Multi-Robot Task Scheduling for Consensus-Based Fault-Resilient Intelligent Behavior in Smart Factories

Abstract

1. Introduction

2. Related Work

3. Problem Statement and Assumptions

- Solely one value that has been proposed can be chosen;

- Solely a single value is chosen;

- A process never determines that a value was chosen unless it really was.

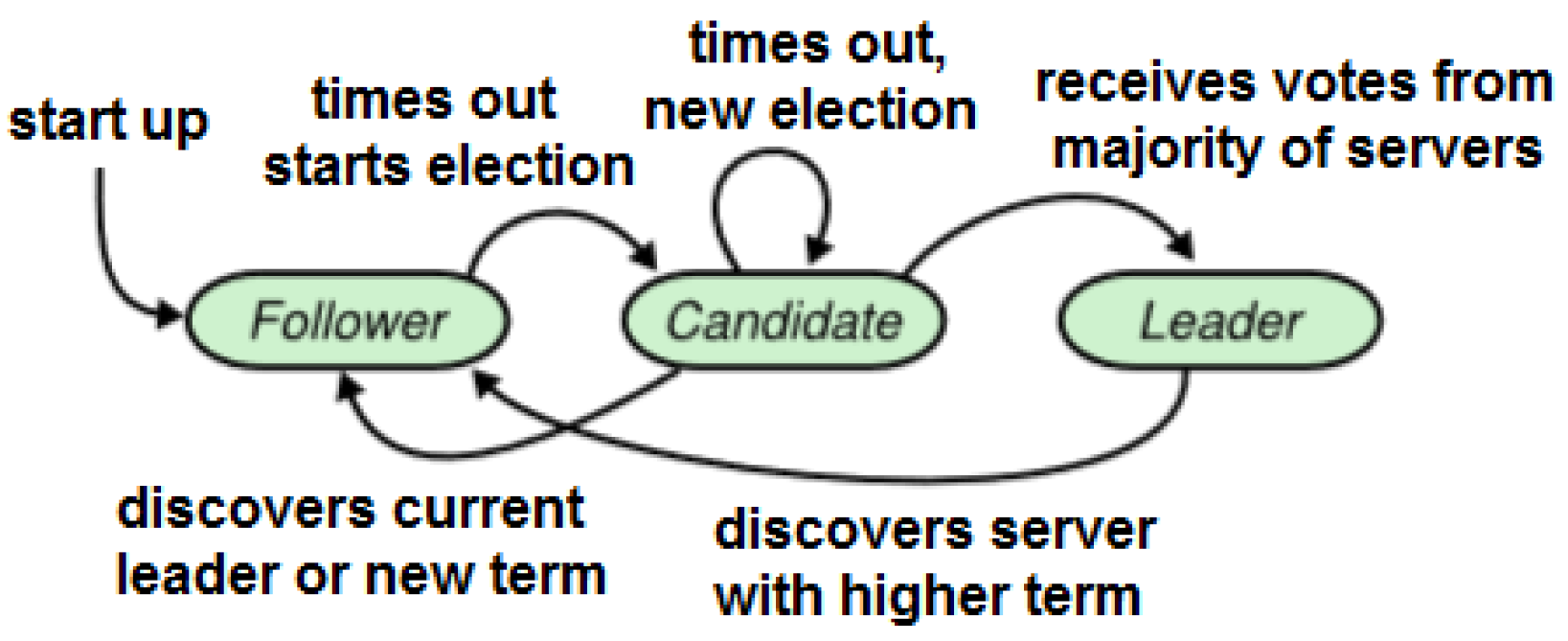

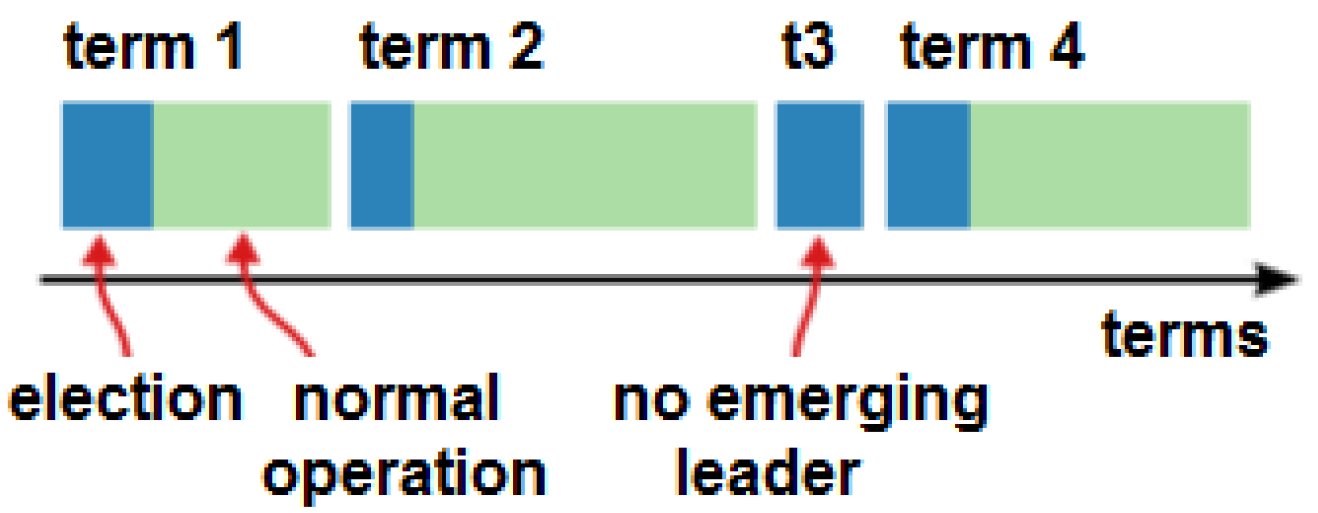

- Leader election: a new leader must be chosen when an existing leader fails;

- Log replication: the leader must accept log entries from clients and replicate them to other servers;

- Safety: if any server has applied a particular log entry to its state machine, then no other server can utilize a different command to a similar log index.

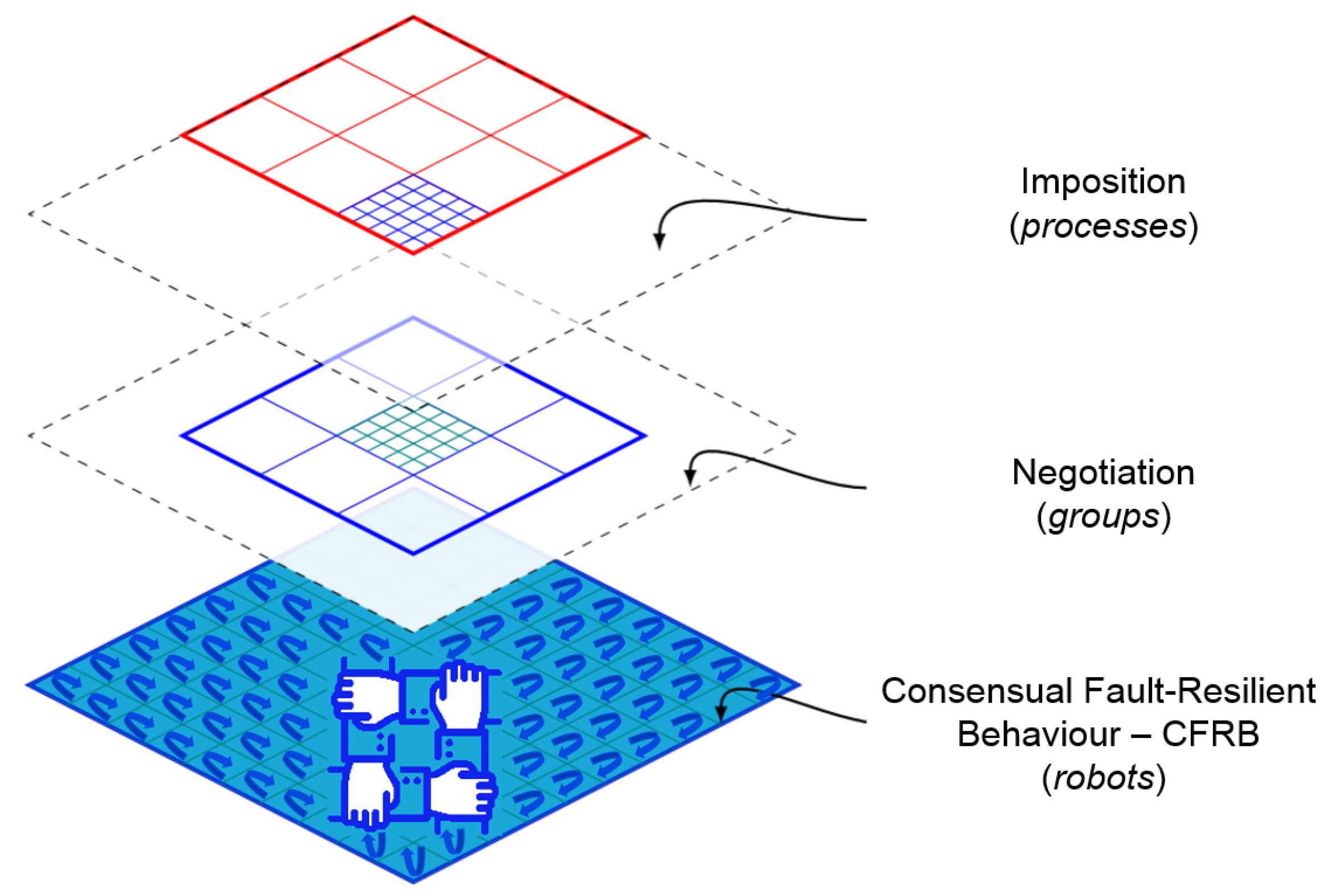

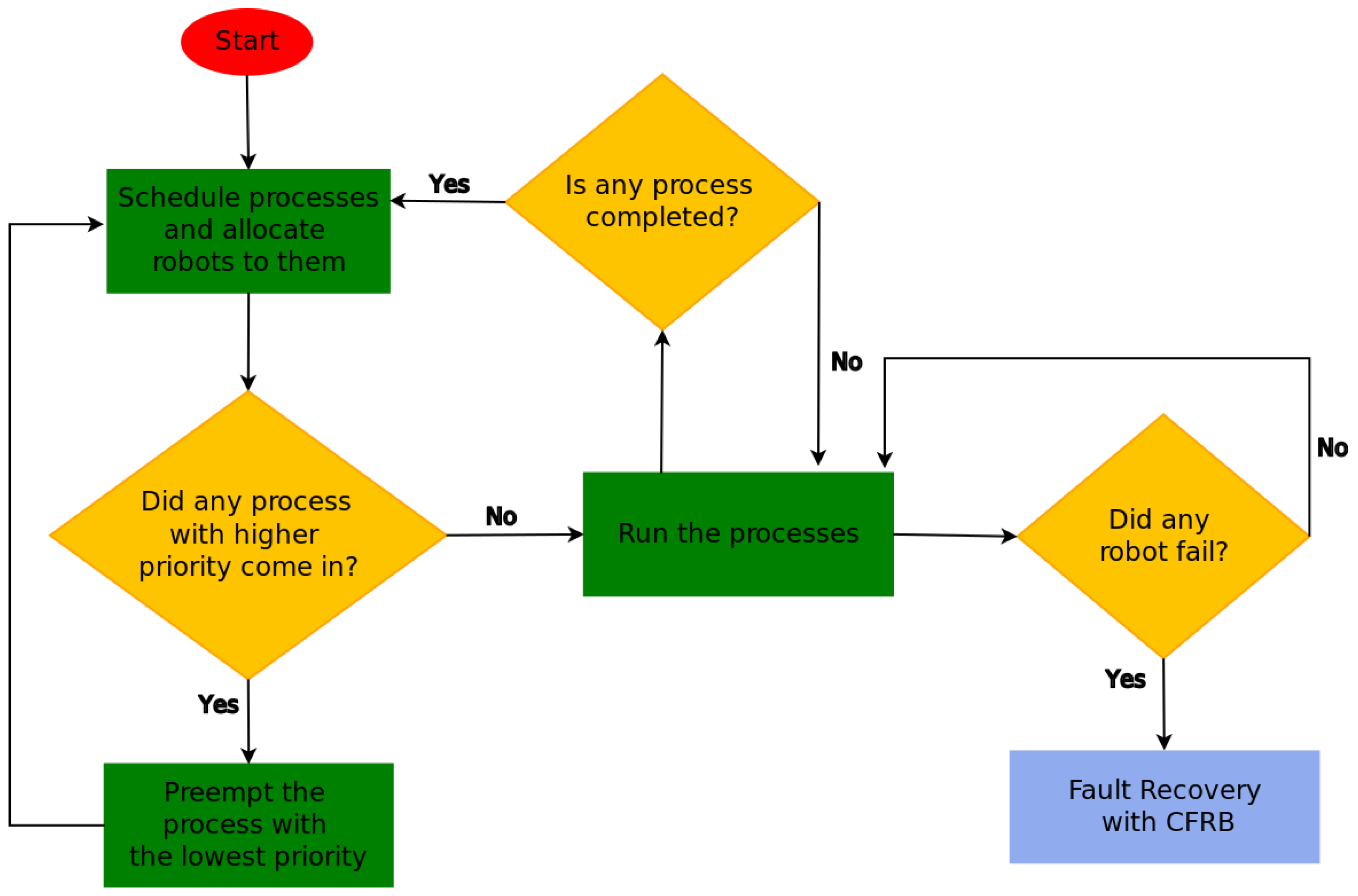

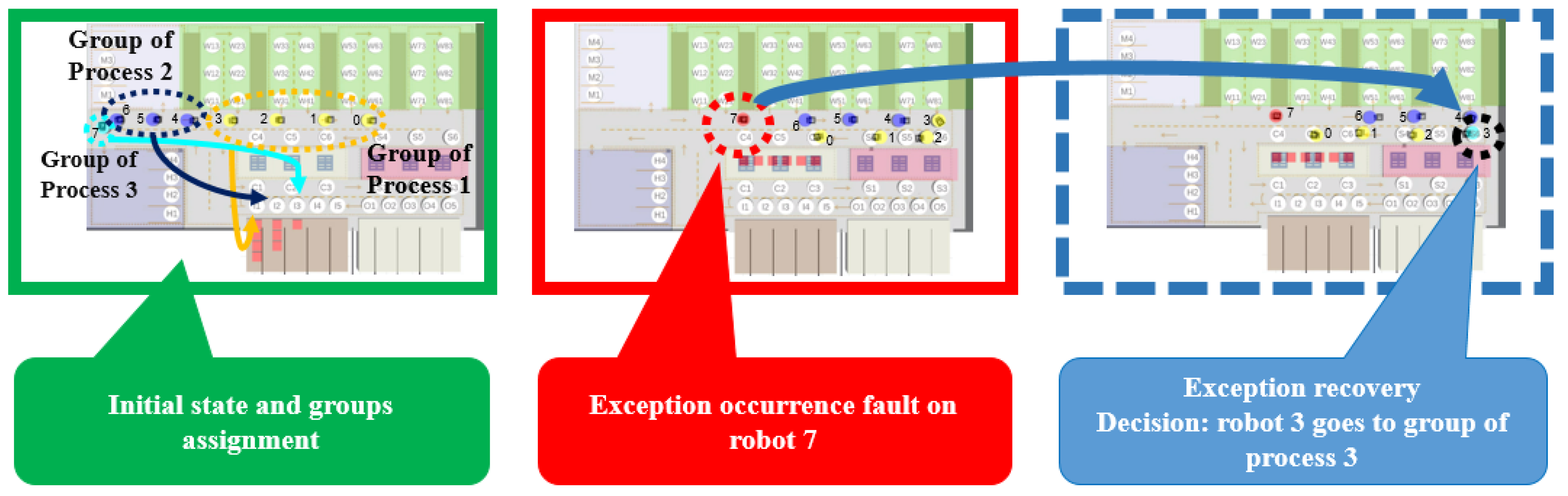

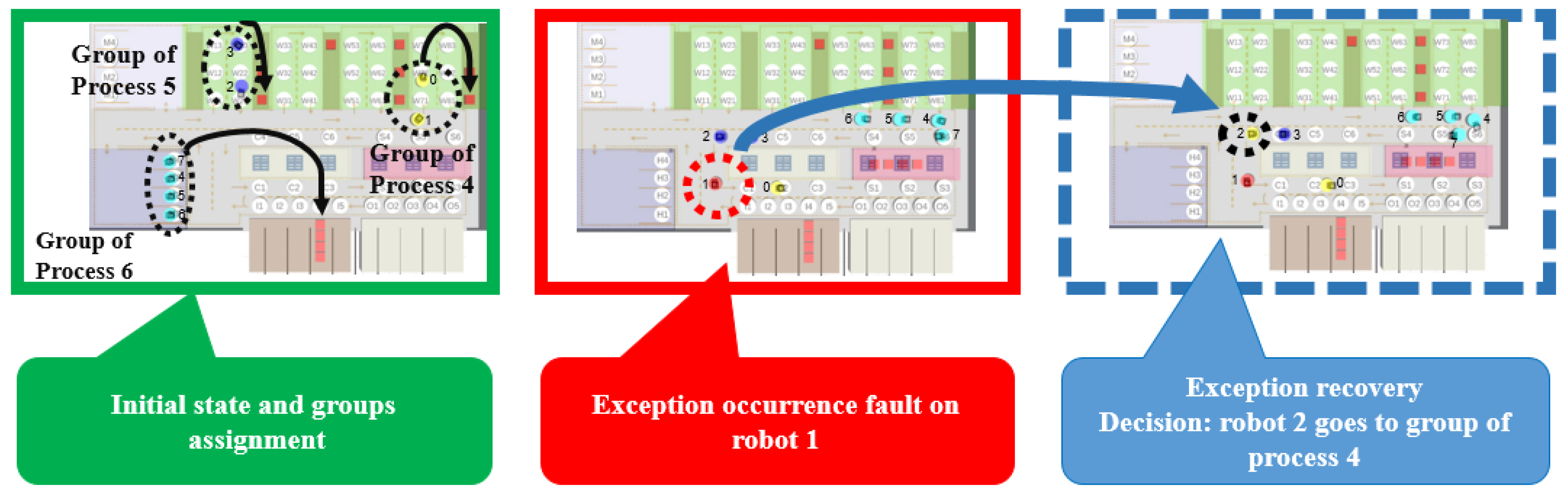

4. Consensual Fault-Resilient Behaviour (CFRB)

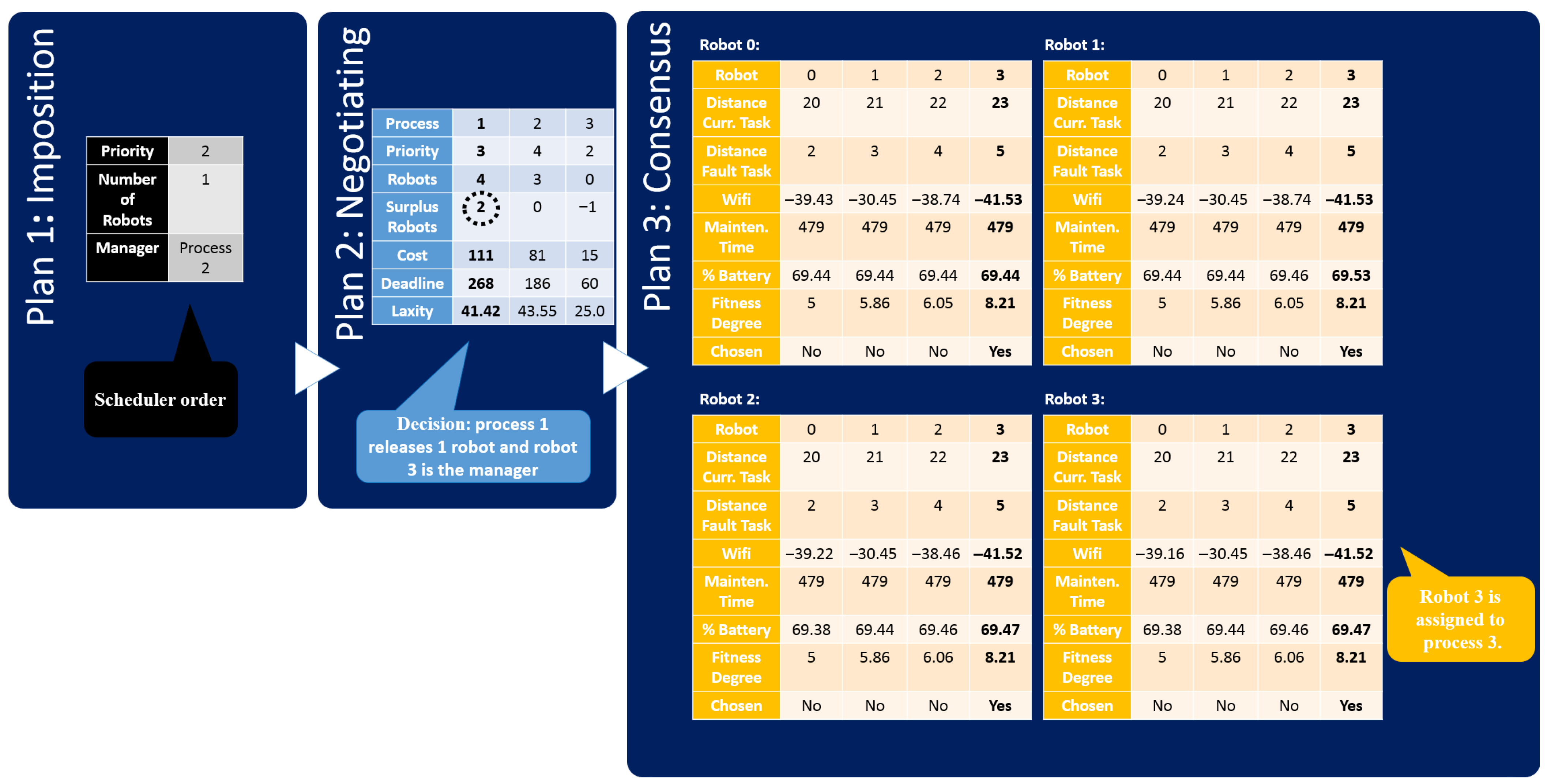

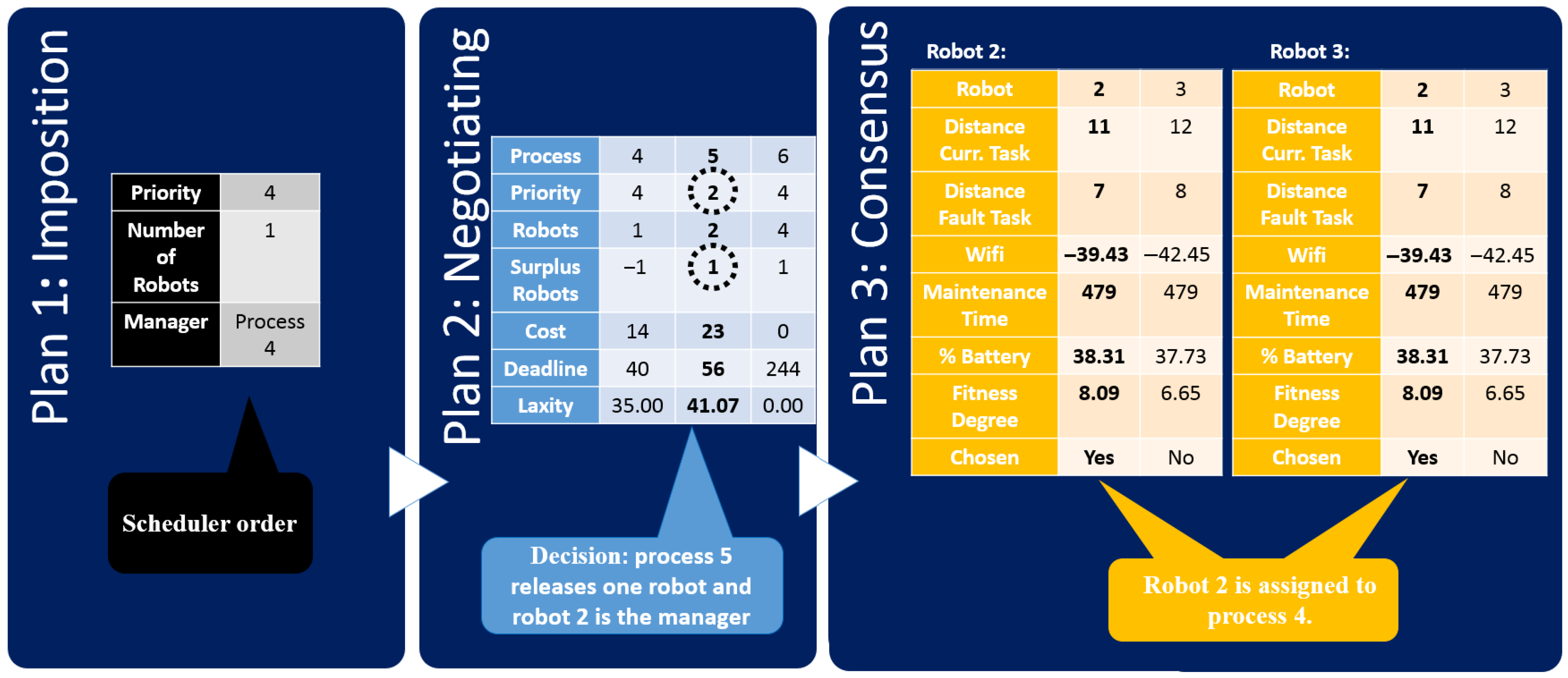

4.1. Imposition

4.2. Negotiation

- Redundancy degree: that is, the number of surplus robots that the process has, in addition to the number required to service the process, according to its priority. If more than one process has extra robots, a process with lower priority is preferred;

- Laxity: the laxity of each process is calculated according to the Least Laxity First (LLF) algorithm [25]. Thus, if two processes have equal priorities and a similar number of robots, the process that presents greater laxity will be considered the lowest priority.

4.3. Consensus

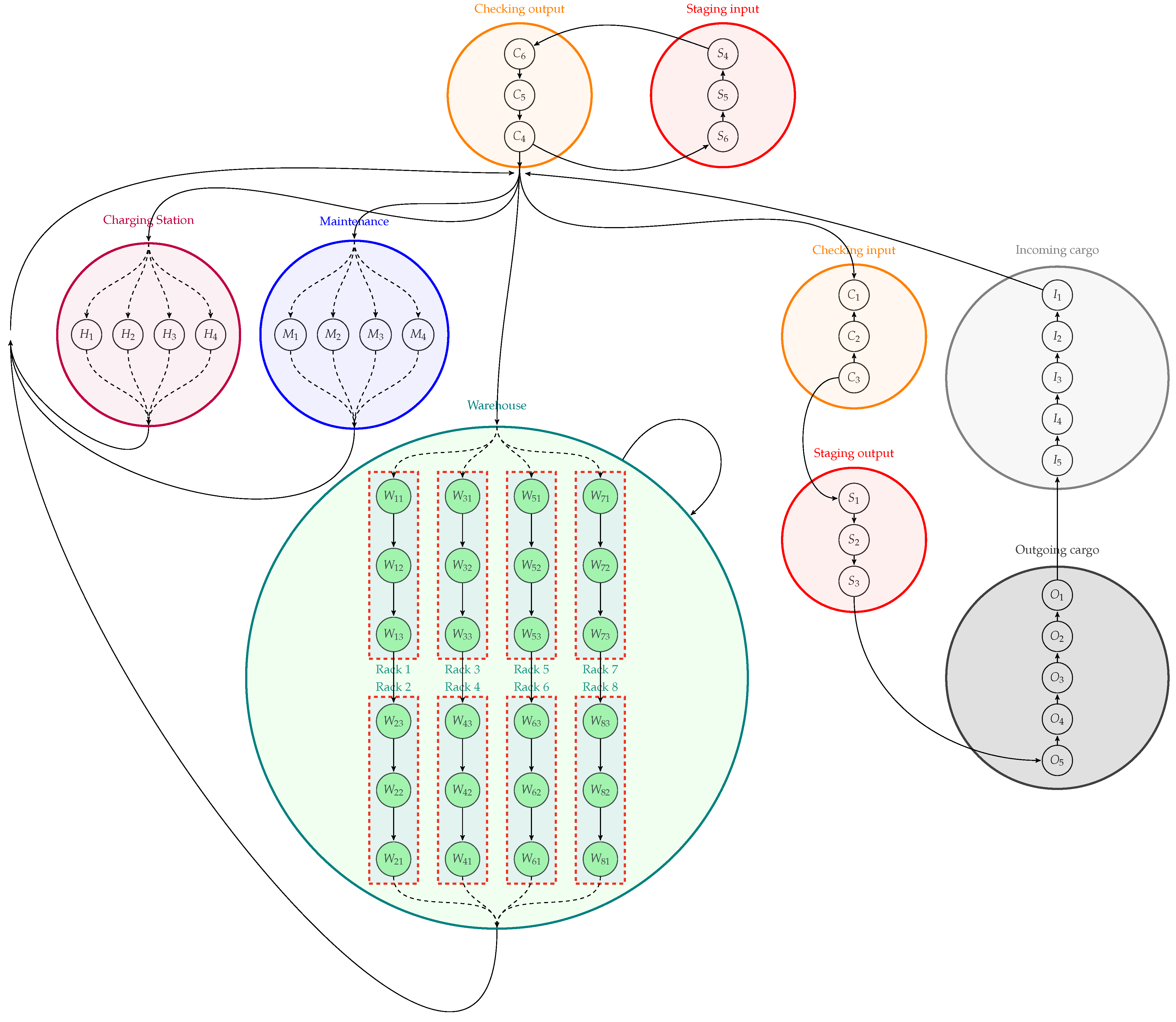

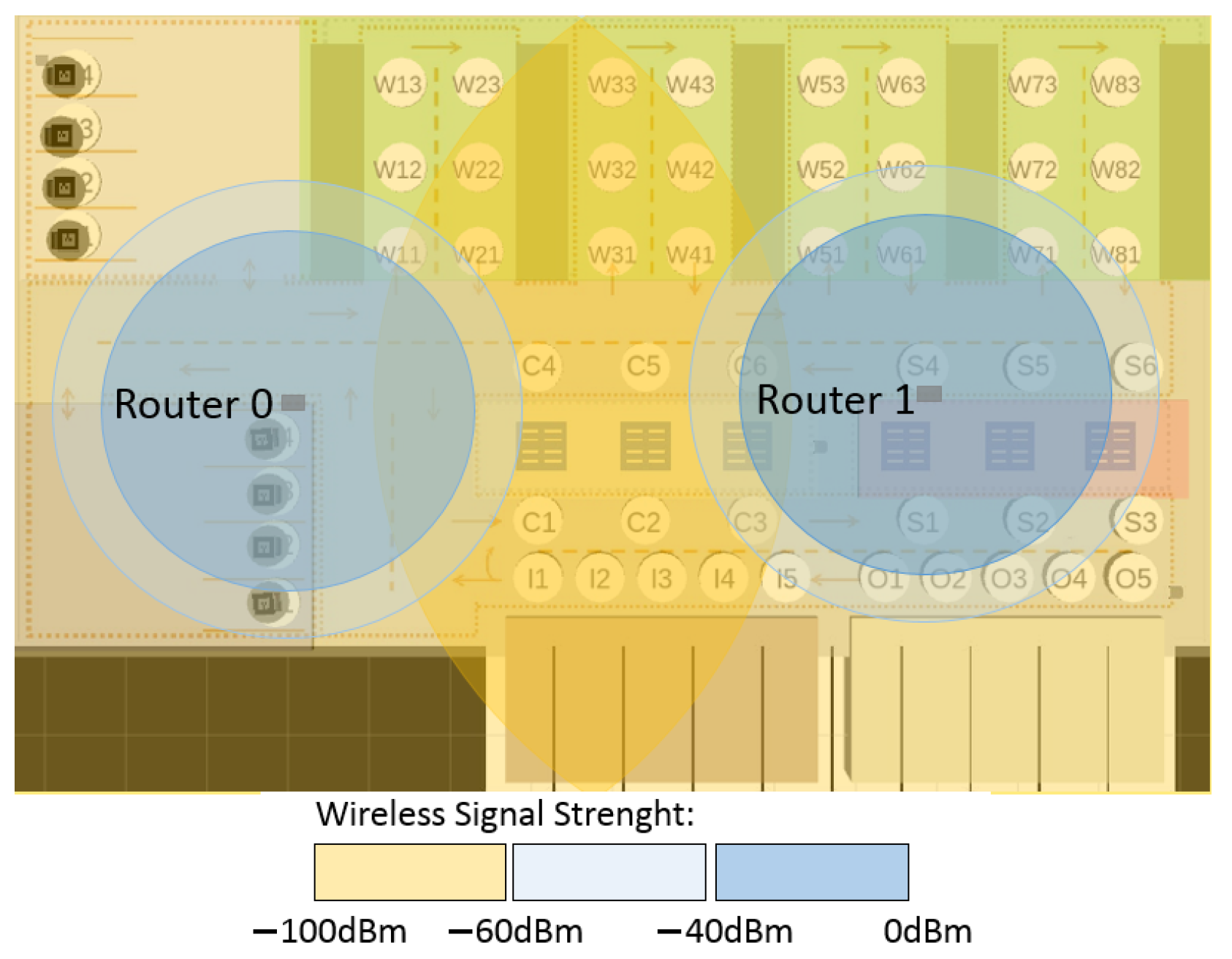

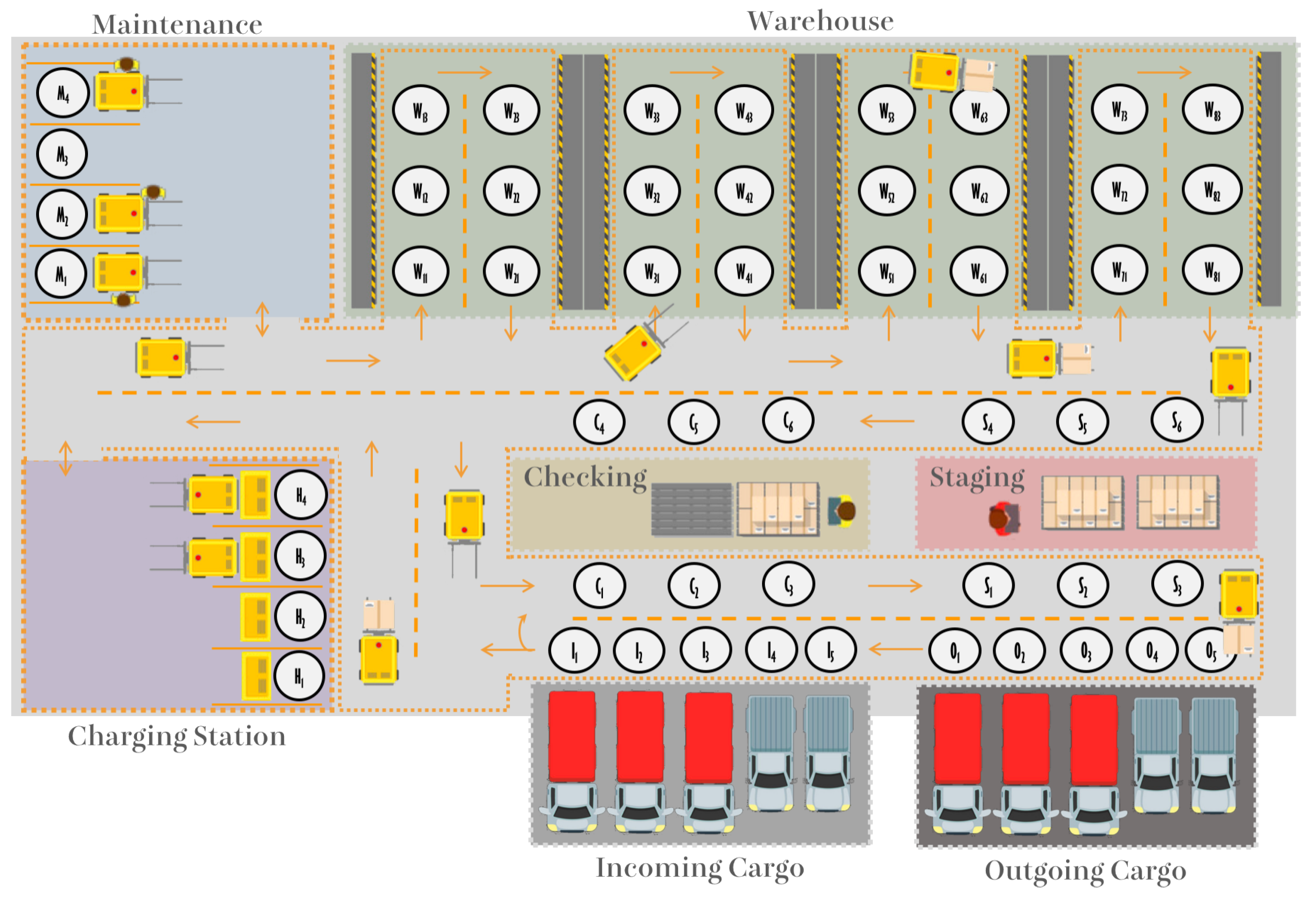

5. Warehouse Logistics

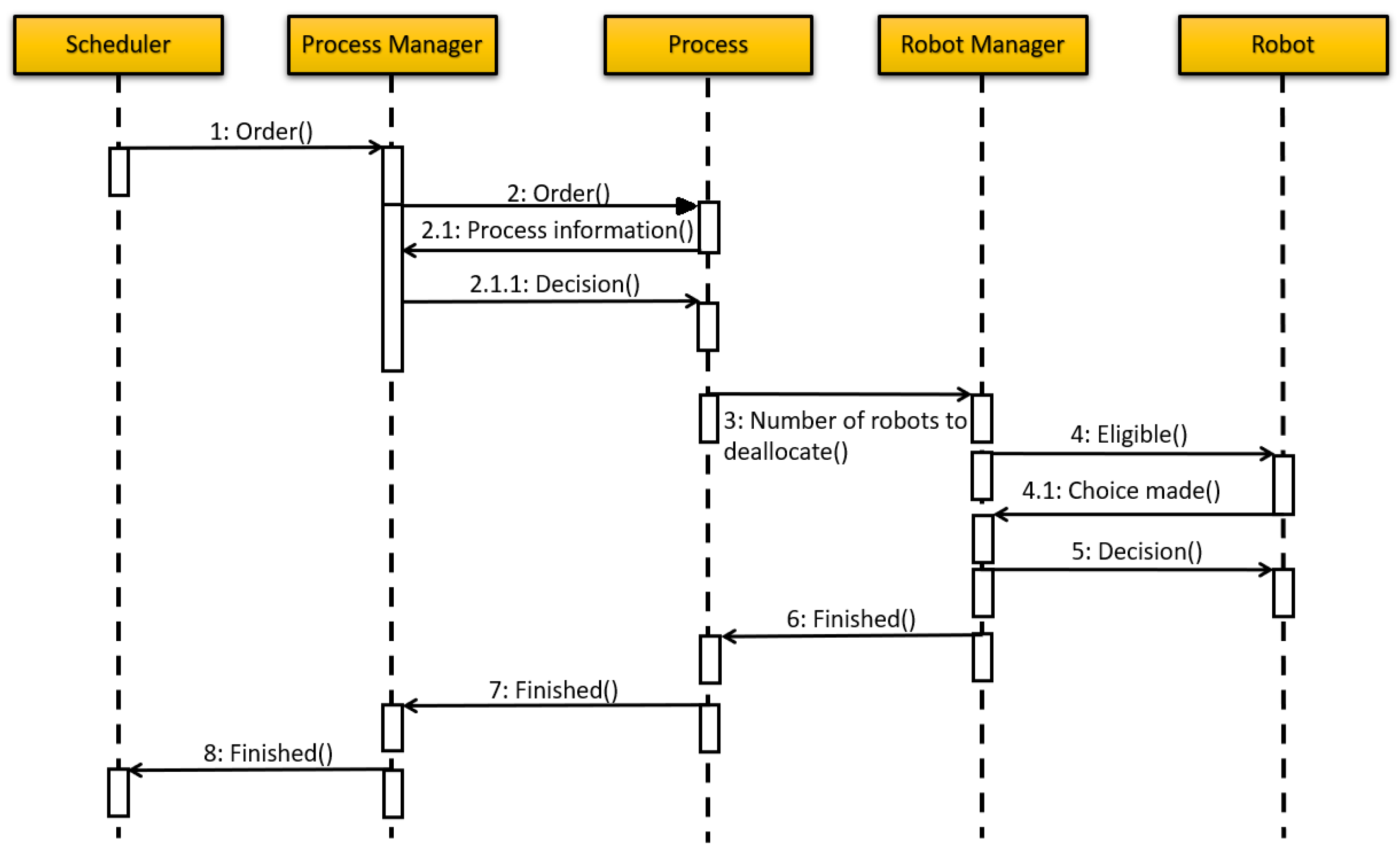

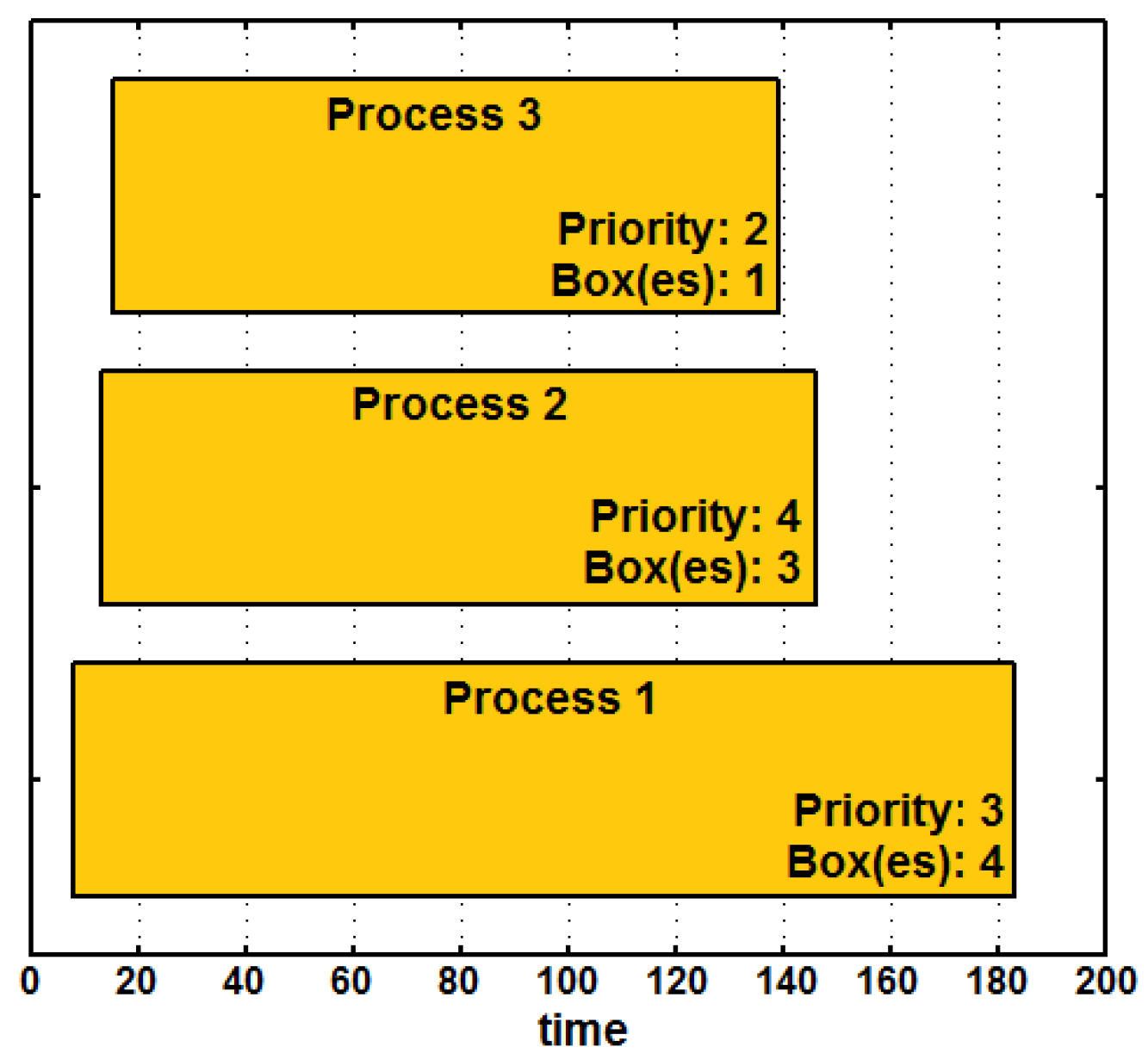

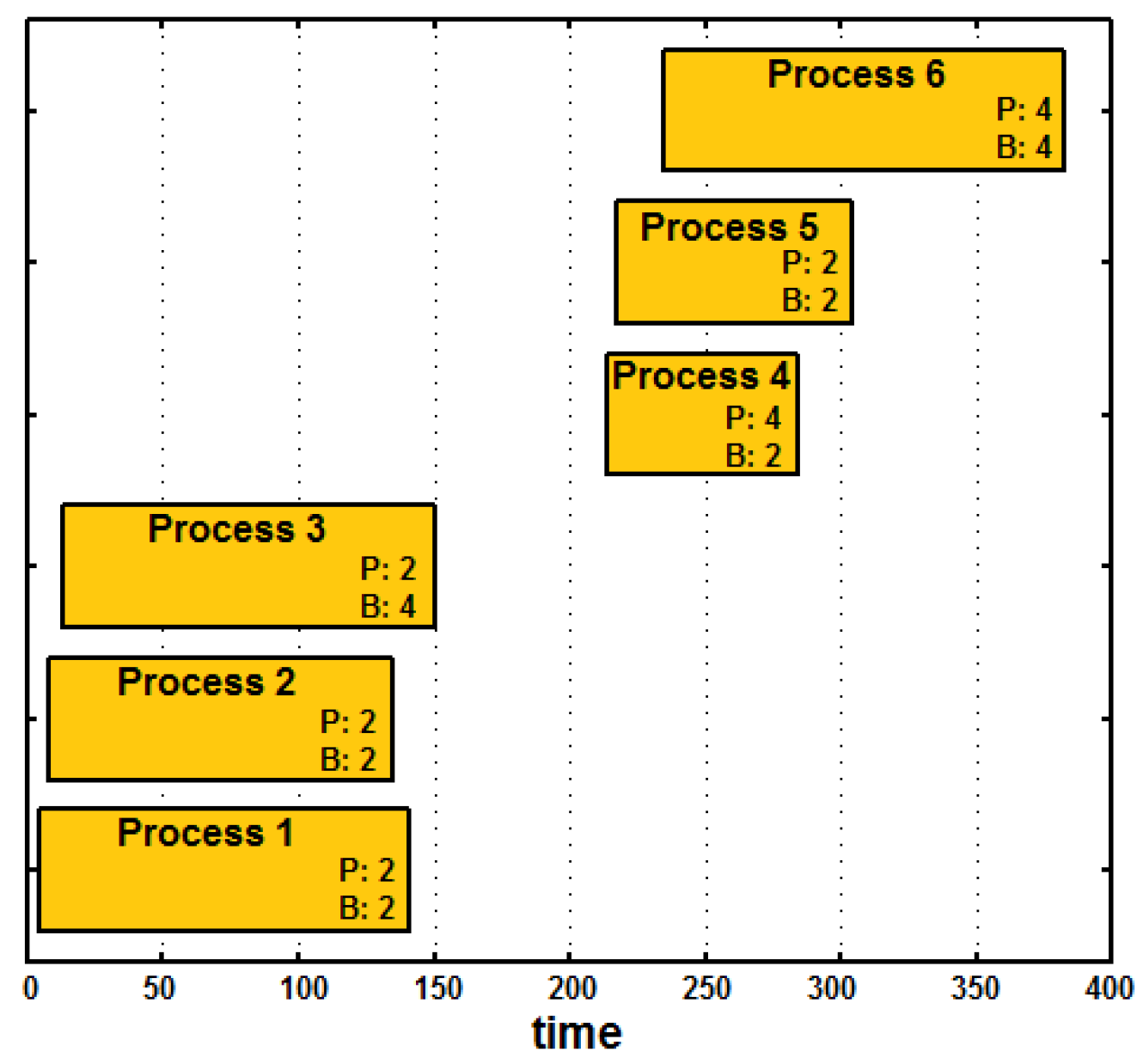

6. Process Scheduling

7. Experimental Evaluation of CFRB

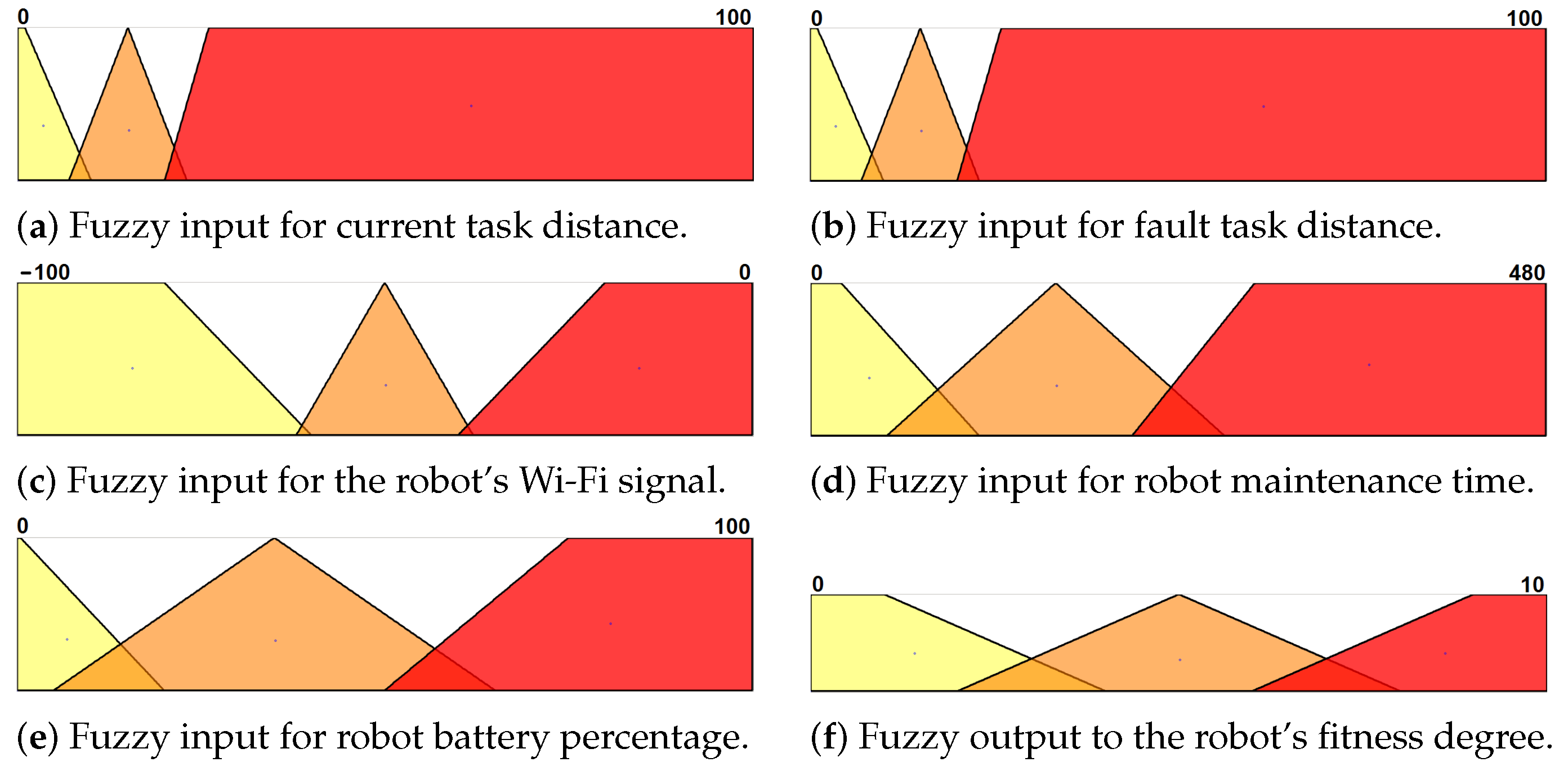

7.1. Experiment 1: Consensual Decision Using Fuzzy Controller for Lower Priorities

7.2. Experiment 2: Consensual Decision Using Fuzzy Controller for Higher Priorities

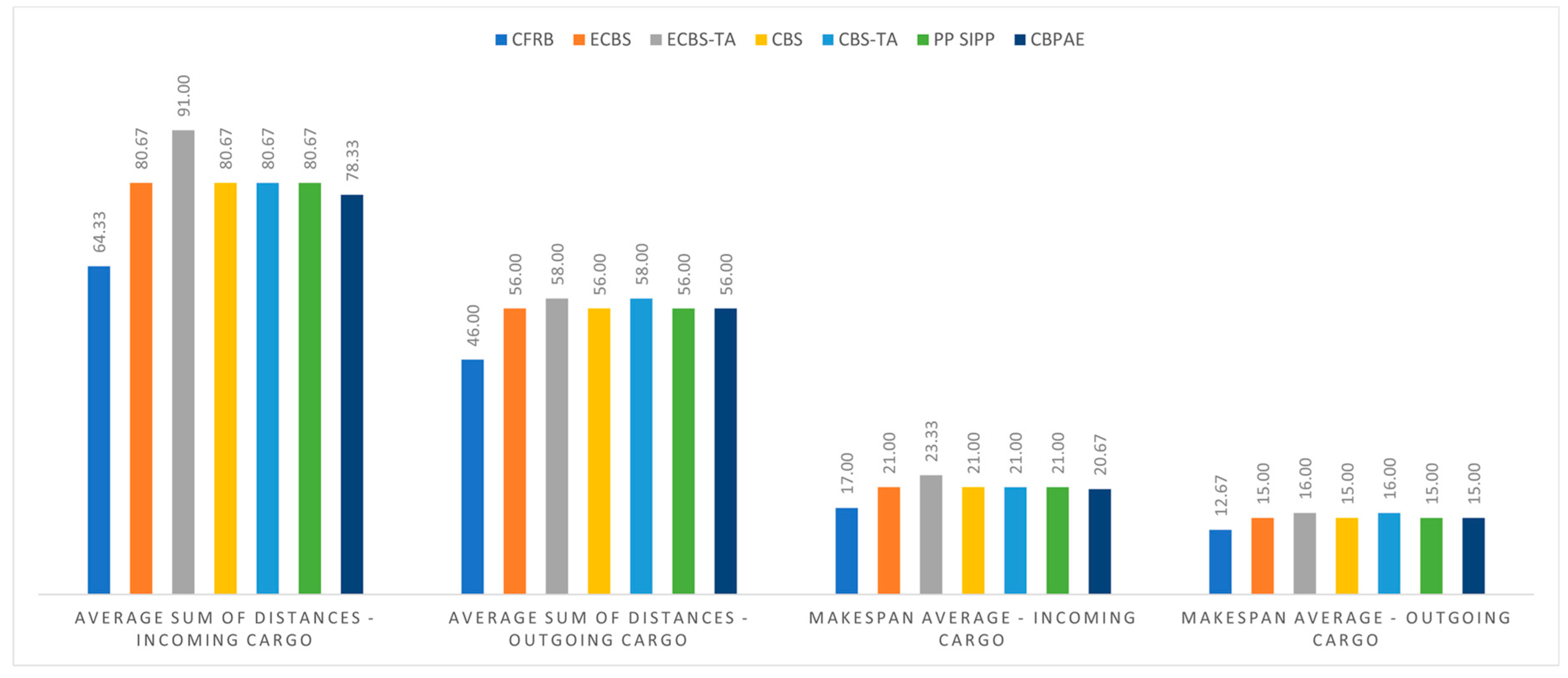

8. Comparison with Other Works

- The sum of the path distances of all robots: the sum of all transitions in the warehouse state machine, as illustrated in Figure 6;

- Makespan: the elapsed time between the completion of the first and last tasks [4]; however, as the work of Das et al. (2015) [12] and Hönig et al. [13] considered the time in milliseconds, in the scheduler cycles of this work, called ticks, this comparison is incompatible. Therefore, to have a fair comparison between the methods, we chose to determine the makespan as the longest distance traveled between all robots while performing a task.

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ARENA | Augmented Reality to Enhanced Experimentation in Smart Warehouses |

| CBPAE | Consensus-Based Parallel Auction and Execution |

| CBS | Conflict-Based Search |

| CBS-TA | Conflict-Based Search—Task Assignment |

| CFRB | Consensual Fault-Resilient Behavior |

| ECBS | Enhanced Conflict-Based Search |

| ECBS-TA | Enhanced Conflict-Based Search—Task Assignment |

| MRS | Multi-robot systems |

| MRTA | Multi-robot task allocation |

| SIPP | Safe Interval Path Planning |

References

- Afrin, M.; Jin, J.; Rahman, A.; Tian, Y.C.; Kulkarni, A. Multi-objective resource allocation for Edge Cloud based robotic workflow in smart factory. Future Gener. Comput. Syst. 2019, 97, 119–130. [Google Scholar] [CrossRef]

- Nie, Z.; Chen, K.C. Hypergraphical Real-time Multi-Robot Task Allocation in a Smart Factory. IEEE Trans. Ind. Inf. 2021, 18, 6047–6056. [Google Scholar] [CrossRef]

- Khamis, A.; Hussein, A.; Elmogy, A. Multi-robot Task Allocation: A Review of the State-of-the-Art. In Cooperative Robots and Sensor Networks 2015; Koubâa, A., Martínez-de Dios, J., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 31–51. [Google Scholar]

- Zitouni, F.; Harous, S.; Maamri, R. A Distributed Approach to the Multi-Robot Task Allocation Problem Using the Consensus-Based Bundle Algorithm and Ant Colony System. IEEE Access 2020, 8, 27479–27494. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Wang, S.; Xia, M.; Li, D.; Liu, C. Fog Computing for Energy-Aware Load Balancing and Scheduling in Smart Factory. IEEE Trans. Ind. Inf. 2018, 14, 4548–4556. [Google Scholar] [CrossRef]

- Gregory, J.M.; Brookshaw, I.; Fink, J.; Gupta, S.K. An investigation of goal assignment for a heterogeneous robotic team to enable resilient disaster-site exploration. In Proceedings of the 2017 IEEE International Symposium on Safety, Security and Rescue Robotics (SSRR), Shanghai, China, 11–13 October 2017; pp. 133–140. [Google Scholar] [CrossRef]

- Xue, F.; Tang, H.; Su, Q.; Li, T. Task Allocation of Intelligent Warehouse Picking System based on Multi-robot Coalition. KSII Trans. Internet Inf. Syst. 2019, 13, 3566–3582. [Google Scholar]

- Tran, V.P.; Santoso, F.; Garratt, M.A.; Anavatti, S.G. Distributed Artificial Neural Networks-Based Adaptive Strictly Negative Imaginary Formation Controllers for Unmanned Aerial Vehicles in Time-Varying Environments. IEEE Trans. Ind. Inf. 2021, 17, 3910–3919. [Google Scholar] [CrossRef]

- Gerkey, B.P.; Matarić, M.J. A Formal Analysis and Taxonomy of Task Allocation in Multi-Robot Systems. Int. J. Robot. Res. 2004, 23, 939–954. [Google Scholar] [CrossRef]

- Kalempa, V.C.; Piardi, L.; Limeira, M.; De Oliveira, A.S. Fault-Resilient Collective Ternary-Hierarchical Behavior to Smart Factories. IEEE Access 2020, 8, 176905–176915. [Google Scholar] [CrossRef]

- Mahmoud, M.S.; Oyedeji, M. Consensus in multi-agent systems over time-varying networks. Cyber-Phys. Syst. 2020, 6, 117–145. [Google Scholar] [CrossRef]

- Das, G.P.; Mcginnity, T.M.; Coleman, S.A.; Behera, L. A Distributed Task Allocation Algorithm for a Multi-Robot System in Healthcare Facilities. J. Intell. Robot. Syst. 2015, 80, 33–58. [Google Scholar] [CrossRef]

- Hoenig, W.; Kiesel, S.; Tinka, A.; Durham, J.; Ayanian, N. Conflict-Based Search with Optimal Task Assignment. In Proceedings of the 17th International Conference on Autonomous Agents and MultiAgent Systems, Stockholm, Sweden, 10–15 July 2018. [Google Scholar]

- Gregory, J.M.; Al-Hussaini, S.; Gupta, S.K. Heuristics-Based Multi-Agent Task Allocation for Resilient Operations. In Proceedings of the 2019 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), Wurzburg, Germany, 2–4 September 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Mayya, S.; D’antonio, D.S.; Saldaña, D.; Kumar, V. Resilient Task Allocation in Heterogeneous Multi-Robot Systems. IEEE Robot. Autom. Lett. 2021, 6, 1327–1334. [Google Scholar] [CrossRef]

- Choudhury, S.; Gupta, J.K.; Kochenderfer, M.J.; Sadigh, D.; Bohg, J. Dynamic multi-robot task allocation under uncertainty and temporal constraints. Auton. Robot. 2022, 46, 231–247. [Google Scholar] [CrossRef]

- Kim, S.; Lee, H. Multi-Robot Task Scheduling with Ant Colony Optimization in Antarctic Environments. Sensors 2023, 23, 751. [Google Scholar] [CrossRef]

- Martin, J.G.; Muros, F.J.; Maestre, J.M.; Camacho, E.F. Multi-robot task allocation clustering based on game theory. Robot. Auton. Syst. 2023, 161, 104314. [Google Scholar] [CrossRef]

- Olfati-Saber, R.; Fax, J.A.; Murray, R.M. Consensus and Cooperation in Networked Multi-Agent Systems. Proc. IEEE 2007, 95, 215–233. [Google Scholar] [CrossRef]

- Gulzar, M.M.; Rizvi, S.T.H.; Javed, M.Y.; Munir, U.; Asif, H. Multi-Agent Cooperative Control Consensus: A Comparative Review. Electronics 2018, 7, 22. [Google Scholar] [CrossRef]

- Vasiljević, G.; Petrović, T.; Arbanas, B.; Bogdan, S. Dynamic Median Consensus for Marine Multi-Robot Systems Using Acoustic Communication. IEEE Robot. Autom. Lett. 2020, 5, 5299–5306. [Google Scholar] [CrossRef]

- Brasileiro, F.; Greve, F.; Mostefaoui, A.; Raynal, M. Consensus in One Communication Step. In Parallel Computing Technologies; Malyshkin, V., Ed.; Springer: Berlin/Heidelberg, Germany, 2001; pp. 42–50. [Google Scholar]

- Lamport, L. Paxos made simple. ACM Sigact News 2001, 32, 18–25. [Google Scholar]

- Ongaro, D.; Ousterhout, J. In search of an understandable consensus algorithm. In Proceedings of the 2014 USENIX Annual Technical Conference USENIX ATC’ 14, Philadelphia, PA, USA, 19–20 June 2014; pp. 305–319. [Google Scholar]

- Oh, S.H.; Yang, S.M. A Modified Least-Laxity-First scheduling algorithm for real-time tasks. In Proceedings of the Fifth International Conference on Real-Time Computing Systems and Applications (Cat. No.98EX236), Hiroshima, Japan, 27–29 October 1998; pp. 31–36. [Google Scholar]

- Passino, K.M.; Yurkovich, S.; Reinfrank, M. Fuzzy Control; Addison-Wesley Reading: Boston, MA, USA, 1998; Volume 42. [Google Scholar]

- Piardi, L.; Kalempa, V.C.; Limeira, M.; de Oliveira, A.S.; Leitão, P. ARENA—Augmented Reality to Enhanced Experimentation in Smart Warehouses. Sensors 2019, 19, 4308. [Google Scholar] [CrossRef]

- Zijm, H.; Klumpp, M.; Heragu, S.; Regattieri, A. Operations, Logistics and Supply Chain Management: Definitions and Objectives. In Operations, Logistics and Supply Chain Management; Zijm, H., Klumpp, M., Regattieri, A., Heragu, S., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 27–42. [Google Scholar]

- de Koster, R.; Le-Duc, T.; Roodbergen, K.J. Design and control of warehouse order picking: A literature review. Eur. J. Oper. Res. 2007, 182, 481–501. [Google Scholar] [CrossRef]

- Limeira, M.A.; Piardi, L.; Kalempa, V.C.; de Oliveira, A.S.; Leitão, P. WsBot: A Tiny, Low-Cost Swarm Robot for Experimentation on Industry 4.0. In Proceedings of the 2019 Latin American Robotics Symposium (LARS), 2019 Brazilian Symposium on Robotics (SBR) and 2019 Workshop on Robotics in Education (WRE), RioGrande, Brazil, 23–25 October 2019; pp. 293–298. [Google Scholar]

| Main Features | This Paper | Das et al. (2015) [12] | Hönig et al. (2018) [13] | Afrin et al. (2019) [1] | Gregory et al. (2019) [14] | Xue et al. (2019) [7] |

|---|---|---|---|---|---|---|

| Approach | Collective ternary-hierarchical behavior resilient to faults | Based on auction and consensus principles | Task allocation with collision-free paths, based on the Conflict-Based Search algorithm | Based on the Non-dominated Sorting Genetic Algorithm II | Task allocation heuristic that incorporates realistic state and uncertainty modeling to improve performance | Based on the mathematical model of linear programming |

| Fault Resilience | ✓ | ✓ | ||||

| Consensus | ✓ | ✓ | ||||

| Target Application | Warehouse/ARENA | Health area | Uninformed | Emergency fire management service in a smart factory | Disaster environment | Industrial plant warehouse picking system |

| Implementation | ROS, Rviz, Coppeliasim (V-REP) | Own Python Simulator, ROS, and Stage | Own C++ Simulator | Matlab | Own Python Simulator | LINGO11 |

| Number of Robots | 8 | 50 | 100 | 50 | 5 | 10 |

| MRS Type | Homogeneous | Heterogeneous | Homogeneous | Homogeneous | Heterogeneous | Homogeneous |

| Considers Priority | ✓ | ✓ | ✓ | |||

| Considers Energy | ✓ | ✓ | ||||

| Considers Distance Traveled | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Main Features | This Paper | Kalempa et al. (2020) [10] | Zitouni et al. (2020) [4] | Mayya et al. (2021) [15] | Choudhury et al. (2022) [16] | Kim and Lee (2023) [17] | Martin et al. (2023) [18] |

|---|---|---|---|---|---|---|---|

| Approach | Collective ternary-hierarchical behavior resilient to faults | Collective ternary-hierarchical behavior resilient to faults | Use of ant colony system and Consensus-Based Bundle Algorithm | Optimization- based | Stochastic Conflict-Based Allocation (SCoBA) | Based on Ant Colony Optimization | Use of cooperative game theory framework |

| Fault Resilience | ✓ | ✓ | ✓ | ||||

| Consensus | ✓ | Consensus based on election | ✓ | ||||

| Target Application | Warehouse/ARENA | Warehouse/ARENA | Search and rescue environment | Environment with difficult environmental conditions | Pick-and-place and delivery | Antarctic environments | Industrial plant |

| Implementation | ROS, Rviz, Coppeliasim (V-REP) | ROS, Rviz, Coppeliasim (V-REP) | Jade Framework and Java language | Coppeliasim (V-REP) | Julia programming language | Own Python Simulator | Matlab |

| Number of Robots | 8 | 8 | 20 | 10 | 30 | 40 | 15 |

| MRS Type | Homogeneous | Homogeneous | Homogeneous | Heterogeneous | Homogeneous | Homogeneous | Homogeneous |

| Considers Energy | ✓ | ✓ | ✓ | ✓ | |||

| Considers Priority | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Considers Distance Traveled | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| # | Type of Process | Priority | Number of Boxes | Initial State | Warehouse Aisle |

|---|---|---|---|---|---|

| Process-1 | Incoming Cargo | 3 | 4 | I1 | 4 |

| Process-2 | Incoming Cargo | 4 | 3 | I2 | 2 |

| Process-3 | Incoming Cargo | 2 | 1 | I3 | 1 |

| # | Type of Process | Priority | Number of Boxes | Initial State | Warehouse Aisle |

|---|---|---|---|---|---|

| Process-4 | Outgoing Cargo | 4 | 2 | O1 | 4 |

| Process-5 | Outgoing Cargo | 2 | 2 | O2 | 1 |

| Process-6 | Incoming Cargo | 4 | 4 | I4 | 1 |

| Sum of path distances | |||||||

|---|---|---|---|---|---|---|---|

| CFRB | ECBS | ECBS-TA | CBS | CBS-TA | PP SIPP | CBPAE | |

| Average Sum of Distances—Incoming Cargo | 64.33 | +25.39% | +41.45% | +25.39% | +25.39% | +25.39% | +21.76% |

| Average Sum of Distances—Outgoing Cargo | 46.00 | +21.74% | +26.09% | +21.74% | +26.09% | +21.74% | +21.74% |

| Average of Both Processes | 55.17 | +23.87% | +35.05% | +23.87% | +25.68% | +23.87% | +21.75% |

| Makespan | |||||||

| Makespan Average—Incoming Cargo | 17.00 | +23.53% | +37.25% | +23.53% | +23.53% | +23.53% | +21.57% |

| Makespan Average—Outgoing Cargo | 12.67 | +18.42% | +26.32% | +18.42% | +26.32% | +18.42% | +18.42% |

| Average of Both Processes | 14.83 | +21.35% | +32.58% | +21.35% | +24.72% | +21.35% | +20.22% |

| Average CFRB Improvement | |||||||

| Distance | −20.43% | ||||||

| Makespan | −19.09% | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalempa, V.C.; Piardi, L.; Limeira, M.; de Oliveira, A.S. Multi-Robot Task Scheduling for Consensus-Based Fault-Resilient Intelligent Behavior in Smart Factories. Machines 2023, 11, 431. https://doi.org/10.3390/machines11040431

Kalempa VC, Piardi L, Limeira M, de Oliveira AS. Multi-Robot Task Scheduling for Consensus-Based Fault-Resilient Intelligent Behavior in Smart Factories. Machines. 2023; 11(4):431. https://doi.org/10.3390/machines11040431

Chicago/Turabian StyleKalempa, Vivian Cremer, Luis Piardi, Marcelo Limeira, and Andre Schneider de Oliveira. 2023. "Multi-Robot Task Scheduling for Consensus-Based Fault-Resilient Intelligent Behavior in Smart Factories" Machines 11, no. 4: 431. https://doi.org/10.3390/machines11040431

APA StyleKalempa, V. C., Piardi, L., Limeira, M., & de Oliveira, A. S. (2023). Multi-Robot Task Scheduling for Consensus-Based Fault-Resilient Intelligent Behavior in Smart Factories. Machines, 11(4), 431. https://doi.org/10.3390/machines11040431