Experimental Characterization of A-AFiM, an Adaptable Assistive Device for Finger Motions

Abstract

1. Introduction

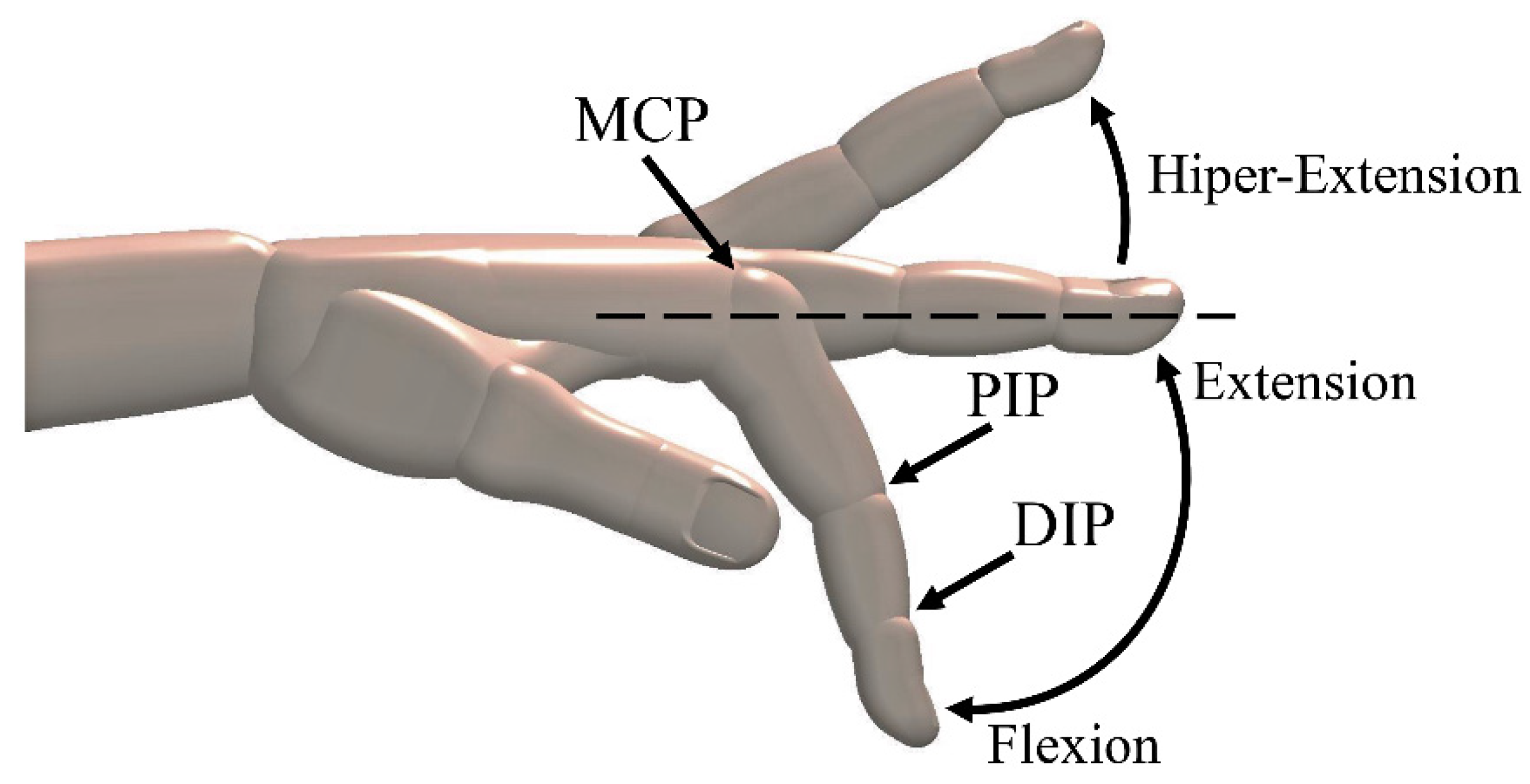

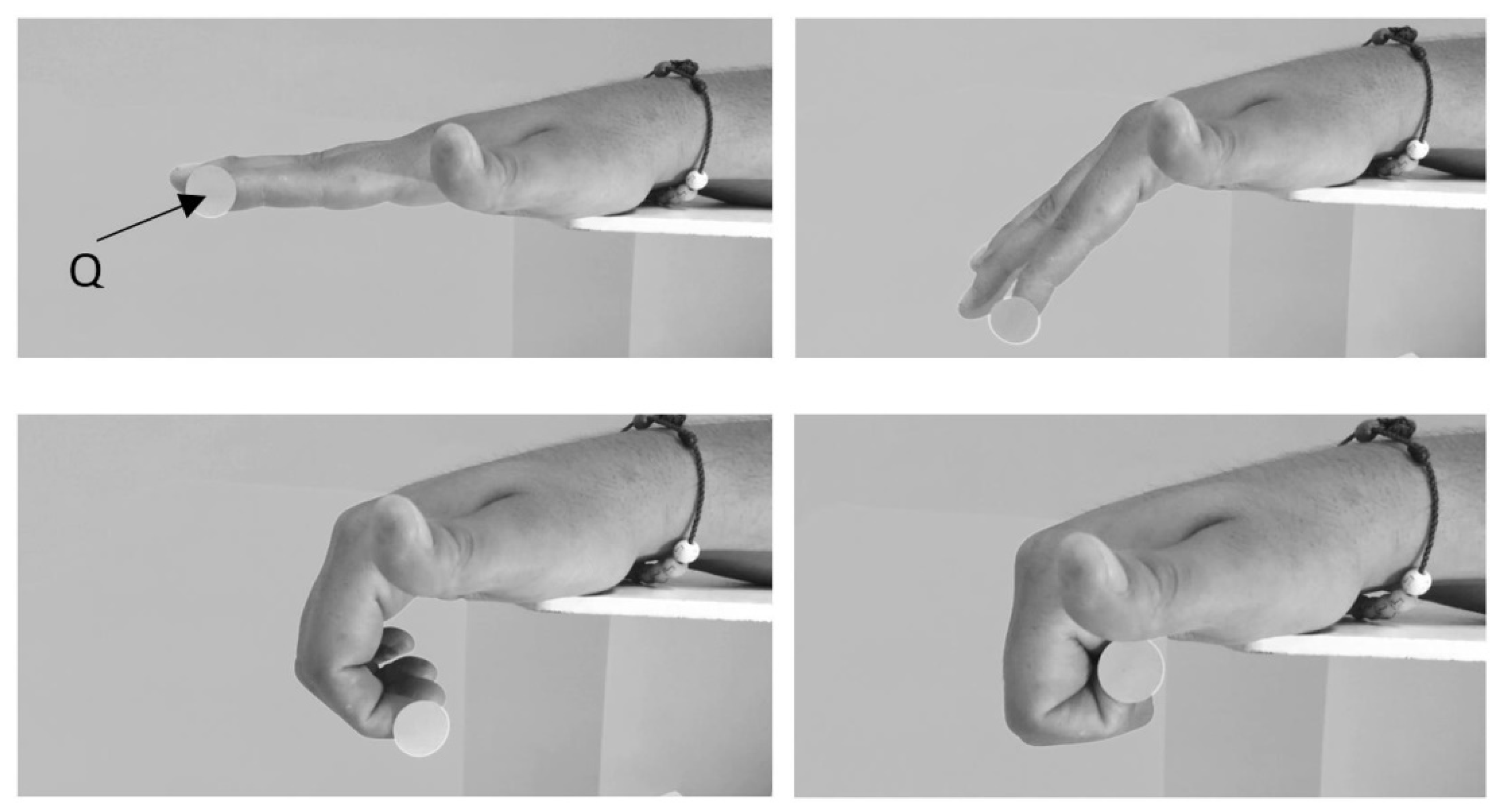

2. Requirements for a Low-Cost Device

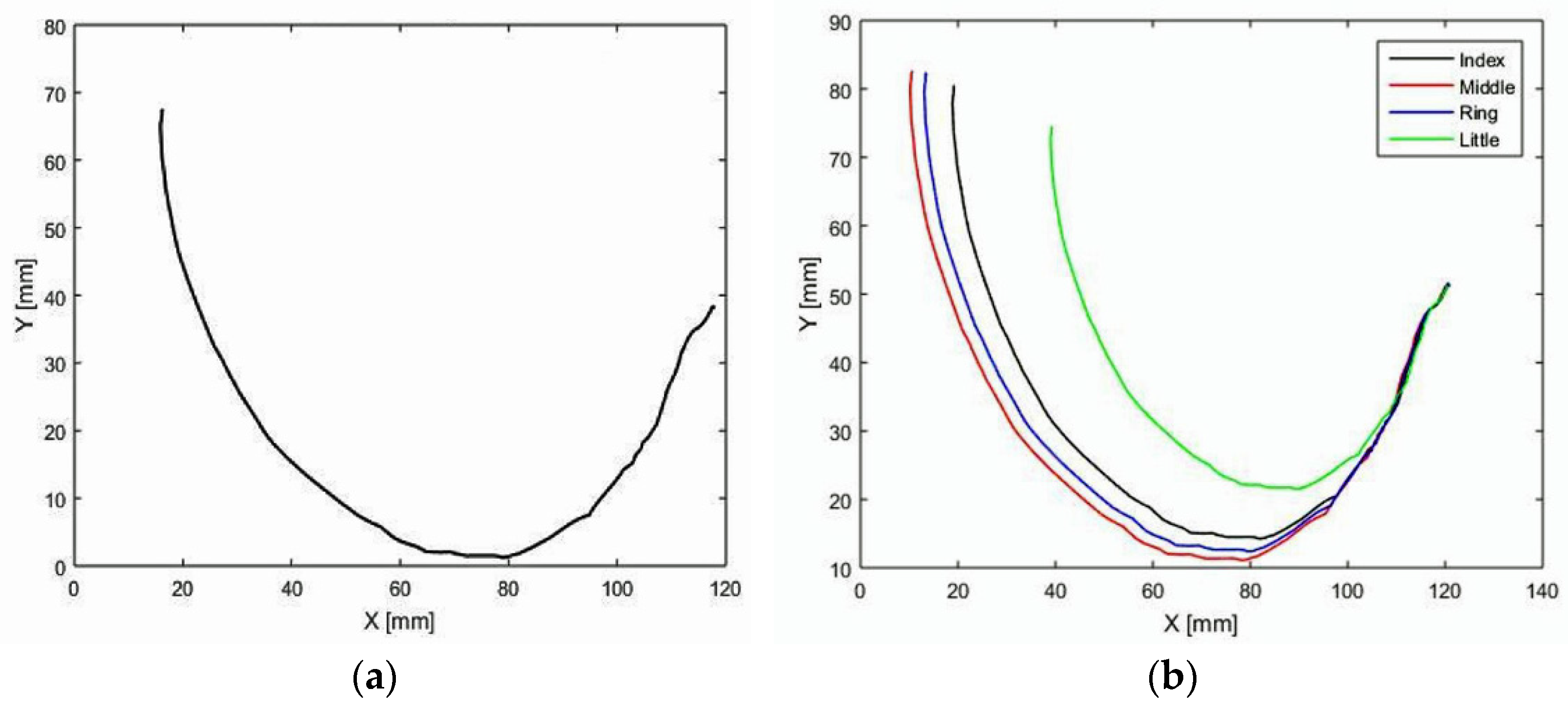

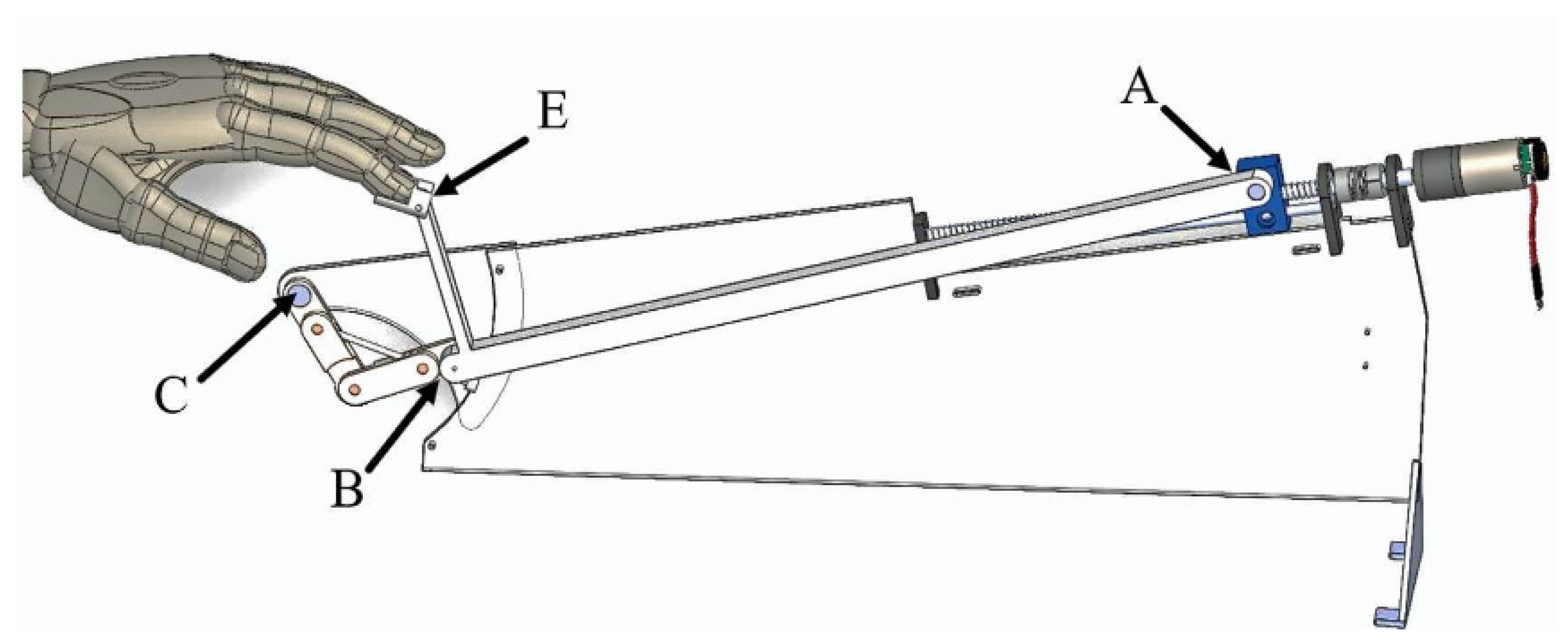

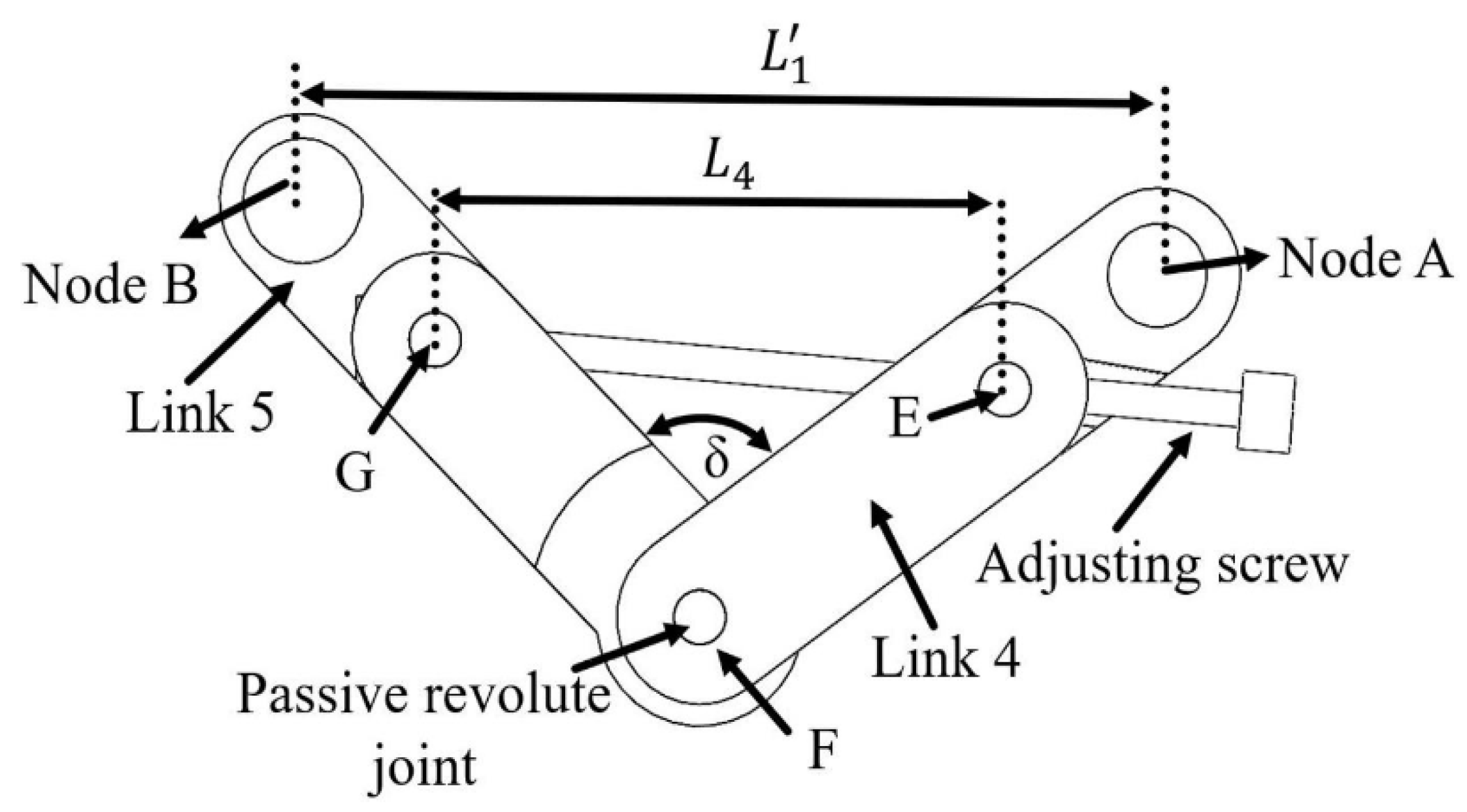

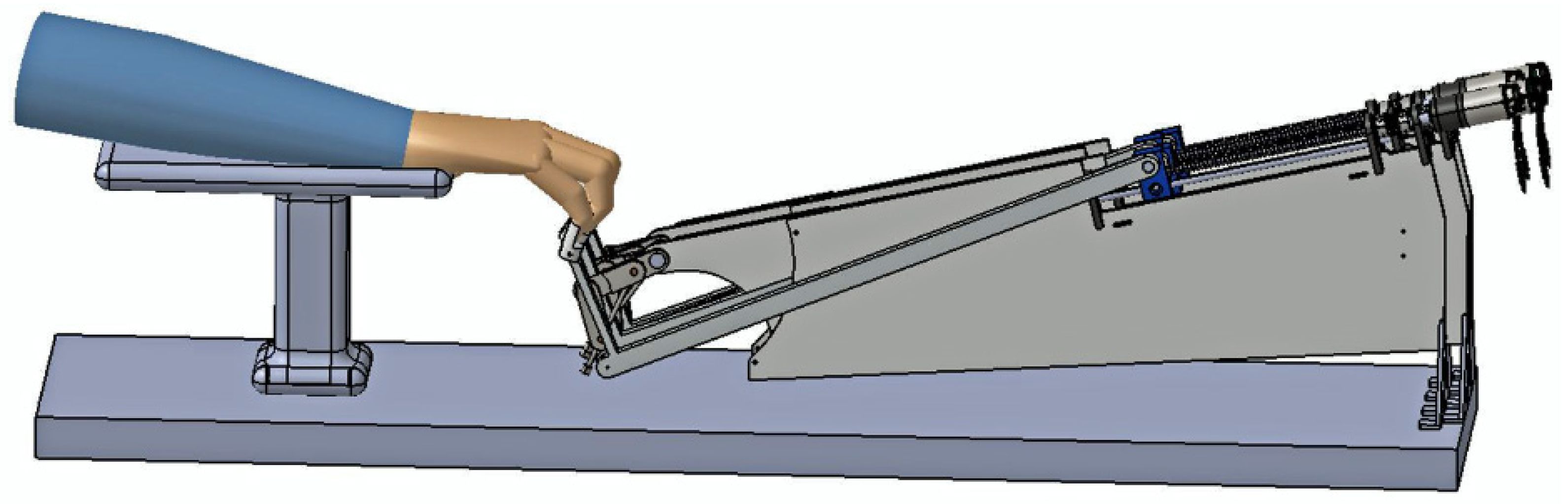

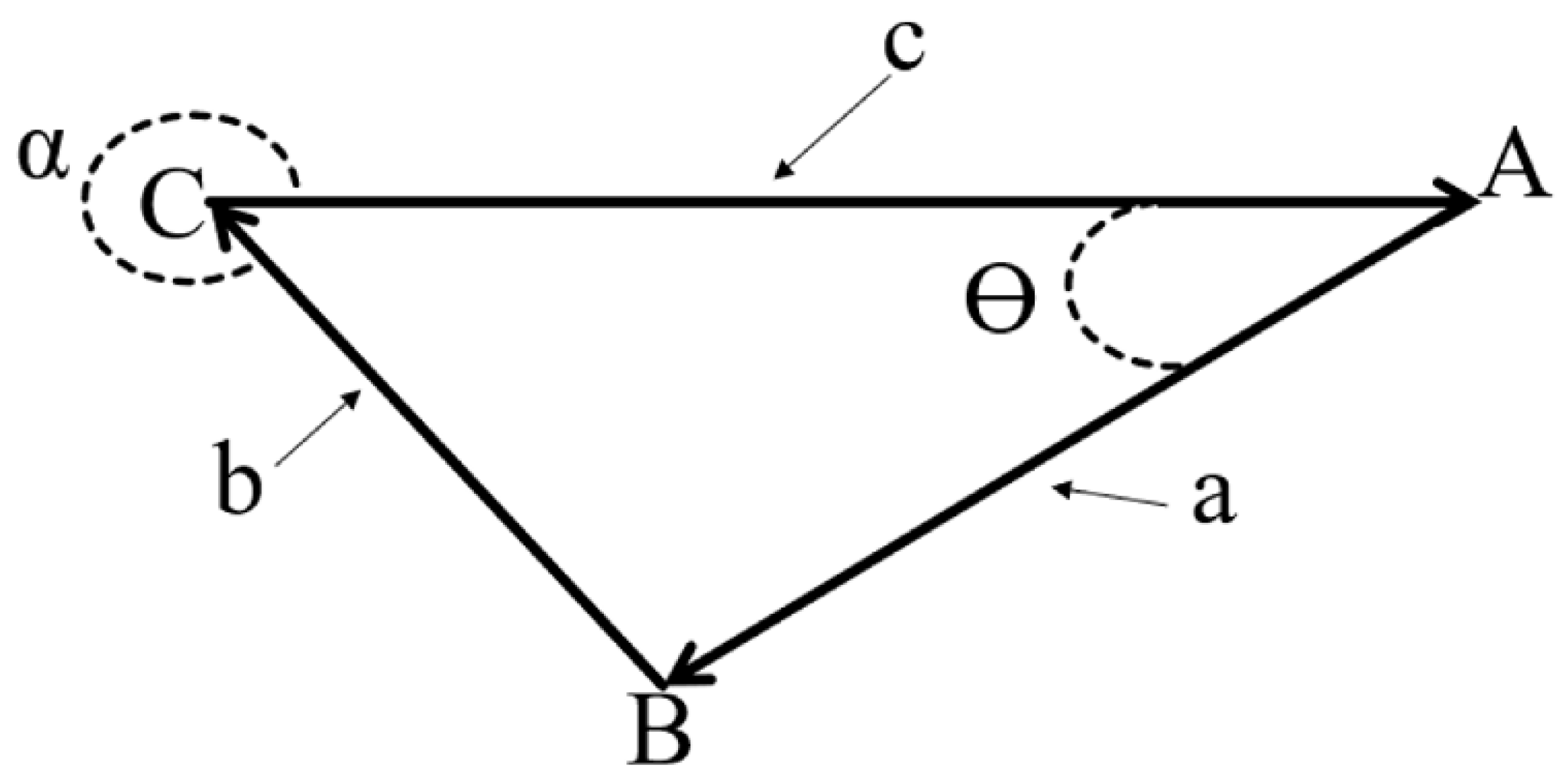

3. Conceptual Design

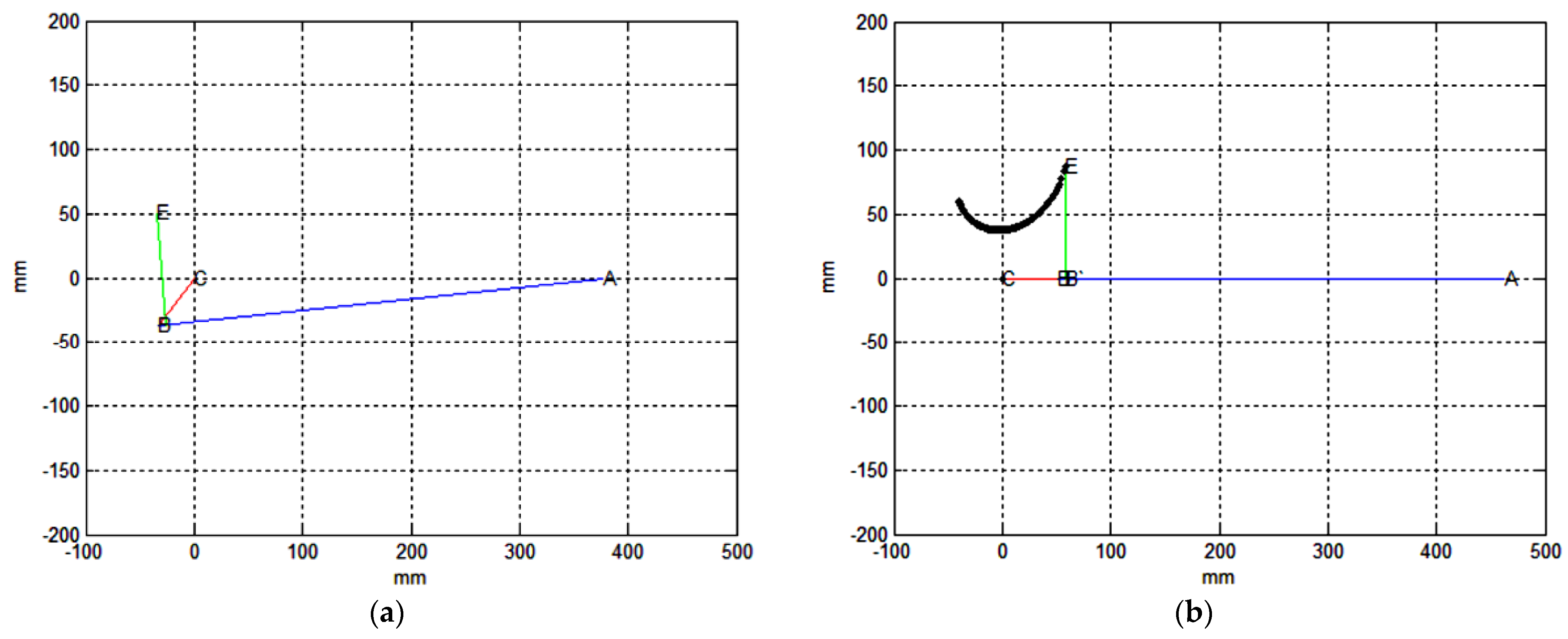

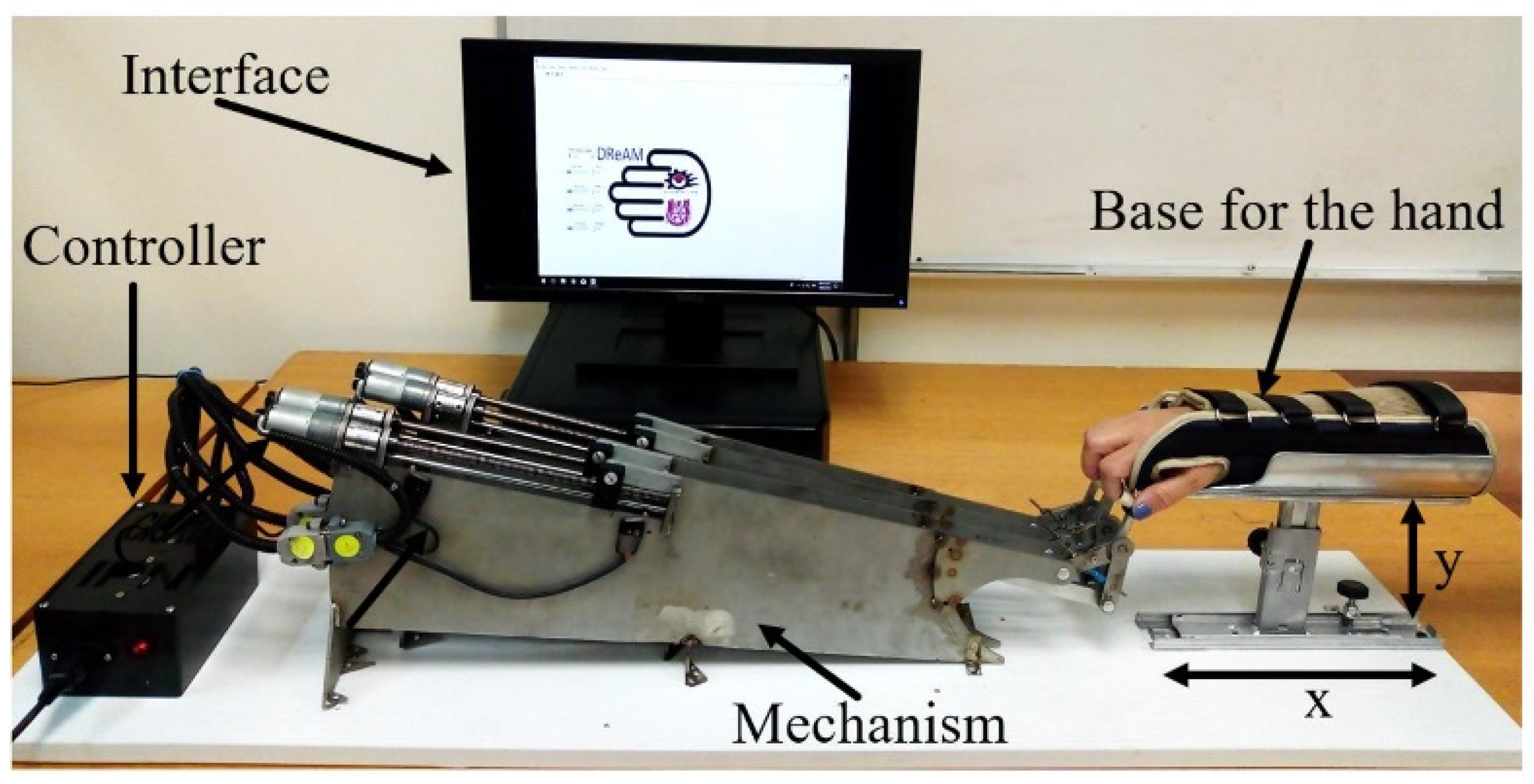

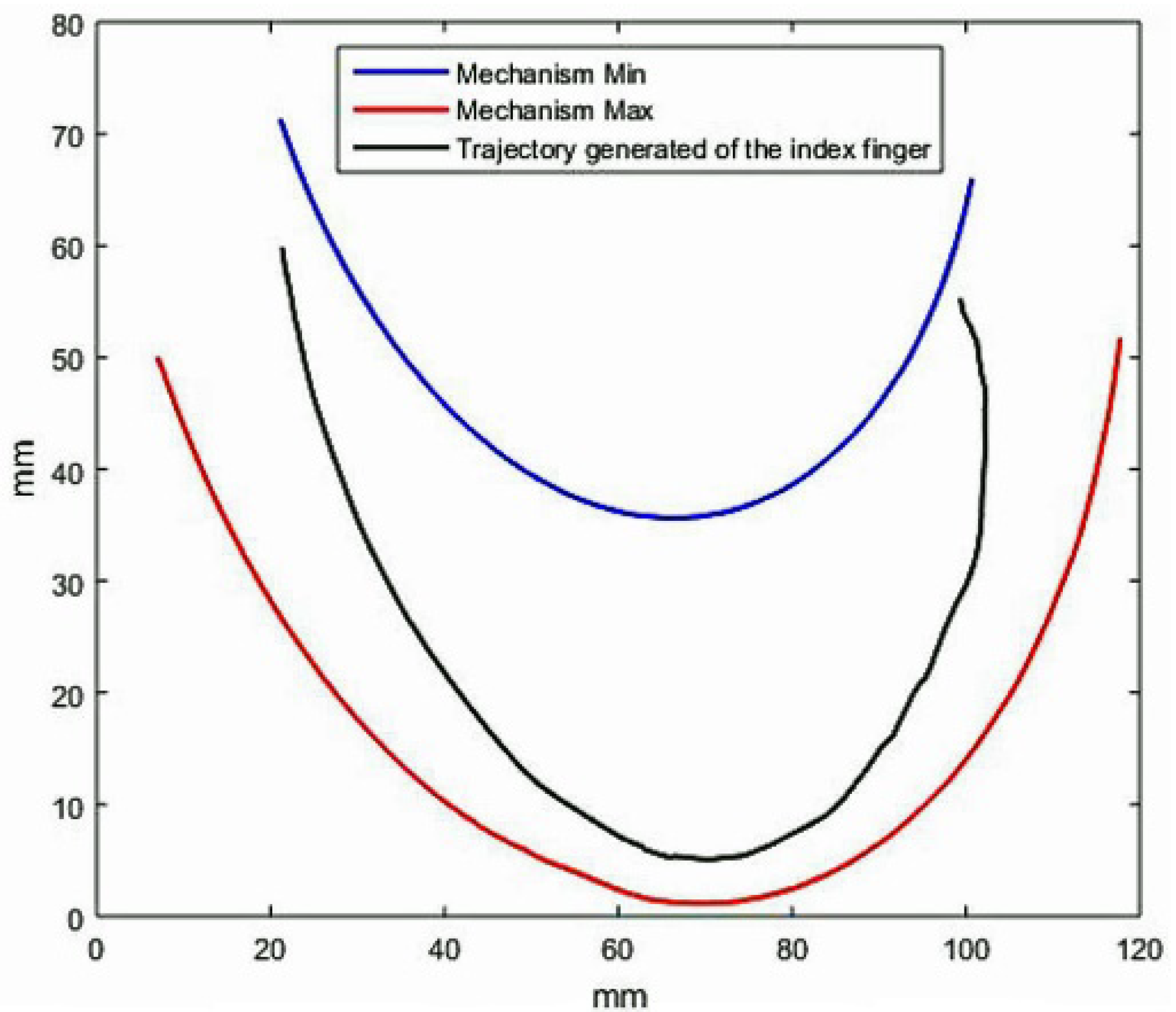

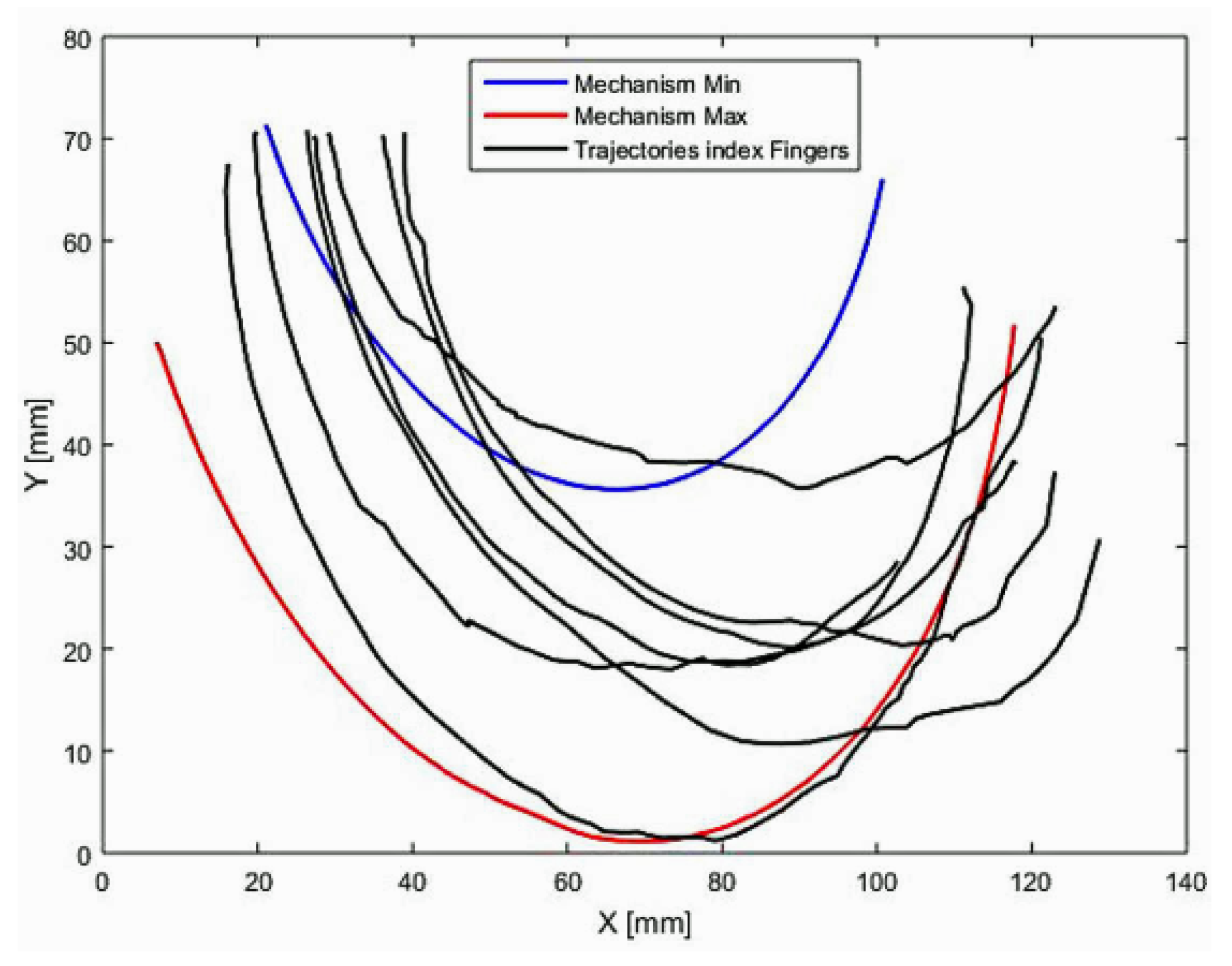

4. Simulations and Prototype Development

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reinkensmeyer, D.J.; Boninger, M.L. Technologies and combination therapies for enhancing movement training for people with a disability. J. Neuroeng. Rehabil. 2012, 9, 17. [Google Scholar] [CrossRef]

- Kolk, S.; Fluit, R.; Luijten, J.; Heesterbeek, P.J.C.; Geurts, A.C.H.; Verdonschot, N.; Weerdesteyn, V. Gait and lower limb muscle strength in women after triple innominate osteotomy. BMC Musculoskelet. Disord. 2015, 16, 68. [Google Scholar] [CrossRef][Green Version]

- Iqbal, J.; Khan, H.; Tsagarakis, N.G.; Caldwell, D.G. A novel exoskeleton robotic system for hand rehabilitation—Conceptualization to prototyping. Biocybern. Biomed. Eng. 2014, 34, 79–89. [Google Scholar] [CrossRef]

- Yue, Z.; Zhang, X.; Wang, J. Hand Rehabilitation Robotics on Poststroke Motor Recovery. Behav. Neurol. 2017, 2017, 3908135. [Google Scholar] [CrossRef]

- Bos, R.A.; Haarman, C.J.; Stortelder, T.; Nizamis, K.; Herder, J.L.; Stienen, A.H.; Plettenburg, D.H. A structured overview of trends and technologies used in dynamic hand orthoses. J. Neuroeng. Rehabil. 2016, 13, 62. [Google Scholar] [CrossRef]

- Iqbal, J.; Tsagarakis, N.G.; Caldwell, D.G. A multi-DOF robotic exoskeleton interface for hand motion assistance. In Proceedings of the 2011 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 1575–1578. [Google Scholar] [CrossRef]

- Brokaw, E.B.; Black, I.; Holley, R.J.; Lum, P.S. Hand Spring Operated Movement Enhancer (HandSOME): A Portable, Passive Hand Exoskeleton for Stroke Rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2011, 19, 391–399. [Google Scholar] [CrossRef]

- Mendis, S. Stroke Disability and Rehabilitation of Stroke: World Health Organization Perspective. Int. J. Stroke 2012, 8, 3–4. [Google Scholar] [CrossRef]

- Olsson, P.; Johansson, S.; Nysjö, F.; Carlbom, I. Rendering Stiffness with a Prototype Haptic Glove Actuated by an Integrated Piezoelectric Motor. In Haptics: Perception, Devices, Mobility, and Communication, Proceedings of the International Conference on Human Haptic Sensing and Touch Enabled Computer Applications, EuroHaptics 2012, Tampere, Finland, 12–15 June 2012; Isokoski, P., Springare, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7282, pp. 361–372. [Google Scholar] [CrossRef]

- Mubin, O.; Alnajjar, F.; Jishtu, N.; Alsinglawi, B.; Al Mahmud, A. Exoskeletons with Virtual Reality, Augmented Reality, and Gamification for Stroke Patients’ Rehabilitation: Systematic Review. JMIR Rehabil. Assist. Technol. 2019, 6, e12010. [Google Scholar] [CrossRef]

- Platz, T.; Lotze, M. Arm Ability Training (AAT) Promotes Dexterity Recovery After a Stroke—A Review of Its Design, Clinical Effectiveness, and the Neurobiology of the Actions. Front. Neurol. 2018, 9, e01082. [Google Scholar] [CrossRef]

- Germanotta, M.; The FDG Robotic Rehabilitation Group; Gower, V.; Papadopoulou, D.; Cruciani, A.; Pecchioli, C.; Mosca, R.; Speranza, G.; Falsini, C.; Cecchi, F.; et al. Reliability, validity and discriminant ability of a robotic device for finger training in patients with subacute stroke. J. Neuroeng. Rehabil. 2020, 17, 1. [Google Scholar] [CrossRef]

- Su, Y.; Wu, K.; Lin, C.H.; Yu, Y.; Lan, C. Design of a Lightweight Forearm Exoskeleton for Fine-Motion Rehabilitation. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; pp. 438–443. [Google Scholar] [CrossRef]

- Attal, A.; Dutta, A. Design of a variable stiffness index finger exoskeleton. Robotica 2021, 40, 1151–1167. [Google Scholar] [CrossRef]

- Li, M.; He, B.; Liang, Z.; Zhao, C.-G.; Chen, J.; Zhuo, Y.; Xu, G.; Xie, J.; Althoefer, K. An Attention-Controlled Hand Exoskeleton for the Rehabilitation of Finger Extension and Flexion Using a Rigid-Soft Combined Mechanism. Front. Neurorobot. 2019, 13, 34. [Google Scholar] [CrossRef] [PubMed]

- Carbone, G.; Ceccarelli, M.; Capalbo, C.E.; Caroleo, G.; Morales-Cruz, C. Numerical and experimental performance estimation for a ExoFing—2 DOFs finger exoskeleton. Robotica 2021, 1–13. [Google Scholar] [CrossRef]

- Dickmann, T.; Wilhelm, N.J.; Glowalla, C.; Haddadin, S.; van der Smagt, P.; Burgkart, R. An Adaptive Mechatronic Exoskeleton for Force-Controlled Finger Rehabilitation. Front. Robot. AI 2021, 8, e716451. [Google Scholar] [CrossRef]

- Sun, N.; Li, G.; Cheng, L. Design and Validation of a Self-Aligning Index Finger Exoskeleton for Post-Stroke Rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2021, 29, 1513–1523. [Google Scholar] [CrossRef]

- Li, H.; Cheng, L.; Sun, N.; Cao, R. Design and Control of an Underactuated Finger Exoskeleton for Assisting Activities of Daily Living. IEEE/ASME Trans. Mechatron. 2021, 1–11. [Google Scholar] [CrossRef]

- Ellis, B.; Bruton, A.; Goddard, J.R. Joint angle measurement: A comparative study of the reliability of goniometry and wire tracing for the hand. Clin. Rehabil. 1997, 11, 314–320. [Google Scholar] [CrossRef]

- Taheri, H.; Rowe, J.B.; Gardner, D.; Chan, V.; Reinkensmeyer, D.J.; Wolbrecht, E.T. Robot-assisted Guitar Hero for finger rehabilitation after stroke. In Proceedings of the 2012 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Diego, CA, USA, 28 August–1 September 2012; pp. 3911–3917. [Google Scholar] [CrossRef]

- Morales-Cruz, C.; Capalbo, C.E.; Caroleo, G.; Ceccarelli, M.; Carbone, G. Numerical and Experimental Validation of ExoFing, a Finger Exoskeleton. In New Trends in Mechanism and Machine Science, Proceedings of the European Conference on Mechanism Science, EuCoMeS 2020, Cluj-Napoca, Romania, 7–10 September 2020; Pisla, D., Corves, B., Vaida, C., Eds.; Springer: Cham, Switzerland, 2020; Volume 87, pp. 115–122. [Google Scholar] [CrossRef]

- Vaida, C.; Plitea, N.; Carbone, G.; Birlescu, I.; Ulinici, I.; Pisla, A.; Pisla, D. Innovative development of a spherical parallel robot for upper limb rehabilitation. Int. J. Mech. Robot. Syst. 2018, 4, 256. [Google Scholar] [CrossRef]

- Cafolla, D.; Carbone, G. A Study of Feasibility of a Human Finger Exoskeleton. In Service Orientation in Holonic and Multi-Agent Manufacturing and Robotics; Springer: Cham, Switzerland, 2014; pp. 355–364. [Google Scholar] [CrossRef]

- Carbone, G.; Gerding, E.C.; Corves, B.; Cafolla, D.; Russo, M.; Ceccarelli, M. Design of a Two-DOFs Driving Mechanism for a Motion-Assisted Finger Exoskeleton. Appl. Sci. 2020, 10, 2619. [Google Scholar] [CrossRef]

- Gerding, E.-C.; Carbone, G.; Cafolla, D.; Russo, M.; Ceccarelli, M.; Rink, S.; Corves, B. Design and Testing of a Finger Exoskeleton Prototype. In Advances in Italian Mechanism Science, Proceedings of the IFToMM ITALY 2018, Cassino, Italy, 29–30 November 2018; Carbone, G., Gasparetto, A., Eds.; Springer: Cham, Switzerland, 2018; Volume 68, pp. 342–349. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Morales-Cruz, C. A prototype characterization of ExoFinger, a finger exoskeleton. Int. J. Adv. Robot. Syst. 2021, 18, 1–8. [Google Scholar] [CrossRef]

- Chen, W.-D.; Zhang, J.-H.; Zhang, J.-C.; Li, Y.; Qi, Y.; Su, Y.; Wu, B.; Zhang, S.-M.; Dai, J.-H.; Zheng, X.-X.; et al. A P300 based online brain-computer interface system for virtual hand control. J. Zhejiang Univ. Sci. C 2010, 11, 587–597. [Google Scholar] [CrossRef]

- Love, L.J.; Lind, L.r.F.; Jansen, J.F. Mesofluidic actuation for articulated finger and hand prosthetics. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, St. Louis, MO, USA, 10–15 October 2009; pp. 2586–2591. [Google Scholar] [CrossRef]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; Dezonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017, 18, 529. [Google Scholar] [CrossRef] [PubMed]

- Heikkila, J.; Silven, O. A four-step camera calibration procedure with implicit image correction. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Juan, PR, USA, 17–19 June 1997; pp. 1106–1112. [Google Scholar] [CrossRef]

- Rodríguez-León, J.F.; Chaparro-Rico, B.D.M.; Russo, M.; Cafolla, D. An Autotuning Cable-Driven Device for Home Rehabilitation. J. Health Eng. 2021, 2021, 6680762. [Google Scholar] [CrossRef] [PubMed]

- Norton, R.L. Design of Machinery: An Introduction to the Synthesis and Analysis of Mechanisms and Machines, 5th ed.; Mcgraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Aguilar-Pereyra, J.F.; Castillo-Castaneda, E. Design of a Reconfigurable Robotic System for Flexoextension Fitted to Hand Fingers Size. Appl. Bionics Biomech. 2016, 2016, 1712831. [Google Scholar] [CrossRef]

- Aguilar, J. Robotic System for Assistance in Rehabilitation of Hand Movements. Ph.D. Thesis, Instituto Politécnico Nacional, Centro de Investigación en Ciencia Aplicada y Tecnología Avanzada Unidad Querétaro, Querétaro, Mexico, 2014. [Google Scholar]

- Ávila Chaurand, R.; Prado León, L.R.; Gonzalez Muñoz, E.L. Dimensiones Antropométricas Población Latinoamericana, 2nd ed.; Universidad de Guadalajara: Guadalajara, Mexico, 2007. [Google Scholar]

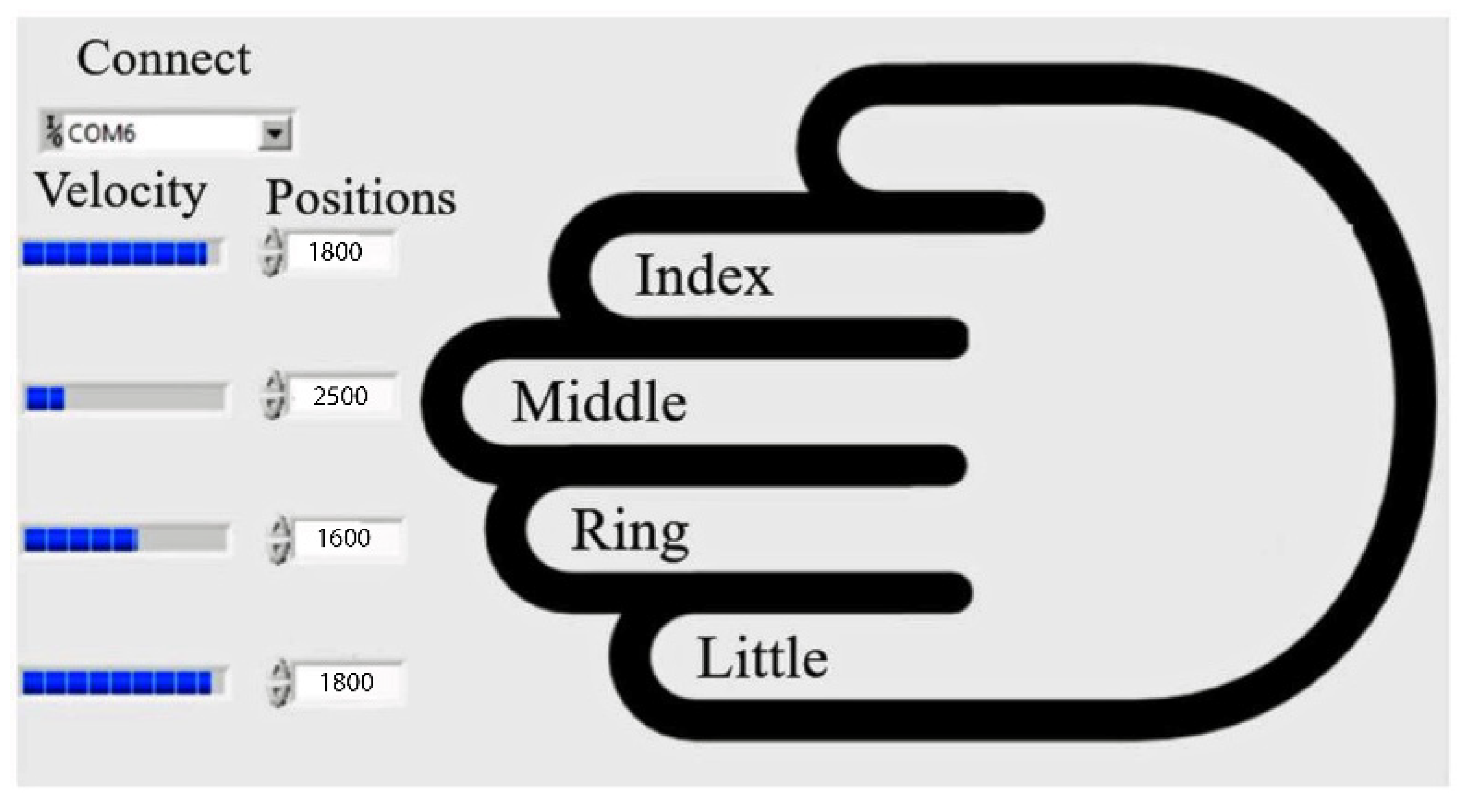

- Zapatero-Gutiérrez, A.; Castañeda, E.C. Control design for a fingers rehabilitation device. In Proceedings of the 2017 IEEE 3rd Colombian Conference on Automatic Control (CCAC), Cartagena, Colombia, 18–20 October 2017; pp. 1–6. [Google Scholar] [CrossRef]

- RoboClaw 2 × 7A Motor Controller. Available online: https://www.pololu.com/product/3284 (accessed on 22 October 2021).

- Rodríguez, J.; Aguilar, J.; Castillo, E. Analysis of the trajectory Flexion and Extension for the Index Finger Based on Image Processing for a Rehabilitation Mechanism. In Innovations in Mechatronics, 1st ed.; Asociación Mexicana de Mecatrónica A.C.: Querétaro, Mexico, 2017; pp. 265–276. ISBN 978-607-9394-11-0. Available online: http://www.mecamex.net/Libros/2017-Libro-InnovacionesEnMecatronica.pdf (accessed on 22 December 2021).

| Fingers | Fingers Joint Movements (Degree) | |||||

|---|---|---|---|---|---|---|

| MCP | PIP | DIP | ||||

| Flexion | Extension | Flexion | Extension | Flexion | Extension | |

| Pinkie | 90 | −32 | 106.5 | 3.5 | 74 | 5.5 |

| Ring | 89 | −26.5 | 107.5 | 6 | 72.5 | 5.5 |

| Middle | 90 | −26 | 106.5 | 6 | 75 | 5.5 |

| Index | 86.5 | −26 | 105.5 | 6 | 71.5 | 5.5 |

| N° Person | Gender [Male/Female] | Ages [Years] | Index Finger Phalanges [mm] | Weight [Kg] | ||

|---|---|---|---|---|---|---|

| Distal | Middle | Proximal | ||||

| 1 | Male | 28 | 25 | 32 | 55 | 85 |

| 2 | Female | 21 | 22 | 30 | 52 | 55 |

| 3 | Male | 26 | 24 | 31 | 51 | 80 |

| 4 | Female | 22 | 21 | 30 | 51 | 60 |

| 5 | Female | 48 | 24 | 31 | 53 | 72 |

| 6 | Male | 62 | 25 | 31 | 54 | 89 |

| 7 | Male | 32 | 23 | 31 | 54 | 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-León, J.F.; Castillo-Castañeda, E.; Aguilar-Pereyra, J.F.; Carbone, G. Experimental Characterization of A-AFiM, an Adaptable Assistive Device for Finger Motions. Machines 2022, 10, 280. https://doi.org/10.3390/machines10040280

Rodríguez-León JF, Castillo-Castañeda E, Aguilar-Pereyra JF, Carbone G. Experimental Characterization of A-AFiM, an Adaptable Assistive Device for Finger Motions. Machines. 2022; 10(4):280. https://doi.org/10.3390/machines10040280

Chicago/Turabian StyleRodríguez-León, Jhon Freddy, Eduardo Castillo-Castañeda, José Felipe Aguilar-Pereyra, and Giuseppe Carbone. 2022. "Experimental Characterization of A-AFiM, an Adaptable Assistive Device for Finger Motions" Machines 10, no. 4: 280. https://doi.org/10.3390/machines10040280

APA StyleRodríguez-León, J. F., Castillo-Castañeda, E., Aguilar-Pereyra, J. F., & Carbone, G. (2022). Experimental Characterization of A-AFiM, an Adaptable Assistive Device for Finger Motions. Machines, 10(4), 280. https://doi.org/10.3390/machines10040280