1. Introduction

With the development of economic globalization, the shipping industry plays an essential role in transport, and almost 90% of merchant ships are driven by marine diesel engines [

1]. The advantages of high efficiency, high power density and reliability allow the marine diesel engines to occupy a dominant position in propulsion power.

In terms of the stringent Tier III regulations and EEDI (Energy Efficiency Design Index), the fuel economy and NOx emissions of marine diesel engines have to be further improved. Apart from that, the radiated noise problem in marine diesel engines, especially combustion noise (CN), is also becoming more and more serious when it moves to high-speed and heavy-load regions. Due to the trade-off relationships among the BSFC, NOx and CN, it is of great importance to balance the BSFC, NOx and CN simultaneously for marine diesel engines, which is also a difficult task.

Variable Valve Timing (VVT) is an efficient approach to optimize the gas exchange process in the engine, which can improve engine performance and pollution emission. Sabaruddin et al. [

2] investigated the optimization of the engine by VVT, and found that VVT achieves fewer emissions, better fuel economy, yet higher torque under any working condition. Bar-Kohany and Sher [

3] reported that the BSFC decreases by 13% and maximum power increases by 6% with the application of VVT for an unthrottled spark ignition engine. Additionally, the inlet and exhaust valves timings were optimized by Menzel et al. [

4] for obtaining maximum thermal and volumetric efficiency. Apart from VVT, the injection strategy changes the combustion phase and ignition delay, which has a direct influence on the fuel and air premixed prior to ignition. It is well-known that the position of combustion phase is crucial for BSFC improvement [

5], and the intensity of premixed combustion is expected to affect NOx emission and CN [

6]. By combining the Miller cycle with a proper injection strategy, NOx and BSFC could be reduced simultaneously in marine engine experiments [

7]. However, the large Miller cycle application increased the ignition delay and premixed combustion magnitude, which increased the CN and peak pressure dramatically, and affected the health of the engine. Considering the complex trade-off relationships among NOx, CN and BSFC due to the sensitive influences of IT and VVT, the traditional sensitivity tests are difficult to optimize the large amount of those control variables, especially for the marine engines with high experimental costs. Therefore, statistical and intelligent algorithms are introduced to optimize multi-objective characteristics of marine engines with increasing complexity technologies.

According to the efficient development of computational capacity, statistical methods are always applied to the numerical simulation modeling of diesel engines, which is beneficial for the optimal design of engine control parameters. Chen et al. [

8] combined non-linear programming by quadratic Lagrangian (NLPQL) with AVL FIRE to optimize the features of injection and combustion chamber geometry. Taghavifar et al. [

9] proposed an optimization method based on Design of Experiment (DoE) with integration of the epsilon-support vector regression (SVR) in AVL FIRE, which was used to reduce both spray droplet diameter and NOx emission at the same time. A multiple linear regression model was employed by Gopal et al. [

10] to predict emissions and performance of a diesel engine fueled by a blend of ethanol, biodiesel and diesel. In practice, however, considering the application of on-line optimization, a large sample database (high computing time) has to be avoided. Unfortunately, although the methods mentioned above have become a powerful tool in the optimization, they cannot guarantee their accuracy of results with a small individual size.

Aiming at this issue, in recent years, with the development of bio-inspired algorithms, intelligent optimization methods, such as genetic algorithm (GA), particle swarm optimization (PSO), artificial bee colony (ABC) algorithm, have received considerable attention in the field of engine performance optimization. Shibata et al. [

11] optimized the heat release shapes of multiple fuel injections to obtain high ITE and low CN level by means of GA. Wu et al. [

12] utilized a micro-genetic algorithm, coupled with an engine computational fluid dynamics code, to optimize a natural gas and diesel dual-fuel engine. However, the basic evolutionary algorithms are easy to fall into the local optima, namely premature phenomenon, which influences the accuracy of the optimization. Hence, improvements on those classical algorithms are introduced by many scholars. Wu et al. [

13] designed an adaptive PSO algorithm to identify optimum engine operating points. Hu et al. [

14] investigated and optimized seven engine design variables by combining the NLPQL algorithm with multi-objective GA. Zhang et al. [

15] presented a hybrid GA-PSO algorithm and applied it to biodiesel engine performance optimization. Cooperative PSO and ABC algorithms are employed by Ogren [

16] to find optimal engine operation parameters for triple and quadruple injection schedules. However, even if good benchmark test results are obtained by those newly developed algorithms, the number of iterations is too large, which increases the computational burden, especially for engine optimization. Accordingly, we must propose, with extreme urgency, a powerful optimization method that has the strongest ability to approach the global optima when the iterations number and individual size are both small.

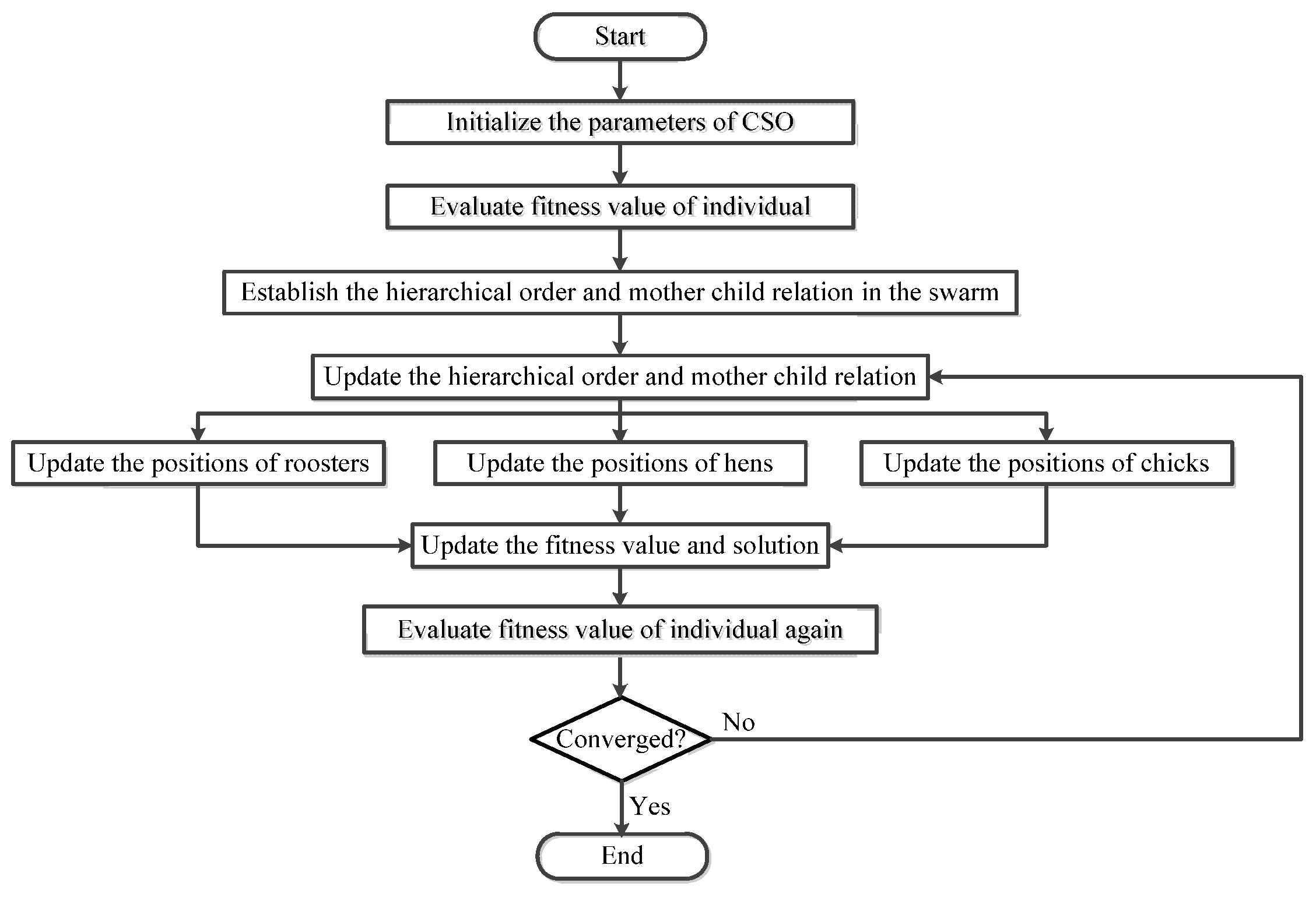

Chicken swarm optimization (CSO) is a new swarm intelligence algorithm developed by Meng et al. [

17], which simulates the behaviors of chicken foraging. Compared to a bat algorithm (BA), GA, PSO, and differential evolution (DE), CSO exhibits better in a lot of popular benchmark test functions [

18]. Hence, the effective techniques that help to increase the diversity of swarm could be applied to basic CSO, which will largely overcome the phenomenon of premature convergence and find better solutions than existing algorithms.

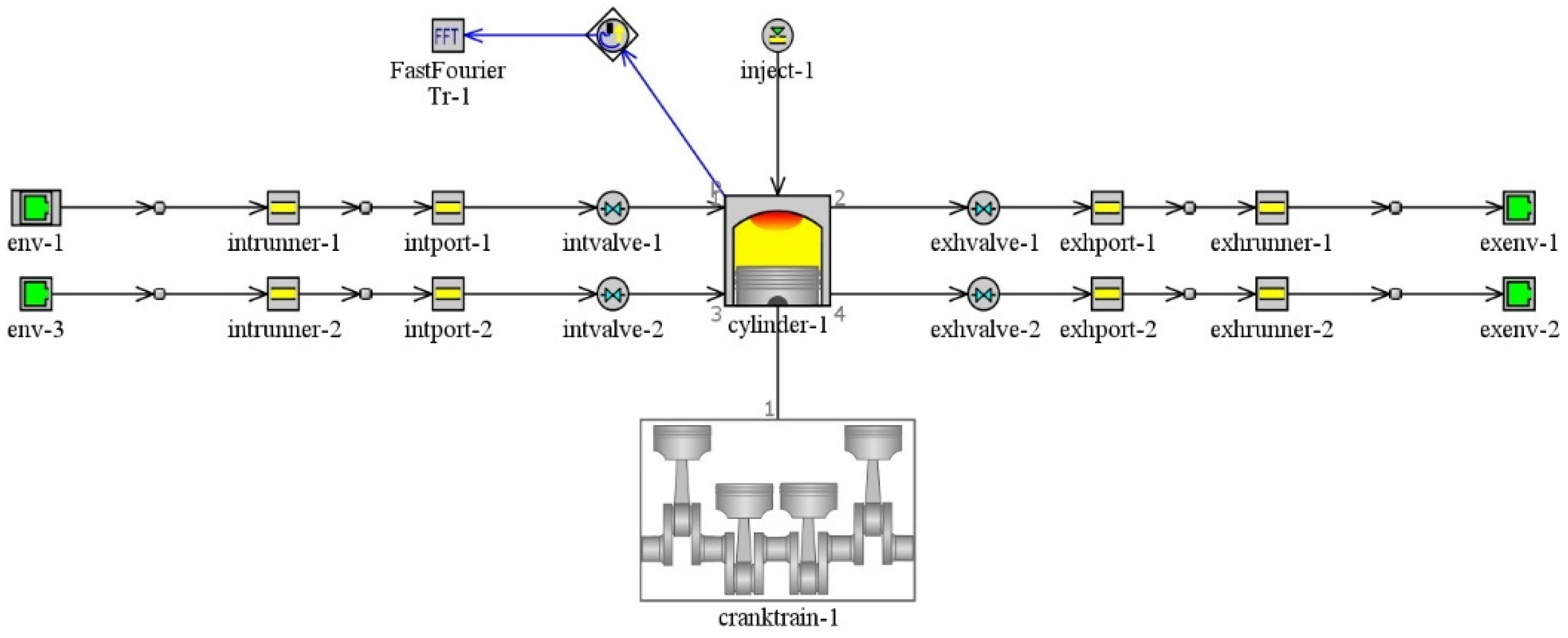

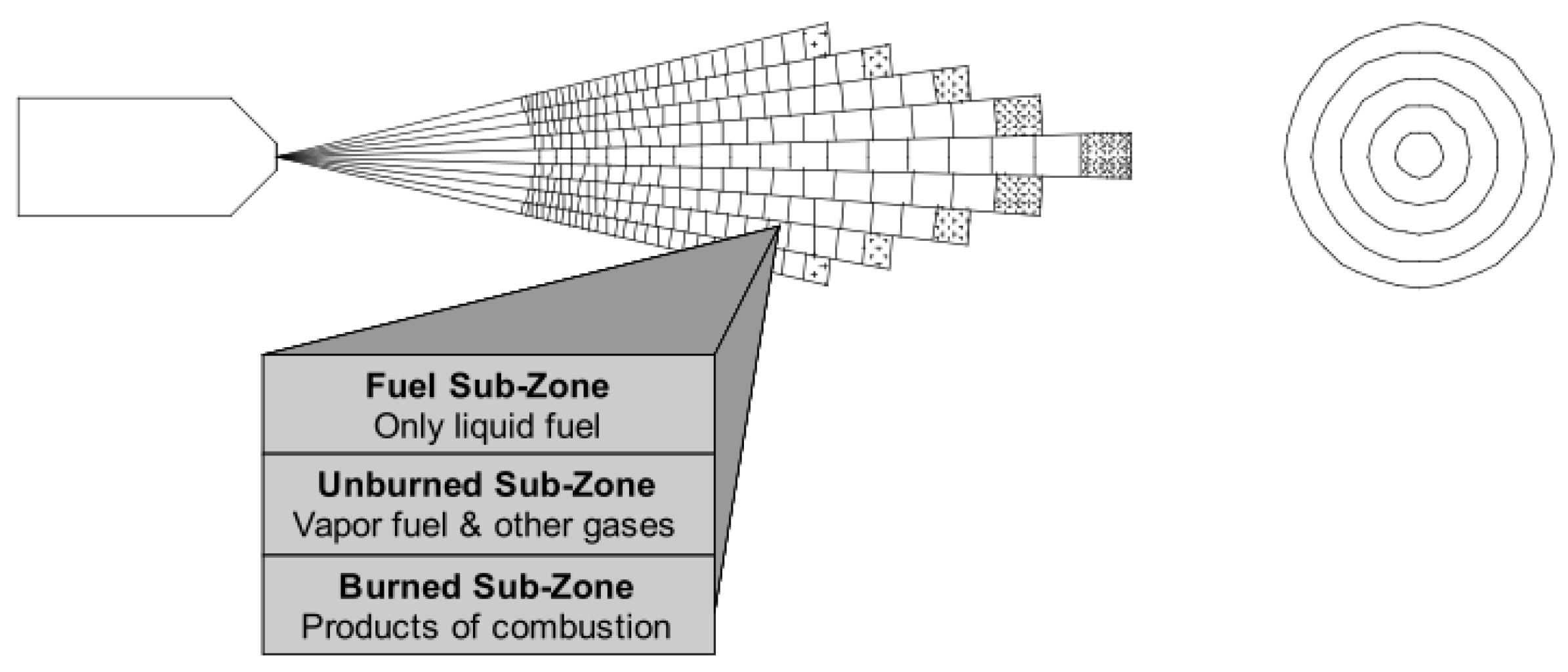

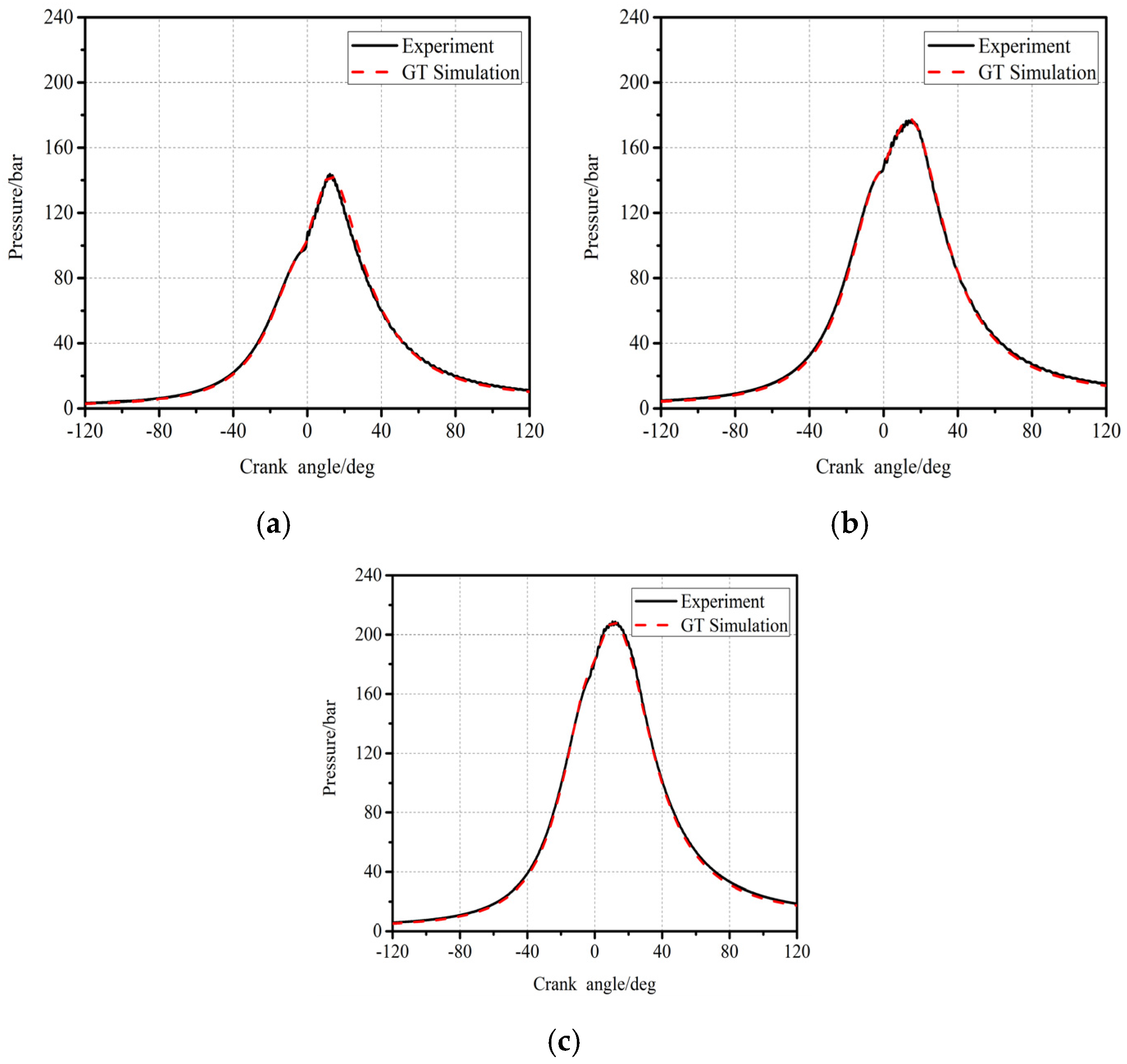

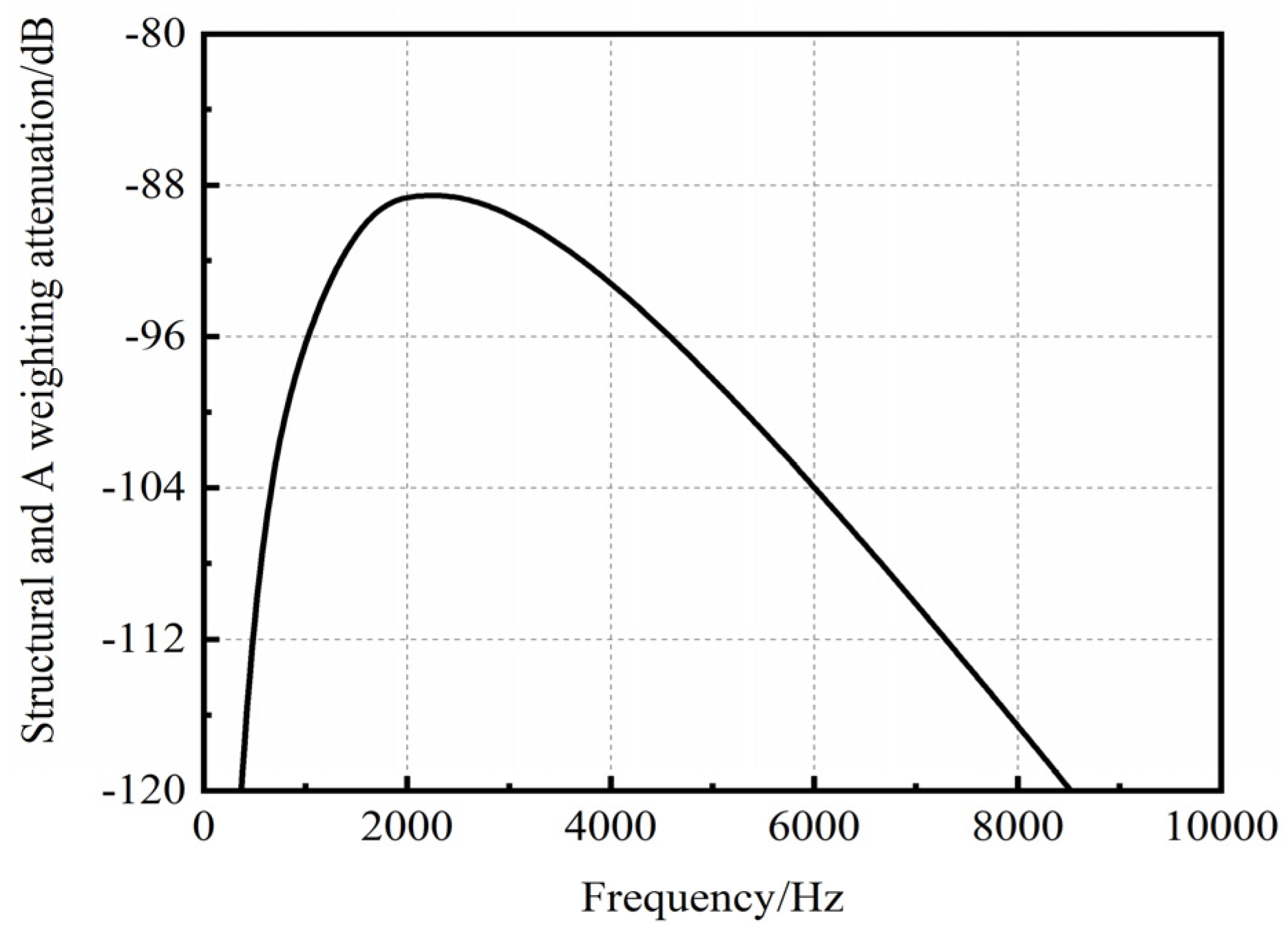

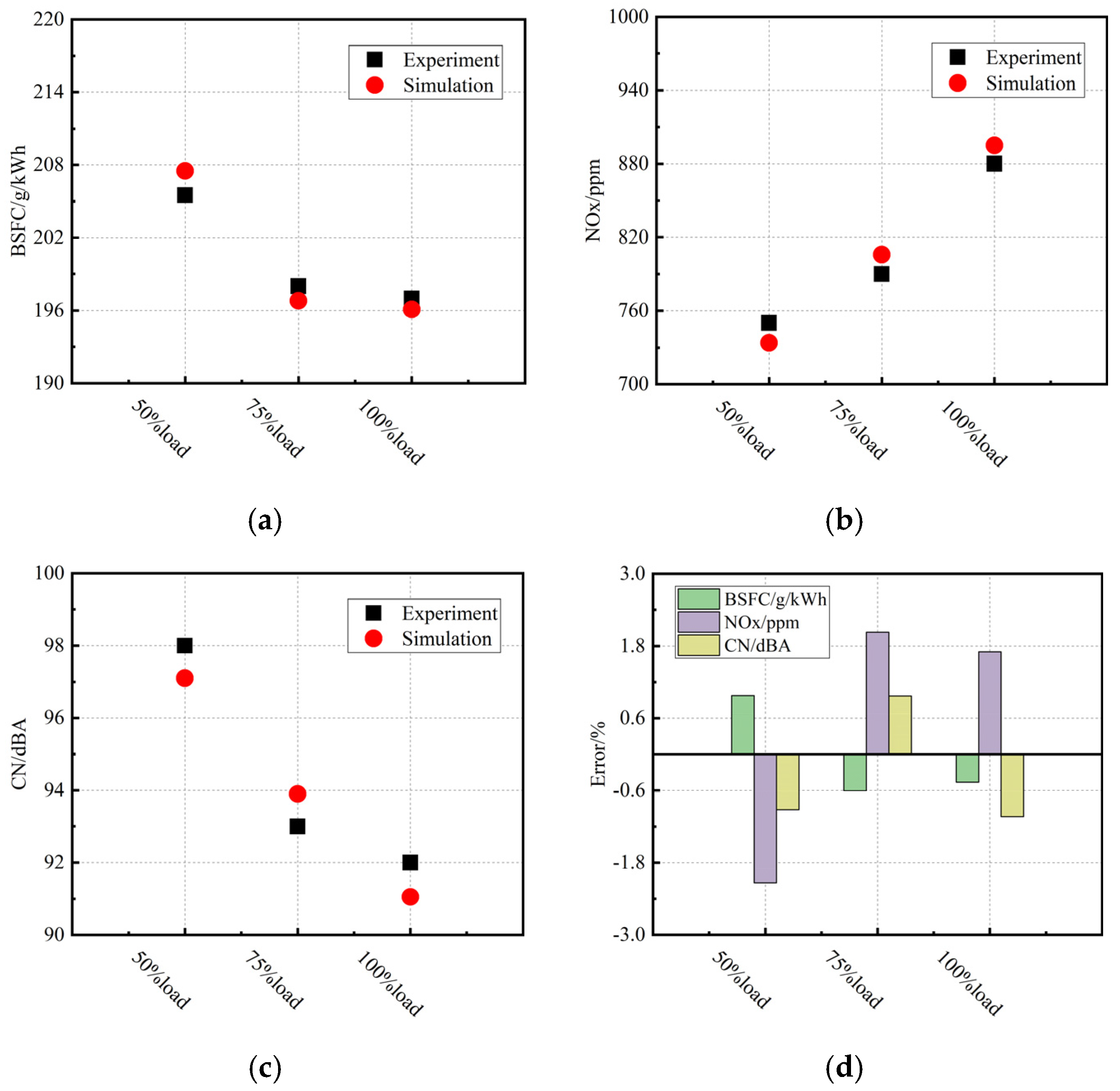

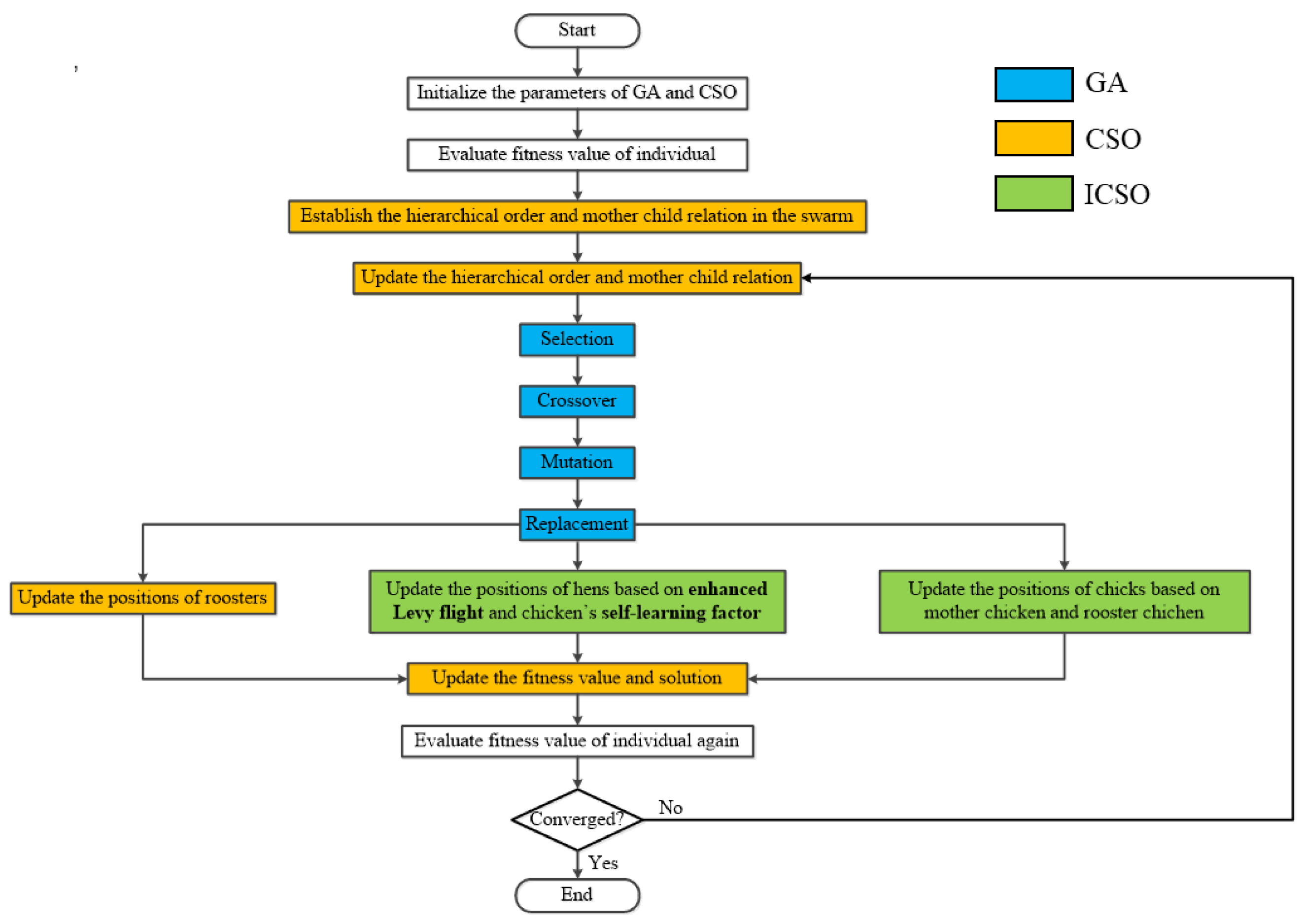

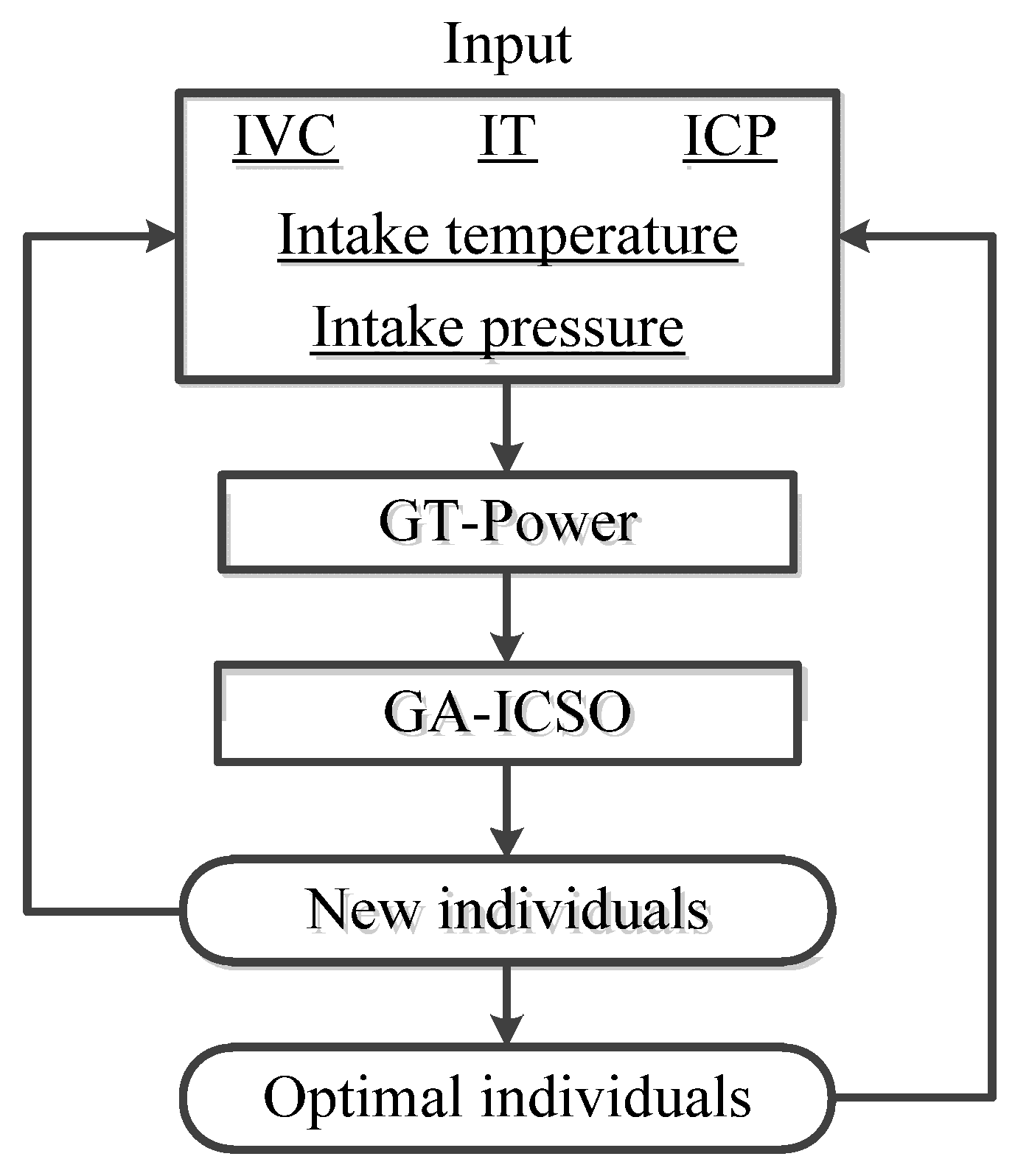

In this study, a GA and improved CSO hybrid algorithm (GA-ICSO) was proposed for optimizing BSFC, CN and NOx simultaneously in a marine diesel engine, where the enhanced Levy flight and adaptive self-learning factor was added to make the chicken swarm distributed evenly. Four benchmark test functions were employed to verify the stability and convergence accuracy of the proposed algorithm. Then, the developed GA-ICSO algorithm was combined with a one-dimensional (1D) predictive model for the optimization of a marine diesel engine, and this model was calibrated and validated by phenomenological approach. IT, ICP, IVC and intake pressure and temperature were selected as design variables in the optimization process. Finally, the optimal engine control parameters were obtained in the conditions of 50%load, 75%load and 100%load. The optimized results were compared with baselines and other widely used optimization algorithms, which demonstrates the ability of GA-ICSO algorithm to optimize and balance the CN, NOx and BSFC.

4. Benchmark Test

In this section, the performance of the proposed GA-ICSO algorithm is tested on four widely used benchmark functions. The descriptions of these benchmark functions, including function, formulation, minimum and range, are listed in

Table 6 [

26]. These functions contain a single local optimum (single peak) and many local optima (multi-peak), which are suitable for testing the effectiveness of the optimization algorithms. Furthermore, in Refs. [

15,

16], it is demonstrated that GA-PSO and an improved artificial bee colony (IABC) show strong abilities in diesel engine performance optimization, although they exhibit poor convergence accuracy and stability when applied to complex multi-input and multi-output problems with a small population size (<20) and low iteration number (<30). So the optimization results of GA-ICSO should be compared to GA-PSO and IABC, which could validate the improvement of optimization accuracy and stability by enhanced Levy flight and adaptive self-learning factor. Meanwhile, in order to validate the improvements of ICSO, GA-CSO and CSO are also run independently for each benchmark function and compared with GA-ICSO.

The parameter settings of these five optimization algorithms are shown in

Table 7. These tuning parameters were selected based on the previous literature [

15,

18] and empirical evaluations, which were demonstrated to accelerate the convergence of iterations. For example, crossover rate is an important parameter for GA, although an extremely large crossover rate may cause an excessive increase in the randomness, which could disturb the optimization direction towards the global best solution and lose the optimal individual. On the contrary, an extremely small crossover rate may be unable to effectively update the population. Hence, the relatively moderate values of tuning parameters were selected in

Table 7. With the aim of validating the global search performance of the proposed GA-ICSO algorithm with a small population, the population size is set to 10 for all the benchmark tests. In addition, the dimensions of all tests are set to be five, which is consistent with the engine design variables defined in

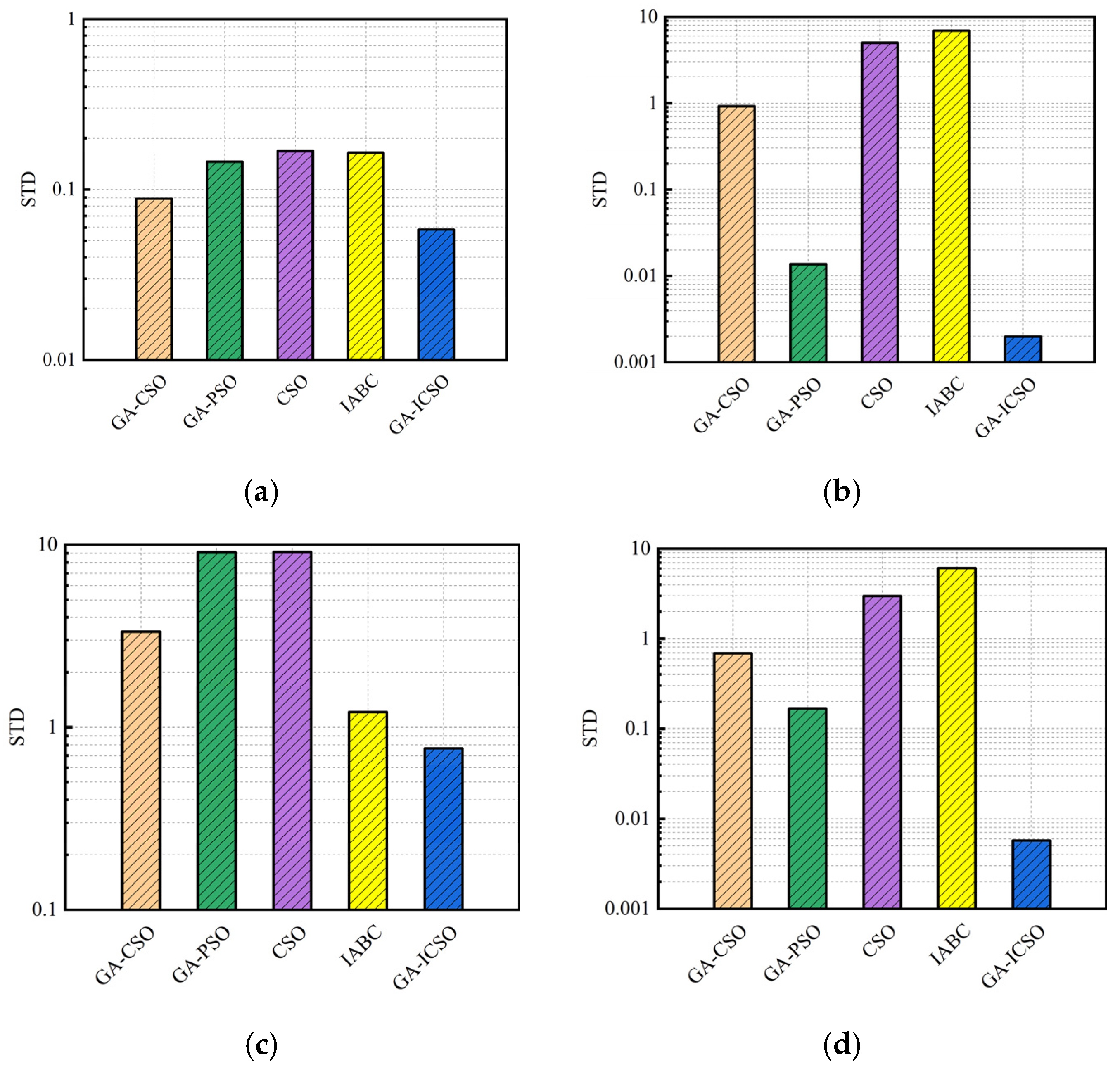

Section 3.4. The maximum iterations of each algorithm are set to 50. As such, the average function evaluations and standard deviation (STD) of the results for 100 trials are obtained, as shown in

Figure 11 and

Figure 12.

From

Figure 11, the proposed GA-ICSO performs higher accuracy than that of other algorithms in finding the objective fitness closest to the global optimization, especially for Griewank and Schwefel function. Moreover, as

Figure 12 can be visually seen, compared with other algorithms, the minimal STD value of GA-ICSO demonstrates the stability of the proposed algorithm. Therefore, according to the results of benchmark tests, GA-ICSO is robust in the process of function optimization, which is suitable for the optimization of engine performance and emission.

5. Results and Discussion

Due to the fact that GA-PSO and IABC have been successfully applied to engine optimizations [

15,

16], both of them are combined with GT-Power for marine diesel engine optimizations in this section, and the results are compared with the proposed GA-ICSO. To reduce the influence of contingency, for each of the three comparison algorithms, the optimization is repeated 10 times independently. The maximum generation is set as 25 and other parameters settings of the algorithms are given to the same values in

Table 7. All of the algorithms are applied to three different working conditions: 50%load, 75%load and 100%load.

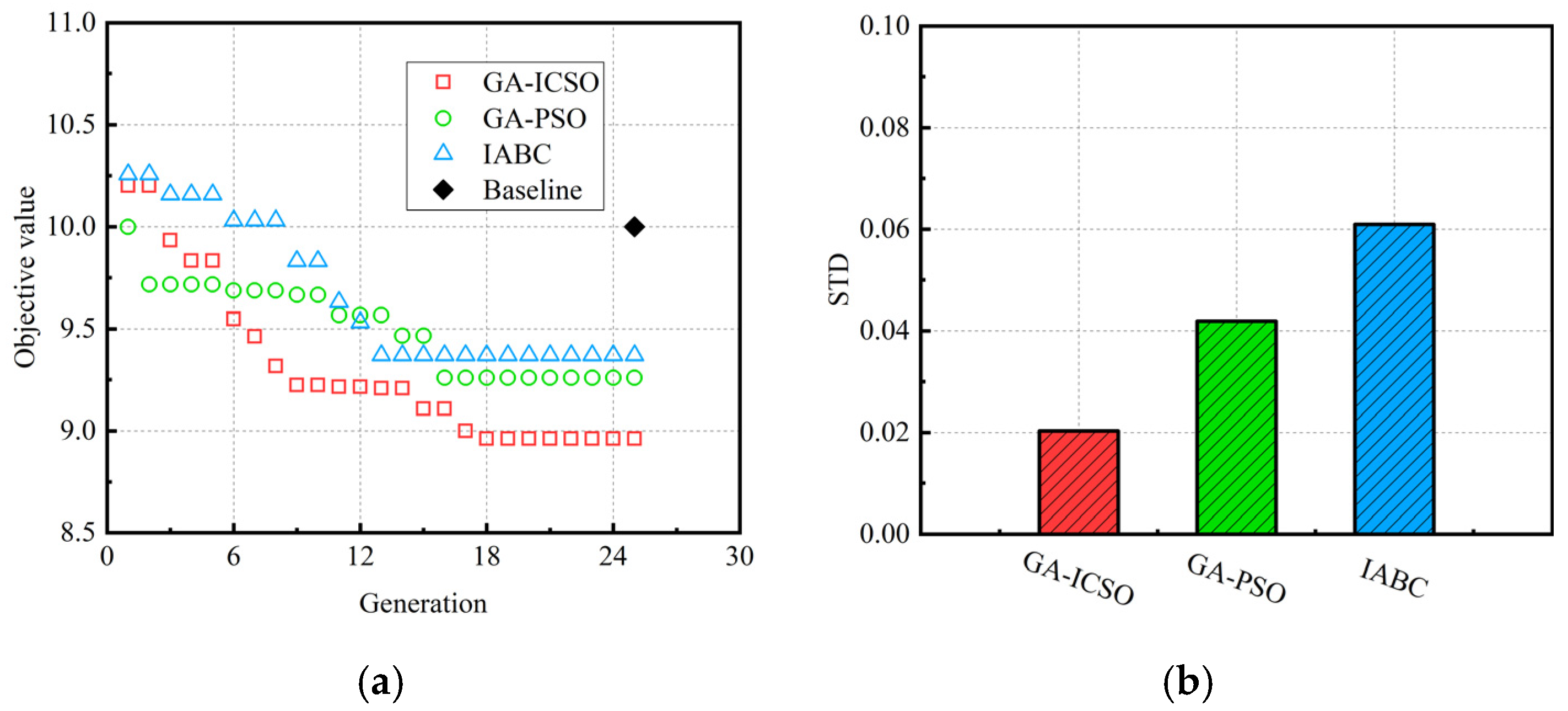

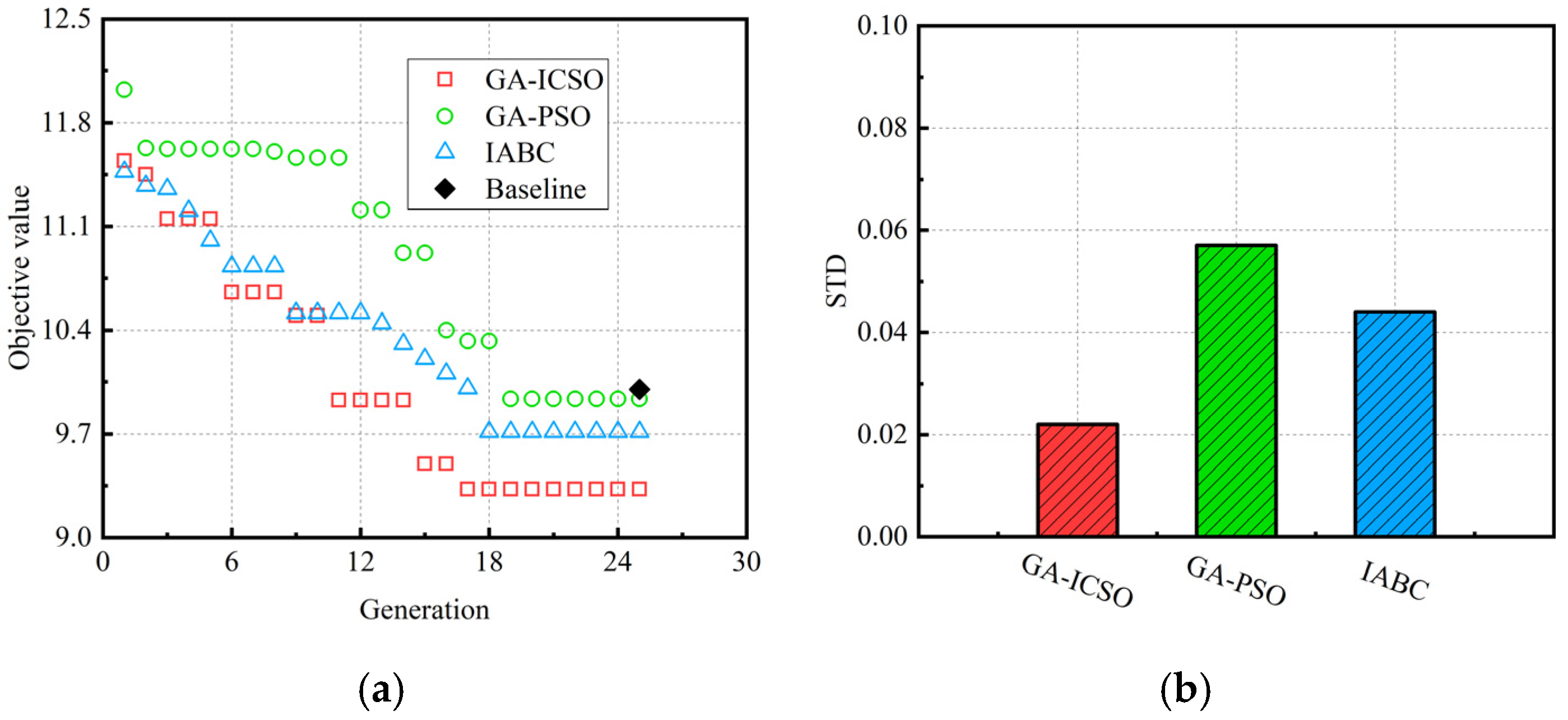

Figure 13,

Figure 14 and

Figure 15 show the optimization history of the best solution and STD of the 10 trails corresponding to three optimization algorithms for the three operating conditions. Observing this progress, the optimizations for all the cases are almost stopped after the 20th generation and the algorithms are considered to have converged. In terms of the baseline values highlighted in each plot, the improvements of overall objective can be observed. Compared with the baselines in

Figure 13,

Figure 14 and

Figure 15, the objective values optimized by GA-ICSO (25th generation) decrease about 1.04, 0.75 and 0.68 for the conditions of 50%load, 75%load and 100%load, respectively, which is larger than that of GA-PSO (0.74, 0.49 and 0.07) and IABC (0.63, 0.55 and 0.29). It indicates that more reasonable optimization results can be obtained by GA-ICSO. Furthermore, the lowest STD values for GA-ICSO algorithm verifies its stability, and only a small number of independent runs is needed to find the global optimal engine control parameters.

In addition, considering the effects of tuning parameters on optimization results, the values of crossover rate, mutation rate and G in GA-ICSO were adjusted for comparative optimization analysis. However, it is found that the obtained optimal solutions are almost unchanged, indicating that the tuning parameters have less of an influence on the optimization results of GA-ICSO. That can be explained by the engine control parameters in baseline conditions having already been roughly optimized by traditional Design of Experiment (DOE) methods, which are used as initial values during GA-ICSO optimization. This can also help to narrow down the optimization range. Therefore, the effects of tuning parameters on optimization process have been weakened.

Subsequently, the inspection of CN, NOx and BSFC is carried out to check the solution success. In order to analyze the optimization results of CN, BSFC and NOx visually, the concept of optimization percentage is defined and expressed as the following:

where the

Optimal in Equation (24) illustrates the best CN/BSFC/NOx value optimized by GA-ICSO. Optimization percentage is a negative value, and the lower this value is, the lower the CN/BSFC/NOx level. The optimization percentage of the baseline case is zero.

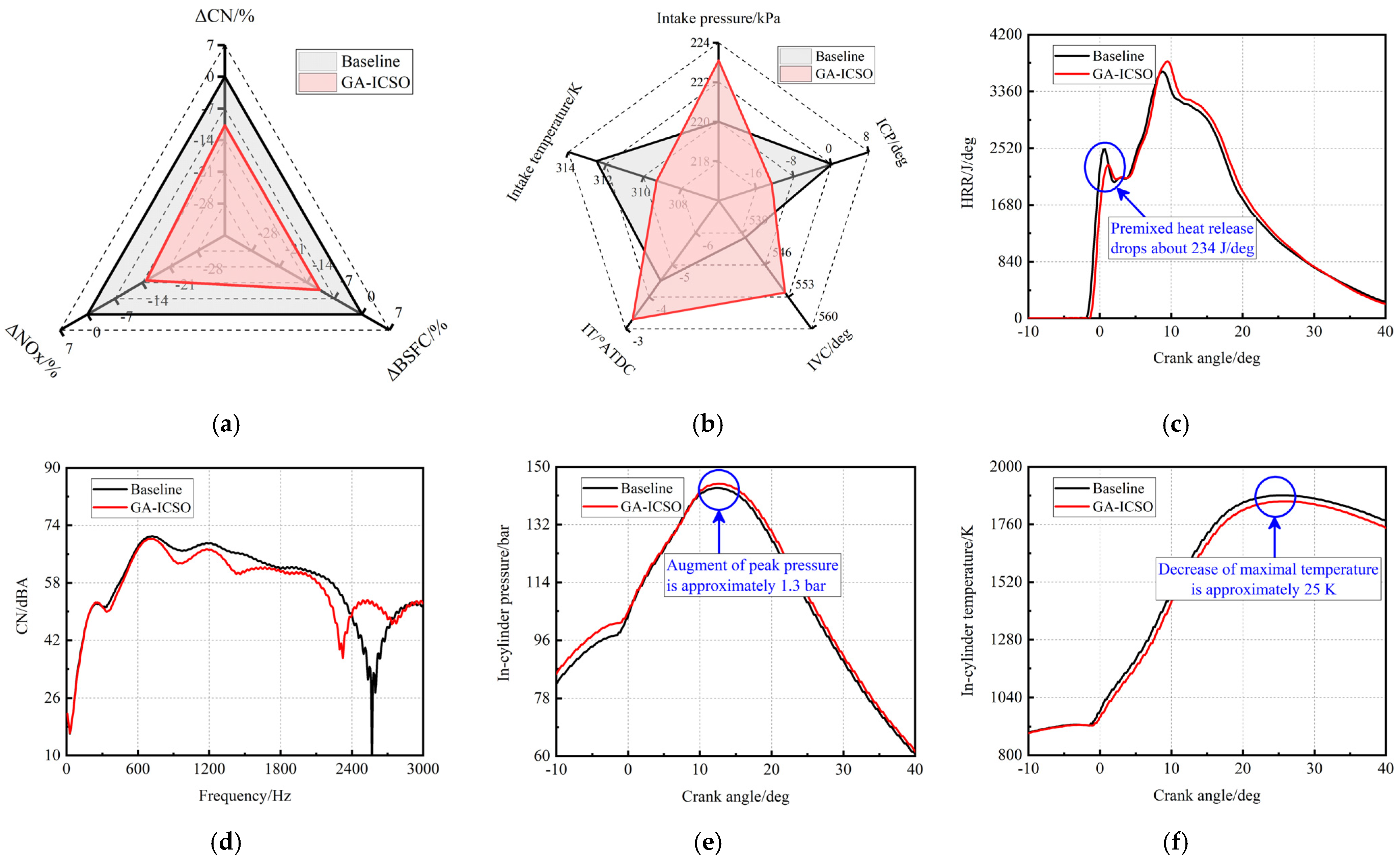

Figure 16a,

Figure 17a and

Figure 18a compare the optimization percentage of CN, BSFC and NOx for all the conditions, where the red line represents the final solution (25th generation) by GA-ICSO and the black line for the baseline. As visible, CN, BSFC and NOx are improved by GA-ICSO algorithm at the same time. Furthermore, the optimization results of IT, ICP, IVC and intake temperature and pressure are also highlighted in

Figure 16b,

Figure 17b and

Figure 18b. In order to explain the different extent of optimization under different working conditions by thermodynamic analysis, the HRRs, combustion noise spectrums, in-cylinder pressures and temperatures of the optimal generation and baseline for the three working cases are provided, as shown in

Figure 16c–f,

Figure 17c–f and

Figure 18c–f.

For the condition of 50%load, as shown in

Figure 16b, IT optimized by GA-ICSO is retarded at about 1.3 CAD (crank angle degree) compared to the baseline, which is the main reason for the premixed combustion attenuation from the HRR plots in

Figure 16c. Premixed combustion contributes directly to CN generation, as violent premixed phasing causes rapid pressure rise and induces pressure fluctuations [

6]. Accordingly, as seen in

Figure 16d, the components of noise spectrum corresponding to the frequency range of 900–1800 Hz are suppressed with the decrease in premixed combustion intensity, and the overall CN level is reduced by about 10.7%.

However, solely retarding the IT may result in lower values of maximal in-cylinder pressure and temperature, subsequently lower NOx emission yet higher BSFC may be achieved. To overcome the trade-off effect of late IT, the GA-ICSO algorithm proposed an optimized in-cylinder environment: slightly rising the compression-end pressure and maintaining the compression-end temperature, as shown in

Figure 16e–f. In this thermodynamic environment, higher air fuel ratio can be achieved and consequently augment the diffusion combustion, as shown in

Figure 16c. Thus, even though late IT attenuates the premixed combustion, the BSFC is reduced 10.8 % due to the augment of in-cylinder pressure, as shown in

Figure 16e. To achieve the optimized in-cylinder thermodynamic environment, the algorithm suggests adjusting the intake air thermodynamic state and intake valve profile. When compared with baseline condition, the intake pressure and temperature of the optimized case is increased 3.1 kPa and decreased three K, leading to an increase in intake air mass flow rate. On the other hand, advancing ICP (shifts the whole valve profile forward 12.7 CAD, as shown in

Figure 16b) enlarges the valve lifts at the start of intake stroke and the valve overlap, which results in larger intake trapped air mass and less in-cylinder residual gas. However, the approaches mentioned above always lead to higher compression pressure. If the compression pressure is over augmented, the peak pressure may exceed the limitation and the temperature may increase as well. Therefore, late IVC is adopted to compensate the effects of other approaches. Finally, the peak value of cylinder pressure rises 1.3 bar in

Figure 16e, and the maximal temperature reduces about 25 K in in

Figure 16f, which reduce the CN, NOx and BSFC simultaneously.

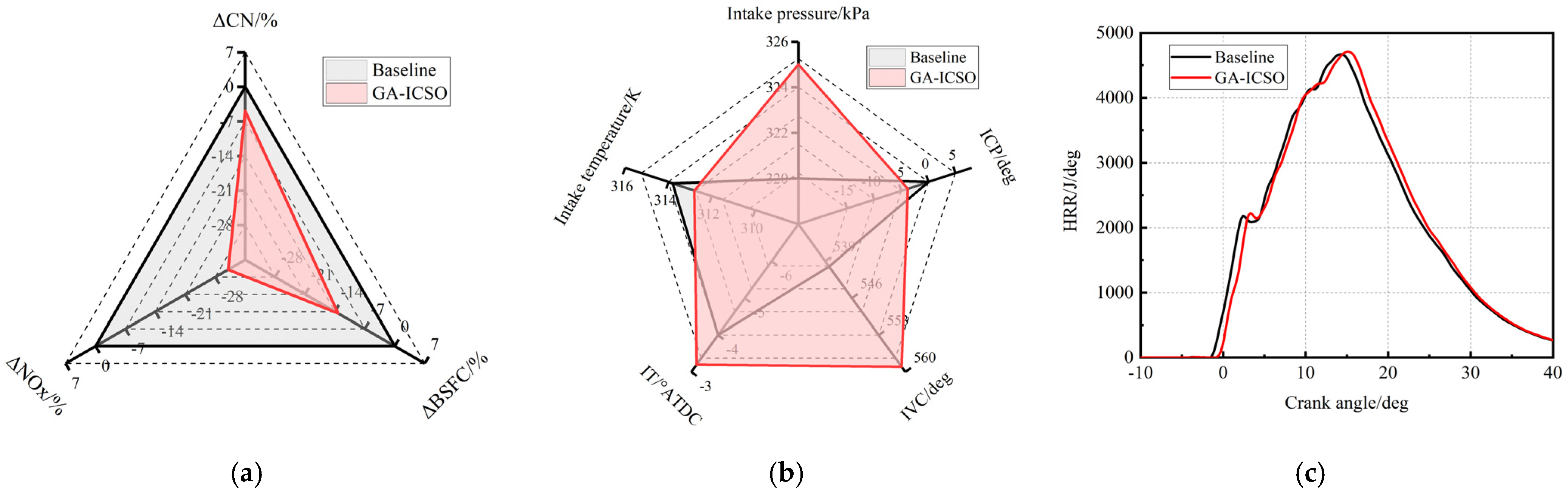

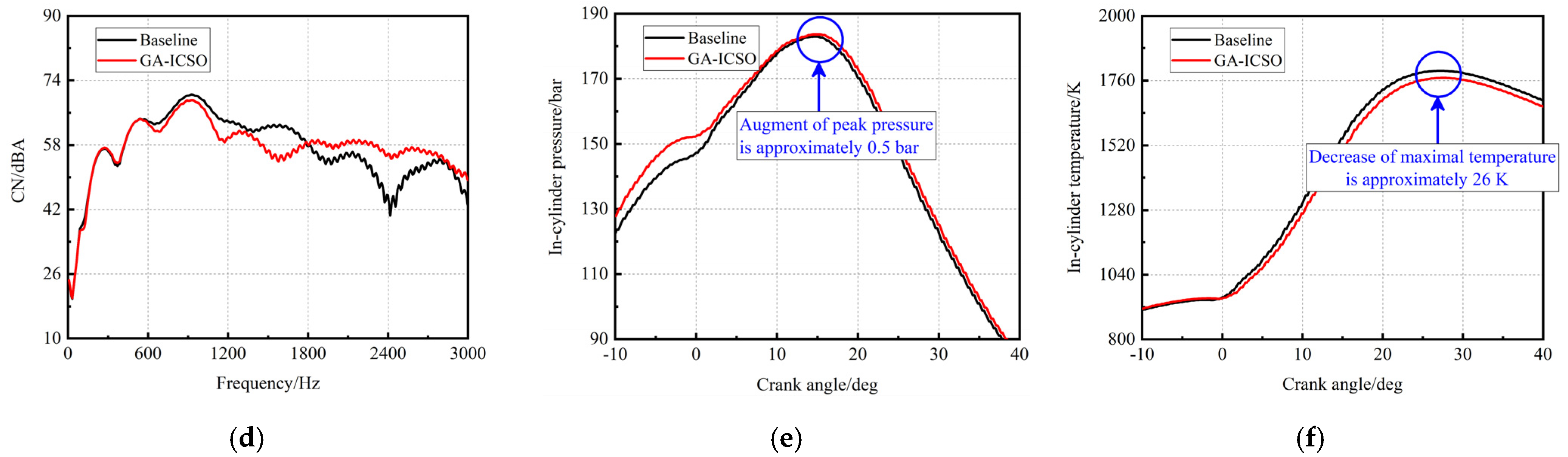

In engine conditions of 75%load and 100%load, similar optimizations of compression-end pressure and temperature are achieved by the GA-ICSO algorithm. Similar approaches (increasing intake air pressure, reducing intake air temperature, advanced ICP and late IVC, shown in

Figure 16b and

Figure 17b) are also applied to increase the in-cylinder pressure to an optimized level while maintaining the compression temperature. After optimization, their increments of compression-end pressure and reductions in maximal temperature are more obvious as the engine load increases, as shown in

Figure 16e–f and

Figure 17e–f. This is due to the rise of trapped air mass caused by the optimization approaches, leading to higher specific heat capacity. Therefore, even though the optimized IT only delay 0.8 CAD and 0.7 CAD under 75% and 100%load, respectively, their improvements of NOx and BSFC are more significant.

Considering their high loads, it is hard to reduce premixed combustion further due to the relatively short ID. This causes that diffusive combustion phase that occupies the majority of the combustion process, which is unable to generate high frequency pressure fluctuations and exert high CN level [

27]. Thus, the optimization percentages of CN in high load regions are always lower than that of low load condition, which is demonstrated in

Figure 16a and

Figure 18a. Meanwhile, in

Figure 17d and

Figure 18d, even if the CN levels in the frequency band of 800–1800 Hz are reduced, it is augmented in other frequency segments, e.g., 1800~3000 Hz for 75%load and 400–1000 Hz for 100%load. This gives rise to the inconspicuous optimization of CN, which is only 4.9% and 3.9% for 75% and 100%load, respectively. Finally, the optimized GA-ICSO approach achieved an attenuated or maintained premixed combustion and augmented diffusion combustion (shown in

Figure 17c and

Figure 18c) in high loads. As such, slight reduction in CN can be achieved with the optimizations of NOx and BSFC.