Motor Current-Based Degradation Modeling for Tool Wear Hybrid Prognostics in Turning Process

Abstract

1. Introduction

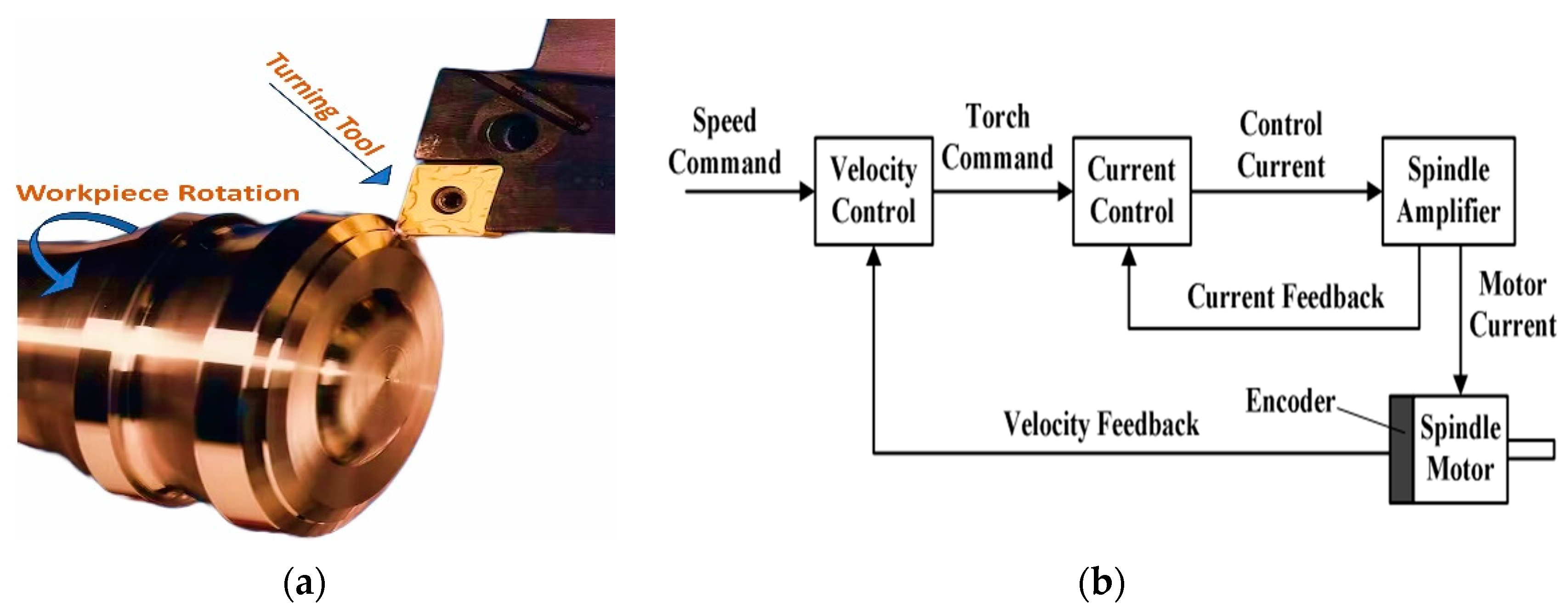

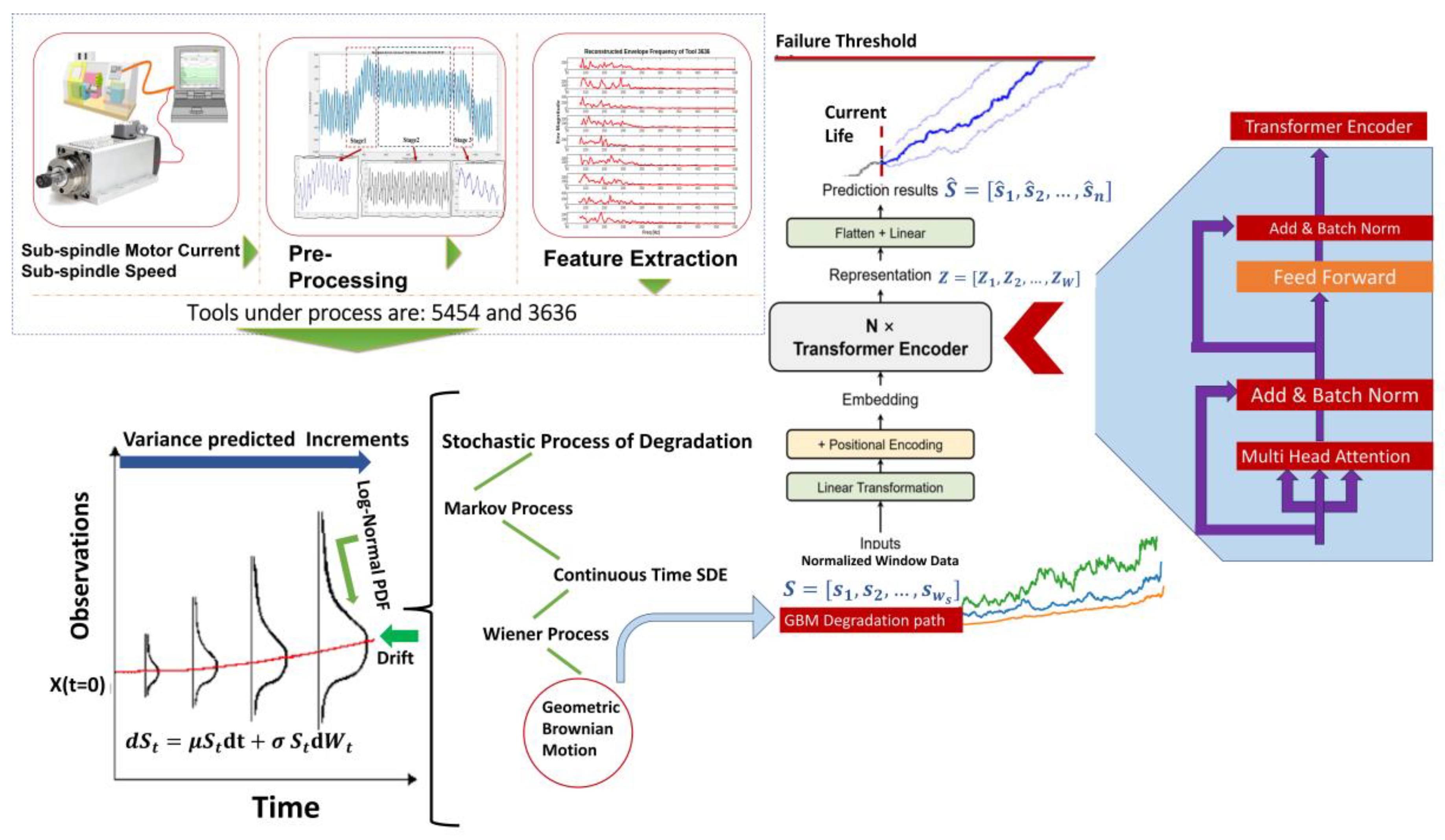

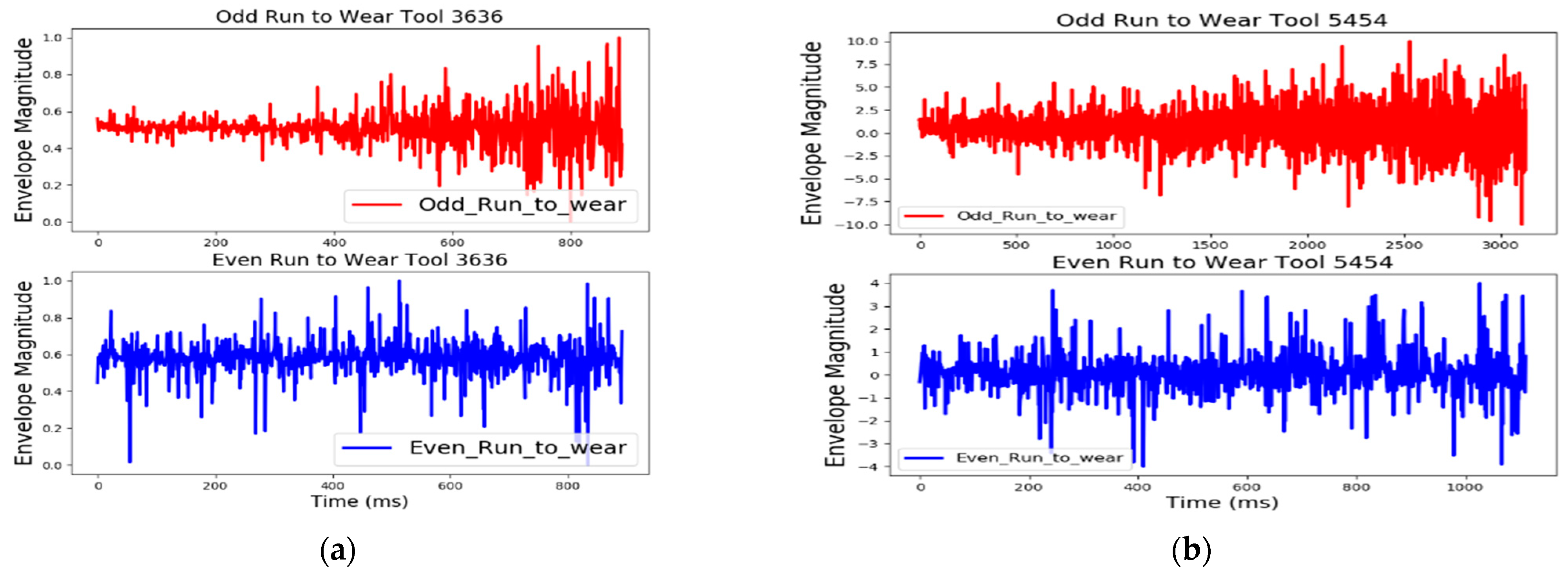

2. Definition of a Tool Wear Model Based on the Motor System

3. Methodologies

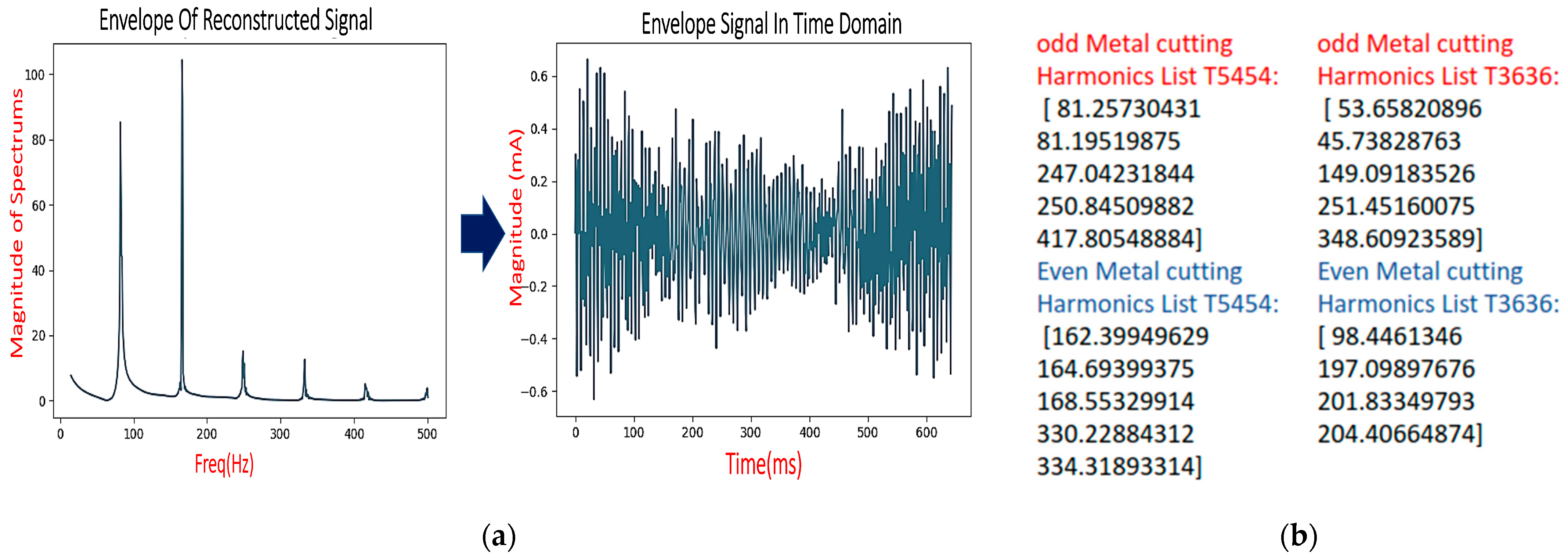

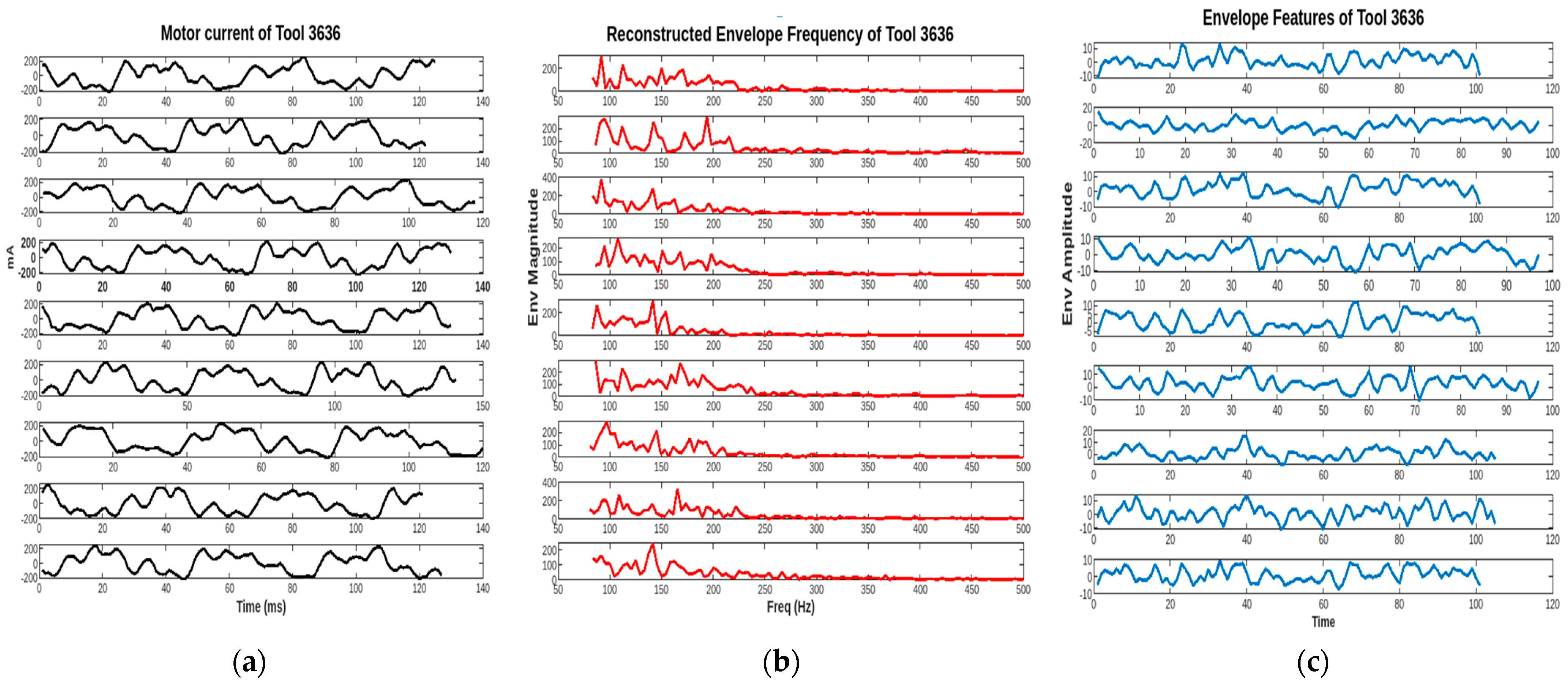

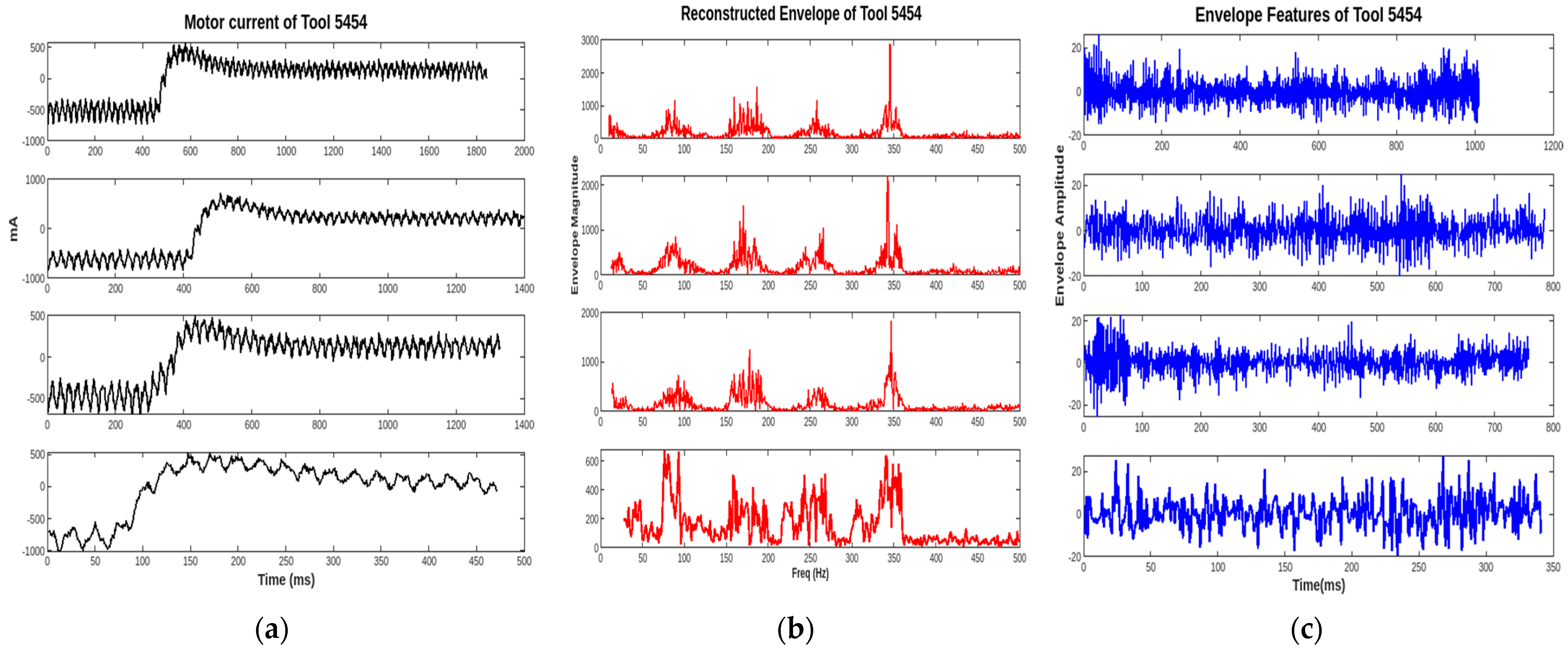

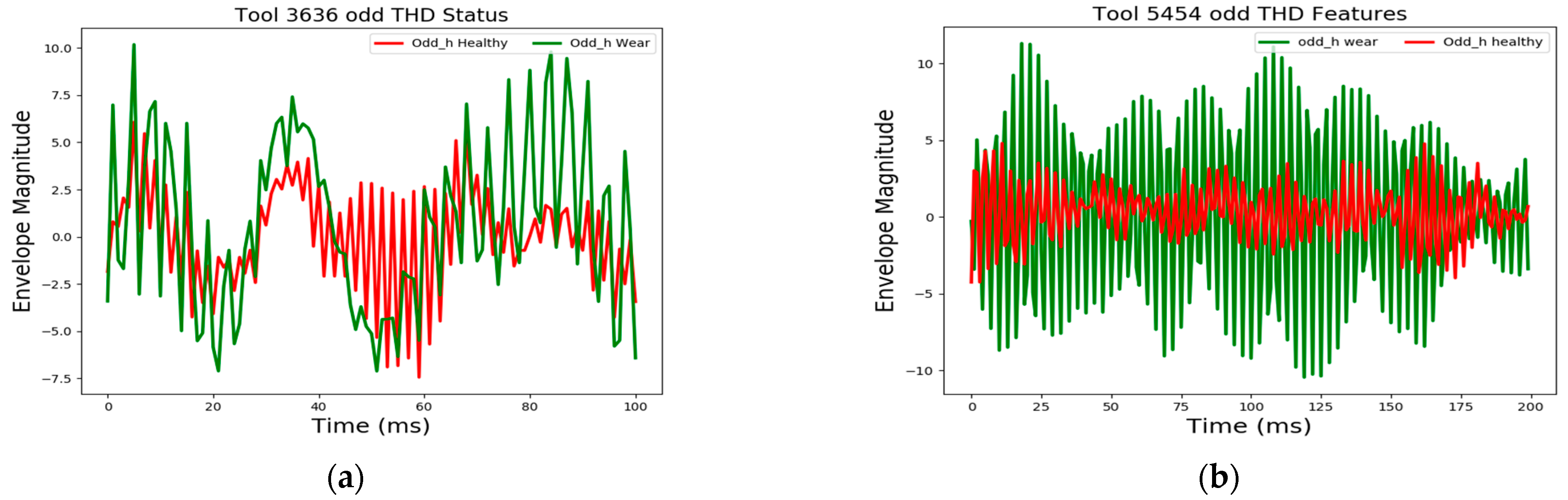

3.1. Feature Extraction

3.1.1. Specific Challenges

- Tool Cutting Frequency

- b.

- Nature of Industrial Data

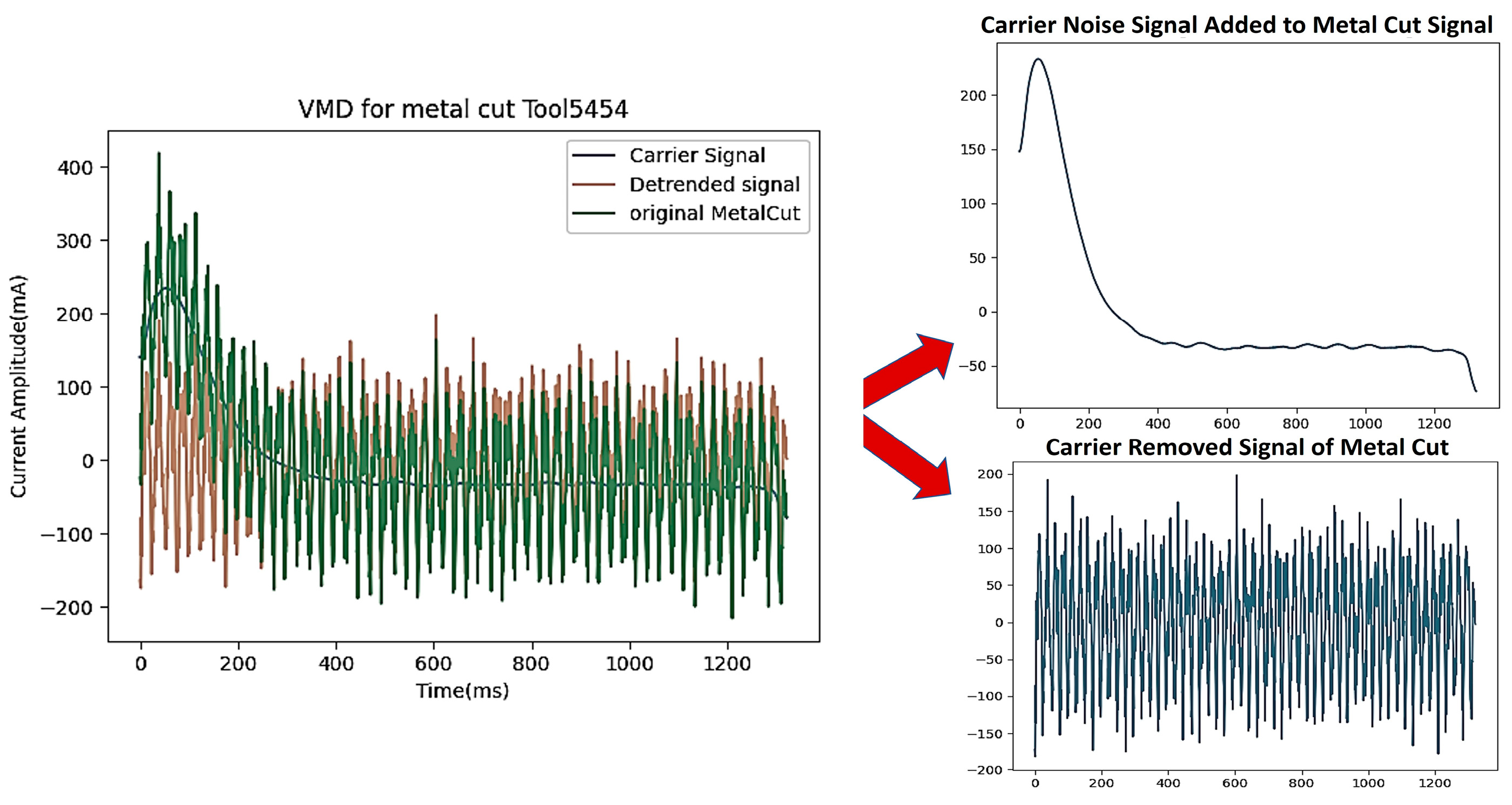

3.1.2. Variational Mode Decomposition

3.1.3. Empirical Envelope Amplitude and Spectrum Analysis

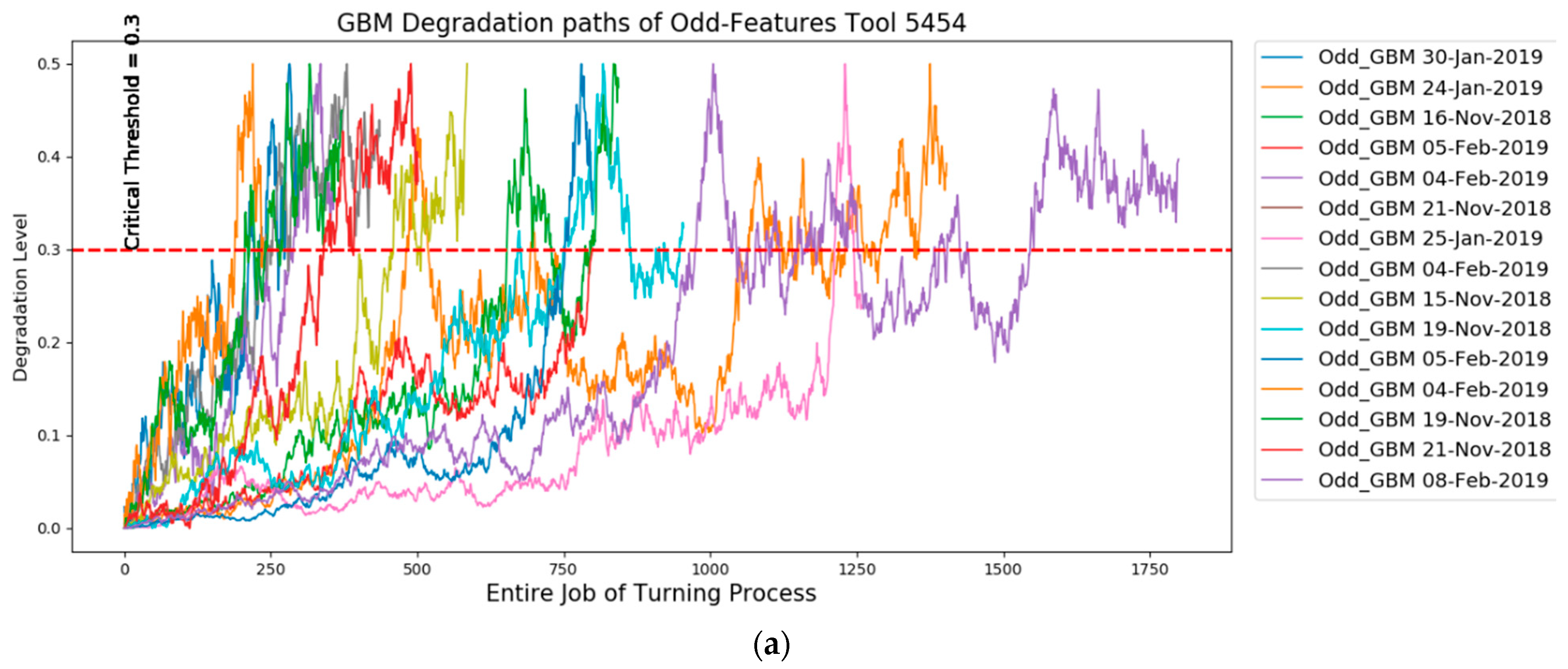

3.2. Degradation Modeling and Prognostics

3.2.1. GBM in Brief

3.2.2. The Time Series Transformer Prediction

4. Experimental Setup and Results

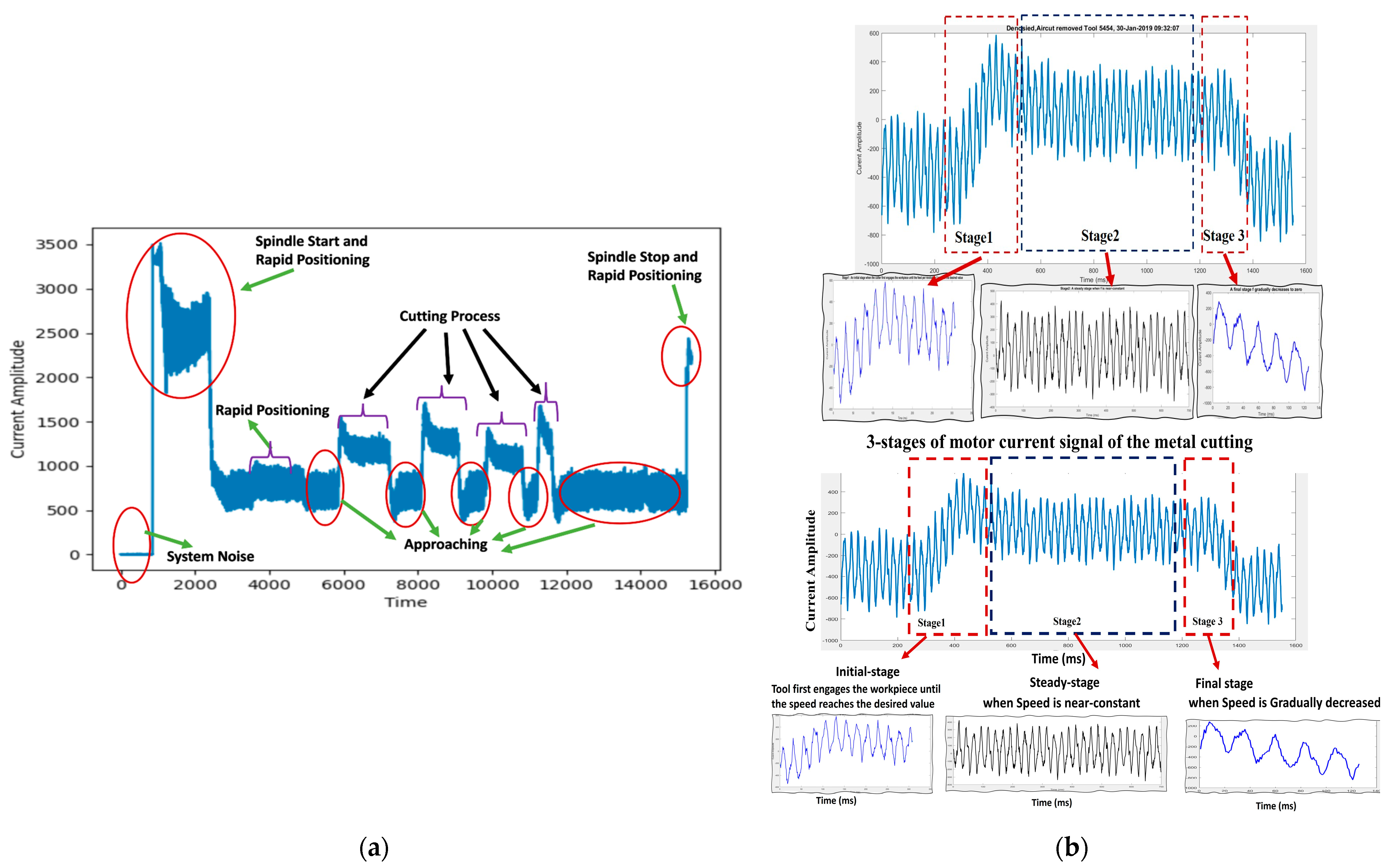

Data Preprocessing

- (a)

- Active Cutting Movement: So-called cutting process, this segment refers to the period when the cutting tool is actively engaged with the workpiece, resulting in material removal.

- (b)

- Passive Cutting Movement: So-called approaching process during this phase, the spindle rotates at the same speed, and the tool turret is distanced from the workpiece. It can be considered an “Air Cut” signal, where the cutting tool is not in contact with the workpiece.

- (c)

- System Noise: In the absence of active positioning and the turning of the sub-spindle, certain noise components may be present in the signal. This noise can originate from various sources, such as cables or sensors, and may introduce unwanted variations in the signal.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Y.; Sun, W. Tool Wear Condition Monitoring in Milling Process Based on Current Sensors. IEEE Access 2020, 8, 95491–95502. [Google Scholar] [CrossRef]

- Trimantec. Machining Processes Overview. Available online: https://trimantec.com/blogs/t/machining-processes-overview (accessed on 14 August 2020).

- Gajate, A.; Haber, R.; del Toro, R.; Vega, P.; Bustillo, A. Tool wear monitoring using neuro-fuzzy techniques: A comparative study in a turning process. J. Intell. Manuf. 2012, 23, 869–882. [Google Scholar]

- Bagga, P.; Makhesana, M.; Patel, H.; Patel, K. Indirect method of tool wear measurement and prediction using ANN network in machining process. Mater. Today Proc. 2021, 44, 1549–1554. [Google Scholar] [CrossRef]

- Jaen-Cuellar, A.Y.; Osornio-Ríos, R.A.; Trejo-Hernández, M.; Zamudio-Ramírez, I.; Díaz-Saldaña, G.; Pacheco-Guerrero, J.P.; Antonino-Daviu, J.A. System for Tool-Wear Condition Monitoring in CNC Machines under Variations of Cutting Parameter Based on Fusion Stray Flux-Current Processing. Sensors 2021, 21, 8431. [Google Scholar] [CrossRef] [PubMed]

- Aghazadeh, F.; Tahan, A.; Thomas, M. Tool condition monitoring using spectral subtraction and convolutional neural networks in milling process. Int. J. Adv. Manuf. Technol. 2018, 98, 3217–3227. [Google Scholar] [CrossRef]

- lvarez-Alcón, M.; López de Lacalle, L.N.; Fernández-Zacarías, F. Multiple sensor monitoring of CFRP drilling to define cutting parameters sensitivity on surface roughness, cylindricity and diameter. Materials 2020, 13, 2796. [Google Scholar] [CrossRef] [PubMed]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2020, 21, 108. [Google Scholar] [CrossRef]

- Del Olmo, A.; De Lacalle, L.L.; De Pissón, G.M.; Pérez-Salinas, C.; Ealo, J.A.; Sastoque, L.; Fernandes, M.H. Tool wear monitoring of high-speed broaching process with carbide tools to reduce production errors. Mech. Syst. Signal Process. 2022, 172, 109003. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of signal behaviors for sensor fusion with tool condition monitoring system in turning. Measurement 2021, 173, 108582. [Google Scholar] [CrossRef]

- Akbari, A.; Danesh, M.; Khalili, K. A method based on spindle motor current harmonic distortion measurements for tool wear monitoring. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 5049–5055. [Google Scholar] [CrossRef]

- von Hahn, T.; Mechefske, C.K. Machine Learning in CNC Machining: Best Practices. Machines 2022, 10, 1233. [Google Scholar]

- Repo, J.; Wretland, A.; Beno, T.; Tu, J. In-Process Tool Wear Detection Using Internal Encoder Signals for Unmanned Robust Machining. High Speed Mach. 2016, 2, 37–50. [Google Scholar]

- Yuan, J.; Liu, L.; Yang, Z.; Zhang, Y. Tool Wear Condition Monitoring by Combining Variational Mode Decomposition and Ensemble Learning. Sensors 2020, 20, 6113. [Google Scholar] [CrossRef]

- Vanus, J.; Kubicek, J.; Vilimek, D.; Penhaker, M.; Bilik, P. A innovative wavelet transformation method optimization in the noise-canceling application within intelligent building occupancy detection monitoring. Heliyon 2023, 9, e16114. [Google Scholar] [CrossRef] [PubMed]

- Bombiński, S.; Błażejak, K.; Nejman, M.; Jemielniak, K. Sensor signal segmentation for tool condition monitoring. Procedia CIRP 2016, 46, 155–160. [Google Scholar] [CrossRef]

- Jemielniak, K. Contemporary challenges in tool condition monitoring. J. Mach. Eng. 2019, 19, 48–61. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, J.; Obaid, A.J.; Patyal, V. Tool-condition Monitoring in turning process of Fe-0.75 Mn-0.51 C steel with coated metal carbide inserts using multi-Sensor fusion strategy: A statistical analysis based ingenious approach. J. Green Eng. 2021, 11, 2998–3013. [Google Scholar]

- Osornio-Rios, R.A.; Zamudio-Ramírez, I.; Jaen-Cuellar, A.Y.; Antonino-Daviu, J.; Dunai, L. Data Fusion System for Electric Motors Condition Monitoring: An Innovative Solution. IEEE Ind. Electron. Mag. 2023, 2–14. [Google Scholar] [CrossRef]

- Zamudio-Ramirez, I.; Antonino-Daviu, J.A.; Trejo-Hernandez, M.; Osornio-Rios, R.A.A. Cutting Tool Wear Monitoring in CNC Machines Based in Spindle-Motor Stray Flux Signals. IEEE Trans. Ind. Inform. 2020, 18, 3267–3275. [Google Scholar] [CrossRef]

- Tarng, Y.; Lee, B. Amplitude demodulation of the induction motor current for the tool breakage detection in drilling operations. Robot. Comput. Manuf. 1999, 15, 313–318. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, D.; Zuo, M.J. Planetary gearbox fault diagnosis via joint amplitude and frequency demodulation analysis based on variational mode decomposition. Appl. Sci. 2017, 7, 775. [Google Scholar] [CrossRef]

- An, X.; Zeng, H.; Li, C. Envelope demodulation based on variational mode decomposition for gear fault diagnosis. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2017, 231, 864–870. [Google Scholar] [CrossRef]

- Al-Greer, M.; Bashir, I.; El-Dalahmeh, M.A.; Demirel, A.; Keysan, O. Autonomous Faults Detection and Diagnosis of Permanent Magnet Synchronous Motors Using Combined Variational Mode Decomposition Plus Hilbert-Huang Transform and Convolution Neural Network; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Kim, D. An applicable predictive maintenance framework for the absence of run-to-failure data. Appl. Sci. 2021, 11, 5180. [Google Scholar] [CrossRef]

- Zhang, C.; Hong, G.S.; Xu, H.; Tan, K.C.; Zhou, J.H.; Chan, H.L.; Li, H. A data-driven prognostics framework for tool remaining useful life estimation in tool condition monitoring. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation, Limassol, Cyprus, 12–15 September 2017; pp. 1–8. [Google Scholar]

- Niu, G. Data-Driven Technology for Engineering Systems Health Management; Springer: Singapore, 2017; Volume 10, pp. 978–981. [Google Scholar]

- Tinga, T.; Loendersloot, R. Physical Model-Based Prognostics and Health Monitoring to Enable Predictive Maintenance. In Predictive Maintenance in Dynamic Systems: Advanced Methods, Decision Support Tools and Real-World Applications; Springer: Cham, Switzerland, 2019; pp. 313–353. [Google Scholar]

- Deng, R.; Chang, B.; Brubaker, M.A.; Mori, G.; Lehrmann, A. Modeling continuous stochastic processes with dynamic normalizing flows. Adv. Neural Inf. Process. Syst. 2020, 33, 7805–7815. [Google Scholar]

- Li, Q.; Ma, Z.; Li, H.; Liu, X.; Guan, X.; Tian, P. Remaining useful life prediction of mechanical system based on performance evaluation and geometric fractional Lévy stable motion with adaptive nonlinear drift. Mech. Syst. Signal Process. 2023, 184, 109679. [Google Scholar] [CrossRef]

- JDMD Editorial Office; Gebraeel, N.; Lei, Y.; Li, N.; Si, X.; Zio, E. Prognostics and Remaining Useful Life Prediction of Machinery: Advances, Opportunities and Challenges. J. Dyn. Monit. Diagn. 2023, 2, 1–12. [Google Scholar]

- Pang, Z.; Li, T.; Pei, H.; Si, X. A condition-based prognostic approach for age- and state-dependent partially observable nonlinear degrading system. Reliab. Eng. Syst. Saf. 2023, 230, 108854. [Google Scholar] [CrossRef]

- Huang, Y.; Tang, Y.; VanZwieten, J. Prognostics with variational autoencoder by generative adversarial learning. IEEE Trans. Ind. Electron. 2021, 69, 856–867. [Google Scholar] [CrossRef]

- Zemouri, R.; Levesque, M.; Boucher, E.; Kirouac, M.; Lafleur, F.; Bernier, S.; Merkhouf, A. Recent research and applications in variational autoencoders for industrial prognosis and health management: A survey. In Proceedings of the 2022 Prognostics and Health Management Conference (PHM-2022 London), London, UK, 27–29 May 2022; pp. 193–203. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention is all you need. Adv. Neural Inf. Process. Syst. 2017, 30. [Google Scholar] [CrossRef]

- Augustin, J.L.; Windmann, A.; Multaheb, S. Machine Learning for Cyber-Physical Systems. In Digital Transformation: Core Technologies and Emerging Topics from a Computer Science Perspective; Springer: Berlin/Heidelberg, Germany, 2023; Volume 415. [Google Scholar]

- Qin, S.; Luo, Y.; Tao, G. Memory-Augmented U-Transformer For Multivariate Time Series Anomaly Detection. In Proceedings of the ICASSP 2023–2023 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Rhodes Island, Greece, 4–10 June 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Bi, X.; Wu, D.; Xie, D.; Ye, H.; Zhao, J. Large-scale chemical process causal discovery from big data with transformer-based deep learning. Process. Saf. Environ. Prot. 2023, 173, 163–177. [Google Scholar] [CrossRef]

- Dai, S.; Yang, J.; Liu, H.; Feng, Y.; Huang, S. Comparative Study on the Performance of High-Speed IPM Motor with Single-layer PM for Electric Spindle. In Proceedings of the 2022 IEEE 5th International Electrical and Energy Conference (CIEEC), Nangjing, China, 27–29 May 2022; pp. 963–968. [Google Scholar] [CrossRef]

- Lenz’s Law and Back EMF by Danielle collins. Available online: https://www.motioncontroltips.com/lenzs-law (accessed on 7 July 2016).

- Brkovic, B.; Jecmenica, M. Calculation of Rotor Harmonic Losses in Multiphase Induction Machines. Machines 2022, 10, 401. [Google Scholar] [CrossRef]

- Zhao, H.; Yu, S.; Sun, F. Harmonic Suppression and Torque Ripple Reduction of a High-Speed Permanent Magnet Spindle Motor. IEEE Access 2021, 9, 51695–51702. [Google Scholar] [CrossRef]

- Neto, H.K.; Diniz, A.E.; Pederiva, R. Influence of tooth passing frequency, feed direction, and tool overhang on the surface roughness of curved surfaces of hardened steel. Int. J. Adv. Manuf. Technol. 2016, 82, 753–764. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Process. 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Huang, N.E.; Wu, Z.H.; Long, S.R.; Arnold, K.C.; Chen, X.Y.; Blank, K. On instantaneous frequency. Adv. Adapt. Data Anal. 2009, 1, 177–229. [Google Scholar] [CrossRef]

- Shahraki, A.F.; Yadav, O.P.; Liao, H. A review on degradation modelling and its engineering applications. Int. J. Perform. Eng. 2017, 13, 299. [Google Scholar]

- Zhang, Z.; Si, X.; Hu, C.; Lei, Y. Degradation data analysis and remaining useful life estimation: A review on Wiener-process-based methods. Eur. J. Oper. Res. 2018, 271, 775–796. [Google Scholar]

- Zhang, X.; Shi, B.; Feng, B.; Liu, L.; Gao, Z. A hybrid method for cutting tool RUL prediction based on CNN and multistage Wiener process using small sample data. Measurement 2023, 213, 112739. [Google Scholar] [CrossRef]

- Deng, R.; Brubaker, M.A.; Mori, G.; Lehrmann, A. Continuous latent process flows. Adv. Neural Inf. Process. Syst. 2021, 34, 5162–5173. [Google Scholar]

- Zerveas, G.; Jayaraman, S.; Patel, D.; Bhamidipaty, A.; Eickhoff, C. A transformer-based framework for multivariate time series representation learning. In Proceedings of the 27th ACM SIGKDD Conference on Knowledge Discovery & Data Mining, Singapore, 14–18 August 2021; pp. 2114–2124. [Google Scholar] [CrossRef]

| Variational Mode Decomposition Algorithm | |

|---|---|

| Step 1. Initialization: | |

| Step 2. Updating and according to Equation (5) | |

| Step 3. Update , for all positive : | |

| , is the Lagrangian multiplier | |

| Step 4. Convergence check: | |

| condition: | |

| |

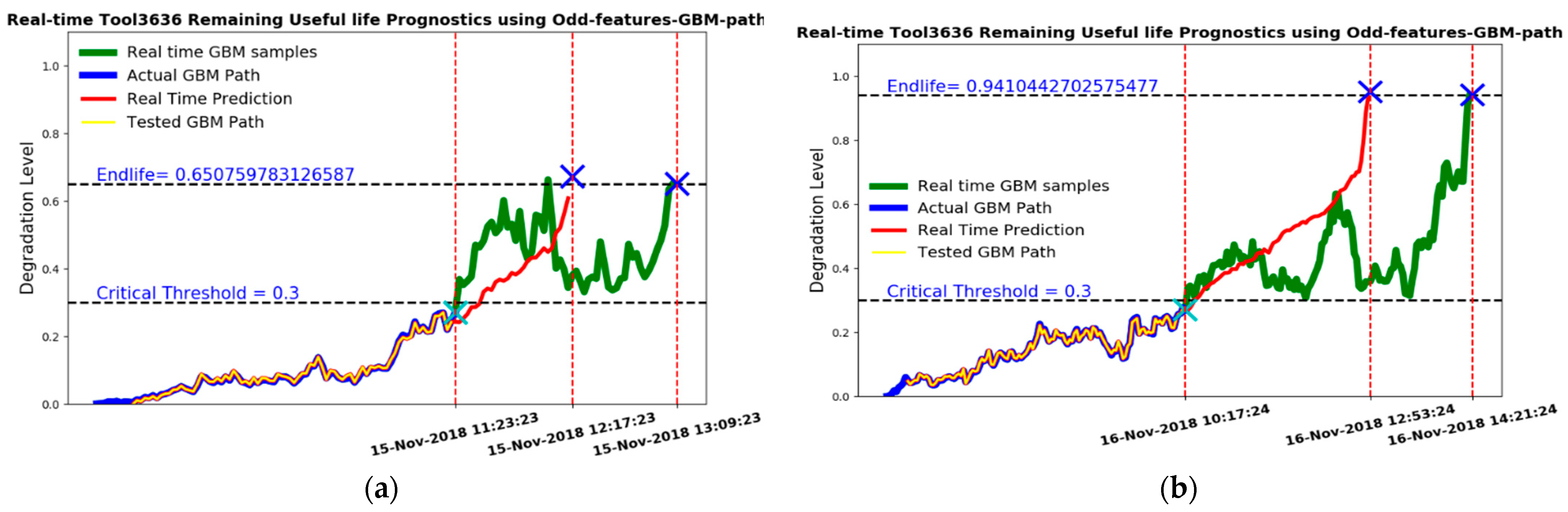

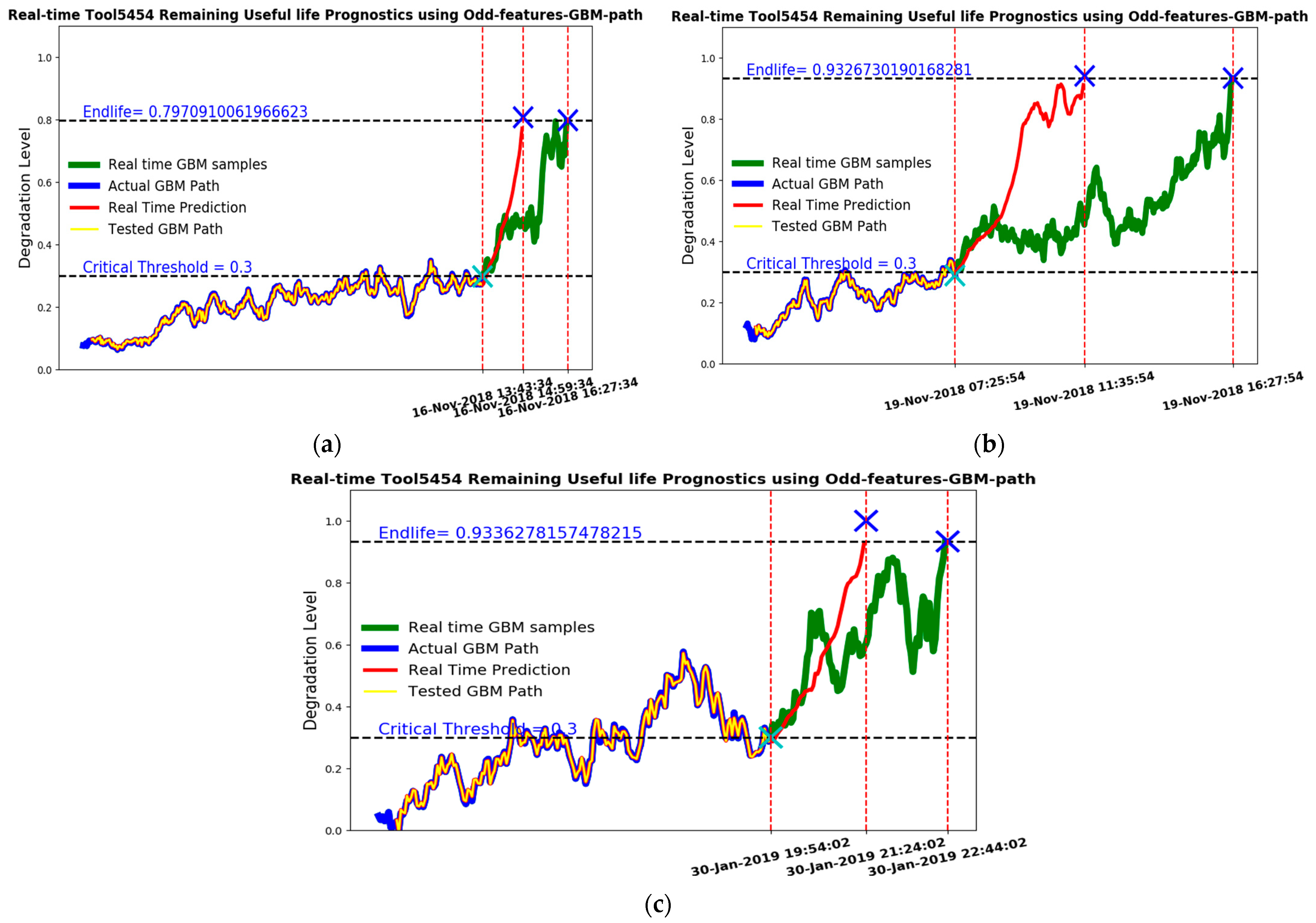

| Tool Number | Failure Type | Date | RUL (Cycle = 2 min) | Predicted Cycles to Wear (Cycle = 2 min) | |

|---|---|---|---|---|---|

| Figure 14a | 3636 | Severe Wear | 15 November 2018 | 28 | 26 |

| Figure 14b | 3636 | Severe Wear | 16 November 2018 | 79 | 44 |

| Figure 14c | 3636 | Severe Wear | 19 November 2018 | 34 | 21 |

| Figure 15a | 5454 | Severe Wear | 16 November 2018 | 44 | 39 |

| Figure 15b | 5454 | Severe Wear | 19 November 2018 | 126 | 146 |

| Figure 15c | 5454 | Broken | 30 January 2019 | 46 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavahian, A.; Mechefske, C.K. Motor Current-Based Degradation Modeling for Tool Wear Hybrid Prognostics in Turning Process. Machines 2023, 11, 781. https://doi.org/10.3390/machines11080781

Gavahian A, Mechefske CK. Motor Current-Based Degradation Modeling for Tool Wear Hybrid Prognostics in Turning Process. Machines. 2023; 11(8):781. https://doi.org/10.3390/machines11080781

Chicago/Turabian StyleGavahian, Atefeh, and Chris K Mechefske. 2023. "Motor Current-Based Degradation Modeling for Tool Wear Hybrid Prognostics in Turning Process" Machines 11, no. 8: 781. https://doi.org/10.3390/machines11080781

APA StyleGavahian, A., & Mechefske, C. K. (2023). Motor Current-Based Degradation Modeling for Tool Wear Hybrid Prognostics in Turning Process. Machines, 11(8), 781. https://doi.org/10.3390/machines11080781