Optimization of Selective Laser Sintering/Melting Operations by Using a Virus-Evolutionary Genetic Algorithm

Abstract

1. Introduction

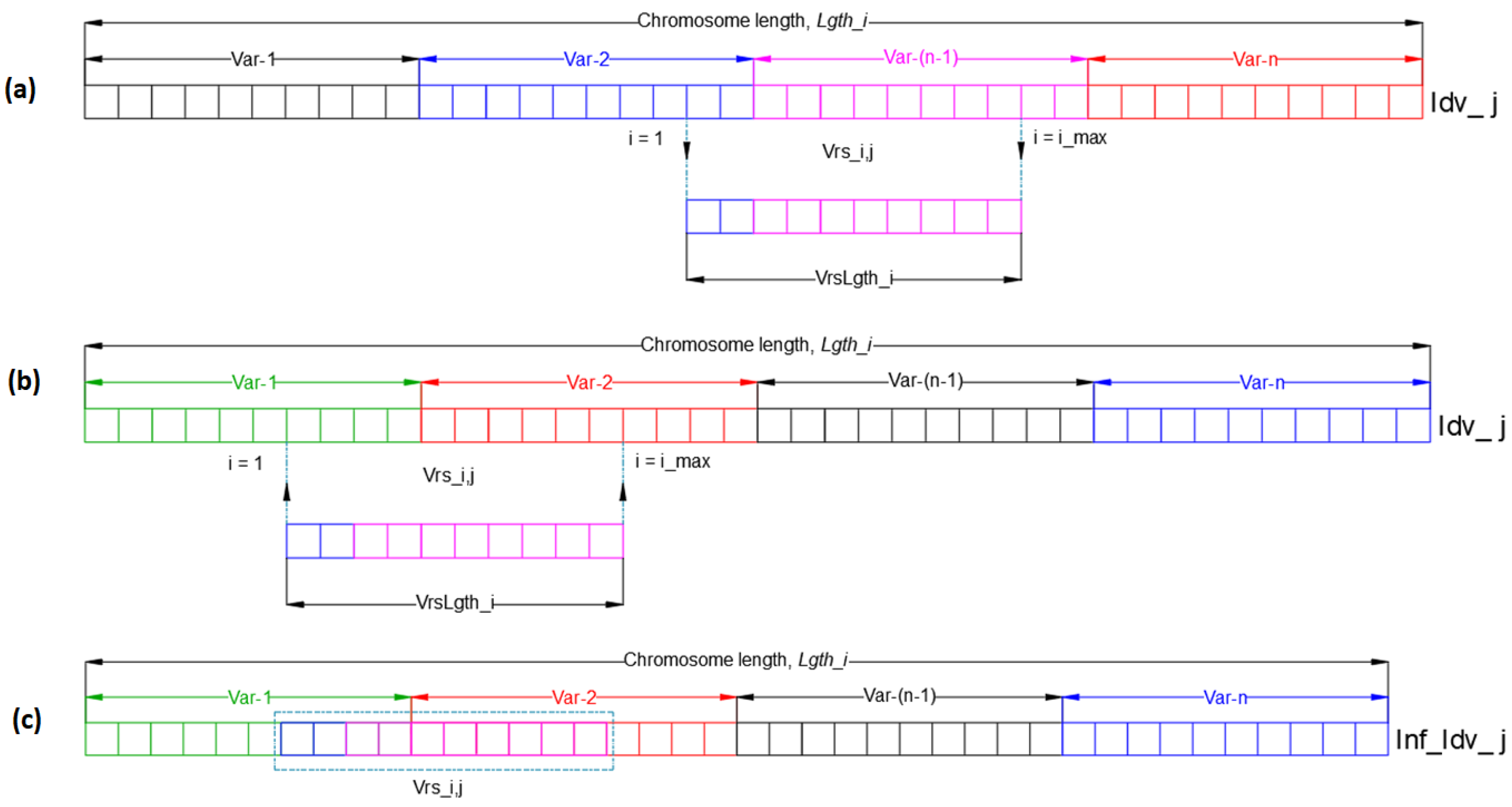

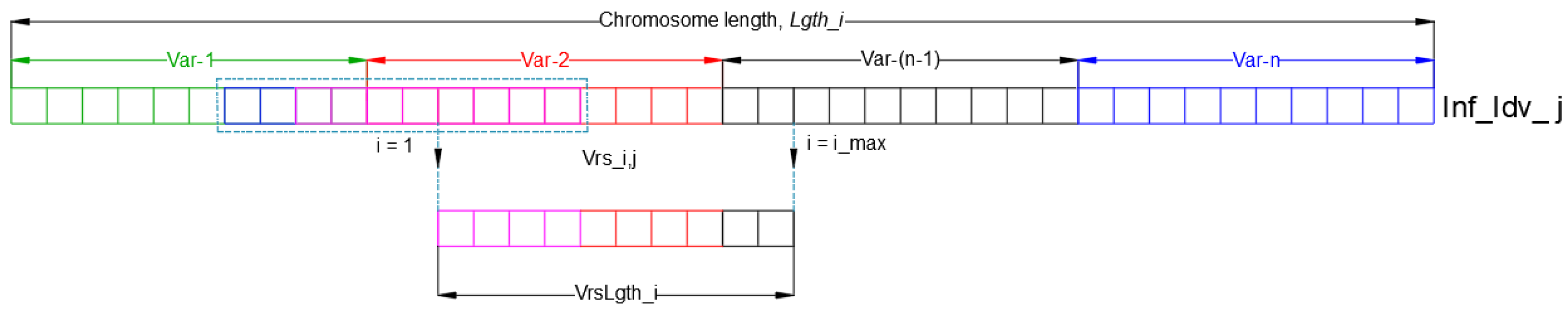

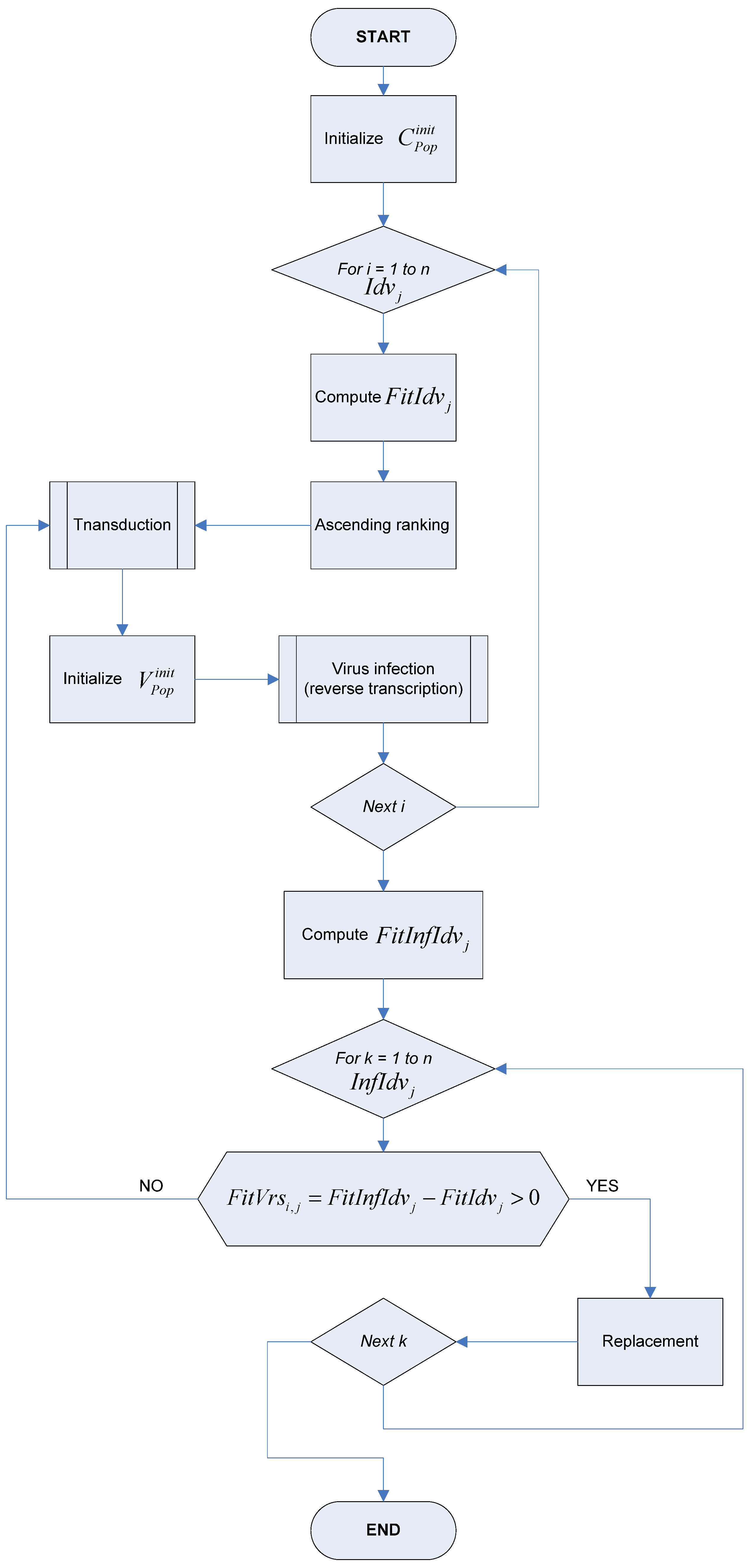

2. Virus-Evolutionary Genetic Algorithm for Multi-Objective Optimization (MOVEGA)

3. Performance Metrics

4. Optimization Problems Related to Selective Laser Sintering/Melting—SLS/SLM

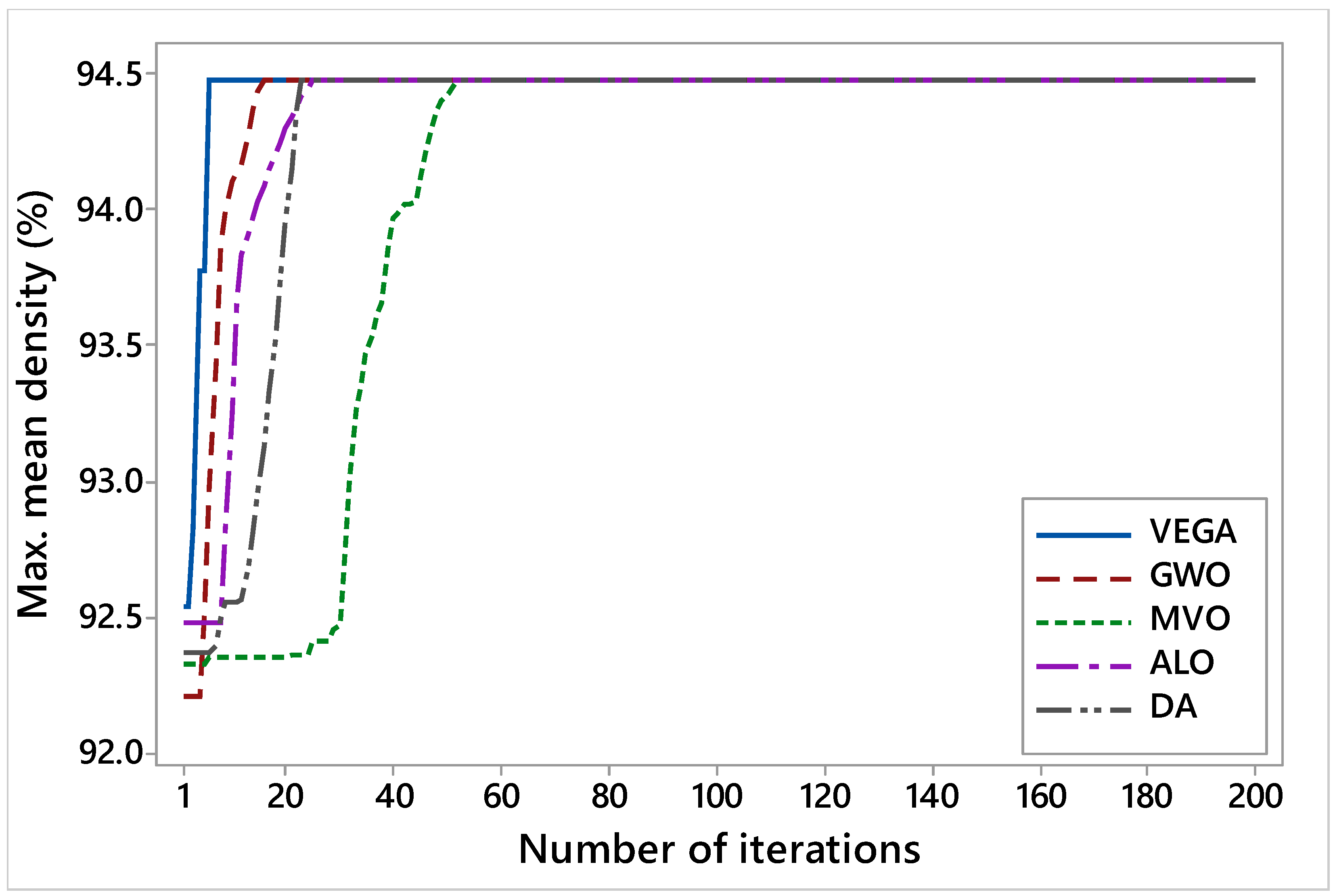

4.1. Optimization of SLM Parameters for Forming Ti6Al4V Alloy Specimens with Maximum Density

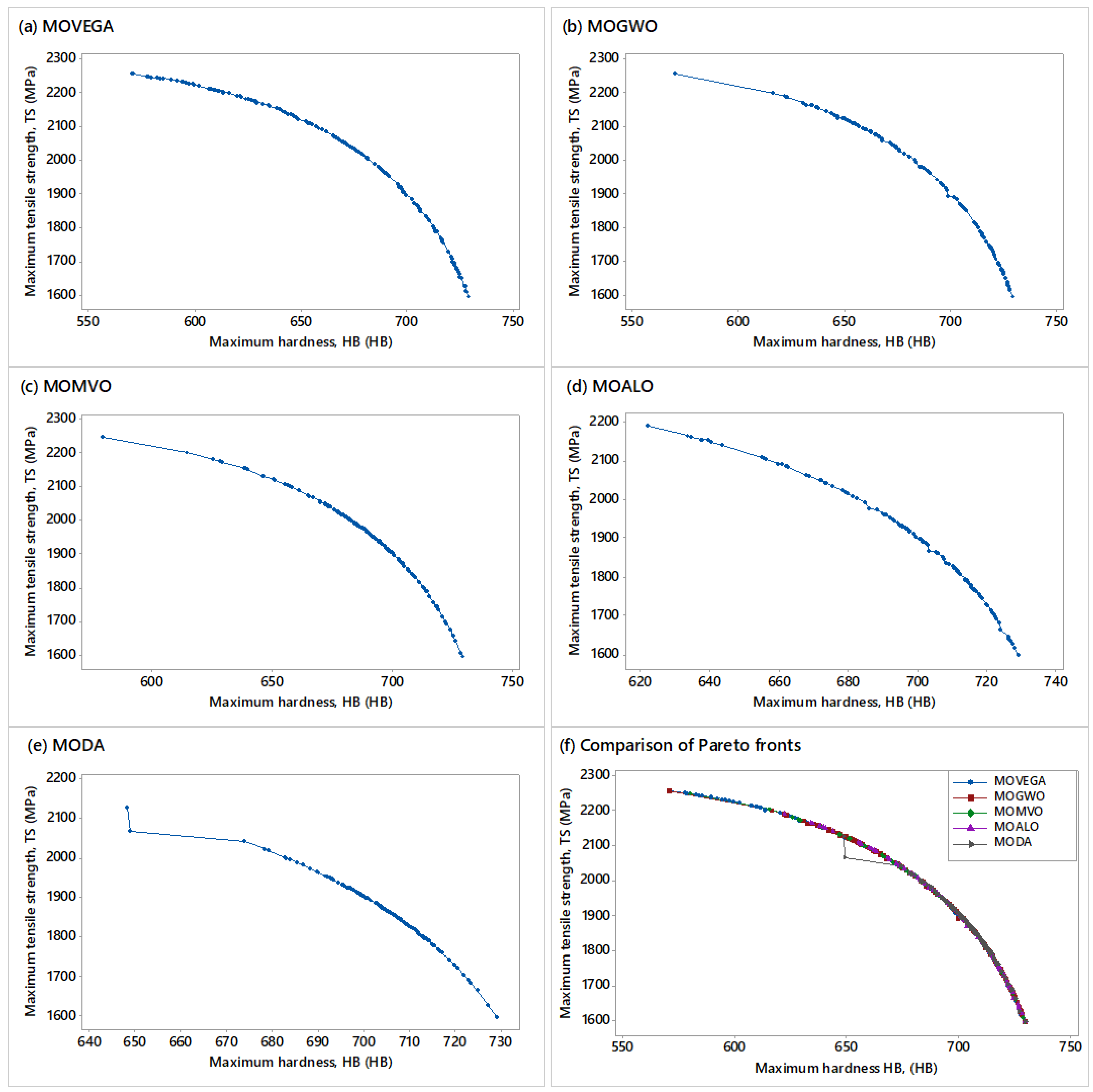

4.2. Case 2: Maximization of Density and Tensile Strength of Laser-Melted Ti6Al-4V Alloy Specimens

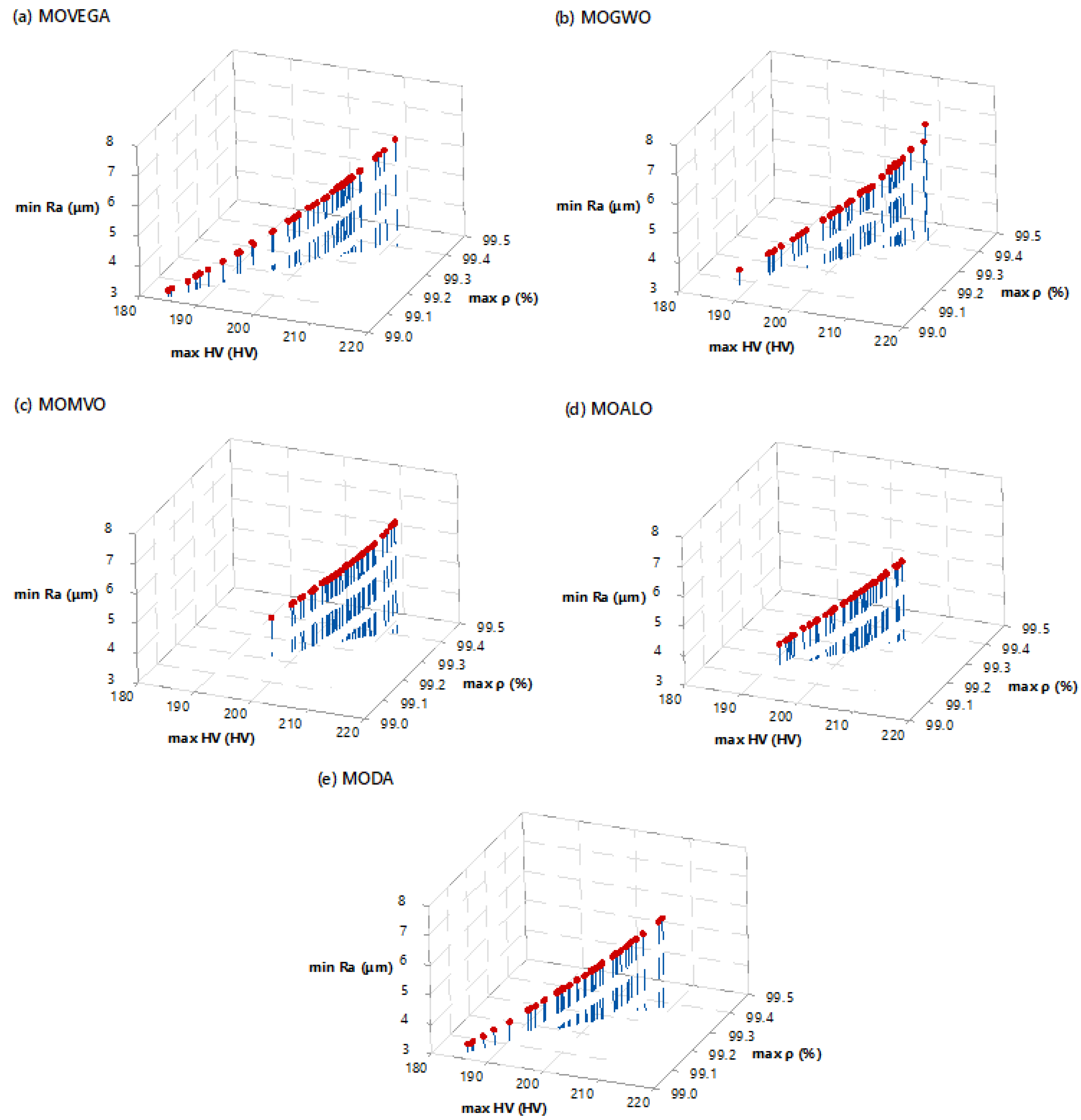

4.3. Case 3: Three-Objective Optimization Problem for 316 L Stainless Steel Powder Bed Fusion Operation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fashanu, O.; Buchely, M.F.; Spratt, M.; Newkirk, J.; Chandrashekhara, K.; Misak, H.; Walker, M. Effect of SLM Build Parameters on the Compressive Properties of 304L Stainless Steel. J. Manuf. Mater. Process. 2019, 3, 43. [Google Scholar] [CrossRef]

- Maurya, H.S.; Kollo, L.; Tarraste, M.; Juhani, K.; Sergejev, F.; Prashanth, K.G. Effect of the Laser Processing Parameters on the Selective Laser Melting of TiC–Fe-Based Cermets. J. Manuf. Mater. Process. 2022, 6, 35. [Google Scholar] [CrossRef]

- Impey, S.; Saxena, P.; Salonitis, K. Selective Laser Sintering Induced Residual Stresses: Precision Measurement and Prediction. J. Manuf. Mater. Process. 2021, 5, 101. [Google Scholar] [CrossRef]

- Mahardika, M.; Setyawan, M.A.; Sriani, T.; Miki, N.; Prihandana, G.S. Electropolishing Parametric Optimization of Surface Quality for the Fabrication of a Titanium Microchannel Using the Taguchi Method. Machines 2021, 9, 325. [Google Scholar] [CrossRef]

- Zolfpour-Arokhlo, M.; Selamat, A.; Mohd Hashim, S.Z.; Afkhami, H. Modeling of Route Planning System Based on Q Value-Based Dynamic Programming with Multi-Agent Reinforcement Learning Algorithms. Eng. Appl. Artif. Intell. 2014, 29, 163–177. [Google Scholar] [CrossRef]

- Liang, R.; Chen, Y.; Zhu, R. A Novel Fault Diagnosis Method Based on the KELM Optimized by Whale Optimization Algorithm. Machines 2022, 10, 93. [Google Scholar] [CrossRef]

- Tyagi, S.K.; Yang, K.; Tyagi, A.; Dwivedi, S.N. Development of a Fuzzy Goal Programming Model for Optimization of Lead Time and Cost in an Overlapped Product Development Project Using a Gaussian Adaptive Particle Swarm Optimization-Based Approach. Eng. Appl. Artif. Intell. 2011, 24, 866–879. [Google Scholar] [CrossRef]

- Li, S.; Mu, N.; Le, J.; Liao, X. A Novel Algorithm for Privacy Preserving Utility Mining Based on Integer Linear Programming. Eng. Appl. Artif. Intell. 2019, 81, 300–312. [Google Scholar] [CrossRef]

- Gong, K.; Chen, C. Multiple-Attribute Decision Making Based on Equivalence Consistency under Probabilistic Linguistic Dual Hesitant Fuzzy Environment. Eng. Appl. Artif. Intell. 2019, 85, 393–401. [Google Scholar] [CrossRef]

- Chakraborty, S.; Mitra, A. Parametric Optimization of Abrasive Water-Jet Machining Processes Using Grey Wolf Optimizer. Mater. Manuf. Process. 2018, 33, 1471–1482. [Google Scholar] [CrossRef]

- Pawar, P.J.; Rao, R.V. Parameter Optimization of Machining Processes Using Teaching–Learning-Based Optimization Algorithm. Int. J. Adv. Manuf. Technol. 2013, 67, 995–1006. [Google Scholar] [CrossRef]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.D.S. Multi-Objective Grey Wolf Optimizer: A Novel Algorithm for Multi-Criterion Optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

- Yue, Z.; Huang, C.; Zhu, H.; Wang, J.; Yao, P.; Liu, Z. Optimization of Machining Parameters in the Abrasive Waterjet Turning of Alumina Ceramic Based on the Response Surface Methodology. Int. J. Adv. Manuf. Technol. 2014, 71, 2107–2114. [Google Scholar] [CrossRef]

- Venkata Rao, R.; Kalyankar, V.D. Parameter Optimization of Modern Machining Processes Using Teaching–Learning-Based Optimization Algorithm. Eng. Appl. Artif. Intell. 2013, 26, 524–531. [Google Scholar] [CrossRef]

- Rao, R.V.; Rai, D.P. Optimization of Fused Deposition Modeling Process Using Teaching-Learning-Based Optimization Algorithm. Eng. Sci. Technol. Int. J. 2016, 19, 587–603. [Google Scholar] [CrossRef]

- Sood, A.K.; Equbal, A.; Toppo, V.; Ohdar, R.K.; Mahapatra, S.S. An Investigation on Sliding Wear of FDM Built Parts. CIRP J. Manuf. Sci. Technol. 2012, 5, 48–54. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Experimental Investigation and Empirical Modelling of FDM Process for Compressive Strength Improvement. J. Adv. Res. 2012, 3, 81–90. [Google Scholar] [CrossRef]

- Peng, A.; Xiao, X.; Yue, R. Process Parameter Optimization for Fused Deposition Modeling Using Response Surface Methodology Combined with Fuzzy Inference System. Int. J. Adv. Manuf. Technol. 2014, 73, 87–100. [Google Scholar] [CrossRef]

- Gurrala, P.K.; Regalla, S.P. Multi-Objective Optimisation of Strength and Volumetric Shrinkage of FDM Parts. Virtual Phys. Prototyp. 2014, 9, 127–138. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric Appraisal of Mechanical Property of Fused Deposition Modelling Processed Parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Rao, R.V.; Rai, D.P.; Balic, J. A Multi-Objective Algorithm for Optimization of Modern Machining Processes. Eng. Appl. Artif. Intell. 2017, 61, 103–125. [Google Scholar] [CrossRef]

- Kuriakose, S.; Shunmugam, M.S. Multi-Objective Optimization of Wire-Electro Discharge Machining Process by Non-Dominated Sorting Genetic Algorithm. J. Mater. Process. Technol. 2005, 170, 133–141. [Google Scholar] [CrossRef]

- Kumar Pandey, A.; Kumar Dubey, A. Simultaneous Optimization of Multiple Quality Characteristics in Laser Cutting of Titanium Alloy Sheet. Opt. Laser Technol. 2012, 44, 1858–1865. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Sorkhel, S.K. Investigation for Controlled Ellectrochemical Machining through Response Surface Methodology-Based Approach. J. Mater. Process. Technol. 1999, 86, 200–207. [Google Scholar] [CrossRef]

- Bhavsar, S.N.; Aravindan, S.; Rao, P.V. Investigating Material Removal Rate and Surface Roughness Using Multi-Objective Optimization for Focused Ion Beam (FIB) Micro-Milling of Cemented Carbide. Precis. Eng. 2015, 40, 131–138. [Google Scholar] [CrossRef]

- Rao, R.V.; Rai, D.P.; Balic, J. Multi-Objective Optimization of Machining and Micro-Machining Processes Using Non-Dominated Sorting Teaching–Learning-Based Optimization Algorithm. J. Intell. Manuf. 2018, 29, 1715–1737. [Google Scholar] [CrossRef]

- Rao, R.V.; Rai, D.P.; Balic, J. Multi-Objective Optimization of Abrasive Waterjet Machining Process Using Jaya Algorithm and PROMETHEE Method. J. Intell. Manuf. 2019, 30, 2101–2127. [Google Scholar] [CrossRef]

- Kubota, N.; Fukuda, T.; Shimojima, K. Virus-Evolutionary Genetic Algorithm for a Self-Organizing Manufacturing System. Comput. Ind. Eng. 1996, 30, 1015–1026. [Google Scholar] [CrossRef]

- Lu, B.; Cheng, B. The Virus Evolutionary Genetic Algorithm for Non- Full Loaded Vehicle Scheduling Problem with Fuzzy Time Window. In Proceedings of the 2011 Seventh International Conference on Natural Computation, Shanghai, China, 26–28 July 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 306–310. [Google Scholar] [CrossRef]

- Fountas, N.A.; Benhadj-Djilali, R.; Stergiou, C.I.; Vaxevanidis, N.M. An Integrated Framework for Optimizing Sculptured Surface CNC Tool Paths Based on Direct Software Object Evaluation and Viral Intelligence. J. Intell. Manuf. 2019, 30, 1581–1599. [Google Scholar] [CrossRef]

- Jakob, W.; Blume, C. Pareto Optimization or Cascaded Weighted Sum: A Comparison of Concepts. Algorithms 2014, 7, 166–185. [Google Scholar] [CrossRef]

- Anderson, N.G. Evolutionary Significance of Virus Infection. Nature 1970, 227, 1346–1347. [Google Scholar] [CrossRef] [PubMed]

- Zitzler, E.; Thiele, L. Multiobjective Evolutionary Algorithms: A Comparative Case Study and the Strength Pareto Approach. IEEE Trans. Evol. Comput. 1999, 3, 257–271. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, D. Parametric Optimization of Selective Laser Melting for Forming Ti6Al4V Samples by Taguchi Method. Opt. Laser Technol. 2013, 49, 118–124. [Google Scholar] [CrossRef]

- Mirjalili, S. Dragonfly Algorithm: A New Meta-Heuristic Optimization Technique for Solving Single-Objective, Discrete, and Multi-Objective Problems. Neural Comput. Appl. 2016, 27, 1053–1073. [Google Scholar] [CrossRef]

- Mirjalili, S.; Jangir, P.; Saremi, S. Multi-Objective Ant Lion Optimizer: A Multi-Objective Optimization Algorithm for Solving Engineering Problems. Appl. Intell. 2017, 46, 79–95. [Google Scholar] [CrossRef]

- Mirjalili, S.; Jangir, P.; Mirjalili, S.Z.; Saremi, S.; Trivedi, I.N. Optimization of Problems with Multiple Objectives Using the Multi-Verse Optimization Algorithm. Knowl.-Based Syst. 2017, 134, 50–71. [Google Scholar] [CrossRef]

- Khorasani, A.; Gibson, I.; Awan, U.S.; Ghaderi, A. The Effect of SLM Process Parameters on Density, Hardness, Tensile Strength and Surface Quality of Ti-6Al-4V. Addit. Manuf. 2019, 25, 176–186. [Google Scholar] [CrossRef]

- Jiang, H.-Z.; Li, Z.-Y.; Feng, T.; Wu, P.-Y.; Chen, Q.-S.; Feng, Y.-L.; Li, S.-W.; Gao, H.; Xu, H.-J. Factor Analysis of Selective Laser Melting Process Parameters with Normalised Quantities and Taguchi Method. Opt. Laser Technol. 2019, 119, 105592. [Google Scholar] [CrossRef]

| Sol. No. | LP (W) | SS (mm/min) | HS (μm) | SPA (°) | HTT (°C) | maxHB | maxTS |

|---|---|---|---|---|---|---|---|

| 1 | 90.0000 | 600.0070 | 65.0000 | 74.9992 | 96.0606 | 724.1530 | 1676.6300 |

| 2 | 90.0000 | 600.0830 | 65.0000 | 75.0000 | 189.6659 | 716.3600 | 1768.1500 |

| 3 | 90.0002 | 600.8099 | 65.0002 | 74.9999 | 369.0359 | 696.4140 | 1922.2800 |

| 4 | 90.0004 | 600.2490 | 65.0015 | 74.9992 | 512.6129 | 677.2990 | 2025.6600 |

| 5 | 90.0004 | 600.0346 | 65.0005 | 74.9990 | 572.3014 | 668.2410 | 2063.6400 |

| 6 | 90.0004 | 600.0497 | 65.0005 | 74.9991 | 572.4180 | 668.2090 | 2063.7000 |

| 7 | 90.0002 | 600.0021 | 65.0014 | 74.9992 | 638.1319 | 657.2870 | 2101.8300 |

| 8 | 90.0002 | 600.0349 | 65.0013 | 74.9995 | 687.7818 | 648.4690 | 2128.1600 |

| 9 | 90.0013 | 600.4803 | 65.0001 | 74.9994 | 74.0921 | 725.1940 | 1654.4900 |

| 10 | 90.0020 | 600.1857 | 65.0008 | 74.9994 | 115.8210 | 722.4130 | 1696.6500 |

| 11 | 90.0001 | 600.7364 | 65.0004 | 74.9993 | 213.9841 | 713.4070 | 1790.9200 |

| 12 | 90.0002 | 600.0025 | 65.0002 | 74.9973 | 48.2313 | 727.4620 | 1626.9200 |

| 13 | 90.0001 | 600.0005 | 65.0009 | 74.9910 | 100.7152 | 723.7120 | 1681.0100 |

| 14 | 90.0002 | 600.0005 | 65.0009 | 74.9910 | 111.3896 | 722.9010 | 1691.7700 |

| 15 | 90.0007 | 600.0103 | 65.0001 | 74.9973 | 322.8056 | 702.6660 | 1885.1000 |

| 16 | 90.0003 | 600.0176 | 65.0007 | 74.9885 | 436.4406 | 688.3110 | 1972.6600 |

| 17 | 90.0006 | 600.0850 | 65.0001 | 74.9961 | 537.9085 | 673.5970 | 2042.0900 |

| 18 | 90.0010 | 600.0852 | 65.0000 | 74.9962 | 575.7634 | 667.6140 | 2065.6100 |

| 19 | 90.0037 | 600.0031 | 65.0004 | 74.9998 | 662.0168 | 653.0600 | 2114.7800 |

| 20 | 90.0001 | 600.0041 | 65.0001 | 74.9997 | 704.9853 | 645.3690 | 2136.8900 |

| 21 | 90.0002 | 600.0046 | 65.0001 | 74.9994 | 740.2719 | 638.7320 | 2153.8000 |

| 22 | 90.0055 | 600.0059 | 65.0003 | 74.9959 | 825.6876 | 621.5840 | 2190.0900 |

| 23 | 90.0030 | 600.0004 | 65.0006 | 74.9958 | 883.3804 | 609.4070 | 2211.2500 |

| 24 | 90.0001 | 600.0022 | 65.0018 | 74.9999 | 959.8236 | 592.3350 | 2235.0000 |

| 25 | 90.0000 | 600.0024 | 65.0009 | 74.9995 | 1049.9481 | 570.7760 | 2256.4100 |

| 26 | 90.0009 | 600.0032 | 65.0008 | 74.9997 | 72.2267 | 725.8430 | 1652.1300 |

| 27 | 90.0000 | 600.1076 | 65.0023 | 75.0000 | 211.0341 | 714.3050 | 1787.8900 |

| 28 | 90.0000 | 600.0121 | 65.0004 | 74.9986 | 300.1269 | 705.2500 | 1866.2800 |

| 29 | 90.0000 | 600.0203 | 65.0004 | 74.9984 | 304.2338 | 704.7820 | 1869.7200 |

| 30 | 90.0000 | 600.0722 | 65.0004 | 74.9967 | 362.5610 | 697.8850 | 1917.1000 |

| 31 | 90.0000 | 600.0714 | 65.0004 | 74.9970 | 362.6760 | 697.8740 | 1917.2000 |

| 32 | 90.0000 | 600.0657 | 65.0001 | 74.9993 | 423.4337 | 690.1280 | 1963.6000 |

| 33 | 90.0000 | 600.0660 | 65.0002 | 74.9993 | 431.3230 | 689.0670 | 1969.3800 |

| 34 | 90.0005 | 600.1135 | 65.0005 | 74.9996 | 482.8846 | 681.8100 | 2005.8100 |

| 35 | 90.0005 | 600.1110 | 65.0007 | 74.9997 | 531.7765 | 674.5350 | 2038.2600 |

| 36 | 90.0009 | 600.0268 | 65.0031 | 75.0000 | 608.8342 | 662.2050 | 2085.2100 |

| 37 | 90.0004 | 600.1641 | 65.0076 | 74.9999 | 689.8788 | 647.8650 | 2128.7900 |

| 38 | 90.0007 | 600.1651 | 65.0079 | 74.9999 | 710.0763 | 644.1420 | 2138.8300 |

| 39 | 90.0003 | 600.0472 | 65.0192 | 75.0000 | 811.1128 | 624.3400 | 2183.5100 |

| 40 | 90.0006 | 600.0391 | 65.0091 | 74.9999 | 875.5373 | 611.0010 | 2208.2300 |

| 41 | 90.0001 | 600.0028 | 65.0100 | 74.9999 | 936.3248 | 597.5660 | 2227.8300 |

| 42 | 90.0000 | 600.0027 | 65.0050 | 74.9998 | 1001.2611 | 582.5420 | 2245.5100 |

| 43 | 90.0043 | 600.0114 | 65.0043 | 74.9999 | 81.6854 | 725.0330 | 1661.7300 |

| 44 | 90.0002 | 600.0909 | 65.0436 | 74.9995 | 353.1494 | 698.1930 | 1907.9500 |

| 45 | 90.0002 | 600.0898 | 65.0461 | 74.9995 | 354.1915 | 698.0200 | 1908.6800 |

| 46 | 90.0000 | 600.0104 | 65.0133 | 75.0000 | 487.6573 | 680.9800 | 2008.5600 |

| 47 | 90.0001 | 600.3778 | 65.0084 | 75.0000 | 552.4658 | 670.9590 | 2050.8700 |

| 48 | 90.0003 | 600.4747 | 65.0014 | 74.9992 | 756.6315 | 635.1890 | 2160.6100 |

| 49 | 90.0002 | 600.4659 | 65.0014 | 74.9992 | 798.6468 | 626.8870 | 2178.7200 |

| 50 | 90.0005 | 600.7370 | 65.0019 | 74.9616 | 860.6133 | 613.5870 | 2200.6600 |

| 51 | 90.0000 | 600.0007 | 65.0044 | 74.9999 | 928.7629 | 599.3840 | 2225.8800 |

| 52 | 90.0000 | 600.0000 | 65.0019 | 74.9999 | 972.2506 | 589.4500 | 2238.3600 |

| 53 | 90.0000 | 600.0231 | 65.0003 | 75.0000 | 1021.0095 | 577.8650 | 2250.3200 |

| 54 | 90.0000 | 600.0224 | 65.0002 | 75.0000 | 1049.6006 | 570.8650 | 2256.3600 |

| 55 | 90.0004 | 600.6827 | 65.0039 | 74.9999 | 280.1177 | 706.7060 | 1849.3300 |

| 56 | 90.0000 | 600.1879 | 65.0004 | 74.9928 | 180.6262 | 716.9880 | 1759.4200 |

| 57 | 90.0008 | 600.1150 | 65.0002 | 74.9970 | 246.9769 | 710.7680 | 1820.2900 |

| 58 | 90.0003 | 600.0007 | 65.0000 | 74.9992 | 20.1417 | 729.2480 | 1596.9400 |

| 59 | 90.0003 | 600.0007 | 65.0001 | 74.9999 | 88.6743 | 724.7030 | 1669.1200 |

| 60 | 90.0002 | 600.0009 | 65.0001 | 74.9999 | 115.1837 | 722.7150 | 1695.9400 |

| 61 | 90.0001 | 600.0007 | 65.0001 | 74.9999 | 150.1976 | 719.8930 | 1730.4600 |

| 62 | 90.0001 | 600.0009 | 65.0001 | 75.0000 | 185.7119 | 716.8010 | 1764.3900 |

| 63 | 90.0042 | 600.0007 | 65.0015 | 74.9996 | 229.7076 | 712.5410 | 1804.7900 |

| 64 | 90.0005 | 600.0004 | 65.0026 | 74.9996 | 291.2892 | 706.1940 | 1858.7500 |

| 65 | 90.0018 | 600.0028 | 65.0023 | 74.9988 | 424.0614 | 690.0180 | 1963.9300 |

| 66 | 90.0018 | 600.0004 | 65.0023 | 74.9989 | 436.8278 | 688.3010 | 1973.2600 |

| 67 | 90.0075 | 600.0098 | 65.0006 | 74.9999 | 504.0405 | 678.6600 | 2020.0500 |

| 68 | 90.0073 | 600.0096 | 65.0004 | 74.9999 | 527.3985 | 675.1570 | 2035.4100 |

| 69 | 90.0028 | 600.0066 | 65.0001 | 74.9998 | 580.7397 | 666.8640 | 2068.7700 |

| 70 | 90.0031 | 600.0065 | 65.0001 | 74.9998 | 589.3602 | 665.4540 | 2073.9200 |

| 71 | 90.0101 | 600.0036 | 65.0005 | 74.9898 | 656.1425 | 653.8770 | 2111.1400 |

| 72 | 90.0000 | 600.0052 | 65.0013 | 74.9980 | 718.4244 | 642.8350 | 2143.3300 |

| 73 | 90.0000 | 600.0051 | 65.0013 | 74.9980 | 725.1892 | 641.5640 | 2146.5800 |

| 74 | 90.0004 | 600.0005 | 65.0003 | 74.9994 | 791.4698 | 628.6960 | 2176.4300 |

| 75 | 90.0003 | 600.0001 | 65.0005 | 74.9998 | 806.9547 | 625.5700 | 2182.8500 |

| 76 | 90.0009 | 600.0003 | 65.0003 | 74.9981 | 916.3233 | 602.2180 | 2222.1800 |

| 77 | 90.0286 | 600.0030 | 65.0050 | 74.9999 | 120.2652 | 721.6730 | 1700.3900 |

| 78 | 90.0041 | 600.0147 | 65.0003 | 74.9999 | 192.6370 | 716.0760 | 1770.8200 |

| 79 | 90.0041 | 600.0148 | 65.0002 | 74.9999 | 224.1196 | 713.1030 | 1799.8000 |

| 80 | 90.0019 | 600.0978 | 65.0022 | 74.9992 | 350.5860 | 699.2630 | 1907.5900 |

| 81 | 90.0018 | 600.0980 | 65.0013 | 74.9993 | 377.1215 | 696.0260 | 1928.5200 |

| 82 | 90.0010 | 600.0072 | 65.0009 | 75.0000 | 460.2781 | 685.1080 | 1990.1300 |

| 83 | 90.0020 | 600.0121 | 65.0008 | 74.9999 | 496.3530 | 679.9050 | 2014.9700 |

| 84 | 90.0023 | 600.0167 | 65.0009 | 75.0000 | 562.1374 | 669.8410 | 2057.4200 |

| 85 | 90.0002 | 600.0046 | 65.0001 | 74.9985 | 619.2623 | 660.5290 | 2091.2900 |

| 86 | 90.0002 | 600.0067 | 65.0000 | 75.0000 | 654.6460 | 654.4410 | 2110.9200 |

| 87 | 90.0004 | 600.0434 | 65.0002 | 74.9980 | 760.4103 | 634.7950 | 2162.8600 |

| 88 | 90.0006 | 600.0443 | 65.0017 | 74.9988 | 823.3227 | 622.1490 | 2189.2300 |

| 89 | 90.0003 | 600.0844 | 65.0009 | 74.9996 | 882.0087 | 609.7240 | 2210.8200 |

| 90 | 90.0003 | 600.0177 | 65.0015 | 74.9979 | 943.9839 | 595.9530 | 2230.4200 |

| 91 | 90.0002 | 600.0176 | 65.0015 | 74.9979 | 951.1902 | 594.3050 | 2232.4900 |

| 92 | 90.0004 | 600.0176 | 65.0004 | 74.9979 | 1018.4691 | 578.4620 | 2249.6600 |

| 93 | 90.0002 | 600.0319 | 65.0009 | 74.9998 | 48.8745 | 727.4000 | 1627.7000 |

| 94 | 90.0006 | 600.0274 | 65.0009 | 74.9999 | 101.5424 | 723.7010 | 1682.2000 |

| 95 | 90.0006 | 600.0512 | 65.0009 | 74.9998 | 136.2923 | 720.9600 | 1716.8700 |

| 96 | 90.0003 | 600.0261 | 65.0000 | 74.9913 | 368.4556 | 697.1580 | 1921.5300 |

| 97 | 90.0004 | 600.0854 | 65.0001 | 74.9977 | 443.7262 | 687.3420 | 1978.2900 |

| 98 | 90.0006 | 600.0226 | 65.0000 | 74.9978 | 445.0121 | 687.2210 | 1979.2300 |

| 99 | 90.0042 | 600.0567 | 65.0008 | 74.9919 | 520.7453 | 676.1180 | 2030.7800 |

| 100 | 90.0023 | 600.0569 | 65.0003 | 74.9919 | 526.9859 | 675.2190 | 2034.8800 |

| 101 | 90.0165 | 601.4028 | 65.0000 | 74.9997 | 676.4436 | 649.0900 | 2120.7600 |

| 102 | 90.0093 | 601.0325 | 65.0000 | 74.9995 | 782.6755 | 629.4820 | 2171.1900 |

| 103 | 90.0001 | 600.0025 | 65.0001 | 74.9998 | 891.3549 | 607.7680 | 2214.1800 |

| 104 | 90.0001 | 600.0033 | 65.0001 | 74.9998 | 916.9145 | 602.1180 | 2222.4500 |

| 105 | 90.0008 | 600.1868 | 65.0000 | 75.0000 | 995.3963 | 583.8910 | 2243.9900 |

| 106 | 90.0050 | 600.2147 | 65.0001 | 74.9740 | 36.8009 | 727.6280 | 1614.0400 |

| 107 | 90.0354 | 600.0887 | 65.0000 | 75.0000 | 339.2562 | 699.9920 | 1898.0800 |

| 108 | 90.0345 | 600.1149 | 65.0000 | 75.0000 | 369.8654 | 696.2760 | 1922.4300 |

| 109 | 90.0008 | 600.3937 | 65.0001 | 74.9969 | 543.6894 | 672.4330 | 2045.6000 |

| 110 | 90.0001 | 600.0295 | 65.0001 | 74.9962 | 586.9384 | 665.8660 | 2072.3700 |

| 111 | 90.0080 | 600.8088 | 65.0015 | 74.9783 | 785.2215 | 628.9980 | 2171.6700 |

| 112 | 90.0010 | 600.1271 | 65.0004 | 74.9988 | 874.0360 | 611.4080 | 2207.9800 |

| 113 | 90.0007 | 600.1159 | 65.0004 | 74.9988 | 893.1665 | 607.2660 | 2214.5200 |

| 114 | 90.0016 | 600.0141 | 65.0000 | 74.9992 | 988.4006 | 585.6400 | 2242.5500 |

| 115 | 90.0000 | 600.0025 | 65.0008 | 74.9991 | 20.3040 | 729.2250 | 1597.0900 |

| 116 | 90.0000 | 600.0005 | 65.0008 | 74.9991 | 33.4874 | 728.4180 | 1611.2800 |

| 117 | 90.0002 | 600.0437 | 65.0000 | 74.9975 | 130.6390 | 721.4280 | 1711.2500 |

| 118 | 90.0002 | 600.0452 | 65.0000 | 74.9968 | 255.4522 | 709.9870 | 1827.7600 |

| 119 | 90.0004 | 600.6115 | 65.0009 | 75.0000 | 310.5811 | 703.4860 | 1875.1500 |

| 120 | 90.0001 | 600.0099 | 65.0000 | 74.9991 | 412.8274 | 691.5840 | 1955.7500 |

| 121 | 90.0000 | 600.0305 | 65.0000 | 74.9945 | 486.1262 | 681.3920 | 2007.8800 |

| 122 | 90.0000 | 600.0510 | 65.0000 | 74.9944 | 519.8299 | 676.3860 | 2030.3800 |

| 123 | 90.0002 | 600.1056 | 65.0001 | 74.9994 | 629.5712 | 658.6990 | 2097.0500 |

| 124 | 90.0004 | 600.0521 | 65.0002 | 74.9998 | 698.4567 | 646.5270 | 2133.5900 |

| 125 | 90.0001 | 600.0234 | 65.0010 | 74.9995 | 774.9020 | 631.9700 | 2169.3000 |

| 126 | 90.0001 | 600.0352 | 65.0021 | 74.9992 | 793.4223 | 628.2500 | 2177.1100 |

| 127 | 90.0008 | 600.2279 | 65.0000 | 74.9988 | 831.5273 | 620.3430 | 2192.2400 |

| 128 | 90.0008 | 600.2258 | 65.0000 | 74.9988 | 850.5332 | 616.3640 | 2199.4100 |

| 129 | 90.0073 | 600.0691 | 65.0014 | 74.9974 | 1011.2398 | 579.9870 | 2247.7200 |

| 130 | 90.0011 | 600.0000 | 65.0001 | 74.9997 | 33.3880 | 728.4230 | 1611.2000 |

| 131 | 90.0015 | 600.0003 | 65.0000 | 74.9999 | 99.9996 | 723.8460 | 1680.6300 |

| 132 | 90.0011 | 600.0006 | 65.0000 | 74.9935 | 175.7097 | 717.6130 | 1754.6800 |

| 133 | 90.0001 | 600.0113 | 65.0002 | 74.9997 | 228.5262 | 712.7510 | 1803.8400 |

| 134 | 90.0004 | 600.0113 | 65.0002 | 74.9999 | 263.4553 | 709.2120 | 1834.8800 |

| 135 | 90.0003 | 600.0115 | 65.0002 | 74.9999 | 287.0514 | 706.6990 | 1855.2500 |

| 136 | 90.0012 | 600.0139 | 65.0001 | 74.9987 | 418.1687 | 690.8460 | 1959.6800 |

| 137 | 90.0008 | 600.0165 | 65.0001 | 74.9994 | 450.2061 | 686.5170 | 1983.0000 |

| 138 | 90.0026 | 600.0003 | 65.0029 | 74.9998 | 524.5331 | 675.6510 | 2033.5100 |

| 139 | 90.0017 | 600.0001 | 65.0004 | 74.9954 | 648.2606 | 655.4900 | 2107.2500 |

| 140 | 90.0005 | 600.0005 | 65.0011 | 74.9997 | 699.6744 | 646.3240 | 2134.2100 |

| 141 | 90.0005 | 600.0005 | 65.0017 | 74.9997 | 733.9239 | 639.9090 | 2150.7700 |

| 142 | 90.0097 | 600.0000 | 65.0000 | 74.9954 | 788.8330 | 628.9920 | 2175.0300 |

| 143 | 90.0099 | 600.0009 | 65.0001 | 74.9954 | 863.4788 | 613.5420 | 2204.1900 |

| 144 | 90.0099 | 600.0009 | 65.0001 | 74.9954 | 864.0086 | 613.4290 | 2204.3800 |

| 145 | 90.0119 | 600.0029 | 65.0002 | 74.9701 | 926.9109 | 599.4130 | 2224.1300 |

| Performance Metric | Statistical Results | ||

|---|---|---|---|

| Best | Mean | St.Dev. | |

| Cvg(MOVEGA, MOGWO) | 0.8328 | 0.7641 | 0.0442 |

| Cvg(MOGWO, MOVEGA) | 0.7213 | 0.0912 | 0.0753 |

| Cvg(MOVEGA, MOMVO) | 0.8412 | 0.7327 | 0.0548 |

| Cvg(MOMVO, MOVEGA) | 0.2674 | 0.1668 | 0.0349 |

| Cvg(MOVEGA, MOALO) | 0.8227 | 0.7808 | 0.0648 |

| Cvg(MOALO, MOVEGA) | 0.2942 | 0.2105 | 0.0599 |

| Cvg(MOVEGA, MODA) | 0.7828 | 0.3571 | 0.0642 |

| Cvg(MODA, MOVEGA) | 0.2118 | 0.2942 | 0.0341 |

| S(MOVEGA) | 0.0257 | 0.0274 | 0.0035 |

| S(MOGWO) | 0.0912 | 0.1077 | 0.0094 |

| S(MOVMVO) | 0.0922 | 0.1752 | 0.0104 |

| S(MOALO) | 0.0697 | 0.1777 | 0.0149 |

| S(MODA) | 0.0984 | 0.2101 | 0.0211 |

| Sol. No. | LP (W) | SS (mm/min) | HS (μm) | minRa | maxHV | maxρ |

|---|---|---|---|---|---|---|

| 1 | 63.0920 | 6.6900 | 1.8800 | 3.22026 | 184.430 | 99.0131 |

| 2 | 57.0923 | 7.0746 | 2.0314 | 6.08493 | 208.998 | 99.3881 |

| 3 | 56.5919 | 7.2272 | 2.0667 | 6.55576 | 211.269 | 99.4072 |

| 4 | 63.3478 | 6.7351 | 1.8882 | 3.30673 | 184.917 | 99.0189 |

| 5 | 59.7448 | 6.6900 | 1.8800 | 4.00626 | 193.844 | 99.1784 |

| 6 | 57.6960 | 6.8654 | 1.9544 | 5.26003 | 203.770 | 99.3269 |

| 7 | 59.0302 | 7.0065 | 2.0128 | 5.40195 | 205.081 | 99.3343 |

| 8 | 59.6797 | 6.7893 | 1.8937 | 4.27655 | 196.154 | 99.2116 |

| 9 | 57.5663 | 7.0654 | 1.9750 | 5.68598 | 206.682 | 99.3604 |

| 10 | 57.4215 | 7.0615 | 2.0316 | 5.97916 | 208.501 | 99.3817 |

| 11 | 60.6645 | 6.7139 | 1.8846 | 3.84318 | 192.136 | 99.1468 |

| 12 | 62.3797 | 6.6900 | 1.8800 | 3.37229 | 186.642 | 99.0521 |

| 13 | 62.3644 | 6.7182 | 1.8866 | 3.46950 | 187.562 | 99.0662 |

| 14 | 58.7394 | 6.9052 | 1.9771 | 5.15238 | 203.262 | 99.3139 |

| 15 | 58.4793 | 7.0090 | 1.9913 | 5.44380 | 205.308 | 99.3399 |

| 16 | 62.3863 | 6.7290 | 1.8862 | 3.48354 | 187.657 | 99.0675 |

| 17 | 58.4011 | 6.9702 | 1.9761 | 5.33356 | 204.510 | 99.3308 |

| 18 | 58.6260 | 6.7573 | 1.9064 | 4.57371 | 198.665 | 99.2541 |

| 19 | 60.9559 | 6.8512 | 1.9448 | 4.35574 | 196.533 | 99.2082 |

| 20 | 61.2156 | 6.7024 | 1.8862 | 3.69831 | 190.570 | 99.1197 |

| 21 | 61.8754 | 6.7370 | 1.8812 | 3.58157 | 188.985 | 99.0912 |

| 22 | 60.6341 | 6.7259 | 1.8868 | 3.88524 | 192.521 | 99.1526 |

| 23 | 58.8913 | 6.8463 | 1.9457 | 4.86012 | 201.031 | 99.2839 |

| 24 | 60.6267 | 6.8324 | 1.9279 | 4.30814 | 196.244 | 99.2062 |

| 25 | 58.4646 | 6.9468 | 1.9886 | 5.34328 | 204.607 | 99.3322 |

| 26 | 58.1004 | 6.9805 | 1.9960 | 5.52379 | 205.786 | 99.3483 |

| 27 | 59.5401 | 6.9638 | 1.9837 | 5.07353 | 202.676 | 99.3008 |

| 28 | 59.6232 | 6.9664 | 1.9792 | 5.03499 | 202.370 | 99.2962 |

| 29 | 58.2348 | 6.9789 | 1.9901 | 5.45795 | 205.362 | 99.3423 |

| 30 | 59.2099 | 6.9712 | 1.9831 | 5.16324 | 203.357 | 99.3115 |

| 31 | 59.5973 | 6.9073 | 1.9500 | 4.80039 | 200.538 | 99.2722 |

| 32 | 58.3600 | 6.9500 | 1.9838 | 5.35188 | 204.644 | 99.3331 |

| 33 | 59.5956 | 6.8831 | 1.9562 | 4.79400 | 200.511 | 99.2722 |

| 34 | 58.2513 | 6.9896 | 1.9909 | 5.47262 | 205.466 | 99.3434 |

| 35 | 57.0567 | 7.1305 | 2.0458 | 6.22802 | 209.792 | 99.3950 |

| 36 | 60.6599 | 6.8332 | 1.9296 | 4.31110 | 196.260 | 99.2062 |

| 37 | 58.2678 | 6.9376 | 1.9778 | 5.32860 | 204.455 | 99.3314 |

| 38 | 60.4834 | 6.9424 | 1.9605 | 4.69952 | 199.536 | 99.2528 |

| 39 | 59.2840 | 7.0080 | 1.9910 | 5.23907 | 203.907 | 99.3178 |

| 40 | 61.9641 | 6.7711 | 1.9043 | 3.76112 | 190.613 | 99.1149 |

| 41 | 60.5560 | 6.8732 | 1.9534 | 4.53106 | 198.169 | 99.2338 |

| 42 | 59.5237 | 6.9291 | 1.9660 | 4.93497 | 201.613 | 99.2871 |

| 43 | 61.6147 | 6.8326 | 1.9338 | 4.11536 | 194.069 | 99.1683 |

| 44 | 59.0104 | 6.9904 | 1.9925 | 5.28737 | 204.261 | 99.3241 |

| 45 | 61.5612 | 6.8335 | 1.9305 | 4.11072 | 194.054 | 99.1684 |

| 46 | 60.1161 | 6.8770 | 1.9438 | 4.59124 | 198.773 | 99.2449 |

| 47 | 62.7393 | 6.7634 | 1.9016 | 3.56492 | 188.083 | 99.0715 |

| 48 | 60.7520 | 6.8414 | 1.9321 | 4.31713 | 196.273 | 99.2057 |

| 49 | 60.5726 | 6.9424 | 1.9639 | 4.69620 | 199.484 | 99.2515 |

| 50 | 58.3231 | 7.0466 | 2.0144 | 5.64501 | 206.650 | 99.3565 |

| Performance Metric | Statistical Results | ||

|---|---|---|---|

| Best | Mean | St.Dev. | |

| Cvg(MOVEGA, MOGWO) | 0.8745 | 0.8524 | 0.0346 |

| Cvg(MOGWO, MOVEGA) | 0.4249 | 0.4390 | 0.0571 |

| Cvg(MOVEGA, MOMVO) | 0.4612 | 0.4588 | 0.0224 |

| Cvg(MOMVO, MOVEGA) | 0.2459 | 0.2547 | 0.0489 |

| Cvg(MOVEGA, MOALO) | 0.4378 | 0.4174 | 0.0542 |

| Cvg(MOALO, MOVEGA) | 0.1947 | 0.2234 | 0.0672 |

| Cvg(MOVEGA, MODA) | 0.7716 | 0.7519 | 0.0516 |

| Cvg(MODA, MOVEGA) | 0.6904 | 0.6815 | 0.0672 |

| S(MOVEGA) | 0.0177 | 0.0179 | 0.0031 |

| S(MOGWO) | 0.0181 | 0.0186 | 0.0046 |

| S(MOVMVO) | 0.0102 | 0.0111 | 0.0012 |

| S(MOALO) | 0.0125 | 0.0128 | 0.0018 |

| S(MODA) | 0.0184 | 0.0178 | 0.0057 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fountas, N.A.; Kechagias, J.D.; Vaxevanidis, N.M. Optimization of Selective Laser Sintering/Melting Operations by Using a Virus-Evolutionary Genetic Algorithm. Machines 2023, 11, 95. https://doi.org/10.3390/machines11010095

Fountas NA, Kechagias JD, Vaxevanidis NM. Optimization of Selective Laser Sintering/Melting Operations by Using a Virus-Evolutionary Genetic Algorithm. Machines. 2023; 11(1):95. https://doi.org/10.3390/machines11010095

Chicago/Turabian StyleFountas, Nikolaos A., John D. Kechagias, and Nikolaos M. Vaxevanidis. 2023. "Optimization of Selective Laser Sintering/Melting Operations by Using a Virus-Evolutionary Genetic Algorithm" Machines 11, no. 1: 95. https://doi.org/10.3390/machines11010095

APA StyleFountas, N. A., Kechagias, J. D., & Vaxevanidis, N. M. (2023). Optimization of Selective Laser Sintering/Melting Operations by Using a Virus-Evolutionary Genetic Algorithm. Machines, 11(1), 95. https://doi.org/10.3390/machines11010095

_Kechagias.jpg)