Recent Development for Ultra-Precision Macro–Micro Dual-Drive System: A Review

Abstract

1. Introduction

2. Ultra-Precision Technology

3. Ultra-Precision Macro–Micro Dual-Drive System

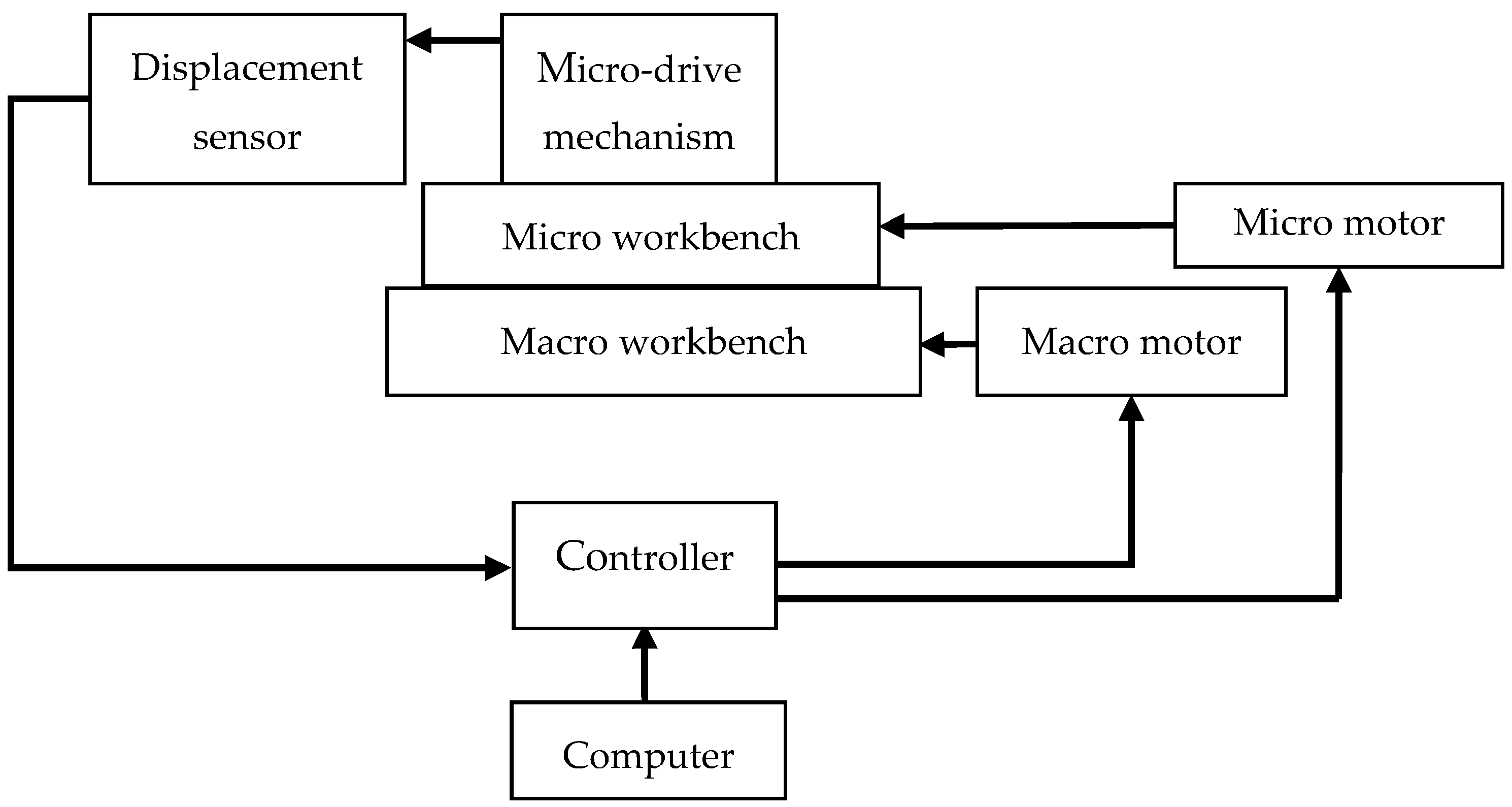

3.1. Research on Macro–Micro Dual-Drive Technology

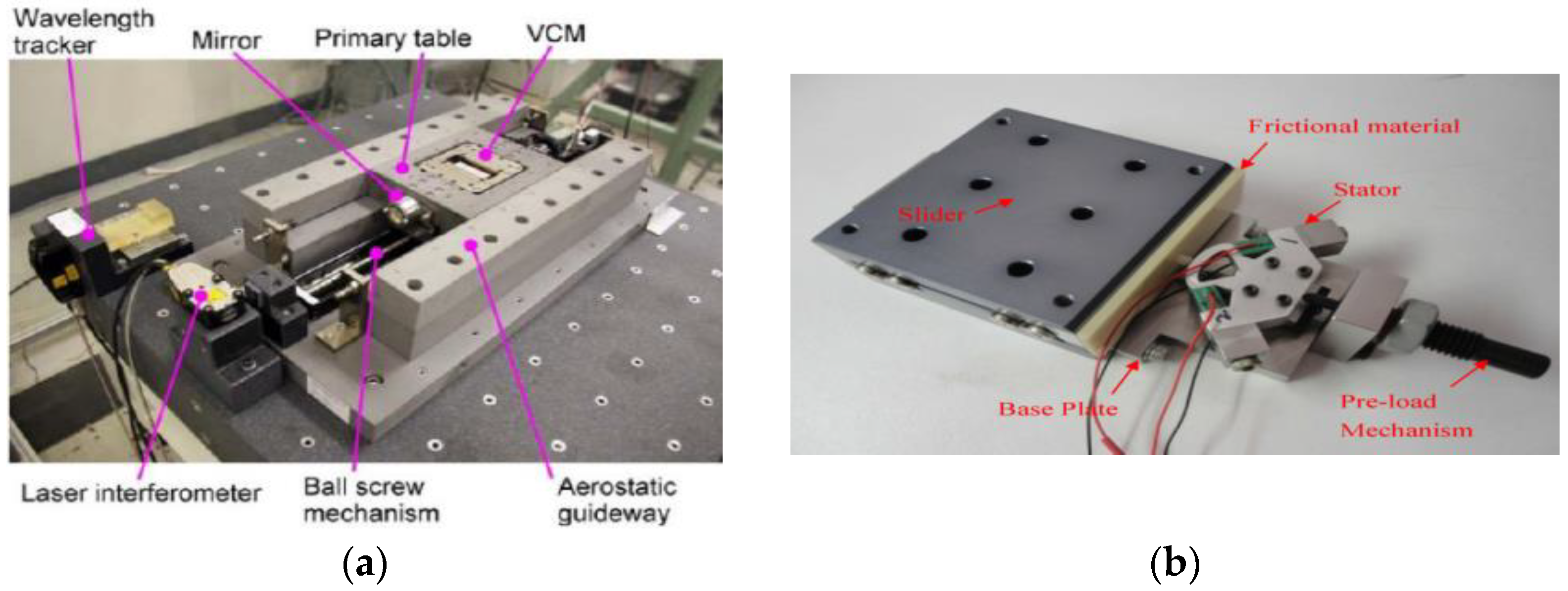

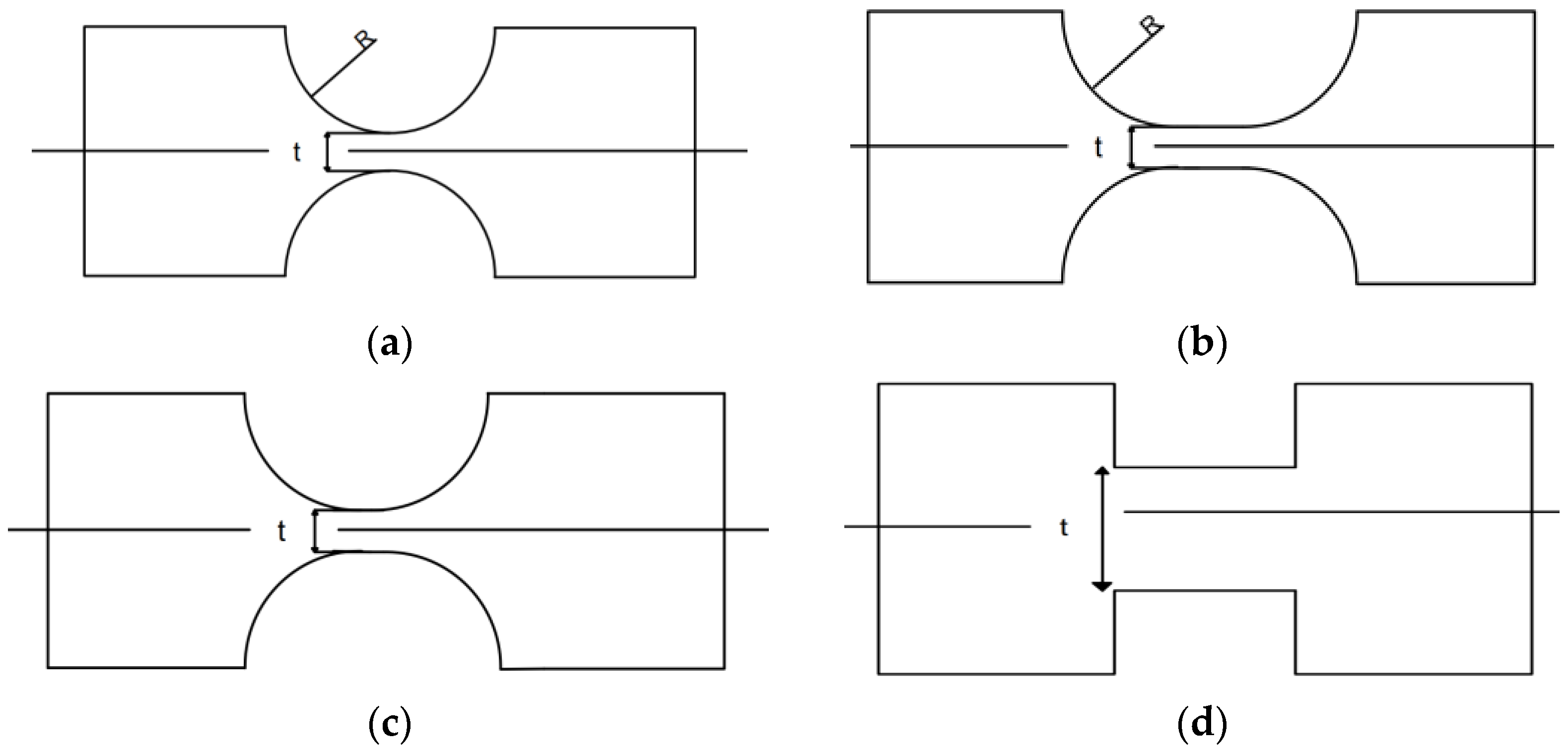

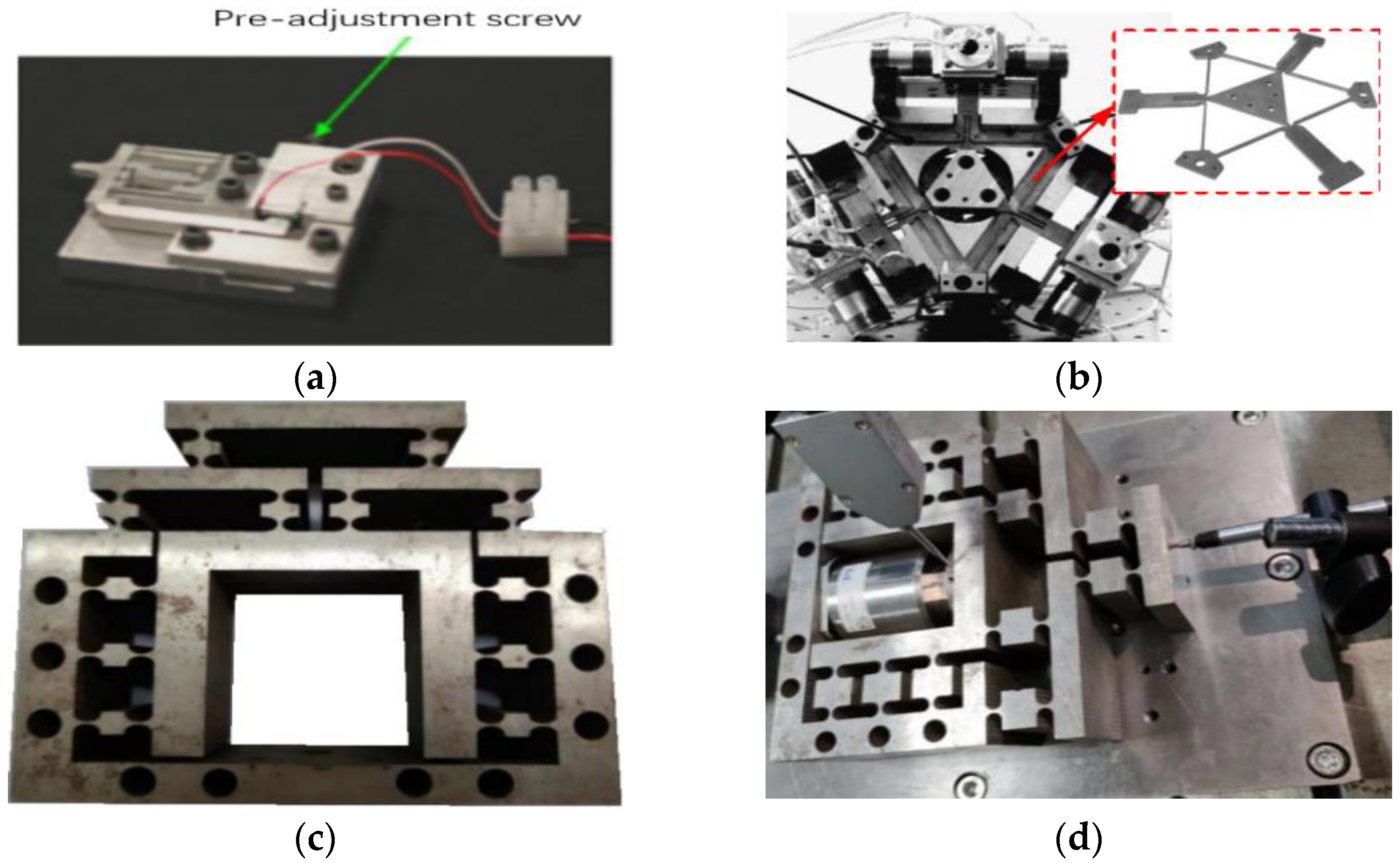

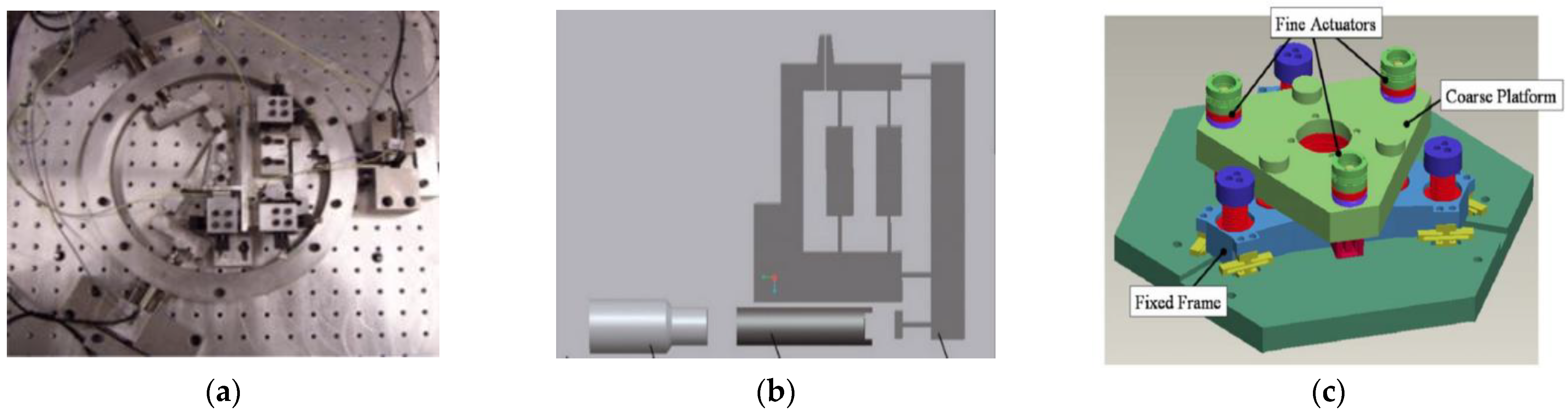

3.1.1. Design of Micro-Drive Mechanism

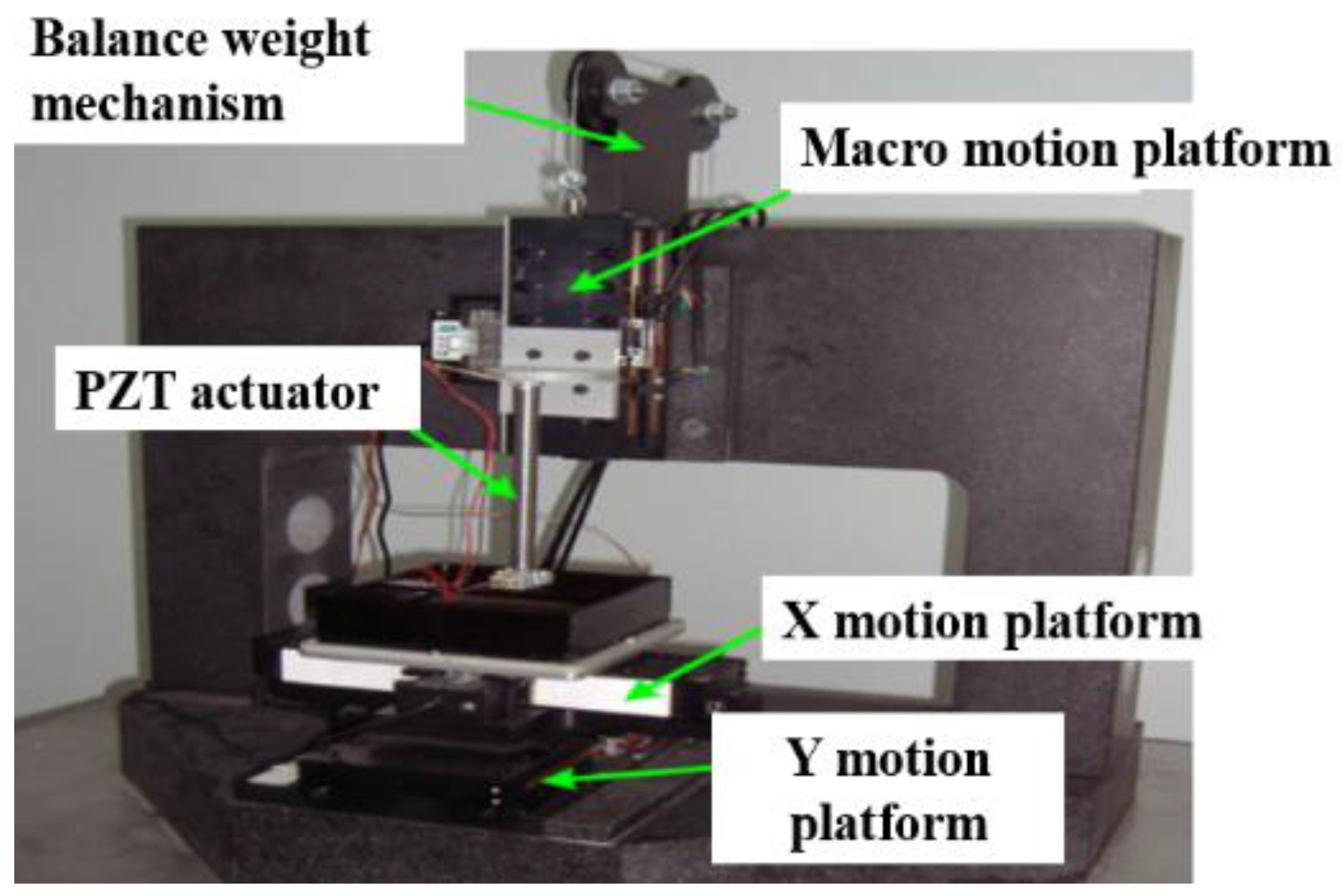

3.1.2. Type of Driver

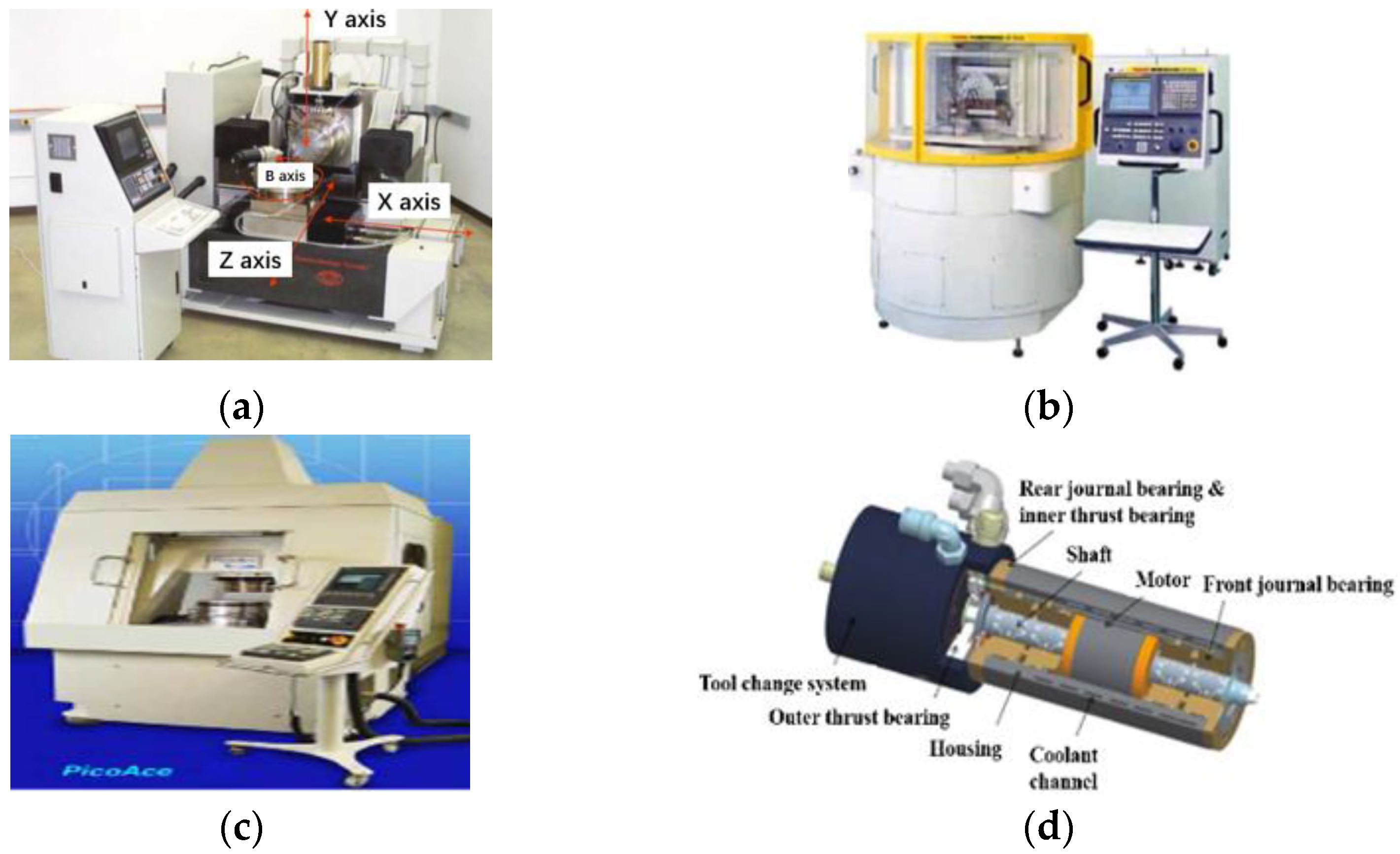

3.1.3. Application of Macro–Micro Dual-Drive Technology in Ultra-Precision System

3.2. The Challenges of Ultra-Precision Macro–Micro Dual-Drive Systems

3.3. Development Trends of Ultra-Precision Macro–Micro Dual-Drive System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pinskier, J.; Shirinzadeh, B.; Ghafarian, M.; Das, T. K; Al-Jodah. A; Nowell, R. Topology optimization of stiffness constrained flexure-hinges for precision and range maximization. Mech. Mach. Theory 2020, 150, 103874. [Google Scholar] [CrossRef]

- Zhongxi, S.; Dedong, H.A.N.; Weijiang, Z. Research on the Full Closed-loop Control Technology to the Stability of the Mechanical Grating Tiling. Chin. J. Mech. Eng. En. 2015, 51, 205–212. [Google Scholar]

- Yu, H.; Liu, Y.; Tian, X.; Zhang, S.; Liu, J. A precise rotary positioner driven by piezoelectric bimorphs: Design, analysis and experimental evaluation. Sens. Actuators A Phys. 2020, 313, 112197. [Google Scholar] [CrossRef]

- Weck, M.; Hennig, J.; Hibing, R. Precision cutting processes for manufacturing of optical components. SPIE 2001, 4440, 145–151. [Google Scholar]

- Luo, X.; Cheng, K.; Webb, D.; Wardle, F. Design of ultraprecision machine tools with applications to manufacture of miniature and micro components. J. Mater. Process. Technol. 2005, 167, 515–528. [Google Scholar] [CrossRef]

- Goto, S.; Hosobuchi, K.; Gao, W. An ultra-precision scanning tunneling microscope Z-scanner for surface profile measurement of large amplitude micro-structures. Meas. Sci. Technol. 2011, 22, 085101. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, K.; Rakowski, R.; Soulard, J. An experimental investigation on ultra-precision instrumented smart aerostatic bearing spindle applied to high speed micro-drilling. J. Manuf. Process. 2018, 31, 324–335. [Google Scholar] [CrossRef]

- Kong, L.B.; Cheung, C.F. Prediction of surface generation in ultra-precision raster milling of optical freeform surfaces using an integrated kinematics error model. Adv. Eng. Softw. 2012, 45, 124–136. [Google Scholar] [CrossRef]

- Liu, H.; Lu, B.; Ding, Y.; Li, H.; Yan, L. Study of ultra precision positioning system and linearity compensation. J. Xi’an JiaoTong Univ. 2003, 37, 277–281. [Google Scholar]

- Shin, H.; Moon, J.H. Design of a Double Triangular Parallel Mechanism for Precision Positioning and Large Force Generation. IEEE ASME Trans. Mech. 2014, 19, 862–871. [Google Scholar] [CrossRef]

- Perez-Diaz, J.L.; Valiente-Blanco, I.; Diez-Jimenez, E.; Sanchez-Garcia-Casarrubios, J. Superconducting Noncontact Device for Precision Positioning in Cryogenic Environments. IEEE ASME Trans. Mech. 2014, 19, 598–605. [Google Scholar] [CrossRef]

- Marinescu, O.; Epureanu, B.I. High-Precision Positioning of Laser Beams for Vibration Measurements. J. Vib. Acoust. 2014, 136, 011009. [Google Scholar] [CrossRef]

- Tuma, T.; Haeberle, W.; Rothuizen, H.; Lygeros, J.; Pantazi, A.; Sebastian, A. Dual·Stage Nanopositioning for High-Speed Scanning Probe Microscopy. IEEE ASME Trans. Mech. 2014, 19, 1035–1045. [Google Scholar] [CrossRef]

- Guo, Y.B.; Yang, W.; Wang, Z.Z.; Peng, Y.F.; Bi, G.; Yang, P. Technology and Application of Ultra-precision Machining for Large Size Optic. Chin. J. Mech. Eng. 2013, 49, 171–178. [Google Scholar] [CrossRef]

- Li, Y.; Huang, J.; Tang, H.A. Compliant parallel XY micromotion stage with complete kinematic decoupling. IEEE T Autom. Sci. Eng. 2012, 9, 538–553. [Google Scholar] [CrossRef]

- Shan, Y.; Leang, K.K. Accounting for hysteresis in repetitive control design: Nanopositioning example. Automatica 2012, 48, 1751–1758. [Google Scholar] [CrossRef]

- Gao, Z.; Geng, H.; Qiao, Z.; Sun, B.; Gao, Z.; Zhang, C. In situ TiBX/TiXNiY/TiC reinforced Ni60 composites by laser cladding and its effect on the tribological properties. Ceram. Int. 2022; in press. [Google Scholar] [CrossRef]

- Gao, Z.; Ren, H.; Geng, H.; Yu, Y.; Gao, Z.; Zhang, C. Effect of CeO2 on Microstructure and Wear Property of Laser Cladding Ni-Based Coatings Fabricated on 35CrMoV Steel. J. Mater. Eng. Perform. 2022, 31, 9534–9543. [Google Scholar] [CrossRef]

- Chapman, G. Ultra-precision machining systems; an enabling technology for perfect surfaces. Moore Nanotechnol. Syst. 2004, 1–9. [Google Scholar]

- Wang, S.; Zhou, Y.; Tang, J.; Tang, K.; Li, Z. Digital tooth contact analysis of face gear drives with an accurate measurement model of face gear tooth surface inspected by CMMs. Mech. Mach. Theory 2022, 167, 104498. [Google Scholar] [CrossRef]

- Tang, Z.; Zhou, Y.; Wang, S.; Zhu, J.; Tang, J. An innovative geometric error compensation of the multi-axis CNC machine tools with non-rotary cutters to the accurate worm grinding of spur face gears. Mech. Mach. Theory 2022, 169, 104664. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Tang, Z.W.; Shi, X.L.; Tang, J.Y. Efficient and accurate worm grinding of spur face gears according to an advanced geometrical analysis and a closed-loop manufacturing process. J. Cent. South Univ. 2022, 29, 1–13. [Google Scholar] [CrossRef]

- Sun, Y.; Jiang, S. Predictive modeling of chatter stability considering force-induced deformation effect in milling thin-walled parts. Int. J. Mach. Tool Manuf. 2018, 135, 38–52. [Google Scholar] [CrossRef]

- Sun, Y.; Jia, J.; Xu, J.; Chen, M.; Niu, J. Path, feedrate and trajectory planning for free-form surface machining: A state-of-the-art review. Chin. J. Aeronaut. 2022, 35, 12–29. [Google Scholar] [CrossRef]

- Yan, S.; Sun, Y. Early chatter detection in thin-walled workpiece milling process based on multi-synchro squeezing transform and feature selection. Mech. Syst. Signal Process. 2022, 169, 108622. [Google Scholar] [CrossRef]

- Yuan, J.; Lyu, B.; Hang, W.; Deng, Q. Review on the progress of ultra-precision machining technologies. Front. Mech. Eng. 2017, 12, 158–180. [Google Scholar] [CrossRef]

- Lucca, D.A.; Klopfstein, M.J.; Riemer, O. Ultra-precision machining: Cutting with diamond tools. J. Manuf. Sci. Eng. 2020, 142, 110817. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Mutlugünes, Y.; Klocke, F.; Aurich, J.C.; Shore, P.; Ohmori, H. Ultra-precision grinding. CIRP Annals 2010, 59, 652–671. [Google Scholar] [CrossRef]

- Cheung, C.F.; Kong, L.B.; Ho, L.T.; To, S. Modelling and simulation of structure surface generation using computer controlled ultra-precision polishing. Precis. Eng. 2011, 35, 574–590. [Google Scholar] [CrossRef]

- Jain, V.K. Advanced (Non-Traditional) Machining Processes. In Machining; Springer: London, UK, 2008; pp. 299–327. [Google Scholar]

- Sencer, B.; Ishizaki, K.; Shamoto, E. High speed cornering strategy with confined contour error and vibration suppression for CNC machine tools. CIRP Annals 2015, 64, 369–372. [Google Scholar] [CrossRef]

- Schönemann, L.; Riemer, O. Thermo-mechanical tool setting mechanism for ultra-precision milling with multiple cutting edges. Precis. Eng. 2019, 55, 171–178. [Google Scholar] [CrossRef]

- Rakuff, S.; Cuttino, J.F. Design and testing of a long-range, precision fast tool servo system for diamond turning. Precis. Eng. 2009, 33, 18–25. [Google Scholar] [CrossRef]

- Aurich, J.C.; Engmann, J.; Schueler, G.M.; Haberland, R. Micro grinding tool for manufacture of complex structures in brittle materials. CIRP Annals 2009, 58, 311–314. [Google Scholar] [CrossRef]

- Namba, Y.; Shimomura, T.; Fushiki, A.; Beaucamp, A.; Inasaki, I.; Kunieda, H.; Ogasaka, Y.; Yamashita, K. Ultra-precision polishing of electroless nickel molding dies for shorter wavelength applications. CIRP Annals 2008, 57, 337–340. [Google Scholar] [CrossRef]

- Kakinuma, Y.; Kidani, S.; Aoyama, T. Ultra-precision cryogenic machining of viscoelastic polymers. CIRP Annals 2012, 61, 79–82. [Google Scholar] [CrossRef]

- Schneider, F.; Das, J.; Kirsch, B.; Linke, B.; Aurich, J.C. Sustainability in ultra precision and micro machining: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 601–610. [Google Scholar] [CrossRef]

- Kang, H.J.; Ahn, S.H. Fabrication and characterization of microparts by mechanical micromachining: Precision and cost estimation. Proc. Inst. Part B J. Eng. Manuf. 2007, 221, 231–240. [Google Scholar] [CrossRef]

- Dornfeld, D.; Wright, P. “Technology Wedges” for Implementing Green Manufacturing. Lab. Manuf. Sustain. 2007, 35, 193–200. [Google Scholar]

- Dornfeld, D.; Min, S.; Takeuchi, Y. Recent advances in mechanical micromachining. CIRP Annals 2006, 55, 745–768. [Google Scholar] [CrossRef]

- Allen, L.N.; Keim, R.E. An ion figuring system for large optic fabrication. Current Developments in Optical Engineering and Commercial Optics. SPIE 1989, 1168, 33–50. [Google Scholar]

- Li, D.; Cheung, C.F.; Ren, M.; Whitehouse, D.; Zhao, X. Disparity pattern-based autostereoscopic 3D metrology system for in situ measurement of microstructured surfaces. Opt. Lett. 2015, 40, 5271–5274. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, K.; Sunappan, V.; Shan, X. Diamond micro engraving of gravure roller mould for roll-to-roll printing of fine line electronics. J. Mater. Process. Technol. 2015, 225, 337–346. [Google Scholar] [CrossRef]

- Li, L.; Allen, Y.Y. Design and fabrication of a freeform microlens array for a compact large-field-of-view compound-eye camera. Appl. Optics 2012, 51, 1843–1852. [Google Scholar] [CrossRef] [PubMed]

- Shore, P.; Morantz, P. Ultra-precision: Enabling our future. Philos. Trans. R. Soc. A 2012, 370, 3993–4014. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.C.; Kim, G.H.; Huh, M.S.; Lee, S.Y.; Kim, S.H.; Lee, G.J. Ultra Precision Machining of the Winston Cone Baffle for Space Observation Camera. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; Volume 516, pp. 42–47. [Google Scholar]

- Sharon, A.; Hogan, N.; Hardt, D.E. High bandwidth force regulation and inertia reduction using a macro/micro manipulator system. In Proceedings of the 1988 IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988; pp. 126–132. [Google Scholar]

- Narikiyo, T.; Nakane, H.; Akuta, T.; Mohri, N.; Saito, N. Control system design for macro/micro manipulator with application to electrodischarge machining. Proceedings of IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS’94), Munich, Germany, 12–16 September 1994; pp. 1454–1460. [Google Scholar]

- Zheng, E.; Zhu, R.; Zhu, S.; Lu, X. A study on dynamics of flexible multi-link mechanism including joints with clearance and lubrication for ultra-precision presses. Nonlinear Dyn. 2016, 83, 137–159. [Google Scholar] [CrossRef]

- Ahn, H.J. Eddy current damper type reaction force compensation mechanism for linear motor motion stage. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 67–74. [Google Scholar] [CrossRef]

- Li, J.; Sedaghati, R.; Dargahi, J.; Waechter, D. Design and development of a new piezoelectric linear Inchworm actuator. Mechatronics 2005, 15, 651–681. [Google Scholar] [CrossRef]

- Mukhopadhyay, D.; Dong, J.; Pengwang, E.; Ferreira, P. ASOI-MEMS-based3-DOF planar parallel—Kinematics nanopositioning stage. Sens. Actuators A Phys. 2008, 147, 340–351. [Google Scholar] [CrossRef]

- Brouwer, D.M.; Jong, B.R.; Soemer, S. Design and modeling of a six DOFs MEMS—Based precision anipulator. Precis. Eng. 2010, 34, 307–319. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y. Topology optimization of multiple inputs and outputs compliant mechanism with coupling terms control. Chin. J. Mech. Eng. En. 2006, 42, 162–165. [Google Scholar] [CrossRef]

- Matin, M.A.; Akai, D.; Kawazu, N.; Hanebuchi, M.; Sawada, K.; Ishida, M. FE modeling of stress and deflection of PZT actuated micro-mirror effect of crystal anisotropy. Comput. Mater. Sci. 2010, 48, 349–359. [Google Scholar] [CrossRef]

- Gozen, B.A.; Ozdoganlar, O.B. Design and evaluation of a mechanical nanomanufacturing system for nanomilling. Precis. Eng. 2012, 36, 19–30. [Google Scholar] [CrossRef]

- Liu, D.; McDaid, A.J.; Aw, K.C.; Xie, S.Q. Position control of an ionic polymer metal composite actuated rotary joint using iterative feedback tuning. Mechatronics 2011, 21, 315–328. [Google Scholar] [CrossRef]

- Qing, Y.; Dong, J.; Ferrera, P.M. Design, analysis, fabrication and testing of a parallel-kinematic micropositioning XY stage. Int. J. Mach. Tool Manuf. 2007, 47, 946–961. [Google Scholar]

- Paros, J.M.; Weisbord, L. How to Design Flexure Hinges. Mach. Des. 1965, 27, 151–156. [Google Scholar]

- Smith, S.T.; Badami, V.G.; Dale, J.S. Elleptical flexure hinges. Rev. Sci. Instrum. 1997, 68, 1474–1483. [Google Scholar] [CrossRef]

- Lobontiu, N.; Paine, J.S.; Garcia, E.; Goldfarb, M. Corner-filleted flexure hinges. J. Mech. Des. 2001, 123, 346–352. [Google Scholar] [CrossRef]

- Lobontiu, N.; Paine, J.S.; O’Malley, E.; Samuelson, M. Parabolic and hyperbolic flexure hinges: Flexibility, motion precision and stress characterization based on compliance closed-form equations. Precis. Eng. 2002, 26, 183–192. [Google Scholar] [CrossRef]

- Kong, J.; Huang, Z.; Xian, X. Generalized model for conic-V-shaped flexure hinges. Sci. Prog. 2020, 103, 300–316. [Google Scholar] [CrossRef]

- Wang, R.Q.; Zhou, X.Q.; Zhu, Z.W. Development of a novel sort of exponent-sine-shaped flexure hinges. Rev. Sci. Instrum. 2013, 84, 95008–95018. [Google Scholar] [CrossRef]

- Li, L.; Zhang, D.; Guo, S.; Haibo, Q. Design modeling and analysis of hybrid flexure hinges. Mech. Mach. Theory 2019, 131, 300–316. [Google Scholar] [CrossRef]

- Zubir, M.N.M.; Shirnzaden, B.J.; Tian, Y.L. A new design of piezoelectric driven compliant-based microgripper for micromanipulation. Mech. Mach. Theory 2009, 44, 2248–2264. [Google Scholar] [CrossRef]

- Wu, T.-L.; Chen, J.-H.; Chang, S.-H. A six-DOF prismatic-spherical-spherical parallel compliant nanopositioner. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2544–2551. [Google Scholar] [PubMed]

- Shang, J.; Tian, Y.; Li, Z.; Wang, F.; Cai, K. A novel voice coil motor-driven compliant micropositioning stage based on flexure mechanism. Rev. Sci. Instrum. 2015, 86, 95001. [Google Scholar] [CrossRef] [PubMed]

- Culpepper, M.L.; Anderson, G. Design of a low-cost nano-manipulator which utilizes a monolithic, spatial compliant mechanism. Precis. Eng. 2004, 28, 469–482. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, X.; Zhang, C.; Wu, H.; Yang, Y. Design and Performance Research of a Precision Micro-Drive Reduction System without Additional Motion. Micromachines 2022, 13, 1636. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Jiang, B.; Fang, J.; Zheng, Y. Research trends in China for macro-micro motion platform for microelectronics manufacturing industry. J. Adv. Mech. Design Syst. Manuf. 2021, 15, JAMDSM0032. [Google Scholar] [CrossRef]

- Fujita, T.; Matsubara, A.; Kono, D.; Yamaji, I. Dynamic characteristics and dual control of a ball screw drive with integrated piezoelectric actuator. Precis. Eng. 2010, 34, 34–42. [Google Scholar] [CrossRef]

- Elfizy, A.T.; Bone, G.M.; Elbestawi, M.A. Design and control of a dual-stage feed drive. Int. J. Mach. Tool Manuf. 2005, 45, 153–165. [Google Scholar] [CrossRef]

- Kang, D.; Kim, K.; Kim, D.; Shim, J.; Gweon, D.G.; Jeong, J. Optimal design of high precision XY-scanner with nanometer-level resolution and millimeter-level working range. Mechatronics 2009, 19, 562–570. [Google Scholar] [CrossRef]

- Watson, B.; Friend, J.; Yeo, L. Piezoelectric ultrasonic micro/milli-scale actuators. Sens. Actuators A Phys. 2009, 152, 219–233. [Google Scholar] [CrossRef]

- Shinno, H.; Yoshioka, H.; Sawano, H. A newly developed long range positioning table system with a sub-nanometer resolution. CIRP Annals 2011, 60, 403–406. [Google Scholar] [CrossRef]

- Kang, C.F.; Li, S.J.; Huang, X.D.; Ma, C.M. Design of the Three-Dimension Motion Platform Control System Based on EtherCAT. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2014; Volume 538, pp. 413–416. [Google Scholar]

- Hsieh, M.F.; Yao, W.S.; Chiang, C.R. Modeling and synchronous control of a single-axis stage driven by dual mechanically-coupled parallel ball screws. Int. J. Adv. Manuf. Tech. 2007, 34, 933–943. [Google Scholar] [CrossRef]

- Zhu, H.; Pang, C.K.; Teo, T.J. A flexure-based parallel actuation dual-stage system for large-stroke nanopositioning. IEEE Trans. Ind. Electron. 2017, 64, 5553–5563. [Google Scholar] [CrossRef]

- Yunbo, H.; ZuoXiong, H.E.; Jian, G.; Chengqiang, C.; Zhijun, Y.; Hui, T.; Yun, C.; Kai, Z.; Xun, C. Research on Feedforward Control in the linear motor direct drive XY two-dimensional platform. In Proceedings of the 2018 IEEE 20th Electronics Packaging Technology Conference (EPTC), IEEE, Singapore, 4–7 December 2018; pp. 729–732. [Google Scholar]

- Li, G.H.; Wu, P.; Ni, X.L.; Peng, W.F.; Tan, G.Y. Study on Speed and Acceleration Characteristics of 100 nm Scale Motion Platform Driven by Linear Servo Motors. In Solid State Phenomena; Trans Tech Publications Ltd.: Zurich, Switzerland, 2011; Volume 175, pp. 357–361. [Google Scholar]

- Dong, W.; Tang, J.; El Deeb, Y. Design of a linear-motion dual-stage actuation system for precision control. Smart Mater. Struct. 2009, 18, 095035. [Google Scholar] [CrossRef]

- Ito, S.; Neyer, D.; Pirker, S.; Steininger, J.; Schitter, G. Atomic force microscopy using voice coil actuators for vibration isolation. In Proceedings of the 2015 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Busan, South Korea, 7–11 July 2015; pp. 470–475. [Google Scholar]

- Takahashi, M.; Yoshioka, H.; Shinno, H. A newly developed long-stroke vertical nano-motion platform with gravity compensator. J. Adv. Mech. Des. Syst. Manuf. 2008, 2, 356–365. [Google Scholar] [CrossRef]

- Dong, W.; Du, Z.; Sun, L. A large workspace macro/micro dual parallel mechanism with wide-range flexure hinges. In Proceedings of the 2005 IEEE International Conference Mechatronics and Automation, Falls, ON, Canada, 29 July–1 August 2005; Volume 3, pp. 1592–1597. [Google Scholar]

- Ho, S.T.; Jan, S.J. A piezoelectric motor for precision positioning applications. Precis. Eng. 2016, 43, 285–293. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, T.; Hu, J.; Huang, Z.; Pan, Q. Resonant-type piezoelectric screw motor for one degree of freedom positioning platform application. IEEE Access 2020, 8, 133905–133913. [Google Scholar] [CrossRef]

- Tian, Y.; Shirinzadeh, B.; Zhang, D. Design and dynamics of a 3-DOF flexure-based parallel mechanism for micro/nano manipulation. Microelectron Eng. 2010, 87, 230–241. [Google Scholar] [CrossRef]

- Qingsong, X. Design of asymmetric flexible micro-gripper mechanism based on flexure hinges. Adv. Mech. Eng. 2015, 7, 1687814015590331. [Google Scholar] [CrossRef]

- Yong, J.; Dai, Y.; Guan, C.; Peng, X.; Peng, T.; Liu, J. Design of High-Performance Fast Tool Servo System Based on Two-Way Piezoelectric Ceramics. In Proceedings of the 2020 the 7th International Conference on Automation and Logistics (ICAL), Beijing, China, 22–24 July 2020; pp. 69–75. [Google Scholar]

- Wu, Z.; Chen, M.; He, P.; Li, H.; Zhang, Q.; Xiong, X.; Mi, H.Y.; Li, Z.; Li, Y. Tracking control of PZT-driven compliant precision positioning micromanipulator. IEEE Access 2020, 8, 126477–126487. [Google Scholar] [CrossRef]

- Woody, S.; Smith, S. Design and performance of a dual drive system for tip-tilt angular control of a 300 mm diameter mirror. Mechatronics 2006, 16, 389–397. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Cheung, C.F.; Zhu, Z.; Chen, X. Design and analysis of a novel compact XYZ parallel precision positioning stage. Microsyst. Technol. 2021, 27, 1925–1932. [Google Scholar] [CrossRef]

- Yoshioka, H.; Shinno, H.; Sawano, H. A newly developed rotary-linear motion platform with a giant magnetostrictive actuator. CIRP Ann. Manuf. Technol. 2013, 62, 371–374. [Google Scholar] [CrossRef]

- Gao, W.; Dejima, S.; Yanai, H.; Katakura, K.; Kiyono, S.; Tomita, Y. A surface motor-driven planar motion stage integrated with an XYθZ surface encoder for precision positioning. Precis. Eng. 2004, 28, 329–337. [Google Scholar] [CrossRef]

- Mori, S.; Hoshino, T.; Obinata, G.; Ouchi, K. Air-bearing linear actuator for highly precise tracking. IEEE Trans. Magn. 2003, 39, 812–818. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Chen, W.; Bai, S. Integrated design, modeling and analysis of a novel spherical motion generator driven by electromagnetic principle. Robot. Auton. Syst. 2018, 106, 69–81. [Google Scholar] [CrossRef]

- Xiao, S.; Li, Y. Optimal Design, Fabrication, and Control of an $ XY $ Micropositioning Stage Driven by Electromagnetic Actuators. IEEE Trans. Ind. Electron. 2012, 60, 4613–4626. [Google Scholar] [CrossRef]

- Russo, M.; Barrientos-Diez, J.; Axinte, D. A kinematic coupling mechanism with binary electromagnetic actuators for high-precision positioning. IEEE ASME Trans. Mech. 2021, 27, 892–903. [Google Scholar] [CrossRef]

- Ho, E.; Gorbet, R. A low cost macro-micro positioning system with SMA-actuated micro stage. Trans. Can. Soc. Mech. Eng. 2007, 31, 75–95. [Google Scholar] [CrossRef]

- Herpe, X.; Walker, R.; Dunnigan, M.; Kong, X. On a simplified nonlinear analytical model for the characterisation and design optimisation of a compliant XY micro-motion stage. Robot. Comput. Integr. Manuf. 2018, 49, 66–76. [Google Scholar] [CrossRef]

- Feng, H.; Pang, A.; Zhou, H. High precision robust control design of piezoelectric nanopositioning platform. Sci. Rep. 2022, 12, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Wei, W.; Dai, J.; Yan, G. Linear yaw compound piezoelectric micro-motion platform. Opt. Precis Eng. 2022, 30, 1058. [Google Scholar] [CrossRef]

- Wang, W.; Guo, Q.; Yang, Z.; Jiang, Y.; Xu, J. A state-of-the-art review on robotic milling of complex parts with high efficiency and precision. Robot Comput. Integr. Manuf. 2023, 79, 102436. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, Z.; Guo, Q.; Xu, J. A novel method to predict surface topography in robotic milling of directional plexiglas considering cutter dynamical displacement. J. Mater. Process. Technol. 2022, 304, 117545. [Google Scholar] [CrossRef]

- Jie, D.; Sun, L.; Liu, Y.; Zhu, Y.; Cai, H. Design and simulation of a macro-micro dual-drive high acceleration precision XY-stage for IC bonding technology. In Proceedings of the 2005 IEEE 6th International Conference on Electronic Packaging Technology, Shenzhen, China, 30 August–2 September 2005; pp. 161–165. [Google Scholar]

- Zhu, G.Z.; Bai, J.C.; Guo, Y.F.; Ma, H.L.; Liu, Y.W. Application of Macro-Micro Dual-Drive System in Micro-EDM. In Advanced Materials Research; Trans Tech Publications Ltd.: Zurich, Switzerland, 2011; Volume 197, pp. 43–46. [Google Scholar]

- Feng, J.; Gao, F.; Zhao, X.; Yue, Y.; Liu, R. A new macro-micro dual drive parallel robot for chromosome dissection. J. Mech. Sci. Technol. 2012, 26, 187–194. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, C.; Zhang, J.; Zhang, X. Synchronized motion control and precision positioning compensation of a 3-DOFs macro–micro parallel manipulator fully actuated by piezoelectric actuators. Smart Mater. Struct. 2017, 26, 115001. [Google Scholar] [CrossRef]

- Tong, H.; Li, Y.; Wang, Y.; Yu, D. Servo scanning 3D micro-EDM based on macro/micro-dual-feed spindle. Int. J. Mach. Tools Manuf. 2008, 48, 858–869. [Google Scholar] [CrossRef]

- Yang, M.; Lv, Z.; Zhang, C.; Yang, Y.; Jing, G.; Guo, W.; Lu, Z.; Huang, Y.; Wei, K.; Li, L.; et al. Positioning Performance of a Sub-Arc-Second Micro-Drive Rotary System. Micromachines 2021, 12, 1063. [Google Scholar] [CrossRef]

- Yang, M.; Jing, G.; Lv, Z.; Guo, W.; Huang, Y.; Wei, K.; Li, L.; Feng, B.; Ge, H.; Li, S. Design and Error Compensation Performance of a Precision Micro-Drive Rotary System. Math. Probl. Eng. 2021, 2021, 3199915. [Google Scholar] [CrossRef]

| Type of Processing | Precision of Machining | Surface Roughness (Ra) | Application Areas | Reference |

|---|---|---|---|---|

| Ultra-precision cutting | Processing of non-ferrous metal materials such as spherical, aspheric and surface reflectors of high precision, surface high smooth parts. | [27] | ||

| Ultra-precision grinding | Less | Various precision parts, such as optical aspherical surface, semiconductor silicon wafer, super hard high-precision mold, missile fairing, hemispherical resonator gyro and so on. | [28] | |

| Ultra-precision polishing | Flattening different materials and flattening multiple layers of materials. | [29] | ||

| Ultra-precision non-traditional machining | All kinds of difficult cutting materials, such as heat-resistant steel, stainless steel, super alloy, and a variety of high strength, high hardness, high toughness, high brittleness and high purity of metal and non-metal processing. | [30] |

| Material Name | Young’s Modulus /MPa | Yield Limit /MPa | Tensile Strength /MPa | Poisson’s Ratio | Density/(g/cm3) |

|---|---|---|---|---|---|

| 60Si2Mn | 2.06 × 105 | 1176 | 1274 | 0.26 | 7.85 |

| 65Mn | 2.00 × 105 | 784 | 980 | 0.30 | 7.81 |

| QBe2 | 1.26 × 105 | 725 | 945 | 0.30 | 8.30 |

| Drive Mode | Scope of Application | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Ball screws | Macro-drive | High precision, high transmission efficiency, low noise, etc. | High price; a larger transmission gap and lower return precision occurred with the time going. | [76,77,78] |

| Direct drive motor | Macro-drive | High precision, high speed, simple structure, fast response, etc. | Difficulty in carrying out high precision compensation. | [79,80,81] |

| Voice coil motor | Macro-drive | Compact structure, high speed, high acceleration, fast response, etc. | Difficult position control, limited range of motion, etc. | [82,83,84] |

| Piezoelectric motor | Macro-drive | High resolution, fast response, small size, large output force, etc. | Piezoelectric materials have creep, hysteresis, nonlinearity, etc. | [85,86,87] |

| Piezoelectric ceramic actuator | Micro-drive | Wide frequency band, high sensitivity, simple structure, reliable operation, etc. | The poor output DC response and small piezoelectric parameters. | [88,89,90,91,92,93] |

| Magneto strictive actuator | Micro-drive | Simple structure, reliable work, low production cost, etc. | The large closing current and low speed of the operating mechanism. | [94,95,96,97,98,99] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Gui, H.; Zhang, C.; Zhao, S.; Han, F.; Dang, M.; Zhang, B. Recent Development for Ultra-Precision Macro–Micro Dual-Drive System: A Review. Machines 2023, 11, 96. https://doi.org/10.3390/machines11010096

Yang M, Gui H, Zhang C, Zhao S, Han F, Dang M, Zhang B. Recent Development for Ultra-Precision Macro–Micro Dual-Drive System: A Review. Machines. 2023; 11(1):96. https://doi.org/10.3390/machines11010096

Chicago/Turabian StyleYang, Manzhi, Haochen Gui, Chuanwei Zhang, Shuanfeng Zhao, Feiyan Han, Meng Dang, and Bin Zhang. 2023. "Recent Development for Ultra-Precision Macro–Micro Dual-Drive System: A Review" Machines 11, no. 1: 96. https://doi.org/10.3390/machines11010096

APA StyleYang, M., Gui, H., Zhang, C., Zhao, S., Han, F., Dang, M., & Zhang, B. (2023). Recent Development for Ultra-Precision Macro–Micro Dual-Drive System: A Review. Machines, 11(1), 96. https://doi.org/10.3390/machines11010096