Sustainable Manufacturing of Asymmetric Miniature-Sized Ratchet Wheels by Wire Electrical Discharge Machining

Abstract

:1. Introduction

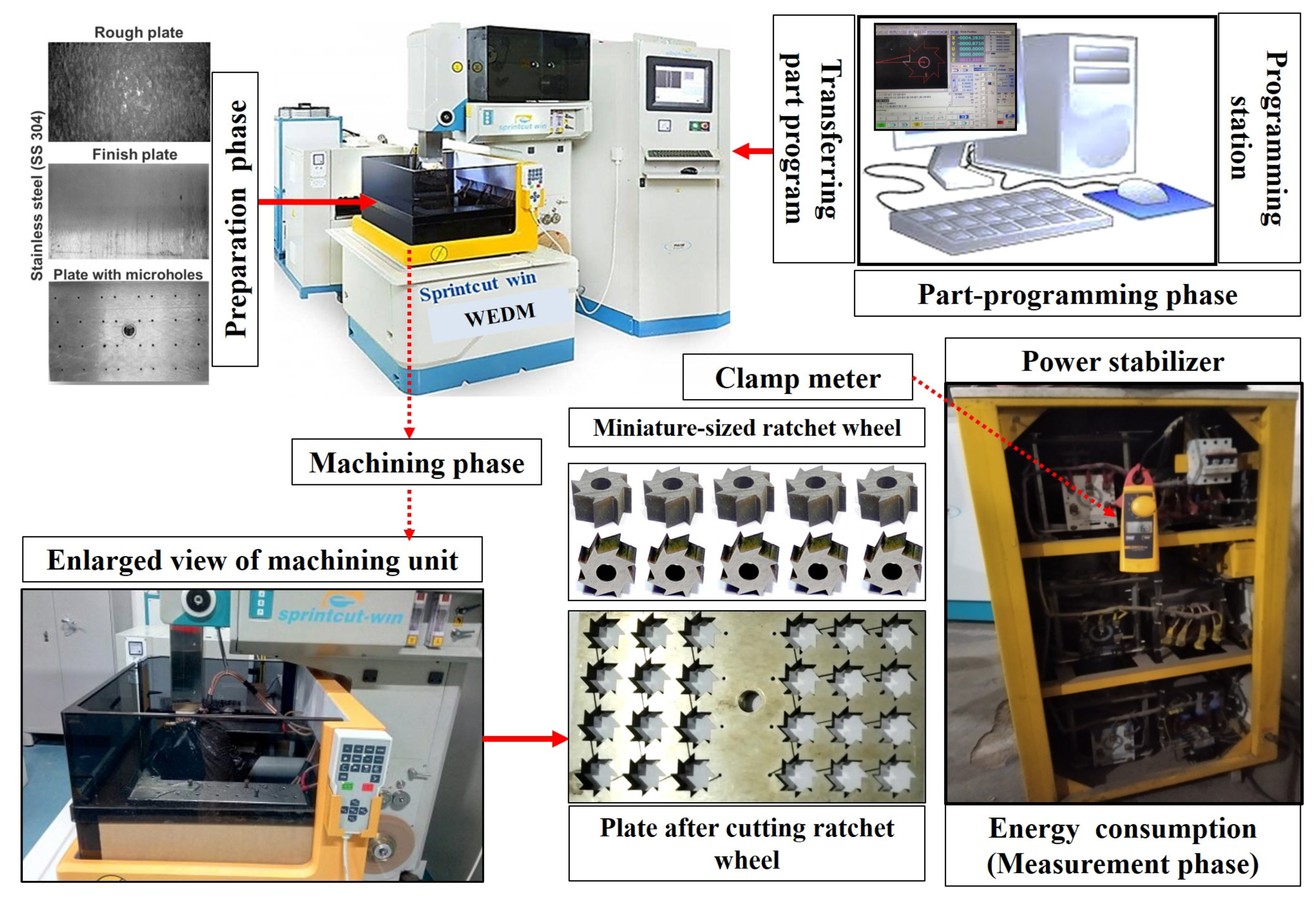

2. Research Methodology

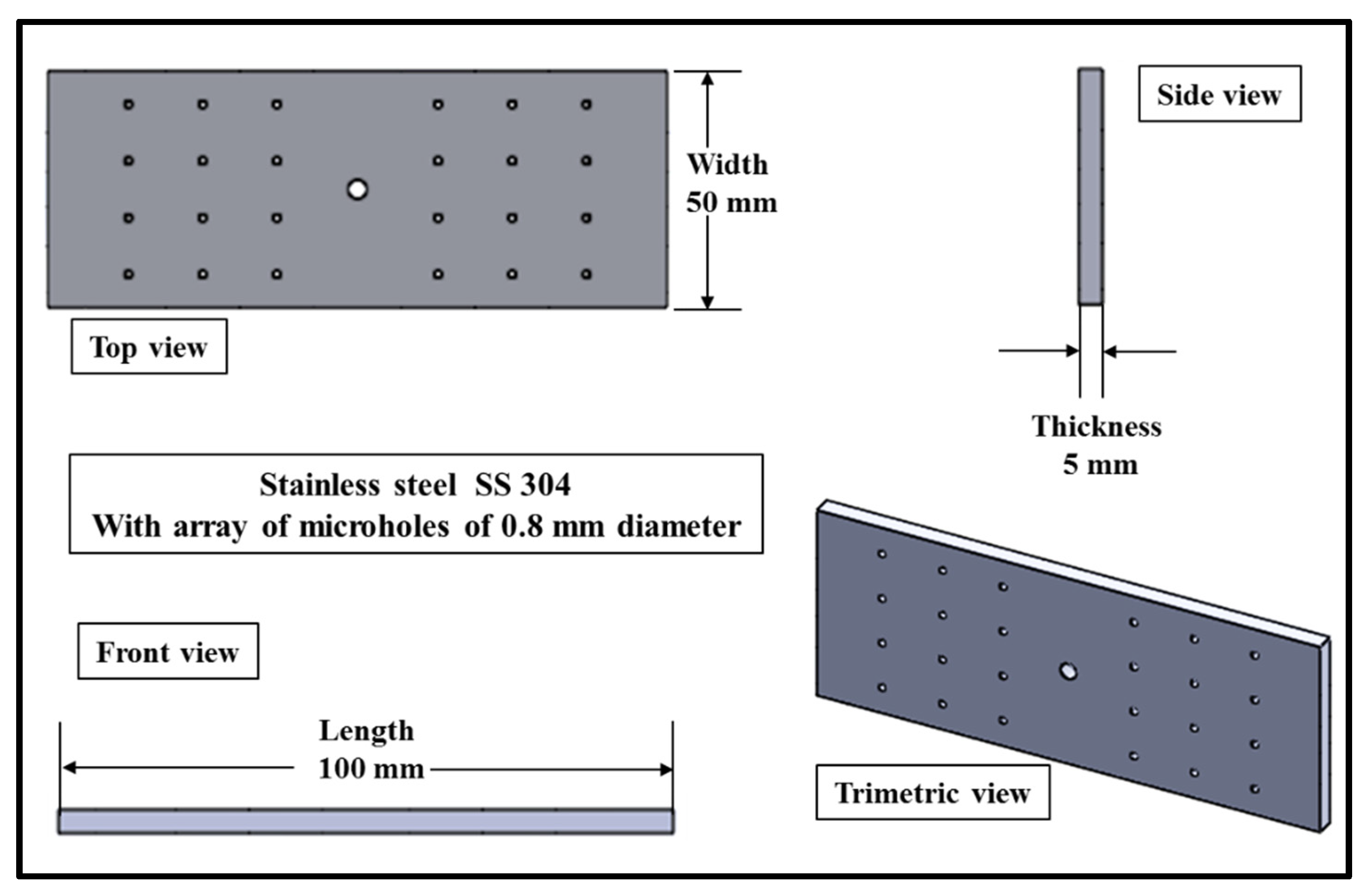

2.1. Materials Selection and Blank Development

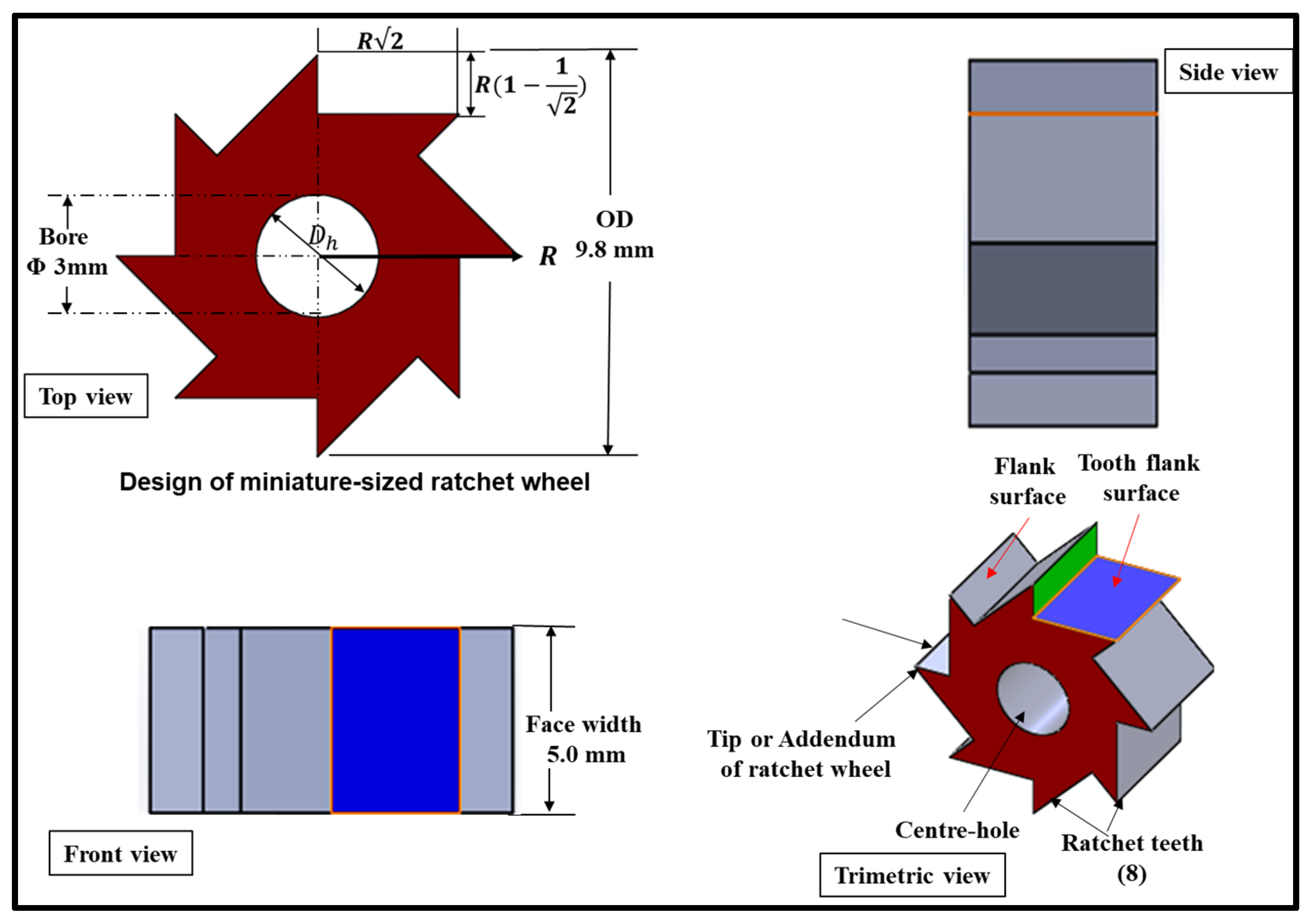

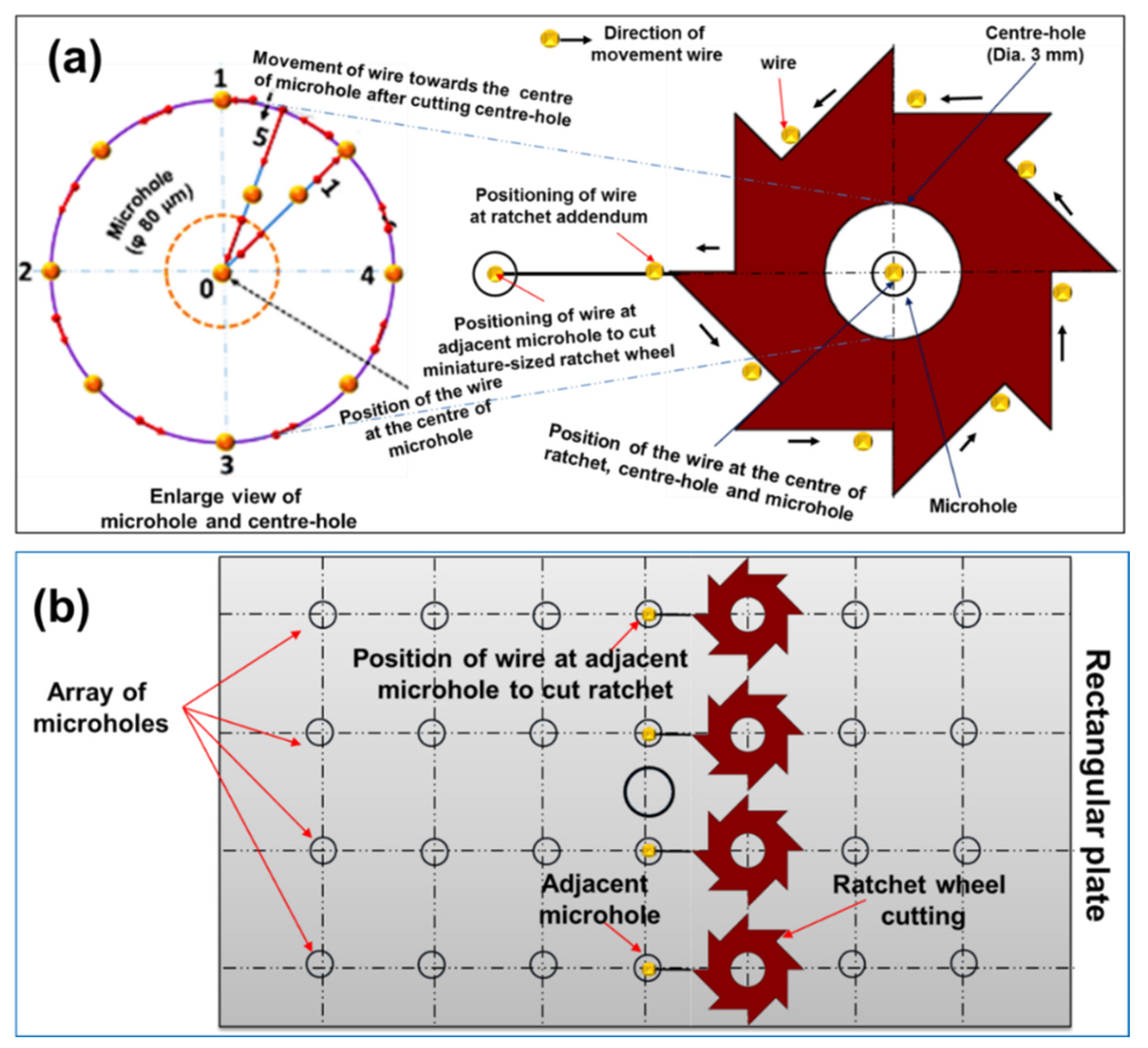

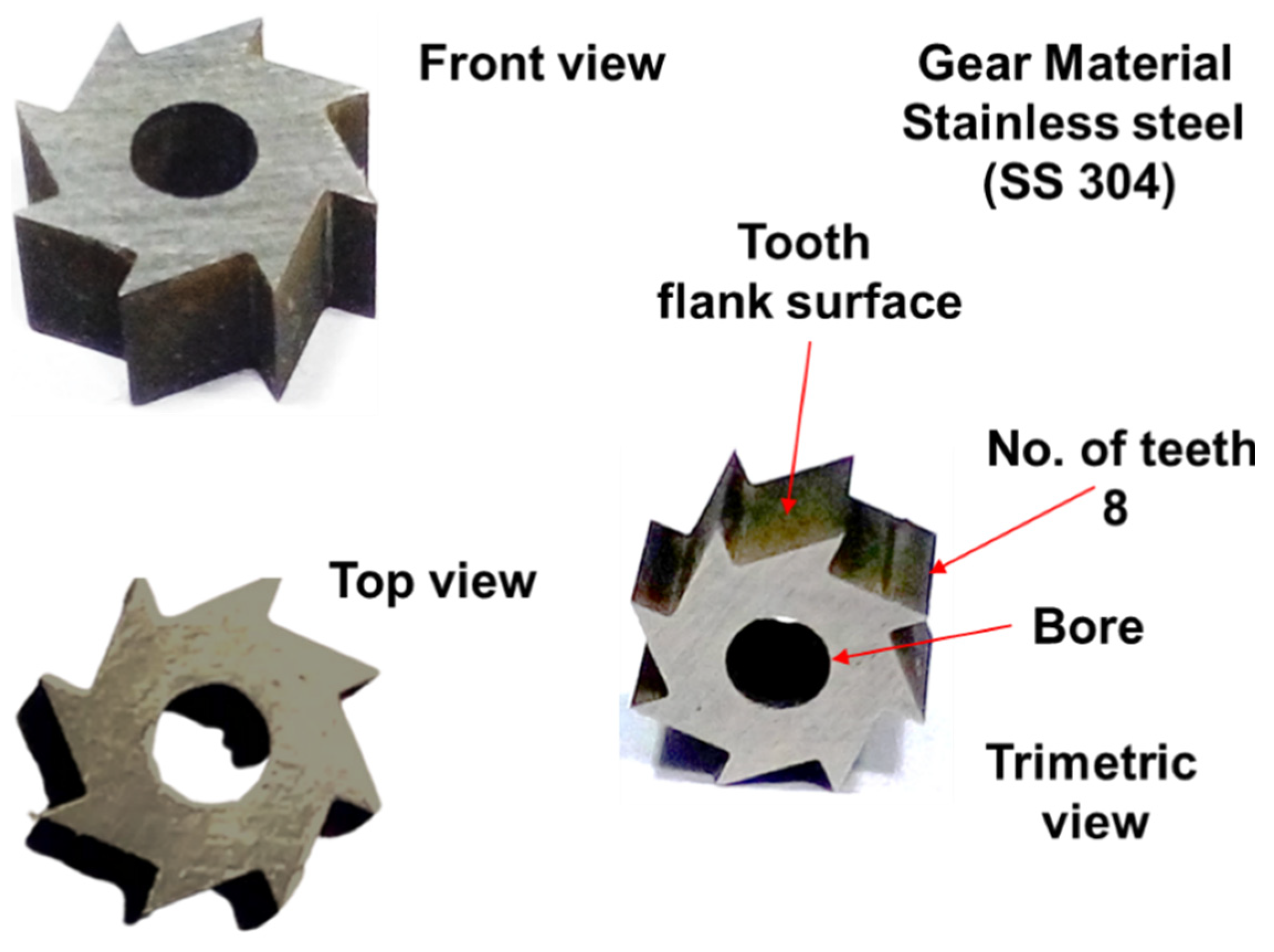

2.2. Design and Development of Asymmetric Miniature-Sized Ratchet Wheel

2.3. Details of Experimentation

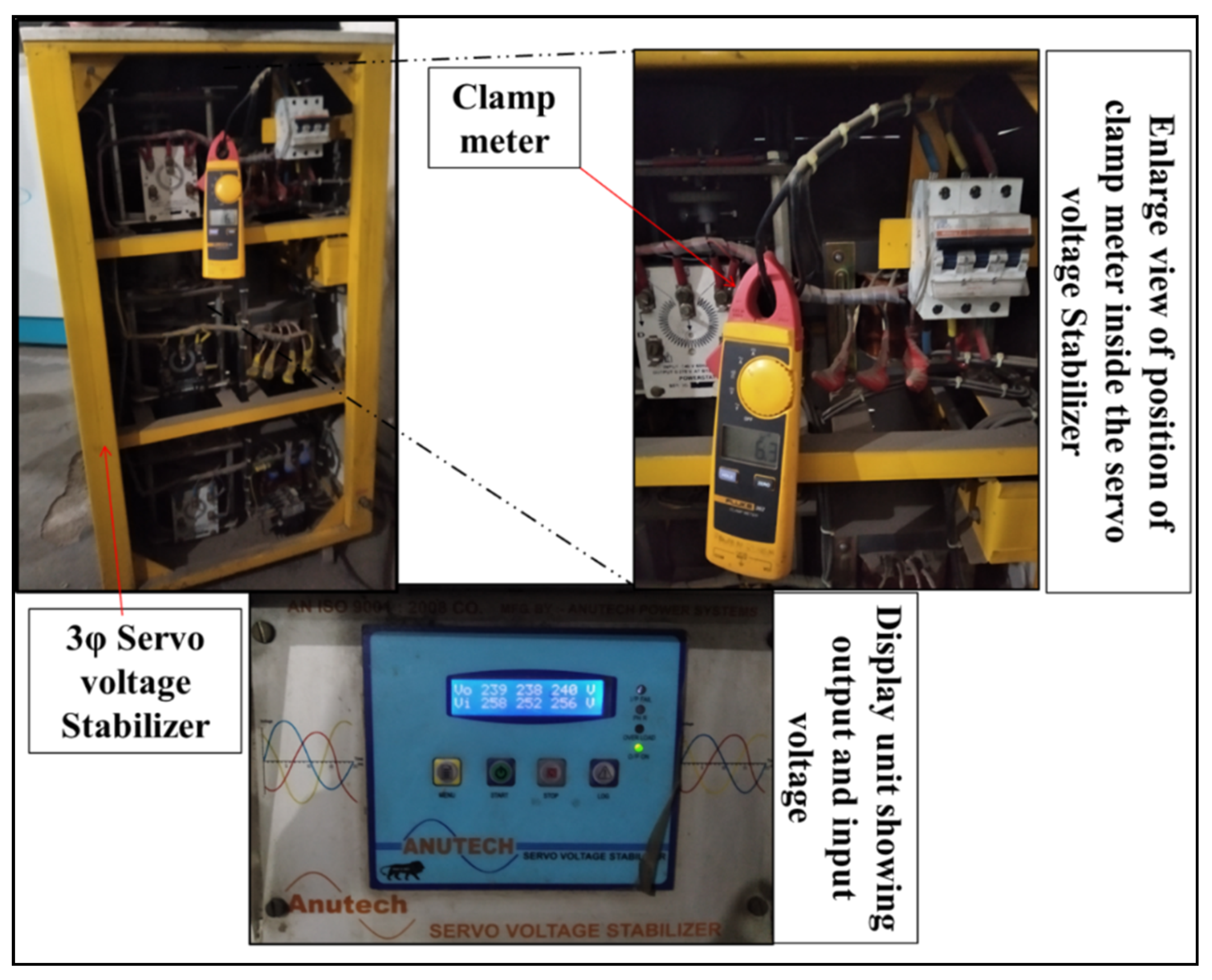

2.4. Measurement of Selected Responses and Surface Quality

2.5. Multi-Response Optimization

3. Results and Discussion

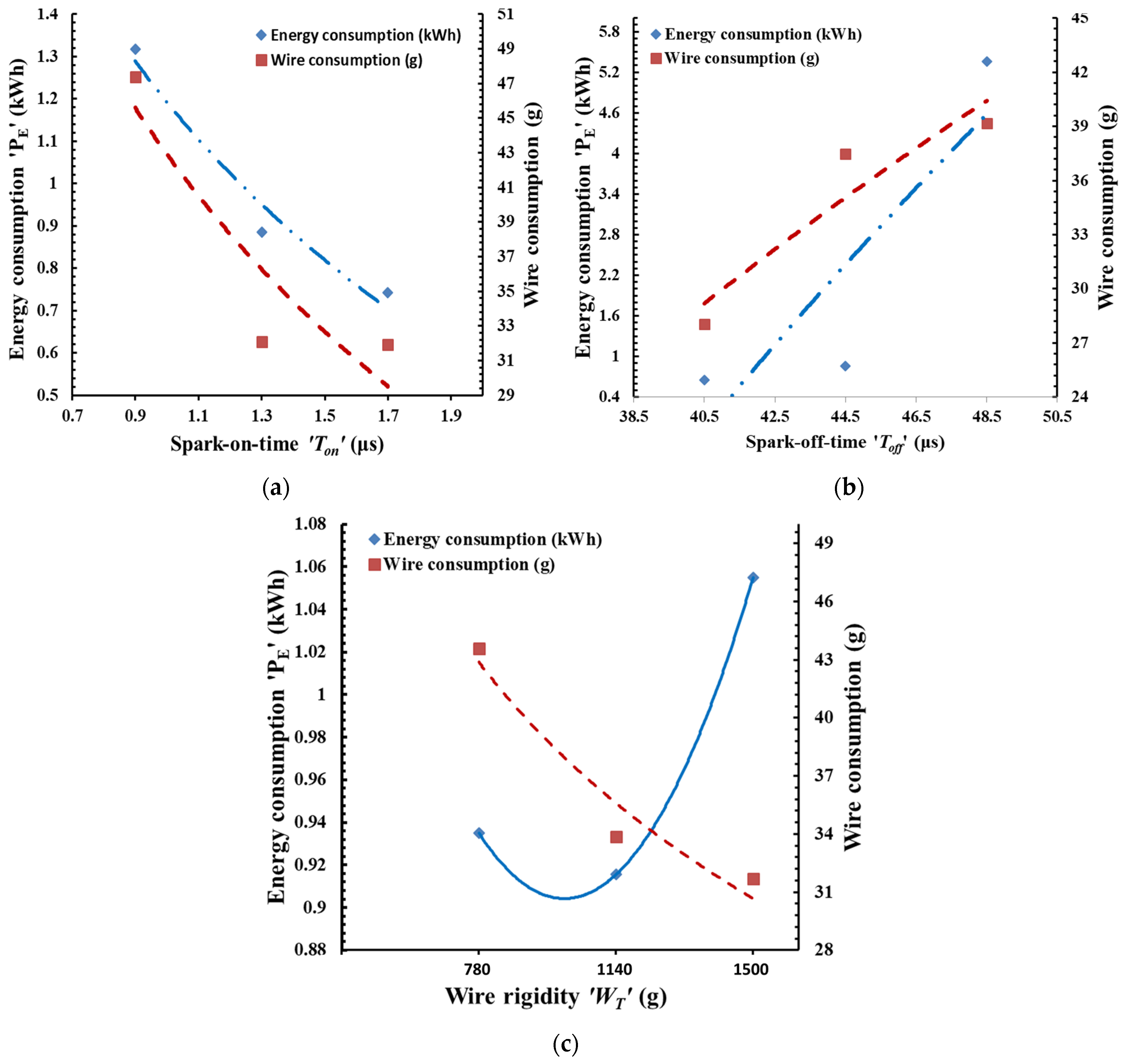

- Ton, Toff, and the interaction between Ton and WT, and squared terms of Ton were found significant for the energy consumption;

- Ton, Toff, and WT, and their squared terms were found significant for wire consumption;

- Interactions between Ton and Toff and Ton and WT were found significant for the wire consumption. The F-value for the developed models indicates the 2nd order polynomials based on RSM are significant;

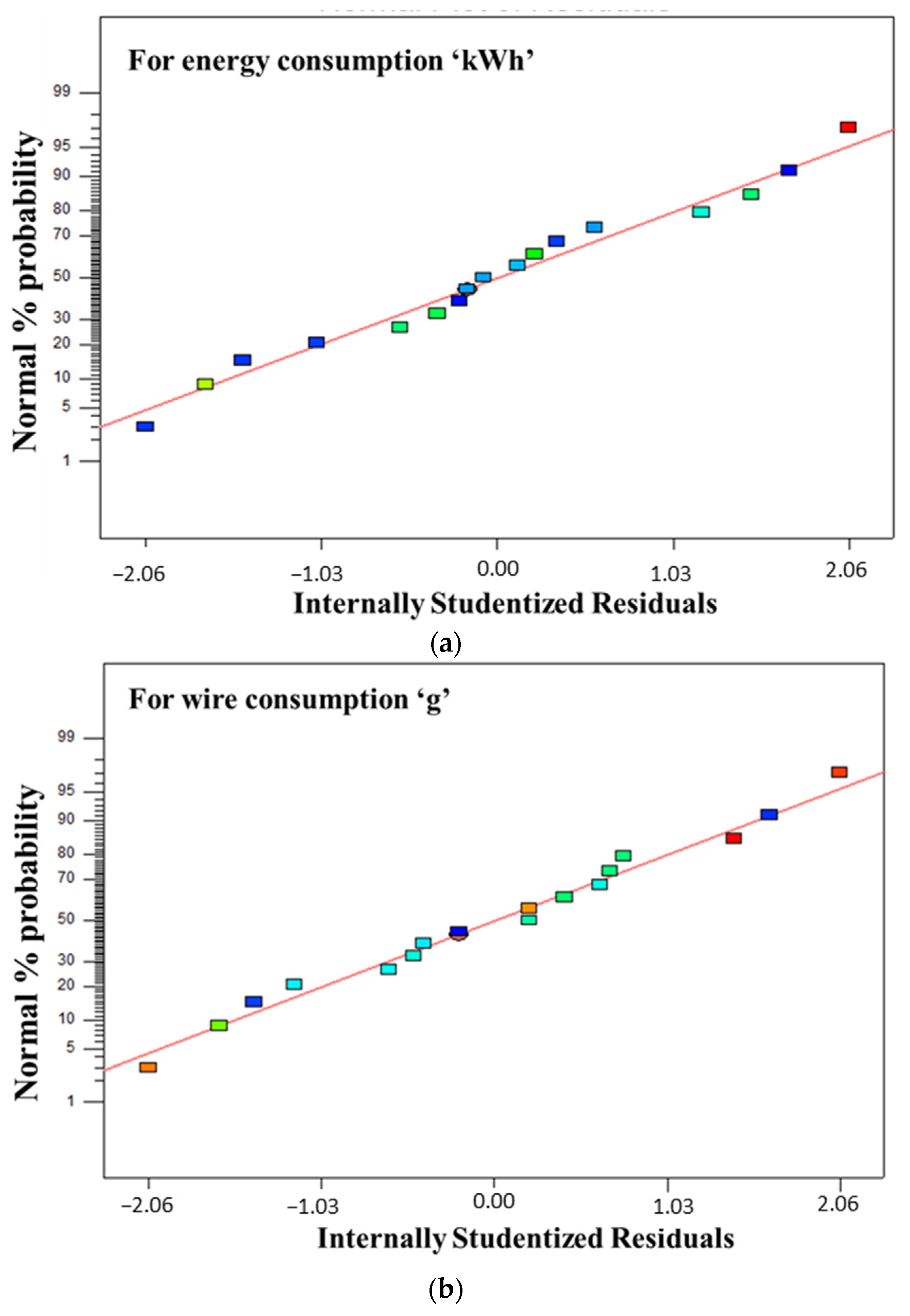

- p-values of the developed models are less than 0.05, indicating that developed models are significant. Non-significant lack of fit is desirable;

- It can be seen from Table A1 that the lack of fit tests of the developed models are not significant (i.e., p-values are greater than 0.05) relative to the pure error. The values of PRESS are 1.07 for energy consumption and 592.24 for wire consumption. The values of R-Squared are 0.9188 for energy consumption and 0.9702 for wire consumption (i.e., close to 1), which confirm the adequacy of the developed models. Adequate precision of the developed models indicates the signal-to-noise ratio, and a ratio greater than 4 is desirable. It can be confirmed from Table A1 that the values of adequate precision are more than 4 for the developed models; thus, models indicate adequate signal.

3.1. Validation of the Optimized Results

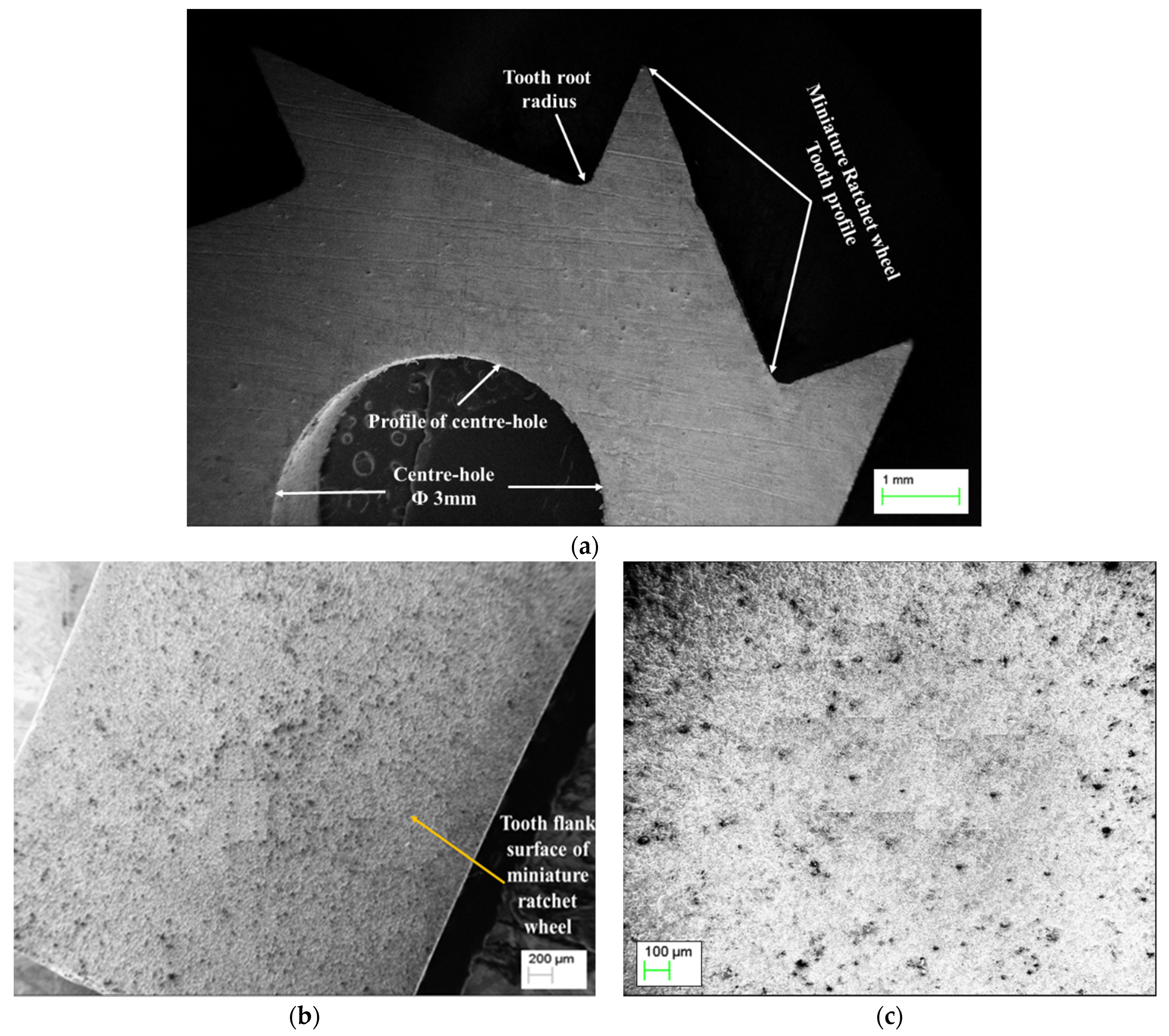

3.2. Surface Quality of Ratchet Wheel

4. Conclusions

- Manufactured SS 304 miniature-sized ratchet wheels of 1.62 g each by WEDM for lightweight applications;

- The park-on-time and spark-off-time are significant parameters that largely affect energy and wire consumption during the manufacturing of miniature-sized ratchet wheels by the WEDM process;

- Wire rigidity is also a significant parameter that only affects the energy wire consumption during the manufacturing of miniature-sized ratchet wheels by the WEDM process;

- During the WEDM of 17 miniature-sized ratchet wheels:

- −16.19 kWh of total energy was consumed, which makes an average of 0.95 kWh for a single ratchet wheel;

- −608.99 g of zinc-coated brass wire was consumed and 35.76 g of wire was consumed for every single ratchet wheel manufactured. It can be concluded that the tool material loss during machining is less, and thus has less impact on the working environment and operators’ health;

- −30.28 g of work material was eroded, out of which 11.8 g of work material was consumed for manufacturing each miniature-sized ratchet wheel. It can be concluded that the maximum utilization of wheel plate (blank) material can be achieved by WEDM;

- Desirability function analysis-based optimization for WEDM of ratchet wheels at optimum parameters’ combination of 1.5 µs spark-on-time, 40.5 µs spark-off-time, and 1260 g wire rigidity resulted in the least energy consumption of 0.64 kWh and a wire consumption of 20.11 g, which enhanced the sustainability of the process;

- The desirability predicted and actual validated values of total energy consumption and total wire consumption, are in close agreement with 4.4% and 2.5% errors, respectively;

- Good surface quality with defect-free tooth surfaces of the ratchet wheel and 1.08 µm average roughness and 6.81 µm maximum flank surface roughness, governs the tribological fitness of the gear obtained at optimum parameters of WEDM.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Remarks |

|---|---|---|---|---|---|---|

| For Energy Consumption ‘’ | ||||||

| Model | 1.03 | 9 | 0.11 | 8.80 | 0.0045 | Significant |

| Ton | 0.66 | 1 | 0.66 | 50.65 | 0.0002 | Significant |

| Toff | 0.16 | 1 | 0.16 | 12.01 | 0.0105 | Significant |

| WT | 0.029 | 1 | 0.029 | 2.21 | 0.1810 | Not significant |

| Ton Toff | 4.225 × 10−003 | 1 | 4.225 × 10−003 | 0.32 | 0.5872 | Not significant |

| Ton WT | 0.070 | 1 | 0.070 | 5.38 | 0.0534 | Significant |

| Toff WT | 6.250 × 10−004 | 1 | 6.250 × 10−004 | 0.048 | 0.8330 | Not significant |

| (Ton2) | 0.085 | 1 | 0.085 | 6.53 | 0.0378 | Significant |

| (Toff2) | 6.845 × 10−004 | 1 | 6.845 × 10−004 | 0.052 | 0.8254 | Not significant |

| (WT2) | 0.022 | 1 | 0.022 | 1.68 | 0.2356 | Not significant |

| Residual | 0.091 | 7 | 0.013 | |||

| Lack of fit | 0.064 | 3 | 0.021 | 3.17 | 0.1474 | Not significant |

| Pure error | 0.027 | 4 | 6.770 × 10−003 | |||

| Cor Total | 1.13 | 16 | ||||

| R-Squared = 0.9188, Adjusted R-Squared = 0.8144, Predicted R-Squared = 0.0482 | ||||||

| PRESS = 1.07, Adequate Precision = 10.955 | ||||||

| For Wire Consumption ‘’ | ||||||

| Model | 1682.21 | 9 | 186.91 | 25.29 | 0.0002 | Significant |

| Ton | 476.48 | 1 | 476.48 | 64.47 | <0.0001 | Significant |

| Toff | 247.64 | 1 | 247.64 | 33.51 | 0.0007 | Significant |

| WT | 282.15 | 1 | 282.15 | 38.18 | 0.0005 | Significant |

| Ton Toff | 52.13 | 1 | 52.13 | 7.05 | 0.0327 | Significant |

| Ton WT | 246.49 | 1 | 246.49 | 33.35 | 0.0007 | Significant |

| Toff WT | 4.22 | 1 | 4.22 | 0.57 | 0.4744 | Not significant |

| (Ton2) | 243.63 | 1 | 243.63 | 32.96 | 0.0007 | Significant |

| (Toff2) | 83.97 | 1 | 83.97 | 11.36 | 0.0119 | Significant |

| (WT2) | 53.94 | 1 | 53.94 | 7.30 | 0.0306 | Significant |

| Residual | 51.74 | 7 | 7.39 | |||

| Lack of fit | 35.42 | 3 | 11.81 | 2.89 | 0.1655 | Not significant |

| Pure error | 16.31 | 4 | 4.08 | |||

| Cor Total | 1733.94 | 16 | ||||

| R-Squared = 0.9702, Adjusted R-Squared = 0.9318, Predicted R-Squared = 0.6584 | ||||||

| PRESS = 592.24, Adequate Precision = 15.432 | ||||||

References

- Khan, A.M.; Gupta, M.K.; Hegab, H.; Jamil, M.; Mia, M.; He, N.; Song, Q.; Liu, Z.; Pruncu, C.I. Energy-based cost integrated modelling and sustainability assessment of Al-GnP hybrid nanofluid assisted turning of AISI52100 steel. J. Clean. Prod. 2020, 257, 120502. [Google Scholar] [CrossRef]

- Viswanth, V.S.; Ramanujam, R.; Rajyalakshmi, G. A Review of Research Scope on Sustainable and Eco-Friendly Electrical Discharge Machining (E-EDM). Mater. Today Proc. 2018, 5, 12525–12533. [Google Scholar] [CrossRef]

- Ming, W.; Xie, Z.; Ma, J.; Du, J.; Zhang, G.; Cao, C.; Zhang, Y. Critical review on sustainable techniques in electrical discharge machining. J. Manuf. Process. 2021, 72, 375–399. [Google Scholar] [CrossRef]

- Fan, Y.; Li, C.; Bai, J.; Li, Q. Experimental study on energy consumption of energy-saving pulse power for WEDM. Int. J. Adv. Manuf. Technol. 2014, 72, 1687–1691. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Analysis and optimization of sustainable machining of AISI O1 tool steel by the wire-EDM process. Adv. Manuf. 2021, 9, 304–317. [Google Scholar] [CrossRef]

- Gupta, K.; Gupta, M.K. Developments in nonconventional machining for sustainable production: A state-of-the-art review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 233, 4213–4232. [Google Scholar] [CrossRef]

- Jain, N.K.; Pathak, S. Fine finishing of gears by electrochemical honing process, Chapter 16. In Nanofinishing Science and Technology: Basic and Advanced Finishing and Polishing Processes, 1st ed.; Jain, V.K., Ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9781315404103. [Google Scholar]

- Połok, B.; Bilski, P. Diagnostics of the ratchet mechanism using the acoustic analysis. In Proceedings of the 17th IMEKO TC 10 and EUROLAB Virtual Conference Global Trends in Testing, Diagnostics & Inspection for 2030, online, 20–22 October 2020. [Google Scholar]

- Chaubey, S.K.; Jain, N.K. On productivity of WSEM process for manufacturing Meso-sized helical and bevel gear. IOP Conf. Ser. Mater. Sci. Eng. 2018, 389, 1–6. [Google Scholar] [CrossRef]

- Jain, N.K.; Chaubey, S.K. Review of Miniature Gear Manufacturing, Chapter 1.17 in Comprehensive Materials Finishing; Hashmi, M.S.J., Ed.; Elsevier: Oxford, UK, 2016; Volume 1, pp. 504–538. [Google Scholar] [CrossRef]

- Chaubey, S.K.; Jain, N.K.; Gupta, K. A Comprehensive Investigation on Development of Lightweight Aluminium Miniature Gears by Thermoelectric Erosion Machining Process. Micromachines 2021, 12, 1230. [Google Scholar] [CrossRef]

- Manikandan, K.; Kumar, P.R.; Kumar, D.R.; Palanikumar, K. Machinability evaluation and comparison of Incoloy 825, Inconel 603 XL, Monel K400 and Inconel 600 super alloys in wire electrical discharge machining. J. Mater. Res. Technol. 2020, 9, 12260–12272. [Google Scholar] [CrossRef]

- Khilji, I.A.; Saffe, S.N.B.M.; Pathak, S.; Ţălu, S.; Kulesza, S.; Bramowicz, M.; Reddy, V.J. Titanium Alloy Particles Formation in Electrical Discharge Machining and Fractal Analysis. JOM 2022, 74, 448–455. [Google Scholar] [CrossRef]

- Ahmed, N.; Naeem, M.A.; Rehman, A.U.; Rafaqat, M.; Umer, U.; Ragab, A.E. High Aspect Ratio Thin-Walled Structures in D2 Steel through Wire Electric Discharge Machining (EDM). Micromachines 2020, 12, 1. [Google Scholar] [CrossRef] [PubMed]

- Dzionk, S.; Siemiątkowski, M.S. Studying the Effect of Working Conditions on WEDM Machining Performance of Super Alloy Inconel 617. Machines 2020, 8, 54. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, H.; Yan, Z.; Han, F.; Yan, H. A new high-speed observation system for evaluating the spark location in WEDM of Inconel 718. J. Mater. Res. Technol. 2021, 13, 184–196. [Google Scholar] [CrossRef]

- Chaubey, S.K.; Singh, S.; Singh, A. Some investigations into machining of AISI D2 tool steel using wire electro discharge machining (WEDM) process. Mater. Today Proc. 2018, 5, 24347–24357. [Google Scholar] [CrossRef]

- Benedict, G.F. Nontraditional Manufacturing Processes; Marcel Dekker Inc.: New York, NY, USA, 1987; ISBN 0-8247-7352-7. [Google Scholar]

- Ablyaz, T.; Shlykov, E.; Muratov, K.; Sidhu, S. Analysis of Wire-Cut Electro Discharge Machining of Polymer Composite Materials. Micromachines 2021, 12, 571. [Google Scholar] [CrossRef]

- Gamage, J.; DeSilva, A. Effect of Wire Breakage on the Process Energy Utilisation of EDM. Procedia CIRP 2016, 42, 586–590. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, D.; Wu, B.; Zhang, Y. Energy Consumption Modeling for EDM Based on Material Removal Rate. IEEE Access 2020, 8, 173267–173275. [Google Scholar] [CrossRef]

- Fatima, A.; Syed, A.I. Identifying Direct Electrical Energy Demand in Wire-Cut EDM. Mehran Univ. Res. J. Eng. Technol. 2020, 39, 171–178. [Google Scholar] [CrossRef]

- Sarhan, A.A.D.; Maher, I.; Hamdi, M. Development of a New Cost Performance Index (CPI) for Selecting the Most Suitable Wire Electrode in Wire-EDM Machining. Arab. J. Sci. Eng. 2021, 46, 12465–12478. [Google Scholar] [CrossRef]

- Hatsuzawa, T.; Yamazaki, A.; Nisisako, T.; Yanagida, Y. Design and evaluation of Artemia-driven micro ratchet gears. Sens. Actuators A Phys. 2015, 235, 182–186. [Google Scholar] [CrossRef]

- Zolpakar, N.A.; Yasak, M.F.; Pathak, S. A review: Use of evolutionary algorithm for optimisation of machining parameters. Int. J. Adv. Manuf. Technol. 2021, 115, 31–47. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 7th ed.; John Willey and Sons: Hoboken, NJ, USA, 2009; ISBN 978-1-118-14692-7. [Google Scholar]

- Hatsuzawa, T.; Ito, D.; Nisisako, T.; Yanagida, Y. Micro-rotary ratchets driven by migratory phytoplankton with phototactic stimulus. Precis. Eng. 2017, 48, 107–113. [Google Scholar] [CrossRef]

- Nur, R.; Muas, M.; Apollo; Risal, S. Effect of Current and Wire Speed on Surface Roughness in the manufacturing of Straight Gear using Wire-cut EDM Process. IOP Conf. Ser. Mater. Sci. Eng. 2019, 619, 12002. [Google Scholar] [CrossRef] [Green Version]

- Chaubey, S.K.; Jain, N.K. Capabilities evaluation of WSEM, milling and hobbing for meso-gear manufacturing. Mater. Manuf. Process. 2018, 33, 1539–1548. [Google Scholar] [CrossRef]

- Payla, A.; Chopra, K.; Mussada, E.K. Investigations on power consumption in WEDM of EN31 steel for sustainable production. Mater. Manuf. Process. 2019, 34, 1855–1865. [Google Scholar] [CrossRef]

| WEDM Input Parameter | Constant Parameters | |||

|---|---|---|---|---|

| Name, ‘Symbol’ and (Unit) | Coded Level | |||

| −1 | 0 | 1 | ||

| Spark-on-time ‘Ton’ (µs) | 0.9 | 1.3 | 1.7 | WEDM input parameters:Peak current ‘IP’: 12 A; Servo voltage ‘SV’: 20 Volts; Wire speed: 4 m/min; Flushing pressure ‘WP’: 15 kg/cm2; Cutting speed ‘CS’: 100% Electrode material: Zinc coated wire; Wire diameter: 0.25 mm; Tensile strength: 800 N/mm2; Machining Medium: Deionized water Wheel materials and thickness: SS 304 and 5 mm |

| Spark-off-time ‘Toff’ (µs) | 40.5 | 44.5 | 48.5 | |

| Wire rigidity ‘WT’ (g) | 780 | 1140 | 1500 | |

| Composition (% wt.) of Ratchet wheel material (SS 304) | ||||

| 0.8% C; 6.8% Ni; 17% Cr; 1.2% Mn; 1% Si; 0.5% S; Balance Fe | ||||

| Ratchet wheel Specifications | ||||

| Material: SS 304; Profile: Involute; Addendum diameter: 9.8 mm; No. of teeth: 8; Face width: 5 mm; Bore/Center hole diameter: 3 mm | ||||

| Considered Responses | ||||

| Energy consumption (kWh) per ratchet wheel and wire consumption | ||||

| Parameters recorded during machining | ||||

| Voltage; current; power factor; machining time; weight of consumed wire; weight of ratchet wheel and plate weight | ||||

| Run | WEDM Process Parameters | Ratchet Wheel | Bore | Pow-er Fact-or (φ) | Energy Consu-mption (kWh) ‘PE’ Avg. R1 + R2 | Wire Consum-ption (Grams) ‘WC’ Avg. R1 + R2 | Time (min) Avg. R1 + R2 | Weight (gram) Avg. R1 + R2 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Electrical Parameters | |||||||||||||||||||||||

| Spark-on-time ‘Ton’ (μs) | Spark-off-time ‘Toff’ (μs) | Wire rigidity ‘WT’ (g) | Voltage (239-41) | Current (Ampere) | Voltage (Volts) | Current (Ampere) | |||||||||||||||||

| (P-L) | (P-L) | ||||||||||||||||||||||

| R | Y | B | R | Y | B | DC | R | Y | B | R | Y | B | DC | Ratchet | Bore | ||||||||

| 1 | 0.9 (−1) | 40.5 (−1) | 1140 (0) | 240 | 239 | 240 | 6.5 | 6.5 | 5.6 | 1.2 | 240 | 239 | 240 | 6.5 | 6.5 | 5.6 | 1.2 | 0.99 | 1.07 | 34.74 | 14.68 | 1.67 | 0.13 |

| 2 | 1.3 (0) | 44.5 (0) | 1140 (0) | 241 | 240 | 240 | 6.5 | 6.5 | 5.8 | 1.2 | 241 | 240 | 240 | 5.3 | 5.3 | 4.5 | 1.5 | 0.99 | 0.98 | 34.16 | 13.60 | 1.69 | 0.13 |

| 3 | 1.3 (0) | 48.5 (1) | 780 (−1) | 239 | 240 | 240 | 6.5 | 6.5 | 5.7 | 1.4 | 239 | 240 | 240 | 6.5 | 6.5 | 5.6 | 1.5 | 0.99 | 1.07 | 41.90 | 14.42 | 1.64 | 0.12 |

| 4 | 0.9 (−1) | 44.5 (0) | 1500 (1) | 241 | 241 | 239 | 6.4 | 6.4 | 5.6 | 1.3 | 241 | 241 | 239 | 6.2 | 6.2 | 5.6 | 1.3 | 0.99 | 1.67 | 50.50 | 22.93 | 1.67 | 0.12 |

| 5 | 1.7 (1) | 44.5 (0) | 780 (−1) | 240 | 240 | 241 | 5.3 | 5.3 | 4.7 | 3.0 | 240 | 240 | 241 | 6.3 | 6.3 | 5.7 | 1.5 | 0.99 | 0.74 | 52.54 | 11.40 | 1.64 | 0.12 |

| 6 | 1.3 (0) | 44.5 (0) | 1140 (0) | 241 | 241 | 239 | 6.1 | 6.1 | 5.3 | 2.0 | 241 | 241 | 239 | 6.1 | 6.1 | 5.2 | 2.0 | 0.99 | 0.84 | 32.99 | 12.17 | 1.64 | 0.12 |

| 7 | 1.3 (0) | 40.5 (−1) | 1500 (1) | 241 | 240 | 241 | 6.2 | 6.2 | 4.9 | 2.1 | 241 | 240 | 241 | 6.4 | 6.4 | 5.9 | 2.1 | 0.99 | 0.74 | 23.35 | 10.60 | 1.62 | 0.13 |

| 8 | 1.3 (0) | 44.5 (0) | 1140 (0) | 241 | 240 | 240 | 6.0 | 6.0 | 5.3 | 2.1 | 241 | 240 | 240 | 6.7 | 6.7 | 6.3 | 2.0 | 0.99 | 0.75 | 29.59 | 10.67 | 1.60 | 0.12 |

| 9 | 1.3 (0) | 40.5 (−1) | 780 (−1) | 239 | 239 | 240 | 6.2 | 6.2 | 5.3 | 2.1 | 239 | 239 | 240 | 5.9 | 5.9 | 5.4 | 2.2 | 0.99 | 0.75 | 30.09 | 10.75 | 1.64 | 0.13 |

| 10 | 0.9 (−1) | 48.5 (1) | 1140 (0) | 240 | 240 | 239 | 6.0 | 6.0 | 5.3 | 1.2 | 240 | 240 | 239 | 6.1 | 6.1 | 5.0 | 1.4 | 0.99 | 1.35 | 54.46 | 19.87 | 1.63 | 0.12 |

| 11 | 1.3 (0) | 44.5 (0) | 1140 (0) | 241 | 240 | 240 | 6.0 | 6.0 | 5.3 | 1.9 | 241 | 240 | 240 | 6.0 | 6.0 | 5.3 | 2.0 | 0.99 | 0.87 | 34.36 | 12.75 | 1.64 | 0.13 |

| 12 | 1.7 (1) | 40.5 (−1) | 1140 (0) | 239 | 241 | 240 | 6.2 | 6.2 | 5.5 | 3.2 | 239 | 241 | 240 | 6.1 | 6.1 | 5.4 | 3.1 | 0.99 | 0.69 | 25.01 | 9.75 | 1.64 | 0.12 |

| 13 | 1.7 (1) | 44.5 (0) | 1500 (1) | 240 | 240 | 240 | 6.1 | 6.1 | 5.6 | 2.8 | 240 | 240 | 240 | 5.9 | 5.9 | 5.4 | 2.6 | 0.99 | 0.70 | 21.88 | 9.95 | 1.69 | 0.12 |

| 14 | 1.3 (0) | 48.5 (1) | 1500 (1) | 241 | 240 | 240 | 6.7 | 6.7 | 6.1 | 1.8 | 241 | 240 | 240 | 5.9 | 5.9 | 5.4 | 1.8 | 0.99 | 1.11 | 31.05 | 14.72 | 1.70 | 0.12 |

| 15 | 1.3 (0) | 44.5 (0) | 1140 (0) | 239 | 240 | 240 | 5.8 | 5.8 | 5.5 | 1.9 | 239 | 240 | 240 | 5.9 | 5.9 | 5.4 | 1.9 | 0.99 | 0.85 | 31.32 | 12.57 | 1.70 | 0.12 |

| 16 | 0.9 (−1) | 44.5 (0) | 780 (−1) | 240 | 241 | 240 | 5.8 | 5.8 | 5.3 | 1.4 | 240 | 241 | 240 | 5.9 | 5.9 | 5.3 | 1.4 | 0.99 | 1.18 | 49.76 | 17.67 | 1.68 | 0.13 |

| 17 | 1.7 (1) | 48.5 (1) | 1140 (0) | 239 | 240 | 240 | 5.8 | 5.8 | 5.5 | 2.1 | 239 | 240 | 240 | 5.6 | 5.6 | 5.6 | 2.1 | 0.99 | 0.84 | 31.29 | 12.53 | 1.69 | 0.12 |

| Details | Name | By DFA | Experimental Validation (i.e., Corresponding Values Avialble in the M/C) | Difference | |

|---|---|---|---|---|---|

| R1 | R2 | ||||

| Optimum values of WEDM variable parameters | Ton (µs) | 1.49 | 1.5 | ||

| Toff (µs) | 40.53 | 40.5 | |||

| WT (g) | 1259 | 1260 | |||

| Optimum values of responses | PE (kWh) | 0.69 | 0.66 | 0.64 | 0.03 (−4.4%) |

| WC (g) | 20.62 | 20.11 | 20.29 | 0.41 (−2.5%) | |

| Machining time in Minutes | 9.4 | 9.6 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaubey, S.K.; Gupta, K. Sustainable Manufacturing of Asymmetric Miniature-Sized Ratchet Wheels by Wire Electrical Discharge Machining. Machines 2022, 10, 506. https://doi.org/10.3390/machines10070506

Chaubey SK, Gupta K. Sustainable Manufacturing of Asymmetric Miniature-Sized Ratchet Wheels by Wire Electrical Discharge Machining. Machines. 2022; 10(7):506. https://doi.org/10.3390/machines10070506

Chicago/Turabian StyleChaubey, Sujeet Kumar, and Kapil Gupta. 2022. "Sustainable Manufacturing of Asymmetric Miniature-Sized Ratchet Wheels by Wire Electrical Discharge Machining" Machines 10, no. 7: 506. https://doi.org/10.3390/machines10070506

APA StyleChaubey, S. K., & Gupta, K. (2022). Sustainable Manufacturing of Asymmetric Miniature-Sized Ratchet Wheels by Wire Electrical Discharge Machining. Machines, 10(7), 506. https://doi.org/10.3390/machines10070506