Abstract

Manufacturing is transitioning from traditional and mass manufacturing to mass personalization, fast, and intelligent production. Through full automation in various fields and data sharing, Industry 4.0 (I4.0) contributes to the digitalization of manufacturing by enhancing industrial flexibility and product customization. I4.0 is being utilized as a strategy for advanced manufacturing to counter global competitiveness. A company’s manufacturing strategy outputs (MSOs) are critical to its ability to move forward and remain competitive. Despite their importance, I4.0 technologies have received less attention in the literature, and it is unclear how they influence MSOs. Thus, this study aims to build a powerful hybrid MCDM method for ranking the influence of I4.0 technologies on MSOs by adopting a combination of AHP and fuzzy TOPSIS. The application of fuzzy set theory has addressed the ambiguity in comparing various I4.0 technologies. The AHP was used to calculate the weights of criteria and sub-criteria, and the fuzzy-TOPSIS method was utilized to rank the I4.0 technologies. The results revealed that the cost criterion is the most critical factor when implementing I4.0 technologies. In contrast, additive manufacturing (AM) is the most suitable I4.0 technology for countering global competition.

1. Introduction

Due to limited and predetermined resources, static routing, no interconnection, independent control, and separate information, traditional manufacturing systems are unable to keep organizations competitive. As a result, I4.0 is a new revolution that overcomes the conventional manufacturing challenges to maintain the organization competitive by leveraging its features such as various resources, dynamic routing, instant interconnection, self-organization, and big data capabilities. There has been a rise in the use of I4.0 in order to help businesses compete on a global scale. The German Federal Government originally introduced the “Industry 4.0” concept in 2011 [1]. The first revolution used water and steam power, the second used electric power and infrastructure growth, and the third used electronics and IT. Independently exchanging data, activating activities, making decisions, and controlling one another are all features of a fully functional cyber-physical system, which is a critical component of I4.0, along with smart technologies that can provide the integration of machinery, factory, and business processes [2,3]. Meanwhile, Industry 5.0 (the Fifth Industrial Revolution) is an emerging era of industrialization in which humans collaborate with advanced technology and robotics to improve work processes. It is based on the observation or assumption that I4.0 focuses less on the fundamental values of social fairness and sustainability and more on digitalization and supporting technologies for enhancing production efficiency and flexibility [4,5].

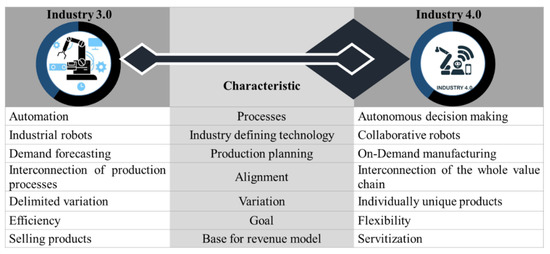

In the 1970s, partial automation with memory-programmable controls and computers marked the beginning of the Third Industrial Revolution (Industry 3.0). Since introducing these technologies, it has automated an entire production process—without human assistance. Robots executing predetermined sequences without human intervention are examples of this revolution [6,7]. In contrast, Industry 4.0 is characterized by the application of information and communication technologies to the industrial sector; the Internet of Things (IoT) has the potential to revolutionize the manufacturing industry. It builds upon the progress made during the Third Industrial Revolution. Existing production systems with computer technology are augmented by a network connection and have a digital twin on the Internet. For practical purposes, a digital twin serves as the indistinguishable digital counterpart to an intended or actual physical product, system, or process. It is designed for simulations, integrations, testing, monitoring, and maintenance of real-world physical products, procedures, or processes. The Digital Twins sector has concentrated on manufacturing and proposed explicit frameworks and architecture, which presented difficulties in supporting different integration levels through an agile process [8,9]. It permits communication with other facilities and the dissemination of information about themselves. The networking of all systems results in “cyber-physical production systems” and, consequently, intelligent factories, where production systems, components, and people communicate via a network and production is nearly autonomous [7,10,11]. Figure 1 summarizes the differences between I3.0 and I4.0 in terms of manufacturing. The transition from Industry 3.0 to Industry 4.0 in terms of technology has likely occurred gradually over the past few decades.

Figure 1.

Comparison of Industry 3.0 and Industry 4.0 manufacturing characteristics.

I4.0 is a revolutionary wave that enables organizations to respond rapidly and effectively to customer demands. Academics and practitioners established it to improve the competitiveness of the manufacturing industry [12]. Cyber-physical systems (CPS), the Internet of Things (IoT), and cloud computing are all examples of automation technologies that are being incorporated into the manufacturing industry as part of the I4.0 program [12]. It all started with the goal of producing items that reflect customer needs through efficient manufacturing processes; designers may refer to this concept as “flexible integration of the global value chain” [13,14]. I4.0 allows cost-effective, intelligent, efficient, effective, individualized, and customized products. With faster computers, smarter machinery, smaller sensors, and more affordable data storage and transmission, machines and products could become more intelligent to communicate and learn from one another [15]. I4.0 promotes industrial flexibility and the customization of goods via automation and data sharing in various settings, hence aiding in the digitization of manufacturing [16]. By utilizing I4.0 technologies, mass personalized production can be achieved with the competitive efficiency of mass production. The rise of individualization and the digital revolution will enable mass personalization to move beyond today’s mass customizations [8].

I4.0 is characterized by highly developed automation and digitalization processes, electronics, and IT in manufacturing and services [17]. In order to manage data flow from intelligent and dispersed system interaction from the perspective of production and service management, I4.0 focuses on developing smart and communicative systems, such as machine-to-machine and human–machine interaction [18]. The traits of autonomy, interoperability, agility, flexibility, decision making and cost-cutting are emphasized throughout I4.0 [19]. Furthermore, I4.0 comprises “new technologies that combine the physical, digital, and biological worlds and influence all disciplines, economies, and organizations”. The technologies include the Internet of Things (IoT), cloud manufacturing (CM), big data (BD), automation and industrial robotics (AIR), additive manufacturing (AM), augmented reality (AR), modeling and simulation (MS), and cybersecurity (CS) [20,21,22,23]. These technologies can potentially connect billions of users to the internet and significantly improve business and organizational effectiveness.

Recent interest in I4.0 has increased due to its numerous advantages for manufacturing organizations. I4.0 is characterized by highly developed automation and digitalization processes, electronics, and IT in manufacturing and services [17]. Machine-to-Machine and Human-to-Machine Interaction are just two examples of the types of intelligent and communicative systems that I4.0 prioritizes in order to manage the flow of data generated by the interaction of smart and distributed systems in production and service delivery [18]. Autonomous interoperability, agility, flexibility, decision making, efficiency, and cost reductions are just some of the benefits of I4.0. Several authors [24,25,26,27,28,29] described the I4.0 technologies. The I4.0 technologies and their descriptions have been summarized in Table 1.

Organizations often struggle to adopt cutting-edge and I 4.0 technologies due to the complexity and expense of arrangement. As part of Industry 5.0’s efforts to address significant concerns, such as economic, social, technological, and cohesion between I4.0 and Industry 5.0, increased cohesion between technology and human-centric models should result in more environmentally friendly products with greater sustainability. Significant obstacles reinforce one another and overlap. According to [30], the frontiers of manufacturing technologies include economic, socio, and technological challenges.

Manufacturing strategies (MS) are long-term plans for using the manufacturing system’s resources to support the business strategy and, consequently, to achieve the organization’s objectives. MS is a collection of manufacturing strategies designed to maximize performance while balancing competing success criteria in order to accomplish production goals. A company’s manufacturing strategy is how it utilizes its resources and prioritizes its activities in order to achieve its company goals. A company’s manufacturing strategy is a pattern of competitiveness that attempts to gain a competitive advantage. The executive team’s job is to ensure that the manufacturing strategy is consistent and that all policies support and supplement the strategic plan [31]. Manufacturing has become a strategic competitive component that manufacturers utilize to differentiate themselves from competitors [32]. Consequently, developing a manufacturing strategy for a business is now crucial. MS is essential to establishing the company’s competitive advantage in the market [33].

The manufacturing strategy implementation process begins with strategy formulation and ends with company performance. MS helps companies establish a well-organized manufacturing system to decrease the associated difficulties [34]. The organized structure of a manufacturing company improves performance and helps gain a competitive advantage [35]. This structure can be achieved by effectively managing manufacturing decisions. A company’s competitiveness is “the firm’s ability to create, produce, and market products that are superior to those offered by competitors, taking price and non-price features into consideration” [36]. Maintaining growth and profits in the manufacturing sector requires a focus on customer loyalty, which can be achieved through the creation of high-quality products that can be delivered in a rapid global market. The degree of manufacturing competitiveness depends on accomplishing competitive priorities and manufacturing performance [37,38]. Utilizing servitization, differentiation, and innovation, companies become more competitive in manufacturing [39]. Manufacturing capability is a company’s output (cost, quality, flexibility, delivery, performance, and innovativeness), which helps maintain a competitive advantage [34,37].

Table 1.

I4.0 technologies.

Table 1.

I4.0 technologies.

| I4.0 Tech | Description |

|---|---|

| Internet of Things (loT) | The Internet of Things allows things to exchange information, collaborate on tasks, and earn real-time decisions [40]. It creates a network between things and people. IoT applications in production systems reduce the magnitude of product recalls, the identification of defective goods early, the change of product designs, and the performance of production systems. |

| Cloud manufacturing (CM) | Described as a service-oriented business model for the cloud-based sharing of manufacturing resources and capabilities. Cloud-based manufacturing offers cloud-based software, a web-based management dashboard, and cloud-based collaboration to manufacturers. It facilitates the integration of distributed manufacturing resources and the creation of a scalable, shared platform across geographically distant production sites and services [41]. |

| Big data and analytics (BD) | It is characterized as enormous collections of heterogeneous data entering from multiple sources in various formats and transferring in real time [42]. This technology and system illustrate how companies can gain a competitive advantage by discovering, processing, and analyzing vast volumes of different data [43]. |

| Automation and industrial robotics (AIR) | There is a growing trend toward using AIR in industrial and increasingly common settings [25]. Electronics, food, logistics, and life sciences will need advanced robot technology to develop production processes (gluing, coating, laser-based processes, precision assembly, and fiber material processing). |

| Additive manufacturing (AM) | Additive manufacturing (AM) involves joining materials to create objects from 3D printing, typically layer-by-layer [44,45]. It helps to reduce waste while also streamlining mass customization and manufacturing on demand. Increased supply chain adaptability is another benefit of producing goods close to their eventual customers. |

| Augmented reality (AR) | Augmented reality (AR) is an exciting new method of bringing computer-generated imagery (CGI) into the real environment [46]. Industrial augmented reality (AR) uses customized goggles, glasses, or smartphone apps to superimpose digital data over a plant worker’s real-world view, enhancing productivity, efficiency, and safety. The purpose of augmented reality is to enhance human performance by giving task-specific information [46]. |

| Modeling and simulation (MS) | A manufacturing system’s design, implementation, testing, and real-time control are all made more accessible by modeling and simulation technology [47]. Modeling simulations can minimize expenses, reduce development time, and enhance product quality. |

| Cyber-Physical Systems (CPS) | CPS are “systems of cooperating computational entities intimately connected to the real world and its activities, simultaneously supplying and consuming internet-based data-access and data-processing services”. CPS-enabled distributed manufacturing systems offer many advantages in effective and flexible manufacturing [48]. |

| Cybersecurity (CS) | Cybersecurity (CS) is a technology that detects, defends against, and responds to cyber-attacks [49]. CS is a new concept for high information security that is broadened to include industrial Internet of Things contexts with the addition of the word cyber. CS technologies include the identification and detection of threats and the prevention of data loss. |

| Block-chain (BC) | BC is a transaction platform that aims to be decentralized and transparent for specific industries. Robustness, openness, immutability, traceability, and process integrity set BC technology apart [50]. Transferring digital knowledge is possible with BC technology. Numerous applications have utilized BC, including design, manufacturing, finance, supply chain, and social [50]. |

To increase the overall manufacturing performance, alignment between I4.0 technologies and long-term strategic goals is required in all of these areas [51]. To maintain a competitive edge, many huge companies are implementing I4.0. BMW, Jaguar Land Rover, Rolls-Royce, General Electric, and Philips are just a few corporations that have already implemented I4.0. Nestlé has been very involved in Germany’s I4.0 agenda to boost efficiency, reduce the environmental impact of packaging waste, and raise productivity through digitalization [52]. The implementation of I4.0 should be transdisciplinary and tightly interconnected amongst many critical domains. Several authors detailed the I4.0 technologies (also called the building blocks of manufacturing) [24,25,26,27,28]. Numerous research studies have been conducted to clarify the significance of implementing I4.0 technologies to enhance the manufacturing strategy’s outputs. Italy has implemented I4.0 technologies (big data analytics, digital supply chain, Internet of Things (IoT), cloud computing, robotics, 3D printing, and automated guided) to increase cost, performance, and innovation [53]. May and Kiritsis [54] utilized I4.0 technologies to achieve zero faults in manufacturing lines, reducing costs and increasing the quality, customer satisfaction, competitiveness, and sustainability of manufacturing operations. Tortorella and Fettermann [55] utilized I4.0 technologies such as 3D printing, virtual model simulation/analysis, big data, cloud service, and IoT to enhance the quality and performance of Brazilian manufacturing firms.

Due to the increased complexity of the manufacturing process, manufacturers are becoming increasingly concerned with decision-making effectiveness. Therefore, multi-criteria decision making (MCDM) methods can significantly reduce the problem’s severity in a fuzzy environment [56,57,58]. Based on expert estimates, the MCDM approaches are used to rate the importance of proposed alternative solutions based on a number of interdependent criteria [59,60]. The evaluative measure may be qualitative or quantitative. It is considered that criteria based on qualitative factors depend on experts and can be subjective, whereas quantitative criteria are independent of experts. Several methods, including ranking and scoring systems, can be utilized to convert qualitative to quantitative variables that are consistent with MCDM procedures. In the literature, a large variety of distinct problem-solving techniques using MCDM are reported [61].

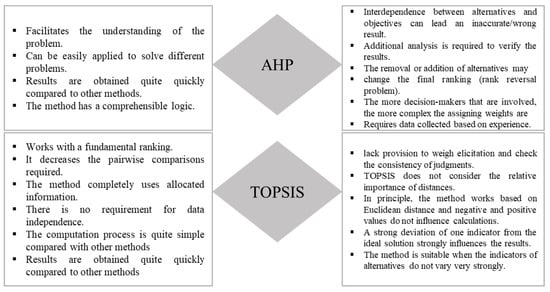

Multi-criteria decision-making (MCDM) began in the 1970s, and at first, several researchers thought it was an interesting area to study. More than seventy strategies for multi-criteria decision-making have developed [62]. Decision analysis is an essential tool in manufacturing because it helps solve problems with different goals, options, and criteria [63]. MADM models are used to find the most suitable options or rank them based on how well they satisfy the goals. It gives a basis for selecting, categorizing, and prioritizing materials and aids the overall evaluation. MCDM is especially important when the application is complex or sophisticated. MCDM is one of the most widely used decision-making techniques in numerous industries [12,13,14,15,16,17,18,19,20,21,22]. MCDM analyzes the criteria to assess whether or not each criterion is favorable or unfavorable for a specific application. In addition, it compares this criterion, based on the selected criteria, to every other possible alternative to aid the decision-maker in choosing the option with the least amount of compromise and the most significant number of advantages. According to previous studies [64,65,66,67,68,69,70,71,72,73], the advantages and disadvantages of the chosen MCDM methods are shown in Figure 2.

Figure 2.

Advantages and disadvantages of existing MCDM methods.

The above literature study demonstrates that very few papers have clarified the relevance of utilizing I4.0 strategies to enhance the manufacturing strategy’s outcomes. Moreover, limited and planned resources, static routing, a lack of connectivity, autonomous control, and isolated information are just a few reasons why the traditional production system cannot keep the organization competitive in its current state. As a result of globalization, organizations now face new challenges, such as a more competitive and sophisticated marketplace, an unpredictable and risky trading environment, and changing customer expectations. If organizations want to maintain their competitive edge, they must prioritize I4.0 technologies that influence MSOs. However, I4.0 is comprised of a variety of technologies, and it is yet unknown how I4.0 technologies can influence manufacturing methods; hence, the literature has received less attention. In addition, prior published articles on the impact of I4.0 technologies on industrial strategy evaluated just one or two outputs. Thus, this paper provides a method for evaluating I4.0 technologies based on the Analytic Hierarchy Process (AHP) and the fuzzy Technique for Order of Preference by Similarity to Ideal Solution (fuzzy-TOPSIS), filling a gap in the existing literature. The current study will investigate the influence of I4.0 technologies on the six MSOs to enhance the manufacturing industries’ competitiveness. The main research contributions are listed below.

- ▪

- This research contributes to a greater comprehension of the fourth industrial revolution by defining I4.0 technologies in connection to MSOs.

- ▪

- This article empirically examines the relationship between I4.0 and MSOs in terms of MSOs by employing a hybrid MCDM model from the perspective of academic and industry experts to help managers gain market competitiveness.

- ▪

- This study identifies the right prioritizations of I4.0 technologies for industrial businesses to counter global competitiveness.

This research is structured as follows: Methods for selecting experts, gathering relevant data and determining I4.0 and MSO technologies are outlined in Section 2. The results are presented in Section 3. Sensitivity analysis results are presented in Section 4. The findings are discussed in Section 5. The final section provides a conclusion, implications, and recommendations for future research.

2. Research Methodology

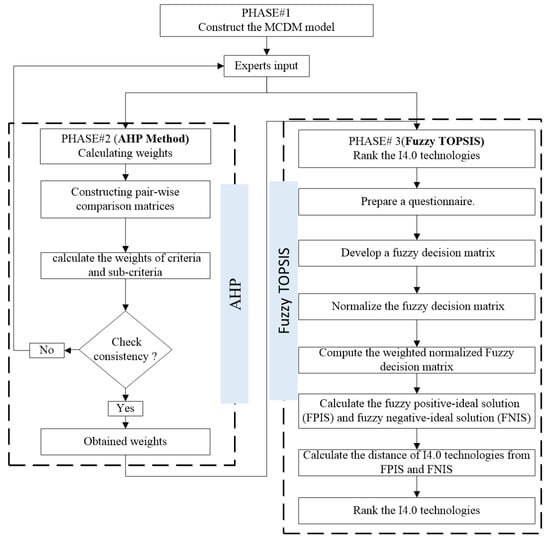

Due to the increased complexity of the manufacturing process, manufacturers are becoming increasingly concerned with decision-making effectiveness. Therefore, multi-criteria decision making (MCDM) methods can significantly reduce the problem’s severity in a fuzzy environment [56,57,58]. MCDM provides a basis for choosing, categorizing, and prioritizing items and aids in the overall evaluation. MCDM is especially useful when the application is complex or sophisticated. MCDM is one of the most widely used decision-making techniques in numerous industries [74]. This study aims to build a powerful hybrid MCDM method for ranking the influence of I4.0 technologies on MSOs. The proposed evaluation approach for I4.0 technologies on MSOs is shown in Figure 3.

Figure 3.

The proposed evaluation approach for I4.0 technologies on MSOs.

AHP is an effective multi-objective decision-making method that combines qualitative and quantitative analysis and is frequently used for comprehensive evaluation. This method supports the importance of qualitative indicators and the rationale underlying subjective factors [75]. The AHP approach can be applied effectively to both qualitative and quantitative data. It can convert a multi-criteria, complex problem into a hierarchical framework [76]. The process necessitates little mathematical calculations [77]. The hierarchy levels are constructed so that there is a set of choices at the lowest level, and at the highest level, there is a broad objective. Criteria and sub-criteria are placed between the minimum and maximum levels (i.e., at the middle level). The AHP determines the relative importance of criteria and sub-criteria. The elements are compared pair-wise using an established scale, as provided by Saaty [78].

TOPSIS is a well-known method for solving the problem of ranking alternatives from most significant to worst. The defining characteristic of TOPSIS is that the favored option should be closest to the ideal positive solution and farthest from the ideal negative solution. Therefore, the optimal resolution is the one that optimizes the benefit criteria while minimizing the cost criteria. In other words, the ideal solution contains the most significant possible values for each criterion, whereas the negative ideal solution has the worst possible values [79]. One of the primary benefits of the TOPSIS method is that it provides influence results for ranking alternatives with unlimited data for every indicator [80]. Dos Santos et al. [81] propose that integrating TOPSIS with other MCDM techniques may result in more efficient and adaptable issue resolution.

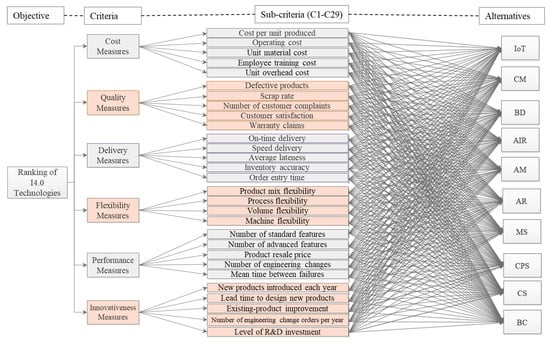

The cost, quality, delivery, flexibility, performance, and inventiveness are all outputs of MS that have been identified as competitive priorities in the literature [27]. MSOs consist of numerous measures (basic elements) obtained from the various functions of manufacturing systems. I4.0 comprises “new technologies that combine the physical, digital, and biological worlds and influence all disciplines, economies, and businesses”. These technologies can connect billions of additional people to the internet and significantly boost commercial and organizational productivity. According to the reported studies [24,25,26,27,28,29], the I4.0 technologies are the loT, CM, BD, AR, AIR, AM, modeling and simulation (MS), CPS, CS, and block-chain (BC). Our previous publication describes MSOs, basic elements, and I4.0 technologies [82,83]. A phase’s methodology (Figure 3) is proposed to rank the I4.0 technologies to achieve market competitiveness. To apply the hybrid MCDM method in order to prioritize the MSOs, all MSOs and their basic measures are initially organized into hierarchical levels (criteria and sub-criteria). Figure 4 shows the decision-making hierarchy to rank I4.0 technologies.

Figure 4.

Decision-making hierarchy to rank I4.0 technologies.

2.1. Expert’s Criteria

Experts were selected for this study based on their knowledge and experience [84]. According to [85], acceptable experts had at least ten years of professional experience in academia, industry, or a combination of both. The majority of specialists chosen from manufacturing companies were associated with I4.0 technologies. The target responders are CEOs, general managers, department heads, specialist engineers, academics, and experts with at least ten years of experience in manufacturing strategies related to industrial organizations, emphasizing MSOs. Experts must have a thorough comprehension of manufacturing, with a focus on manufacturing strategies.

Additionally, professionals should have theoretical or practical knowledge of I4.0 technologies [55]. They were in charge of market strategy or manufacturing and operations. Therefore, they have a comprehensive understanding of manufacturing strategies. Since these specialists have worked for manufacturing or consulting organizations, the information acquired through questionnaires is quite reliable. Similarly, academic specialists were selected from professors and doctorates who have published articles on manufacturing strategies and Industry 4.0 in reputable journals. Therefore, the chosen academic experts have a substantial impact on this field.

To explain the research, experts were interviewed individually, and those who were geographically unable to participate in person were interviewed online. They were initially sent an email describing the purpose of the study and confirming their participation. Most experts responded favorably to the email. However, only fourteen professionals completed the surveys.

2.2. Analytic Hierarchy Process (AHP)

The Analytical Hierarchical Process (AHP) was developed by Saaty [78]. It is an efficient method for resolving complicated problems. AHP determines the relative significance of factors in multi-criteria decision problems. It allows it to incorporate human judgment based on qualitative and quantitative factors [86]. AHP has been extensively utilized to handle complex, multi-criteria decision-making issues. The AHP is based on the following steps:

Step 1: Construct an AHP structure. MCDM has a hierarchical structure. The MCDM is disassembled into a hierarchy of interconnected decision factors. The AHP organizes objectives, criteria, sub-criteria, and alternatives in a hierarchical structure. Typical hierarchy levels are shown in Figure 4: the problem’s overall goal on the left, several criteria and sub-criteria in the center, and decision alternatives on the right.

Step 2: Establish a decision matrix for pair-wise comparisons. The pair-wise comparison of criteria is the second step in determining the relative weight of the criteria. Multiple, multiple pair-wise comparisons in AHP are based on a standard comparison scale with different levels, as illustrated in Table 2. Suppose that = 1, 2, …, n} is the set of criteria. An evaluation matrix can be obtained in which every factor (i, j = 1, 2, …, n) represents the relative weights of the criteria illustrated in Equation (1).

Table 2.

Pair-wise comparison scale for AHP method.

Step 3: Calculating the criteria weight. The weight can be calculated by Equation (2).

The can be acquired. A is consistent if the equals n and the rank of the matrix A is n. In this instance, the relative criteria are discussed. The weight of each criterion will be computed by normalizing any of matrix A’s rows or columns.

Step 4: Calculate the consistency using the following equations to determine its consistency index (CI) and consistency ratio (CR). The CR must be less than 0.1 to claim that the comparison matrix is consistent and identify RI as the random index. The matrix size is applied to RI determine the amount of randomness created. RI equals 0.90 when n is equal to four, 1.12 when n is equal to five, and 1.24 when n is equal to six [87]

where represents the maximum eigenvalue of the comparison matrix, and n represents the total number of criteria. RI is a random index.

2.3. Fuzzy TOPSIS Method

Chen [88] created the fuzzy TOPSIS method for resolving uncertain MCDM issues. Decision-makers use linguistic variables to estimate the weights of criteria and the ratings of alternatives. Thus, represents the importance of the criterion, (j = 1, …, m), outlined by the decision-maker. Similarly, represents the score of the I4.0 technology (alternatives), (i = 1, …, n), regarding criterion j, as indicated by the decider. The fuzzy triangular numbers required by Fuzzy TOPSIS are shown in Table 3. Given these conditions, the method comprises the subsequent steps [89,90,91,92].

Table 3.

Fuzzy TOPSIS Linguistic Scale.

Step 1. Collect the weights and ratings of options supplied by k decision-makers, as illustrated by Equations (5) and (6).

Step 2. Combining the fuzzy decision matrix of criteria (W) and alternatives (D) using Equations (7) and (8)

Step 3. Normalize the fuzzy choice matrix of the alternatives using a linear scale transformation (D). Equations (9)–(11) generate the normalized fuzzy decision matrix R.

Step 4. Multiply the weights of the evaluation criterion, , by the normalized fuzzy decision matrix elements, to obtain the weighted normalized decision matrix, V, by equation (12)

where is given by Equation (13)

Step 5. Determine the fuzzy positive ideal solution (FPIS, ) and fuzzy negative ideal solution (FNIS, ) using Equations(14) and (15)

Step 6. Calculate the distances and for each alternative based on Equations (16) and (17)

where d represents the vertex-based distance between two fuzzy numbers. This can be demonstrated for TFNs via Equation (18)

Step 7. Determine the proximity coefficient, , using Equation (19)

Step 8. Based on the closeness coefficient, , compute the decreasing order of possibilities. The optimal option is the one that is closest to the FPIS and farthest from the FNIS.

3. Results

3.1. AHP Calculations

A questionnaire in the form of pair-wise comparison, utilizing the previously mentioned hierarchical structure, is developed. Respondents were then asked to use the five linguistic scores listed in Table 2 to evaluate how each criterion related to the others. The AHP initial direct relation matrix was obtained from all experts, as shown in Table 4. Criteria weights and corresponding parameter values are shown in Table 5.

Table 4.

Pair-wise comparison matrix for all experts.

Table 5.

Criteria weights and related parameter values.

Then, the consistency ratios (CR) were computed to confirm the accuracy of the data. Since CR values do not exceed 10%, estimated weights can be utilized to establish the MSOs’ priority ranking. Participants were neither inconsistent nor random when comparing the criteria and sub-criteria. The consistency ratios (CR) (%) for other factors, cost measures, quality measures, delivery measures, flexibility measures, performance measures, and innovativeness measures are (8.9, 8.3, 5.1, 8.2, 6.4, and 6.0). Thus, the evaluation technique can be regarded as satisfactory, and the AHP scale and survey format can be made available for replication in real-world settings.

Table 6 shows the summary of weights obtained from the AHP method. The table displays the final weights assigned to the factors that affect MSOs adopting I4.0 technologies (smart manufacturing). The highest weighed sub-factor for MSOs is the operating cost (C2) with 0.1006. The next most crucial sub-factor was cost per unit produced (C1), given a weight of 0.0980. In this perspective, other measures appear to be moderately or less significant to MSOs when adopting I4 technologies (Table 6).

Table 6.

Summary of weights obtained from the AHP method.

3.2. Fuzzy TOPSIS Method

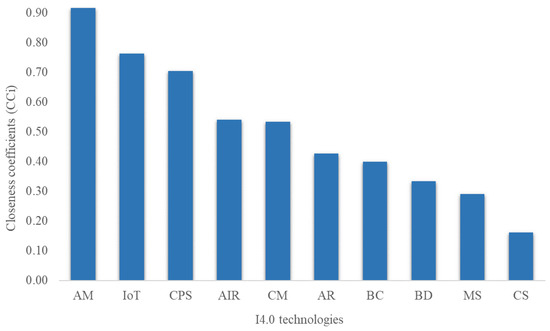

This section describes the implementation of the TOPSIS method, which ranks I4.0 technologies. In addition, the sub-criteria that contribute the most to the overall separation of each technology can be identified, allowing for the effective creation and implementation of improvement plans. The experts are asked to evaluate the expected performance of each I4.0 technology concerning each sub-criteria using a questionnaire. Ten technologies are reviewed, and fourteen experts, k1–k14, are asked to complete the questionnaire. Due to space constraints in this research, this article only provides an example of the collected data from one of the experts for the alternatives evaluation, as illustrated in Table 7. Therefore, the distances and for each alternative and closeness coefficient, I4.0 technologies are shown in Table 8 and Figure 5. Figure 5 shows the closeness coefficients and final ranking of I4.0 technologies.

Table 7.

An example of the collected data from one of the experts for the alternatives evaluation.

Table 8.

Fuzzy TOPSIS result (distances and closeness coefficient).

Figure 5.

Ranking of I4.0 technologies.

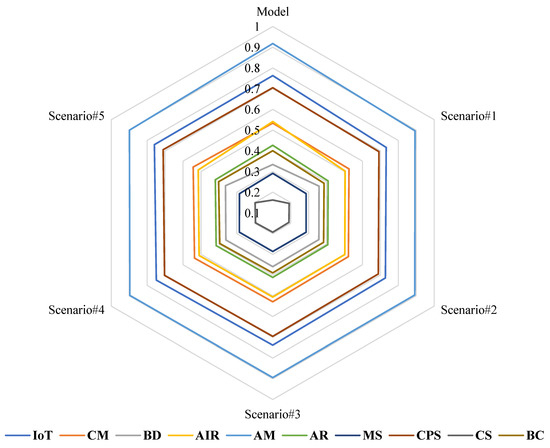

4. Sensitivity Analysis

The sensitivity analysis aims to demonstrate the impact of varying criterion weights on ranking I4.0 technologies. It was conducted to illustrate the implications of modifying the weights on the final TOPSIS results and alternative rankings. The sensitivity analysis is carried out in this study to investigate the robustness and consistency of the ranking in terms of criterion weight. In addition, it focuses on qualitatively and quantitatively enhancing the output of this model, given the sensitivity involved in decision making due to uncertain input values. To do this, the primary purpose of this research is to reduce or minimize cost measures and improve or maximize outputs (quality, delivery, flexibility, performance, and innovativeness). The configuration of sensitivity analysis is shown in Table 9.

Table 9.

The configuration of sensitivity analysis.

Consequently, the weights of the decision criteria were changed across five different scenarios. In the first scenario, all weights are equal; in the second scenario, Max%85 Min%15; in the third scenario, Max%80 Min%20; in the fourth scenario, Max%75 Min%25; and in the fifth scenario, Max%70 Min%30. Using the TOPSIS approach, the closeness co-efficients were then determined. Table 10 shows the findings of the sensitivity analysis. It should be noted that the first row of the table (Main) represents the model’s obtained results. Figure 6 displays the graphical representation of the sensitivity analysis. As demonstrated in Table 10, changing the criteria weights has no significant effect on the model’s output and ranking. However, additive manufacturing (AM) achieved the greatest

value under all evaluated scenarios. As a result, AM was chosen as the most suitable I4.0 technology for achieving market competitiveness.

Table 10.

Results of the sensitivity analysis.

Figure 6.

Sensitivity analysis.

5. Discussion

In recent years, researchers have significantly emphasized I4.0 technologies concerning MSOs. However, a well-structured approach is still lacking to assist a company in assessing and selecting the appropriate I4.0 technologies. Consequently, this study aims to evaluate the potential and influence of I4.0 technologies on MSO and to rank these technologies using a hybrid fuzzy MCDM methodology. In addition, a sensitivity analysis was conducted to examine the sensitivity of the results to changes in the weights of the criterion. Thus, the objective of this study was to seek an improved ranking and selection of I4.0 technologies. This study prioritizes and ranks the ten I4.0 technologies using the AHP and fuzzy TOPSIS methods.

According to the overall weights, the most crucial factor for MSOs to become competitive in the market is operating cost (C2). The operating cost is expenses related to the operation of a business or the operation of a machine, component, piece of equipment, or facilities to prepare the product. As a result of the implementation of integrated automated systems and data management, manufacturing facilities will experience a remarkable reduction in production costs. I4.0 technologies have enhanced production line efficiencies, resulting in greater material consumption and decreased waste as well as new ways to reuse and recycle trash to bring it back into production processes and smaller package sizes, which reduces production costs [93].

Cost per unit produced (C1) is the second critical enabler for MSOs to achieve market competitiveness. The cost per unit produced refers to how much a business pays to manufacture each unit of a product it sells. The manufacturing firms should offer reduced total costs at market-competitive prices [94]. The most effective methods for organizations to maintain their competitive advantage are low-cost strategies and differentiation. The low-cost corporation may engage in several activities to maintain or improve its market competitiveness. Frequently, I4.0-driven manufacturing provides operational gains by reducing unit production costs. As shown in Table 8, various enablers tend to have a moderate to minor impact on MSOs’ adoption of I4 technology.

Figure 5 illustrates the ranking of I4.0 technologies and the closeness coefficients . Equation (19) was used to calculate these values. According to the findings, AM obtained the first technology in order to gain market competitiveness with 0.9175 Additive manufacturing is often considered the most critical pillar of the I4.0 transition. Value and earlier studies support this finding. The capabilities of traditional manufacturing technologies constrain the physical component of intelligent factories. As a result, additive manufacturing is one of the most critical components of Industry 4.0. Because of the need for mass customization in I4.0, non-traditional production methods must be developed [95]. Thus, AM became a crucial technology for the fabrication of customized items due to its capacity to produce complex things with enhanced properties (new materials, shapes). AM is utilized in several industries, including aerospace, biomedical, and manufacturing, due to its higher product quality [96].

The Internet of Things (IoT) is listed as the second technology in market competitiveness for MSOs with a value of 0.7629 . The Internet of Things enables physical objects to communicate with one another, share data, and coordinate actions [40]. In the context of I4.0, the IoT is commonly referred to as the industrial Internet of Things (IIoT), which focuses on the IoT’s industrial applications [97]. The IoT is utilized extensively, for instance, in transportation, healthcare, and construction [98]. Consequently, mobile devices can facilitate more intelligent control of homes and towns. It increases safety and provides personal protection. By automating tasks, we save a great deal of time. Even when we are far from our actual location, information is readily available and constantly updated in real time. With a ranking of 0.7044 , the cyber-physical system (CPS) is the third-ranked I4.0 technology. The fourth-ranked I4.0 technology is automation and industrial robotics (AIR), which has a score of 0.5410. As indicated in Figure 5, other I4.0 technologies tend to be of moderate or less relevance to MSOs when implementing I4.0 technologies.

6. Conclusions, Implications, Limitations, and Future Work

This study aims to rank the I4.0 technologies in order to achieve market competitiveness. The implications of this research are both practical and theoretically significant. Theoretically, this study has presented arguments for empirically analyzing the relationship between MSOs and Industry 4.0 in order to achieve market competitiveness. It started with identifying I4.0 technologies and MSOs with their measures. The influence of I4.0 technologies on MSOs was quantitatively examined, consolidating the understanding of the relationship between I4.0 technologies and MSOs. This made it simpler to comprehend their impact on smart manufacturing. In order to improve MSOs’ competitiveness in the market, this study also offered theoretical justifications for empirically assessing the factors that influence their adoption of I4.0 technologies. In order to compete against global competition, manufacturing firms should prioritize the right I4.0 technologies, according to the research findings. Moreover, the results indicate that organizations and businesses seeking to implement higher Industry 4.0 must properly align I4.0 technologies with MSOs.

From a managerial implications perspective, this research provides managers with key insights for boosting the adoption of I4.0 technologies on MSO. To achieve market competitiveness and obtain pertinent feedback from this study’s findings, managers should prioritize the proper I4.0 technologies concerning production plans. The I4.0 technologies ranking helps the organization’s managers obtain the full benefits of implementing these technologies into well-designed and established processes (either strategic or operational). In addition, this research facilitates the transition from conventional to smart manufacturing by highlighting the crucial impact these technologies may play in driving a company to gain a competitive edge. This finding illustrates that adopting I4.0 technologies is becoming a new “must” in manufacturing enterprises, emphasizing the need for businesses to begin using I4.0 technologies in order to maintain or perhaps increase their competitiveness.

According to the findings, the most critical sub-criterion is the operating cost (C2), which is followed by the cost per unit produced (C1). Other measures are usually of moderate or less importance to MSOs when implementing I4 technologies. According to the ranking of I4.0 technologies, additive manufacturing (AM) is the most appropriate I4.0 technology to counter global competition. Following that are the Internet of Things (IoT) and the cyber-physical system (CPS). Other I4.0 technologies are of moderate or less relevance to MSOs when I4 technologies are implemented.

This paper has several limitations and shortcomings. Firstly, as I4.0 technology adoption is still in its infancy in most industries, no case study or empirical study has been undertaken to determine the influences of I4.0 technologies on MSOs. Consequently, future research should conduct empirical research in manufacturing areas. Secondly, future work and studies may employ various approaches, such as FANP or PROMETHEE, and combine them with additional surveys to acquire a larger perspective on the problem. Thirdly, I4.0 is being developed yearly with discoveries and advancements in industry 4.0-related technology. Thus, other technologies, such as ”Digital Twins”, should be considered in future studies to study the influence of these technologies on MSOs.

Author Contributions

F.M.A.: Conceptualization, data curation, investigation, methodology, visualization, and writing—original draft, writing—review, and editing. A.M.A.-A.: Conceptualization, funding acquisition, investigation, resources, supervision, and writing—review and editing funding acquisition; S.A.: Supervision, and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This study received funding from the Raytheon Chair for Systems Engineering. The authors are grateful to the Raytheon Chair for Systems Engineering for funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data are available in the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kagermann, H.; Lukas, W.-D.; Wahlster, W. Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen Revolution. VDI Nachr. 2011, 13, 2–3. [Google Scholar]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Ullah, A.S.; Teti, R.; Kubo, A. Developing sensor signal-based digital twins for intelligent machine tools. J. Ind. Inf. Integr. 2021, 24, 100242. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards more sustainable, resilient and human-centric industry. Eur. Comm. 2021. Available online: https://data.europa.eu/doi/10.2777/073781 (accessed on 8 June 2022).

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Chien, C.-F.; Hong, T.-y.; Guo, H.-Z. A conceptual framework for “Industry 3.5” to empower intelligent manufacturing and case studies. Procedia Manuf. 2017, 11, 2009–2017. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Sokolov, A.; Tantawi, O. Advances in industrial robotics: From industry 3.0 automation to industry 4.0 collaboration. In Proceedings of the 2019 4th Technology Innovation Management and Engineering Science International Conference (TIMES-iCON), Bangkok, Thailand, 11–13 December 2019; pp. 1–4. [Google Scholar]

- Aheleroff, S.; Mostashiri, N.; Xu, X.; Zhong, R. Mass personalisation as a service in industry 4.0: A resilient response case study. Adv. Eng. Inform. 2021, 50, 101438. [Google Scholar] [CrossRef]

- El Saddik, A. Digital twins: The convergence of multimedia technologies. IEEE MultiMedia 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Zakoldaev, D.; Shukalov, A.; Zharinov, I. From Industry 3.0 to Industry 4.0: Production modernization and creation of innovative digital companies. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Novosibirsk, Russian Federation, 12–14 December 2019; p. 012206. [Google Scholar]

- Zakoldaev, D.; Shukalov, A.; Zharinov, I.; Zharinov, O. Realization of project procedures in the item designing companies of the Industry 3.0 and Industry 4.0. J. Phys. Conf. Ser. 2019, 1333, 072030. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Sony, M.J.P.; Research, M. Industry 4.0 and lean management: A proposed integration model and research propositions. Prod. Manuf. Res. 2018, 6, 416–432. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0–a glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Sung, T. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Chang. 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Salkin, C.; Oner, M.; Ustundag, A.; Cevikcan, E. A conceptual framework for Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 3–23. [Google Scholar]

- Perales, D.P.; Valero, F.A.; García, A.B. Industry 4.0: A classification scheme. In Closing the Gap between Practice and Research in Industrial Engineering; Springer: Berlin/Heidelberg, Germany, 2018; pp. 343–350. [Google Scholar]

- Kolberg, D.; Zühlke, D. Lean automation enabled by industry 4.0 technologies. IFAC-Pap. 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Kolberg, D.; Knobloch, J.; Zühlke, D. Towards a lean automation interface for workstations. Int. J. Prod. Res. 2017, 55, 2845–2856. [Google Scholar] [CrossRef]

- Jackson, M.; Hedelind, M.; Hellström, E.; Granlund, A.; Friedler, N. Lean automation: Requirements and solutions for efficient use of robot automation in the swedish manufacturing industry. Int. J. Eng. Res. Innov. 2011, 3, 36–43. [Google Scholar]

- Henning, K. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; Forschungsunion: Berlin, Germany, 2013. [Google Scholar]

- Alcácer, V.; Cruz-Machado, V. Scanning the industry 4.0: A literature review on technologies for manufacturing systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Ko, M.; Kim, C.; Lee, S.; Cho, Y. An assessment of smart factories in Korea: An exploratory empirical investigation. Appl. Sci. 2020, 10, 7486. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Akarte, M. Smart manufacturing: A framework for managing performance. Int. J. Comput. Integr. Manuf. 2021, 34, 227–256. [Google Scholar] [CrossRef]

- Dohale, V.; Gunasekaran, A.; Akarte, M.M.; Verma, P. 52 Years of manufacturing strategy: An evolutionary review of literature (1969–2021). Int. J. Prod. Res. 2022, 60, 569–594. [Google Scholar] [CrossRef]

- Ghasempour, A. Internet of things in smart grid: Architecture, applications, services, key technologies, and challenges. Inventions 2019, 4, 22. [Google Scholar] [CrossRef]

- Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 26, 1–20. [Google Scholar] [CrossRef]

- Badurdeen, F.; Jawahir, I. Strategies for value creation through sustainable manufacturing. Procedia Manuf. 2017, 8, 20–27. [Google Scholar] [CrossRef]

- ElMaraghy, H.; Schuh, G.; ElMaraghy, W.; Piller, F.; Schönsleben, P.; Tseng, M.; Bernard, A. Product variety management. Prod. Var. Man-Agement. 2013, 62, 629–652. [Google Scholar] [CrossRef]

- Dohale, V.; Gunasekaran, A.; Akarte, M.M.; Verma, P. Twenty-five years’ contribution of “Benchmarking: An International Journal” to manufacturing strategy: A scientometric review. Benchmarking Int. J. 2020, 27, 2887–2908. [Google Scholar] [CrossRef]

- Miltenburg, J. Setting manufacturing strategy for a factory-within-a-factory. Int. J. Prod. Econ. 2008, 113, 307–323. [Google Scholar] [CrossRef]

- Miltenburg, J. Manufacturing Strategy: How to Formulate and Implement a Winning Plan; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Ajitabh, A.; Momaya, K. Competitiveness of firms: Review of theory, frameworks and models. Singap. Manag. Rev. 2004, 26, 45–61. [Google Scholar]

- Lekurwale, R.; Akarte, M.; Raut, D. Framework to evaluate manufacturing capability using analytical hierarchy process. Int. J. Adv. Manuf. Technol. 2015, 76, 565–576. [Google Scholar] [CrossRef]

- Kulkarni, S.; Verma, P.; Mukundan, R. Assessing manufacturing strategy definitions utilising text-mining. Int. J. Prod. Res. 2019, 57, 4519–4546. [Google Scholar] [CrossRef]

- Sminia, H.; Ates, A.; Paton, S.; Smith, M. High value manufacturing: Capability, appropriation, and governance. Eur. Manag. J. 2019, 37, 516–528. [Google Scholar] [CrossRef]

- Al-Fuqaha, A.; Guizani, M.; Mohammadi, M.; Aledhari, M.; Ayyash, M. Internet of things: A survey on enabling technologies, protocols, and applications. IEEE Commun. Surv. Tutorials 2015, 17, 2347–2376. [Google Scholar] [CrossRef]

- Xu, X. From cloud computing to cloud manufacturing. Robot. Comput.-Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Ferreira, P.; Maffei, A.; Podržaj, P.; Mądziel, M.; Antonelli, D.; Lanzetta, M.; Barata, J.; Boffa, E.; Finžgar, M.J.S. Mapping Industry 4.0 Enabling Technologies into United Nations Sustainability Development Goals. Sustainability 2021, 13, 2560. [Google Scholar] [CrossRef]

- LaValle, S.; Lesser, E.; Shockley, R.; Hopkins, M.S.; Kruschwitz, N. Big data, analytics and the path from insights to value. MIT Sloan Manag. Rev. 2011, 52, 21–32. [Google Scholar]

- Esmaeilian, B.; Behdad, S.; Wang, B. The evolution and future of manufacturing: A review. J. Manuf. Syst. 2016, 39, 79–100. [Google Scholar] [CrossRef]

- M Abdullah, F.; Anwar, S.; Al-Ahmari, A.J.M. Thermomechanical Simulations of Residual Stresses and Distortion in Electron Beam Melting with Experimental Validation for Ti-6Al-4V. Metals 2020, 10, 1151. [Google Scholar] [CrossRef]

- Yew, A.; Ong, S.; Nee, A.Y. Towards a griddable distributed manufacturing system with augmented reality interfaces. Robot. Comput. Manuf. 2016, 39, 43–55. [Google Scholar] [CrossRef]

- Adamson, G.; Wang, L.; Moore, P. Feature-based control and information framework for adaptive and distributed manufacturing in cyber physical systems. J. Manuf. Syst. 2017, 43, 305–315. [Google Scholar] [CrossRef]

- Kocian, J.; Tutsch, M.; Ozana, S.; Koziorek, J. Application of modeling and simulation techniques for technology units in industrial control. In Frontiers in Computer Education; Springer: Berlin/Heidelberg, Germany, 2012; pp. 491–499. [Google Scholar]

- Mullet, V.; Sondi, P.; Ramat, E. A review of cybersecurity guidelines for manufacturing factories in industry 4.0. IEEE Access 2021, 9, 23235–23263. [Google Scholar] [CrossRef]

- Abeyratne, S.A.; Monfared, R. Blockchain ready manufacturing supply chain using distributed ledger. Int. J. Res. Eng. Technol. 2016, 5, 1–10. [Google Scholar]

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2019, 25, 323–346. [Google Scholar] [CrossRef]

- Salam, M. Analyzing manufacturing strategies and Industry 4.0 supplier performance relationships from a resource-based perspective. Benchmarking Int. J. 2019, 28, 1697–1716. [Google Scholar] [CrossRef]

- Chiarini, A.; Belvedere, V.; Grando, A. Industry 4.0 strategies and technological developments. An exploratory research from Italian manufacturing companies. Prod. Plan. Control. 2020, 31, 1385–1398. [Google Scholar] [CrossRef]

- May, G.; Kiritsis, D. Zero Defect Manufacturing Strategies and Platform for Smart Factories of Industry 4.0. In Proceedings of the International Conference on the Industry 4.0 Model for Advanced Manufacturing, Belgrade, Serbia, 3–6 June 2019; pp. 142–152. [Google Scholar]

- Tortorella, G.L.; Fettermann, D. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Govindan, K.; Kannan, D.; Mathiyazhagan, K.; de Sousa Jabbour, A.B.L.; Jabbour, C. Analysing green supply chain management practices in Brazil’s electrical/electronics industry using interpretive structural modelling. Int. J. Environ. Stud. 2013, 70, 477–493. [Google Scholar] [CrossRef]

- Wu, C.; Barnes, D. An integrated model for green partner selection and supply chain construction. J. Clean. Prod. 2016, 112, 2114–2132. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Bongo, M.F.; Alimpangog, K.M.S.; Loar, J.F.; Montefalcon, J.A.; Ocampo, L.A. An application of DEMATEL-ANP and PROMETHEE II approach for air traffic controllers’ workload stress problem: A case of Mactan Civil Aviation Authority of the Philippines. J. Air Transp. Manag. 2018, 68, 198–213. [Google Scholar] [CrossRef]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Liu, Z. Combining multi-criteria decision making (MCDM) methods with building information modelling (BIM): A review. Autom. Constr. 2021, 121, 103451. [Google Scholar] [CrossRef]

- Huang, C.-N.; Liou, J.J.; Chuang, Y.-C. A method for exploring the interdependencies and importance of critical infrastructures. Knowl.-Based Syst. 2014, 55, 66–74. [Google Scholar] [CrossRef]

- Alias, M.A.; Hashim, S.Z.M.; Samsudin, S. Multi criteria decision making and its applications: A literature review. J. Teknol. Mklm. 2008, 20, 129–152. [Google Scholar]

- Chakraborty, S. Applications of the MOORA method for decision making in manufacturing environment. Int. J. Adv. Manuf. Technol. 2011, 54, 1155–1166. [Google Scholar] [CrossRef]

- Mahmoodzadeh, S.; Shahrabi, J.; Pariazar, M.; Zaeri, M. Project selection by using fuzzy AHP and TOPSIS technique. Int. J. Ind. Manuf. Eng. 2007, 1, 270–275. [Google Scholar]

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T. Evaluating barriers for reverse logistics implementation under a multiple stakeholders’ perspective analysis using grey decision making approach. Resour. Conserv. Recycl. 2018, 128, 315–335. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Barriers to environmentally-friendly clothing production among Chinese apparel companies. Asian Bus. Manag. 2011, 10, 425–452. [Google Scholar] [CrossRef]

- Aghelie, A.; Mustapha, N.; Sorooshian, S.; Azizan, N. Mathematical modeling of interrelationship analysis to determine multi-criteria decision making casual relations. J. Adv. Res. Des. 2016, 20, 18–33. [Google Scholar]

- Sivakumar, K.; Jeyapaul, R.; Vimal, K.; Ravi, P. A DEMATEL approach for evaluating barriers for sustainable end-of-life practices. J. Manuf. Technol. Manag. 2018, 29, 1065–1091. [Google Scholar]

- Aruldoss, M.; Lakshmi, T.M.; Venkatesan, V.P. A survey on multi criteria decision making methods and its applications. Am. J. Inf. Syst. 2013, 1, 31–43. [Google Scholar]

- Mills, A.F. A simple yet effective decision support policy for mass-casualty triage. Eur. J. Oper. Res. 2016, 253, 734–745. [Google Scholar] [CrossRef]

- Zaidan, B.; Zaidan, A. Software and hardware FPGA-based digital watermarking and steganography approaches: Toward new methodology for evaluation and benchmarking using multi-criteria decision-making techniques. J. Circuits Syst. Comput. 2017, 26, 1750116. [Google Scholar] [CrossRef]

- Siksnelyte, I.; Zavadskas, E.K.; Streimikiene, D.; Sharma, D. An overview of multi-criteria decision-making methods in dealing with sustainable energy development issues. Energies 2018, 11, 2754. [Google Scholar] [CrossRef]

- Boran, F.E.; Genç, S.; Kurt, M.; Akay, D. A multi-criteria intuitionistic fuzzy group decision making for supplier selection with TOPSIS method. Expert Syst. Appl. 2009, 36, 11363–11368. [Google Scholar] [CrossRef]

- Liu, C.-H.; Tzeng, G.-H.; Lee, M.-H.; Lee, P.-Y. Improving metro–airport connection service for tourism development: Using hybrid MCDM models. Tour. Manag. Perspect. 2013, 6, 95–107. [Google Scholar] [CrossRef]

- Vonk, S.M.; Hollander, D.J.; Murk, A. Was the extreme and wide-spread marine oil-snow sedimentation and flocculent accumulation (MOSSFA) event during the Deepwater Horizon blow-out unique? Mar. Pollut. Bull. 2015, 100, 5–12. [Google Scholar] [CrossRef]

- Triantaphyllou, E.; Lin, C.-T. Development and evaluation of five fuzzy multiattribute decision-making methods. Int. J. Approx. Reason. 1996, 14, 281–310. [Google Scholar] [CrossRef]

- Javanbarg, M.B.; Scawthorn, C.; Kiyono, J.; Shahbodaghkhan, B. Fuzzy AHP-based multicriteria decision making systems using particle swarm optimization. Expert Syst. Appl. 2012, 39, 960–966. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Beikkhakhian, Y.; Javanmardi, M.; Karbasian, M.; Khayambashi, B. The application of ISM model in evaluating agile suppliers selection criteria and ranking suppliers using fuzzy TOPSIS-AHP methods. Expert Syst. Appl. 2015, 42, 6224–6236. [Google Scholar] [CrossRef]

- Onat, N.C.; Gumus, S.; Kucukvar, M.; Tatari, O. Application of the TOPSIS and intuitionistic fuzzy set approaches for ranking the life cycle sustainability performance of alternative vehicle technologies. Sustain. Prod. Consum. 2016, 6, 12–25. [Google Scholar] [CrossRef]

- Dos Santos, B.M.; Godoy, L.P.; Campos, L.M. Performance evaluation of green suppliers using entropy-TOPSIS-F. J. Clean. Prod. 2019, 207, 498–509. [Google Scholar] [CrossRef]

- Abdullah, F.M.; Al-Ahmari, A.M.; Anwar, S. Exploring Key Decisive Factors in Manufacturing Strategies in the Adoption of Industry 4.0 by Using the Fuzzy DEMATEL Method. Processes 2022, 10, 987. [Google Scholar] [CrossRef]

- Abdullah, F.M.; Saleh, M.; Al-Ahmari, A.M.; Anwar, S. The Impact of Industry 4.0 Technologies on Manufacturing Strategies: Proposition of Technology-Integrated Selection. IEEE Access 2022, 10, 21574–21583. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Pradhan, N.; Macias de Anda, E.; Trevino Martinez, S.; Sawhney, R.; Kumar, M. Designing lean value streams in the fourth industrial revolution era: Proposition of technology-integrated guidelines. Int. J. Prod. Res. 2020, 58, 5020–5033. [Google Scholar] [CrossRef]

- Baker, J.; Lovell, K.; Harris, N. How expert are the experts? An exploration of the concept of ‘expert’within Delphi panel techniques. Nurse Res. 2006, 14, 59–70. [Google Scholar] [CrossRef]

- Badri, M.A. A combined AHP–GP model for quality control systems. Int. J. Prod. Econ. 2001, 72, 27–40. [Google Scholar] [CrossRef]

- Aliyev, R.; Temizkan, H.; Aliyev, R.J.S. Fuzzy analytic hierarchy process-based multi-criteria decision making for universities ranking. Symmetry 2020, 12, 1351. [Google Scholar] [CrossRef]

- Chen, C.-T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Jumarni, R.F.; Zamri, N.J. An integration of fuzzy TOPSIS and fuzzy logic for multi-criteria decision making problems. Int. J. Eng. Technol. 2018, 7, 102–106. [Google Scholar] [CrossRef]

- Basahel, A.; Taylan, O.J.; Engineering, S. Using fuzzy AHP and fuzzy TOPSIS approaches for assessing safety conditions at worksites in construction industry. Int. J. Saf. Secur. Eng. 2016, 6, 728–745. [Google Scholar] [CrossRef]

- Carnero, M.C. Developing a fuzzy TOPSIS model combining MACBETH and fuzzy shannon entropy to select a gamification App. Mathematics 2021, 9, 1034. [Google Scholar] [CrossRef]

- Ocampo, L.; Deiparine, C.B.; Go, A.L. Mapping strategy to best practices for sustainable food manufacturing using fuzzy DEMATEL-ANP-TOPSIS. Eng. Manag. J. 2020, 32, 130–150. [Google Scholar] [CrossRef]

- Genc, T.S.; De Giovanni, P. Closed-loop supply chain games with innovation-led lean programs and sustainability. Int. J. Prod. Econ. 2020, 219, 440–456. [Google Scholar] [CrossRef]

- Wang, J.; Cao, D. Relationships between two approaches for planning manufacturing strategy: A strategic approach and a paradigmatic approach. Innov. Manag. Strateg. Technol. Plan. 2008, 115, 349–361. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Zawadzki, P.; Żywicki, K. Smart product design and production control for effective mass customization in the Industry 4.0 concept. Manag. Prod. Eng. Rev. 2016, 7, 105–112. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C.J. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Sezer, O.B.; Dogdu, E.; Ozbayoglu, A. Context-aware computing, learning, and big data in internet of things: A survey. IEEE Internet. Things J. 2017, 5, 1–27. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).