2. Theory of Hybrid Element Solving Elastic Equation

Firstly, we consider a 2D linear elastic equation as shown in Equation (

1).

In Equation (

1), the displacement function can be written as

, the displacement boundary function is

, and the right end term function of the equation is also called the external load vector

. According to the relationship between the displacement component and stress, the two-dimensional linear elastic equation can also be written as follows:

The elements in the stress tensor can ultimately be represented by displacement:

where

and mu are Lamé coefficients, and the matrix form of the two-dimensional stress tensor

is written as:

The stress tensor of classical continuum theory is symmetric. We call it the Cauchy stress tensor

, and then we can use the displacement component to represent the stress tensor.

For the two-dimensional elastic equation, the finite element method is used for discretization.

is a trial function, and

is a test function vector. Let

act on the original equation; the weak form corresponding to the original elastic Equation (

2) is then as follows:

The integral is carried out on both sides of the first equation of Equation (

1). For the two-dimensional elastic equation, the Gauss divergence theorem is applied [

24,

25]. The divergence term of the stress tensor can be obtained, and then the first term on the left side is transformed into the linear integral by using the divergence theorem. Finally, we can obtain Equation (

7):

Here,

is the unit normal vector of the boundary

, and then the differential Equation (

7) is converted to an integral expression, Equation (

8):

As for the displacement boundary of the two-dimensional linear elastic thin-plate problem , the test function we choose is .

Then,

is on the boundary

, and

. Meanwhile,

can be written as:

If the equation does not consider the surface force term, only for the first kind of boundary conditions there are

. Then, it is easy to obtain Equation (

10)

According to the form of the displacement component and combined with the variational principle, the left term of Equation (

10) is transformed into Equation (

11).

After further expanding Equation (

11), we can obtain

Similarly, the right term of the equation can be expressed as Equation (

13):

Finally, we combine Equations (

12) and (

13) to obtain Equation (

14):

We denote the bilinear function as

. Similarly, the right term of Equation (

14) can also be written as

We find a trail function

such that

, for any

, if there is a finite dimensional subspace

. As for the Galerkin formulation, the aim is to find a finite element solution

such that

for any

.

Then, the displacement function

and the test function

need to be linearly approximated by the finite element basis function. In this paper, a new hybrid FEM discretization algorithm is proposed. The solution domain is divided into multiple subregions, and each subregion has different basis functions [

26,

27]. The main characteristics of the nested mesh FEM algorithm are that the solution domain can be discretized by a variety of different types of meshes, and the subregions meshes relation satisfies

is a discrete mesh region formed by the continuous solution region

, and

represents each local subgrid region of different types.

represents the number of elements in the subgrid of type

i,

, and

are the number of nodes in the subgrid of type

i; the node sitting mark of the subgrid of type

i is

. The total number of elements in the mesh is

, and the total number of nodes is

. The relationship between global mesh number

S and local subgrid node number

is

. There are

units in the type i grid, with

nodes on each unit. A total of

node coordinates in the type

i mesh can be recorded as:

The finite element subspace . Among them, is the basis function, and .

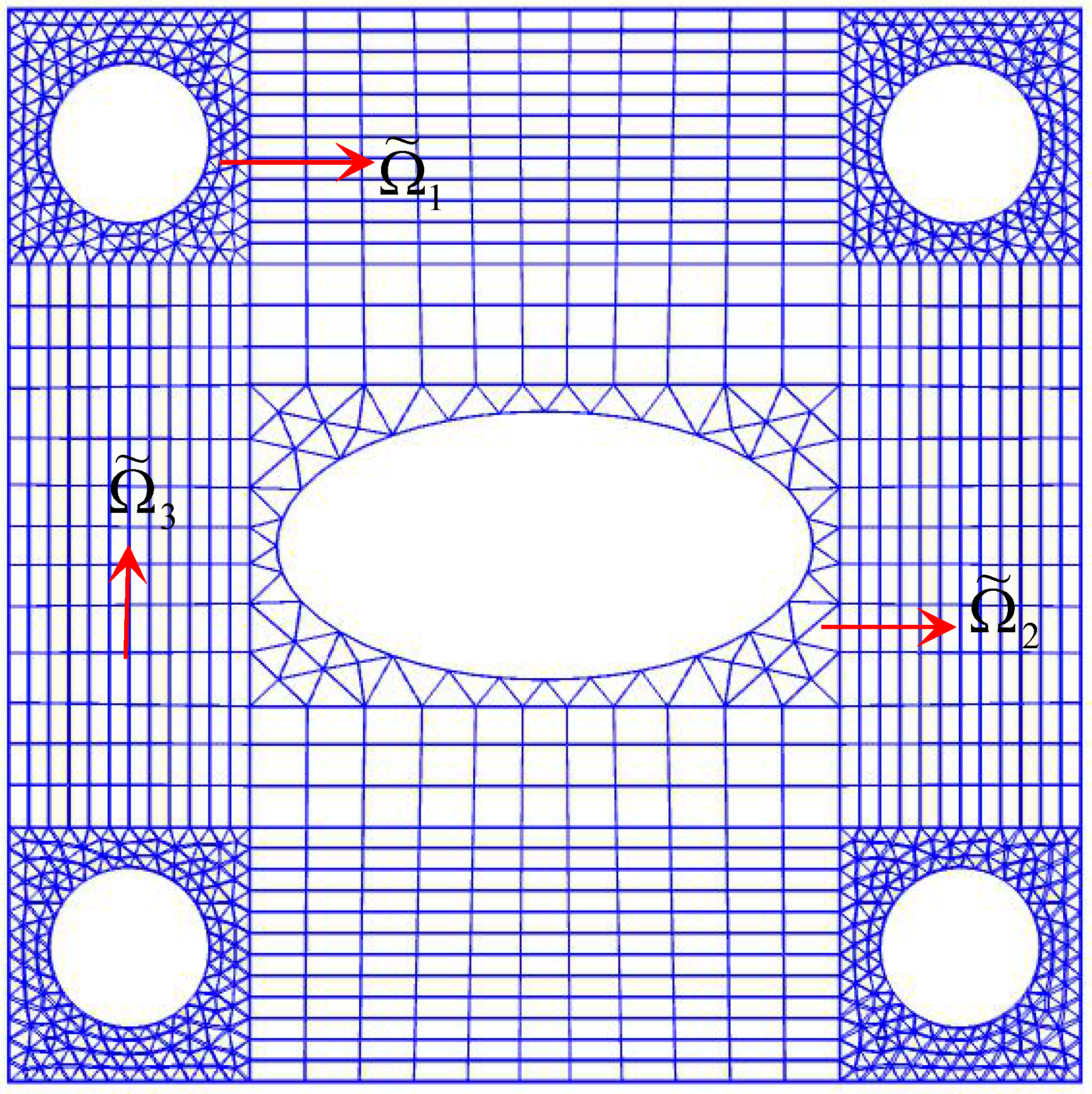

A square thin plate with a hole is shown in

Figure 1 below. Four circles with radius R and around the ellipse are wrapped by small rectangles. Four square areas wrapped by small circles are denoted by

, one small rectangle wrapped by an ellipse is denoted by

, and the other areas are denoted by

. The CST element is used for discretization on

, the LST element is used for discretization on

, and the Q4 element is used for discretization on

. Three different types of mesh are common nodes on the junction line of the boundary to ensure that the calculated data can be transmitted to each other.

There are three different types of meshes in the square plate

with holes, and the region division is completed by nesting and combining them with each other. Different subregions are discretized by different element types. In a specific subregion

, the displacement component function of any element node (the common node on the boundary line of the non-subregion mesh) can be linearly expressed by the same set of basis functions [

28,

29]. Because the subregion is of the same element type, its discretization method is similar to the ordinary finite element discretization method. The finite numerical solution corresponding to any coordinate point can be approximated as:

The idea of a weighted basis function is used to approximate the function value of common nodes on the intersection line of subregional grids. If the common nodes on the intersection line of subregional grids contain

element types, the corresponding displacement component function approximation value of common nodes on the intersection line can be expressed as Equations (

19) and (

20):

where

is the total number of different sub-mesh types, and the minimum value

= 2, indicating that the discrete region of the mixed element is composed of at least two different types of elements.

,

and

represent the number of the CST, LST and Q4 elements, respectively.

represents the basis function corresponding to the

jth element node in the

-th mesh region.

is a judgment function of the element node, which is used to determine whether the current node coordinate

belongs to the common node in the discrete region, and different subgrid regions are denoted by

. Then, each element and vertex of the element in the discrete region is numbered.

is the element in the subgrid region

when the node coordinate

has the corresponding basis function

. When the node coordinate

has the displacement component function value

, the judgment function of the mixed-element sharing nodes is:

In order to facilitate the calculation, all the node coordinates, element number and vertex number in the mesh area are classified and stored. The same type of mesh element is stored in the same set. It should be noted that the common node is the same vertex number in different element types, in order to prevent the error of data information transmission at the common intersection of the mesh in different subregions. The difference between the hybrid element and the traditional finite element is that the basis function of the hybrid element is the basis function combination of multiple different types of elements, while the traditional finite element is the linear combination of the same type of basis function [

30,

31]. Therefore, the hybrid finite element method is an extension of the traditional finite element method and has stronger flexibility.

Three different subgrid regions correspond to three different cell-based functions. If CST cell-based functions are used in the sub-mesh region, any point of function value on the surface in the subgrid region can be linearly represented by CST cell-based functions. Using isoparametric element transformation, the cell-based functions can be written in vector form, as shown in Equation (

22):

The mesh subregion

is discretized by a six-node LST element, where

. The corresponding basis function is Equation (

23):

The Q4 element with four nodes is used for discretization on the mesh subregion

, and the corresponding basis function is shown in Equation (

24):

Equation (

25) is divided into two equations according to the displacement component. If

is denoted, there is

Similarly, when

, Equation (

26) holds:

The continuous calculation region

is divided into discrete grid regions, denoted by

, with a total of

unit vertices and

units. The trial function

is expressed by linear basis function.

The test function is

.

Then, the linear combination of the basis function is substituted into Equation (

25) to obtain:

Similarly, let

. Bring the basis function to Equation (

26), and we can obtain Equation (

30):

Finally, all the elements in the mesh subregion are assembled to obtain the algebraic equation expression of the first displacement component:

By using the same method, the algebraic equation expression of the second displacement component can be obtained:

The above is mainly for the discrete region

, and all subregions have only one type of basis function. For example, the specific subregion

uses the CST unit or the LST element. However, there is another case, namely, the type of shared nodes on the intersection of subregions with different unit types [

32,

33,

34]. The derivation of discrete process and weak situation is very similar to Equations (

33) and (

34). The difference is that only the linear combination of mixed basis functions is used to represent the value of the function to be approximated. We bring the mixed basis functions, as expressed in Equation (

27), into the displacement component Equations (

31) and (

32), respectively. After sorting these out, we can obtain the following two algebraic discrete equations:

The algebraic discrete equation of the second displacement component is:

The numerical solution of the mixed finite element can be obtained by solving the above algebraic equations. Of course, the error and convergence of the approximation of the node function value in the subregion are related to the selected element type, the mesh quality and the order of the basis function, and the convergence will not change within the subregion. The difference is generally on the boundary line of different mesh types. Due to the combination of the mixed basis function, the convergence of the numerical solution at the common node is related to the proportion of the basis function in the approximation term, and the higher the proportion of a specific basis function is. The overall convergence is close to the theoretical convergence order of the basis function type, or it can be considered that the convergence order of the mixed finite element is a linear weighting of the convergence order of multiple basis functions, and the final order depends on the proportion of the basis function in the approximation term [

35]. The above is mainly the discrete theory of the mixed finite element. Next, a specific numerical example is given to verify the feasibility of the method.

3. Numerical Example of 2D Thin-Plate Deformation Solved by Hybrid FEM

This numerical example mainly considers a two-dimensional porous elastic plate, and uses the hybrid finite element numerical method to solve the two-dimensional elastic equation. The purpose of this numerical example is to study the advantages of the hybrid finite element in the discretization and numerical solution of special regions. The traditional discrete method of porous thin plate in the regional grid division is to select the triangular element, and the discrete information of the element can be obtained quickly. However, it is not a simple matter to obtain a discrete grid with very high quality. First, the grid division has variability, and it is difficult for a single discrete element to meet the specific requirements. In view of the above problems to be solved, in this paper, a hybrid finite element method is proposed which can effectively improve the grid quality of the calculation area and obtain the numerical solution of the hybrid element [

36,

37]. The theoretical model given in this paper is equivalent to optimizing the grid structure, and it also expands the application range of the traditional finite element.

In this example, the mixed finite element method is mainly used to solve the deformation problem of the porous elastic plate, and the relevant parameters of the porous elastic plate need to be given. The common structural steel materials are selected in this example, with the Young’s modulus

GPa, Poisson ratio

v = 0.3, and density

. The geometric appearance is mainly a rectangular plate, with four small circular holes and a central elliptical hole inside. The length of the rectangular plate is

, and the width is

. The center coordinates of the four small circles are

and

in turn. The radius of the four small circles is

. The center elliptical hole long axis

, and the short axis

. The two-dimensional linear elastic mechanics equation solved by this example is:

The left boundary of the rectangular thin plate is fixed; that is, the displacement boundary condition is:

The right boundary

is subjected to vertical downward external force:

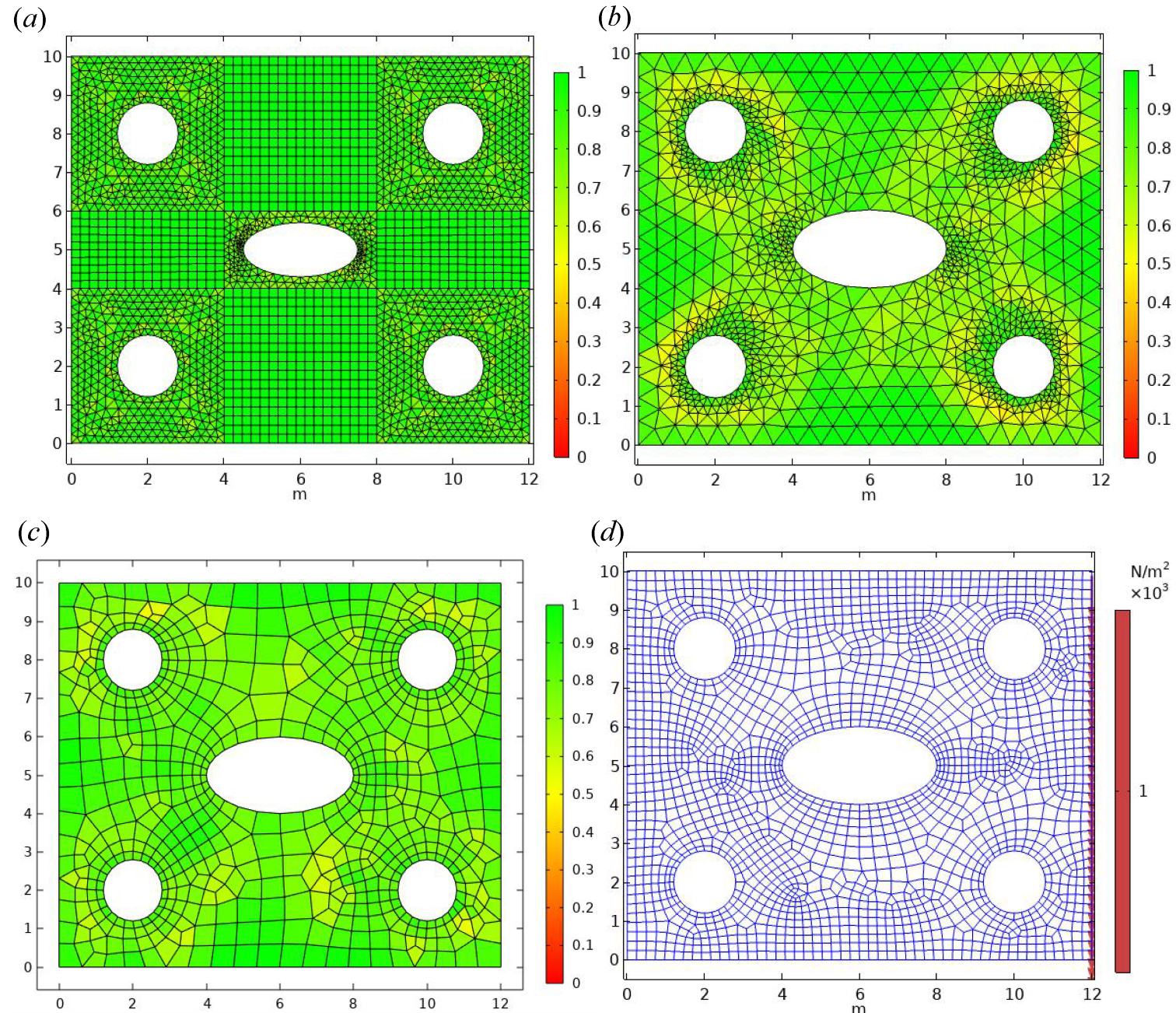

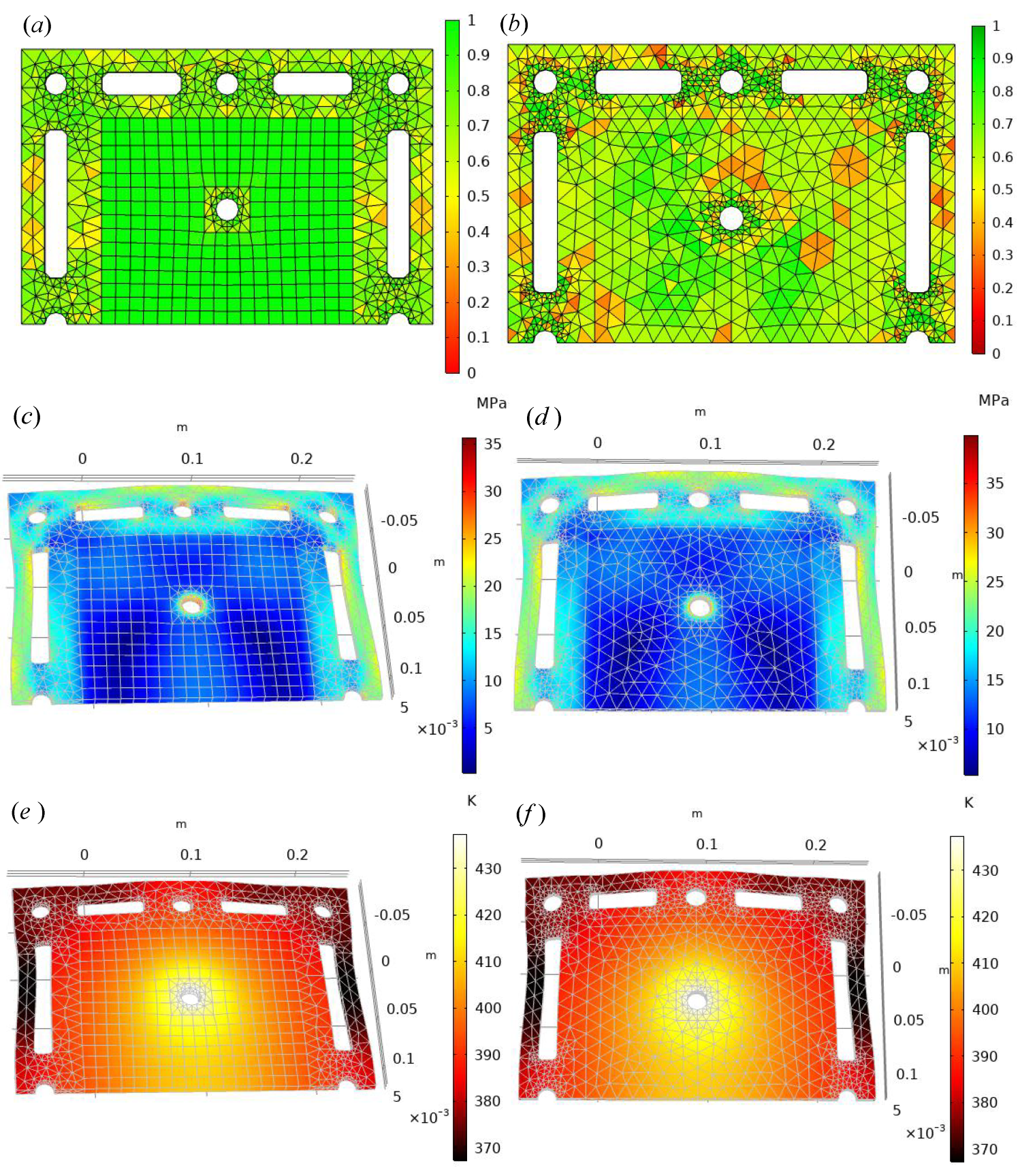

Firstly, the regional grid is divided. In this paper, two different grid division methods are used. One is the hybrid element grid division method, that is, the combination of triangular grid elements and quadrilateral grid elements. The other is the single-grid-type division method, and the discrete element obtained using the single-grid division method has only one type. The grid quality is different in different drawing methods. In this section, the grid quality evaluation formula is given. The results of the two grid divisions are shown in

Figure 2.

Mesh quality evaluation can be evaluated from different perspectives, such as area ratio, skewness, maximum angle, condition number, growth rate, circumcircle radius, etc. This example is evaluated according to area ratio, as shown in Equation (

38). When the unit is selected as Q4,

represents the edge length of any quadrilateral unit,

and

are the area of the quadrilateral unit, and the best reference object for mesh quality evaluation is the square.

When the unit is CST,

,

is the area of the triangle unit to be evaluated. When the optimal reference object is an equilateral triangle,

is constant. When the optimal reference object is an isosceles right triangle,

is constant. The grid quality evaluation formula of the triangle unit is Equation (

39):

According to the above method, we can evaluate the two mesh generation methods. The first is the hybrid element grid generation method, which divides the whole solution area into two elements, Q4 and CST. As shown in

Figure 2a, the CST element is used near the circular hole, and the Q4 element is used in the other areas. Then, the grid quality is calculated according to the area ratio grid quality evaluation formula for each unit of the region. The closer the mesh quality evaluation result is to 1, the better the grid division effect is, and green is used to show the units in the discrete area. When the mesh quality is closer to 0, which is shown in red color,

Figure 2b–d are generated by the second mesh type, and there is only one element type in the solution domain.

Figure 2b only uses the CST element for the mesh division, and the division form is combined with the adaptive method.

Figure 2c,d only use the Q4 element for the mesh division, and the mesh also has adaptive characteristics when it is close to the circular hole and central ellipse. Then, the mesh quality of each element is calculated. From the effect of mesh quality evaluation, the mesh quality of the mixed-element type is better than that of the single-element type. This also reflects the advantages of hybrid-element combination. Then, the mesh division is equal to the basic information of the calculation.

Figure 2a contains 3092 CST elements, with an average quality of

. It also contains 918 Q4 elements, with an average quality of

, if all the porous elastic plates are discretized by CST elements.

The average mesh quality is

, and all the meshes are discretized using Q4 elements, with an average quality of

. The hybrid finite element of this example only contains two types of basis functions, namely, CST and Q4. The four circular holes and central ellipses belong to the subregion

. In this example, the same CST element is used for discretization. The remaining part belongs to the subregion

, and the Q4 element is used for discretization. Therefore, the relationship between the total discrete region

and the two subregions can be written as

. The purpose of

Figure 2 is to compare the grid quality of different element types. It can also be seen from the calculation results that the mesh quality of the hybrid element is better. This comparison is mainly to calculate the average grid quality. For each discrete element in each region, its grid quality

is calculated, and then averaged to obtain the average grid quality

of the whole region. For

Figure 2, there are three cases, namely, the hybrid-element grid, and the adaptive mesh formed by the CST and Q4 elements. In fact, the final comparison is the average mesh quality, which only requires the average mesh size of the element to meet

. We believe that these discrete regions are at the same level, and we then compared the average mesh quality

so that the comparison results would meet the principle of control variables and in order to ensure the scientific nature of the research method. We performed a comparison of the grid quality at three scales and obtained the same numerical results. This also reflects the rigor of this study.

For the hybrid-element pairs to solve the two-dimensional linear elastic equation, there are mainly two cases. One is that the function value approximation of the nodes in the subregion is similar to that of the traditional finite-element method, because there is only one type of element in the region. At this time, the displacement basis functions of the element in the subregion are shown in Equations (

40) and (

41):

The second case is that of two different subregional mesh share nodes on the interface connection line. The function value approximation of these points is special, and the common node belongs to the node of the CST element and the Q4 element. Therefore, there are different types of base functions in the approximation terms of these function values. According to this example, there are two kinds of base functions in the approximation terms of the function value of the common node, which can be expressed as:

In Equations (

42) and (

43),

is a hybrid-element node judgment function, selecting node coordinates with hybrid basis functions. Then, according to the mixed-element discrete theory introduced above, the approximation term of the displacement component is introduced into the elastic mechanics equilibrium equation represented by displacement, and the differential equation is transformed into an algebraic equation with an integral term.

Finally, by solving the linear equations, the numerical solution of the displacement component

, stress

and strain

can be obtained. Another feature of this example is the visualization of deformation. Among them,

is the initial node coordinate position,

is the grid node coordinate after the deformation, and

is the deformation factor. The specific calculation formula of displacement numerical solution deformation is shown in the following expression, Equation (

44):

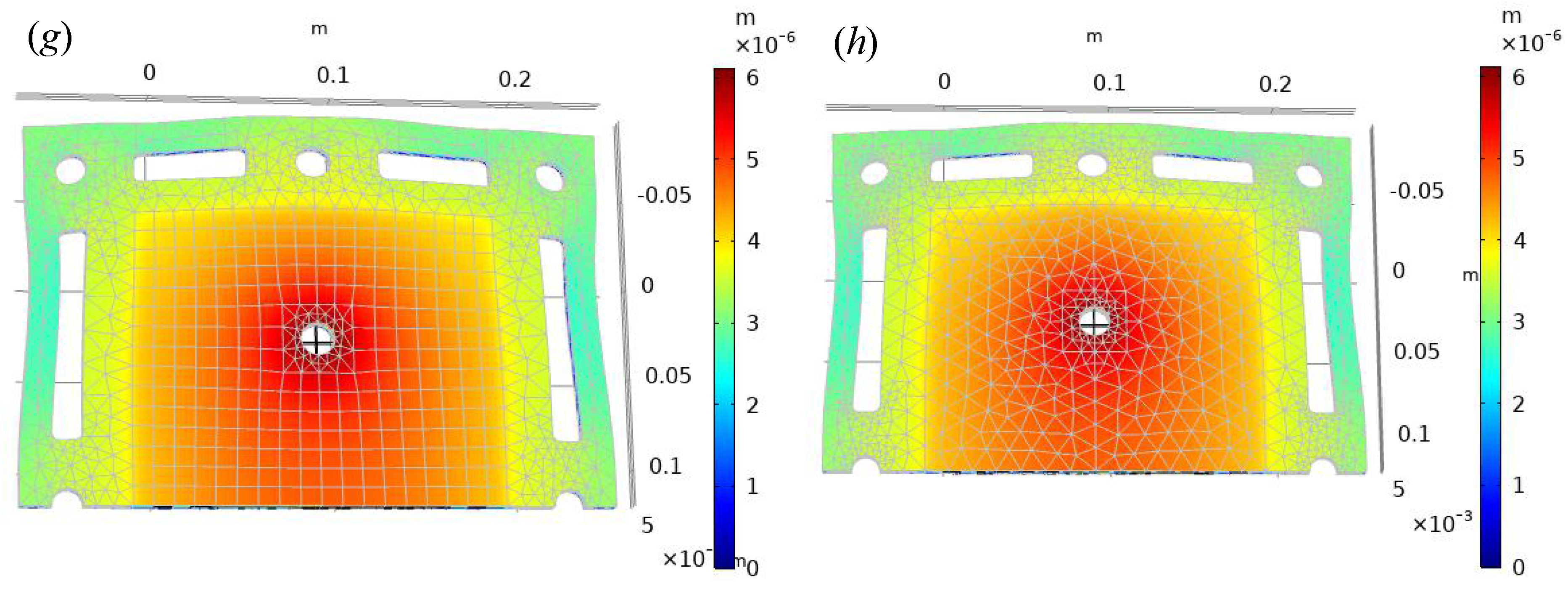

Figure 3 provides the specific numerical solution of mixed elements.

Figure 3a is the numerical solution of displacement solved under the mixed-element theory. The white background grid is the original position, and the displacement nephogram of the porous plate with color is the deformation nephogram after deformation. The numerical solution can obviously see that the left fixed is basically unchanged. Because the left end is subjected to the vertical downward force, the downward displacement component

U is generated, and the deformation factor

.

Figure 3b is the numerical solution nephogram of Von Mises stress. The characteristics of this figure are also the results obtained by solving the mixed-element numerical theory. The stress change near the hole is obvious. Another feature of this figure is that the stress diagram is combined with the displacement strain diagram, which can see not only the change in stress but also the change in displacement.

Figure 3c is the result of a single triangular mesh. The mesh has adaptive characteristics and obvious encryption characteristics near the hole. This figure represents the numerical solution cloud of Von Mises stress, which can be compared with

Figure 3b. The stress distribution of the two is basically the same. However, the hybrid element has more advantages in the numerical accuracy of specific regions and the overall solution time.

Figure 3d is mainly the grid generated by the quadrilateral element, and the discrete region only contains one CST element. The figure shows the numerical solution cloud of the displacement component

V in the y direction. The deformation amplification factor

. It can also be seen from the deformation results that when the deformation factor

increases, the deformation results are increased.

The numerical results show that the hybrid finite-element method is an extension of the traditional finite-element method; the mesh is also more flexible and can be composed of a variety of mesh types. Different regions choose different element types according to need. In addition, the mesh quality is evaluated according to the formula of mesh element area ratio defined in this chapter. The results show that the quality of the hybrid-element mesh is better than that of the triangular mesh and the structured quadrilateral mesh. From the numerical calculation process, the hybrid finite element has a feature through which the substrate is free to choose, and even the high-order element can be used in the key analysis area. The linear element can be used for the calculation area with relatively flat change, and the mixed approximation idea can be used at the interface nodes, which can greatly balance the calculation efficiency and accuracy.

Therefore, the mixed-element theory has greater advantages for the complex geometric calculation area, realizing the free combination of the mesh type and the basis function type, and greatly expanding the application range of the finite element. However, the analysis of the error and the convergence order is more complex than that of the traditional finite element, because the basis function fixed by the traditional finite element has a stable convergence order and error estimation mode, and the mixed finite element needs a specific analysis of specific problems. Without a fixed error range and convergence order, what can be obtained in the form of the basis function combination is a theoretical reference range. Therefore, the contribution of this paper is to provide specific numerical results and a theoretical analysis in numerical modeling, equation discretization and comparison with the traditional finite element. It can also further extend the mixed-element theory to the three-dimensional case.

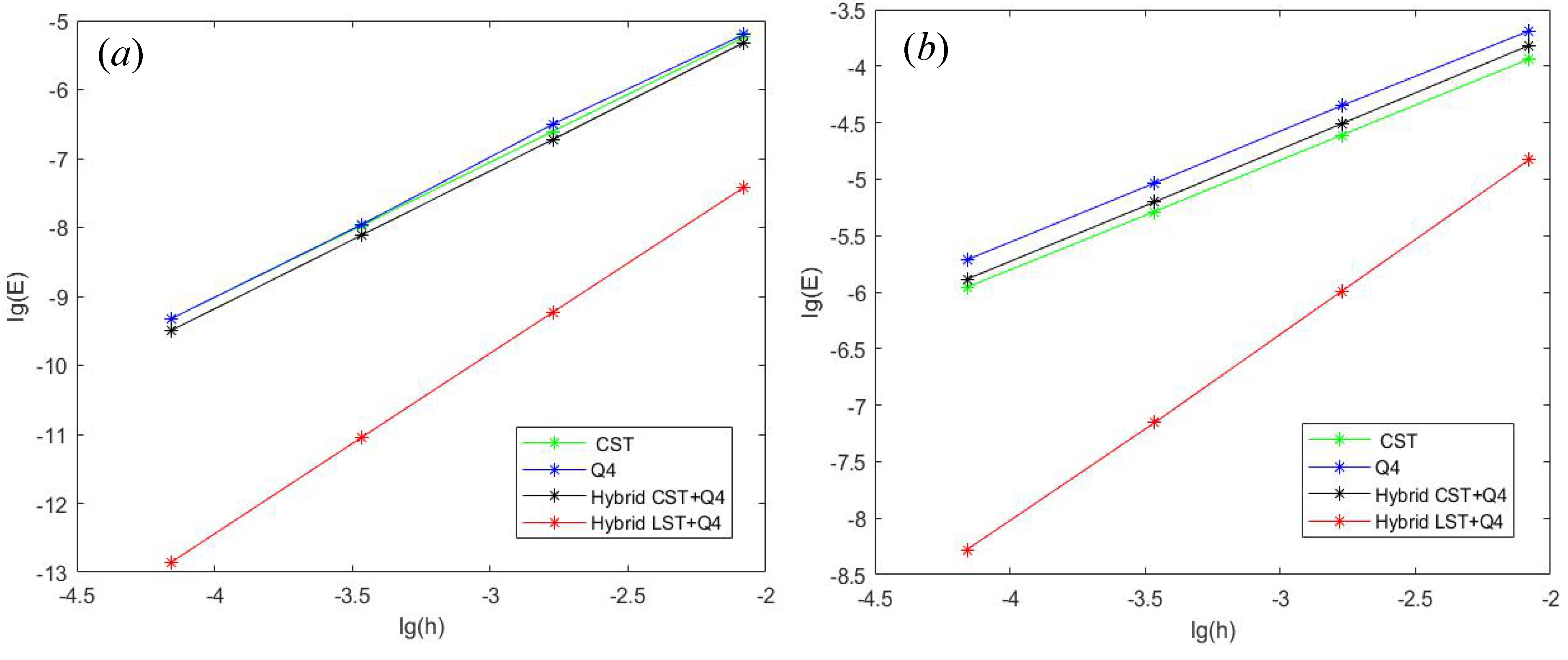

It is one-sided to discuss the quality of the numerical method simply from the mesh quality, because the solution of PDE is constantly related to the discrete element quality, and also related to the selection of the basis function and the type of the equation. On the one hand, the hybrid element can realize the free combination of the mesh. Firstly, the discrete quality of each sub-mesh is optimized, and then the average mesh quality of the whole calculation area is optimized. The comparison of the numerical convergence order is to select a numerical method with a faster calculation speed. The total number of discrete elements of the hybrid element is controlled to 0.75–1 times that of the self-use mesh.

When the number of mixed elements is

= 4010 (3092 triangular elements and 918 quadrilaterals), the total number of triangular CST elements is 5012, and the total number of Q4 elements is 4811, the calculation time of

= 4 s triangular element is

= 4.45 s, and the calculation time of Q4 element is

= 4.23 s. However, in terms of convergence rate, the numerical convergence order of displacement is close to order 2. The convergence order of mixed-element displacement using LST + Q4 is about 2.61, and the stress solved by adaptive FEM is about linear convergence. However, the stress convergence order of mixed-element LST + Q4 is close to 1.67. From

Figure 4a,b, it can be seen that the convergence speed of the LST + Q4 hybrid element is the fastest. Therefore, when the hybrid element selects the appropriate basis function and good grid combination, the numerical method has the characteristics of short calculation time and fast convergence speed, which also reflects the effectiveness of the method.

5. Conclusions

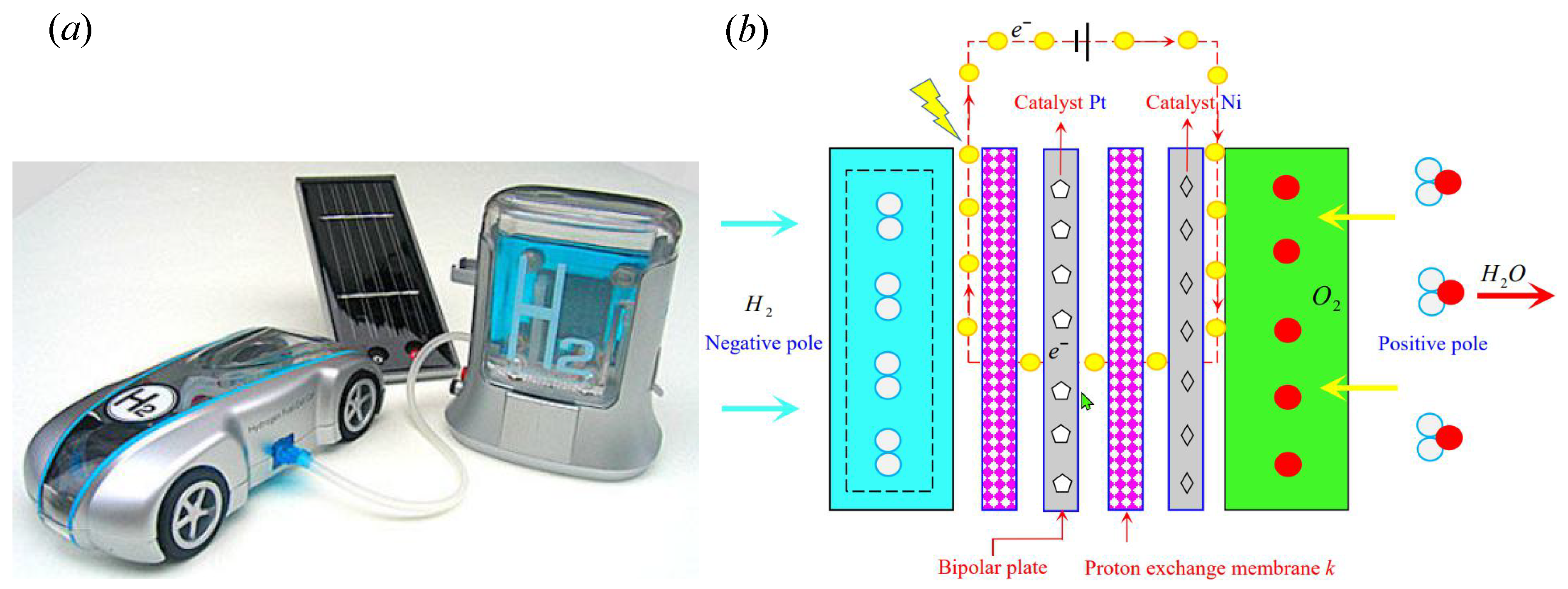

In this paper, a hybrid-element method was proposed to solve the thermal-mechanical coupling model of the fuel cell plate, which can effectively solve the thermal stress change, temperature field distribution and displacement change in the fuel cell plate at work. In this paper, the hybrid-element algorithm for the deformation of a 2D plate was given first, and then the deformation application of a 3D fuel cell plate was given. This paper mainly studied the deformation problem of a porous elastic plate. In view of the defects of the traditional method, such as the poor quality of discrete grids, the low efficiency of numerical calculation and the difficulty in the local adjustment of calculation area, etc., in this paper, an efficient hybrid finite-element numerical method was proposed. The hybrid finite-element solution theory was given for the deformation of porous elastic plates. Compared with the traditional CST adaptive finite-element method and Q4 adaptive finite-element method, the hybrid finite-element method is more flexible for realizing the flexible combination of the grid and the finite-element basis function. This paper also provided a new formula for the evaluation of grid quality, which can effectively evaluate the mesh quality of triangular and quadrilateral elements. For the grid quality evaluation of the hybrid element, the average method was used in this paper. From the numerical experiment results, it can be seen that the mesh quality of the hybrid element was significantly higher than that of the traditional CST and Q4 adaptive mesh. Another advantage of the hybrid element is that the refined mesh can be realized for the key areas, and the order of the basis function can also be adjusted according to the actual needs.

Therefore, this method realizes the balance between numerical accuracy and solution efficiency, especially for the local porous elastic plate problem. The hybrid-element method is obviously superior to the traditional method. The hybrid element can use fewer elements to achieve rapid convergence, and the method proposed in this paper is obviously adaptive FEM convergence fast. In addition, this paper also gives the deformation control formula, which can display the displacement deformation and stress combined diagram on the graphics at the same time, which is convenient to quickly compare the regions where the displacement and stress extremum appear. In short, this paper provides a good foundation for the expansion of the finite-element numerical method, and can provide a mechanical model reference for solving the mechanical problems of porous elastic plates and complex topological geometric regions. Finally, the three-dimensional numerical results were similar to the two-dimensional results; that is, the hybrid finite-element numerical method realized the free combination of the mesh and the basis function, and could form a higher grid quality. In addition, the numerical convergence rate was more advantageous. In this paper, the discrete theory of 2D and 3D problems was provided. These are an extension of the traditional FEM method and an interdisciplinary application case. The hybrid finite element has more applications and further applications to be found. For example, it is still a very difficult scientific research problem to expand toward crack and discontinuous problems with defects. However, it is also a very valuable algorithm innovation and has broad application prospects.