Analysis and Design of Novel Axial Field Flux-Modulation Permanent Magnet Machines for Direct Drive Application

Abstract

:1. Introduction

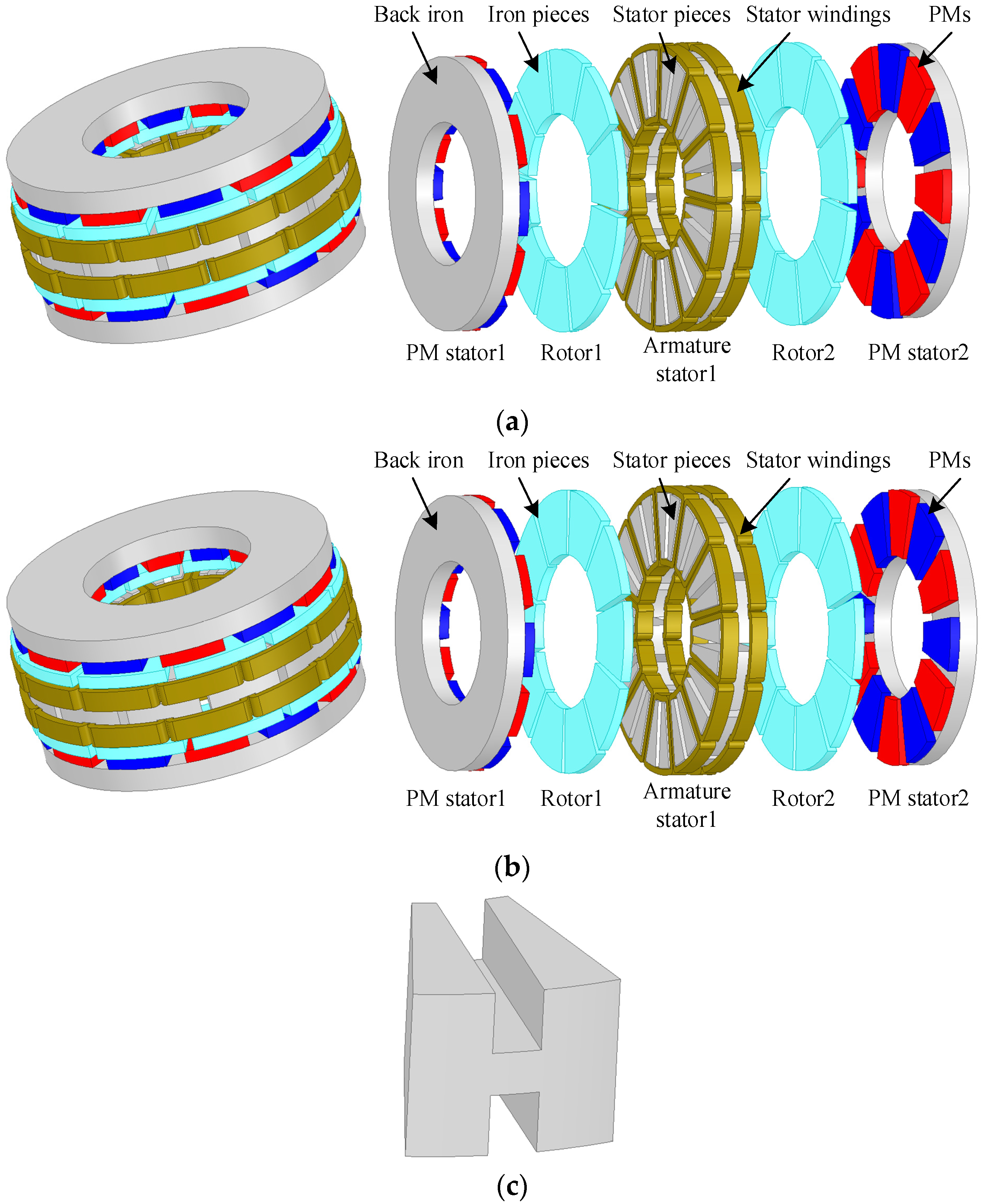

2. Proposed Machine Configurations and Operation Principle

2.1. Proposed Machine Configurations

- (1)

- The static PM stator can prevent the PM from falling off when the machine runs, also the structure is easier to cool.

- (2)

- The prominent salient teeth of the PM stator and the salient rotor presents abundant field harmonics in the air gap of the proposed AF-FMPM machines, which makes the machine output to present stable electromagnetic torque.

- (3)

- Owing to the disc structure of multi-stator and multi-rotor, the torque density of the proposed machine can be significantly increased, making it suitable for direct drive applications.

- (4)

- Concentrated windings of the proposed machine can reduce the usage of copper and depress the copper loss, resulting in high machine efficiency.

- (5)

- The rotor is simple and robust.

- (6)

- Symmetrical machine structure is also easy to manufacture.

2.2. Operation Principle

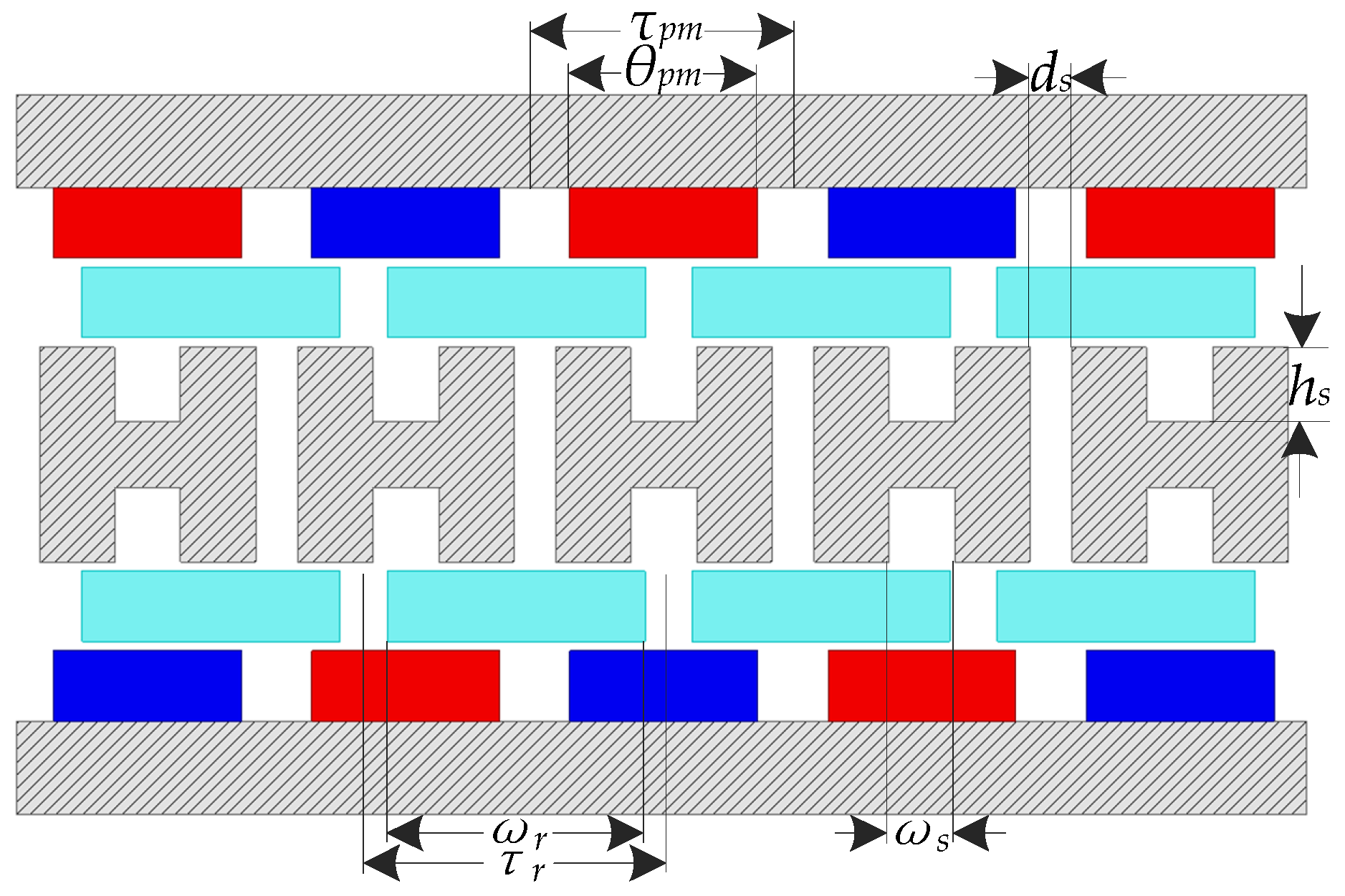

3. Influence of Critical Parameters on Machine Performance

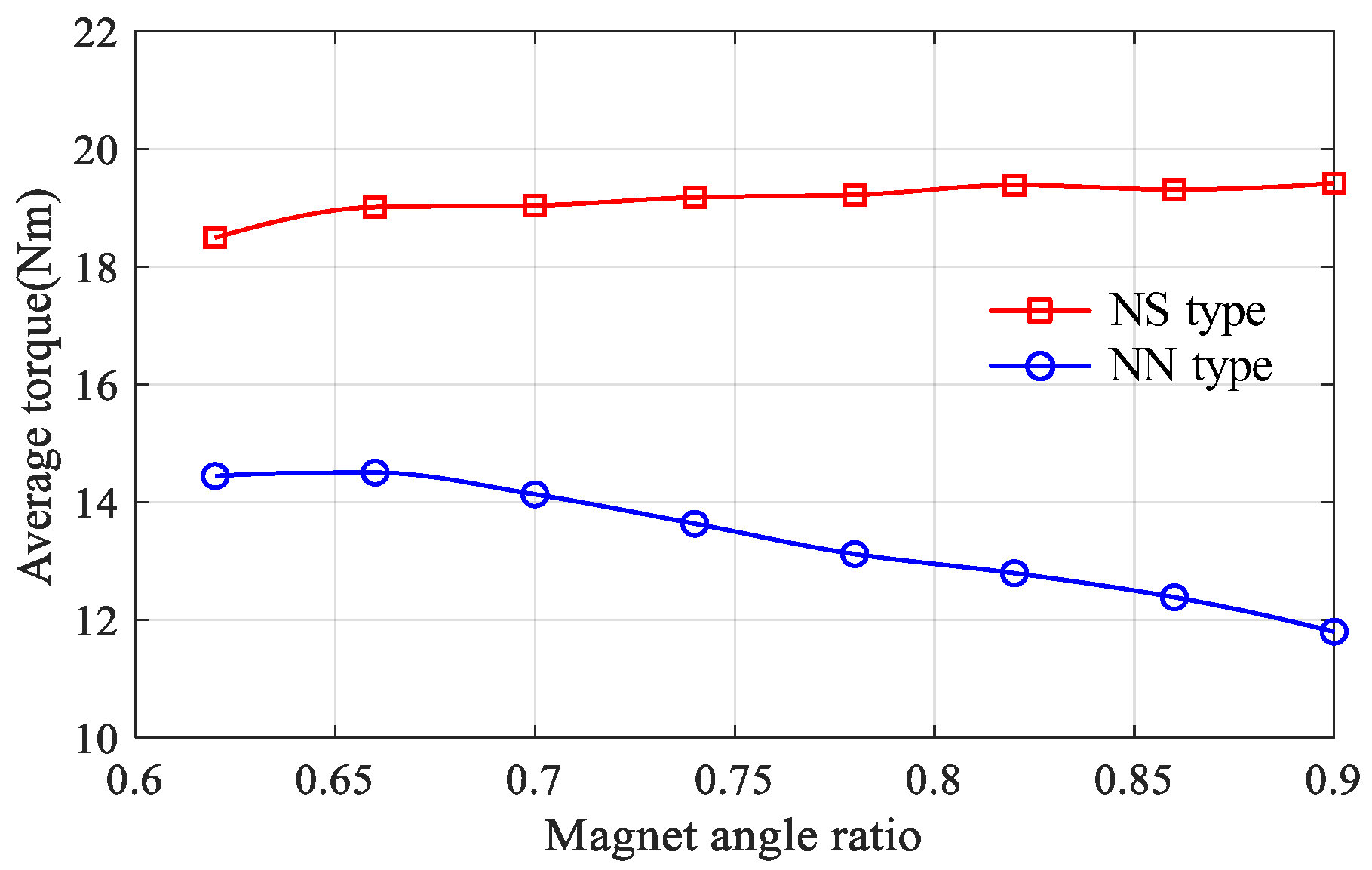

3.1. Influence of Magnet Angle

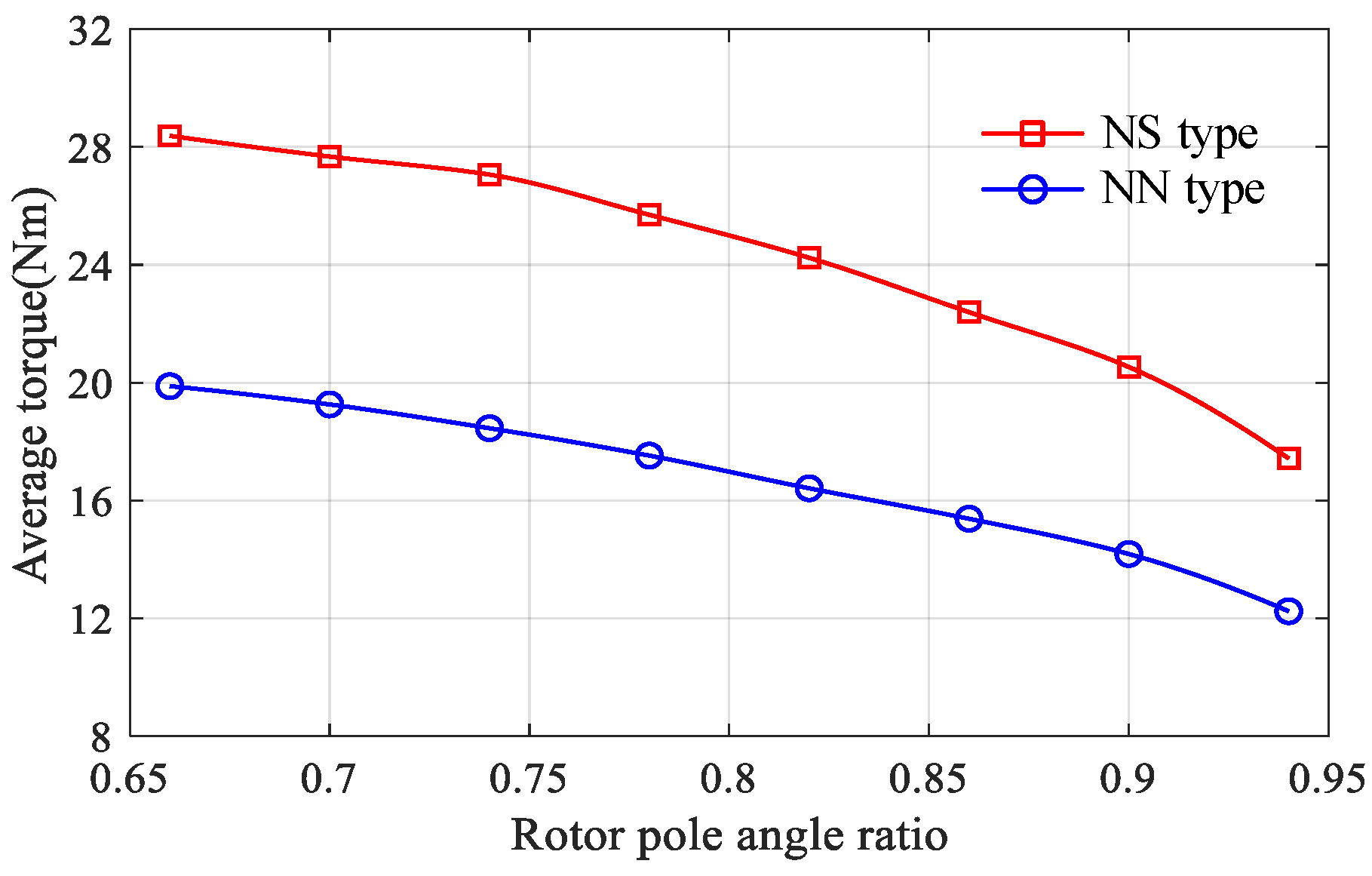

3.2. Influence of Rotor Pole Angle

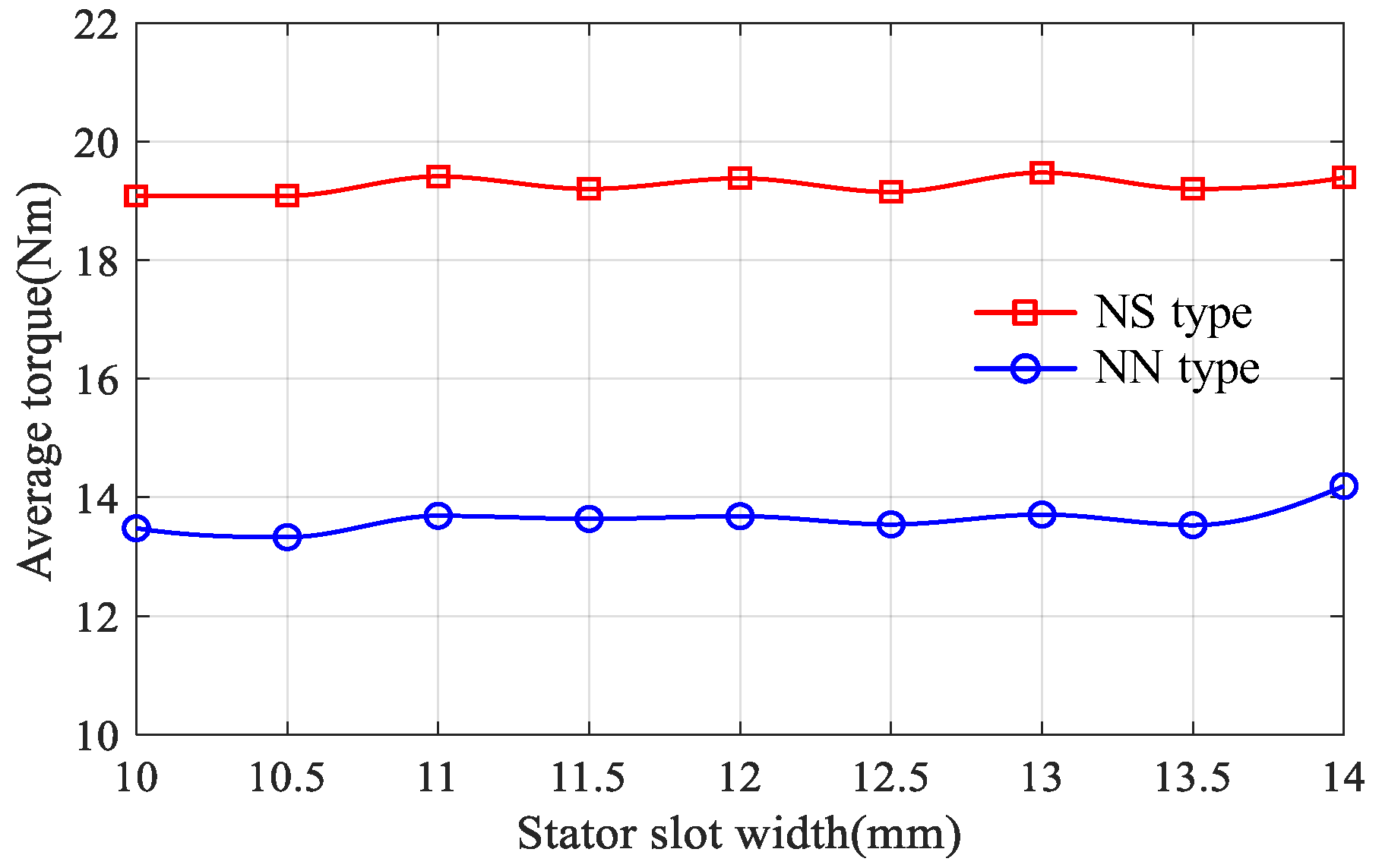

3.3. Influence of Slot Width

3.4. Influence of Slot Depth

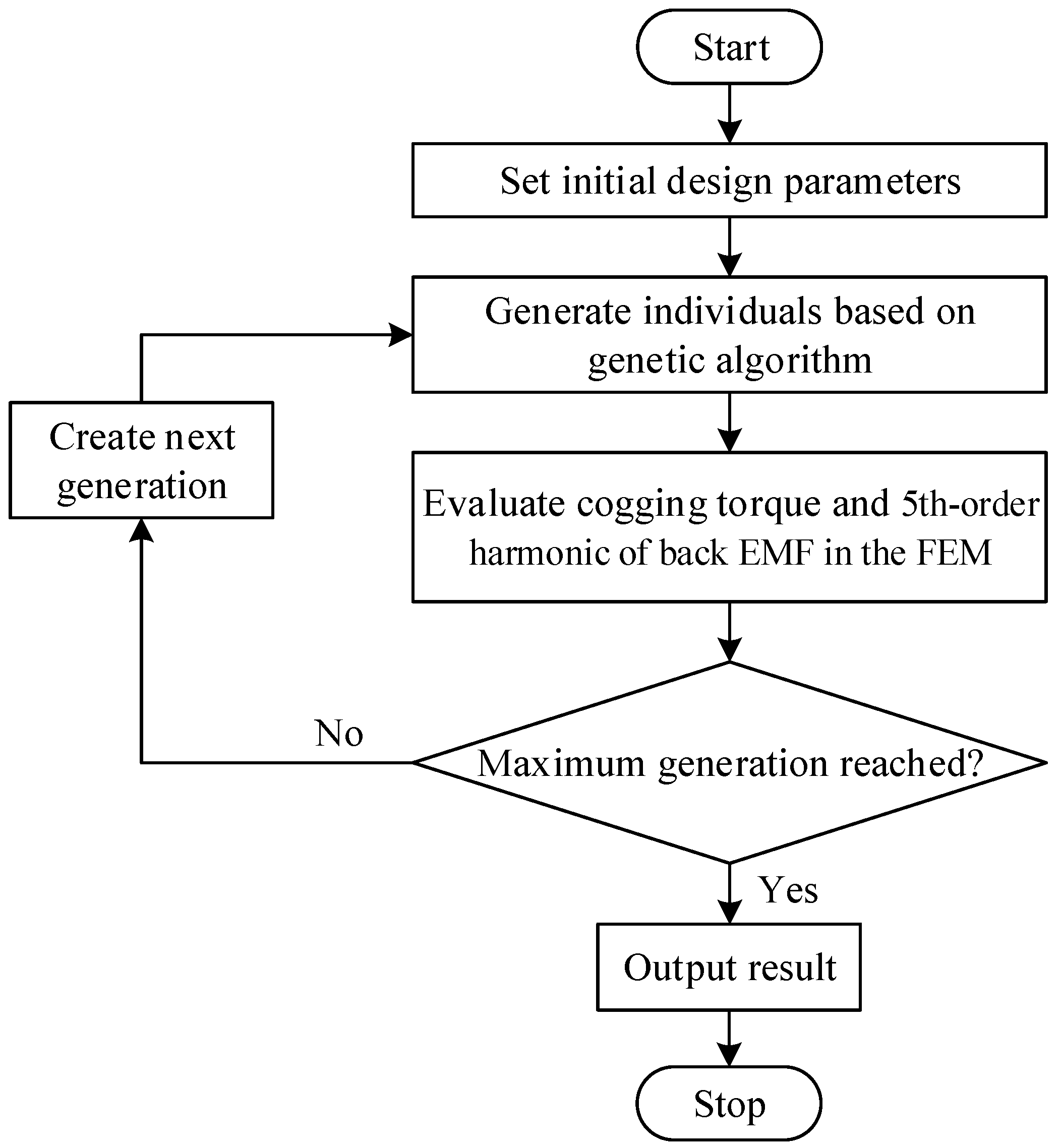

4. Design Optimization

- (1)

- The crossover probability and mutation probability are 0.5 and 0.2, respectively.

- (2)

- The whole optimization process uses 20 individuals for each generation and 15 generations in total to find the optimal machine.

5. Electromagnetic Performance Analysis

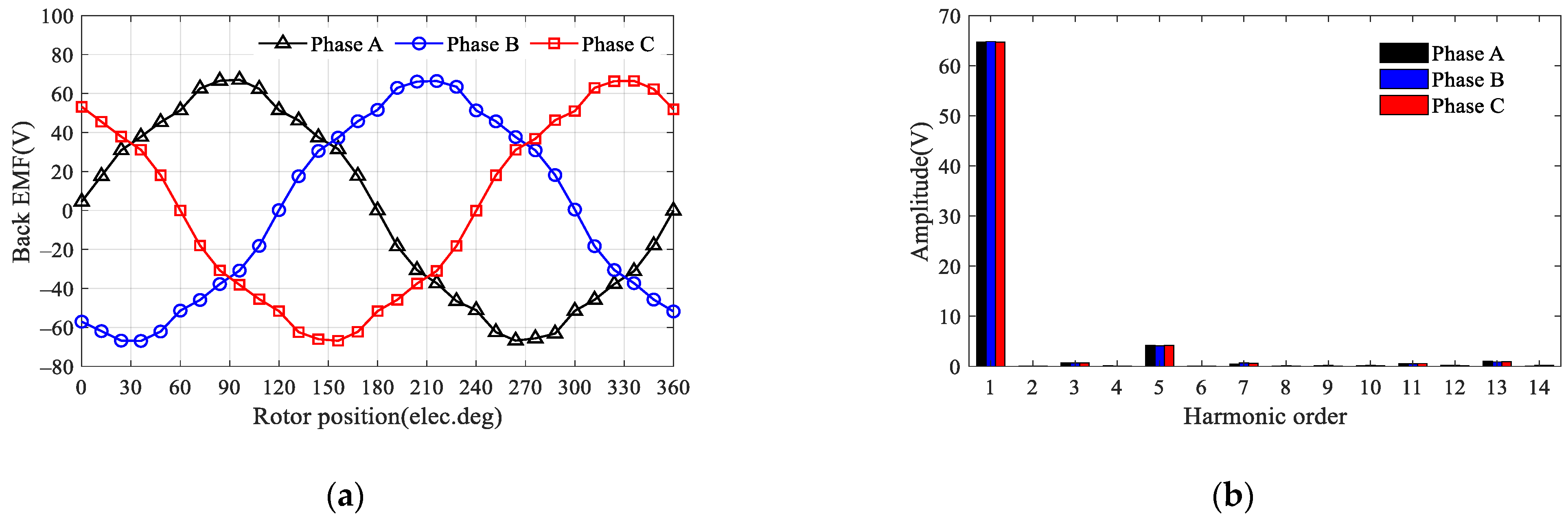

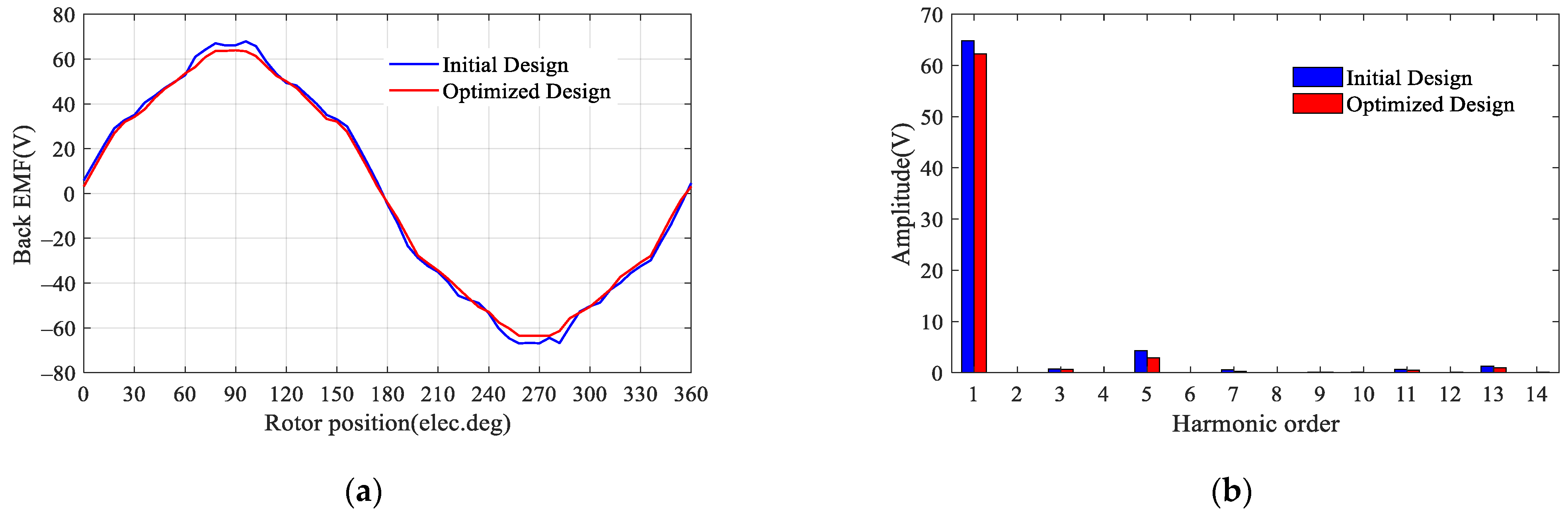

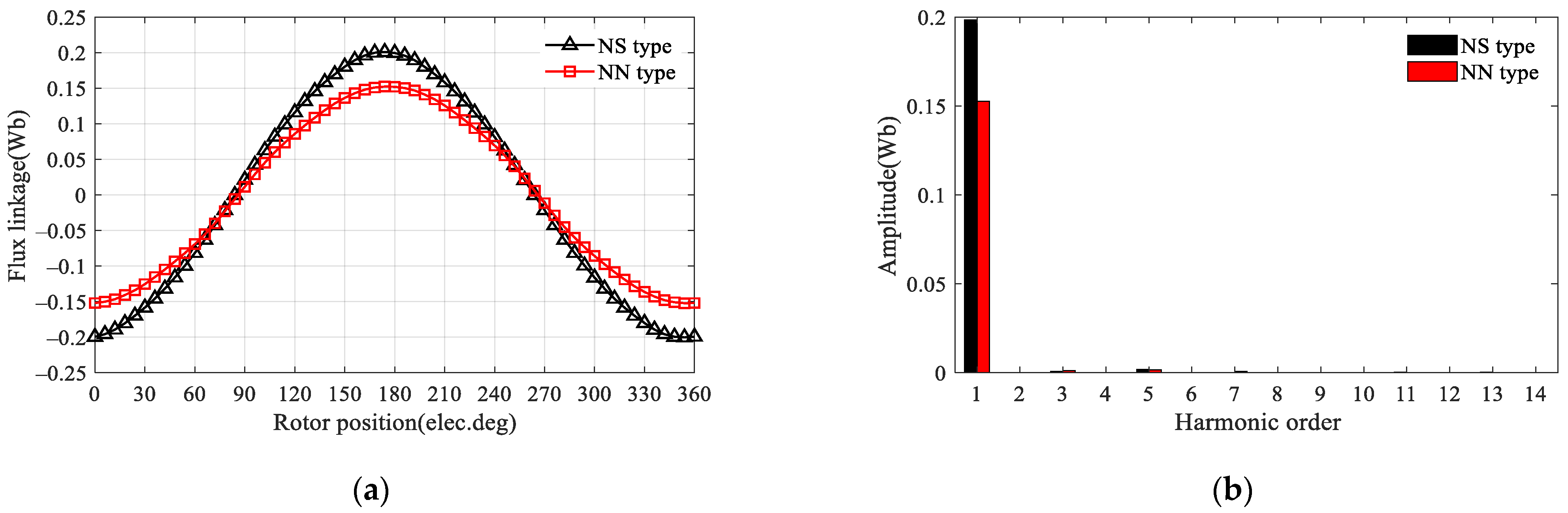

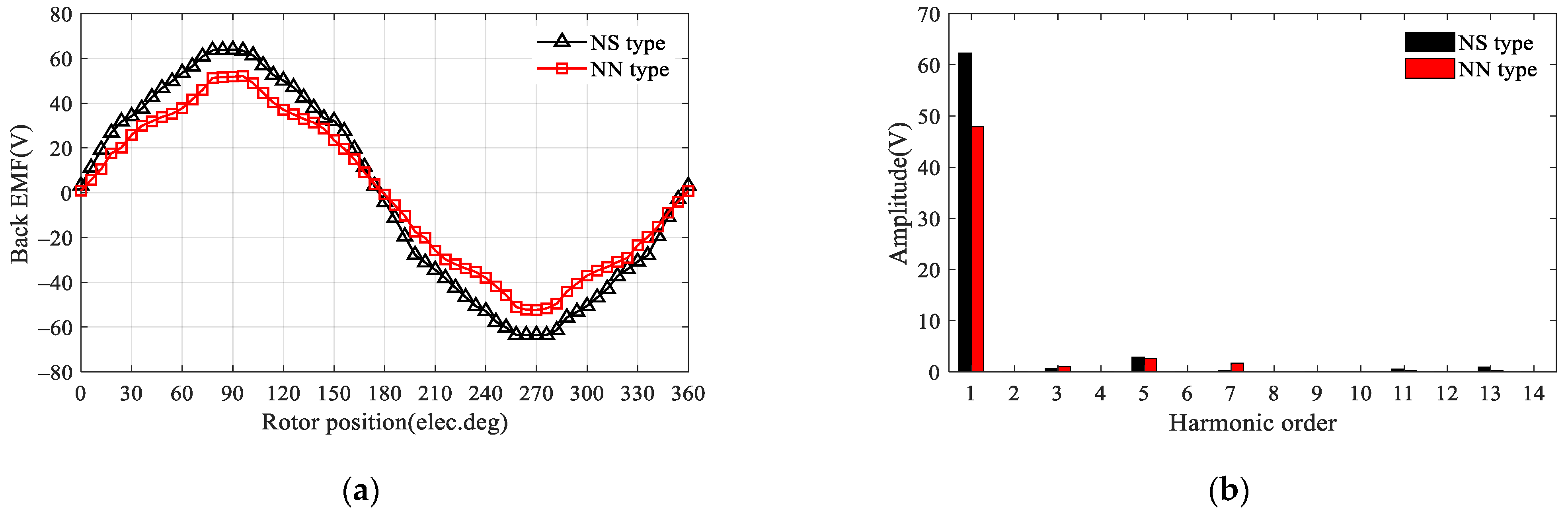

5.1. Open-Circuit Performance

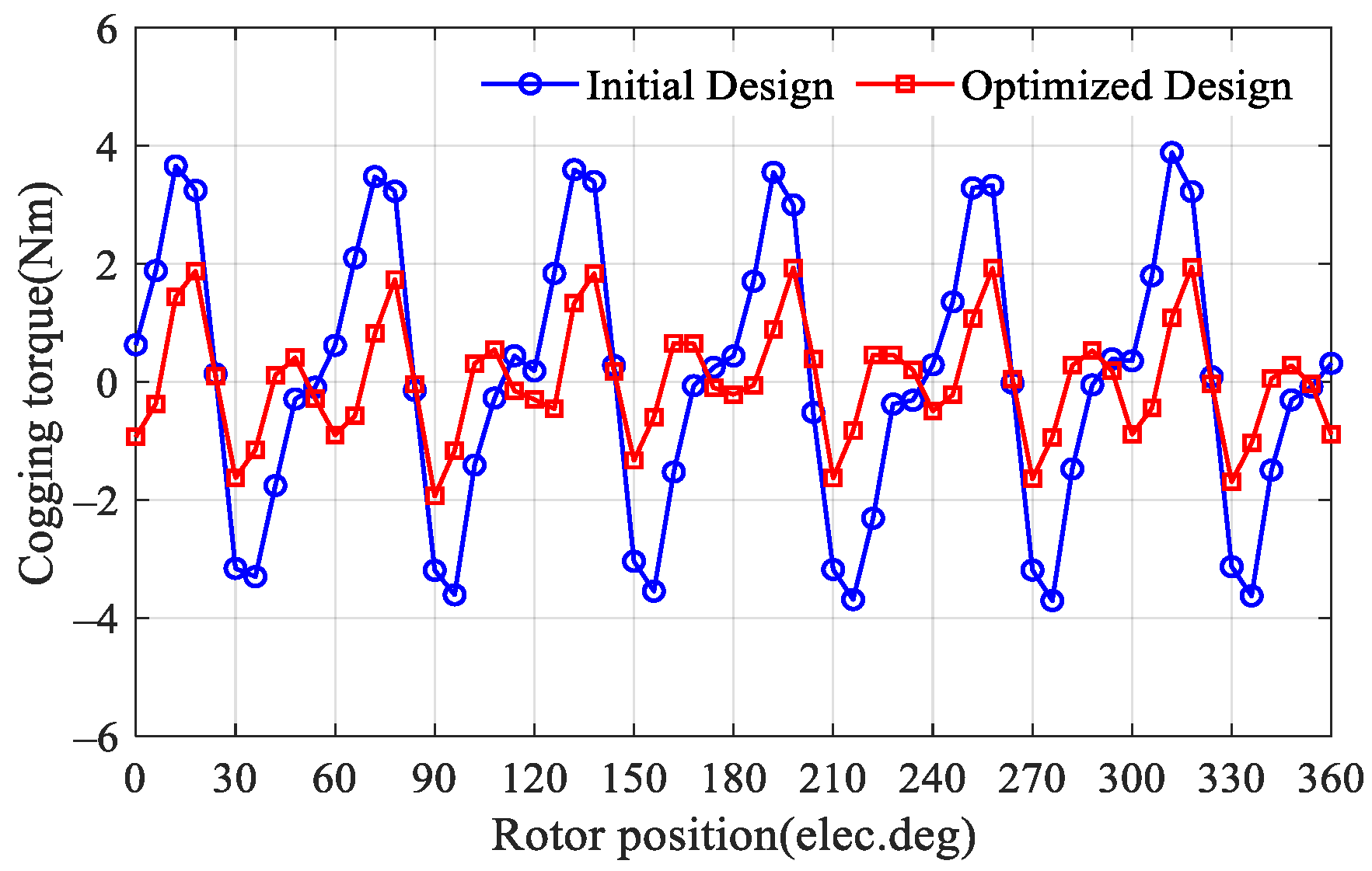

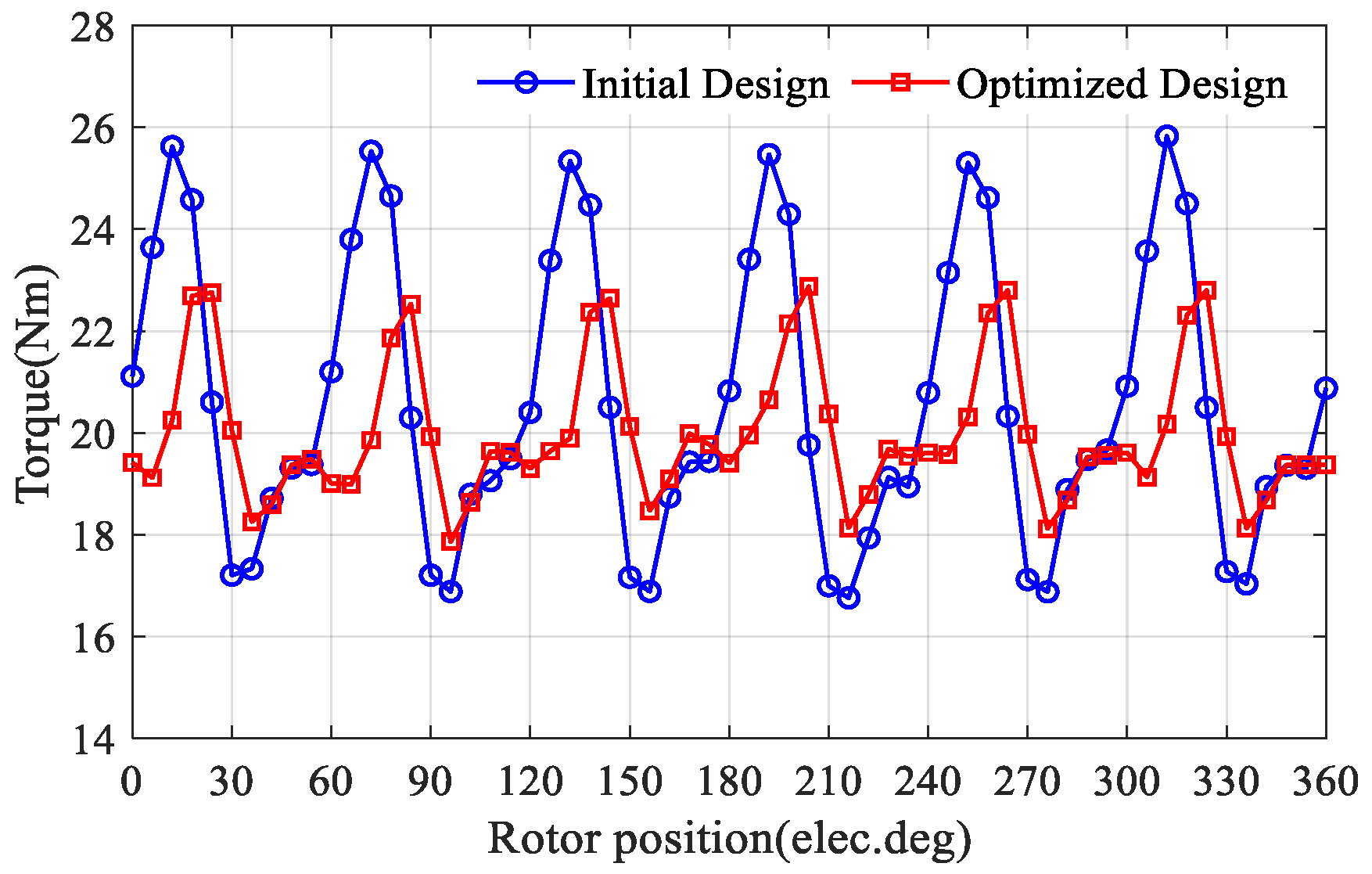

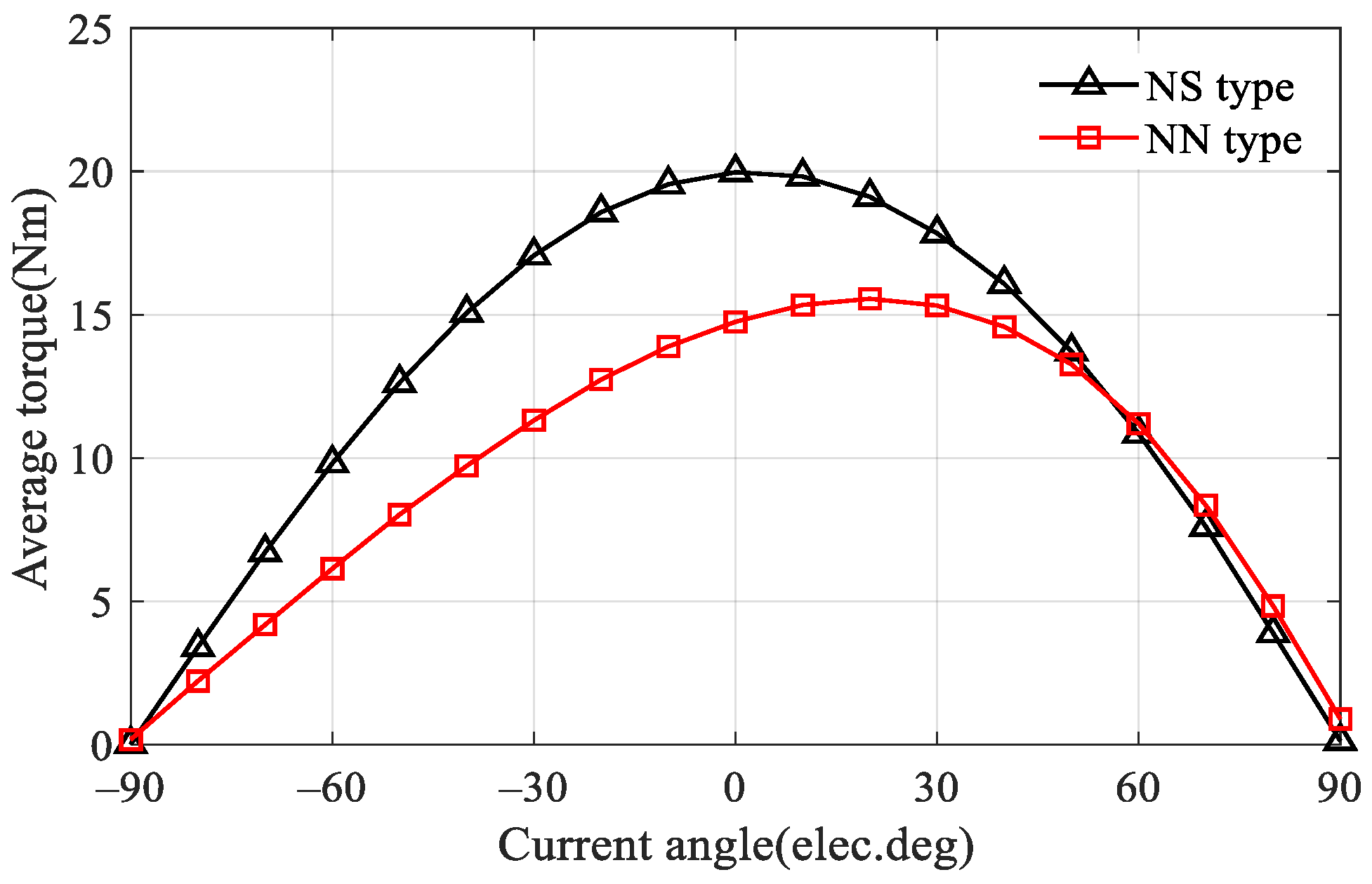

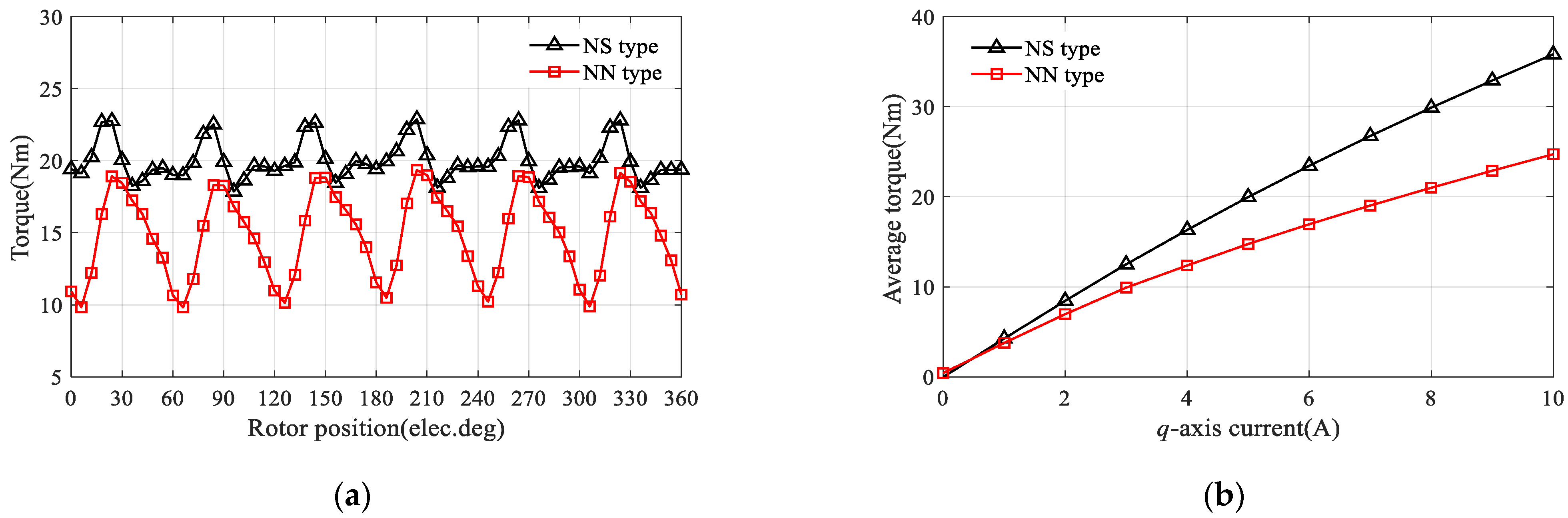

5.2. On-Load Torque Characteristics

6. Conclusions

- (1)

- The prominent salient teeth of the PM stator and the salient rotor presents abundant field harmonics in the air gap of the proposed AF-FMPM machine, which makes the machine output to present stable electromagnetic torque.

- (2)

- The magnet arc angle, rotor pole angle, stator slot width, stator slot depth have significant influence on the proposed machine either the NN type or the NS type.

- (3)

- There are many odd-order harmonic components in the back EMF of the proposed machine, and the THDs of AF-FMPM machine (NS) and AF-FMPM machine (NN) are 4.9% and 6.79%, respectively.

- (4)

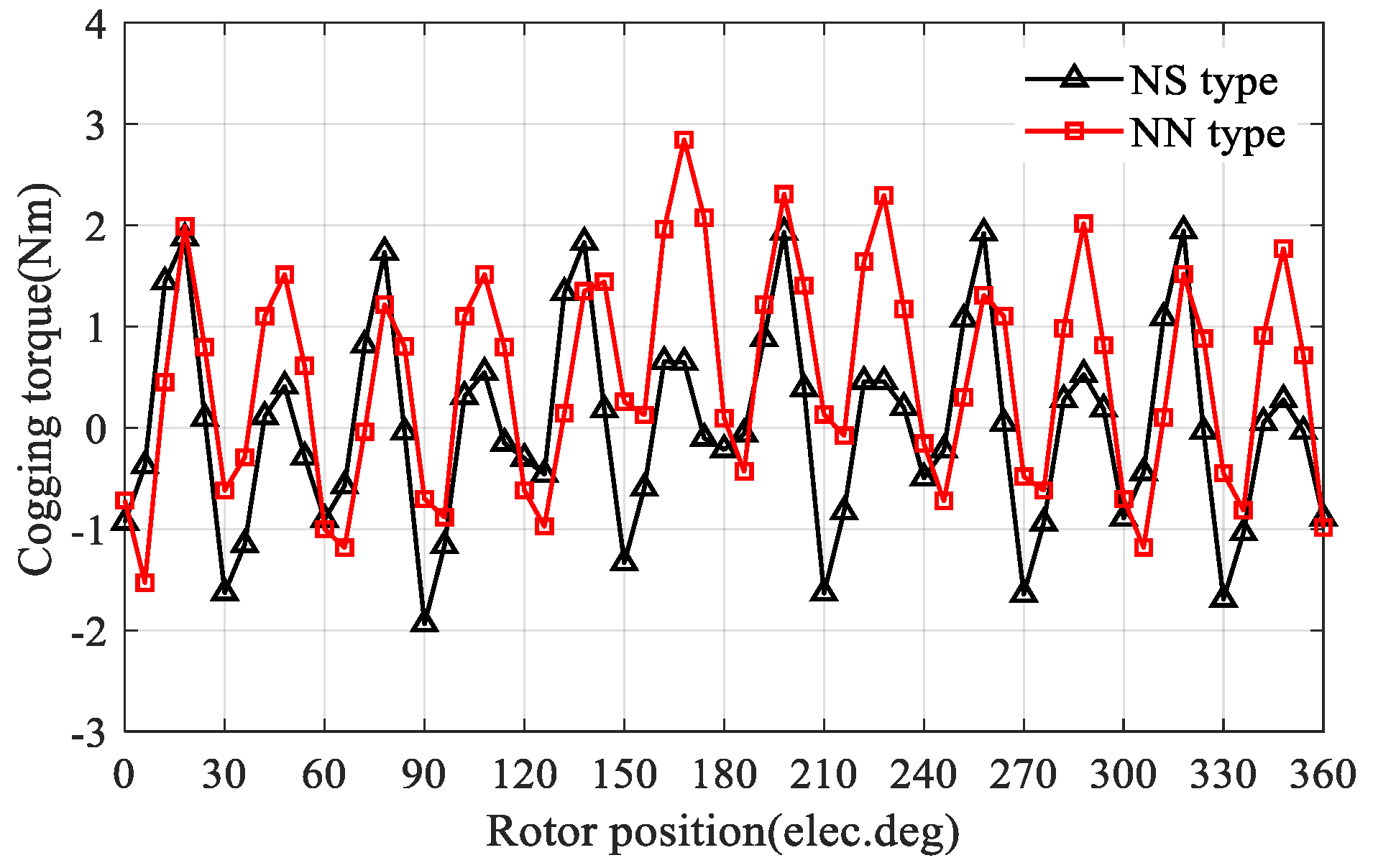

- The peak-to-peak value of the cogging torque is 4.37 N·m, obtained in the AF-FMPM machine (NN), while that of the AF-FMPM machine (NS) is only 3.88 N·m.

- (5)

- The AF-FMPM machine (NS) shows non-salient characteristics, while the AF-FMPM machine (NN) is a salient machine.

- (6)

- The AF-FMPM machine (NS) was analyzed and the results indicated that it can obtain a high torque density of 9.58 kNm/m3, and a torque density of approximately 7.12 kNm/m3 was achieved by the AF-FMPM (NN) machine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gardner, M.; Toliyat, H. Analysis of high gear ratio capabilities for single-stage, series multistage, and compound differential coaxial magnetic gears. IEEE Trans. Energy Convers. 2019, 34, 665–672. [Google Scholar] [CrossRef]

- Shuai, M.; Shuai, M.; Guang, J.; Xiang, Y. Research on dynamic load-sharing characteristics of two-stage asymmetric star gear system. IEEE Access 2019, 7, 126799–126811. [Google Scholar] [CrossRef]

- Prieto, M.; Millán, D. Chromatic monitoring of gear mechanical degradation based on acoustic emission. IEEE Trans. Ind. Electron. 2017, 64, 8707–8717. [Google Scholar] [CrossRef] [Green Version]

- Rasmussen, P.; Andersen, T.; Jorgensen, F.; Nielsen, O. Development of a high-performance magnetic gear. IEEE Trans. Ind. Appl. 2005, 41, 764–770. [Google Scholar] [CrossRef]

- Zhu, X.; Lee, T.; Chan, C.; Xu, L.; Zhao, W. Overview of flux-modulation machines based on flux-modulation principle: Topology, theory, and development prospects. IEEE Trans. Trans. Electrif. 2020, 6, 612–624. [Google Scholar] [CrossRef]

- Wang, Y.; Niu, S.; Fu, W. A novel dual-rotor bidirectional flux-modulation PM generator for stand-alone DC power supply. IEEE Trans. Ind. Electron. 2019, 66, 818–828. [Google Scholar] [CrossRef]

- Zhou, Y.; Qu, R.; Gao, Y.; Shi, C.; Wang, C. Modeling and analyzing a novel dual-flux-modulation consequent-pole linear permanent-magnet machine. IEEE Trans. Magn. 2019, 55, 8203906. [Google Scholar] [CrossRef]

- Liang, Z.; Gao, Y.; Li, D.; Qu, R. Design of a novel dual flux modulation machine with consequent-pole spoke-array permanent magnets in both stator and rotor. CES Trans. Electric. Mach. 2018, 2, 73–81. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, Z.; Yu, L.; Gu, X. Development and analysis of a new hybrid excitation brushless DC generator with flux modulation effect. IEEE Trans. Ind. Electron. 2019, 66, 4189–4198. [Google Scholar] [CrossRef]

- Zhao, W.; Zhu, J.; Ji, J.; Zhu, X. Improvement of power factor in a double-side linear flux-modulation permanent-magnet motor for long stroke applications. IEEE Trans. Ind. Electron. 2018, 66, 3391–3400. [Google Scholar] [CrossRef]

- Jiang, M.; Zhu, X.; Xiang, Z.; Quan, L.; Que, H.; Yu, B. Suppression of torque ripple of a flux-switching permanent magnet motor in perspective of flux-modulation principle. IEEE Trans. Trans. Elect. 2022, 8, 1116–1127. [Google Scholar] [CrossRef]

- Yu, Z.; Gan, C.; Chen, Y.; Qu, R. DC-biased sinusoidal current excited switched reluctance motor drives based on flux modulation principle. IEEE Trans. Power Electron. 2020, 35, 10614–10628. [Google Scholar] [CrossRef]

- Zhu, X.; Zhao, W.; Xu, L. Distribution design of modulator for split-pole flux-modulation permanent-magnet machine. IEEE Trans. Energy Convers. 2021, 36, 1614–1624. [Google Scholar] [CrossRef]

- Cheng, B.; Pan, G.; Mao, Z. Analytical calculation and optimization of the segmented-stator dual-rotor axial flux permanent magnet motors. IEEE Trans. Magn. 2020, 56, 8101709. [Google Scholar]

- Zhang, W.; Liang, X.; Lin, M. Analysis and comparison of axial field flux-switching permanent magnet machines with three different stator cores. IEEE Trans. Appl. Supercond. 2016, 26, 0607806. [Google Scholar] [CrossRef]

- Hao, L.; Lin, M.; Xu, D.; Fu, X.; Zhang, W. Static characteristics of a novel axial field flux-switching permanent magnet motor with three stator structures. IEEE Trans. Magn. 2014, 50, 4002604. [Google Scholar] [CrossRef]

- Mezani, S.; Atallah, K.; Howe, D. A high-performance axial-field magnetic gear. J. Appl. Phys. 2006, 99, 08R303-1–08R303-3. [Google Scholar] [CrossRef]

- Zaytoon, H.; Abdel-Khalik, A.; Massoud, A.; Ahmed, S. An axial magnetic gearbox with an electric power output port. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition—APEC, Fort Worth, TX, USA, 16–20 March 2014. [Google Scholar]

- Khatab, M.; Zhu, Z.; Li, H.; Liu, Y. Comparative study of novel axial flux magnetically geared and conventional axial flux permanent magnet machines. CES Trans. Electric. Mach. 2018, 2, 392–398. [Google Scholar] [CrossRef]

- Zhu, Z.; Khatab, M.; Li, H.; Liu, Y. A novel axial flux magnetically geared machine for power split application. IEEE Trans. Ind. Appl. 2018, 54, 5954–5966. [Google Scholar]

- Tong, C.; Song, Z.; Zheng, P.; Bai, J.; Zhao, Q. Research on electromagnetic performance of an axial magnetic-field-modulated brushless double-rotor machine for hybrid electric vehicles. In Proceedings of the International Conference on Electrical Machines & Systems, Berlin, Germany, 2–5 September 2014. [Google Scholar]

- Lai, J.; Jian, L.; Qu, R.; Zhang, R.; Li, D. A novel axial flux magnetic-field-modulated dual-mechanical-port dual-electrical-port machine for hybrid electric vehicle. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016. [Google Scholar]

- Zhang, R.; Li, J.; Qu, R.; Li, D. A novel triple-rotor axial-flux vernier permanent magnet machine. IEEE Trans. Appl. Supercond. 2016, 26, 0610405. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Qu, R.; Li, D. Analysis and design of triple-rotor axial-flux spoke-array vernier permanent magnet machines. IEEE Trans. Ind. Appl. 2018, 54, 244–253. [Google Scholar]

- Rallabandi, V.; Han, P.; Kesgin, M.; Taran, N.; Ionel, D. Axial-field Vernier-type Flux Modulation Machines for Low-speed Direct-drive Applications. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019. [Google Scholar]

- Wang, S.; Lin, K.; Lin, M.; Kong, Y.; Xu, D.; Li, N.; Wang, P. Comparative study of E- and U-core modular dual-stator axial-field flux-switching permanent magnet motors with different stator/rotor-pole combinations based on flux modulation principle. IEEE Access 2021, 9, 78635–78647. [Google Scholar]

- Shi, Y.; Jian, L.; Wei, J.; Shao, Z.; Li, W.; Chan, C. A new perspective on the operating principle of flux-switching permanent-magnet machines. IEEE Trans. Trans. Electron. 2016, 63, 1425–1437. [Google Scholar]

- Le, W.; Lin, M.; Jia, L.; Ai, J.; Fu, X.; Chen, Z. Multi-Objective Optimization of an Air-Cored Axial Flux Permanent Magnet Synchronous Machine with Segmented PMs based on Support Vector Machine and Genetic Algorithm. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS 2019), Harbin, China, 11–14 August 2019. [Google Scholar]

| Parameter | AF-FMPM Machine (NS) | AF-FMPM Machine (NN) |

|---|---|---|

| Rated speed (rpm) | 300 | 300 |

| Pole-pair number of rotor | 10 | 10 |

| Pole-pair number of armature field | 4 | 4 |

| Pole-pair number of PM field | 6 | 6 |

| Outer diameter (mm) | 210 | 210 |

| Inter diameter (mm) | 110 | 110 |

| Axial length (mm) | 104 | 104 |

| Air-gap length (mm) | 0.5 | 0.5 |

| Parameter | Symbol | Definition |

|---|---|---|

| Magnet angle ratio | spm_ratio | |

| Rotor pole angle ratio | rratio | |

| Stator slot width | sw | |

| Stator slot depth | sd | hs |

| Stator tooth distance | st | ds |

| Parameter | Range |

|---|---|

| Magnet angle ratio | 0.6~0.9 |

| Rotor pole angle ratio | 0.7~0.95 |

| Stator slot width (mm) | 10~14 |

| Stator slot depth (mm) | 14.5~16 |

| Stator tooth distance (mm) | 6~8 |

| Parameter | Symbol | Initial Value | Optimized Value |

|---|---|---|---|

| Magnet angle ratio | spm_ratio | 0.8 | 0.759 |

| Rotor pole angle ratio | r_ratio | 0.9 | 0.915 |

| Stator slot width (mm) | sw | 12 | 11.33 |

| Stator slot depth (mm) | sd | 15 | 14.8 |

| Stator tooth distance (mm) | st | 7 | 6.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yang, G.; Rao, F. Analysis and Design of Novel Axial Field Flux-Modulation Permanent Magnet Machines for Direct Drive Application. Machines 2022, 10, 495. https://doi.org/10.3390/machines10070495

Li J, Yang G, Rao F. Analysis and Design of Novel Axial Field Flux-Modulation Permanent Magnet Machines for Direct Drive Application. Machines. 2022; 10(7):495. https://doi.org/10.3390/machines10070495

Chicago/Turabian StyleLi, Jie, Gongde Yang, and Fei Rao. 2022. "Analysis and Design of Novel Axial Field Flux-Modulation Permanent Magnet Machines for Direct Drive Application" Machines 10, no. 7: 495. https://doi.org/10.3390/machines10070495

APA StyleLi, J., Yang, G., & Rao, F. (2022). Analysis and Design of Novel Axial Field Flux-Modulation Permanent Magnet Machines for Direct Drive Application. Machines, 10(7), 495. https://doi.org/10.3390/machines10070495