High-Torque Electric Machines: State of the Art and Comparison

Abstract

:1. Introduction

2. Electric Motor Classification Based on Airgap Structure

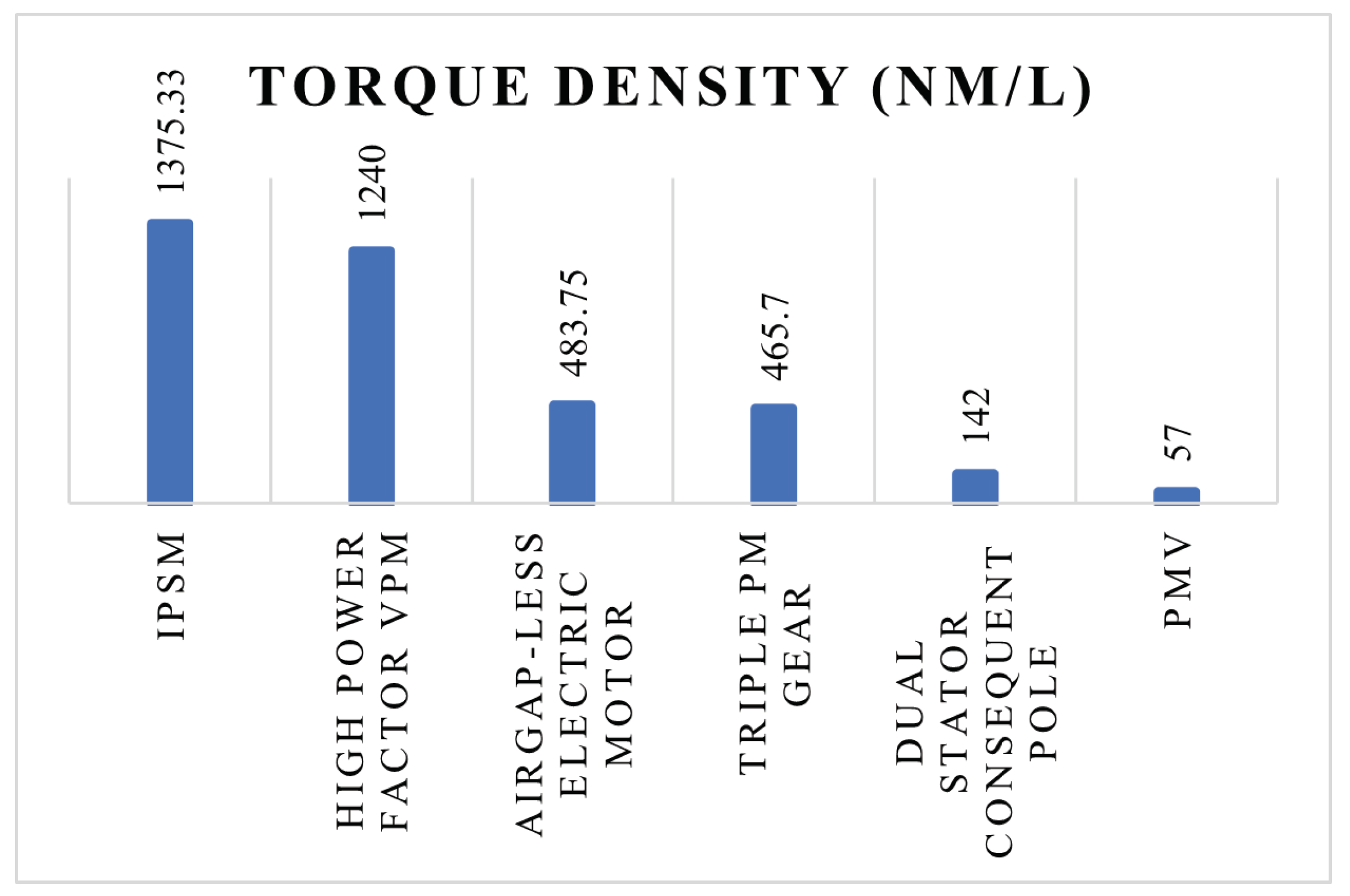

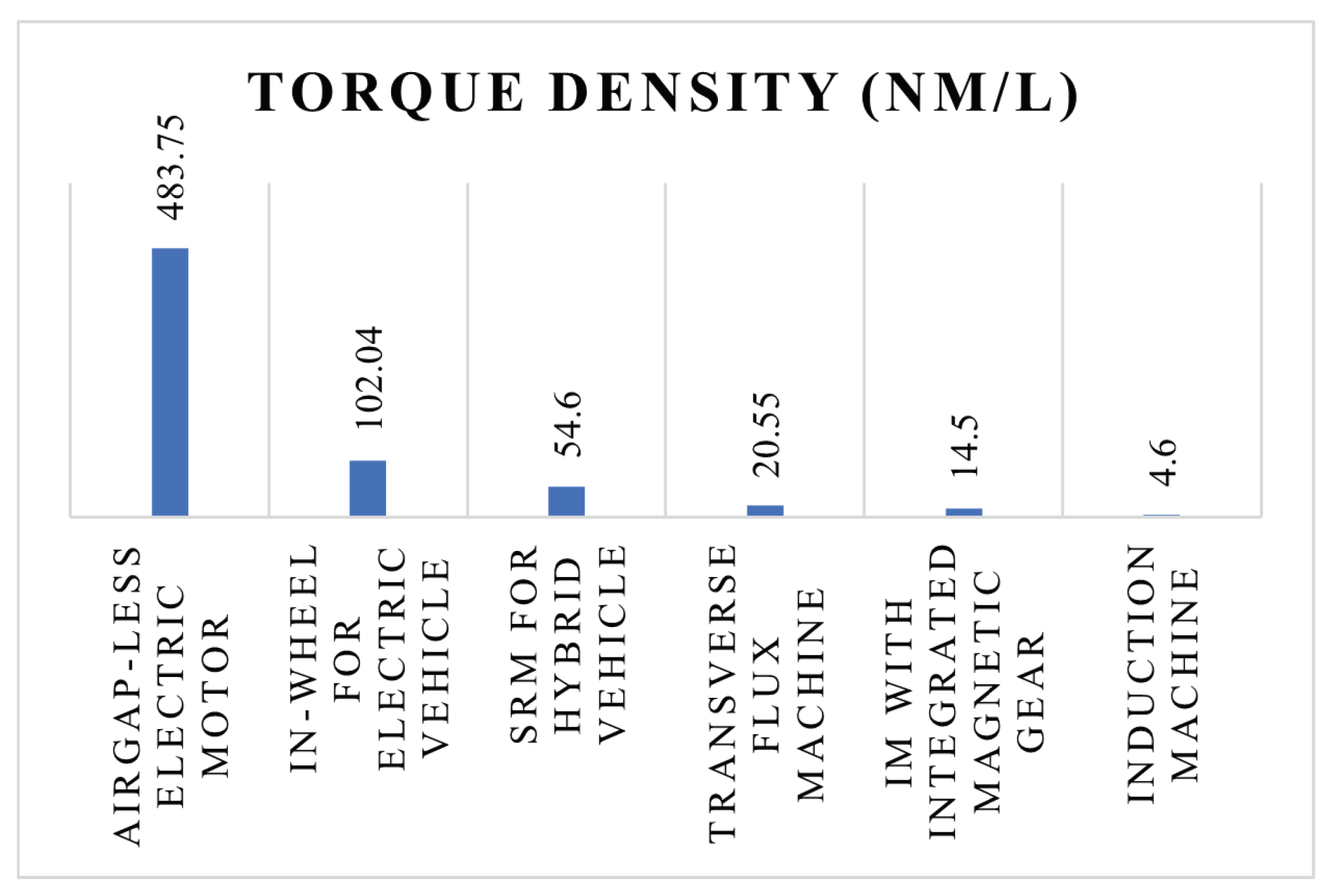

2.1. Machines with Constant Airgap

2.1.1. Induction Machines

2.1.2. Synchronous Machines

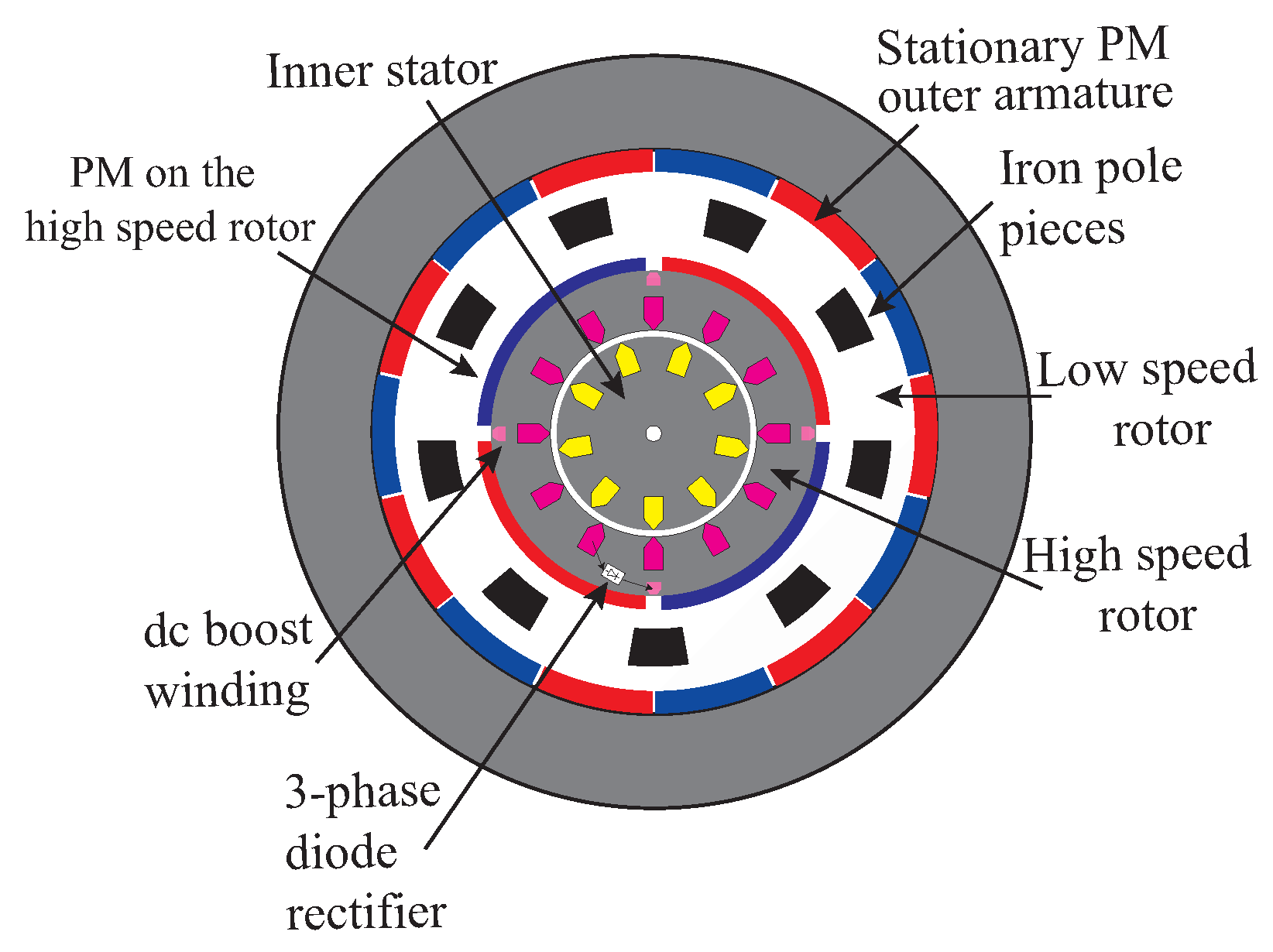

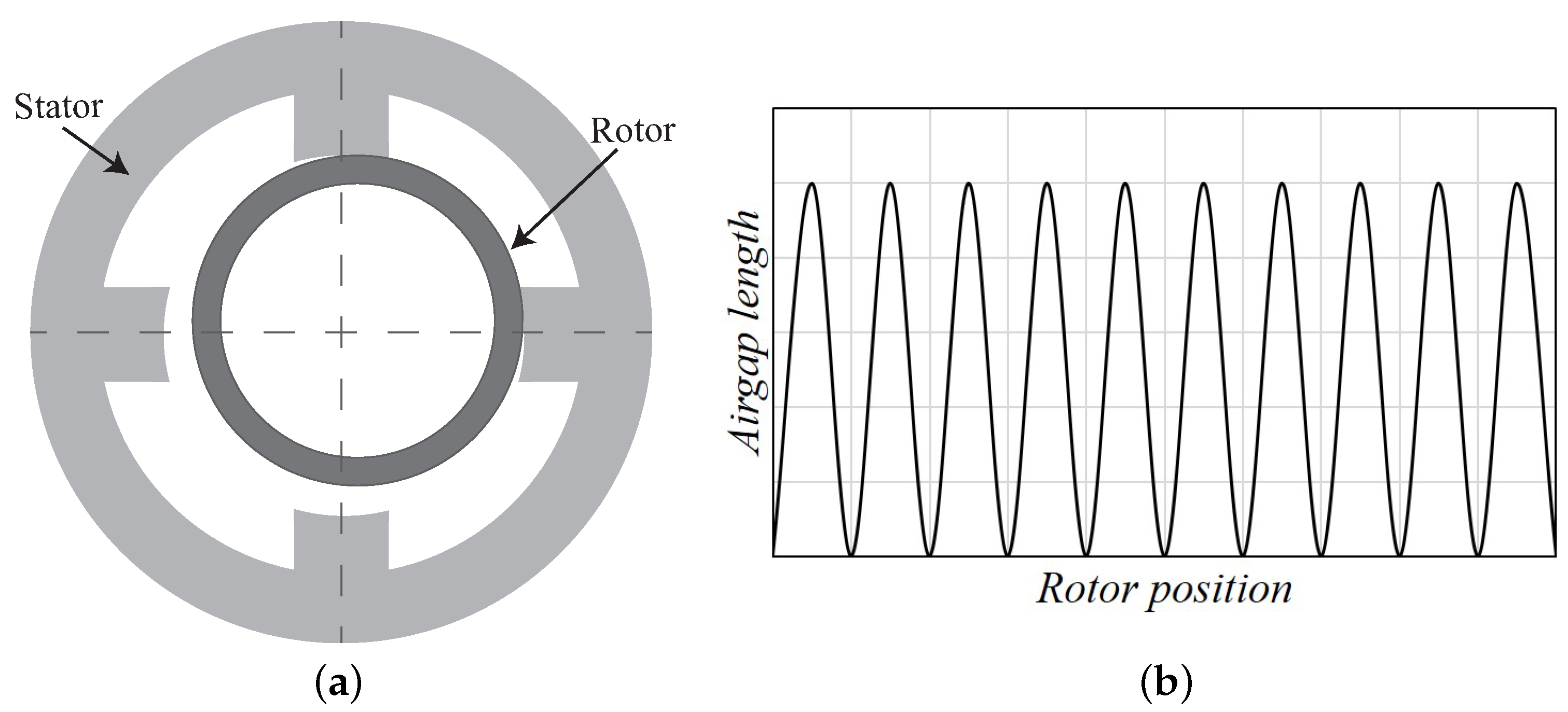

2.2. Machines with Variable Airgap

2.2.1. Synchronous Machines

2.2.2. Permanent-Magnet Machines

2.2.3. Interior Permanent-Magnet Synchronous Machines

2.2.4. Synchronous Reluctance Machine

2.2.5. Permanent-Magnet Flux-Switching Machines

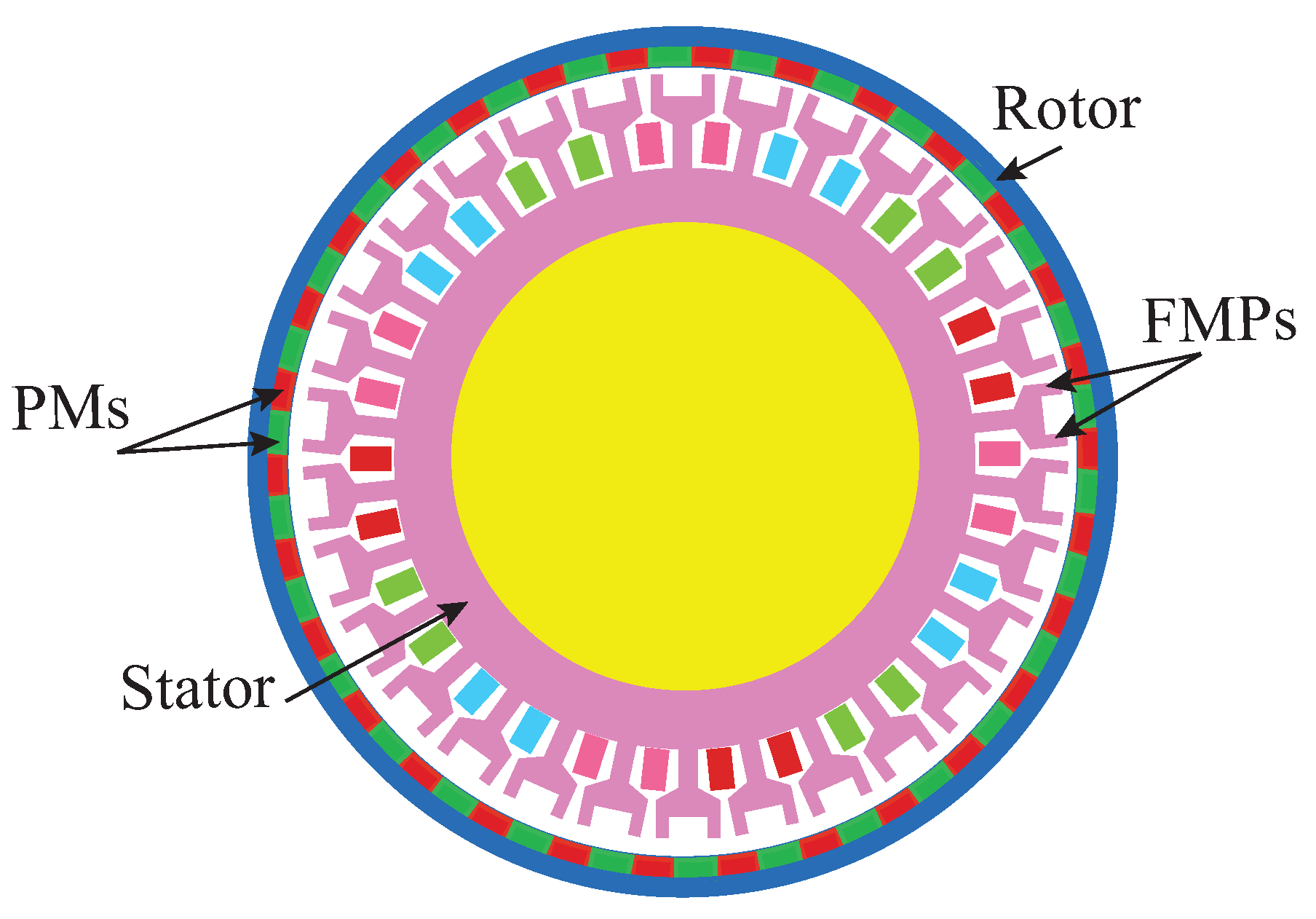

2.2.6. Permanent-Magnet Vernier Machines

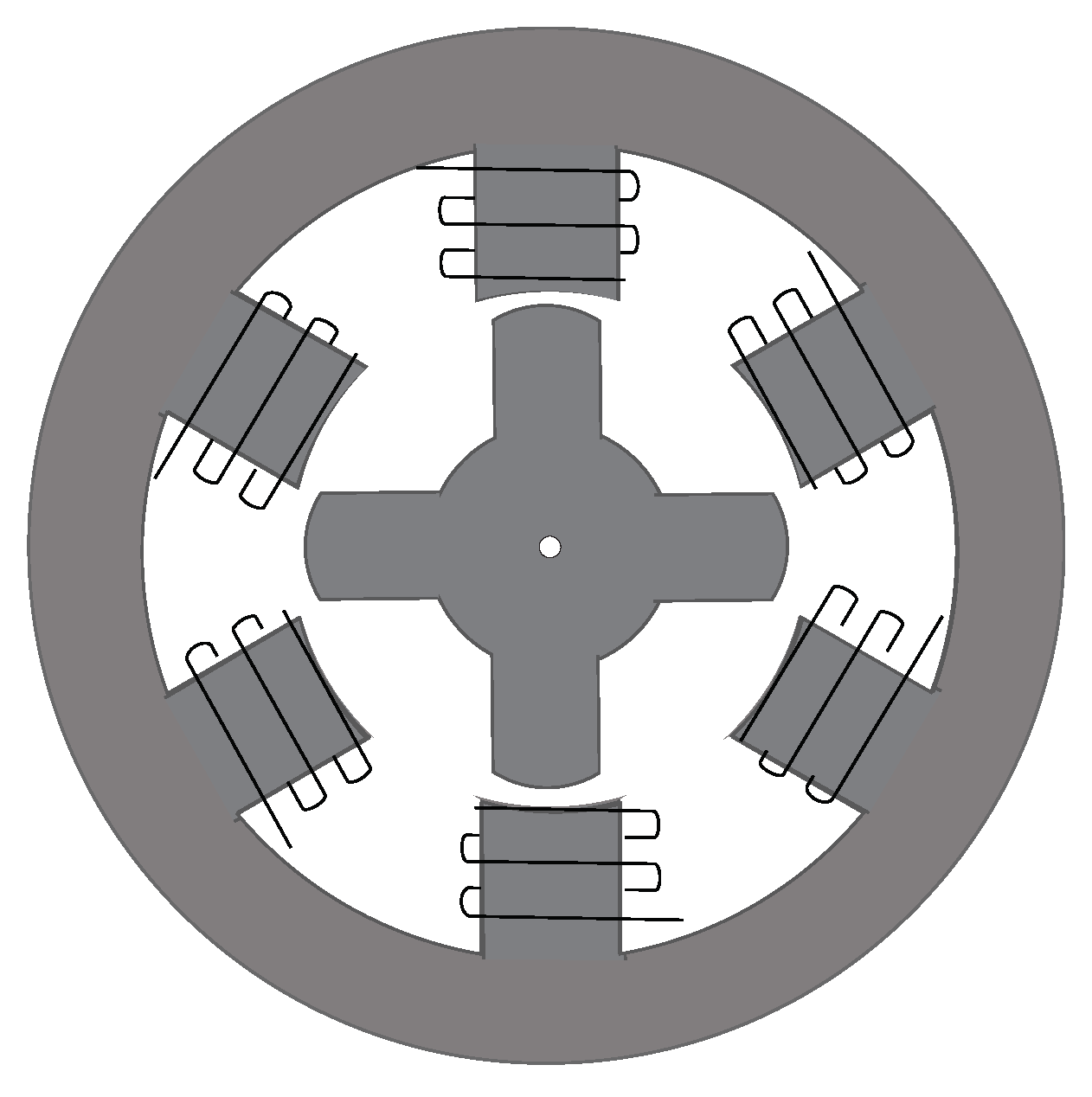

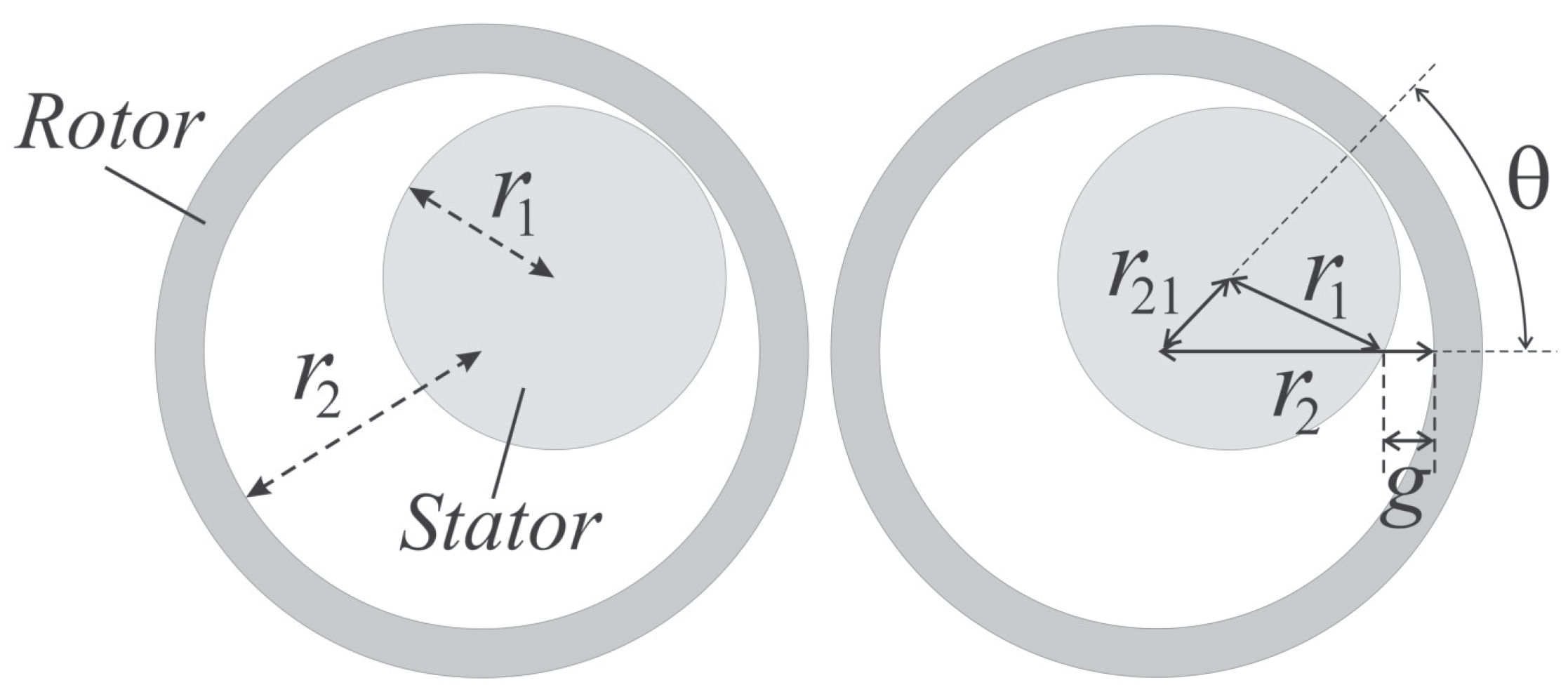

2.3. Machines with Eccentric Airgaps

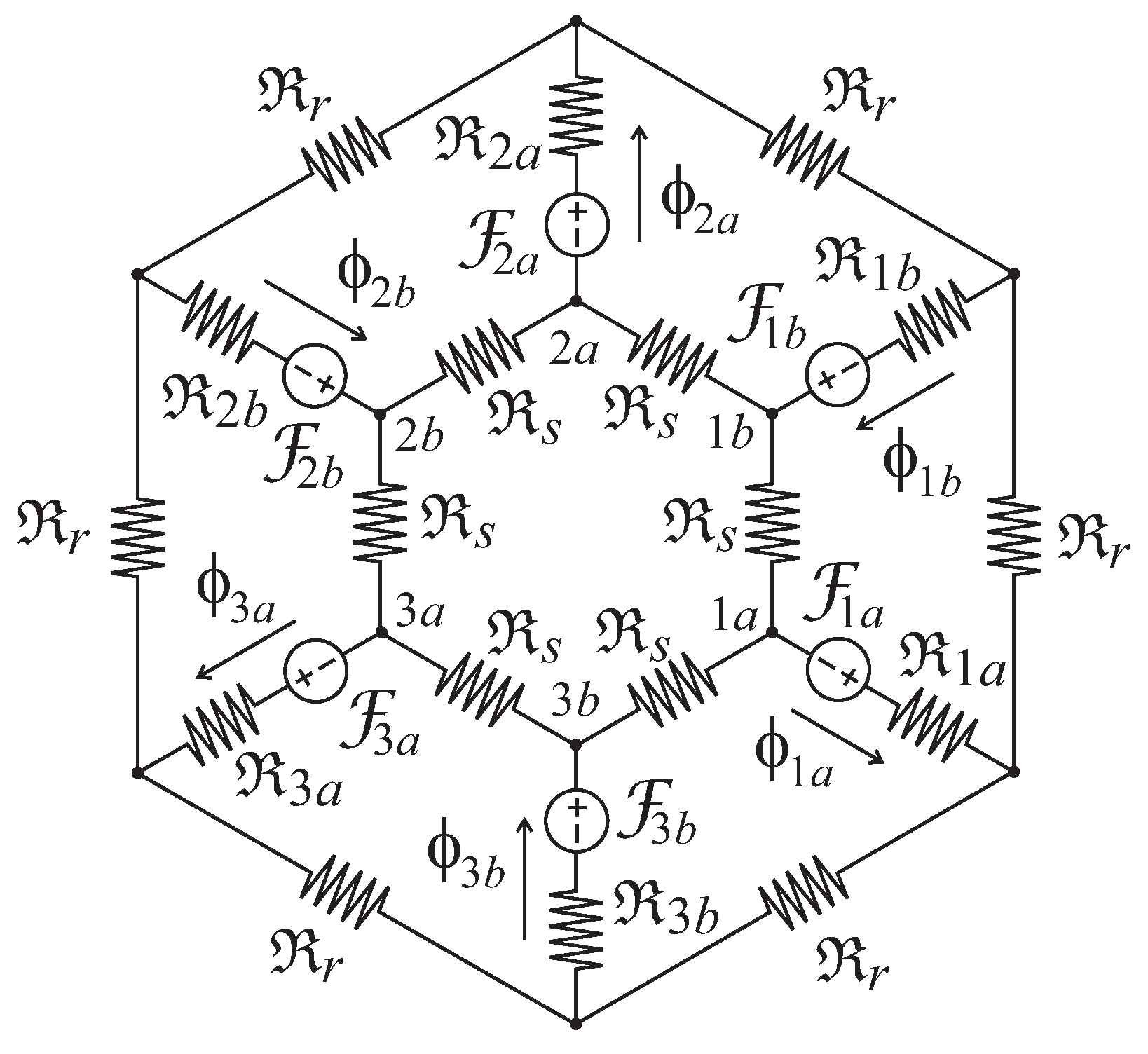

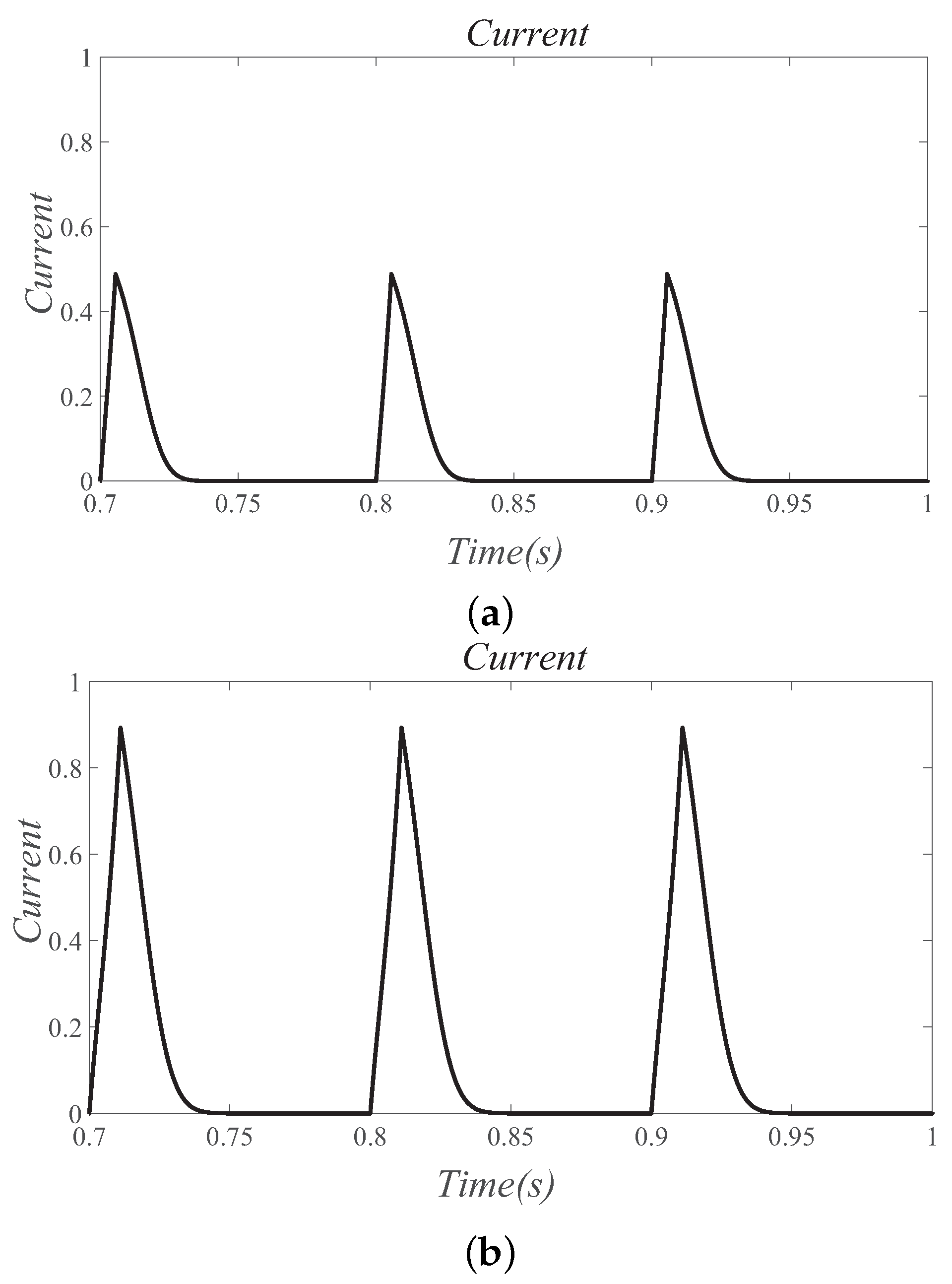

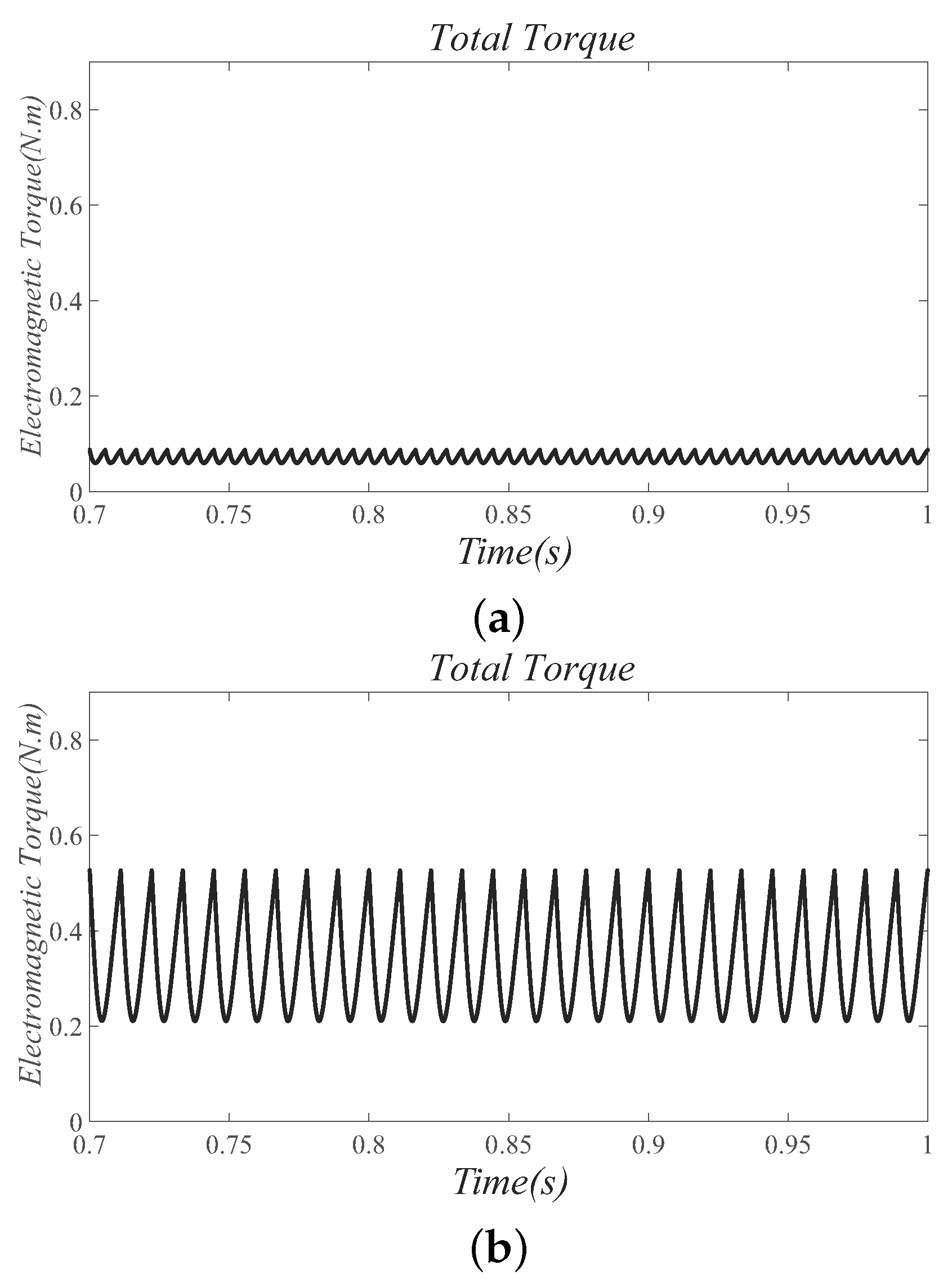

3. Modeling of the Airgap-Less Electric Motor

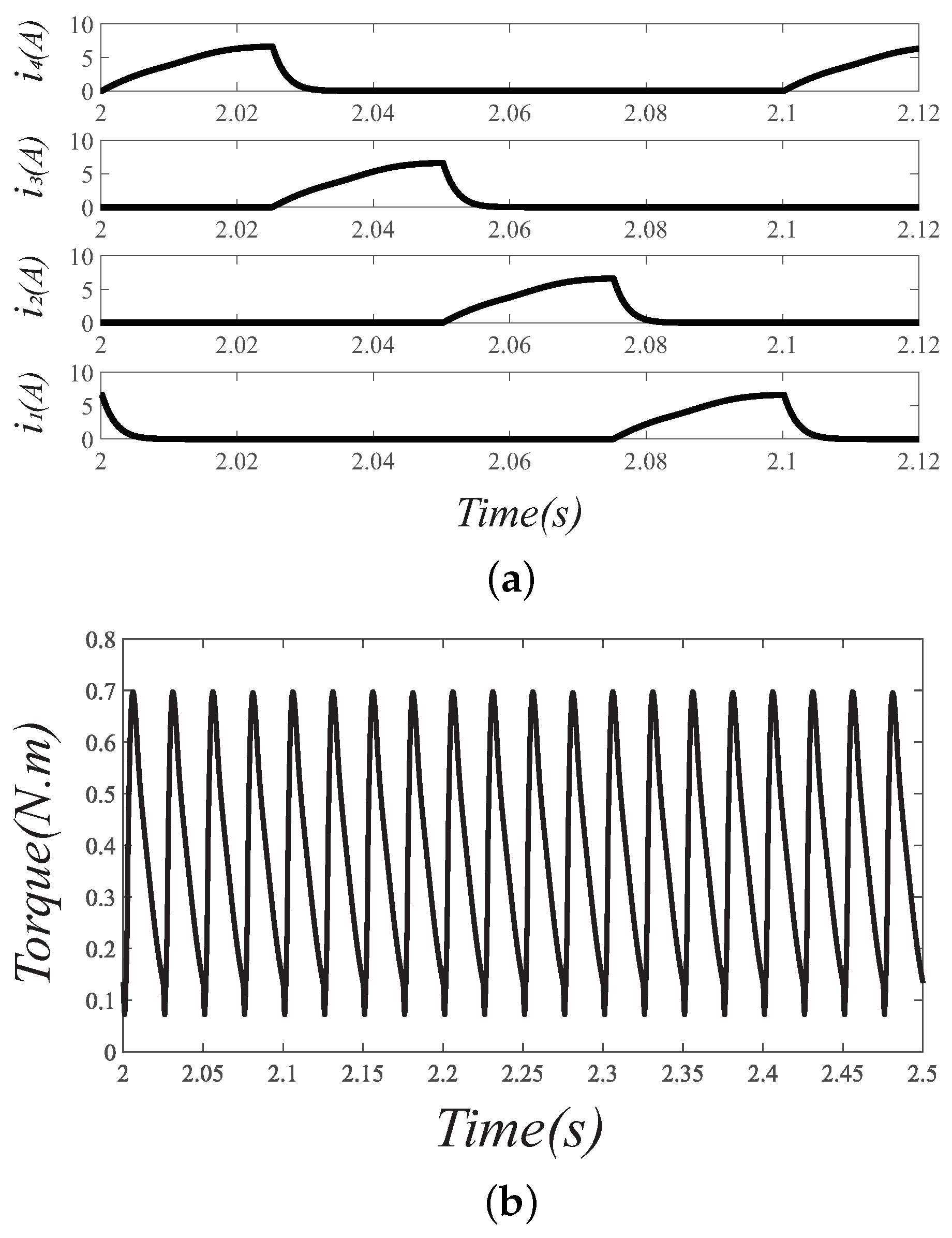

4. Comparison of Airgap-Less Electric Motors with a Switched- Reluctance Motor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manescu, V.; Paltanea, G.; Horia, G.; Scutaru, G.; Peter, I. High Efficiency Electrical Motors State of the Art and Challenges. Rev. Roum. Des Sci. Tech.-Ser. Électrotech. Énergetique 2017, 62, 14–18. [Google Scholar]

- Guo, N.; Li, Y.; Han, L.; Wang, S. The effects of climate change on different types of grassland in Maqu County in Northeast Tibetan Plateau. In Proceedings of the 2012 IEEE International Geoscience and Remote Sensing Symposium, Munich, Germany, 22–27 July 2012; pp. 1139–1142. [Google Scholar]

- Wang, X.; Guo, N.; Wang, J.; Yang, J. Impacts of the climate change on the vegetation in Maqu County in the upper reaches of Yellow River. In Proceedings of the 2007 IEEE International Geoscience and Remote Sensing Symposium, Barcelona, Spain, 23–27 July 2007; pp. 3412–3415. [Google Scholar]

- Instanes, A. Impacts of a changing climate on Infrastructure: Buildings, Support Systems, and Industrial Facilities. In Proceedings of the 2006 IEEE EIC Climate Change Conference, Ottawa, ON, Canada, 9–12 May 2006; pp. 1–4. [Google Scholar]

- De Almeida, A.; Ferreira, F.; Fong, J.; Fonseca, P. EuP Lot 11 Motors Ecodesign Assessment of Energy Using Products Final Report for the European Commission Brussels Belgium. 2008. Available online: file:///C:/Users/MDPI/Downloads/Lot11%20Motors%201-8%20final%2028-04-08.pdf (accessed on 21 June 2022).

- Albulescu, C.T.; Boatca-Barabas, M.; Miclea, S. Greenhouse gas emissions, investment and prices in the EU electricity and gas industry. In Proceedings of the 2019 International Conference on ENERGY and ENVIRONMENT (CIEM), Timisoara, Romania, 17–18 October 2019; pp. 187–190. [Google Scholar]

- Barauskas, D.; Pelenis, D.; Sergalis, G.; Vanagas, G.; Mikolajunas, M.; Virzonis, D.; Baltrusaitis, J. CMUT for high sensitivity greenhouse gas sensing. In Proceedings of the 2015 IEEE International Ultrasonics Symposium (IUS), Taipei, Taiwan, 21–24 October 2015; pp. 1–4. [Google Scholar]

- Junxia, M.; Linmin, J.; Erfeng, X.; Dunnan, L. Study on Greenhouse Gas Emission Source Identification and Emission Calculation Method for Power Grid Enterprises. In Proceedings of the 2018 8th International Conference on Power and Energy Systems (ICPES), Colombo, Sri Lanka, 21–22 December 2018; pp. 289–292. [Google Scholar]

- Carbon Dioxide Concentration|NASA Global Climate Change. 2019. Available online: https://climate.nasa.gov/vital-signs/carbon-dioxide/ (accessed on 21 June 2022).

- Balog, R.S.; Sorchini, Z.; Kimball, J.W.; Chapman, P.L.; Krein, P.T. Modern laboratory-based education for power electronics and electric machines. IEEE Trans. Power Syst. 2005, 20, 538–547. [Google Scholar] [CrossRef]

- Collins, E.R.; Huang, Y. A programmable dynamometer for testing rotating machinery using a three-phase induction machine. IEEE Trans. Energy Convers. 1994, 9, 521–527. [Google Scholar] [CrossRef]

- Shehadeh, S.H.; Alluhaidah, B.M.; Aly, H.H.; El-Hawary, M.E. Co2 Emissions Reduction of Photovoltaic Thermal Model Using Variable Flow Rate Values. In Proceedings of the 2018 IEEE Canadian Conference on Electrical Computer Engineering (CCECE), Quebec, QC, Canada, 13–16 May 2018; pp. 1–5. [Google Scholar]

- Tanaka, Y.; Hasanuzzaman, M. A review of global current techniques and evaluation methods of photocatalytic CO2 reduction. In Proceedings of the 5th IET International Conference on Clean Energy and Technology (CEAT2018), Kuala Lumpur, Malaysia, 5–6 September 2018; pp. 1–6. [Google Scholar]

- Doffe, L.; Kadiri, M. Alternator contribution to CO2 emission reduction policies. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–5. [Google Scholar]

- Junak, J. Development of vehicle drivetrain and its components—Solutions for CO2 reduction. In Proceedings of the 2015 International Conference on Sustainable Mobility Applications, Renewables and Technology (SMART), Kuwait City, Kuwait, 23–25 November 2015; pp. 1–6. [Google Scholar]

- WaIde, P.; Brunner, C.U. IEA (2011), Energy Efficiency Policy Opportunities for Electric Motor-Driven Systems, IEA, Paris. Available online: https://www.iea.org/reports/energy-efficiency-policy-opportunities-for-electric-motor-driven-systems (accessed on 21 June 2022).

- Yoon, M.K.; Jeon, C.S.; Kauh, S.K. Efficiency increase of an induction motor by improving cooling performance. IEEE Trans. Energy Convers. 2002, 17, 1–6. [Google Scholar] [CrossRef]

- Szabó, L. A Survey on the Efficiency Improve of Electrical Machines. In Proceedings of the 2019 26th International Workshop on Electric Drives: Improvement in Efficiency of Electric Drives (IWED), Moscow, Russia, 30 January–2 February 2019; pp. 1–6. [Google Scholar]

- Akhtar, S.S.; Posly, A.; Preis, R. Increasing efficiency with a high temperature Kiln ID fan upgrade. In Proceedings of the 2017 IEEE-IAS/PCA Cement Industry Technical Conference, Calgary, AB, Canada, 21–25 May 2017; pp. 1–4. [Google Scholar]

- Xu, Z.; Xu, F.; Jiang, D.; Cao, W.; Wang, F. A high temperature traction inverter with reduced cooling and improved efficiency for HEV applications. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 2786–2792. [Google Scholar]

- Binesti, D.; Ducreux, J.P. Core losses and efficiency of electrical motors using new magnetic materials. IEEE Trans. Magn. 1996, 32, 4887–4889. [Google Scholar] [CrossRef]

- Widmer, J.D.; Martin, R.; Kimiabeigi, M. Electric vehicle traction motors without rare earth magnets. Sustain. Mater. Technol. 2015, 3, 7–13. [Google Scholar] [CrossRef]

- Takano, Y.; Chiba, A.; Ogasawara, S.; Takeno, M.; Hoshi, N.; Imakawa, T.; Takemoto, M. Torque density and efficiency improvements of a Switched Reluctance Motor without rare earth material for hybrid vehicles. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 2653–2659. [Google Scholar]

- Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [CrossRef]

- Ronning, F.; Bader, S. Rare earth replacement magnets. J. Phys. Condens. Matter 2014, 26, 060301. [Google Scholar] [CrossRef]

- Sato, K.; Shin, J.S.; Koseki, T.; Aoyama, Y. Basic experiments for high-torque, low-speed permanent magnet synchronous motor and a technique for reducing cogging torque. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar]

- Rafajdus, P.; Peniak, A.; Peter, D.; Makyś, P.; Szabó, L. Optimization of switched reluctance motor design procedure for electrical vehicles. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Cheile Gradistei, Romania, 22–24 May 2014; pp. 397–404. [Google Scholar]

- Abdel-Khalik, A.S.; Massoud, A.M.; Ahmed, S. A Senior Project-Based Multiphase Motor Drive System Development. IEEE Trans. Educ. 2016, 59, 307–318. [Google Scholar] [CrossRef]

- Armstrong, B.S.R.; Yuan, Q. Multi-level control of hydraulic gerotor motors and pumps. In Proceedings of the 2006 American Control Conference, Minneapolis, MN, USA, 14–16 June 2006; p. 8. [Google Scholar]

- Ahmad, M.Z.; Sulaiman, E.; Haron, Z.A.; Kosaka, T. Design improvement of a new outer-rotor hybrid excitation flux switching motor for in-wheel drive EV. In Proceedings of the 2013 IEEE 7th International Power Engineering and Optimization Conference (PEOCO), Langkawi, Malaysia, 3–4 June 2013; pp. 298–303. [Google Scholar]

- Wang, Y.; Zhang, Z.; Liang, R.; Yuan, W.; Yan, Y. Torque Density Improvement of Doubly Salient Electromagnetic Machine with Asymmetric Current Control. IEEE Trans. Ind. Electron. 2016, 63, 7434–7443. [Google Scholar] [CrossRef]

- Lyra, R.O.C.; Lipo, T.A. Torque density improvement in a six-phase induction motor with third harmonic current injection. IEEE Trans. Ind. Appl. 2002, 38, 1351–1360. [Google Scholar] [CrossRef]

- Nikbakht, M.; Liasi, S.G.; Abbaszadeh, K.; Markadeh, G.A. An Enhanced Model Predictive Control Strategy to Drive PMSM with reduced Torque and Flux Ripples. In Proceedings of the 2020 11th Power Electronics, Drive Systems, and Technologies Conference (PEDSTC), Tehran, Iran, 4–6 February 2020; pp. 1–6. [Google Scholar]

- Aberkane, H.; Sakri, D.; Rahem, D. Improvement of Direct Torque Control Performances Using FCS-MPC and SVM Applied to PMSM: Study and Comparison. In Proceedings of the 2018 International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Algiers, Algeria, 29–31 October 2018; pp. 1–6. [Google Scholar]

- Li, Z.; Wang, J.; Zhou, L.; Liu, X.; Jiang, F. Enhanced Generalized Vector Control Strategy for Torque Ripple Mitigation of IPM-Type Brushless DC Motors. IEEE Trans. Power Electron. 2019, 34, 12038–12049. [Google Scholar] [CrossRef]

- Lee, J. Structural Design Optimization of Electric Motors to Improve Torque Performance. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2010. [Google Scholar]

- Zhao, W.; Zhao, F.; Lipo, T.A.; Kwon, B. Optimal Design of a Novel V-Type Interior Permanent Magnet Motor with Assisted Barriers for the Improvement of Torque Characteristics. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Yu, G.; Yongxiang, X.; Zou, J.; Xiao, L.; Lan, H. Development of a Radial-Flux Slotted Limited-Angle Torque Motor with Asymmetrical Teeth for Torque Performance Improvement. IEEE Trans. Magn. 2019, 55, 1–5. [Google Scholar] [CrossRef]

- Zou, J.B.; Yu, G.D.; Xu, Y.X.; Li, J.L.; Wang, Q. Design and analysis of a permanent magnet slotted limited-angle torque motor with special tooth-tip structure for torque performance improvement. In Proceedings of the 2015 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), Shanghai, China, 20–23 November 2015; pp. 246–247. [Google Scholar]

- Pinky, K.; Reeba, S.V. Torque improvement in IPMSM for Electric vehicle application. In Proceedings of the 2015 International Conference on Control Communication Computing India (ICCC), Trivandrum, India, 19–21 November 2015; pp. 224–229. [Google Scholar]

- Judge, A. Air Gap Elimination in Permanent Magnet Machines. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2012. [Google Scholar]

- Zeng, G.; Xiang-yu, Y.; Yin, H.; Pei, Y.; Zhao, S.; Cao, J.; Qiu, L. Asynchronous Machine with Ferrofluid in Gap: Modeling, Simulation, and Analysis. IEEE Trans. Magn. 2020, 56, 1–4. [Google Scholar] [CrossRef]

- Galchev, T.; Barutçu, D.; Paul, O. A gap-varying electrostatic transducer utilizing ferrofluid-based actuation for motion harvesting. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 350–353. [Google Scholar]

- Nethe, A.; Scholz, T.; Stahlmann, H.; Filtz, M. Ferrofluids in electric motors-a numerical process model. IEEE Trans. Magn. 2002, 38, 1177–1180. [Google Scholar] [CrossRef]

- He, K.; Li, J.; Qu, R. A Speed Sensorless Control of Induction Machine Based on Single DC Current Sensor. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju City, Korea, 7–10 October 2018; pp. 1691–1695. [Google Scholar]

- Morsy, A.S.; Abdel-khalik, A.S.; Ahmed, S.; Massoud, A. Sensorless field oriented control of five-phase induction machine under open-circuit phase faults. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 5112–5117. [Google Scholar]

- Dermentzoglou, J.C. Investigating the incorporation of a doubly fed induction machine as a shaft generator into a ship’s system: Application of a vector control scheme for controlling the doubly fed induction machine. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; pp. 2319–2324. [Google Scholar]

- Barendse, P.S.; Pillay, P. The Detection of Unbalanced Faults in Inverter-Fed Induction Machines. In Proceedings of the 2007 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cracow, Poland, 6–8 September 2007; pp. 46–51. [Google Scholar]

- Abdelhamid, D.Z.; Knight, A.M. Performance of a high torque density induction motor with an integrated magnetic gear. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 538–544. [Google Scholar]

- Mezani, S.; Hamiti, T.; Belguerras, L.; Lubin, T.; Rashed, M.; Gerada, C. Magnetically Geared Induction Machines. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Liu, C.; Hung, K.; Hwang, C. Developments of an Efficient Analytical Scheme for Optimal Composition Designs of Tubular Linear Magnetic-Geared Machines. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Kang, D.H.; Kim, D.; Song, J.; Kim, Y.; Jung, S. Analysis of Transfer Torque Characteristics of Magnetic Geared Machine Using Frozen Permeability Method. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju City, Korea, 7–10 October 2018; pp. 285–288. [Google Scholar]

- Zhang, X.; Liu, X.; Chen, Z. Investigation of Unbalanced Magnetic Force in Magnetic Geared Machine Using Analytical Methods. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Li, W.; Gao, S.; Wu, D.; Zhang, X. Design of a linear magnetic-geared free-piston generator for series hybrid electric vehicles. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar]

- Abdelhamid, D.Z.; Knight, A.M. High torque density induction motor with integrated magnetic gear. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–7. [Google Scholar]

- Bidouche, B.; Lubin, T.; Mezani, S. Design and Analysis of a Magnetically Geared Induction Machine. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 629–634. [Google Scholar]

- Peng, S.; Fu, W.N.; Ho, S.L. A Novel High Torque-Density Triple-Permanent-Magnet-Excited Magnetic Gear. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Al-Timimy, A.; Giangrande, P.; Degano, M.; Galea, M.; Gerada, C. Comparative study of permanent magnet-synchronous and permanent magnet-flux switching machines for high torque to inertia applications. In Proceedings of the 2017 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Nottingham, UK, 20–21 April 2017; pp. 45–51. [Google Scholar]

- Kucuk, F.; Nakamura, T. Torque Density and Efficiency Improvement of a Switched Reluctance Motor via low-cost Permanent Magnets. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 2318–2322. [Google Scholar]

- Xu, G.; Liu, G.; Chen, M.; Du, X.; Xu, M. Cost-Effective Vernier Permanent-Magnet Machine with High Torque Performance. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Nakano, S.; Kiyota, K.; Chiba, A. Design consideration of high torque-density switched reluctance motor for hybrid electrical vehicle. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016. [Google Scholar]

- Shi, J.; Chai, F.; Li, X.; Cheng, S. Study of the number of slots/pole combinations for low speed high torque permanent magnet synchronous motors. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011; pp. 1–3. [Google Scholar]

- Umans, S.; Fitzgerald, A.; Kingsley, C. Fitzgerald & Kingsley’s Electric Machinery, 7th ed.; McGraw-Hill Higher Education: New York, NY, USA, 2013; Available online: https://www.mheducation.com/highered/product/fitzgerald-kingsley-s-electric-machinery-umans/M9780073380469.html (accessed on 21 June 2022).

- Singh, B.; Singh, S. State-of-Art on Permanent Magnet Brushless DC Motor Drives. J. Power Electron. 2009, 9, 1–17. [Google Scholar]

- Krause, P.C.; Wasynczuk, O.; Sudhoff, S.D. Analysis of Electric Machinery and Drive Systems; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Zhang, Y.; Shen, J.X.; Li, P. Optimal design of an interior permanent magnet synchronous motor for electrical vehicle applications. In Proceedings of the 2013 International Conference on Electrical Machines and Systems (ICEMS), Busan, Korea, 26–29 October 2013; pp. 982–985. [Google Scholar]

- Liu, Y.; Fu, W.N.; Guo, X.; Li, Z.; Fang, R. A dual permanent magnet machine for high-torque low-speed applications. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, Australia, 11–14 August 2017; pp. 1–4. [Google Scholar]

- Liang, J.; Parsapour, A.; Cosoroaba, E.; Wu, M.; Boldea, I.; Fahimi, B. A High Torque Density Outer Rotor Claw Pole Stator Permanent Magnet Synchronous Motor. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 389–393. [Google Scholar]

- Chen, Z.; Ma, H.; Li, Z. Rotor parameter analysis for surface-mounted and interior hybrid permanent magnet synchronous machine. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–5. [Google Scholar]

- Ocak, O.; Onsal, M.; Aydin, M. Development of a 7.5 kW High Speed Interior Permanent Magnet Synchronous Spindle Motor for CNC Milling Machine. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 704–709. [Google Scholar]

- Chen, Y.; Kong, L.; Zhong, W. Finite element analysis of interior composite-rotor controllable flux permanent magnet synchronous machine. In Proceedings of the 2009 International Conference on Electrical Machines and Systems, Tokyo, Japan, 15–18 November 2009; pp. 1–4. [Google Scholar]

- Duan, S.; Zhou, L.; Wang, J. Flux Weakening Mechanism of Interior Permanent Magnet Synchronous Machines with Segmented Permanent Magnets. IEEE Trans. Appl. Supercond. 2014, 24, 1–5. [Google Scholar] [CrossRef]

- Sun, T.; Wang, J.; Koc, M. On Accuracy of Virtual Signal Injection based MTPA Operation of Interior Permanent Magnet Synchronous Machine Drives. IEEE Trans. Power Electron. 2017, 32, 7405–7408. [Google Scholar] [CrossRef]

- Lavrinovicha, L.; Dirba, J. Comparison of permanent magnet synchronous motor and synchronous reluctance motor based on their torque per unit volume. In Proceedings of the 2014 Electric Power Quality and Supply Reliability Conference (PQ), Rakvere, Estonia, 11–13 June 2014; pp. 233–236. [Google Scholar]

- Cheng, M.; Hua, W.; Zhang, J.; Zhao, W. Overview of Stator-Permanent Magnet Brushless Machines. IEEE Trans. Ind. Electron. 2011, 58, 5087–5101. [Google Scholar] [CrossRef]

- Hua, W.; Cheng, M.; Zhu, Z.Q.; Howe, D. Analysis and Optimization of Back EMF Waveform of a Flux-Switching Permanent Magnet Motor. IEEE Trans. Energy Convers. 2008, 23, 727–733. [Google Scholar] [CrossRef]

- Bonthu, S.S.R.; Choi, S.; Gorgani, A.; Jang, K. Design of permanent magnet assisted synchronous reluctance motor with external rotor architecture. In Proceedings of the 2015 IEEE International Electric Machines Drives Conference (IEMDC), Coeur d’Alene, ID, USA, 10–13 May 2015; pp. 220–226. [Google Scholar]

- Hua, W.; Zhang, G.; Cheng, M. Investigation and Design of a High-Power Flux-Switching Permanent Magnet Machine for Hybrid Electric Vehicles. IEEE Trans. Magn. 2015, 51, 1–5. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, C. A Efficient Nine-Phase PM Flux-Switching Machine with High Torque Density and Low Torque Ripple. In Proceedings of the 2018 Asia-Pacific Magnetic Recording Conference (APMRC), Shanghai, China, 15–17 November 2018; pp. 1–2. [Google Scholar]

- Xiang, Z.; Quan, L.; Zhu, X. A New Partitioned-Rotor Flux-Switching Permanent Magnet Motor with High Torque Density and Improved Magnet Utilization. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Awah, C.C.; Zhu, Z.Q.; Wu, Z.; Wu, D. High torque density magnetically-geared switched flux permanent magnet machines. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monaco City, Monaco, 31 March–1 April 2015; pp. 1–6. [Google Scholar]

- Kim, B.; Lipo, T.A. Operation and Design Principles of a PM Vernier Motor. IEEE Trans. Ind. Appl. 2014, 50, 3656–3663. [Google Scholar] [CrossRef]

- Li, D.; Qu, R.; Li, J.; Xiao, L.; Wu, L.; Xu, W. Analysis of Torque Capability and Quality in Vernier Permanent-Magnet Machines. IEEE Trans. Ind. Appl. 2016, 52, 125–135. [Google Scholar] [CrossRef]

- Kim, B.; Lipo, T.A. Analysis of a PM Vernier Motor with Spoke Structure. IEEE Trans. Ind. Appl. 2016, 52, 217–225. [Google Scholar] [CrossRef]

- Li, D.; Qu, R.; Lipo, T.A. High-Power-Factor Vernier Permanent-Magnet Machines. IEEE Trans. Ind. Appl. 2014, 50, 3664–3674. [Google Scholar] [CrossRef]

- Zou, T.; Li, D.; Qu, R.; Jiang, D.; Li, J. Advanced High Torque Density PM Vernier Machine with Multiple Working Harmonics. IEEE Trans. Ind. Appl. 2017, 53, 5295–5304. [Google Scholar] [CrossRef]

- Zhong, H.; Liu, G.; Xu, L. Comparative Study of Linear Primary Permanent-Magnet Vernier Machine and Conventional Linear Permanent-Magnet Machine. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Rao, J.; Qu, R.; Li, D.; Gao, Y. A novel surface permanent magnet vernier machine with Halbach array permanent magnet in stator slot opening. In Proceedings of the 2016 IEEE Conference on Electromagnetic Field Computation (CEFC), Miami, FL, USA, 13–16 November 2016; p. 1. [Google Scholar]

- Raza, M.; Zhao, W.; Lipo, T.A.; Kwon, B. Performance comparison of dual airgap and single airgap spoke-type Vernier permanent magnet machines. In Proceedings of the 2016 IEEE Conference on Electromagnetic Field Computation (CEFC), Miami, FL, USA, 13–16 November 2016; p. 1. [Google Scholar]

- Shi, C.; Li, D.; Qu, R.; Zhang, H.; Gao, Y.; Huo, Y. A Novel Linear Permanent Magnet Vernier Machine with Consequent-Pole Permanent Magnets and Halbach Permanent Magnet Arrays. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Niu, S.; Ho, S.L.; Fu, W.N.; Wang, L.L. Quantitative Comparison of Novel Vernier Permanent Magnet Machines. IEEE Trans. Magn. 2010, 46, 2032–2035. [Google Scholar] [CrossRef]

- Li, J.; Chau, K.T. Performance and Cost Comparison of Permanent-Magnet Vernier Machines. IEEE Trans. Appl. Supercond. 2012, 22, 5202304. [Google Scholar]

- Franke, M.; Brutscheck, M.; Schmucker, U. Modeling and simulation of a rolling rotor switched reluctance motor. In Proceedings of the 2009 32nd International Spring Seminar on Electronics Technology, Brno, Czech Republic, 13–17 May 2009; pp. 1–6. [Google Scholar]

- Arkkio, A.; Biernat, A.; Bucki, B.; Kaminski, G.; Niemenmaa, A.; Smak, A.; Staszewski, P. Finite-Element Analysis for a Rolling-Rotor Electrical Machine. IEEE Trans. Magn. 2010, 46, 2727–2730. [Google Scholar] [CrossRef]

- Alibeik, M.; Nezamuddin, O.N.M.; Bagwe, R.M.; Rubin, M.J.; Cipriano dos Santos, E. Airgapless Electric Motors with an External Rotor. IEEE Trans. Ind. Electron. 2018, 65, 6923–6935. [Google Scholar] [CrossRef]

- Nezamuddin, O.; Alibeik, M.; Bagwe, R.; Rubin, M.; dos Santos, E. Internal rotor airgap-less electric motors. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 5009–5016. [Google Scholar]

- Akune, R.; Akatsu, K.; Fujihara, M.; Yamamoto, T. Study of high torque density interior permanent magnet synchronous motor with flexible orientation Nd2Fe14B sintered magnet. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 578–584. [Google Scholar]

- Alibeik, M.; Nezamuddin, O.; Rubin, M.; Wheeler, N.; Silvestri, S.; dos Santos, E. Airgap-less electric motor: A solution for high-torque low-speed applications. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; pp. 1–8. [Google Scholar]

| Machine | Power (W) | Speed (r/min) | Voltage (V) |

|---|---|---|---|

| IPSM | 3728.5 | 1000 | 325 |

| High Power Factor VPM | 2400 | 30 | 27 |

| Dual Stator Consequent Pole | 398 | 300 | 47 |

| Airgap-less Electric Motor | 100 | 0.6 | 20 |

| In-Wheel for Electric Vehicle | 75,000 | 4000 | 900 |

| IM with Integrated MG | 44,000 | 975 | 400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alibeik, M.; dos Santos, E.C. High-Torque Electric Machines: State of the Art and Comparison. Machines 2022, 10, 636. https://doi.org/10.3390/machines10080636

Alibeik M, dos Santos EC. High-Torque Electric Machines: State of the Art and Comparison. Machines. 2022; 10(8):636. https://doi.org/10.3390/machines10080636

Chicago/Turabian StyleAlibeik, Maryam, and Euzeli C. dos Santos. 2022. "High-Torque Electric Machines: State of the Art and Comparison" Machines 10, no. 8: 636. https://doi.org/10.3390/machines10080636

APA StyleAlibeik, M., & dos Santos, E. C. (2022). High-Torque Electric Machines: State of the Art and Comparison. Machines, 10(8), 636. https://doi.org/10.3390/machines10080636