Constraint Definition for Gripper Selection and Grasp Planning for Robotic Assembly Using Product Manufacturing Information from STEP AP242Ed2 Files

Abstract

1. Introduction

2. Robotic Gripping

2.1. Gripper Performance and Selection

- Static force;

- Dynamic force;

- Part geometry.

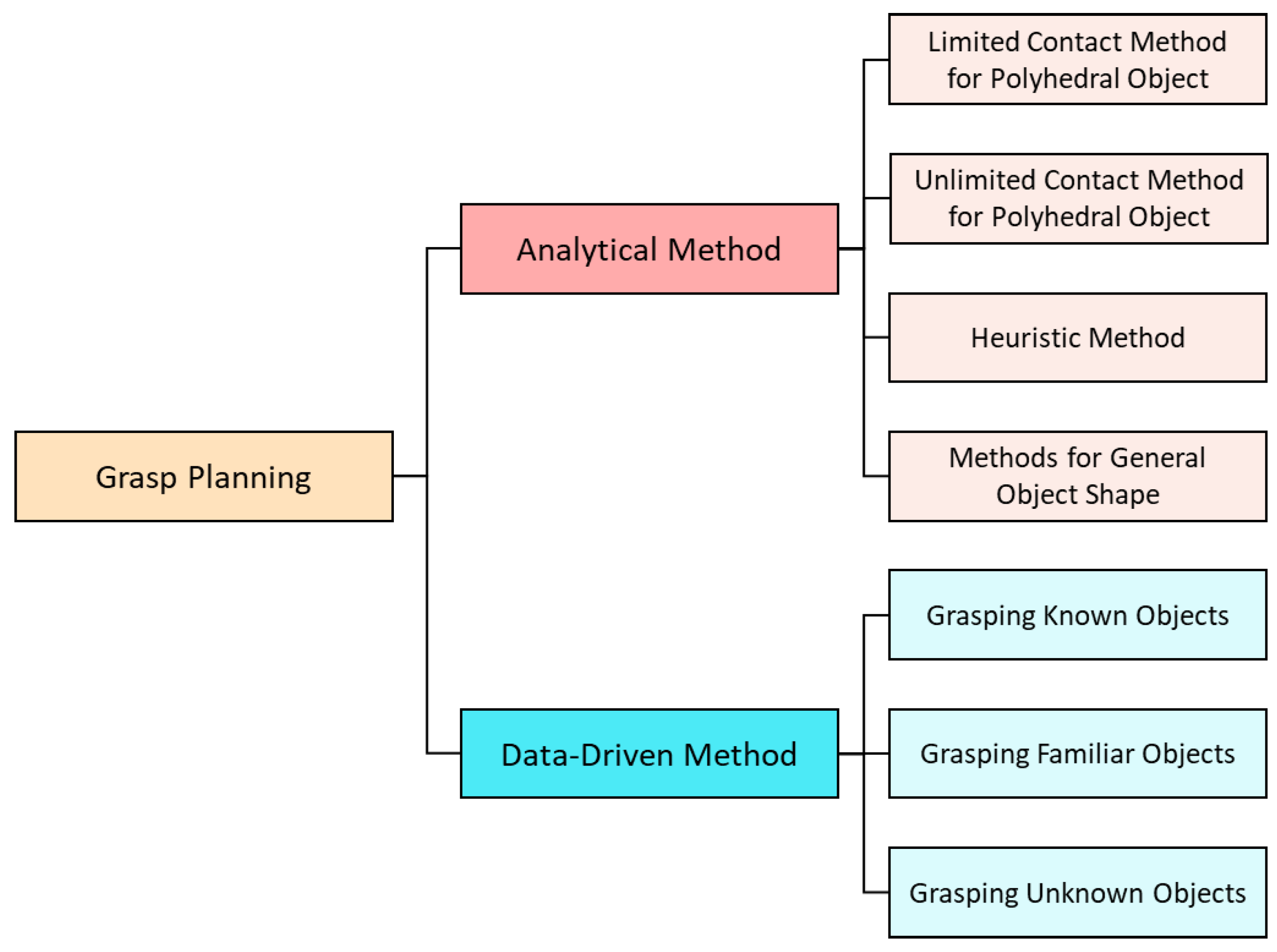

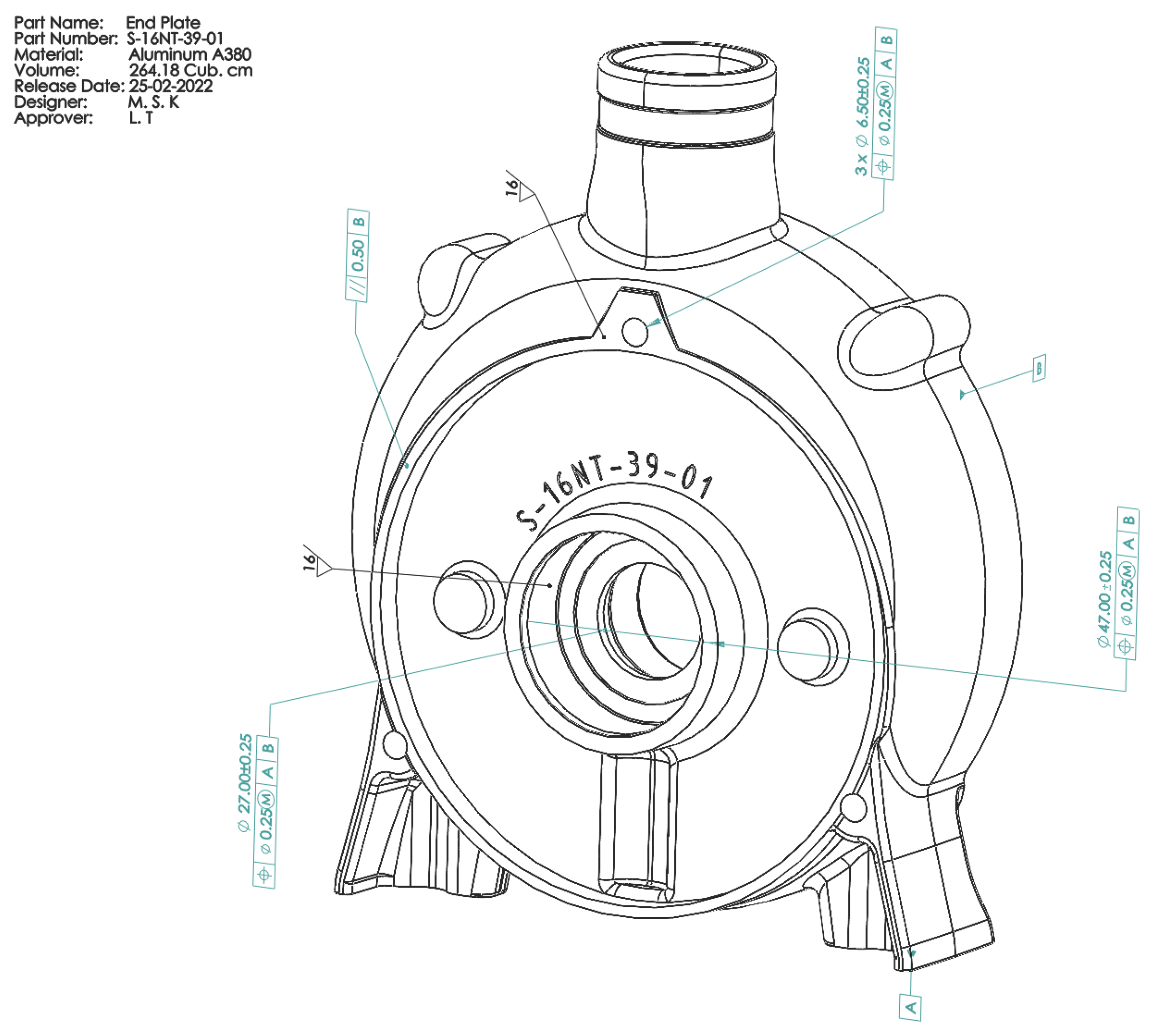

2.2. Grasp Planning Using CAD

- Dimensional size

- Material: strength, hardness, density

- Weight

- Surface texture

- Special coatings

- Thread information [21]

- Assembly constraints and mating information

- Center of gravity

- Shape

- Part features: holes, surfaces

3. Model-Based Definition (MBD)

4. STEP AP242

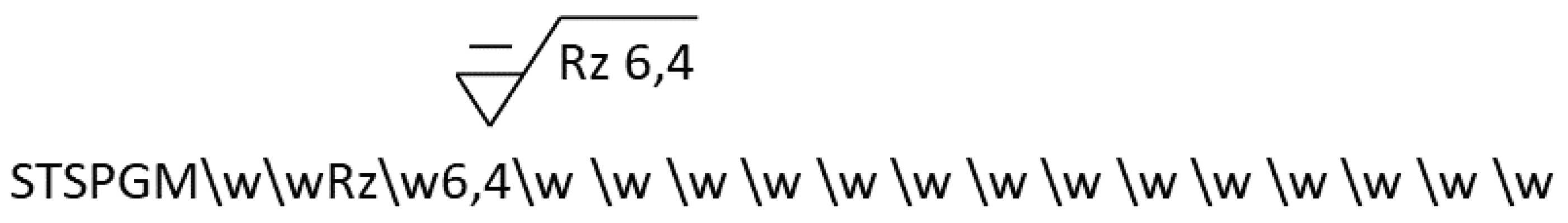

5. Surface Finish Symbols

- a: tolerance type

- b: symbol for R-parameter/P-parameter/W-parameter

- c: tolerance limit value of the profile surface texture parameter

- d: tolerance acceptance rule

- e: profile S-filter type

- f: profile S-filter nesting index

- g: profile L-filter type

- h: profile L-filter nesting index

- i: section length

- k: number of sections

- m: evaluation length, used when indicating evaluation length replaces the section parameters i and k

- n: profile F-operator association method and element

- p: profile F-operator nesting index

- q: method for profile extraction

- r: other requirements using OR(n) symbol

- s: manufacturing process

- t: surface lay and direction of lay

- u: profile direction relative to the surface lay

6. Adding Surface Finish Symbols to the STEP AP242 Files

6.1. Using Custom Annotation String

- The method described in the CAx recommendation [48] is based on ISO 1302: 2002. However, the present method is extended to match the latest ISO standard 21920-1: 2021, which replaced the earlier standard ISO 1302: 2002.

- The current method deals with the profile method of surface texture annotations. It incorporates the features for adding surface texture annotations as per the areal method specified in ISO 25178-1: 2016.

- While Unicode characters are used for welding and GD&T annotations, this method does not use any Unicode characters. The surface texture annotation has only a few symbols which can be directly mapped to the Unicode characters and most of the values used in surface finish symbols are text-based. Hence, custom codes are used for all the parameters in the surface texture annotation.

Forming the Annotation String:

- The annotation string starts with a six-letter combination ‘STSXXX’. The first three letters in this combination ‘STS’ stands for ‘Surface Texture Symbol’.

- The following letter is used to indicate the methodology of surface texture symbols whether profile or areal. The next two letters are used to specify the symbol type and manufacturing/machining, respectively. The letter identifiers for these parameters are shown in Table 3.

- The ‘All Around’ symbol is added after this six-letter combination using ‘SAAS’ using ‘\w’ as a separator between the two combinations.

- ‘\w’ is used as a separator between various parameters and regions. ‘\u’ is used to separate different values/combinations under a single parameter, for example, separating section length and number of sections. Therefore, the string values representing the section length (i) and number of sections (k) will be of the form ‘\wi\uk’. When the evaluation length (m) is given instead of section length (i) and number of sections (k), then the string equivalent will be ‘\wm\u’.

- A four-letter combination such as ‘SXXX’ is used to indicate various abbreviations, symbols and identifiers. Table 2 shows the various custom codes for some of the symbols used in surface texture annotation.

- The profile direction value ‘at an angle’ can be included using ‘SA<XX>’. Here, the angle value is added in the place of ‘<XX>’, for example ‘SA45’.

- The direction of lay and profile direction may carry a ‘Feature Control Frame’ to indicate the direction and the datum plane. This can be added using ‘\u’ after the direction of lay/profile direction symbol and the datum indicator is separated from the direction in the feature control frame using ‘\x’.

- Any other values inside various parameters can be added using the separator ‘\v’. For example, the R-parameter values ‘Rdc(p, q)’ can be added as ‘\wRdc\vp\vq’.

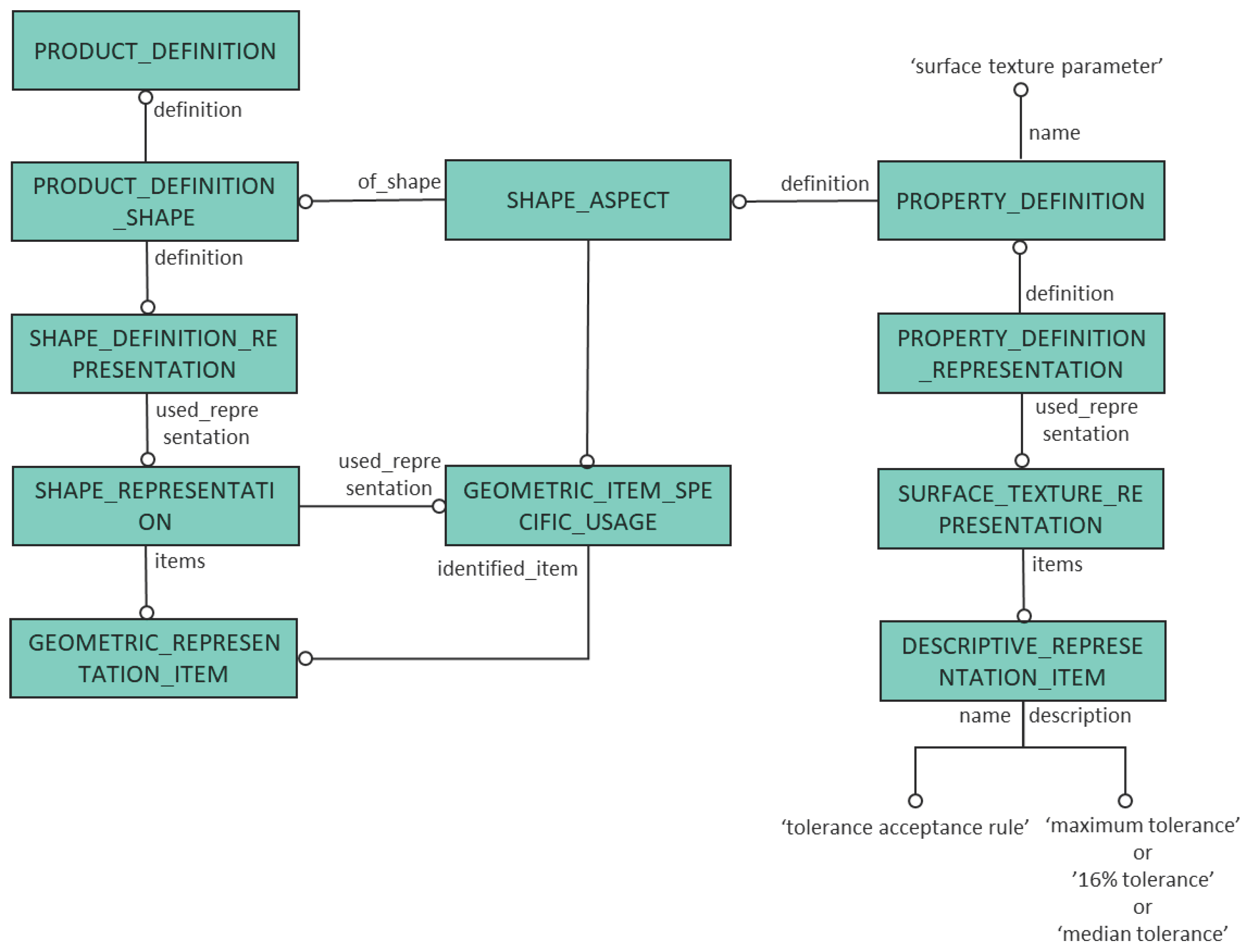

6.2. Using the Standard Entities from STEP AP242Ed2

- Type Definitions:

- −

- surface_lay_and_orientation

- −

- surface_texture_characteristic_type

- −

- surface_texture_material_removal_condition_enumeration

- −

- surface_texture_requirement_type

- Entity Definitions:

- −

- Standard_surface_texture_parameter

- −

- Surface_texture

- −

- Surface_texture_parameter

- −

- User_defined_surface_texture_parameter

Addition of Custom Annotation String Using Standard Entities

7. Adding Other Relevant PMI to STEP Files

7.1. Thread Information

7.2. Special Coatings and Paints

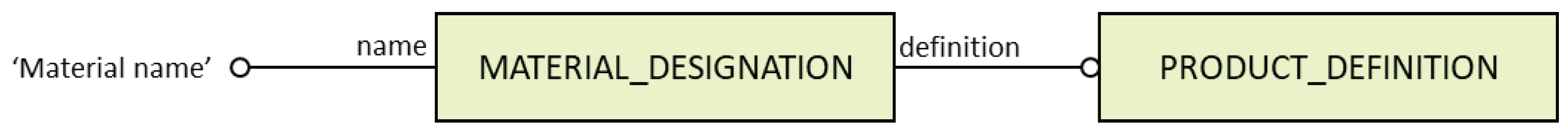

7.3. Material

Material Properties

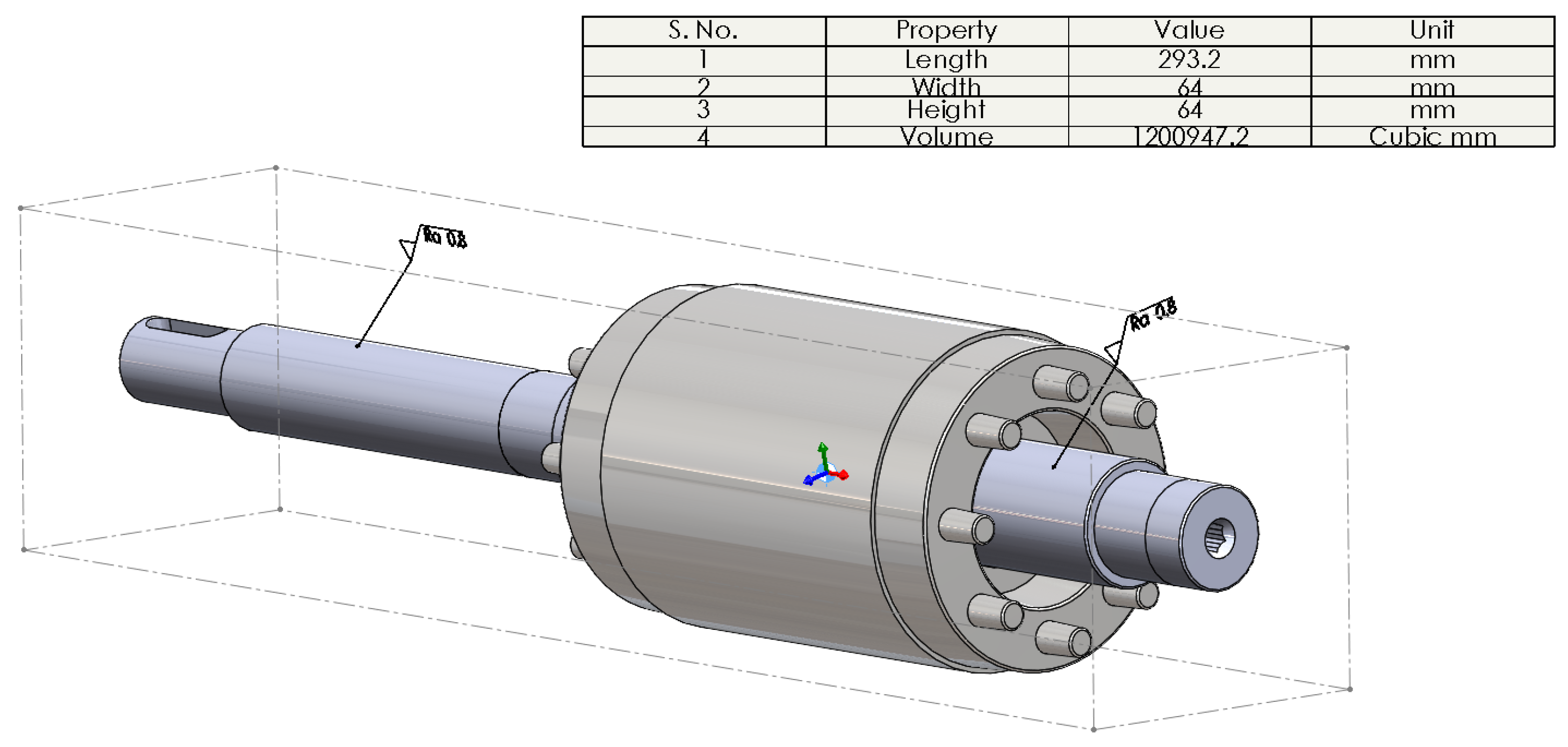

7.4. Volume and Mass

7.5. Bounding Box

8. Constraint Identification

8.1. Identification of Handling Features from STEP Files

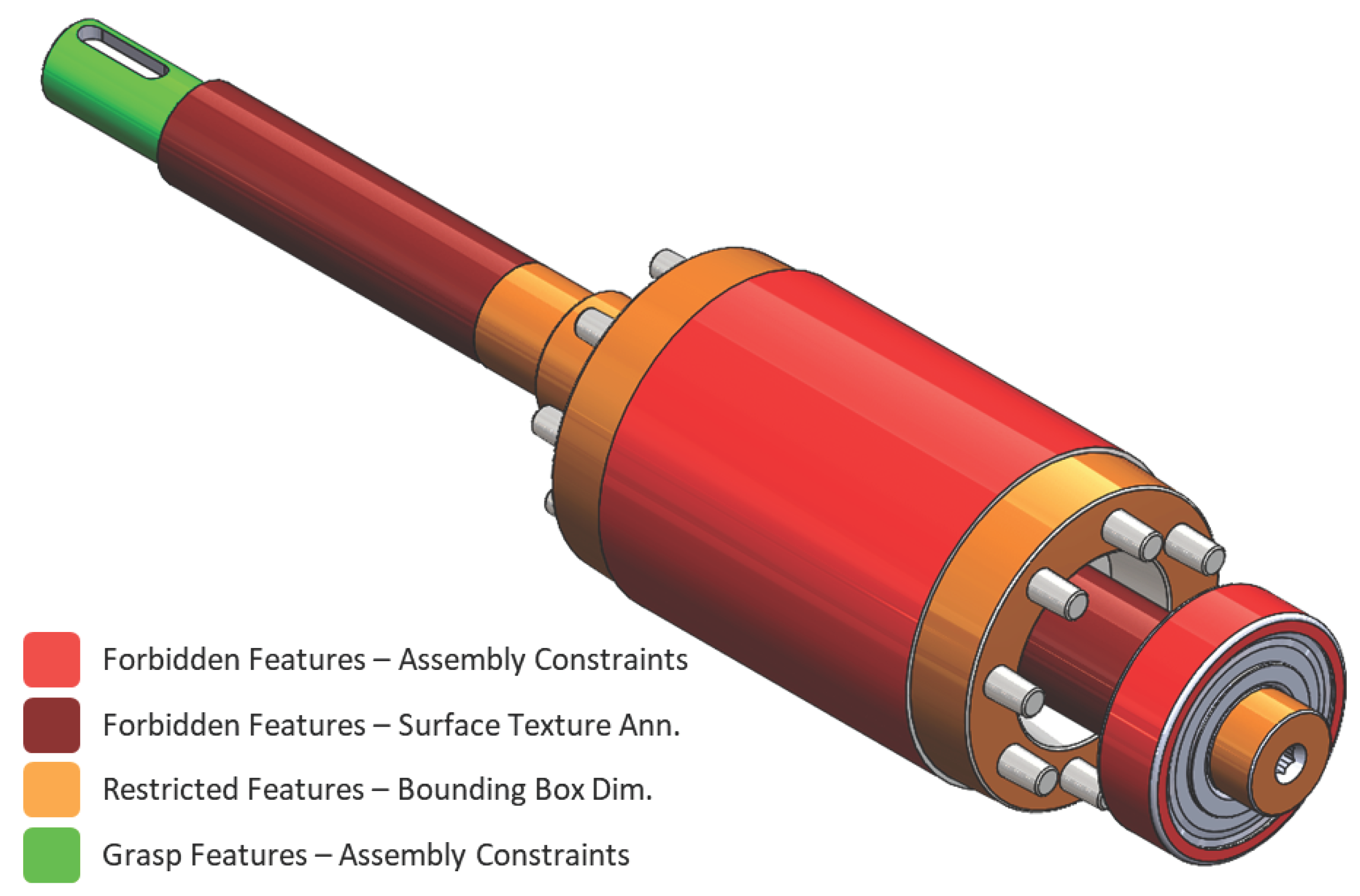

- Forbidden Features: The features that are strictly not available for grasping are referred to as forbidden features. These include the assembly/mating features and the functional features that might be damaged by the grippers, like threaded regions [21], surfaces with special coatings and surface finish requirements. Only special surface finish specifications on particular features are used to identify forbidden features, not the default surface finish requirement that applies to the entire part.

- Restricted Features: The features that can be used during the initial stages of handling tasks like re-orienting and moving from the initial position to the start of assembly engagement are considered as restricted features. For example, in the case of a shaft and housing assemblies both the ends of the shaft are available for grasping in the initial stages of handling. As the shaft starts engaging with the housing during the assembly, one end becomes unavailable for grasping depending on the direction of assembly. Here, such an end of the shaft is a restricted feature and can be used during the initial stages of handling and assembly process. Bounding box dimensions are used to derive the restricted features.

- Grasp Features: The remaining features on the part are open for grasping during all the stages of handling and assembly. These features are called grasp features.

- Identify the global coordinate system of the assembly

- Identify the forbidden features: Features with

- Assembly constraints

- Surface texture annotations

- Thread annotations

- Coating information

- Identify the bounding box dimensions of part and mating sub-assembly

- Convert the bounding box of the part to the global coordinate system

- Using the mating features, find the final position of the part and its bounding box

- Find the restricted features, by calculating the interference of the part bounding box with the bounding box of the mating part/sub-assembly

- The remaining features are identified as grasp features

- Extract the shape and dimensions of the grasp features

- Extract/calculate the part properties like density, strength, volume and weight

- Use these properties for gripper selection, grasp planning and motion planning with collision avoidance

8.2. Gripper Selection

- Level 1:

- The size of the grasp features (width/diameter) should be between the minimum and maximum grasp width of the gripper.

- When the minimum grasp width of the gripper is not available, the stroke should be greater than the grasp features’ size.

- The gripper’s payload should be greater than the part weight. This paper suggests a maximum limit to the gripper’s payload to twice the weight of the part.

- Level 2:

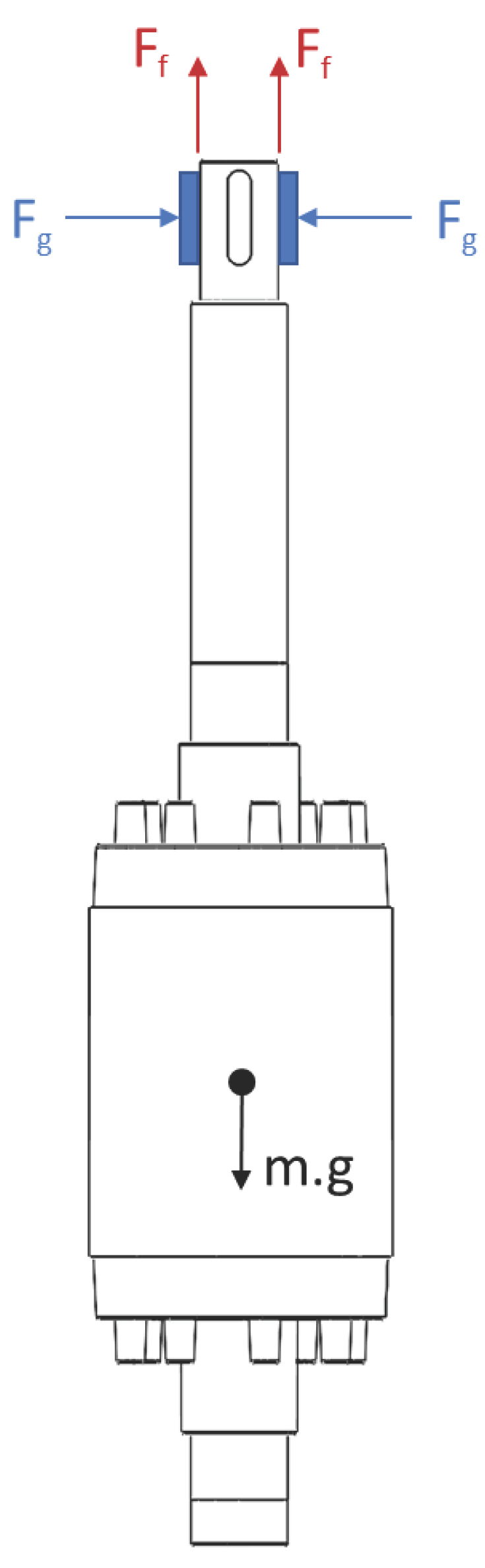

- The gripping force should be able to lift the part only through friction, i.e., the frictional force () should be greater than the gravitational force [1], as shown in Figure 9.where : Gripping force;m: mass of the object;g: acceleration due to gravity;: coefficient of friction between the gripper fingers and the object;n: number of gripper finger.

8.3. Grasp Planning/Execution

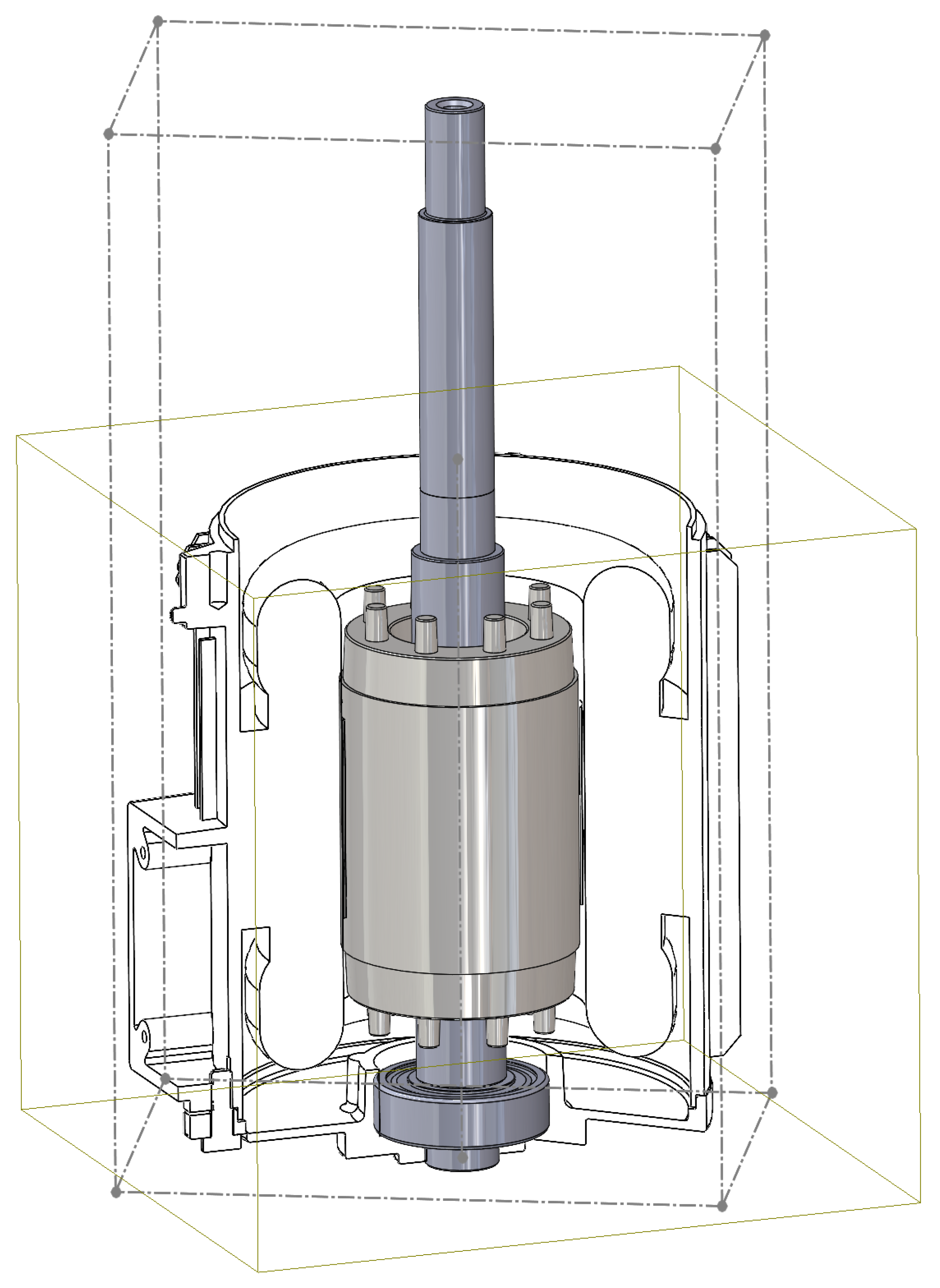

8.4. Motor Use Case

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASME | American Society of Mechanical Engineers |

| CAD | Computer Aided Design |

| CAE | Computer Aided Engineering |

| DT | Digital Thread |

| GD&T | Geometric Dimensioning and Tolerancing |

| ISO | International Standards Organisation |

| MBD | Model Based Definition |

| MBE | Model Based Enterprise |

| NC | Numerical Controlled |

| OEM | Original Equipment Manufacturer |

| PMI | Product Manufacturing Information |

| SME | Small and Medium Enterprise |

| STEP | STandard for the Exchange of Product Model Data |

References

- Monkman, G.J.; Hesse, S.; Steinmann, R.; Schunk, H. Robot Grippers; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2007. [Google Scholar]

- Wolf, A.; Steinmann, R.; Schunk, H. Grippers in Motion: The Fascination of Automated Handling Tasks; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Lundstrom, G. Industrial Robot Grippers. Ind. Robot. 1973, 1, 72–82. [Google Scholar] [CrossRef]

- Dzedzickis, A.; Subaciute-Zemaitiene, J.; Sutinys, E.; Samukaite-Bubniene, U.; Bucinskas, V. Advanced Applications of Industrial Robotics: New Trends and Possibilities. Appl. Sci. 2022, 12, 135. [Google Scholar] [CrossRef]

- Lotter, B. Manufacturing Assembly Handbook; VDI-Verlag GmbH: Düsseldorf, Germany, 1986. [Google Scholar]

- Boothroyd, G.; Dewhurst, P.; Knight, W.A. Product Design for Manufacture and Assembly; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Mohammed, S.K.; Arbo, M.H.; Tingelstad, L. Constraint Identification from STEP AP242 files for Automated Robotic Welding. In Proceedings of the 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021; pp. 277–282. [Google Scholar]

- Bohg, J.; Morales, A.; Asfour, T.; Kragic, D. Data-Driven Grasp Synthesis—A Survey. IEEE Trans. Robot. 2014, 30, 289–309. [Google Scholar] [CrossRef]

- Honarpardaz, M.; Tarkian, M.; Olvander, J.; Feng, X. Finger design automation for industrial robot grippers: A review. Robot. Auton. Syst. 2017, 87, 104–119. [Google Scholar] [CrossRef]

- De Souza, J.P.C.; Rocha, L.F.; Oliveira, P.M.; Moreira, A.P.; Boaventura-Cunha, J. Robotic Grasping: From Wrench Space Heuristics to Deep Learning Policies. Robot. Comput.-Integr. Manuf. 2021, 71, 102176. [Google Scholar] [CrossRef]

- Kleeberger, K.; Bormann, R.; Kraus, W.; Huber, M.F. A Survey on Learning-Based Robotic Grasping. Curr. Robot. Rep. 2020, 1, 239–249. [Google Scholar] [CrossRef]

- Owen, A.E. Flexible Assembly Systems; Springer Science + Business Media: New York, NY, USA, 1984. [Google Scholar]

- Cuadrado, J.; Naya, M.A.; Ceccarelli, M.; Carbone, G. An optimum design procedure for two-finger grippers: A case of study. IFToMM Electron. J. Comput. Kinemat. 2002, 15403, 2002. [Google Scholar]

- Fantoni, G.; Capiferri, S.; Tilli, J. Method for supporting the selection of robot grippers. Procedia CIRP 2014, 21, 330–335. [Google Scholar] [CrossRef]

- Birglen, L.; Schlicht, T. A statistical review of industrial robotic grippers. Robot. Comput.-Integr. Manuf. 2018, 49, 88–97. [Google Scholar] [CrossRef]

- Nguyen, V.D. Constructing Force-Closure Grasps. In Proceedings of the 1986 IEEE International Conference on Robotics and Automation, San Francisco, CA, USA, 7–10 April 1986; pp. 1368–1373. [Google Scholar]

- Reuleaux, F. Kinematics of Machinery; (First Published in Germany, 1875); Macmillan and Co.: London, UK, 1876. [Google Scholar]

- Bicchi, A. On the Closure Properties of Robotic Grasping. Int. J. Robot. Res. 1995, 14, 319–334. [Google Scholar] [CrossRef]

- Kleeberger, K.; Schnitzler, J.; Khalid, M.U.; Bormann, R.; Kraus, W.; Huber, M.F. Precise Object Placement with Pose Distance Estimations for Different Objects and Grippers. In Proceedings of the 2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September 2021–1 October 2021; pp. 4639–4646. [Google Scholar]

- Shimoga, K.B. Robot Grasp Synthesis Algorithms: A Survey. Int. J. Robot. Res. 1996, 15, 230–266. [Google Scholar] [CrossRef]

- Van Bruggen, M.; Baartman, J.P.; Bronsvoort, W.F. Grips on Parts. In Proceedings of the Proceedings IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; Volume 2, pp. 828–833. [Google Scholar]

- Miller, A.T.; Knoop, S.; Christensen, H.I.; Allen, P.K. Automatic Grasp Planning Using Shape Primitives. In Proceedings of the 2003 IEEE International Conference on Robotics and Automation, Taipei, Taiwan, 14–19 September 2003; Volume 2, pp. 1824–1829. [Google Scholar]

- Schmalz, J.; Giering, L.; Holzle, M.; Huber, N.; Reinhart, G. Method for the Automated Dimensioning of Gripper Systems. Procedia CIRP 2016, 44, 239–244. [Google Scholar] [CrossRef]

- Somani, N. Constraint-Based Approaches for Robotic Systems: From Computer Vision to Real-Time Robot Control. Ph.D. Thesis, Technical University, Munich, Germany, 2018. [Google Scholar]

- Lanni, C.; Ceccarelli, M. An Optimization Problem Algorithm for Kinematic Design of Mechanisms for Two-Finger Grippers. Open Mech. Eng. J. 2009, 3, 49–62. [Google Scholar] [CrossRef]

- Department of Defense, United States of America (USA). MIL-STD-31000A: Technical Data Packages; Federal Standardization Manual, Department of Defense: Picatinny Arsenal, NJ, USA, 2009. [Google Scholar]

- Herron, J.B. Re–Use Your CAD: The Model–Based CAD Handbook; Action Engineering LLC: Golden, CO, USA, 2013. [Google Scholar]

- Urbas, U.; Vrabic, R.; Vukasinovic, N. Displaying Product Manufacturing Information in Augmented Reality for Inspection. Procedia CIRP 2019, 81, 832–837. [Google Scholar] [CrossRef]

- Goher, K.; Shehab, E.; Al-Ashaab, A. Model-Based Definition and Enterprise: State-of-the-art and future trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 235, 2288–2299. [Google Scholar] [CrossRef]

- ISO 10303–242:2014; Industrial Automation Systems and Integration—Product Data Representation and Exchange—Part 242: Application Protocol: Managed Model-Based 3D Engineering. International Organization for Standardization: Geneva, Switzerland, 2014.

- Kramer, T.; Xu, X. STEP in a Nutshell. In Advanced Design and Manufacturing Based on STEP; Xu, X., Lee, A.Y.C., Eds.; Springer Series in Advanced Manufacturing: Advanced Design and Manufacturing Based on STEP; Springer: London, UK, 2009; Chapter 1; pp. 1–22. [Google Scholar]

- STEP AP242 Project Committee. Development of STEP AP 242 ed2: “Managed Model Based 3D Engineering. Whitepaper. STEP AP242 Project Committee: 2014. Available online: http://www.ap242.org/edition-2 (accessed on 27 November 2022).

- ISO 10303–242:2020; Industrial Automation Systems and Integration—Product Data Representation and Exchange—Part 242: Application Protocol: Managed Model-Based 3D Engineering. International Organization for Standardization: Geneva, Switzerland, 2020.

- Praveen, O.V.S.; Dileep, B.; Gayatri, S.; Lawrence, D.; Manu, R. Automated Tolerance Analysis of Mechanical Assembly Using STEP AP242 Managed Model-Based 3D Engineering. In Industry 4.0 and Advanced Manufacturing; Lecture Notes in Mechanical Engineering; Springer: Gateway East, Singapore, 2021; pp. 149–157. [Google Scholar]

- Feeney, A.B.; Frechette, S.P.; Srinivasan, V. A Portrait of an ISO STEP Tolerancing Standard as an Enabler of Smart Manufacturing Systems. ASME J. Comput. Inf. Sci. Eng. 2015, 15, 021001. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Thomas, R.G.; Lawrence, D.; Manu, R. STEP AP242 Managed Model–based 3D Engineering: An Application Towards the Automation of Fixture Planning. Int. J. Autom. Comput. 2021, 18, 731–746. [Google Scholar] [CrossRef]

- ASME Y14.41:2019; Digital Product Definition Data Practices. The American Society of Mechanical Engineers: New York, NY, USA, 2019.

- Mohammed, S.K.; Arbo, M.H.; Tingelstad, L. Leveraging Model Based Definition and STEP AP242 in Task Specification for Robotic Assembly. Procedia CIRP 2021, 97, 92–97. [Google Scholar] [CrossRef]

- Mohammed, S.K.; Arbo, M.H.; Tingelstad, L. Using Semantic Geometric Dimensioning and Tolerancing (GD&T) Information from STEP AP242 Neutral Exchange Files for Robotic Applications. Int. J. Interact. Des. Manuf. (IJIDeM) 2022. Submitted for publication. [Google Scholar]

- ISO 21920-1:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 1: Indication of Surface Texture. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 1302:2002; Geometrical Product Specifications (GPS)—Indication of Surface Texture in Technical Product Documentation. International Organization for Standardization: Geneva, Switzerland, 2002.

- ISO 25178-1:2016; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 1: Indication of Surface Texture. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 21920-3:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 3: Specification Operators. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal —Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 25178-3:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 3: Specification Operators. International Organization for Standardization: Geneva, Switzerland, 2012.

- CAx Implementor Forum. PMI Unicode String Specification Examples and Mapping Strategies—for Dimensioning and Tolerancing, GD&T, Surface Texture Symbol and Welding Symbol PMI Annotation Entities. Revision J. 2011. Available online: https://www.mbx-if.org/documents/rec_prac_unicode_strings_rev_j_2011-05-25.pdf (accessed on 27 November 2022).

- CAx Implementor Forum. Recommended Practices for User Defined Attributes. Release 1.3. 2014. Available online: https://www.mbx-if.org/documents/rec_prac_user_def_attributes_v13.pdf (accessed on 27 November 2022).

- CAx Implementor Forum. Recommended Practices for Geometric and Assembly Validation Properties. Release 4.4. 2016. Available online: https://www.mbx-if.org/documents/rec_prac_gvp_v44.pdf (accessed on 27 November 2022).

- Van Holland, W.; Bronsvoort, W.F. Assembly Features in Modeling and Planning. Robot. Comput. Integr. Manuf. 2000, 16, 277–294. [Google Scholar] [CrossRef]

- Van Holland, W. Assembly Features in Modeling and Planning. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1997. [Google Scholar]

- Schutter, J.D.; Laet, T.D.; Rutgeerts, J.; Decre, W.; Smits, R.; Aertbelien, E.; Claes, K.; Bruyninckx, H. Constraint-based task specification and estimation for sensor-based robot systems in the presence of geometric uncertainty. Int. J. Robot. Res. 2007, 26, 433–455. [Google Scholar] [CrossRef]

- Şucan, I.A.; Moll, M.; Kavraki, L.E. The Open Motion Planning Library. IEEE Robot. Autom. Mag. 2012, 19, 72–82. [Google Scholar] [CrossRef]

- LKSoftWare GmbH, Germany. JSDAI. Available online: https://www.jsdai.net/ (accessed on 27 November 2022).

| Symbol | Type | Name | Description | ISO Standard |

|---|---|---|---|---|

| Profile | Basic symbol | Any manufacturing process permitted | 1302:2002 (Obsolete) |

| Profile | Expanded symbol | Material removal required | 1302:2002 (Obsolete) |

| Profile | Expanded symbol | Material removal not permitted | 1302:2002 (Obsolete) |

| Profile | Complete symbol | Any manufacturing process permitted | 1302:2002 (Obsolete) |

| Profile | Complete symbol | Material removal required | 1302:2002 (Obsolete) |

| Profile | Complete symbol | Material removal not permitted | 1302:2002 (Obsolete) |

| Profile | Graphical symbol | Any manufacturing process permitted | 21920-1:2021 |

| Profile | Graphical symbol | Material removal | 21920-1:2021 |

| Profile | Graphical symbol | Material removal not permitted | 21920-1:2021 |

| Areal | Basic symbol | Any manufacturing process permitted | 25178-1:2016 |

| Areal | Expanded symbol | Material removal required | 25178-1:2016 |

| Areal | Expanded symbol | Material removal not permitted | 25178-1:2016 |

| Areal | Complete symbol | Any manufacturing process permitted | 25178-1:2016 |

| Areal | Complete symbol | Material removal required | 25178-1:2016 |

| Areal | Complete symbol | Material removal not permitted | 25178-1:2016 |

| Areal | Complete symbol | Showing ‘All Around’ symbol | 25178-1:2016 |

| Symbol | Label | Parameter | Description | Custom Code |

|---|---|---|---|---|

| Tmax | d | Tolerance acceptance rule | Maximum tolerance | STMX |

| T16% | d | Tolerance acceptance rule | 16% tolerance | ST16 |

| Tmed | d | Tolerance acceptance rule | Median tolerance | STMD |

| M | t | Surface lay | Multi-directional | SMLD |

| C | t | Surface lay | Circular | SCRC |

| R | t | Surface lay | Radial | SRDL |

| P | t | Surface lay | Particulate | SPRT |

| t | Surface lay and direction of lay | Parallel | SPRL |

| t | Surface lay and direction of lay | Perpendicular | SPPD |

| t | Surface lay and direction of lay | Crossed | SCRS |

| u | Profile direction | Perpendicular to the predominant direction | SPPD |

| u | Profile direction | Parallel to the predominant direction | SPRL |

| u | Profile direction | Circular | SCRC |

| u | Profile direction | At an angle to the predominant direction | SA<XX> |

| Description | Identifier |

|---|---|

| Profile | P |

| Areal | A |

| Basic symbol | B |

| Expanded symbol | E |

| Complete symbol | C |

| Graphical symbol | G |

| Any manufacturing process permitted | A |

| Material removal required | M |

| Material removal not permitted | N |

| Entity.Attribute | Indicator | Parameter |

|---|---|---|

| Standard_surface_texture_parameter.tolerance_type | a | tolerance type |

| Standard_surface_texture_parameter.characteristic_type | b | symbol for R-parameter/P-parameter/W-parameter |

| Standard_surface_texture_parameter.characteristic_value | c | tolerance limit value of the profile surface texture parameter |

| – | d | tolerance acceptance rule |

| Standard_surface_texture_parameter.transmission_band_filter_short_wave | e | profile S-filter type |

| – | f | profile S-filter nesting index |

| Standard_surface_texture_parameter.transmission_band_filter_long_wave | g | profile L-filter type |

| – | h | profile L-filter nesting index |

| Standard_surface_texture_parameter.evaluation_length | i | section length |

| Standard_surface_texture_parameter.number_of_sampling_lengths | k | number of sections |

| Standard_surface_texture_parameter.evaluation_length | m | evaluation length |

| – | n | profile F-operator association method and element |

| – | p | profile F-operator nesting index |

| – | q | method for profile extraction |

| Standard_surface_texture_parameter.additional_information | r | other requirements using OR(n) symbol |

| Surface_texture.manufacturing_method | s | manufacturing process |

| Surface_texture.direction | t | surface lay and direction of lay |

| – | u | profile direction relative to the surface lay |

| Product Information | Grasp Planning Constraints |

|---|---|

| Assembly constraints | Forbidden features |

| Special surface texture annotations | Forbidden features |

| Thread annotation | Forbidden features |

| Special coatings | Forbidden features |

| Bounding box dimensions | Restricted features |

| Material and material properties | Gripper selection |

| Volume | Gripper selection |

| Mass | Gripper selection |

| Feature dimensions | Gripper selection |

| Feature shape | Grasp points and gripper selection |

| Center of Gravity | Selection of grasp points |

| Manufacturer | Number of Grippers | Payload Range (Kg) | Maximum Grasp Width | Stroke (mm) | Max. Gripping Force (N) |

|---|---|---|---|---|---|

| OnRobot | 5 | 2–20 | 430 | 38–160 | 450 |

| Shunk | 11 | 0.55–42 | 620 | 5–90 | 8460 |

| Robotiq | 3 | 2.5–5 | 140 | 50–140 | 235 |

| Festo | 5 | 0.2–4.24 | 40 | 20–40 | 3716 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, S.K.; Arbo, M.H.; Tingelstad, L. Constraint Definition for Gripper Selection and Grasp Planning for Robotic Assembly Using Product Manufacturing Information from STEP AP242Ed2 Files. Machines 2022, 10, 1230. https://doi.org/10.3390/machines10121230

Mohammed SK, Arbo MH, Tingelstad L. Constraint Definition for Gripper Selection and Grasp Planning for Robotic Assembly Using Product Manufacturing Information from STEP AP242Ed2 Files. Machines. 2022; 10(12):1230. https://doi.org/10.3390/machines10121230

Chicago/Turabian StyleMohammed, Shafi Khurieshi, Mathias Hauan Arbo, and Lars Tingelstad. 2022. "Constraint Definition for Gripper Selection and Grasp Planning for Robotic Assembly Using Product Manufacturing Information from STEP AP242Ed2 Files" Machines 10, no. 12: 1230. https://doi.org/10.3390/machines10121230

APA StyleMohammed, S. K., Arbo, M. H., & Tingelstad, L. (2022). Constraint Definition for Gripper Selection and Grasp Planning for Robotic Assembly Using Product Manufacturing Information from STEP AP242Ed2 Files. Machines, 10(12), 1230. https://doi.org/10.3390/machines10121230