’s housing is at an angle, allowing the motor to drill at a specific, predefined trajectory [8].

- Best sub: In this configuration, there are hubs that connect two different bent subs at different angles. It provides a greater degree of freedom when drilling [8].

4. Automated Mining and Intelligent Machines

4.1. Rotary Steerable Drilling Systems

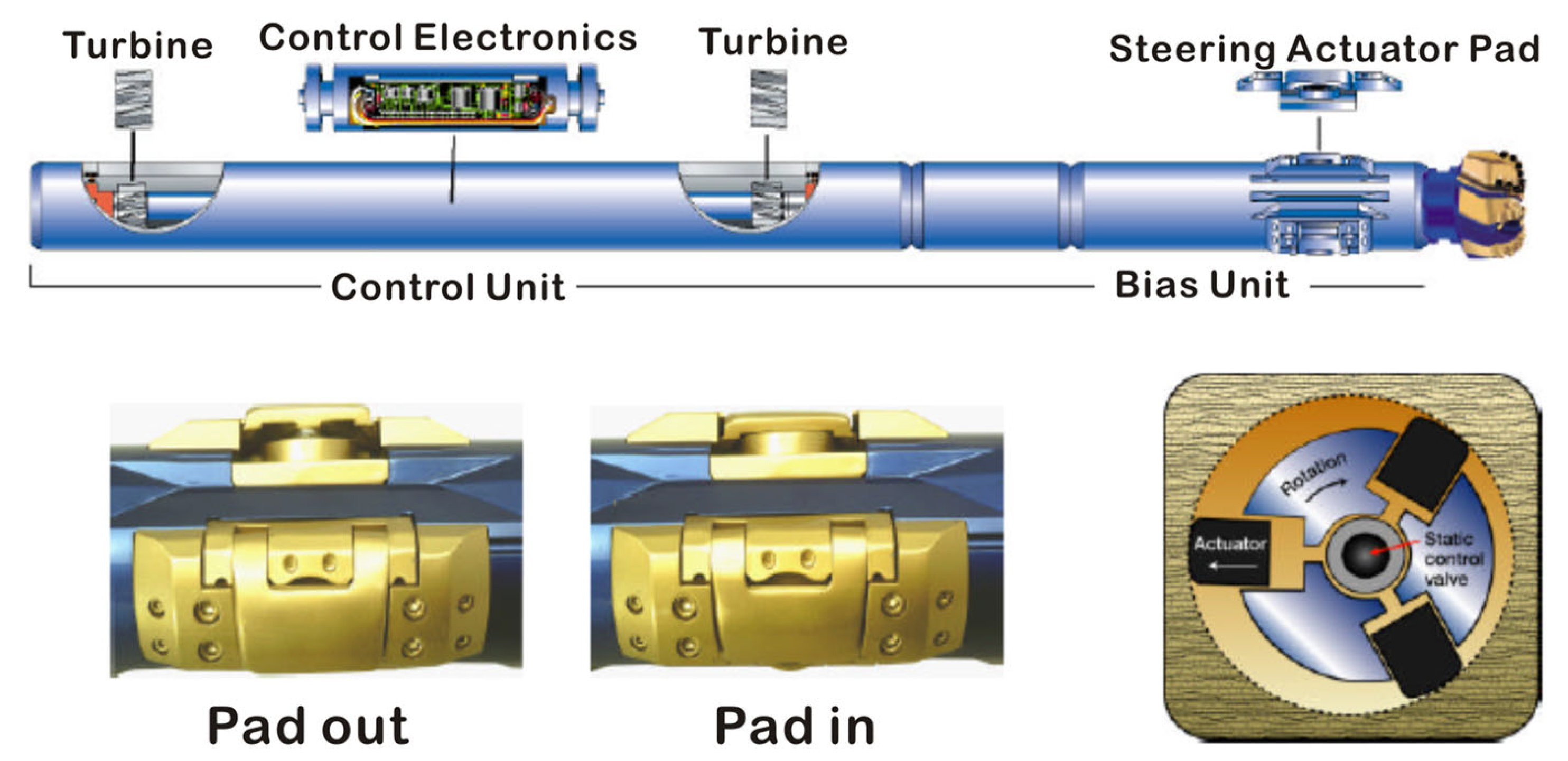

- Push-the-bit systems: Push-the-bit systems have a pump that pushes actuators fixated on the system’s external housing. These pneumatic systems utilize the polar array of these actuators, normally pads, to push the bit to the desired direction [10], as can be seen in Figure 1. The most famous implementations are the Schlumberger PowerDrive and Baker-Hughes Autotrak systems, as in [9,11].

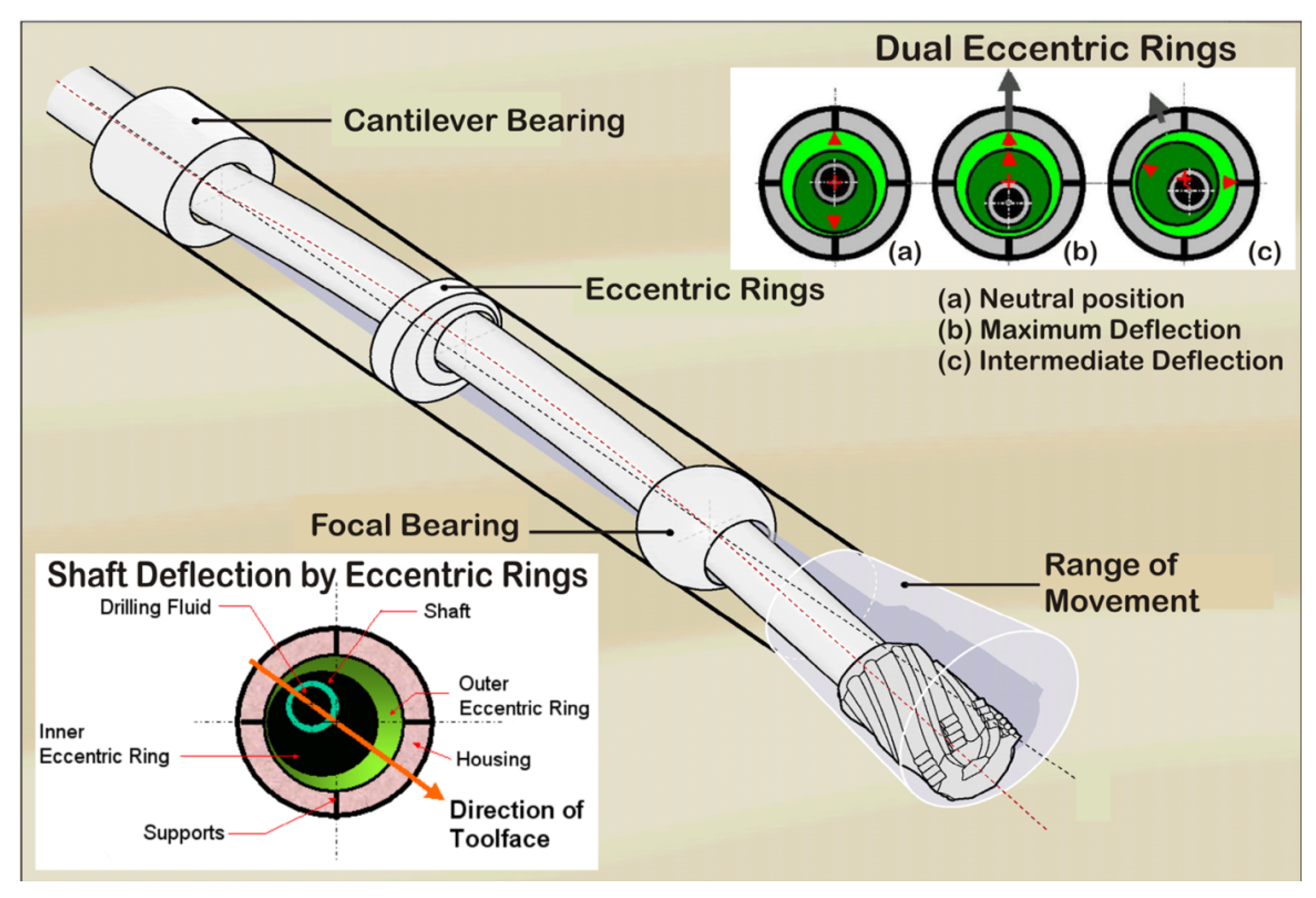

- Point-the-bit systems: These systems vary from the push-the-bit systems in that the actuators reside on the inside of the configuration [10,11]. The most well-explored example of this is the Halliburton Sperry-sun Geo-Pilot system [9]. In these cases, the control of the direction of the bit is possible by using two eccentric rings, changing its angle directly using motors, as shown in Figure 2.

- Hybrid systems: Hybrid systems are, in essence, a combination of the previous two systems. They have multiple actuators that assist them in better controlling every aspect of the drilling procedure. In the Schlumberger PowerDrive Archer system, the bit’s shaft uses a universal joint and internal actuators to push to orient it at the desired angle [9,11].

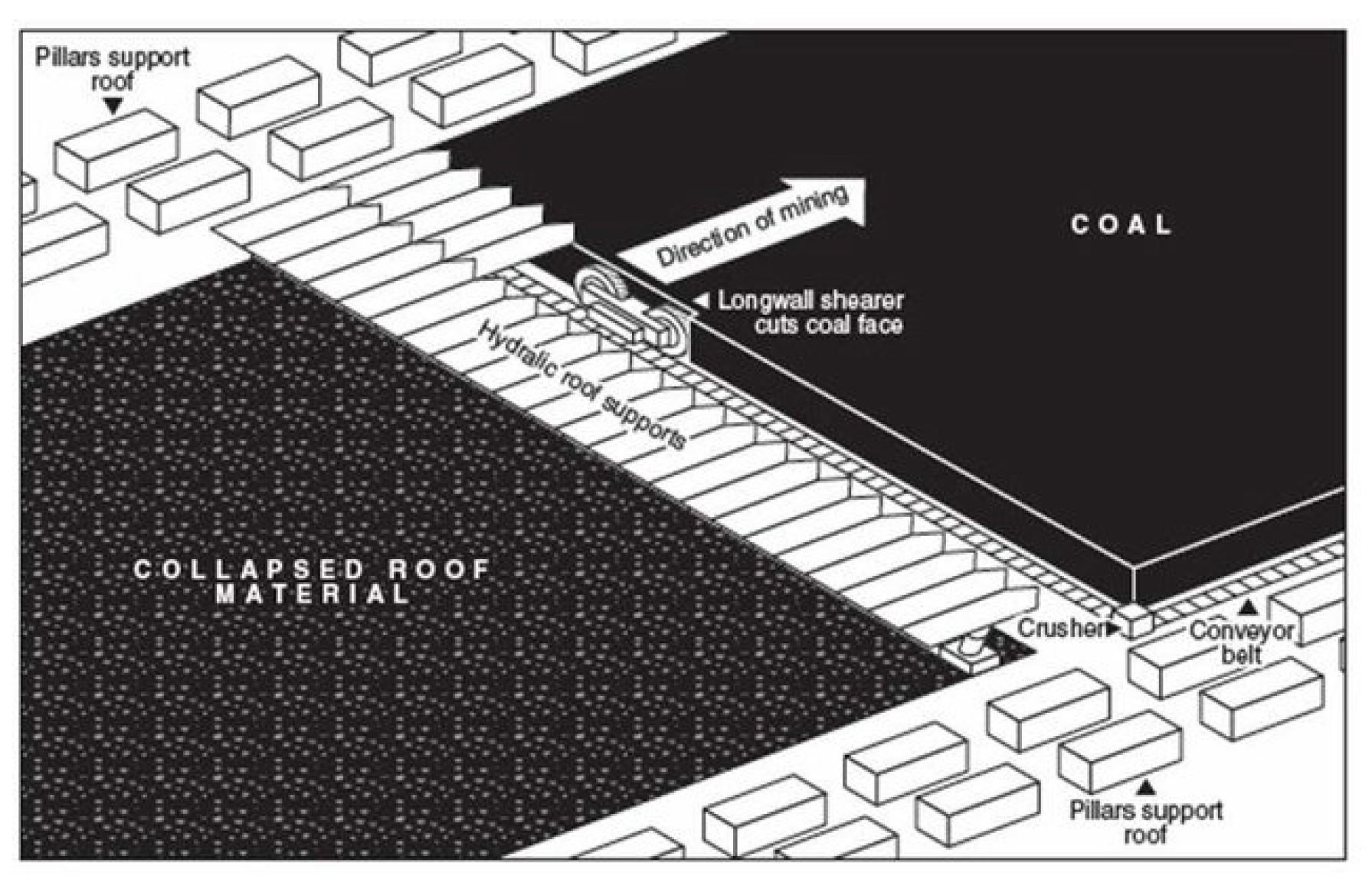

4.2. Longwall

4.3. Automated Hauling

4.4. Charging Robots

4.5. Intelligent Rock-Drilling Jumbo and DTH Drill

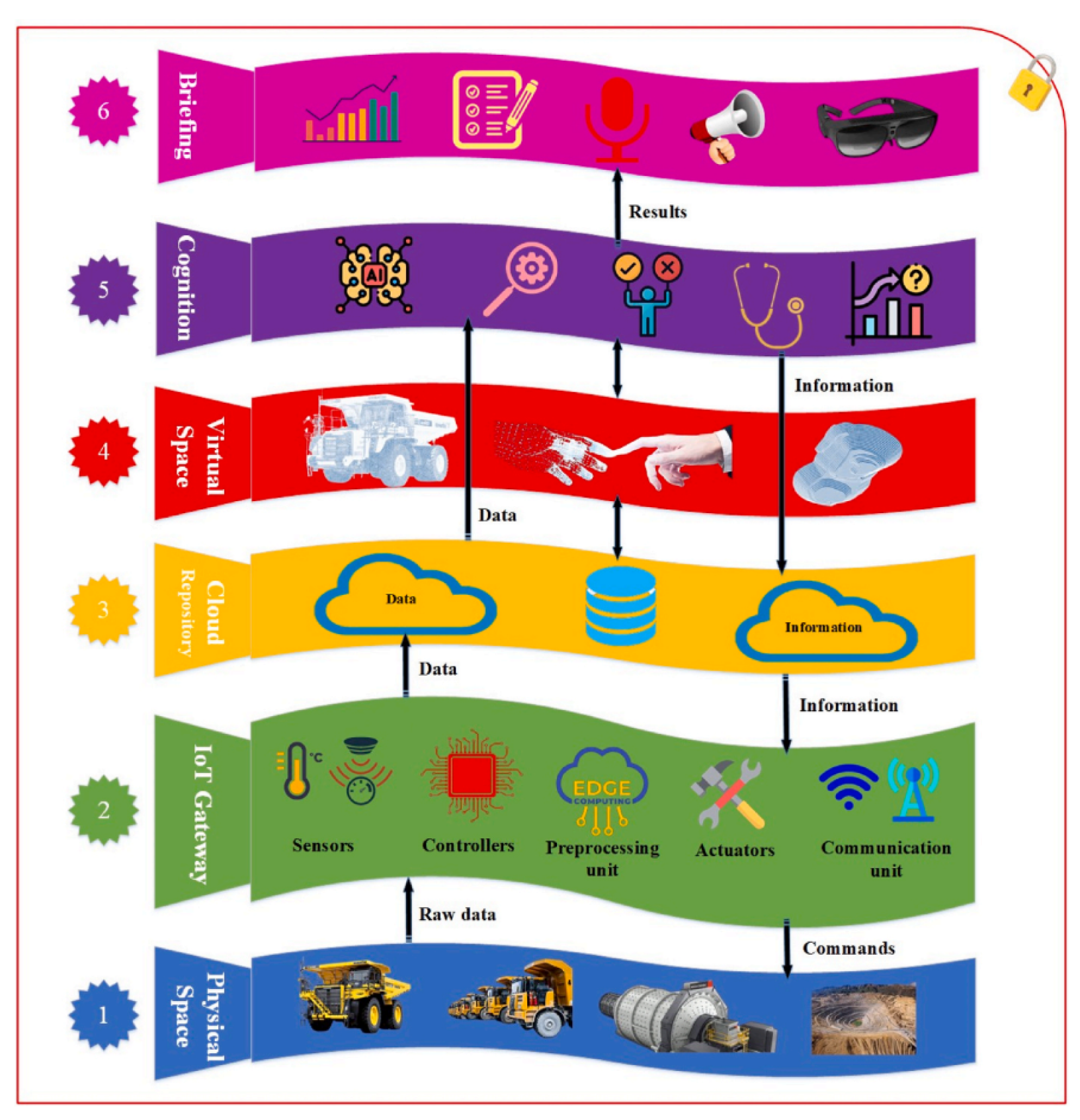

5. Technological Infrastructure in Automated Mining

5.1. Sensors Used in Automated Mining

5.1.1. LIBS

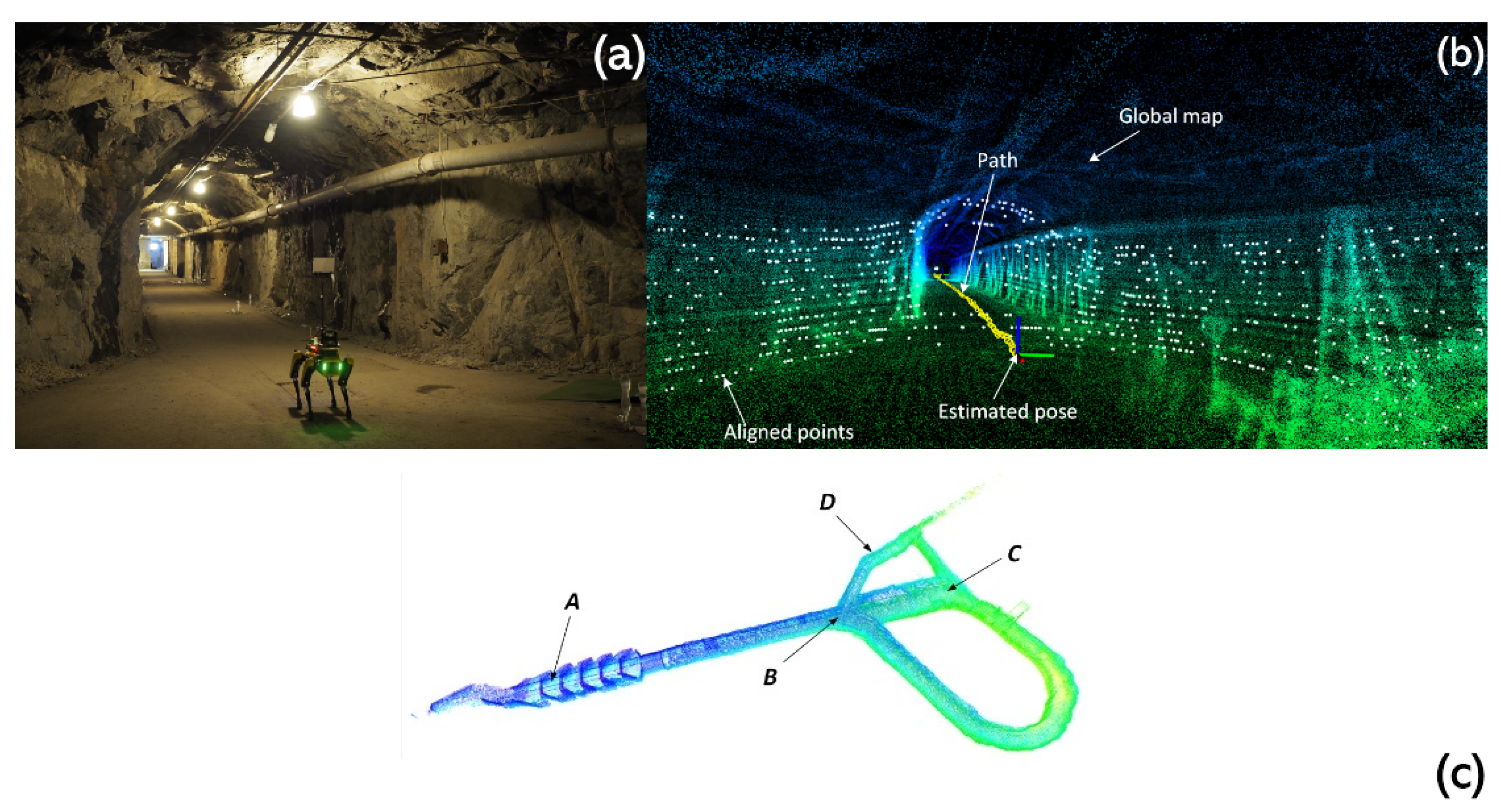

5.1.2. LIDAR

5.1.3. Time-of-Flight Camera

5.2. Communication and Localization Systems Used in Automated Mining

5.2.1. Light-Based Localization Systems

5.2.2. Daisy Chaining of Fiducial Markers

5.2.3. Magnetic Induction

5.2.4. WiFi and LoRaWAN

5.3. Simulations Using Digital Models

5.4. Software Used in Intelligent Systems

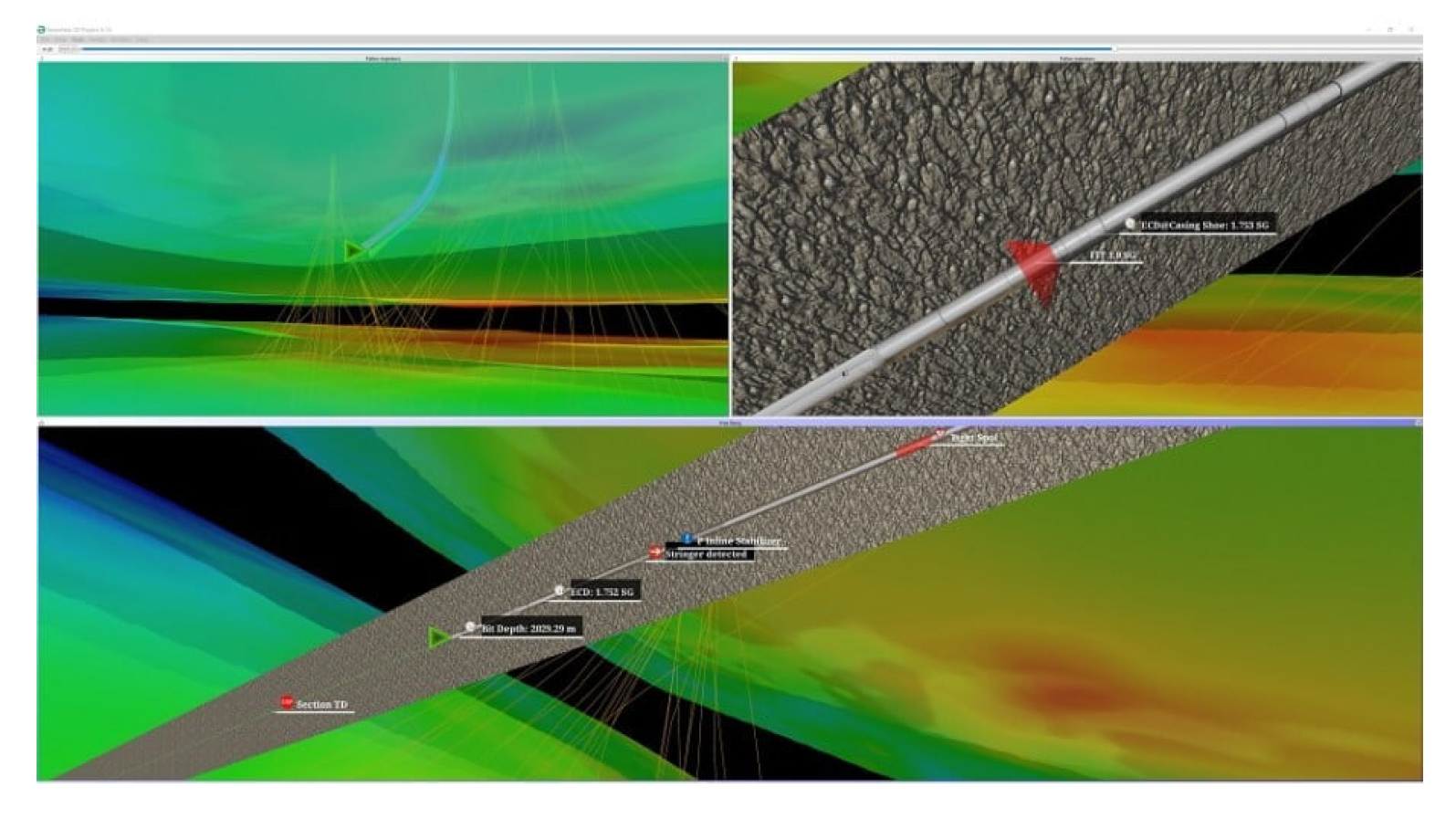

5.4.1. e-Drilling’s Software Suite

5.4.2. Draco

5.4.3. Forestall

5.4.4. TIMining Aware

5.5. Collaborative Robotics in Mining

6. Possible Evolution of Intelligent Mining Machines

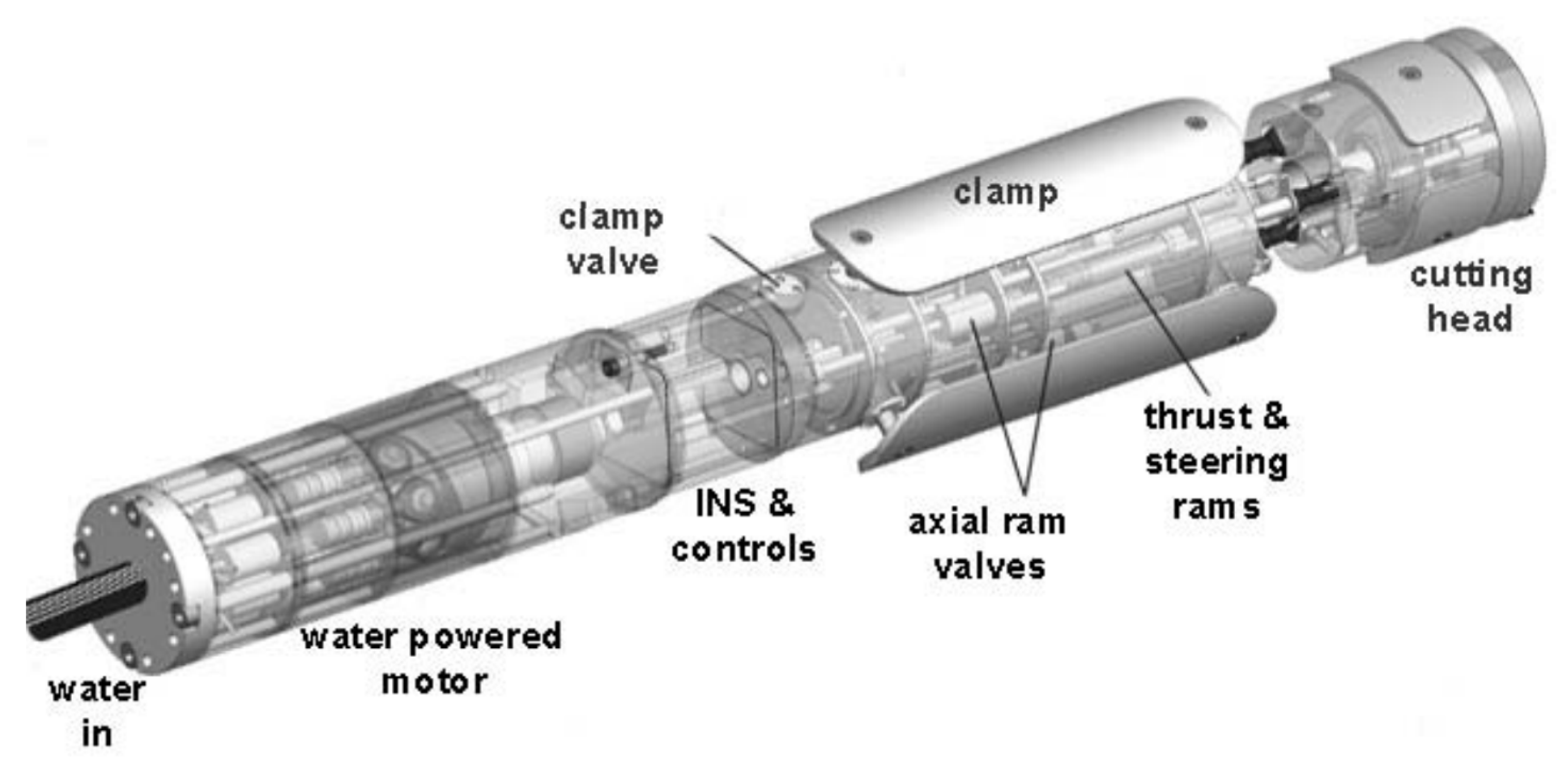

- Drill piston control for better bit-pointing accuracy: This approach promises better results when it comes to pointing the bit of an RSDS. It uses multiple pistons, valves, water, and stabilization clamp pads to better control the orientation and force applied by the bit [55].

- Photogrammetry in the mining industry: While Virtual Reality technology is being used today for minor tasks, it is being researched and worked upon extensively due to the presently unexplored advantages described in [56,57], especially with the improvement in modern cameras. Mining professionals are already adopting technologies from research, especially within the area of the digitization and mapping of mines with high-resolution cameras. Additionally, large-area scans for open-pit sites, which once required the use of special fiducial markers (ground control points) [58], are no longer needed with the introduction of Real-Time Kinematics and Post-Process Kinematics technologies [59]. Furthermore, there is ongoing research on multi-camera systems that can produce rock-mass digital models with a camera rig and can also support UAVs [25].

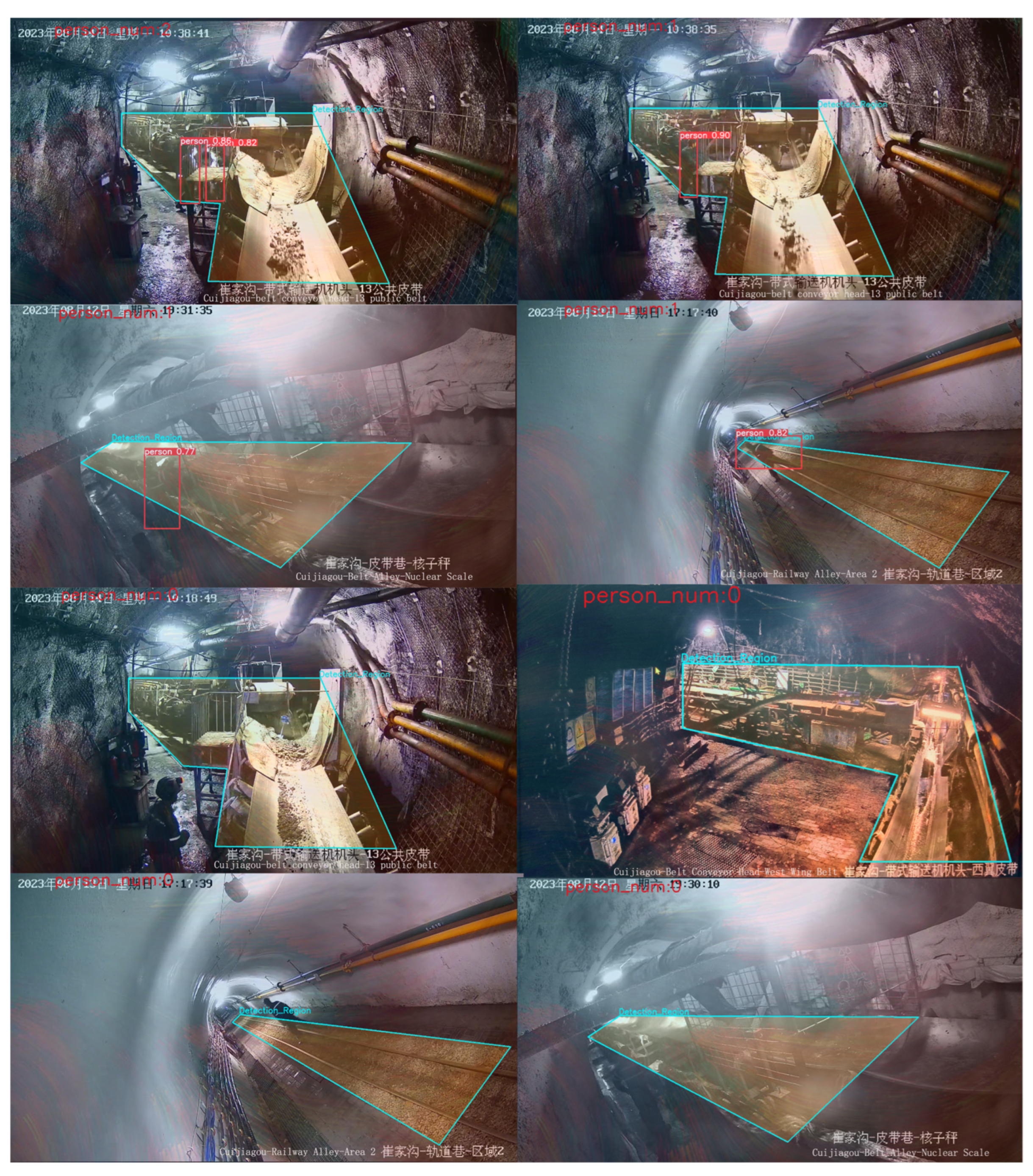

- Neural networks for augmented personnel safety: Neural networks can be used for a diversity of tasks. Research has shown that one of their uses can be the monitoring of the activity of personnel inside the mine to decrease accidents and exposure to hazardous areas [60]. One such example is the use of a YOLOv8 model (Figure 8) to determine the location of humans and hazardous areas [61]. YOLOv8 is a convolutional neural network that makes predictions of bounding boxes and class probabilities all at once.

- Virtual Reality simulation for multi-agent system action planning: Virtual Reality’s importance is already underlined, but the range of its applications cannot be stressed enough. Currently, there are ready-to-use software solutions that allow for the simulation of multiple robots in a virtual mining environment, expressed through the game development engine Unity3D [62]. Simulators of this kind may prove essential in mining procedure planning, especially in more complex systems with multiple interactions [57].

- AI-assisted DTs: Advancements that are currently being made in the field of artificial intelligence suggest that AI will be further integrated into FEA simulation software to provide better insights regarding mining data [63,64]. Surveys report that AI will be refined enough to be widely accepted in the industry by 2030 [65], providing a better bridge of communication between the real and digital worlds.

- Optimized haulage scheduling using Reinforcement Learning: Reinforcement Learning (RL) methods can be used to schedule the operation of fleets of autonomous haulers in real time utilizing model-free Q-Learning algorithms. In a simulated environment, this method resulted in a reduction in the wait time of each hauler and reduced the emission of greenhouse gases that resulted from the extensive fuel consumption of the machines. This reduction in fuel consumption was as high as 30% in comparison to fixed-schedule approaches while increasing productivity by 50% [66].

- Controlling equipment using Deep Reinforcement Learning: Deep Reinforcement Learning (DRL) can be used to control underground, individually operating machines as a substitute for human operators. Machines such as Load-Haul-Dump machines can be controlled with the use of a DRL framework by implementing a soft actor-critic (SAC) algorithm in a simulated environment, lowering energy consumption and increasing productivity [68]. In more detail, in [68], the energy consumption was found to be 21% lower for the autonomous vehicle in comparison with the energy consumed when a similar vehicle was operated by a human in the real world, and productivity was increased by 7%. Another example of operating multiple machines using RL, implementing proximal policy optimization (PPO) and SAC, can be examined in [67].

- Using DRL in mine production scheduling: DRL methods can even be utilized for the design of underground mine production layouts [69]. Utilizing DRL in the pre-production stages of the mining process allows for a better evaluation of the mineral grade since it utilizes uncertainty to create a stochastic design in comparison to deterministic designs. Deterministic designs are created by the more conventional geostatistical methods, such as mineable shape optimizers, which tend to lead to the under-performance of mining projects. A case study of underground stoping for gold production in [69] resulted in 8.3% higher expected profit and 3.4% more gold mined than the baseline that was provided by a mineable shape optimizer.

- Monitoring of the drilling rig: Research on monitoring drilling bit wear has been conducted to predict and analyze the drilling bit’s condition. These studies have shown that sound and vibration signals, as well as examining the geological and mechanical properties of rocks, can be used to survey the drilling bit’s wear condition [72].

- Intelligent control of the drilling: Computer vision and Deep Neural Networks for image classification are used to control the drilling rig and improve procedures such as drilling path planning and intelligent hole positioning [72].

- Measurement while drilling (MWD) and machine learning for rock monitoring: MWD is a technology that provides real-time measurements of drilling parameters, e.g., torque, rotation speed, and drilling speed. These parameters are used to determine the magnitude of the rock stress caused by the drilling operation with the aid of digital panoramic imaging technology for boreholes. Additionally, intelligent rock property sensing can be achieved by implementing machine learning techniques with the data provided by MWD [72].

- AI and big data technology in ventilation systems: Current research on ventilation systems focuses on acquiring ventilation parameters, such as wind volume and pressure, temperature, humidity, and the detection/concentration of toxic gases. To achieve this, research focuses on the proper placement of the minimum number of sensors that provide reliable data about those parameters. After obtaining these data, diagnostic methods are proposed based on learning algorithms and big data analysis, as well as airflow control methods [72].

- Intelligent rock stress monitoring: Rock stress during drilling operations causes the deformation of the surrounding rock. Therefore, real-time monitoring methods have been developed based on machine vision and learning algorithms that provide early warning and predictions about surrounding rock deformation and damage [72].

7. Future Trends and Visions in the Robotization and Digitalization of the Mining Industry

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| 5G | Fifth-generation mobile network |

| AHS | Autonomous Haulage System |

| AI | Artificial intelligence |

| DRL | Deep Reinforcement Learning |

| DT | Digital twin |

| DTH | Down the hole |

| FEA | Finite Element Analysis |

| GPS | Global Positioning System |

| IoT | Internet of Things |

| LED | Light-Emitting Diode |

| LIBS | Laser-Induced Breakdown Spectroscopy |

| LiDAR | Light Detection and Ranging |

| LoRaWAN | Long-Range Wide-Area Network |

| MWD | Measurement while drilling |

| PPO | Proximal policy optimization |

| RF | Radio Frequency |

| RL | Reinforcement Learning |

| RSDS | Rotary Steerable Drilling System |

| SAC | Soft actor-critic |

| SLAM | Simultaneous Localization and Mapping |

| TFC | Time-of-flight camera |

| TFS | Time-of-flight sensor |

| UAV | Unmanned Aerial Vehicle |

| UGV | Unmanned Ground Vehicle |

| UHF | Ultra-High Frequency |

| YOLO | You Only Look Once |

References

- Yinka-Banjo, C.; Bagula, A.; Osunmakinde, I.O. Autonimous multi-robot behaviours for safety inspection under the constraints of underground mine terrains. Ubiquitous Comput. Commun. J. 2012, 7, 1316–1328. [Google Scholar]

- Mueller, C.; Assibey-Bonsu, W.; Baafi, E.; Dauber, C.; Doran, C.; Jerzy Jaszczuk, M.; Nagovitsyn, O. Mining Goes Digital: Proceedings of the 39th International Symposium’Application of Computers and Operations Research in the Mineral Industry’ (APCOM 2019), June 4–6, 2019, Wroclaw, Poland, 1st ed.; CRC Press: London, UK, 2019. [Google Scholar] [CrossRef]

- Kalisz, S.; Kibort, K.; Mioduska, J.; Lieder, M.; Małachowska, A. Waste Management in the Mining Industry of Metals Ores, Coal, Oil and Natural Gas—A Review. J. Environ. Manag. 2022, 304, 114239. [Google Scholar] [CrossRef] [PubMed]

- Agboola, O.; Babatunde, D.E.; Isaac Fayomi, O.S.; Sadiku, E.R.; Popoola, P.; Moropeng, L.; Yahaya, A.; Mamudu, O.A. A Review on the Impact of Mining Operation: Monitoring, Assessment and Management. Results Eng. 2020, 8, 100181. [Google Scholar] [CrossRef]

- Akpedeye, K.U. Advancement on Drilling Technology in Petroleum Industry. Bachelor’s Thesis, University of Applied Sciences, Riihimäki, Finland, 2010. [Google Scholar]

- Todd, D.K.; Mays, L.W. Groundwater Hydrology; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Zacny, K.; Paulsen, G.; McKay, C.; Glass, B.; Dave, A.; Davila, A.; Marinova, M.; Mellerowicz, B.; Heldmann, J.; Stoker, C.; et al. Reaching 1m Deep on Mars: The Icebreaker Drill. Astrobiology 2013, 13, 1166–1198. [Google Scholar] [CrossRef] [PubMed]

- Tianshou, M.; Chen, P.; Zhao, J. Overview on Vertical and Directional Drilling Technologies for the Exploration and Exploitation of Deep Petroleum Resources. Geomech. Geophys. Geo-Energy Geo-Resour. 2016, 2, 365–395. [Google Scholar] [CrossRef]

- Li, F.; Ma, X.; Tan, Y. Review of the Development of Rotary Steerable Systems. J. Phys. Conf. Ser. 2020, 1617, 012085. [Google Scholar] [CrossRef]

- Sugiura, J. Systematic Testing with Push- and Point-the-Bit Rotary-Steerable Systems Leads to the Optimal BHA Design for Stability, Steerability and Borehole Quality. In Proceedings of the 2008 AADE Fluids Conference and Exhibition held at the Wyndam Greenspoint Hotel, Houston, TX, USA, 8–9 April 2008. [Google Scholar]

- Ivanova, T.; Božek, P.; Korshunov, A.; Koretskiy, V. Analysis of Distortion Mechanisms Used in Rotary Steerable Systems. Multidiscip. Asp. Prod. Eng. 2020, 3, 331–346. [Google Scholar] [CrossRef]

- Saki, S. Gob Ventilation Borehole Design and Performance Optimization for Longwall Coal Mining Using Computational Fluid Dynamics. Ph.D. Thesis, Colorado School of Mines, Golden, CO, USA, 2016. [Google Scholar] [CrossRef]

- Peng, S. Longwall Mining, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Famur. ‘Machinery & Equipment for Underground Mining’, 6 October 2024. Available online: https://famur.com/en/machinery-equipment-for-underground-mining/ (accessed on 6 October 2024).

- Bołoz, Ł.; Biały, W. Automation and Robotization of Underground Mining in Poland. Appl. Sci. 2020, 10, 7221. [Google Scholar] [CrossRef]

- Li, J.; Zhan, K. Intelligent Mining Technology for an Underground Metal Mine Based on Unmanned Equipment. Engineering 2018, 4, 381–391. [Google Scholar] [CrossRef]

- Bonchis, A.; Duff, E.; Roberts, J.; Bosse, M. Robotic Explosive Charging in Mining and Construction Applications. IEEE Trans. Autom. Sci. Eng. 2014, 11, 245–250. [Google Scholar] [CrossRef]

- Fayyaz, A.; Ali, R.; Waqas, M.; Liaqat, U.; Ahmad, R.; Umar, Z.A.; Baig, M.A. Analysis of Rare Earth Ores Using Laser-Induced Breakdown Spectroscopy and Laser Ablation Time-of-Flight Mass Spectrometry. Minerals 2023, 13, 787. [Google Scholar] [CrossRef]

- Bhatt, C.R.; Jain, J.C.; Goueguel, C.L.; McIntyre, D.L.; Singh, J.P. Determination of Rare Earth Elements in Geological Samples Using Laser-Induced Breakdown Spectroscopy (LIBS). Appl. Spectrosc. 2018, 72, 114–121. [Google Scholar] [CrossRef] [PubMed]

- Bellie, V.; Gokulraju, R.; Rajasekar, C.; Vinoth, S.; Mohankumar, V.; Gunapriya, B. Laser Induced Breakdown Spectroscopy for New Product Development in Mining Industry. Mater. Today Proc. 2021, 45, 8157–8161. [Google Scholar] [CrossRef]

- Zeeshan, M.; Chavda, M.; Ehshan, K.M.; Nayek, R.; Malik, S. A Review on Non-RF Underground Positioning Techniques for Mining Applications. IEEE Trans. Instrum. Meas. 2023, 72, 9510217. [Google Scholar] [CrossRef]

- Dima, E.; Sjöström, M. Camera and Lidar-Based View Generation for Augmented Remote Operation in Mining Applications. IEEE Access 2021, 9, 82199–82212. [Google Scholar] [CrossRef]

- Wang, G.; Wu, J.; Xu, T.; Tian, B. 3D Vehicle Detection With RSU LiDAR for Autonomous Mine. IEEE Trans. Veh. Technol. 2021, 70, 344–355. [Google Scholar] [CrossRef]

- Stathoulopoulos, N.; Pagliari, E.; Davoli, L.; Nikolakopoulos, G. Redundant and Loosely Coupled LiDAR-Wi-Fi Integration for Robust Global Localization in Autonomous Mobile Robotics. In Proceedings of the 2023 21st International Conference on Advanced Robotics (ICAR), Abu Dhabi, United Arab Emirates, 5–8 December 2023; pp. 121–127. [Google Scholar] [CrossRef]

- Janiszewski, M.; Prittinen, M.; Uotinen, L.; Torkan, M.; Rinne, M. Rapid Photogrammetric Method for Rock Mass Characterization in Underground Excavations. In Proceedings of the ISRM IV Nordic Symposium on Rock Mechanics and Rock Engineering, Reykjavik, Iceland, 24–26 May 2023. [Google Scholar] [CrossRef]

- Hansard, M.; Lee, S.; Choi, O.; Horaud, R.P. Time-of-Flight Cameras: Principles, Methods and Applications; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Horaud, R.; Hansard, M.; Evangelidis, G.; Ménier, C. An Overview of Depth Cameras and Range Scanners Based on Time-of-Flight Technologies. Mach. Vis. Appl. 2016, 27, 1005–1020. [Google Scholar] [CrossRef]

- Kanellakis, C.; Nikolakopoulos, G. Evaluation of Visual Localization Systems in Underground Mining. In Proceedings of the 2016 24th Mediterranean Conference on Control and Automation (MED), Athens, Greece, 21–24 June 2016; pp. 539–544. [Google Scholar] [CrossRef]

- Keskin, M.F.; Sezer, A.D.; Gezici, S. Localization via Visible Light Systems. Proc. IEEE 2018, 106, 1063–1088. [Google Scholar] [CrossRef]

- Capozzi, R.; Wilde, M.; Kish, B. Daisy Chain Navigation and Communication in Underground Environments. In Proceedings of the 2021 IEEE Aerospace Conference (50100), Big Sky, MT, USA, 6–13 March 2021; pp. 1–9. [Google Scholar] [CrossRef]

- Tardioli, D.; Riazuelo, L.; Sicignano, D.; Rizzo, C.; Lera, F.; Villarroel, J.L.; Montano, L. Ground Robotics in Tunnels: Keys and Lessons Learned after 10 Years of Research and Experiments. J. Field Robot. 2019, 36, 1074–1101. [Google Scholar] [CrossRef]

- Pasku, V.; De Angelis, A.; De Angelis, G.; Arumugam, D.D.; Dionigi, M.; Carbone, P.; Moschitta, A.; Ricketts, D.S. Magnetic Field-Based Positioning Systems. IEEE Commun. Surv. Tutor. 2017, 19, 2003–2017. [Google Scholar] [CrossRef]

- Lin, S.C.; Alshehri, A.; Wang, P.; Akyildiz, I. Magnetic Induction-Based Localization in Randomly-Deployed Wireless Underground Sensor Networks. IEEE Internet Things J. 2017, 4, 1454–1465. [Google Scholar] [CrossRef]

- Seguel, F.; Palacios-Játiva, P.; Azurdia-Meza, C.A.; Krommenacker, N.; Charpentier, P.; Soto, I. Underground Mine Positioning: A Review. IEEE Sens. J. 2022, 22, 4755–4771. [Google Scholar] [CrossRef]

- Branch, P.; Cricenti, T. A LoRa Relay Based System for Detonating Explosives in Underground Mines. In Proceedings of the 2020 IEEE International Conference on Industrial Technology (ICIT), Buenos Aires, Argentina, 26–28 February 2020; pp. 259–264. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Hazrathosseini, A.; Moradi Afrapoli, A. The Advent of Digital Twins in Surface Mining: Its Time Has Finally Arrived. Resour. Policy 2023, 80, 103155. [Google Scholar] [CrossRef]

- Josef, N. Using Digital Technologies to Automat and Optimize Drilling Parameters in Real-Time, Its Impact on Value Creation, and Work Process. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2023. [Google Scholar]

- eDrilling. eDrilling Products, 6 Octomber 2024. Available online: https://www.edrilling.no/products (accessed on 6 October 2024).

- Jansen van Rensburg, B.; Puech, W.; Pedeboy, J.P. The First Draco 3D Object Crypto-Compression Scheme. IEEE Access 2022, 10, 10566–10574. [Google Scholar] [CrossRef]

- Source, G.O. Google Open Source. Introducing Draco: Compression for 3D Graphics. Google Open Source Blog(blog), 6 October 2024. Available online: https://opensource.googleblog.com/2017/01/introducing-draco-compression-for-3d.html (accessed on 6 October 2024).

- Google/Draco. C++. 2016.Reprint, Google, 5 October 2024. Available online: https://github.com/google/draco (accessed on 6 October 2024).

- PETRA. FORESTALL®, 16 July 2024. Available online: https://www.petradatascience.com/forestall/ (accessed on 6 October 2024).

- Hazrathosseini, A.; Afrapoli, A.M. Intelligent Fleet Management Systems in Surface Mining: Status, Threats, and Opportunities. Min. Metall. Explor. 2023, 40, 2087–2106. [Google Scholar] [CrossRef]

- TIMining. TIMining AWARE—TIMining. TIMining AWARE, 6 October 2024. Available online: https://www.timining.com/en/timining-aware/ (accessed on 6 October 2024).

- Cat Mining. Cat® MineStar™ Command for Underground, 17 October 2016. Available online: https://www.youtube.com/watch?v=WU6u5XTMKNI (accessed on 6 October 2024).

- Gustafson, A.; Paraszczak, J.; Tuleau, J.; Schunnesson, H. Impact of Technical and Operational Factors on Effectiveness of Automatic Load-Haul-Dump Machines. Min. Technol. 2017, 126, 185–190. [Google Scholar] [CrossRef]

- George, B.K. Optimization of Quarry Operations and Maintenance Schedules. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2023. [Google Scholar]

- George, B.; Nojabaei, B. Data Analyses of Quarry Operations and Maintenance Schedules: A Production Optimization Study. Mining 2023, 3, 347–366. [Google Scholar] [CrossRef]

- Dinelli, C.; Racette, J.; Escarcega, M.; Lotero, S.; Gordon, J.; Montoya, J.; Dunaway, C.; Androulakis, V.; Khaniani, H.; Shao, S.; et al. Configurations and Applications of Multi-Agent Hybrid Drone/Unmanned Ground Vehicle for Underground Environments: A Review. Drones 2023, 7, 136. [Google Scholar] [CrossRef]

- Miller, I.D.; Cladera, F.; Cowley, A.; Shivakumar, S.S.; Lee, E.S.; Jarin-Lipschitz, L.; Bhat, A.; Rodrigues, N.; Zhou, A.; Cohen, A.; et al. Mine Tunnel Exploration Using Multiple Quadrupedal Robots. arXiv 2020, arXiv:1909.09662. [Google Scholar] [CrossRef]

- Nordström, S.; Stathoulopoulos, N.; Dahlquist, N.; Lindqvist, B.; Tevetzidis, I.; Kanellakis, C.; Nikolakopoulos, G. Safety Inspections and Gas Monitoring in Hazardous Mining Areas Shortly After Blasting Using Autonomous UAVs. Authorea 2024. [Google Scholar] [CrossRef]

- Lindqvist, B.; Stathoulopoulos, N.; Karlsson, S.; Bai, Y.; Haluska, J.; Tevetzidis, I.; Koval, A.; Kanellakis, C.; Nikolakopoulos, G.; Patel, A. Deployment of Autonomous Uavs in Underground Mines: Field Evaluations and Use-Case Demonstrations. SSRN Electron. J. 2023. [Google Scholar] [CrossRef]

- Zimroz, P.; Trybała, P.; Wróblewski, A.; Góralczyk, M.; Szrek, J.; Wójcik, A.; Zimroz, R. Application of UAV in Search and Rescue Actions in Underground Mine—A Specific Sound Detection in Noisy Acoustic Signal. Energies 2021, 14, 3725. [Google Scholar] [CrossRef]

- Wendt, M.; Einicke, G. Development of a Water-Hydraulic Self-Propelled Robotic Drill for Underground Mining. In Field and Service Robotics; Springer Tracts in Advanced Robotics; Springer: Berlin/Heidelberg, Germany, 2005; Volume 25, pp. 355–366. [Google Scholar] [CrossRef]

- Akbulut, N.; Anani, A. Application of Virtual Reality in the Mining Industry—Where Are We Now? In Proceedings of the SME Annual Conference and Expo, Denver, CO, USA, 26 February–1 March 2023. [Google Scholar]

- Xie, J.; Yang, Z.; Wang, X.; Zeng, Q.; Li, J.; Li, B. A Virtual Reality Collaborative Planning Simulator and Its Method for Three Machines in a Fully Mechanized Coal Mining Face. Arab. J. Sci. Eng. 2018, 43, 4835–4854. [Google Scholar] [CrossRef]

- Patikova, A. Digital Photogrammetry In The Practice Of Open Pit Mining. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2004, 34, 1–4. [Google Scholar]

- Jaud, M.; Bertin, S.; Beauverger, M.; Augereau, E.; Delacourt, C. RTK GNSS-Assisted Terrestrial SfM Photogrammetry without GCP: Application to Coastal Morphodynamics Monitoring. Remote Sens. 2020, 12, 1889. [Google Scholar] [CrossRef]

- Akhmetov, T. Industrial Safety Using Augmented Reality and Artificial Intelligence. Ph.D. Thesis, Nazarbayev University, Astana, Kazakhstan, 2023. [Google Scholar]

- Automation.AutoMine®, 16 July 2024. Available online: https://www.rocktechnology.sandvik/En/Products/Technology/Automation/Automine/ (accessed on 6 October 2024).

- Shi, H.; Xie, J.; Wang, X.; Li, J.; Ge, X. An Operation Optimization Method of a Fully Mechanized Coal Mining Face Based on Semi-Physical Virtual Simulation. Int. J. Coal Sci. Technol. 2019, 7, 147–163. [Google Scholar] [CrossRef]

- Zayed, S.M.; Attiya, G.M.; El-Sayed, A.; Hemdan, E.E.D. A Review Study on Digital Twins with Artificial Intelligence and Internet of Things: Concepts, Opportunities, Challenges, Tools and Future Scope. Multimed. Tools Appl. 2023, 82, 47081–47107. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef]

- Rosen, R.; Hartmann, D.; Van der Auweraer, H.; Hermann, M.; Wolfrum, P. Simulation & DigitalTwin; Siemens Corporation: Princeton, NJ, USA, 2020. [Google Scholar]

- Huo, D.; Sari, Y.A.; Kealey, R.; Zhang, Q. Reinforcement Learning-Based Fleet Dispatching for Greenhouse Gas Emission Reduction in Open-Pit Mining Operations. Resour. Conserv. Recycl. 2023, 188, 106664. [Google Scholar] [CrossRef]

- Fidêncio, A.X.; Glasmachers, T.; Naro, D. Application of Reinforcement Learning to a Mining System. In Proceedings of the 2021 IEEE 19th World Symposium on Applied Machine Intelligence and Informatics (SAMI), Herl’any, Slovakia, 21–23 January 2021; pp. 000111–000118. [Google Scholar] [CrossRef]

- Backman, S.; Lindmark, D.; Bodin, K.; Servin, M.; Mörk, J.; Löfgren, H. Continuous Control of an Underground Loader Using Deep Reinforcement Learning. Machines 2021, 9, 216. [Google Scholar] [CrossRef]

- Noriega, R.; Boisvert, J. Optimization of Underground Mining Production Layouts Considering Geological Uncertainty Using Deep Reinforcement Learning. Eng. Appl. Artif. Intell. 2025, 139, 109493. [Google Scholar] [CrossRef]

- Song, W.; Song, W.; Gu, H.; Li, F. Progress in the Remote Sensing Monitoring of the Ecological Environment in Mining Areas. Int. J. Environ. Res. Public Health 2020, 17, 1846. [Google Scholar] [CrossRef] [PubMed]

- Myaskov, A.; Temkin, I.; Deryabin, S.; Marinova, D. Factors and Objectives of Sustainable Development at the Implementation of Digital Technologies and Automated Systems in the Mining Industry. E3S Web Conf. 2020, 174, 04023. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Wang, L.; Qu, F.; Shao, A.; Zhao, L.; Wang, H.; Yue, X.; Li, Y.; Yan, W.; et al. Research Progress and Prospects of Intelligent Technology in Underground Mining of Hard Rock Mines. Green Smart Min. Eng. 2024, 1, 12–26. [Google Scholar] [CrossRef]

- Hindy, Y.; Pointing, J.; Tolunay, M.; Venkatarao, S.; Motta, M.; Latone, J. A Quantum Computational Approach to the Open-Pit Mining Problem. arXiv 2021, arXiv:2107.11345. [Google Scholar]

- Paradezhenko, G.; Pervishko, A.; Yudin, D. Quantum-Assisted Open-Pit Optimization. JETP Lett. 2024, 119, 470–478. [Google Scholar] [CrossRef]

- Hindy, Y.; Pointing, J.; Tolunay, M.; Venkatarao, S.; Motta, M.; Latone, J.A. Application of the Variational Quantum Eigensolver to the Ultimate Pit Problem. In Proceedings of the 2023 IEEE International Conference on Quantum Computing and Engineering (QCE), Bellevue, WA, USA, 17–22 September 2023; Volume 1, pp. 681–691. [Google Scholar] [CrossRef]

- Zhironkina, O.; Zhironkin, S. Technological and Intellectual Transition to Mining 4.0: A Review. Energies 2023, 16, 1427. [Google Scholar] [CrossRef]

- Zhironkin, S.; Ezdina, N. Review of Transition from Mining 4.0 to Mining 5.0 Innovative Technologies. Appl. Sci. 2023, 13, 4917. [Google Scholar] [CrossRef]

- Clausen, E.; Sörensen, A.; Nienhaus, K. Mining 4.0. In Handbook Industry 4.0: Law, Technology, Society; Frenz, W., Ed.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 785–792. [Google Scholar] [CrossRef]

- Faz-Mendoza, A.; Gamboa-Rosales, N.K.; Medina-Rodríguez, C.E.; Casas-Valadez, M.A.; Castorena-Robles, A.; López-Robles, J.R. Intelligent Processes in the Context of Mining 4.0: Trends, Research Challenges and Opportunities. In Proceedings of the 2020 International Conference on Decision Aid Sciences and Application (DASA), Sakheer, Bahrain, 8–9 November 2020; pp. 480–484. [Google Scholar] [CrossRef]

- Stathoulopoulos, N.; Koval, A.; Nikolakopoulos, G. A Comparative Field Study of Global Pose Estimation Algorithms in Subterranean Environments. Int. J. Control Autom. Syst. 2024, 22, 690–704. [Google Scholar] [CrossRef]

- Automatic Realtime Monitoring Enhances Safety and Reduces Cost of Drilling Operations—eDrilling. 2024. Available online: https://www.edrilling.no/blogs/post/automatic-realtime-monitoring-enhances-safety-and-reduces-cost-of-drilling-operations (accessed on 6 October 2024).

- Cerna, G.E.P.; Hernández, J.R.C.; Herazo, J.C.M.; Castillo, A.P. Evaluation of the Overall Effectiveness (OEE) of Autonomous Transportation System (AHS) Equipment and Its Impact on Mine Design. Open Pit Mine Case Study. Procedia Comput. Sci. 2023, 224, 468–473. [Google Scholar] [CrossRef]

- Frank, M. A Step Towards the Design of Collaborative Autonomous Machines: A Study on Construction and Mining Equipment; Blekinge Institute of Technology: Karlskrona, Sweden, 2019. [Google Scholar]

- Ding, X.; Guo, J.; Ren, Z.; Deng, P. State-of-the-Art in Perception Technologies for Collaborative Robots. IEEE Sens. J. 2022, 22, 17635–17645. [Google Scholar] [CrossRef]

- Patil, S.D.; Mitra, A.; Tuggali Katarikonda, K.; Wansink, J.D. Predictive Asset Availability Optimization for Underground Trucks and Loaders in the Mining Industry. Opsearch 2021, 58, 751–772. [Google Scholar] [CrossRef]

- Matsui, K.; Adan, F.; Angeloudis, P. Decentralised Motion Planning for Autonomous Mining Haulage Trucks Using Prioritised Multi-Agent MPPI. IFAC-PapersOnLine 2024, 58, 154–161. [Google Scholar] [CrossRef]

- Ishimoto, H.; Hamada, T. Safety Concept and Architecture for Autonomous Haulage System in Mining. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction, Kitakyushu, Japan, 27–28 October 2020. [Google Scholar] [CrossRef]

- Yinka-Banjo, C.; Osunmakinde, I.O.; Bagula, A. Multi-Robot Systems: A Cooperative Behaviour and Performance Evaluations for Mine Safety Inspections. In Proceedings of the Southern African Institute for Computer Scientist and Information Technologists Annual Conference 2014 on SAICSIT 2014 Empowered by Technology, New York, NY, USA, 29 September–1 October 2014; SAICSIT ’14. pp. 241–250. [Google Scholar] [CrossRef]

- Ni, Y.; Huo, J.; Hou, Y.; Wang, J.; Guo, P. Detection of Underground Dangerous Area Based on Improving YOLOV8. Electronics 2024, 13, 623. [Google Scholar] [CrossRef]

| Type | Topic | References |

|---|---|---|

| Drilling approaches | Cable tool drilling | [5,6] |

| Auger drilling | [5,6,7] | |

| Rotary drilling | [5,6] | |

| Diamond drilling | [5,6] | |

| Directional drilling | [8] | |

| Automated mining intelligent machines | Rotary Steerable Drilling Systems | [9,10,11] |

| Longwall | [12,13,14,15] | |

| Automated hauling | [16] | |

| Charging robots | [16,17] | |

| Intelligent Rock-Drilling Jumbo and DTH Drill | [16] | |

| Sensors in automated mining | LIBS | [18,19,20] |

| LIDAR | [21,22,23,24,25] | |

| TFS | [26,27] | |

| Localization systems | Light-based localization systems | [16,28,29] |

| Daisy chaining of fiducial markers | [30,31] | |

| Magnetic induction | [21,32,33] | |

| Communication systems | WiFi | [21,24] |

| LoRaWAN | [21,34,35] | |

| Digital model | DT | [36,37] |

| Software in intelligent systems | e-Drilling’s software suite | [38,39] |

| Draco | [40,41,42] | |

| Forestall | [43,44] | |

| TIMining Aware | [44,45] | |

| Collaborative robotics | Caterpillar’s MineStar Command for Underground Systems (AHS) | [46,47,48,49] |

| EH-RemoteHeadControl v2 by Elgór-Hanses S.A. | [15] | |

| UGVs | [50] | |

| UAVs | [50,51,52,53,54] | |

| Research about intelligent mining machines | Drill piston control | [55] |

| Photogrammetry | [25,56,57,58,59] | |

| Neural networks | [60,61] | |

| VR simulation for multi-agent system action planning | [57,62] | |

| Research about intelligent mining machines | AI-assisted DTs | [63,64,65] |

| Optimized haulage scheduling using RL | [66] | |

| Controlling equipment using DRL | [67,68] | |

| Using DRL in mine production scheduling | [69] | |

| Development and research for environmental monitoring | [70,71] | |

| Monitoring of the drilling rig | [72] | |

| Intelligent control of drilling | [72] | |

| MWD and machine learning for rock monitoring | [72] | |

| AI and big data technology in ventilation systems | [72] | |

| Intelligent rock stress monitoring | [72] | |

| Quantum computing for open-pit profile optimization | [73,74,75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kokkinis, A.; Frantzis, T.; Skordis, K.; Nikolakopoulos, G.; Koustoumpardis, P. Review of Automated Operations in Drilling and Mining. Machines 2024, 12, 845. https://doi.org/10.3390/machines12120845

Kokkinis A, Frantzis T, Skordis K, Nikolakopoulos G, Koustoumpardis P. Review of Automated Operations in Drilling and Mining. Machines. 2024; 12(12):845. https://doi.org/10.3390/machines12120845

Chicago/Turabian StyleKokkinis, Athanasios, Theodore Frantzis, Konstantinos Skordis, George Nikolakopoulos, and Panagiotis Koustoumpardis. 2024. "Review of Automated Operations in Drilling and Mining" Machines 12, no. 12: 845. https://doi.org/10.3390/machines12120845

APA StyleKokkinis, A., Frantzis, T., Skordis, K., Nikolakopoulos, G., & Koustoumpardis, P. (2024). Review of Automated Operations in Drilling and Mining. Machines, 12(12), 845. https://doi.org/10.3390/machines12120845