Multi-Disciplinary Analysis of Working Fluids on Thermal Performance of the High-Power Diesel Engine System

Abstract

1. Introduction

2. Methodology

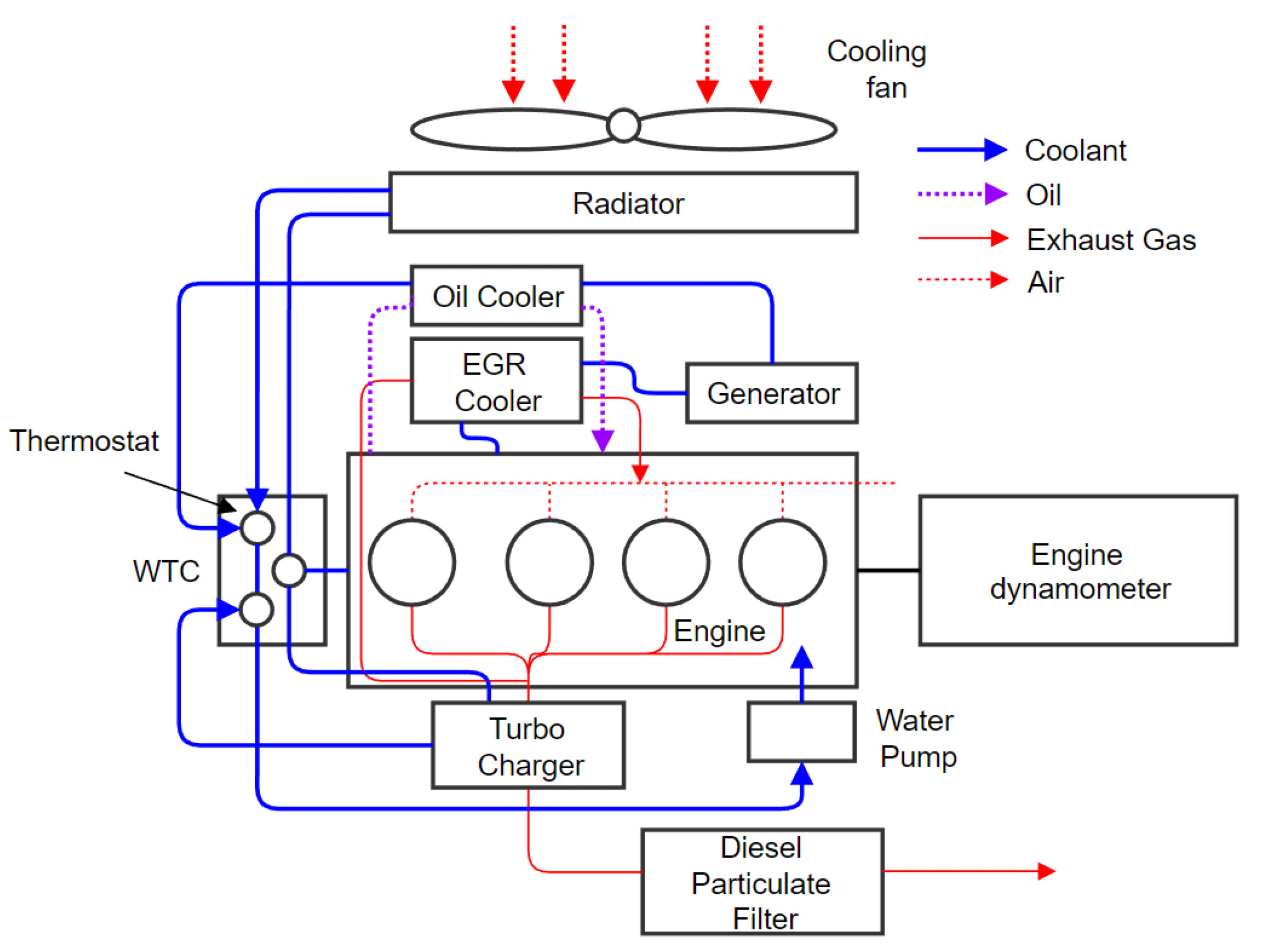

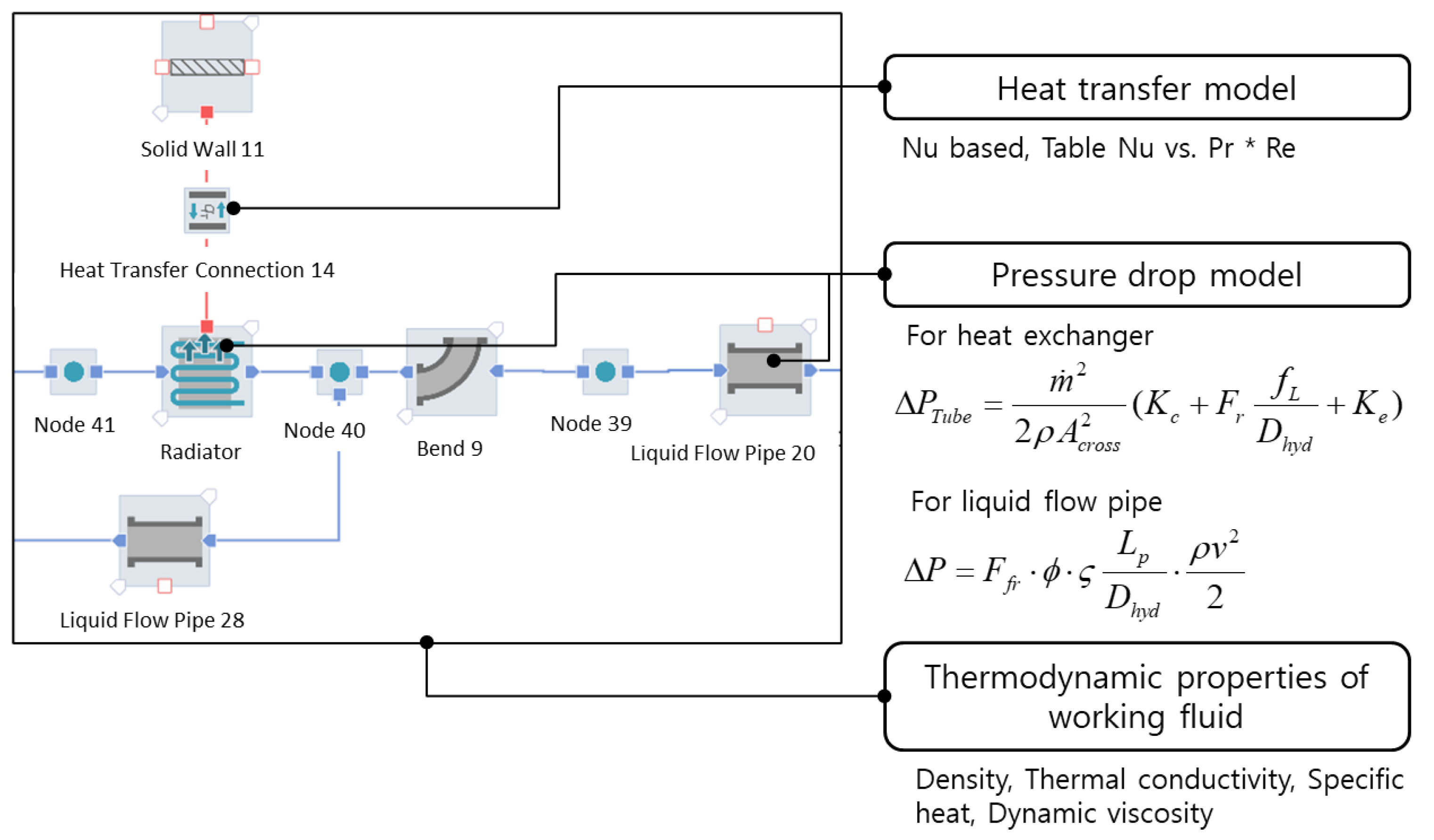

2.1. Multi-Disciplinary Model of the Diesel Engine

2.2. Modeling of the Properties of the Working Fluids

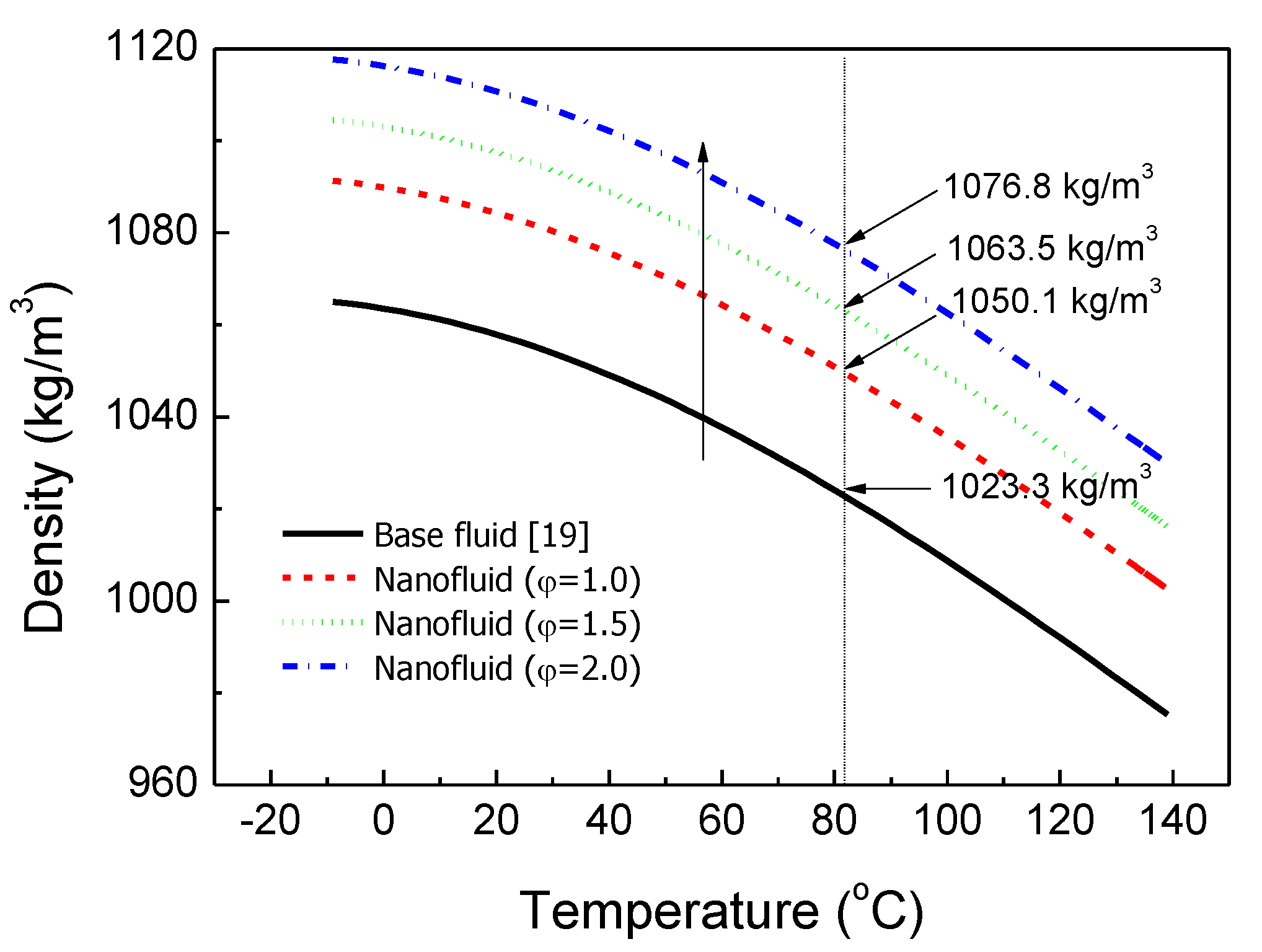

2.2.1. Density

2.2.2. Dynamic Viscosity

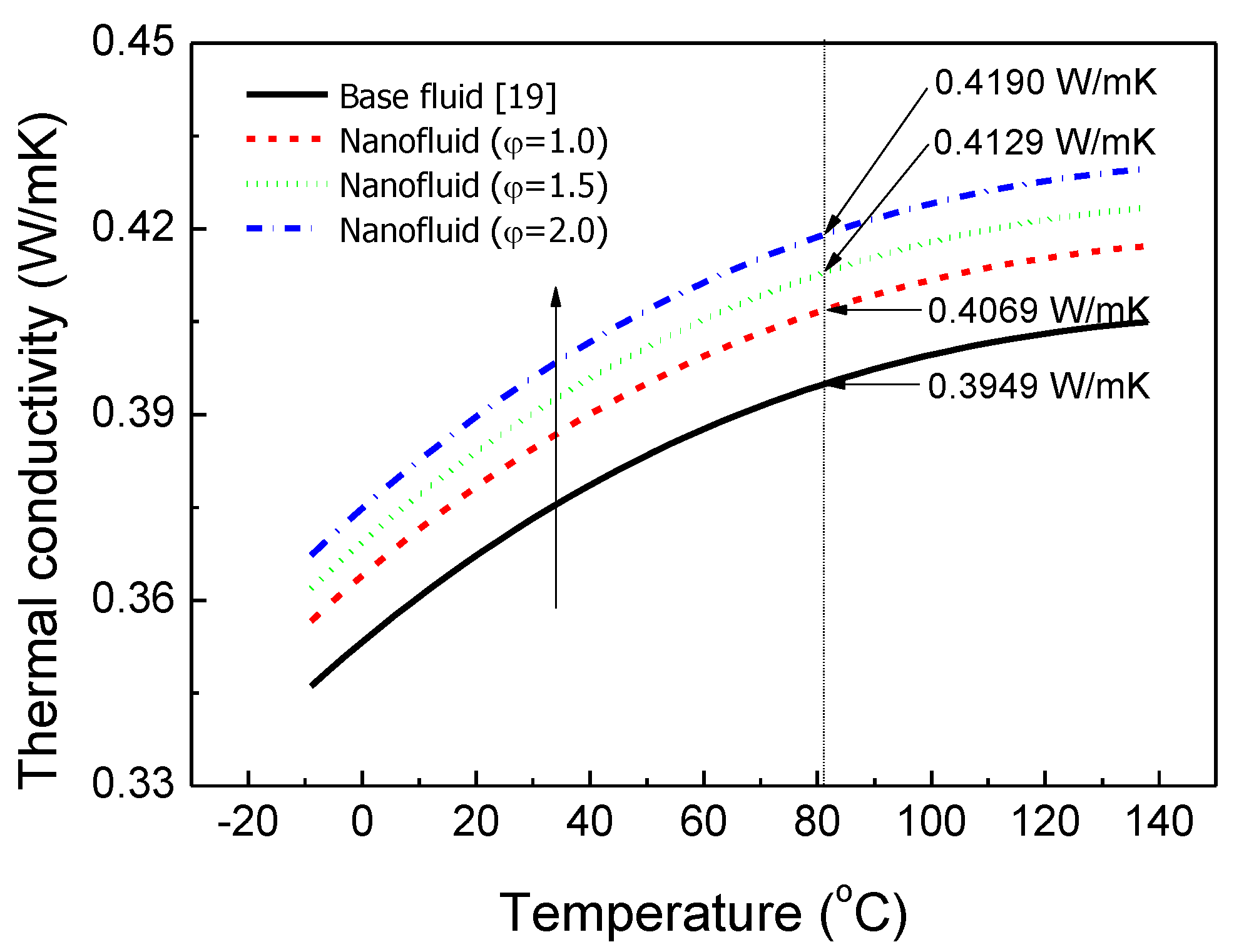

2.2.3. Thermal Conductivity

2.2.4. Specific Heat

2.2.5. Heat Transfer Coefficient

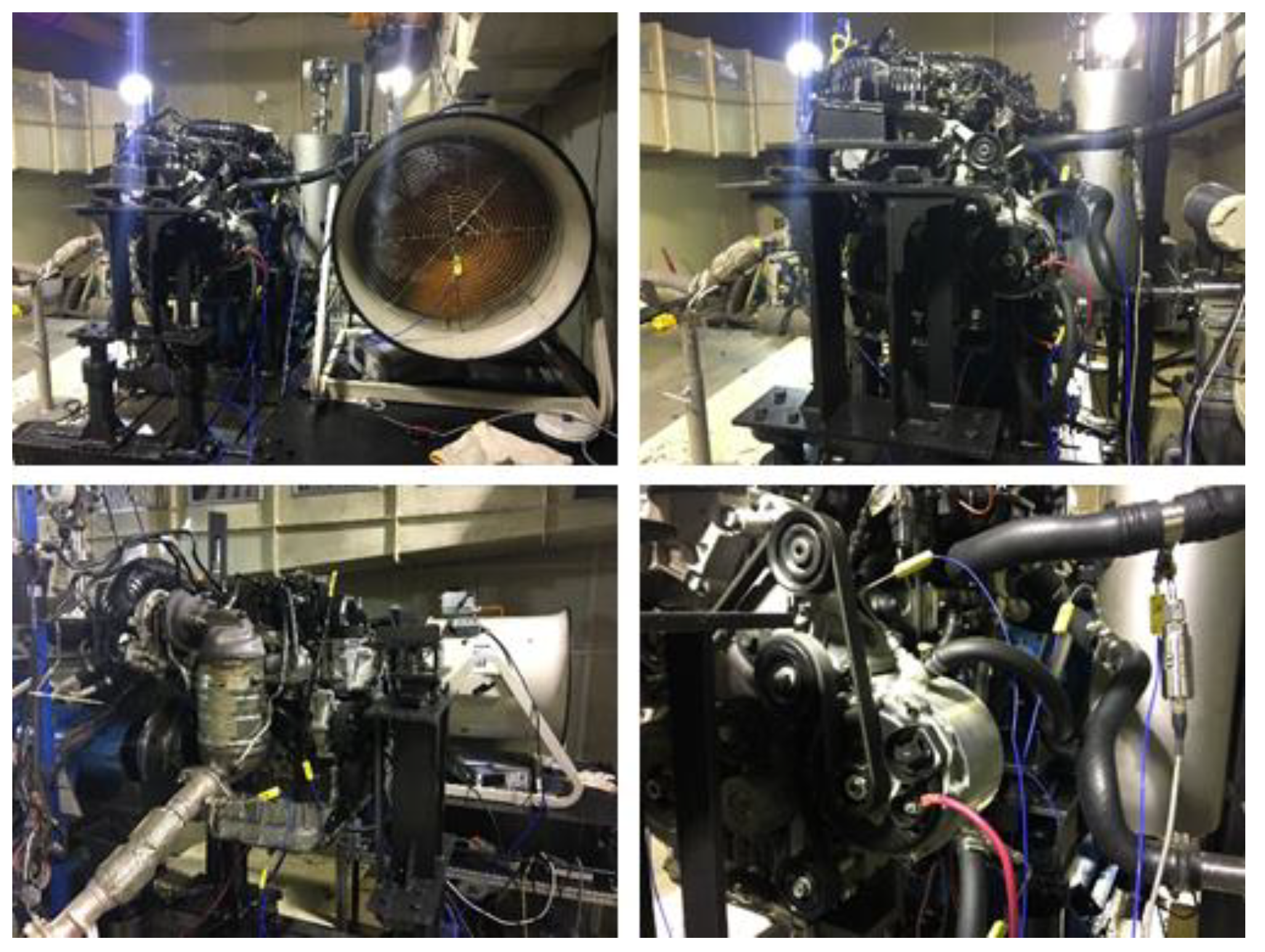

2.3. Experimental Setup and Test Condition of the Diesel Engine

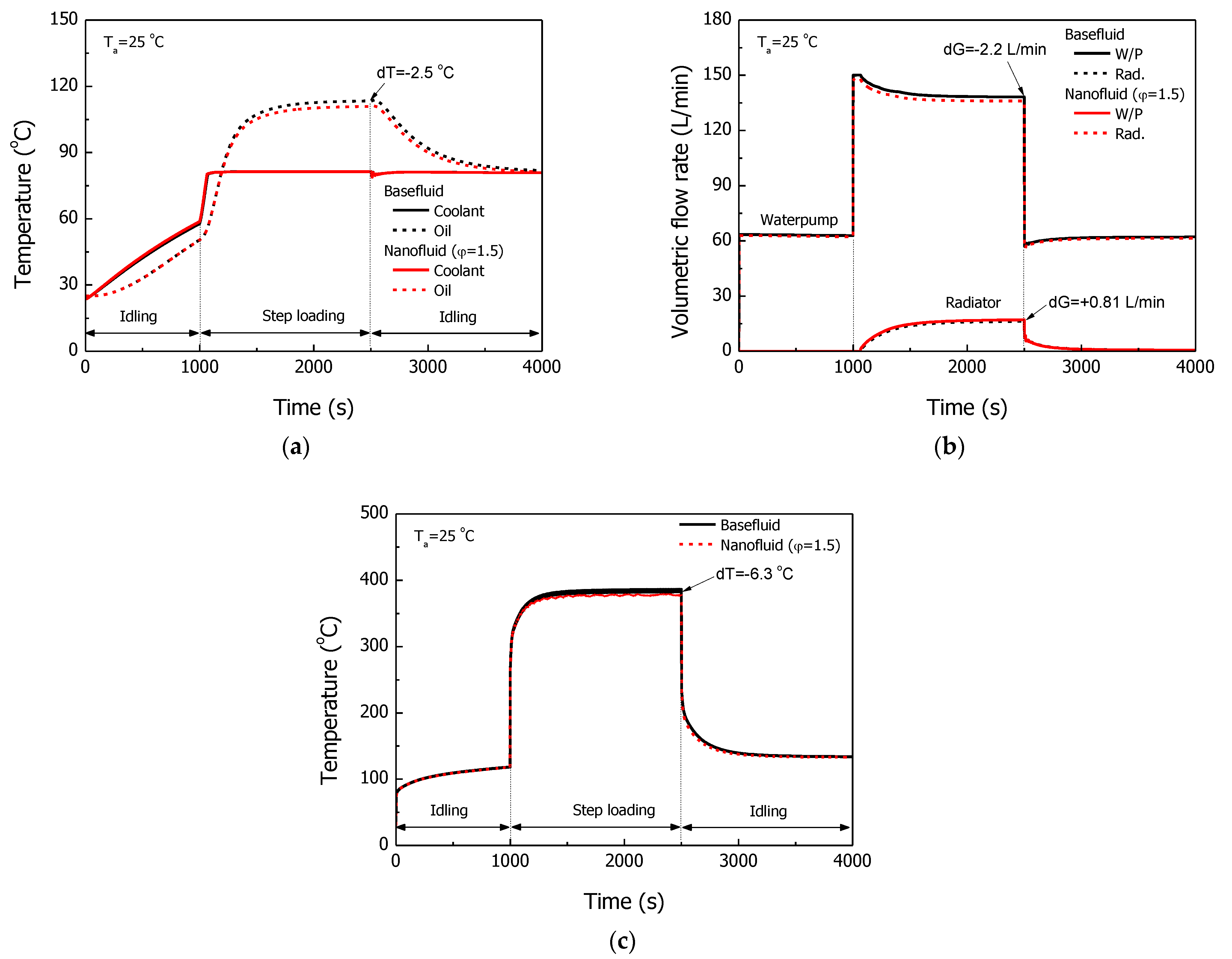

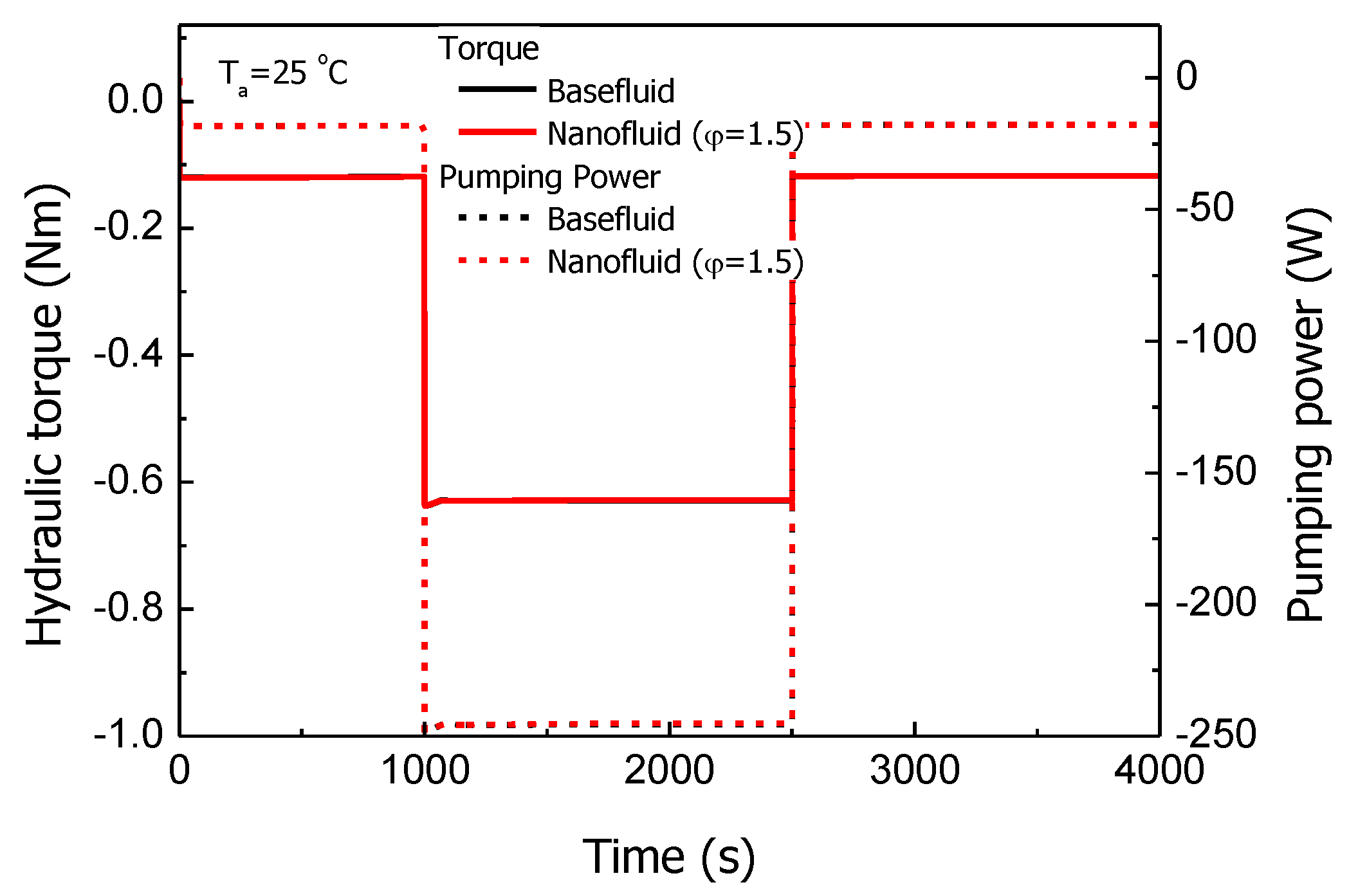

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roberts, A.; Brooks, R.; Shipway, P. Internal Combustion Engine Cold-Start Efficiency: A Review of the Problem, Causes and Potential Solutions. Energy Convers. Manag. 2014, 82, 327–350. [Google Scholar] [CrossRef]

- Bent, E.; Shayler, P.J.; Rocca, A.L.; Rouaud, C. The Effectiveness of Stop-Start and Thermal Management Measures to Improve Fuel Economy. In Proceedings of the Vehicle Thermal Management Systems Conference Proceedings (VTMS11), Coventry Technocentre, UK, 15–16 May 2013. [Google Scholar]

- Taylor, O.; Pearson, R.; Stone, R. Reduction of CO2 Emissions through Lubricant Thermal Management During the Warm Up of Passenger Car Engines. In SAE Technical Paper 2016-01-0892; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Shayler, P.J.; Allen, A.J.; Leong, D.K.M.; Pegg, I.; Brown, A.; Dumenil, J.C. Characterising Lubricating Oil Viscosity to Describe Effects on Engine Friction. In SAE Technical Paper 2007-01-1984; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Dhinesh, K.D.; Valan, A.A. A Review on Preparation, Characterization, Properties and Applications of Nanofluids. Renew. Sustain. Energy Rev. 2016, 60, 21–40. [Google Scholar]

- Minli, B.; Zhe, X.; Jizu, L. Application of Nanofluids in Engine Cooling System. In SAE Technical Paper 2008-01-1821; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Nor, A.C.S.; Muhammad, N.A.W.M.Y.; Rizalman, M. Recent Advancement of Nanofluids in Engine Cooling System. Renew. Sustain. Energy Rev. 2017, 75, 137–144. [Google Scholar]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles. ASME FED 1995, 231, 99–105. [Google Scholar]

- Gabriela, H.; Angel, H. Application of Nanofluids in Heat Exchangers: A Review. Renew. Sustain. Energy Rev. 2012, 16, 5625–5638. [Google Scholar]

- Choi, S.U.S.; Yu, W.; Hull, J.R.; Zhang, Z.G.; Lockwood, F.E. Nanofluids for Vehicle Thermal Management. In SAE Technical Paper 2001-01-1706; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Tzeng, S.C.; Lin, C.W.; Huang, K.D. Heat Transfer Enhancement of Nanofluids in Rotary Blade Coupling of Four-Wheel-Drive vehicles. Acta Mech. 2005, 179, 11–23. [Google Scholar] [CrossRef]

- Zhang, K.J.; Wang, D.; Hou, F.J.; Jiang, W.H.; Wang, F.R.; Li, J.; Liu, G.J.; Zhang, W.X. Characteristic and Experiment Study of HDD Engine Coolants. Neiranji Gongcheng/Chin. Internal. Combust. Engine Eng. 2007, 28, 75–78. [Google Scholar]

- Saripella, S.K.; Yu, W.; Routbort, J.L.; France, D.M.; Rizwan, U. Effects of Nanofluid Coolant in a Class 8 Truck Engine. In SAE Technical Papers 2007-01-2141; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Ali, M.; El-Leathy, A.M.; Al-Sofyany, Z. The Effect of Nanofluid Concentration on the Cooling System of Vehicles Radiator. Adv. Mech. Eng. 2014, 6, 962510. [Google Scholar] [CrossRef]

- Esfe, M.H.; Esfandeh, S.; Afrand, M.; Rejvani, M.; Rostamian, S.H. Experimental Evaluation, New Correlation Proposing and ANN modeling of Thermal Properties of EG Based Hybrid Nanofluid Containing ZnO-DWCNT Nanoparticles for Internal Combustion Engines Applications. Appl. Therm. Eng. 2018, 133, 452–463. [Google Scholar] [CrossRef]

- Balitskii, A.; Kindrachuk, M.; Volchenko, D.; Abramek, K.F.; Balitskii, O.; Skrypnyk, V.; Zhuravlev, D.; Bekish, I.; Ostashuk, M.; Kolesnikov, V. Hydrogen Containing Nanofluids in the Spark Engine’s Cylinder Head Cooling System. Energies 2022, 15, 59. [Google Scholar] [CrossRef]

- Erkan, A.; Tüccar, G.; Tosun, E.; Özgür, T. Comparison of Effects of Nanofluid Utilization (Al2O3, SiO2, TiO2) with Reference Water in Automotive Radiators on Exergetic Properties of Diesel Engines. SN Appl. Sci. 2021, 3, 365. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K.; Namburu, P.K. Numerical Study of Fluid Dynamic and Heat Transfer Performance of Al2O3 and CuO Nanofluids in the Flat Tubes of a Radiator. Int. J. Heat Fluid Flow 2010, 31, 613–621. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A. Numerical Analysis of Laminar Flow Heat Transfer of Nanofluids in a Flattened Tube. Int. Commun. Heat Mass Transf. 2013, 44, 52–57. [Google Scholar] [CrossRef]

- Abbasi, M.; Baniamerian, Z. Analytical Simulation of Flow and Heat Transfer of Two-Phase Nanofluid (Stratified Flow Regime). Int. J. Chem. Eng. 2014, 2014, 474865. [Google Scholar] [CrossRef]

- Delavari, V.; Hashemabadi, S.H. CFD Simulation of Heat Transfer Enhancement of Al2O3/water and Al2O3/ethylene glycol Nanofluids in a Car Radiator. Appl. Therm. Eng. 2014, 73, 390. [Google Scholar] [CrossRef]

- AVL. CRUISE M User Manual 2020R 2. Available online: https://www.avl.com/cruise-m (accessed on 11 August 2022).

- Fotukian, S.M.; Nasr Esfahany, M. Experimental Investigation of Turbulent Convective Heat Transfer of Dilute γ-Al2O3/water Nanofluid inside a Circular Tube. Int. J. Heat Fluid Flow 2020, 31, 606–612. [Google Scholar] [CrossRef]

- Sommers, A.D.; Yerkes, K.L. Experimental Investigation into the Convective Heat Transfer and System-level Effects of Al2O3-Propanol Nanofluid. J. Nanopart. Res. 2010, 12, 1003–1014. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y. Hydrodynamic and Heat Transfer Study of Dispersed Fluids with Submicron Metallic Oxide Particle. Exp. Heat Transf. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Einstein, A. Eine neue Bestimmung der Moleküldimensionen. Ann. Phys. 1906, 324, 289–306. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism, 1st ed.; Clarendon Press: Oxford, UK, 1873; pp. 360–366. [Google Scholar]

- Xuan, Y.; Roetzel, W. Conceptions for Heat Transfer Correlation of Nanofluids. Int. J. Heat Mass Transf. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Dittus, F.W.; Boelter, L.M.K. Heat Transfer in Automobile Radiators of the Tubular Type. Univ. Calif. Publ. Eng. 1930, 2, 443–461. [Google Scholar] [CrossRef]

- Wikipedia. Hyundia R Engine. Available online: https://en.wikipedia.org/wiki/Hyundai_R_engine (accessed on 11 August 2022).

- Mancaruso, E.; Sequino, L. Measurements and Modeling of Piston Temperature in a Research Compression Ignition Engine during Transient Conditions. Results Eng. 2019, 2, 100007. [Google Scholar] [CrossRef]

- Reichstein, S.; Weiss, R.; Kenningley, S.; Lades, K.; Konrad, P.; Doemenburg, F. High-performance Cast Aluminum Pistons for Highly Efficient Diesel Engines. In SAE Technical Papers 2007-01-1438; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

| Nanosized Particles | Mean Diameter (mm) | Density (kg/m3) | Thermal Conductivity (W/mK) | Specific Heat (kJ/kg-K) |

|---|---|---|---|---|

| Al2O3 | 20 | 3700 | 880 | 0.046 |

| Parameter | Description |

| Type | DI diesel engine with e-VGT |

| Bore × Stroke (mm) | 84.0 × 90.0 |

| Displacement (cc) | 1995 |

| Compression ratio (-) | 16.0 |

| Fuel injection system | Bosch common-rail system |

| Max. power (HP/rpm) | 184/4000 |

| Max. torque (kg-m/rpm) | 40/2000 |

| Step | Engine Condition | Driving Time |

|---|---|---|

| 1 | Idle | 1000 s |

| 2 | 2050 rpm@216 Nm | 1500 s |

| 3 | Idle | 1500 s |

| Base Fluid (°C) | Al2O3 Nanofluid (°C) | dT (°C) | |

|---|---|---|---|

| Experiment | 113.03 | 112.34 | −0.7 |

| Simulation | 113.4 | 110.91 | −2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, G. Multi-Disciplinary Analysis of Working Fluids on Thermal Performance of the High-Power Diesel Engine System. Machines 2022, 10, 1023. https://doi.org/10.3390/machines10111023

Lee G. Multi-Disciplinary Analysis of Working Fluids on Thermal Performance of the High-Power Diesel Engine System. Machines. 2022; 10(11):1023. https://doi.org/10.3390/machines10111023

Chicago/Turabian StyleLee, Geesoo. 2022. "Multi-Disciplinary Analysis of Working Fluids on Thermal Performance of the High-Power Diesel Engine System" Machines 10, no. 11: 1023. https://doi.org/10.3390/machines10111023

APA StyleLee, G. (2022). Multi-Disciplinary Analysis of Working Fluids on Thermal Performance of the High-Power Diesel Engine System. Machines, 10(11), 1023. https://doi.org/10.3390/machines10111023