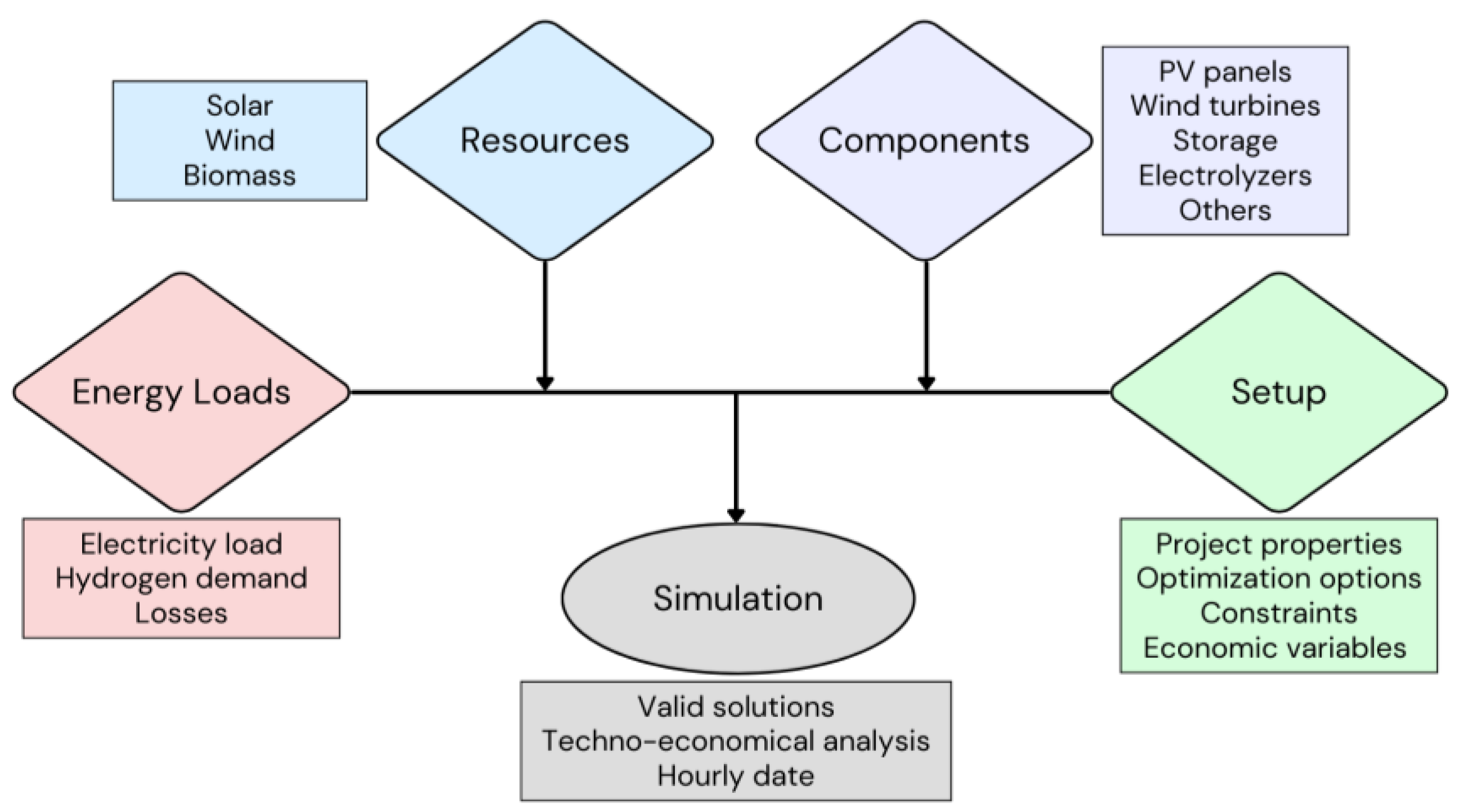

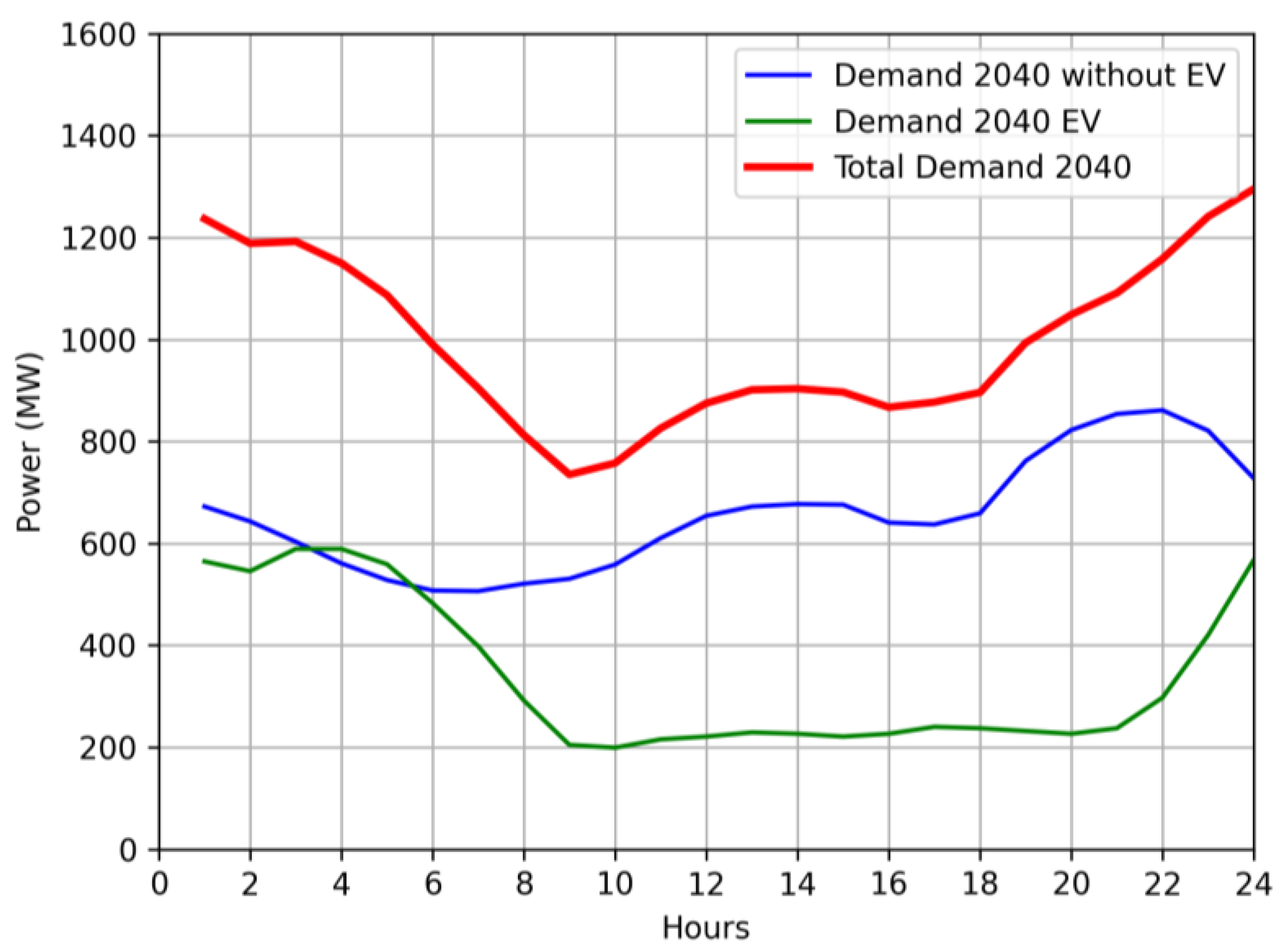

This section presents and discusses the main findings of the proposed scenario. The economic and technical aspects will be taken into account, analyzed and discussed. The system has been optimized to cover the demand entirely, both for electrical and hydrogen. To achieve this 100% demand coverage, the different available resources and generation systems, namely wind, sun and biomass, and their conditioning factors previously mentioned (maximum available capacities of solar PV and biomass mainly because of land occupation criteria) have been considered. Due to the unavoidable need to use storage technologies to manage a fully renewable system of this scale, the implementation of a significant mega-battery storage system has been needed. In other words, the power to be installed for wind, solar PV and biomass has been determined, along with the power and storage capacities of the mega-batteries and the Spanish mainland grid connection to make the system self-sufficient. Added to the dimensioning of the hydrogen production sub-system.

4.1. Technical Characteristics of the Systems

Table 5,

Table 6 and

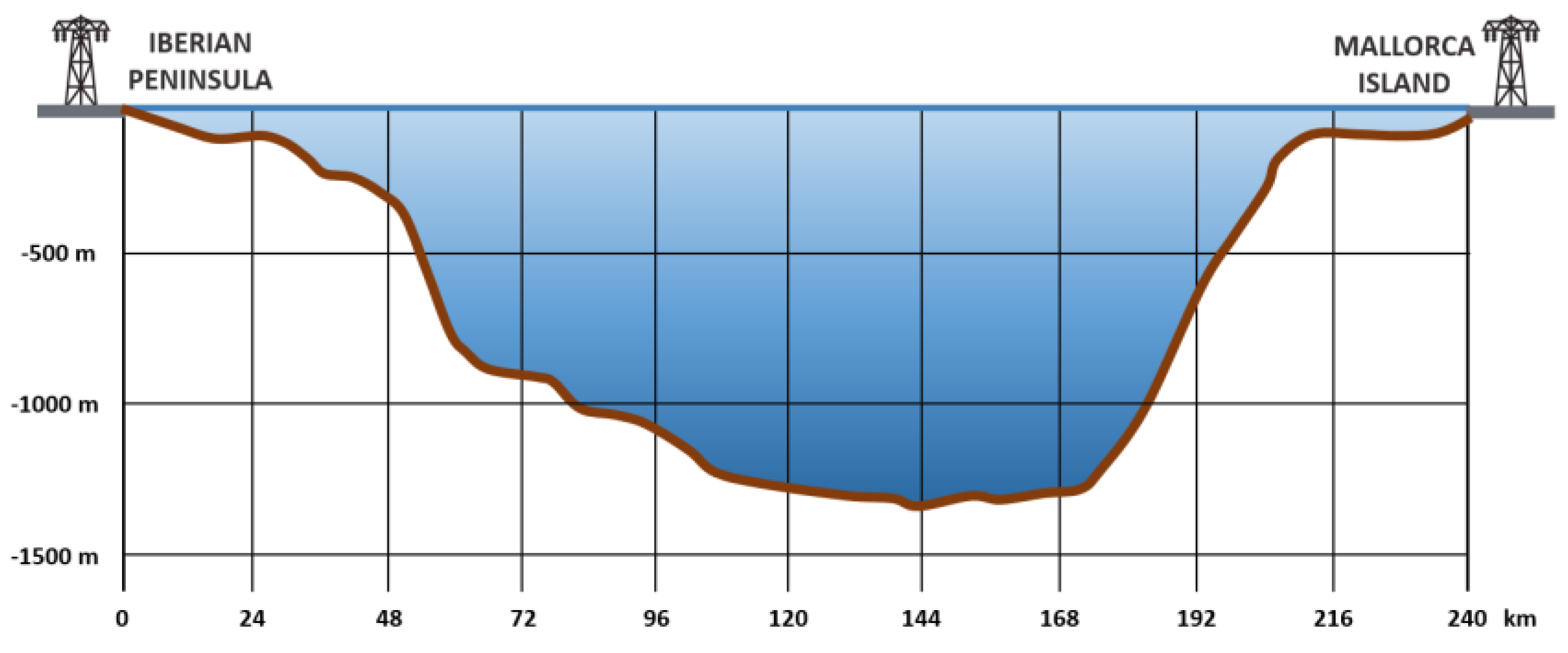

Table 7 summarize the main characteristics of the power generation, storage and hydrogen production systems proposed for the Balearic Islands. A significant aspect is that these islands have an interconnection with the mainland, which gives them greater flexibility in the implementation of fully renewable systems. As shown in

Table 5, only sources with very low GHG emissions have been used (wind, solar PV and biomass), together with exchanges with the grid. By far the largest installed power is solar PV, with more than 75% of the total (six GW of nominal capacity), followed by wind with around 15% (slightly below 1.2 GW) and lastly, gasification technology with around 7.7% (600 MW). The capacity factors of solar PV and wind power sources are high, with values quite similar to those typical of existing installations in mainland Spain, around 20% and 40%, respectively. Noteworthy is the importance of biomass, which, together with the grid and batteries, provides the necessary flexibility to the system to take advantage of the large installed capacity of solar and wind generation. This highlights the relatively low percentage of energy waste (below 9%) for a fully renewable system, especially considering that not only are all end uses of energy being covered by a GHG-free system but also by electricity generation combined with hydrogen production.

Table 6 summarizes the major characteristics of the storage system. It has been decided to only use battery storage since the islands do not have the pumping sites required to use this system, although it is true that the necessary infrastructures could be built and this resource could be used. Nevertheless, in this case, the pumping station installations would require high initial investments; it would be necessary to build from the dams, the hydraulic circuit to the power line and the rest of the installations, probably even a desalination plant to provide the necessary water for its exploitation. All this, together with the more than likely opposition to the large landscape interventions required by the population, means that given the flexibility provided by the network, together with the installed capacity of biomass and the mega-batteries, it has not been necessary to resort to the extra storage of reversible pumping. As shown in

Table 6, the total installed capacity of this technology has been about 2.64 GW with a total energy storage capacity of slightly over 21 GWh; a total of 8700 units have been installed. The system has been able to recover more than 10% of the electricity generated, which otherwise would have been impossible to use. In other words, this amount was not wasted but fed back into the grid when needed, albeit with a round-trip efficiency of 70%.

Table 7 shows the main characteristics of the hydrogen production sub-system. From the results shown in the table in

Figure 7, it can be noted that the total installed power of the electrolyzers is less than 2 GW, which has a relatively low capacity factor (19.2%). This is due to the fact that H

2 production takes place when there is excess electricity generation, i.e., given the high weight of solar generation, production takes place especially in the central hours of the day. So from the calculations performed, it has been shown that it is more convenient to oversize the H

2 production sub-system than any of the sub-systems of electricity generation and/or storage. Another aspect to consider, which has not been reflected in the table, is that the water electrolysis process produces a significant amount of oxygen as a by-product (approximately 9 kg of O

2 for each kg of H

2 produced), so this oxygen could be used in different processes. In this case, there would be more than 4.5 × 10

5 tons of O

2. Some possible applications would be, among others: sanitary, welding, oxy-cutting, and replacement of air in wastewater aeration. Therefore, it is an extra benefit obtained from this by-product that could be considered, although this is beyond the scope of this work since it would be necessary to consider the cost associated with this infrastructure (approval, storage, distribution, etc.).

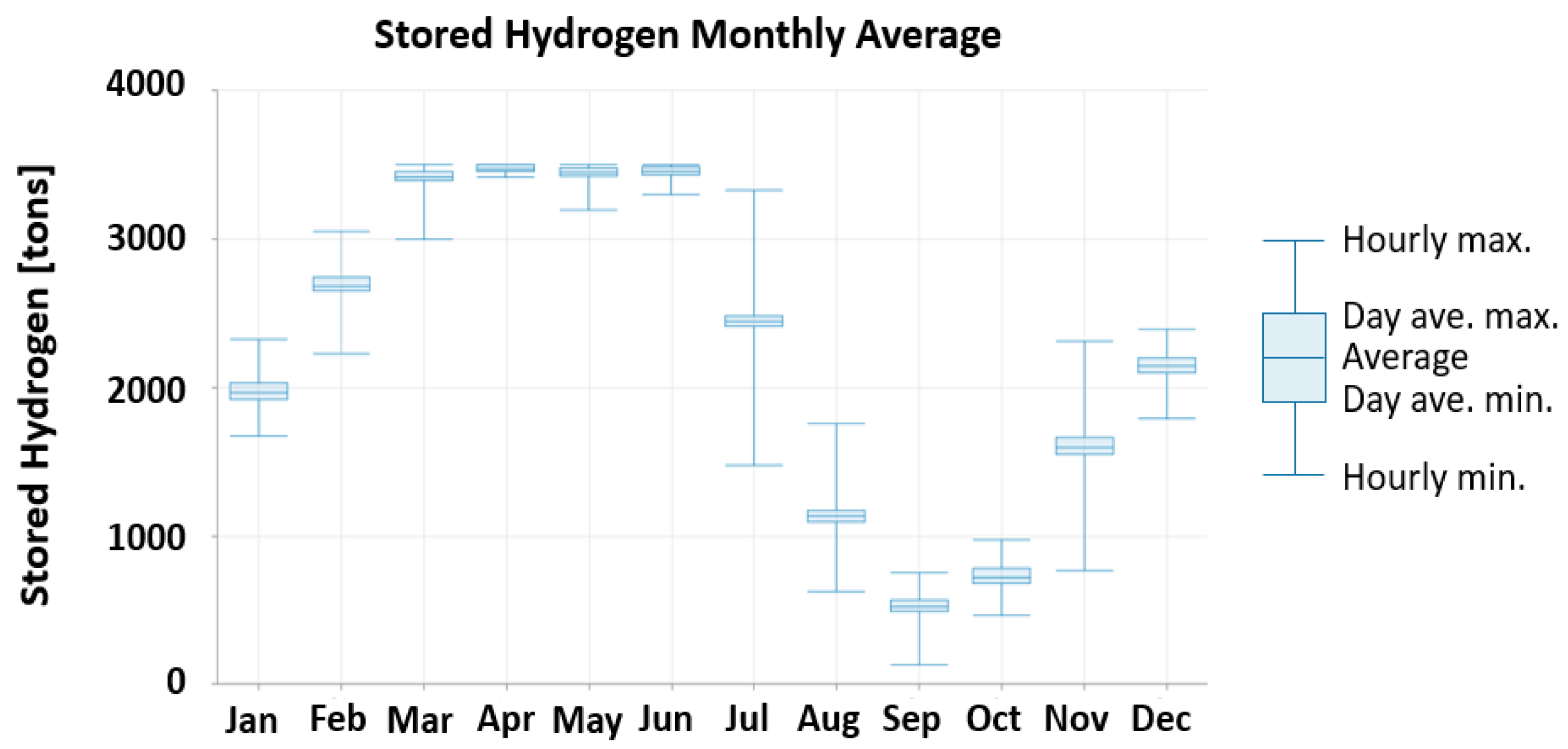

To provide an overview of the overall performance of the proposed system,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12 show the behavior of the different generation sources and the two consumptions. The first two provide the general view of the performance of the generation sources (in fact, generation, re-feed of the storage system and grid purchases) and the electric consumptions (charge of batteries, sales to the grid and electrolyzers consumption).

Figure 9 displays the monthly state of charge of the batteries. While

Figure 11 shows the performance of the entire system for four typical days of the year. Finally,

Figure 10 and

Figure 12 focus on the behavior of the hydrogen production sub-system, showing the monthly evolution of the hydrogen reservoir inventory, while the last figure displays the performance of the hydrogen sub-system for typical winter and summer days.

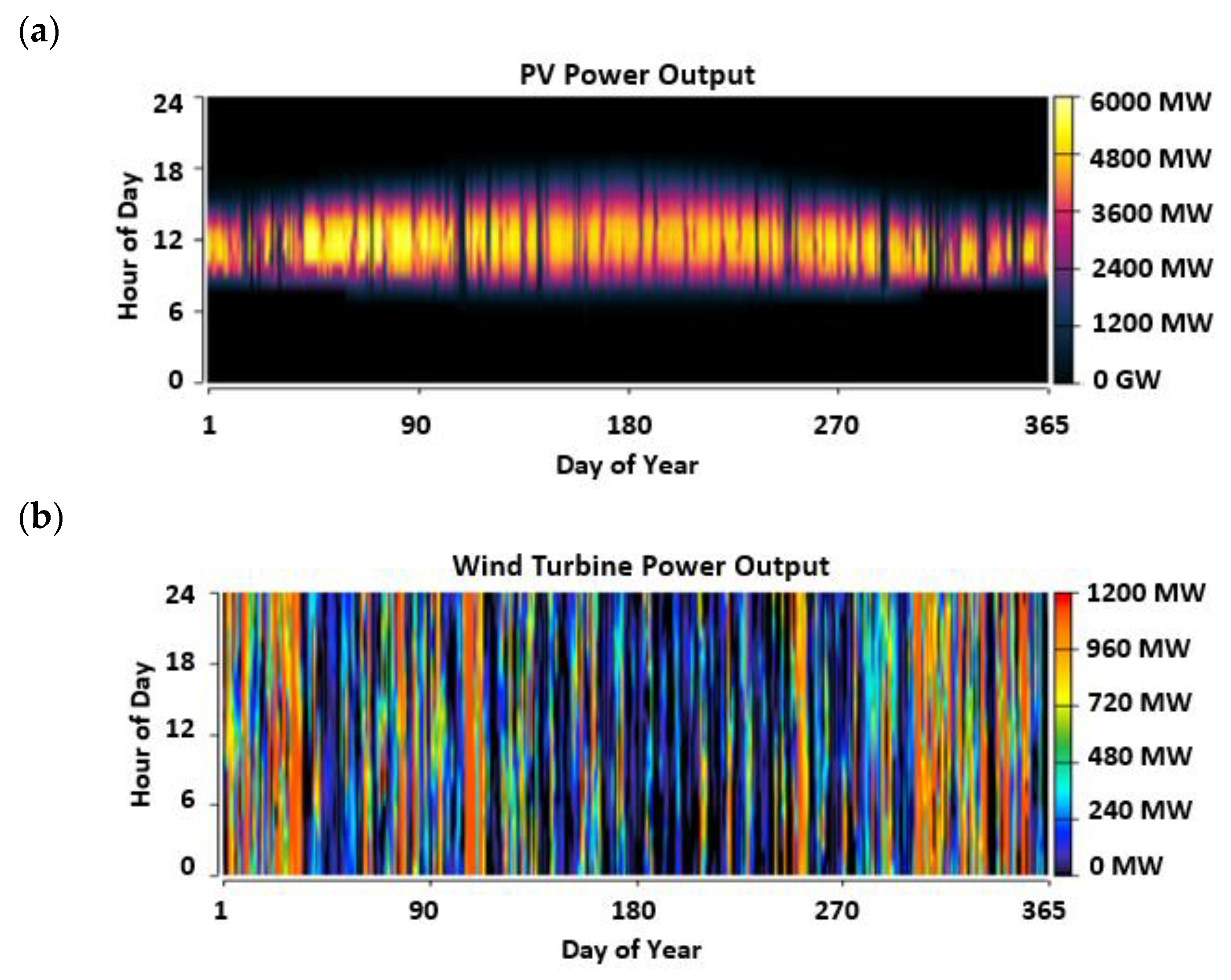

Particularly,

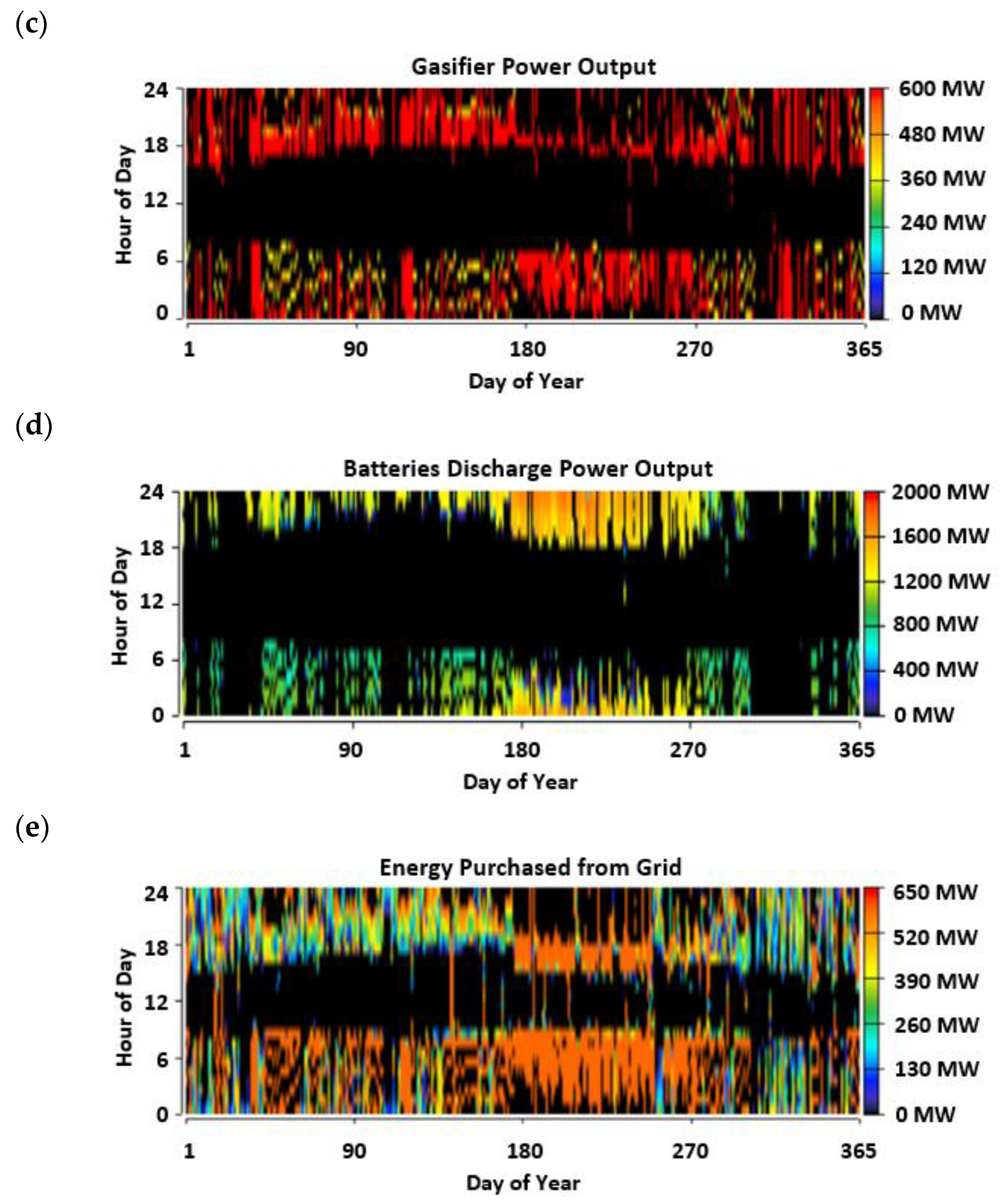

Figure 7 and

Figure 8 show the annual representation of the behavior of the generation and consumption components.

Figure 7 shows solar photovoltaic, wind and biomass electricity generation, also including the contributions of both the general grid and the electricity refeed from the mega-batteries. As shown in the first figure, the solar resource has its maximum contribution during the summer months (

Figure 7a); between the months of April to September approximately, there is greater insolation and more daylight hours, therefore, the power and total energy generated are higher. As for wind power generation, as shown in

Figure 7b, there is very high variability and unpredictability, although the highest contributions occur during the winter months, while the months between June and September (days 150–280) have the lowest values, but in any case, there are many time periods in which the wind generation is zero or almost zero. Then, the combination of wind and sun profiles makes nights the critical time period for the overall performance of the system. On the one hand, solar generation (more than 60% of the energy generated) is obviously null during the night, which means that other sub-systems must cover this deficiency (i.e., wind, biomass, batteries and/or grid). In addition, as mentioned above, wind generation (the second most important source of generation, accounting for almost 20% of total generation) is highly unpredictable, with long periods of wind shortage, with a greater degree of severity in the summer months. All this means that during most nights, especially in the summer months, it is necessary to have a very strong backup from other sources to solve this problem.

Figure 7d shows the battery performance diagram, where it can be seen how, especially in the summer months, the batteries are the main source of supply for the demand during the first hours of the night, reaching their complete emptying during most of the time after midnight approximately;

Figure 9 shows how their charge reaches zero during those summer months. Therefore, as shown in

Figure 7c,e, it is at these times when the biomass gasifiers and purchases from the peninsular grid are most important. In fact, in the summer months (mainly between days 180 to 270), from approximately midnight onwards, both are at their maximum power until 7 a.m. (solar time), which is when solar generation begins to make an important contribution, given that it has already been dawn for a couple of hours.

As for the recharge of the battery system (

Figure 8a), it should be noted that, in addition to what happened in its discharge (

Figure 7d, where it was discharged in the early hours of the night), this occurs mainly in the central hours of the day (produced with excess energy, especially from the sun). Additionally, as the batteries become essential in the summer months (

Figure 7d), it is then when during the night they suffer deep discharges, and during the day they are recharged (

Figure 8a) so that on many occasions, they are not fully charged (as shown in

Figure 9). This situation means that on most days, it is necessary to resort to other systems in a very significant way (biomass and purchase from the peninsular grid).

Figure 8a represents the charge power input, while

Figure 8b shows the sales to the peninsular grid, where it can be seen that in the summer months, practically no energy is sold at all. While in the rest of the year, there are significant sales, especially during the spring, when solar and wind generation are very important. It should also be noted that purchases from the grid are made throughout the year (

Figure 7e) but become more significant in the summer months when the system presents its most critical performance intervals (purchase during long periods of time of the maximum 650 MW). Thus, the final balance with the peninsular grid shows a deficit value, with purchases amounting to 11.7% of total energy consumed while sales amount to slightly less than 5%.

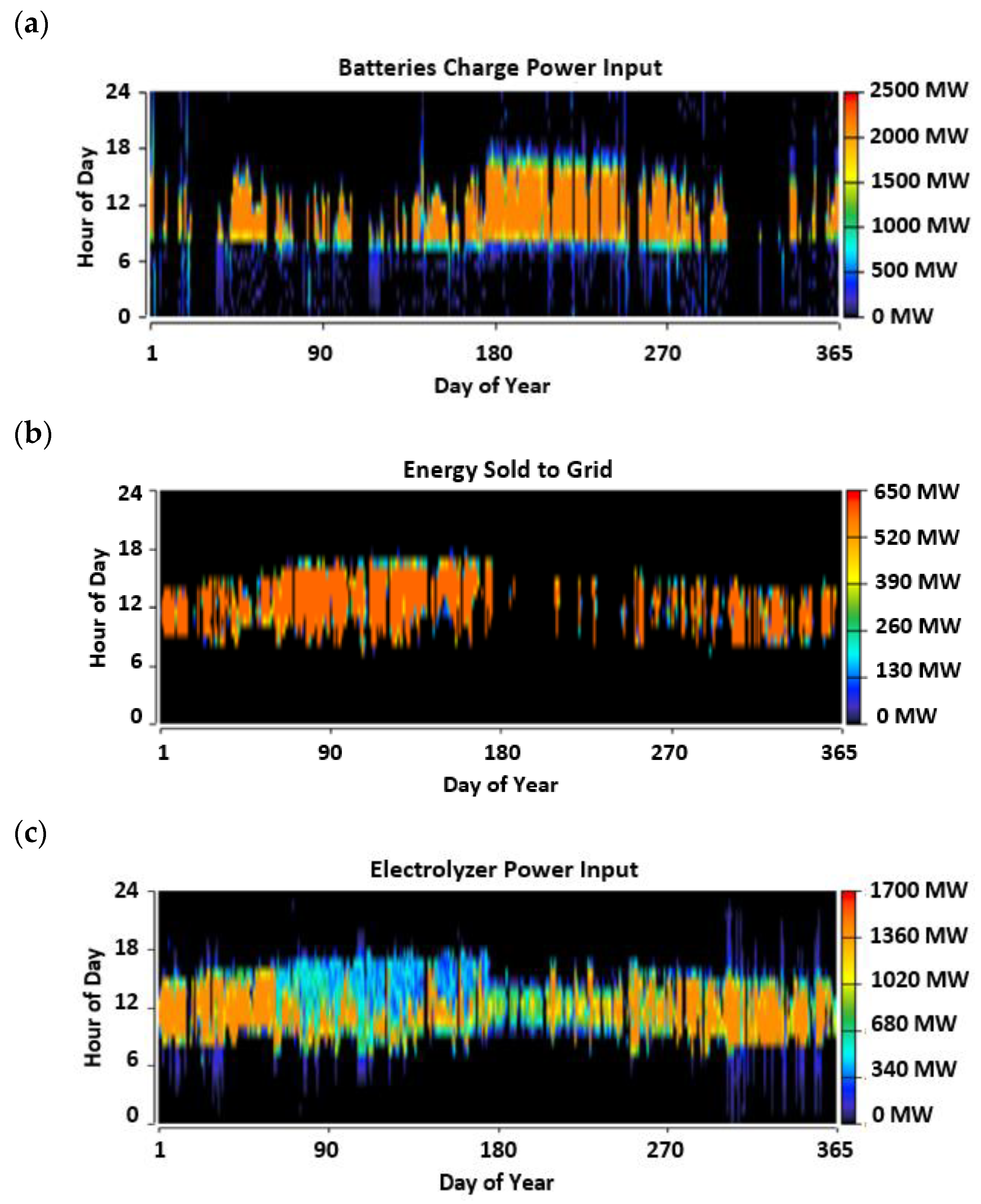

Analyzing the performance of the electrolyzers, as shown in

Figure 8c, sway that it is also during the summer months when the critical performance of this sub-system is the highest. So that during these summer months, the hydrogen storage tank is progressively emptied (

Figure 10); as shown in

Figure 8c, the power and time of use of the electrolyzers are much lower than in the winter months. So the hydrogen tank begins its progressive emptying in April, reaching its minimum level in September; it is filled again progressively until March, and it remains practically full until July, when it begins to empty again. As shown in the figure, only the summer months will be critical since there is not enough energy available for the production of the hydrogen demanded, and the excess stored during the rest of the year must be used.

Regarding

Figure 9 and

Figure 10, it should be noted that the behavior of the charging and discharging cycles of the batteries and the filling of the hydrogen tanks show many similarities. As the system, in general, has its critical performance fundamentally at the end of the summer months, it is then when both systems present their minimum values. While from the beginning of autumn, both systems begin to present increasing values of battery charging and hydrogen tank filling until mid to late winter, when they reach their maximum values. They remain at these values until late summer, when the progressive discharge or emptying begins again, respectively, so that a new annual cycle of similar characteristics would be carried out again.

To analyze the performance of the system as a whole in a more detailed way,

Figure 11 shows the hourly values for three typical consecutive days for both summer and winter months. As can be seen in this figure, the average daily electricity demand in summer is higher than in winter. However, in spite of this, for the central hours of typical summer days (

Figure 11a), due to the higher contribution of solar PV (due to higher average irradiation and more hours of sunshine and the high installed capacity, 6 GW), the system does not present problems to provide the energy required by the loads. However, the difficulties in covering the supply start in the case of low or no wind (quite the usual case in summer, as shown in

Figure 7a). In this case, the system must resort to the use of the batteries practically at their maximum power, as well as to the use of the gasification system and the purchase from the grid. In fact, in the last two nights, the batteries are exhausted, the first one around 5:30 in the morning and the second one shortly after 1:00 a.m., having to resort in both cases to the use of the gasifiers and purchases from the peninsular grid, both at their maximum power (600 and 650 MW, respectively). While for typical winter days (

Figure 11b), as long as there is a significant contribution from wind generation, the system does not need to resort to any of the other systems (storage, gasification, grid purchases), while in the absence of wind, the system must resort to these systems, but in this case, to a lesser extent due to the lower load requirements and the fact that the battery systems are in a higher degree of load (

Figure 9). Thus, the high power and capacity of the batteries mean that the system does not present major problems, although it does resort to the use of biomass and purchase from the grid, but to a much lesser extent than in the case of typical summer days.

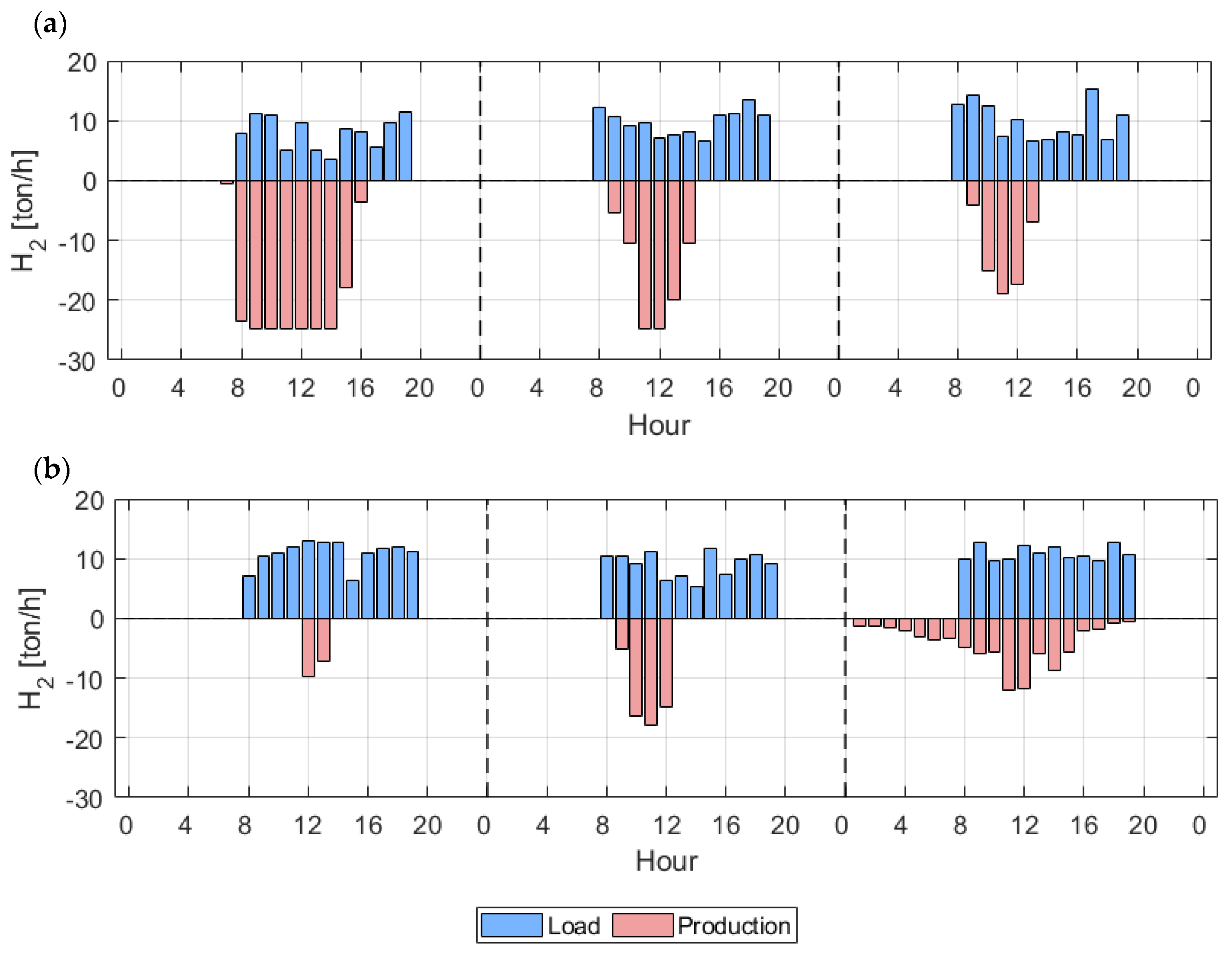

Similarly, for a more detailed analysis of the hydrogen production system,

Figure 12 shows the behavior of this hydrogen production and consumption system during three consecutive “typical” summer and winter days. These days correspond to those shown in the behavior of the system (

Figure 11). The graphs in the previous figure show a constant H

2 demand but with some variability (a random hourly variability of up to 20% and up to 10% between consecutive days). On typical winter days (

Figure 12b), as the H

2 reservoirs are practically full (

Figure 10), the system produces at maximum capacity for several hours so that when the reservoir is completely full again, the system only has to cover approximately current H

2 demand, leaving hydrogen production until the next day. However, on a typical winter day (

Figure 12a), the system works at its maximum power during the central hours of the day, while surplus electricity is produced (the first day when there is wind). However, from the second day on, there are practically no surpluses available, so the system is not able to produce the hydrogen needed to cover the demand for it, so it has to resort to part of the reserves, emptying the storage tank progressively throughout these months (as discussed above and shown in

Figure 10).

It should be noted that, contrary to what one might intuitively think, the late summer months are the most critical for the system. As mentioned above and corroborated in the figures analyzed, all months except the summer months (especially the spring months) have an electricity generation and hydrogen production capacity higher than the aggregate demands. Thus, except in the summer months, when the system has to resort to the maximum use of biomass gasification generation, the storage system and the purchase from the mainland grid, in the rest of the year, the system has no major difficulties in covering the electricity demand, not having to resort to these systems on a continuous basis. This need is mainly due to the existence of long periods of time with little or no wind resources.

4.2. Economic Analysis

Table 8 presents the main variables associated with a financial analysis of the proposed system. It is important to note that the total costs are directly influenced by the installed capacity of each system, thus establishing a direct relationship with the information presented in

Table 5, which outlines the electrical generation and power of each system. The total capital cost necessary to carry out the installation of the entire electric and hydrogen system is 27,306 million euro. Of which the initial investment accounts for almost 75%, while the Operation and Maintenance costs of the different sub-systems account for about 23%, while finally, the replacement costs account for less than 2% since only the replacement of the hydrogen system is foreseen during the life of the project, as the electrolyzers used have about 100,000 h of operation.

Breaking down the total costs by sub-systems, the cost of solar photovoltaic generation is almost 30%, followed by the cost of mega-batteries with almost 17%, while the wind and hydrogen sub-systems both have around 14%, being slightly higher than the wind sub-system, followed by the gasification sub-system with almost 13%. The two sub-systems related to electricity transmission, i.e., interconnections and upgrading of the internal transmission grid, with almost 7% and 5%, respectively, occupy the two lowest positions. As for the capital costs, which is the contribution with the highest weight by far, the order of importance in the contributions is similar, although slightly changing the weights; in this case, the solar photovoltaic system is the largest contributor with around 39%, the mega-batteries also increase their weight with almost 20%, the wind sub-system has a weight of almost 14%, while hydrogen, gasifier and interconnection have a cost of around 10%, relegating to the last position the network upgrades almost 2%. The Operation and Maintenance costs present some remarkable aspects; the solar photovoltaic sub-system and interconnections present very low costs, while at the other extreme is the gasification sub-system with almost 25%, close to the wind generation sub-system, with almost 20%, followed by the internal distribution network and mega-batteries with almost 15% and just over 11%, respectively.

In the analysis of the relationship between capital costs versus operating costs over the lifetime of the system, there are some situations to highlight. The costs of the solar sub-system come almost exclusively from its installation (more than 95%); something similar occurs in the interconnections and mega-batteries (with about 85%), wind also presents a high value (about 70%), while the hydrogen production and biomass gasification sub-systems present proportions of approximately 50% in capital and Operation and Maintenance costs during the useful life. Finally, the Operation and Maintenance of the internal network of the islands has a weight much higher than the initial investment (almost 75%–25%).

The hydrogen system analyzed in this study considers the different costs from production to distribution at the final consumption points,

Table 9. Thus, the system consists of several components, and the referenced table shows a breakdown of the different contributions involved in hydrogen production. The largest contribution comes from the electrolyzers, accounting for about 40% of the total system costs, followed by the costs of the storage system and the compression it undergoes, with about 28%. The following contributions are those of the second compression and transportation, both with similar contributions of 15% and 13%, respectively. Finally, about 3% corresponds to the water demand of the electrolyzers; this water comes from seawater desalination, given that the island is deficient in water resources.

Table 10 summarizes the LCOE costs of the different technologies; these values, together with their contribution in percentage, provide the final average LCOE of the system. The average LCOE value is 13.75 c€/kWh, which is relatively low for a system of these characteristics since it is a system with a connection to a central grid but only capable of covering around 34% of the system’s peak power (peak demand power of 1915 MW compared to the 650 MW of maximum power of the interconnection with the mainland). In addition, the system covers all energy end-uses, i.e., electricity generation, and part of this is used for hydrogen production. As shown in the table, all generation systems have assumable LCOEs, being the exchanges with the mainland a very important contribution to providing the mandatory system stability of these semi-isolated regions of the grid. Solar and wind generation present very competitive values, but due to their variability and unpredictability, they introduce an extra need for reliable systems. Therefore, the system requires, in addition to the aforementioned continental and inter-island interconnections, a large storage system; in this case, a mega-batteries sub-system has been selected (

Table 6). In addition, there is quite a high biomass power (acting as a base generation system or backup), so it is available for any contingency. Although the cost of this system is high due, on the one hand, to its occasional use and, on the other hand, to the intrinsic difficulties existing in the islands for the exploitation of these resources, but is offset by the extra reliability it brings to the system. Finally, the hydrogen system also has a high cost, but it should be remembered that this system provides an energy vector in those energy end uses where electricity is not a good option. Therefore, despite its high cost, it is considered the most suitable option to cover these energy uses. The use of hydrogen as an energy vector for non-electrification uses is probably the most realistic option for the future (Deloitte Monitor [

19]). This report points out that decarbonizing these non-electrifiable uses would hardly imply a cost similar to decarbonizing the rest of the previous uses.

To conclude this economic analysis,

Table 11 shows the main economic data and indicators of the proposed system. A reference value of 150 €/MWh for the grid electricity cost has been chosen, this value comes from typical values for the Spanish Islands during recent years, but higher prices are expected in the coming years; in fact, last year, the electricity costs in the Balearic Islands exceeded 200 €/MWh many times [

25]. Consequently, this price range has been considered to make two forecasts of the main economic variables related to the profitability of the system. It is important to highlight that despite the strong investments of the implemented systems, the return on investment periods and the payback are relatively low. Therefore, the selected system is considered to be feasible and profitable, obviously much better in the case of high electricity costs.